GRASS VALLEY JUPITER CM-4400 - VERSION 7.9.0 - 10-2010, JUPITER Installation And Operating Manual

Page 1

JUPITER

CM-4400: AccuSwitch Control System

Installation and Operating Manual

Software Version 7.9.0

071876600

OCTOBER 2010

Page 2

Affiliate with the N.V. KEMA in The Netherlands

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Thomson Inc, and it’s wordwide Grass Valley division affiliates DBA

GRASS VALLEY

Headquarters

400 Providence Mine Rd

Nevada City, CA 95959

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

10 Presidential Way

Suite 300

Woburn, MA 01801

United States

Kapittelweg 10

4827 HG Breda

The Nederlands

7140 Baymeadows Way

Ste 101

Jacksonville, FL 32256

United States

2300 So. Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Rue du Clos Courtel

CS 31719

35517 Cesson-Sevigné Cedex

France

1 rue de l’Hautil

Z.I. des Boutries BP 150

78702 Conflans-Sainte

Honorine Cedex

France

Technopole Brest-Iroise

Site de la Pointe du Diable

CS 73808

29238 Brest Cedex 3

France

40 Rue de Bray

2 Rue des Landelles

35510 Cesson Sevigné

France

Spinnereistrasse 5

CH-5300 Turgi

Switzerland

Brunnenweg 9

D-64331 Weiterstadt

Germany

Carl-Benz-Strasse 6-8

67105 Schifferstadt

Germany

Including its implementation, meets the requirements of the standard:

ISO 9001:2008

Scope:

The design, manufacture and support of video and audio hardware and software products and

related systems

.

This Certificate is valid until: June 14, 2012

This Certificate is valid as of: June 14, 2009

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms

And Conditions For Quality And Environmental Management Systems Certifications.

Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 073004

ccredited By:

ANAB

A

Page 3

JUPITER

CM-4400: AccuSwitch Control System

Installation and Operating Manual

Software Version 7.9

071876600

OCTOBER 2010

Page 4

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley, Inc. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.grassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 JUPITER CM-4400 Control Module - Installation and Operating Manual

Page 5

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terms in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Certifications: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Recommended ESD Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sources of ESD and Risks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Grounding Requirements for Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Section 1 — Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CM-4400 System Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Distribution Switcher Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

External Control Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Control panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

File Server (Configuration PC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Section 2 — Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connecting the CM-4400 to the Jupiter LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CM-4400 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connecting the Jupiter File Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connecting the Ethernet Switch to the System Controller . . . . . . . . . . . . . . . . . 41

Configuring the AccuSwitch Control Panels Connections . . . . . . . . . . . . . . . . . 41

CM-4400 Control System’s Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Alarm Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Alarms in a Single CM-4400 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Alarms in a Redundant CM-4400 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Replacing a Failed Redundant Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Preparing and Activating a Replacement CM-4400 . . . . . . . . . . . . . . . . . . . . . . . 47

JUPITER L-S and LCD Series Control Panel Instruction Manual 5

Page 6

Contents

Installing Redundant CM-4400 Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Connecting to Serial Controlled Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Jupiter Control of Encore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Non-Redundant Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Redundant Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Logical Level Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Data Matrix Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Encore Control of Jupiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connecting to Multiple Crosspoint Bus Distribution Switchers. . . . . . . . . . . . . . 65

Connection Using a Single CM-4400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

DEDICATED CM-4400 PER SWITCHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Connection to Multiple Distribution Switchers with Path Finding . . . . . . . . . 66

Path Finding with Data Routers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Installing a File Server PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

The Jupiter LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Installing Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Sync Reference Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Time Code Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Connecting to a Master Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

The CC 2010 Matrix (Crosspoint Bus) Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

The CB 3000 Control Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Connection To Thomson/Philips DD Series (“Diamond”) . . . . . . . . . . . . . . . . 79

Connection to Automation and Other Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Section 3 — Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Caveats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Software Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Materials Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Optional Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Software Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Updating Existing Jupiter Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Installing the Jupiter Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Updating a Previous Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Removing Jupiter Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Section 4 — Jupiter Network Suite Control Console. . . . . . . . . . . . . . . . . . 97

Launching the Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Program Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Restart Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Clearing Persistent Memory (PMEM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Section 5 — The Configurator Application . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Starting the Configurator Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

AccuSwitch Configuration File Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Configuring a New Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Exporting a Configuration Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Uploading a Configuration File from AccuSwitch . . . . . . . . . . . . . . . . . . . . . . 114

Configuration Error Checking for the CPES-SER Device Type. . . . . . . . . . . . 116

Accessing the Jupiter Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6 JUPITER L-S and LCD Series Control Panel Instruction Manual

Page 7

Closing the Configurator Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Configurator Editing Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Find / Fill / Increment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Copy and Paste Rows between the Windows Clipboard and Jupiter. . . . . . . 127

Jupiter Naming Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Configuration Set Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Modifying and Downloading a System Configuration Set. . . . . . . . . . . . . . . . 129

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Changing Passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Network Description Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Serial Protocol Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Entering Protocol for Controller Board Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Connecting L-S or LCD Series Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Switcher Description Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Entering Switcher Levels Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Switcher Input Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Split Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Entering or Editing Input Names and Numbers . . . . . . . . . . . . . . . . . . . . . . . . 164

Switcher Output Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Entering or Editing Output Names and Numbers. . . . . . . . . . . . . . . . . . . . . . . 169

The Control Panel Set Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Creating a CP Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

The Control Panel Level Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

The Control Panel Input Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

The Control Panel Output Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

The Control Panel Override Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Defining Overrides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

The Control Panel Sequence Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Defining a Sequence Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

The Control Panel Category Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Defining Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

CPESXTND Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

The MPK Devices Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

MPK Devices Table Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Zero-Downtime Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Entries for the L-S or LCD Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

The Sequential Path Finding Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Path Finding For Three or More Switchers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Path Finding Between Analog and Digital Equipment. . . . . . . . . . . . . . . . . . . . . 198

The Non-Sequential Path Finding Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Exclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Configuring an Exclusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

The Time Standard Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Setting the Time Code Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Video Reference Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Point-to-Point Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Remote System Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Remote System Routing Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AccuSwitch Software

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

211

Contents

Section 6 — Jupiter Board Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Table Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

JUPITER L-S and LCD Series Control Panel Instruction Manual 7

Page 8

Contents

Section 7 — Jupiter Control Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

The JNS Control Center Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Section 8 — The Router Control Application . . . . . . . . . . . . . . . . . . . . . . . . . 241

Section 9 — Force Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Table Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Unlocking and Un-protecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Section 10 — Logger and Log Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Section 11 — Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

CM-4400 Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

CB 3000 Crosspoint Buffer and Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

CM-4400 System Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Startup Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Shutdown Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Other Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Section 12 — Jupiter ASCII Communications Protocol. . . . . . . . . . . . . . 273

Appendix A — CM-4400 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

File Server Minimum Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Software Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Equipment Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

System Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Supported Data Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Appendix B — Connecting Legacy and 3rd Party Routers. . . . . . . . . . . 285

Matrix Router Control Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Triton Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

SMS 7000 CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Pro-Bel SW-P-08 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Jupiter Router Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Remote Router Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Pro-Bel SW-P-08 Interface Implementation Notes. . . . . . . . . . . . . . . . . . . . . . . 303

Physical Serial Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

8 JUPITER L-S and LCD Series Control Panel Instruction Manual

Page 9

Preface

About This Manual

This manual provides the hardware installation, software configuration,

and operating instructions for the Jupiter CM-4400 Control Module, which

only supports the Jupiter AccuSwitch control software.

This manual can also be accessed thr

Editor’s Help menu.

Additional Documentation

The following is comprised of supporting documentation, which is stored

on Grass Valley’s Web site.

• The Routing Products Documentation

copies of manuals, Release Notes, Release Notes Addendum, and Field

bulletins.

• JEP-100 Jupiter / Encore Control Panel v1.2.0 Installation and Operating Manual

• Jupiter Control System L-S and LCD Series Control Panels Installation

and Operating Manual.

• Jupiter AccuSwitch Soft Panels and Visual Status Display Instruction

Manual.

• Jupiter Getting Started Guide. Describes simplified software configuration procedures for quick system startup

ough the Jupiter Configuration

CD-ROM provides electronic

Other Manuals

• Jupiter CM 4000 System Controller Installation and Operating Manual.

• Jupiter VM/SI 3000 System Controller Installation and Operating

• Saturn Installation and Operating Manual.

• Triton to Jupiter Serial Control Kit Installation Instructions.

JUPITER CM-4400 Control Module Installation and Operating Manual 9

Manual. Describes Jupiter Plus and Jupiter LE applications

Page 10

Preface

10 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 11

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

Terms on the Product

The following terms may appear on the product:

DANGER — A personal injury hazard is immediately accessible as you read

the marking.

WARNING — A personal injury hazard exists but is not immediately acces-

sible as you read the marking.

CAUTION — A hazard to property, product, and other equipment is present.

