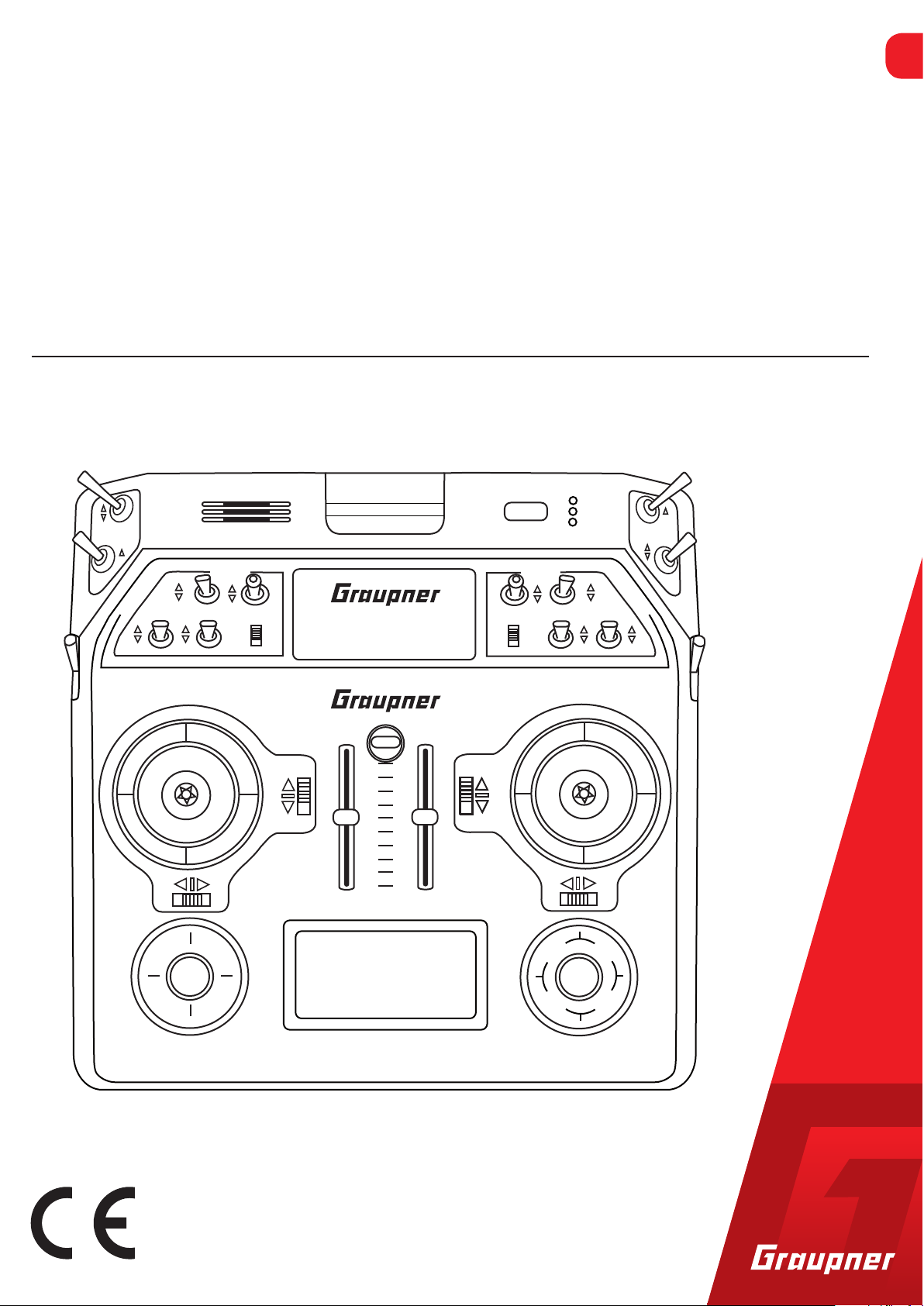

Page 1

Programming manual

mc-26 / mc-28 / mc-28 4D

16 channel HoTT 2,4 GHz transmitter

No. S1036 / 33028 / S1033

EN

esc

MC-28

MC-28

MC-28

MC-28

set

Part 2

Page 2

Page 3

Index

Introduction ............................................................................. 7

Service Centre ................................................................................7

Use and menu functions ......................................................... 8

Short-Cuts ......................................................................................8

Definition of terms .................................................................. 9

Receiver configuration .......................................................... 10

Fixed-wing models .......................................................................10

Helicopter models .......................................................................11

Vehicles, boats .............................................................................11

Copter ..........................................................................................12

Receiver power supply .................................................................12

Symbols explication .............................................................. 13

Menus description ................................................................ 13

Meaning of the warnings ...................................................... 13

Model selection ..................................................................... 14

Copy/Delete ........................................................................... 15

Export to SD card .........................................................................16

Import from SD ............................................................................16

Suppress menus .................................................................... 18

Suppress models ................................................................... 18

Model basic settings ............................................................. 18

Control mode ...............................................................................19

Binding type .................................................................................19

Module .........................................................................................20

Receiver binding ..........................................................................21

Receiver output ...........................................................................22

RF module ....................................................................................22

Range test ....................................................................................22

33028_mc_28_Teil2_jh

DSC port .......................................................................................23

Throttle Cut ..................................................................................23

Switch-on warning .......................................................................24

Auto trim ......................................................................................24

Timer auto reset ..........................................................................24

3 / 80

Page 4

Model type ............................................................................ 25

Motor on CH1 ..............................................................................26

Tail ................................................................................................26

Ailerons/Flaps ..............................................................................27

Brake offset ..................................................................................27

Servo adjustment .................................................................. 27

Sticks setting .......................................................................... 29

Controls setting ..................................................................... 29

Dual Rate / Expo .................................................................... 31

Throttle curve ........................................................................ 32

Switch display ........................................................................ 34

Control switch ........................................................................ 34

Logical switch......................................................................... 35

Announce ............................................................................... 35

Phase setting ......................................................................... 36

Motor ...........................................................................37

Phase assignation

.................................................................. 38

Phase trim .............................................................................. 38

Channels without delay ........................................................ 39

Timers (general) .................................................................... 39

Phase timer ............................................................................ 41

Wing Mix ................................................................................ 42

Programming of the wing type ....................................................43

Model type: "1AIL" ......................................................................43

Model type: "1AIL 1FLAP"............................................................43

Model type: "2AIL" ......................................................................44

Model types with "2/4AIL 1/2/4FLAP" ........................................45

Model type: "2AIL 1FLAP"............................................................45

Model type: "2AIL 2FLAP"............................................................45

4 / 80

Model type: "2AIL 4FLAP"............................................................46

Model type: "4AIL 2FLAP"............................................................46

Model type: "4AIL 4FLAP"............................................................47

Multiflaps menu ...........................................................................48

Brake setting ................................................................................50

AIL -> RUD (aileron -> rudder) .......................................................52

33028_mc_28_Teil2_jh

Page 5

FLAP -> ELE (flaps -> elevator) .......................................................52

Free mixers ............................................................................ 53

MIX act. / Phase .................................................................... 56

Only mix channel ................................................................... 56

Dual mixer .............................................................................. 57

Fail Safe .................................................................................. 57

Trainer .................................................................................... 58

Transmitter output ................................................................ 58

Profitrim ................................................................................. 59

Trim memory ......................................................................... 60

Telemetry ............................................................................... 60

Channel sequencer ................................................................ 61

Multichannel ......................................................................... 62

MP-3 Player ........................................................................... 64

Basic settings ......................................................................... 64

Loudspeaker (LS) Voice / Vario / Buttons ....................................64

Owner ..........................................................................................64

Control mode (preset) .................................................................65

Stick-type (only by mc-26) ...........................................................66

Module .........................................................................................66

DSC port .......................................................................................66

Pitch min ......................................................................................66

Contrast (upper/lower display) ....................................................66

Display light ..................................................................................66

Switch-on melody ........................................................................67

Battery alarm threshold ...............................................................67

Switch-on warning .......................................................................67

Touch sensitivity ...........................................................................67

DATA sel. .......................................................................................67

33028_mc_28_Teil2_jh

Ph. Name 1 … 10 ..........................................................................67

BT headset and following lines ....................................................67

Vibration ................................................................................ 68

Servo display .......................................................................... 68

Servo test ............................................................................... 68

Key lock .................................................................................. 68

5 / 80

Page 6

Info display ............................................................................ 69

Digital trim / Throttle switch-off trim (function) ................ 69

Heli programming .................................................................. 70

Throttle curve (Heli) .............................................................. 73

Sticks setting (Heli) ................................................................ 73

Control adjust (Heli) .............................................................. 73

Ring limit ................................................................................ 75

Firmware update ................................................................... 76

Update through memory card .....................................................76

Update through USB port ............................................................77

Problems during firmware update ..............................................77

Declaration of conformity ..................................................... 77

Notes on environmental protection..................................... 78

Care and maintenance .......................................................... 78

Warranty ................................................................................ 78

6 / 80

33028_mc_28_Teil2_jh

Page 7

Introduction

Service Centre

Thank you very much for purchasing the Graupner mc-28 HoTT.

The transmitter manual is composed by two parts. Part 1, the short

manual, is included in the packaging. Part 2, the programming manual, can be found in its last version on www.graupner.de by the

related page of the transmitter.

Read this manual carefully to achieve the best results with your

transmitter and first of all to safely control your models. If you experience any trouble during operation, take the instructions to help or

ask your dealer or Graupner Service Centre.

Due to technical changes, the information may be changed in this

manual without prior notice. Keep updated by regularly checking

our own website,

www.graupner.de to be always updated with

the products and firmware.

Graupner Central Service

Graupner/SJ GmbH

Henriettenstraße 96

D-73230 Kirchheim/Teck

Servicehotline

(+49) (0)7021/722-130

Monday - Thursday:

9:15 am - 4:00 pm

Friday:

9:15 am - 1:00 pm

service@graupner.de

Graupner USA

3941 Park Dr Suite 20-571

El Dorado Hills, CA 95762

Website: www.graupnerusa.com

Phone: +1 855-572-4746

Email:service@graupnerusa.com

Graupner in Internet For the service centers outside Germany please refer to our web site

www.graupner.de

33028_mc_28_Teil2_jh

7 / 80

Page 8

Use and menu functions

Short-Cuts

The following key combinations can be used to directly call up certain menus and options:

CLEAR

Brief simultaneous touch of the

keys or on the right touch pad

will restore the active entry fi eld's changed parameter value back to

its default value.

"Servo screen"

Brief simultaneous activation of the

keys of the left touch pad will

cause a jump from the transmitter's base screen or from almost any

menu position to the "Servo" menu.

"Telemetry" menu

Press the center ESC key in the left touch pad for about 1 s to call up

the "Telemetry" menu from the transmitter's base screen.

To come back to the base screen it is enough a "normal" touch on

the ESC key.

Graphic display of telemetry data

Briefly touching one of the selection keys

of the left or right touch

pad will cause a jump from the base screen directly to the transmitter's graphic display of telemetry data or will allow paging back and

forth between individual graphic displays.

Briefly touching the ESC or SET key will cause a return back to the

base screen.

