Page 1

Page 2

Number: 510057.001

The Quality System of:

Thomson Broadcast & Media Solutions

TBMS TBMS

400 Providence Mine Road 17 rue du Petit Albi-BP 8244

Nevada City, CA 95945 95801 Cergy Pontoise

Cergy, France

TBMS

Weiterstadt, Germany TBMS

Brunnenweg 9 10 Presidential Way, 3rd Floor, Suite 300

D-64331 Weiterstadt, Germany Woburn, MA 08101

TBMS TBMS

15655 SW Greystone Ct. 2300 South Decker Lake Blvd.

Beaverton, OR 97006 Salt Lake City, UT 84119

TBMS TBMS - PCB

Nederland B.V. Rennes, France

4800 RP BREDA Rue du Clos Courtel

The Nederlands Cesson-Sevigne, Cedex

France

TBMS/Nextream TBMS/Nextream

Rennes, France Technopole Brest Iroise

Rue du Clos Courtel CS 73808

Cesson-Sevigne, Cedex 29238 Brest Cedex 3

France France

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope: The design, manufacture and support of video hardware and software products

and related systems.

This Certificate is valid until: June 14, 2006

Revision Date: September 9, 2003

Renewal Date: June 14, 2003

Issued for the first time: June 14, 2000

Page 3

IngestStation

Automated Tape Digitization System

System Guide

SOFTWARE VERSION 1.0

071834200

AUGUST 2004

Page 4

Copyright

Copyright © 2004 Thomson Broadcast and Media Solutions, Inc. All rights

reserved. Printed in the United States of America.

This document may not be copied in whole or in part, or otherwise reproduced

except as specifically permitted under U.S. copyright law, without the prior written

consent of Thomson Broadcast and Media Solutions, Inc., P.O. Box 59900,

Nevada City, California 95959-7900

Trademarks

Disclaimer

U.S. Government

Restricted Rights

Legend

Revision Status

Encore, Grass Valley, IngestStation, NewsQ, NewsQ Pro and Profile are either

registered trademarks or trademarks of Thomson Broadcast and Media Solutions,

Inc. in the United States and/or other countries. Other trademarks used in this

document are either registered trademarks or trademarks of the manufacturers or

vendors of the associated products. Thomson Broadcast and Media Solutions, Inc.

products are covered by U.S. and foreign patents, issued and pending. Additional

information regarding Thomson Broadcast and Media Solution, Inc.’s trademarks

and other proprietary rights may be found at www.thomsongrassvalleygroup.com.

Product options and specifications subject to change without notice. The

information in this manual is furnished for informational use only, is subject to

change without notice, and should not be construed as a commitment by Thomson

Broadcast and Media Solutions, Inc. Thomson Broadcast and Media Solutions,

Inc. assumes no responsibility or liability for any errors or inaccuracies that may

appear in this publication.

Use, duplication, or disclosure by the United States Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data

and Computer Software clause at DFARS 252.277-7013 or in subparagraph c(1)

and (2) of the Commercial Computer Software Restricted Rights clause at FAR

52.227-19, as applicable. Manufacturer is Thomson Broadcast and Media

Solutions, Inc., P.O. Box 59900, Nevada City, California 95959-7900 U.S.A.

Rev Date Description

August, 2004 Release for Software Version 1.0

Page 5

Contents

Preface

Grass Valley Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Summaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Environmental Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1 Introducing IngestStation

What is IngestStation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tour of the IngestStation Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Channel Window Toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

VTR Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Channel Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Clip Record Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Feed Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Channel Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Clip Record Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 2 Installing IngestStation

Installing the IngestStation Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing the IngestStation Software . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Obtaining a Software License Number. . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 3 Configuring Your System

Setting Up Your Media Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

M-Series iVDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Profile Media Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DCOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

RS-422 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configuring IngestStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuring Recording Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuring the Router. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuring Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configuring NewsQ Pro Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Digital News Production

3

Page 6

Contents

Chapter 4 Using IngestStation

Recording Clips from a VTR Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Adding Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Creating a Batch List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Controlling the VTR with IngestStation. . . . . . . . . . . . . . . . . . . . 38

Marking In and Out Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Importing an EDL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Rearranging the Batch List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Recording Clips to the Media Server. . . . . . . . . . . . . . . . . . . . . . . . 42

Recording a Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Linking Clips to NewsQ Pro Placeholders . . . . . . . . . . . . . . . . . . . . . . 45

Tour of the Assignment List Manager . . . . . . . . . . . . . . . . . . . . . . . 45

Linking Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Creating New Placeholders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Appendix A The IngestStation Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Index

4

Digital News Production

Page 7

Grass Valley Product Support

To get technical assistance, check on the status of problems, or report new

problems, contact Grass Valley Product Support via e-mail, the Web, or by

phone or fax.

Web Technical Support

To access support information on the Web, visit the product support Web page

on the Grass Valley Web site. You can download software or find solutions to

problems by searching our Frequently Asked Questions (FAQ) database.

Grass Valley Product Support

World Wide Web:

Technical Support E-mail Address:

http://www.thomsongrassvalley.com/support/

gvgtechsupport@thomson.net.

