Page 1

INSTRUCTION BOOK

WARRANTY

Great Planes Model Manufacturing Co , Inc guarantees this kit to be free of defects in both material

and workmanship at the date of purchase This warranty does not cover any component parts damaged

by use or modification In no case shall Great Planes' liability exceed the original cost of the purchased

kit Further, Great Planes reserves the right to change or modify this warranty without notice

In that Great Planes has no control over the final assembly or material used for final assembly, no

liability shall be assumed nor accepted for any damage resulting from the use by the user of the final userassembled product By the act of using the user-assembled product the user accepts all resulting liability

If the buyer is not prepared to accept the liability associated with the use of this product, he is

advised to immediately return this kit in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION BOOK FIRST.

IT CONTAINS IMPORTANT INSTRUCTIONS AND

WARNINGS CONCERNING THE ASSEMBLY AND

USE OF THIS MODEL.

P 0 BOX 788 URBANA ILL NOIS 61801 (217) 398-8970

Entire Contents ©1992 Hobbico, Inc F146P03 V1 1

Page 2

TABLE OF CONTENTS

INTRODUCTION ........................3

Precautions...................................3

Other Items Required..................4

Supplies and Tools Needed..........4

Decisions You Must Make Now ..5

Common Abbreviations ...............5

Types of Wood .............................5

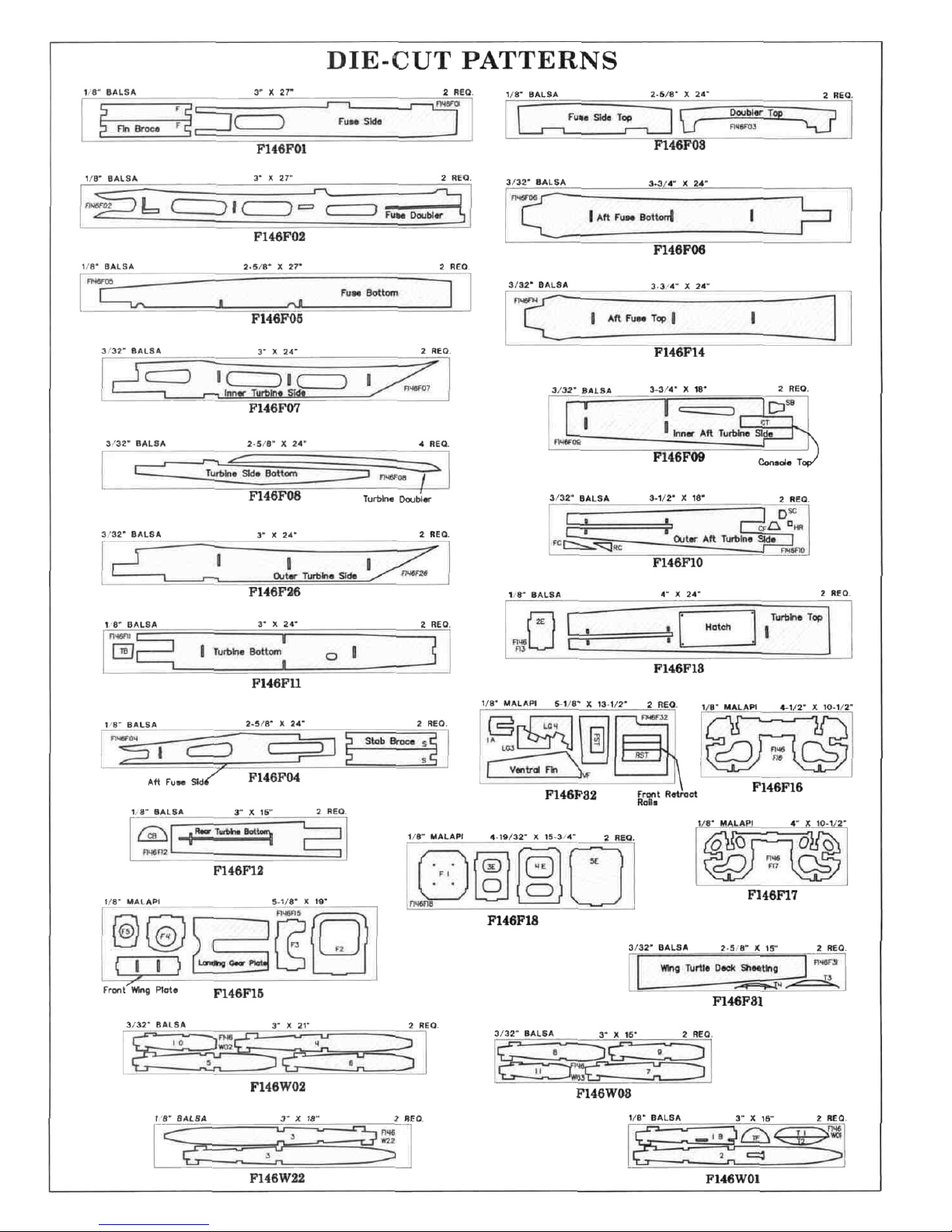

Die Patterns..................................6

Get Ready to Build.......................7

TAIL FEATHERS ........................7

Build the Fins and Rudders..........7

Build the Stabs and Elevators ......8

Temporarily Install Hinges ..........9

WING.............................................10

Spars.............................................10

Build the Wing Panels..................10

Assemble the Two Panels ............12

Install the Wing Sheeting.............14

Install the Aileron Torque Rods... 18

FUSELAGE ASSEMBLY............19

Prepare the Sides..........................19

Prepare the Firewall .....................21

Assemble Fuselage.......................21

Landing Gear (Fixed)...................23

Landing Gear (Retracts)...............25

General Fuselage Assembly.........27

Install the Nose Gear Retract .......28

Install Radio .................................29

Retract Pushrods ..........................30

Pushrods.......................................31

Drill Engine Mount......................34

Install Fuel Tank...........................35

Final Fuselage Construction.........35

Fit the Wing to the Fuselage ........37

Build the Wing Turtle Deck.........39

Engine Compartment ...................40

FINAL ASSEMBLY .......................42

Install Wing Tips ...........................43

Install Ailerons ..............................43

Install Aileron Servo......................44

Install Exhaust Nozzles .................45

Cut Main Gear Retract Openings ..46

FINISHING....................................47

Blend Wing to Fuse .......................47

Instrument Console & Seats ..........47

Prepare Canopy..............................47

Balance the Airplane Laterally ......48

Final Sanding.................................48

Covering ........................................48

Glue Fins and Stabs in Place .........49

Glue Aileron Hinges......................49

Glue Elev. and Rudder Hinges ......49

Install Cockpit................................50

Decals and Trim.............................50

Wing Seating .................................51

Re-install Engine and Radio..........51

Balance Your Model ......................51

Final Hookups and Checks............53

PRE-FLIGHT.................................53

Charge the Batteries.......................53

Find a Safe Place to Fly.................53

Ground Check the Model ..............53

Range Check Your Radio ..............53

Engine Safety Precautions.............53

AMA Safety Code.........................54

FLYING..........................................54

Takeoff...........................................54

Flying............................................54

Important Caution..........................55

Landing..........................................55

Control Surface Throws.................55

2-VIEW............................................56

Page 3

WARNING! THIS IS NOT A TOY!

THIS IS NOT A BEGINNERS AIRPLANE!

This R/C kit and the model you will build is not a toy! It is capable of serious bodily harm and

property damage IT IS YOUR RESPONSIBILITY AND YOURS ALONE — to build this kit

correctly, properly install all R/C components and flying gear (engine, tank, pushrods, etc ) and to

test the model and fly it only with experienced, competent help, using common sense and in

accordance with all safety standards as set down in the Academy of Model Aeronautics Safety Code

It is suggested that you join the AMA and become properly insured before you attempt to fly this

model IF YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR LOCAL HOBBY

SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS TO FIND AN

EXPERIENCED INSTRUCTOR IN YOUR AREA

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252 (800) 435-9262

INTRODUCTION

Congratulations and thank you for purchasing the

Great Planes F-14 TOMCAT'

The Great Planes F-14 is a high performance

propeller-driven sport airplane that resembles the real

F-14 Tomcat In the air, the prop is invisible, adding to

the realism The smoothness and speed of this airplane

allow you to experience the thrills of flying a jet-like

airplane without the complexity and high cost of a dueled

fan model

Please inspect all parts carefully before

starting to build! If any parts are missing,

broken or defective, or if you have any

questions about building or flying this

airplane, please call us at (217) 398-8970 and

we'll be glad to help. If you are calling for

replacement parts, please look up the part

numbers and the kit identification number

(stamped on the end of the carton) and have

them ready when calling.

This is not a beginner's airplane! While the F-14

TOMCAT is not difficult to build and flies great, we

must discourage you from selecting this kit as your first

R/C airplane It is very fast, highly maneuverable and

lacks the self-recovery characteristics of a good basic

trainer such as the Great Planes PT Series airplanes

On the other hand, if you are confident with your flying

skill and can safely handle aileron airplanes such as the

Great Planes Ultra-Sport Series or Big Stik Series

airplanes, the F-14 is an excellent choice. If you

currently fly an aileron airplane but you are unsure about

your ability to handle the F-14. we recommend that you

build and fly a low-wing sport plane before building and

flying your F-14

PRECAUTIONS

1. You must build the plane according to the plans

and instructions. Do not alter or modify the model as

doing so may result in an unsafe or unflyable model In

a few cases the plans and instructions may differ slightly

from the photos In those instances you should assume

the plans and written instructions are correct Also you

may notice a slight difference in length between longer

parts and the plans This is normal and is caused by the

plans expanding and shrinking with the changing

moisture content in the an Do not modify the paits to fit

the plan

2 You must take time to build straight, true and

strong IMPORTANT - Glue should never be

substituted tor a good joint Take a little extra time to get

a close fitting joint and glue it properly It will be

stronger, neater, and much lighter than a bad joint held

together with a glob of glue!

3

Page 4

3. You must use a proper R/C radio that is in first class

condition and meets the current AMA and FCC

requirements and the requirements of your local flying

club, the correct sized engine and correct components

(fuel tank, wheels, etc )

4. You must properly install all R/C and other

components so that the model operates properly on the

ground and in the air

5. You must test the operation of the model before the

first and each successive flight to insure that all equipment

is operating Also you must make certain that the model

has remained structurally sound

6. You must fly the model only with the competent

help of a well experienced R/C pilot if you are not already

an experienced and knowledgeable R/C pilot.

Note We, as the kit manufacturer, can provide you with a

top quality kit and great instructions, but ultimately the

quality and flyability of your finished model depends on

how you build it, therefore, we cannot in any way

guarantee the performance of your completed model, and

no representations are expressed or implied as to the

performance or safety of your completed model

Remember: Take your time and follow

directions to end up with a well-built model that

is straight and true.

OTHER ITEMS REQUIRED

D Four-channel radio with 4 or 5 servos (additional channel

and retract servo required if retracts are being used)

D Propellers (see engine instructions for recommended

sizes) Top Flite® "Power Props" recommended.

D 2-1/4" Spinner (Hobbico 2-1/4" Jet spinner #HCAQ3750

recommended)

D Fuel Tank (GPMQ4104)

D 5/32" Wheel Collars (GPMQ4306)

D Iron-on Covering Material (Top Flite Super MonoKote®

gray, black and cub yellow recommended)

D Fuelproof Paint for Tail Cones, and possibly for trim

Note Chevron "Perfect Paint" matches Top Flite Super

MonoKote, and is available in spray cans.

D 36" Throttle Pushrod (GPMQ3710)

D Silicone Fuel Tubing (GPMQ4131)

D 1/16" thick Wing Seating Tape (GPMQ4422) or silicone

sealer see instructions

D Latex Foam Rubber Padding (HCAQ 1000)

D 2 Plastic Pilots Williams Bros Military 1-1/2" Scale #171

D Wheels (see page 5)

THE OPTIONAL RETRACTS ALSO REQUIRE:

D Hobbico Low-Profile Retracts (HCAP4000)

D #2 X 3/8" Socket Head Screws (GPMQ3120)

D Dubro #103 Strip Aileron Horn (DUBQ1780)

D Nose Gear Retract Pushrod (A Sullivan red outer

guide tube and a 34" threaded rod works well for this)

D Three 3/32" Wheel Collars (GPMQ4302)

D Screw-Lock Pushrod Connector (GPMQ3870)

D 2-56 Metal Clevises (GPMQ3790)

SUPPLIES AND TOOLS NEEDED

D 2 oz Thin CA Adhesive (GPMR6003)

D 2 oz Medium or Thick CA Adhesive (GPMR6009)

D 2 5 oz Epoxy (GPMR6047)

D Silicone Adhesive

D 7/64 Ball Driver (GPMR8003)

D 440Tap(GPMR8101)

D Hand or Electric Drill

D Drill Bits 1/16", 5/64", 7/64", 1/8", 5/32", 3/16",

13/64", 1/4" and 5/16"

D Sealing Iron and Heat Gun (Hobbico or Top Flite

recommended)

D Hobby Saw (X-acto Razor Saw)

D X-acto Knife, #11 Blades

D Pliers

D Screw Drivers

D T-Pins (HCAR5200)

D Straightedge

D Masking Tape (Required for construction)

D Sandpaper (coarse, medium, fine grit)*

D T-Bar Sanding Block (or similar)

D Waxed Paper

D Lightweight Balsa Filler

D Vaseline Petroleum Jelly

D Isopropyi Rubbing Alcohol (70%)

D 3M "77" Spray Adhesive (optional)

D Dremel Moto Tool or similar (optional)

D 5/64 and 2mm Ball Driver (for Hobbico Retracts)

*NOTE: On our workbench, we have four 11" T-Bar

sanders, equipped with #50, #80, #100 and #150-grit

sandpaper. This setup is all that is required for

almost any sanding task. We also keep some #320grit wet-or-dry sandpaper handy for finish sanding

before covering.