"HIDDEN MODE"

Press and hold arrow keys

of the left touch pad then momentarily

touch the SET key of the right touch pad.

Key lock

Entry lockout is activated and deactivated from the base screen by

simultaneously pressing the ESC and SET keys for about two seconds.

The key lock function is displayed by a key symbol:

The controls remain operational.

Press the ESC and ENT buttons at the same time again for about two

second to release the lock.

Quick-Select

From the multi-function list, a jump can be made to a "Structure

overview" by a brief, simultaneous touch on the

or keys of the

right touch pad.

8 / 80

33028_mc_28_Teil2_jh

Page 9

Definition of terms

Control function

A control function is understood as the signal for a specific control

function. The signal of a control function can be transmitted directly

into one control channel or through a mixer to several control channels. The control function includes the influence of the mechanical

control path on the corresponding servo. This can be spread or concentrated and modified from linear to highly exponential.

Controls

As "control" are meant the function elements that the pilot can actuate directly in the transmitter. Through the controls the connected

servos, ESC etc. will be controlled by the receiver.

Control channel

If a signal contains all control information necessary for a particular

servo, whether directly from the control or indirectly via a mixer,

then the term control channel is used.

Mixer

The transmitter software contains a variety of mixing functions.

These allow a control function to influence several control channels

and several servos. It is also possible to let several control function

influence control channel (one servo).

Switch

The series of toggle switches can be included in the control programming. The switches are however generally also intended to switch

program options such as to start and stop the timers, turn mixers on

and off, as trainer switches etc. Each of the switches can be assigned

any number of functions.

Control switch

In these software switches, labelled with "G1 ... G8", the switching

point within the control travel can be set by simply pushing a button.

Logical switch

Through this option two switches, controls and logical switches or

the favorite combination of them, can be interconnected in an "AND"

or "OR" switch. A total amount of 8 logical switches "L1 … L8" can be

programmed.

Fix switch FXI and FX

This kind of switch switches a function always on or off. You can also

assign to a control function a fix input signal, e.g. FX = +100 % and

FXi = -100 %.

33028_mc_28_Teil2_jh

9 / 80

Page 10

Receiver configuration

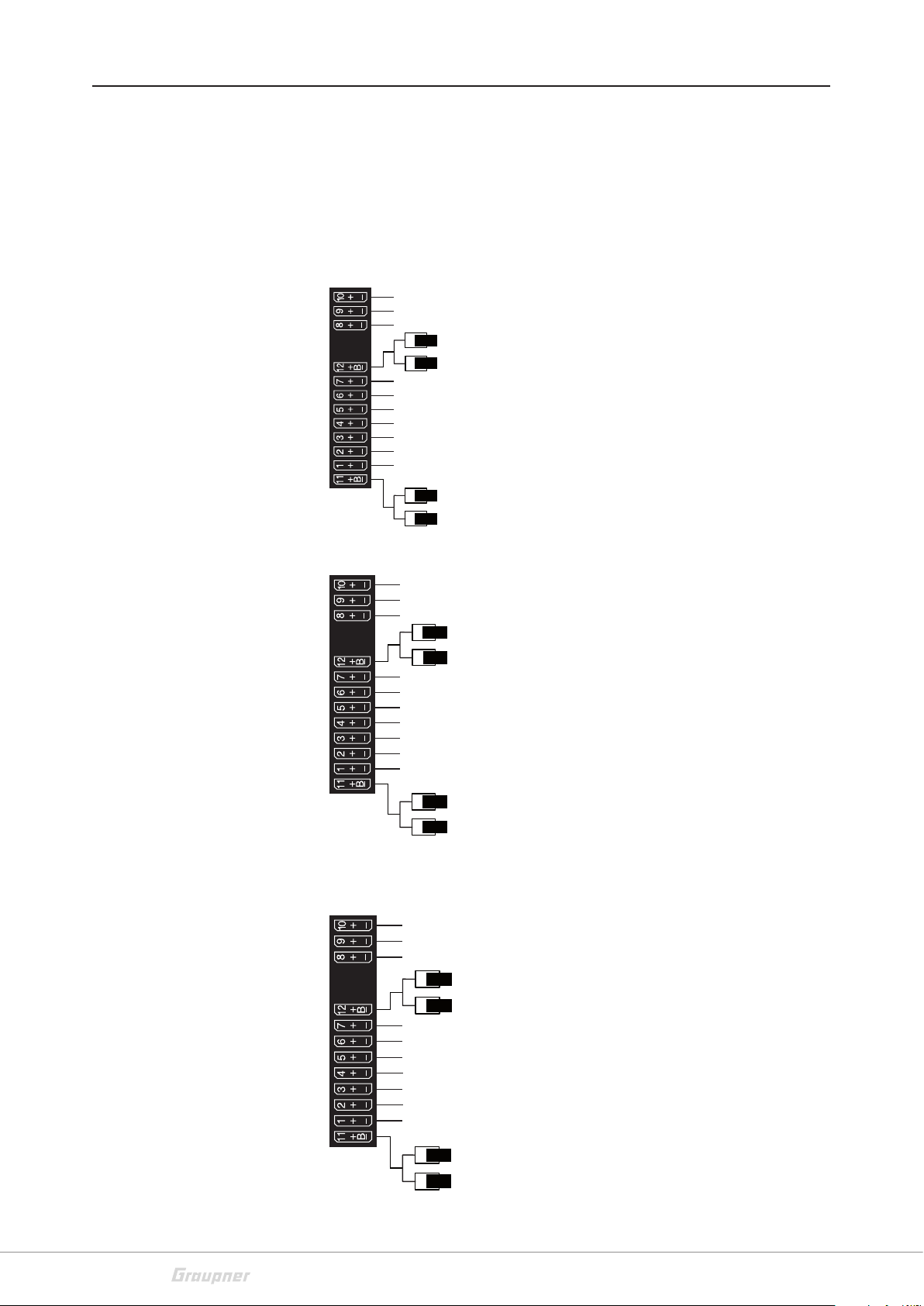

Fixed-wing models

The servos must be connected to the receiver in the indicated

sequence. Not assigned outputs remain free. It is possible to change

the settings in the line "Receiver outputs" in the "Model basic setting" menu.

Fixed-wing models with and without a motor with up to 4 ailerons

and up to 4 flaps and tail type "normal" or "2 elevator servos"

free or FLAP2 right or special function

free or FLAP2 left or special function

free or 2nd elevator or special function

free or AILERON2 right or special function

receiver power supply

FLAP right or free or special function

FLAP of FLAP left

AILERON right or special function

rudder

elevator or elevator1

AILERON or AILERON left

Airbrake or engine servo or electric drive controller

receiver power supply

free or AILERON2 left or special function

Tail type "V tail

free or FLAP2 right or special function

free or FLAP2 left or special function

free or special fucntion

free or AILE2 right or special function

receiver power supply

flap right or free or special function

flap or flap left

aileron right or special function

elevator/rudder right

elevator/rudder left

aileron or aileron left

airbrake or engine servo or drive controller

receiver power supply

free or AILE2 left or special function

Delta/flying wing models with and without a motor with up to 4

ailerons/elevators and 4 flap/elevator servos

free or special function or flap 2 / elev right

free or special function or flap 2 / elev left

free or special function

free or special function

receiver power supply

free or flap / elev right

fre or flap / elev left

free or special function

free or rudder

aile/elev right

aile/elev left

Airbrake or motor servo

or ESC for electric models

receiver power supply

10 / 80

free or special function

33028_mc_28_Teil2_jh

Page 11

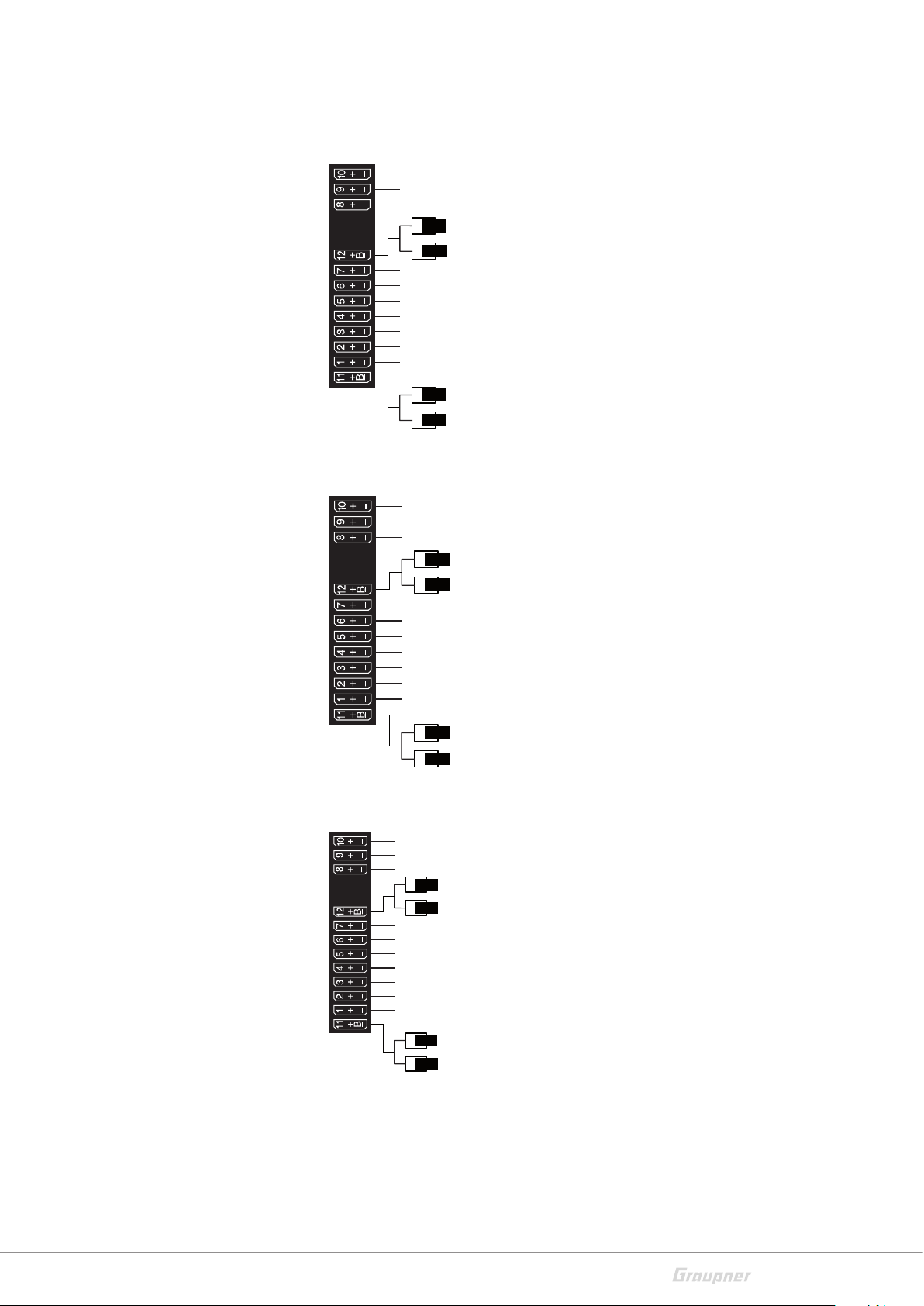

Helicopter models

engine servo or speed controller (forward/backward)

