Page 1

JEP Series

Jupiter / Encore Control Panels

Installation Manual

Software Version 1.3.0

071837202

SEPTEMBER 2011

Page 2

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley USA, LLC and its Grass Valley Affiliates

Headquarters:

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

Brunnenweg 9

D-64331 Weiterstadt

Germany

Kapittelweg 10

4827 HG Breda

The Nederlands

2300 So. Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2008

Scope:

The design, manufacture and support of video and audio hardware and software products and related

systems.

This Certificate is valid until: June 14, 2012

This Certificate is valid as of: December 23, 2010

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms And Conditions For

Quality And Environmental Management Systems Certifications. Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 042108

ccredited By:

ANAB

A

Page 3

JEP Series

Jupiter / Encore Control Panels

Installation Manual

Software Version 1.3.0

071837202

SEPTEMBER 2011

Page 4

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley USA, LLC. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.grassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 JEP Series — Installation Manual

Page 5

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Regulatory Notices

Safety Summary

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FCC Emission Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Certifications: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Terms in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ESD Protection

Recommended ESD Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sources of ESD and Risks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Grounding Requirements for Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Section 1 — JEP-100 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Hardware Installation - Jupiter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

LAN Only System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

LAN + Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Serial Data Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

VDE Modifications to Serial Data Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Joystick Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Internet Protocol Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Single Network IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LAN Only System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Serial System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LAN + Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Software Installation Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the Latest Software Version to the PC . . . . . . . . . . . . . . . . . . . . . . . . . 35

Updating to the Latest Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

JEP Series — Installation Manual 5

Page 6

— Contents

Using the Network Download Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Using the Update Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Updating the JEP-100 panel Using NetConfig. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

IP Configuration Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Multi-Network IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuration - Jupiter System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

LAN Only System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

MPK Table Entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Serial Protocol Table Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

MPK Table Entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Special Entries Needed to Upgrade Serial Panels . . . . . . . . . . . . . . . . . . . . . . 55

LAN + Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Serial Protocol Table Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

MPK Table Entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Special Entries Needed to Upgrade Serial Panels . . . . . . . . . . . . . . . . . . . . . . 58

All Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Control Panel Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Audio Mode (Special Stereo Switching) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Salvo Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Compiling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Section 2 — JEP-100 CP Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

LED Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Show Button Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Destination Selection / Status Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Source Selection (All Levels Take) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

BPS button programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Level Breakaways (Split Switching). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Default Mode Breakaway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Button-per-Level Mode Breakaway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Checking Status of Selected Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Defining a Source Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Defining a Destination Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Defining a Level Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Locking or Unlocking an Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Salvo Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Setting Up a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Executing a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Assigning a Sequence to a Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Joystick Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Configuring a JEP-100 GPI Port (Joystick Override Control Line) . . . . . . . . . . 76

Menu Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

AlM. - Alternate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

SelAMod. - Select Audio Mode (Special Stereo Switching) . . . . . . . . . . . . . . 79

DspAMod. - Display Audio Mode (Special Stereo Switching) . . . . . . . . . . . 80

Locking or Unlocking an Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

M.O. - Multiple Output Mode On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

ELAN - Ethernet Mode On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

D.T. - Display Time On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Chg ID - Change Panel ID Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

v - Version Number Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Internet Protocol Address Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6 JEP Series — Installation Manual

Page 7

Diag - Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

C.B. - Change Brightness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Output Button Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Disabling the Configuration and Setup Menus. . . . . . . . . . . . . . . . . . . . . . . . . 85

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

JEP Series — Installation Manual 7

Page 8

— Contents

8 JEP Series — Installation Manual

Page 9

Preface

About This Manual

This manual provides installation and operating information for the JEP control

panel series. These control panels are designed for use with a Jupiter CM-

4000 or CM-4400 System Controller.

Additional Documentation

Printed and electronic copies of this manual are normally provided with

the system. Individual manuals may be ordered by contacting Technical

Support. For contact information, see

Configuration information for the Jupiter control system itself is contained

in the control system’s documentation set:

Contacting Grass Valley on page 4.

Jupiter Control System Release Notes.

Jupiter CM-4000 Installation and Operating Manual

Jupiter CM-4400 Installation and Operating Manual

Jupiter Getting Started Guide.

Electronic copies of other routing products documents are available on the

following documentation CDs:

Routing Products Documentation CD. Includes all Jupiter manuals.

These documents are also available on the www.grassvalley.com web site.

JEP Series — Installation Manual 9

Page 10

Preface

10 JEP Series — Installation Manual

Page 11

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equip

ment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equip

ment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

-

-

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regula

tions of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

In a domestic environment, products that comply with Class A may cause

radio interference in which case the user may be required to take adequate

measures.

-

JEP Series — Installation Manual 11

Page 12

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

Laser Compliance

Laser Safety Requirements

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

The device used in this product is a Class 1 certified laser product. Operating this product outside specifications or altering from its original design

may result in hazardous radiation exposure, and may be considered an act

of modifying or new manufacturing of a laser product under U.S. regula

tions contained in 21CFR Chapter 1, subchapter J or CENELEC regulations

in HD 482 S1. People performing such an act are required by law to recertify

and reidentify this product in accordance with provisions of 21CFR sub

chapter J for distribution within the U.S.A., and in accordance with

CENELEC HD 482 S1 for distribution within countries using the IEC 825

standard.

-

-

Laser Safety

Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The International Electrotechnical Commission (IEC) Standard 825, “Radiation of Laser Products, Equipment Classification, Requirements and

User’s Guide,” governs laser products outside the United States. Europe

and member nations of the European Free Trade Association fall under the

jurisdiction of the Comite European de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected through a 7 mm aperture at

a distance of 200 mm from the source focused through a lens with a focal

length of 100 mm.

For IEC compliance: The radiant power is detected through a 7 mm aperture at a distance of 100 mm from the source focused through a lens with a

focal length of 100 mm.

12 JEP Series — Installation Manual

Page 13

FCC Emission Limits

Certifications:

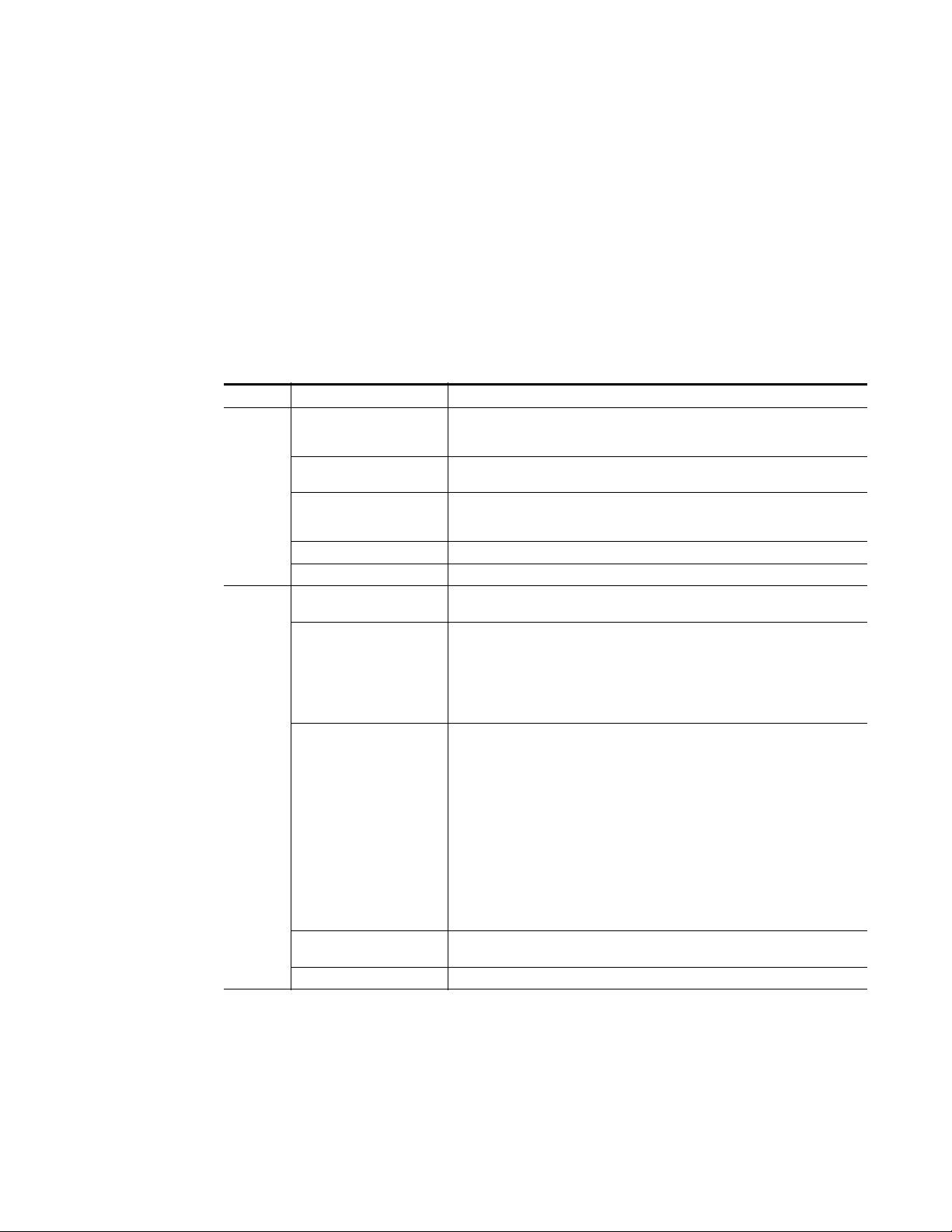

Category Standard Designed/tested for compliance with:

Safety

EMI

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful inter

ference, and (2) this device must accept any interference received,

including interference that may cause undesirable operation. This device

has been tested and found to comply with FCC Part 15 Class B limits for a

digital device when tested with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channel Standard.