4

Page 5

DECISIONS YOU MUST MAKE NOW

ENGINE, MOUNT AND MUFFLER

SELECTION

The recommended engine for the F 14 is a 60* - 75

cubic inch displacement 2-cycle *NOTE: Performance

may be marginal if a non-Schneurle-ported 60 cu in

2-Cycle engine is used. The engine you select will

determine how you build the fuselage, so it is important

that you have the engine close at hand while building

Because of the size limitations and the nature of this

model, 4-cycle engines are more difficult to install and

balance and therefore are not recommended.

This kit includes a Great Planes MM60 engine mount

(or similar mount) that fits most 60 - 61 (2-Cycle)

engines (slight modification of this mount is required to

mount the OS 61 SF by filing the inside edges of the

engine mount beams) If the supplied mount can't be

modified to fit your engine, it may be necessary to

purchase a different mount (check with your hobby

dealer).

SELECTION OF WHEELS

To save weight, we recommend using lightweight

wheels REMEMBER: Large wheels are ugly and

unrealistic on a model of this type, so try to keep the

wheels as small as possible.

If you will be flying from a concrete or asphalt runway, we

recommend 2-1/4" main wheels and a 2" nose wheel

For grass fields, larger wheels will be required, such as 2-1/2"

main wheels and a 2-1/4" to 2-1/2" nose wheel.

If you will be installing retracts, you should try to limit the

wheel size to a maximum of 2-1/4" main wheels and a 2" nose

wheel or the wheel wells will be excessively large.

POSSIBLE RADIO INSTALLATIONS

The F-14 is designed to satisfy a wide variety of

modelers' desires The following radio installation

options will allow you to customize the plane to fit

whichever radio you want to use.

Our recommended radio installation requires 5

standard servos and a 180 degree retract servo (if retracts

are used) This will allow you to use one standard servo

for the rudders, two servos for the elevators (one for

each), one for the throttle and one for the ailerons This

set-up will give you very precise control and is easy to

install

You can also fly the plane with 4 standard servos by

using only one servo to drive both elevators In this case

the elevator servo is mounted up in a front servo tray and

two long pushrods are used This will work Ok, but there

is generally more "play" in the elevators (due to the

longer, curved pushrods) This method is not

recommended if you intend to use a high powered engine

or do a lot of high speed flying

Both rudders can be operated from one servo without

any problems because their linkage is much straighter If

you don't plan on doing much acrobatic flying, you can

even get by with only one operating rudder In this case

you would just run one pushrod straight back to the

rudder on the same side as the servo The other rudder

would be glued on to the fin and would not move

RETRACTABLE LANDING GEAR (optional)

This airplane flies very well with a fixed landing gear,

and retracts are not necessary, however, they do add

realism and speed, and are a nice addition (it you are

prepared for the extra work involved in their installation)

Since the retracts are all located in the fuselage, one

retract servo (such as the Futaba FP-S136G) can be used

to actuate all three retracts

COMMON ABBREVIATIONS USED IN

THIS BOOK AND ON THE PLANS:

Elev = Elevator

Fuse = Fuselage

LE = Leading Edge (front)

LG = Landing Gear

Ply = Plywood

Stab = Stabilizer

TE = Trailing Edge (rear)

= Inches

TYPES OF WOOD

Balsa Basswood Plywood

Page 6

6

Page 7

GET READY TO BUILD

D 1. Unroll the plan sheets and re-roll them inside

out. This will help them lie flat.

D 2. Remove all parts from the box. As you do,

determine the name of each part by comparing it with the

plans and the parts list at the back of this book. Using a

felt tip pen, write the part name or size on each piece to

avoid confusion later. Use the die-cut part patterns

shown on page 6 to identify the die-cut parts, but do not

punch them out until you are ready to use them. Save

all scraps. If any of the die-cut parts are difficult to

punch out, do not force them! Instead, first cut around

the parts with an X-acto knife. After punching out the

die-cut parts, use your T-Bar or sanding block to lightly

sand the edges to remove any die-cutting irregularities.

D 3. As you identify and mark the parts, separate

them into groups, such as fuse (fuselage), wing, fin and

stab (stabilizer), and hardware.

"TAIL FEATHERS"

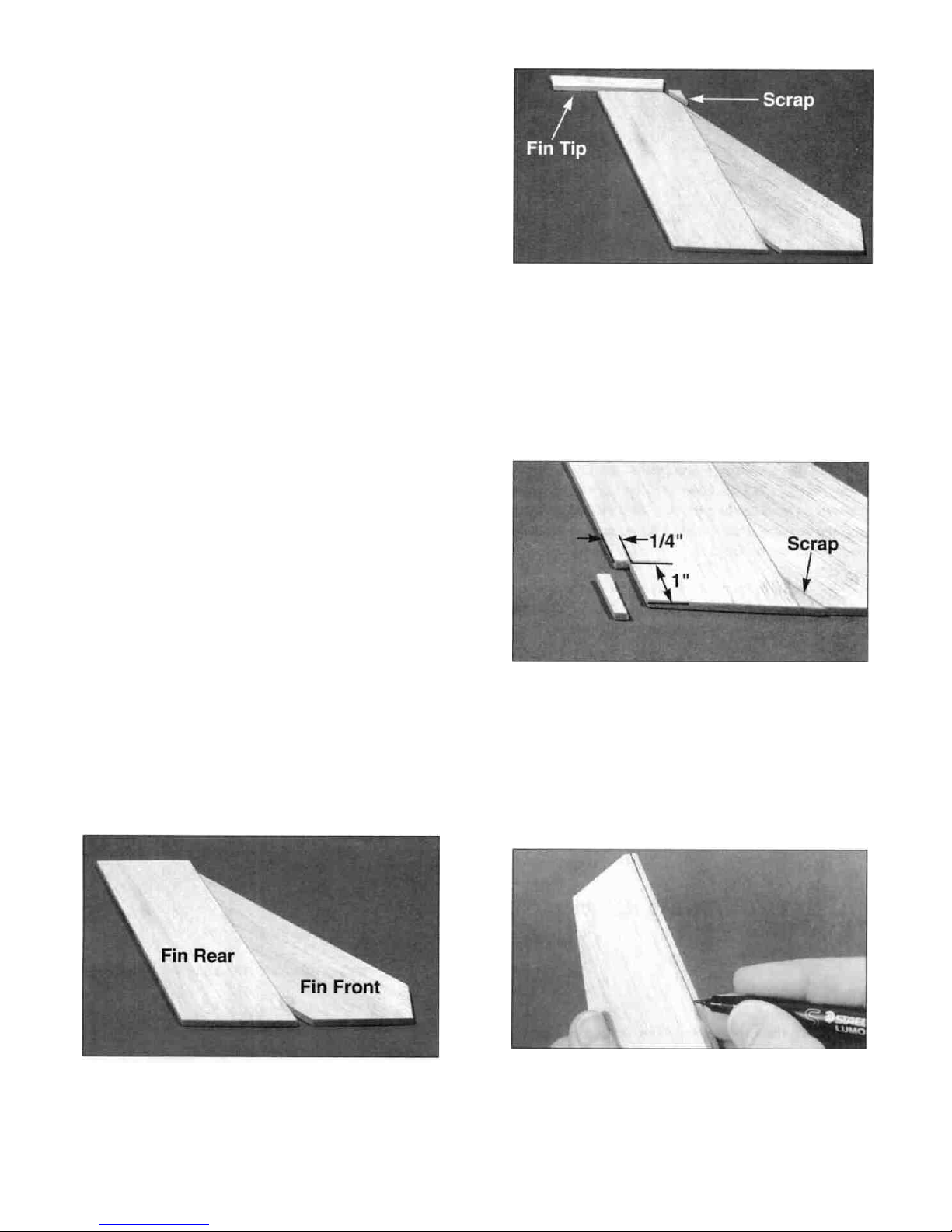

D D 3. Cut the tip of the fin rear to match the leading

edge sweep of the fin front. Glue the little triangle piece

of scrap into the "V" at the bottom. Cut the 1/4" x 5/8"

x 9" balsa stick (F146R04) in half to make two 4-1/2"

long fin tips. Glue the tip in place at the end of the fin

rear.

BUILD THE FINS AND RUDDERS

D 1. Tape the fuselage side view portion of the plan

down onto your flat work surface. Tape a piece of waxed

paper over the fin and rudder portion of the plan.

D D 4. Draw a line parallel with the trailing edge of

the fin and 1/4" in front of it. Draw another line parallel

with the bottom edge of the fin and 1" above it. Cut out

a clearance notch for the torque rods using the lines as a

guide as shown in the photo.

D D

2.

Glue

the

1/4"

balsa

fin from

(146R01)

to

the 1/4" balsa fin rear (F146R03) so their bottoms are

even with each other. Note that there will be a triangle of

wood missing between the two pieces. This can be filled

in the next step.

D D 5. Use a sanding block with medium (150) grit

sandpaper to sand the edges and both sides of the stab

smooth. Carefully draw a centerline all around the

edges of the stab and elevator. This will make it easier to

maintain symmetry when sanding later.

7

Page 8

D D 6. Using a sanding block and coarse (50 or 80-

grit) sandpaper, sand both sides of the rudder to a taper

(see cross-section on plans). The trailing edge should

end up approximately 3/32" wide. (Do not sand to a

sharp edge). Leave the top and bottom edges square.

Sand the leading edge of the rudder to a "V-shape" as

shown on the plan. NOTE: If you are going to have

only one operating rudder, do not sand the LE of the

fixed rudder to a "V" as described above. Leave it

square and Just glue it in place against the TE and tip of

the fin. HINT: It is a good idea to keep new, sharp

sandpaper on your sanding blocks. You will notice that it

"cuts" the wood and the glue much cleaner and produces

a much smoother finish.

D D 7. Sand the top and front edges of the fin to a

rounded shape (see cross-section on plans). Sand the

trailing edge of the fin tip (at the top of the rudder) to the

same taper as the rudder.

D 8. Go back to step 2 and build another fin and

rudder.

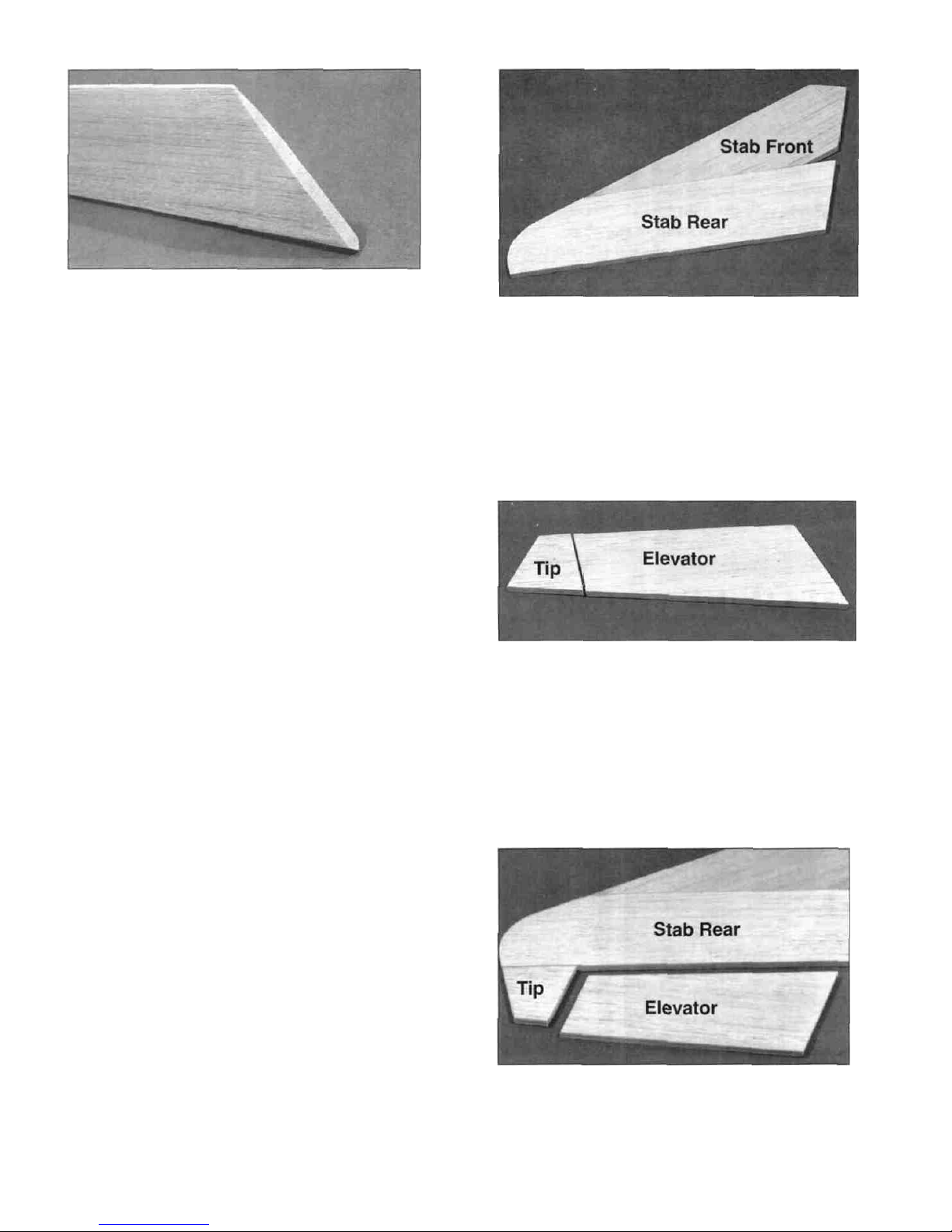

D D 2. Glue the 1/4" balsa stab front (F146S01) to

the 1/4" balsa stab rear (F146S03) so the root ends are

even with each other. Note that there is a triangle of

missing wood formed when the two pieces are properly

joined. There are no scrap pieces to fit in there. You can

cut one if you desire, although it is not necessary.

