Page 1

33032.mc-32 HoTT.3.en

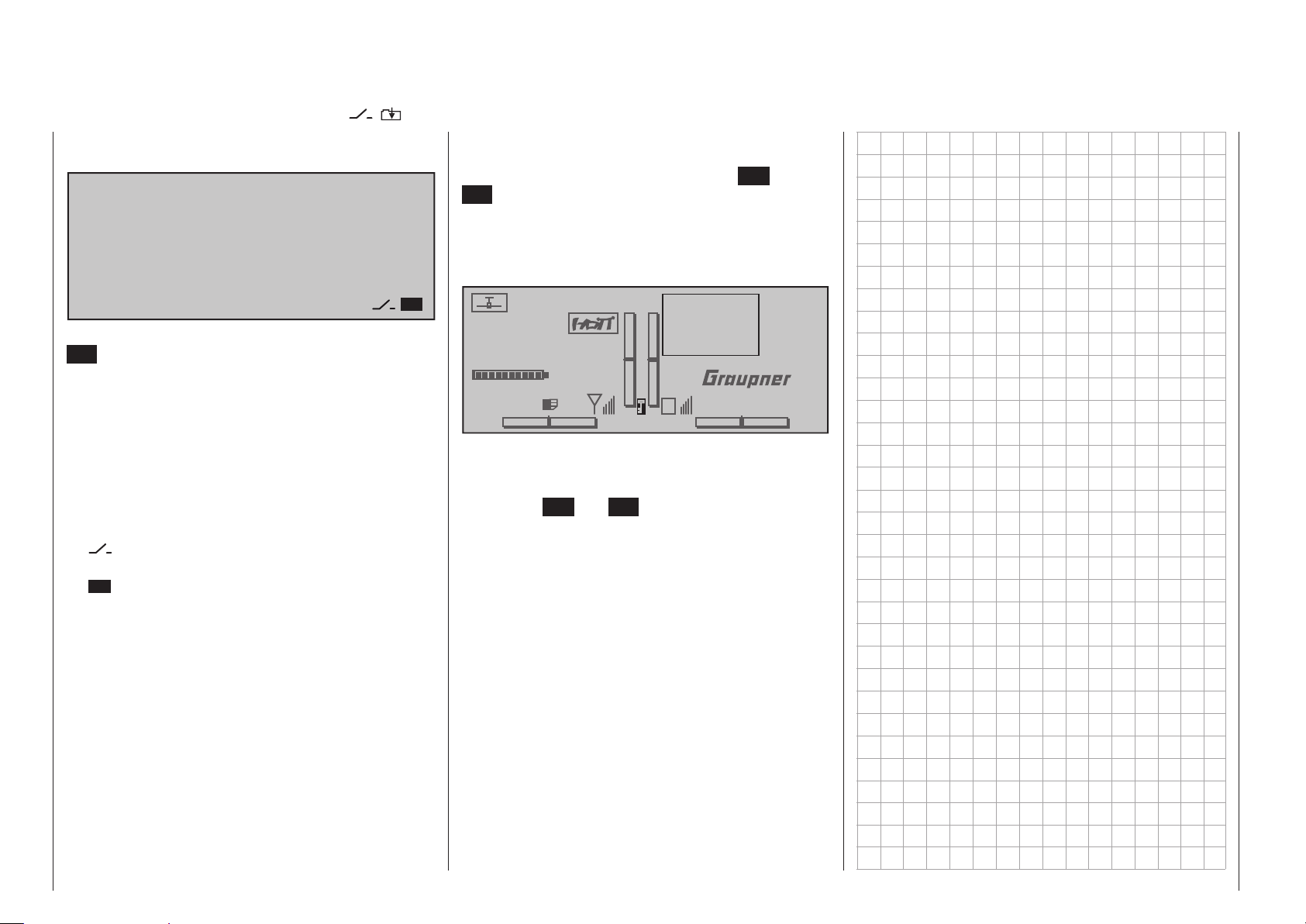

mc-32

Programming Manual

Page 2

Table of contents

General notices

Warning and note symbols ......................................... 3

Safety notices ........................................................... 4

Safety notices and handling regulations for

Lithium-Ion (LiIo) and Lithium-Polymer (LiPo)

batteries ..................................................................... 8

