Page 1

SERIAL DIGITAL I/O UPGRADE

Installation Manual

071-8074-00

NOVEMBER 2000

PROFILE FAMILY

VIDEO FILE SERVERS

Page 2

Copyright Copyright © 2000 Grass Valley Group Inc. All rights reserved. Printed in the United

States of America.

This document may not be copied in whole or in part, or otherwise reproduced

except as specifically permitted under U.S. copyright law, without the prior written

consent of Grass Valley Group Inc., P.O. Box 59900, Nevada City, California

95959-7900

Trademarks Grass Valley, GRASS VALLEY GROUP, Profile and Profile XP are either

registered trademarks or trademarks of Grass Valley Group in the United States

and/or other countries. Other trademarks used in this document are either

registered trademarks or trademarks of the manufacturers or vendors of the

associated products. Grass Valley Group products are covered by U.S. and foreign

patents, issued and pending. Additional information regarding

Grass Valley Group's trademarks and other proprietary rights may be f ound at

www.grassvalleygroup.com.

Disclaimer Product options and specifications subject to change without notice. The

information in this manual is furnished for informational use only, is subject to

change without notice, and should not be construed as a commitment by Grass

Valley Group. Grass Valley Group assumes no responsibility or liability for any

errors or inaccuracies that may appear in this publication.

U.S. Government

Restricted Rights

Legend

Use, duplication, or disclosure by the United States Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data

and Computer Software clause at DFARS 252.277-7013 or in subparagraph c( 1)

and (2) of the Commercial Computer Software Rest ricted Rights clause at FAR

52.227-19, as applicable. Manufacturer is Grass Valley Group Inc., P.O. Box

59900, Nevada City, California 95959-7900 U.S.A.

Revision Status

Rev Date Description

December 1997 Original issue. Manual Part Number 070-9977-00.

November 2000 Revised Product Support contact information.

Part Number 071-8074-00.

Page 3

Grass Valley Group Product Support

You can get technical assistance, check on the status of problems, or report new

problems by contacting our Product Support Group.

United States and Canada

Monday–Friday 5:30AM–5:00PM Pacific Time

(800) 547-8949

Europe

Monday–Friday 9:00AM–5:30PM

France

Germany 49 221 1791 234 Other +44 1753 218 777

Italy 02 25086606

01 45 29 73 00

Asia and South America

Australia

- from overseas

Beijing 86-10-62351230

Brazil 55-11-3741-8422 Taiwan 886-2-27571571

Hong Kong 852-2585-6579

02-9888 0100

61-2-9888 0100

ext. 711

World Wide

24-hour Emergency Hotline (530) 478-4148 (Contract and warranty customers)

World Wide Web http://www.grassvalleygroup.com/support//

FTP Site ftp.grassvalleygroup.com

E-mail profile-users@grassvalleygroup.com

United Kingdom 01628 405830

Japan 81-3-3448-3111

Korea 82-2-528-5299

Mexico 52-5-666-6333

Singapore 65-356-3900

Serial Digi t al I/O Upgrade Installat ion iii

Page 4

General Safety Summary

Review the following safety precautions to avoid injury and

prevent damage to this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to acce ss other parts of the

system. Read the g eneral safety s ummary in other sys tem manuals

for warnings and cautions related to operating the system.

Injury Precautions

Do Not Operate

Without Product

Covers in Place

Do Not Operate in

Wet/Damp

Conditions

Do Not Operate in an

Explosive

Atmosphere

Avoid Exposed

Circuitry

To avoid electric shoc k or fire hazar d, do not o per ate t his pro duct

with covers or panels removed.

To avoid electric shock, do not opera te this product in wet or damp

conditions.

To avoid injury or fire hazard, do not operate this product in an

explosive atmosphere.

To avoid injury, remove jewelry such as ri ngs, watches, and other

metallic objects. Do not touch exposed connections and

components when power is present.

iv Serial Digital I/O Upgrade Installation

Page 5

Product Damage Precautions

Product Damage Precautions

Use the Proper

Voltage Setting

Provide Proper

Ventilation

Do Not Operate If

You Suspect

Product Failures

Ensure that the lin e selector is in the proper po sition for t he power

source before applying power.

Prevent product overheating by providing proper ventilation.

If you suspect there is damage to this pro duct, have it in spected by

qualified service personnel.

Safety Terms and Symbols

Terms in This

Manual

!

!

Terms on the

Product

These terms may appear in this manual:

WARNING: Warning statements id ent ify conditions or practic es

that can res ult in person al injury or loss of life.

CAUTION: Caution statements identify conditions or practices

that can result in damage to the equipment or other property.

These terms may appear on the product:

DANGER indicates a personal injury hazard immediately

accessible as one reads the marking.

WARNING indicates a personal injury hazard not immediately

accessible as you read the marking.

CAUTION indicates a hazard to property, including the product.

Serial Digi t al I/O Upgrade Installat ion v

Page 6

Symbols on the

Product

The following symbols may appear on the product:

DANGER high voltage

Protective ground (earth) terminal

!

ATTENTION – refer to manual

Service Safety Summary

!

Do Not Service

Alone

Disconnect Power To avoid electric shock, disconnect the main power by means of

Use Care When

Servicing With

Power On

WARNING: These instructions are for use by qualified service

personnel only. To avoid personal injury, do not perform any

servicing unless you are qualified to do so. Refer to all safety

summaries before performing service.

Do not perform internal service or adjustment of this product

unless another person capable of rendering first aid and

resuscitation is present.

the power cord or, if provided, the power switch.

Dangerous voltages or currents may exist in this product.

Disconnect power and remove battery (if applicable) before

removing protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

vi Serial Digital I/O Upgrade Installation

Page 7

Certifications and Compliances

Certifications and Compliances

FCC Emission

Control

Canadian EMC

Notice of

Compliance

This equipment has been tested and found to comply with the

limits for a Cl as s A digital device, p ursuant to Part 15 of the FCC

Rules. These limits are de signed to provi de reas ona ble prot ecti on

against harmful interference when the equipment is operated in a

commercial environment . This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this

equipment in a residential area is lik ely to cause harmful

interference in which case the user will be required to correct the

interference at his own expense. Changes or modifications not

expressly approved by Grass Valley Group can affect emission

compliance and could void the user’s authority to operate this

equipment.