D D 3. Position the 1/4" balsa elevator (F146S04)

over the plan and mark where the stab tip will be cut oft.

Cut the tip off with a razor saw and glue it to the stab

rear. Do this over the plans so you will be sure to

position it correctly.

BUILD THE STABILIZERS AND

ELEVATORS

D 1. Tape the fuselage top view portion of the plan

down onto your flat work surface and cover the stabilizer

portion of the fuselage top view with wax paper.

D D 4. Use a sanding block with medium (150) grit

sandpaper to sand the edges and both sides of the stab

smooth. Carefully draw a centerline all around the

edges of the stab and elevator. This will make it easier to

maintain symmetry when sanding later.

8

Page 9

D D 5. Using a sanding block and coarse (50 or 80-

grit) sandpaper, sand both sides of the elevator to a taper

(see cross-section on plans). The trailing edge should

end up approximately 3/32" wide. (Do not sand to a

sharp edge). Leave the ends square. Sand the leading

edge of the elevator to a "V-shape" as shown on the

plan.

D D 6. Sand the tip and front edges of the stab to a

rounded shape (see cross-section on plans). Sand the

trailing edge of the stab tip to the same taper as the

elevator.

D D 7. Draw a line parallel with the trailing edge of

the stab and 1/4" in front of it. Draw another line

parallel with the root edge of the stab and 1" out from it.

Cut out a clearance notch for the torque rods just as you

did on the fins earlier.

D 8. Go back to step 2 and build another stab and

elevator.

B. Make three or four more cuts in the same line, going

slightly deeper each time. As you make these

additional cuts. work on going straight into the wood.

Continue this process while "wiggling" the knife

handle forward and backward until the blade has

reached the proper depth for the hinge.

C. Trial fit the hinge into the slot. If the hinge is

difficult to push in. re-insert the knife and move it

back and forth in the slot a few times to enlarge the

slot. Do not glue the hinges yet.

TEMPORARILY INSTALL HINGES

AND TORQUE RODS

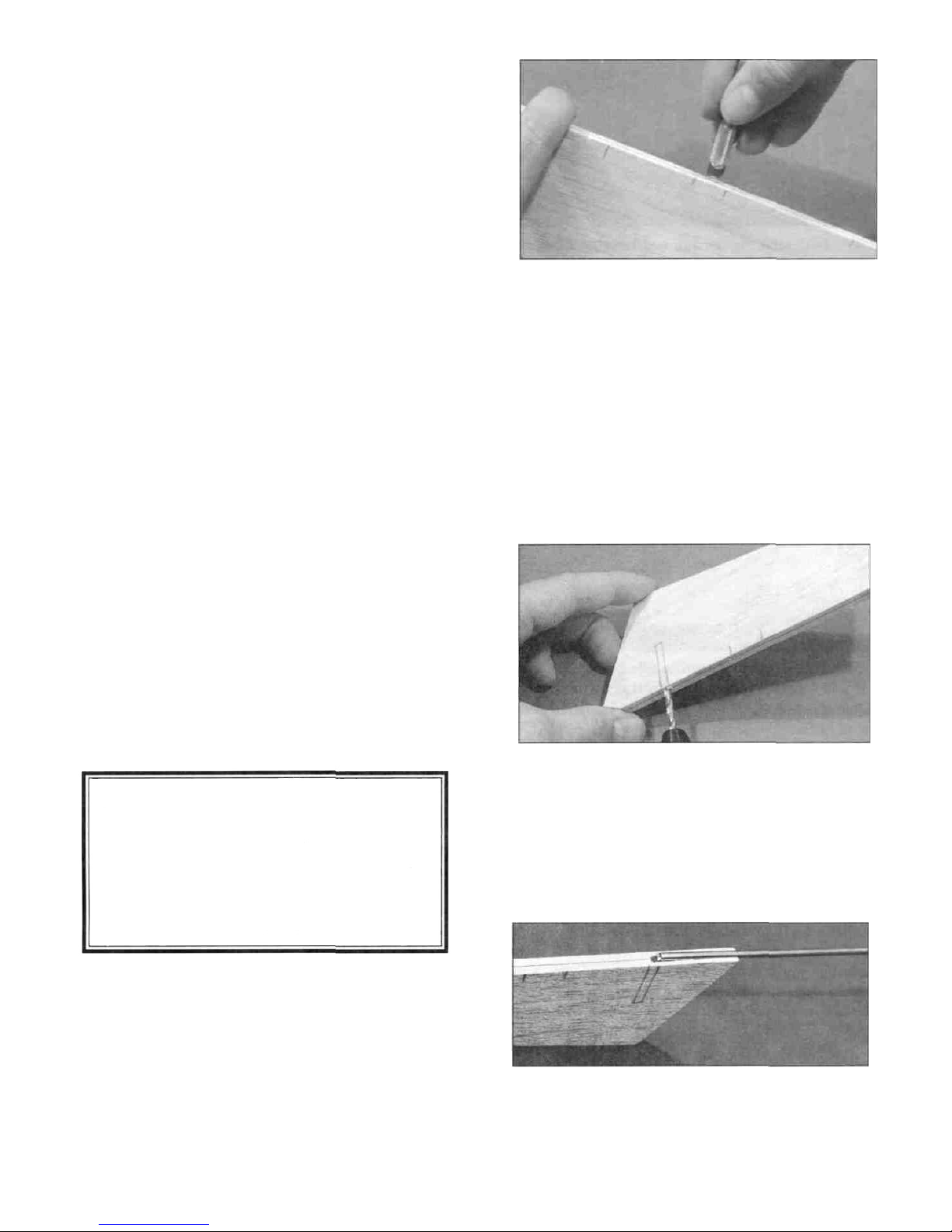

D 1. Using the plans as a guide, mark the hinge

locations on the stabs, elevators, fins and rudders. Also

designate one of each surface as being "right" and the

others as "left."

CAUTION!!! You must use extreme care when

cutting hinge slots with an X-acto knife, to

avoid cutting yourself! If the balsa part breaks

while you are pushing on the knife, the blade

could go into your hand before you know it! A

good precaution is to wear leather gloves while

performing the following steps.

D 2. Cut the hinge slots on the centerlines you drew

earlier. Our recommended hinge slotting method is

described below.

A. Begin by carefully cutting a very shallow slit at the

hinge location. The first cut is to establish your cut in

the right place, so concentrate on staying on the line

and don't cut too deep.

D 3. Check the plans and mark the location of the

torque rods on the rudders and elevators. Drill 7/64"

holes in the rudders and elevators (the holes are drilled

slightly oversize to allow for positioning, and to create a

hard epoxy "sleeve" around the wire). Groove the rudder

and elevator LE to accept the torque rod wires and nylon

bearings (See below).

HINT: Using an X-acto knife, sharpen the inside of one

end of a 1/8" diameter brass tube. and use it to cut the

groove in the leading edge of the rudders and elevators.

9

Page 10

D 4. Determine the torque rod bearing locations

from the plan. Then use a hinge slotting tool to cut the

slots in the stabs and fins tor the nylon torque rod

bearings. Cut a groove in the trailing edge of the stabs

and fins to accept the torque rods and nylon bearings.

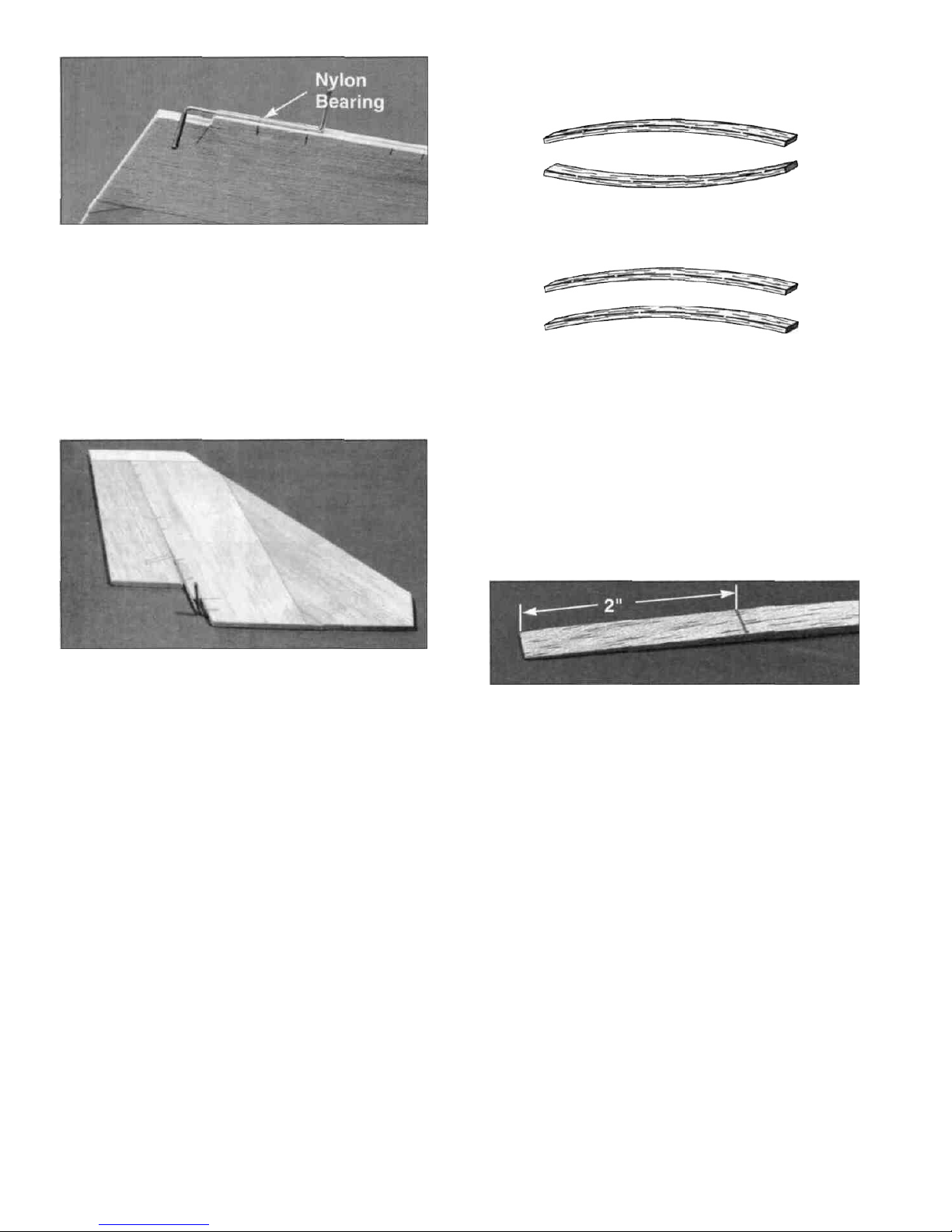

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

STRAIGHT WING

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

WARPED WING

D 5. Trial fit all these parts together using the torque

rods and hinges and trim the fin tips flush with the

trailing edges of the rudders. Check the operation of the

control surfaces but do not glue anything yet.

"WING"

NOTE: The following instructions explain how to build

the wing on a flat surface, directly on the plans. The jig

tabs will automatically build in 1-3/4 degrees of washout

and enable you to build a wing as straight as your work

surface. Because this wing has a lot of taper and sweep,

it is not advisable to build it on a Great Planes Wing Jig.

imperfections. If possible, position each spar so the

imperfections (if any) are on the outer half of the wing

panel (toward the tip), where they will be least affected

by high stress. If the spars are warped slightly, try to

"balance them out" by installing the warped spars in

opposite directions (see sketch). NOTICE: If you feel

that any of the wing parts are unusable due to severe

warps or other defects, give us a call and we'll replace

the parts.

