Page 1

Programmier-Handbuch

33110.mx-10 HoTT.1

HOPPING.TELEMETRY.TRANSMISSION

mx-10

Programming Manual

Manuel de programmation

Page 2

70

Contents

Binding receivers ........................................... 106

Range-checking ............................................ 106

Model helicopter ..................................................108

Country setting ..............................................108

Binding receivers ........................................... 110

Range-checking ............................................ 110

“Servo settings” ........................................................111

“

“F

ail-Safe” ................................................................111

“Telemetry” ...............................................................113

SETTING & DATA VIEW ...................................... 114

TX display .....................................................114

RX Data

view .................................................115

RX Servo ....................................................... 116

RX Fail Safe ..................................................117

RX Free mixers ............................................. 119

RX Expo ........................................................120

RX Servotest .................................................121

DATA VIEW ..........................................................124

Receiver ........................................................ 125

General Module ............................................. 125

Electric Air Module ........................................ 125

Vario Module .................................................126

GPS Module .................................................. 126

“Trainer mode”

......................................................... 127

Teacher ................................................................ 127

Pupil .................................................................... 128

Appendix

Appendix .................................................................... 174

Conf

ormity declaration ............................................... 202

FCC Information ........................................................ 203

Guarantee certifi cate .................................................204

General Information

Safety Notes ................................................................71

Saf

ety notes and handling instructions relating

to Nickel-Metal-Hydride rechargeable batteries ..........75

Foreword ......................................................................77

Description of radio control set ....................................78

Recommended battery chargers ................................. 80

Transmitter power supply ............................................. 81

Receiver power supply ................................................ 82

Adjusting the stick length ............................................. 83

Opening the transmitter case ......................................83

Changing the stick mode .............................................84

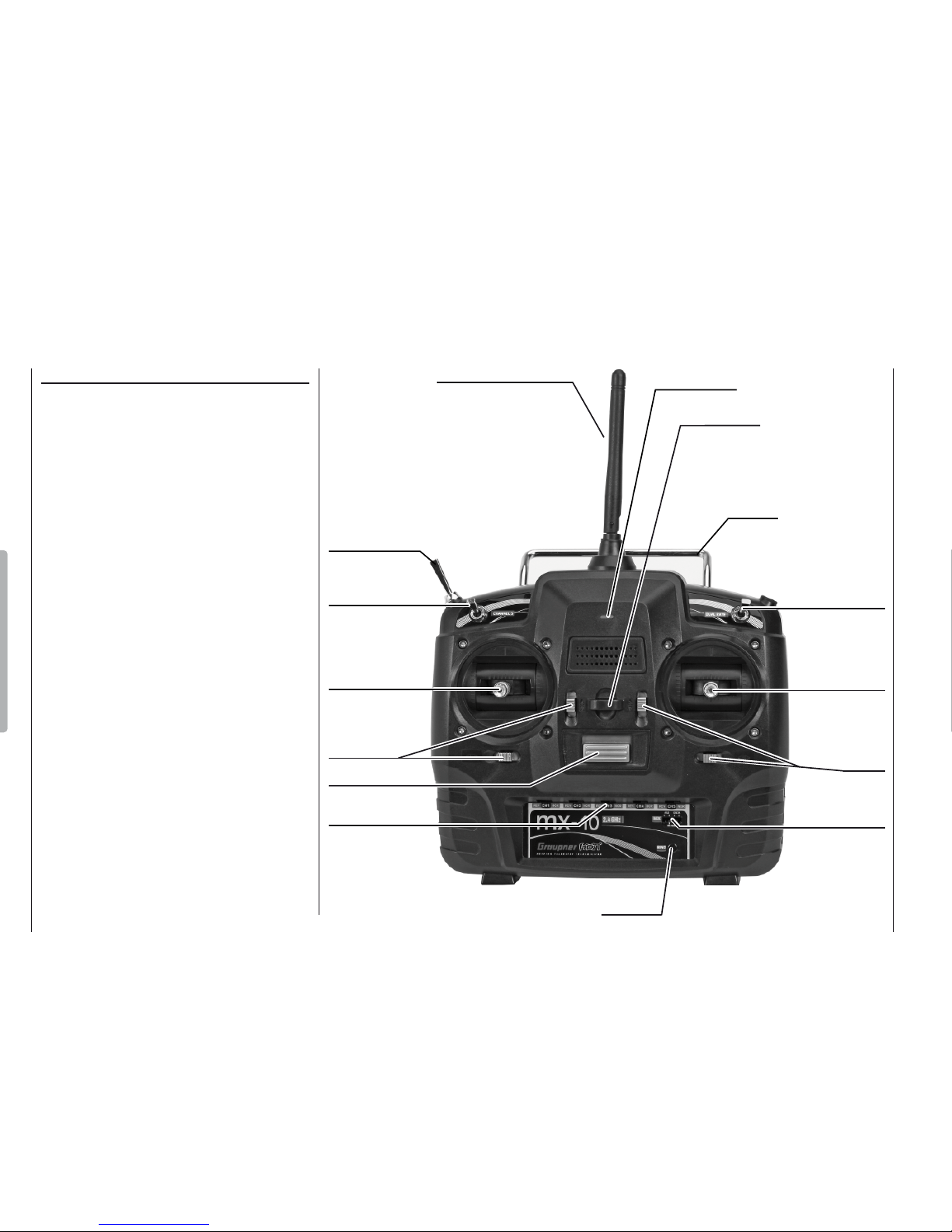

Description of transmitter............................................. 86

Transmitter controls ...............................................86

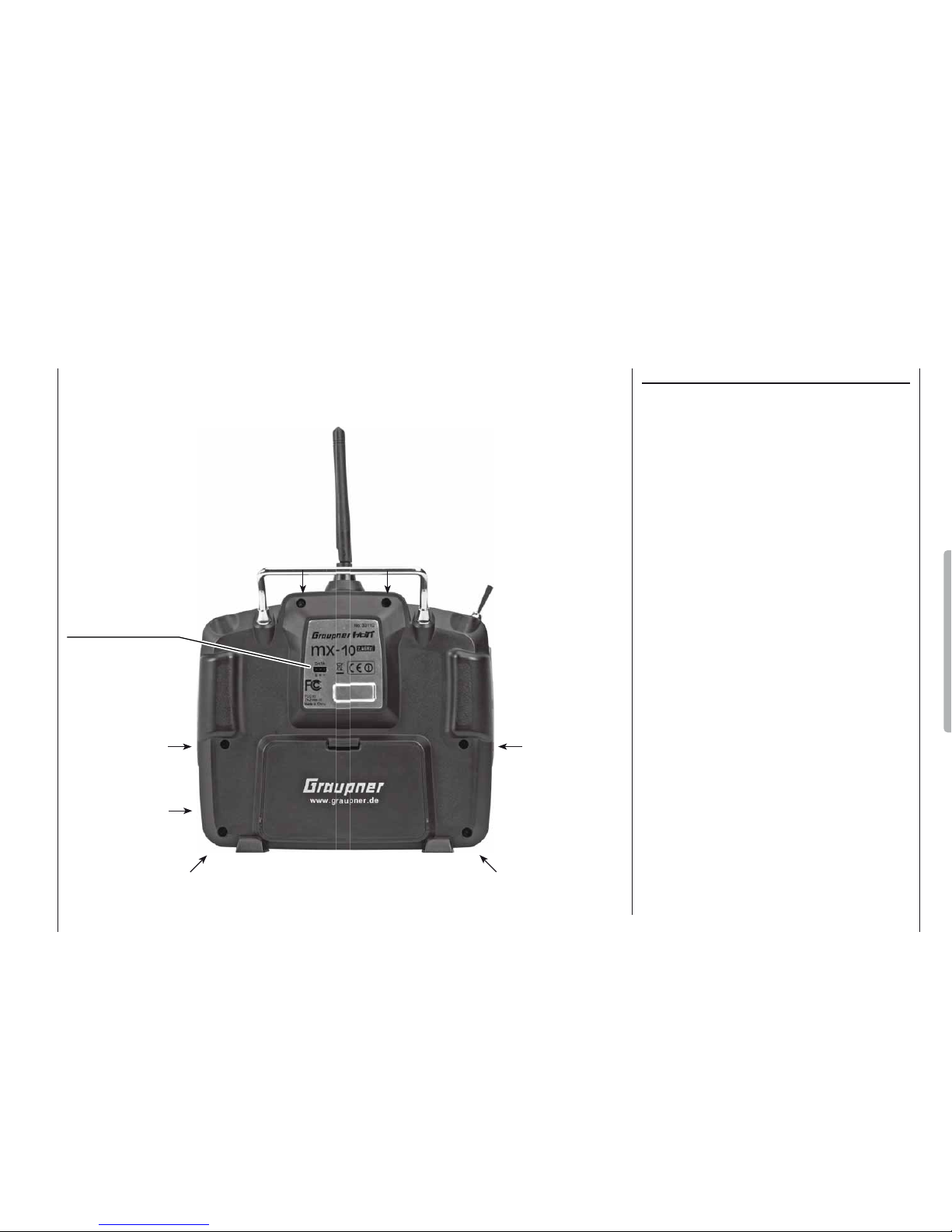

Rear of transmitter ................................................. 87

Data socket ...........................................................87

Using the transmitter for the fi rst time .......................... 88

Transmitter fi rmware update ..................................89

Using the receiver for the fi rst time .............................. 92

Receiver fi rmware update .....................................94

Installation notes .......................................................... 96

Receiving system power supply ............................97

Defi nition of terms ....................................................... 99

Digital trims and stick calibration ............................... 100

Fixed-wing model aircraft...........................................101

Receiver socket sequence .................................. 102

Model helicopters ......................................................103

Receiver socket sequence .................................. 103

Program descriptions

“Base settings”

(model)

Fixed-wing model aircraft .................................... 104

Country setting ..............................................104

Tail type setting .............................................105

Contents

Environmental protection

This symbol on the product, in the operating instructions

or the packaging indicates that the product must not be

discarded via the normal household refuse at the end

of its useful life. Instead it must be taken to a collection

point for the recycling of electrical and electronic apparatus.

The materials can be re-used according to their identifi cation code. You can make an important contribution to

the protection of our shared environment by recycling

old equipment and making use of its

basic materials.

Dry and rechargeable batteries must

be removed from the device and taken

to the appropriate collection point.

Please ask your local authority for the

location of your nearest waste disposal site.

The sole purpose of this manual is to provide information; it is subject to amendment without prior notifi cation.

Graupner accepts no responsibility or liability for errors

or inaccuracies which may occur in the information

section of this manual.

Page 3

71

Safety Notey

We all want you to have many hours of pleasure in our

mutual hobby of modelling, and safety is an important

aspect of this. It is absolutely essential that you read

right through these instructions and take careful note

of all our safety recommendations. We also strongly

recommend that you register without delay at http://

www.graupner.de/en/service/product_registration, as

this ensures that you automatically receive the latest

information relating to your product by e-mail.

If you are a beginner to the world of radio-controlled

model aircraft, boats and cars, we strongly advise that

you seek out an experienced modeller in your fi eld, and

ask him or her for help and advice.

If you ever dispose of this transmitter, these instructions

must be passed on to the new owner.

Application

This radio control system may only be used for the

purpose for which the manufacturer intended it, i. e. for

operating radio-controlled models which do not carry hu-

mans. No other type of use is approved or permissible.

Safety notes

SAFETY IS NO ACCIDENT

and

RADIO-CONTROLLED MODELS

ARE NOT PLAYTHINGS

Even small models can cause serious personal injury

and damage to property if they are handled incompetently, or if an accident occurs due to the fault of others.

Technical problems in electrical and mechanical systems can cause motors to rev up or burst into life unexpectedly, with the result that parts may fl y off at great

speed, causing considerable injury.

Short-circuits of all kinds must be avoided at all times.

Short-circuits can easily destroy parts of the radio control system, but even more dangerous is the acute risk

of fi re and explosion, depending on the circumstances

and the energy content of the batteries.