This digital apparatus does not exceed the Clas s A limits for radio

noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de la

classe A préscrites dans le R èglement sur le brouillage

radioélectrique édicté par le ministère des Communications du

Canada.

EN55022 Class A

Warning

For products that comply with Class A. In a domestic

environment, this produ ct ma y cause radio interferenc e, in which

case the user may be required to take adequate measures.

Serial Digi t al I/O Upgrade Installat ion vii

Page 8

Certification

Category Standard

Safety Designed/tested for compliance with:

UL1950 – Safety of Information Technology Equipment, including Electrical

Business Equipment (Third Edition, 1995)

IEC 950 – Safety of Information Technology Equipment, including Electrical

Business Equipm ent (Second edition, 1991)

CAN/CSA C22.2, No. 950- 95 – Safety of Information Technology Equipment,

including Electrical Business Equipment

EN60950 – Safety of Information Technology Equipment, including Electrical

Business Equipment (includes Appendix ZB)

viii Serial Digital I/O Upgrade Installation

Page 9

Serial Digital I/O Upgrade Installation

Introduction

These instructions explain how to install the new serial digital I/O board in a

PDR100 Video Disk Recorder or a PDR200 Video File Server. The latest boards

have Sharcnet connectors so that embedded audio can be routed to and from the

Audio Signal Processing Board (ASPB). These instructions also assume that you

have already installed a slave disk recorder board field upgrade. The slave board

converts a two-channel Profile system into a four-channel system.

NOTE: Embedded audio does not work wi th the Analog Audio I/ O boards that

came standard with the PDR100. You must install an ASPB in a PDR100 to

use embedded audio.

The instructions include procedures for:

• Opening the Profile chassis.

• Moving existing boards, if necessary, to make room for the new board.

• Installing the new board.

• Closing the Profile chassis.

• Verifying that the insta lled board is functionin g correctly.

System Requirements

The Profile system software installed in the Profile system must be version 2.1 or

higher. To check the software version installed in your Profile system, open the

VrdPanel application and cho ose

listed in the Product Version field in the displayed window.

Kit Contents

This upgrade kit includes the following:

• A serial digital component I/O board.

• Two Sharcnet cables.

• Two 50

• A set of stick-on identification labels.

• This installation manual.

Ω audio clock cables.

Help | About VdrPanel. The software version is

Serial Digi t al I/O Upgrade Installat ion 1

Page 10

Serial Digital I/O Upgrade Installation

Tools Required

Tools required, but not supplied, to install this kit are:

• A Torx tool with T10 and T15 tips.

• Electrostatic discharge (ESD) grounding straps.

Electrostatic Precautions

CAUTION: This product contains components that are highly sensitive to

!

!

electrostatic discharge. To protect these components from damage and to

maintain product reliability, take the following precautions whe n handling

the circuit boards:

• Handle all circuit boards in a static-protected area capable of controlling

static charge on conductive materials, people, and nonconductive

materials. Static-prot ected areas include nonstati c table tops and nonstatic

floor mats.

• Leave the board in its ESD static -shielded bag unt il you are re ady to install

the board.

• Wear ESD grounding straps when handling boards outside of their ESD

static-shielded bags.

• Handle the circuit boards only by the edges. Avoid touching the printed

wires on the back of the circuit board as much as possible.

2 Serial Digital I/O Upgrade Installation

Page 11

Installation Procedures

The procedures that follow take you step-by-step through the installation of the

serial digital I/O board. You can install the board with the Profile chassis fully

extended on the rack slides if the equipment rack is adequately anch ored to prevent

tipping, and if t her e is sufficient slack in the cables con nec ted to the rear panel t o

allow the chassis to fully extend on the slides.

If it is necessary for you to remove the Profile unit from the equipment rack to

perform this installation, refer to the Profile sy stem’s instal lation manual for

instructions.

WARNING: Unless the equipment rack is adequately anchored, the rack

!

could tip when the chassis is extended on the rack slides. To avoid possible

injury, make sure the rack is firmly secured before extending the chassis on

the rack slides.