D 2. Sand 2" of one end of each 1/8" x 3/8" x 18"

balsa spar doubler (F146W05) to a taper as shown in

the "Wing Spar Detail" on the plan.

D 3. Glue the spar doublers to the 1/8" x 3/8" x 30"

balsa spars (F146F04) with thick CA as shown in the

"Wing Spar Detail." Take your time and press the spar

assembly flat against the work surface while the glue is

curing. Also rotate the assembly onto its side and press

it down to keep the doubler and spar aligned and straight.

Do this on a flat work surface and most warps can be

eliminated. Wipe off any excess glue before it cures.

SPARS

D 1. Before using the hard balsa spars, examine

them carefully for possible imperfections. Look for

knots, soft spots, diagonal gram and any other

BUILD THE WING PANELS

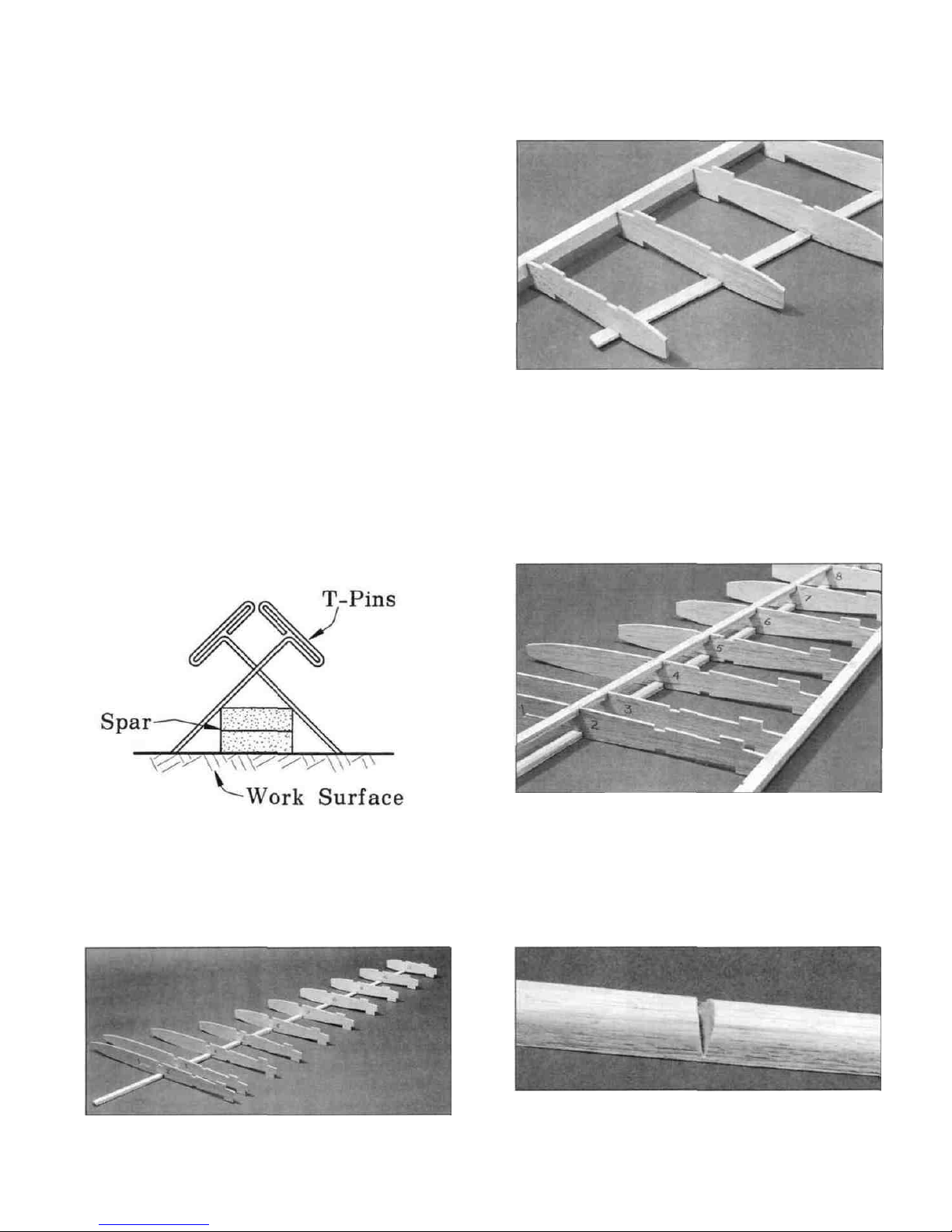

NOTE: If you build in the conventional manner, by

pinning the components to your workbench, it will be

helpful to build the wing on a piece of "Celotex"* or

10

Page 11

other semi-soft (and flat) surface, into which you may

easily stick pins to firmly hold down the wing parts

while building, to avoid warps. *Available from lumber

companies and home centers.

NOTE: You should also be aware of the following:

This wing is constructed with 1-3/4 degrees of washout

(TE higher than LE at the wing tip) built-in. When the

wing is upright, the tabs on the rear portion of the ribs set

the ribs at the proper angles to achieve this slight twist.

When you flip the wing over to work on the bottom side,

the jig tabs on the top of the wing will hold the correct

washout in the wing.

D D 1. Cut the Wing Plan apart on the heavy dashed

line. Tape the right (or left) wing panel plan to your flat

work surface, and cover the wing drawing with waxed

paper (so you won't glue the wing to the plan!).

D D 2. Carefully punch out all the die-cut 3/32" and

1/8" balsa wing ribs. Sand the edges slightly to remove

any die-cutting irregularities or "fuzz."

with the rear-most jig tab against the work surface.

Use a 90-degree triangle to keep the ribs vertical.

D D 5. The shaped and notched wing trailing edges

(F146W07) are fastened together by a thin strip of balsa.

Separate them by cutting with an X-acto knife. Position

the TE in place by working the rear ends of the ribs into

the notches in the TE. Center the TE vertically on each

rib and glue it in place with thin CA.

D D 3. Cross-pin one of the spars to the plan with the

long spar down. and with the thick end (2 laminations)

toward the root. The tapered end of the spar doubler

should end just inside (1/4") of rib W8.

D D 6. Glue the top spar in place (with the long spar

on top). Make sure it is fully seated in the notches so it

does not stick above the top surface of the ribs.

Remember, the spar doubler stops just inside rib W8.

D D 4. Glue ribs W2 through W11 onto the spar in

their correct position. Notice that the ribs are installed

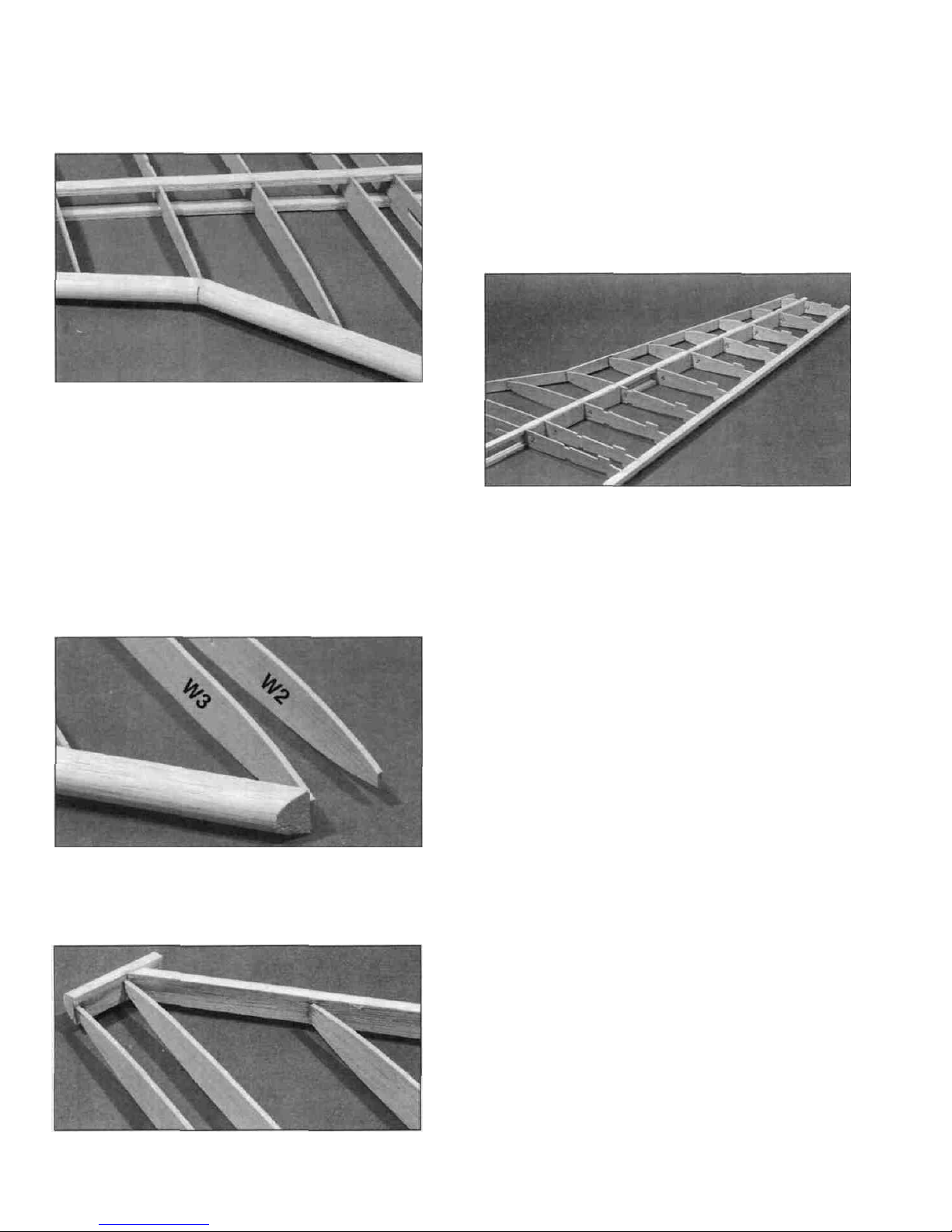

D D 7. Position a shaped balsa Leading Edge

(F146W06) over the Leading Edge Template on the wing

plan and mark where the notch goes. Use a razor saw to

11

Page 12

cut the notch. Make sure you cut the notch perpendicular

to the LE and notice that it does not need to go all the

way through the LE.

W3 and the slanted piece of LE already installed. Trim

the LE flush with W2 and the slanted piece of LE.

D D 8. Glue the LE to rib W5 so the notch is

positioned as shown on the plan and the LE is centered

(up and down) on the rib. Center the LE on ribs W6

through W11 and glue it in place with thin CA. Next,

glue the LE to rib W3 and lastly to rib W4. The LE may

break in two during this step, but this is OK, just glue it

back together as you perform the step. IMPORTANT -

Use the plans as a guide to keep the front of rib W3

positioned correctly.

D D 9. Cut the excess LE off flush with the front of

rib W3. Sand it if necessary to get the face of the LE cut

aligned with rib W2.

D D 10. Glue the remaining piece of LE to ribs W2,

NOTE: In the following steps you'll find it necessary to

remove some of the pins holding the wing down to your

building board. As you do, take other steps as necessary

to continue holding the wing down, such as by applying

weight to the top of the wing, or by relocating the pins.

D D 11. Glue the pre-cut 1/16" balsa vertical grain

shear webs to the rear edge of the spars in all rib bays

except inside of rib W2 and between ribs W5 and W6.

Also glue shear webs on the front edge of the spars in

the first 5 rib bays starting with the W2-W3 bay.

NOTE: You may wish to trial fit, mark, and trim each

web before gluing it in. The webs must be securely

glued to the spars.

D D 12. Trim the tip end of the LE, TE and spars off

flush with rib W11.

D D 13. Trim off the root end of the spars and TE

slightly longer than their correct length (approx. 1/64"

longer). Later, when the two wing halves are joined,

they will be sanded to the correct length. Remove the

wing panel from the work surface.

D 14. Go back to step 1 and assemble the other wing

half. Be sure to build a right wing and a left wing!

ASSEMBLE THE TWO PANELS

D 1. Cut out the two dashed semi-circles on the left

wing plan. Place the left wing plan over the right wing

plan and carefully line-up the centerlines of each plan.

Tape the two plans together. Test fit the two panels

together over the plans and sand the spars and TE as

necessary until you achieve the proper spacing and wing

sweep. Insert the die-cut 1/8" ply front wing plate

(F146F15) and the 1/4" x 1" x 4-13/32" ply front wing

12

Page 13

bolt plate (F146W18) to check the spacing. Make sure

both panels are on a flat surface and lined up correctly

with the jig tabs against the work surface. Refer to the

plans and the following photo. NOTE: The notches for

the middle spar should form a straight line when the

proper amount of sweep is achieved.

D 2. When satisfied with the fit of the two panels,

insert the front wing bolt plate along with the wing front

plate into the slots in the W-2 ribs and glue the spars and

TE'S together with epoxy. Also glue the plates in place.

D 4. Securely glue the 1/8" x 23/32" x 4-5/32" ply

dihedral brace (F146W12) in place between the spars

and against the W1B ribs with epoxy.