Receiver assignment for helicopter models with 1 to 3 swashplate

servos

free or special function

free or special function

free or governor or special function

free or special function

receiver power supply

gyro suppression

throttle servo or motor controller

free or special function

tail servo (gyro-system)

Nick-1-servo

Roll-1-servo

Pitch- or Roll-2 or Nick-2-servo

receiver power supply

free or special function

Receiver assignment for helicopter models with 4 swashplate servos

free or special function

free or special function

free or governor or special function

free or special function

receiver power supply

gyro suppression

throttle servo or motor controller

Nick-2-servo

Tail-servo (gyro-system)

Nick-1-servo

Roll-1-servo

Roll-2-servo

Vehicles, boats

receiver power supply

free or special function

free or special function

free or special function

free or special function

free or special function

receiver power supply

free or special function

free or special function

free or special function

free or special function

free or special function

steering (left/right function)

receiver power supply

free or special function

33028_mc_28_Teil2_jh

11 / 80

Page 12

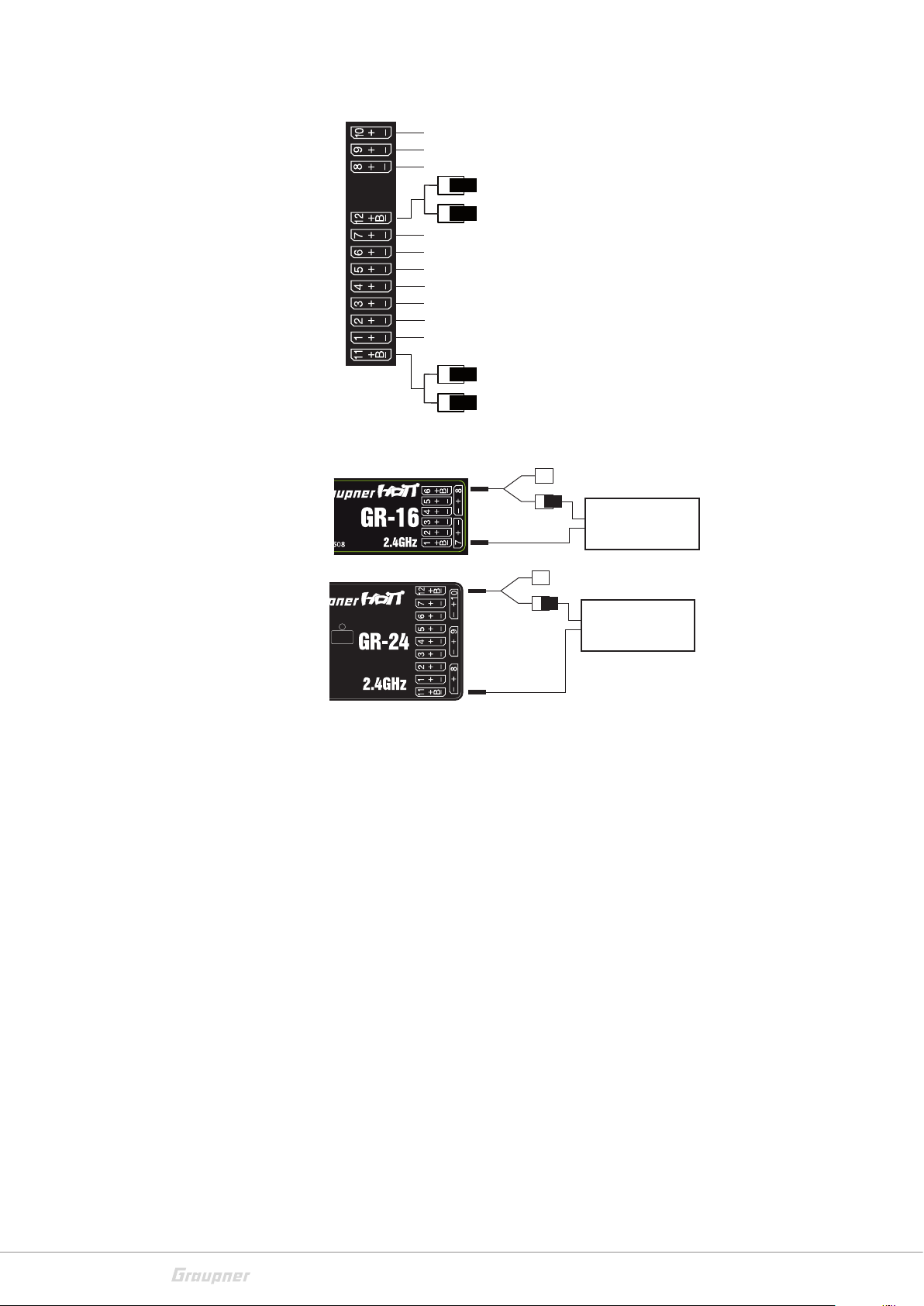

Copter

free or special function

Receiver power supply

free or special function

free or special function

free or special function

free or special function

receiver power supply

free or special function

free or special function

free or special function

Yaw

Nick

Roll

Motor/Pitch (up/down)

receiver power supply

special function

V-cable

No. 3936.11

V-cable

No. 3936.11

PRX stabilized

receiver power

supply No. 4136

special function

PRX stabilized

receiver power supply

No. 4136

12 / 80

33028_mc_28_Teil2_jh

Page 13

Symbols explication

!

Menus description

Always observe the information indicated by this warning sign. Par-

ticularly those which are additionally marked with the

WARNING. The signal word WARNING indicates the poten-

or

tial for serious injury, the signal word

ity of lighter injuries.

The signal word

Note indicates potential malfunctions.

CAUTION indicates possibil-

CAUTION

Attention indicates potential damages to objects.

The menus are described in the same sequence as they appear in

the lower display. Tap on the SET button in the base display to switch

in the multifunction menu.

The chapters of the manual are marked with model type symbols.

The symbols are exactly the same used in the transmitter. It shows

you which paragraph is related to your model type. Thus makes it

easier to find which paragraph is required for each model programming.

Meaning of the warnings

Battery

needs

charging !!

BIND?

OK

Warning!

Switch OFF the receiver

first!

CAN‘T

RECEIVE

DATA

OK

Please select

RF on/off?

ON

OFF

Transmitter input voltage too low

"Bind?"

No receiver is bound to the actually active model memory. By

shortly tapping the SET button you can accede the related option.

You want to perform a model change in the "

but the receiver of the actually active model is however still

switched on.

No bound receiver in range.

Should the RF transmission be switched "ON" or "OFF"?

It appears only after switching the transmitter on with already

bound receiver in active model memory.

Model select" menu

33028_mc_28_Teil2_jh

Switch

RF module

OFF

OK

Request to switch the RF transmission off

13 / 80

Page 14

Fail-Safe

setup

t.b.d.

Fail Safe setting not performed yet

Thr

too

high!

No

pupil

signal

insert

SD card

OK

Power-on warning

is active!!!

actually not possible

voltage too low

Please select

Trainer connection?

ON OFF

Throttle or pitch control stick position or throttle limit for helicopters too high

Connection between teacher and pupil transmitter disturbed

No SD or SDHC memory card in the card slot or card not readable.

Within the time set in the line "Switch-on warning" of the "general

settings"

menu the transmitter has not been used. In the display it

appears the warning and the WARNING LED on the right side

of the On/Off switch blinks and an acoustic warning alarm is emitted.

If the transmitter is still not being used it will autonomously switch

off after about three minutes.

In case of too low battery voltage a model change is not possible for

safety reasons. In the display appears a related message:

Should the "Wireless Teacher/pupil connection" used before the last

switch off of the transmitter be continued (CONTINUE) or interrupted (INTERRUPT)?

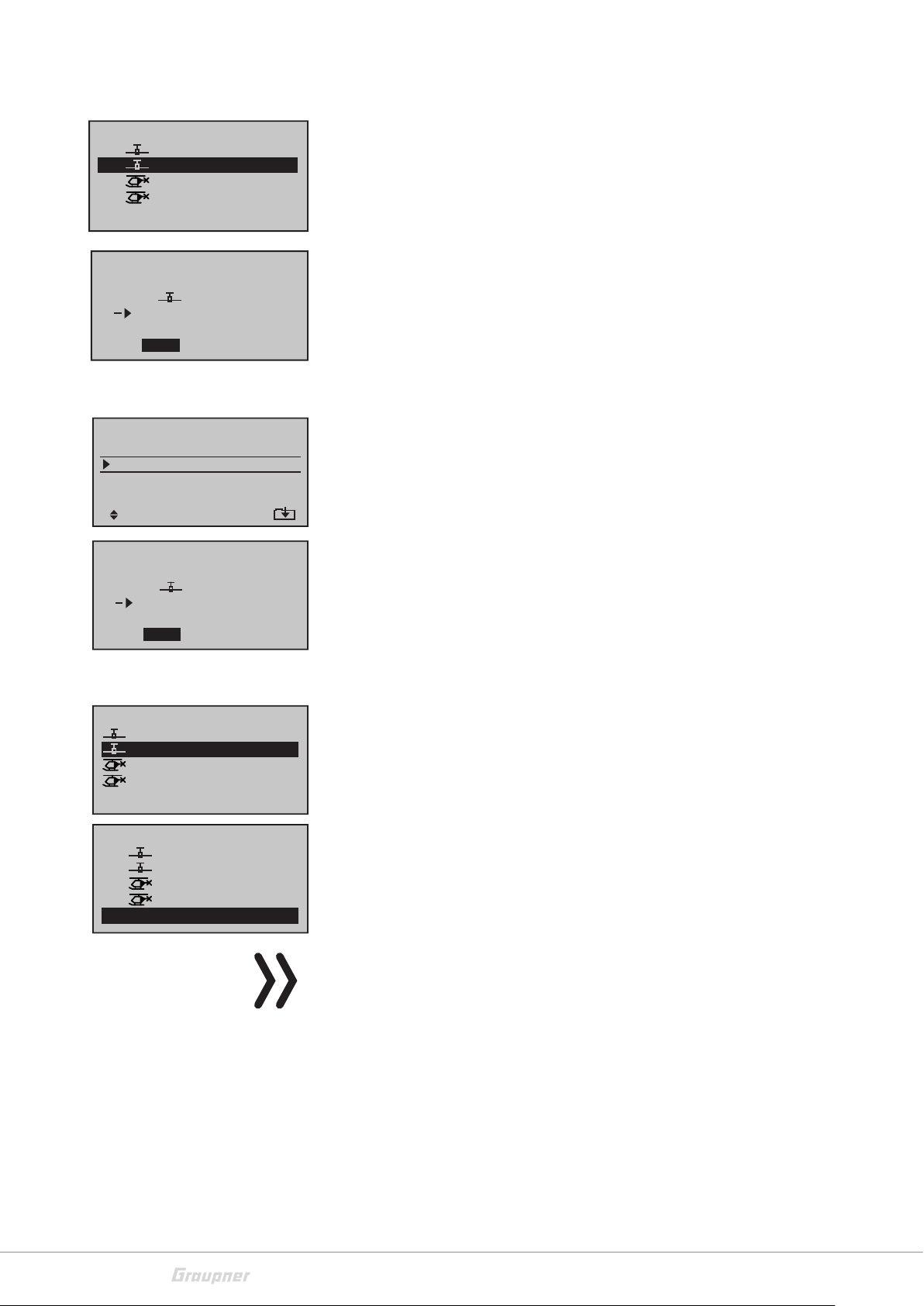

Model selection

Model select

Copy / Erase

Suppress menus

Suppress models

Base setup model

Model type

01

02

03

04

05

06

free

free

free

free

free

Tap on the SET button to access the menu. Now you can see the list

of the available model memories. Selection of the desired model

memory through the or buttons of the left or right touch-pad.