Aircraft and boat propellers, helicopter rotors, open

gearboxes and all other rotating parts which are driven

by a motor or engine represent a constant injury hazard.

Do not touch these items with any object or part of your

body. Remember that a propeller spinning at high speed

can easily slice off a fi nger! Ensure that no other object

can make contact with the driven components.

Never stand in the primary danger zone, i. e. in the rotational plane of the propeller or other rotating parts, when

the motor is running or the drive battery is connected.

Please note that a glowplug engine or electric motor

could burst into life accidentally if the receiving system

is switched on when you are transmitting the transmitter.

To be on the safe side, disconnect the fueltank or the

fl ight battery.

Protect all electronic equipment from dust, dirt, damp,

and foreign bodies. Avoid subjecting the equipment

to vibration and excessive heat or cold. Radio control

equipment should only be used in “normal” ambient

temperatures, i. e. within the range -15°C to +55°C.

Avoid subjecting the equipment to shock and pressure.

Check the units at regular intervals for damage to cases

and leads. Do not re-use any item which is damaged

or has become wet, even after you have dried it out

thoroughly.

Use only those components and accessories which

we expressly recommend. Be sure to use only genuine

matching Graupner connectors of the same design with

contacts of the same material.

When deploying cables ensure that they are not under

strain, are not tightly bent (kinked) or broken. Avoid

sharp edges, as they can chafe through insulating

materials.

Before you use the system, check that all connectors

are pushed home fi rmly. When disconnecting components, pull on the connectors themselves – not on the

wires.

It is not permissible to carry out any modifi cations to the

RC system components, as any such changes invalidate

both your operating licence and your insurance cover.

Installing the receiving system

In a model aircraft the receiver must be packed in soft

foam and stowed behind a stout bulkhead, and in a

model boat or car it should be protected effectively from

dust and spray.

The receiver must not make direct contact with the

fuselage, hull or chassis at any point, otherwise motor

vibration and landing shocks will be transmitted directly

to it. When installing the receiving system in a model

with a glowplug or petrol engine, be sure to install all

the components in well-protected positions, so that no

exhaust gas or oil residues can reach the units and

get inside them. This applies above all to the ON / OFF

switch, which is usually installed in the outer skin of the

model.

Secure the receiver in such a way that the aerial, servo

leads and switch harness are not under any strain. The

receiver aerial should be at least 5 cm away from all

large metal parts and any wiring which is not connected

directly to the receiver. This includes steel and carbon

fi bre components, servos, electric motors, fuel pumps,

cabling of all kinds, etc..

Ideally the receiver should be installed well away from

Safety Notes

Please read carefully!

Page 4

72

Safety Notes

Safety Notes

Ensure that no metal parts are able to rub against each

other, e. g. when controls are operated, when parts

rotate, or when motor vibration affects the model. Metalto-metal contact causes electrical “noise” which can

interfere with the correct working of the receiver.

Directing the transmitter aerial

Transmitter fi eld strength is at a minimum in an imaginary line extending straight out from the transmitter

aerial. It is therefore fundamentally misguided to “point”

the transmitter aerial at the model with the intention of

obtaining good reception.

When several radio control systems are in use on adjacent channels, the pilots should always stand together in

a loose group. Pilots who insist on standing away from

the group endanger their own models as well as those

of the other pilots.

However, if two or more pilots operating 2.4 GHz radio

control systems stand closer together than 5 m, the

down-link channel may be swamped, triggering a very

premature range warning. If this should occur, walk

away from the other pilots until the range warning

ceases again.

Pre-fl ight checking

Before you switch on the receiver, ensure that the

throttle stick is at the stop / idle end-point.

Always switch on the transmitter fi rst,

and only then the receiver.

Always switch off the receiver fi rst,

and only then the transmitter.

If you do not keep to this sequence, i. e. if the receiver

is at any time switched on when “its” transmitter is

switched OFF, then the receiver is wide open to signals

from other transmitters and any interference, and may

respond. The model could then carry out uncontrolled

movements, which could easily result in personal injury

or damage to property.

Please take particular care if your model is fi tted with

a mechanical gyro: before you switch your receiver off,

disconnect the power supply to ensure that the motor

cannot run up to high speed accidentally.

As it runs down, the gyro can generate such a high

voltage that the receiver picks up apparently valid

throttle commands, and the motor could respond by

unexpectedly bursting into life.

Range checking

Before every session check that the system works properly

in all respects, and has adequate range.

Secure the model

adequately, and ensure that no persons are standing in

front of the model.

Carry out at least one complete function check on the

ground, followed by a complete simulated fl ight, in order

to show up any errors in the system and the model’s

programming. Be sure to read the notes on pages 106

and 110 in this regard.

When operating a model, i. e. when fl ying or driving,

do not operate the transmitter without the aerial fi tted.

Check that the transmitter aerial is fi rmly seated.

Operating your model aircraft, helicopter, boat or car

Never fl y directly over spectators or other pilots, and

take care at all times not to endanger people or animals.

Keep well clear of high-tension overhead cables. Never

operate your model boat close to locks and full-size vessels. Model cars should never be run on public streets or

motorways, footpaths, public squares etc..

any other installed equipment in the model, but in an

easily accessible position. Under no circumstances

allow servo leads to run close to the aerial, far less

coiled round it!

Ensure that cables are fastened securely, so that they

cannot move close to the receiver aerial when the model

is fl ying.

Deploying the receiver aerial(s)

The receiver and its aerials should be installed as far

away as possible from all kinds of power system. If your

model has a carbon fi bre fuselage, the aerial tips must

always be deployed outside the fuselage. The orientation

of the aerial(s) is not critical, but we recommend installing them vertically (upright) in the model. If the receiver

features aerial diversity (two aerials), the second aerial

should be arranged at 90° to the fi rst.

Installing the servos

Always install servos using the vibration-damping

grommets supplied. The rubber grommets provide some

degree of protection from mechanical shock and severe

vibration.

Installing control linkages

The basic rule is that all linkages should be installed in

such a way that the pushrods move accurately, smoothly

and freely. It is particularly important that all servo output

arms can move to their full extent without fouling or

rubbing on anything, or being obstructed mechanically

at any point in their travel.

It is essential that you should be able to stop your

motor at any time. With a glow motor this is achieved by

adjusting the throttle so that the barrel closes completely

when you move the throttle stick and trim to their endpoints.

Page 5

73

Safety Notes

Checking the transmitter and receiver batteries

It is essential to stop using the radio control system and

recharge the batteries well before they are completely

discharged. In the case of the transmitter this means –

at the very latest – when the message “battery needs

charging” appears on the screen, and you hear an

audible warning signal.

It is vital to check the state of the batteries at regular

intervals – especially the receiver pack. When the

battery is almost fl at you may notice the servos running

more slowly, but it is by no means safe to keep fl ying or

running your model until this happens. Always replace or

recharge the batteries in good time.

Keep to the battery manufacturer’s instructions, and

don’t leave the batteries on charge for longer than stated. Do not leave batteries on charge unsupervised.

Never attempt to recharge dry cells, as they may explode.

Rechargeable batteries should always be recharged before every session. When charging batteries it is important to avoid short-circuits. Do this by fi rst connecting the

banana plugs on the charge lead to the charger, taking

care to maintain correct polarity. Only then connect the

charge lead to the transmitter or receiver battery.

Disconnect all batteries and remove them from your model if you know you will not be using it in the near future.

Capacity and operating times

This rule applies to all battery types: capacity diminishes

with each charge. At low temperatures the battery’s

internal resistance rises, and capacity falls. This means

that its ability to deliver current and maintain voltage is

reduced.

Frequent charging, and / or the use of maintenance

programs, tends to cause a gradual reduction in battery

capacity. We recommend that you check the capacity of

all your rechargeable batteries at least every six months,

and replace them if their performance has fallen off

signifi cantly.

Use only genuine Graupner rechargeable batteries!

Suppressing electric motors

All conventional (brushed) electric motors generate

sparks between the commutator and the brushes, which

cause more or less serious interference to the radio

control system, depending on the type of motor. If an

RC system is to work correctly, it is therefore important

to suppress the electric motors, and in electric-powered

models it is essential that every motor should be effectively suppressed. Suppressor fi lters reliably eliminate

such interference, and should always be fi tted where

possible.

Please read the notes and recommendations supplied

by the motor manufacturer.

Refer to the main Graupner FS catalogue or the Internet

website at www.graupner.de for more information on

suppressor fi lters.

Servo suppressor fi lter for extension leads

Order No. 1040

Servo suppressor fi lters are required if you are obliged

to use long servo extension leads, as they eliminate the

danger of de-tuning the receiver. The fi lter is connected

directly to the receiver input. In very diffi cult cases a

second fi lter can be used, positioned close to the servo.

Using electronic speed controllers

The basic rule is that the electronic speed controller

must be chosen to suit the size of the electric motor it is

required to control.

There is always a danger of overloading and possibly

damaging the speed controller, but you can avoid this by

ensuring that the controller’s current-handling capacity is

at least half the motor’s maximum stall current.

Particular care is called for if you are using a “hot” (i. e.

upgrade) motor, as any low-turn motor (small number of

turns on the winding) can draw many times its nominal

current when stalled, and the high current will then burn

out the speed controller.

Electrical ignition systems

Ignition systems for internal combustion engines can

also produce interference, which has an adverse effect

on the working of the radio control system.

Electrical ignition systems should always be powered by

a separate battery – not the receiver battery.

Be sure to use effectively suppressed spark plugs and

plug caps, and shielded ignition leads.

Keep the receiving system an adequate distance away

from the ignition system.

Static charges

Lightning causes magnetic shock waves which can

interfere with the operation of a radio control transmitter

even if the thunderstorm actually occurs several kilometres away. For this reason …

… cease fl ying operations immediately if you notice

an electrical storm approaching. Static charges

through the transmitter aerial can be life-threatening!

Caution

In order to fulfi l the FCC RF radiation regulations •

Page 6

74

Safety Notes

applicable to mobile transmitting apparatus, the •

equipment’s aerial must be at least 20 cm from any

person when the system is in use. We therefore do

not recommend using the equipment at a closer

range than 20 cm.

Ensure that no other transmitter is closer than 20 cm •

from your equipment, in order to avoid adverse

effects on the system’s electrical characteristics and

radiation pattern.

The radio control system should not be operated •

until the Country setting has been set correctly at

the transmitter. This is essential in order to fulfi l the

requirements of various directives - FCC, ETSI, CE

etc. Please refer to the instructions for your particular

transmitter and receiver for details of this procedure.

Check all working systems and carry out at least one •

full range check on the ground before every fl ight, in

order to show up any errors in the system and the

model’s programming.

Never make any changes to the programming of the •

transmitter or receiver whilst operating a model.

Care and maintenance

Don’t use cleaning agents, petrol, water or other solvents to clean your equipment. If the case, the aerial etc.

gets dirty, simply wipe the surfaces clean with a soft dry

cloth.

Components and accessories

As manufacturers, the company of Graupner GmbH &

Co. KG recommends the exclusive use of components

and accessories which have been tested by Graupner

and approved for their capability, function and safety. If

you observe this rule, Graupner accepts responsibility

for the product.

Graupner cannot accept liability for non-approved

components or accessories made by other manufacturers. It is not possible for Graupner to assess

every individual item manufactured by other companies, so we are unable to state whether such parts

can be used without incurring a safety risk.

Liability exclusion / Compensation

It is not possible for Graupner to ensure that the user

observes the installation and operation instructions, and

the recommended conditions and methods when installing, operating, using and maintaining the radio control

components. For this reason Graupner denies all liability

for loss, damages or costs which arise through misuse

or mishandling of this equipment, or are connected with

such use in any way.

Unless obliged by law, Graupner’s obligation to pay compensation, regardless of the legal argument employed,

is limited to the invoice value of that quantity of Graup-

ner products which were immediately involved in the

event in which the damage occurred, unless the company is deemed to have unlimited liability on account of

deliberate or gross negligence.