Environmental protection notices .............................. 10

Foreword .................................................................. 10

Remote control set description ................................. 13

Technical data .......................................................... 16

General operating notices

Transmitter .......................................................... 18

Opening the transmitter housing ..................... 18

Transmitter power supply ............................... 18

Recommended chargers (accessory) ............. 19

Battery operation timer ................................. 19

General charging notices ................................ 20

Lithium battery CR 2032 .............................. 20

Stick length adjustment .................................. 20

Stick conversions ........................................... 21

Transmitter neckstrap support bars .............. 22

Installation of switches, switch modules and

knob modules ............................................... 22

Aligning the antenna ..................................... 22

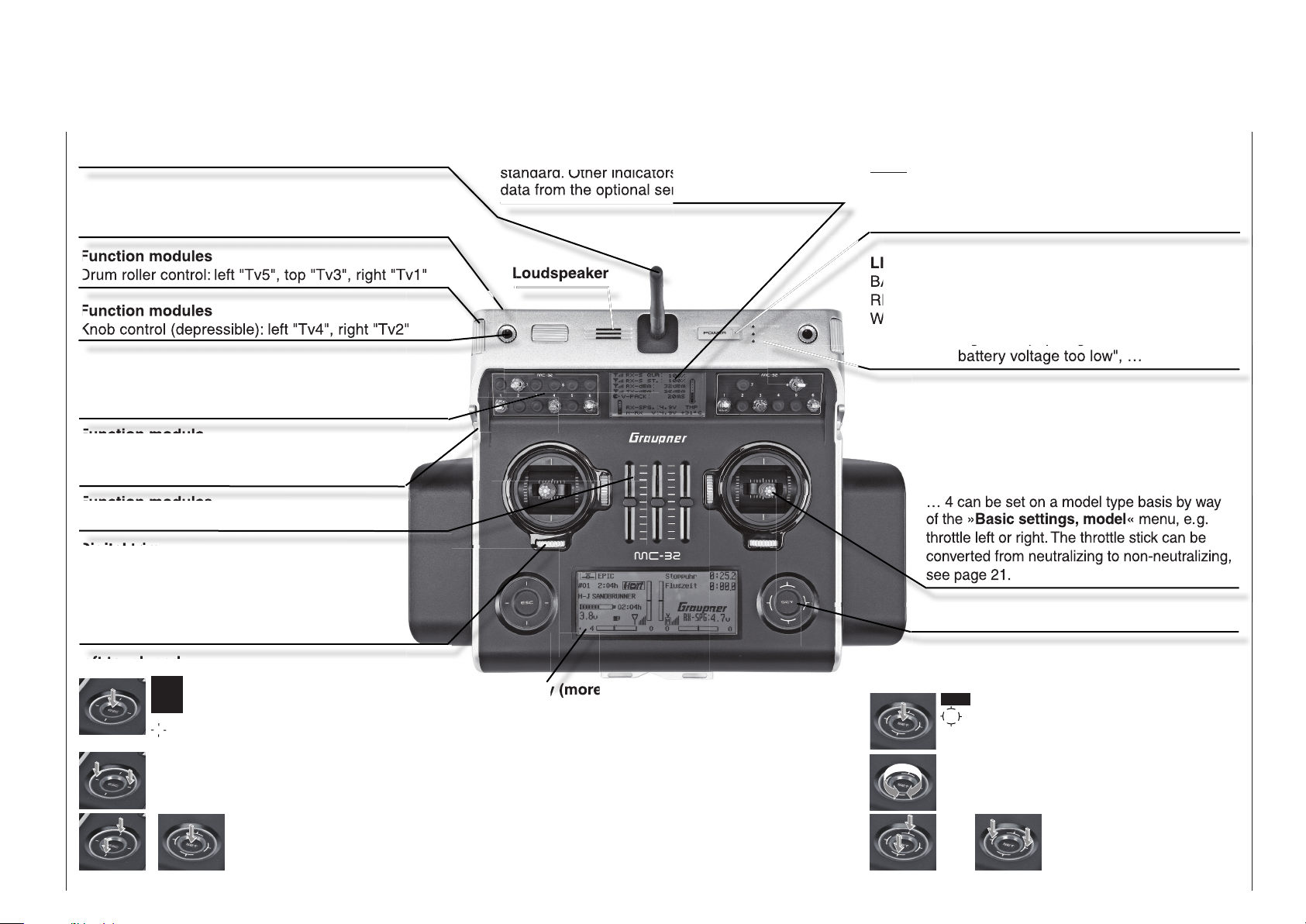

Transmitter description

Front side ....................................................... 23

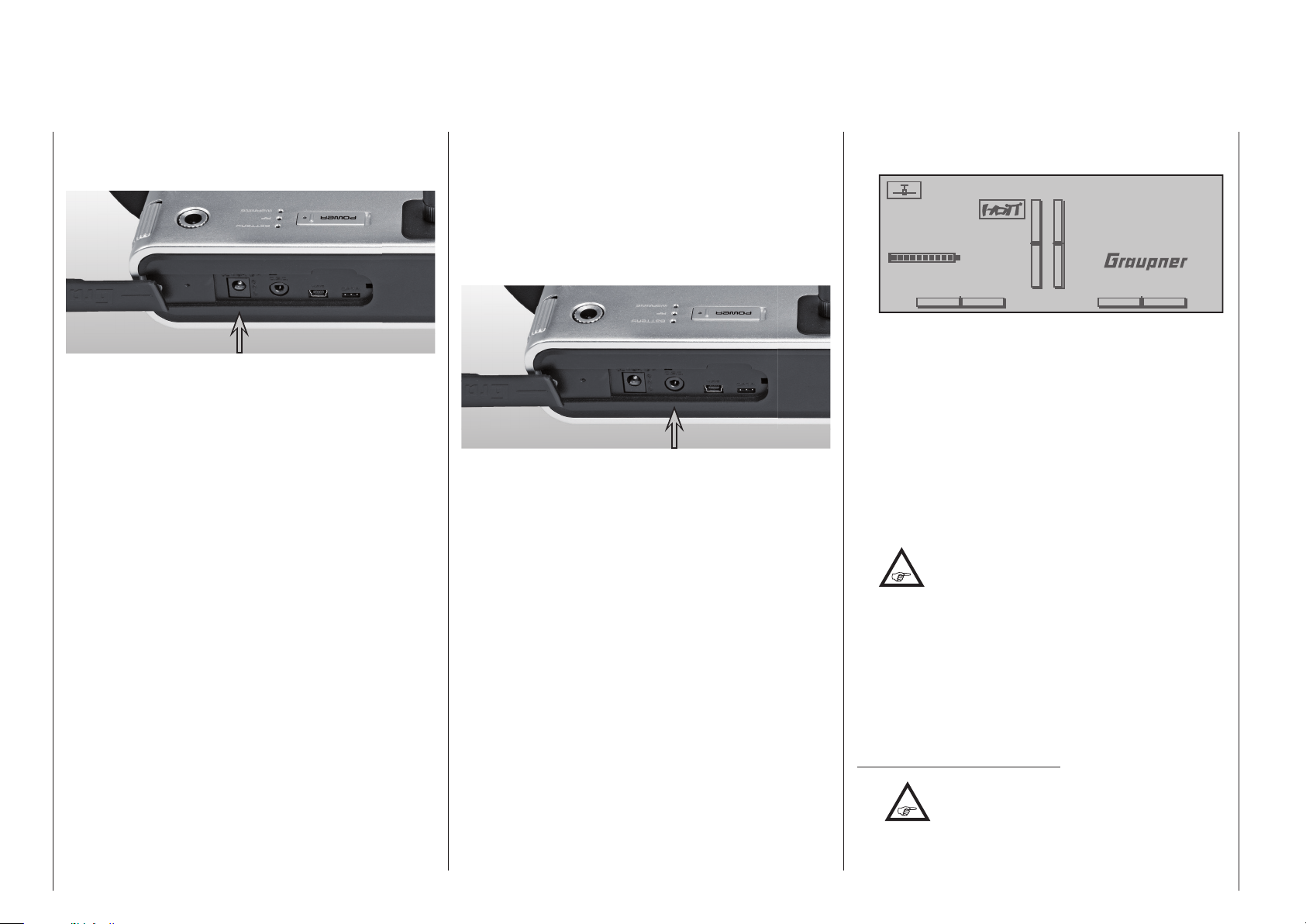

Face-side connectors

Charger socket ............................................. 24

DSC jack ........................................................ 24

Mini USB connector ....................................... 25

Data jack ........................................................ 25

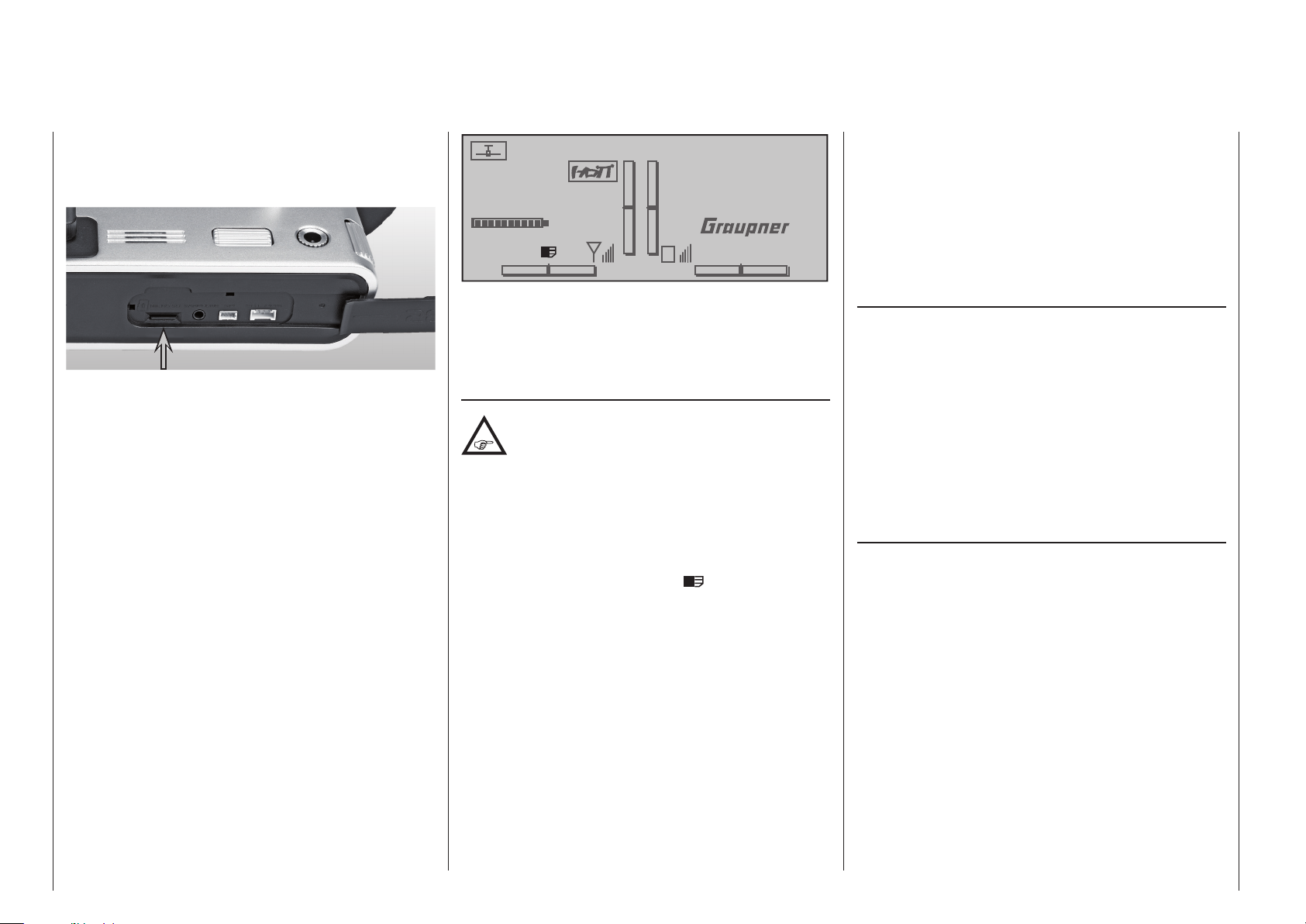

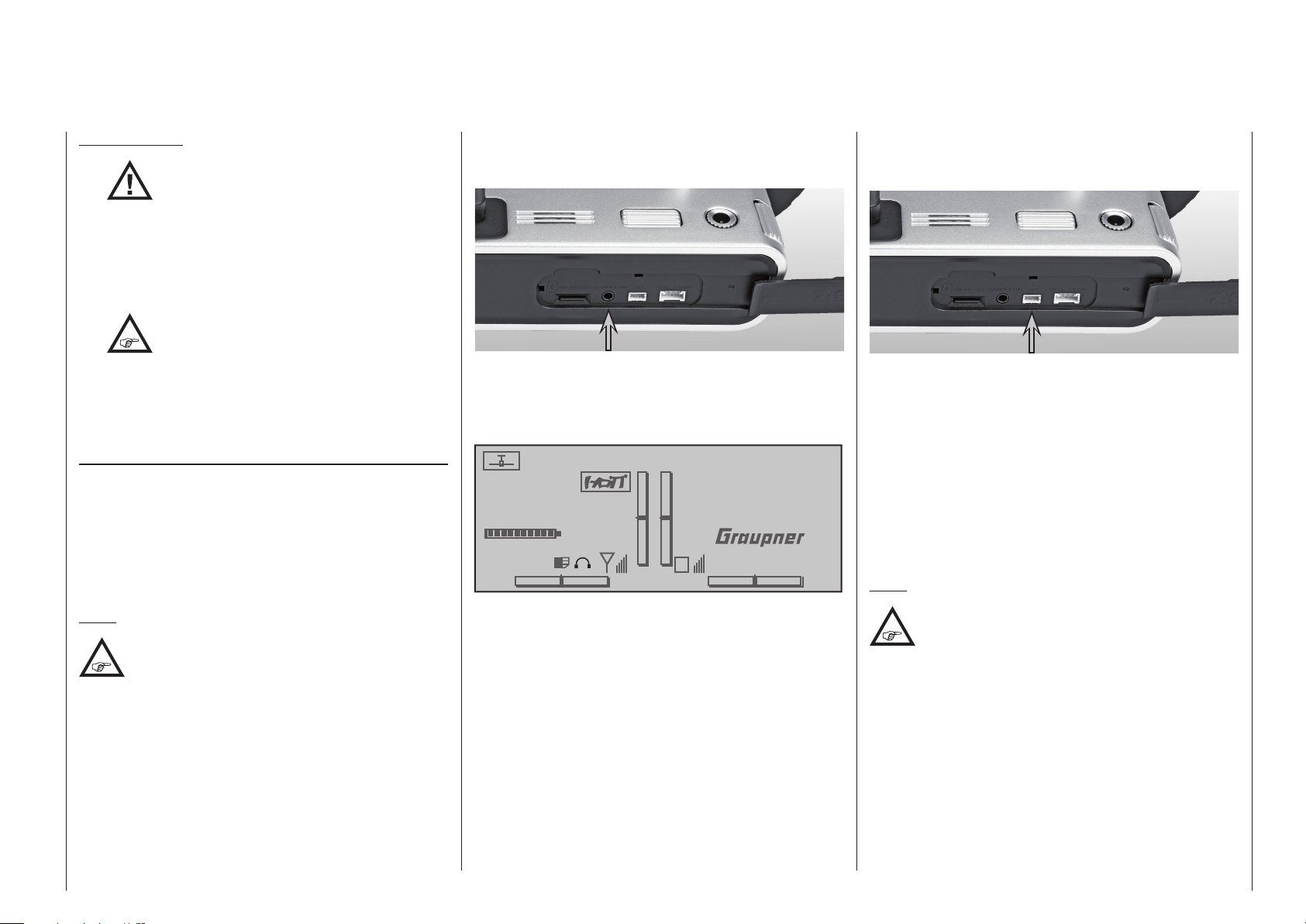

Card slot ........................................................ 26

Headset connector ......................................... 27

Ext. PPM ........................................................ 27

SPI ................................................................. 28

Bottom side transmitter interior ............................ 29

Display and keypad ............................................. 30

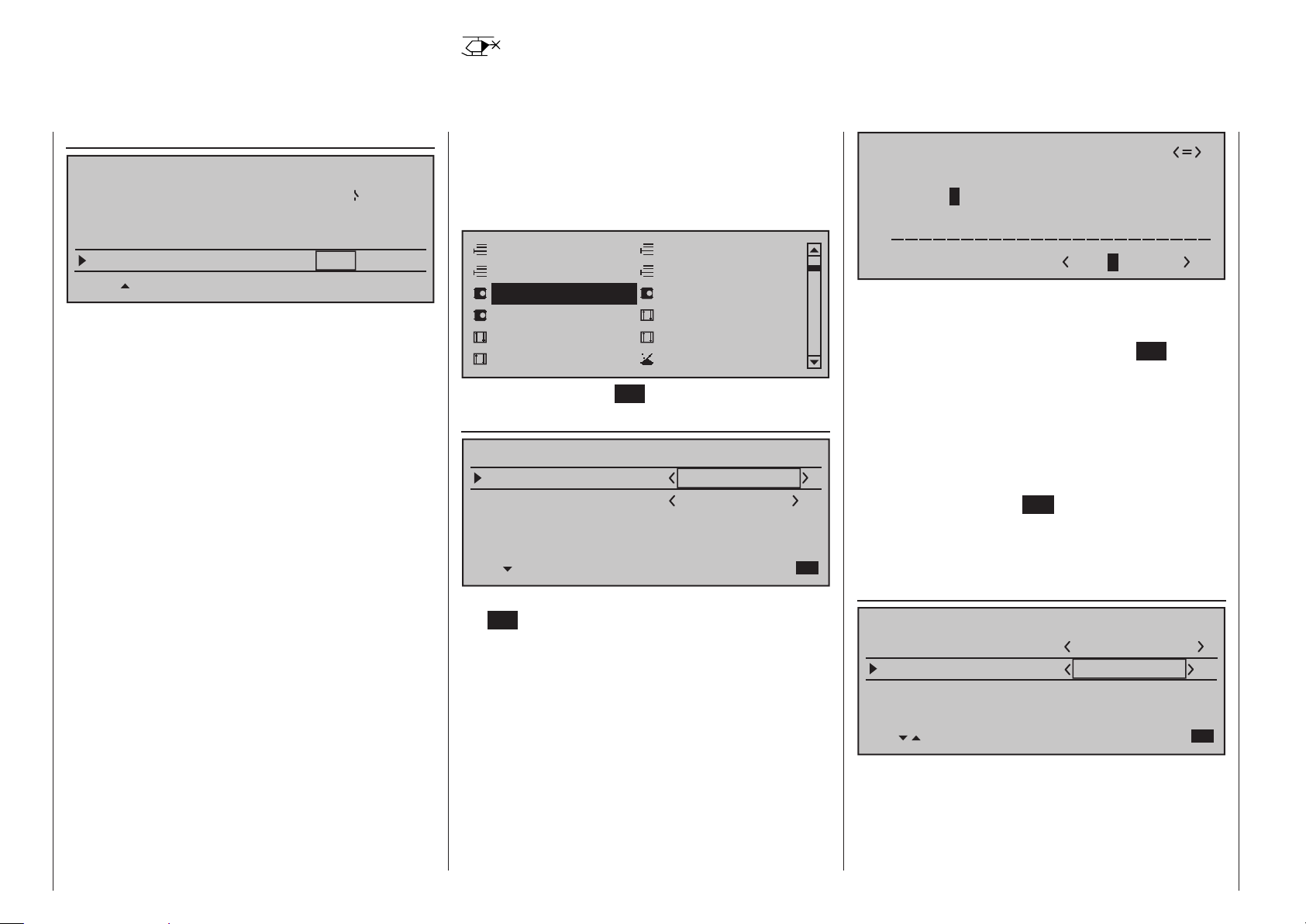

Operating the “data terminal“ ............................... 31

Table of contents

2

Shortcuts ............................................................ 32

Warning notices in the display ............................. 33

Function fields in the display ................................ 34

Entry lockout ....................................................... 34

HIDDEN MODE ................................................... 35

Display contrast .................................................. 35

Language selection

VOICE .................................................. 35

Change of display language ................. 36

Firmware update via SD card ......................... 36

STICK CALIBRATION ..................................... 37

Bluetooth initialization ..................................... 39

Telemetry data display ......................................... 40

Commissioning the transmitter ........................... 48

Transmitter firmware updates............................... 50

Restoring the transmitter software ....................... 51

Receiver initialization ............................................ 52

Receiver firmware updates .................................. 53

Secure receiver settings....................................... 53

Installation notices ................................................ 54

Receiver power supply ........................................ 55

Definitions of terms ................................................... 58

Physical control, switch and control switch assignments ...... 60

Digital trim ................................................................ 62

Winged models ...................................................... 64

Receiver layout .................................................... 65

Servos in wrong direction .................................... 66

Helicopter models ................................................. 68

Receiver layout .................................................... 69

Program descriptions

Loading a new memory location .............................. 70

»Model select« ....................................................... 73

»Copy / Erase« ....................................................... 74

Erase model ....................................................... 74

Copy model Model ......................................... 75

Export to SD card ............................................... 75

Import from SD card ........................................... 76

Copy flight phase ................................................ 77

Changes ............................................................. 77

»Suppress codes« ................................................. 80

»Suppress models« ............................................... 81

»Basic settings, model«

Winged model .................................................... 82

Binding type .................................................. 83

Binding receivers ........................................... 84

Range test ..................................................... 88

Helicopter model ................................................ 92

Binding type .................................................. 93

Binding receivers ........................................... 94

Range test ..................................................... 99

»Model type« ........................................................ 104

»Helicopter type« ................................................. 108

»Servo adjustment« ............................................ 112

»Stick mode«

Winged model .................................................. 114

Helicopter model .............................................. 116

»Control adjust«

Winged model .................................................. 118

Helicopter model .............................................. 122

Throttle limit function ................................... 128

Idle setting ................................................... 129

Throttle limit in combination with AR

in the »Stick mode menu« ......................... 131

»Dual Rate / Expo«

Winged model .................................................. 132

Helicopter model .............................................. 136

»Channel 1 curve«

Winged model .................................................. 140

Helicopter model .............................................. 143

»Switch display« .................................................. 146

»Control switch« .................................................. 146

»Logical switches« .............................................. 150

How do I program a flight phase? .......................... 152

»Phase settings«

Winged model .................................................. 154

Helicopter model .............................................. 158

»Phase assignment« ........................................... 160

»Phase trim« (winged model) ............................... 162

Page 3

»Non-delayed channels« .................................... 163

»Timers (general)« ............................................... 164

»Flight phase timers« .......................................... 168

What is a mixer ...................................................... 171

»Wing mixers« ..................................................... 172

1 aileron ............................................................ 175

1 aileron and 1 camber flap .............................. 176

2 ailerons .......................................................... 178

2/4 ailerons and 1/2/4 camber flaps ................. 180

»Helicopter mixer« .............................................. 190

Adjusting the throttle and pitch curve ............... 202

Autorotation setting ........................................... 206

General remarks about freely progr. mixers .......... 208

»Free mixers« ...................................................... 209

Linear mixers .................................................... 213

Exponential mixers ........................................... 215

Examples .......................................................... 218

»MIX active/phase« .............................................. 220

»Mix only Channel« ............................................. 221

»Dual mixer« ........................................................ 222

»Swashplate mixer« ............................................ 223

»Fail Safe« ............................................................ 224

»Teacher/pupil« ................................................... 226

Connection schematic ...................................... 229

Wireless HoTT system ..................................... 230

»Transmitter output« ........................................... 234

»Pro-trim«

Winged model .................................................. 236

Helicopter model .............................................. 238

»Trim memory«

Winged model .................................................. 240

Helicopter model .............................................. 242

»Telemetry« .......................................................... 244

Important notes ................................................ 244

Setting & dataview ............................................ 246

Satellite mode of two receivers ................... 255

Sensor/s ...................................................... 257

Selecting sensor/s ............................................ 258

RF status view .................................................. 259

Select voice update .......................................... 260

»Channel sequence« ........................................... 262

»Multichannel« ..................................................... 264

»Ring Limiter« ...................................................... 268

»MP3-Player« ....................................................... 272

»Basic settings« .................................................. 275

»Servo display« ................................................... 282

»Servo test« ......................................................... 283

»Code lock« ......................................................... 284

»Info display« ....................................................... 286

Programming examples

Introduction ............................................................ 288

Winged model

First steps ......................................................... 290

Incorporating an electric drive .......................... 296

C1 stick switchover between

Electric motor and butterfly .......................... 300

Electric motor and airbrake ......................... 303

Timer activation by control or switch ................. 304

Parallel operating servos .................................. 306

Using flight phases

Example 1 ................................................... 308