Then tap on the SET button.

Create a new model memory, select an empty model memory:

You will be requested to select the desired model type among the

M

R12

five available model types.

Select through the or buttons the related symbol and then tap

on the SET button. In this way the selected model memory will be

installed with the selected model type.

14 / 80

33028_mc_28_Teil2_jh

Page 15

With this selection model specific settings will be available in the

menus. Now you can program your model in this model memory.

Select model type

Copy/Delete

Model select

Copy / Erase

Suppress menus

Suppress models

Base setup model

Model type

Erase model

Copy model–>model

Export to SD

Import from SD

Copy phase

BIND?

OK

=>

=>

=>

=>

=>

=>

=>

After the initialization of the selected model memory with the

desired model type the display changes to the base display of the

new assigned model memory. At the same time it will appear for

some seconds the warning message that there is no connection with

a receiver. Tapping on the SET button you will directly enter the "Base

menu". Here you are directly in the line for binding. For the binding

process, please read the description in the "Model base setting"

menu. Tap on the ESC button to procede without binding.

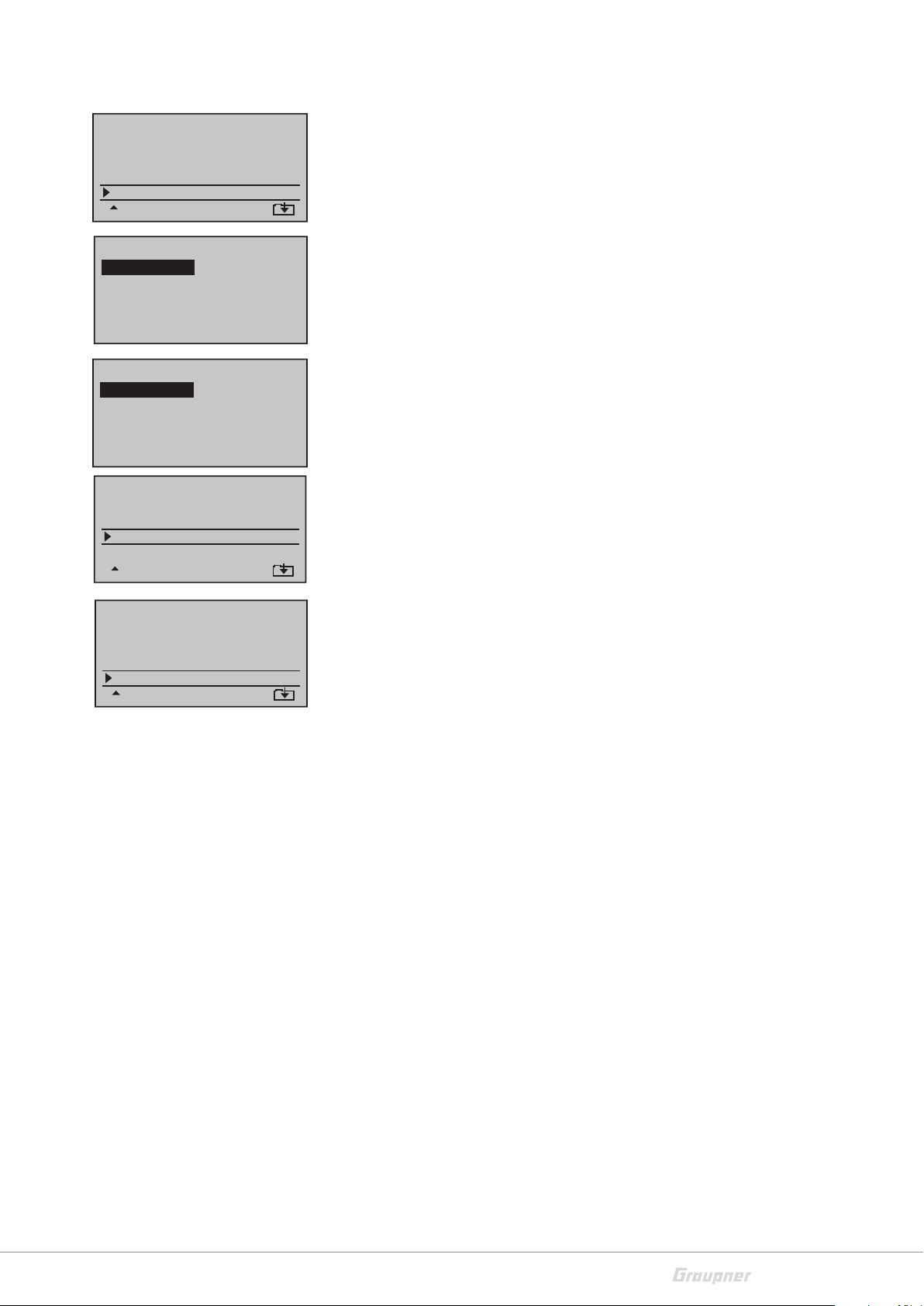

Tap on the SET button to access the menu. Now you can see the list

of the available functions. On the right side of the display there is a

scrollbar. That indicates you that there are other menu points other

than the actually visible ones. Scroll with the selection buttons up or

down.

Delete model

Select the "delete model" point an confirm through the SET button.

On the lower left side you can see an arrow facing down. That indicates you that there are other menu points other than the actually

visible ones. Scroll with the selection buttons up or down.

Model to be erased:

01

02

03

04

05

GRAUBELE

ULTIMATE

STARLET

BELL47G

frei

Model really

01

to be erased ?

NO

GRAUBELE

YES

Note

This deletion cannot be restored. All of the data in the selected

model memory are completely deleted.

If the actually active model memory is deleted, soon after the dele-

M

R12

G

R12

R12

M

M

–––

tion process it must be defined a favorite model type. If an inactive

model memory is deleted, soon after the model selection appears

"àààfreeààà".

Use the selection buttons of the left or right touch-pad to select

the model to delete.

It appears a safety query. The deletion process will be performed

only if you move to YES and tap on the SET button. Selecting NO and

tapping on SET button interrupts the deletion process.

33028_mc_28_Teil2_jh

15 / 80

Page 16

Copy from model:

01

02

03

04

05

GRAUBELE

ULTIMATE

STARLET

BELL47G

frei

Copy Mod¢Mod

Select the point "Copy Mod¢Mod" and confirm through the SET

R12

M

R12

G

R12

M

–––

M

button.

Through the ESC button you can always interrupt the process.

• Select the model to copy and confirm the selection through the

SET button.

Model

01

SD-CARD

export ?

NO

ULTIMATE

YES

Export to SD card

Erase model

Copy model–>model

Export to SD

Import from SD

Copy phase

Model

01

SD-CARD

export ?

NO

ULTIMATE

YES

Import from SD

Import from SD-CARD:

ALPINA

EXTRA

COBRA

BELL47G

05

Import to model:

01

02

03

04

05

frei

GRAUBELE

ULTIMATE

STARLET

BELL47G

free

16/08/10

16/08/11

16/08/12

16/08/13

• Select the target memory and confirm through the SET button.

It appears a safety query. If you change to YES and press the SET button, the copy process will be performed. The copy process is interrupted if you select NO.

=>

=>

=>

=>

=>

=>

=>

Select the "Export to SD" point an confirm through the SET button.

Through the ESC button you can always interrupt the process.

Select the model to export and confirm the selection through the

SET button.

It appears a safety query. If you change to YES and press the SET button, the export process will be performed. The process is interrupted

if you select NO.

Select the "Import from SD" point an confirm through the SET button.

Through the ESC button you can always interrupt the process.

• Select the model to export from the SD card and confirm through

the SET button.

R12

M

G

R12

R12

M

–––

M

• Select the target memory and confirm through the SET button.

It appears a safety query. If you change to YES and press the SET button, the import process will be performed. The import process is

interrupted if you select NO.

16 / 80

Note

If the imported model memory has been created in the transmitter

and is imported to the same model memory then the receiver connection remains. If the model memory is imported in another transmitter, then the receiver must be bound again.

33028_mc_28_Teil2_jh

Page 17

Erase model

Copy model–>model

Export to SD

Import from SD

Copy phase

=>

=>

=>

=>

=>

=>

=>

Copy phase

Select the "Copy phase" point an confirm through the SET button.

Through the ESC button you can always interrupt the process.

• Select the phase to copy and confirm the selection through the

SET button.

Copy from phase:

1

3

5

7

Copy to phase:

1

3

5

7

Export to SD

Import from SD

Copy phase

Store changes

undo changes

Export to SD

Import from SD

Copy phase

Store changes

undo changes

2

4

6

2

4

6

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

• Select the target phase and confirm the selection through the

SET button.

A safety query appears. If you change to YES and press the SET button, the copy process will be performed. The copy process is interrupted if you select NO.

Permanently save changes / undo changes

If you perform a model change or if you switch the transmitter off

the last stand of the programming of the model is saved in the model

memory. With the "Permanently save changes / undo changes"

function the change will be manually edited during the use.

Through the "Permanently save changes / undo changes" menu

point you can immediately save permanently the edited programming in the model memory.

Through the "Permanently save changes / undo changes" menu

point you can undo programming performed during the use. In this

way you can restore the last performed programming. You can

choose since when the undo action should start, between the last

switch-off or the last manual saving.

It appears a safety query. If you change to YES and press the SET button, the related process will be performed. The process is interrupted if you select NO.

33028_mc_28_Teil2_jh

17 / 80

Page 18

Suppress menus

Model select

Copy / Erase

Suppress menus

Suppress models

Base setup model

Model type

Model select

Copy / Erase

Suppress models

Base setup model

Model type

Suppress : SET

Suppress models

Model select

Copy / Erase

Suppress menus

Suppress models

Base setup model

Model type

In this menu you can hide menu points from the menu function list.

The hiding is related to the model memory.

Select the menu point to hide or to show and switch the status

through the SET button. The crossed-out menu points are then no

longer displayed in the multifunction list.

The menu points are not deactivated, programmed functions in the

hidden menus remain active.

In this menu you can hide model memories from the model selection list.

Select the model memory to hide or to display, tap on the SET button to switch the status. The crossed-out model memories are then

no longer displayed in the model selection list.

R12

SET

M

G

R12

M

R12

–––

M

01

02

03

04

05

Suppress :

GRAUBELE

ULTIMATE

STARLET

BELL47G

free

Model basic settings

Suppress models

Base setup model

Model type

Servo adjustment

Stick mode

Control adjust

Base setup model

Mod. Name

Stick mode

HoTT

Module

Rcv Ch Map n/a

!"#$%&’()�+,–./0123

456789:;

FGHIJKLMNOPQRSTUVWX

YZ[¥]^_`abcdefghijk

bind

R08

BD1

?@ AB CDE

BD2

1

n/a

The model memories will not be deactivated, the programmed

options will be retained.