Safety Notes

Page 7

75

Safety Notes

Safety notes and handling instructions relating to Nickel-Metal-Hydride rechargeable

batteries

As with all sophisticated technical products, it is vitally

important that you observe the following safety notes

and handling instructions if you wish the equipment to

operate safely and reliably for an extended period.

Safety notes

Rechargeable batteries are not playthings, and must •

be kept well away from children.

Store rechargeable batteries out of the reach of children.

Check that the batteries are in perfect, serviceable •

condition before every use. Do not re-use defective or

damaged batteries.

Rechargeable batteries must be used within the •

specifi ed limits stated for the corresponding cell type.

Do not heat, incinerate or short-circuit rechargea-•

ble batteries, and never charge them with excessive currents or reversed polarity.

Never use rechargeable batteries consisting of •

parallel-wired cells, combinations of old and new

cells, cells of different construction, size, capacity, make, brand or cell type.

Batteries installed inside equipment should always be •

removed from the device when it is not in use and not

about to be used. Always keep equipment switched

off in order to avoid deep-discharged cells. Batteries

must be recharged in good time.

The battery to be charged should be placed on a •

non-infl ammable, heat-resistant, non-conductive

surface for the whole of the charge period. Keep

infl ammable and volatile objects and materials well

clear of the charging area.

Batteries must always be supervised when on char-•

ge. Never exceed the maximum fast-charge current

specifi ed for the cell type in use.

If the battery heats up to more than 60°C whilst on •

charge, halt the charge process immediately and

allow the pack to cool down to about 30°C.

Never recharge a battery which is already charged, •

hot, or not completely discharged.

Do not make any modifi cations to batteries. Never •

solder or weld directly to cells.

If incorrectly handled, rechargeable batteries are at •

risk of combustion, explosion, corrosive action and

burns. Suitable extinguishing materials include fi re

blankets, CO2 fi re extinguishers and sand.

Escaped electrolyte is corrosive - do not allow it to •

contact skin or eyes. In an emergency rinse the area

immediately with plenty of clean water before seeking

medical help.

The cells’ air vents must never be blocked or sealed, •

e. g. by solder. When soldering, the iron temperature

should not exceed 220°C, and each joint should be

completed in less than twenty seconds.

To avoid cell deformation, do not exert excessive •

mechanical pressure on battery cells.

If a battery should be accidentally overcharged, use •

the following procedure:

Simply disconnect the battery and leave it on a noninfl ammable surface (e. g. stone fl oor) until it has

cooled down. Never hold the battery in your hand, as

there is a risk that cells might explode.

Always observe the recommended rates for charging •

and discharging.

General information

The capacity of your rechargeable battery diminishes

with every charge / discharge process. Stored batteries

may eventually exhibit reduced capacity.

Storage

Batteries should not be stored in a completely discharged state. Store them in a dry enclosed space at an

ambient temperature of +5°C to +25°C. If you are storing

a battery for a period longer than four weeks, ensure

that the cell voltage does not fall below 1.2 V

Balancing individual battery cells

To balance new battery cells, i. e. to bring them all •

to the same state of charge, charge them at what

is known as the ‘normal’ rate until they are full. As a

general guideline a fully discharged battery needs to

be charged for a period of twelve hours at a current

corresponding to one tenth of the capacity printed on

the cell label (the “1/10C” method). After this treatment all the cells will be fully charged, and exhibit

the same voltage. This method of balancing battery

cells should be repeated after every ten fast-charge

processes, so that the cells are repeatedly balanced;

this helps to ensure an extended useful life for your

batteries.

If you have the facilities to discharge individual cells, •

we recommend that you make use of this before every charge process. Otherwise the battery pack should

be run down to a discharge voltage of 0.9 V per cell.

For example, this corresponds to a fi nal discharge

voltage of 3.6 V in the case of the four-cell pack used

in the transmitter.

Charging

Ni-MH batteries should only be charged using the specifi ed currents, charge times and temperature range, and

should be supervised constantly when on charge. If you

do not have access to a suitable fast charger, i. e. one

Page 8

76

Safety Notes

which allows you to set the charge current accurately,

then the battery should always be recharged using the

“normal” charge rate of 1/10C; see the example stated

above.

Wherever possible, transmitter batteries should

always be recharged at the 1/10C rate, in order to

avoid differences in cell states. The charge current

must never exceed the maximum permissible value

stated in the transmitter instructions.

Fast charging

If your battery charger includes the facility to adjust •

the Delta Peak charge cut-off voltage, set this value

to 5 mV per cell. However, most chargers are set to

a fi xed cut-off value of 15 … 20 mV per cell, which

makes them suitable for use with both NiCd and

NiMH batteries. If you are not sure about this, please

refer to the operating instructions supplied with your

charger, or ask at your local model shop whether

your charger is also suitable for Ni-MH packs. If in

any doubt, charge your batteries at half the stated

maximum charge current.

Discharging

All rechargeable batteries sold by Graupner and GMRacing are suitable for a maximum continuous current

load of 6C … 13C, according to battery type (refer to the

manufacturer’s specifi cation!). The higher the continuous

current load, the shorter the batteries’ useful life.

Use your battery until its performance falls off, or until •

the low voltage warning is triggered.

Caution:

When stored for a long period, the cell voltage should

not be allowed to fall below 1.2 V. This means that

you may have to recharge the battery before sto-

ring it.

Refl ex charging and charge / discharge (cycle) •

programs shorten the effective life of batteries unnecessarily, and are only suitable for checking battery

quality or “reviving” relatively old cells. It also makes

no sense to charge / discharge a battery before using

it - unless you simply wish to check its quality.

Disposal of exhausted dry and rechargeable batteries

The German Battery Order places a legal requirement

on every consumer to return all used and exhausted

dry cells and rechargeable batteries. It is prohibited to

dispose of these items in the ordinary domestic waste.

At no charge to the user, old dry and rechargeable

batteries can be surrendered at local authority collection points, Graupner retail outlets, and any other shop

where dry and rechargeable batteries of the same type

are sold. You can also send batteries supplied by us to

the following address - with adequate pre-paid postage

- for disposal:

Graupner GmbH & Co. KG

Service: Gebrauchte Batterien (Used batteries)

Henriettenstr. 94 - 96

D-73230 Kirchheim unter Teck

You can make an important contribution to environmen-

tal protection in this way.

Caution:

Damaged batteries may require special packaging before despatch, as some contain highly toxic materials!!!!!

Page 9

77

Introduction

mx-10 the latest generation of radio control technology

HoTT (Hopping Telemetry Transmission) is the synthesis of expertise, engineering and world-wide testing by

professional pilots. The equipment operates on the 2.4

GHz band, and offers bi-directional communication between transmitter and receiver via a down-link channel

integrated into the receiver.

The mx-10 HoTT RC system is based on the Graup-

ner/JR mc-24 computer radio control system which

was introduced back in 1997. It has been developed

specifi cally for the beginner, but the mx-10 HoTT is

still capable of controlling all current model types without problem - whether fi xed-wing model or helicopter,

model boat or car.

In the area of fi xed-wing models it is often necessary

to employ complex mixer functions for the control

surfaces. Computer technology enables you to activate

a vast range of functions to cope with special model

requirements – with the simple setting of a „jumper“.

With the mx-10 HoTT all you do is select the appro-

priate model type, and the software then presents you

automatically with the appropriate mixer and coupling

functions. This means that the transmitter requires no

additional modules in order to implement complex coupled functions, and you can forget all about old-fashioned

mechanical mixers in the model. Even helicopters can

be controlled by a „Flybarless“ system.

The mx-10 HoTT provides an extremely high level of

safety and reliability in use.

The beginner quickly becomes familiar with the different

functions thanks to the clear, logically arranged program

structure.

In theory the Graupner HoTT process allows more than

200 models to be operated simultaneously. Although in

practice the mixed operation of different technical sys-

tems in the 2.4 GHz ISM band – as required by the approval regulations – reduces this number considerably.

Generally, however, it will always be possible to operate

even more models simultaneously on the 2.4 GHz band

than on the 35 / 40 MHz frequency bands which we

have used to date. However, the actual limiting factor –

as it has always been – is likely to remain the size of the

(air-) space available. The simple fact that no frequency

control procedure is necessary equates to an enormous

gain in safety, especially at fl ying sites such as gliding

slopes where groups of pilots may be distributed over a

large area, with nobody in overall control.

The optional Smart-Box provides a simple means of

accessing data and programming HoTT receivers. For

example, this method can be used to map receiver

outputs, distribute control functions to multiple servos,

and match servo travels and directions to each other.

This manual describes each menu in detail, and also

provides dozens of useful tips, notes and programming examples to complement the basic information.

Please refer to the Appendix for additional information

on the HoTT system. This manual concludes with the

transmitter’s conformity declaration and guarantee

certifi cate.

Please read the safety notes and the technical information. We recommend that you read right through the

instructions with great care, and check all the functions

as described in the text. This can be carried out simply

by connecting servos to the supplied receiver, and

watching their response as you program the transmitter. However, please read the notes on page 96 in this

regard. This is the quickest method of becoming familiar

with the essential procedures and functions of the mx-

10 HoTT.

Always handle your radio-controlled model with a

responsible attitude to avoid endangering yourself and

others.

The Graupner team wishes you great pleasure and success with your mx-10 HoTT - a radio control system of

the latest generation.

Kirchheim-Teck, October 2011

Page 10

78

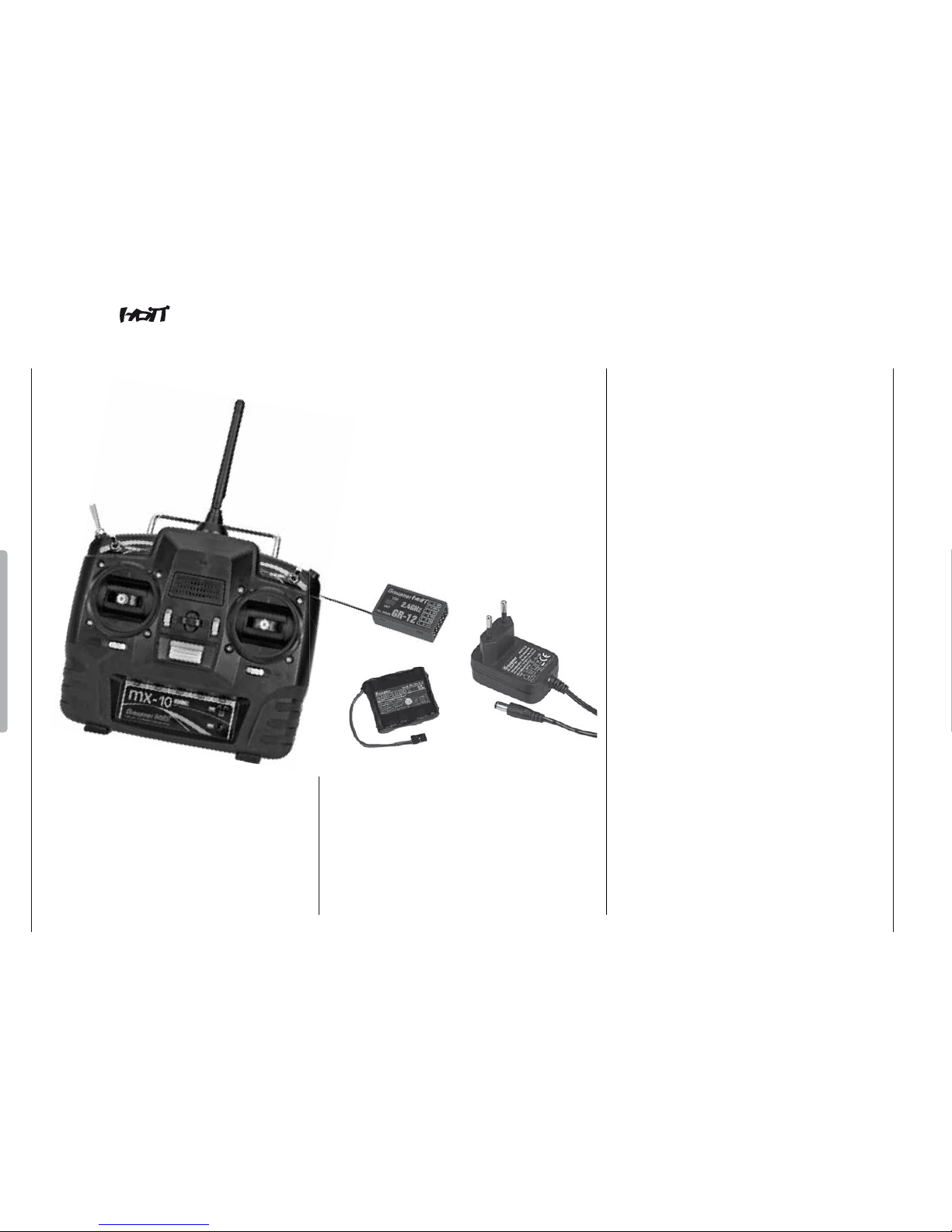

Description of radio control set

mx-10 Computer System

Five-channel radio control set with Graupner HoTT 2.4 GHz technology (Hopping Telemetry Transmission)

Graupner HoTT technology offers excellent reliability in use, with bi-directional communication between transmitter and receiver, integrated telemetry

(with the optional Smart-Box) and ultra-fast response times.