Example 2 ................................................... 312

Control of temporal processes ......................... 318

Delta and flying wing models ............................ 320

F3A model ........................................................ 324

Helicopter model .................................................... 328

Appendix

FCC declaration ..................................................... 342

Conformity declaration ........................................... 343

Guarantee certificate ............................................. 344

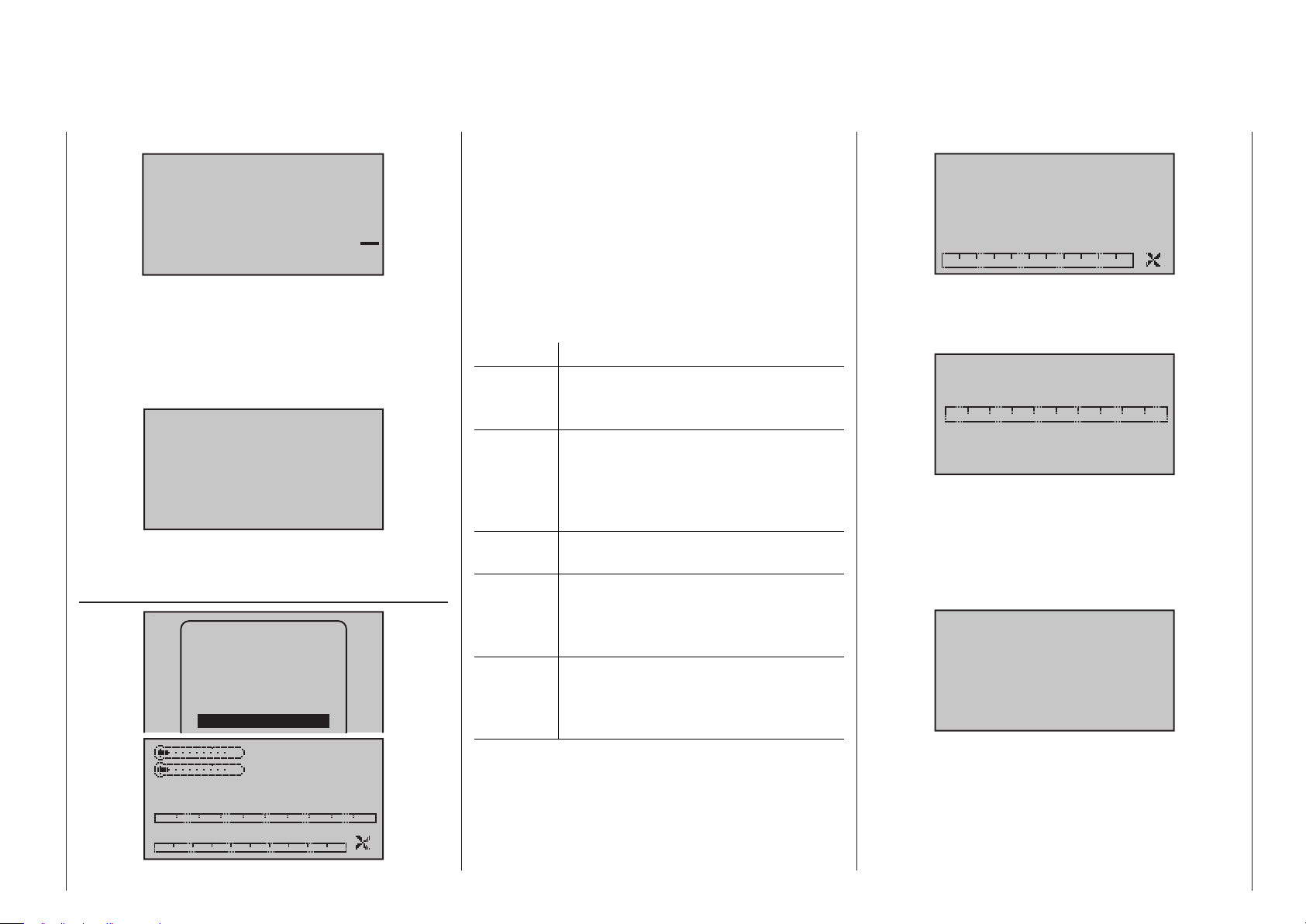

Warning and notice

symbols

and their meaning

WARNING:

This symbol highlights the adjacent or following instructions, which absolutely must be

adhered to by the user! Any disregard of

these instructions, can affect the safe operation and safety of the operator as well as

bystanders.

ATTENTION:

This symbol highlights the adjacent or following instructions which must be observed by

the user! Any disregard of these instructions

can lead to damage of any kind, loss of guarantee and so on.

This symbol without specific headline emphasizes the adjacent or following notes and tips

which should be strictly observed by the user!

Any disregard of these instructions and tips

can result in damage of any kind.

This symbol highlights hints and tips of all

kinds, which should be observed by the user.

This symbol highlights information about

cleaning the device, which should be strictly

observed by the operator in order to ensure a

long life of the device.

Table of contents

3

Page 4

Safety notices

Be sure to pay attention!

In order to enjoy your modelling hobby for a long time,

please read these instructions thoroughly and give

particular attention to the safety notices.

If you are a beginner with remote controlled model

aircraft, ships or cars, you should really ask an experienced model pilot for assistance.

INTENDED USE

ATTENTION:

This remote control system may only be

used for the purpose intended by the

manufacturer, i.e. for the operation of

unmanned remote controlled models. Any other

usage is not permissible and can cause damages

to the remote control system, to other things and/

or to the people. For damages derived from other

use we offer no warranty and take no liability.

ATTENTION:

NOT SUITABLE FOR KIDS UNDER 14

YEARS OLD, SAFETY IS NO ACCIDENT

and REMOTE CONTROLLED MODELS ARE

NOT TOYS

… because even small models can cause substantial

property damage and/or personal injuries if they are

not handled properly - even if caused by third parties.

This manual is an important part of the set, it

contains important information for a proper

and safe use and maintenance. If this remote

control system changes ownership, these instructions

should surely be included with remote control system.

Failure to comply with the operating instruc-

tions and the safety instructions will void the

warranty.

Other notes and warnings

Technical defects of an electrical or mechanical nature can lead to unexpected startup of a motor and/or

parts being hurled through the air to pose a danger of

injury to you and to others.

Short circuit conditions are to be avoided absolutely!

A short circuit condition may not only destroy parts

of the remote control system but, depending on the

circumstances and the battery energy involved, may

also pose acute danger of incineration or even explosion.

All motor-driven parts, such as aircraft or ship propellers, helicopter rotors, open gearboxes etc. represent

a constant danger. Contact with these parts must be

avoided. A rapidly turning aircraft propeller can, for

example, sever a finger. Also pay attention that other

objects do not come into contact with driven parts.

When a drive battery is connected or a motor is

running: never get into the danger zone of driving

mechanisms.

Be sure to pay attention that motors do not start up

unintentionally while performing programming operations. Disconnect the fuel supply or battery terminals

to motors before programming.

Protect all units from dust, dirt, moisture and other

foreign parts. Never expose these units to vibrations

or excessive hot or cold temperatures. Remote control operation may only be performed under “normal”

outdoor temperatures, i.e. within a range of -10 °C to

+55 °C.

Avoid mechanical jarring and pressure stresses. Always check units for damage to housings and cables.

Do not use units which have been damaged or become wet, even after they are dry again.

Only those components and accessories which we

recommend may be used. Always use original Graup-

ner plug and jack connectors which are made for one

another out of the same materials.

When routing cables, pay attention that they are not

stressed, unduly kinked or broken. The sharp edges

of adjacent parts also represent a hazard for insulated conductors.

Be sure that all plug and jack connections are firmly

seated. Do not pull on the cable to disconnect a

plugged connector.

No modifications whatsoever may be made to units.

Modifications will void the operating permit and all

insurance protection. If necessary, send the device

concerned to your local Graupner Service Centre;

see page 343.

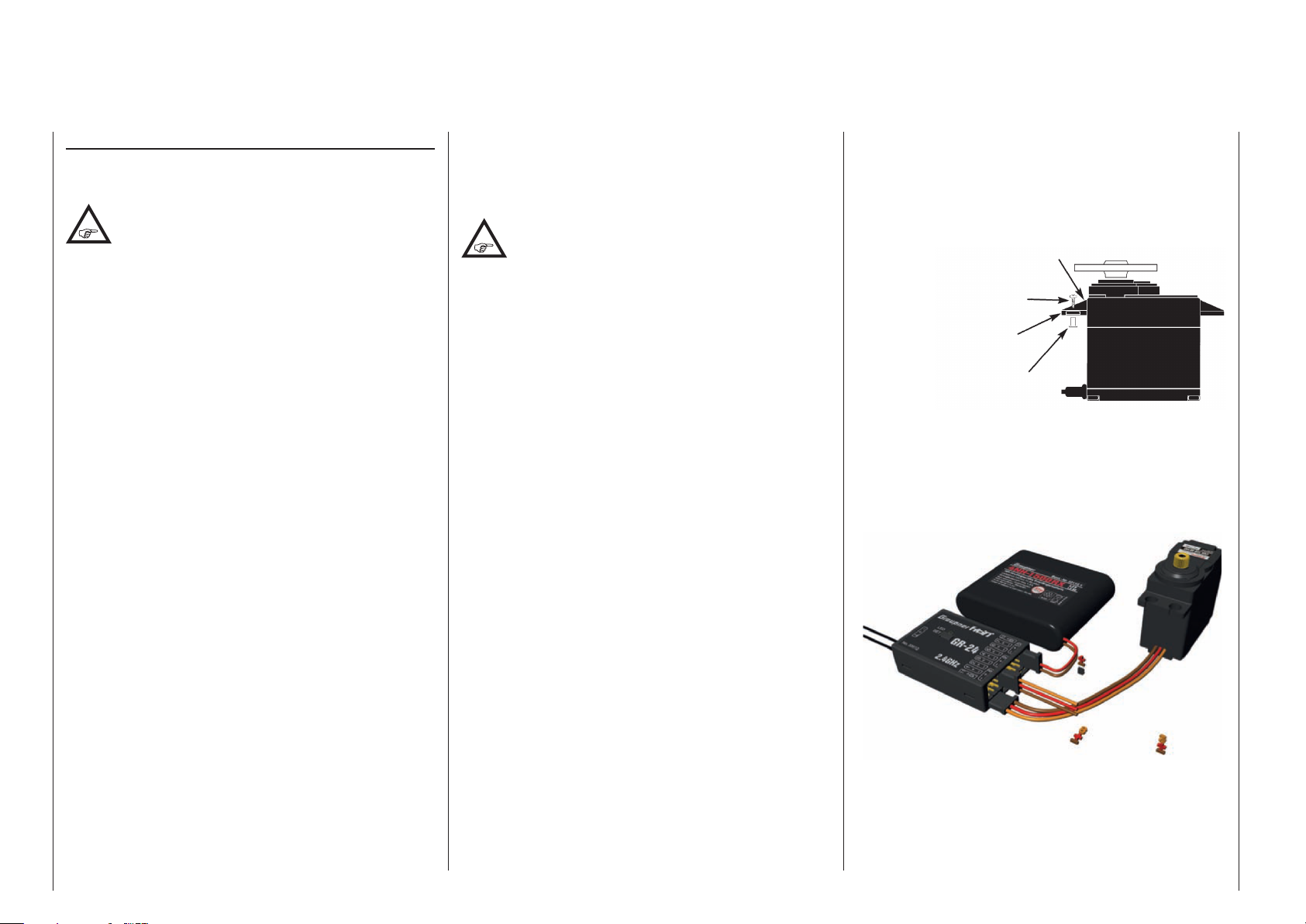

Installing the receiver

The receiver is to be installed with a cushion

of foam rubber to afford protection against

jarring; in aircraft models behind a strong rib,

for a car or ship model the location must be protected

against dust and spray water. However, do not enclose your receiver completely, otherwise it may

overheat in use.

The receiver may not be mounted in direct contact

with the hull or chassis as this would allow motor

vibrations and/or roadway jarring to be transferred

directly to the receiver. When a receiver system is

installed in a model with a combustion motor, all

receiver parts should always be protected against the

intrusion of exhaust gases and oil residue. Above all,

this applies to the model’s ON/OFF switch, which is

typically built into the model’s outer surface.

Position the receiver such that connecting cables to

the servos and the power supply are routed with a bit

of slack and that the receiver’s antennas are at least

5 cm away from any large metal parts or wiring except

for other receiver wires/cables. In addition to steel,

this also includes carbon fiber parts, servos, electric

motors, fuel pumps and all sorts of cables, etc.

Optimally the receiver should be placed at a readily

accessible location that is well away from all other

Safety notices

4

Page 5

equipment. Under no circumstances may a servo

cable be wrapped around the antenna or routed close

to it.

Make sure that cables near the antenna cannot move

about during flight.

Routing the receiver’s antennas

The receiver and its antennas must be positioned

as far away as possible from drives of any kind. If

the model’s hull is made of carbon fiber material, the

ends of the antennas must extend outside of the hull.

If your model features a carbon fibre fuselage, the

aerial tips must always extend outside the fuselage

for a length of at least 35 mm. If this is not possible, it is essential to substitute longer aerials for the

standard ones (approx. 145 mm long) fitted to HoTT

receiver(s).

The orientation of the aerial(s) is not critical, but

it is advantageous to install one receiver aerial in

a vertical – upright – position in the model. If your

receiver is a Diversity type – two aerials – the active

tip of the second aerial should be positioned at 90 °

to the tip of the first aerial, and ideally the distance

between the two tips should be greater than 125 mm.

Servo installation

Always mount servos with the provided rubber vibration-damper parts, see “installation notes” on page

54. Only in this manner can these parts be protected against excessively hard vibrations.

Installing control rods

Control rods must be installed such that they operate

freely and smoothly. It is particularly important that

all rudder levers are able to move to their full limits,

i.e. not otherwise mechanically blocked.

In order to be able to stop a running motor at any

time, control rods must be adjusted such that the

carburettor tap is completely closed when the joystick

and trim lever are brought into their end idle position.

Pay attention that no metal parts, e. g. as a result of

rudder actuation, vibration, rotating parts, etc., rub

against one another. Metal-to-metal contact causes

electrical “noise” which can interfere with the correct

operation of the receiver.

Transmitter antenna orientation

Transmission field strength is minimal in an imaginary

line extending straight out from the end of the transmitter’s antenna. This means that “pointing” the transmitter’s antenna directly toward the model will not

produce good reception but rather degrade reception.

When multiple remote controls are operating simultaneously, pilots should position themselves in a loose

group. Pilots standing off to themselves not only endanger their own models but those of others as well.

However, when 2 or more pilots using 2.4 GHz remote

control systems are closer than 5 m to one another

this can lead to return channel overdrive which, in

turn, will trigger a range warning much too early.

Increase your distance between one another until the

range warning ceases.

Pre-start checks

Before switching the receiver on, be sure the throttle

control is at its Stop/Idle position.

Always switch the transmitter on rst

and then the receiver.

Always switch the receiver off rst

and then the transmitter.

If this sequence is not maintained, such that the

receiver is still switched on when the corresponding

transmitter is switched to “OFF”, then the receiver

may respond to other transmitters or general radio

frequency noise. This can cause the model to execute

uncontrolled operations that may cause personal

injuries and/or property damage.

In particular, for models equipped with a mechanical

gyro:

before switching off the receiver, disconnect the

model’s power supply to prevent the motor from revving up unintentionally.

The residual spin of a gyro often produces

so much voltage that the receiver may

falsely interpret a throttle signal! This will

then cause the motor to start up unexpectedly.

WARNING:

If this order is not respected, that the receiver

is turned on, but the corresponding transmit-

ter is “OFF”, the receiver could respond by

other transmitters and any interference.

The model can be run as a result uncontrolled steering movements, thus possibly causing property damage and / or personal injury.

In particular with a mechanical gyro for models:

Before you switch your receiver off, make sure by

interrupting the power supply, that the motor can not

run up unintentionally.

An expiring gyro can generate such a voltage that

the receiver picks up as an apparently valid throttle command. Then, the motor may start unintentionally!