ANSI / UL60950 “Standard for Safety of Information Technology Equipment - Safety - Part 1: General

IEC 60950 “Standard for Safety for Information Technology Equipment - Safety - Part 1: General

CAN/CSA C22.2, No. 60950 “Standard for Safety of Information Technology Equipment - Safety - Part 1: General

EN60950 Safety of Information Technology Equipment, including Electrical Business Equipment.

73/23/EEC Low Voltage Directive

EMC Directive 89/336/EEC via

EN 55103-1 and 2

EN 55103-1 standards Electromagnetic compatibility.

EN55103-2 standards Electromagnetic compatibility--Product family standard for audio, video, audio-visual

US FCC Class A

Canada FCC Industry Canada

Australia & New Zealand: AS/NZS 3548

Requirements”, (ANSI/UL 60950-1, First Edition, Dated April 1, 2003, with revision

through and including November 26, 2003.)

Requirements”, (IEC 60950-1, First Edition, 2001, Corrigendum 1:10-2002)

Requirements”, (CAN/CSA-C22.2 No. 60950-1-03. First Edition Dated April 1, 2003,

with revisions through and including November 26, 2003)

Audio, Video and Entertainment Lighting Control for the European Community.

Product family standard for audio, video, audio-visual and entertainment lighting control

apparatus for professional use.

Part 1 Emissions, Environment E1/E2

EN 55022: Class A Radiated and Conducted Emissions

EN 61000-3-2: Power Line Harmonic Emissions, Radiated Magnetic Field Emissions,

Peak Inrush Current

and entertainment lighting control apparatus for professional use.

Part 2 Immunity, Environment E1/E2

EN 50082-1: Immunity

EN 61000-4-2:

Electrostatic Discharge “ESD” Immunity

EN 61000-4-3:

Radiated RF Electromagnetic Field Immunity

EN 61000-4-4:

Electrical Fast Transient/Burst “EFT” Immunity

EN 61000-4-5: Surge Immunity

EN 61000-4-6: Conducted RF Immunity

EN 61000-4-11: Voltage Dips, Short Interruptions and Voltage Variations

Annex A - Radiated Magnetic Field Immunity

Note: This only applies to assemblies sensitive to magnetic fields

CISPR Pub. 22 (1985)

-

JEP Series — Installation Manual 13

Page 14

Regulatory Notices

14 JEP Series — Installation Manual

Page 15

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

Terms on the Product

The following terms may appear on the product:

DANGER — A personal injury hazard is immediately accessible as you read

the marking.

WARNING — A personal injury hazard exists but is not immediately acces-

sible as you read the marking.

CAUTION — A hazard to property, product, and other equipment is present.

JEP Series — Installation Manual 15

Page 16

Safety Summary

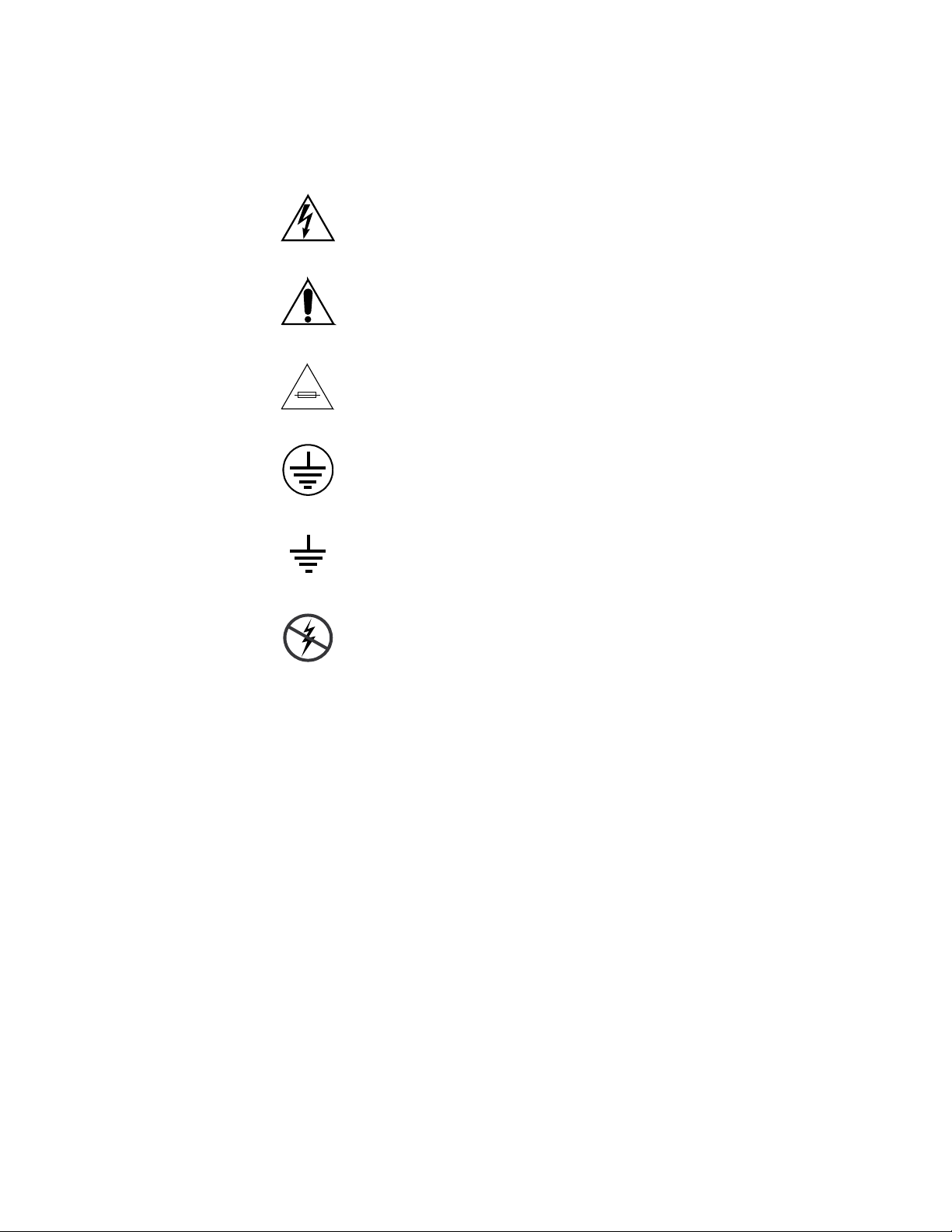

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground prior to making any

connections.

other equipment

Warnings

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or

replacing components.

Do not service alone — Do not internally service this product unless another

person capable of rendering first aid and resuscitation is present.

Remove jewelry — Prior to servicing, remove jewelry such as rings, watches,

and other metallic objects.

Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

16 JEP Series — Installation Manual

Page 17

Safety Summary

Use proper power cord — Use only the power cord supplied or specified for

this product.

Ground product — Connect the grounding conductor of the power cord to

earth ground.

Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

Use correct fuse — Use only the fuse type and rating specified for this

product.

Use only in dry environment — Do not operate in wet or damp conditions.

Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

High leakage current may be present — Earth connection of product is essential

before connecting power.

Dual power supplies may be present — Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Cautions

Double pole neutral fusing — Disconnect mains power prior to servicing.

Use proper lift points — Do not use door latches to lift or move equipment.

Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

Use correct voltage setting — If this product lacks auto-ranging power sup-

plies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation — To prevent product overheating, provide equip-

ment ventilation in accordance with installation instructions.

Use anti-static procedures — Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

JEP Series — Installation Manual 17

Page 18

Safety Summary

Do not operate with suspected equipment failure — If you suspect product damage

or equipment failure, have the equipment inspected by qualified service

personnel.

Ensure mains disconnect — If mains switch is not provided, the power cord(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly — Route power cords and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid con

nector damage.

Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery — This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used bat

teries according to the manufacturer’s instructions.

-

-

Troubleshoot only to board level — Circuit boards in this product are densely

populated with surface mount technology (SMT) components and applica

tion specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For war

ranty compliance, do not troubleshoot systems beyond the board level.

-

-

18 JEP Series — Installation Manual

Page 19

ESD Protection

Electronics today are more susceptible to electrostatic discharge (ESD)

damage than older equipment. Damage to equipment can occur by ESD

fields that are smaller than you can feel. Implementing the information in

this section will help you protect the investment that you have made in

purchasing Grass Valley equipment. This section contains Grass Valley’s

recommended ESD guidelines that should be followed when handling

electrostatic discharge sensitive (ESDS) items. These minimal recommen

dations are based on the information in the Sources of ESD and Risks area.