JUPITER CM-4400 Control Module Installation and Operating Manual 11

Page 12

Safety Summary

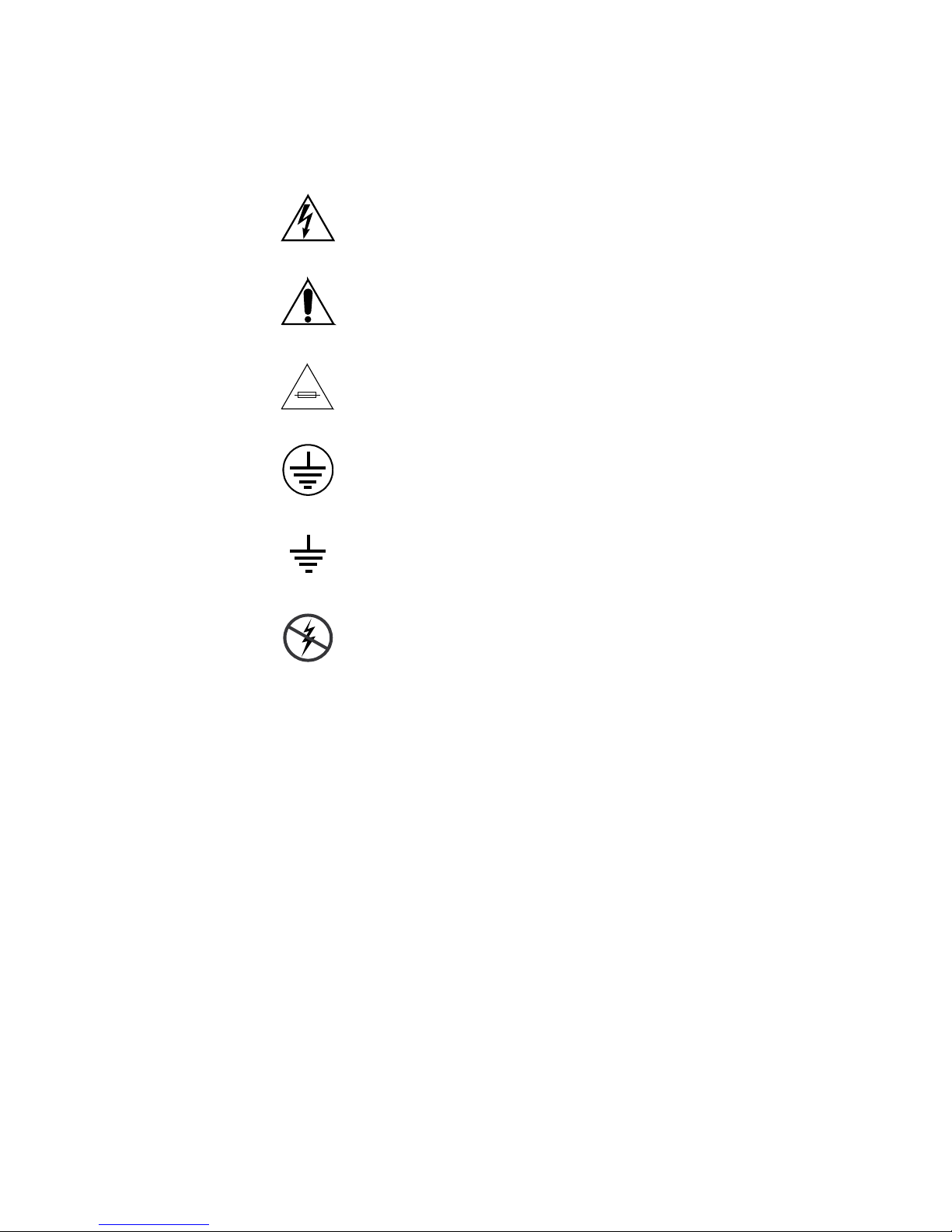

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground prior to making any other

connections.

equipment

Warnings

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life:

Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or

replacing components.

Do not service alone — Do not internally service this product unless another

person capable of rendering first aid and resuscitation is present.

Remove jewelry — Prior to servicing, remove jewelry such as rings, watches,

and other metallic objects.

Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

12 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 13

Safety Summary

Use proper power cord — Use only the power cord supplied or specified for

this product.

Ground product — Connect the grounding conductor of the power cord to

earth ground.

Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

Use correct fuse — Use only the fuse type and rating specified for this

product.

Use only in dry environment — Do not operate in wet or damp conditions.

Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

High leakage current may be present — Earth connection of product is essential

before connecting power.

Dual power supplies may be present — Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Cautions

Double pole neutral fusing — Disconnect mains power prior to servicing.

Use proper lift points — Do not use door latches to lift or move equipment.

Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property:

Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

Use correct voltage setting — If this product lacks auto-ranging power sup-

plies, before applying power ensure that t

match the power source.

Provide proper ventilation — To prevent product overheating, provide equip-

ment ventilation in accordance with installati

he each power supply is set to

on instructions.

Use anti-static procedures — Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

JUPITER CM-4400 Control Module Installation and Operating Manual 13

Page 14

Safety Summary

Do not operate with suspected equipment failure — If you suspect product damage

or equipment failure, have the equipment inspected by qualified service

personnel.

Ensure mains disconnect — If mains switch is not provided, the power cord(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly — Route power cords and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery — This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

Troubleshoot only to board level — Circuit boards in this product are densely

populated with surface mount technology (SMT) components and application specific integrated circuits (ASICS). As a r

the component level is very difficult in the field, if not impossible. For warranty compliance, do not troubleshoot

systems beyond the board level.

esult, circuit board repair at

14 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 15

Sicherheit – Überblick

Lesen und befolgen Sie die wichtigen Sicherheitsinformationen dieses

Abschnitts. Beachten Sie insbesondere die Anweisungen bezüglich

Brand-, Stromschlag- und Verletzungsgefahr

nicht aufgeführte Warnungen finden Sie im gesamten Handbuch.

WARNUNG Alle Anweisungen in diesem Handbuch, die das Abnehmen der

Geräteabdeckung oder des Gerätegehäuses erfordern, dürfen nur von

qualifiziertem Servicepersonal ausgeführt werden. Um die

Stromschlaggefahr zu verringern, führen Sie keine Wartungsarbeiten

außer den in den Bedienungsanleitungen genannten Arbeiten aus, es sei

denn, Sie besitzen die entsprechende Qualifikationen für diese Arbeiten.

Sicherheit – Begriffe und Symbole

en. Weitere spezifische, hier

Safety Summary

In diesem Handbuch verwendete Begriffe

Sicherheitsrelevante Hinweise können in diesem Handbuch in der folgenden Form auftauchen:

WARNUNG Warnungen weisen auf Situationen oder Vorgehensweisen hin, die

Verletzungs- oder Lebensgefahr bergen.

VORSICHT Vorsichtshinweise weisen auf Situationen oder Vorgehensweisen hin, die zu

Schäden an Ausrüstungskomponenten oder anderen Gegenständen oder

zum zeitweisen Ausfall wichtiger Komponenten in der Arbeitsumgebung

führen können.

Hinweise am Produkt

Die folgenden Hinweise können sich am Produkt befinden:

GEFAHR — Wenn Sie diesen Begriff lesen, besteht ein unmittelbares Verlet-

zungsrisiko.

WARNUNG — Wenn Sie diesen Begriff lesen, besteht ein mittelbares Verlet-

zungsrisiko.

VORSICHT — Es besteht ein Risiko für Objekte in der Umgebung, den Mixer

selbst oder andere Ausrüstungskomponenten.