Simplifi ed programming technology with „Jumpers“.

Micro-computer radio control system exploiting the •

latest Graupner HoTT 2.4 GHz technology

Bi-directional communication between transmitter •

and receiver

Ultra-fast response times through direct, ultra-reliable •

data transmission from the main processor to the 2.4

GHz RF module.

Telemetry menu (with the optional Smart-Box) for •

displaying telemetry data, and programming receiver

outputs and optional sensors.

Short, folding aerial•

Easy programming and accurate setting with toggle •

switches and a switch key

3 switches: a three-position switch for Trainer/pupil-•

mode, 2 two-position switches for dual rate and

channel 5 are already built

5 control functions, including 1 switching channel•

Servo reverse•

Mode selector for simple switching between stick •

MODES 1 ... 4 (throttle left / right, etc.) All applicable

settings are automatically converted.

Wing menu: 1 Ail, 2 Ail, V-tail, delta/fl ying wing•

The following settings can only be done via the optional

Smart-Box:

User-selectable servo cycle times for digital servos, •

min. 10 ms

Servo-control ± 150% for all servo outputs can be set •

separately for each side (Single Side Servo Throw)

Sub-trim in the range of ± 125% to adjust the neutral •

position of all servos

General features of the HoTT system

Simple, ultra-fast binding of transmitter and receiver•

Multiple receivers can be bound per model for paral-•

lel operation

Extremely fast re-binding, even at maximum range•

Two-receiver satellite operation using special cable •

connection

Page 11

79

Description of radio control set

mx-10 Computer System

Five-channel radio control set with Graupner HoTT 2.4 GHz technology (Hopping Telemetry Transmission)

Range-check and warning function•

Receiver low-voltage warning on transmitter screen•

Ultra-wide receiver operating voltage range: 3.6 V to •

8.4 V (fully operational down to 2.5 V)

Fail-Safe•

Unrestricted channel assignment (channel-mapping), •

mixer functions and all servo settings programmable

in the Telemetry menu

Up to four servos can be actuated simultaneously •

as a block, with a servo cycle time of 10 ms (digital

servos only)

Optimised frequency hopping and broad channel •

spread for maximum interference rejection

Intelligent data transmission with corrective function•

Real-time telemetry analysis•

More than 200 systems can be operated simultane-•

ously

Future-proof update capability using data interface•

Page 12

80

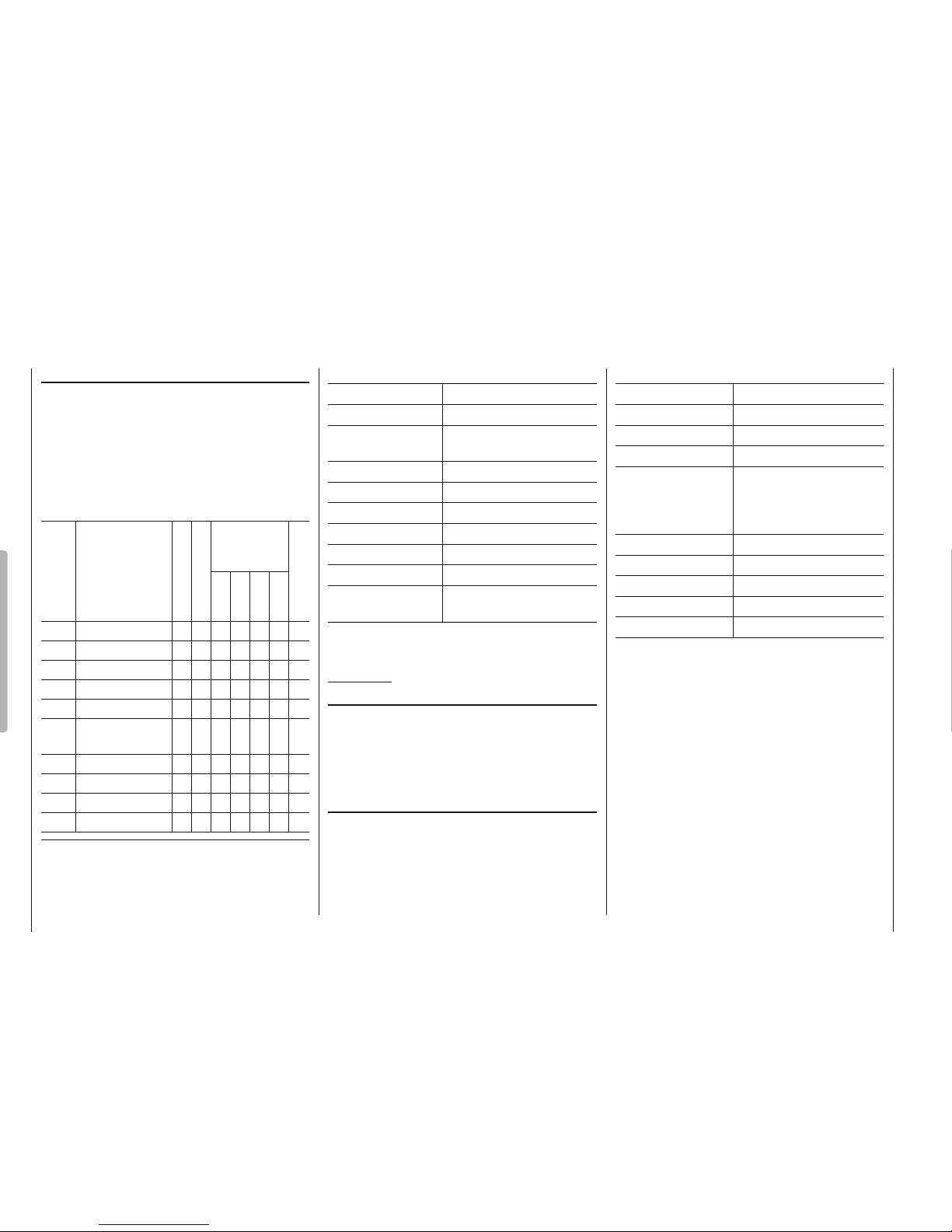

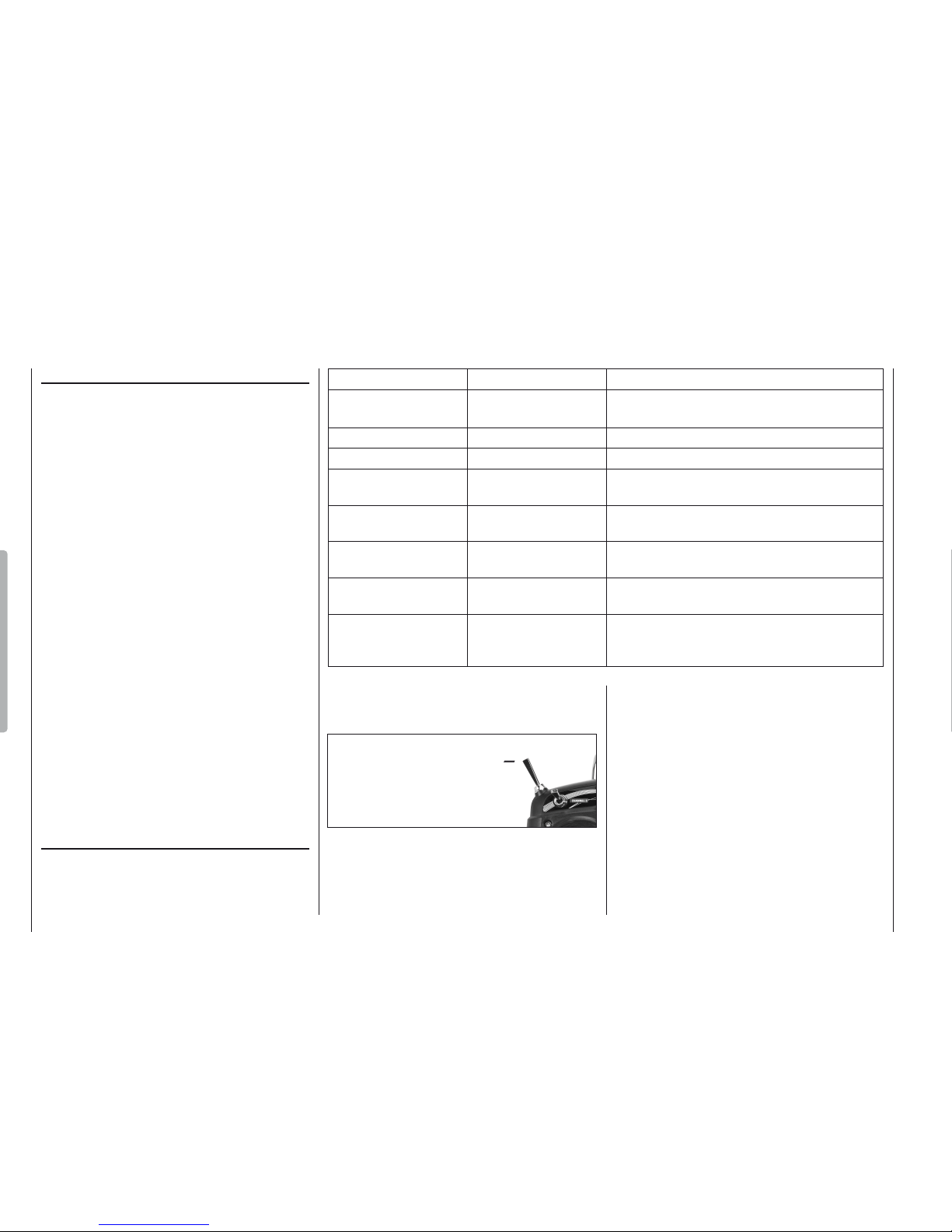

Description of radio control set

Specifi cation, mx-10 HoTT transmitter

Frequency band 2,4 … 2,4835 GHz

Modulation FHSS

Transmitter power see country setting, page

104/108

Control functions fi ve functions; four with trims

Temperature range -10 … +55 °C

Aerial folding

Operating voltage 3,4 … 6 V

Current drain approx. 125 mA

Dimensions approx. 190 x 195 x 90 mm

Weight approx. 630 g with transmitter

battery

Accessories

Order No. Description

1121 Neckstrap, 20 mm wide

70 Neckstrap, 30 mm wide

3097 Wind-shield for hand-held transmitter

Replacement parts

Order No. Description

33112.1

4NH-1500 RX RTU, fl at-pack

33800 HoTT transmitter aerial

Specifi cation, GR-12 HoTT receiver

Operating voltage 3,6 … 8,4 V

Current drain ca. 70 mA

Frequency band 2,4 … 2,4835 GHz

Modulation FHSS

Aerial approx. 145 mm long,

approx. 115 mm encapsulated and approx. 30 mm

active

Servo sockets 6

Sensor socket 1 (instead of servo 5)

Temperature range approx. -15° … +70 °C

Dimensions approx. 36 x 21 x 10 mm

Weight approx. 7 g

The set Order No. 33110 contains:

mx-10 HoTT micro-computer transmitter with integral

4NH-1500 RX RTU fl at-pack Ni-MH transmitter battery

(specifi cation reserved), Graupner GR-12 HoTT bi-directional receiver, switch harness and plug-type battery

charger

Recommended battery chargers (optional)

Order

No. Description

220 V mains conn.

12 V DC connect.

Suitable for

the following

battery types

Integral charge. lead

NiCd

Ni-MH

LiPo

Lead-ac.

