Page 1

JEP-100

Jupiter / Encore Control Panel

Installation and Operating Manual

SOFTWARE VERSION 1.2.0

071837201

February 20, 2007

Page 2

Affiliate with the N.V. KEMA in The Netherlands

A

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley, Inc.

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

10 Presidential Way

rd

3

Floor, Suite 300

Woburn, MA 01801

United States

Nederland B.V.

4800 RP BREDA

The Netherlands

Technopole Brest Iroise

CS 73808

29238 Brest Cedex 3

France

7140 Baymeadows Way

Suite 101

Jacksonville, FL 32256

United States

Weiterstadt, Germany

Brunnenweg 9

D-64331 Weiterstadt

Germany

17 rue du Petit Albi-BP 8244

95801 Cergy Pontoise

Cergy, France

Rennes, France

Rue du Clos Courtel

Cesson-Sevigne, Cedex

France

2300 South Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope:

The design, manufacture and support of video hardware and software products and

related systems.

This Certificate is valid until: June 14, 2009

This Certificate is valid as of: August 30, 2006

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms

And Conditions For Quality And Environmental Management Systems Certifications.

Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 073004

ccredited By:

ANAB

Page 3

JEP-100

Jupiter / Encore Control Panel

Installation and Operating Manual

SOFTWARE VERSION 1.2.0

071837201

February 20, 2007

Page 4

Contacting Grass Valley

International

Support Centers

Local Support Centers

(available during normal

business hours)

France

24 x 7

Asia

Australia and New Zealand: +61 1300 721 495

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

Copyright © Grass Valley, Inc. All rights reserved. All specifications subject to change without notice.

This product may be covered by one or more U.S. and foreign patents.

+800 8080 2020 or +33 1 48 25 20 20

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent:

+91 22 24933476

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore:

+65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225

Switzerland: +4114878002

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +390248414658 S. Europe/

Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1

N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel:

+44 118 923 0499

United States/Canada

24 x 7

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

2 JEP-100 — Installation and Operating Manual

Page 5

Contents

= New or changed information

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Summary

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terms in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Regulatory Notices

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FCC Emission Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 1 — JEP-100 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hardware Installation - Jupiter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LAN Only System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

LAN + Serial System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Serial Data Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

VDE EMI/RFI Modifications to Serial Data Cables . . . . . . . . . . . . . . . . . . . . . 23

Power Surge Protection using JUP-485-SUP Module. . . . . . . . . . . . . . . . . . . . 23

Joystick Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Internet Protocol Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Single Network IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LAN Only System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Serial System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LAN + Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

IP Configuration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Multi-Network IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Software Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Configuration - Jupiter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LAN Only System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

JEP-100 — Installation and Operating Manual 3

Page 6

— Contents

MPK Table Entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Serial Protocol Table Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MPK Table Entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Special Entries Needed to Upgrade Serial Panels . . . . . . . . . . . . . . . . . . . . . . 40

LAN + Serial System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Serial Protocol Table Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

MPK Table Entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Special Entries Needed to Upgrade Serial Panels . . . . . . . . . . . . . . . . . . . . . . 44

All Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Panel Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Audio Mode (Special Stereo Switching) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Salvo Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Compiling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

LED Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Show Button Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Destination Selection / Status Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Source Selection (All Levels Take) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

BPS button programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Level Breakaways (Split Switching). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Default Mode Breakaway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Button-per-Level Mode Breakaway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Checking Status of Selected Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Defining a Source Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Defining a Destination Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Defining a Level Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Locking or Unlocking an Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Salvo Switching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Setting Up a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Executing a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Assigning a Sequence to a Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Joystick Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configuring a JEP-100 GPI Port (Joystick Override Control Line) . . . . . . . . . . 62

Menu Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

AlM. - Alternate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

SelAMod. - Select Audio Mode (Special Stereo Switching) . . . . . . . . . . . . . . 64

DspAMod. - Display Audio Mode (Special Stereo Switching) . . . . . . . . . . . 65

S.M. - Sticky Level Mode On/Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

M.O. - Multiple Output Mode On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

ELAN - Ethernet Mode On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.T. - Display Time On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chg ID - Change Panel ID Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

v - Version Number Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Internet Protocol Address Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Diag - Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

C.B. - Change Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4 JEP-100 — Installation and Operating Manual

Page 7

Preface

About This Manual

This manual provides installation and operating information for the JEP100 control panel. This control panels is designed for use with a Jupiter CM4000 System Controller.

Additional Documentation

An electronic copy of this manual is normally provided with the system.

Individual manuals may be ordered by contacting Technical Support. For

contact information, see page 2.

Configuration information for the Jupiter control system itself is contained

in the control system’s documentation set:

Jupiter Control System Release Notes series, 0718275xx.

Jupiter CM-4000 Installation and Operating Manual, 0718261xx.

Jupiter Getting Started Guide, 04-045707-003.

Electronic copies of other routing products documents are available on the

following documentation CDs:

CD 0718274xx. Includes Jupiter CM-4000 manuals.

These documents are also available on our web site. See page 2.

JEP-100 — Installation and Operating Manual 5

Page 8

Preface

6 JEP-100 — Installation and Operating Manual

Page 9

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

Terms on the Product

The following terms may appear on the product:

DANGER — A personal injury hazard is immediately accessible as you read

the marking.

WARNING — A personal injury hazard exists but is not immediately acces-

sible as you read the marking.

CAUTION — A hazard to property, product, and other equipment is present.

JEP-100 — Installation and Operating Manual 7

Page 10

Safety Summary

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground prior to making any other equipment

connections.

Warnings

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or

replacing components.

Do not service alone — Do not internally service this product unless another

person capable of rendering first aid and resuscitation is present.

Remove jewelry — Prior to servicing, remove jewelry such as rings, watches,

and other metallic objects.

Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

8 JEP-100 — Installation and Operating Manual

Page 11

Safety Summary

Use proper power cord — Use only the power cord supplied or specified for

this product.

Ground product — Connect the grounding conductor of the power cord to

earth ground.

Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

Use correct fuse — Use only the fuse type and rating specified for this

product.

Use only in dry environment — Do not operate in wet or damp conditions.

Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

High leakage current may be present — Earth connection of product is essential

before connecting power.

Dual power supplies may be present — Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Cautions

Double pole neutral fusing — Disconnect mains power prior to servicing.

Use proper lift points — Do not use door latches to lift or move equipment.

Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

Use correct voltage setting — If this product lacks auto-ranging power sup-

plies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation — To prevent product overheating, provide equip-

ment ventilation in accordance with installation instructions.

Use anti-static procedures — Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

JEP-100 — Installation and Operating Manual 9

Page 12

Safety Summary

Do not operate with suspected equipment failure — If you suspect product damage

or equipment failure, have the equipment inspected by qualified service

personnel.

Ensure mains disconnect — If mains switch is not provided, the power cord(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly — Route power cords and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid con-

nector damage.

Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery — This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used bat-

teries according to the manufacturer’s instructions.

Troubleshoot only to board level — Circuit boards in this product are densely

populated with surface mount technology (SMT) components and applica-

tion specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For war-

ranty compliance, do not troubleshoot systems beyond the board level.

10 JEP-100 — Installation and Operating Manual

Page 13

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

In a domestic environment, products that comply with Class A may cause

radio interference in which case the user may be required to take adequate

measures.

JEP-100 — Installation and Operating Manual 11

Page 14

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

Laser Compliance

Laser Safety Requirements

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

The device used in this product is a Class 1 certified laser product. Oper-

ating this product outside specifications or altering from its original design

may result in hazardous radiation exposure, and may be considered an act

of modifying or new manufacturing of a laser product under U.S. regula-

tions contained in 21CFR Chapter 1, subchapter J or CENELEC regulations

in HD 482 S1. People performing such an act are required by law to recertify

and reidentify this product in accordance with provisions of 21CFR sub-

chapter J for distribution within the U.S.A., and in accordance with

CENELEC HD 482 S1 for distribution within countries using the IEC 825

standard.

Laser Safety

Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The International Electrotechnical Commission (IEC) Standard 825, “Radi-

ation of Laser Products, Equipment Classification, Requirements and

User’s Guide,” governs laser products outside the United States. Europe

and member nations of the European Free Trade Association fall under the

jurisdiction of the Comite European de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected through a 7 mm aperture at

a distance of 200 mm from the source focused through a lens with a focal

length of 100 mm.

For IEC compliance: The radiant power is detected through a 7 mm aper-

ture at a distance of 100 mm from the source focused through a lens with a

focal length of 100 mm.