Range test and function test

Perform checks for proper operation and

range before every session. Secure the mod-

el adequately in place and ensure that no one

is in front of the model.

Perform a complete functional test on the ground and

execute a complete simulated flight to exclude the

possibility of system faults or problems with the model’s programming. When doing this, be sure to follow

the notices provided on pages 88 and 99.

Never operate the transmitter in Model mode, i.e.

for flying or driving, without an antenna. Be sure the

antenna is firmly seated in its socket.

Safety notices

5

Page 6

Safety notices

WARNING:

If the range and functional test, and ight

simulation are not carried out in detail and

conscientiously, this may have undetected malfunction and / or reception failures result in

eg loss of control or even a crash of the model

and can lead to signicant things and / or personal injury as a result.

Operating a winged aircraft, helicopter, ship or

car

WARNING:

•

high-voltage wires. Do not operate the model

in the vicinity of sluice locks or where real

boats or ships are operating. Do not operate a

model on public streets or highways, paths or

plazas, etc.

• Never switch the transmitter off whilst operat-

ing a model! If this should happen accidentally, keep your nerve and wait until the transmitter screen is entirely blank, i. e. until the

transmitter has shut down completely; this

takes at least three seconds. Do not switch

your transmitter on again until this has occurred. If you neglect this, there is a risk that

the transmitter will “hang” immediately after

being switched on, and you will lose control

of the model. In this case your only recourse

is to switch the transmitter off again, allow it

to shut down completely, and then switch on

once more after the correct interval.

Never y over spectators or other

pilots. Never endanger humans or

animals. Never y in the vicinity of

Aero-towing

WARNING:

When operating a powered tug, ensure

that the receiving systems in the two

models are always at least 50 cm apart. We

recommend the use of satellite receivers in such

situations. If you neglect this, there is a chance of

interference from the downlink channel.

Monitoring transmitter and receiver batteries

You must stop running the model to recharge

the transmitter’s battery no later than when

low transmitter battery voltage triggers the

“Batt must be recharged!!” display and acoustic

signal.

Check the charge in batteries routinely, particularly

the receiver’s battery. Do not wait until the movements

of controlled mechanisms are noticeably slower.

Replace expended batteries before they cause problems.

The battery manufacturer’s charging instructions are

always to be followed, this includes mandatory adherence to the length of charging time. Never leave

batteries being charged unattended.

Never attempt to charge primary batteries (non-rechargeable batteries) because they can explode.

All secondary batteries (rechargeable batteries) must

be charged before every session. To avoid short

circuit conditions, first connect the charger cable’s

banana plugs, polarity correct, into the charger and

thereafter connect the charger cable’s plugs to the

transmitter and receiver batteries.

Disconnect all power sources from the model when it

is not to be used for an extended period of time.

Never attempt to use defective batteries, damaged

batteries or mixed-type battery combinations as a single group. Do not use mixed combinations of old and

new batteries or batteries of different manufacture.

Capacity and operating time

The rule: “capacity is reduced with every successive

recharging”, applies to all batteries. Internal resistance increases at low temperatures to further reduce

capacity. As a consequence, the battery’s ability to

provide current and hold its voltage is reduced.

Frequent charging or the use of battery maintenance

programs can also result in gradual loss of battery

capacity. Therefore the capacity of batteries should

be checked at regular intervals, not in excess of every

six months, and replaced if performance is found to

be significantly deficient.

Purchase only genuine Graupner batteries!

Interference suppression for electric motors

All conventional electric motors produce

sparks between their collector and brushes.

Depending on the type of motor involved, this

may cause more or less interference with the functionality of the remote control system.

The electric motors of a properly built system should

therefore have interference suppression features. For

electric drive models it is particularly important that

every one of its motors is provided with proper interference suppression. Interference filters extensively

suppress such disturbances and should always be

included.

Follow the respective recommendations included in

the motor’s operating and installation notices.

For further details about interference filters, refer to

the Graupner RC main catalog or in Internet at

www.graupner.de.

Servo interference lters for extension cables

No. 1040

The servo interference filter is necessary when an

extended-length servo cable is used. This filter is attached directly to the receiver output. In critical cases

a second filter can be attached to the servo.

Safety notices

6

Page 7

Using electronic speed controllers

Choosing the right electronic controller is largely a

matter of matching controller performance to the motor to be controlled.

In order to prevent an overload or damage to the

speed controller, its current rating should be at least

half of the maximum locked-rotor current draw of the

motor to which it is connected.

Particular attention is appropriate for so-called “tuning

motors”. Because of their low-turns coils these motors

can draw a multiple of their rated current in a lockedrotor condition and this can lead to the destruction of

the speed controller.

Electric ignition systems

Combustion motor ignition systems also produce

interference that can negatively influence remote

control functionality.

Always supply power to an electric ignition system

from a separate, dedicated battery.

Use only interference-suppressed spark plugs, spark

caps and shielded ignition leads.

Mount the receiver sufficiently far away from ignition

system components.

Static charges

WARNING:

A remote control system will be destroyed

by the magnetic shock waves produced

by a lightning strike – even if the storm is

miles away. Therefore, stop ying right away if a

storm is approaching. Static charging via the

antenna also represents a lethal hazard.

Attention

•

between this system’s antenna and other persons

In order to fulfill FCC HF emission requirements for mobile transmitters, a distance

of at least 20 cm must be maintained

when this system is operating. Operation of this

system at a lesser distance is therefore not recommended.

• To avoid disturbance caused by the electrical

characteristics and emissions of other transmitters, keep at least a 20 cm distance from other

transmitters.

• Operation of the remote control system requires a

correct program setting for the given country in the

transmitter unit. This is necessary for compliance

with diverse regulations like FCC, ETSI, CE etc.

Follow the respective instructions provided for this

with the transmitter and receiver.

• Prior to every flight, perform a complete functional

test, range test and execute a complete simulated

flight in order to exclude the possibility of system

faults or problems with the model’s programming.

• Never program the transmitter or receiver while

the model is being operated.

Care and maintenance

Never clean the housing, antenna, etc. with

cleaning agents, gasoline, water or similar

P

means. Use only a dry, soft cloth.

Components and accessories

WARNING:

As manufacturer of this equipment Graupner GmbH & Co. KG recommends only com-

ponents and accessories which have been

tested and approved by Graupner for their suitability,

functionality and safety. If this recommendation is

followed, Graupner accepts responsibility for the

product.

Graupner cannot accept any responsibility for

the parts or accessories of other manufacturers

which have not been approved and Graupner

cannot evaluate every individual product made by

other companies to assess if they are safe to use.

Liability exclusion / damage compensation

This manual serves only as a source of information

and can be changed without prior notification. Graup-

ner accepts no responsibility or liability for errors or

inaccuracies which may be contained in this manual.

Graupner cannot monitor compliance with the assembly instructions, the operating instructions or the

conditions and methods under which remote control

components are installed, operated, utilized or maintained. Therefore Graupner accepts no form of liability

for loss, damage or costs consequential to incorrect

usage or operation or which can be attributed to

same.

Unless otherwise prescribed by law, the obligation of

Graupner to provide damage compensation, regardless of legal grounds, is limited to the invoice value of

the quantity of Graupner goods contributing directly

to the damage-inducing event. This does not apply if

Graupner is found to be subject to unlimited liability

pursuant to binding legal stipulations with respect to

intent or gross negligence.

Furthermore we will only consider claims

if a log le is present; see page 26 un-

der “Data recording” so as page 159

under “Flight time”. For the same reason the

transmitter must always be updated to the latest

software status.

Keep in mind, however, that for technical reasons

during playback of MP3 les NO data recording is

possible.

It is essential that you register at https://www.graupner.de/en/service/product_registration.aspx to ensure

that you are constantly informed of important software updates. This is the only means by which we

can automatically keep you aware of new updates by

e-mail.

Safety notices

7

Page 8

Safety notices and handling regulations for Lithium-Ion

(LiIo) and Lithium-Polymer (LiPo) batteries

As applicable for all highly technical products, observance of the following safety notices and handling instructions is essential for a long service life, fault-free

operation, and harmless utilization of lithium/polymer

batteries.

These instructions are to be safeguarded. If the unit is

transferred to another user, these instructions should

certainly be passed along to the new user.

LiIo-/LiPo batteries require particularly attentive handling. This applies to charging, discharging as well

as for storage and other handling. Adherence to the

following special specifications is necessary:

Special notices for charging LiIo-/LiPo batteries

from Graupner

WARNING:

•

of improper charging or discharging.

• Only approved chargers with appropriate charging

cables may be used for charging LiIo-/LiPo batteries. Any manipulation to the charger or charger

cables can lead to severe damage.

• The maximum charging capacity must be limited

to 1.05 times the battery’s capacity.

Example: 700 mAh battery = 735 mAh max.

charging capacity

• Use only the outlet-charger included with the set

or a specially designed charger/discharger from

Graupner to charge and discharge LiIo-/LiPo batteries, refer to page 18 or www.graupner.de.

Since Graupner GmbH cannot supervise

the correct charging and discharging of

cells, the entire guarantee is void in cases

• Ensure the settings for the number of cells or for

final charging voltage and final discharge voltage are correct. Be sure to observe the operating

instructions for your charger/discharger.

• Under these conditions Graupner LiIo-/LiPo batteries can be charged with a maximum of 2 C (the

value 1 C corresponds to the cell capacity) charging current. At a voltage of maximum 4.2 V per cell

and above, charging must continue a constant

voltage of 4.2 V per cell until charging current

drops below 0.1 … 0.2 A.

• The permissible temperature range for charging

and storing LiIo-/LiPo batteries is 0 … +50 °C.

• Never leave batteries being charged unattended.

• The battery to be charged must be placed on a

non-combustible, heat resistant, non-conducting

surface during the charging process. Combustible

or readily ignited objects are to be kept away from

the charging configuration. Batteries may only be

charged under supervision.

• Avoid short circuit. Never pierce a LiIo/LiPo battery, by doing it you may cause a short circuit and

a fire, explosion and other problems.

• Charging voltage over 4.20 V per cell must be

avoided absolutely as the cell would otherwise be

permanently damage and could cause a fire. In order to prevent the over-charging of individual cells

in a pack, a cut-off voltage between 4.1 … 4.15 V

per cell should be set to increase service life.

• Incorrect handling can lead to explosions, fire,

smoke and poisoning hazards. Furthermore,

disregard for instructions and warnings can lead to

performance losses and other defects.

• Before every use check the state of your batteries.

Damaged or ruined batteries or cells should not

be used.

• LiIo/LiPo batteries contain electrolytes and electrolyte vapours which are unhealthy. Never enter in

touch directly with electrolytes. In case of contact

with eyes, skin or other parts of the body, wash

soon with a lot of water and call soon a doctor.

• The battery’s capacity is reduced by every charge/

discharge cycle. Storing the battery at temperatures which are too high or too low can also lead

to a gradual reduction in capacity. In model operation, battery capacity drops to about 50 … 80 %

of new battery capacity after about 50 charge/discharge cycles – even though all charge/discharge

rules are followed. This is due in part to the high

discharge currents and inductive currents caused

by motors.

• Never attempt to charge battery cells with the

wrong polarity. Abnormal chemical reactions

take place when batteries are charged with reversed polarity and the battery will be useless.

This can cause breaks, smoke and ames.

• Battery packs may only be connected in series or

parallel in exceptional cases as cell capacities and

charged state can differ too greatly. This is why the

battery packs we deliver are selected.

• LiIo-/LiPo batteries connected in series within

a pack may only be charged as a group if the

voltage of individual cells do not differ by

more than 0.05 V. The LiIo battery included

with the set is equipped with a special safety

circuit such that “compensation” for voltage

differences between individual cells, by way of

an otherwise typical balancer plug connection,

is not necessary.

• Individual battery cells and batteries are not toys

and must therefore not get into the hands of children. Batteries/cells must be kept out of the reach

of children.

Safety notices

8

Page 9

• Batteries must not get into the vicinity of babies or

small children. If a battery is swallowed, immediately go to a doctor or emergency medical facility.

• Batteries must not be put in a microwave oven or

put under pressure. Smoke, fire and more can be

the consequences.

• Never dismantle a LiIo-/LiPo battery. Dismantling

a battery can cause internal short-circuits. Gas,

fire, explosions and other problems can result.

• The electrolyte and electrolytic vapors in LiIo-/LiPo

batteries are harmful. Absolutely avoid all direct

contact with electrolytes. If electrolytes come into

contact with skin, eyes or other body parts, immediately wash out or rinse out with generous

amounts of fresh water then be sure to consult

a doctor.

• Batteries built into equipment must always be

removed from that equipment when it is not currently in use. Always switch off equipment after it is

used to prevent deep discharging. Always charge

batteries before it is too late. Store batteries on a

non-combustible, heat resistant, non-conducting

surface! Deep-discharged LiIo-/LiPo batteries are

defective and may no longer be used!

Storage

LiIo-/LiPo cells should have a 10 … 20 %

charge capacity when stored. If cell voltage

drops below 3 V, then LiIo-/LiPo cells must

absolutely be recharged to a capacity of 10 … 20 %

of full capacity. Otherwise, further deep-discharging of

the battery will make it useless during storage in a

discharged state.

Special notices for discharging LiIo-/LiPo

batteries from Graupner

•

currents, please follow the catalog specifications.

A continuous current rate of about 1 C

does not represent a major problem for

Graupner LiIo-/LiPo batteries. For larger

In any case, observe the maximum current rating

for the connector system, see maximum discharge

current on the battery.

• Discharging below 2.5 V per cell damages cells

permanently and is therefore to be avoided absolutely.

Short circuit conditions are to be avoided

absolutely. Permanent short circuits lead to

destruction of the battery, high temperatures and

perhaps even self-ignition may follow.

• During discharge, battery temperature must not

rise, in any case, to over +70 °C. Otherwise, better

cooling or a lower rate of discharge must be introduced. The temperature can easily be checked

with the infrared thermometer, No. 1963. The battery must never be discharged via the transmitter’s

charging socket. This socket is not suitable for this

purpose.

Other handling notices

•

loss of electrolyte, the production of gases and

perhaps even explosions. In the vicinity of, or while

handling, Graupner LiIo-/LiPo batteries, avoid

electrically conducting surfaces because of the

danger of creating a short-circuit condition.

• Battery packs may only be connected in series or

parallel in exceptional cases as cell capacities and

charged state can differ too greatly. This is why the

battery packs we deliver are selected.

Handling connectors

•

can easily be broken off. Due to thermal transfer,

the connector tabs may not be soldered directly.

• The connections of LiLo / LiPo batteries are not

Never short-circuit the battery. A shortcircuit allows very high current to flow and

this heats up the cells. This will lead to

These connectors are not as robust as for

other batteries. This applies particularly to

the plus pole connector. The connections

as robust as those of other batteries. This applies

in particular to the positive pole connection. The

connections can easily break off.

Cell connection

Direct soldering on battery cells is not

permitted.

The heat of direct soldering can damage

battery components, such as separator or isolator.

Battery connections should only be made by

industrial spot welding. A professional repair made

by the manufacturer or distributor is necessary to

replace missing or torn-off cables.