6407 Multilader 3 x x x x

6411 Ultramat 8 xxxxx

6425 Twin Charger x x

6427 Multilader 3 x x x x

6455 Multilader 7E x x x x

6463

Ultramat 12 plus

Pocket

xxxxx

6464 Ultramat 14 plus xxxxxx

6466 Ultra Trio plus 14 xxxxxx

6468 Ultramat 16S xxxxxx

6470 Ultramat 18 xxxxxx

To recharge the radio system you will also need the transmitter charge

lead, Order No. 3022, and the receiver battery charge lead, Order No.

3021, unless stated otherwise in the table.

For details of additional battery chargers, and details of the chargers

listed here, please refer to the main Graupner FS catalogue, or our

Internet site at www.graupner.de.

Page 13

81

Operating Notes

Operating Notes

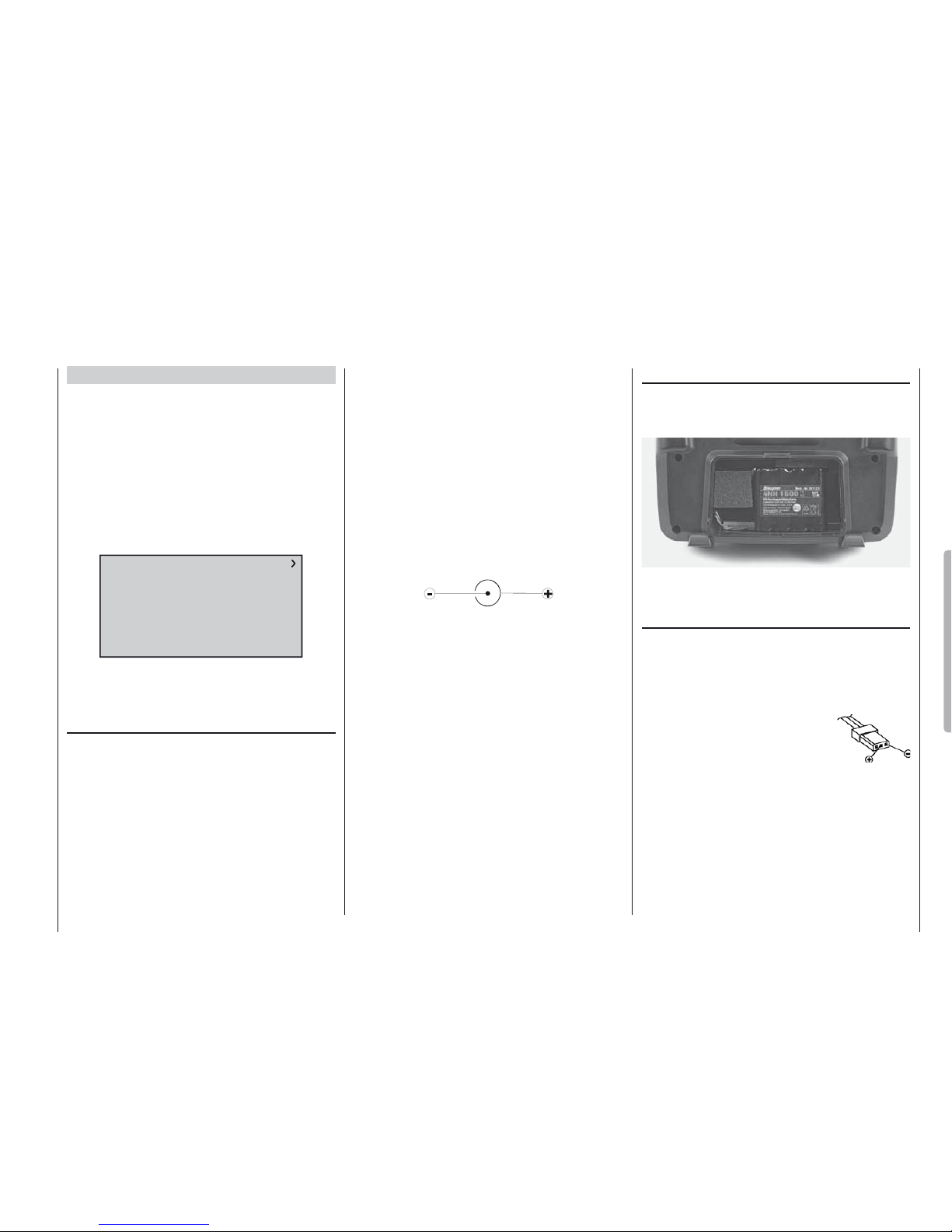

Transmitter power supply

The mx-10 HoTT transmitter is fi tted as standard with

a high-capacity rechargeable 4NH-1500 RX RTU Ni-MH

battery (Order No. 33112.1) (specifi cation reserved).

When delivered, the standard rechargeable battery

is not charged.

When you are using the transmitter you can monitor the

battery voltage on the Status-LED. If it drops below the

in the line „ALARM VOLT“ of the menu „TX“ of the optional Smart Box, page 114,

adjustable voltage (default

4.5 V), an audible warning signal starts and the orange

Status-LED starts blinking 5 - times in quick succession.

TX

MAXIMUM VOLT: 05.5V

MINIMUM VOLT: 05.4V

ALARM VOLT: 04.7V

COUNTRY : GENERAL

ACTION VOLT: 05.4V

RANGE TEST : OFF 90s

Always recharge the transmitter battery in good time.

When you see this message, cease operations immediately and recharge the transmitter battery.

Charging the transmitter battery

The rechargeable Ni-MH transmitter battery can be

recharged with the battery charger (Order No. 33116.2)

supplied in the set, using the charge socket located on

the right-hand side of the transmitter. Leave the battery

inside the transmitter for charging, to avoid premature

damage to the internal battery socket.

As an approximate guideline a discharged battery

should be charged for twelve hours at a current corresponding to one tenth of the capacity printed on the pack.

If you are using the standard transmitter battery and the

charger supplied in the set, this current is 200 mA.

The transmitter must be switched “OFF” for the whole

period of the charge process. Never switch on the

transmitter when it is still connected to the charger; even

a very brief interruption in the process can cause the

charge voltage to rise to the point where the transmitter

is immediately damaged. For this reason check carefully

that all connectors are secure, and are making really

good contact.

Polarity of the mx-10 HoTT charge socket

Commercially available battery charge leads produced

by other manufacturers are often made up with the opposite polarity. For this reason it is essential to use only

the genuine Graupner charge lead, Order No. 3022.

Using automatic battery chargers

Although the standard transmitter charge socket is protected against reversed polarity, it is still possible to use

suitable chargers to fast-charge the transmitter battery.

If possible, set the delta peak voltage difference of your

fast charger to a value in the range 10 mV … 20 mV or

equivalent, as described in the charger’s instructions;

this ensures that it is suitable for fast-charging Ni-MH

cells.

First connect the banana plugs on the charge lead

to the charger, and only then connect the other end

of the charge lead to the charge socket on the transmitter. When the charge lead is connected to the

transmitter, never allow the bare ends of the plugs to

touch! To avoid damage to the transmitter, the charge

current must never exceed 1 A. If necessary, limit the

current on the charger itself.

Removing the transmitter battery

To remove the transmitter battery, fi rst disengage the

cover over the battery compartment on the back of the

transmitter, then lift it off:

Remove the battery, then carefully pull on the power

lead to disconnect the transmitter battery connector.

Installing the transmitter battery

Hold the connector attached to the transmitter battery

in such a way that the black or brown wire faces the

aerial, and the unused socket of the battery connector

is on the side facing the bottom, then push the battery

connector onto the three pins projecting out of the inside

of the transmitter, in the direction of the

circuit board. (The battery connector is

protected against reversed polarity by

two chamfered edges; see illustration).

Finally place the battery in the compartment, and close the cover.

Polarity of

transmitter battery

connector

Page 14

82

Operating Nores

Receiver power supply

A wide range of rechargeable four-cell and fi ve-cell NiMH

batteries varying in capacity is available for use as the

receiver power supply. If you are using digital servos

we recommend that you use a fi ve-cell (6 V) pack of

generous capacity. If your model is fi tted with a mixture of

digital and analogue servos, it is important to check the

maximum permissible operating voltage of all the types.

The PRX unit, Order No. 4136, provides a stabilised

receiver power supply with a user-variable voltage from

one or two receiver batteries; see Appendix.

For reasons of safety battery boxes or dry cells should

never be used.

The voltage of the airborne power supply is displayed on

the optional Smart-Box screen while the model is fl ying:

RX DATAVIEW

S–STR100% R–TEM.+28°C

L PACK TIME 00010msec

R-VOLT :05.0V

L.R-VOLT:04.5V

S–QUA100%S–dBM–030dBM

SENSOR1 :00.0V 00°C

SENSOR2 :00.0V 00°C

If the voltage falls below the pre-set warning threshold -

3.8 Volt as standard, but variable in the Telemetry menu;

see page 115 - a visual and audible low-voltage warning

is triggered.

Nevertheless it is important to check the state of the

batteries at regular intervals. Don’t put off charging

the batteries until the warning signal is triggered.

Note:

Please refer to the main Graupner FS catalogue or visit

the Internet site at www.graupner.de for full details of

batteries, chargers, measuring equipment and battery

monitor units.

Charging the receiver battery

The charge lead, Order No. 3021, can be connected

directly to the NC receiver battery for charging. If the

battery is installed in a model and you have installed one

of the following switch harnesses: Order No. 3046, 3934

or 3934.1 or 3934.3, the battery can be charged via the

separate charge socket, or the charge socket which is

built into the switch. The switch on the switch harness

must be left at the “OFF” position for charging.

Polarity of the receiver battery connector

General notes on battery charging

Observe the recommendations provided by the •

charger manufacturer and the battery manufacturer

at all times.

Keep to the maximum permissible charge current •

stated by the battery manufacturer.

The maximum charge current for the transmitter •

battery is 1.5 A. Limit the charge current to this value

on the charger.

If you wish to charge the transmitter battery at a •

current higher than 1.5 A, you must fi rst remove the

pack from the transmitter, otherwise you risk damaging the circuit board through overloading the conductor tracks, and / or overheating the battery.

Carry out a series of test charges to ensure that the •

automatic charge termination circuit works correctly

with your battery. This applies in particular if you

wish to charge the standard Ni-MH battery using an

automatic charger designed for Ni-Cd batteries.

You may need to adjust the Delta Peak trigger volta-•

ge, if your charger provides this option.

Do not discharge the battery or carry out a battery •

maintenance program via the integral charge socket.

The charge socket is not suitable for this application.

Always connect the charge lead to the charger fi rst, •

and only then to the transmitter or receiver battery.

Observing this rule eliminates the danger of accidental short-circuits between the bare contacts of the

charge lead plugs.

If the battery becomes hot when on charge, it is time •

to check the pack’s condition. Replace it if necessary,

or reduce the charge current.

Never leave batteries unsupervised when on •

charge.