12 JEP-100 — Installation and Operating Manual

Page 15

FCC Emission Limits

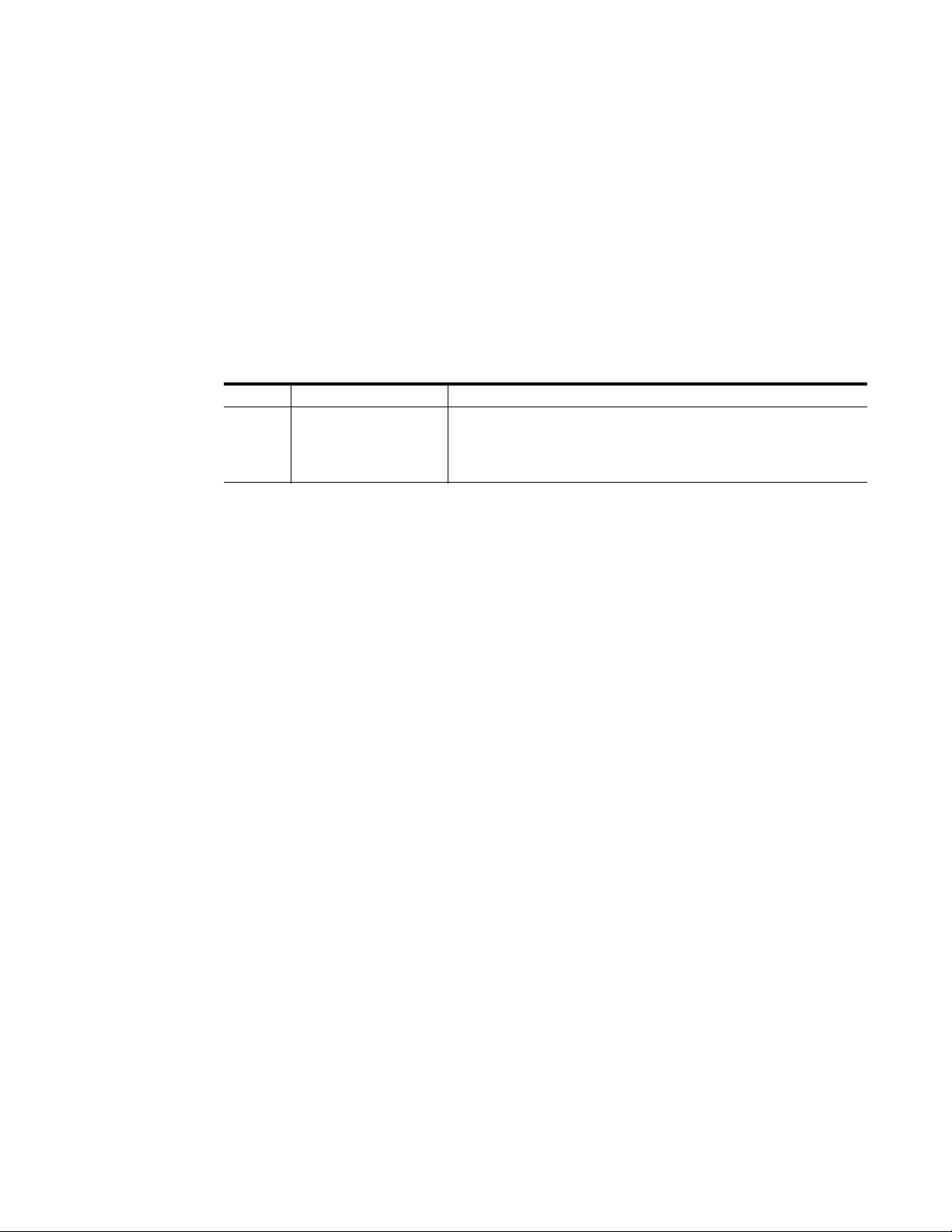

Certification

Category Standard Designed/tested for compliance with:

Safety ANSI/UL 1950-1997 3rd ed.

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesirable operation. This device

has been tested and found to comply with FCC Part 15 Class B limits for a

digital device when tested with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channel Standard.

Professional Video and Audio Equipment

CAN/CSA-C22.2 No. 950-95

EN 60950

JEP-100 — Installation and Operating Manual 13

Page 16

Regulatory Notices

14 JEP-100 — Installation and Operating Manual

Page 17

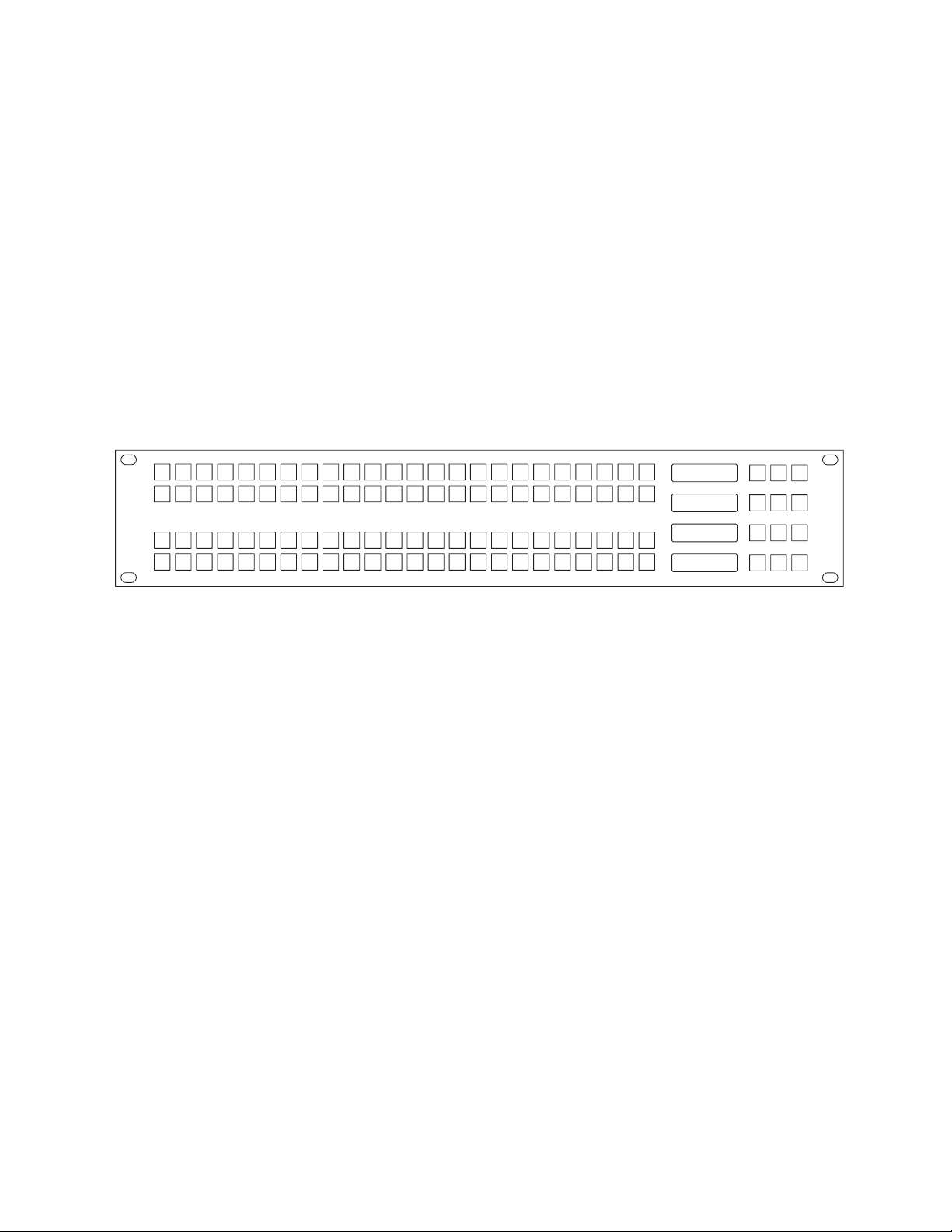

JEP-100 Control Panel

Introduction

Figure 1. JEP-100 C ontrol Panel

Section 1

Destination

Status

Preset

Level

536_02

The JEP-100 Jupiter/Encore Control Panel is a locally-programmable,

eight-character mnemonic, full-matrix control, multiple level break away

panel designed especially for use in television production vans.

The current version of the panel uses a 15-pin D female connector on the

rear panel to provide a total of 14 control lines (GPI ports) plus ground.

Each port can be used to trigger a switching event when initiated by a

contact closure on a customer-provided device. In the joystick override

application, a joystick such as found on a camera control unit (CCU) can be

used to select a camera for QC evaluation.

The panel includes a fully-enclosed auto-sensing power supply with an

inrush current rating of 7.9 A. The nominal power requirement is 0.4 A @

240 VAC or 0.65 A @ 120 VAC. There is no power switch (the AC cord must

be disconnected to power down the panel).

The 96 keys on the left side of the panel are initially assigned to inputs using

the control system file server, but some or all can be re-assigned to new

inputs at any time using only the panel itself. The keys can alternatively be

used to control outputs or levels.

Sources, destinations, and levels can also be selected by scrolling up/ down

in the various LED displays.

JEP-100 — Installation and Operating Manual 15

Page 18

Section 1 — JEP-100 Control Panel

Space has been provided for adhesive strips to be placed on the front

surface for identification of buttons as they are arranged for specific

projects.

The JEP-100 control panel is designed for use with either a Jupiter CM-4000

System Controller or an Encore Control System.

Note At present the JEP-100 can only be used with Jupiter CM-4000 Sys tem Con-

Note The CM-4000 must be operating with Jupiter / Saturn / AccuSwitch version

Note The JEP-100 is not intended for use with Jupiter VM-3000 System Control-

In Jupiter applications, the JEP-100 can be connected to the CM-4000

System Controller via a 115k Baud serial bus (maximum distance of 2000

feet); or via a Cat 5 Ethernet connection (maximum distance per segment

329 feet). An Ethernet connection is required for software upgrade pur-

poses.

trollers.