Replacing individual battery cells

The replacement of battery cells may only be

made by the manufacturer or distributor and

never by the user himself.

Damaged cell usage

Damaged cells may never be used or

returned to service.

Characteristics of damaged cells include:

damaged housing packing, deformed battery cells,

electrolyte or leaking electrolyte. In these cases,

further use of the battery is not permissible.

Damaged or useless cells are hazardous waste items

and must be appropriately disposed.

General warning notices

Batteries must never be put in fire or burned.

Battery cells must not be submerged in liq-

uids, such as water, seawater or beverages.

Any contact with liquids, of whatever nature, is to be

avoided.

Safety notices

9

Page 10

Notes for environmental protection

Notice for remote control set mc- 3 2 HoTT

No. 33016 / 33020

These radio control sets are fi tted as standard with a LiIo transmitter battery with integral

protective circuit (changes reserved). Once

the factory preset voltage limit of 3.60 V has been

reached, a warning will appear in the display.

Disposal of used batteries

Some countries have laws requiring that all

used batteries be turned over to an author-

ized collection centre.

Disposing of batteries along with common household

garbage is forbidden. Old batteries can be turned into

communal collection centres for disposal at no charge

or they can be returned to one of our dealerships or

anywhere else where batteries of that given type are

sold. Used batteries we have delivered can also be

sent back to us, at your cost, through the mail. Use

the return address below:

Graupner GmbH

Service: Used batteries

Henriettenstr. 94-96

D-73230 Kirchheim unter Teck

This represents an essential contribution to environ-

mental protection.

Environmental protection notices

The symbol on this product, its operating

instructions or packaging gives notice that

this product may not be discarded as common household waste at the end of its service life. It

must be turned over to a recycling collection point for

electric and electronic apparatus.

The materials can be recycled according to their

markings. You make an important contribution to

protection of the environment by utilizing facilities for

reuse, material recycling or other means of exploiting

obsolete equipment.

Batteries must be removed from the

unit and disposed of separately at an

appropriate collection point.

Please inquire with local authorities

about the responsible waste collection

locations.

Caution:

Damaged batteries require among

other things, special packaging,

because they are very toxic!

Foreword

10

This manual serves only as a source of infor-

mation and can be changed without prior noti-

fi cation. Graupner accepts no responsibility or

liability for errors or inaccuracies which may be contained in the information section of this manual.

Page 11

11Remote control set description

Page 12

mc-16 and mc-20

The Newest Generation of Remote Control Technology

The technical advances across the entire spectrum of

model building is an ever-present challenge to design

engineers. This is why the introduction of new transmission technology in the 2.4 GHz band represents a

new milestone.

The HoTT-System (Hopping Telemetry Transmission)

developed by Graupner is a synthesis of know-how,

engineering and testing done around the world by

professional pilots.

Established Graupner HoTT techniques theoretically permit over 200 models to be operated at the

same time. However, because of the interspersed

radio-frequency utilization permitted by certifi cation

for the 2.4 GHz ISM band, this number is signifi cantly

lower in practical application. Nevertheless, in general

more models can be operated simultaneously in the

2.4 GHz band than would be the case in conventional

35 or 40 MHz frequency bands. The real limiting factor is – as often before – is still likely to be the size of

available operating space (i. e. airspace for aircraft).

Alone the fact that it is no longer necessary to coordinate transmitting frequencies with other pilots in the

vicinity (which is sometimes quite diffi cult in broken

landscapes, such as on hillside slopes) represents an

enormous boost for remote control operating security.

Bidirectional communication between transmitter

and receiver, by way of a return channel built into

the receiver, permits convenient access to data and

programming in the HoTT receiver. For example, this

makes it possible to swap receiver outputs or to divide

up control functions among multiple servos (channel

mapping). Servo travel and servo rotation directions

in the receiver can also be matched to one another

with these facilities. Telemetry data, like VARIO and

GPS data, can be called up from optionally available

modules.

Based on the mc-24 Graupner/JR computerized

remote control system, the

control system has been especially developed for ex-

mc- 3 2 HoTT remote

perienced RC pilots All conventional model types can

be readily operated with the

regardless of whether the model is a winged aircraft,

helicopter, ship or land vehicle.

Complex mixed-control functions of guiding surfaces

are often necessary for winged aircraft (rudder, elevators) and helicopter models (swashplate). Thanks to

modern computer technology, very diverse model

requirements can be programmed in the simplest

conceivable manner with touch-sensitive keys (CAP

Touch). Simply select the given model type from the

mc- 3 2 HoTT system,

mc- 3 2 HoTT program and its software will assem-

ble all signifi cant mixer functions and coupling functions automatically. This eliminates the need for separate modules in the transmitter to implement complex

coupled functions and also makes sophisticated

mechanical mixer mechanisms in the model unnecessary. For example, this makes the mc-3 2 HoTT

transmitter fully equipped with both software and

hardware to operate the well-known NAUTIC modules

on the receiver side. The “channel sequencer” is new.

It permits the operation of up to three servos to be

automated.

mc- 3 2 HoTT system offers optimal security

The

and reliability without having to forgo great operating

convenience. The m c-32 HoTT remote control system has 80 model memory locations. Additional fl ightphase-specifi c settings can be stored in every model

memory location. For example, such settings can be

made for various parameters that can be called up to

implement particular fl ight maneuvers at the “press of

a button”. Additional model memories can be stored

on the SD card, which is included standard with the

set. Even telemetry data can be recorded for subsequent evaluation on a PC.

Since the

plays, the lower display has been optimized for comprehensible, simple operation of the software. The

graphic representation of mixer functions is particu-

mc- 3 2 HoTT is equipped with two dis-

larly helpful. The upper display allows telemetry data

to be called up from the receiver.

Functionally-related options are clearly arranged by

content in a simple organization. The clear, comprehensible program structure permits a beginner to

quickly become familiar with the various functions and

able to use all options pertinent to his level of expertise with remote control models.

This handbook describes every menu in detail. There

are tips, many notices and programming examples to

supplement the descriptions and also explanations for

model specifi c technical terms, like transmitter control, dual rate, butterfl y, and so on.

Please observe the safety notices and technical

notices. Read through the instructions attentively.

Before usage, test all functions by simply attaching

servos to the receiver included in the set. While doing

this, observe respective notes on page 68. This will

help you learn the essential operating techniques and

functions of the

Always handle your remote controlled model with a

sense of responsibility so that you do not endanger

yourself or others.

The Graupner team wishes you much pleasure and

success with your

eration of remote control systems.

mc- 3 2 HoTT.

mc- 3 2 HoTT, the newest gen-

Kirchheim-Teck, july 2015

Remote control set description

12

Page 13

mc-16 and mc-20 series computer systems

two remote control sets with 2,4-GHz-Graupner-HoTT technology

(Hopping Telemetry Transmission)

• Integrated Graupner HoTT 2.4 GHz transmission

system

• The high-speed primary processor is used for data

transfer, ensuring ultra-fast response times. No

additional delays through detours via a module

processor.

• Maximum interference immunity made possible by

optimized frequency hopping through as many as

75 channels and wider channel spread

• Intelligent data transfer with correction function

• Over 200 systems can be used simultaneously

• The HoTT technique of bidirectional communication between sender and receiver, as well as the

fastest possible transmission rate (10 ms) assures

extremely short reaction times.

• Modulation can be switched by software: when

necessary, you can switch from “HoTT” to “EXT.” or

“SP.” by pressing a button.

• Case incorporates integral patch aerial

• Transmitter features integral slot for SD and SDHC

memory cards, formatted to FAT or FAT32, for

saving log fi les, model programming data and supplementary functions such as transmitter fi rmware

updates.

• Transmitter features alternative method of battery

charging via the USB socket.

• 6 different languages (Dutch, English, French,

Technology that enthralls.

The superior functional security of Graupner

HoTT technology accomplished with bidirectional

communications between transmitter and receiver with integrated telemetry, freely programmable

voice output via headset connector, and ultra-fast

response times.

Simpli ed programming using capacitive touch-

buttons on the

buttons on the mc-16 HoTT.

mc- 2 0 HoTT and four-way push-

High-contrast eight-line graphic screen provides

a clear display of all set-up parameters. Switchable blue backlighting. The

tures an independent second screen for displaying telemetry data. Storage of telemetry data on a

micro SD memory card.

USB connection to read and write the model’s

memories as well as for making rmware up-

dates.

mc- 2 0 HoTT fea-

German, Italian and Spanish) available per software update.

• Simplifi ed arrangement of operating elements,

such as joysticks, external switches, proportional

controls and trim levers as control functions

• CONVENIENCE MODE SELECTOR to simplify

changeovers between operating modes 1 … 4

(e. g. throttle left/throttle right)

• Extremely wide receiver operating voltage range

of 3.6 V to 8.4 V (functional to 2.5 V)

Remote control set description

13

Page 14

Computer System mc-32

32 channel remote control set in 2.4 GHz Graupner-HoTT technology

(Hopping Telemetry Transmission)

• As many as four servos can be controlled simultaneously as a block in the SAME operating mode

with a servo cycle time of 10 ms (digital servos

only).

• Thanks to cycle time reduced down to as little as

10 ms, extremely short response times are achieved.

• Real-time telemetry evaluation in the transmitter

display Additionally, telemetry data can also be

selectively displayed by the SMART-BOX.

Additional HoTT features of the

• Super-fast response time through use of a fast

main processor for data transmission.

• Micro-SD card for storage of telemetry data and

for additional functions

• Obsolescence-proof through update capability over

USB interface as well as via the micro-SD card

• The included Lilo battery (changes reserved) has

a capacity of over 6000 mAh. This makes extremely long fl ight times possible and also reduces the

number of charging repetitions.

• Modulation changeover per software: e. g. from

"EXT. PPM" (e. g. Weatronic) to HoTT at the press

of a button.

• Swashplate limiting: This function limits the

swashplate's tilt angle to prevent the potential for

mechanical collision in helicopter 3D operation at

full-limit roll and pitch-axis

• Ring-limiter: functions similar to swashplate limitation but is used for control of up to three VoithSchneider drives in ship models

• Channel sequencer for automating servo motion

sequences of up to three servos, e. g. to automate

the lowering of landing gear or to extend/retract

drives in self-launching gliders

• Multi-channel function for operating Graupner

product line NAUTIC modules

• Digital trimming with pseudo »analog« endless

pinions, effective per specifi c fl ight-phase

Remote control set description

14

mc- 3 2

• Auto-trim function. The current stick positions

for trimming fi xed-wing or helicopter models will

be stored in trim memory at the press of a button. (Model »compensation«, activate switch and

release stick. The correction will be blended in

»gently« upon return of the stick.

• C1 changeover, brake/elec. motor: This changeover

can be implemented very easily via enhanced fl ight

phase programming. The pilot determines the stick

positions (forward/rear) at which the motor is to

switched off or the airbrakes are to be retracted.

• 16 control functions maximum

• Simplifi ed arrangement of operating elements,

such as sticks, external switches, proportional

controls and trim levers as control functions

• Protection against obsolescence is provided by

virtue of a fast 32-bit operating system with modern fl ash memory that can be updated.

• Blue back-lighted MULTI-DATA-GRAPHIK-LCD

monitor with signifi cantly better legibility under

unfavorable light conditions

• CONVENIENCE MODE SELECTOR to simplify

changeovers between operating modes 1 … 4

(e. g. throttle left/throttle right)

• Twelve freely programmable mixers for fi xed-wing

or helicopter models, each with freely selectable

input and output functions; four curve mixers with

innovative 8-point curve technology for easy to set

and adjust curve values at up to eight points for

throttle, pitch, tail or other non-linear characteristics. The arithmetic unit in the CPU employs an

ingenious method of calculating polynomial approximations for truly-rounded, ideal MPC (multipoint curve) mixer curves

• Shifting curve mixer points can be done along

both axes with the CAP touch pad keys

• Eight fl ight-phase programs can be individually

adapted for each model and given a name. The

switchover time is programmable separately.

• SUPER SERVO menu with a perfect overview of

all servo setting data and simple parameter correction at four "levels": direction of rotation, midpoint setting, separate servo travel on both sides

and separate travel limiting on both sides for 16

servos with a total of 96 setting options

• SUPER-DUAL-RATE, EXPO and EXPO/DUALRATE menu with 36 potential setting variants for

three servo functions and six fl ight phases

• Practice-optimized multi-function menu for aerofoils and helicopter models. Entry of the number

of aileron and fl ap servos automatically programs

all necessary mixer functions in the multi-function

"Wing mixers" menu. Differential aileron mixer,

butterfl y mixer, dual-fl ap mixer, automatic gyro set

function and other special functions

• Helicopter swashplate mixer for 1, 2, 3, or 4 point

steering.

• Selectable cycle time: 10 ms or 20 ms/30 ms,

depending on receiver and operating mode

• A convenient timers menu with a system of eight

stopwatches, alarm timer, countdown timer, laps

counter and so on. Two running timers and one lap

timer can be displayed at the same time in large

characters.

• Stopwatch with history: In addition to the lap counter there is a "Time 1" which captures the switchon time and a "Time 2" which records the ON and

OFF times separately

• Channel mapping in the receiver allows free distribution of control functions.

• The travel distance and rotation direction settings

integrated into the receiver make it possible, for

example, to match up mapped servos with one

another

• The programmable fail-safe functions »Hold«,

»Off« and »Move to preset positions« that are built

Page 15

into the receiver for every individual servo channel

can be set separately

• A slot for FAT or FAT32 formatted SD and SDHC

memory cards is available on the transmitter for

log files and model programs

Model programs

• Transmitter operating time timer

• Flight phase switch assignments: six switches, two

with a priority function. Every switch combination

can be named freely. This makes the number of

flight phases independent of the number of flight

phase switches.

• Tail type normal, V-tail, Delta/flying-wing and 2 HR

Sv 3+8 (which immediately makes two coupled

elevator servos available without using free mixers

or dual mixers)

• Flap count 4 AIL/4 FL: Full support of eight wing

servos, even without use of free mixers

• Flight phase switching cutoff delay:

the delay time can be switched off for individual

channels on a flight-phase basis (e. g. for motor

off in electric models or to activate/deactivate

helicopter head lock).

Ten additional, user definable phase names: aside

from the prescribed flight phase names, the user

can also freely assign up to ten phase names of

his own choice.

• Enhanced transmitter control menu: option to assign input-side mid-point setting for C1 control +

trim as a transmitter control. A single input can be

assigned to two switches for a true 3-way switch

function.

• Wing mixers: New concept for the multi-flap menu

to simplify settings of one to eight wing servos on

a flight-phase specific basis in a comprehensible

manner without requiring the use of free mixers

• »Info« sub-option in the Base setup model menu

Any kind of additional information about every

model can be entered here. This additional information will then appear in the newly designed

model select function

• »Logical switches«: this function permits two

switches to be coupled as »and« or »or« logic

functions. The result can be employed as a virtual

switch. Typical application: The activation of certain

functions should only be possible in conjunction

with other functions, e. g. wheel brake can only be

activated when the landing gear is down. A number of functions which are normally independent

of one another, are to be put in their base settings

by way of an »Emergency switch«. This program

automation can be activated by multiple switches

that also select the appropriate program.

