Page 1

mx-20

33124.mx-20 HoTT.1.en

HOPPING.TELEMETRY.TRANSMISSION

Programming Manual

Page 2

Table of contents

General notices

Table of contents ...........................................................2

Environmental protection notices ..................................3

Safety notices ................................................................ 4

Safety notices and handling regulations

for nickel-metal-hydride rechargeable batteries ............. 8

Foreword ......................................................................10

Remote control set description .................................... 11

Recommended chargers .............................................13

Transmitter power supply ............................................. 14

Receiver power supply .......................................... 16

Joystick length adjustment...........................................17

Opening the transmitter housing .................................17

Changing joystick behavior ..........................................18

Transmitter description ................................................20

Operating elements ............................................... 20

Backside of the transmitter .................................... 21

Headset connector ................................................21

Mini-USB connector ..............................................21

Data jack ...............................................................21

DSC (Direct Servo Control) ................................... 22

Data storage / card slot .........................................22

Display and keypad ............................................... 24

Operating the "data terminal" ................................25

Shortcuts ............................................................... 26

Hidden menu columns ...........................................27

Hidden mode ......................................................... 28

Language selection and display contrast ..............28

Joystick calibration ................................................29

Telemetry data display ........................................... 32

Displayed warnings ...............................................36

Function fi eld displays ........................................... 37

Position display for rotary controls, CTRL 7 & 8 .... 37

Entry lockout ..........................................................37

Table of contents

2

Transmitter initialization ...............................................38

Firmware update ...................................................39

Receiver initialization ................................................... 42

Firmware update ...................................................43

Installation notices ....................................................... 46

Receiver system power supply ..............................47

Term defi nitions ...........................................................50

Switch and control assignments .................................. 52

Digital trimming ............................................................ 54

Winged models ............................................................ 56

Receiver layout ......................................................57

Helicopter models ........................................................ 58

Receiver layout ......................................................59

Program descriptions

Loading a new memory location .................................. 60

"Model select" ............................................................ 63

"Copy / Erase" ............................................................ 64

Erase model ..........................................................64

Copy model model ........................................... 64

Export to SD card .................................................. 65

Import from SD card .............................................. 66

Copy fl ight phase ................................................... 66

"Suppress menus" ..................................................... 67

"Suppress models" .................................................... 67

"Base setup model"

Winged model .......................................................68

Model name ....................................................68

Stick mode ......................................................68

Bound receiver ................................................ 68

Binding receivers ............................................69

Receiver output ............................................... 70

RF transmit ......................................................71

Range test ....................................................... 71

DSC output...................................................... 72

Cut-off ............................................................. 72

Helicopter model ...................................................74

Model name ....................................................74

Stick mode ......................................................74

Bound receiver ................................................ 74

Binding receivers ............................................75

Receiver output ............................................... 76

RF transmit ......................................................77

Range test ....................................................... 77

DSC output...................................................... 78

Autorotation ..................................................... 78

Auto.C1 Pos. ....................................................79

Cut-off ............................................................. 79

Model type" ............................................................... 82

"

"Helicopter type" ........................................................ 86

"Servo adjustment" .................................................... 90

"Stick mode"

Winged model .......................................................92

Helicopter model ...................................................94

"Control adjust"

Winged model .......................................................96

Helicopter model .................................................100

Throttle limit function ......................................104

Idle setting ...................................................... 105

Throttle limit in combination with AR in the

"Stick mode" menu ...................................... 107

"Dual Rate / Expo"

Winged model .....................................................108

Helicopter model .................................................112

"Channel 1 curve"

Winged model .....................................................116

Helicopter model .................................................119

"Switch display" ....................................................... 122

"Control switch" ....................................................... 123

How do I program a fl ight phase? .............................. 126

Page 3

"Phase settings"

Winged model .....................................................128

Helicopter model .................................................132

Phase assignment" ................................................ 134

"

"Phase trim" (winged model) ....................................136

"Non-delayed channels" .......................................... 137

"Timers (general)" .................................................... 138

"Flight phase timers" ............................................... 142

What is a mixer? ........................................................ 145

"Wing mixers" ...........................................................146

"Helicopter mixer" .................................................... 164

Adjusting the throttle and pitch curve ..................175

Autorotation setting .............................................178

General remarks about freely progr. Mixers ..............180

"Free mixers" ............................................................ 181

Linear mixers ...................................... beginning 185

Curve mixer ........................................ beginning 187

Examples............................................................. 190

"MIX active/phase" ................................................... 192

"Mix Only Channel" .................................................. 193

"Dual mixer" ..............................................................194

"Swashplate mixer" ..................................................196

"Fail-safe" .................................................................196

"Teacher / pupil" .......................................................198

Connection schematic ......................................... 201

Wireless HoTT system ........................................202

"Tx. output swap" ..................................................... 206

"Telemetry" ...............................................................208

Setting& Data View .............................................. 209

Satellite operation of two receivers ..............218

Sensor Select ...................................................... 220

RF Status View ....................................................221

Voice Trigger ........................................................222

"Basic Settings" ....................................................... 224

"Servo display" ......................................................... 230

"Servo test" ...............................................................231

Code lock" ............................................................... 232

"

"Info display" ...........................................................234

Programming examples

Introduction ................................................................ 236

Winged model

First steps ............................................................ 238

Incorporating an electric drive .............................244

C1 joystick switchover between

electric motor and butterfl y ............................247

electric motor and airbrake ............................250

Timer activation by control or switch ...................252

Parallel operating servos ..................................... 254

Using fl ight phases

Example 1 .....................................................256

Example 2 .....................................................260

Control of temporal processes ............................266

Eight-fl ap wing ..................................................... 268

Delta and fl ying wing models ............................... 272

F3A model ........................................................... 276

Helicopter model ........................................................280

Appendix

Appendix .................................................................... 290

FCC Information ........................................................293

Declaration of Conformity .......................................... 294

Warranty Certifi cate ...................................................295

Environmental protection notices

The symbol on this product, its operating instructions

or packaging gives notice that this product may not

be discarded as common household waste at the end

of its service life. It must be turned over to a recycling

collection point for electric and electronic apparatus.

The materials can be recycled according to their

markings. You make an important contribution to

protection of the environment by utilizing facilities for

reuse, material recycling or other means of exploiting

obsolete equipment.

Batteries must be removed from the unit and disposed

of separately at an appropriate

collection point.

Please inquire with local authorities

about the responsible waste collection

locations.

This manual serves only as a source of information and

can be changed without prior notifi cation. Graupner

accepts no responsibility or liability for errors or

inaccuracies which may be contained in the information

section of this manual.

Table of contents

3

Page 4

Safety notices

Be sure to pay attention!

In order to enjoy your modeling hobby for a long time,

please read these instructions thoroughly and give

particular attention to the safety notices. You should

also register yourself at https://www.graupner.de/de/

service/produktregistrierung.aspx right away in order

to automatically receive current information per email

about your product.

If you are a beginner with remote controlled model

aircraft, ships or cars, you should really ask an

experienced model pilot for assistance.

If this remote control system changes ownership, these

instructions should surely be included with remote

control system.

Intended usage

This remote control system may only be used for the

purpose intended by the manufacturer - specifi cally - for

the operation of unmanned remote controlled models.

Any other usage is not permissible.

Safety notices

SAFETY IS NO ACCIDENT

and

REMOTE CONTROLLED MODELS ARE NOT

TOYS

… because even small models can cause substantial

property damage and/or personal injuries if they are not

handled properly - even if caused by third parties.

Technical defects of an electrical or mechanical nature

can lead to unexpected startup of a motor and/or parts

being hurled through the air to pose a danger of injury to

you and to others.

Short circuit conditions are to be avoided absolutely!

A short circuit condition may not only destroy parts

of the remote control system but, depending on

Safety notices

4

the circumstances and the battery energy involved,

may also pose acute danger of incineration or even

explosion.

All motor-driven parts, such as aircraft or ship

propellers, helicopter rotors, open gearboxes etc.

represent a constant danger. Contact with these parts

must be avoided. A rapidly turning aircraft propeller

can, for example, sever a fi nger. Also pay attention that

other objects do not come into contact with driven parts.

When a drive battery is connected or a motor is running:

never get into the danger zone of driving mechanisms.

Be sure to pay attention that motors do not start

up unintentionally while performing programming

operations. Disconnect the fuel supply or battery

terminals to motors before programming.

Protect all units from dust, dirt, moisture and other

foreign parts. Never expose these units to vibrations

or excessive hot or cold temperatures. Remote control

operation may only be performed under "normal"

outdoor temperatures, i. e. within a range of -15 ° C to

+55 ° C.

Avoid mechanical jarring and pressure stresses. Always

check units for damage to housings and cables. Do not

use units which have been damaged or become wet,

even after they are dry again.

Only those components and accessories which we

recommend may be used. Always use original Graupner

plug and jack connectors which are made for one

another out of the same materials.

When routing cables, pay attention that they are not

stressed, unduly kinked or broken. The sharp edges

of adjacent parts also represent a hazard for insulated

conductors.

Be sure that all plug and jack connections are fi rmly

seated. Do not pull on the cable to disconnect a plugged

connector.

No modifi cations whatsoever may be made to units.

Modifi cations will void the operating permit and all

insurance protection.

Receiver installation

The receiver is to be installed with a cushion of foam

rubber to afford protection against jarring; in aircraft

models behind a strong rib, for a car or ship model the

location must be protected against dust and spray water.

The receiver may not be mounted in direct contact with

the hull or chassis as this would allow motor vibrations

and/or roadway jarring to be transferred directly to the

receiver. When a receiver system is installed in a model

with a combustion motor, all receiver parts should

always be protected against the intrusion of exhaust

gasses and oil residue. Above all, this applies to the

model's ON/OFF switch, which is typically built into the

model's outer surface.

Position the receiver such that connecting cables to

the servos and the power supply are routed with a bit

of slack and that the receiver's antenna is at least 5 cm

away from any large metal parts or wiring except for

other receiver wires/cables. In addition to steel, this also

includes carbon fi ber parts, servos, electric motors, fuel

pumps and all sorts of cables, etc.

Preferably, the receiver should be mounted in a readily

accessible location in the model that is well apart from

all electrically operated units. Under no circumstances

may a servo cable be wrapped around the antenna or

routed close to it.

Make sure that cables near the antenna cannot move

about during fl ight.

Page 5

Routing the receiver's antenna

The receiver and its antennas must be positioned as far

away as possible from drives of any kind. If the model's

hull is made of carbon fi ber material, the ends of the

antennas must extend outside of the hull.

The orientation of antennas is not critical. Nevertheless,

a vertical (upright) installation of receiver antennas is

advantageous. In the case of diversity antennas (two

antennas), the second antenna should be oriented at a

90° angle to the fi rst antenna.

Servo installation

Always mount servos with the provided rubber vibrationdamper parts. Only in this manner can these parts be

protected against excessively hard vibrations.

Installing control rods

Control rods must be installed such that they operate

freely and smoothly. It is particularly important that all

rudder levers are able to move to their full limits, i.e. not

otherwise mechanically blocked.

In order to be able to stop a running motor at any time,

control rods must be adjusted such that the carburetor

tap is completely closed when the joystick and trim lever

are brought into their end idle position.

Pay attention that no metal parts, e. g. as a result of

rudder actuation, vibration, rotating parts, etc., rub

against one another. Metal-to-metal contact causes

electrical "noise" which can interfere with the correct

operation of the receiver.

Transmitter antenna orientation

Transmission fi eld strength is minimal in an imaginary

line extending straight out from the end of the

transmitter's antenna. This means that "pointing" the

transmitter's antenna directly toward the model will not

produce good reception but rather degrade reception.

When multiple remote controls are operating

simultaneously, pilots should position themselves in a

loose group. Pilots standing off to themselves not only

endanger their own models but those of others as well.

However, when 2 or more pilots using 2.4 GHz remote

control systems are closer than 5 m to one another this

can lead to return channel overdrive which, in turn, will

trigger a range warning much too early. Increase your

distance between one another until the range warning

ceases.

Pre-start checks

Before switching the receiver on, ensure that the gas

control is at its Stop/Idle position.

Always switch the transmitter on fi rst and then the

receiver.

Always switch the receiver off fi rst and then the

transmitter.

If this sequence is not maintained, such that the receiver

is still switched on when the corresponding transmitter

is switched to "OFF", then the receiver may respond to

other transmitters or general radio frequency noise. This

can cause the model to execute uncontrolled operations

that may cause personal injuries and/or property

damage.

In particular, for models equipped with a mechanical

gyro:

before switching off the receiver, disconnect the model's

power supply to prevent the motor from revving up

unintentionally.

The residual spin of a gyro often produces so much

voltage that the receiver may falsely interpret a

throttle signal! This will then cause the motor to

start up unexpectedly.

Range test

Perform checks for proper operation and range before

every session. Secure the model adequately in place

and ensure that no one is in front of the model.

Perform a complete functional test on the ground and

execute a complete simulated fl ight to exclude the

possibility of system faults or problems with the model's

programming. When doing this, be sure to follow the

notices provided on pages 71 and77.

Never operate the transmitter in Model mode, i.e.

for fl ying or driving, without an antenna. Be sure the

antenna is fi rmly seated in its socket.

Operating a winged aircraft, helicopter, ship or car

Never fl y over spectators or other pilots. Never endanger

humans or animals. Never fl y in the vicinity of highvoltage wires. Do not operate the model in the vicinity of

sluice locks or where real boats or ships are operating.

Do not operate a model on public streets or highways,

paths or plazas, etc.

Monitoring transmitter and receiver batteries

You must stop running the model to recharge the

transmitter's battery no later than when low transmitter

battery voltage triggers the "Batt must be recharged!!"

display and acoustic signal.

Check the charge in batteries routinely, particularly the

receiver's battery. Do not wait until the movements of

controlled mechanisms are noticeably slower. Replace

expended batteries before they cause problems.

The battery manufacturer's charging instructions

Safety notices

5

Page 6

Safety notices

are always to be followed, this includes mandatory

adherence to the length of charging time. Never leave

batteries being charged unattended.

Never attempt to charge primary batteries (nonrechargeable batteries) because they can explode.

All secondary batteries (rechargeable batteries) must

be charged before every session. To avoid short circuit

conditions, fi rst connect the charger cable's banana

plugs, polarity correct, into the charger and thereafter

connect the charger cable's plugs to the transmitter and

receiver batteries.

Disconnect all power sources from the model when it is

not to be used for an extended period of time.

Never attempt to use defective batteries, damaged

batteries or mixed-type battery combinations as a single

group. Do not use mixed combinations of old and new

batteries or batteries of different manufacture.

Capacity and operating time

The rule: "capacity is reduced with every successive

recharging", applies to all batteries. Internal resistance

increases at low temperatures to further reduce capacity.

As a consequence, the battery's ability to provide

current and hold its voltage is reduced.

Frequent charging or the use of battery maintenance

programs can also result in gradual loss of battery

capacity. Therefore the capacity of batteries should be

checked at regular intervals, not in excess of every six

months, and replaced if performance is found to be

signifi cantly defi cient.

Purchase only genuine Graupner batteries!

Interference suppression for electric motors

All conventional electric motors produce sparks between

their collector and brushes. Depending on the type of

Safety notices

6

motor involved, this may cause more or less interference

with the functionality of the remote control system.

The electric motors of a properly built system should

therefore have interference suppression features.

For electric drive models it is particularly important

that every one of its motors is provided with proper

interference suppression. Interference fi lters extensively

suppress such disturbances and should always be

included.

Follow the respective recommendations included in the

motor's operating and installation notices.

For further details about interference fi lters, refer to the

Graupner RC main catalog or in Internet at

www.graupner.de.

Servo interference fi lters for extension cables

Order No. 1040

The servo interference fi lter is necessary when an

extended-length servo cable is used. This fi lter is

attached directly to the receiver output. In critical cases

a second fi lter can be attached to the servo.

Using electronic speed controllers

Choosing the right electronic controller is largely a

matter of matching controller performance to the motor

to be controlled.

In order to prevent an overload or damage to the speed

controller, its current rating should be at least half of

the maximum locked-rotor current draw of the motor to

which it is connected.

Particular attention is appropriate for so-called "tuning

motors". Because of their low-turns coils these motors

can draw a multiple of their rated current in a lockedrotor condition and this can lead to the destruction of the

speed controller.

Electric ignition systems

Combustion motor ignition systems also produce

interference that can negatively infl uence remote control

functionality.

Always supply power to an electric ignition system from

a separate, dedicated battery.

Use only interference-suppressed spark plugs, spark

caps and shielded ignition leads.

Mount the receiver suffi ciently far away from ignition

system components.

Static charges

A remote control system will be destroyed by the

magnetic shock waves produced by a lightning strike even if the storm is miles away. Therefore …

… stop fl ying right away if a storm is approaching.

Static charging via the antenna also represents a

lethal hazard.

Attention

In order to fulfi ll FCC HF emission requirements for •

mobile transmitters, a distance of at least 20 cm

must be maintained between this system's antenna

and other persons when this system is operating.

Operation of this system at a lesser distance is

therefore not recommended.

To avoid disturbance caused by the electrical •

characteristics and emissions of other transmitters,

keep at least a 20 cm distance from other

transmitters.