7.3.2 to support the JEP-100 1.1.1 feature set (except Salvo. JEP-100 salvo

requires Jupiter version 7.4 software).

lers.

Specifications

Physical Dimensions: 2 RU rack mount: 19 in. W x 3.5 in. H x approx. 4 in.

D (483 mm W x 89 mm H x 102 mm D)

Weight: 2.25 lb. (1.02 kg.)

Operating voltage: 90 to 260 VAC

Operating current: 0.4 A @ 240 VAC or 0.65 A @ 120 VAC

Inrush current rating: 7.9 A

Power consumption: <100 W

Joystick override: Connector, 15-pin D, female.

Wiring between rear-panel connector and customer-supplied contact

closure device: minimum 22 AWG (American Wire Gauge); maximum

length, 30 feet (10 meters).

16 JEP-100 — Installation and Operating Manual

Page 19

Hardware Installation - Jupiter System

The JEP-100 can be connected to the CM-4000 System Controller via a 115k

Baud serial bus or via a Cat 5 Ethernet connection. It is also possible to

combine these methods by connecting some panels serially and others

through the LAN.

In all cases, an Ethernet connection is required for software upgrade purposes.

Hardware Installation - Jupiter System

JEP-100 — Installation and Operating Manual 17

Page 20

Section 1 — JEP-100 Control Panel

t

F

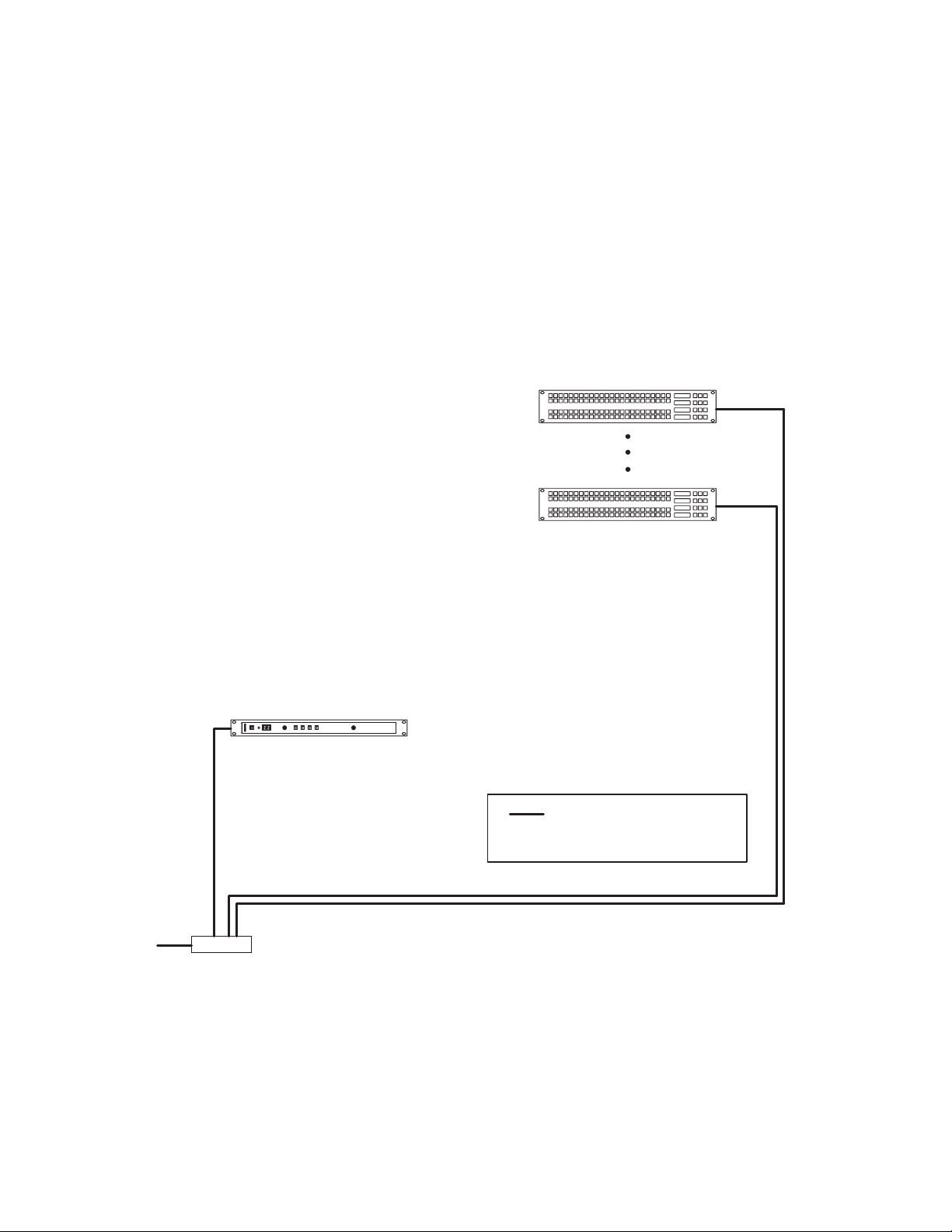

LAN Only System

In this arrangement the JEP is operated in Ethernet mode, where the LAN

connection is used both for operation and for software upgrade purposes.

See Figure 2.

Note The LAN must be capable of 100 Mb operation.

Note Each Ethernet segment (hub to panel) has a 100 meter limit.

Figure 2. LAN only system connections.

64 LAN-operated

JEP-100s per CM

maximum

o Jupiter

ile Server

CM-4000

System

Controller

LAN (Cat 5 Ethernet) cable.

Max. recommended length per

segment = 100 meters (329 ft)

100baseT Jupiter LAN

8536_08

IP switch

18 JEP-100 — Installation and Operating Manual

Page 21

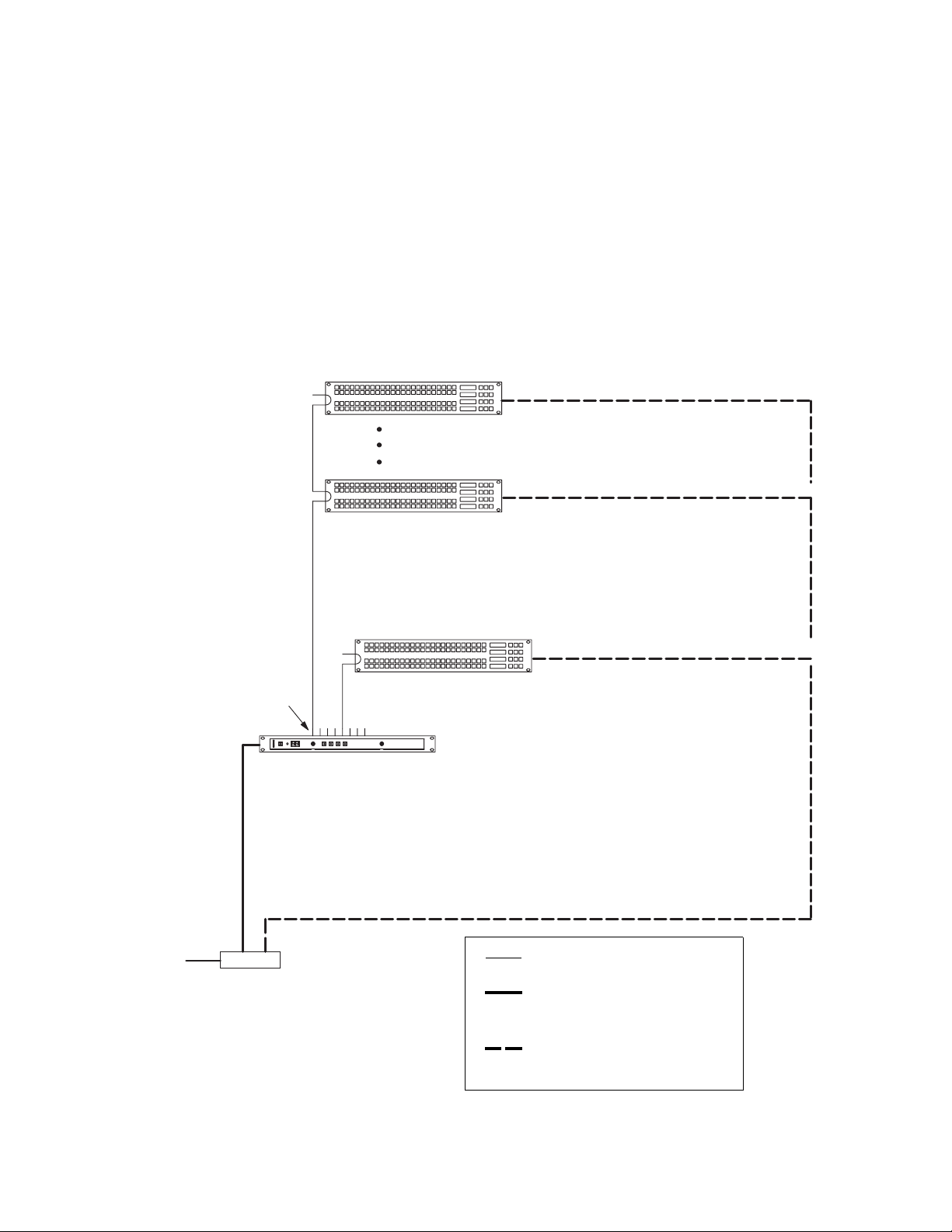

Serial System

t

File Server

8536_09

Serial bus

Hardware Installation - Jupiter System

This wiring arrangement assumes that the JEP-100(s) will be operated in

Serial mode, with the LAN typically connected to one panel at a time only

during software upgrades. See Figure 3.