• Servo-middle setting range extended to ±125 %

• Number of flight phases: (fixed-wing: 8, helicopter:

7 + AR)

• Settable »Throttle too high« warning threshold

in the helicopter menu, programmable switch-on

warning

• Phase trim for all axes of fixed-wing models possible

• Servo occupancy swap on the receiver output

• CAP TOUCH operating elements with key lock

function to prevent unintentional operation.

• CAP TOUCH display change from the main menu

to the telemetry main menu via ESC.

• Numerous telemetry displays, programming functions and evaluation functions are presented

directly in the transmitter's screen

• Graphic presentation of model icons for the model

type display (fixed-wing/helicopter)

• Built-in connector sockets for PC-USB interface,

headset, SMART BOX, external RF module,

DSC system. Prepared for teacher/pupil operation.

• Teacher/pupil system with or without cable for

complete transfer; all settings are made on the

teacher transmitter.

Additional functions

• Super Fast response time by using the fast main

processor for data transmission

• Binding of any number of receivers for channel

expansion

• Range: test and warning function

• Low voltage warning

• Selectable cycle time 10ms or 20ms / 30ms,

depending on the receiver and connected thereto

servo and transmitter-side mode

• Up to four servos in the SAME mode blocks with

a signal repetition time of 10 ms are driven simultaneously (only digital servos!)

• The reduced cycle time of up to 10ms an extremely short reaction time is achieved.

• Telemetry analysis in the transmitter display in

real time. In addition, the telemetry data can be

displayed either with the SMART-BOX.

• Numerous Telemetry displays, programming and

evaluation functions directly in the transmitter

display

• Software switchable modulation: If necessary,

deactivate by pressing a button of HoTT to “EXT.

PPM“ or ”SP Mode“.

• Using Channel mapping in the receiver arbitrarily

divisible control functions.

• Select integrated rotational direction setting for

example mapped servos receiver successive

• In the receiver, programmable fail-safe “Hold”

function, “Off” or “pre-set positions” for each individual servo channel can be set separately

• Future-proof design with update fast 32-bit operating system with modern Flash memory

Remote control set description

15

Page 16

Computer System mc-32

32 channel remote control set in 2.4 GHz Graupner-HoTT technology

(Hopping Telemetry Transmission)

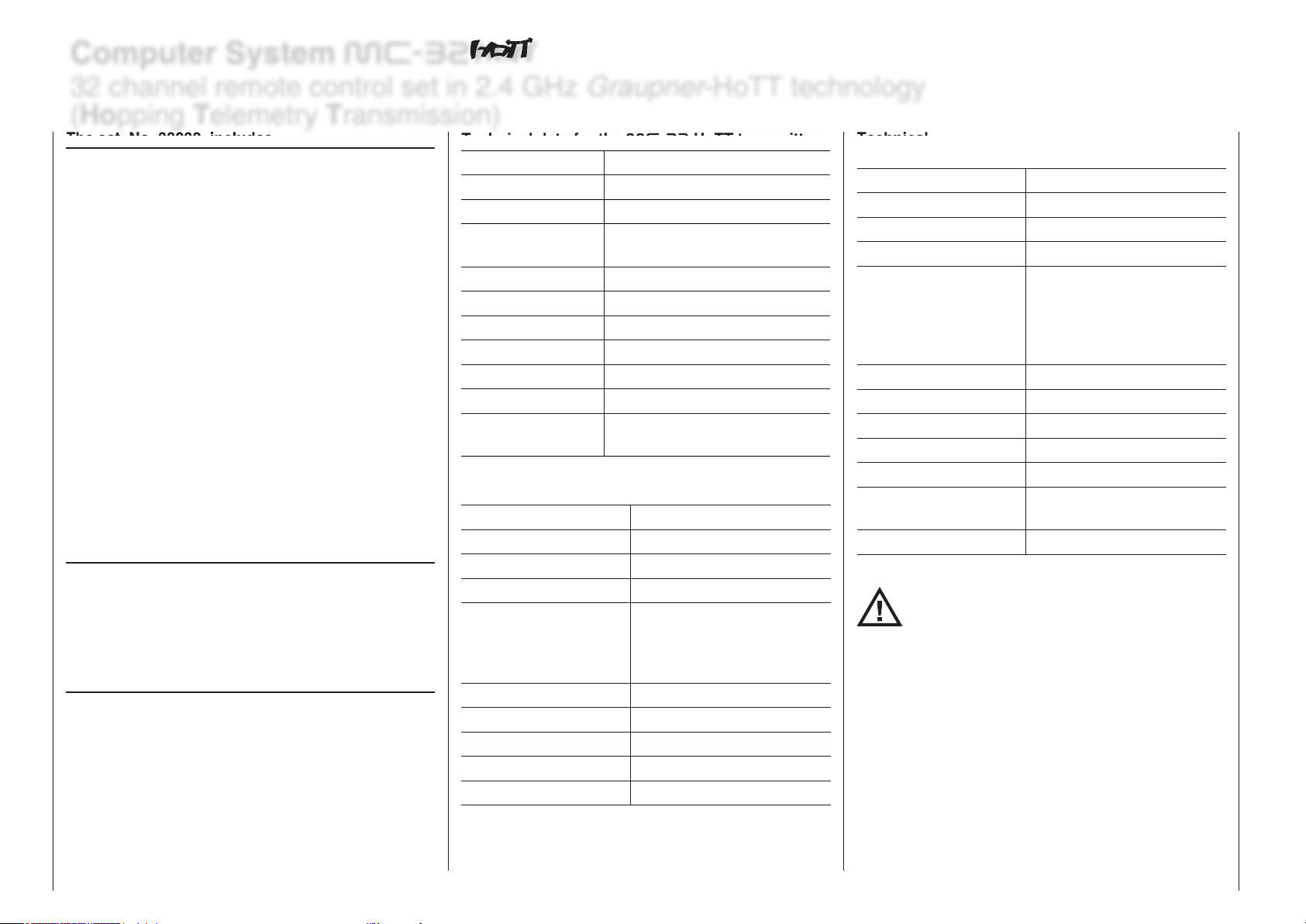

The set, No. 33032, includes

• Microcomputer transmitter

built-in LiIo single cell six-pack/6000 mAh/3.7 V

transmitter battery (change reserved)

• Graupner HoTT 2,4 GHz FHSS module

• integrated Bluetooth ® v2.1+ EDR module

• Electric outlet charger (4.2 V, 500 mA)

• Graupner bidirectional receiver, GR-12L HoTT

(No. S1012) for connection of up to 6 servos and

GR-32 Dual HoTT (No. 33516) for connection of

up to 16 servos

• USB adapter/interface (No. 7186.6) including

suitable USB cable for connection to a PC and an

adapter cable for receiver updates

• Micro-SD card with an adapter for a card reader

• Sturdy aluminum transmitter case with foam cushioning (No. 3080)

• Graupner HoTT transmitter strap

Accessories

No.

Description

72.40 Transmitter straps, deluxe

Teacher/pupil cable for

see page 213

Replacement parts

No.

Description

71.26 Transmitter straps, Graupner HoTT

3080 Aluminum transmitter case, HoTT,

400x300x150 mm

33000.1 Transmitter battery, fl at LiIo, single cell six-

pack/6000 3.7 V TX

33002.1

33032.2 Transmitter metal hanger for mc- 3 2

33032.3 Hand rests for mc-32 (2 pieces)

33801 HoTT transmitter antenna

16

Micro-SD card, 2 GB for HoTT transmitter

Remote control set description

mc- 3 2 HoTT with

mc- 3 2 HoTT

Technical data for the

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Transmitter power 100 mW EIRP

Control functions 16 functions, 4 of these can be

Temperature range -10 … +55 °C

Antenna collapsible

Operating voltage 3.2 … 4.8 V

Current draw about 500 mA

Range up to about 4 000 m

Dimensions about 252 x 252 x 60 mm

Weight about 1,685 g with transmitter

Technical data for the GR-12L HoTT receiver

No. S1012

Operating voltage 3.6 … 8.4 V*

Current draw about 70 mA

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Antenna 1 x about 145 mm long,

Plug-in servos 6

Plug-in sensors 1 (port 5T)

Temperature range about -10 … +55 °C

Dimensions about 36 x 21 x 10 mm

Weight about 7 g

mc- 3 2 HoTT transmitter

trimmed

battery

about 115 mm of this

length encapsulated and

about 30 mm active

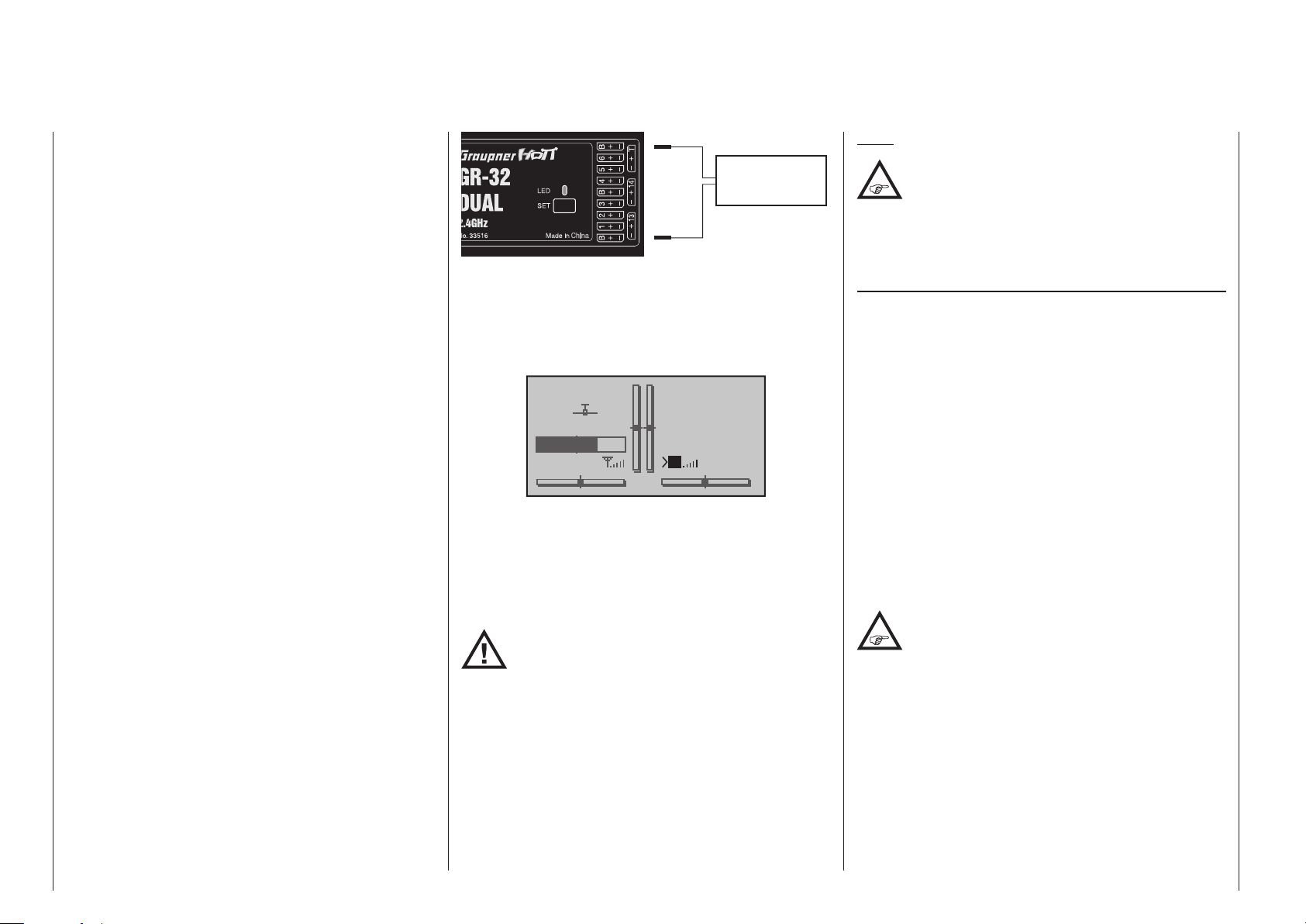

Technical data for the GR-32 Dual HoTT receiver

No. 33516

Operating voltage 3.6 … 8.4 V*

Current draw about 140 mA

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Antenna 2 x 2 diversity antennas,

Plug-in servos 16

Plug-in sensors up to four sensors

Temperature range about -10 … +55 °C

Range up to about 5 000 m

Dimensions about 63 x 30 x 14 mm

Antenna length 4 x wire 145 mm (active

Weight about 24 g

*

The speci cation for permissible operating voltage range

applies only to the receiver. Please note in this context

that receiver input voltage is applied without regulation to

connected servos but the voltage range for most connectible

servos (speed controls, gyros, etc.) is only 4.8 to 6 V.

Other accessories in Internet at www.graupner.de.