Environmental protection notes

Important information on the disposal of dry and

rechargeable batteries:

The German Battery Order places a legal requirement

on every consumer to return all used and exhausted

dry cells and rechargeable batteries. It is prohibited to

dispose of these items in the ordinary domestic waste.

At no charge to the user, old dry and rechargeable

batteries can be surrendered at local authority collection points, Graupner retail outlets, and any other shop

where dry and rechargeable batteries of the same type

are sold. You can also send batteries supplied by us to

the following address - with adequate pre-paid postage

- for disposal:

Graupner GmbH & Co. KG

Service: Gebrauchte Batterien (Used batteries)

Henriettenstr. 94 - 96

D-73230 Kirchheim unter Teck

You can make an important contribution to environmen-

tal protection in this way.

Operating Notes

Page 15

83

Operating Notes

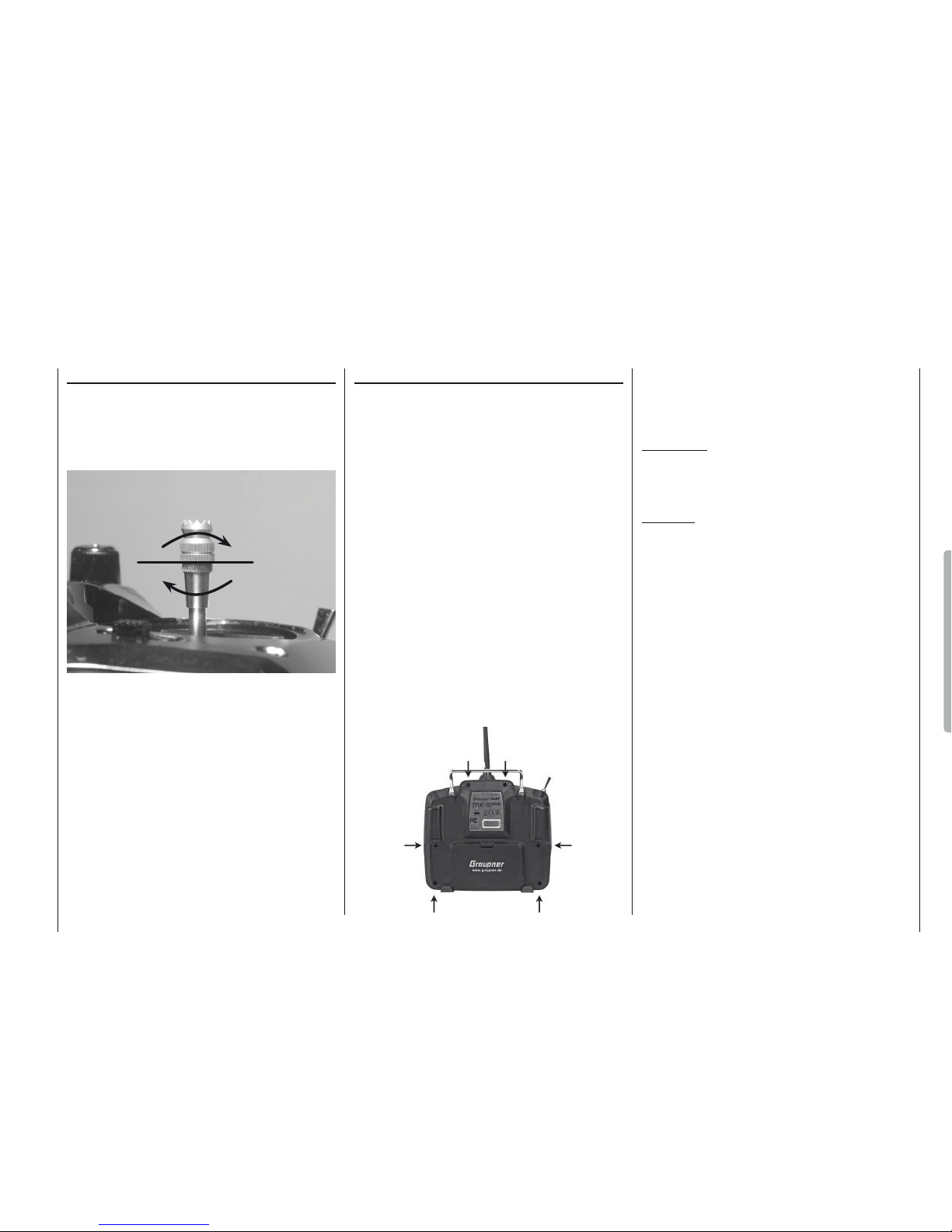

Adjusting stick length

Both sticks are infi nitely variable in length over a broad

range, enabling you to set them to suit your personal

preference.

Hold the bottom half of the knurled grip fi rmly, and

unscrew the top section:

Now screw the stick top in or out (shorter or longer)

to the length you prefer before tightening the top and

bottom sections against each other to fi x the stick top.

Opening the transmitter case

Please read the following notes carefully before you

open the transmitter. If you have no experience in such

matters, we recommend that you ask your nearest

Graupner Service Centre to carry out the work for you.

The transmitter should only be opened in the following

cases:

When a self-neutralising stick needs to be converted •

to non-neutralising action, or a non-neutralising stick

to a self-neutralising action.

If you wish to adjust the stick centring spring tension.•

Before opening the transmitter check that it is switched

off (move Power switch to “OFF”).

Open the battery compartment and remove the transmitter battery as described on the previous double page.

After this, use a PH1-size cross-point screwdriver to

undo the six screws recessed into the back panel of the

transmitter, as shown in the illustration:

Arrangement of the case back screws

Hold the two case sections together with your hand, and

turn the unit over to allow these six screws to fall out

onto the table. Now carefully raise the case back and

fold it open to the right, as if you were opening a book.

C A U T I O N

Two multi-core cables connect the lower shell to the

transmitter electronics located in the top section.

Please take great care not to damage this cable!

Important:

Do not modify the transmitter circuit in any way, •

as this invalidates your guarantee and offi cial approval for the system.

Do not touch any part of the circuit boards with •

any metal object. Avoid touching the contacts

with your fi ngers.

Never switch the transmitter on while the case is •

open.

Please note the following points when closing the

transmitter:

Make sure that no cables are jammed between the •

transmitter case sections when you close the back.

Check that the two case sections fit together flush all •

round before fitting the retaining screws. Never force

the two case components together.

Fit the case screws in the existing threads, and tigh-•

ten them gently. Over-tightening them will strip the threads in the plastic.

Remember to re-connect the battery.•

Page 16

84

Operating Notes

Operating Notes

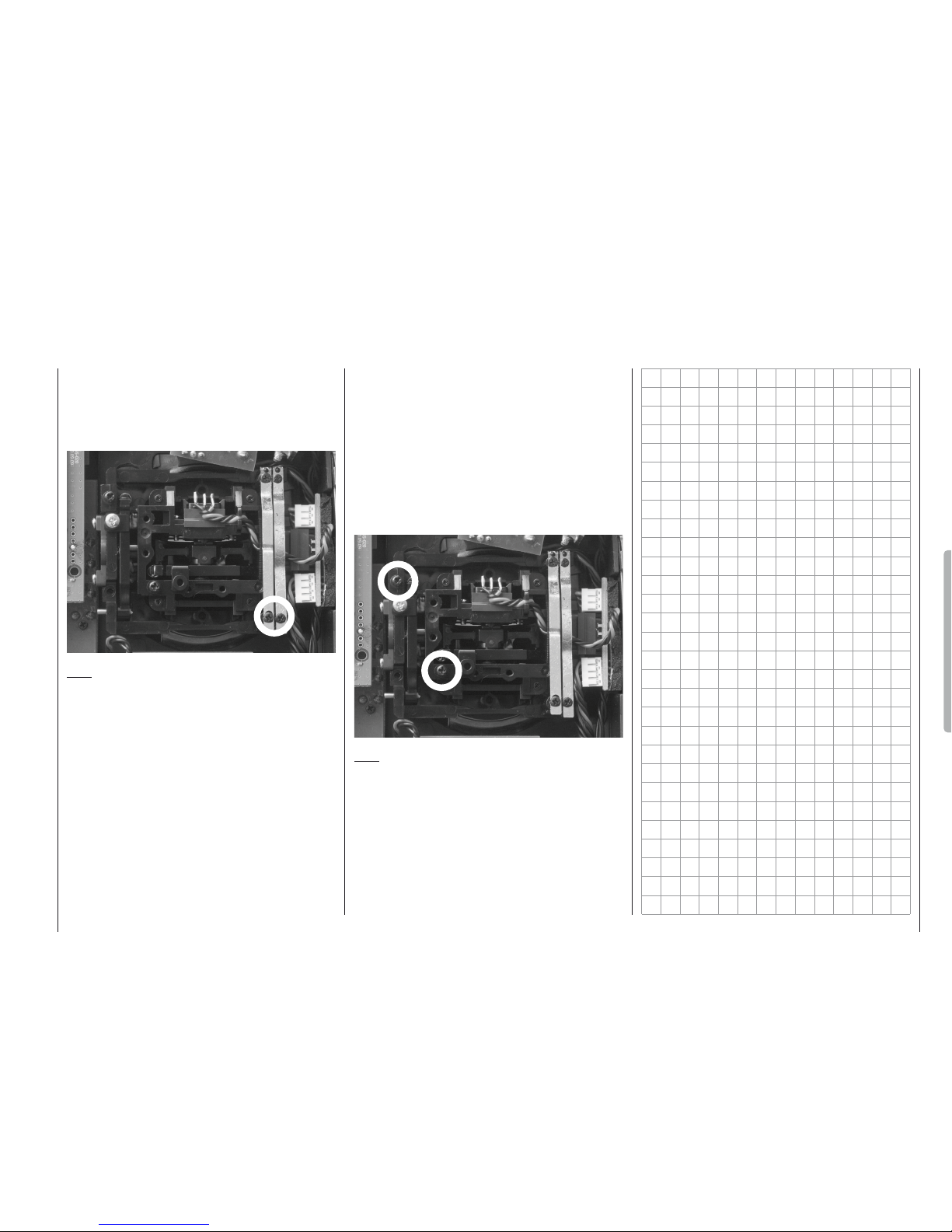

Converting the dual-axis stick units

Self-centring action

Either or both sticks can be converted from self-neutralising to non self-neutralising action: start by opening the

transmitter as described on the previous page.

If you wish to change the standard stick unit arrangement, start by locating the screw on the left-hand stick

unit shown circled in white in the photo below.

Note:

The right-hand stick unit is of mirror-image construction,

i. e. the screw you require is located on the right, below

centre.

Turn this screw clockwise until the stick on that side

moves freely from one end-stop to the other; alternatively unscrew it until the stick is fully self-centring again.