Note The LAN must be capable of 100 Mb operation.

Note The Ethernet segment (IP switch to panel) has a 100 meter limit.

Figure 3. Serial system connections.

16 JEP-100s per

serial bus maximum

o Jupiter

Serial

Ports

CM-4000 System Controller

100baseT Jupiter LAN

IP switch

Serial bus

Serial data cable (see page 22)

LAN (Cat 5 Ethernet) cable.

Max. recommended length per

seqment = 100 meters (329 ft)

Temporary LAN connection for

software upgrade

JEP-100 — Installation and Operating Manual 19

Page 22

Section 1 — JEP-100 Control Panel

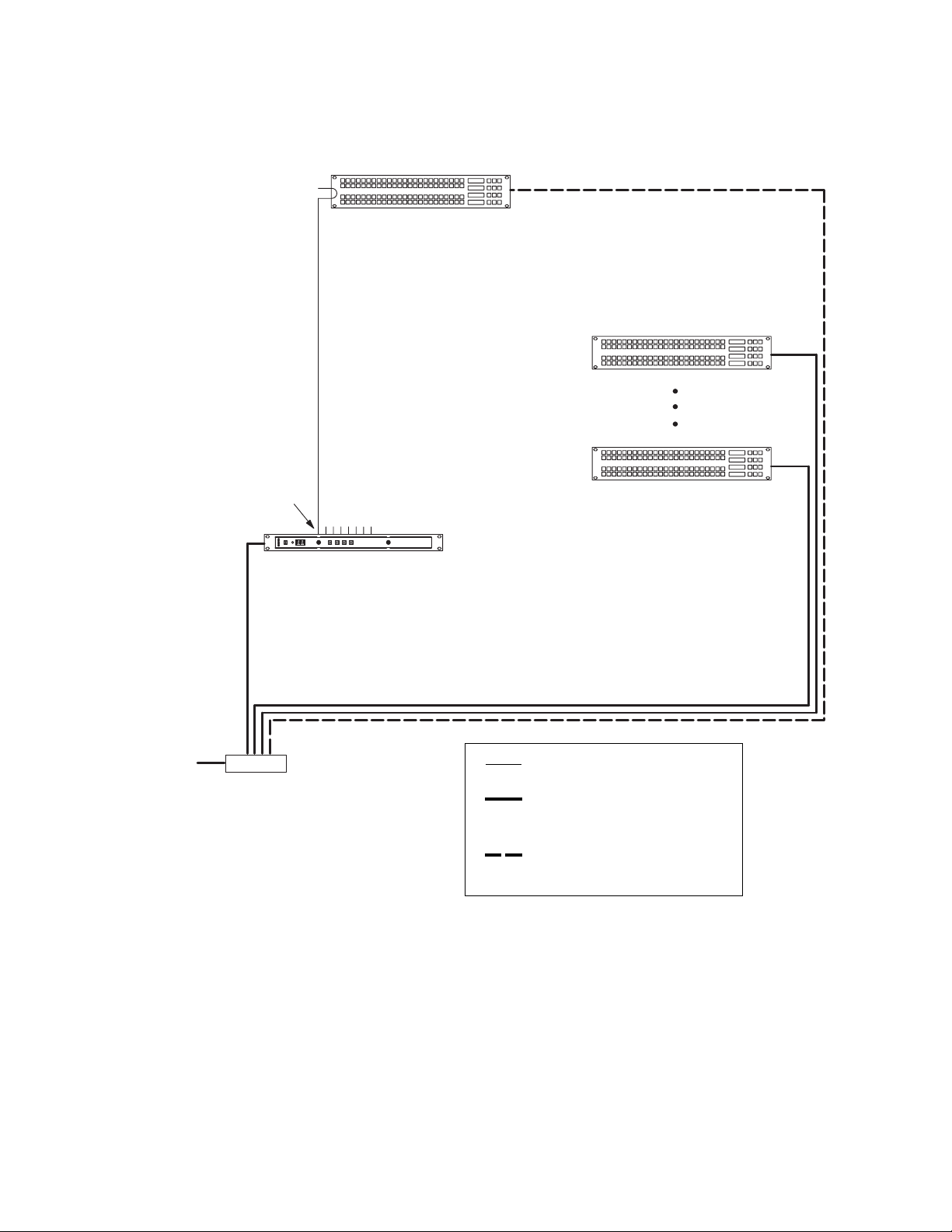

LAN + Serial System

In this system, one or more JEP-100s are operated in Serial mode, while

other JEP-100s are operated in LAN mode. The JEP-100(s) operated in

Serial mode will require a LAN connection only during a software upgrade

session. See Figure 4.

Note The LAN must be capable of 100 Mb operation.

Note Each Ethernet segment (hub to panel) has a 100 meter limit.

20 JEP-100 — Installation and Operating Manual

Page 23

Figure 4. LAN + Serial system connections

t

F

16 JEP-100s per

serial bus maximum

Serial bus

Serial

Ports

Hardware Installation - Jupiter System

64 LAN-operated

JEP-100s per CM

maximum

o Jupiter

ile Server

CM-4000 System Controller

100baseT Jupiter LAN

IP switch

8536_10

Serial data cable (see page 22)

LAN (Cat 5 Ethernet) cable.

Max. recommended length per

seqment = 100 meters (329 ft)

Temporary LAN connection for

software upgrade

JEP-100 — Installation and Operating Manual 21

Page 24

Section 1 — JEP-100 Control Panel

(male)

(male)

F

T

T

+)

#)

)

)

d

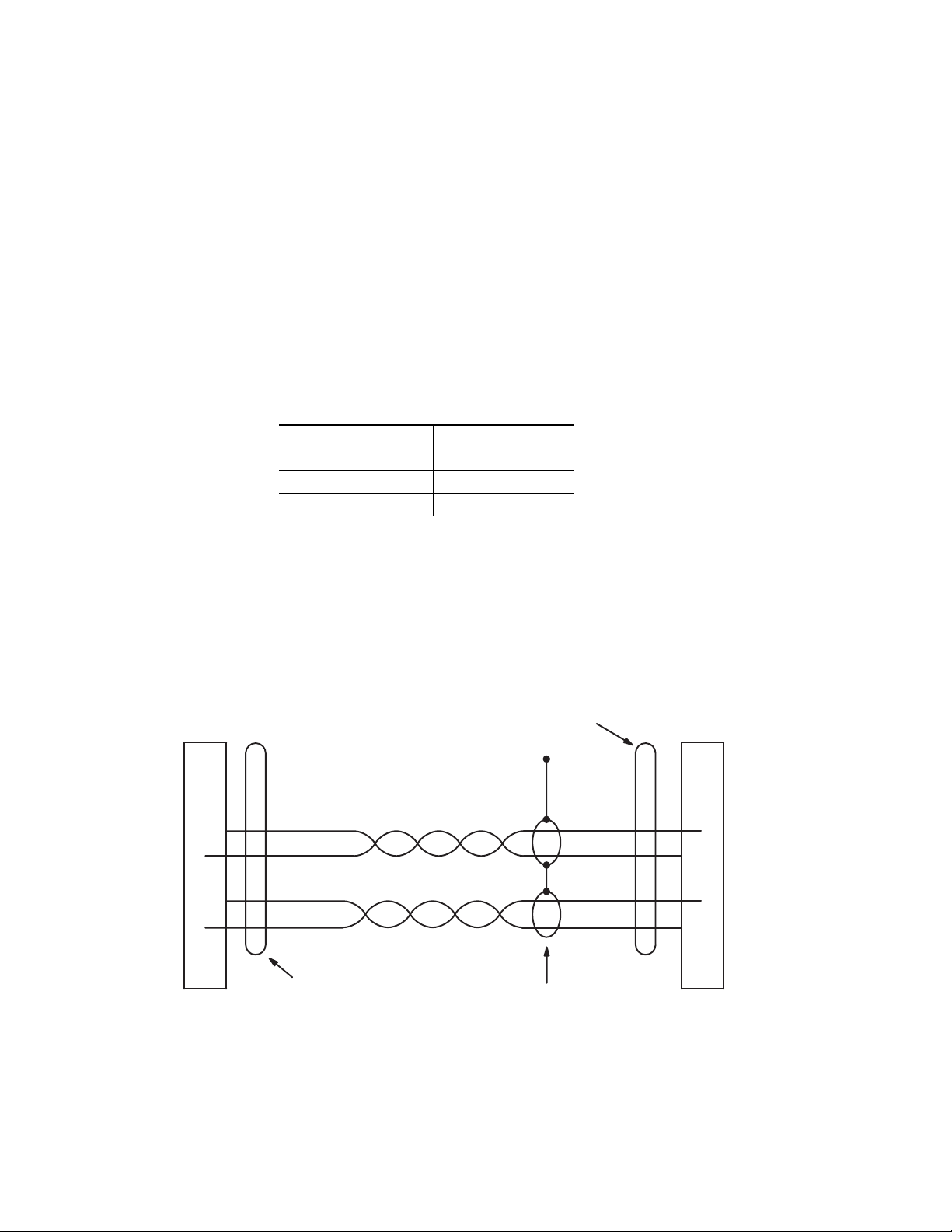

Serial Data Cables

The RS-422 cables used to connect CM-4000 System Controllers and control

panels consist of a 4-conductor (plus ground) cable. Maxi mum length per

bus, at 115k Baud, is 610 meters (2000 ft).