Installation Procedures

Serial Digi t al I/O Upgrade Installat ion 3

Page 12

Serial Digital I/O Upgrade Installation

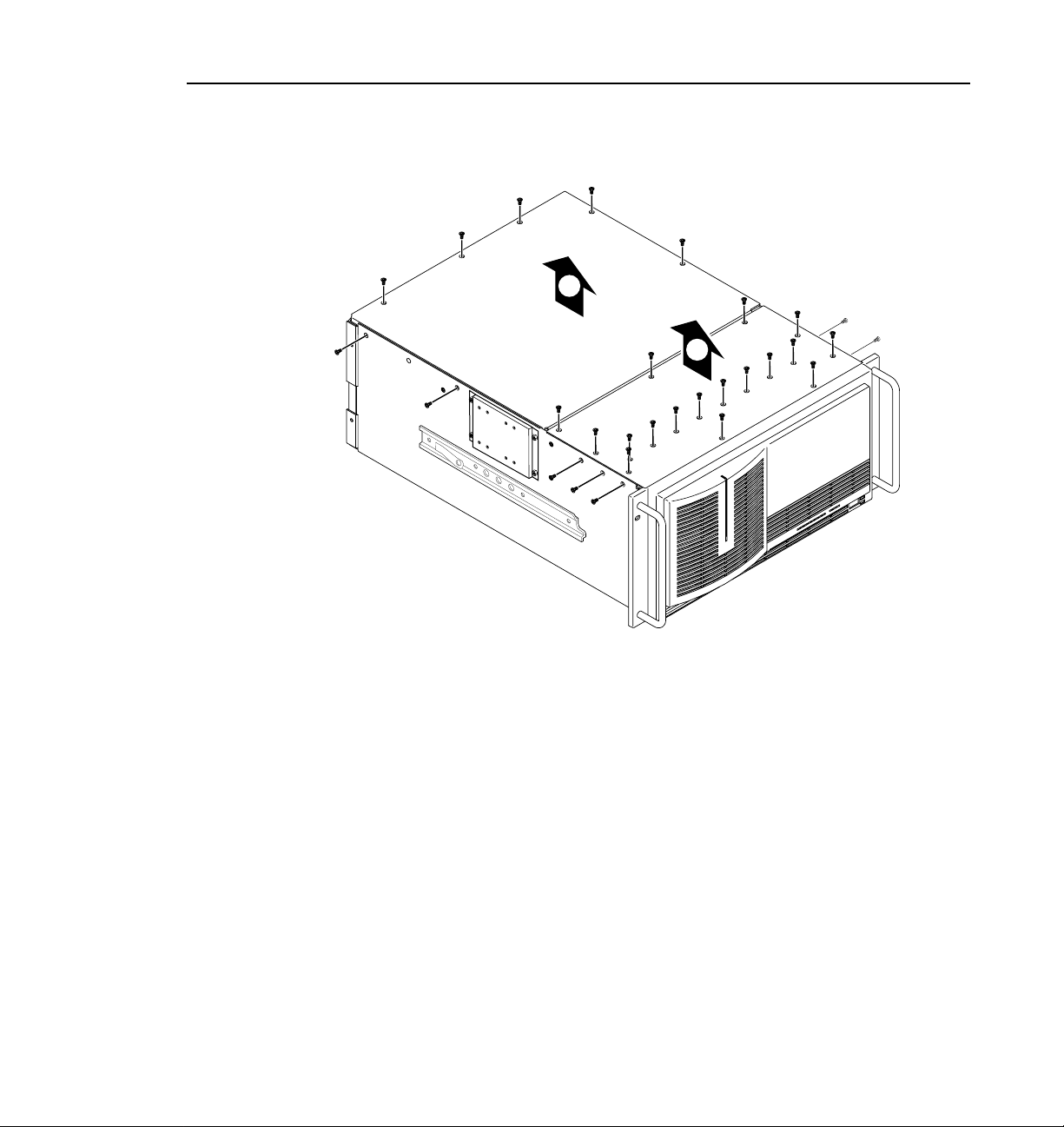

Removing the Chassis Covers

To remove the chassis covers:

1. Turn Profile system power off and remove the power cord.

2. Loosen the front pane l retaining s crew and pull the chassis out fr om the rack

until the slide sections latch. If the rack is not anchored firmly, remove the

chassis from the rack.

3. Use the T orx tool with the T10 tip to remove the top screws from the front

chassis cover (

screws.The front chas sis cover mus t be removed f irst because i t overlaps the

rear chassis cover (

NOTE: Take care not to lose these chassis screws. They are requi red to meet

the EMI specifications for the Profile unit. Also, not all the screws on a

PDR200, as shown in Figure 1, are present on a PDR100.

in Figure 1) and use the T15 tip to remove the side

Ê

in Figure 1).

Ë

4. Use the Torx tool with the T10 tip to remove the rear chassis cover (

Figure 1) which covers the circuit boards.