Phone Support

Use the following information to contact product support by phone during

business hours. Afterhours phone support is available for warranty and contract

customers.

United States (800) 547-8949 (Toll Free) France +33 (1) 34 20 77 77

Latin America (800) 547-8949 (Toll Free) Germany +49 6155 870 606

Eastern Europe +49 6155 870 606 Greece +33 (1) 34 20 77 77

Southern Europe +33 (1) 34 20 77 77 Hong Kong +852 2531 3058

Middle East +33 (1) 34 20 77 77 Italy +39 06 8720351

Australia +61 3 9721 3737 Netherlands +31 35 6238421

Belgium +32 2 3349031 Poland +49 6155 870 606

Brazil +55 11 5509 3440 Russia +49 6155 870 606

Canada (800) 547-8949 (Toll Free) Singapore +656379 1390

China +86 106615 9450 Spain + 34 91 512 03 50

Denmark +45 45968800 Sweden +46 87680705

Dubai + 971 4 299 64 40 Switzerland +41 (1) 487 80 02

Finland +35 9 68284600 UK +44 870 903 2022

Digital News Production

5

Page 8

Preface

Authorized Support Representative

Profile Users Group

A local authorized support representative may be available in your country. To

locate the support representative for your country, visit the product support

Web page on the Grass Valley Web site.

You can connect with other Profile XP Media Platform users to ask questions

or share advice, tips, and hints. Send e-mail to profile-users@thomson.net to

join the community and benefit from the experience of others.

6

Digital News Production

Page 9

Safety Summaries

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system.

Read the

cautions related to operating the system.

Review all system operator manuals, including manuals in electronic format on

the system hard drive.

Injury Precautions

General Safety Summary

Safety Summaries

in other system manuals for warnings and

Use Proper Power

Cord

Ground the Product

Do Not Operate

Without Covers

Do Not Operate in

Wet/Damp

Conditions

Do Not Operate in

an Explosive

Atmosphere

Avoid Exposed

Circuitry

To avoid fire hazard, use only the power cord specified for

this product.

This product is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making

connections to the input or output terminals of the product,

ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this

product with covers or panels removed.

To avoid electric shock, do not operate this product in wet or

damp conditions.

To avoid injury or fire hazard, do not operate this product in

an explosive atmosphere.

To avoid injury, remove jewelry such as rings, watches, and

other metallic objects. Do not touch exposed connections and

components when power is present.

Digital News Production

7

Page 10

Preface

Product Damage Precautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspected Failures

Battery

Replacement

Do not operate this product from a power source that applies

more than the voltage specified.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it

inspected by qualified service personnel.

To avoid damage, replace only with the same or equivalent

type recommended by the circuit board manufacturer.

Dispose of used battery according to the circuit board

manufacturer’s instructions.

Safety Terms and Symbols

Terms in This

Manual

!

!

Terms on the

Product

These terms may appear in this and other product manuals:

WARNING

: Warning statements identify conditions or

practices that can result in personal injury or loss of life.

CAUTION

: Caution statements identify conditions or practices

that can result in damage to the equipment or other property.

These terms may appear on the product:

DANGER

indicates a personal injury hazard immediately

accessible as one reads the marking.

WARNING

indicates a personal injury hazard not immediately

accessible as you read the marking.

CAUTION

8

Digital News Production

indicates a hazard to property including the product.

Page 11

Service Safety Summary

Symbols on the

Product

The following symbols may appear on the product:

DANGER high voltage

Protective ground (earth) terminal

!

ATTENTION – refer to manual

Service Safety Summary

Do Not Service

Alone

No Power Switch

Use Care When

Servicing With

Power On

Do not perform internal service or adjustment of this product

unless another person capable of rendering first aid and

resuscitation is present.

To avoid electric shock, disconnect the main power by means

of the power cord. The power cord is the main power

disconnect. Ensure that the power cord is easily accessible at

the rear of the product or at the power receptacle.

Dangerous voltages or currents may exist in this product.

Disconnect power and remove battery (if applicable) before

removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

Digital News Production

9

Page 12

Preface

Certifications and Compliances

Canadian Certified

Power Cords

Canadian approval includes the products and power cords

appropriate for use in the North America power network. All

other power cords supplied are approved for the country of use.

FCC Emission

Control

Canadian EMC

Notice of

Compliance

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own

expense. Changes or modifications not expressly approved

by Tektronix can affect emission compliance and could void

the user’s authority to operate this equipment.

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits

radioélectriques dépassant les limites applicables aux

appareils numériques de la classe A préscrites dans le

Règlement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

Canadian Certified

EN55022 Class A

10

Digital News Production

AC Adapter

Warning

Canadian approval includes the AC adapters appropriate for

use in the North America power network. All other AC

adapters supplied are approved for the country of use.