The rear panel serial data cable connectors on the CM-4000 and con trol

panels are 9-pin D, female. The control panel connectors are ar ranged for

loop-through wiring. No termination is required. While these connectors

are ESbus compatible, it should be noted that the Thomson serial data

cables use only 5 of the 9 pins described in the ESbus specification.

The following ready-made cables, with installed 9-pin D male connectors,

are available from Grass Valley (VDE cables include ferrite cores):

Tab l e 1 .

1 meter (3.3 ft) 8 meters (26.2 ft)

2 meters (6.6 ft) 16 meters (52.5 ft)

4 meters (13.1 ft) 32 meters (105 ft)

For those who wish to prepare their own cables, the pin-outs are shown in

Figure 5. The cable itself should be Belden 8723 or equiva lent.

Details concerning ferrite cores are given in Figure 6 .

Figure 5. Serial data cable wiring. Reference: "Assembly, BCS-3000 Serial Data Cable," GrassValley

drawing no. 01-041600-TAB.

CM#4000 System

Controller

(bus controller)

rame ground

Receive A (#)

Receive B (+)

ransmit B (+)

ransmit A (#)

1

2

7

3

8

P1

DB9P

Shield (drain)

Green

White

Red

Black

Ferrite core

Individually shielded, twisted pairs

Ferrite core

Green

White

Red

Black

Control panel or

VTR

(tributary)

1

Frame groun

Transmit A (

2

7

Transmit B (

3

Receive B (+

Receive A (#

8

P2

DB9P

8536_11

22 JEP-100 — Installation and Operating Manual

Page 25

VDE EMI/RFI Modifications to Serial Data Cables

0

l

.

8

User-supplied serial data cables for VDE installations require a ferrite core

over each end of the cable, adjacent to the connector.

Figure 6. Serial data cable VDE modifications.

Type 43 material

0.250 inch (6.35 mm) inside diameter

.95 inch (24.13 mm) length (or longer)

Power Surge Protection using JUP-485-SUP Module

Hardware Installation - Jupiter System

Type 43 material sources

Fair Rite, part no. 2643480002

Fair Rite Products Corp., P .O. Box J, Commercia

Row, Wallkill, NY 12589, USA; Tel. (914) 895 2055

Chomerics, part no. 83 10 A636 1000

Chomerics Inc., 77 Dragon Ct., Woburn, MA 0188

USA; Tel. (617) 935 4850.

8536_12

Voltage surges may occur in mobile van environments or other applications

involving long serial cable runs or cases where there is a possibility of a

power spike appearing between the Jupiter CM-4000 System Controller

and a Jupiter control panel. Voltage surges in the 25-volt range have been

known to damage the RS-422/485 driver ICs used in the CM controller. The

JUP-485-SUP module, available as an option, connects to the CM serial port

and uses an internal diode array to limit the voltage on each of the RS-485

conductors to approximately eight volts. For more information, refer to

Field Modification Note 0750790xx or contact Grass Valley Technical Support.

Joystick Override

This function applies only to the current JEP-100 model, which has a 15-pin

D female connector on the rear panel to provide a total of 14 joystick control

lines plus ground. For more information, see page 59.

JEP-100 — Installation and Operating Manual 23

Page 26

Section 1 — JEP-100 Control Panel

Internet Protocol Configuration

IP connection and configuration allows Ethernet operation and pro vides a

downloading path for software upgrades. The JEP-100, CM-4000, and file

server PC must be on the same IP network, or else be connected through a

network router/gateway.

The following applies to JEP-100 configuration using the panel's built-in

HTTP web page.

Single Network IP Configuration

The following discussion applies when the Jupiter equipment (file server,

CM-4000, and JEP-100) is in an isolated network environment.

24 JEP-100 — Installation and Operating Manual

Page 27

LAN Only System

Figure 7 shows an example of a system addressing where the JEP-100s will

be operated entirely in Ethernet mode. Up to 64 JEP-100s can be controlled

per CM-4000.

Figure 7. LAN only system addressing(example).

Internet Protocol Configuration

64 JEP-100s per CM maximum

Jupiter

File Server

“192.168.253.1”

IP

“192.168.253.10”

Panel ID

“64”

Panel ID

“02”

Panel ID

“01”

Panel IP

“192.168.253.164”

Panel IP

“192.168.253.102”

Panel IP

“192.168.253.101”

CM-4000 System Controller

10/100baseT

IP switch

Jupiter LAN

JEP-100 — Installation and Operating Manual 25

8536_13

Page 28

Section 1 — JEP-100 Control Panel

“

8536_14

Serial System

Figure 8 shows an example of a system addressing where the JEP-100s will

be operated in Serial mode (the LAN connections are for software

upgrade). Because there are more than 16 panels, the 17th panel must be

connected to a second CM port. This results in two panels with an ID of

"01."

This arrangement assumes that the LAN connections will be made to one

panel at a time only for the purpose of software upgrade. In this case, it isn't

strictly necessary to have a different IP address for each panel; however, to

prevent confusion if more than one panel is con nected it is recommended

that unique IP addresses are assigned.

Figure 8. Serial system addressing (example).

16 JEP-100s per

serial bus maximum

Panel ID

“16”

Panel ID

“02”

Panel ID

“01”

Serial

buses

Serial

Ports

IP

“192.168.253.10”

Panel ID

“01”

Panel IP

“192.168.253.116”

Panel IP

“192.168.253.102”

Panel IP

“192.168.253.101”

Panel IP

“192.168.253.117”

CM

4000 System Controller

Jupiter

File Server

192.168.253.1”

IP switch

26 JEP-100 — Installation and Operating Manual

100baseT Jupiter LAN

Page 29

LAN + Serial System

Figure 9 shows an example of system addressing where one or more JEP100s will be operated in Serial mode, while other JEP-100s are operated in

LAN mode.

The JEP-100(s) operated in serial mode will require a LAN connection only

during a software upgrade session.

Figure 9. LAN + serial system addressing (example)

Internet Protocol Configuration

16 JEP-100s per serial

bus maximum

Serial

Ports

Panel ID

“01”

Serial bus

Panel IP

“192.168.253.117”

64 LAN operated JEP-100s per CM

Panel ID

“16”

Panel ID

“02”

Panel ID

“01”

Panel IP

“192.168.253.116”

Panel IP

“192.168.253.102”

Panel IP

“192.168.253.101”

CM

Jupiter

File Server

“192.168.253.1”

4000 System Controller

100baseT Jupi-

ter LAN

IP switch

8536_15

JEP-100 — Installation and Operating Manual 27

Page 30

Section 1 — JEP-100 Control Panel

IP Configuration Procedure

During the following steps, you will need to know the IP address of the

CM-4000 that will be associated with the JEP-100. Use the Jupiter File

Server JNS Control Center application to determine the CM-4000 IP

address (the Control Center application is described in the Jupiter CM-4000

manual).

You will also need to know the normal IP settings of the file server so they

can be restored at the end of this procedure.

1. At the (first) JEP-100, determine the present IP address of the panel by

pressing MENU, then UP/DOWN until the address is displayed in the

Preset and Level windows.

2. If there are other devices on the Jupiter LAN with this same address,

they must be disconnected at this time.

JEP-100 panels are normally shipped with a default IP address of

192.168.253.100.

3. At the file server PC:

a. Use the PC's Network Settings dialog to temporarily set the TCP/IP

address within the same local network as the JEP-100.

For example, if the JEP-100 address is presently 192.168.253.100,

then the PC address should be changed to be compatible with the

192.168.253.x network (such as "192.168.253.1"). The PC's sub net

mask should be set to 255.255.255.0 (class C network). In a simple

network environment, all other TCP/IP network settings are irrelevant at this point.

b. Reboot the PC to apply the changes.

If desired, you can use the MS-DOS "ipconfig" command to verify

the settings.

You must have admin privileges to change Internet settings on a

Windows 2000 PC.

c. Start the http browser (e.g. MS Internet Explorer).

The browser Proxy setting must be turned off. To check the Proxy

setting for Internet Explorer, go to Tools > Internet Options > Connections > LAN Settings.

d. Enter the JEP-100 IP address in the URL window. This will display

the JEP-100 web page:

28 JEP-100 — Installation and Operating Manual

Page 31

Figure 10.

Internet Protocol Configuration

8536_16

4. The Panel Information fields are system-generated.

5. For the Network Configuration section:

a. Select DHCP - OFF (unless IP addresses are being set automatically

by a Dynamic Host Configuration Protocol server).

b. IP address - set to a unique value within the same network as the

CM-4000.