Ë

in

4 Serial Digital I/O Upgrade Installation

Page 13

9675-9

Removing the Chassis Covers

2

1

Figure 1. Removing the front and rear chassis covers

Serial Digi t al I/O Upgrade Installat ion 5

Page 14

Serial Digital I/O Upgrade Installation

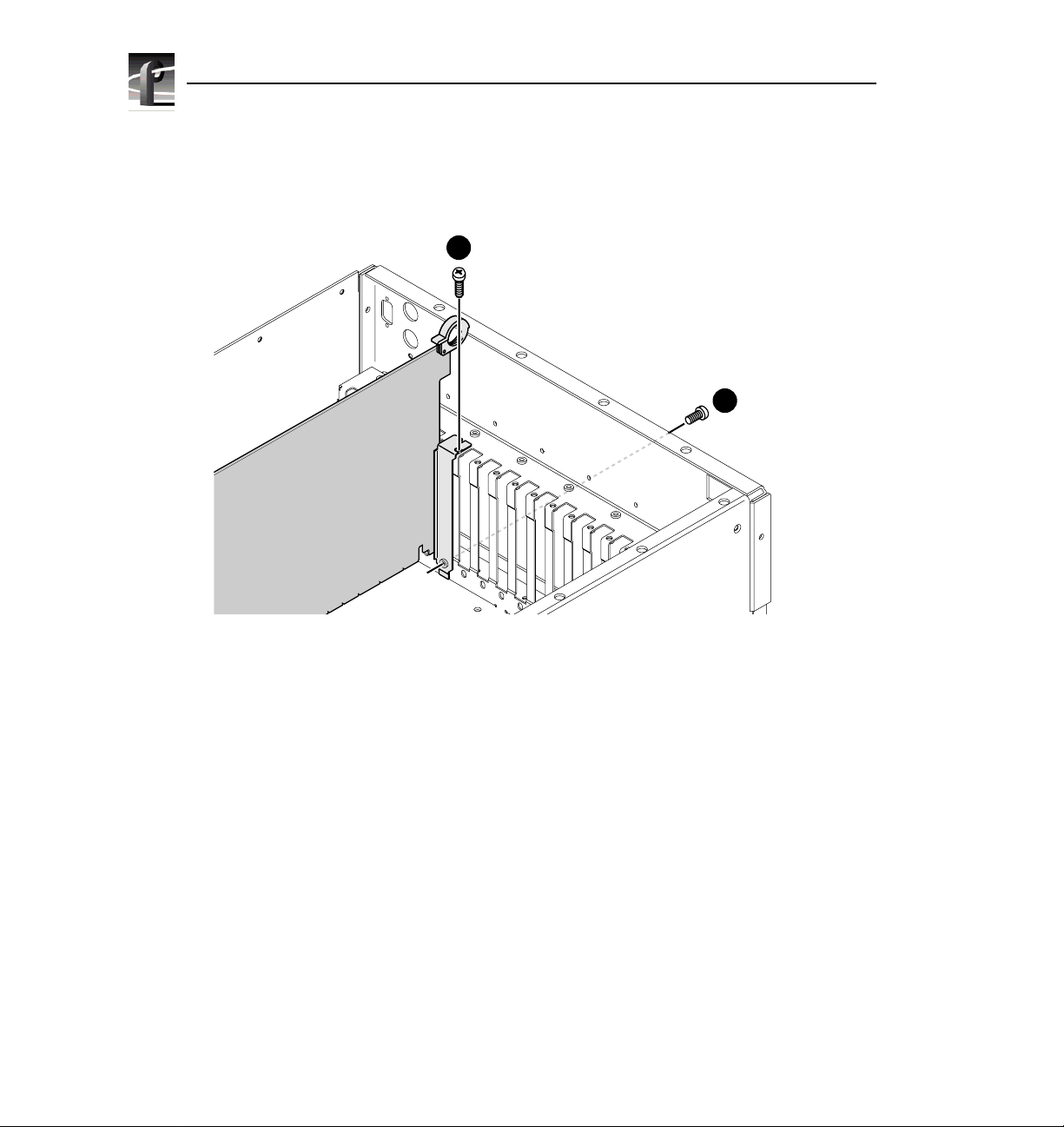

Removing the Circuit Board Hold-down Brackets

There are two hold-down brackets located in the circuit board area that must be

removed in order to remove and replace circuit boards. Figure 2 shows these

brackets.

To remove the hold-down brackets:

1. Use the Torx tool with the T10 tip to remove the screw (

secures the rear board hold-down bracket.

2. Lift the hold-down bracket (

aside.

3. Use the Torx tool with the T10 tip to remove the screw (

secures the front board hold-down bracket.

4. Lift the hold-down bracket (

aside.

in Figure 2) up and out of t he ch assis and s et

Ë

in Figure 2) up and out of the chass is an d s et

Í

in Figure 2) which

Ê

in Figure 2) which

Ì

6 Serial Digital I/O Upgrade Installation

Page 15

Removing the Circuit Board Hold-down Brackets

3

4

2

9675-2

Figure 2. Removing the circuit board hold-down brackets

1

Serial Digi t al I/O Upgrade Installat ion 7

Page 16

Serial Digital I/O Upgrade Installation

Removing Circuit Boards

Installing the serial digital I/O board may require that you remove or reposition

one or more currently insta lled board s to make room for the n ew board or to meet

internal cabling constraints.

When unplugging boards, you may also find it necessary to remove the screw

mounting an adjacent circuit board, and i n the case of shorter c ircuit boards, it may

be necessary to remove an adja cent tall ci rcuit board t o ease remova l of the short er

board.

Use the following procedure to unplug circuit boards from the motherboard:

1. Remove all interior and rear panel cables from the circuit boards that are to

be removed.

2. Use the Torx tool with the T15 tip to remove the screw from the bracket

inside the chassis (

outside the chassis (

CAUTION: To avoid damage to the circuit board when removing or

installing it:

in Figure 3) and the screw through the rear panel

Ê

in Figure 3).

Ë

- Do not rock the circuit boar d in the EISA bus connector — pull straight

up to remove.

- Do not grasp or push on the rear-panel connectors when removing or

installing circuit boards in the card slots.

3. Extract the circuit board. If the circuit board is tall, use the extraction lever

on the front of the board and the extraction ring at the back of the board to

lift the circuit board free of the connectors on the motherboard. For shorter

circuit boards, carefully grasp the board and lift upward to free the circuit

board from the motherboard connectors. You might need to remove an

adjacent tall board to get enough room for a safe hold on the shorter board.

8 Serial Digital I/O Upgrade Installation

Page 17

Removing Circuit Boards

1

Figure 3. Screw locations for board mounting bracket

2

9040-13

Serial Digi t al I/O Upgrade Installat ion 9

Page 18

Serial Digital I/O Upgrade Installation

Board Location Guide

This board location guide is provi ded to help you ins tall a serial dig ital I/O board

in a PDR200 or PDR100. The guide identifies t he video router inputs and outpu ts

of each Profile board currently available, as well as the input and output

connections on the video router connectors on the motherboard. Use this

information when:

• Adding a board to the Profil e system a nd selecting a s lot into whi ch you can

install it.

• Moving boards to meet requirements for new boards.

As you move boards, remember that some circuit boards must occupy specific

slots, while others can be installed in almost any slot as long as their I/O

requireme nts are met (see Table 1).

From the factory, a s ingle, two- channe l ser ial d igit al I/ O board comes inst alle d in

slot J14 in a PDR202D. The recommend ed slot for th e additional serial digi tal I/O

is slot J15, although it could be installed in any available slot from J5 to J15. In

order to use embedded audio , however, th e serial di gital I/ O boards must be clo se

enough to the Audio Signal Processing Board (ASPB) for the audio clock and

Sharcnet cables to reach. Also, the board must not be in a slot with shared inputs

when all the inputs are taken by the adjacent board, such as the four-channel

analog output board or the analog composite monitor board.

This section provi des a gen eral, simple a pproach t o board l ocation. It expl ains the

relationship between the motherboard and video router connectors and provides

tables, charts and examples to assist you in installing this and other boards.

Video Router to Motherboard Relationship

The video router provides and controls video data to twelve connectors on the

motherboard. These v ideo data con nectors are aligned wit h the main mothe rboard

connectors for slots J 5 through J16. Since the Reference Genlock (Re f Gen) board

must occupy J16 to provide t he necessar y system clo cks, this di scussion excludes

J16.

When choosing a slot for a board, the majo r constraint for a slot is how the board

connects to the vi deo ro uter. No t all boards requi re th e sa me number o f vide o I/O

connections, and n ot all video data connectors provide the same number of vi de o

I/O connections. Therefore, you must know how many input and output

connections the bo ard need s, if any, and the s lots availab le that me ets those needs.