Operation of the remote control system requires a •

correct program setting for the given country in the

transmitter unit. This is necessary for compliance with

diverse regulations like FCC, ETSI, CE etc. Follow

the respective instructions provided for this with the

Page 7

transmitter and receiver.

Prior to every fl ight, perform a complete functional •

test, range test and execute a complete simulated

fl ight in order to exclude the possibility of system

faults or problems with the model's programming.

Never program the transmitter or receiver while the •

model is being operated.

Care and maintenance

Never clean the housing, antenna, etc. with cleaning

agents, gasoline, water or similar means. Use only a dry,

soft cloth.

Components and accessories

As manufacturer of this equipment Graupner GmbH

& Co. KG recommends only components and

accessories which have been tested and approved by

Graupner for their suitability, functionality and safety.

If this recommendation is followed, Graupner accepts

responsibility for the product.

Graupner cannot accept any responsibility for the

parts or accessories of other manufacturers which

have not been approved and Graupner cannot

evaluate every individual product made by other

companies to assess if they are safe to use.

Graupner accepts no form of liability for loss, damage or

costs consequential to incorrect usage or operation or

which can be attributed to same.

Unless otherwise prescribed by law, the obligation of

Graupner to provide damage compensation, regardless

of legal grounds, is limited to the invoice value of the

quantity of Graupner. goods contributing directly to the

damage-inducing event. This does not apply if Graupner

is found to be subject to unlimited liability pursuant to

binding legal stipulations with respect to intent or gross

negligence.

Liability exclusion / damage compensation

This manual serves only as a source of information and

can be changed without prior notifi cation. Graupner

accepts no responsibility or liability for errors or

inaccuracies which may be contained in this manual.

Graupner cannot monitor compliance with the assembly

instructions, the operating instructions or the conditions

and methods under which remote control components

are installed, operated, utilized or maintained. Therefore

Safety notices

7

Page 8

Safety notices and handling instructions for nickel-metal-hydride rechargeable batteries

As applicable for all highly technical products,

observance of the following safety notices, along with

the handling instructions, is essential for a long service

life, fault-free operation, and harmless utilization.

Safety notices

Individual battery cells and batteries are not toys and •

must therefore not get into the hands of children.

Batteries/cells must be kept out of the reach of

children.

Batteries are to be checked for fl awless condition •

prior to every use. Defective or damaged cells/

batteries may no longer be used.

Cells/batteries may only be utilized within the limits •

specifi ed by the technical data for the given battery

type.

Batteries/cells may not be heated, burned, short-•

circuited or subjected to overload current or

reverse polarity.

Battery confi gurations formed by parallel •

connected cells, combinations of old and new

cells, or cells of different production, size,

capacity, manufacturer, brand or cell type may

not be used.

Remove batteries from the unit prior to long-term •

storage periods (weeks or months). Always switch

off units whenever they are no longer in use (shortterm). Always charge batteries before it is too late.

The battery to be charged must be placed on a non-•

combustible, heat resistant, non-conducting surface

during the charging process. Combustible or readily

ignited objects are to be kept away from the charging

confi guration.

Batteries may only be charged under supervision. •

The quick charge current rating for the given type of

battery must never be exceeded.

If the battery heats up during charging above 60 °C •

charging must be stopped immediately. Allow the

battery to cool off to about 30 °C before resuming the

charging process.

Never charge batteries which are already charged, •

batteries which are hot or batteries which have not

been discharged to their end-point voltage.

No modifi cations may be made to the batteries. •

Never solder or weld directly on battery terminals.

The mistreatment of batteries presents a danger of •

ignition, explosion, chemical burns and combustion

burns. Use of an extinguishing blanket, CO

extinguisher or sand are suitable methods of

extinguishing such a fi re.

Leaking electrolyte is caustic; do not allow it •

to contact the skin or eyes. In the event of an

emergency, immediately rinse with a generous

amount of water and get the care of a doctor.

Battery vent openings may never be blocked or •

sealed, e. g. by solder. Soldering temperature may

not exceed 220 °C and not be applied for longer than

20 seconds.

To avoid deformation, do not exert excessive •

mechanical force.

If a battery should become overcharged, proceed as •

follows:

Simply disconnect the battery and place it on a noncombustible surface (e. g. masonry fl oor) until it has

cooled off. To avoid the hazards associated with an

explosion, never hold the battery in your hands.

-fi re

2

Pay attention that the charging and discharging rules •

are followed.

General notices

Battery capacity is reduced by every charge/discharge

cycle. Storage can also be cause for a gradual reduction

of battery capacity.

Storage

Batteries should only be stored when they are not in a

completely discharged condition. They should be stored

in a dry room having an ambient temperature between

+5 °C to +25 °C. When stored for longer than 4 weeks,

cell voltage should not be more than 1.2 V.

Matching up individual batteries

To match new batteries with older ones, put a full •

charge on all of the batteries using a standard

charging process. As a rule of thumb, an empty

battery must be charged for 12 hours at a current

rate equal to one tenth of its specifi ed capacity

("1/10 C" method). The batteries are then all charged

equally. Such a matching procedure should be

repeated about every 10th charge cycle so that

batteries are matched again, which contributes to

longer battery life.

If it is possible to discharge individual batteries, this •

should be done prior to every charging process.

Otherwise the battery pack should be discharged

to a voltage of 0.9 V per cell. For example, this

corresponds to a charge voltage of 3.6 V for the

4-cell pack used in the transmitter.

Charging

Charging is only permissible at specifi ed current rates,

charging durations, temperature ranges and continuous

Safety notices

8

Page 9

supervision. If a suitable quick charger is not available

on which the exact charging current can be set, the

battery can be charged by standard charging according

to the 1/10 C-method, see example above.

Whenever possible, transmitter batteries should

charged with the 1/10 C method because of the

differing charge states of the cells. However,

charging current may never be allowed to exceed

the maximum permissible rate specifi ed in the given

transmitter's instructions.

Quick charging

If your charger offers this option then set the delta •

peak charge cutoff voltage to 5 mV per cell. However,

most chargers are set to a fi xed value of 15 …

20 mV per cell so they can be used for both NiCd

batteries as well as NiMH batteries If in doubt, fi nd

out if your charger is also suitable for NiMH batteries

by referring to the charger's operating instructions

or consulting a dealership. If you are unsure, charge

your batteries at half of the specifi ed maximum

current rate.

Discharge

All batteries sold under the Graupner and GM-Racing

trade names are, depending on battery type, suitable for

a continuous maximum current load of 6 … 13 C (check

the manufacturer's data). In general, the higher the

continuous current load, the lower the battery's service

life will be.

Use your battery until its performance degrades or •

the under-voltage warning sounds.

Attention:

A cell voltage of 1.2 V should not be underrun during

a long storage period. If necessary, charge the

battery before putting it into storage.

Refl ex charging and charge/discharge programs •

unnecessarily shorten a battery's service life and are

only useful in checking battery quality or to "revive"

old cells. It is also meaningless to charge/discharge a

battery before using it. The exception to this is if your

intention is to check the battery's quality.

Disposal of used batteries

Some countries have laws requiring that all used

batteries be turned over to an authorized collection

center.

Disposing of batteries along with common household

garbage is forbidden. Old batteries can be turned into

communal collection centers for disposal at no charge

or they can be returned to one of our dealerships or

anywhere else where batteries of that given type are

sold. Used batteries we have delivered can also be sent

back to us, at your cost, through the mail. Use the return

address below:

Graupner GmbH & Co. KG

Service: Used batteries

Henriettenstr. 94 - 96

D-73230 Kirchheim unter Teck

This represents an essential contribution to

environmental protection.

Caution:

Damaged batteries require among other things, special

packaging, because they are very toxic!

Safety notices

9

Page 10

mx-20 the newest generation of remote control technology

HoTT (Hopping Telemetry Transmission) is a synthesis

of know-how, engineering and testing done around the

world by experienced model pilots. HoTT technology

combines 2.4 GHz band transmission/reception with

bi-directional communications via a "return channel"

integrated into the receiver unit.

Based on the Graupner/JR computerized remote

control system mc-24 that was introduced in 1997,

the mx-20 HoTT remote control system has been

especially developed for experienced RC pilots All

conventional model types can be readily operated

with the mx-20 HoTT system, regardless of whether

the model is a winged aircraft, helicopter, ship or land

vehicle.

Complex mixed-control functions of guiding surfaces are

often necessary for winged aircraft (rudder, elevators)

and helicopter models (swashplate). Thanks to this

computer technology it is possible to activate these

diverse functional requirements with a single "press

of a button". Simply select the given model type from

the mx-20 HoTT program and its software will

automatically assemble signifi cant mixed-control and

coupled functions. This eliminates the need for separate

modules in the transmitter to implement complex

coupled functions and also makes sophisticated

mechanical mixer mechanisms in the model

unnecessary. The mx-20 HoTT remote control system

offers the highest level of safety and reliability.

Its software is clearly structured. Functionally-related

options are clearly arranged by content in a simple

organization.

The mx-20 HoTT remote control system has 24

model memory locations. Additional fl ight-phase-specifi c

settings can be stored in every model memory location.

For example, such settings can be made for various

parameters that can be called up to implement particular

fl ight maneuvers at the "press of a button".

The large graphic display is well organized and simple

to operate. The mixer's graphic representation is

exceptionally helpful.

Familiarization with the various functions in this remote

control system is quick, even for a beginner, because

of its clear, straightforward program structure. The user

makes his settings with the four-way, touch sensitive

buttons located to the left and right of the high-contrast

display. Thus, with only little practice, the pilot learns to

implement all of the remote controlled model options

with which he/she has experience.

This Graupner HoTT technique theoretically allows over

200 models to be operated simultaneously However,

because of the interspersed radio-frequency utilization

permitted by certifi cation for the 2.4 GHz ISM band, this

number is signifi cantly lower in practical application.

Nevertheless, in general more models can be operated

simultaneously in the 2.4 GHz band than would be the

case in conventional 35 or 40 MHz frequency bands.

The real limiting factor is – as often before – is still likely

to be the size of available operating space (i.e. airspace

for aircraft). Alone the fact that it is no longer necessary

to coordinate transmitting frequencies with other pilots in

the vicinity (which is sometimes quite diffi cult in broken

landscapes, such as on hillside slopes) represents an

enormous boost for remote control operating security.

The integrated telemetry menu affords simple access

to data and HoTT receiver programming. For example,

this can be used to map receiver outputs, assign control

functions to multiple servos, and to coordinate the

magnitude and direction of multiple servo movements

with one another.

This handbook describes every menu in detail. There

are tips, many notices and programming examples to

supplement the descriptions and also explanations for

model specifi c technical terms, like transducer, dual

rate, butterfl y, etc.

An appendix is provided which contains additional

information about the HoTT system. This manual is

rounded out with the conformity declaration and the

guarantee certifi cate for the transmitter.

Please observe the safety notices and technical notices.

Read the instructions carefully then test all functions by

simply attaching servos to the receiver included in the kit

for order no. 33124. When doing this, please observe the

corresponding notice provided on page 20. This will help

you learn the essential operating steps and functions of

the mx-20 HoTT in the least amount of time.

Always handle your remote controlled model with a

sense of responsibility so that you do not endanger

yourself or others.

The Graupner team wishes you much fun and success

with your mx-20 HoTT remote control system of the

newest generation

Kirchheim-Teck, September 2011

10

Introduction

Page 11

Computer System mx-20

12 channel remote control s et in 2.4 GHz Graupner HoTT technology (Hopping Telemetry Transmission)

Microcomputer remote control system in modern •

2.4 GHz Graupner HoTT technology

Bidirectional communications between transmitter •

and receiver

Five different languages:•

German, English, French, coming soon per software

update Italian and Spanish.

Ultra fast response times due to reliable, direct •

transmission of data from the main processor to the

2.4 GHz HF module. No additional delays due to

routing over a module processor.

Telemetry menu for display of telemetry data and •

for programming optional attachment sensors and

receiver outputs

The telemetry screen provides many programming •

and evaluation functions to be presented directly in

the transmitters display

Voice output can be called up via freely •

programmable switches

Digital servo cycle times of 10 ms selectable•

Short antenna, collapsible•

Operating and programming techniques are similar •

to the proven concepts implemented in mc-19 to

mc-24

The superior functional security of Graupner

HoTT technology accomplished with bidirectional

communications between transmitter and receiver

with integrated telemetry, freely programmable

voice output via headset connector, and ultra-fast

response times.

Programming is simplifi ed by a programming

technique implemented with capacitive touch

buttons.

High contrast, 8 line, blue illuminated graphic

display for perfect presentation of all parameter

settings and telemetry data. Storage of telemetry

data on a micro SD memory card.

Integrated real time clock

4096 steps of 12-bit resolution on the channel signal

assures extreme control sensitivity.

USB connection to read and write the model's

memories as well as for making fi rmware updates.

High contrast, blue illuminated graphic display •

assures perfect control of parameter settings like

model type, model memory, clocks and operating

voltage.

Function encoder with two touch-sensitive, four-way •

buttons permit simplifi ed programming and precise

settings

Key-lock function to prevent unintentional operation.•

7 fl ight phases can be programmed•

Introduction - Remote control set

11

Page 12

Computer System mx-20

12 channel remote control set with 2.4 GHz Graupner HoTT technology (Hopping Telemetry Transmission)

24 model memories with storage for all model-•

specifi c programs and parameter settings

7 switches (2 three stage switches, 3 two stage •

switches and 2 touch switches) and 3 digital

actuators are already built-in and can be used as

desired

Free assignment of switches to switched functions by •

simply switching the desired switch

Simple programming of motor and brake switchover •

for electric gliders on the K1 joystick.

Internal realtime clock for time-stamping log fi les•

User-replaceable CR2032 buffer battery for the •

internal realtime clock

Model memory storage in a modern, non-volatile •

backup system

12 control functions with simplifi ed arrangement •

of operating elements for supplementary functions

like switches and proportional transducers make

operating convenient

Convenience mode selector for simplifi ed switchover •

between MODES 1 … 4 (Gas left/right, etc.)

All affected settings are also automatically switched

over.

Graphic servo position display for fast, simple •

overview and for checking servo movements

Transmitter output swapping•

Extensive programs for winged aircraft and helicopter •

models:

Winged aircraft menu for: 1 QR, 2 QR, 2 QR + 1, 2

and 4 WK as well as 4 QR + 2 and 4 WK, V tail unit,

delta/all-wing, 2 elevator servos

Surface mix: QR-diff, WK-diff, QR SR, QR

WK, brake HR, brake WK, brake QR, HR

WK, HR QR, WK HR, WK QR and diff.

reduction

Heli menu for: 1-, 2-, 3- and 4-point linkage (1 Sv,

2 Sv, 3 Sv (2 roll), 3 Sv (140°), 3 Sv (2 nick), 4 Sv

(90°))

16 free mixers, • 8 linear mixers, 4 curve mixers and 4

cross mixers

Swashplate limiter•

±150 % servo adjustment for all servo outputs, •

independently adjustable per side (Single Side Servo

Throw)

Sub-trim in the ±125 % range for setting all neutral •

servo positions

Servo reverse can be programmed for all servos •

Two stage DUAL RATE/EXPO system, individually •

adjustable for specifi c fl ight phase and switchable

during fl ight

Stop watches/countdown timers with alarm function•

Copy function for model memory•

Built-in DSC jack for connecting fl ight simulators or a •

teacher/pupil system

Envisioned for a later update:•

Voith-Schneider limiter, works similar to a swashplate

limiter

Door sequencer, e. g. for putting down landing gear

automatically or retractable powerplant with runout

controller

Nautical program

General HoTT features

Maximum noise immunity due to optimized frequency •

hopping and wider channel spread

Intelligent data transfer with correction function•

Realtime telemetry evaluation•

Over 200 systems can be used simultaneously•

Update capability via USB interface guarantees •

future viability

Simple, very fast transmitter to receiver binding•

Binding with multiple receivers per model • in parallel

operation is possible

Extremely fast rebinding, even at maximum distance•

Range test and warning function•

Receiver under-voltage warning in the transmitter's •

display

Extremely wide receiver operating voltage range of •

3.6 V to 8.4 V (fully functional to 2.5 V)

Failsafe•

Arbitrary channel assignment (channel mapping), mix •

functions and all servo settings can be programmed

in the telemetry menu

Up to 4 servos can be controlled simultaneously as •

a block at a servo cycle time of 10 ms (digital servos

only)