For example, if the CM-4000 address is 192.168.253.10, then the JEP100 address should be changed to reside in the 192.168.253.x

network (such as "192.168.253.101").

c. Subnet Mask - set to 255.255.255.0.

JEP-100 — Installation and Operating Manual 29

Page 32

Section 1 — JEP-100 Control Panel

d. Gateway - not used in a simple network environment.

6. ES Control Panel Configuration:

a. Protocol Type:

b. Device Number:

If the JEP-100 and the CM-4000 are on separate networks, the

gateway connecting them must be specified.

For a LAN only system (as shown on page 25): select "LAN."

For a Serial system (page 26): select "Serial" for normal operation of

panel. Select "LAN" only during the software upgrade pro cess.

For a LAN + Serial system (page 27): For panels always operated in

LAN mode, select "LAN." For panels normally operated in Se rial

mode, select "Serial" (select "LAN" only during the software

upgrade process).

Note that this selection is identical to the "ELAN on" setting ac

cessed with the front-panel MENU button.

LAN only system: enter a number from 1 to 64. This number must

be unique on this LAN (e.g., unique on network 192.168.253.x).

Serial system: enter a number from 1 to 16. This number must be

unique on the CM-4000 serial bus being used.

LAN + Serial system: for panels always operated in LAN mode,

enter a number from 1 to 64. For panels normally operated in Se rial

mode, enter a number from 1 to 16; this number must be unique on

the CM-4000 serial bus being used.

Note that the Device Number is referred to as the "ID" within the

JEP-100 MENU system and as the "Address" on the Jupiter MPK

Devices table.

c. ES-LAN Host ID Address: enter the IP address of the CM-4000

associated with this panel.

d. Secondary Host ID Address: enter the IP address of the redundant

CM-4000 (if any).

7. Select Submit.

This will apply the settings and reboot the JEP-100.

Note Once the JEP-100 reboots the panel may (depending on the address used)

no longer be visible from the PC. To return to the page, enter the new IP

address in the browser's URL window.

8. Go to the next JEP-100 and repeat steps 1 through 7 above.

9. When finished, restore the file server PC to the original IP settings.

10. Proceed to the panel configuration instructions in the following section.

30 JEP-100 — Installation and Operating Manual

Page 33

Multi-Network IP Configuration

A "remote" JEP-100 can be placed on a network separate from the other

Jupiter devices, such as on a facility LAN. In Figure 11, an IP router serves

as a gateway between two networks.

Figure 11. LAN addressing with remote JEP-100 (example)

Multi-Network IP Configuration

Panel ID

“02”

Panel ID

“01”

Panel IP

“192.168.253.102”

Panel IP

“192.168.253.101”

CM-4000 System Controller

IP: “192.168.253.10”

Jupiter

File Server

IP switch

IP:

“192.168.253.1”

Jupiter LAN

Remote JEP-100

Facility LAN

Panel IP:

“192.168.1.101”

Gateway:

“192.168.1.1”

Gateway

IP:

“192.168.1.1”

8536_17

Configuration is similar to that just described, except that the address of the

gateway must be entered on the web page for the remote JEP-100.

JEP-100 — Installation and Operating Manual 31

Page 34

Section 1 — JEP-100 Control Panel

Software Installation

JEP-100 panels are shipped with all current software installed.

If the software is being upgraded from a previous version, you must follow

the special upgrade instructions in the appropriate Grass Valley Release

Notes or Field Engineering Bulletin. Failure to do so could result in loss of

user data. For more information, please contact Grass Valley Technical

Support (see page 2).

32 JEP-100 — Installation and Operating Manual

Page 35

Configuration - Jupiter System

The following overview of JEP-100 installation and configuration assumes

that the reader is familiar with the Jupiter Facility Control System. If not,

please refer to the Jupiter CM-4000 Installation and Operating manual,

part. no. 0718261xx.

Configuration - Jupiter System

JEP-100 — Installation and Operating Manual 33

Page 36

Section 1 — JEP-100 Control Panel

F

LAN Only System

In this system, the JEP is operated in Ethernet mode, where the LAN connection is used both for operation and for software upgrade purposes. See

Figure 12.

Figure 12. LAN only system naming and addresssing

“JEP64”

“JEP2”

64 JEP!100s per

CM maximum

Panel ID

“64”

Panel ID

“02”

Jupiter

ile Server

“JEP1”

CM!4000 System Controller

100baseT Jupi-

IP switch

ter LAN

“CM1”

Panel ID

“01”

8536_18

34 JEP-100 — Installation and Operating Manual

Page 37

MPK Table Entries

3

Although the JEP is not actually an MPK-type panel (it has an on-board

microprocessor and does not use the Message Per Keystroke protocol), the

MPK table is used for configuration purposes. An ex ample is shown in

Figure 13.

Figure 13. MPK Devices table corresponding to system shown in Figure 12

MPK Devices

MPK

Devices word

JEP1 ES LAN 01

1

JEP2 ES LAN 02

2

Device

Type

Expansion

Pass

Board

CM1

CM1 KXYZ INP KXYZ OUT KXYZ LEV

Configuration - Jupiter System

Port Address Input Sets Output Sets Level Set Overide Set Sequence Set

KXYZ INP

In Panel Out Panel

KXYZ OUT

KXYZ LEV

K

JEP64 ES LAN 64

64

CM1 KXYZ INP KXYZ OUT KXYZ LEV

MPK Devices - This column is used to create a name, up to eight characters

in length, for each JEP-100. This name must be unique system-wide.

Typ e - Select type "ES-LAN" on the pull-down menu.

Expansion - Not used for JEP-100 (leave unchecked).

Password - Not used for JEP-100.

Board - Name of CM-4000 associated with this JEP-100. The source of this

name is the Network Description table.

Port - Not used for LAN-only installation.

Address - Panel address from 01 to 64. Must be unique for panels associ-

ated with the same CM-4000.

JEP-100 panels are normally shipped with a panel address of "01." Modification of this address was discussed on page 30.

This number is referred to as the "Device Number" on the IP configuration

page and "ID" within the JEP-100 MENU system .

8536_0

Input Set - Name of CP Input Set to be assigned to this panel. The usu al

practice is to have one CP Input Set, containing the names of all in puts,

apply to all panels. However, special CP Input Sets could be created which

list only selected inputs; such a set could be used to prevent certain panels

from selecting specific inputs.

In Panel - This column is not used for JEP-100 panels.

Out Set - Output Set name. If the entry is an actual CP Output Set, then the

control panel will be able to control all the outputs listed in that Set.

Depending on the con tents of the set, this would allow for full-matrix or

multi-bus control.

JEP-100 — Installation and Operating Manual 35

Page 38

Section 1 — JEP-100 Control Panel

Alternatively, this field can be used to enter the name of a single switcher

output to be controlled. The source of the output name is the Switcher

Output table.

Out Panel - This column is not used for JEP-100 panels.

Level Set - Select the CP Level Set name.

Override - Not used for JEP-100 panels.

Sequence - Not used for JEP-100 panels.

36 JEP-100 — Installation and Operating Manual

Page 39

This page intentionally left blank.

Configuration - Jupiter System

JEP-100 — Installation and Operating Manual 37

Page 40

Section 1 — JEP-100 Control Panel

Serial System

In this application the JEP-100 is operated in Serial mode, with the LAN

connection used only for software upgrade purposes. See Figure 14.

Figure 14. Serial system naming and adressing (example)

“JEP16”

“JEP2”

“JEP1”

16 JEP 100s per

serial bus maximum

Panel ID

“16”

Panel ID

“02”

Panel ID

“01”

Jupiter

File Server

Serial

buses

Serial

Ports

CM 4000 System Controller

100baseT Jupi-

ter LAN

IP switch

“CM1”

“JEP17”

Panel ID

“01”

8536_19

38 JEP-100 — Installation and Operating Manual

Page 41

Serial Protocol Table Entries

When a JEP-100 is connected to a CM-4000 serial port (and operated in

Serial mode), the panel must be configured for "ESCP" protocol using the

Serial Protocol table. The Baud rate should be set at 115K.

MPK Table Entries

Although the JEP-100 is not actually an MPK-type panel (it has an on-board

microprocessor and does not use the Message Per Key stroke protocol), the

MPK table is used for configuration purposes. An example is shown in

Figure 15.

Figure 15. MPK Devices table corresponding to system shown in Figure 14

MPK Devices

MPK

Devices word

JEP1 Serial 011

1

JEP2 Serial 02

2

JEP16 Serial 16

16

JEP17 Serial 01

17

Device

Type

Expansion

Pass

Board

CM1

CM1 KXYZ INP KXYZ OUT KXYZ LEV

CM1 KXYZ INP KXYZ OUT KXYZ LEV

CM1 KXYZ INP KXYZ OUT KXYZ LEV

Configuration - Jupiter System

Port Address Input Sets Output Sets Level Set Overide Set Sequence Set

KXYZ INP

1

1

8

In Panel Out Panel

KXYZ OUT

KXYZ LEV

8536_04

MPK Devices - This column is used to create a name, up to eight characters

in length, for each JEP-100. This name must be unique system-wide.

Typ e - Select type "Serial" on the pull-down menu.

Expansion - Not used for JEP-100 (leave unchecked).