10 Serial Digital I/O Upgrade Installa tion

Page 19

Board Location Guide

Board I/O Requirements and Restrictions

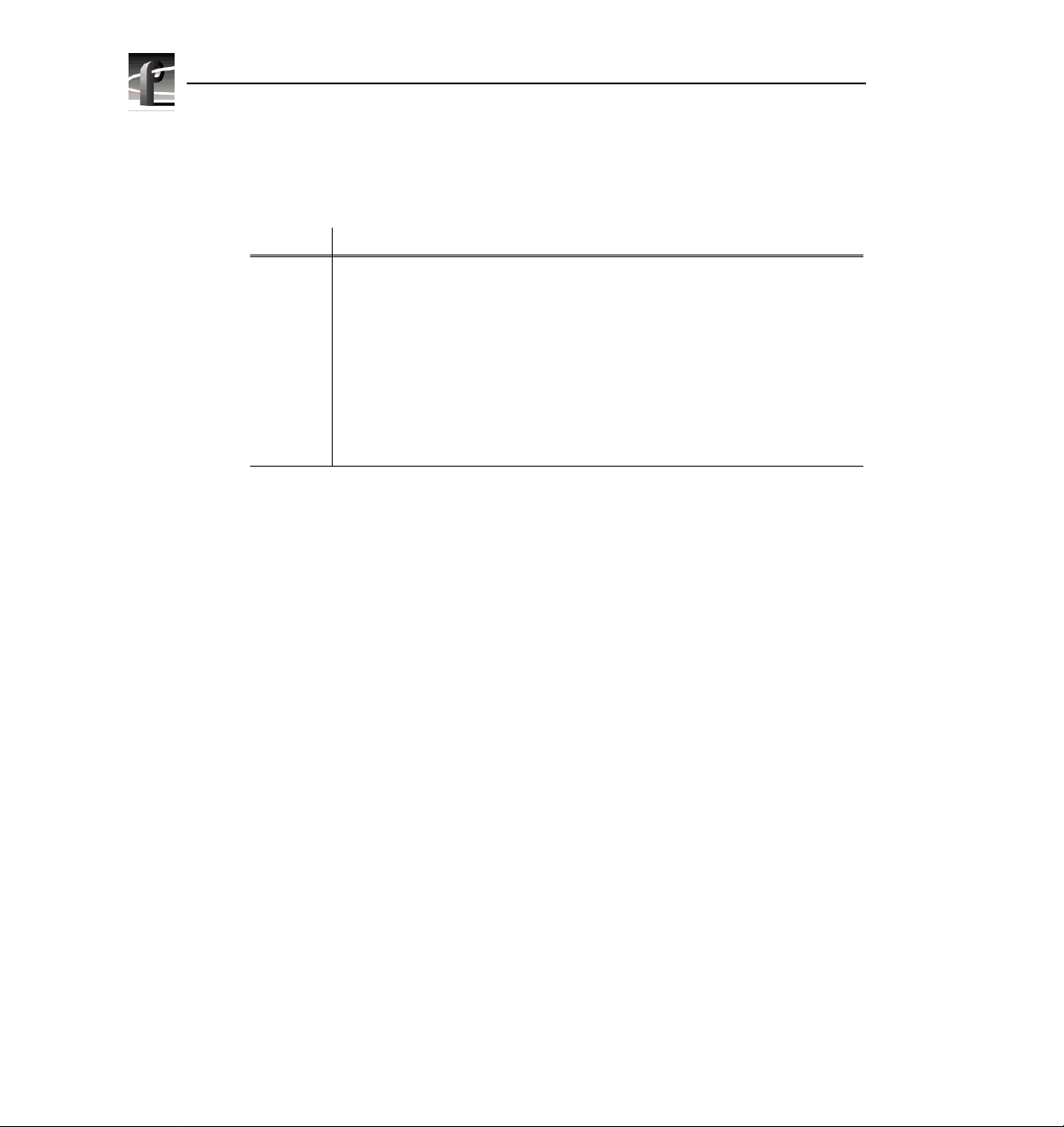

Table 1 lists each of the boards which may be installed in the Profile system and

the recommended slots, possible alternatives, and restrictions for each board. If

more than one slot is recommended or possible for a board, those slots are listed

in the order of preference.