In this menu you will set the base setting for the actual model memory.

Model name

You can insert a maximum of nine characters for a model name of

the active model memory.

Through the left and right selection buttons you can move up or

down to the next place. Through the SET button you confirm the

selection and move to the next place. You can insert an empty space

if you tap at the same time on the up and dow or left and right buttons.

Through the ESC button you can leave the menu.

Mod Name

18 / 80

GRAUB

33028_mc_28_Teil2_jh

Page 19

Control mode

Base setup model

Mod. Name

Stick mode

Module

Rcv Ch Map n/a

GRAUBELE

HoTT

bind

R08

SEL

1

n/a

In this function you can choose a control mode which will be used

for this model memory. In this way it will be determined which control movement of the related control stick will we associated to

which channel. Tap n the SET button, set the desired mode through

the selection buttons. In the "receiver assignation" section you can

see where each servo should be connected.

Fixed-wing model

MODE 1 (Throttle right)

Elevator

Rudder

Elevator

Full throttle

Rudder

Querruder

Motor idle

MODE 3 (Throttle right)

Elevator

Aileron

Elevator

Full throttle

Aileron

Rudder

Motor idle

Car / boat

MODE 1 (for/backward right)

forward/backward

left

MODE 3 (for/backward right)

right

forward/backward

forward/backward

left

MODE 2 (Throttle left)

Full throttle

Querruder

Rudder

Motor idle

Rudder

MODE 4 (Throttle left)

Full throttle

Rudder

Aileron

Motor idle

Aileron

MODE 2 (for/backward left)

forward/backward

left

forward/backward

right

MODE 4 (for/backward left)

forward/backward

right

Elevator

Aileron

Elevator

Elevator

Rudder

Elevator

left

Aileron

Rudder

right

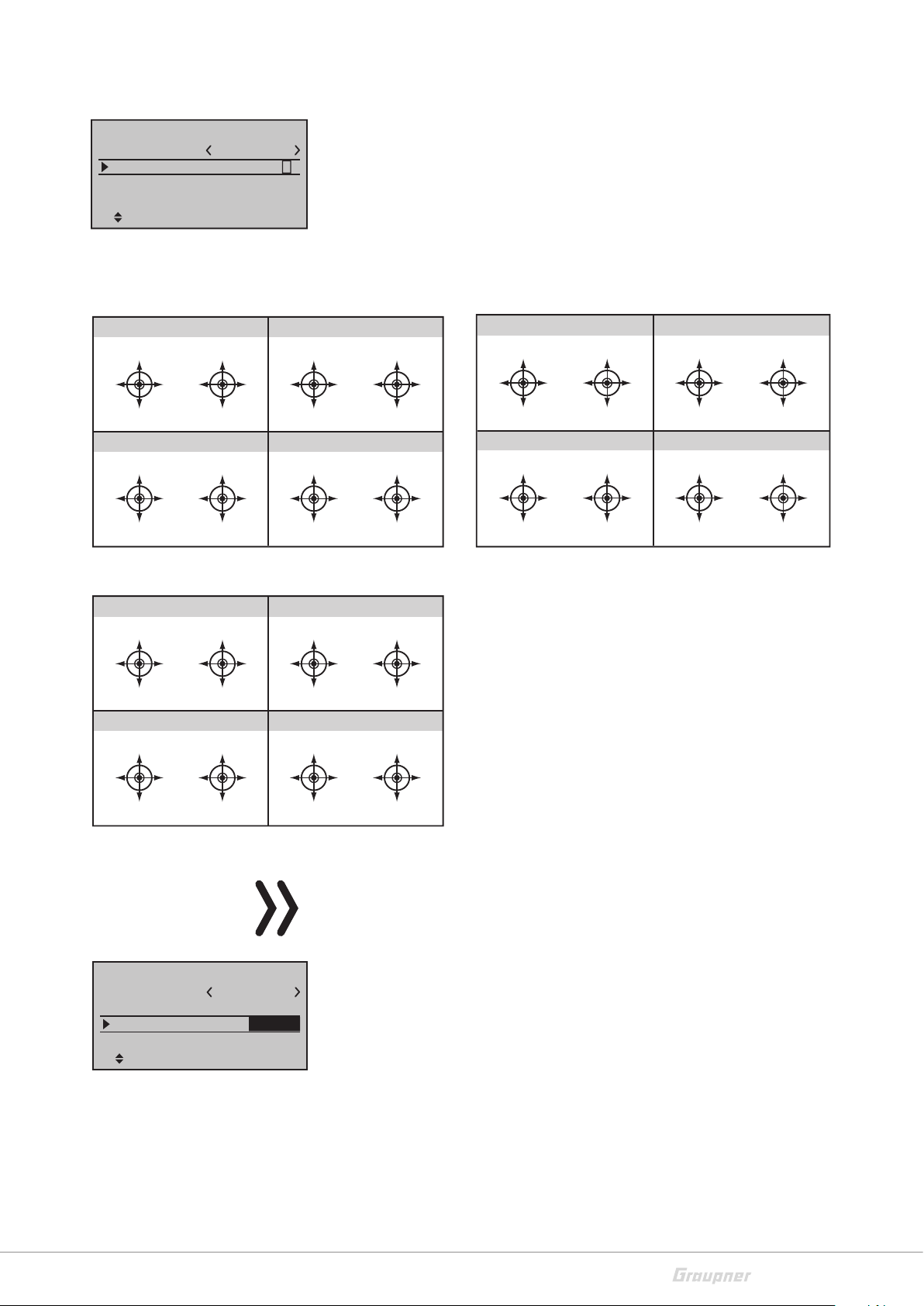

Helicopter model / Copter model

MODE 1 (Throttle right)

Nick

Tail rotor

Nick

Tail rotor

Motor / Pitch

Roll

Motor / Pitch

MODE 3 (Throttle right)

Nick

Roll

Nick

Motor / Pitch

Roll

Tail rotor

Motor / Pitch

Roll

Tail rotor

MODE 2 (Throttle left)

Motor / Pitch

Tail rotor

Motor / Pitch

MODE 4 (Throttle left)

Motor / Pitch

Roll

Motor / Pitch

Tail rotor

Roll

Nick

Roll

Nick

Nick

Tail rotor

Nick

Roll

Tail rotor

Binding type

Base setup model

Mod. Name

Control mode

Binding type

Module

HoTT

forward/backward

GRAUBELE

n/a

forward/backward

1

Model

n/a

SEL

Note

This menu line is only visible until no receiver is bound to the active

model memory.

This option must be selected before the binding of a receiver. You

can select between "Global" and "Model", which means:

"Global": All bound receivers react to the signals of each model

memory of the transmitter. For safety reasons it is then only possible

to change model memory only after having switched the receiver off.

"Model": Bound receivers react only to the signals of the assigned

model memory. An accidental use thorough a non specifically

assigned model memory is not possible.

33028_mc_28_Teil2_jh

19 / 80

Page 20

01

02

03

04

05

06

GRAUBELE

ULTIMATE

STARLET

BELL47G

free

free

Module

Base setup model

Mod. name

Stick mode

Module

Rcv Ch Map R12

HoTT

M

R12

G

R12

R12

M

M

bind

BD1

–––

n/a

n/a

BD2

GRAUBELE

The binding type is indicated in the model memory list near the

model memory name:

"G" means global binding

"M" means model memory specific binding

Through the left and right selection buttons you can select the fields

in the lines. In the first "HoTT" field you have the following selection

1

possibilities:

HoTT - the integrated HoTT module will be used for the signal trans-

mission.

The following settings (EXT. and SP.) are included for eventual external RF modules of other manufacturers and they do not work with

HoTT receivers.

Base setup model

Mod. name

Stick mode

Module

EXT.PPM sig. normal

Base setup model

Mod. name

Stick mode

Module

SP channel 6

GRAUBELE

EXT.

SEL

GRAUBELE

S P.

Mod

PPM10

BIND1

BD

EXT. - the signal transmission is emitted through the DSC port to an

optional external RF module. Here is set the value PPM 10 (max. 10

1

control channels). The "Range test" and "Receiver outputs" functions are not available. Underneath appears a new line. Here you can

set if the PPM signal has to be emitted normally or inverted.

SP. - The signal transmission will be emitted as a special digital signal

through the DATA port. The binding will be performed through the

1

"BIND" field. Two new lines will appear underneath. In the first line

the number of the emitted channels

(6 or 8) will be set. In the second line you can set if the signal has to

be emitted normally or inverted. The "Range test" and "Receiver

outputs" functions are not available.

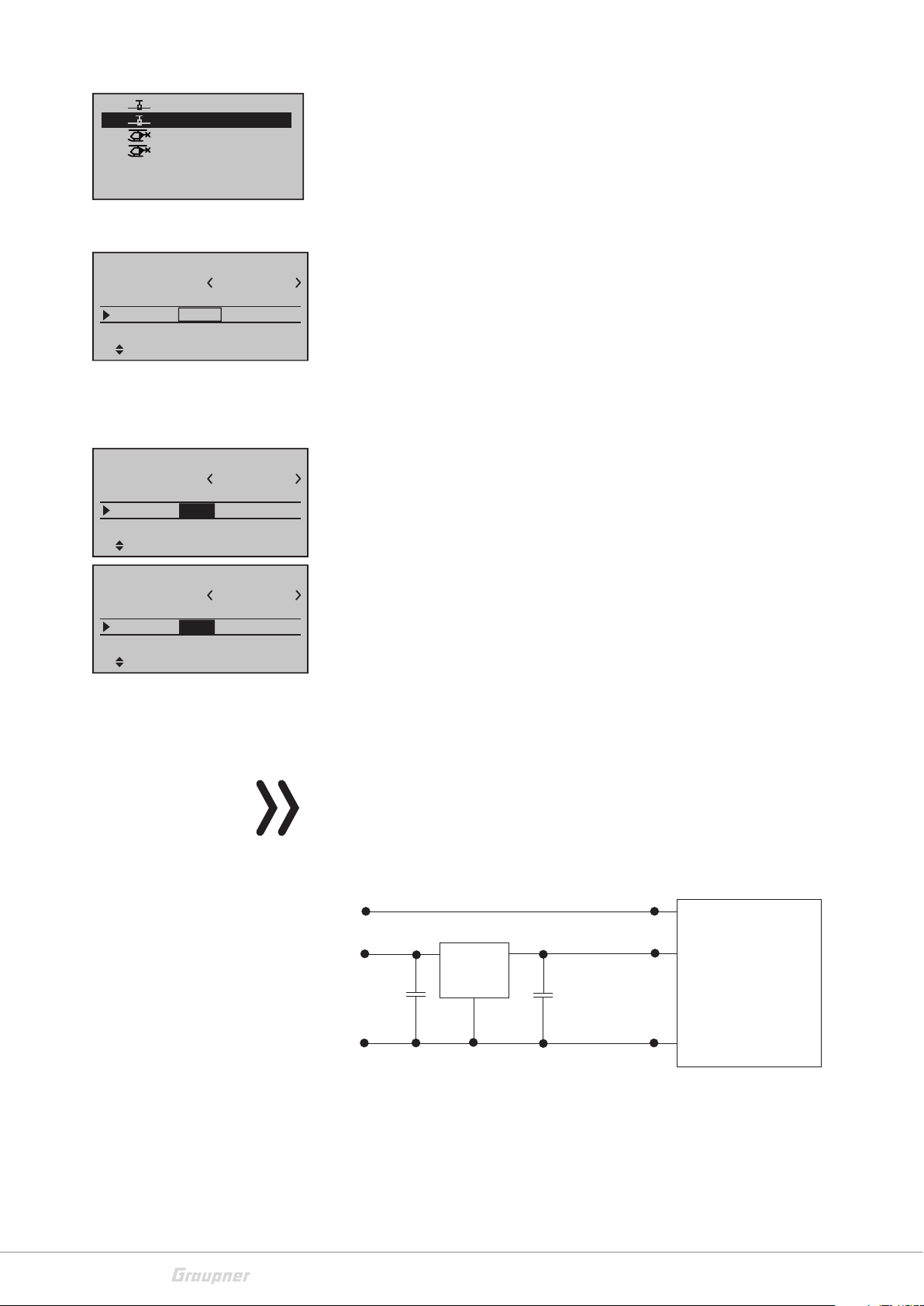

If the external RF module has to be powered with the current coming from the DATA port, then pay attention to what follows:

Note

The output tension of the DATA port of about 5 V must be reduced

through a stabilized step-down module to 3 / 3,3 V.