JUPITER CM-4400 Control Module Installation and Operating Manual 15

Page 16

Safety Summary

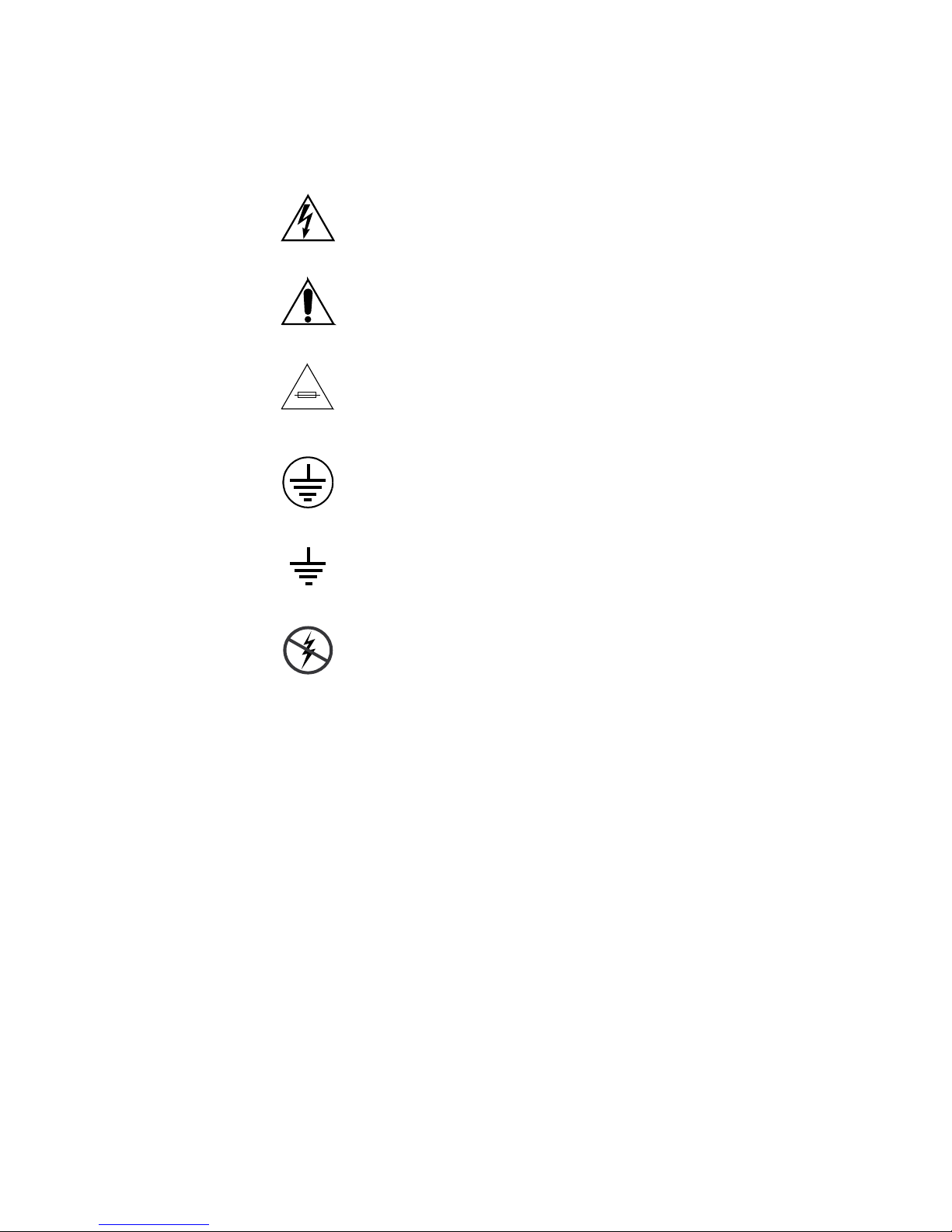

Symbole am Produkt

Die folgenden Symbole können sich am Produkt befinden:

Weist auf eine gefährliche Hochspannung im Gerätegehäuse

hin, die stark genug sein kann, um eine Stromschlaggefahr

darzustellen.

Weist darauf hin, dass der Benutzer, Bediener oder Servicetechniker wichtige Bedienungs-, Wa

weisungen in den Produkthandbüchern lesen sollte.

Dies ist eine Aufforderung, beim Wechsel von Sicherungen

auf deren Nennwert zu achten. Die im Text angegebene Sicherung muss durch eine Sicherung ersetzt we

angegebenen Nennwerte besitzt.

Weist auf eine Schutzerdungsklemme hin, die mit dem

Erdungskontakt verbunden werden muss, bevor weitere Ausrüstungskomponenten angeschlossen werden.

rtungs- oder Servicean-

rden, die die

Warnungen

Weist auf eine externe Schutzerdungsklemme hin, die als

Ergänzung zu einem internen Erdungskontakt an die Erde

angeschlossen werden kann.

Weist darauf hin, dass es statisch empfindliche Komponenten

gibt, die durch eine elektrostatische Entladung beschädigt

werden können. Verwenden Sie antistatische Prozeduren,

Ausrüstung und Oberflächen während der Wartung.

Die folgenden Warnungen weisen auf Bedingungen oder Vorgehensweisen

hin, die Verletzungs- oder Lebensgefahr bergen:

Gefährliche Spannungen oder Ströme — Schalten Sie den Strom ab, und ent-

fernen Sie ggf. die Batterie, bevor sie Schutz

oder Komponenten austauschen.

Servicearbeiten nicht alleine ausführen — Führen Sie interne Servicearbeiten nur

aus, wenn eine weitere Person anwesend ist, die erste Hilfe leisten und

Wiederbelebungsmaßnahmen einleiten kann.

abdeckungen abnehmen, löten

Schmuck abnehmen — Legen Sie vor Servicearbeiten Schmuck wie Ringe,

Uhren und andere metallische Objekte ab.

16 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 17

Safety Summary

Keine offen liegenden Leiter berühren — Berühren Sie bei eingeschalteter Strom-

zufuhr keine offen liegenden Leitungen, Komponent

Richtiges Netzkabel verwenden — Verwenden Sie nur das mitgelieferte Netzk-

abel oder ein Netzkabel, das den Spezifikationen für dieses Produkt

entspr

Gerät erden — Schließen Sie den Erdleiter des Netzkabels an den Erdung-

skontakt an.

Gerät nur mit angebrachten Abdeckungen und Gehäuseseiten betreiben — Schalten Sie

dieses Gerät nicht ein, wenn die Abdeckungen oder Gehäuseseiten entfernt

wurden.

Richtige Sicherung verwenden — Verwenden Sie nur Sicherungen, deren Typ

und Nennwert den Spezifikationen für dieses Produkt entsprechen.

Gerät nur in trockener Umgebung verwenden — Betreiben Sie das Gerät nicht in

nassen oder feuchten Umgebungen.

Gerät nur verwenden, wenn keine Explosionsgefahr besteht — Verwenden Sie dieses

Produkt nur in Umgebungen, in denen keinerlei Explosionsgefahr besteht.

icht.

en oder Schaltungen.

Vorsicht

Hohe Kriechströme — Das Gerät muss vor dem Einschalten unbedingt geerdet

werden.

Doppelte Spannungsversorgung kann vorhanden sein — Schließen Sie die beiden

Anschlußkabel an getrennte Stromkreise an. Vor Servicearbeiten sind beide

Anschlußkabel vom Netz zu trennen.

Zweipolige, neutrale Sicherung — Schalten Sie den Netzstrom ab, bevor Sie mit

den Servicearbeiten beginnen.

Fassen Sie das Gerät beim Transport richtig an — Halten Sie das Gerät beim Trans-

port nicht an Türen oder anderen beweglichen Teilen fest.

Gefahr durch mechanische Teile — Warten Sie, bis der Lüfter vollständig zum

Halt gekommen ist, bevor Sie mit den Servicearbeiten beginnen.

Die folgenden Vorsichtshinweise weisen auf Bedingungen oder Vorgehensweisen hin, die zu Schäden an Ausr

anderen Gegenständen führen können:

üstungskomponenten oder

Gerät nicht öffnen — Durch das unbefugte Öffnen wird die Garantie ungültig.

Richtige Spannungsquelle verwenden — Betreiben Sie das Gerät nicht an einer

Spannungsquelle, die eine höhere Spannung liefert als in den Spezifikationen für dieses Produkt angegeben.

JUPITER CM-4400 Control Module Installation and Operating Manual 17

Page 18

Safety Summary

Gerät ausreichend belüften — Um eine Überhitzung des Geräts zu vermeiden,

müssen die Ausrüstungskomponenten entsprechend den Installationsanweisungen belüftet werden. Legen Sie kein Papier

könnte die Belüftung behindern. Platzieren Sie das Gerät auf einer ebenen

Oberfläche.

Antistatische Vorkehrungen treffen — Es gibt statisch empfindliche Kompo-

nenten, die durch eine elektrostatisch

nen. Verwenden Sie antistatische Prozeduren, Ausrüstung und

Oberfläche

CF-Karte nicht mit einem PC verwenden — Die CF-Karte ist speziell formatiert.

Die auf der CF-Karte gespeicherte Software könnte gelöscht werden.

Gerät nicht bei eventuellem Ausrüstungsfehler betreiben — Wenn Sie einen Produk-

tschaden oder Ausrüstungsfehler vermuten, lassen Sie die Komponente

einem qualifizierten Servicetechniker untersuchen.

von

Kabel richtig verlegen — Verlegen Sie Netzkabel und andere Kabel so, dass Sie

nicht beschädigt werden. Stützen Sie schwere Kabelbündel ordnungsgemäß ab, damit die Anschlüsse nicht beschädigt wer

n während der Wartung.

e Entladung beschädigt werden kön-

unter das Gerät. Es

den.

Richtige Netzkabel verwenden — Wenn Netzkabel mitgeliefert wurden, erfüllen

diese alle nationalen elektrischen Normen. Der Betrieb dieses Geräts mit

Spannungen über 130 V AC erfordert Netzkabel, die NEMA-Konfigurationen entsprechen. Wenn internationale

sind diese für das Verwendungsland zugelassen.

Richtige Ersatzbatterie verwenden — Dieses Gerät enthält eine Batterie. Um die

Explosionsgefahr zu verringern, prüfen Sie die Polarität und tauschen die

Batterie nur gegen eine Batterie desselben Typs oder eines gleichwertigen,

vom Hersteller empfohlenen Typs aus. Entsorgen Sie gebrauchte Batterien

entsprechend den Anweisungen des Batterieherstellers.

Das Gerät enthält keine Teile, die vom Benutzer gewartet

Wenden Sie sich bei Problemen bitte an den nächsten Händler.

Netzkabel mitgeliefert wurden,

werden können.

18 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 19

Consignes de sécurité

Il est recommandé de lire, de bien comprendre et surtout de respecter les

informations relatives à la sécurité qui sont exposées ci-après, notamment

les consignes destinées à prévenir les risques d’incendie, les décharges électriques et les blessures aux personnes. Les avertissements complémentaires, qui ne sont pas nécessairement r

toutes les sections du manuel, sont également à prendre en considération.

AVERTISSEMENT Toutes les instructions présentes dans ce manuel qui concernent

l’ouverture des capots ou des logements de cet équipement sont

destinées exclusivement à des membres qualifiés du personnel de

maintenance. Afin de diminuer les risques de décharges

électriques, ne procédez à aucune intervention d’entretien autre

que celles contenues dans le manuel de l’utilisateur, à moins que

vous ne soyez habilité pour le faire.

epris ci-dessous, mais présents dans

Safety Summary

Consignes et symboles de sécurité

Termes utilisés dans ce manuel

Les consignes de sécurité présentées dans ce manuel peuvent apparaître

sous les formes suivantes:

AVERTISSEMENT Les avertissements signalent des conditions ou des pratiques

susceptibles d’occasionner des blessures graves, voire même

fatales.