Introduction - Remote control set

12

Page 13

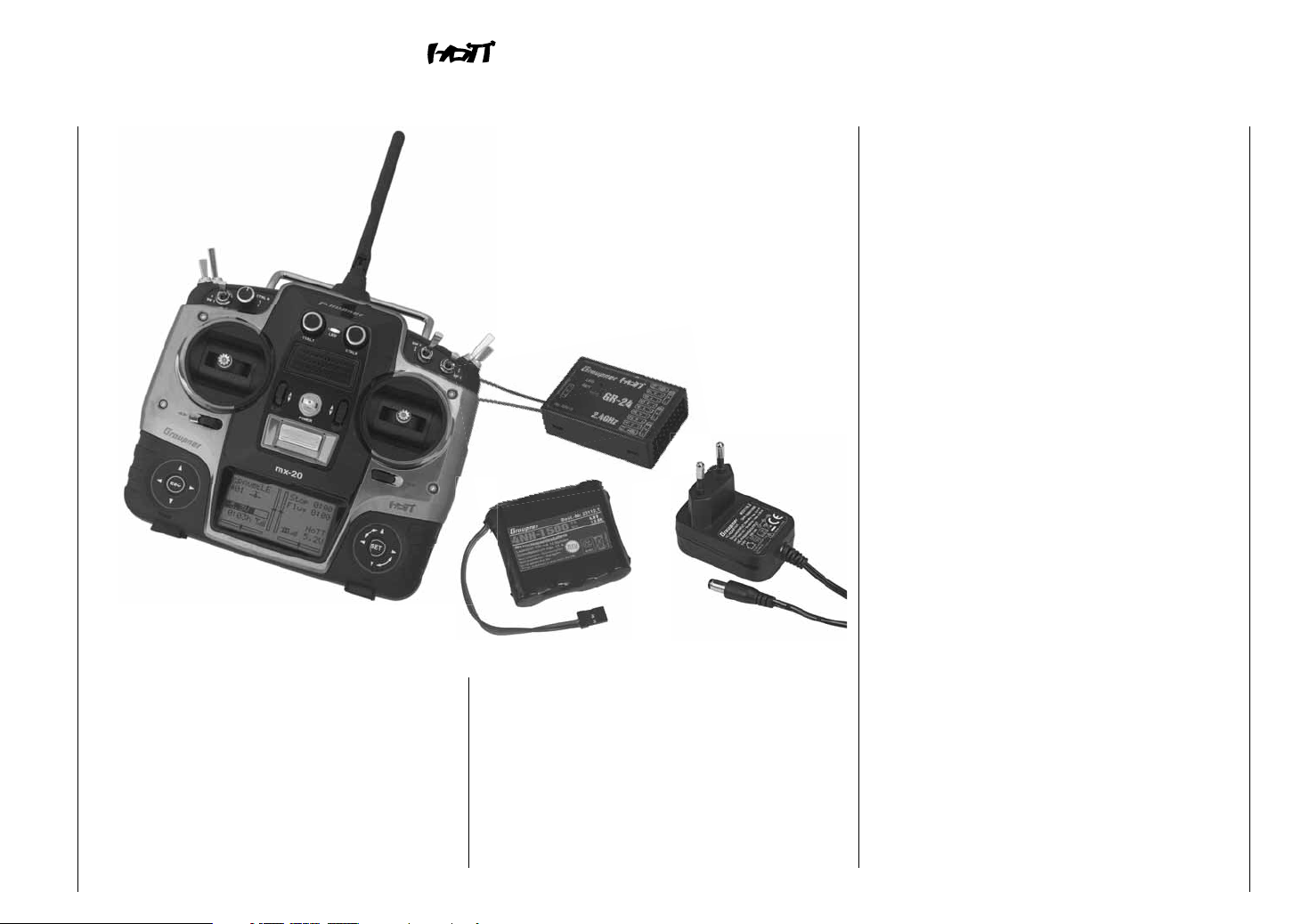

The Order No. 33124 set includes

Microcomputer transmitter mx-20 HoTT with built-

in NiMH transmitter battery 4NH-2000 RX RTU fl at

(change reserved), plug-in charger and Graupner

bidirectional receiver GR-24 HoTT.

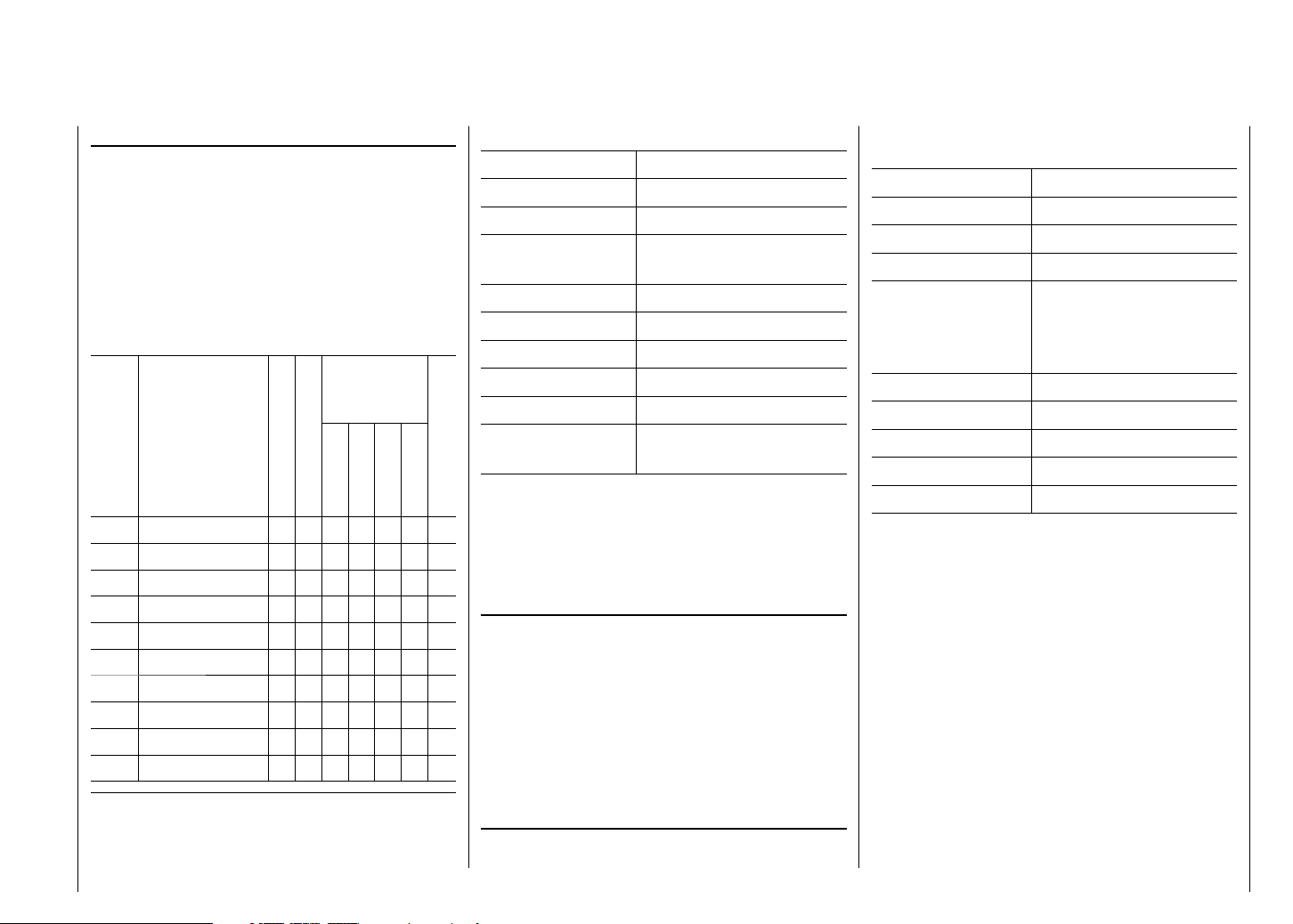

Recommended charger units (accessories)

appropriate for

the following

batteries

Order

No. Designation

Input voltage 220 V

Input voltage 12 V

NiCd

NiMH

LiPo

lead battery

6411 Ultramat 8 x x x x x

6463 Ultramat 12 plus x x x x x x

6424 Ultramat 14 plus x x x x x x x

6466 Ultra Trio plus 14 x x x x x x x

6468 Ultramat 16S x x x x x x x

6469 Ultra Trio Plus 16 x x x x x x

6470 Ultramat 18 x x x x x x x

6475 Ultra Duo Plus 45 x x x x x x x

6478 Ultra Duo Plus 60 x x x x x x x

6480 Ultra Duo Plus 80 x x x x x x x

Transmitter charger cable, order no. 3022 and receiver charger cable,

order no. 3021 are also needed to charge batteries.

Other charger units and details about the listed chargers can be found

in the Graupner RC main catalog or in Internet at www.graupner.de.

mx-20 HoTT technical data

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Transmit power see country setting, page 227

Control functions 12 functions, 4 of these can

be trimmed

Temperature range -10 … +55 °C

Antennae collapsible

Operating voltage 3.4 … 6 V

Current draw about 180 mA

Dimensions about 190 x 195 x 90 mm

Weight about 770 g with transmitter

battery

integr. balancer

Accessories

Order No. Description

1121 Neck strap, 20 mm wide

70 Neck strap, 30 mm wide

3097 Hand transmitter wind protection

Teacher/pupil cable for mx-20 HoTT

see page 201

Replacement parts

Order No. Description

2498.4FBEC 4NH-2000 RX RTU fl at

33800 HoTT transmitter antenna

Technical data, receiver GR-24 HoTT

Order No. 33512

Operating voltage 3.6 … 8.4 V*

Current draw about 70 mA

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Antenna Diversity antennas,

2 x about 145 mm long,

about 115 mm encapsulated

and about 30 mm active

Plug-in servos 12

Plug-in sensors 1

Temperature range about -10 … +55 °C

Dimensions about 46 x 31 x 14 mm

Weight about 16 g

* The specifi cation for permissible operating voltage range applies

only to the receiver. Please note in this context that receiver input

voltage is applied without regulation to connected servos but the

voltage range for most connectible servos (speed controls, gyros,

etc.) is only 4.8 to 6 V.

Other accessories are listed in the appendix or can

be found in Internet at www.graupner.de. Feel free

to contact your dealer too. He will be glad to provide

advice.

Introduction - Remote control set

13

Page 14

Operating notices

Transmitter power supply

The mx-20 HoTT transmitter has a highly capacitive,

rechargeable NiMH battery, 4NH-2000 RX RTU (Order

no. 2498.4FBEC), as standard equipment. (changes

reserved) However, the standard built-in battery is

not charged upon delivery of the transmitter.