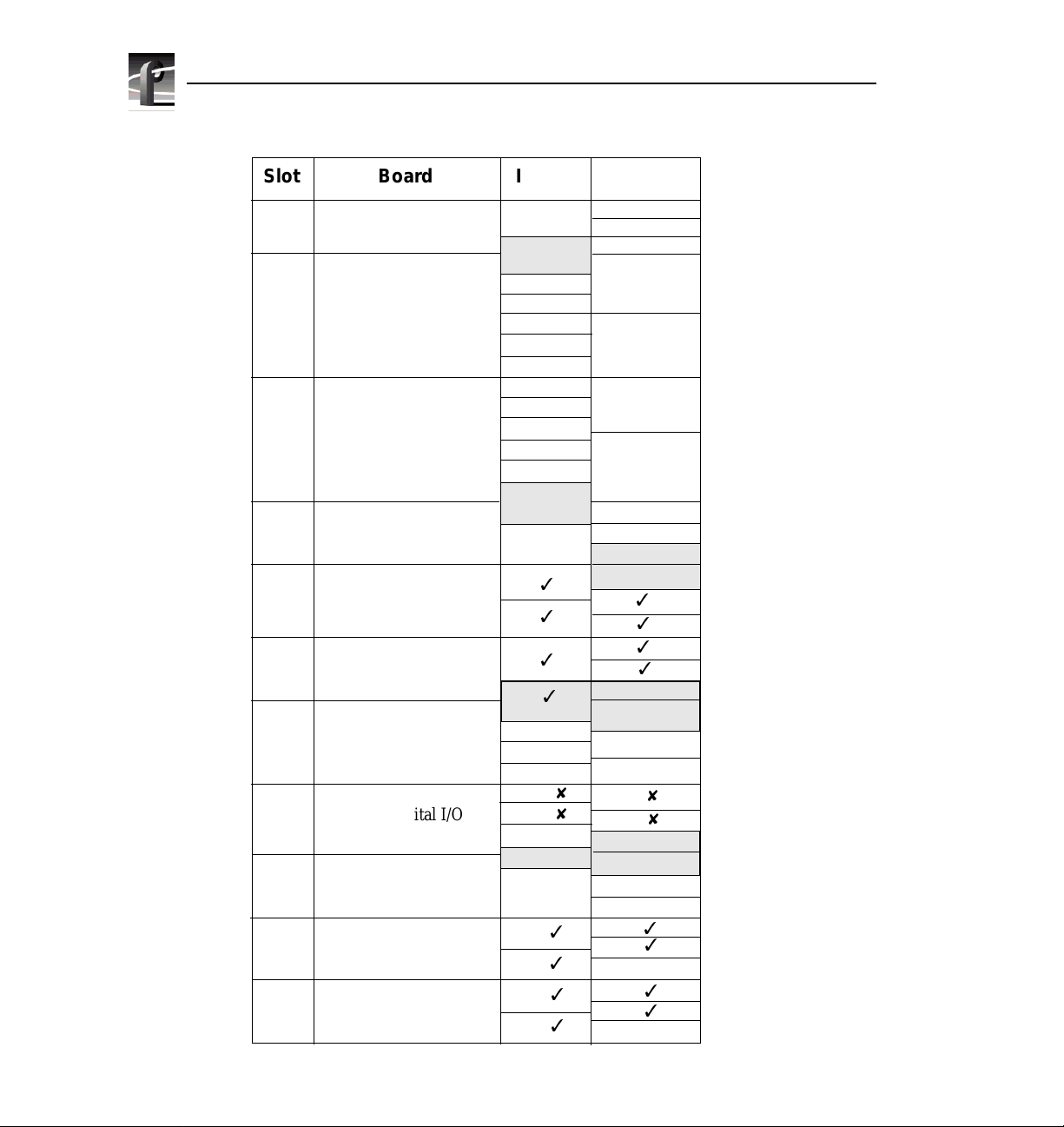

Video Router I/O Connections

Now let’s look at the vid eo router co nnections ava ilable at slots J5–J15. Table 2 is

a board location chart with the video router input and output connections. In this

table:

• The

Slot column lists each slot on the motherboard connected to the video

router.

• The

Board column is where y ou write the boards cur rent ly in stal led an d the

name of the board you want to install.

• The

Inputs column identifies data input connections available to the slots

(boards) from the video rout er. The numbers in t he blocks corr espond to the

order input connections are assigned at the video router connector.

• The

Outputs column identifies data output connections available from the

slots (boards) to the video router. The numbers in the blocks correspond to

the order output connections are assigned at the video router connector.

• The shaded blocks in the diagram indicate video router connections shared

between slots. A shared conne ction is av ailable to either s lot, but not b oth at

the same tim e. For instance:

- The shaded blocks between slots J5 an d J6, sl ots J7 and J8, slots J10 and

J11, and slots J12 and J13 indicate shared input connections.

- The shaded blocks between slots J8 and J9, slots J10 and J11, and slots

J12 and J13 indicate shared output connections.

Serial Digi t al I/O Upgrade Installat ion 11

Page 20

Serial Digital I/O Upgrade Installation

Table 1. Board I/O requirements and restrictions

Board Video Router

CPU n/a n/a J1 J1 None

VGA n/a n/a J2 J2 None

LAN n/a n/a J3 J3 None

SCSI n/a n/a J4 J4 None

RefGen n/a n/a J16 J16 None

RS422 n/a n/a J17 J17 None

Fibre Channel n/a n/a J15 J8 J5–J15 Must be adjacent to Master EDR

Master EDR 2 2 J14 J9 J5–J15 Must be adjacent to Slave EDR and

Slave EDR 2 2 J13 J10 J5–J15 Must be adjacent to Master EDR

Master DR 2 2 J14 n/a J5–J15 Must be in adjacent to Slave DR

Slave DR 2 2 J15 n/a J5–J15 Must be adjacent to Master DR

Serial Digital I/O 2 2 J11 J14, J15 J5–J15 Cables must be able to reach other

Decoder None None J8 J5 J7, J11 Must be adjacent to Analog

Analog

Composite In

Analog

Composite I/O

Mix Effects 6 2 J7 J7 J6 Only J6 and J7 have 5 inputs; board

Four Channel

Analog Out

Analog

Composite

Monitor

Audio Signal

Processing

Board (ASPB)

CAV In None 1 J5 J5 J5–J15

Audio I/O None None J5-J15 n/a J5–J15

Connection

Requirements

Inputs Outputs PDR 100 PDR 200

None 1 J9 J6 J 8, J12 Must be adjacent to Decoder

2 2 J11 J14, J15 J5–J15 Can’t go in J5 if Mix Effects is in J6 or

4 None J6 J6 J12, J7,

4 None J12 J12 J6, J7, J11 Only J6, J7, J11, and J12 have 3 (or

None None J13 J13 (1st)

Recommended Slot Other

Possible

Slots

J11

J5–J15 Cables must be able to reach video

J12 (2nd)

Restrictions

(if installed) Fibre Channel

serial digital I/O or ASPB

Composite In

in J8 if Mix Effects is in J7

must be able to get a shared input

(the 6th) from an adjacent slot (J5 or

J8)

Only J6, J7, J11, and J12 have 3 (or

more) inputs. If in J11 or J12, board

must be able get a shared input (the

4th) from an adjacent slot (J10 or

J13)

more) inputs. If in J11 or J12, board

must be able get a shared input (the

4th) from an adjacent slot (J10 or

J13)

boards or additional ASPB

12 Serial Digital I/O Upgrade Installa tion

Page 21

Table 2. Board location chart

Board Location Guide

Slot Board Inputs

J5

1

2

J6

1

2

J7

3

4

5

6

J8

1

J9

2

1

J10

2

J11

1

J12

2

3

4

J13

J14

1

2

J15

1

2

6

5

4

3

2

1

2

1

4

3

2

1

2

1

Outputs

1

2

3

1

2

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

1

2

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

Serial Digi t al I/O Upgrade Installat ion 13

Page 22

Serial Digital I/O Upgrade Installation

Selecting a Location

Here’s how to use the tables to select a location for a board:

1. Write the board name in Table 2 an d, refer ring to Table 1, pu t a check mark

(

3

) in each input and output block used by each board currently installed in

your Profile system. Start with the 1 block for each board.