D 3. Install the die-cut 1/8" balsa W1B ribs

(F146W01) by inserting them into the trailing edge slots

and rotating them until the front notches contact the

spars. Make sure the aileron servo rail slots in the ribs

are positioned down (near the work surface) and glue

them in place.

D 5. Slide the die-cut 1/8" ply W1A ribs (F146F32)

into place by positioning them at an angle as shown on

the left side of the photo and rotating them until they fit

into place as shown on the right side of the photo. Be

careful not to push the wing front plate out away from

the wing bolt plate during this step. Sand the inside slot

of the W1A ribs if they are hard to slide over the wing

bolt plate. Glue all these pieces together with thin CA

followed by either epoxy or thick CA.

D 6. Soak the entire outer side of each W2 rib with

13

Page 14

thin CA to help harden the wood. Cut four 1" long

pieces of 1/2" triangle from the 1/2" x 36" triangle

(WSTR001H) and glue them in place above and below

the front wing bolt plate and against the W2 ribs. Add

epoxy or thick CA around every joint in this area to

make sure everything is securely glued in place.

of the middle spar in all rib bays. The shear webs will be

too tall and too wide, so just trim them to fit and securely

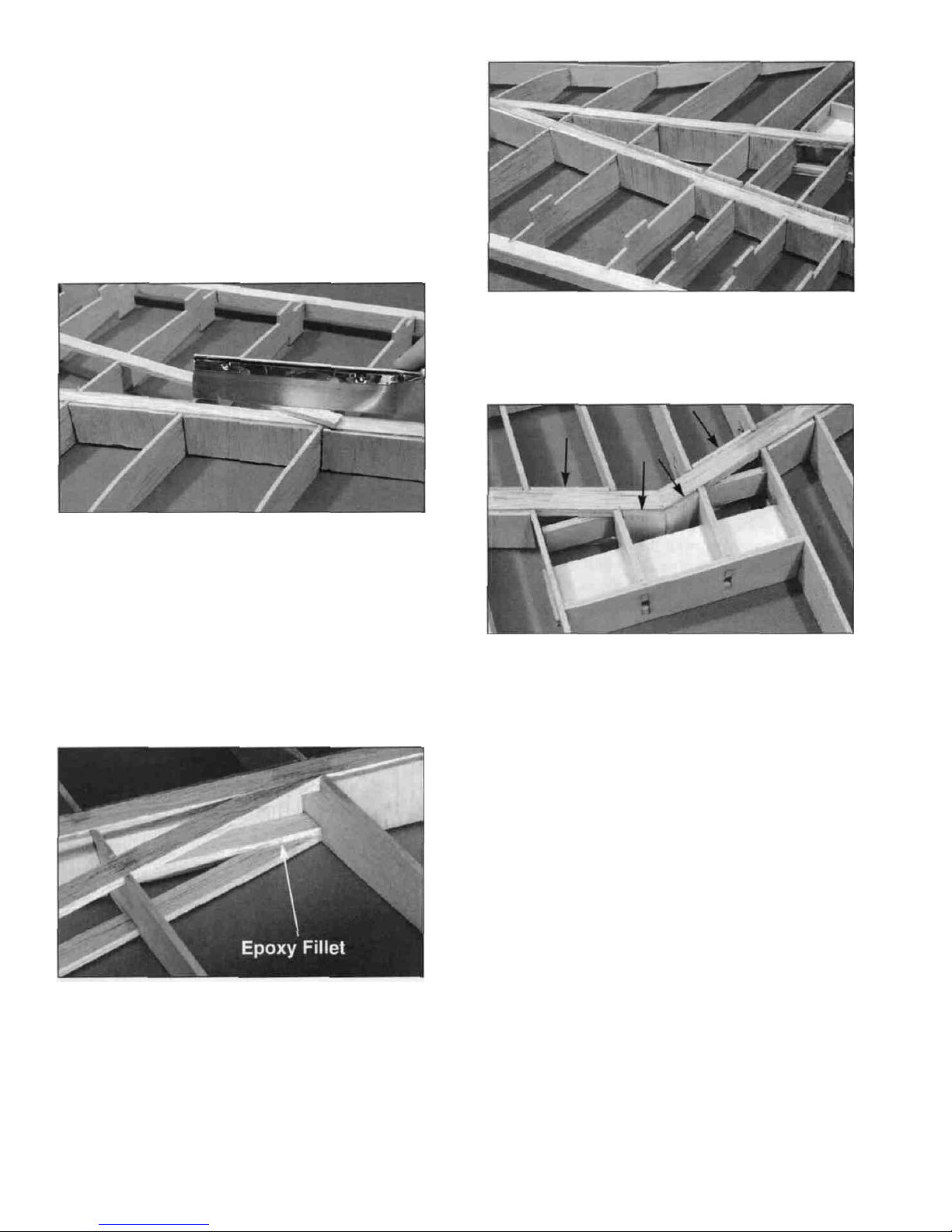

glue them in place.

D 7. Trim the 1/8" x 3/8" x 24" balsa top middle

spar (F146W17) to fit in place by positioning it in the

notches and using a razor saw to accurately cut the taper

on both ends. NOTE: It is important to get the best

joint possible between the middle spars and the main

spars. Securely glue the middle spar in place with epoxy.

D 8. Flip the wing over and install the 1/8" x 3/8" x

24" balsa bottom middle spar just as you did the top

one in the last step. Make a nice epoxy fillet where both

middle spars contact the main spars.

D 10. Cut pieces of shear webs to lit in the three center

bays of the main spar and securely glue them in place.

D 11. Cut two 1-1/2" long aileron servo rails from

the 1/8" x 3/8" x 15" basswood strip (F146F30). Slide

these into the slots in the W1 ribs and use your aileron

servo to properly space them. They should be installed

as far forward as possible and far enough apart to allow

you to get the servo in and out. Securely glue them in

place.

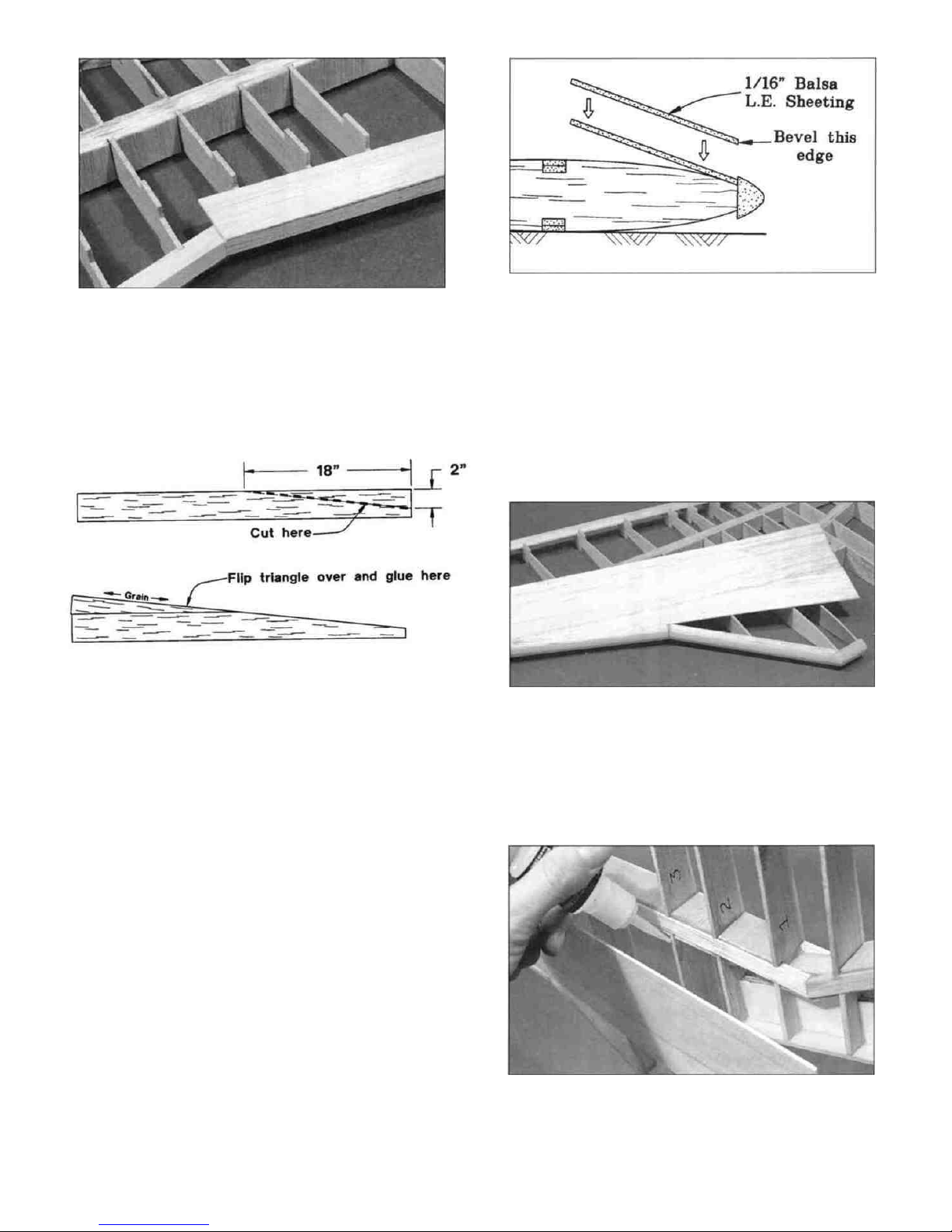

INSTALL THE WING SHEETING

NOTE: In the next steps, maintain straightness by

keeping the jig tabs and spar down on the flat

surface.

D 9. Turn the wing back over so the top is up and

install 1/16" balsa shear webs on the front and the back

D 1. Lightly sand the tops of the ribs to blend with

the notched trailing edge, then glue the two top 1/16" x

1" x 30" balsa trailing edge sheets (F146W14) in place.

14

Page 15

NOTE: The edge of the TE sheet may not be exactly

straight, but just position the sheet so it slightly overlaps

past the TE, and any overlap can be sanded off flush with

the TE later.

aft edge of the sheeting is approximately in the middle of

the spar, then cut off the excess sheeting on the ends,

leaving approx. 1/4" extra to allow for positioning.

D 2. Make four leading edge sheets by cutting a

triangle 2" wide on the end and 18" long off of one end

of each 1/16" x 3" x 36" balsa wing sheet (F146W13).

HINT: Use an X-acto knife and cut a straight line using a

metal straightedge. Flip the triangle over and glue it to

the rest of the sheet as shown in the sketches above.

Notice the grain direction on the small triangle.

NOTE: It will be helpful to have the following items

handy for the next steps: Thin CA, thick (slow cure) CA

and a straight piece of wood (such as an aileron).

D 6. Hold the sheeting tightly against the LE at a

slight angle so it sits down on the LE of the ribs. Use

thin CA to glue the sheeting to the LE only. Do not glue

it to the ribs yet.

D 3. Sand the both sides of each LE sheet smooth

with a sanding block and fine grit sandpaper.

D 4. Before applying the leading edge sheeting in the

next steps, use your T-bar to lightly sand off the edges of

the shear webs and smoothly blend the ribs to the spar.

Also, clean up the LE/rib joints to remove any glue

globs.

D 5. Sand the front edge (the edge with the triangle

glued to it) to a slight bevel so it will fit snugly against

the back of the leading edge. Trial fit it before

proceeding. Position the sheeting left or right until the

D 7. Tilt the wing up, with the LE down, and apply a

drop or two of thick or slow curing CA to each rib. Hold

the wing at an angle so the glue will flow down and coat

the edge of each rib. Apply a line of glue to the

15

Page 16

front edge of the spar. Immediately place the wing on

your flat work surface and press the sheeting into place.

Use a piece of wood (an aileron works OK) to hold the

sheeting in place while the glue cures. It is important to

keep the wing flat during this process as the LE sheeting

will "lock" the wing together.

D 10. First glue the sheeting against the LE sheeting

already in place. Try to line up the edges as closely as

possible. Drip some thick CA down the ribs and press

the sheeting into place. Add CA along the LE and use a

small but flat piece of wood to keep the sheeting straight

along the LE (turtle deck former T1 works well for this).

Trim the end of the sheeting flush with rib W2.

D 8. Trim the tip end of the sheeting flush with rib

W11. Trim the root end of the sheeting flush with the

centerline of the wing, rib W2 and the wing front plate.