Pay attention to the switch scheme:

20 / 80

DATA S

Vcc IN = 5 V

DATA +

22µF/6.3 V

DATA -

Low Drop

Voltage

Regulator

GND

Vcc OUT = 3 ... 3.3 V

22µF/6.3 V

125000 baud signal

Vcc

SP.-MODULE

with

digital input signal

GND

33028_mc_28_Teil2_jh

Page 21

Receiver binding

Base setup model

Mod. name

Stick mode

Module

Rcv Ch Map

HoTT

GRAUBELE

n/a

n/a

n/a

n/a

You can bind two receivers to the transmitter. The two bound receivers can be also managed in this option. You can split the control

channels of the receivers in the "Receiver output" as you prefer.

Binding process

Move to the "n/v" field near the "HoTT" field through the selection

buttons. Set your HoTT receivers in the binding mode. The binding

1

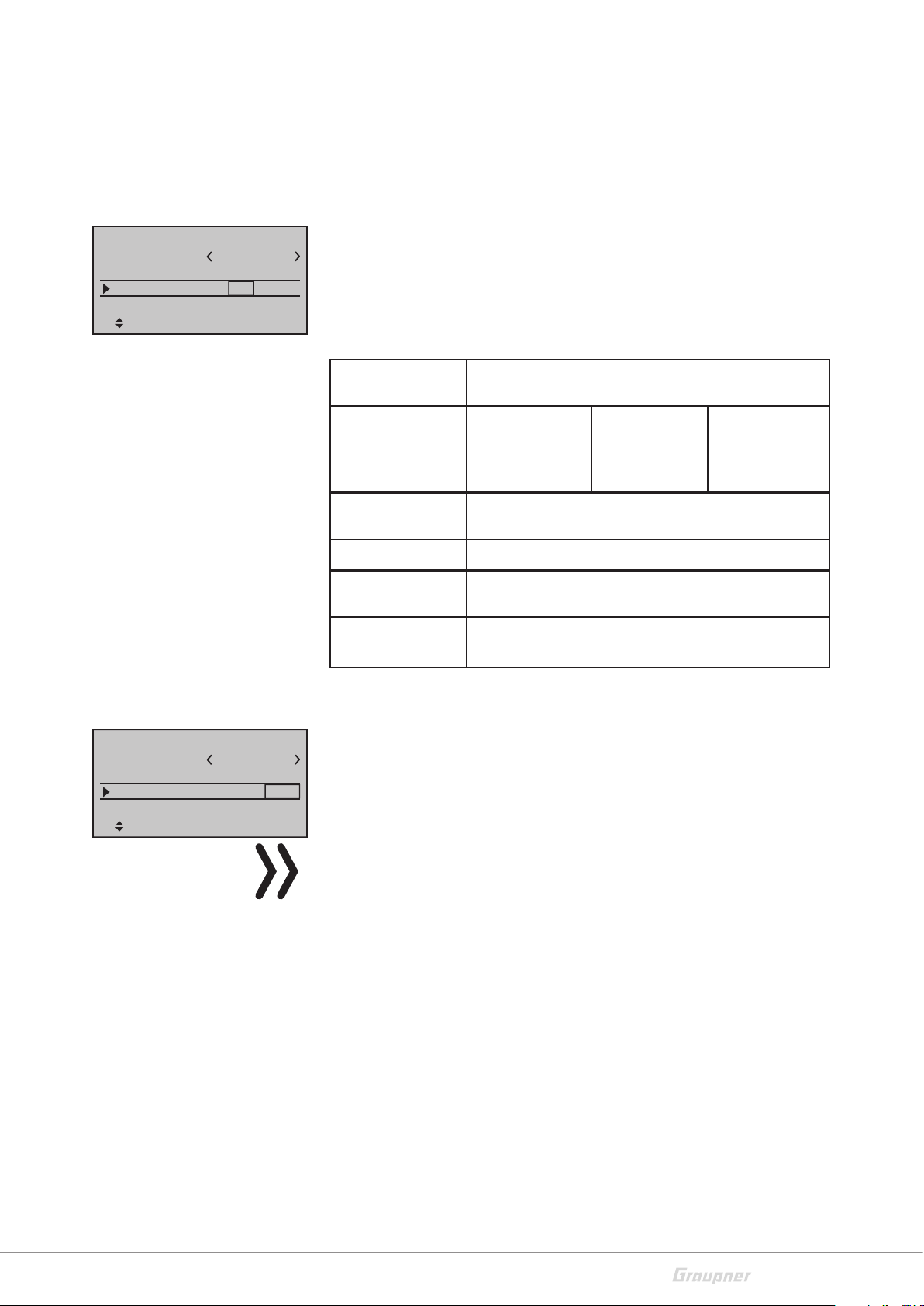

method is different for the different types of receiver, see the following table.

1. Set the receiver in the binding mode

Base setup model

Mod. name

Stick mode

Module

Rcv Ch Map R12

GRAUBELE

HoTT

bind

BD1

1

n/a

n/a

BD2

1st binding

Push and hold the binding button

method

Receiver type GR-12

green LED on

= bound

2nd binding

method

Push and hold the button until the LED blinks

red/green

GR-12L

red LED off =

bound

GR-18/24

green LED on

= bound

Receiver type GR-16 / 24 / 32 - green LED on = bound

3rd binding

method

No binding button, the receiver enters automatically the binding mode after switching on

Receiver type Gr-10C, GR-12 SC / SH

red LED off = bound

2. Tap now on the SET button, a "BIND" info window will appear.

If the binding process has been successful in the left field it appears

now "bound". In the line "Receiver output" appears now under the

"bound" field the identification of the receiver (e.g. E12 = GR-24). It

also appears BD1 and BD2 in the lowest line of the display. The meaning of the message will be cleared in the "Telemetry menu" section.

Note

33028_mc_28_Teil2_jh

If the binding process was not successful, verify the following conditions:

Is the distance between transmitter and receiver at least 50 cm?

Is the power source of the receiver OK?

Is the polarity of the power supply correct?

Was the binding button correctly pushed?

If you want to bind a second receiver, then proceed as described

before. Move therefore first to the right "n/v" field.

21 / 80

Page 22

Receiver output

Base setup model

Mod. name

Stick mode

Module

Rcv Ch Map R12

HoTT

GRAUBELE

bind

bind

R08

SET

SET

This function (Channel Mapping) is available as soon as in the line

"Module" is bound at least one receiver. Here you can split the con-

1

trol channels of the transmitter to the bound receivers. You can also

select freely the channel order within the receiver. In this way the

control channels coming from the transmitter will be assigned to a

free selectable output of the receiver.

Receiver CH – BIND1

In Ch 1

In Ch 2

In Ch 3

In Ch 4 Out Ch 4

Out Ch 1

Out Ch 2

Out Ch 3

RF module

Base setup model

Stick mode

Module

Rcv Ch Map

RF transmit

HoTT

bind

R12

Range test

Base setup model

Module

Rcv Ch Map

RF transmit ON

RF Range Test 99sec

HoTT

bind

R12

1

bind

R08

ON

SEL

bind

R08

SEL

Use the selection buttons to move to the receiver field that you want

to edit. Select the input that you want to assign to another output.

Tap on the SET button. Set the desired channel. Confirm the selection by pushing the SET button.

In this menu line the RF module of the transmitter is switched manually on and off. This line is only available if a receiver is bound.

The integrated range test reduces the transmitter output so that you

can perform a function test at a limited distance.

Perform the range test before each operation and simulate all servo

movements which are part of the operation. In order to guarantee a

safe model operation, the range must always be at least 50 m on the

ground.

Place the model on a flat surface (cement, mowed lawn or ground)

so that the receiver antennas are at least 15 cm above the ground.

If necessary, place a support underneath the model during the test.

Hold the transmitter at hip level at a slight distance from your body.

Keep the surface of the patch antenna of the transmitter in direction

of the model.

Start the range test by pushing the SET button. The time display "99

sec" will start the countdown. You will hear two acoustic signals each

two seconds, in the last five seconds the acoustic signals will be 3

each second.

During this time, move away from the model, and also move

the transmitter's control sticks. Let the control movements be

observed by a second person.

If within a distance of about 50 m there is no interference in the control movements of the model, then the range test can be considered

as successful. After the end of the 99 seconds

the transmitter switches again to full transmission power and the

green LED on the right of the main switch lights again permanently.

If the range test has not been successful, verify the following conditions:

22 / 80

33028_mc_28_Teil2_jh

Page 23

DSC port

Base setup model

Rcv Ch Map R12

RF transmit ON

RF Tange Test 99sec

DSC Output PPM10

R08

SEL

Is the power supply of the receiver OK?

Is the position of the receiver antennas correct?

Are there any interference from electronic component in the

model?

If you have verified these conditions and against it you coul not perform a successful range test, then please contact ou Customer Service (see section "Service Center").

This selection influences the number of control channels available at

the DSC port. The selection means:

PPM10 = Channel 1 - 5

PPM16 = Channel 1 - 8

PPM18 = Channel 1 - 9

PPM24 = Channel 1 - 12

Throttle Cut

Base setup model

RF transmit ON

RF Range Test 99sec

DSC Output PPM10

cut off +150%–100%

SEL

Move desired switch

to ON position

(ext. switch: SET)

STO

–––

This function is only available if in the "Model type" menu you have

set "forward" or "backward" in the Motor to CH1 option.

With this function the throttle channel (CH1) can be switched and

hold in a specific position (-100%) through a switch. In this position

it is then not possible that the motor starts accidentally, no matters

in which position the throttle stick is.