2. Look in Table 1 to see the input and output requirements and both the

recommended slot and alternative slots for the board you want to install.

3. Look in Table 2 for a slot with the required video router connections

available. Starting with the 1 block, put an

to an input and output requirement for the newly added board. If the

recommended slot i s occupied, or t here are not enou gh input or outpu t blocks

available, look at the alternative slots.

4. If all input and output requirements for the board match the available ones

for the slot, write the board name in the

the board.

NOTE: If you can’t find an open slot with the I/O connections which meets

the I/O requirements of the board you want to install, you will have to move

existing boards. You can use Table 1 and Table 2 to experi ment with various

board locations before deciding on one.

8

in each block that correspo nds

Board co lumn for the slot and i nstall

The following examples demonstrate how to use these Table 1 and Table 2.

14 Serial Digital I/O Upgrade Installa tion

Page 23

Board Location Guide

Example 1: Installing a Second Serial Digital I/O Board

This example shows how to use Tabl e 1 and Ta ble 2 t o insta ll an additi onal s erial

digital I/O board in a two-channel PDR202D with a Fibre Channel board and a

Mix Effects board.

NOTE: The example assumes that the Profile sys tem has been upgraded with

a slave enhanced disk recorder board field kit.

1. Fill in Table 2 with th e informatio n for all the boards currently install ed in

the system.

a. For the Mix Effects in slot J7, which requires six inputs and two outputs:

- Put check marks in the five J7 Input blocks, 1–5.

- Put a check mark in the J8 shared Input Block.

- Put check marks in the J7 Output blocks 1 and 2.

b. For the Fibre Channel in slot J8, there are no video router I/O

requirements.

c. For the Master EDR in slot J9, which requires two i nputs and two ou tputs:

- Put check marks in the J9 Input blocks 1 and 2.

- Put check marks in the J9 Output blocks 1 and 2.

d. For the Slave EDR in slot J10, whic h requires two inp uts and two outputs :

- Put check marks in the J10 Input blocks 1 and 2.

- Put check marks in the J10 Output blocks 1 and 2.

e. For the ASPB in slot J13, there are no video router I/O requirements.

f. For the Serial Digital I/O in slot J14, which requires two inputs and two

outputs:

- Put check marks in J14 Input blocks 1 and 2.

- Put check marks in J14 Output blocks 1 and 2.

2. From Table 1, note that the second serial digital I/O board’s recommended

slot is J15, with J5 through J15 as other possible slots.

3. Write Serial Digital I/O in the Bo ard column for slot J15 and install the

board.

- Put an

- Put an

Your board location chart would then look similar to Table 3.

8

in J15 Input blocks 1 and 2.

8

in J15 Output blocks 1 and 2.

Serial Digi t al I/O Upgrade Installat ion 15

Page 24

Serial Digital I/O Upgrade Installation

Table 3. Example 1, Installing a Second Serial Digital I/O Board

Slot Board Inputs

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

J15

Mix Effects

Fibre Channel

Master Enhanced

Disk Recorder

Slave Enhanced

Disk Recorder

ASPB

Serial Digital I/O

Serial Digital I/O

1

2

1

3

3

2

3

3

4

3

3

5

6

3

1

3

2

3

1

3

2

3

1

2

3

1

3

2

3

1

8

8

2

6

5

4

3

2

1

2

1

4

3

2

1

24

1

Outputs

1

2

3

1

3

2

3

1

2

3

4

3

3

3

1

2

3

3

4

1

2

3

4

1

3

3

2

3

1

8

2

8

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

16 Serial Digital I/O Upgrade Installa tion

Page 25

Board Location Guide

Example 2: Adding Serial Digital I/O to an Analog System

This example shows how to use Table 1 and Table 2 to install a serial digital I/O

board in a four-channel PDR204A.

1. Fill in Table 2 with th e informatio n for all the boards currently install ed in

the system.

a. For the Analog Composite I/O in slots J14 and J15, which require two

inputs and two outputs:

- Put check marks in both J14 and J15 Input blocks 1 and 2.

- Put check marks in both J14 and J15 Output blocks 1 and 2.

b. For the Master EDR in slot J9, which requir es two inputs and two outputs :

- Put check marks in the J9 Input blocks 1 and 2.

- Put check marks in the J9 Output blocks 1 and 2.

c. For the Slave EDR in slot J10, which requires two inputs and two outputs:

- Put check marks in the J10 Input blocks 1 and 2.

- Put check marks in the J10 Output blocks 1 and 2.

d. For the ASPB in slot J13, there are no video router I/O requirements.

2. From Table 1, note that the serial digital I/O board’s possible slots are J5

through J15.

3. Write Serial Digital I/O in the Bo ard column for slot J12 and install the

board.

- Put an

- Put an

Your board location chart would then look similar to Table 4.

8

in J12 Input blocks 1 and 2.

8

in J12 Output blocks 1 and 2.

Serial Digi t al I/O Upgrade Installat ion 17

Page 26

Serial Digital I/O Upgrade Installation

Table 4. Example 2, Adding Serial Digital I/O to an Analog System

Slot Board Inputs

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

J15

Master Enhanced

Disk Recorder

Slave Enhanced

Disk Recorder

Serial Digital I/O

ASPB

Analog Composite I/O

Analog Composite I/O

1

2

1

2

3

4

5

6

1

3

2

3

1

3

2

3

8

1

2

8

3

1

3

2

3

1

3

3

2

6

5

4

3

2

1

2

1

4

3

2

1

24

1

Outputs

1

2

3

1

2

1

2

3

4

3

3

3

1

2

3

3

4

1

8

2

8

3

4

1

3

3

2

3

1

3

2

3

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

18 Serial Digital I/O Upgrade Installa tion

Page 27

Installing the Serial Digital I/O Board

Refer to the board I/O requirements and restrictions in Table 1 and install the

board as follows:

1. If necessary, r emove the slot cover where you want to inst all the board—J15,

in this example.