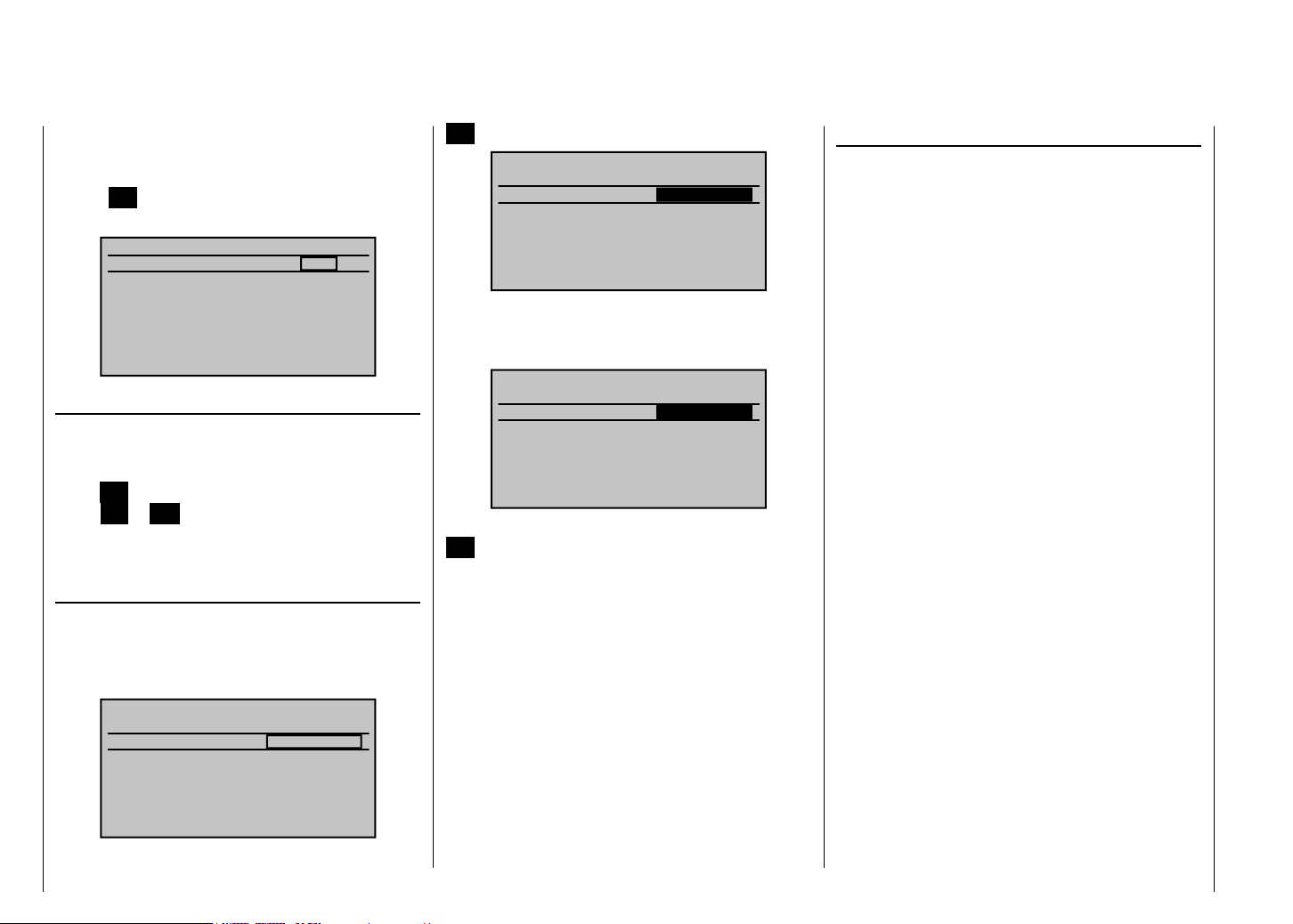

When the transmitter is used, its battery voltage

should be monitored by way of the indicators provided

in the LCD display. If battery voltage drops below

the adjustable voltage setting (set via item "Batterie

warning" in the "Basic Settings" menu, page 226,),

default value 4.7 V, an audible warning signal will sound

and the message window shown below will appear in

the screen

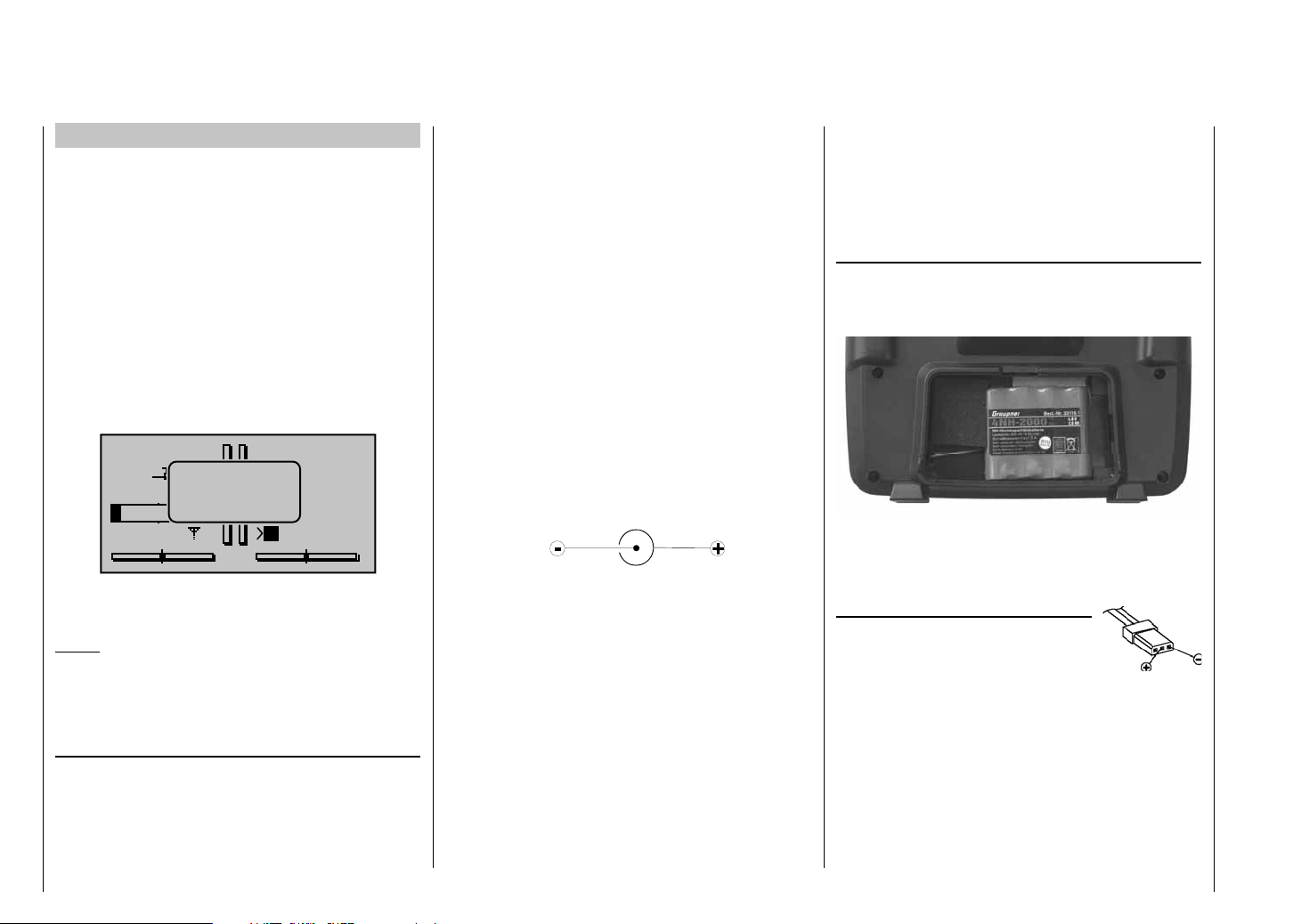

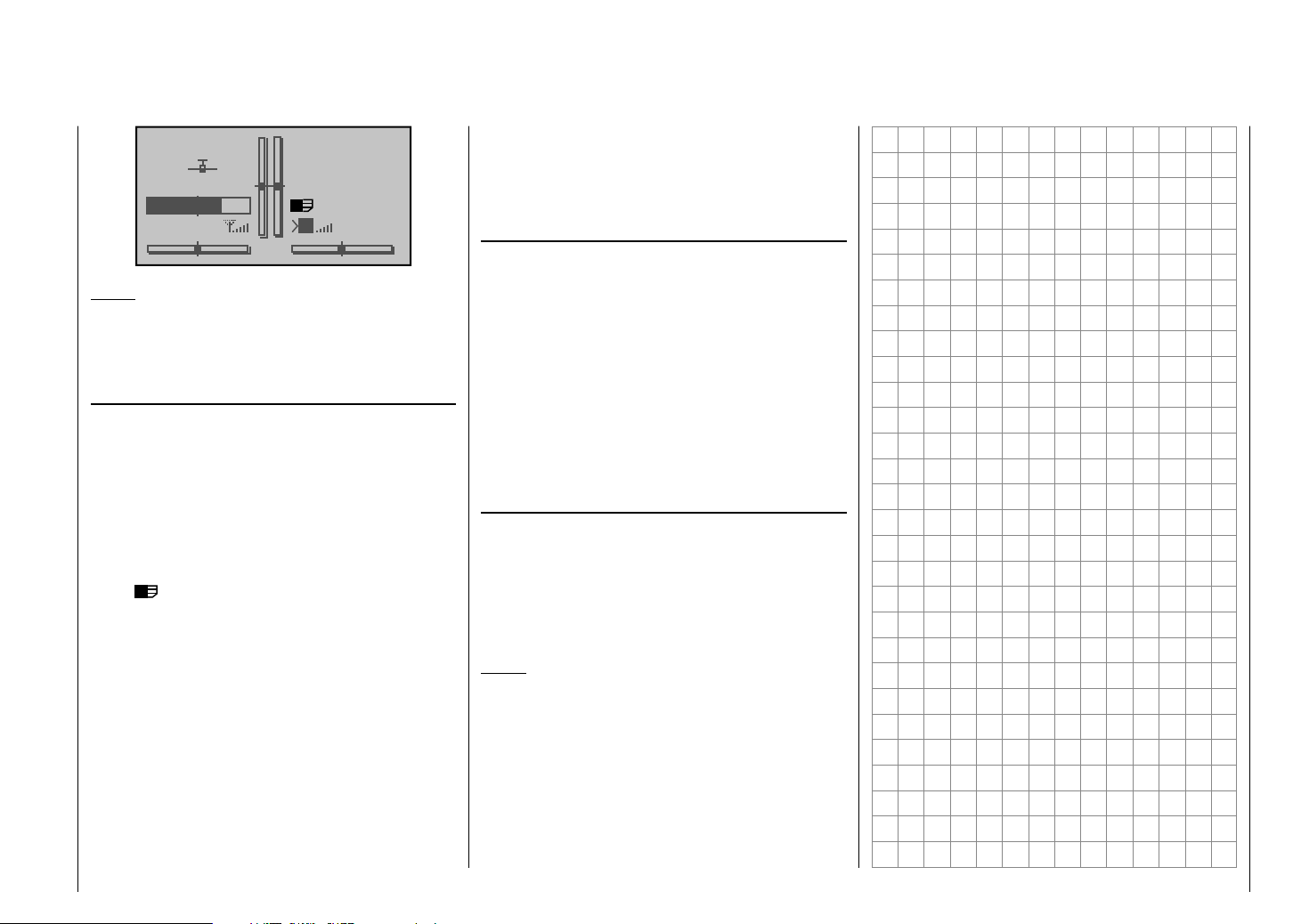

GRAUBELE

#01

0:22h

No later than now, operation must be terminated so the

battery can be charged again.

Notice:

Be sure that the correct battery type is set in the "Basic

Settings" menu, page 224! NiMH must be set as

standard.

Charging the transmitter's battery

The transmitter's rechargeable NiMH battery can be

recharged by connecting the charging jack located,

on the right side of the transmitter, with the included

charger (order no. 33116.2).

As a rule of thumb for charging time, an completely

Operating notices

14

4.6V

battery

needs

charging

10%

x

Stop

Flug

«normal »

K78

Mx

0:00

0:00

HoTT

0.0V

discharged battery will require 12 hours to recharge at a

current rate equal to one tenth of its specifi ed capacity.

For the standard transmitter battery and included

charger, this is a current rate of 200 mA. However,

you must yourself ensure that the charging process is

terminated when it should be …

The transmitter must be switched "OFF" during

the entire charging procedure. Never switch on the

transmitter when it is connected to the charger. Even

a brief interruption to charging can cause charging

voltage to rise to a level that will immediately damage

the transmitter with over-voltage. Also for this reason, be

sure all connectors are always plugged in securely and

have good contact.

mx-20 HoTT charging jack polarity

The charger cables on the market from other

manufacturers often have different polarities. Therefore use

only an original Graupner charger cable, order no. 3022.

Charging with automatic chargers

The transmitter's charger jack does come standard

with reverse polarity protection but nevertheless it can

be used with suitable chargers for quick charging the

transmitter's battery.

Set the quick charger unit, according to its manual, for

a delta peak voltage difference of 5 mV … 20 mV or

equivalent such that it is adapted for quick charging

NiMH cells

First connect the charger cable's banana plugs to

the charger and only then connect the cable's other

end into the charging jack on the transmitter. Never

allow the bare ends of the banana plugs to come

into contact with one another when the other end of

the cable is plugged into the transmitter. In order to

prevent damage to the transmitter, charging current

should never exceed 1 A. If necessary, limit the

current at the charger.

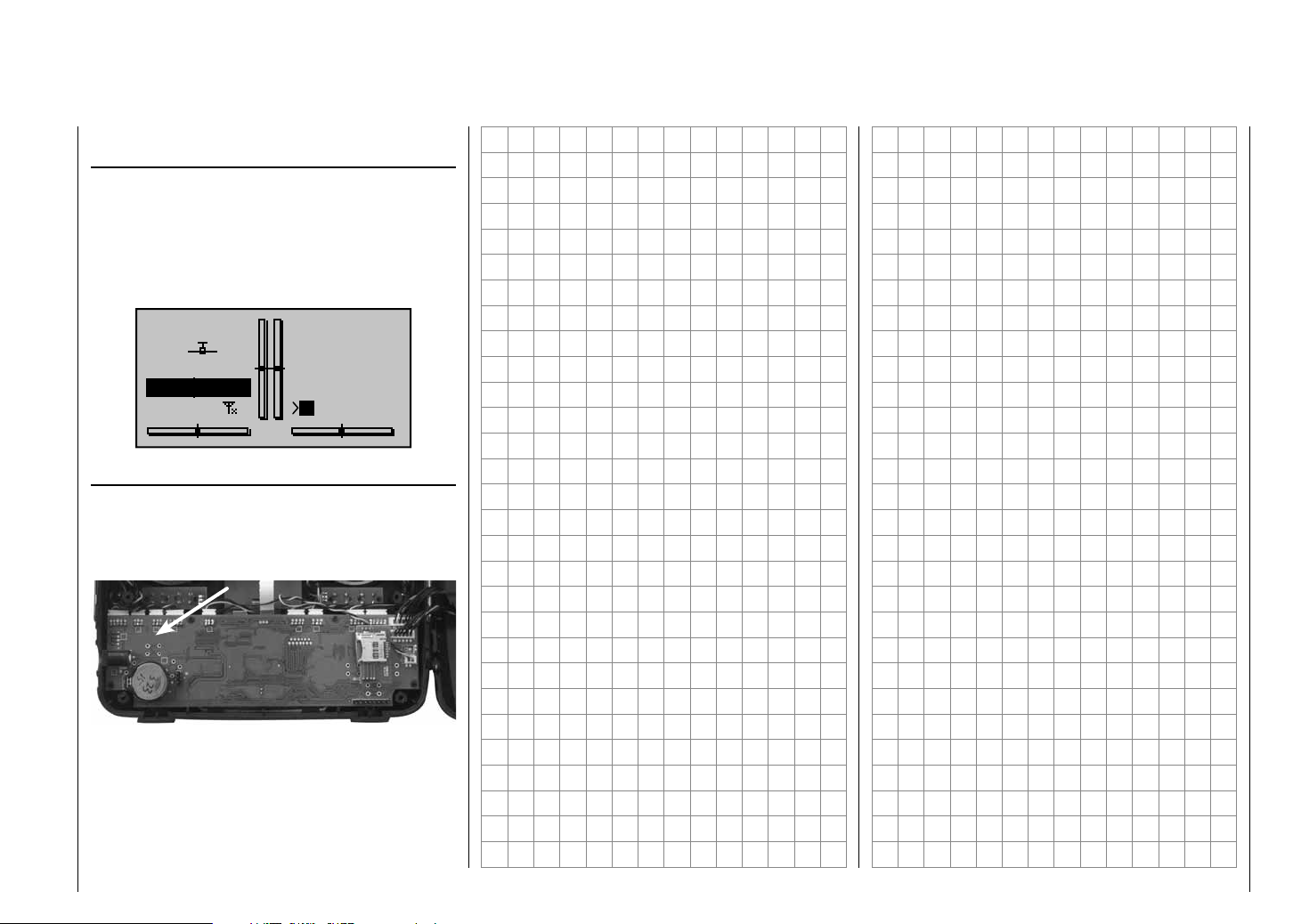

Removing the transmitter's battery

To remove the transmitter's battery, fi rst unlatch the

cover of the battery compartment on the rear side of the

transmitter housing then remove the cover.

Take out the transmitter's battery then disconnect the

transmitter battery's connector by carefully pulling on the

supply line cable.

Inserting the transmitter's battery

Hold the transmitter battery connector

such that the black or brown cable is

oriented toward the antenna side and

the empty jack of the battery connector

is oriented toward the fl oor side then push the battery

connector in the direction of the board onto the three pins

sticking out out of the board inside the transmitter. (The

battery connector is protected against a reverse polarity

connection by two slanted edges, see illustration.)

Place the battery into its compartment and close the

cover.