ATTENTION Les mises en garde s

susceptibles d’occasionner un endommagement à l’équipement ou

aux installations, ou de rendre l’équipement temporairement non

opérationnel, ce qui peut porter préjudice à vos activités.

Signalétique apposée sur le produit

La signalétique suivante peut être apposée sur le produit:

DANGER — risque de danger imminent pour l’utilisateur.

ignalent des conditions ou des pratiques

AVERTISSEMENT — Risque de danger non imminent pour l’utilisateur.

MISE EN GARDE — Risque d’endommagement du produit, des installations

ou des autres équipements.

JUPITER CM-4400 Control Module Installation and Operating Manual 19

Page 20

Safety Summary

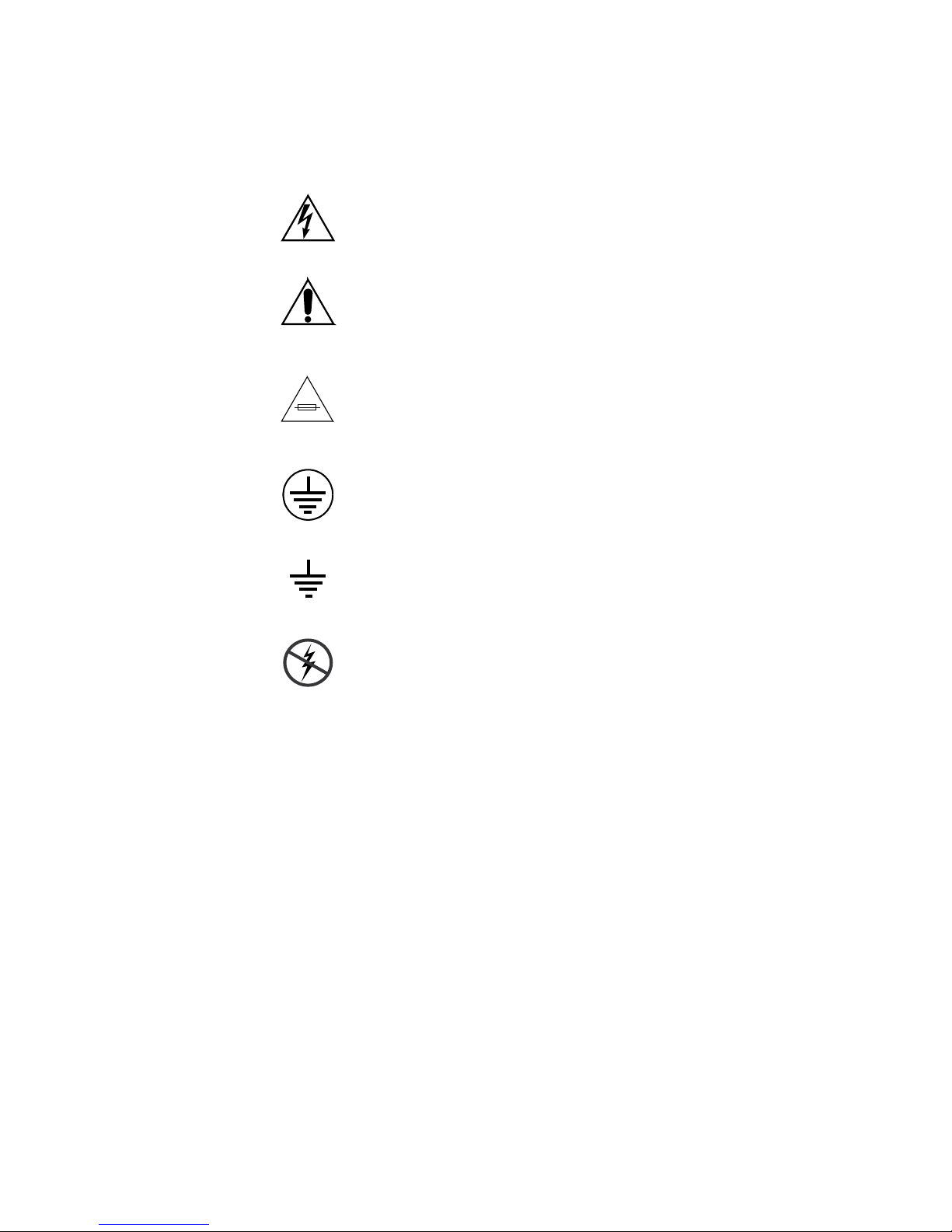

Symboles apposés sur le produit

Les symboles suivants peut être apposés sur le produit:

Signale la présence d’une tension élevée et dangereuse dans le

boîtier de l’équipement ; cette tension peut être suffisante

pour constituer un ri

Signale que l’utilisateur, l’opérateur ou le technicien de maintenance doit faire référence au(x

naissance des instructions d’utilisation,

d’entretien.

Il s’agit d’une invite à prendre note du calibre du fusible lors

du remplacement de ce dernier. Le fusible auquel il est fait

référence dans le texte doit être remplacé par un fusible du

même calibre.

Identifie une borne de protection de mise à la masse qui doit

être raccordée correctement avant de procéder au raccordement des autres équipements.

sque de décharge électrique.

) manuel(s) pour prendre con-

de maintenance ou

Avertissements

Identifie une borne de protection de mise à la masse qui peut

être connectée en tant que borne de mise à la masse supplémentaire.

Signale la présence de composants sensibles à l’électricité statique et qui sont susceptibles d’êt

décharge électrostatique. Utilisez des procédures, des équipements et des surfaces antistatiques durant

d’entretien.

Les avertissements suivants signalent des conditions ou des pratiques susceptibles d’occasionner des blessures graves, voire même fatales:

Présence possible de tensions ou de courants dangereux — Mettez hors tension,

débranchez et retirez la pile (le cas échéant) avant de déposer les couvercles

de protection, de défaire une soudure ou de remplacer des composants.

Ne procédez pas seul à une intervention d’entretien — Ne réalisez pas une interven-

tion d’entretien interne sur ce produit si une

pour fournir les premiers soins en cas d’accident.

re endommagés par une

les interventions

personne n’est pas présente

Retirez tous vos bijoux — Avant de procéder à une intervention d’entretien,

retirez tous vos bijoux, notamment les bagues, la montre ou tout autre objet

métallique.

20 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 21

Safety Summary

Évitez tout contact avec les circuits exposés — Évitez tout contact avec les connex-

ions, les composants ou les circuits exposés s’ils sont sous tension.

Utilisez le cordon d’alimentation approprié — Utilisez exclusivement le cordon

d’alimentation fourni avec ce produit ou spécifié pour ce produit.

Raccordez le produit à la masse — Raccordez le conducteur de masse du cordon

d’alimentation à la borne de masse de la prise secteur.

Utilisez le produit lorsque les couvercles et les capots sont en place — N’utilisez pas

ce produit si les couvercles et les capots sont déposés.

Utilisez le bon fusible — Utilisez exclusivement un fusible du type et du

calibre spécifiés pour ce produit.

Utilisez ce produit exclusivement dans un environnement sec — N’utilisez pas ce

produit dans un environnement humide.

Utilisez ce produit exclusivement dans un environnement non explosible — N’utilisez

pas ce produit dans un environnement dont l’atmosphère est explosible.

Présence possible de courants de fuite — Un raccordement à la masse est indis-

pensable avant la mise sous tension.

Mises en garde

Deux alimentations peuvent être présentes dans l’équipement — Assurez vous que

chaque cordon d’alimentation est raccordé à des circuits de terre séparés.

Débranchez les deux cordons d’alimentation avant toute intervention.

Fusion neutre bipolaire — Débranchez l’alimentation principale avant de pro-

céder à une intervention d’entretien.

Utilisez les points de levage appropriés — Ne pas utiliser les verrous de la porte

pour lever ou déplacer l’équipement.

Évitez les dangers mécaniques — Laissez le ventilateur s’arrêter avant de pro-

céder à une intervention d’entretien.

Les mises en garde suivantes signalent les conditions et les pratiques susceptibles d’occasionner des endommage

lations:

N’ouvrez pas l’appareil — Toute ouverture prohibée de l’appareil aura pour

effet d’annuler la garantie.

ments à l’équipement et aux instal-

Utilisez la source d’alimentation adéquate — Ne branchez pas ce produit à une

source d’alimentation qui utilise une tension supérieure à la tension nominale spécifiée pour ce produit.

JUPITER CM-4400 Control Module Installation and Operating Manual 21

Page 22

Safety Summary

Assurez une ventilation adéquate — Pour éviter toute surchauffe du produit,

assurez une ventilation de l’équipement conformément aux instructions

d’installation. Ne déposez aucun document sous l’appareil — ils peuvent

gêner la ventilation. Placez l’appareil sur une surface plane.

Utilisez des procédures antistatiques - Les composants sensibles à l’électricité

statique présents dans l’équipement sont susceptibles d’être endommagés

par une décharge électrostatique. Utilisez des procédures, des équipements

et des surfaces antistatiques durant les interventions d’entretien.