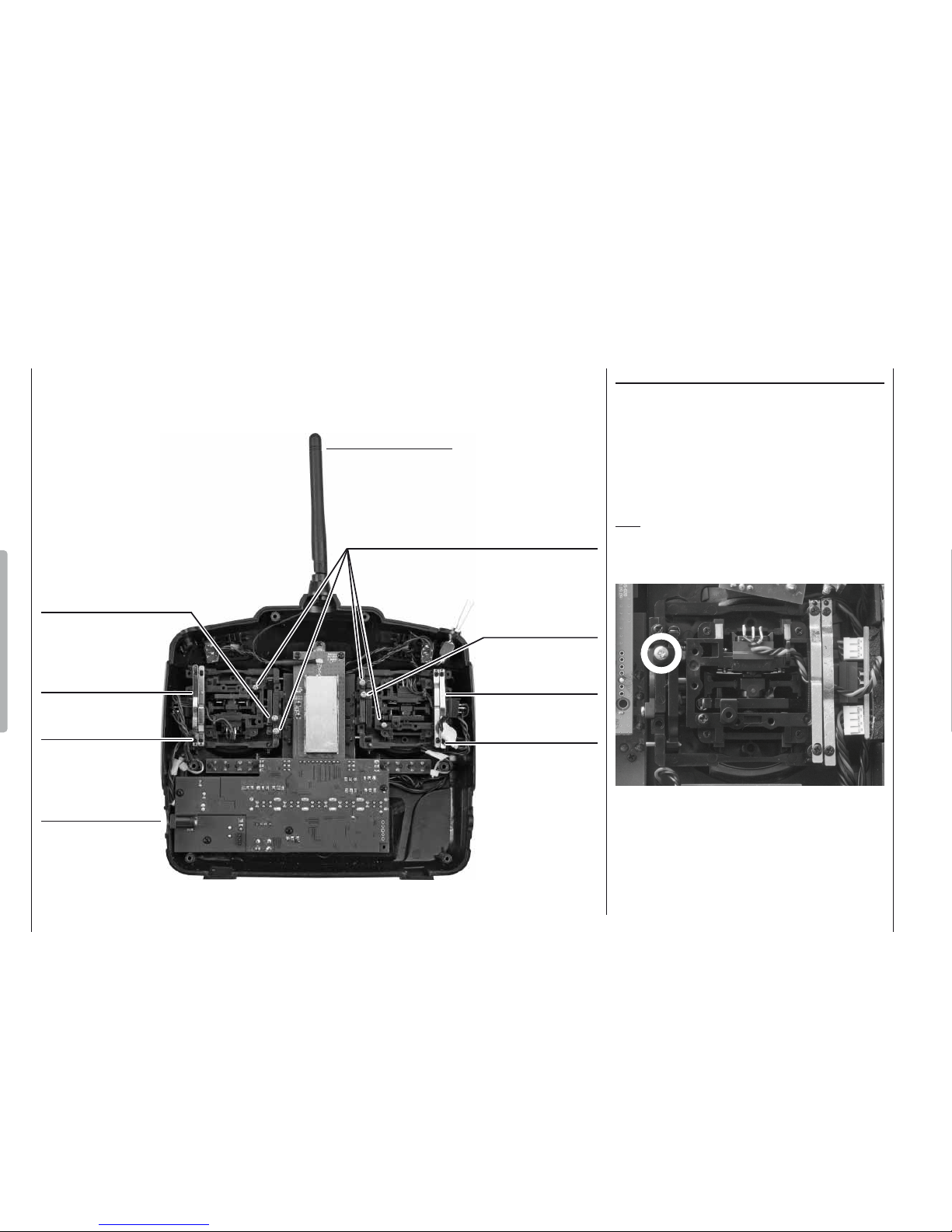

Charge socket

Brake springs

Adjuster screws

Brake springs

Adjuster screws

folding areal

Self-centring screw

Self-centring screw

Adjuster screws for stick centring force

Do not touch trans-

Do not touch trans-

mitter circuit board

mitter circuit board

Do not touch trans-

Do not touch trans-

mitter circuit board

mitter circuit board

Left-hand stick unit

Left-hand stick unit

Right-hand stick unit

Right-hand stick unit

Page 17

85

Operating Notes

Stick centring force

The centring force of the sticks is also variable to suit

your preference. The adjustment system is located

adjacent to the centring springs; see the white circles in

the following photo.

You can set the preferred centring spring force by

rotating the corresponding adjuster screw using a crosspoint screwdriver:

Turn to the right = harder spring tension;•

Turn to the left = softer spring tension.•

horizontal

horizontal

vertical

vertical

Note:

The right-hand stick unit is of mirror-image construction,

i. e. the screw you require is located on the right, below

centre.

Brake spring and ratchet

You can alter the braking force of the stick by adjusting

the outer of the two screws circled in white in the next

picture; adjusting the inner screw alters the strength of

the ratchet:

Note:

The right-hand stick unit is of mirror-image construction,

i. e. the screw you require is located on the right, below

centre.

Page 18

86

Description of transmitter

Description of transmitter

Transmitter controls

Attaching the transmitter neckstrap

You will fi nd a strap lug mounted in the centre of the

front face of the mx-10 HoTT transmitter, as shown in

the drawing on the right. This lug is positioned in such a

way that the transmitter is perfectly balanced even when

suspended from a neckstrap.

Order No. 1121 Neckstrap, 20 mm wide

Order No. 70 Neckstrap, 30 mm wide

Aerial with folding / rotating base

3-position switch

Mode: Pupil / Teacher /

normal

2-position switch

Channel 5

left hand stick

Tr im

ON / OFF switch

Tr im

Right-hand stick

2-position switch

Dual Rate

Carry handle

Neckstrap lug

Central Status LED

Servoreverse switch

Wing mixer

Channel 1 - 5

BIND-Button

Page 19

87

Description of transmitter

Data socket

For connecting the optional Smart-Box, Order No. 33700.

The Smart Box allows many other HoTT functions such

as Servo curve, servo travel, cycle time or channel mapping and HoTT telemetry - see the section „telemetry“

on page 113.

For more details about the Smart-Box please refer to the

main Graupner FS catalogue, or refer to that product on

the Internet at www.graupner.de.

This socket can be used also to connect the transmitter

to a PC running Windows XP, Vista or 7 using the optional USB adapter, Order No. 7168.6 and the connecting

lead, Order No. 7168.6A.

The software required at the PC, including a suitable

USB driver, can be found in the Download section for

the corresponding product at www.graupner.de.

Once you have installed the software required, you can

also update the transmitter via this connection.

Case screw

Case screw

Case screw

Case screw

Battery Case Cover

Case screw

Case screw

Transmitter battery

charge socket

Data socket for connecting

Smart-Box, Order No. 33700

and for connecting with a PC

Page 20

88

Using the transmitter for the fi rst time

Preliminary notes

In theory the Graupner HoTT system permits the simul-

taneous operation of more than 200 models.

However, in practice the mixed operation of different

technical systems in the 2.4 GHz ISM band - as required by the approval regulations - reduces this number

considerably. Generally, however, it will always be

possible to operate even more models simultaneously

on the 2.4 GHz band than on the 35 / 40 MHz frequency

bands which we have used to date. However, the actual

limiting factor - as it has always been - is likely to remain

the size of the (air-) space available. The simple fact that

no frequency control procedure is necessary - a great

convenience in itself - equates to an enormous gain in

safety, especially at fl ying sites where groups of pilots

may be distributed over a large area, with nobody in

overall control.

Battery charged?

When you take receipt of your transmitter, the battery

will be in the discharged state, so you must fi rst charge

it as described on page 81. Otherwise you will hear a

warning signal and the Status-LED fl ashes fi ve times in

quick succession when falling below a certain voltage to

remind you to recharge it.

This warning threshold for the transmitter battery can be

selected in the menu „TX“ of the optional the Smart Box,

page 114.

Switching the transmitter on

After switching on the Status-LED glows constantly or is

blinking to indicate the current transmitter mode.

See the following table:

Using the transmitter for the fi rst time

Preliminary notes regarding the mx-10 HoTT transmitter

To change the mode, move the mode switch on the

transmitter in the desired position, press and hold the

BIND-button and then switch on the transmitter.

Note: after programming the „normal“ mode, the transmitter is in fail-safe programming mode (see page 111),

if you do not want to program anything here, turn off the

transmitter again now.

The programmed mode is indicated with LED and

buzzer signals after switching on the transmitter, see the

table above.

Mode normal

teacher

pupil

©

ª

LED Status Buzzer Description

green LED on - Transmitter ON, but no bounded receiver

or receiver bound, but no telemetry signal

orange LED on - Transmitter mode „normal“, country setting: general

orange LED fl ashes - Transmitter mode „normal“, country setting: France

orange LED fl ashes once beeping twice after swit-

ching on

Transmitter mode: pupil

orange LED fl ashes twice 2x beeping twice after

switching on

Transmitter mode: teacher

orange LED fl ashes three

times

beeping three times after

switching on

Bad receiving quality of the receiver

orange LED fl ashes four

times

beeping four times after

switching on

Bad receiving quality of the downlink channel

orange LED fl ashes fi ve

times

beeping fi ve times after

switching on

Transmitter battery empty. Hit the battery warning

threshold, 4.5 V as standard, set in the menu „TX“ of

the optional Smart-Box, page 114

First select the transmitter mode „normal“, „teacher“ or

„pupil“ by the transmitter mode switch on the left top side

of the transmitter:

The transmitter is delivered in the mode „normal“. For

normal operation you have to change nothing. In order

to select the teacher or pupil mode, read the chapter

„Trainer model“ on page 127.

Page 21

89

Using the transmitter for the fi rst time

Firmware update

Firmware updates for the transmitter are carried out at

the owner’s discretion using the three-pin PC interface

on the back of the transmitter, in conjunction with a PC

running Windows XP, Vista or 7. To connect the transmitter to a PC you also require the optional USB adapter,

Order No. 7168.6 and the connecting lead, Order No.

7168.6A.

The latest software and information can be found in the

Download section for the corresponding product at www.

graupner.de.

Note:

Once you have registered your transmitter at http://

graupner.de/de/service/produktregistrierung you will

automatically be informed of new updates by e-mail as

they become available.

Updating the mx-16 HoTT software

Attention:

It is essential to check the state of charge of your

transmitter battery before carrying out any update.

To be on the safe side we recommend that you give

the battery a full charge.

1. Installing the driver

In order to be able to use the transmitter’s integral

port you must fi rst install the driver software required,

which is included in the program packages in the

“USB driver” folder.

Start the driver installation by double-clicking on the

appropriate fi le and following the on-screen instruc tions. When the installation is complete, your comput-

Important notes:

The transmitter included in the set is prepared at •

the factory with the correct settings for most European countries (except France).

If you wish to operate the RC system in France,

you MUST fi rst set the Country setting on the

transmitter to “FRANCE” mode; see page 104

or 108. IT IS PROHIBITED to use the system IN

FRANCE using the Universal / EUROPE mode!

You can operate up to fi ve servos using the • mx-

10 HoTT transmitter and the receiver supplied in

the set, which is already bound to the transmitter.

When switching on, binding or setting up the ra-•

dio control system, please ensure at all times

that the transmitter aerial is an adequate distance

from the receiver aerials. If the transmitter aerial is too close to the receiver aerials, the receiver

will be swamped, and the green LED on the receiver will go out. At the same time the down-link

channel will stop working. In parallel the orange

status LED blinks four times in quick succession

and starts the corresponding buzzer warnings. At

the same time the radio control system switches

to Fail-Safe mode.

If this should happen, simply increase the distance between transmitter and receiver until the

displays revert to “normal”.

Transmitter fi rmware update

er must be re-started. The driver only has to be

installed once.

2. Connecting the transmitter to the PC

Make sure the transmitter is switched off, then con nect the USB lead to the 3-pole socket on the back

of the transmitter. Install the cable so that the orange

cord shows to the left (center of the transmitter) and

the brown cord to the right edge of the transmitter.

Do not apply excessive force.