Transmitter

connector polarity

Page 15

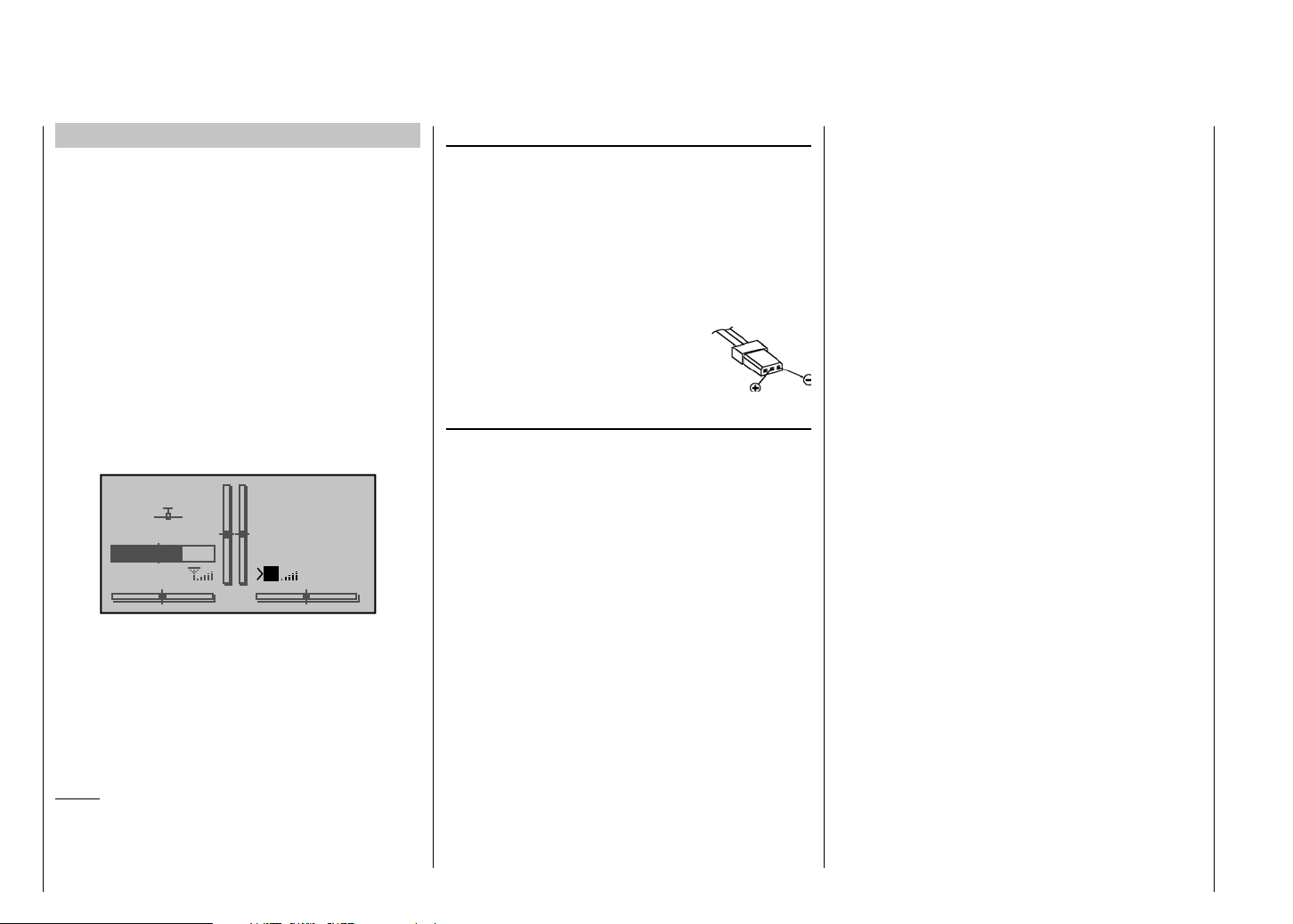

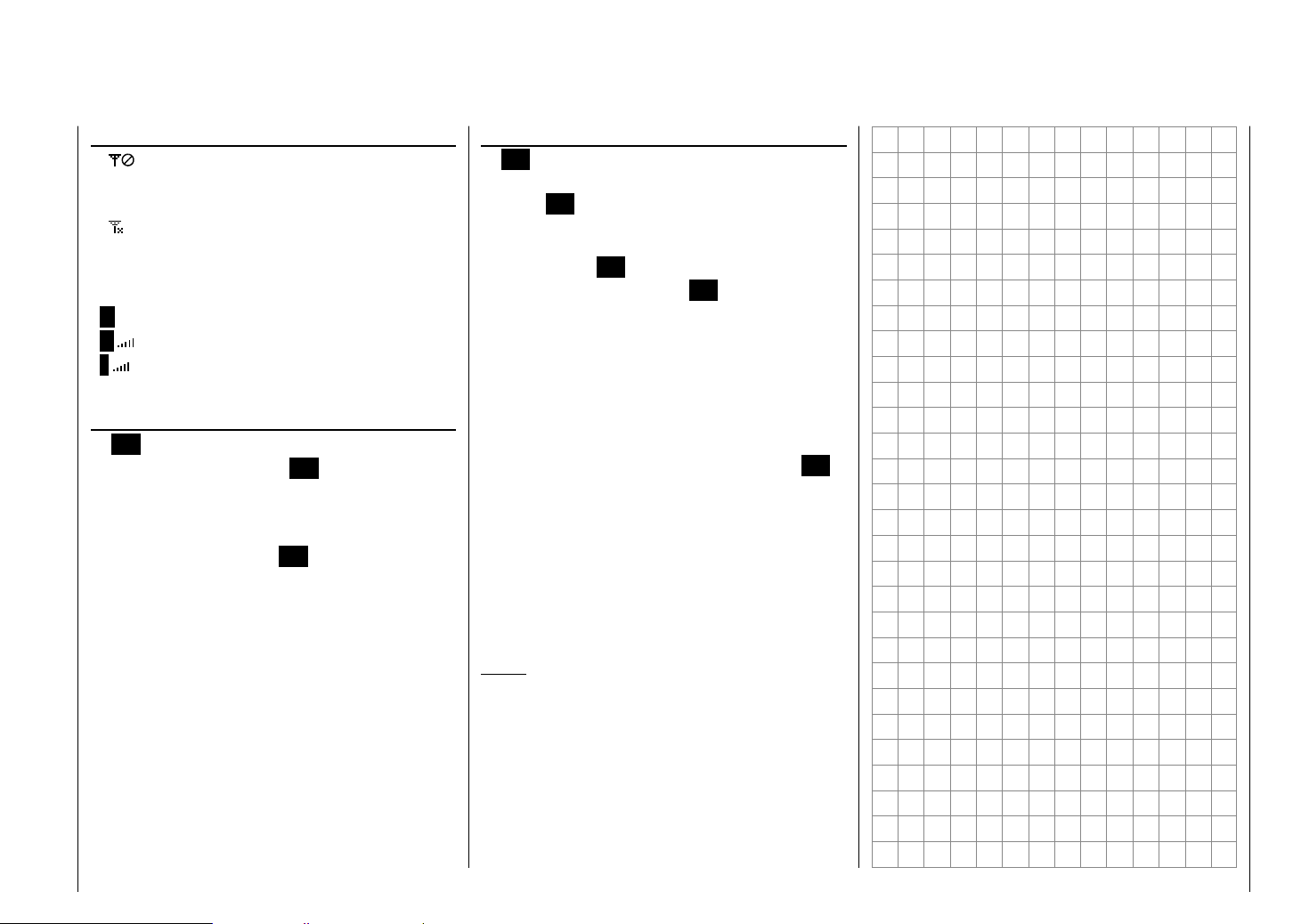

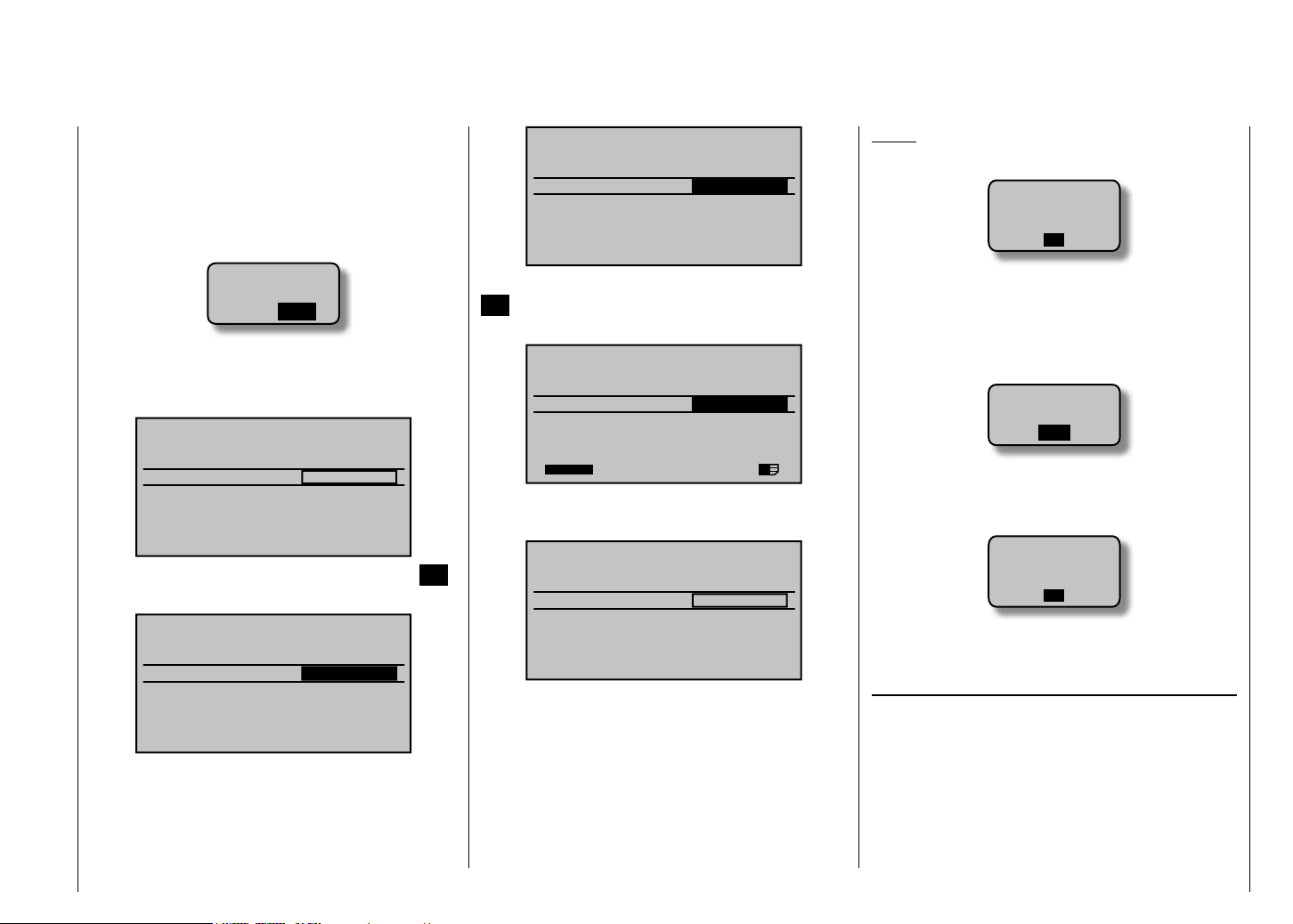

Battery operation timer at the bottom left of the

screen

This timer shows the transmitter's cumulative operating

time since the transmitter's battery was last charged.

This timer is automatically reset to "0:00" when the

transmitter is switched on and its battery voltage is

signifi cantly higher than when the transmitter was last

used, e. g. because the battery was charged.

GRAUBELE

#01

5.9V

0:00h

Lithium battery, CR 2032

At the left side of the transmitter board there is a fi xture

for a lithium battery. The user can replace this battery

when necessary with another lithium battery of type

CR 2032:

This battery maintains the date and time settings during

a transmitter power supply outage, for example when

the transmitter's main battery is being replaced.

Stop

Flt

«normal »

K78

Mx

0:00

0:00

HoTT

0.0V

Operating notices

15

Page 16

Operating notices

Receiver power supply

A selection of 4 and 5 cell NiMH battery packs having

different capacities are available to power the receiver. If

digital servos are in use, we recommend a 5 cell battery

pack (6 V) to afford adequate battery capacity. If analog

and digital servos are used in mixed operation, be sure

to pay attention to the given maximum permissible

operating voltage. A stabilized, adjustable power

supply for the receiver with 1 or 2 receiver batteries

can be provided, e. g. the PRX-unit, order no. 4136, see

appendix.

For reasons of safety, do not use battery boxes or dry

cell batteries.

The voltage of the on-board power supply will be

displayed at the bottom right of the transmitter's screen

while the model is in operation.

GRAUBELE

#01

5.2V

2:22h

If the adjustable warning threshold (default value 3.8 V)

set in the Telemetry menu, see page 217, is underrun,

an optical and acoustic under-voltage warning will be

issued.

Despite this feature, be sure to check the condition

of the battery at regular intervals. Do not wait for the

warning to be issued before recharging the battery.

Notice:

An overview of available batteries, chargers and current

source test instruments can be found in the Graupner

RC main catalog or in Internet at www.graupner.de.

Operating notices

16

Stop

Flt

«normal »

K78

M

0:00

0:00

HoTT

5.5V

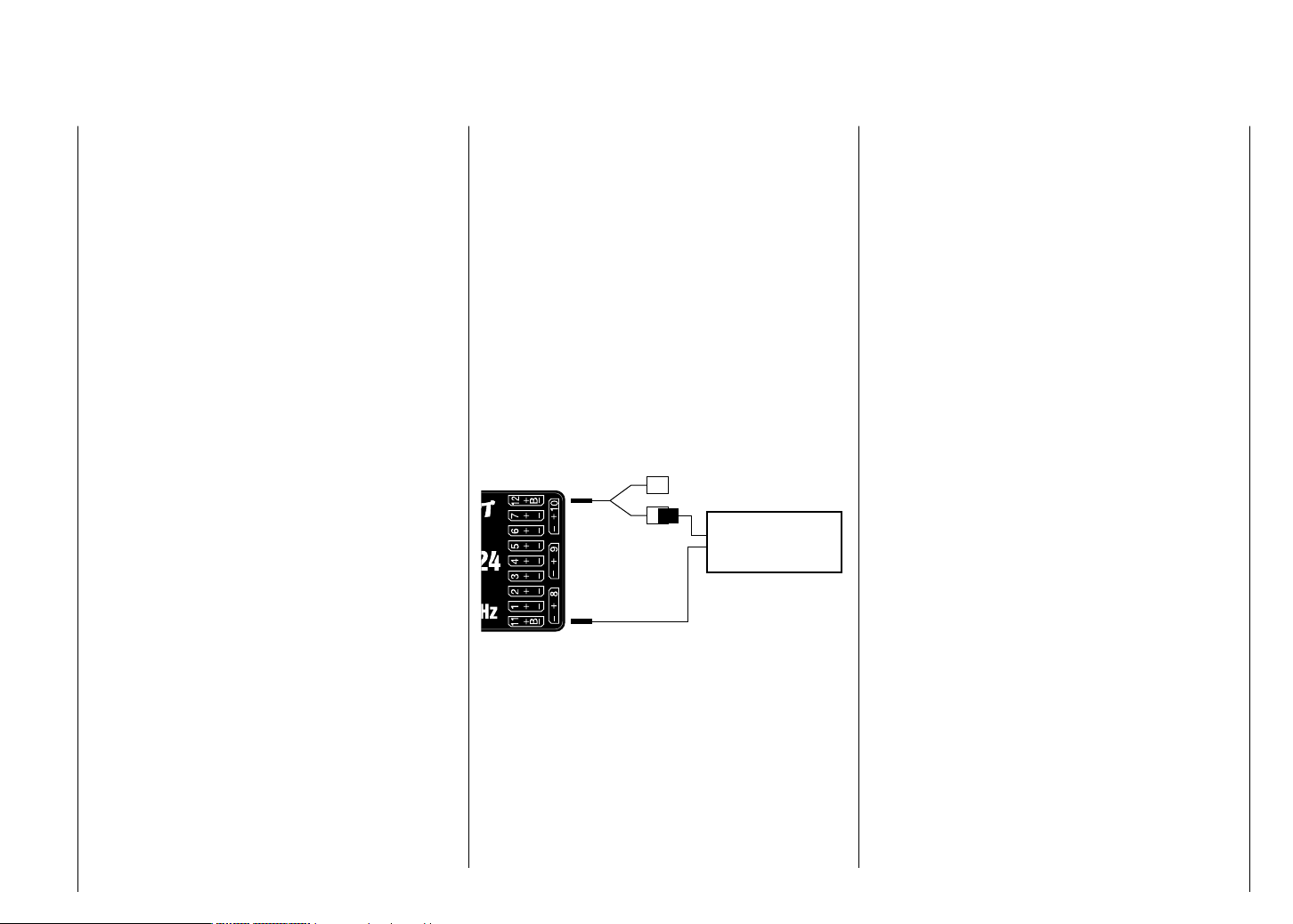

Charging the receiver battery

Charger cable, order no. 3021, can be plugged directly

onto the receiver's battery for charging. If the battery in

the model is connected by way of an order no. 3046,

3934, 3934.1 or 3934.3 power supply cable, then

charging can be accomplished via the charging jack or

special charging connector integrated into the switch.

The switch in the power supply cable must be in its

"OFF" position for charging.

Receiver battery connection polarity

General charging notices

The charging instructions for the charger as well as •

for the battery from its manufacturer to be observed.

Pay attention to the maximum permissible charging •

current specifi ed by the battery's manufacturer. In

order to prevent damage to the transmitter, charging

current should never exceed 1 A. If necessary, limit

the current at the charger.

If the transmitter battery is nevertheless to be •

charged at a current rate in excess of 1 A, then

it is imperative that this is done outside the

transmitter. Otherwise there is a risk of damage to

the transmitter's board due to overloading its printed

circuit paths and/or overheating of the battery.

If an automatic charger is to be used for charging, •

perform several test charging procedures to ensure

the fl awless functionality of its automatic shut-off.

This applies particularly if you want to charge the

standard installed NiMH battery with an automatic

charger unit intended for NiCd batteries Monitor the

charger's shut-off behavior if it has that option.

Do not execute a battery discharge or battery •

maintenance program through the charger jack. The

charger jack is not suitable for this purpose.

Alway connect the charger cable to the charger fi rst •

and then to the receiver or transmitter battery. This

avoids the possibility of shorting the bare banana

plug ends together.

If the battery heats up signifi cantly, check the •

battery's condition, replace the battery or reduce the

charging current.

Never leave a charging battery unattended.•

Follow the safety notices and handling •

instructions provided on page 8.

Page 17

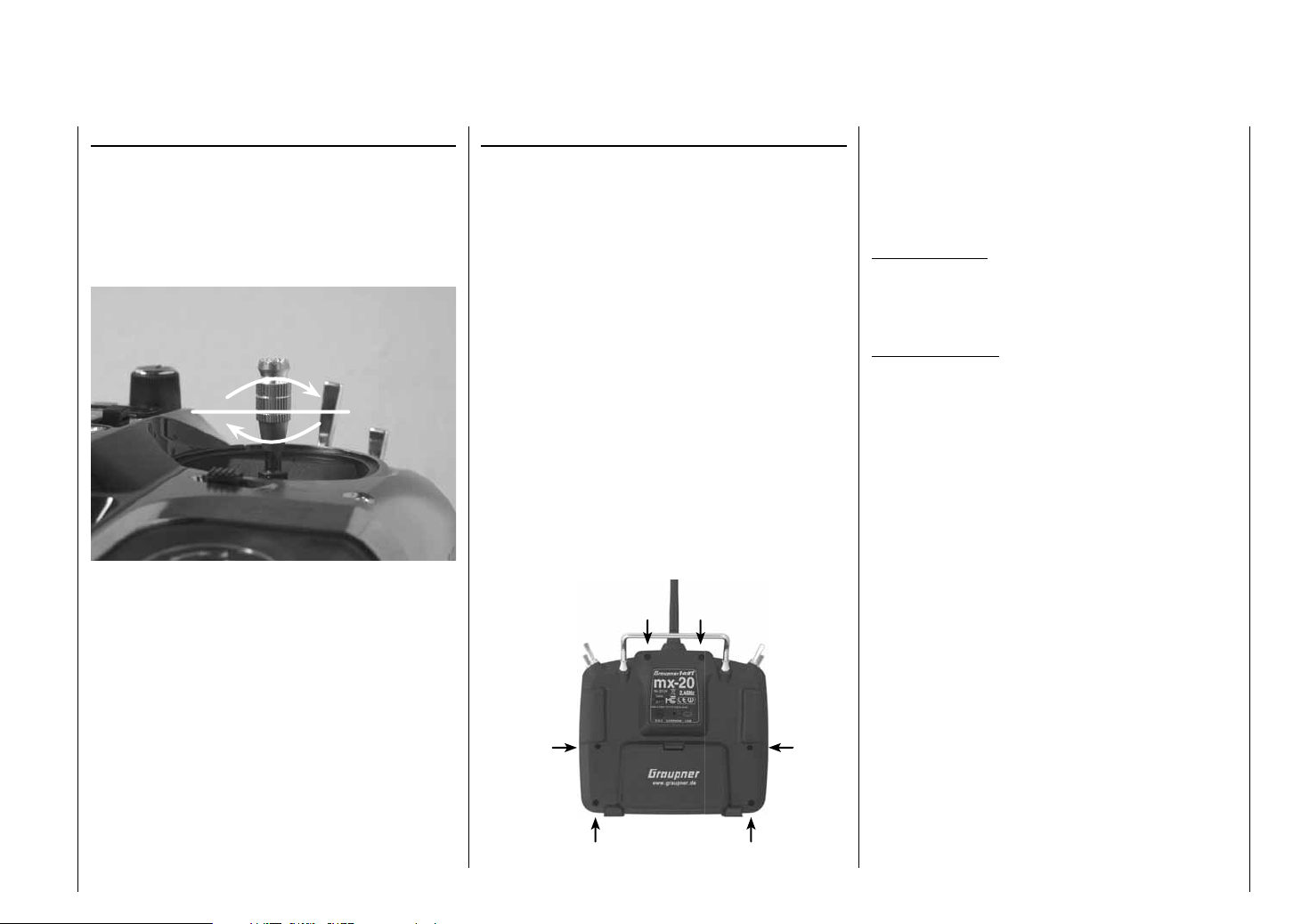

Joystick length adjustment

The length of both joysticks can be continuously

adjusted to adapt these transmitter controls to the pilot's

preference.

Hold the lower half of the knurled grip in place then turn

the upper section to release its counter-locked threads.

Now pull up or push down on the joystick's end to the

desired length. When the length is suitable, tighten the

counter-locked threads of the upper and lower sections

again.

Opening the transmitter housing

Carefully read the notices below before opening the

transmitter housing. It may be better if unexperienced

users ask a Graupner Service location to take care of

the procedures described below.