The information in Grounding Requirements for Personnel on page 21 is provided to assist you in selecting an appropriate grounding method.

Recommended ESD Guidelines

Follow these guidelines when handling Grass Valley equipment:

• Only trained personnel that are connected to a grounding system

should handle ESDS items.

• Do not open any protective bag, box, or special shipping packaging

until you have been grounded.

-

Note When a Personal Grounding strap is unavailable, as an absolute minimum,

touch a metal object that is touching the floor (for example, a table, frame, or

rack) to discharge any static energy before touching an ESDS item.

• Open the anti-static packaging by slitting any existing adhesive tapes.

Do not tear the tapes off.

• Remove the ESDS item by holding it by its edges or by a metal panel.

• Do not touch the components of an ESDS item unless it is absolutely

necessary to configure or repair the item.

• Keep the ESDS work area clear of all nonessential items such as coffee

cups, pens, wrappers and personal items as these items can discharge

static. If you need to set an ESDS item down, place it on an anti-static

mat or on the anti-static packaging.

JEP Series — Installation Manual 19

Page 20

ESD Protection

Sources of ESD and Risks

The following information identifies possible sources of electrostatic discharge and can be used to help establish an ESD policy.

Personnel

One of the largest sources of static is personnel. The static can be released

from a person’s clothing and shoes.

Environment

The environment includes the humidity and floors in a work area. The

humidity level must be controlled and should not be allowed to fluctuate

over a broad range. Relative humidity (RH) is a major part in determining

the level of static that is being generated. For example, at 10% - 20% RH a

person walking across a carpeted floor can develop 35kV; yet when the rel

ative humidity is increased to 70% - 80%, the person can only generate

1.5kV.

-

Static is generated as personnel move (or as equipment is moved) across a

floor’s surface. Carpeted and waxed vinyl floors contribute to static build

up.

Work Surfaces

Painted or vinyl-covered tables, chairs, conveyor belts, racks, carts, anodized surfaces, plexiglass covers, and shelving are all static generators.

Equipment

Any equipment commonly found in an ESD work area, such as solder

guns, heat guns, blowers, etc., should be grounded.

Materials

Plastic work holders, foam, plastic tote boxes, pens, packaging containers

and other items commonly found at workstations can generate static elec

tricity.

-

20 JEP Series — Installation Manual

Page 21

Grounding Requirements for Personnel

The information in this section is provided to assist you in selecting a

grounding method. This information is taken from ANSI/ESD S20.20-2007

(Revision of ANSI/ESD S20.20-1999).

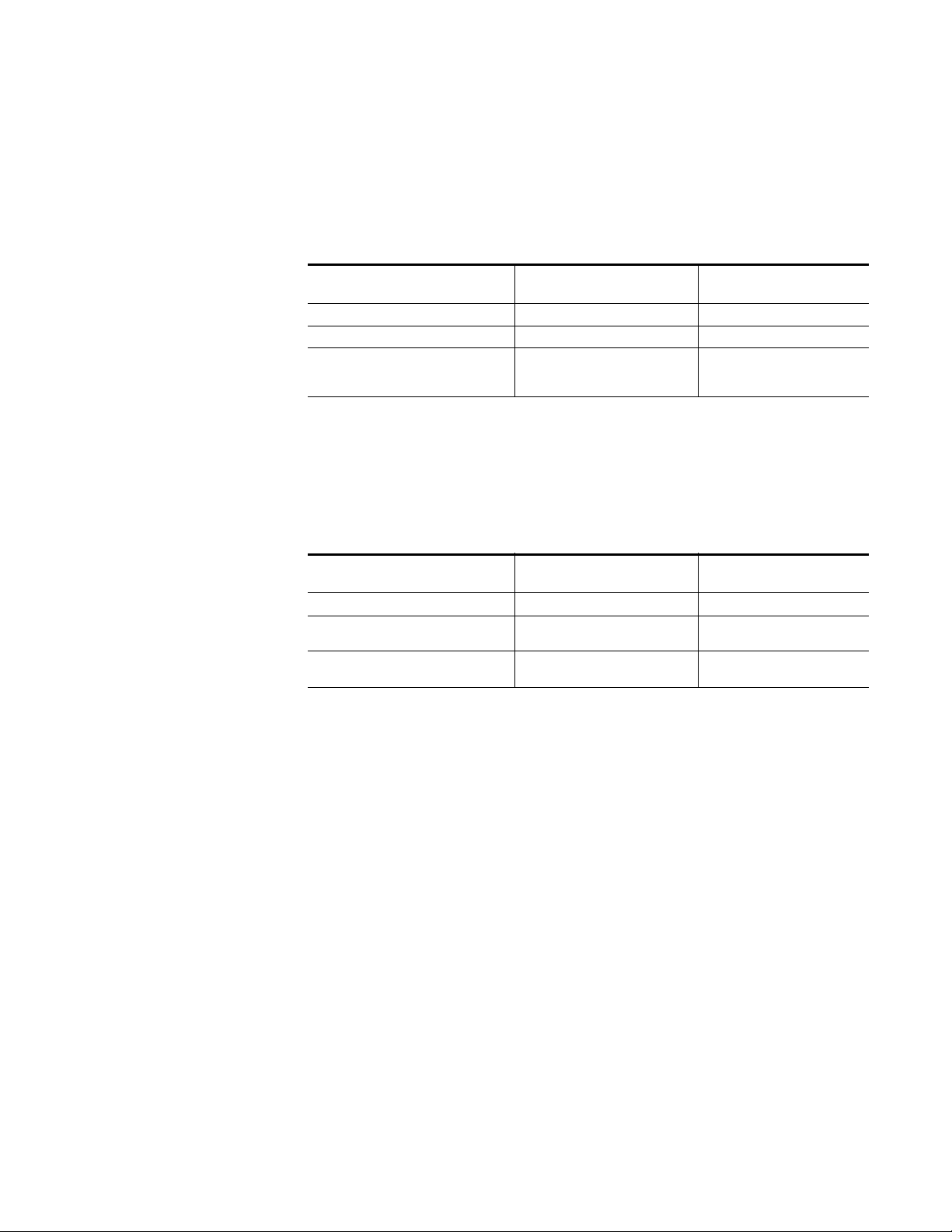

Table 1. Product Qualification

Personnel Grounding Technical

Requirement

Wrist Strap System* ANSI/ESD S1.1 (Section 5.11) < 3.5 x 107 ohm

Flooring / Footwear System – Method 1 ANSI/ESD STM97.1 < 3.5 x 10

Flooring / Footwear System – Method 2

(both required)

ANSI/ESD STM97.1

ANSI/ESD STM97.2

Product qualification is normally conducted during the initial selection of

ESD control products and materials. Any of the following methods can be

used: product specification review, independent laboratory evaluation, or

internal laboratory evaluation.

Test Method Required Limits

9

< 10

< 100 V

ESD Protection

7

ohm

ohm

Table 2. Compliance Verification

Personnel Grounding Technical

Requirement

Wrist Strap System* ESD TR53 Wrist Strap Section < 3.5 x 107 ohm

Flooring / Footwear System – Method 1 ESD TR53 Flooring Section and ESD

Flooring / Footwear System – Method 2

(both required)

TR53 Footwear Section

ESD TR53 Flooring Section and ESD

TR53 Footwear Section

Test Method Required Limits

< 3.5 x 10

< 1.0 x 10

7

ohm

9

ohm

* For situations where an ESD garment is used as part of the wrist strap

grounding path, the total system resistance, including the person, garment,

7

and grounding cord, must be less than 3.5 x 10

ohm.