Password - Not used for JEP-100.

Board - Name of CM-4000 connected to this JEP-100. The source of this

name is the Jupiter Network Description table.

Port - Number of CM-4000 port connected to this JEP-100.

Address - Pan el a ddre ss fr om 1 to 1 6. M ust be u niq ue f or p ane ls s hari ng th e

same CM-4000 serial port.

JEP-100 panels are normally shipped with a panel address of "01." Modification of this address was discussed on page 30.

This number is referred to as the "Device Number" on the IP configuration

page and "ID" within the JEP-100 MENU system.

Input Set - Name of CP Input Set to be assigned to this panel. The usu al

practice is to have one CP Input Set, containing the names of all in puts,

apply to all panels. However, special CP Input Sets could be created which

list only selected inputs; such a set could be used to prevent certain panels

from selecting specific inputs.

JEP-100 — Installation and Operating Manual 39

Page 42

Section 1 — JEP-100 Control Panel

In Panel - This column is not used for JEP-100 panels.

Out Set - Output Set name.

If the entry is an actual CP Output Set, then the control panel will be able

to control all the outputs listed in that Set. Depending on the con tents of

the set, this would allow for full-matrix or multi-bus control.

Alternatively, this field can be used to enter the name of a single switcher

output to be controlled. The source of the output name is the Switcher

Output table.

Out Panel - This column is not used for JEP-100 panels.

Level Set - Select the CP Level Set name.

Override Set - Not used for JEP-100 panels.

Sequence - Not used for JEP-100 panels.

Special Entries Needed to Upgrade Serial Panels

In a Serial system, downloading new software to panels normally op erated

in Serial mode will require IP settings. These settings are en tered using the

web page. See page 24 .

40 JEP-100 — Installation and Operating Manual

Page 43

This page intentionally left blank.

Configuration - Jupiter System

JEP-100 — Installation and Operating Manual 41

Page 44

Section 1 — JEP-100 Control Panel

F

LAN + Serial System

Figure 16 shows an example of a system where one or more JEP-100s will

normally be operated in Serial mode, while other JEP-100s are always operated in LAN mode.

The JEP-100(s) operated in Serial mode will require a LAN connection only

during a software upgrade session.

Figure 16. LAN + serial system naming and addressing (example)

“JEP65”

16 JEP 100s per

serial bus maximum

Panel ID

“01”

64 LAN operated

JEP 100s per CM

maximum

“JEP64”

Jupiter

ile Server

Serial bus

Serial

Ports

CM 4000 System Controller

100baseT Jupi-

ter LAN

IP switch

“CM1”

“JEP2”

“JEP1”

Panel ID

“64”

Panel ID

“02”

Panel ID

“01”

8536_20

42 JEP-100 — Installation and Operating Manual

Page 45

Serial Protocol Table Entries

8536_05

When a JEP-100 is connected to a CM-4000 serial port (and operated in

Serial mode), the panel must be configured for "ESCP" protocol using the

Serial Protocol table. The Baud rate should be set at 115K. Panels normally

operated in LAN mode do not require a Serial Proto col table entry.

MPK Table Entries

Although the JEP-100 is not actually an MPK-type panel (it has an on-board

microprocessor and does not use the Message Per Key stroke protocol), the

MPK table is used for configuration purposes. An example is shown in

Figure 17.

Figure 17. MPK table for system shown in Figure 16.

Configuration - Jupiter System

MPK Devices

MPK

Devices word

JEP1 ES LAN 01

1

JEP2 ES LAN 02

2

JEP64 ES LAN 64

64

JEP65 Serial 011

65

Device

Type

Expansion

Pass

Board

CM1

CM1 KXYZ INP KXYZ OUT KXYZ LEV

CM1 KXYZ INP KXYZ OUT KXYZ LEV

CM1 KXYZ INP KXYZ OUT KXYZ LEV

Device Type - For the panels always operated in LAN mode, select type

"ES-LAN" on the pull-down menu. For the panels normally operated in

Serial mode, select type "Serial."

Expansion - Not used for JEP-100 (leave unchecked).

Password - Not used for JEP-100.

Board - Name of CM-4000 connected to this JEP-100. The source of this

name is the Jupiter Network Description table.

Port - For LAN panels: Not used. For serial panels: Number of CM-4000

port connected to this JEP-100.

Port Address Input Sets Output Sets Level Set Overide Set Sequence Set

KXYZ INP

In Panel Out Panel

KXYZ OUT

KXYZ LEV

Address - For the panels always operated in LAN mode: enter the panel

address from 1 to 64; must be unique for panels associated with the same

CM-4000. For the panels normally operated in Serial mode: enter the panel

address from 1 to 16; must be unique for panels shar ing the same CM-4000

serial port.

JEP-100 panels are normally shipped with a panel address of "01." Modification of this address was discussed on page 30 .

This number is referred to as the "Device Number" on the IP configuration

page and "ID" within the JEP-100 MENU system.

JEP-100 — Installation and Operating Manual 43

Page 46

Section 1 — JEP-100 Control Panel

Input Set - Name of CP Input Set to be assigned to this panel. The usual

practice is to have one CP Input Set, containing the names of all in puts,

apply to all panels. However, special CP Input Sets could be created which

list only selected inputs; such a set could be used to prevent certain panels

from selecting specific inputs.

Input Panel - This column is not used for JEP-100 panels.

Output Set - Output Set name.

If the entry is an actual CP Output Set, then the control panel will be able

to control all the outputs listed in that Set. Depending on the con tents of

the set, this would allow for full-matrix or multi-bus control.

Alternatively, this field can be used to enter the name of a single switcher

output to be controlled. The source of the output name is the Switcher

Output table.

Out Panel - This column is not used for JEP-100 panels.

Level Set - Select the CP Level Set name.

Override Set - Not used for JEP-100 panels.

Sequence Set - Not used for JEP-100 panels.

Special Entries Needed to Upgrade Serial Panels

In a LAN + Serial system, downloading to panels normally operated in

Serial mode will require IP settings. These settings are entered using the

web page. See page 24.

44 JEP-100 — Installation and Operating Manual

Page 47

All Systems

Control Panel Sets

Configuration - Jupiter System

Switcher inputs and outputs for the JEP-100 are specified by creating a CP

Level Set of type "CP3000," a CP Input Set of type "Serial," and a CP Output

Set of type "Serial." These sets are assigned to each panel using the MPK

Devices table.

Note With the JEP-100, the CP Level Set does establish the order in which levels

are displayed on the panel; however, this table is not the source of the display

mnemonics used for the various levels ("Video," "Left," etc.). The level names

are instead based on the Switcher "Name" (i.e., level name) as entered in the

Switcher Description table, with a maximum length of eight characters. For

this reason, systems with JEP-100 panels require that all Switcher Names in

the Switcher Description table be unique (not just unique within a given

switcher). For example, if switcher "Main" has a level Name "Video," then

switcher "News" could not also have a level name "Video."

Note The Type "Serial" Input and Output sets used for the JEP-100 must have an

Entry number "0" in the first row, Entry number "1" in the second row, and so

on in sequence.

The CP Input and Output sets are also the source of the eight-charac ter

mnemonics displayed on the panel.

Further, the CP Input set determines which of the 96 button-per-source

buttons is assigned to which source. The upper left-hand but ton of the JEP100 will select the first input listed on the CP Input Set created and selected

for this particular panel, the next button to the right will select the next

listed input, etc. Override sets are not used.

Audio Mode (Special Stereo Switching)

When used to control Venus or Apex audio routers, the JEP-100 can provide

stereo switching modes, which are Normal, Left, Right, Mix, and Reverse.

In this case, the Switcher Description table must define Left and Right

levels in the Audio column. For more information, re fer to the Switcher

Description Table in Section 5 of the Jupiter CM-4000 manual.

Audio mode operating instructions are detailed on page 64.

Salvo Switching

The SALVO key can be used to execute a list of pre-built Jupiter se quences,

where a sequence is a switch of one or more sources to one or more destinations. For more information, see page 57.

JEP-100 — Installation and Operating Manual 45

Page 48

Section 1 — JEP-100 Control Panel

Compiling

Before the panel can be used, the edited Jupiter set must be compiled and

the appropriate configuration set made active using the Control Center. For

more information, please refer to Section 5, "Configurator" in the Jupiter

CM-4000 manual.

46 JEP-100 — Installation and Operating Manual

Page 49

Operation

8536_06

Figure 18. JEP-100 LEDs and mode select buttons

Destination

24

23

22

46

4847

VTR 001

Status

COLORBAR

Preset

VTR 002

70

94

7271

9695

Level

VIDEO

Assign

and

Select

Menu

Level Salvo Preset

Lock Dest Src

Up

Down Clean Take

Operation

LED Displays

Destination - the output presently controlled by the panel.

Status - the source presently switched to the panel's controlled out put.

Preset - shows the new sources as they being entered, e.g., scrolled using

the UP and DOWN buttons. After TAKE is pressed, the previous source is

shown in the Preset window. This allows "flip-flopping" the sources, or

switching between the current and preset sources by sim ply pressing the

TAKE b utton.

Level - used for level breakaway (split) switching and level-by-level statusing.