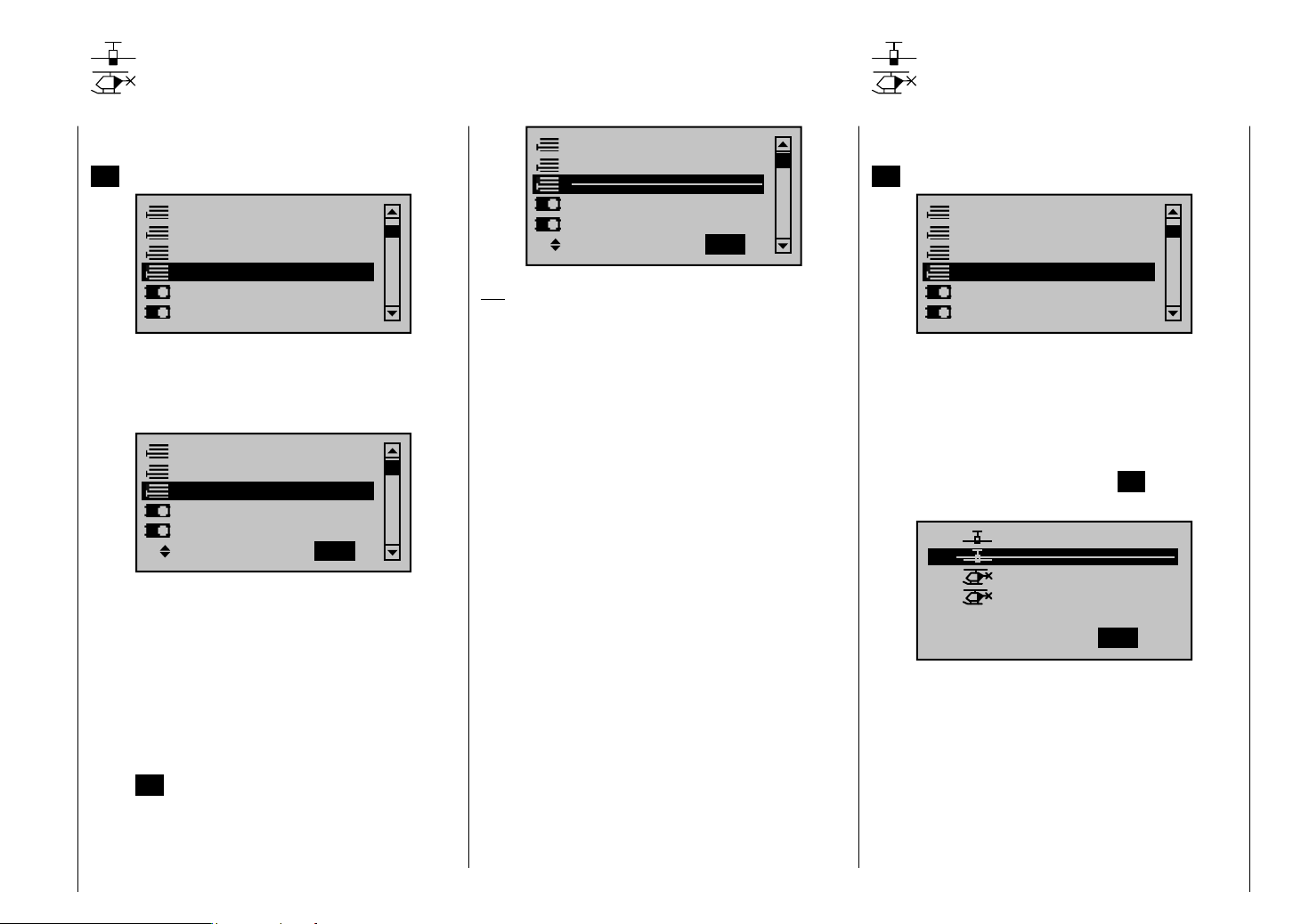

The transmitter should only be opened in the following

situations:

to convert a neutralized joystick to a non-neutralized •

joystick or a non-neutralized joystick to a neutralized

joystick.

to adjust joystick return tension.•

Switch off the transmitter before opening its cover

(power switch to "OFF").

Open the battery compartment as described on the

previous double-page, remove the battery and if a micro

SD card is inserted be sure to remove it too.

Once the battery and any micro SD card have been

removed, loosen the six countersunk screws on the rear

of the transmitter with a Phillips, size PH1, screwdriver,

see illustration.

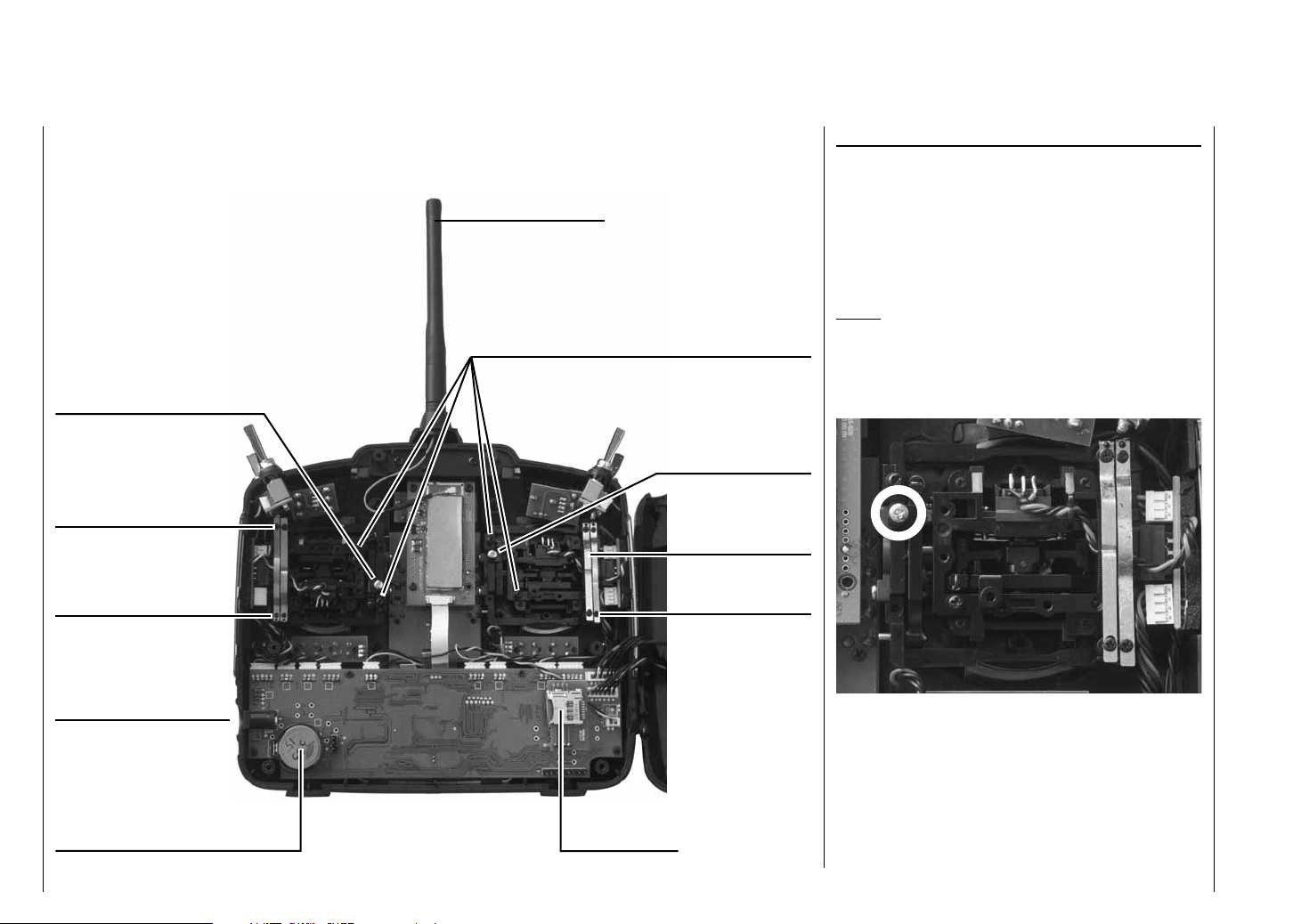

Housing screw locations

Hold the two housing sections together by hand then

turn the transmitter upright over a suitable surface so

these 6 screws can fall out without getting lost. Now lift

up on the backplate carefully and turn it open to the right

like you would open a book.

A T T E N T I O N:

Two multi-conductor cables connect the backplate

with the transmitter electronics in the upper section.

These connections must not be damaged.

Important notices:

Make no modifi cations of any kind to the circuitry •

as this will void the guarantee as well as the

unit's offi cial permit.

Be sure not to touch the circuit boards with any •

metallic objects. Do not touch contacts with your

fi ngers.

Never switch the transmitter on when its housing •

is open.

When you close the transmitter again, be sure

that …

… no cables are caught between housing edges •

when the backplate is put into position.

… both housing parts are properly seated with one •

another before screwing them together. Never force

the housing sections together.

Turn the screws down into the existing housing •

threads without stripping them out.

… reconnect the battery.•

Operating notices

17

Page 18

Operating notices

Do not touch the

circuit board!

Do not touch t

he circuit board!

left

joystick aggregate

right

joystick aggregate

neutralization screw

brake springs

collapsible antenna

adjustment screw for joystick restoration force

Do not touch t

he circuit board!