JEP Series — Installation Manual 21

Page 22

ESD Protection

22 JEP Series — Installation Manual

Page 23

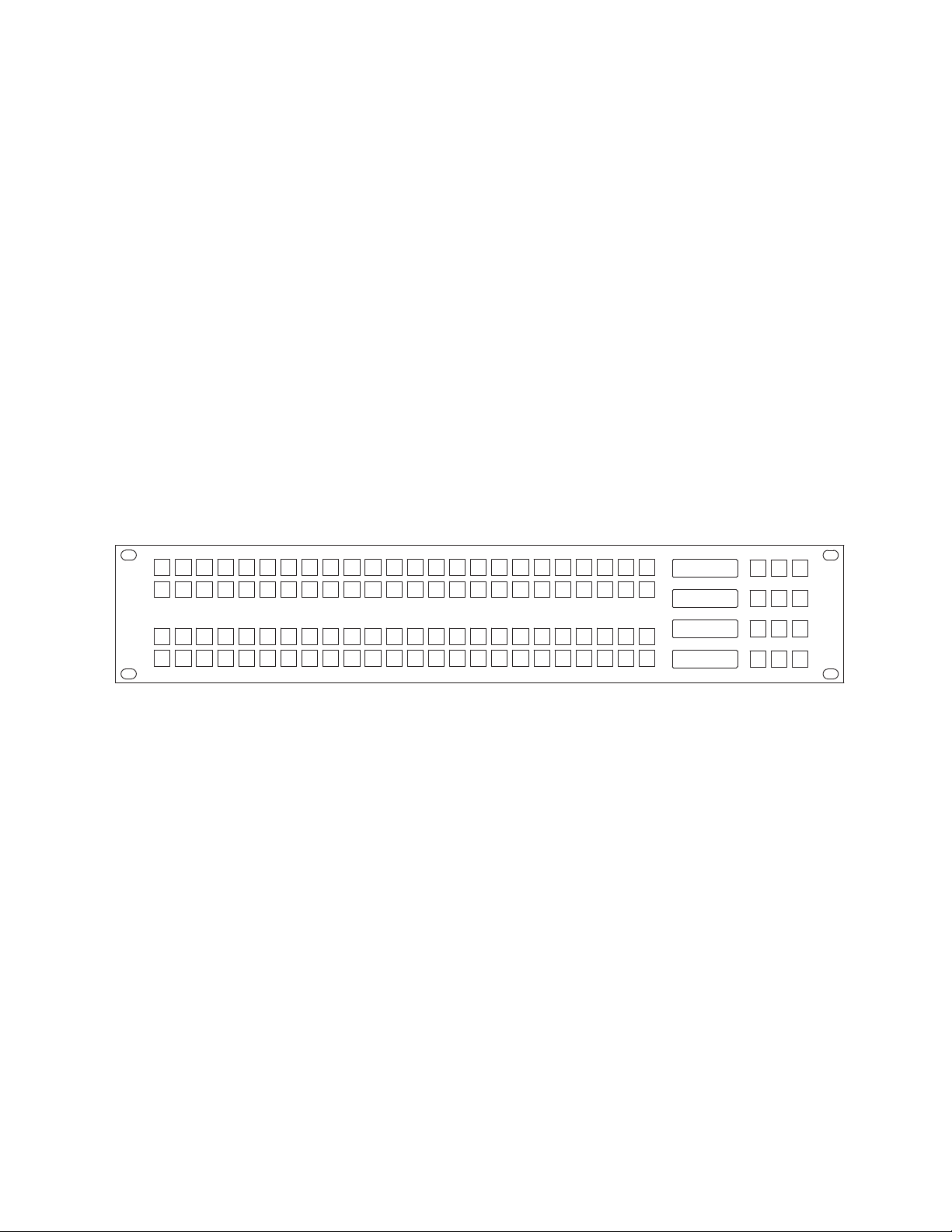

JEP-100 Control Panel

Destination

Status

Preset

Level

Introduction

The JEP-100 Jupiter/Encore Control Panel, which was the first example in

the JEP series, is a locally-programmable, eight-character mnemonic, fullmatrix control, multiple level break away panel designed especially for use

in television production vans. (

Figure 1. JEP-100 Control Panel

Figure 1)

Section 1

The current version of the panel uses a 15-pin D female connector on the

rear panel to provide a total of 14 control lines (GPI ports) plus ground.

Each port can be used to trigger a switching event when initiated by a

contact closure on a customer-provided device. In the joystick override

application, a joystick such as found on a camera control unit (CCU) can be

used to select a camera for QC evaluation.

The panel includes a fully-enclosed auto-sensing power supply with an

inrush current rating of 7.9 A. The nominal power requirement is 0.4 A @

240 VAC or 0.65 A @ 120 VAC. There is no power switch (the AC cord must

be disconnected to power down the panel).

The 96 keys on the left side of the panel are initially assigned to inputs using

the control system file server, but some or all can be re-assigned to new

inputs at any time using only the panel itself. The keys can alternatively be

used to control outputs or levels.

Sources, destinations, and levels can also be selected by scrolling up/ down

in the various LED displays.

JEP Series — Installation Manual 23

Page 24

Section 1 — JEP-100 Control Panel

Space has been provided for adhesive strips to be placed on the front

surface for identification of buttons as they are arranged for specific proj

ects.

The JEP-100 control panel is only designed for use with either a Jupiter CM4000, CM-4400 System Controller, or an Encore Control System. The JEP100 panel is not intended for use with Jupiter VM-3000 System Controllers.

Note The CM-4000/4400 must be operating with Jupiter / AccuSwitch version

Note The CM-4000/4400 must be operating with Jupiter / Saturn / AccuSwitch

In Jupiter applications, the JEP-100 can be connected to the CM-4000/4400

System Controller via a 115k Baud serial bus (maximum distance of 2000

feet); or via a Cat 5 Ethernet connection (maximum distance per segment

329 feet). An Ethernet connection is required for software upgrade pur

poses.

-

7.9.1 to support the JEP-100 1.3.0 feature set.

version 7.3.2 to support the JEP-100 1.1.1 feature set (except Salvo. JEP-100

salvo requires Jupiter version 7.4 software).

-

Specifications

Physical Dimensions: 2 RU rack mount: 19 in. Width x 3.5 in. Height x

approx. 4 in. Depth (483 mm W x 89 mm H x 102 mm D)

Weight: 2.25 lb. (1.02 kg.)

Operating voltage: 90 to 260 VAC

Operating current: 0.4 A @ 240 VAC or 0.65 A @ 120 VAC

Inrush current rating: 7.9 A

Power consumption: <100 W

Joystick override: Connector, 15-pin D, female.

The wiring between the rear-panel connector and a customer-supplied

contact closure device: minimum 22 AWG (American Wire Gauge);

maximum length, 30 feet (10 meters).

24 JEP Series — Installation Manual

Page 25

Hardware Installation - Jupiter System

The JEP-100 can be connected to the CM-4000 or CM-4400 System Controller via a 115k Baud serial bus or via a Cat 5 Ethernet connection. It is also

possible to combine these methods by connecting some panels serially and

others through the LAN.

An Ethernet connection is required for upgrading the panel software, for all

panels, even if you use a serial connection to connect to the CM-4000 or

CM-4400 to the panels.

Hardware Installation - Jupiter System

JEP Series — Installation Manual 25

Page 26

Section 1 — JEP-100 Control Panel

LAN (Cat 5 Ethernet) cable.

Max. recommended length per

segment = 100 meters (329 ft)

CM-4000/4400

System

Controller

100baseT Jupi-

ter LAN

to Jupiter

File Server

IP switch

64 LAN#operated

JEP#100s per CM

maximum

8536_08

LAN Only System

In this arrangement the JEP is operated in Ethernet mode, where the LAN

connection is used both for operation and for software upgrade purposes.

See

Figure 2.

Note The LAN must be capable of 100 Mb operation. Each Ethernet segment (hub

Figure 2. LAN only system connections.

to panel) has a 100 meter limit.