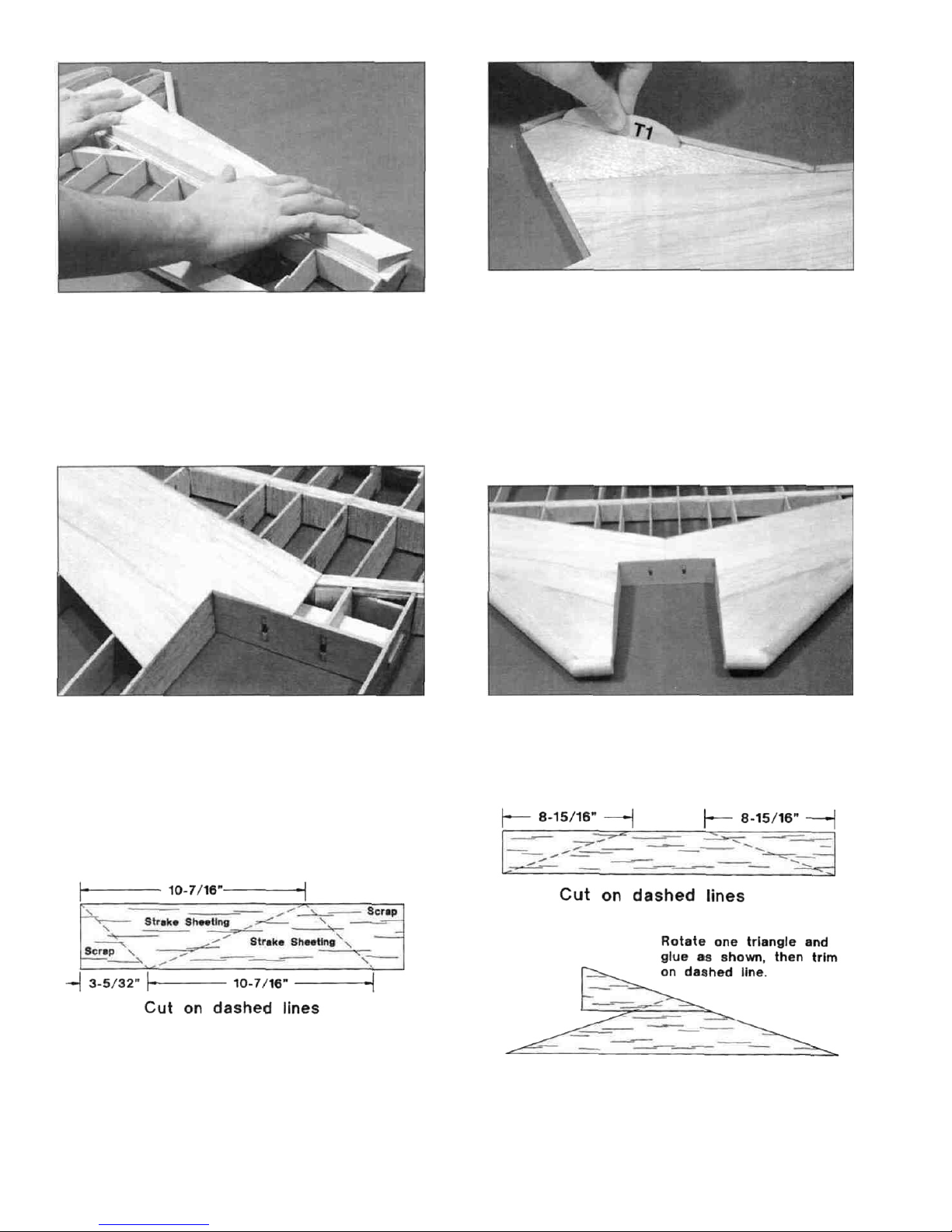

D 9. Cut the four pieces of 1/16" x 3" x 15" balsa

stock

sheeting

(F146W23)

as

shown

in

the sketch

above. Test fit one of the pieces in place in front of the

leading edge sheeting and trim and sand it as necessary

to make it fit. NOTE: The grain should run along the

LE.

D 11. Sheet the opposite wing panel using the same

procedure outlined above.

D 12. Cut two 1/16" x 3" x 24" balsa center sheets

(F146W15) and assemble two triangles as shown above.

Use one in the next step and save the other for the bottom

of the wing.

16

Page 17

D 13. Test fit the triangle sheeting into place and sand

it if necessary to achieve a good fit. It should go half

way back on the middle spar. Glue it in place by

applying thick or slow curing CA to the ribs and spars

and holding the sheeting in place while the glue cures.

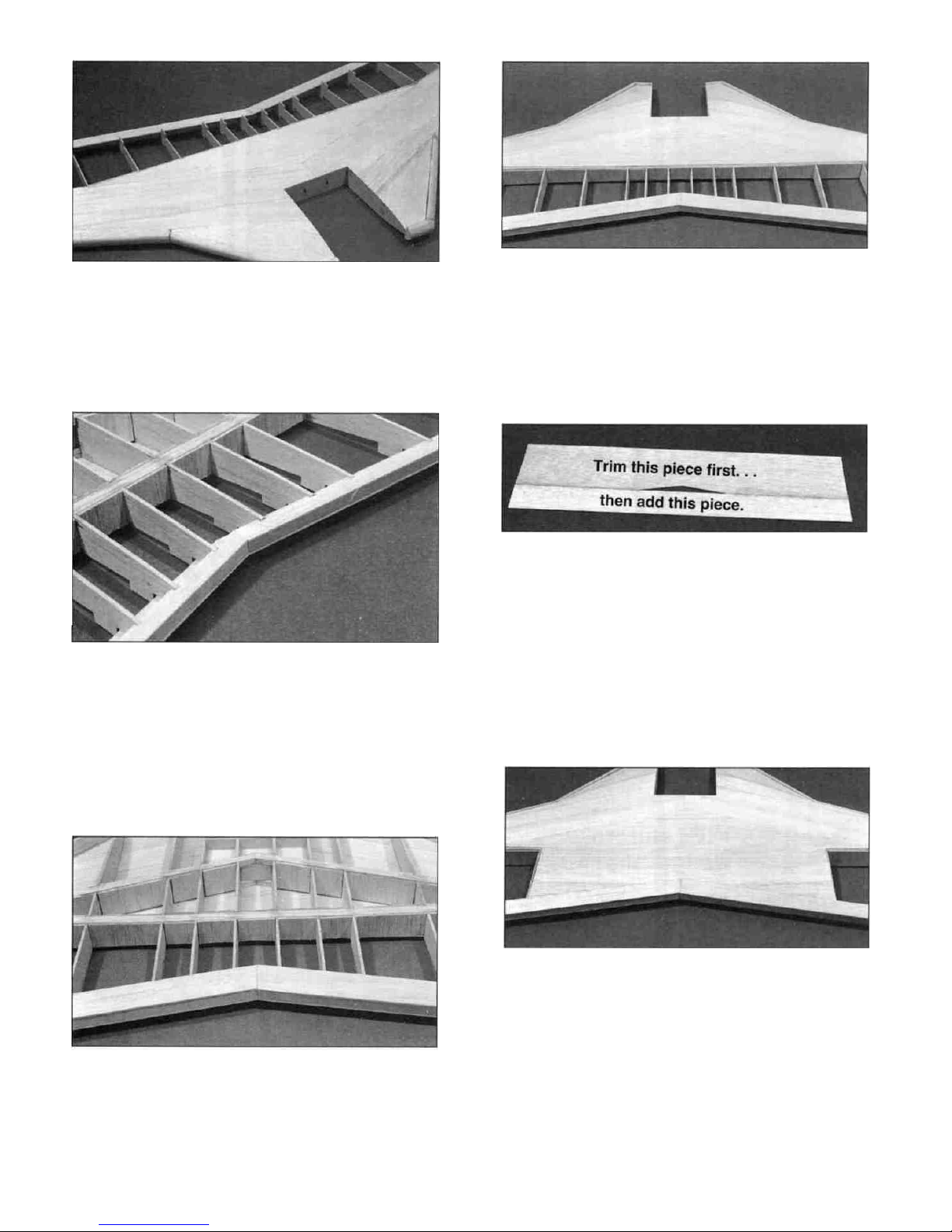

D 16. Install the remaining 1/16" leading edge

sheeting, the strake sheeting and the center triangle sheet

using the same procedure outlined in steps 2-13.

D 14. Flip the wing over and carefully trim off the jig

tabs on the bottom of the wing (the side opposite the side

you just sheeted). Use a sanding block with a fine grit

sandpaper to touch up where the tabs were and to blend

the ribs into the TE. Be careful not to change the

shape of the ribs during this step.

D 17. Trim one of the 1/16" x 3" x 18" balsa rear

wing sheeting (F146W21) pieces to fit in place behind

the triangle center sheet. An easy way to do this is to

tape it in place behind the triangle center sheet and lay a

straight edge along the front edge of the 1" TE sheeting.

Mark where both sides of the TE sheeting continue under

the rear sheeting. Remove the rear sheeting and cut out

the triangle formed by the lines you marked. Cut another

of the rear sheeting pieces in half lengthwise and glue

one half to the rear edge of the piece you just trimmed to

fit.

Tape the sheeting back into place and mark where the TE

sheeting intersects the outside edges. Cut the aft piece of

sheeting to fit and glue the rear sheeting in place with

thick or slow CA.

D 15. Add the remaining two 1/16" x 1" x 30" balsa

TE sheets just as you did earlier on the top surface. Do

one panel at a time and keep the panel flat on the work

surface until the glue cures. Note: Due to the taper of

the wing, the jig tabs on the top surface of the wing will

only keep one panel flat at a time.

D 18. Cut a semicircle out of the sheeting between ribs

W4 and W5 as shown in the next photo.

17

Page 18

D 19. Flip the wing over. On the side that still has the

jig tabs attached, write the word "top" near the center of

the wing. Trim and sand off the remaining jig tabs.

Touch up the ribs with a fine grit sanding block and add

the rear sheeting just as you did in steps 17 and 18. Trim

all sheeting flush with the W11 ribs and lay the wing

aside until later.

INSTALL AILERON TORQUE RODS

rods come up through it. Cut notches there to clear the

torque rods. Test fit the wedge on the wing and sand it if

needed to get a good fit. Test fit the torque rods in the

groove to make sure they fit OK. If not, sand the groove

and notch until they do. Also cut small clearance

notches on the bottom side of the wing where the

threaded portion of the torque rod will be located. Note:

The torque rod horns must exit the BOTTOM of the

wing!

D 5. Slide the plastic bearings toward the threaded

end of the torque rods. Then use a toothpick to apply a

small amount of petroleum jelly to the ends of the plastic

tubes (to help prevent glue from getting inside and

locking up the torque rods).

D 1. Roughen the un-threaded end of the aileron

torque rods (WBNT167) with 100-grit sandpaper, and

file the same end to a wedge shape.

D 6. Use epoxy to glue the plastic bearing tubes into

the grooves in the rear wedge. Make sure the torque rods

are fully seated in the groove. Wipe off any excess glue

and allow it to harden.

D 2. Roughen the surface of the plastic bearing tubes

with 100-grit sandpaper.

D 3. Clean the torque rods and bearing tubes with

alcohol.

D 4. Position the 1/2" balsa grooved rear wedge

(F146W10) over the plans and mark where the torque

D 7. Sand the TE of the wing to make it straight with

square edges.

D 8. Trial fit the rear wedge/torque rod assembly

onto the wing trailing edge. It should be centered up and

down on the wing TE so the torque rods are located at

the centerline of the TE. Sand the TE if necessary to get

a good fit then glue the wedge in place with epoxy.

HINT: Use masking tape to hold the wedge against the

wing TE and to aid in positioning it.

D 9. Locate the tapered balsa center TE (F146W09)

(it is 10-1/8" long and has the same cross section as the

18

Page 19

ailerons) and cut a notch in both ends to clear the torque

rods. Also sand the very front of the ends if needed to

make it fit in place against the rear wedge. Tape it in

place with masking tape and check to make sure it is not

tilted up or down You can use the edge of a 1/8" balsa

fuse doubler (F146F02) as a template to check the

center TE alignment, but be sure to check it from the top

and the bottom of the wing When satisfied with its

alignment, glue it in place with thin CA Be very

careful around the ends so you don't glue the torque

rods!

D

10

Use some

lightweight

wood

filler

to

blend

the

rear wedge and center TE in with the contour of the

wing. After the filler has cured, use a sanding block to

smooth things out.

This is all we will do to the wing until after it has

been fitted to the fuselage and the turtle deck has been

added This will help keep the wing tips, cap strips and

ailerons from getting dinged up in the process.

top (F146F03), fuse side bottom (F146F01) and aft fuse

side (F146F04) together, sanding as necessary for a good

fit Make sure they line up with the plans and glue them

together.

D D 2 Assemble a 1/8" balsa fuse doubler by

gluing a die-cut 1/8" balsa doubler top (F146F03) to a

die-cut 1/8" balsa doubler bottom (F146F02).

D D 3 Position the doubler on top of the fuse side

and align its edges and lightening holes with the edges

and lightening holes of the fuse side Glue the doubler to

the fuse side by applying thin CA around all edges of the

doubler, including the lightening holes NOTE: The

doubler stops 1/4" before the front of the fuse side to

hold F-l Important: Do not make two right sides'

Glue the doubler to the opposite side when making the

second side.

FUSELAGE ASSEMBLY

PREPARE FUSE SIDES

D D 1. Working over the fuselage side view covered

with waxed paper, trial fit a die-cut 1/8" balsa fuse side

D D 4. Assemble a turbine inner side by test fitting a

die-cut 3/32" balsa turbine inner side (F146F07),

turbine side bottom (F146F08) and turbine inner aft

19

Page 20

side (F146F09) together over the plans Carefully sand

them if needed to achieve close fitting joints When

satisfied with the fit. add thin CA to all joints After the

glue has cured, apply thick CA to any loose-fitting joints.