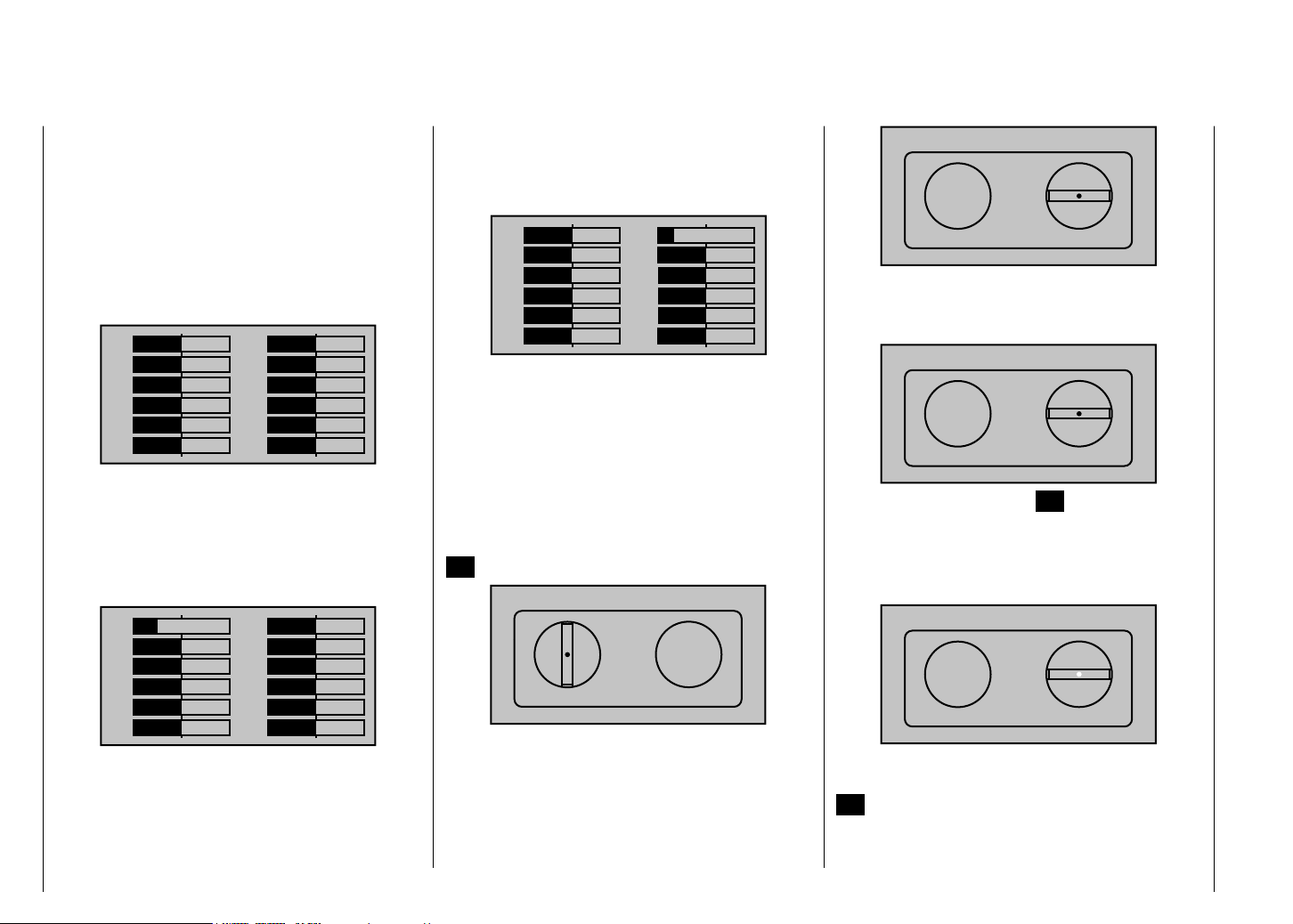

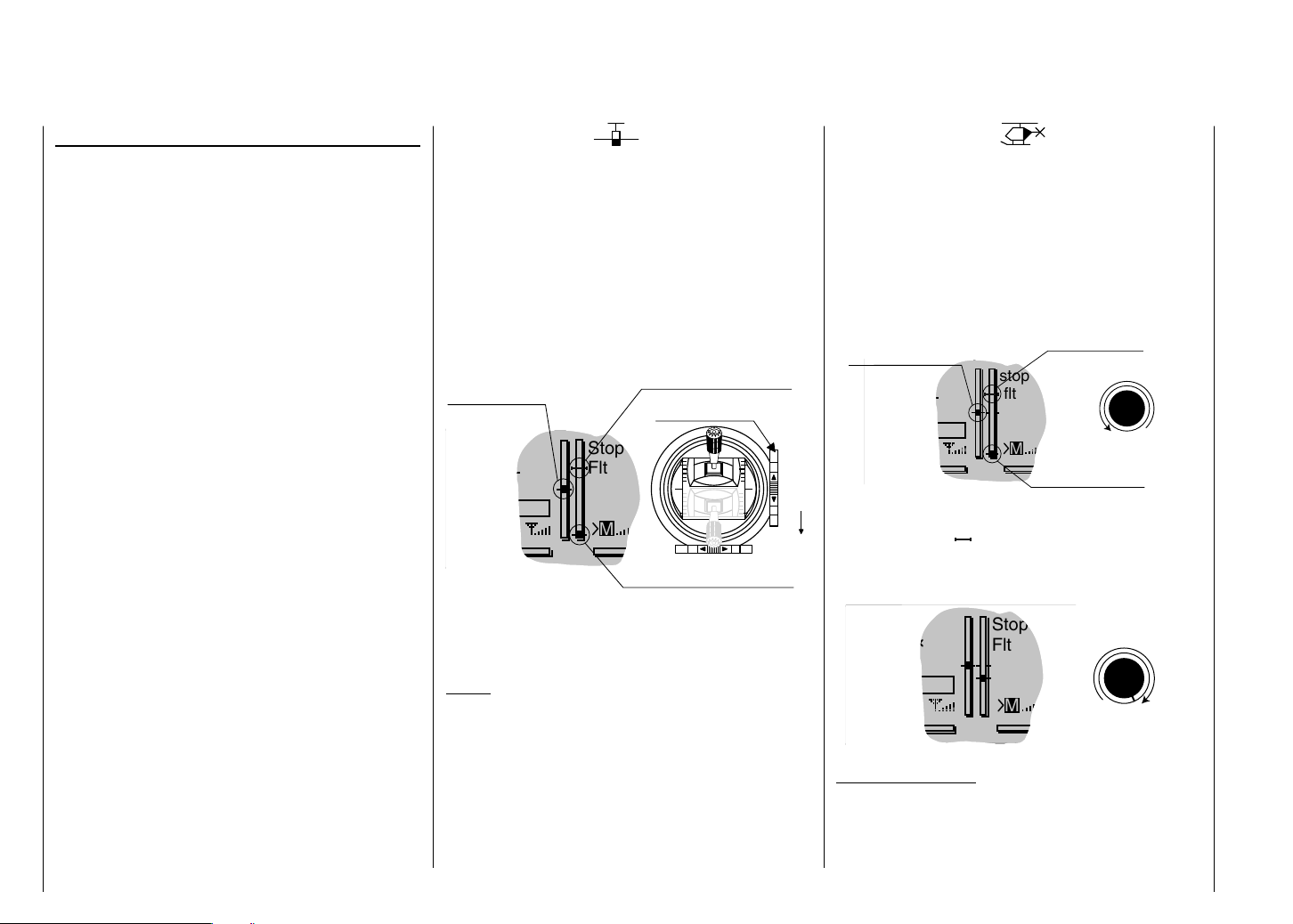

Converting joysticks

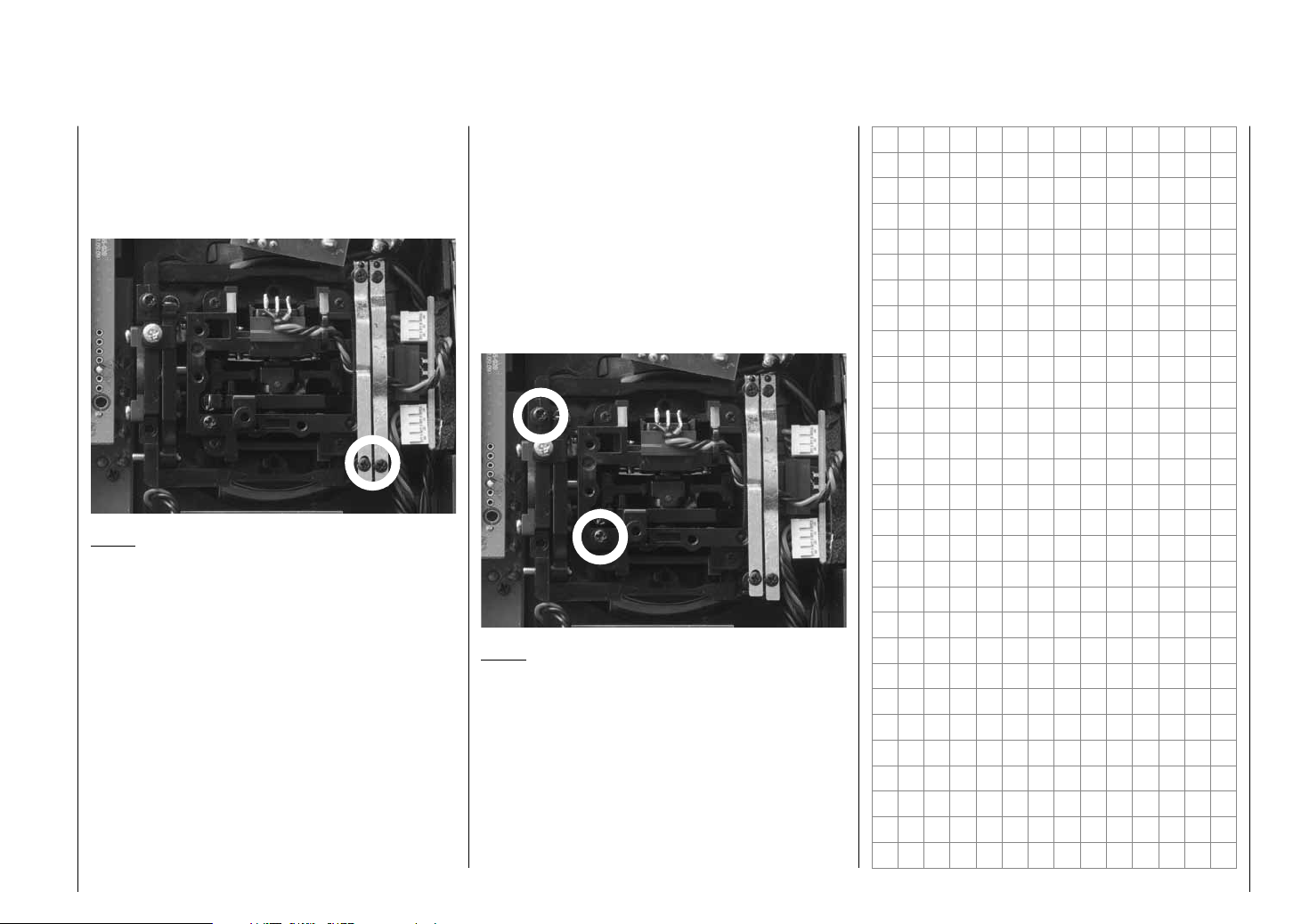

Neutralization

Both the left and the right joystick can be confi gured

for neutralized or non-neutralized operation as desired.

Open the transmitter housing as previously described.

To change the joystick's factory setting, locate the screw

shown in the fi gure below enclosed in a white circle.

Notice:

The aggregate for the right joystick is a mirror image of

the left joystick so the corresponding screw for the right

joystick is on the right side just below the middle.

neutralization screw

brake springs

adjustment screws

Charger jack

user-replaceable

CR2032 lithium battery to buffer the

integrated realtime clock

Operating notices

18

right

joystick aggregate

Do not touch the

circuit board!

left

joystick aggregate

Slot for

memory cards

adjustment screws

Now turn this screw down until the respective joystick

is free to move from limit to limit - or turn the screw out

until the joystick again completely self-restoring.

Page 19

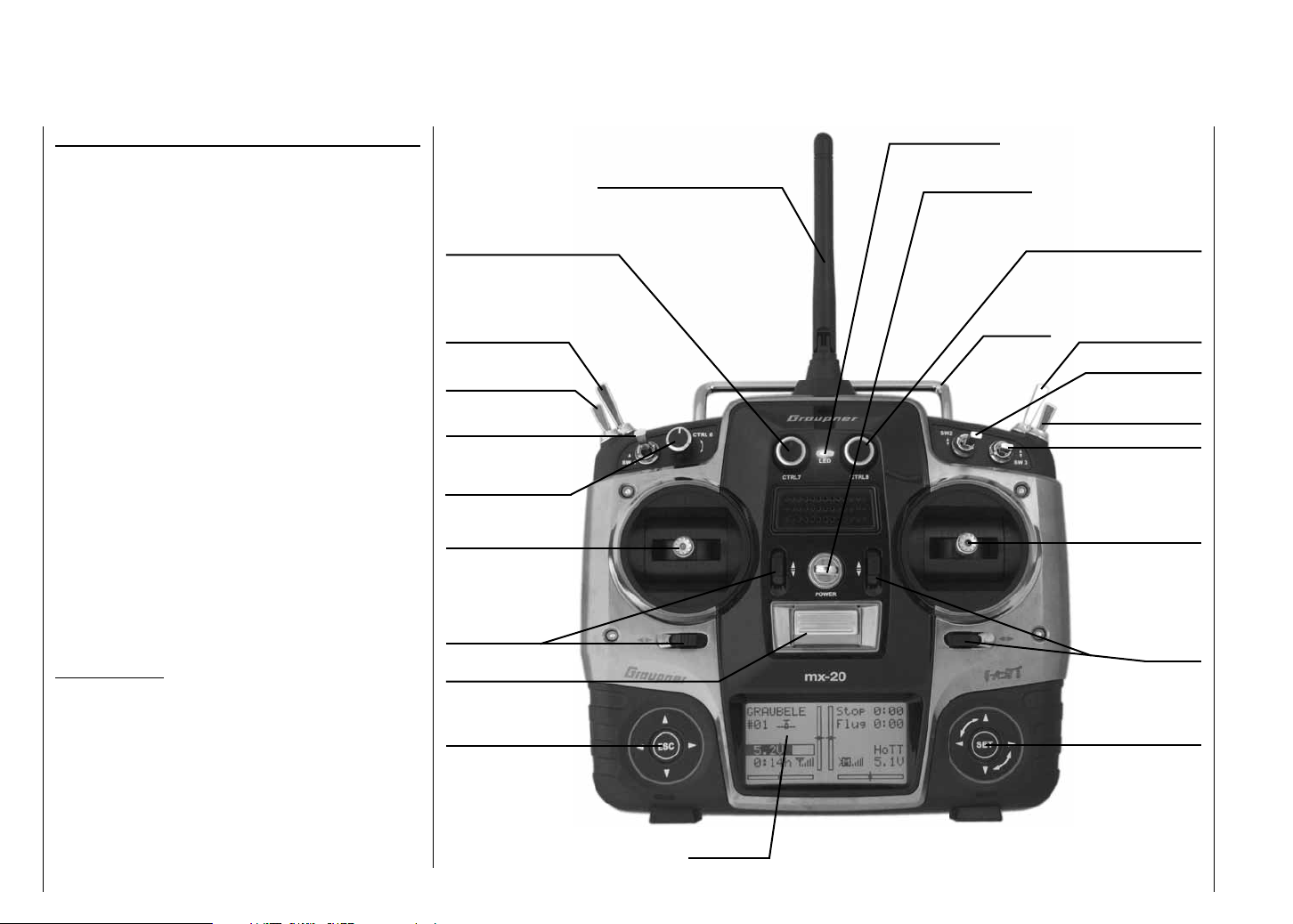

horizontal

vertical

Brake spring and ratchet

The outboard screw of the two marked in the next fi gure

adjusts the braking force and the inboard screw adjusts

the strength of the ratchet for the respective joystick.

Notice:

The aggregate for the right joystick is a mirror image of

the left joystick so corresponding screws for the right

joystick are located at the top left.

Joystick restoring force

The joystick's restoring force can also be adjusted to the

pilot's preference. The adjustment is located next to the

return springs, see markings in the fi gure below.

Spring force for the given direction of motion can be

adjusted by turning the respective screw with a Phillips

screwdriver.

Right turn (clockwise) = return harder,•

Left turn (counter clockwise) = return softer.•

vertical

horizontal

Notice:

The aggregate for the right joystick is a mirror image of

the left joystick so corresponding screws for the right

joystick are located to the right of the middle.

Operating notices

19

Page 20

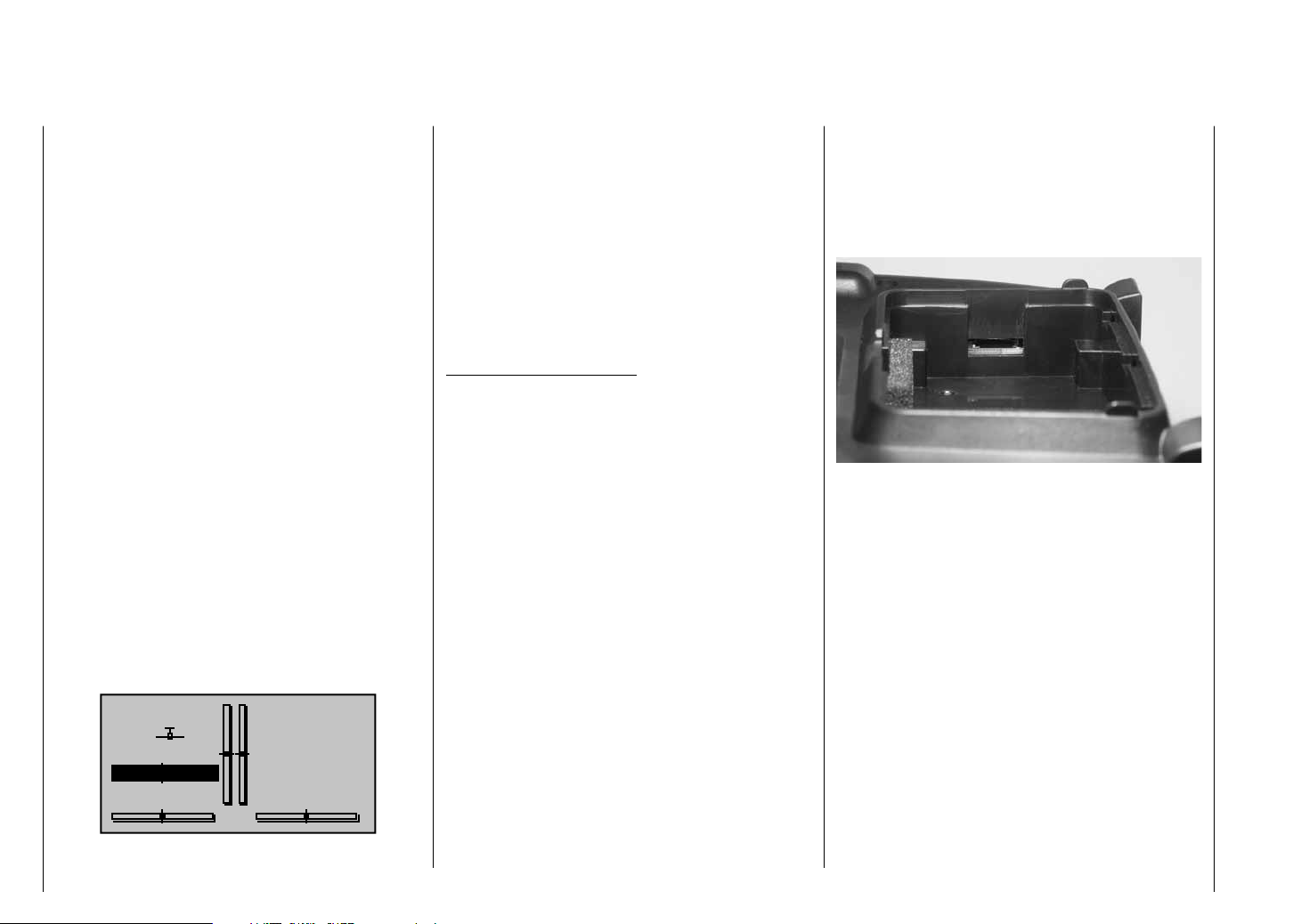

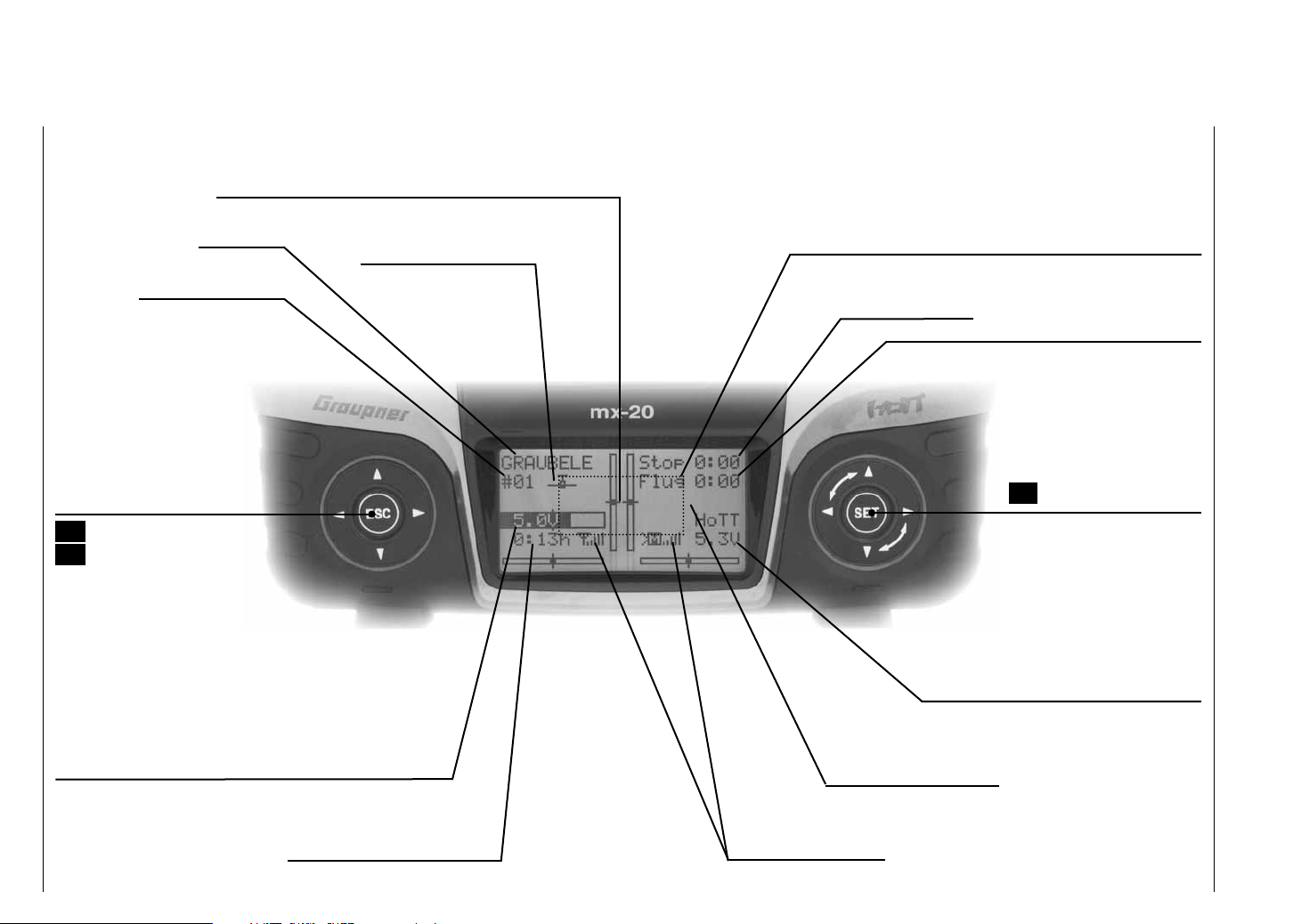

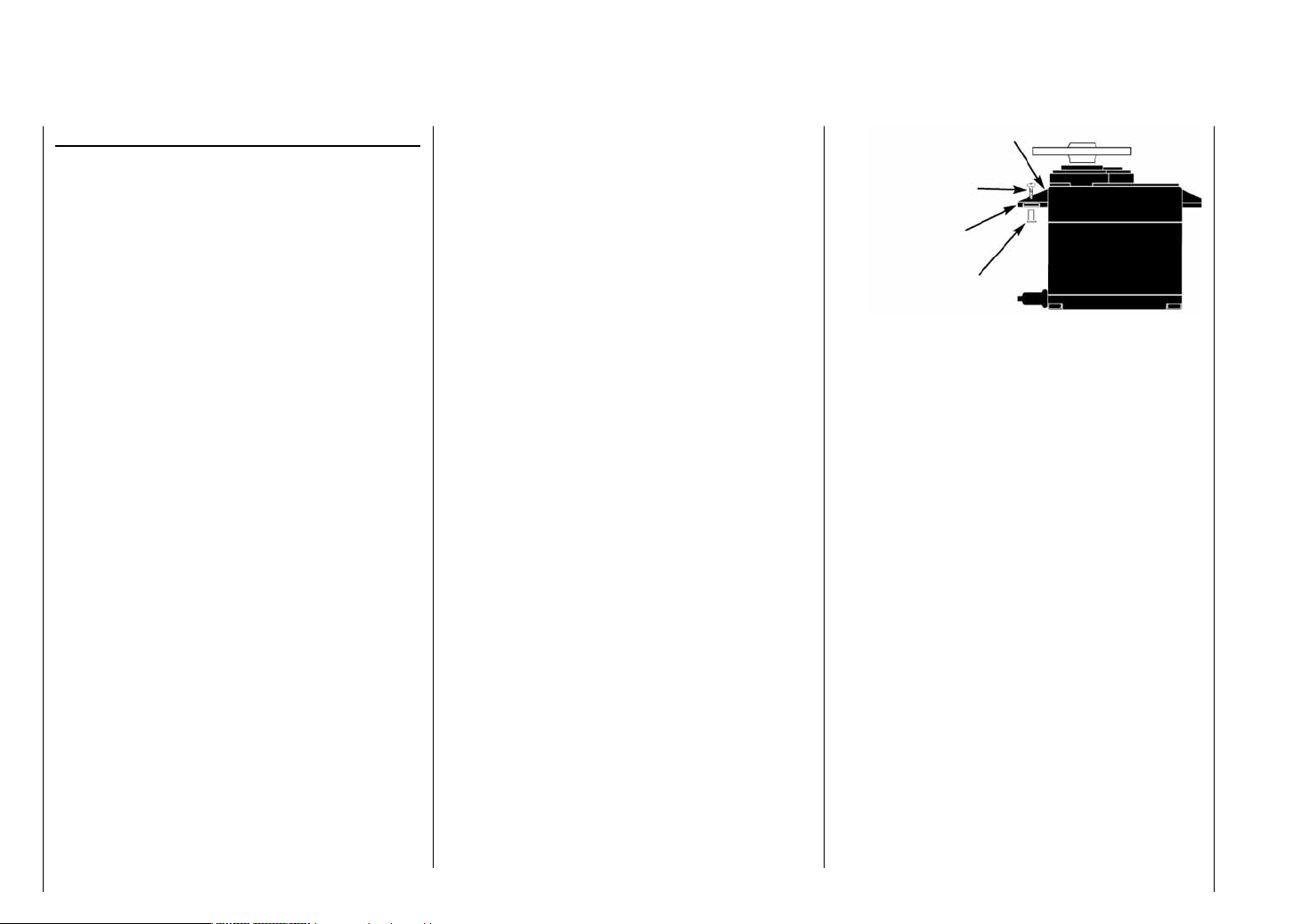

Transmitter description

Transmitter operating elements

Attaching the transmitter's neck strap

There is an eyelet on the top side of the mx-20 HoTT

transmitter (see fi gure at the right) to which a neck strap

can be attached. This anchor point has been chosen

because the transmitter is optimally balanced here when

it hangs from the strap.