Contact or visit your local dealer. He will be glad to

provide advice.

about 145 mm long, about

115 mm of this length

encapsulated and about

30 mm active

antennae 30 mm)

Page 17

For your notes

17

Page 18

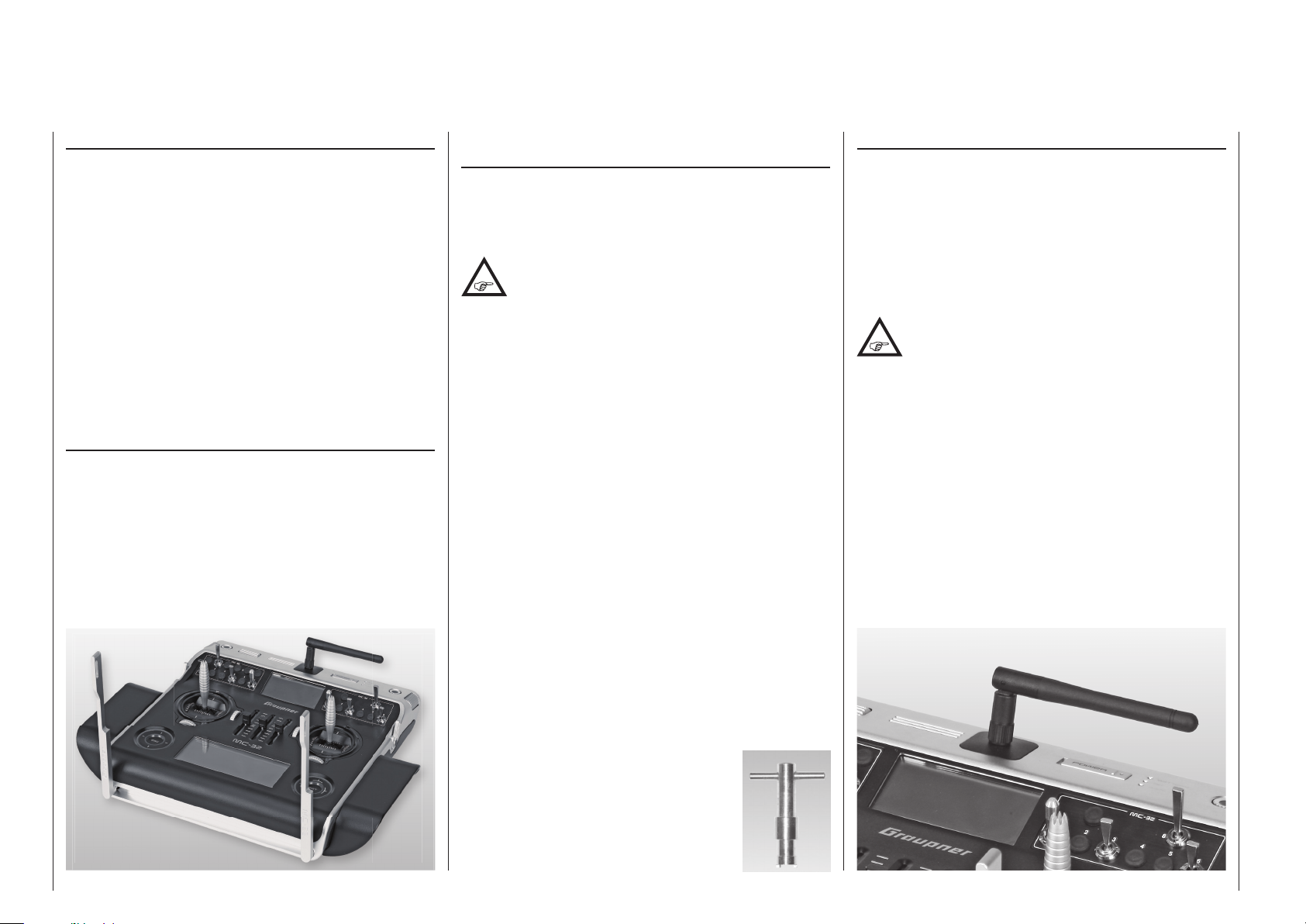

General operating notices

Transmitter

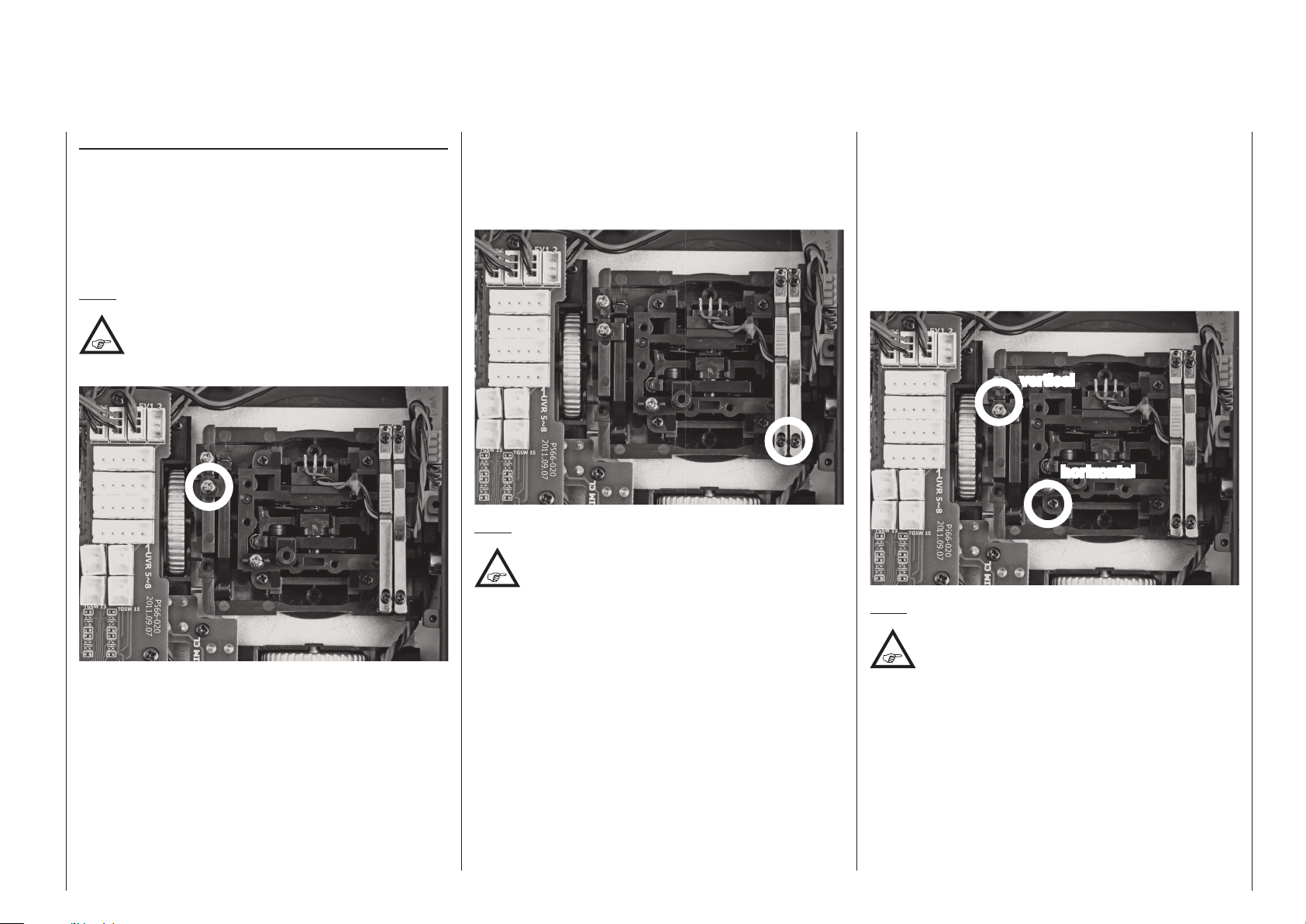

Opening the transmitter housing

Switch off the transmitter before opening it

(power switch to »OFF«). Push both housing

base latches in the opposite the direction of

the arrow marks, toward the inside, to their limits.

Now tilt the transmitter somewhat to the rear so the

housing base can fl ip open and can be unhooked.

Close the transmitter's housing base by fi rst hooking

it to the underside, fl ip the base closed then push

both latches toward the outside. When closing the

base, pay attention that no cables are pinched.

Notes:

•

• Be sure not to touch the circuit boards

with any metallic objects. Do not touch

contacts with your fi ngers.

• Before performing any tasks inside the

transmitter, disconnect the transmitter's

battery (see next page) to avoid potential

short circuit damage to the transmitter's

circuit boards.

Make no modifi cations of any kind

to the circuit boards as this will

void the guarantee as well as the

unit's offi cial permit.

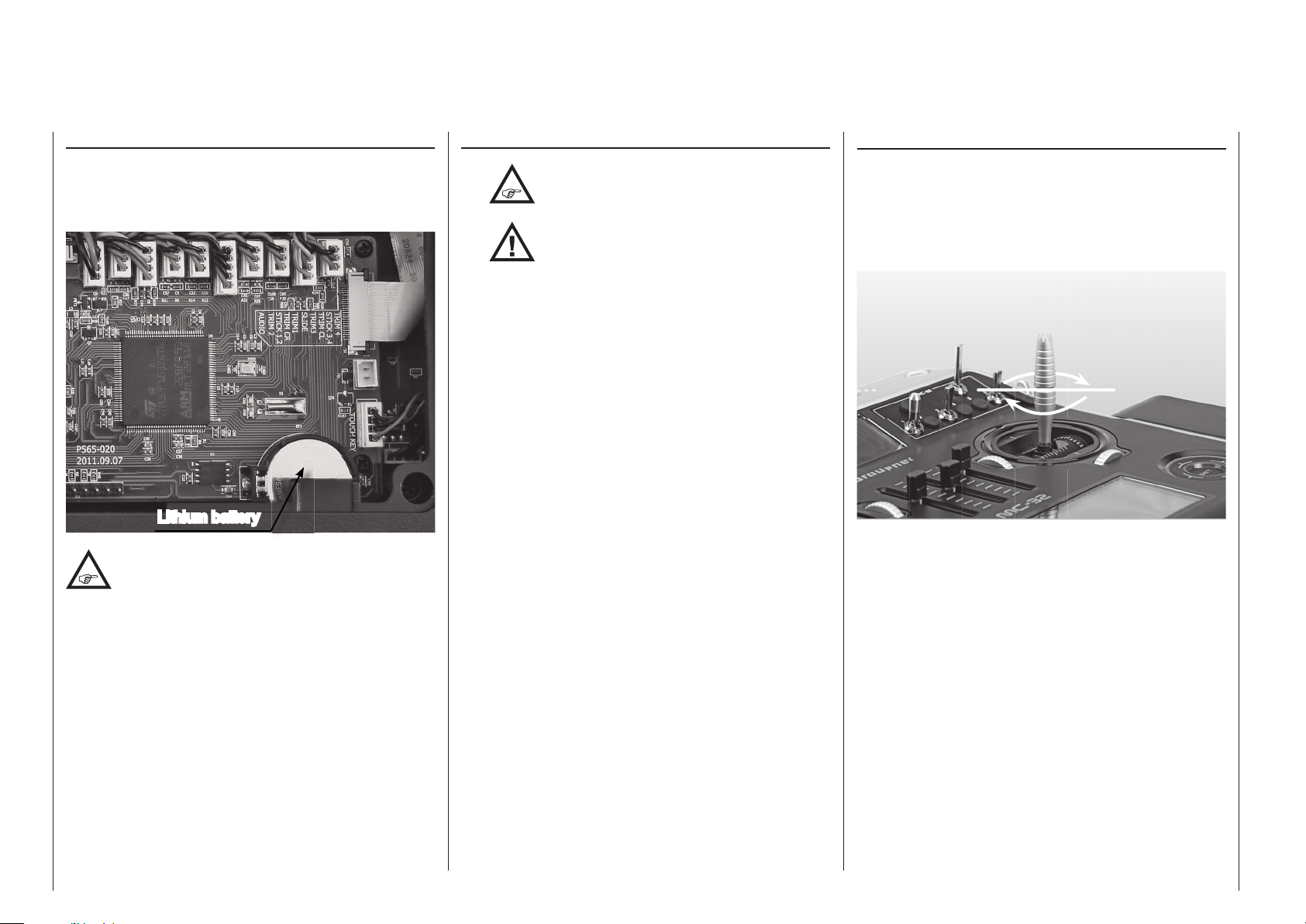

Transmitter power supply

The

mc- 3 2 HoTT transmitter is equipped with a

high-capacity, rechargeable LiIo 1s6p/6000 3.7 V

TX battery (No. 33000.1) as standard equipment.

(changes reserved)

However, the standard built-in battery is

not charged upon delivery of the transmitter.

When the transmitter is used, its battery voltage should

be monitored by way of the indicators provided in the

LCD display. If the voltage level preset in the "Battery

warning" line of the »General basic settings« menu,

page 279, (default setting 3.60 V) is underrun, an

acoustic signal will be sounded and a warning message will appear in the display.

Stoppuhr

Batt must

0

be re-

Flugzeit

charged!!

K78

V

M

#01

0:00h

0:00h

3.5V

0

No later than now, operation must be terminated so

the battery can be charged again.

Note:

Be sure the correct battery type is set in the

»General basic settings« menu, page

260! The standard setting for this is

"Lith.".

0:00.0

0:00.0

00

Charge the transmitter battery with the plug-in

charger.

The transmitter's rechargeable LiIo battery can be

charged by way of the charger socket located behind

a cover on the left, front side of the transmitter – as

viewed from the front – with the included plug-in

charger (No. 32032.4).

Depending on the state of discharge, the included

plug-in charger (4.2 V/500 mA) requires up to about

15 hours to fully recharge the transmitter battery.

Never use plug-in chargers from other manufacturers or chargers intended for other bat-

tery types. Charger output voltage which is

too high or possibly even different plug polarity, see

further below, can cause immense damage. We

recommend that this plug-in charger be appropriately

labelled.

Also observe the safety notices provided on pages

4 … 7.

The transmitter must be switched "OFF"

during the entire charging procedure. Never

switch on the transmitter when it is connected

to the charger. Even a brief interruption to charging

can cause charging voltage to rise to a level that will

immediately damage the transmitter with over-voltage. Also for this reason, be sure all connectors are

always plugged in securely and have good contact.

General operating notices

18

Page 19

Charging with automatic chargers

To achieve quicker recharging of the single cell LiIo

battery, Graupner automatic chargers can also be

used. The table below shows a selection of these

chargers.