D D 5. Assemble a turbine outer side by test fitting a

die-cut 3/32" balsa turbine outer side (F146F26),

turbine side bottom (F146F08) and turbine outer aft

side (F146F10) together over the plans Carefully sand

them if needed to achieve close fitting joints When

satisfied with the fit. add thin CA to all joints After the

glue has cured, add thick CA to any loose fitting joints.

Sand both sides smooth with a fine sanding block.

D D 6 Glue a die-cut 3/32" balsa turbine side

doubler (F146FOS) to the outer turbine side Line if up

with the wing saddle and add thin CA around the edges

When doing this step for the second side, make sure you

glue the doubler to the opposite side, making a right and

a left set

D 9 Carefully position a turbine inner side on each

fuse side Do this over the fuse side view on the plans

and use the wing saddle to help align them Make sure

they are correctly positioned and add thin CA around the

edges, lightening holes and former notches.

IMPORTANT - Be very accurate when doing this.

Make sure the two turbine sides are installed at the same

angle and position in relation to the sides To check this,

hold the two fuse sides together and compare the

alignment of the turbine sides before securely gluing the

second side NOTE: The turbine inner side is attached

to the fuse side, not the doubler

D 10 Test fit the two die-cut 1/8" balsa front fuse

bottom halves (F146F05) together Sand them slightly

if needed and glue them together Test fit the die-cut

3/32" balsa rear fuse bottom (F146F06) in place

D D 7 Inspect all glue joints for gaps and add thick

CA if necessary to strengthen the joints Repeat the

above steps to make another set of sides. Make sure

you assemble a RIGHT and a LEFT set of sides!

D 8 Place the two assembled fuse sides together.

Lightly sand the edges as necessary to make the two

sides identical Do the same for the turbine sides Also

sand the sides of each assembly smooth with a fine

sanding block It is rather hard to do this later'

Line up the entire bottom over the plans to keep if

straight and glue the rear onto the front Make sure both

pieces are pressed flat against the work surface Write

the word "TOP" on the side facing up (this will keep the

smooth side towards the outside of the fuse) When the

glue has cured, flip if over and sand the bottom smooth

with a tine sanding block.

20

Page 21

PREPARE THE FIREWALL (F1) ASSEMBLE FUSELAGE

NOTE: Photos show a 60-size engine mount (Great

Planes MM60 included) set up for a side mounted

2-cycle engine. If you will be using a different mount,

you'll have to determine the correct mounting position.

D 1. Locate the two 1/8" die-cut ply F-l's (F146F18)

and use a fine sanding block to remove any fuzzy edges.

Use epoxy to glue the two pieces together, making a 1/4"

thick firewall. Make sure they are accurately lined up

with one another and one of the sides with the punch

marks is showing. Wipe off any excess glue before it

cures.

D 1. Trial fit the die-cut 1/8" ply formers F-2, F-3,

F-4, F-5 (F146F15). the 1/4" ply front wing bolt block

(F146F20) and the 1/4" ply rear wing bolt block

(F146F25) to make sure they fit into the appropriate

slots. If there is any excess glue in any of the fuse

doubler slots, clean it out with an X-acto knife. If it is

necessary to trim any of the formers, be sure to trim both

sides of the formers the same amount to keep them

symmetrical.

D 2. If you are using the engine mount supplied, you

can drill at the punch marks provided. If you are using a

different mount, center the engine mount on the firewall

and mark the bolt locations through the mount. Drill

5/32" holes at the bolt locations, then install the 6-32

blind nuts (NUTS003) on one side of F-l. This will be

the back. Press the

blind nuts in with a

vise, or tap them in

with a hammer.

D 3. Temporarily attach the engine mount to the

firewall with the 6-32 x 5/8" socket head bolts

(SCRW037) to make sure the holes are in the correct

position. Adjust the holes if necessary and then glue the

blind nuts in place. Remove

the mount.

D 2. Assemble formers F-2, F-3 and the 1/4" ply

front wing bolt block between the two fuse sides. Add

the bottom (with the word "top" toward the formers) to

keep everything straight and use masking tape and/or

rubber bands to hold things together. Make sure all the

tabs are fully seated in their notches and add a couple of

drops of thin CA to each joint. Use only as much glue as

required to hold things together. We will come back and

securely glue everything a few steps later.

D 3. Install the 1/4" ply rear wing bolt block and

former F-4 using thin CA. Push the rear of the fuse

bottom down below the fuse sides to allow the sides to

relax some. This will make it easier to hold the fuse

sides against F-4.

21

Page 22

D 4. Snap former F-5 into place and glue it to the

fuse sides only. Keep the fuse bottom pushed down for

now.

D 5. Slide formers F-6 (F146F16) and F-7 (F146F17)

into their respective slots and pull the fuse sides out

against the formers. Push the fuse bottom up against the

bottom of F-5, F-6 and F-7 to lock the fuse sides in

place. Glue the fuse sides and the fuse bottom to the

formers below the fuse bottom but do not glue the sides

above the bottom yet.

fuselage. Sand the tank floor if necessary to get a good

fit around the firewall and glue these in place with epoxy.

Before the epoxy cures, pull the fuse bottom up into

place and center the fuse sides with the bottom. Glue the

bottom into place with CA The triangular gaps formed

are for 1/2" triangle stock which will be added later.

NOTE: If you are not installing retracts and would like

to use a larger than 10oz. fuel tank, you can leave the

fuel tank floor out. It does add some rigidity to the front

but it is not absolutely necessaiy. Although the fuselage

will hold a much larger tank, the balance of the plane

may be greatly affected by the extra fuel in the nose.

D 8. Tack glue former F-2E (F146F13) into place on

the turbine inner side with one drop of thin CA. Tack

glue a turbine outer side onto F-2E, F-6 and F-7 with the

doubler facing the fuselage. Install the opposite turbine

side the same way. Do not securely glue around F-2E

until the rest of the formers are installed.

D 6. Sight along the rear portion of the fuse bottom

to make sure it lays smoothly and then add thin CA along

the fuse bottom from F-2 back to F-7.

D 7. Test fit the 1/8" ply fuel tank floor (F146F15)

and the firewall (F-l) into place in the front of the

D 9. Snap formers F-3E. F-4E and F-5E (F146F18)

into place on both sides of the fuselage. Do not glue

22

Page 23

yet! Due to the bending of the turbine side. it is normal

for formers F-2E to slant slightly. This is all right but try

to make both slant the same amount.

D 10. Locate the die-cut 1/8" balsa front turbine

bottoms (F147F11) and rear turbine bottoms

(F146F12) and assemble the turbine bottoms over the

plans. Sand the pieces if needed to achieve a good joint

and glue them together. Test fit the assembled turbine

bottoms in place on the bottom of each turbine. Do not

glue the bottoms in place! Use the bottoms as guides to

align the formers and glue the formers to the sides only.

FIXED GEAR

D 1. Test fit the 1/8" ply landing gear doublers LG-3

and LG-4 (F146F32) against formers F-3 and F-4

respectively. They should be positioned as shown in the

D 11. Position the die-cut 1/8" balsa inlet braces

(F146F11) so they hold the turbine outer sides at a

natural curve, as shown on the plans and glue them in

place. Remove the bottoms after the glue has cured.

D 12. Add 1/2" balsa triangle (WSTR001H) above

and below both 1/4" ply wing bolt blocks and then soak

the fuse sides around both with thin CA to strengthen

this area.

SUGGESTION: From this point on, we recommend

using a padded "cradle" such as a Robart Super Stand to

protect the fuselage from dents and dings. You can

modify the stands to fit the fuselage by cutting one

upright off flat and enlarging the other upright to fit the

front of the fuselage.

LANDING GEAR

Skip ahead to the "RETRACTS" section if you are

installing retracts.

cross section views on the plans. LG-3 on the back of

F-3 and LG-4 on the front of F-4. Sand them if

necessary and then epoxy them in place.

D 2. Position a nylon landing

gear strap (NYLON36) towards

one end of a 7/16" x 5/8" x 1-1/8"

basswood short grooved LG

block (F146F28) and mark where the holes will be

located. Drill 1/16" holes at these locations. Do this to

both 1-1/8" pieces.

23

Page 24

D 3. Test fit the 7/16" x 5/8" x 5-1/8" basswood

grooved landing gear blocks (F146F27) into the middle

slot on the landing gear doublers with the groove towards

the top of the fuse. Center it between the two doublers

and draw a line on the grooved block at the front of LG-4.

D 4. Remove the grooved block and drill a 3/16"

hole 3-1/4" in front of the midpoint of the line you just

drew. Drill the hole perpendicular to the LG block and

centered so it connects with the groove on the other side.

D 7. Insert the axle end of the 5/32" main gear wire

(WBNT165)

from the top of the fuse

through

the

3/16"

hole and pull the gear down into the groove. Notice

there is a right and a left main gear. Press the 1-1/8"

block (with the holes up) onto the wire sticking up out of

the groove. Install the three nylon landing gear straps

using #2 x 3/8" sheet metal screws

(SCRW024) to pull the wire fully

into the grooves. Check to make

sure the 1-1/8" block will seat flat

against LG-4. If not, adjust the bend in the wire and/or

elongate the 3/16" hole to get things to fit correctly. Do

not glue the short blocks in yet!

D 5. Flip the grooved landing gear block over and

drill two sets of 1/16" holes using the nylon landing gear

straps as templates. One set of holes should start near the

3/16" hole and the other should start about 1" from the

other end of the block as shown in the photo.

D 6. Epoxy the 7/16" x 5/8" x 5-1/8" grooved

hardwood landing gear block in place with the line you

drew earlier even with the front of LG-4. NOTE: The

groove should be towards the top of the fuselage.

D 8. With both main gear installed, set the fuse on

the work surface to check the alignment and tilt of both

main gear. Hold each axle flat against the work surface

and allow the fuselage to rest on former F-7 so it is level.

Make any necessary adjustments and then epoxy the

1-1/8" blocks into place. Remove the main gear and

apply a generous fillet of epoxy around all landing gear

components.

24

Page 25

D 9. Glue the turbine bottoms into place. Make sure

the die-cut strut opening is near the outside of the

fuselage. Temporarily replace the main gear to check the

size and location of the strut opening. Enlarge it if

necessary to allow for the flexing that will occur during

rough landings. Skip ahead to GENERAL FUSELAGE

ASSEMBLY on page 27.

F-3 and LG-4 on the front of F-4. Sand them if

necessary and then epoxy them in place.

RETRACTS

The following instructions explain how to install

Hobbico Low Profile Mechanical Retracts (HCAP4000).

If you are using another type of retract, you will have to

modify the following instructions to suit your

installation.

D 1. Test fit the 1/8" ply landing gear doublers LG-3

and LG-4 (F146F32) against formers F-3 and F-4

respectively. They should be positioned as shown in the

cross section views on the plans: LG-3 on the back of

D 2. Locate the 1/4" x 1/2" x 4-7/8" basswood

retract rails (F146F23) and sand them to fit between

F-3E and F-4E. Take your time and try to get a good

joint between the rails and the formers. Epoxy them in

place.

D 3. Position the retract between the rails (from the

bottom of the fuse) so the strut is approx. 1-1/2" behind

F-3E. Mark where the retract mounting holes should be,

remove the retract and drill 1/16" holes in the retract

rails. It is important to keep the drill perpendicular to

the rails when drilling since the retract is actually going

to be installed from the top. NOTE: Due to the angle of

the retract, it is very helpful to use socket head sheet

metal screws (not included) along with a ball driver to

secure the retract. We used Du-Bro #380 #2 x 3/8"

SHSMS. Larger #4 screws could be used but are not

necessary.

25

Page 26

D 4. Using the socket head sheet metal screws, install

the retract (from the top), with the actuator arm pointing

towards the rear. using the socket head sheet metal

screws. Note: There is a right and a left strut. Install

the retracts so the bottom leg of the strut is "outside" of

the coil.

D 5. Use a 2 mm ball driver to loosen the strut

retaining set screw in the retract and twist the strut so the

coil is pointing towards the rear of the plane. Re-tighten

the set screw.

D 6. Retract the strut until it hits former F-4E. Use a

razor saw to cut through the former approx. 1/8" on each

side of the strut. Fully retract the strut to make sure the

coil doesn't hit the actuator arm. If it does, loosen the set

screw and twist the strut slightly until it retracts without

binding. Re-tighten the set screw.

D 7. With the retract in the down position, check to

make sure the top end of the strut is flush with the top of

the retract mechanism (this is how they came). If it isn't,

loosen the set screw and move the strut up or down until

it is. Make a mark 3-3/4" below the bottom of the coil

on the front of the strut. If your strut is black, you can

make a light scratch. It is important that you mark the

front as best as possible so you make the bend correctly

and keep the coil pointing the way it should.

D 8. Remove the strut from the retract and make a

bend where you made the mark. Try to keep the bend

perpendicular to the front of the strut (where your mark

is) and be sure to make a right and a left. Use the

Retract Strut Template on the plan to achieve the

correct angle. If you don't have a wire bender that will

bend the wire in a tight radius, you can use a vise and a

hammer. Insert what will be the axle part of the strut into

the vise with the front mark even with the top of the vise

jaws. Make sure the mark is directly facing the side of

the vise jaws and use the hammer to help bend the strut.