N’utilisez pas la carte CF avec un PC — La carte CF a été spécialement formatée.

Le logiciel enregistré sur la carte CF risque d’être effacé.

N’utilisez pas l’équipement si un dysfonctionnement est suspecté — Si vous sus-

pectez un dysfonctionnement du produit, faites

membre qualifié du personnel d’entretien.

Acheminez les câbles correctement — Acheminez les câbles d’alimentation et les

autres câbles de manière à ce qu’ils ne risquent pas d’être endommagés.

Supportez correctement les enroulements de câbles afin de ne pas endommager les connecteurs.

inspecter celui-ci par un

Utilisez les cordons d’alimentation adéquats — Les cordons d’alimentation de cet

équipement, s’ils sont fournis, satisfont aux exigences de toutes les réglementations régionales. L’utilisation de cet équipement à des tensions

dé

passant les 130 V en c.a. requiert des cordons

aux exigences des configurations NEMA. Les cordons internationaux, s’ils

sont fournis, ont reçu l’approbation du pays dans lequel l’équipement est

utilisé.

Utilisez une pile de remplacement adéquate — Ce produit renferme une pile. Pour

réduire le risque d’explosion, vérifiez la polarité et ne remplacez la pile que

par une pile du même type, recommandée par le fabricant. Mettez les piles

usagées au rebut conformément aux instructions du fabricant des piles.

Cette unité ne contient aucune partie qui peut

par l’utilisateur. Si un problème survient, veuillez contacter votre distributeur local.

d’alimentation qui satisfont

faire l’objet d’un entretien

22 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 23

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

radio frequency energy and, if not

cause harmful interference in which

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Departme

Le présent appareil numérique n’emet pas de bruits radioélectriques

passant les limites applicables aux appareils numeriques de la classe A

dé

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

In a domestic environment, products that comply with Class A may cause

radio interference in which case the user may be required to take adequate

measures.

nt of Communications.

JUPITER CM-4400 Control Module Installation and Operating Manual 23

Page 24

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

Laser Compliance

Laser Safety Requirements

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

The device used in this product is a Class 1 certified laser product. Operating this product outside spec

may result in hazardous radiation exposure, and may be considered an act

of modifying or new manufacturing of a laser product under U.S. regulations contained in 21CFR Chapter 1, subchapter J or CENELE

in HD 482 S1. People performing such an act are required by law to recertify

and reidentify this product in accordance with provisions of 21CFR subchapter J for distribution within the U.S.A.

CENELEC HD 482 S1 for distribution within countries using the IEC 825

standard.

ifications or altering from its original design

C regulations

, and in accordance with

Laser Safety

Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The International Electrotechn

ation of Laser Products, Equipment Cl

User’s Guide,” governs laser products outside the United States. Europe

and member nations of the European Free Trade Association fall under the

jurisdiction of the Comite European de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected through a 7 mm aperture at

a distan

length of 100 mm.

For IEC compliance: The radiant power is detected through a 7 mm aperture at a distance of 100 mm from the source focused through a lens with a

focal

24 JUPITER CM-4400 Control Module Installation and Operating Manual

ce of 200 mm from the source focused through a lens with a focal

length of 100 mm.

ical Commission (IEC) Standard 825, “Radi-

assification, Requirements and

Page 25

FCC Emission Limits

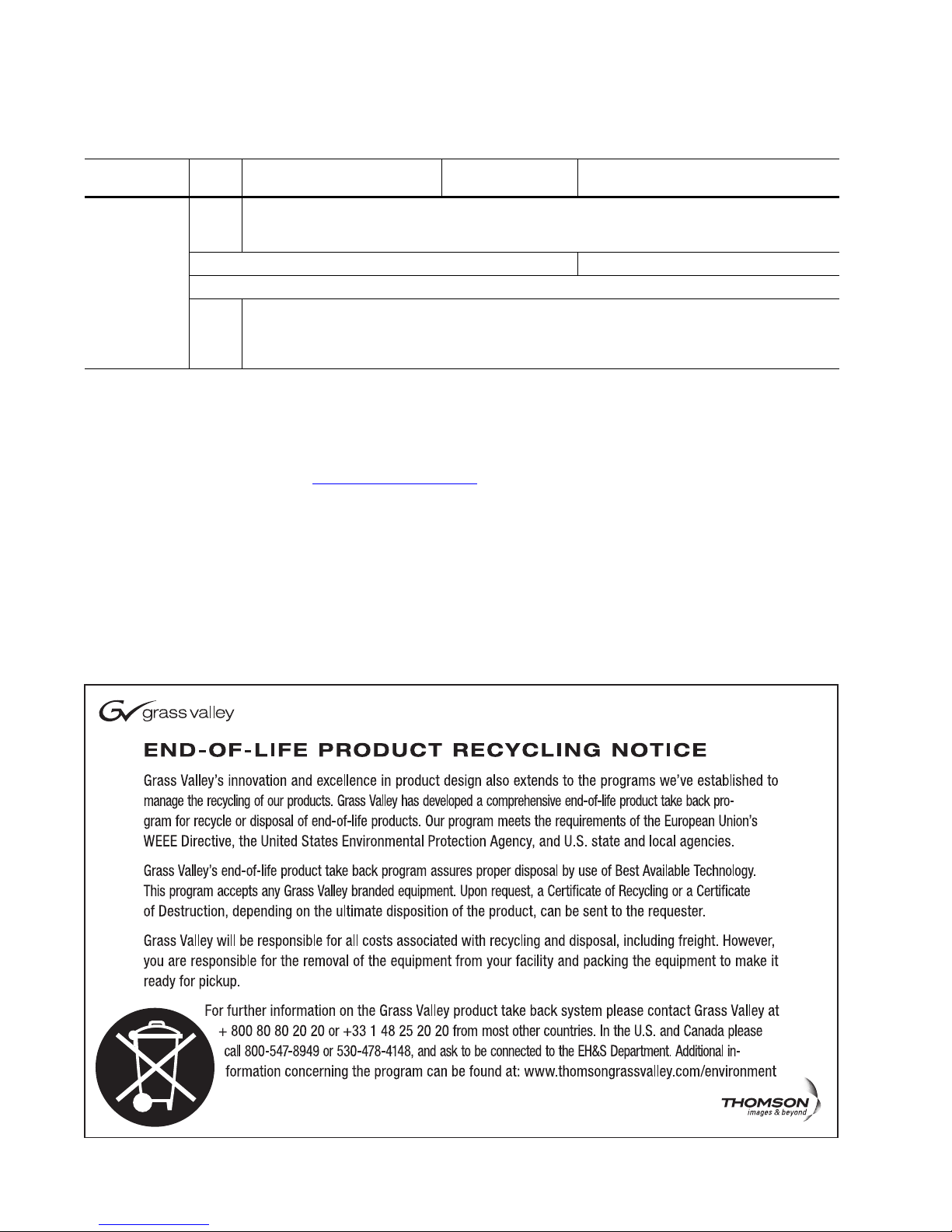

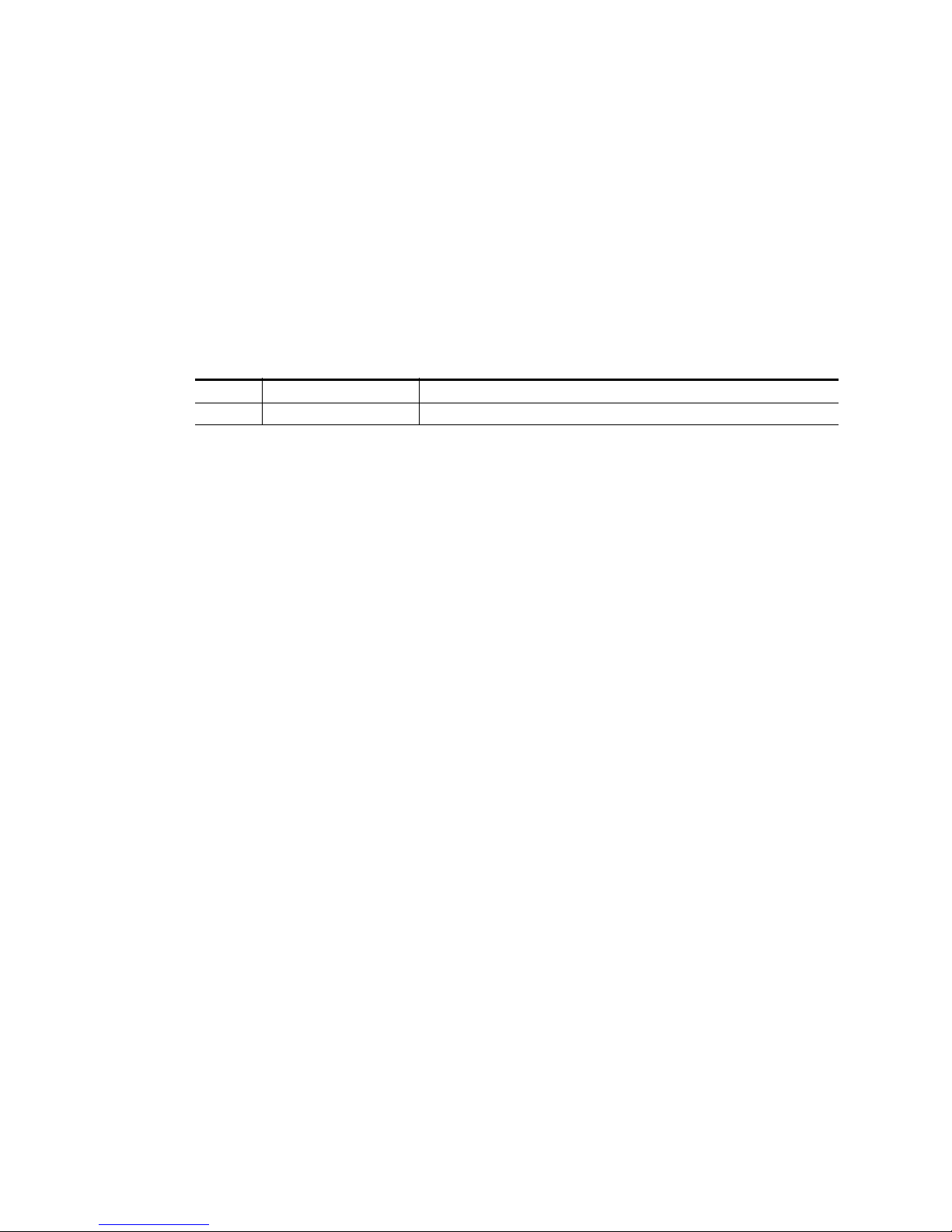

Certifications:

Category Standard Designed/tested for compliance with:

Safety

EMI

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference, and (2) this device must ac

cept any interference received,

including interference that may cause undesirable operation. This device

has been tested and found to comply with FCC Part 15 Class B limits for a

digital device when tested with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channel Standard.

ANSI / UL60950 “Standard for Safety of Information Technology Equipment - Safety - Part 1: General

IEC 60950 “Standard for Safety for Information Technology Equipment - Safety - Part 1: General

CAN/CSA C22.2, No. 60950 “Standard for Safety of Information Technology Equipment - Safety - Part 1: General

EN60950 Safety of Information Technology Equipment, including Electrical Business Equipment.

73/23/EEC Low Voltage Directive

EMC Directive 89/336/EEC via

EN 55103-1 and 2

EN 55103-1 standards Electromagnetic compatibility.

EN55103-2 standards Electromagnetic compatibility--Product family standard for audio, video, audio-visual

US FCC Class A

Canada FCC Industry Canada

Australia & New Zealand: AS/NZS 3548

Requirements”, (ANSI/UL 60950-1, First Edition, Dated April 1, 2003, with revision

through and including November 26, 2003.)

Requirements”, (IEC 60950-1, First Edition, 2001, Corrigendum 1:10-2002)

Requirements”, (CAN/CSA-C22.2 No. 60950-1-03. First Edition Dated April 1, 2003,

with revisions through and including November 26, 2003)

Audio, Video and Entertainment Lighting Control for the European Community.

Product family standard for audio, video, audio-visual and entertainment lighting control

apparatus for professional use.

Part 1 Emissions, Environment E1/E2

EN 55022: Class A Radiated and Conducted Emissions

EN 61000-3-2: Power Line Harmonic Emissions, Radiated Magnetic Field Emissions,

Peak Inrush Current

and entertainment lighting control apparatus for professional use.

Part 2 Immunity, Environment E1/E2

EN 50082-1: Immunity

EN 61000-4-2:

Electrostatic Discharge “ESD” Immunity

EN 61000-4-3:

Radiated RF Electromagnetic Field Immunity

EN 61000-4-4:

Electrical Fast Transient/Burst “EFT” Immunity

EN 61000-4-5: Surge Immunity

EN 61000-4-6: Conducted RF Immunity

EN 61000-4-11: Voltage Dips, Short Interruptions and Voltage Variations

Annex A - Radiated Magnetic Field Immunity

Note: This only applies to assemblies sensitive to magnetic fields

CISPR Pub. 22 (1985)

IMPORTANT NOTE TO WRITERS - SEE THE FOLLOWING PARAGRAPHS AND DELETE THIS

TEXT BEFORE PUBLICATION.

JUPITER CM-4400 Control Module Installation and Operating Manual 25

Page 26

Regulatory Notices

THE INFORMATION IN THE CERTIFICATION TABLES ABOVE MUST BE REVIEWED TO CONFIRM THE PROPER COMPLIANCE NOTICES ARE INCLUDED. STANDARDS MAY HAVE

CHANGED SINCE THIS BOILERPLATE INFORMATION WAS DRAFTED. REGULATORY COMPLIANCE IS ESTABLISHED WHEN THE PRODUCT IS RELEASED THE FIRST TIME. THAT COMPLIANCE LEVEL IS RETAINED UNLESS THE PRODUCT OR MARKET CHANGES IN SOME WAY

THAT REQUIRES NEW COMPLIANCE TESTING. DO NOT BLINDLY REPLACE INFORMATION

IN OLDER MANUALS WITH THIS BOILERPLATE INFORMATION. CHECK WITH THE PRODUCT MANAGER TO CONFIRM WHAT NOTICES ARE REQUIRED.

SOME OLDER PRODUCTS (KAYAK DD FOR EXAMPLE) MAY REQUIRE OLDER “UL1419” SAFETY INFORMATION. THE INFORMATION BELOW REPLACES THE “ANSI/UL60950” SAFETY INFORMATION LISTED AS THE FIRST ITEM IN THE TABLE ABOVE FOR THESE OLD PRODUCTS.

Category Standard Designed/tested for compliance with:

Safety UL1419 Professional Video and Audio Equipment

26 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 27

ESD Protection

Electronics today are more susceptible to electrostatic discharge (ESD)

damage than older equipment. Damage to equipment can occur by ESD

fields that are smaller than you can feel. Implementing the information in

this section will help you protect the investment that you have made in

purchasing Grass Valley equipment. This section contains Grass Valley’s

recommended ESD guidelines that should be followed when handling

electrostatic discharge sensitive (ESDS) items. These minimal recommendations are based on the information in the Sources of ESD and Risks area.

The information in Grounding Requirements for Personnel on

vided to assist you in selecting an appr

Recommended ESD Guidelines

Follow these guidelines when handling Grass Valley equipment:

• Only trained personnel that are connected to a grounding system

should handle

• Do not open any protective bag, box, or special shipping packaging

until you have been grounded.

page 29 is pro-

opriate grounding method.

ESDS items.

Note When a Personal Grounding strap is unavailable, as an absolute minimum,

touch a metal object that is touching the floor (for example, a table, frame, or

rack) to discharge any static energy before touching an ESDS item.

• Open the anti-static packaging by slitting any existing adhesive tapes.

Do not tear the tapes off.

• Remove the ESDS item by holding it by its edges or by a metal panel.

• Do not touch the components of an ESDS item unless it is absolutely

necessary to configure or repair the item.

• Keep the ESDS work area clear of all nonessential items such as coffee

cups, pens, wrappers and personal items as these items can discharge

static. If you need to set an ESDS item down, place it on an anti-static

mat or on the anti-static packaging.

JUPITER CM-4400 Control Module Installation and Operating Manual 27

Page 28

ESD Protection

Sources of ESD and Risks

The following information identifies possible sources of electrostatic discharge and can be used to help establish an ESD policy.

Personnel

One of the largest sources of static is personnel. The static can be released

from a person’s clothing and shoes.

Environment

The environment includes the humidity and floors in a work area. The

humidity level must be controlled and should not be allowed to fluctuate

over a broad range. Relative humidity (RH) is a major part in determining

the level of static that is being generated. For example, at 10% - 20% RH a

person walking across a carpeted floor can develop 35kV; yet when the relative humidity is increased to 70% - 80%,

1.5kV.

the person can only generate

Static is generated as personnel move (or as

floor’s surface. Carpeted and waxed vinyl floors contribute to static build

up.

equipment is moved) across a

Work Surfaces

Painted or vinyl-covered tables, chairs, conveyor belts, racks, carts, anodized surfaces, plexiglass covers, and she

lving are all static generators.

Equipment

Any equipment commonly found in an ESD work area, such as solder

guns, heat guns, blowers, etc., should be grounded.

Materials

Plastic work holders, foam, plastic tote boxes, pens, packaging containers

and other items commonly found at workstations can generate static electricity.

28 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 29

Grounding Requirements for Personnel

The information in this section is provided to assist you in selecting a

grounding method. This information is taken from ANSI/ESD S20.20-2007

(Revision of ANSI/ESD S20.20-1999).