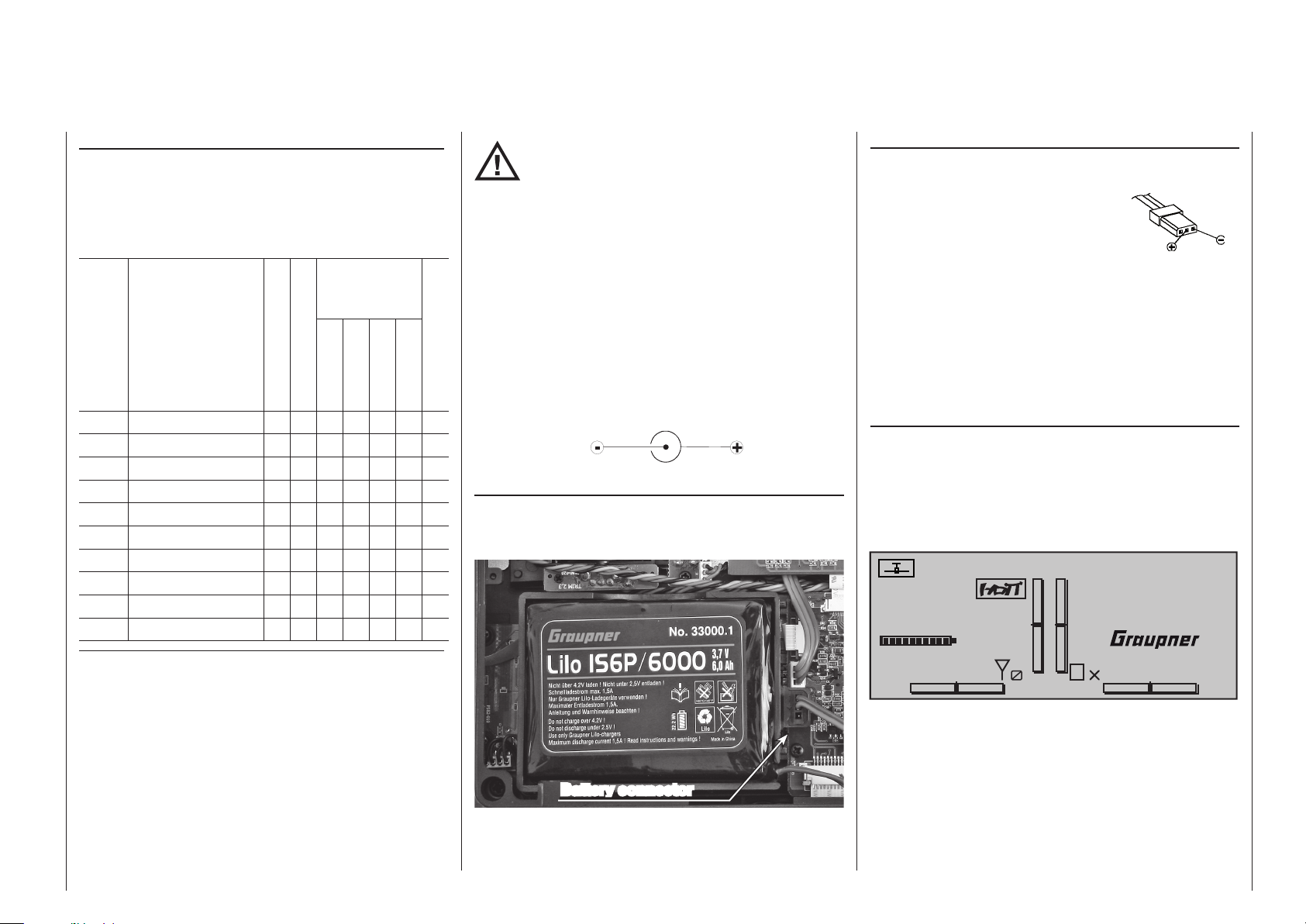

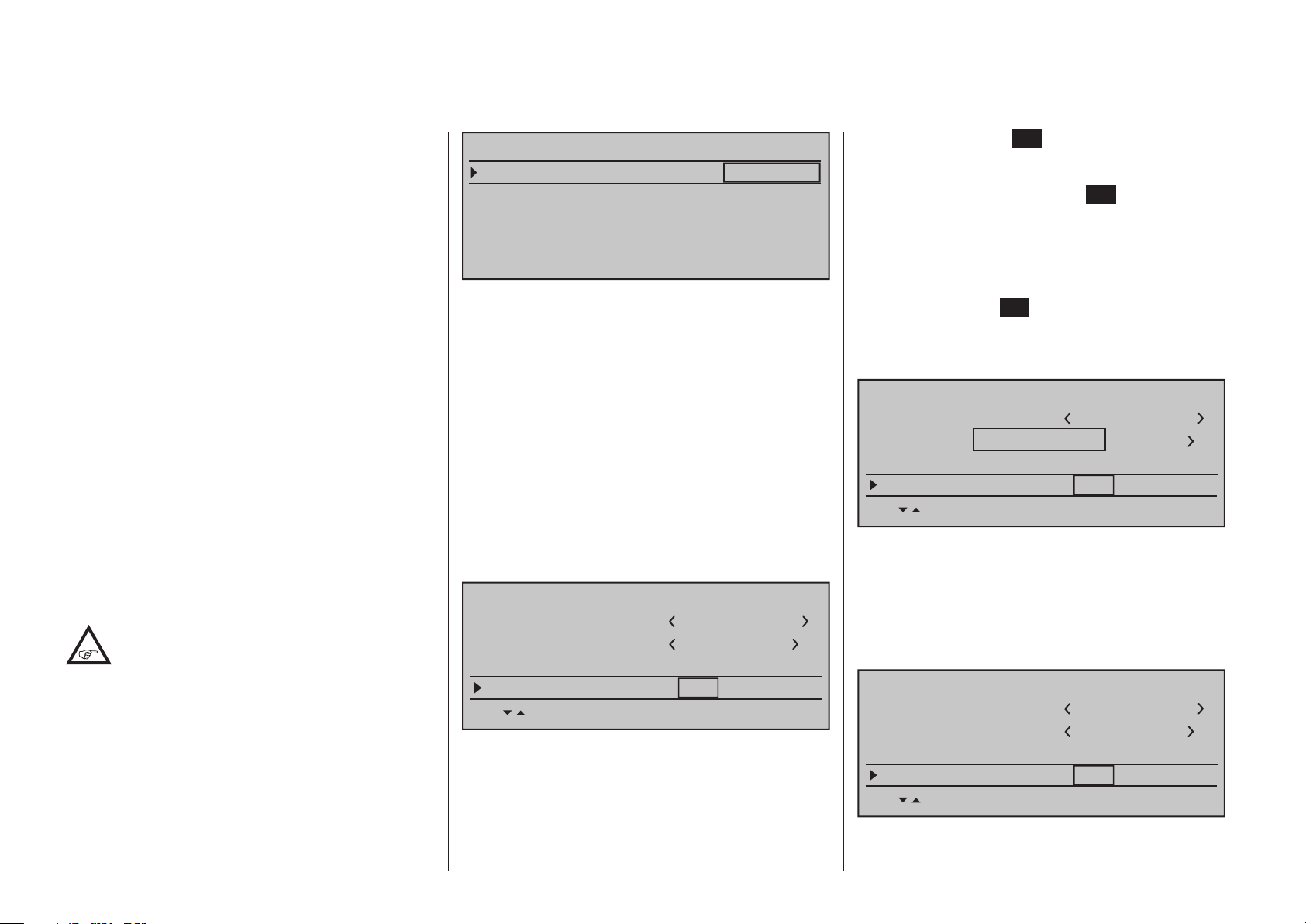

Recommended chargers (accessory)

suitable for

battery types

Order

No. Designation

6411

6463

6464

6466

6468

6469

6470

6475

6478

6480

Charger cable, No. 3022 is additionally needed for the transmitter

and charger cable, No. 3021 is additionally

needed for the receiver.

Other charger units and details about the listed chargers can

be found in the Graupner RC main catalog or in Internet at

www.graupner.de.

Ultramat 8 x x x x x

Ultramat 12 plus x x x x x x

Ultramat 14 plus x x x x x x x

Ultra Trio plus 14 x x x x x x x

Ultramat 16S x x x x x x x

Ultra Trio Plus 16 x x x x x x

Ultramat 18 x x x x x x x

Ultra Duo Plus 45 x x x x x x x

Ultra Duo Plus 60 x x x x x x x

Ultra Duo Plus 80 x x x x x x x

Input voltage 220 V

Input voltage 12 V

NiCd

NiMH

LiPo/LiIo

lead battery

The charger socket is equipped standard with a

diode to protect against reversed polarity. Original

Graupner automatic chargers also detect battery

voltage polarity.

Observe the confi guration notices for the charger

used.

First connect the charger cable's banana

plugs to the charger and only then con-

nect the cable's other end into the charging jack on the transmitter. Never allow the bare

ends of the banana plugs to come into contact

with one another when the other end of the cable

is plugged into the transmitter.

Charging current may not exceed 1.5 A as otherwise the diode, and perhaps other components,

could be damaged. If necessary, limit the current

at the charger.

mc- 3 2 HoTT charging jack polarity

The charger cables on the market from other manufacturers often have different polarities. Therefore use

integr. balancer

only an original Graupner charger cable, No. 3022.

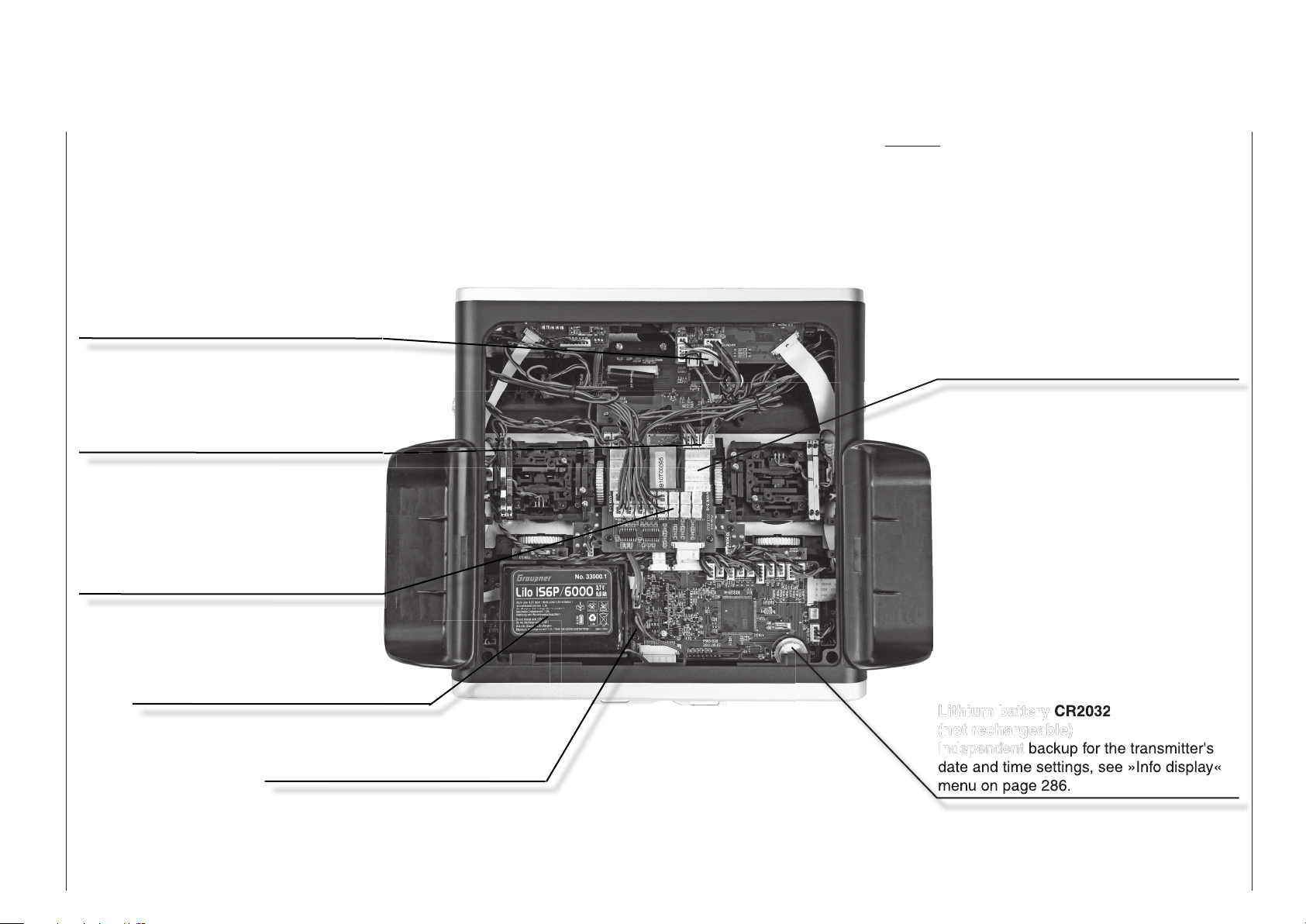

Removing the transmitter's battery

To remove the transmitter's battery, fi rst unlatch the

cover of the battery compartment on the rear side of

the transmitter housing then remove the cover.

Battery connector

Take out the transmitter's battery then disconnect the

transmitter battery's connector by carefully pulling on

the supply line cable.

Inserting the transmitter's battery

The battery connector is protected against a reverse

polarity connection by two slanted edges, see illustration. When correctly plugged in, the

unconnected pin of the connector

is at the bottom, as shown in the

illustration. The plus pole (red lead)

is in the middle and the minus pole

Transmitter

connector polarity

(brown or black lead) is toward the

antenna side.

Never try to force the connector

onto its circuit-board socket.

Place the battery into its compartment and close the

transmitter's cover.

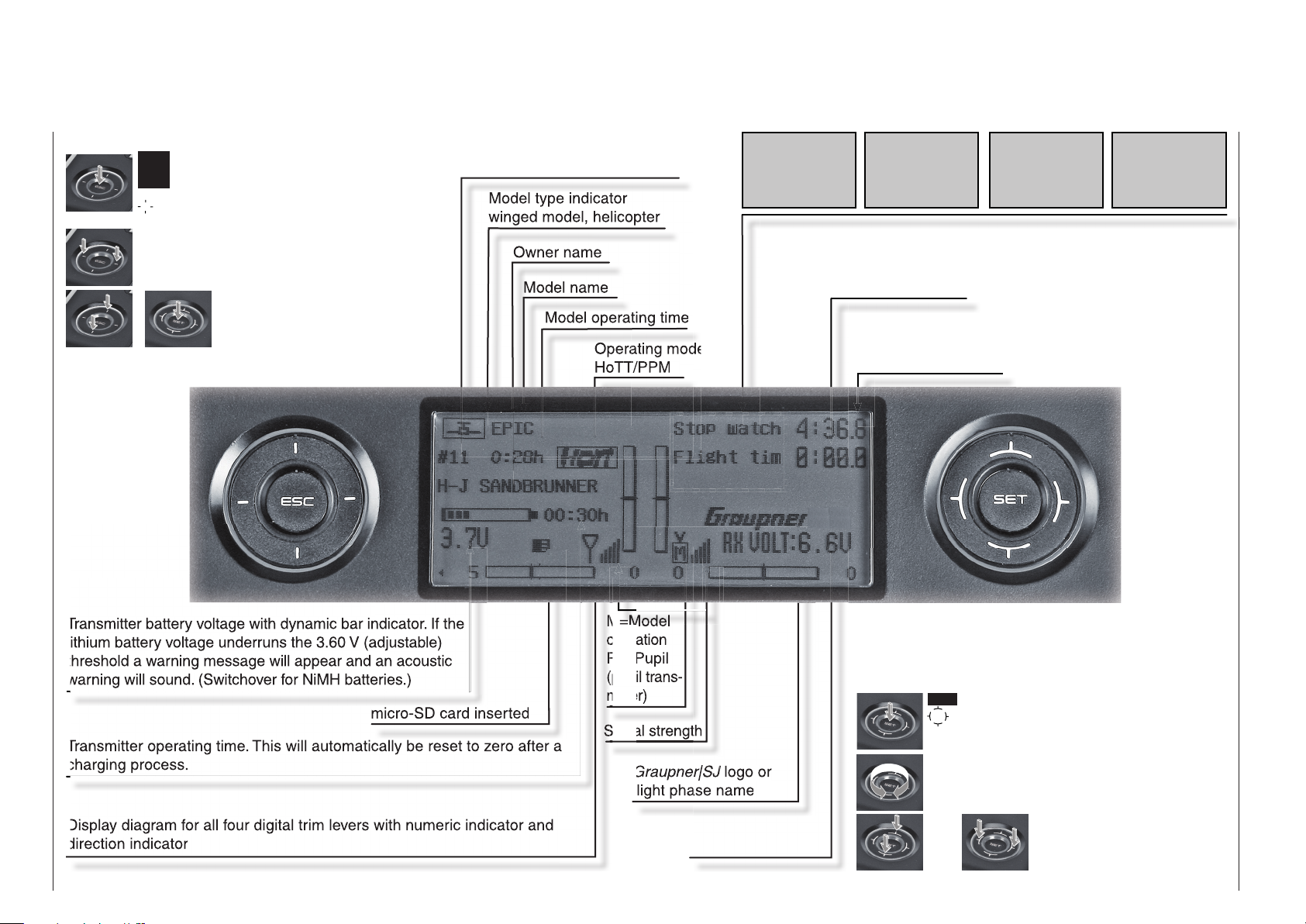

Battery operation timer at the bottom left of the screen

This timer shows the transmitter's cumulative operating

time since the transmitter's battery was last charged.

This timer is automatically reset to "0:00" when the

transmitter is switched on and its battery voltage is

signifi cantly higher than when the transmitter was last