In the left column you can set the position in which the throttle channel (CH1) will be switched. In the third column you can set the switch

threshold. To do that you have to move the stick to the desired position and tap on the SET button. In this way the switch range will be

set.

In the right column you can assign the desired switch. Proceed as follows:

Tap on the SET button in the "Thr.cut" line.

Move the desired switch to the position in which the motor will

be switched off. Combinations with logical switches are also possible.

33028_mc_28_Teil2_jh

23 / 80

Page 24

Switch-on warning

Base setup model

RF transmit ON

RF Range Test

DSC Output PPM10

Power on warning

99sec

–––

With this option it is possible to program the query for the position

of a switch or control so that when the transmitter is switched on in

the base display a warning will appear.

To do that you have to assign in this line a switch, a control switch or

a logical switch.

Activate a warning:

Move desired switch

to ON position

(ext. switch: SET)

GRAUBELE

01

! Warning !

4.1V

0:01h

S

L

«normal »

K78

M

Auto trim

Base setup model

RF Range Test

DSC Output PPM10

Power on warning

Auto Trim

0:00.0

0:00.0

HoTT

4.8V

99sec

–––

8

Tap on the SET button in the "Switch-on warning" line.

Move the desired switch to the position that has to be verified.

Combinations with logical switches are also possible.

If the warning is active the blue LED

WARNING in the transmit-

ter blinks while the transmitter is switched on and the RF module

remains switched off. To deactivate the warning move the programmed switch in another position.

Deactivate the warning:

Tap on the SET button in the "Switch-on warning" line.

Tap on the Up and Down buttons of the right selection field.

In the selection field will be displayed three lines. No switch is

assigned any more.

With this function you can save the actually controlled position of a

model in the trim memory. The function acts on channel 2, 3 and 4

only. This function will be activated through a switch. Select the line

"Auto trim" and tap on the SET button. Move a switch in the desired

position. We recommend to select a momentary switch.

Timer auto reset

Base setup model

RF Range Test

DSC Output PPM10

Power on warning

Auto timer reset

99sec

–––

yes

Save the position in the trim memory step-by-step:

3. Move the model to the desired position through the control

sticks.

4. Actuate the assigned switch and move the control sticks back

to the neutral position.

5. After 1 sec. the position will be saved in the trim ( ± 30%).

Note

If the auto trim function is not required any more, then we suggest

to deactivate the switch assigned to the "Auto trim function".

Thereby you avoid an accidental error function.

In this line you can select:

"Yes" - all timers, excluded model timer and transmitter operating

timer, will be set back to zero when you switch the transmitter on.

"No" - all timers hold the stand from the last use of the transmitter.

The timer will however be reset when the transmitter is switched on.

24 / 80

33028_mc_28_Teil2_jh

Page 25

Model type

Suppress models

Base setup model

Model type

Servo adjustment

Stick mode.

Control adjust

In this menu you can adjust the settings for the actual model type.

Here you can select for example the tail and wing type or whether

the model has motor or not.

Model type

Motor at C1

Leitwerk

Querr./Wölb

Bremsoffs. Ein1+100%

None

normal

1QR

SEL

If in the model selection you have chosen copter, car or boat in this

menu will appear only the line "Motor at CH1". Here you have the

following selection possibilities:

"None"

You are using a model without drive. The warning "Throttle too

high!" is deactivated and the sub-menu "Brake settings" of the "Wing

mix" menu is available.

"Backward"

The idle position of the Throttle/Airbrakes control stick (CH1) is in

the backward position, in the pilot direction. The warning "Throttle

too high!" so as the "Throttle cut" option of the "Model base settings" menu are active.

"Forward"

The idle position of the Throttle/Airbrakes control stick (CH1) is in

the forward position, in the opposite direction of the pilot. The warning "Throttle too high!" and the "Throttle cut" option of the "Model

base settings" menu are active.

Note

The CH1 trim acts accordingly to your selection "normally" or only

"backward" or "forward", then through the entire control travel or

only in the related idle direction.

Please pay attention to the "Switch-off trim" function described in

the "Digital trim" section.

33028_mc_28_Teil2_jh

25 / 80

Page 26

Motor on CH1

Model type

Motor at C1

Tail type

Aile/flaps

Brake Off In1+100%

Tail

Model type

Motor at C1

Tail type

Aile/flaps

Brake Off In1+100%

None

Normal

1AIL

SEL

None

normal

1AIL

SEL

If you have selected airplane in the model selection, it will also

appear the line "Motor at CH1". The setting are also here as previously described.

Here you can select the tail type of your model to obtain the related

control signals at the receiver outputs (see "Receiver assignation"

menu).

"Normal"

The elevator and rudder are controlled each by only one servo.

"V tail"

The elevator and rudder are controlled by two separately-articulated

rudders arranged in a V-shape. The coupling function for the rudder

and elevator control is automatically transferred from the program.

The influence of the rudder on the elevator component can be set

in the "Dual Rate / Expo" menu. The servo travels can be adjusted

one to the other in the "Servo setting" menu. If the rudder travel has

to be differentiated, then you have to select here the tail type "normal" and the V tail has to be set alternatively in the "Cross mixer"

menu.

"Delta"

This option must be selected for delta wing models. In case of selection of "2 AILE" in the line "Ailerons/Flaps", see following, the aileron

and elevator control is actuated respectively by one servo each halfwing. In case of selection of "2/4AILE 2/4FLAP" the aileron and elevator control depends on the settings in the "Multi-flap menu" submenu of the "Wing mix" menu.

"2 ELE Sv 3+8"

This option is indicated for models with two elevator servos. When

the elevator control is actuated, the servo connected to the output

8 works in parallel with servo 3. The elevator trim acts on both servos.

Note

In case of "2ELE Sv 3+8", for safety reasons, there is no selection possibility for the input 8 in the "Control setting" menu. An already programmed control would be useless.

26 / 80

33028_mc_28_Teil2_jh

Page 27

Ailerons/Flaps

Model type

Motor at C1

Tail type

Aile/flaps

Brake Off In1+100%

None

normal

1AIL

SEL

In this line you can select the number of servos installed in the wings.

The following table shows the control channels to which the servos

must be connected.

Control surfaces

Occupied control channel

count

1AILE 2

1AILE 1FLAP 2 | 6

2AILE 2 + 5

2AILE 1FLAP 2 + 5 | 6

2AILE 2FLAP 2 + 5 | 6 + 7

2AILE 4FLAP 2 + 5 | 6 + 7 / 9 + 10

4AILE 2FLAP 2 + 5 / 11 + 12 | 6 + 7

4AILE 4FLAP 2 + 5 / 11 + 12 | 6 + 7 / 9 +

10

According to this scheme the related required mixers and their setting possibilities are activated in the "Wing mix" menu.

Brake offset

Model type

Motor at C1

Tail type

Aile/flaps

Brake Off In1+90%

Servo adjustment

None

normal

1AIL

SELSTO

In this line is set the offset point in which the control surfaces (AILE/

FLAP) are completely retracted or closed.

The function will be assigned to the related input in the right column.

Offset_point assignation:

Move the control element of the input CH1-control stick input 1,7,8

or 9 in the position where the control surfaces have to be retracted

or closed. Tap on the SET button to save the "Offset" point.

The flaps are extended for brake offset values with a "+" when

the corresponding control element is moved from front to rear

toward the pilot.

The flaps are extended for brake offset values with a "-" when the corresponding control element is moved from back to front away from

the pilot.

Suppress models

Base setup model

Model type

Servo adjustment

Stick mo de

Control adjust

33028_mc_28_Teil2_jh

In this menu the servo parameters are set for each servo: servo

direction, neutral point, servo travel and limits. Start the servo setting basically in the left column.

27 / 80

Page 28

Column 1

S

e

r

v

o

t

r

a

v

e

l

S1

S2

S3

S4

S5

Rev cent

0%

0%

0%

0%

0%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

trv

+

In the first column are listed the control outputs.

The numbers for the servos refer to the servos connected to the corresponding receiver outputs providing that the transmitter and

receiver outputs have not been switched. A change in the control

mode therefore does not influence the numbering of the servos.

Column 2 "Rev"

With this option it is possible to adapt the servo direction to the specifics of each model.

Selection through the SET button and t u: "=>" normal, "<="

reverse

j

u

d

s

a

t

m

e

r

t

n

e

C

e

n

t

Column 3 "Cent"

You can slip the servo centre in a ±125 % area within the servo travel

of max. ±150 %. The servo is always adjusted directly independent

of all other trim and mix settings.

Column 4 "– Trv +"

In this column you can set the servo travel for both sides, together

or separated for each side. The setting range is 0 … 150% of the normal travel. The set values always refer to the settings in the column

"Centre".

Symmetrical travel setting:

Move the related control element (control stick, proportional control or switch) into a position in which both sides of the travel adjustment are surrounded by the marking frame.

Asymmetrical travel setting:

Move the related control element (control stick, proportional control or switch) into a position in which the single side of the travel

adjustment is surrounded by the marking frame.

Column 5 "Lim"

S1

S2

S3

S4

S5

Rev cent

0%

0%

0%

0%

0%

150%

150%

150%

150%

150%

150%

150%

150%

150%

150%

lim

+

In this column you can limit the servo travel. You can reach the column "- lim +", if you move the marking frame to the right over the

column "- Trv +" through the selection button .

Symmetrical or asymmetrical setting of the limit as explained in the

"– Trv +".

point

28 / 80

33028_mc_28_Teil2_jh

Page 29

Sticks setting

Servo adjustment

Stick mode

Control adjust

Dual Rate / Expo

Channel 1 curve

Switch display

Ch.1

Aile

Elev

Rudd

GL

PH

PH

PH

Tr

St

In this menu you can set the step value of the trim and the control

speed. This settings are valid for the channels one to four. The channels are listed with their function in the first column, according to

the chosen model type.

Column "Tr"

4

4

4

4

0.0s

0.0s

0.0s

0.0s

time

0.0s

0.0s

0.0s

0.0s

+

In this column you can choose if the function has to act globally (GL)

or according to the phase (PH). (Not for "CH1"). In the main display

the related setting will be displayed through a shadow on the trim

columns.

Shadow = global

No shadow = according to the phase

Column "St"

Here you can set the step "width" of the trim (0 to 10)

The setting acts always globally, max ±30% of the servo travel.

Column "- time +"

In this column "Time" it is possible to set the movement speed for

each movement direction of the control sticks 1 to 4 individually. The

setting acts always globally.

Controls setting

Servo adjustment

Stick mode

Control adjust

Dual Rate / Expo

Channel 1 curve

Switch display

GL

GL

GL

GL

typ

fr

fr

fr

fr

SEL

–––

–––

–––

–––

In5

In6

In7

In8

normal

0%

0%

0%

0%

offset

Symmetrical setting of time:

Move the related control stick into a position in which both sides of

the time adjustment are surrounded by the marking frame.

Asymmetrical setting of time:

Move the related control stick into a position in which each single

side of the time adjustment is surrounded by the marking frame.

In this menu it is possible to assign the control elements (controls)

of the transmitter to the channels. It is only possible for channels 5

to 16, because the channels one to four are preassigned to the control sticks.

The other channels will be visible if you scroll down with the selection buttons.