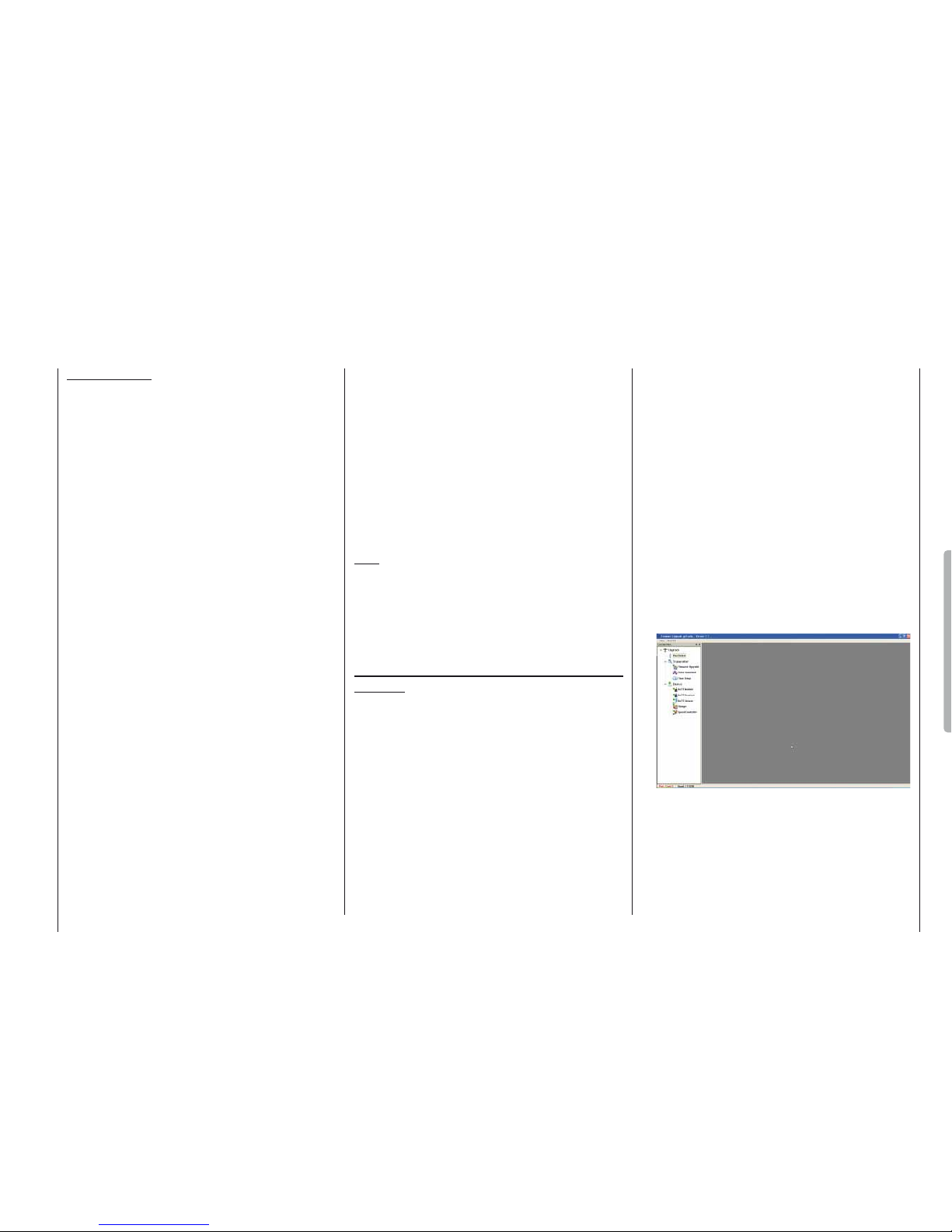

3. Updating the mx-16 HoTT transmitter software

Start the program “Firmware_Upgrade_grStudio_

Ver-SX.X.exe” from the appropriate folder by a

double-click. (The at the time of printing this manual

current version 1.3 starts without prior installation.):

Select “Port Setup” under “Menu”; alternatively open

the “Controller Menu” and click on “Port select”:

Page 22

90

Using the transmitter for the fi rst time

In the “Port select” window you can now select the

correct COM port, i.e. the one to which the USB interface is connected. This can be identifi ed by the

name “Silicon Labs CP210x USB to UART Bridge” in

the “Device Name” column; in the screen-shot above

this would be the “COM 3” port.

Now call up the “HoTT Module Upgrade option under “Menu”, open the “Controller Menu” and click on

“HoTT Module”:

Click on the button labelled “File Browse” and select

the desired fi rmware update fi le (with the suffi x “bin”)

in the “Open fi le” dialogue which now appears.

The fi rmware fi les are present in a product-specifi c encoded form, i.e. if you inadvertently select a fi le

which does not match the product (e.g. receiver update fi le instead of transmitter update fi le), the popup window “Product code error” appears, and the update process cannot be started.

If you have not already done so, switch the transmitter OFF at this point and start the transmitter update

procedure by clicking on the “Download Start” button.

Wait until the progress bar starts running. This can

take up to several seconds. Now switch the transmitter ON with the BIND-Button pressed. After a few seconds, the status display „Found target device ...“

appears. Now release the BIND-Button. The actual

update process now commences, and a progress bar

starts running:

Do not interrupt the update process until the progress

bar has reached the right-hand margin, and you see

the message “Firmware Download Success” - also a

a brief buzzer sound appears and the STATUS-LED

of the transmitter changes from orange to green:

Page 23

91

Using the transmitter for the fi rst time

Click on “OK”, then switch the transmitter off and fi nally disconnect the PC or laptop.

If the progress bar does not move forward, close the

program and repeat the update procedure, taking

note of any error messages which might appear.

4. Initialisation of the transmitter

After a successful update process you MUST - before re-use the transmitter - proceed an initialization for

safety reasons:

Press and hold to the BIND-Button on the transmitter

and turn it on. Now release the BIND-Button. Except

the binding information all other necessary pre-programmed settings in the transmitter are reset to factory settings and must be entered again if needed.

Attention: When initialisation in mode „normal“ is

complete, the transmitter will be in Fail-Safe setting

mode (page 111),

if you do not want to program any-

thing here, turn off the transmitter now.

Page 24

92

Using the receiver for the fi rst time

Using the receiver for the fi rst time

Preliminary notes regarding the GR-12 receiver

Receiving system

The mx-10 HoTT radio control set includes a GR-12

2.4 GHz bi-directional receiver which is suitable for

connection to a maximum of six servos.

In order to create a connection to the transmitter, the

Graupner HoTT receiver must fi rst be “bound” to “its”

model memory in “its” Graupner HoTT transmitter; this

procedure is known as “binding”. However, binding is

only necessary once for each receiver / model memory

combination (see pages 106 or 109), and has already

been carried out at the factory using the components

supplied in the set. You therefore only need to carry out

the “binding” process with additional receivers, or if you

switch to a different model memory. The procedure can

also be repeated whenever you wish - for instance, if

you change the transmitter.

For this reason, if you connect the GR-12 HoTT receiver

supplied in the set to a power supply and switch it on,

the integral LED briefl y lights up green, and then goes

out again, assuming that “its” transmitter is not in range,

or is switched off. If a connection is made, the LED

glows a constant green.

Note:

If the LED glows a constant green, but the receiver

responds neither to the SET button nor to control commands, then please check the polarity of your receiver

power supply.

Receiver voltage display

Once a telemetry connection exists, the actual voltage

of the receiver power supply is displayed on the righthand side of the transmitter screen.

Temperature warning

If the temperature of the receiver falls below a limit value

set on the receiver (the default is -10°C), or exceeds

the upper warning threshold, which is also set on the

receiver (the default is +70°C), the transmitter generates

a warning in the form of steady beeps at intervals of

about one second.

Servo connections and polarity

The ser

vo sockets of Graupner HoTT receivers are

numbered. The connector system is polarised: look for

the small chamfers when inserting the connectors, and

on no account force the plugs into the sockets.

The power supply is through-connected via all the numbered sockets. If there is no vacant servo socket, it is

also possible to connect the power supply via a Y-lead,

Order No. 3936.11, in parallel with a servo.

Do not connect the battery to these sockets with

reversed polarity, as this is likely to ruin the receiver

and any devices connected to it.

The function of each individual channel is determined by

the transmitter you are using, rather than by the receiver.

The throttle servo socket is defi ned by the radio control

system, and may differ according to the make and type.

For example, in the case of Graupner radio control

systems the throttle function is assigned to channel 1 for

fi xed-wing models, and channel 6 for helicopters.

Servo socket 5: “SERVO” or “SENSOR”

The servo socket 5, which is marked with an additional

“T” …

Servo

sensor

OR

… can be used not only to update the receiver by connecting the adapter lead, Order No. 7168.6A, but also to

connect a telemetry sensor.

However, to ensure that the receiver correctly detects

the device connected to this socket, servo socket 5

MUST be reset from “SERVO” to “SENSOR” and vice

versa to suit the device. This is carried out in the “Te-

lemetry” menu on the “RX CURVE” page of the “SETTING & DATA VIEW” sub-menu. See the section starting

on page 120

for more details:

RX CURVE

TYPE : A

CURVE1 CH : 02

TYPE : A

CURVE2 CH : 05

TYPE : B

CURVE3 CH : 04

5CH FUNCTION:SERVO

On this menu page locate the “>” symbol at the left-hand

edge of the screen, use the INC or DEC button to move

it to the bottom line, and then press the INC+DEC button

simultanously:

RX CURVE

TYPE : A

CURVE1 CH : 02

TYPE : A

CURVE2 CH : 05

TYPE : B

CURVE3 CH : 04

5CH FUNCTION:SERVO

Now select the alternative “SENSOR” setting using one

of the INC or DEC buttons:

Page 25

93

Using the receiver for the fi rst time

* Battery Elimination Circuit

Reset

If you wish to carry out a receiver reset, locate the

SET

b

utton on the top of the receiver and hold it in while you

connect its power supply; release the button again.

If the reset is carried out with the transmitter switched

off, or if the receiver is not already bound, the receiver

LED fl ashes red slowly after about two or three seconds;

at this stage it is immediately possible to initiate a

binding process at the transmitter. If the reset is carried

out with an already bound receiver, if the transmitter

is switched on, and if the associated model memory is

active, then the LED lights up green after a short interval

to indicate that your transmitter / receiving system is

ready for use once more.

Please note the following:

Resetting the receiver resets ALL the settings

stored in the receiver to the default settings, with

the exception of the binding information! If you

carry out a reset by mistake, this means that you

will have to restore all the receiver settings entered

using the Telemetry menu.

On the other hand, a deliberate RESET is particularly useful if you wish to “re-house” a receiver in a

different model, as it represents an easy method of

avoiding the transference of unsuitable settings.

RX CURVE

TYPE : A

CURVE1 CH : 02

TYPE : A

CURVE2 CH : 05

TYPE : B

CURVE3 CH : 04

5CH FUNCTION:SENSOR

A further press of the INC+DEC buttons concludes your

choice.

Concluding notes:

The much higher servo resolution of the HoTT sys-•

tem results in a substantially more direct response

compared with previous technologies. Please take a

little time to become accustomed to the fi ner control

characteristics offered by the system!

If you wish to use a speed controller with integral •

BEC* system in parallel with a separate receiver battery, in most cases (depending on the speed controller) the positive terminal (red wire) must be removed

from the three-pin connector, as shown in the diagram. Be sure to read the appropriate notes in the instructions supplied with your speed controller before doing this.

Carefully raise the central lug of the connector slight-

ly (1), withdraw the red

wire (2) and insulate the

bare contact with tape

to avoid possible short

circuits (3).

red

1

2

3

Observe the installation notes regarding the receiver, receiver aerial and servos, which you will fi nd on

page 96.

Page 26

94

Using the receiver for the fi rst time

Firmware updates for the receiver are carried out using

the receiver’s telemetry socket - in the case of the GR12 receiver supplied as standard in the set this is servo

socket 5, which is also marked with a “T” - in conjunction

with a PC running Windows XP, Vista or 7. To connect

the receiver to a PC you require the separately available

USB interface, No. 7168.6 and the adapter lead, Order

No. 7168.6A. The latter - like all other connecting leads

- must always be connected to the GR-12 receiver with

the brown or black wire facing up.

The latest software and information can be found in the

Download area for the corresponding product at www.

graupner.de.

Note:

Once you have registered your transmitter at http://

graupner.de/de/service/produktregistrierung you will

automatically be informed of new updates by e-mail as

they become available.

Updating the GR-12 software

Attention:

It is essential to check the state of charge of your

receiver battery before carrying out any update. To

be on the safe side we recommend that you give the

battery a full charge.

1. Installing the driver

If you have not already done so, install the driver

software for the USB interface, Order No. 7168.6, as

described on page 89.

2. Connecting the receiver to the PC

Connect the USB interface, Order No. 7168.6 to the

receiver socket marked “-+T” using the adapter lead,