Order No. 1121 Neck strap, 20 mm wide

Order No. 70 Neck strap, 30 mm wide

Important notice:

In its delivered confi guration, the transmitter can only

operate any servos attached to the receiver by way

of the two joysticks. For reasons of fl exibility, all other

operating elements (CTRL 6 … 8, SW 1 … 9) are

designated as "free" by the software. These other

operating elements can be freely assigned to actuators

as described in the text for the "Control adjust" menu

on page 96 (winged aircraft models) or page 100

(helicopter models).

Transmitter description

20

antenna with kink and twist joint

proportional speed control CTRL 7

2 position switch SW 8

3 position switch

SW 4/5 or CTRL 9

2 position momentary

contact switch SW 1

proportional speed

control CTRL 6

left joystick

trimmer

ON/OFF switch

left touch pad

LC display

main status LED

eyelet for neck strap

proportional speed control CTRL 8

carrying handle

2 position momentary

contact switch SW 9

2 position switch SW 2

3 position switch

SW 6/7 or CTRL 10

2 position switch SW 3

right joystick

trimmer

right touch pad

Page 21

Transmitter rear side

Data jack for connecting

the Smart-Box, Order

No. 33700

DSC jack for connecting

fl ight simulators and for

teacher/pupil mode

housing screw

housing screw

housing screw

earplugs or

headset connector

fi ve-pole mini USB

socket for connecting

the transmitter to a PC

housing screw

Headset connector

The jack centered in the lower portion of the type

plate on the back of the transmitter is for connecting

conventional earplugs or a headset by way of a 3.5 mm

audio plug. (not included in the set)

The transmitter's acoustic signals as well as those

signals associated with the telemetry menu are output

via this connection. These announcements are made in

German language by default. More details about "Voice

output" can be found in the section "HIDDEN MODE"

beginning on page 28 and "Telemetry" beginning on

page 208.

The headset connector's volume control can be adjusted

in the "Voice volume" line of the "Basic Settings" menu,

see page 227.

Mini-USB connector

This connector socket is used to establish a connection

between the transmitter and a PC running a Windows

operating system (XP, Vista or Windows 7). The PC

software required, such as a suitable USB driver, can be

found on the download page for the given product on the

Graupner website at www.graupner.de.

Once the necessary software is installed on the PC, this

USB connection can be used to update the transmitter

or even just to set the date and time in the transmitter.

Charger jack for

transmitter battery

housing screw

battery compartment cover

housing screw

Data jack

For connecting the optionally available Smart-Box,

Order No. 33700.

Details about the Smart-Box can be found with the given

product in the Graupner RC main catalog or in Internet

at www.graupner.de.

Transmitter description

21

Page 22

DSC

Direct Servo Control

The acronym "DSC" is a carryover which stands for the

original "Direct Servo Control" function. However, in

HoTT systems the "direct servo control" function is no

longer available via a diagnose cable due to technical

reasons.

The standard two-pole DSC jack in the mx-20 HoTT

transmitter is used as the teacher or pupil jack as well

as an interface to fl ight simulators.

To ensure a proper DSC connection, please observe:

Make any necessary menu changes.

Refer to the section beginning on page 198 to

adapt the mx-20 HoTT transmitter to a teacher/pupil

system.

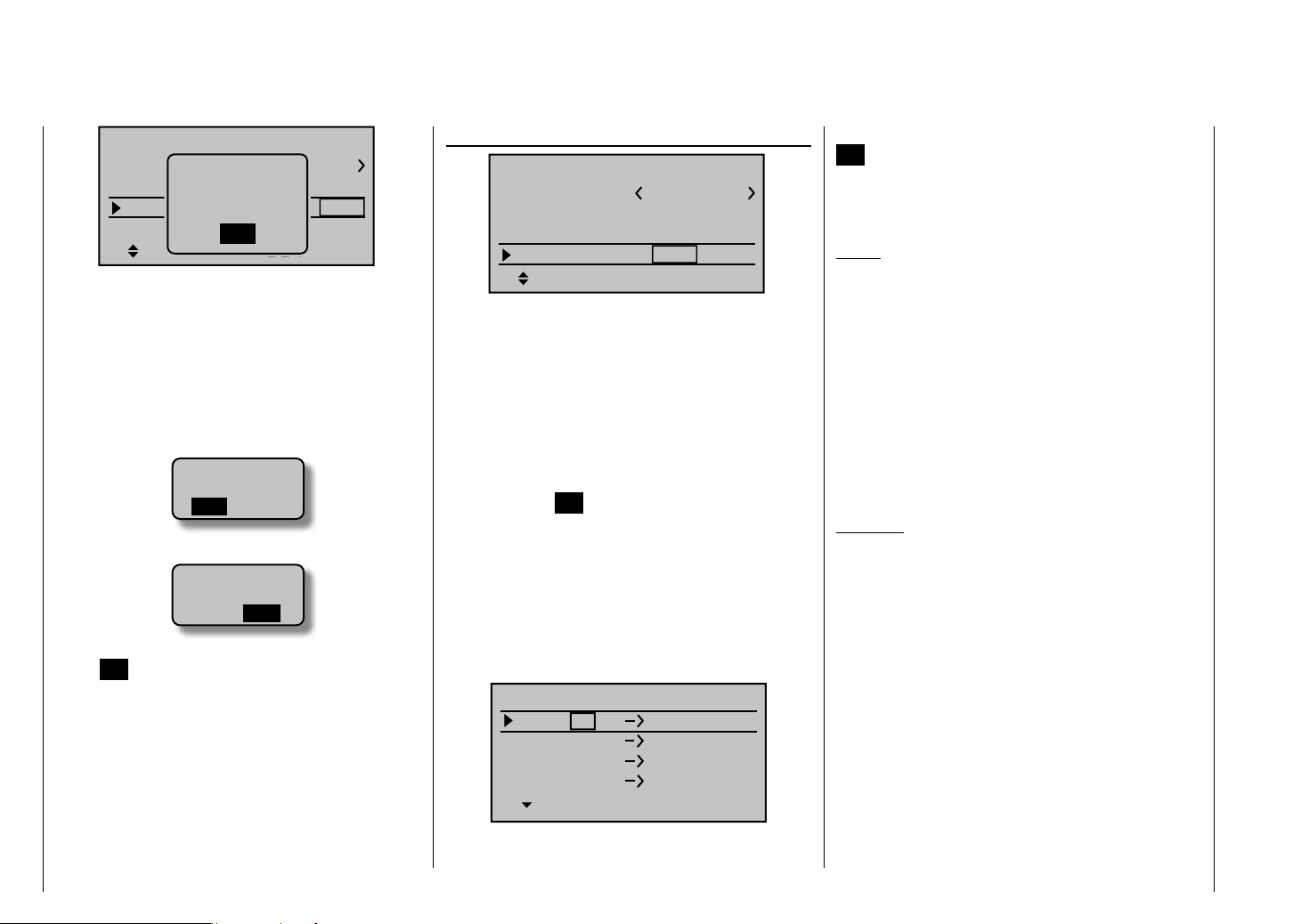

When operating a fl ight simulator or when operating 1.

the mx-20 HoTT transmitter as a pupil transmitter,

ALWAYS leave the transmitter's ON/OFF switch

in the "OFF" position as only in this position does

the transmitter's RF module remain inactive after

the DSC cable is inserted. This also reduces the

transmitter's power consumption somewhat.

The main status LED should now constantly

illuminate red and the transmitter's basic setup

screen should show the string "DSC pupil" on the

right just below the middle timer. At the same time,

the display of telemetry indicators will be suppressed.

PUPIL

#11

5.9V

0:01h

Stop

Flt

DSC

«normal »

0:00

0:00

HoTT

0.0V

Thus the transmitter is ready for operation.

To the contrary, teacher mode for the mx-20 HoTT

transmitter requires that the transmitter be switched

on prior to plugging in the respective cable.

Connect the other end of the cable to the desired unit 2.

in compliance with the given operating instructions

for that unit.

Important:

Be sure that all connectors are seated fi rmly in

their respective sockets.

Notice about fl ight simulators:

Because of the myriad of fl ight simulators available on

the market, it may be necessary to have the contact

layout of the audio plug or DSC module appropriately

modifi ed by Graupner Service.

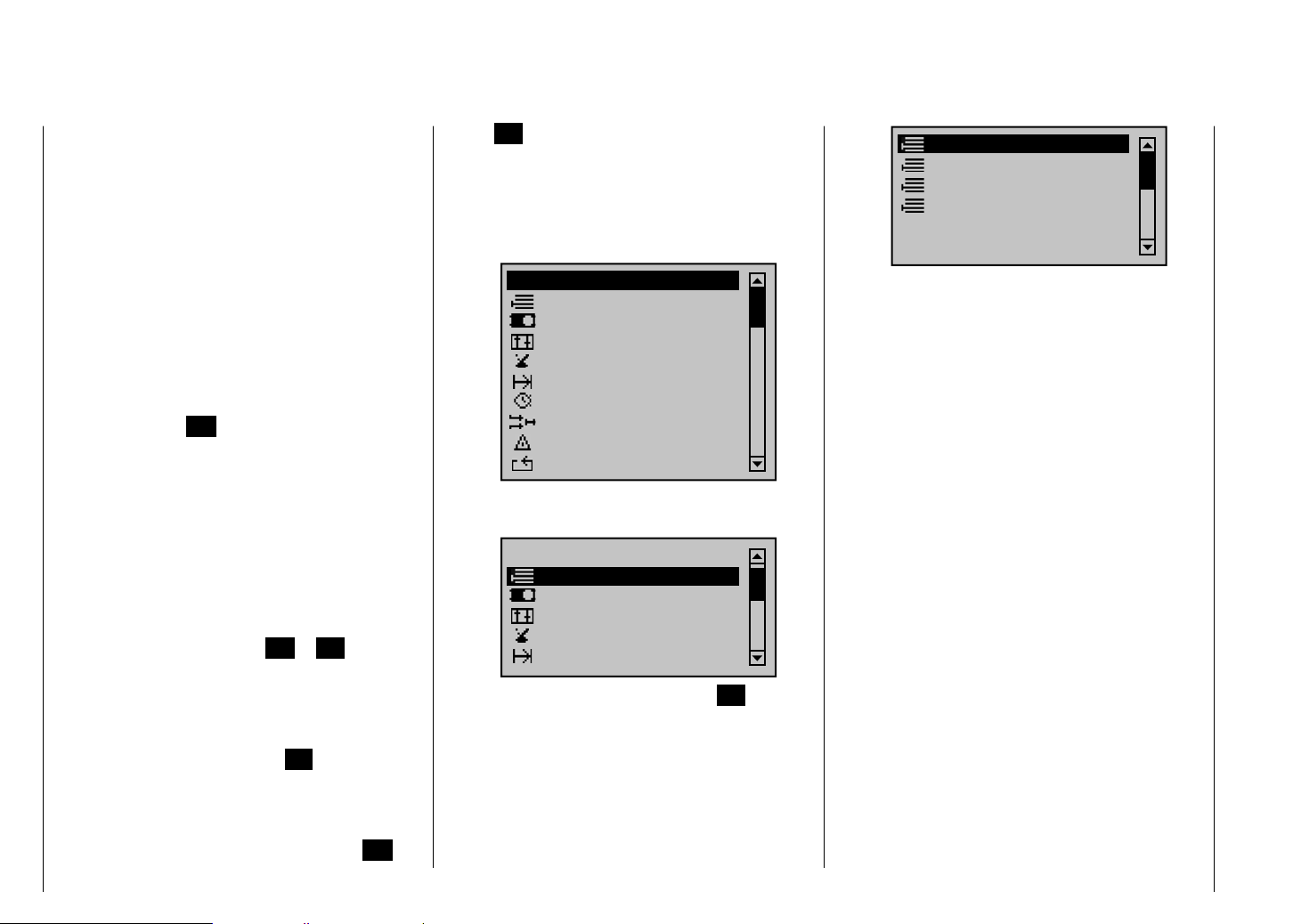

Data storage

Card slot

micro SD and micro SDHC

With the mx-20 HoTT transmitter switched off,

removing the battery compartment cover and the

transmitter's battery will make the card slot accessible

(located in the right sidewall of the battery compartment).

This card slot is intended for micro SD and micro SDHC

type memory cards.

All conventional micro SD memory cards up to 2 GB and

micro SDHC cards up to 32 GB storage capacity can

be used. However, as a manufacturer we recommend

the use of memory cards no larger than 4 GB as this is

completely adequate for all normal situations.

The type of memory card referred to here became

known in conjunction with digital cameras and cell

phones. It is to be pushed into the slot with its contacts

upward, front facing the rear wall and latched in position

there. After re-installing the battery and closing the

battery compartment, the transmitter can be switched on

again. The stylized image of a memory card will appear

in the basic setup screen to indicate the presence of the

inserted memory card.

Transmitter description

22

Page 23

GRAUBELE

#01

5.2V

3:33h

Notice:

If a micro SD card is inserted, be sure to remove

it BEFORE taking off the transmitter's backplate.

Otherwise there is a risk of damaging the memory card.

Data acquisition / storage

The storage of data on the SD card is coupled to the

fl ight timer. If this timer is started – when a suitable

memory card is inserted in the card slot and a telemetry

link to the receiver exists – both the timer and data

acquisition will stop when the fl ight timer is stopped. The

fl ight timer is started and stopped as described in the

section "Timers (general)" on page 138.

While data acquisition is ongoing, the on-screen card

image will blink continuously at a slow rate.

The amount of data written on the memory card is

presented as a black bar graph which grows from left to

right as data fi lls the memory card.

After a data acquisition session is fi nished, there will

be an (empty) folder "Models" and a "LogData" folder

on the memory card. Within the "LogData" folder there

will be log fi les in sub-folders that are designated with

names in the format 0001_year-month-day.bin, 0002_

year-month-day.bin, etc. If a model memory folder is still

"unnamed" when the memory card is removed from the

transmitter and inserted into the card slot of a PC or

laptop, the respective log fi les can be found in a sub-

Stop

Flt

«normal »

K78

M

0:00

0:00

HoTT

5.5V

folder designated "NoName". There is a PC program

available on the transmitter's download web page at

www.graupner.de with which the stored data can be

evaluated on a compatible PC.

Importing voice fi les

As already mentioned in the section "Headsets" on

page 21, this connection can also be used to output

the transmitter's acoustic signals as well as those

signals and announcements associated with telemetry

menu settings. These announcements are made in

German language by default. These announcements

are summarized in a voice packet which is stored in a

transmitter-internal memory but they can be replaced

by a voice packet of a different language at any time.

More information about this can be found in the section

"HIDDEN MODE" beginning on page 28.

Importing/exporting model memories

Any model memory can be stored to an inserted memory

card or from an inserted card into the transmitter. This

feature is intended to support data exchange between

identical transmitters or even use as data backup.

More information about this can be found in the section

"Copying/deleting" beginning on page 64.

Notice:

Some special symbols that can be used in model names

are subject to specifi c restrictions associated with the

FAT or FAT32 fi le system used by the memory cards and