The transmitter is supplied with switches, buttons and rotary encoders that act separately on the channels.

If you scroll to the right with the selection buttons, other columns

will be visible.

33028_mc_28_Teil2_jh

29 / 80

Page 30

In5

In6

In7

In8

Normal

In5

In6

In7

In8

Normal

In5

E6

Move desired switch

E7

to ON position

E8

(ext. switch: SET)

Normal

fr

fr

fr

fr

SEL

fr

fr

fr

fr

SEL

fr

SD2

fr

fr

SEL

–––

–––

–––

–––

–––

–––

–––

–––

–––

–––

–––

–––

GL

GL

GL

GL

typ

GL

GL

Move desired

GL

control adj.

GL

typ

GL

GL

GL

GL

typ

0%

0%

0%

0%

offset

0%

0%

0%

0%

offset

0%

0%

0%

0%

offset

"Type"

In this column you can select if the control setting for this channel

has to act globally "G" or according to the phase "PH". If the control

has to be assigned specifically to the phase, the related phase must

be active. In the second line from the bottom of the display will be

shown the phase name.

"fr"

Here you can assign the desired proportional control. If no control is

assigned, it will be displayed "fr" (free). Here you can assign proportional controls only, no switch. Assign a control by pushing the SET

button and actuate the desired control. It will appear the abbreviation of the selected control.

"SEL "

Here you can assign the desired switch. If a proportional control is

already assigned, it will be deactivated and you will be able to assign

a second switch in the column. Ta again on SET, you can also assign

logical switches or normal switches.

Assign a switch by pushing the SET button and actuate the desired

switch. It will appear the abbreviation of the selected switch.

In5

In6

In7

In8

Normal

GL

GL

GL

GL

typ

Delete proportional control or switch:

• Use the SET button to select the desired field

• Tap on the selection buttons

t u or at the same time

"Offset"

Here, move the center of the channel in a possible range from -125%

fr

–––

3

2

fr

–––

fr

–––

0%

0%

0%

0%

offset

to + 125%.

Symmetrical travel setting:

Move the related control element (control stick, proportional control or switch) into a position in which both sides of the travel adjustment are surrounded by the marking frame. Set with the SET button

and the selection buttons.

Asymmetrical travel setting:

Move the related control element (control stick, proportional control or switch) into a position in which the single side of the travel

adjustment is surrounded by the marking frame. Set with the SET

button and the selection buttons.

30 / 80

33028_mc_28_Teil2_jh

Page 31

In5

Servo travel

Servo travel

Control travel

Control travel

Dual Rate = 50%

Dual Rate = 20%

Servo travel

Control travel

Dual Rate = 20%

In6

In7

In8

Normal

In5

In6

In7

In8

Normal

+100%

+100%

+100%

+100%

– trv +

0.0s

0.0s

0.0s

0.0s

– time +

Dual Rate / Expo

+100%

+100%

+100%

+100%

0.0s

0.0s

0.0s

0.0s

"- Trv +"

You can reach the column by moving the marking frame with the

selection buttons over the "Offset" column to the right side.

In this column you can set the control travel for both sides, together

or separated for each side. The setting range is 0 … 150% of the normal control travel. The set values always refer to the settings in the

column "Centre". Perform a symmetrical or asymmetrical setting as

described in the "Offset" section.

"– Time +"

You can reach the column by moving the marking frame with the

selection buttons over the "Trv" column to the right side.

In this column, a time delay is set for the respective channel. The set

seconds indicate the time that elapses between the switching states.

If the encoder or switch is actuated, the switching process then runs

in the set time. Perform a symmetrical or asymmetrical setting as

described in the "Offset" section.

Servo adjustment

Stick mode

Control adjust

Dual Rate / Expo

Channel 1 curve

Switch display

–––

–––

–––

DUAL

Dual Rate = 100%

Servo travel

Control travel

Dual Rate = 50%

100%

100%

100%

SEL

Ail

Ele

Rud

In this menu you can set the options Dual Rate and Expo.

Dual Rate

With this option you can reduce the travel of each control function.

This reduction is activated through a switch or, if no switch is assigned,

it will be always active. The graphical representation to the right

shows the control path profile for the selected control function.

Setting the Dual Rate step-by-step:

• Select the line of the desired control function

• Assign the switch in the column

section "Control settings")

• Input the reduction value in the column SEL

Now you can use the selected switch to pass from reduced control

travel to full control travel.

If the function has to be assigned specifically to the phase, the

related phase must be active. In the second line from the bottom of

the display will be shown the phase name.

(process as described in the

Servo travel

33028_mc_28_Teil2_jh

Control travel

31 / 80

Page 32

Ail

Servoweg

Servoweg

Servoweg

Geberweg

Geberweg

Geberweg

Expo = +100%

Expo = +50%

Expo = –100%

Servoweg

Geberweg

Expo = –100%

Ele

Rud

Normal

3

–––

–––

EXPO

+33%

0%

0%

SEL

Expo

You can reach the column by moving the marking frame with the

selection buttons over the "SEL" column to the right side. It will

be shown "EXPO" instead of "DUAL".

With this function you can influence the travel of each control function. You can set an exponential curve. The graphical representation

to the right shows the control path profile for the selected control

function.

This function can also be activated through an assignable switch.

Setting the Expo step-by-step:

• Select the line of the desired control function

Expo = +50%

Servoweg

Geberweg

Throttle curve

• Assign the switch in the column

(process as described in the

section "Control settings")

• Input the Expo curve value in the column SEL

Now you can use the selected switch to pass from linear control

travel to exponential control travel.

Combining Dual Rate and Expo

If you have set Dual Rate and Expo so that they act at the same time,

the travels will overlap. You get a reduced, exponential course of the

control travel.

Asymmetrical setting of Dual Rate and/or Expo

If you wish to set an asymmetrical travel of the control function, you

can also assign a control switch (see the "Transmitter switch" menu).

As a result, the Dual Rate or Expo functions only affect one side of

the control travel.

32 / 80

Servo adjustment

Stick mode

Control adjust

Dual Rate / Expo

Channel 1 curve

Switch display

curve

Ch1

Curve

Input

Output

Point

Normal

off

?

0%

0%

0%

This menu allows you to change the control characteristics of the

control function 1. The control function acts directly on the servo

connected to control channel 1 or via several mixers to several servos. Settings in this menu affect the throttle / brake control function

for an airplane model and the throttle / pitch function for a helicopter model.

If the function has to be assigned specifically to the phase, the

related phase must be active. In the last line of the display will be

shown the phase name.

33028_mc_28_Teil2_jh

Page 33

Kurve

K1

Kurve

Eingang

Ausgang

Punkt

Normal

1

aus

+50%

+50%

+50%

The control curve is defined by up to 6 points (points of intersection)

along the entire control stick path. The graphical representation

shows how the support points are set and adjusted.

In the first line, the effect of the curve function is switched "on" or

"off".

The "Input" and "Output" lines are only displays. The values indicate

the current position of the control stick "Input" and the position of

the control signal (output).

In the line "Point", the changeable points are set on the curve line.

The number (1 - 4) or the letter (L = low or H = high) after "Point"

indicates which point is currently selected. The percentage of the

current point is displayed in the field nearby.

curve

Ch1

Ch1

Ch1

off

2

curve

?

curve

1

Curve

Input

Output

Point

Normal

Trim X axis

Input

Output

Point

Normal

Trim offset

Input

Output

Point

Normal

+50%

–75%

–75%

0%

–33%

0%

0%

+50%

+50%

Setting the support point step-by-step:

• Select the line "Point"

• Move the throttle stick or the other control element for CH1 into

the desired position

• Pressing the SET button generates a point (maximum 4 possible)

Support points moving step by step:

• Select the line "Point", activate the field with the SET button

• Through the buttons

control element select the point, it appears "Trim point" in the

second line of the display

• Through the buttons

the point into the desired direction

Trim offset

With this function the entire curve will be moved vertically (max.

±25%). Therefore tap on the buttons of the left touch-pad, in

the second lines appears "Trim offset"

If the function is set to "on" in the line "curve", the curve is rounded

automatically.

t u of the left touch-pad or through the

t u or of the right touch-pad move

curve

Ch1

Curve

Input

Output

Point

Normal

33028_mc_28_Teil2_jh

on

1

–50%

0%

0%

33 / 80

Page 34

Switch display

Channel 1 curve

Switch display

Control switch

Logical switch

Announce

Phase settings

Schalter

7 8 9 10

6

12 13 14 1511

C1

C5

C2

C6

Control switch

4

C3 C4

C7 C8

The switch display is a mere display, it is a check function of the

switches and control switch in the transmitter.

Active switches are highlighted. On the right near the switch number

the switch position is displayed with a switch-symbol.

51 2 3

Channel 1 curve

Switch display

Control switch

Logical switch

Announce

Phase settings

Control switch

Gb1

C1

Gb1

C2

C3

C4

STO

SEL

Control switch

Gb1

Gb1

–75%

+75%

STO

G1

Move desired

G2

control adj.

C3

C4

SEL

0%

0%

0%

0%

0%

0%

SEL

SEL

–––

–––

–––

–––

–––

–––

–––

–––

In this menu a switch function is paired to the control travel of a proportional control.

Assigning the control switch:

• Select the line of the desired control switch

• Activate the column "SEL" through the SET button

• Actuate the desired control, the abbreviation of the control will

appear

Deleting the control switch:

• Use the SET button to select the desired field

• Tap on the selection buttons "left/right" or "up/down" at the

same time

Setting the switching point

• Select the STO column,

• move the control to the desired position

C1

C2

C3

C4

34 / 80

Control switch

SD2 +85%

0%

0%

0%

STO

SEL

SEL

10

–––

–––

–––

• Save the position through the SET button

Setting the switch direction:

• Select the column SEL, change the switch direction through the

SET button

Combining the control switch

A control switch can be controlled by another switch, so that in specific situations the function to be switched can be switched, independently from the control position and from the control switch

position. Therefore assign a switch in the column "

combine 2 control switches. Therefore select a control switch in the

column “

“

". You can also

33028_mc_28_Teil2_jh

Page 35

Logical switch

Channel 1 curve

Switch display

Control switch

Logical switch

Announce

Phase settings

Logical switch

–––

–––

–––

–––

AND

AND

AND

AND

SEL

L1

L2

L3

L4

–––

–––

–––

–––

L1

L2

L3

L4

Through this function two switches, controls and/or logical switches

or the favorite combination of them, can be interconnected. It is

realized through a "AND" or "OR" switch. You can program a total of

eight logical switches ("L1 ... L8") in each model memory. The result

of such a logical switch function can be used as alternative switch

function.

In the column “

“ you can assign both switches that have to be

connected. In the column SEL you can select the connection "AND"

or "OR". In the column on the right side is represented the state of

the logical switch.

Function of the connection

Function "AND": A logical switch is then "closed", when both switches

are "closed".

Function "OR": A logical switch is "closed" when one of both assigned

switches is closed.

Programming the logical switch step-by-step:

• Select the line of the desired logical switch

Move desired switch

to ON position

(ext. switch: SET)

Control/Logic/fix sw

C3i

C4i C5i C6i C7i

C8i L1i L2i L4i

L3i