26 JEP Series — Installation Manual

Page 27

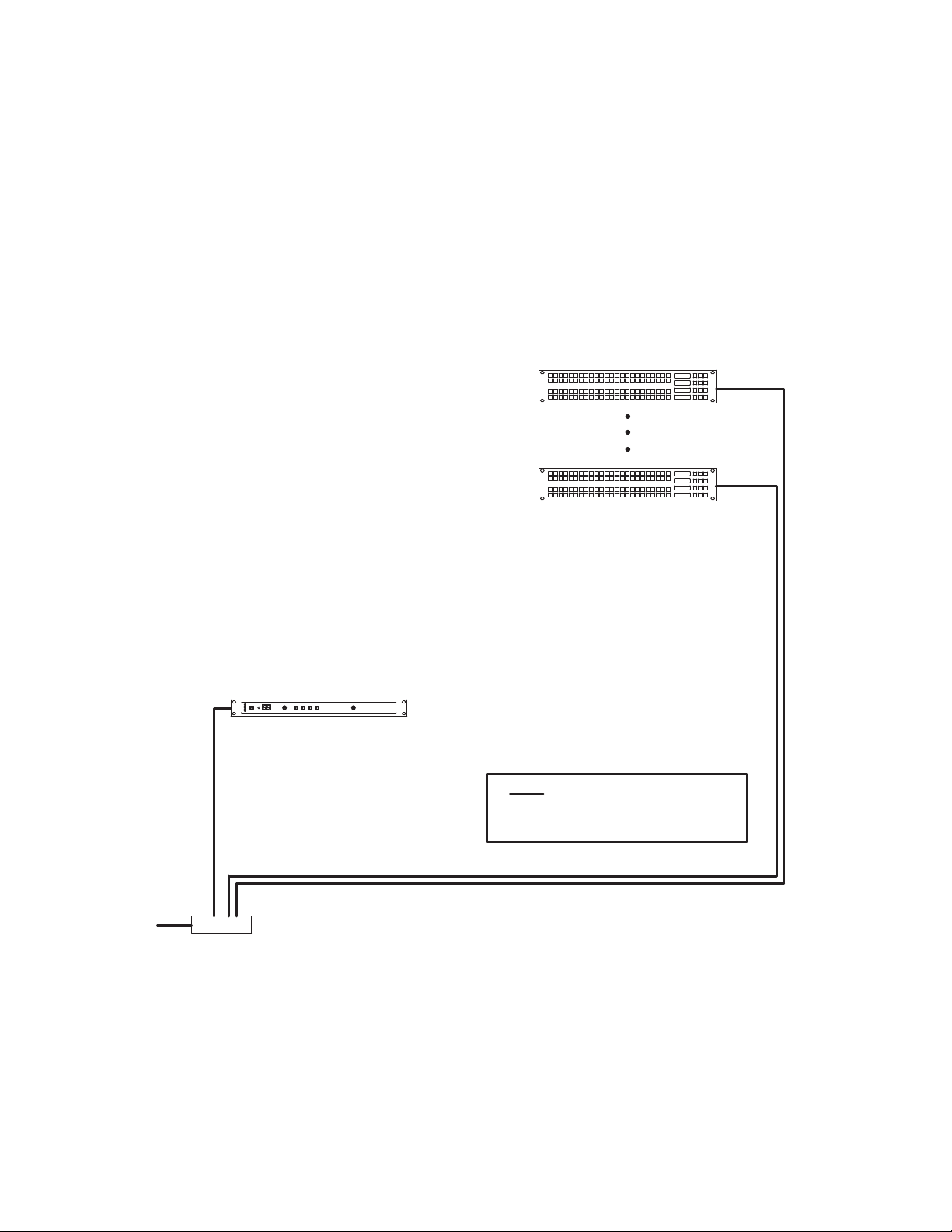

Serial System

CM

CM -4000 System Controller

Serial

Ports

100baseT Jupi-

ter LAN

16 JEP

100s per

serial bus maximum

IP switch

to Jupiter

File Server

Serial data cable

LAN (Cat 5 Ethernet) cable.

Max. recommended length per

segment = 100 meters (329 ft)

Temporary LAN connection for

software upgrade.

Serial bus

Serial bus

8536_09

-4400 or

Hardware Installation - Jupiter System

This wiring arrangement assumes that the JEP-100(s) will be operated in

Serial mode, with the LAN typically connected to one panel at a time only

during software upgrades. See

Note The LAN must be capable of 100 Mb operation. Each Ethernet segment (hub

to panel) has a 100 meter limit.

Figure 3. Serial system connections.

Figure 3.

JEP Series — Installation Manual 27

Page 28

Section 1 — JEP-100 Control Panel

Serial data cable

LAN (Cat 5 Ethernet) cable.

Max. recommended length per

segment = 100 meters (329 ft)

Serial bus

CM -4000 or

CM - 4400 System Controller

Serial

Ports

100baseT Jupi-

ter LAN

A maximum of 16 JEP100s per

serial bus

to Jupiter

File Server

Temporary LAN connection for

software upgrade.

IP switch

A maximum of 64 LAN operated

JEP-100s per C M

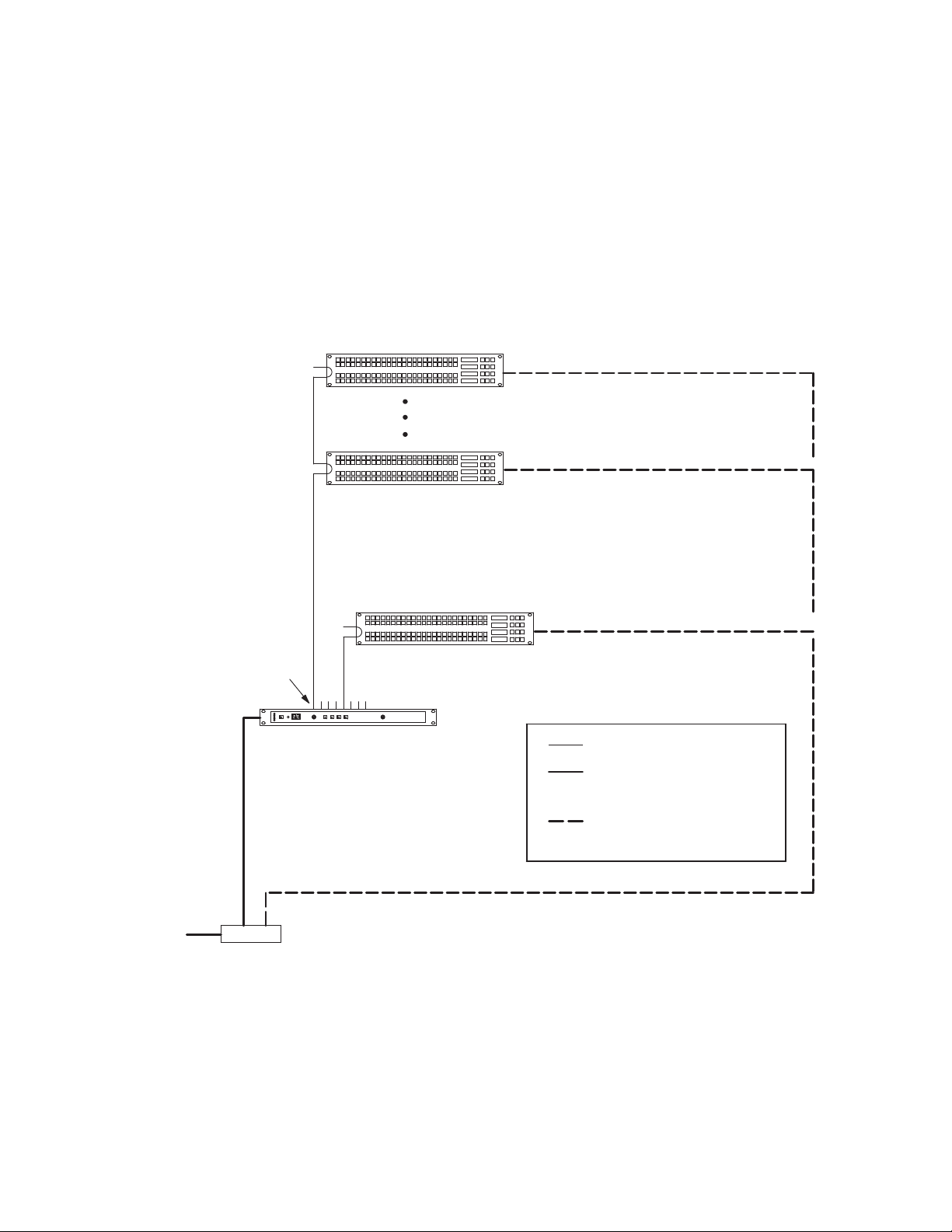

LAN + Serial System

In this system, one or more JEP-100s are operated in Serial mode, while

other JEP-100s are operated in LAN mode (

The JEP-100(s) operated in Serial mode will require a LAN connection only

during a software upgrade session. See

Note The LAN must be capable of 100 Mb operation. Each Ethernet segment (hub

Figure 4. LAN + Serial system connections

Figure 4).

Figure 3 on page 27.

to panel) has a 100 meter limit.

Maximum of JEP-100 panels per CM:

• Connected to a Serial Bus - 16.

• Connected to a LAN - 64.

28 JEP Series — Installation Manual

Page 29

Serial Data Cables

1

2

3

7

8

1

2

8

P1

DB9P

(male)

Shield (drain)

Green

Black

White

P2

DB9P

(male)

3

7

Red

Frame ground

CM-4000/4400 System

Controller

(bus controller)

Control panel or

VTR

(tributary)

Receive A (#)

Transmit A (#)

Receive B (+)

Transmit B (+)

Transmit B (+)

Transmit A (#)

Receive B (+)

Receive A (#)

Frame ground

Individually shielded, twisted pairs

Ferrite core

Ferrite core

Green

Black

White

Red

8536_11

The RS-422 cables used to connect CM-4000 or CM-4400 System Controllers

and control panels consist of a 4-conductor (plus ground) cable. Maximum

length per bus, at 115k Baud, is 610 meters (2000 ft.).

The rear panel serial data cable connectors on the CM-4000 or CM-4400 and

control panels are 9-pin D, female. The control panel connectors are

arranged for loop-through wiring. No termination is required. While these

connectors are ESbus compatible, it should be noted that the Grass Valley

serial data cables use only 5 of the 9 pins described in the ESbus specifica

tion.

The following ready-made cables, with installed 9-pin D male connectors,

are available from Grass Valley (VDE cables include ferrite cores):

Table 3. Ready-Made Cables

1meter (3.3 ft.) 8 meters (26.2 ft.)

2 meters (6.6 ft.) 16 meters (52.5 ft.)

4 meters (13.1 ft.) 32 meters (105 ft.)

Hardware Installation - Jupiter System

-

For those who wish to prepare their own cables, the pin-outs are shown in

Figure 5. The cable itself should be Belden 8723 or equivalent.

Details concerning ferrite cores are given in Figure 6 on page 30.

Figure 5. Serial Data Cable Wiring.

JEP Series — Installation Manual 29

Page 30

Section 1 — JEP-100 Control Panel

Type 43 material

0.250 inch (6.35 mm) inside diameter

0.95 inch (24.13 mm) length (or longer)

Type 43 material sources

Fair Rite, part no. 2643480002

Fair Rite Products Corp., P .O. Box J, Commercial

Row, Wallkill, NY 12589, USA; Tel. (914) 895 2055.