2. Align the board with the connectors on the motherboard. Make sure the

extractor on the fro nt e nd of the board i s in th e up posi tion, t he n press down

on the board firm ly unt il the board is seated. As you push the board in to the

connectors, you will feel the board engage first one, then a second set of

contacts in the connector. The board is properly seated when the top of the

rear mounting bracket is resting on the rear chassis wall shelf.

3.

Use the Torx tool with the T15 tip to install the mounting screws in the top

of the bracket inside the chassis (

at the bottom of the bracket (

in Figure 4) and through the rear panel

Ê

in Figure 4).

Ë

Installing the Serial Digital I/O Board

Serial Digi t al I/O Upgrade Installat ion 19

Page 28

Serial Digital I/O Upgrade Installation

1

2

9040-13

Figure 4. Screw locations for board mounting bracket

4. Install the blan k circuit board bracket s (if necessary) i n the empty board slots

on the rear panel.

5. Connect the audio clock and Sharcnet cables (see “Audio Clock and

Sharcnet Cabling” on page 22).

6. Use the Torx tool with the T10 tip to reinstall the rear board hold-down

bracket (see Figure 2).

7. If necessary, reconfigure the front board hold-down bracket, moving or

removing a short board extension, and use the Torx tool with the T10 tip to

reinstall the front board hold-down bracket (see Figure 2).

8. Use the Torx tool with the T10 tip to reinstall the rear top cover with the

screws previously removed.

9. Use the Torx tool with the T10 and T15 tips to reinstall the front top cover

with the screws previously removed.

20 Serial Digital I/O Upgrade Installa tion

Page 29

Installing the Serial Digital I/O Board

10. Apply th e stick-on label at the appropriat e location in the Pro file chassis rea r

panel to identify the location of the serial digital I/O board and any other

board you repositioned.

11. Reinstall t he Profile chassis in the rack and reconnect all cables previ ously

removed.

12. Apply power to the Profile system and check the presence of the second

serial digital I/O board in slot J15 with the procedure under “Installation

Verification” on page 24.

Serial Digi t al I/O Upgrade Installat ion 21

Page 30

Serial Digital I/O Upgrade Installation

Audio Clock and Sharcnet Cabling

This example shows the external audio clock and Sharcnet cabling necessary for

two serial digi ta l I /O boards (two channels e ach for a total of four c h ann els ) used

with an ASPB. The cable conn ections are lis ted in Tab le 5 and shown in Fi gure 5.

Table 5. PDR200 cabling for two serial digital I/O boards and an ASPB

Cable Type Serial Digital

I/O Slot

Sharcnet J15 Sharcnet A S harcnet 1

Sharcnet J14 Sharcnet A S harcnet 2

Sharcnet J15 Sharcnet B Sharcnet 3

Sharcnet J14 Sharcnet B Sharcnet 4

Audio clock J14 Channel A Audio 1

Audio clock J14 Channel B Audio 2

Audio clock J15 Channel A Audio 3

Audio clock J15 Channel B Audio 4

From Serial

Digital I/O

To ASPB

Each ASPB provides input of four external audio clock signals, one to each

Audio 1 through Audio 4 ba nk, whe re each bank consists of four audio channels.

ASPB Audio 1 through Audio 4 connec tors b egin cl osest to the rear pa nel and go

toward the front panel.

In general, the video board in the lowest numbered slot must provide the audio

clock signal to the Audi o 1 bank, then the vi deo board in the next l owest numbered

slot must provide the audio clock signal to the Audio 2 bank, and so forth. For

example, if you have vi deo board s in slot s J5 and J11, th e audio c lock sign al from

the video board in J5 must be connected to Audio 1 on the ASPB and the audio

clock signal from the vi deo board i n slot J11 must be connected to Audio 2 on the

ASPB. If there are no available clock connect ors on the ASPB, video inputs on the

unclocked board must be synchronous with a clocked input.

22 Serial Digital I/O Upgrade Installa tion

Page 31

Installing the Serial Digital I/O Board

J17 J13J16

J11 J9

J15 J14 J6J7

Sharcnet In

Sharcnet Out

Channel B

J12

J10

J8

Sharcnet Out 1

Sharcnet Out 2

Sharcnet In 2

Sharcnet In 1

Sharcnet Expansion 1

Sharcnet Expansion 2

Audio 4

Audio 3

Audio 2

Audio 1

J5

J4 J3

Channel A

Serial

Digital I/O

Figure 5. PDR200 cabling with two serial digital I/O boards and an ASPB

Serial Digi t al I/O Upgrade Installat ion 23

ASPB

9977-1

Page 32

Serial Digital I/O Upgrade Installation

Installation Verification

Verification for installation of the serial digital I/O board consists of ensuring that

the system recognizes the board. Use the Diagnostics window, which lists all

installed and recognized boards, to see if the system recognizes the board. To

check for recognition of the added serial digital I/O in a PDR200, for example:

1. From the Windows NT 4.0 desktop, open the Diagnostics window by

choosing

2. On the left side of the window, ensure that the additional serial digital I/O

appears at slot J15 or wherever the board was installed (see Figure 6 for an

example).

Start | Programs | PDR Debug Tools | PDR Diagnostics.

Slot J1

Slot J2

Slot J3

Slot J4

Slot J5

Slot J6

Slot J7

Slot J8

Slot J9

Slot J10

Slot J11

Slot J12

Slot J13

Slot J14

Slot J15

Slot J16

Slot J17

Mother Bd

Pentium CPU

Non-EISA slot

SMCA010

BUS4202

Mix Effects (Rev 0)

Fibrechannel I/F (Rev 0)

Master EDR (Rev 0)

Slave EDR (Rev 0)

ASPB (Rev 1)

Serial UA (Rev 1)

Serial UA (Rev 1)

Ref Gen (4 LTC) (Rev 0)

RS422, if installed

Mother Board (Rev 0)

Quit

Figure 6. Diagnostics window board recognition example for PDR204D

24 Serial Digital I/O Upgrade Installa tion

Loading...

Loading...