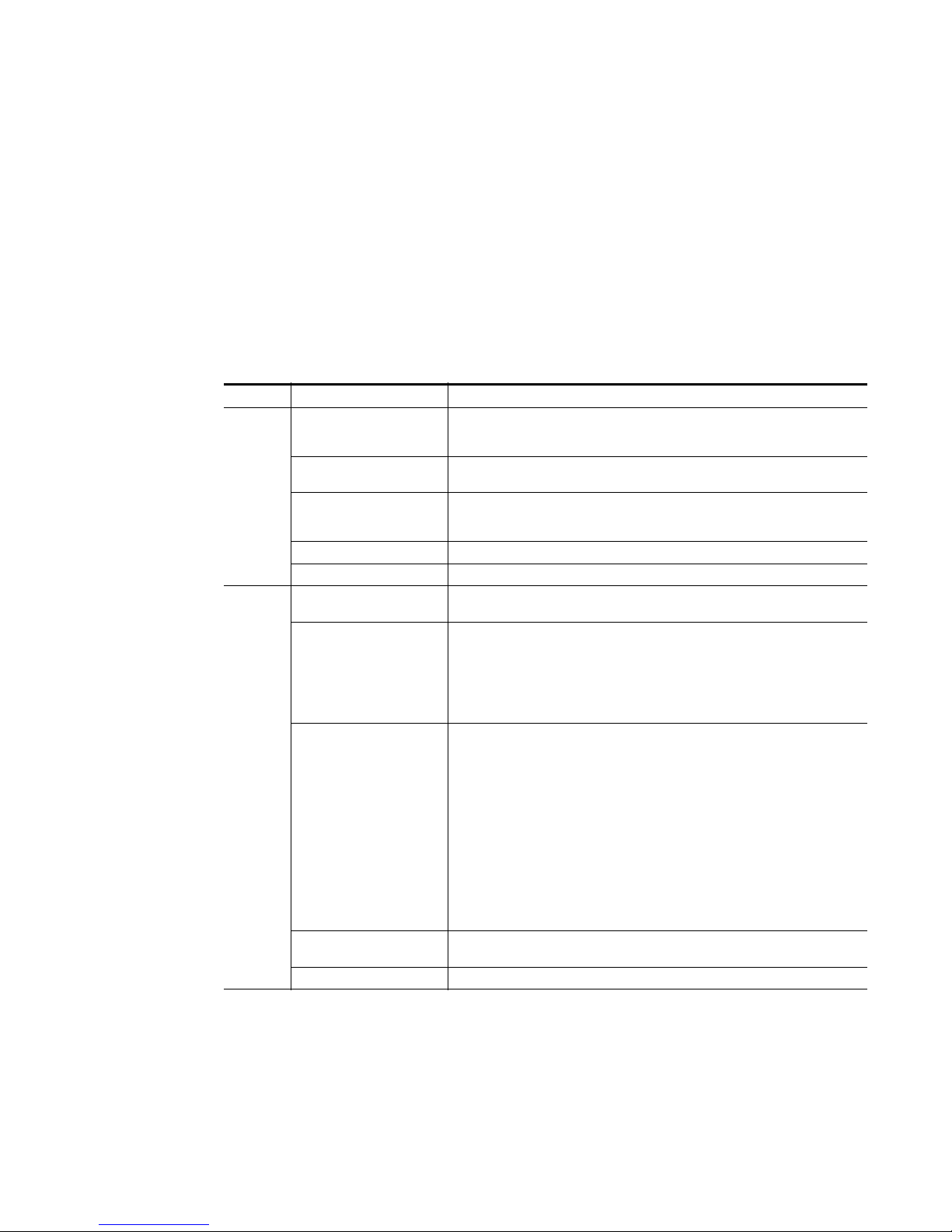

Table 1. Product Qualification

Personnel Grounding Technical

Requirement

Wrist Strap System* ANSI/ESD S1.1 (Section 5.11) < 3.5 x 107 ohm

Flooring / Footwear System – Method 1 ANSI/ESD STM97.1 < 3.5 x 10

Flooring / Footwear System – Method 2

(both required)

ANSI/ESD STM97.1

ANSI/ESD STM97.2

Test Method Required Limits

9

< 10

< 100 V

ESD Protection

7

ohm

ohm

Product qualification is normally conduc

ted during the initial selection of

ESD control products and materials. Any of the following methods can be

used: product specification review, independent laboratory evaluation, or

internal laboratory evaluation.

Table 2. Compliance Verification

Personnel Grounding Technical

Requirement

Wrist Strap System* ESD TR53 Wrist Strap Section < 3.5 x 107 ohm

Flooring / Footwear System – Method 1 ESD TR53 Flooring Section and ESD

Flooring / Footwear System – Method 2

(both required)

TR53 Footwear Section

ESD TR53 Flooring Section and ESD

TR53 Footwear Section

* For situations where an ESD garment is

Test Method Required Limits

7

< 3.5 x 10

< 1.0 x 10

ohm

9

ohm

used as part of the wrist strap

grounding path, the total system resistance, including the person, garment,

7

and grounding cord, must be less than 3.5 x 10

ohm.

JUPITER CM-4400 Control Module Installation and Operating Manual 29

Page 30

ESD Protection

30 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 31

Introduction

0718766

00_CM-4400-Rearpn

l

Time Code 8 Serial ports LANXPT Bus

The CM-4400 Jupiter Control Module (CM) is designed to control Grass

Valley Routing switchers, specific third party routers, and certain other RS422 devices. The devices to be operated are connected to the CM-4400,

which is in turn connected to Jupiter control panels. The CM-4400 is configured using the Jupiter file server (Figure 3 on page 33).

Note Sony machine control is not supported by Jupiter AccuSwitch control soft-

ware.

This manual is for the CM-4400, which only supports the Jupiter AccuSwitch control software. For all other systems, including the CM-4000

System

Controller, you should refer to that system’s manual. See head

Section 1

CM-4400 System Controller

The CM-4400 System Controller (Figure 1 and Figure 2 on page 32) provides a hardware platform for the Jupi

The AccuSwitch application, when c

automation system, allows deterministic switching of a Crosspoint Bus

router.

Figure 1. CM-4400 Control Module-Rear

Note Connect the Ethernet cable to the NET 1 port only. NET 2 is for future use.

ter AccuSwitch application.

onnected to and operated by a suitable

JUPITER CM-4400 Control Module Installation and Operating Manual 31

Page 32

Section 1 — Introduction

0718

76600_CM4400-

Fro

ntpnl

Activate Button

Reset Button

LED Display

CM-4400 Jupiter AccuSwitch Control System

Figure 2. CM-4400 Control Module-Front

The Jupiter AccuSwitch Control System allows you to configure and

control routers, control panels, and diverse connected equipment.

The Jupiter control system includes:

• CM-4400 system controllers (Primary and Secondary (Redundant)

ollers)

contr

• Jupiter AccuSwitch Control software (7.6 or newer)

• File Server PC (Grass Valley or customer supplied)

• Control Panels (either Hardware or Software)

• Jupiter LAN

• Other various options

The Jupiter LAN must be a standalone, isolat

ed network. No other equip-

ment should be connected to, or communicating on, the Jupiter LAN.

An example of the Jupiter Control system is shown in Figure 3 on page 33.

32 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 33

CM-4400

System

Controller

CC 2010 Matrix (Crosspoint bus)

cables.

Apex, Concerto,

GS 400, Trinix, or

Venus router

House SMPTE

time code required

for deterministic

switching

Binary protocol

Crosspoint (XPT) bus port

For jumper and switch

setting information, re-

fer to the installation

manual supplied with

the router.

Serial Ports

House sync

required for

vertical inter-

val switching.

Jupiter file

server

10/100baseT

LAN

CB 3000 Control Buffer

May be required when more than 50 matrix

boards are installed in switcher.

Automation

computer

VTR

ASCII protocol

RS−422/232

converter

1

master control unit

Video Processing Unit

Audio Processing Unit

Audio Processing Unit

Media con-

verter or Hub

10base2

LAN

L-S-LCD panels

Triton router

LAN 1

port

071826105_28Apr09

Figure 3. Example Jupiter System

JUPITER CM-4400 Control Module Installation and Operating Manual 33

Page 34

Section 1 — Introduction

Control Functions

Distribution Switcher Control

Grass Valley matrix routers that can be controlled by the CM-4400 include

Trinix, Apex, Concerto, and Venus. The crosspoint bus on the matrix router

is connected to a CM-4400. This CM-4400 is connected to the Jupiter file

server.

Note The Triton line of routers and some third-party routers can be controlled

Path Finding Option

The Path finding option provides you with the means to communicate

between video routing switchers (“routers”), including automatic standards conversion when switching betw

using a serial connection.

een analog and digital routers.

Path finding is only an option for video r

routers is not supported.

Remote (Serial Control) Router Interface Option

The CM-4400 can optionally support several third-party matrix router protocols. Multiple routers with different pr

if preferred. For a list of supported remote routers, please contact your

Sales representative.

External Control Protocols

These protocols can be used by external computers and Automation

systems to send switch messages into the Jupiter Control System. Each

device will use one serial port on the CM-4400.

outers; Path finding for data

otocols can be mixed in one system

34 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 35

The CM-4400 supports the following protocols:

•Alpha Image

Data Tek

•

• GVG Native (outgoing)

•Nexus

• Pro-bel Eclipse

•Utah 96

• EScontrol

•Utah 12

•Nexus Star

•GVG Horizon

Control Functions

Please contact Grass Valley’s Technical su

page 4).

Control panels

The JEP-100, L-S, and LCD panels are available for use with the AccuSwitch

application. For more information about these panels, see the associated

manuals (JEP-100 Jupiter / Encore Control Panel v1.2.0 Installation and Oper-

ating Manual, Jupiter Con

lation and Operating Manual.)

Software Control Panels (GUI Control Panel)

The Software Control Panel Suite that is shown in the JNS Applications

group is not supported by Jupiter AccuSwitch. The GUI panels that are

supported by AccuSwitch are described in the Jupiter AccuSwitch Soft Panels

and Visual Status Display Instruction Manual.