Chomerics, part no. 83 10 A636 1000

Chomerics Inc., 77 Dragon Ct., Woburn, MA 01888

USA; Tel. (617) 935 4850.

8536_12

VDE Modifications to Serial Data Cables

User-supplied serial data cables for VDE installations require a ferrite core

over each end of the cable, adjacent to the connector.

Figure 6. Serial data cable VDE modifications.

Joystick Override

This function applies only to the current JEP-100 model, which has a 15-pin

D female connector on the rear panel to provide a total of 14 joystick control

lines plus ground.

30 JEP Series — Installation Manual

Page 31

Internet Protocol Configuration

IP connection and configuration allows Ethernet operation and provides a

download path for software upgrades using the NetConfig application.

The JEP-100, CM-4000 or CM-4400, and file server PC must be on the same

IP network, or else be connected through a network router/gateway.

The following applies to JEP-100 configuration using the panel's built-in

HTTP web page.

Single Network IP Configuration

The following discussion applies when the Jupiter equipment (file server,

CM-4000 or CM-4400, and JEP-100) is in an isolated network environment.

Internet Protocol Configuration

JEP Series — Installation Manual 31

Page 32

Section 1 — JEP-100 Control Panel

CM-4400 or

4000 System Controller

10/100baseT

Jupiter LAN

IP switch

Panel IP

“192.168.253.102”

Panel ID

“02”

Panel IP

“192.168.253.101”

Panel ID

“01”

Panel IP

“192.168.253.164”

Panel ID

“64”

Jupiter

File Server

“192.168.253.1”

IP

“192.168.253.10”

8536_13

LAN Only System

Figure 7 shows an example of a system addressing where the JEP-100s will

be operated entirely in Ethernet mode. Up to 64 JEP-100s can be controlled

per CM-4000 or CM-4400.

Figure 7. LAN only System Addressing (example).

32 JEP Series — Installation Manual

Page 33

Serial System

CM-4400 or

CM-4000 System Controller

Serial

Ports

100baseT Jupi-

ter LAN

IP switch

Serial

buses

Panel IP

“192.168.253.102”

Panel ID

“02”

Panel IP

“192.168.253.101”

Panel ID

“01”

Panel IP

“192.168.253.116”

Panel ID

“16”

Panel IP

“192.168.253.117”

Panel ID

“01”

IP

“192.168.253.10”

Jupiter

File Server

“192.168.253.1”

8536_14

Figure 8 shows an example of a system addressing where the JEP-100s will

be operated in Serial mode (the LAN connections are for software

upgrade). Because there are more than 16 panels, the 17th panel must be

connected to a second CM port. This results in two panels with an ID of

“01.”

This arrangement assumes that the LAN connections will be made to one

panel at a time only for the purpose of software upgrade. In this case, it isn't

necessary to have a different IP address for each panel; however, to prevent

confusion if more than one panel is connected it is recommended that

unique IP addresses are assigned.

Figure 8. Serial System Addressing (example).

Internet Protocol Configuration

JEP Series — Installation Manual 33

Page 34

Section 1 — JEP-100 Control Panel

Serial bus

CM-4000/4400 System Controller

Serial

Ports

100baseT Jupi

ter LAN

IP switch

64 LAN-operated

JEP-100s per CM

maximum

Panel IP

192.168.253.102"

Panel ID

02"

Panel IP

192.168.253.101"

Panel ID

01"

Panel IP

192.168.253.116"

Panel ID

16"

Jupiter

File Server

192.168.253.1"

LAN + Serial System

Figure 9 shows an example of system addressing where one or more JEP-

100s will be operated in Serial mode, while other JEP-100s are operated in

LAN mode.

The JEP-100(s) operated in serial mode will require a LAN connection only

during a software upgrade session.

Figure 9. Example of LAN + serial system addressing

34 JEP Series — Installation Manual

Page 35

Software Installation Process

JEP-100 series hardware panels are shipped with the current software

installed. There is no need to install panel software on newly shipping sys

tems. However, the IP address must be set on each panel so it can operate

on the network. The NetConfig application is used to discover and set IP

addresses of the JEP-100 series panels. Once version 1.3.0 is installed, Net

Config may also used to update JEP-100 series panel software, by transferring panel code from the computer running NetConfig directly to the

panels.

This section will describe the steps needed to Install the latest software on

the PC, Download the new firmware to the panel using the Network

Download Utility and Updating the panel using the Update Manager

application.

Note The Panels MUST be connected to a LAN connection during a software

upgrade session even if the panel is uses a Serial connection.

Software Installation Process

-

-

Installing the Latest Software Version to the PC

Follow these steps to begin installing the JEP-100 software:

1. Insert the supplied software CDROM into the computer’s CD Drive

and follow the prompts.

Note The CD should automatically start the installation process. If not, browse to

the CD, using Window Explorer, and then click the setup.exe icon.

The JEP-100 Welcome screen will then appear. The space requirements

will be gathered (

Figure 10. JEP-100 Installer Welcome Screen

Figure 10).

JEP Series — Installation Manual 35

Page 36

Section 1 — JEP-100 Control Panel

The Next button will be active when the space requirement gathering is

finished (

Figure 11. JEP-100 Installer Welcome Screen

Figure 11).

2. Click the Next> button to begin the installation process. The Setup Type

screen will then appear (

Figure 12. JEP-100 Installer Setup Type Screen

3. Click the Complete radio button.

4. Click the Next> button to begin the installation process.

Figure 12).

5. Follow the instructions on the following installation screens, click the

Next> button as needed (Figure 13).

36 JEP Series — Installation Manual

Page 37

Software Installation Process

Figure 13. Jupiter VSD Installation Screens

6. The Installed Wizard Completed screen will appear when the

installation process is finished (

Figure 14).

Figure 14. Installation Completed Screen

7. Click the Finish button. The Installation application will then close.

JEP Series — Installation Manual 37

Page 38

Section 1 — JEP-100 Control Panel

Updating to the Latest Software Version

Versions 1.2.0 and earlier used the Network Download Utility to update

software. Follow this process for converting the panels to work with Net

Config.

NetConfig is used to update panels for versions after 1.3.0.

The update process will use three applications: the Download Manager

and the Update Manager. You will then use NetConfig.

All of these programs are installed with the JEP-100 panel software installation.

You will need to know the IP address and Device ID of the hardware that

will be associated with the JEP-100. Grass Valley recommends that you

identify and write down the Device IDs and IP Address for the current

panels before you start the update process.

Using the Network Download Utility

-

This step you will download the new firmware to the panel using the

Network Download Utility.

Follow these steps to load the software onto the panels:

1. Start the Network Download Utility application. (Start>All Programs

>Grass Valley>Jep100 >DownloadManager) Any JEP-100 panels with

1.2.0 on the network should be displayed

Leave the RAM Loader and User Program fields with their default settings,

these are the correct files.

38 JEP Series — Installation Manual

Page 39

Figure 15. The Network Download Utility

2. Click Download

1. Click this area

Updating to the Latest Software Version

2. Highlight the line with the 1.2.0 panel in the middle message area.

3. Click Download (Figure 15) the download process will then start. Watch

the messages in the window to know when the download is complete.

The JEP-100 panel will display “Download is Pending.”

Figure 16. The JEP-100 panel will display “Download is Pending”

Destination

JEP-100

Status

Download

Preset

IS

Level

Pending

Using the Update Manager

In this section you will update the panel, with the previously updated firmware, using the Update Manager application. Control Panels should only

be upgraded one at a time using this tool.

071837202_JEP100_display

Note After using the Download manager, the control panel's IP address was

altered; you will be required to reset the control panel's IP address before

proceeding.

JEP Series — Installation Manual 39

Page 40

Section 1 — JEP-100 Control Panel

Double-click the

Displayed Panel

Enter 6 digit Serial # or the last

6 digits of the MAC address

Follow these steps to load the latest software onto the panels:

1. Start the Update Manager application. (Start>All Programs >Grass

Valley>Jep100 >UpdateManager) Any JEP-100 panels on the network

should be displayed.

The program will find the JEP-100 panels

Figure 17. The Update Manager Application

2. Select the panel and then click the Change IP button. The Change IP

Addresses dialog will then appear.

Note The IP Addresses shown in Figure 18 are used for example only. Enter your

Network settings.

Figure 18. The Change IP Addresses Dialog

3. Select the IP Address check box and then enter a free IP address on your

network.

4. Select and enter the information about your network in the field.

5. Click the OK button.

40 JEP Series — Installation Manual

Page 41

Updating to the Latest Software Version

Selecting the Files to Download

1. Double click the first control panel to upgrade.

2. Select the Download tab at the top of the dialog.

The order of the following steps is very important. The backup file

JEP100backup.bin must be added as the first file in the list.

3. Select the Add File button in the left margin and navigate to C:\program

files\grass valley\jupiter control panels\jep100\...then select the

JEP100backup.bin file.

This file is used as a secondary application in the event that the primary

application should ever fail, and allows you a way to re-load the soft

ware using the NetConfig application again in if the primary application fails.