If you push on the coil while you tap the strut just above

the vise jaws, you will get a nice tight bend.

Occasionally remove the strut and check it against the

Retract Strut Template on the plans to get the right

amount of bend.

D 9. Determine the correct length for the axles by

installing the wheels and collars, and cut off the excess

axle flush with the wheel collar. A Dremel tool with a

reinforced cut-off wheel works well for cutting this

hardened wire, but always wear eye protection.

D 10. Use a small piece of 150 grit sandpaper to make

some fine scratches on the front of the strut in the area

where the existing notch (for the set screw) is. Use a

black permanent marker to color the area you just

scratched up. Replace the struts in the retracts with the

wheels attached and twist them until the wheels are

26

Page 27

pointing straight ahead in relation to the fuselage. Also

check to be sure the top of the strut is flush with the

retract mechanism. Gently tighten the set screw and then

check to make sure they retract smoothly without the

coils binding on anything. When satisfied with their

operation and alignment, tighten and loosen the set screw

a couple of times to make a mark where it is touching the

strut.

D 11. Remove the struts and locate the marks where

the set screw was. Lay the strut down with the axle flat

against the work surface. The set screw mark should be

pointing directly up. Use a small file or a dremel tool

with a cutoff wheel to make a notch (not just a flat spot)

that extends 1/8" above and 1/8" below where the mark

was. Be careful to keep the notch level with the work

surface or your wheel will be twisted off line.

GENERAL FUSELAGE ASSEMBLY

D 1. Cut the 3/32" x 3" x 7-7/8" balsa inlet sheeting

(F146F33) into four 1-7/8" long pieces. Use these to

sheet the bottom of the turbine inlets as shown in the

photo. Trim and sand them flush with the turbine outer

side. Trim the front of the sheets perpendicular with the

fuse sides approx. 1/8" in front of where the turbine sides

end.

D 2. Use a sanding block to sand the edges of the

turbine sides and bottoms down to the formers. Use a

long sanding block (10" or longer) and keep it pressed

against the side and the bottom to keep from sanding

dips and unnecessary angles into the balsa.

D 12. Replace the struts in the retracts and tighten the

set screws down onto the notches you just made. Check

to make sure the wheels are still pointing straight ahead.

If not, remove the strut from the retract and adjust the

notch until the wheel is straight. If your notch gets too

deep, you can use a vise or a couple pair of pliers to twist

the wheel straight. Do this by holding the axle (don't

scratch it) and twisting the coil. Operate the retract to

make sure everything works smoothly.

D 13. Remove the strut from the retract and glue the

turbine bottoms in place. Make sure you install them

with the die-cut strut opening near the outside of the

fuselage.

D 3. Glue the four bottom 1/4" x 1-3/8" x 27" balsa

turbine corners (F146F21) into place. Thin CA works

27

Page 28

well for this because it allows you to hold them in

position and then add the glue. After gluing them in

position apply a bead of medium CA from the inside of

the fuselage.

top corner of the fuselage. Trim them if necessary to

make them fully seat in the notches and insert a piece of

1/4" thick balsa (a fin) to check the support positioning.

A tight fit is preferred and a loose fit is not acceptable.

Hold the supports against the balsa if neccessary to get a

good fit and glue them to the formers.

D 4. Trim the excess wood off of the turbine comers

with a hobby knife. Save a couple large scraps of this

wood for use when constructing the nose cowl. Then use

a razor plane and a sanding block with coarse sandpaper

to roughly shape the turbine corners to the cross sections

shown on the plans. There is no need to fine sand the

comers yet, because they may get banged around during

the rest of the construction.

D 5. Locate the four die-cut 1/8" balsa stab supports

(F146F04) and notice that they have an "S" embossed on

them near one corner of the support. Test fit them into

place between F-6 and F-7 so the "S" is in the forward,

outside corner of the fuselage. Trim them if necessary to

make them fully seat in the notches and insert a piece of

1/4" thick balsa (a stab) to check the support positioning.

A tight fit is preferred and a loose fit is not acceptable.

Hold the supports against the balsa if neccessary to get a

good fit and glue them to the formers.

D 6. Locate the four die-cut 1/8" balsa fin supports

(F146F01) and notice that they have an "F" embossed on

them near one corner of the support. Test fit them into

place between F-6 and F-7 so the "F' is in the forward,

D 7. Cut two 10-1/2" pieces of 1/2" triangle from the

1/2" x 30" triangle stock (WSTR001H). Slide these

into place along the fuse bottom through the gaps by the

firewall. They extend from F-2 to the front of the

firewall. Press them into the corner of the fuselage and

glue them in place with thin CA. If you are not using

retracts, skip ahead to "Install Radio" on page 29.

INSTALL NOSE GEAR RETRACT

D 1. Glue the die-cut 1/8" ply front retract rails

(F146F32) in place on top of the fuel tank floor as shown

in the photo for step 5 of this section.

28

Page 29

D 2. Cut the front retract opening pattern out of

the plans and position it on the fuse bottom with the back

edge against the turbine inlets. Trace the opening onto

the fuse bottom.

screws, we drilled 1/16" holes. Mount the retract using

the screws you're going to use and then grind off any of

the screws that protrude up into the fuel tank

compartment. This will keep the screws from damaging

the fuel tank.

INSTALL RADIO

As discussed on page 5, there are several possible

radio installation options that you can use with the F-14.

The following instructions explain our recommended

radio installation. It requires one rudder servo, two

elevator servos, and one retract servo. If you prefer to

use a different installation, read these instructions but

ignore or modify any steps that do not apply to your

installation.

D 3. Carefully cut the front retract opening into the

fuse. It is a good idea to cut about 1/16" inside the

opening and use a Dremel tool with a sanding drum to

nicely shape the opening to the desired size. NOTE: If

you are using retracts other than Hobbico low profile or

your nose strut is a different length or shape, you will

have to modify the retract opening to fit your nose gear.

D 4. Position the nose retract unit inside the fuse and

line it up with the centerline of the fuse bottom. Move it

forward so the front of the unit is approx. 1/4" behind the

front edge of the retract cutout. Mark where the

mounting holes should be drilled and remove the retract.

D 5. Drill the mounting holes where marked. Since

we mounted our retracts with #2 socket head sheet metal

D 1. Locate one of the die-cut 1/8" ply Front servo

trays (F146F32) and test fit it in place on the right* side

of the fuse. This tray will be for the rudder servo, so test

fit your rudder servo in the opening to make sure it will

fit. Enlarge the opening if necessary. *NOTE: As a

general rule, the rudder servo should go on the same side

as the nose gear retract steering arm. If you are using

fixed gear, install the rudder servo on the left side of

the fuse. The nose gear pushrod will then pass

through the firewall on the opposite side of the

throttle pushrod. Tack glue the servo tray in place

approx. 3/8" below the lightening hole in the inner

turbine side. Put your servo in place and check to see if

the servo arm is positioned correctly in relation to the

lightening hole. The bottom surface of the servo arm

should be slightly above the bottom of the lightening

hole so the nose gear pushrod can go under the front

wing bolt block. Adjust the height of the servo tray if

necessary and securely glue it in place. Mount the

rudder servo using the screws that came with your radio.

If you are only using one elevator servo, install the

remaining front servo tray on the other side of the

fuselage. If you are using two elevator servos, there is

no need to install the other front servo tray.

29

Page 30

D 2. Punch out the two die-cut 1/8" ply rear servo

trays (F146F32) and test fit your servos to make sure

they fit. You will normally have to enlarge the opening

for the retract servo. Test fit the trays in place. Refer to

the plans to see how they are positioned and sand them if

needed to get them to fit. Tack glue the rear servo trays

in place approx. 1/2" below the lightening hole in the

inner turbine side. Put your servos in place and check to

see that the servo arms are positioned just below the

middle of the lightening hole. Adjust the servo trays if

necessary and securely glue them in place. If you are not

installing retracts, skip ahead to step 10.

so they don't flex during operation. Install an E-Z

connector approximately 9/16" from the center on a large

servo arm. Put the retract servo in place with the servo

arm on it to get an idea where the three pushrods must

meet. Use a 2-56 steel clevis on the retract end of each.

NOTE: There are a couple of places in the construction

sequence where you are required to solder certain metal

parts together. When you find it necessary to solder, use

the following procedure:

A. Roughen the area to be soldered with fine

sandpaper, then thoroughly clean the items to be

soldered with alcohol or degreasing solvent.

B. Assemble the items to be soldered.

C. Apply a small dab of soldering flux.

D. Heat the metal with a soldering gun or iron, and

apply solder to the metal. The metal must get

hot enough to melt the solder, and the solder

must freely flow into the joint.

E. Do not move the parts until the solder has

cooled.

F. Clean off the excess flux with alcohol or solvent.

G. Test the joint by pulling hard.

RETRACT PUSHRODS

D 3. Route the nose retract pushrod first. Try to run

it in a straight line from the servo, through F-2 and along

the fuse side up to the fuel tank floor. The retract

pushrods are not included in the kit. We used a Sullivan

red pushrod outer tube as a guide tube and a steel rod

with yellow pushrod spacers (see step 12 on page 32) on

it for the nose gear. Do not cut the pushrod to length yet.

D 5. The two main gear pushrods need to be joined as

shown in the photo. Bend the two rods so they come

together parallel with each other and cut one off 3/4"

after they join. Wrap the two rods with soft bare copper

wire and actuate the retracts to make sure they both

operate together without the rods binding. When

satisfied with the fit, flow solder into the copper wire to

hold the two together (acid core solder works best for

this). This whole process is a "trial and error" type task

that takes some patience. If the rods get bent more than

necessary during the fitting process, just use them as a

pattern to make new rods with the correct bends. You

want to get this right now because it is tough to correct

after the fuselage is closed up.

D 4. Route the main gear pushrods as shown in the

photo. Due to the short distance here, we just used steel

pushrod wires without guide tubes. This will work fine

if you keep them running in as straight a line as possible

D 6. Remove the main gear pushrods and slide a DuBro #103 Strip Aileron Horn and wheel collar onto the

pushrod that runs on the same side as the nose gear rod.

Replace the main gear pushrods and position the aileron

30

Page 31

horn as shown in the next photo. Tighten the set screw

on the horn.

D 7. Pull the nose gear pushrod back and position it

on top of the fuel tank floor. Thread a 2-56 steel clevis

onto the nose gear pushrod and hook it up to the strip

aileron horn. Position the red pushrod outer tube where

you want it and cut it to the correct length.

Pull all three retract pushrods towards the rear of the

plane until both main gear actuating arms are pulled as

far as they will go. Pull the nose gear actuating arm

back. Bend the nose gear wire so it will pass through the

hole in the actuating arm as shown in the photo. Slide a

3/32" wheel collar (not included) onto the nose gear rod.

D 8. Return the nose gear pushrod below the fuel

tank floor and slide it through the actuating arm. Secure

it with another 3/32" wheel collar and check the

operation of all three retracts. The actuating arms of all

three retracts should hit the front and back stops together.

If they don't, adjust the steel clevises and the nylon

aileron horn until they all work together.

D 9. Mount the retract servo using the screws that

came with the radio or servo. Hook the pushrods up to

the retract servo wheel using the E-Z connector and

rotate the wheel by hand (180 degrees) to check the

operation of the pushrods. Make sure they are not

binding.

PUSHRODS

D 10. Route the two- rudder pushrod outer tubes

(PLTB002) as shown in the photo. A long 3/16" drill bit

is very handy here. Drill holes wherever necessary to

run the rods as straight as possible. Cut the excess

tubes off about an inch or so in front of F-7. *If you are

going to operate only one rudder, just run one outer tube

straight back from the servo. (See comments regarding

rudder options on p. 5.)

D 11. Assemble the rudder servo horn by installing the

three EZ connectors as shown in the photo (three parts

31

Page 32

make up each EZ connector EZCONN01. EZCONN02 and

EZCONN03). The two inner

connectors should be the same

distance from the center of the horn. The outer

connector is for the nose gear steering pushrod. Make

sure the plastic washers are fully pushed onto the

connector bodies.

halfway through the hole in the nylon swivels using a

4-40 tap. IMPORTANT - We have noticed that the

swivels are sometimes looser than desired if you tap the

threads all the way through the swivel. This looseness is

not very noticeable but can cause control surface flutter

and therefore cannot be permitted. Cut the threads a

little at a time, checking the swivel on the torque rod

each time until it rotates with very little friction. Cut the

excess threads off of the torque rod just past the swivel.

D 12. Screw a nylon swivel clevis (NYLON21) 3/4 of

the way onto the end of two 34" pushrod wires

(WIRES 17). Cut 1/4" long spacers from the 6-1/2" piece

of yellow pushrod inner tube (PLTB004) and slide 7

spacers onto each wire approx. 3" apart. Note: If these

spacers do not slide on easily, cut them to a shorter

length. When installing pushrods, position the plastic

spacers so they always stay inside the pushrod guide

tubes. If the spacers are not a tight fit on the pushrod

wires, apply a drop of thin CA to secure each spacer.

D 14. Hook the swivel clevises up to the nylon swivels

on the torque rod. Install the torque rods in the fins and

rudders, slide the rudder pushrod wire into the outer

tubes and insert the fin/rudder assemblies into their slots.