Show Button Assignment

The 96 keys on the left side of the panel can be assigned to inputs, outputs,

levels, and salvos. To check button assignments, press PRE SET and one of

the "96 keys;" the name of the in/output, level, or sal vo assigned to the key

will be displayed in the Preset window. No ac tual switching takes place

during this procedure.

JEP-100 — Installation and Operating Manual 47

Page 50

Section 1 — JEP-100 Control Panel

Destination Selection / Status Check

To select a destination prior to making a switch or to check status:

1. ASSIGN/SELECT button - ON.

2. DEST button - ON.

3. Select a new destination by using the UP and DOWN arrows to scroll

through all destinations.

When using the UP/DOWN buttons, scrolling past the end of the list

will wrap around to the other end.

It is also possible to program one or more buttons to control outputs

directly. See page 52.

4. When the desired destination is displayed in the Destination window,

press the TAKE button to select it.

The name of the input currently switched to this destination will be

shown in the Status window.

Note If panel "A" does not have access to a certain input, but that input has been

selected by panel "B" for the output presently being statused by panel A, then

panel A has no way of reporting the mnemonic of the input. Under these conditions, panel A will show asterisks (****) for status.

Note If the panel cannot be changed to the desired output, it may have been limited

to certain outputs by the CP Output set used on the MPK Devices table. See

Output Set - Output Set name. on page 44.

48 JEP-100 — Installation and Operating Manual

Page 51

Source Selection (All Levels Take)

Figure 19.

Button-per-source keys

1. The PRESET and LEVEL buttons should be OFF.

2. Select the desired input:

–Press one of the button-per-source (BPS) keys on the left side of the

panel (which immediately completes the switch), or

Operation

Destination

Status

Preset

Level

8536_07

–When the SOURCE button is ON, the UP/DOWN buttons can be

used to find a source in the Preset window. Press TAKE to complete

the switch.

The newly switched source will be shown in the Status window.

If a BPS button was used to select the source (or if an BPS button cor

responds to the selected source) the button will illuminate. However,

the button will not illuminate if the first level assigned to the panel on

the Level set table has been set to "No" switching. Nor will it illuminate

unless all levels assigned to the button are switched.

BPS button programming

The BPS button assignments are based on the entries to the CP Input table

(see page 45), but these assignments can be changed using the panel itself

(see page 52).

It is also possible to assign these buttons to a destination (see page 54) or to

levels (see page 55).

JEP-100 — Installation and Operating Manual 49

Page 52

Section 1 — JEP-100 Control Panel

Level Breakaways (Split Switching)

This function allows different sources to be selected for different levels. For

example, switching video without switching audio.

Note Breakaway in v1.1.1 and later includes a method similar to that used for the

There are two breakaway methods available:

• Default mode - level names are scrolled in the Level window and

• Button-per-level mode - levels are assigned to specific buttons and

Default Mode Breakaway

Jupiter CP-300/330 panels. With this method, levels are selected first; when

the source is selected with a button-per-source (BPS) key, the switch is executed.

toggled on/off before the switch is made.

toggled on/off before the switch is made. A level can be assigned to

to one of the 96 keys on the left side of the panel or one of the top

six keys on the right side of the panel.

1. LEVEL button - ON.

2. Select the wanted levels:

a. Use UP/DOWN to step to the first wanted level.

b. Press ASSIGN/SELECT to toggle the level on/off. Dashes in the

Level window mean the level is de-selected.

c. Repeat as needed for remaining levels.

3. Select the desired input:

–Press one of the button-per-source (BPS) keys on the left side of the

panel (which immediately completes the switch), or

–Toggle the SOURCE button ON, and use the UP/DOWN buttons to

find a source in the Preset window. Press TAKE to complete the

switch. Toggling SOURCE to OFF will exit.

As long as LEVEL is ON, the panel will remember the breakaway level(s)

previously selected and switch accordingly. When LEVEL is OFF, the panel

will revert to All Level switching.

Checking Status of Selected Level

Press CLEAR. With the LEVEL button ON, press UP/DOWN to step to the

desired level. The status of the selected level with be shown in the Status

window.

50 JEP-100 — Installation and Operating Manual

Page 53

Button-per-Level Mode Breakaway

This method assumes that the levels have been assigned to specific buttons;

if not see "Defining a Level Button" on page 55 or "Alternate Mode" on

page 63.)

1. LEVEL - ON.

Note In this mode, when using a subset of the 96 buttons on the left side of the

panel, the LEVEL button must always be ON for the Level but tons to be effec-

tive.

2. Toggle on/off the desired level(s).

3. Select the desired input:

–Press one of the button-per-source (BPS) keys on the left side of the

panel (which immediately completes the switch), or

–Toggle the SOURCE button ON and use the UP/DOWN buttons to

find a source in the Preset window. Press TAKE to complete the

switch. Toggling SOURCE to OFF will exit.

Operation

As long as LEVEL is ON, the panel will remember the breakaway level(s)

previously selected and switch accordingly. When LEVEL is OFF, the panel

will revert to All Level switching.

Checking Status of Selected Level

Press CLEAR. With the LEVEL button ON, press UP/DOWN to step to the

desired level. The status of the selected level with be shown in the Status

window.

JEP-100 — Installation and Operating Manual 51

Page 54

Section 1 — JEP-100 Control Panel

8536_21

Defining a Source Button

By default, the 96 keys on left side of the panel are assigned to Entry

numbers 0 through 95 listed in the the CP Input set table.

See Figure 20.

Figure 20.

Input Set - JEP

1

2

3

4

5

6

7

8

BARS

Logical

Input

Entry

0

1 TONE

2TC

3 VTO1

4 BARS

5 TONE

6TC

7 VTO1

JEP64 ES LAN

64

JEP65 Serial

65

Button "1" (the first button) is always equivalent to Entry 0, which in this

example maps to BARS. Buttons can also be programmed from the front

panel using the ASSIGN/SELECT key, as follows:

1. Press CLEAR.

This returns the panel to the "home state."

2. (Optional) Check the desired key position for the new input:

a. PRESET - ON.

b. Press the key you would like to use. Check the Preset window for

the current assignment.

c. Repeat if necessary to find a suitable location.

d. PRESET - OFF.

3. ASSIGN/SELECT - ON

4. SOURCE - ON.

5. Use the UP/DOWN buttons to select the new input.

The name of the new input is shown in the Preset window.

52 JEP-100 — Installation and Operating Manual

Page 55

Operation

6. Press the desired button.

The input is now assigned to the button.

The top six function buttons on the right side of the panel can also be

used for sources but only when Alternate mode is active (see page 63).

Note A source button assignment always refers to an Entry number in the CP Input

Set table. If the table is changed such that the Entry number points to a different Logical Input, the source button will now select the new Logical Input.

JEP-100 — Installation and Operating Manual 53

Page 56

Section 1 — JEP-100 Control Panel

Defining a Destination Button

Any group of the "96 buttons" can be assigned to individual outputs for "XY" style switching where the operator first selects an output button and

then completes the switch by selecting an input button.

1. Press CLEAR.

This returns the panel to the "home state."

2. (Optional) Check the desired key position for the output:

a. PRESET - ON.

b. Press the key you would like to use. Check the Preset window for

c. Repeat if necessary to find a suitable location.

d. PRESET - OFF.

3. ASSIGN/SELECT - ON

4. DEST - ON.

the current assignment.

5. Use the UP/DOWN buttons to select the new output.

The name of the new output is shown in the Preset window.

6. Press the desired button.

The output is now assigned to the button.

The top six function buttons on the right side of the panel can also be used

for destinations but only when Alternate mode is active (see page 63).

Note A destination button assignment always refers to an Entry number in the CP

Output Set table. If the table is changed such that the Entry number points to

a different Logical Output, the destination button will now select the new

Logical Output.

54 JEP-100 — Installation and Operating Manual

Page 57

Defining a Level Button

Any group of the "96 buttons" can be assigned to individual levels,

allowing the operator to toggle buttons on and off during a split switch.

1. Press CLEAR.

This returns the panel to the "home state."

2. (Optional) Check the desired key position for the level:

a. PRESET - ON.

b. Press the key you would like to use. Check the Preset window for

the current assignment.

c. Repeat if necessary to find a suitable location.

d. PRESET - OFF.

3. ASSIGN/SELECT - ON

4. LEVEL - ON.

Operation

5. Use the UP/DOWN buttons to select the level.

The name of the level is shown in the Level window.

6. Press the desired button.

The Level is now assigned to the button.

The button will illuminate to show that the level is selected for

switching.

For level breakaway instructions, see page 50.

The top six function buttons on the right side of the panel can also be used

for levels but only when Alternate mode is active (see page 63).

Note A level button assignment always refers to a row number in the CP Level Set

table. If the table is changed such that the row number points to a different

level, the level button will now select the new level.

JEP-100 — Installation and Operating Manual 55

Page 58

Section 1 — JEP-100 Control Panel

Locking or Unlocking an Output

Locking an output prevents that output from being switched by any panel

in the system, including the initiating panel.

To lock an output:

1. Press the LOCK button.

This has the effect of locking only those levels this control panel can

control (as defined on the CP Level set assigned to the panel). The

LOCK button will remain on, indicating the output has been locked by

this panel.

If another Jupiter panel selects this output for control, that panel's

LOCK button will light.