4. Select the Add File button in the left margin again and navigate to

C:\program files\grass valley\jupiter control panels\jep100\... to

select the JEP100.bin primary file.

-

Figure 19. Selecting the Backup and Bin Files

Assigning Primary and Backup Status to the files

1. Highlight the JEP100backup.bin file and then select the Set Backup

button in the left margin to set Backup file.

2. Highlight the JEP100.bin file and then select the Set Primary button in the

left margin to set Primary file (

Figure 20 on page 42).

JEP Series — Installation Manual 41

Page 42

Section 1 — JEP-100 Control Panel

Click the Reset

Device button

Figure 20. Selecting the Backup and Bin Files

3. Select the Search/Select Device tab.

4. Select the Reset Device button.

Figure 21. The Update Manager Application

Using NetConfig to Reset Network and Panel Settings

The control panel's name and network settings were cleared. This section

describes the steps needed to use the NetConfig application to reset the

control panel's name and network settings.

42 JEP Series — Installation Manual

Page 43

Updating to the Latest Software Version

Select the JEP-100

panel

Note This procedure will work if the Default IP address of the control panel is on

the same network as the computer. If the Default IP address is not, then you

will not be able to access the Panel Web page; in this case you will have to

use Netconfig's change IP tool to set the IP, Gateway, Mask, and Server IP

addresses. After changing the IP address, navigate to the Web page and set

the control panels device ID.

Follow these steps to reset the control panel's name and network settings:

1. Select the JEP-100 panel from the Navigation panel on the left side

(

Figure 22). The JEP Panel page will appear on the right frame.

Figure 22. The Update Manager Application

2. Select the Panel Network link. The Panel Network Configuration page

will then appear.

3. Enter a name in the Panel Device name field.

4. Verify and modify the network settings as necessary.

JEP Series — Installation Manual 43

Page 44

Section 1 — JEP-100 Control Panel

Enter a Device

name

Verily or modify

Network settings

Enter a number ID

5. Enter a number ID in the Device Number field (Figure 23 on page 44).

Figure 23. The JEP Panel Network Configuration Page

The Panel upgrade is now complete.

44 JEP Series — Installation Manual

Page 45

Updating the JEP-100 panel Using NetConfig

Updating the JEP-100 panel Using NetConfig

This section describes the steps that are needed to update the JEP-100 using

the NetConfig application.

Follow these steps to update the JEP-100 software:

1. Start NetConfig.

2. Click the Load SW button in the Tool bar row (Figure 24).

Note You only need to click the Load SW button to access the load software page.

However, you can click the IP View button to see the IP addresses on the left

panel (Figure 25).

Figure 24. Tool bar Row of the NetConfig Application

3. Select the panel from the navigation panel on the left hand side.

4. Select the Panels (v1.3.0) in the select devices to Load area.

5. Click the Preferred panel’s check box under the Client column.

6. Select the Re-boot when complete check box.

7. Click the Load button

Figure 25. Updating the JEP-100

JEP Series — Installation Manual 45

Page 46

Section 1 — JEP-100 Control Panel

IP Configuration Procedure

During the following steps, you will need to know the IP address of the

CM-4000 or CM-4400 that will be associated with the JEP-100. Use the

Jupiter File Server JNS Control Center application to determine the IP

address of the CM-4000 or CM-4400 (the Control Center application is

described in the Jupiter CM-4000 or CM-4400 manual).

You will also need to know the normal IP settings of the file server so they

can be restored at the end of this procedure.

1. At the (first) JEP-100, determine the present IP address of the panel by

pressing MENU, then UP/DOWN until the address is displayed in the

Preset and Level windows.

2. If there are other devices on the Jupiter LAN with this same address,

they must be disconnected at this time.

JEP-100 panels are normally shipped with a default IP address of

192.168.253.100.

3. At the file server PC:

a. Use the PC's Network Settings dialog to temporarily set the TCP/IP

address within the same local network as the JEP-100.

For example, if the JEP-100 address is presently 192.168.253.100,

then the PC address should be changed to be compatible with the

192.168.253.x network (such as "192.168.253.1"). The PC's subnet

mask should be set to 255.255.255.0 (class C network). In a simple

network environment, all other TCP/IP network settings are irrele

vant at this point.

b. Reboot the PC to apply the changes.

If preferred, you can use the MS-DOS "ipconfig" command to

verify the settings.

You must have admin privileges to change Internet settings on a

Windows 2000 PC.

c. Start the http browser (e.g. MS Internet Explorer).

The browser Proxy setting must be turned off. To check the Proxy

setting for Internet Explorer, go to Tools > Internet Options > Con

nections > LAN Settings.

d. Enter the JEP-100 IP address in the URL window. This will display

the JEP-100 web page:

-

-

4. The Panel Information fields are system-generated.

5. For the Network Configuration section:

a. Select DHCP - OFF (unless IP addresses are being set automatically

by a Dynamic Host Configuration Protocol server).

46 JEP Series — Installation Manual

Page 47

Updating the JEP-100 panel Using NetConfig

b. IP address - set to a unique value within the same network as the

CM-4000.

For example, if the CM-4000 or CM-4400 address is 192.168.253.10,

then the JEP-100 address should be changed to reside in the

192.168.253.x network (such as "192.168.253.101").

c. Subnet Mask - set to 255.255.255.0.

d. Gateway - not used in a simple network environment.

If the JEP-100 and the CM-4000, or CM-4400, are on separate networks, the gateway connecting them must be specified.

ES Control Panel Configuration:

a. Protocol Type:

For a LAN only system: select "LAN."

For a Serial system: select "Serial" for normal operation of panel.

Select “LAN” only during the software upgrade process.

For a LAN + Serial system: For panels always operated in LAN

mode, select “LAN.” For panels normally operated in Serial mode,

select “Serial” (select “LAN” only during the software upgrade pro

cess).

-

Note that this selection is identical to the “ELAN on” setting

accessed with the front-panel MENU button.

b. Device Number:

LAN only system: enter a number from 1 to 64. This number must

be unique on this LAN (e.g., unique on network 192.168.253.x).

Serial system: enter a number from 1 to 16. This number must be

unique on the CM-4000 or CM-4400 serial bus being used.

LAN + Serial system: for panels always operated in LAN mode,

enter a number from 1 to 64. For panels normally operated in Serial

mode, enter a number from 1 to 16; this number must be unique on

the CM-4000 or CM-4400 serial bus being used.

Note that the Device Number is referred to as the “ID” within the

JEP-100 MENU system and as the “Address” on the Jupiter MPK

Devices table.

c. ES-LAN Host ID Address: enter the IP address of the CM-4000 or

CM-4400 associated with this panel.

d. Secondary Host ID Address: enter the IP address of the redundant

CM-4000 or CM-4400 (if any).

6. Select Submit.

This will apply the settings and reboot the JEP-100.

JEP Series — Installation Manual 47

Page 48

Section 1 — JEP-100 Control Panel

Note Once the JEP-100 reboots the panel may (depending on the address used)

7. Go to the next JEP-100 and repeat steps 1 through 7 above.

8. When finished, restore the file server PC to the original IP settings.

9. Proceed to the panel configuration instructions in the following section.

no longer be visible from the PC. To return to the page, enter the new IP

address in the browser's URL window.

48 JEP Series — Installation Manual

Page 49

Multi-Network IP Configuration

CM-4000 System Controller

Panel IP

192.168.253.101"

IP switch

Jupiter

File Server

Panel ID

01"

IP: 192.168.253.10"

IP:

192.168.253.1"

Panel IP

192.168.253.102"

Panel ID

02"

Remote JEP-100

Gateway

Facility LAN

Jupiter LAN

IP:

192.168.1.1"

Panel IP:

192.168.1.101"

Gateway:

192.168.1.1"

A “remote” JEP-100 can be placed on a network separate from the other

Jupiter devices, such as on a facility LAN. In Figure 11, an IP router serves

as a gateway between two networks.

Figure 26. Example of LAN addressing with remote JEP-100.

Multi-Network IP Configuration

Configuration is similar to that just described, except that the address of the

gateway must be entered on the web page for the remote JEP-100.

JEP Series — Installation Manual 49

Page 50

Section 1 — JEP-100 Control Panel

100baseT Jupi

ter LAN

IP switch

Panel ID

02"

Panel ID

01"

64 JEP-100s per

CM maximum

Panel ID

64"

Jupiter

File Server

CM-4000 System Controller

CM1"

JEP1"

JEP2"

JEP64"

Configuration - Jupiter

Configuration - Jupiter System

The following overview of JEP-100 installation and configuration assumes

that the reader is familiar with the Jupiter Facility Control System. If not,

please refer to the latest Jupiter CM-4000 or CM-4400 Installation and Oper

ating manual.