File Server (Configuration PC)

pport for more information (see

trol System L-S and LCD Series Control Panels Instal-

When the AccuSwitch system is started, program information is downloaded from the file server to the control processors. Field upgrades and

mod

To avoid compatibility issues due to evolving s

use of a customer-supplied computer is discouraged. If circumstances

require a customer-supplied computer, see File Server Minimum Specifica-

tions on pa

JUPITER CM-4400 Control Module Installation and Operating Manual 35

ifications can thus be made through this single station.

oftware requirements, the

ge 279.

Page 36

Section 1 — Introduction

System Logger

The System logger provides you with system status display in a window

on the Jupiter file server or Jupiter remote PC.

Jupiter Configurator Editor

Microsoft Windows-style menus are used to configure the various components of the system. For example, these menus are used to set the individual buses of the CM-4400 to MPK, or other pr

Ordering Information

Contact your sales representative when ordering CM-4400 parts.

otocols as needed.

36 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 37

Hardware Installation

Unpacking and Inspection

Before unpacking the equipment, inspect the shipping carton for evidence

of freight damage. Notify the carrier and Grass Valley if the contents have

been damaged. Retain all shipping cartons and padding material for

inspection by the carrier.

Do NOT return damaged merchandise to Grass Valley until an appropriate

has been filed with the carrier and a material return authorization

claim

number has been received from Grass Valley.

Note If your Jupiter equipment was purchased from Grass Valley as a “turnkey”

system, you may wish to refer to the Jupiter Getting Started Guide. This

booklet provides an abbreviated version of the information in this section and

is available on Grass Valley’s Web site.

Section 2

Verifying 110 or 230 VAC Selection

Most panels are auto sensing; otherwise, power line adjustments are normally made at the factory, based on the

tomers’ facility. However, verifying these s

a good practice.

File Server

Verify that the File server has the correct mains voltage setting. The

minimum specifications for the File server can be found in File Server

Minimum Specifications on

page 279.

Rack Mounting

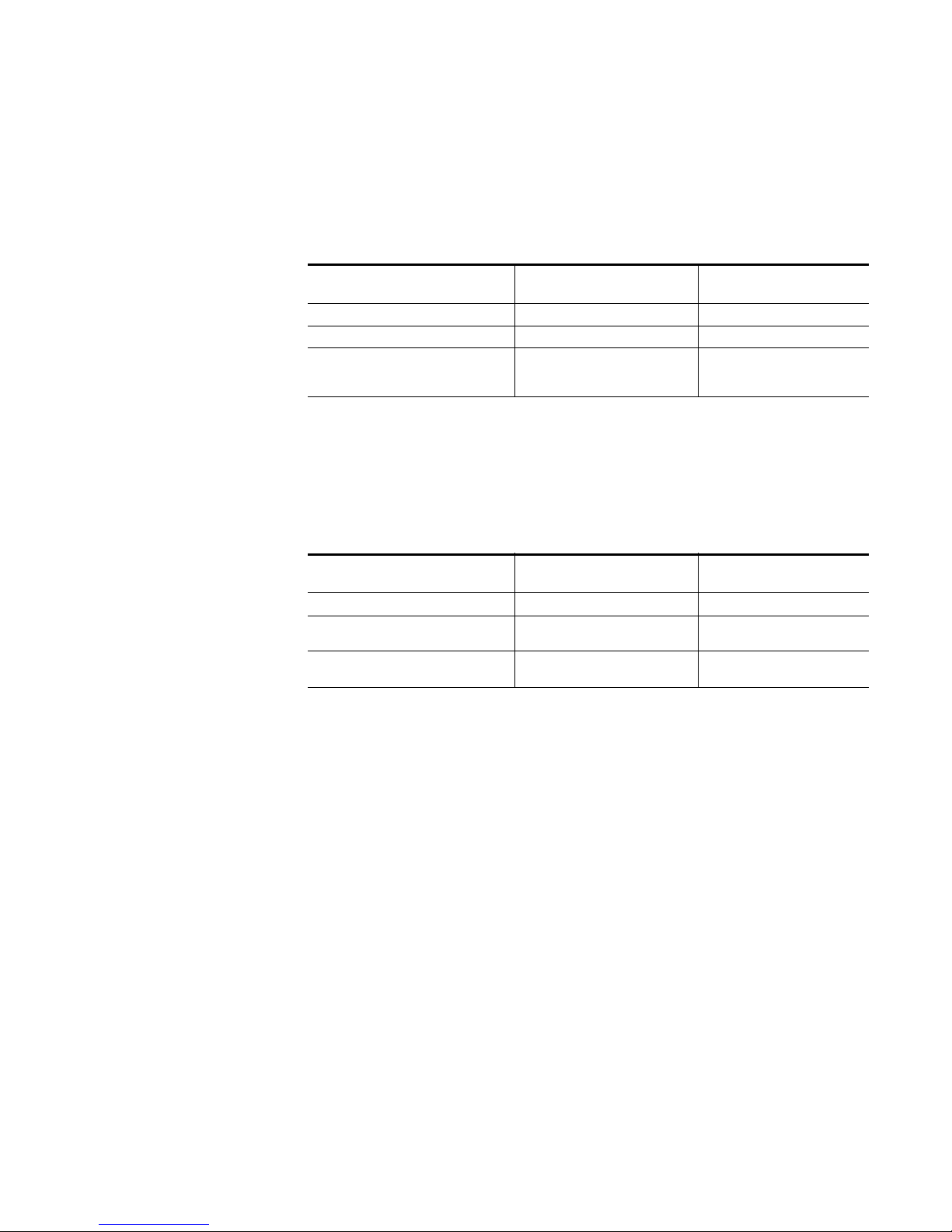

Grass Valley recommends that each CM-4400 be installed close to the

devices that it will control, which will reduce system cabling. An example

system diagram is shown in Figure 4 on page 38.

geographical location of the cus-

ettings before applying power is

JUPITER CM-4400 Control Module Installation and Operating Manual 37

Page 38

Section 2 — Hardware Installation

CM-4400

Control

Module

CC 2010 Matrix (Crosspoint bus)

cables.

Apex,

Concerto§,

and Trinix routers

§§

House SMPTE

time code required

for deterministic

switching

Crosspoint bus

Crosspoint Bus port

For jumper and switch

setting information, re-

fer to the installation

manual supplied with

the router.

House sync

required for

vertical inter-

val switching.

CB 3000 Control Buffer

May be required when more than 50 matrix

boards are installed in switcher.

§

Concerto requires Crosspoint Bus Adapter and

CRS−MC−C2 Controller Board.

LAN

¶

Figure 4. Jupiter AccuSwitch application - Connection to Crosspoint Bus Router

Follow these steps to install the CM-4400 in a rack:

1. Position the CM-4400 on the rack close to the devices that it will control.

Note Grass Valley recommends that a second person help hold the control module

(CM) in place while it is secured to the frame.

2. Install the screws into the Rack-Mounting holes on the front of the CM-

4400.

Do not block the CM-4400’s ventilation openings on both sides of the

If necessary, rack mount support must be cut shorter to avoid

CM.

blocking the airflow. The chassis fan and ventilation openings are

shown in Figure 5 on page 39.

38 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 39

Figure 5. CM-4400 Ventilation Openings

071826106_cm4000-ventalation

Do not block ventilation holes

Unpacking and Inspection

JUPITER CM-4400 Control Module Installation and Operating Manual 39

Page 40

Section 2 — Hardware Installation

0718766

00_CM-4400-Rearpn

l

Time Code 8 Serial ports LANXPT Bus

Connecting the CM-4400 to the Jupiter LAN

The Routers, Control Panels, and PC's that comprise the Jupiter Control

System communicate through the CM-4400 on the Jupiter LAN. The IP

address that is defined as the Base IP is assigned to the first controller in the

system when loading the Jupiter Control Software. The other CM-4400s are

assigned their IP addresses by automatically incrementing addresses following the first controller’s address.

CM-4400 Connections

This section describes the connections on the rear panel of the CM-4400.

Figure 6. CM-4400 Connections

Follow these steps to connect the System controller to the routers:

1. Connect the Crosspoint Bus cable to the XPT BUS connector on the rear

of the CM-4400 controller and the other end to either the BOP-4000, one

of the XPT BUS connector on the rear of the router, or the CB 3000.

(Figure6)

2. Connect the redundant CM-4400 if needed.

Note When adding up all XPT Bus cable segments, the approximate maximum

length is 50 feet. There is also a load limit for how many connections that can

be on one bus. See CM-4400 Serial Bus Loading on page 281 for more information,

40 JUPITER CM-4400 Control Module Installation and Operating Manual

Page 41

Connecting the CM-4400 to the Jupiter LAN

Connecting the Jupiter File Server

The Jupiter File Server PC must be on the local Jupiter LAN and running

Windows XP Professional with at least Service Pack 2. Grass Valley recommends that the Jupiter File server be a separate computer that is dedicated

for Jupi

server; this includes the Windows Firewall application and any firewalls

that are associated with anti-virus programs. For your own protection, DO

NOT allow the Internet to be accessed from this computer.

1. Connect the PC that will serve as the Jupiter File Server to the Ethernet

2. Install Grass Valley’s NetConfig program on the Jupiter File Server.

ter. All firewall applications must be disabled for the Jupiter File

switch. Use a network cable for this connection.

NetConfig is used for L-S-LCD control panels, Trinix, and Concerto.