LAN Only System

In a system that uses LAN only, the JEP is operated in Ethernet mode,

where the LAN connection is used both for operation and for software

upgrade purposes. (

Figure 27. LAN only system naming and addressing

Figure 27)

-

50 JEP Series — Installation Manual

Page 51

MPK Table Entries

JEP1 ES LAN 01

JEP2 ES LAN 02

1

MPK Devices

MPK

Expansion

Pass

Board

CM1

Port Address Input Sets Output Sets Level Set Overide Set Sequence Set

2

CM1 KXYZ INP KXYZ OUT KXYZ LEV

Devices word

In Panel Out Panel

JEP64 ES LAN 64

64

CM1 KXYZ INP KXYZ OUT KXYZ LEV

KXYZ INP

KXYZ OUT

K

KXYZ LEV

Type

Device

8536_03

Although the JEP is not actually an MPK-type panel (it has an on-board

microprocessor and does not use the Message Per Keystroke protocol), the

MPK table is used for configuration purposes. An example is shown in

Figure 28.

Figure 28. MPK Devices table corresponding to system shown in Figure [12]

MPK Devices - This column is used to create a name, up to eight characters

in length, for each JEP-100. This name must be unique system-wide.

Typ e - Select type “ES-LAN” on the pull-down menu. Select either

“CPESXTND” or “CPES-SER” type for the latest features.

Configuration - Jupiter System

JEP Series — Installation Manual 51

Expansion - Not used for JEP-100 (leave unchecked).

Password - The panel may use the password level entry to enable or disable

certain control panel features.

• If the password is blank, the panel will act as normal.

• If any number from 1 to 89 will disable button assignments, and the

“Change ID”, and connection type menu items.

Board - Name of CM-4000 or CM-4400 associated with this JEP-100. The

source of this name is the Network Description table.

Port - Not used for LAN-only installation.

Address - Panel address from 01 to 64. Must be unique for panels associ-

ated with the same CM-4000 or CM-4400.

JEP-100 panels are normally shipped with a panel address of “01.” Modification of this address was discussed on page 47.

This number is referred to as the “Device Number” on the IP configuration

page and “ID” within the JEP-100 MENU system.

Input Set - Name of CP Input Set to be assigned to this panel. The usual

practice is to have one CP Input Set, containing the names of all inputs,

apply to all panels. However, special CP Input Sets could be created which

list only selected inputs; such a set could be used to prevent certain panels

from selecting specific inputs.

The panel now uses the CPEXTN type input set.

Page 52

Section 1 — JEP-100 Control Panel

In Panel - This column is not used for JEP-100 panels.

Out Set - Output Set name. If the entry is an actual CP Output Set, then the

control panel will be able to control all the outputs listed in that Set.

Depending on the con tents of the set, this would allow for full-matrix or

multi-bus control.

The panel now uses the CPEXTN type set. The panel now has the ability to

assign buttons as destinations, Using the output sets button field same as

the S100 panel.

The CP output set will have to be the CPESXTND type to work with the

newer features.

Alternatively, this field can be used to enter the name of a single switcher

output to be controlled. The source of the output name is the Switcher

Output table.

Out Panel - This column is not used for JEP-100 panels.

Level Set - Select the CP Level Set name. Select the CP3800 Level for the

panel to work with the newer features.

Override - Not used for JEP-100 panels.

Sequence - Now used for JEP-100 panels. Select a CP Sequence set name.

A Sequence set is used to execute a list of switches with a single command.

52 JEP Series — Installation Manual

Page 53

Serial System

Serial

Ports

100baseT Jupi

ter LAN

16 JEP-100s per

serial bus maximum

IP switch

Serial

buses

Panel ID

02"

Panel ID

01"

Panel ID

16"

Panel ID

01"

Jupiter

File Server

CM-4000 System Controller

CM1"

JEP1"

JEP2"

JEP16"

JEP17"

Configuration - Jupiter System

In this application the JEP-100 is operated in Serial mode, with the LAN

connection used only for software upgrade purposes.. (Figure 29)

Figure 29. Serial System Naming and Addressing (Example)

Serial Protocol Table Entries

When a JEP-100 is connected to a CM-4000 or CM-4400 serial port (and

operated in Serial mode), the panel must be configured for “ESCP” protocol

using the Serial Protocol table. The Baud rate should be set at 115K.

JEP Series — Installation Manual 53

Page 54

Section 1 — JEP-100 Control Panel

JEP1 ES LAN 01

JEP2 ES LAN 02

1

MPK Devices

MPK

Expansion

Pass

Board

CM1

Port Address Input Sets Output Sets Level Set Overide Set Sequence Set

2

CM1 KXYZ INP KXYZ OUT KXYZ LEV

Devices word

In Panel Out Panel

JEP64 ES LAN 64

64

CM1 KXYZ INP KXYZ OUT KXYZ LEV

KXYZ INP

KXYZ OUT

K

KXYZ LEV

Type

Device

8536_04

MPK Table Entries

Although the JEP-100 is not actually an MPK-type panel (it has an on-board

microprocessor and does not use the Message Per Key stroke protocol), the

MPK table is used for configuration purposes. An example is shown in

Figure 30.

Figure 30. MPK Devices table corresponding to system shown in Figure [16]

MPK Devices - This column is used to create a name, up to eight characters

in length, for each JEP-100. This name must be unique system-wide.

Typ e - Select type “Serial” on the pull-down menu. To use the extended features, you need to configure CPES-SER type.

Expansion - Not used for JEP-100 (leave unchecked).

Password - Passwords can be used to inhibit certain menu items and

button assignments. This functionality is described in

MPK Table Entries on

page 51 of the LAN section.

Board - Name of CM-4000 or CM-4400 connected to this JEP-100. The

source of this name is the Jupiter Network Description table.

Port - Number of CM-4000 or CM-4400 port connected to this JEP-100.

Address - Panel address from 1 to 16. Must be unique for panels sharing the

same CM-4000 or CM-4400 serial port.

JEP-100 panels are normally shipped with a panel address of “01.”

This number is referred to as the “Device Number” on the IP configuration

page and “ID” within the JEP-100 MENU system.

Input Set - Name of CP Input Set to be assigned to this panel. The usual

practice is to have one CP Input Set, containing the names of all inputs,

apply to all panels. However, special CP Input Sets could be created which

list only selected inputs; such a set could be used to prevent certain panels

from selecting specific inputs.

Use CPEXTN to use the latest features.

54 JEP Series — Installation Manual

In Panel - This column is not used for JEP-100 panels.

Out Set - Output Set name.

Page 55

If the entry is an actual CP Output Set, then the control panel will be able

to control all the outputs listed in that Set. Depending on the contents of the

set, this would allow for full-matrix or multi-bus control. Use CPEXTND to

use the latest features.

Alternatively, this field can be used to enter the name of a single switcher

output to be controlled. The source of the output name is the Switcher

Output table is the same as the LAN Only mode.

Out Panel - This column is not used for JEP-100 panels.

Level Set - Select the CP Level Set name.

Override Set - Not used for JEP-100 panels.

Sequence - Same as the LAN Only mode.

Special Entries Needed to Upgrade Serial Panels

In a Serial system, downloading new software to panels normally operated

in Serial mode will require IP settings. These settings are entered using the

web page..

Configuration - Jupiter System

JEP Series — Installation Manual 55

Page 56

Section 1 — JEP-100 Control Panel

Serial bus

Serial

Ports

100baseT Jupi

ter LAN

16 JEP-100s per

serial bus maximum

IP switch

64 LAN-operated

JEP-100s per CM

maximum

Panel ID

02"

Panel ID

01"

Panel ID

64"

Panel ID

01"

ile Server

CM-4000/4400 System Controller

CM1"

JEP1"

JEP2"

JEP64"

JEP65"

_

LAN + Serial System

The example shown in Figure 31 is of a system where one or more JEP-100s

will normally be operated in Serial mode, while other JEP-100s are always

operated in LAN mode.

The JEP-100(s) operated in Serial mode will require a LAN connection only

during a software upgrade session.

Figure 31. Example of LAN + serial system naming and addressing

Serial Protocol Table Entries

When a JEP-100 is connected to a CM-4000 or CM-4400 serial port (and

operated in Serial mode), the panel must be configured for “ESCP” protocol

using the Serial Protocol table. The Baud rate should be set at 115K. Panels

56 JEP Series — Installation Manual

Page 57

normally operated in LAN mode do not require a Serial Protocol table

JEP1

8536_05

ES LAN 01

JEP2 ES LAN 02

1

MPK Devices

MPK

Expansion

Pass

Board

CM1

Port Address Input Sets Output Sets Level Set Overide Set Sequence Set

2

CM1 KXYZ INP KXYZ OUT KXYZ LEV

Devices word

In Panel Out Panel

JEP64 ES LAN 64

64

CM1 KXYZ INP KXYZ OUT KXYZ LEV

JEP65 Serial 011

65

CM1 KXYZ INP KXYZ OUT KXYZ LEV

KXYZ INP

KXYZ OUT

KXYZ LEV

Type

Device

entry.

MPK Table Entries

Although the JEP-100 is not actually an MPK-type panel (it has an on-board

microprocessor and does not use the Message Per Key stroke protocol), the

MPK table is used for configuration purposes. An example is shown in

Figure 32.

Figure 32. MPK table for system shown in Figure [16]

Configuration - Jupiter System

Device Type - For the panels always operated in LAN mode, select type