For products that comply with Class A. In a domestic

environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Page 13

Laser Compliance

Laser Safety

Requirements

Certifications and Compliances

The device used in this product is a Class 1 certified laser

product. Operating this product outside specifications or

altering its original design may result in hazardous radiation

exposure, and may be considered an act of modifying or new

manufacturing of a laser product under U.S. regulations

contained in 21CFR Chapter 1, subchapter J or CENELEC

regulations in HD 482 S1. People performing such an act are

required by law to recertify and reidentify this product in

accordance with provisions of 21CFR subchapter J for

distribution within the U.S.A., and in accordance with

CENELEC HD 482 S1 for distribution within countries using

the IEC 825 standard.

Laser Safety

FCC Emission

Limits

Laser safety in the United States is regulated by the Center for

Devices and Radiological Health (CDRH). The laser safety

regulations are published in the “Laser Product Performance

Standard,” Code of Federal Regulation (CFR), Title 21,

Subchapter J.

The International Electrotechnical Commission (IEC)

Standard 825, “Radiation of Laser Products, Equipment

Classification, Requirements and User’s Guide,” governs

laser products outside the United States. Europe and member

nations of the European Free Trade Association fall under the

jurisdiction of the Comité Européen de Normalization

Electrotechnique (CENELEC).

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this

device must accept any interference received, including

interference that may cause undesirable operation.

Digital News Production

11

Page 14

Preface

Certification

Category Standard

Safety

Designed/tested for compliance with:

ANSI/UL60950-2000

IEC 60950

CAN/CSA C22.2, No. 60950-00

EN60950:2000

- Safety of Information Technology Equipment (3rd edition, 1999)

- Safety of Information Technology Equipment

- Safety of Information Technology Equipment (3rd edition)

Environmental Criteria

The following table lists the environmental criteria for IngestStation.

Characteristics Description

Operating Temperature

Storage Temperature

Operating Altitude

Storage Altitude

Mechanical Shock

Random Vibration

Requirement:

Requirement:

Requirement:

Supplemental Data:

Requirement:

Supplemental Data:

Requirement:

Requirement:

10° to 40°C

-40° to 65°C

To 10,000 feet

To 40,000 feet

Non-Operational: Class 5 Grass Valley 001131500

IEC 60950 compliant to 2000 meters

Class 5 (30G) Grass Valley 001131500

- Safety of Information Technology Equipment

Operational: Class 6 Grass Valley 001131500

Transportation

Equipment Type

Equipment Class

Installation Category

Pollution Degree

Relative Humidity

12

Digital News Production

Requirement:

Supplemental Data:

Supplemental Data:

Requirement:

Requirement:

Requirement:

Grass Valley 001131500

Category II Local level mains, appliances,

Operating 80% from +30° to +40°C

Information Technology

Class 1

portable equipment, etc.

Level 2 operating environment, indoor use only.

Non-Operating 90% from +30° to +60°C

Do not operate with visible moisture on the circuit boards.

Page 15

1

Chapter

1

Introducing IngestStation

IngestStation is an automated tape digitization system that allows you to record

footage from VTR tapes or feeds from a router directly to a Media Server in

your newsroom. You can also ingest VTR material directly to a rundown in the

NewsQ Pro automated news playback system.

This manual shows you how to install and configure IngestStation in your

newsroom, and how to use IngestStation to capture and record clips for later use

in a newscast.

This chapter discusses:

• What IngestStation is

• IngestStation kit contents

• System requirements

• The IngestStation window

Digital News Production

13

Page 16

Chapter 1 Introducing IngestStation

What is IngestStation?

IngestStation lets you get news footage from VTR tapes and router feeds and

ingest it directly to your Media Server. With IngestStation, you can select clips

from a VTR tape, create a batch list, and record it to the server. You can also

ingest feeds from a router source directly to the same server.

The IngestStation system supports two types of Media Servers—Profile 6g and

Profile XP Media Platform servers, and M-Series iVDRs. These media servers

are controlled through Ethernet-based AMP.

Raw footage comes from two sources—a VTR connected directly to the

IngestStation PC or a router source. While you can connect to the IngestStation

using either DCOM or RS-422, you need RS-422 connection from the VTR to

the IngestStation PC in order to have control of the VTR in the IngestStation

windows. For router sources, IngestStation supports both the Grass Valley

Series 7000 and Encore control systems, and allows source selection and

renaming.

Supporting up to six channels, IngestStation can record footage in one of two

modes—VTR (batch) mode and feed mode. VTR mode allows for recording

with configurable handle durations, lets you set mark points using either the

VTR, the PC keyboard, or the mouse, and allows you to reorganize clips in your

batch list. You use Feed mode to crash record, manually starting and stopping

the recording of a feed from a router source.

14

If you use NewsQ Pro as a playback system in your newsroom, you can ingest

clips directly to a NewsQ Pro rundown by linking clips to a NewsQ Pro

placeholder at the point of record.

Digital News Production

Page 17

Kit Contents

IngestStation comes in a kit containing all of the items you need to get

IngestStation up and running on your PC.

The IngestStation kit contains these items:

• CD-ROM containing the IngestStation software

• One video capture board

• One RS-422 board

• Cable assembly for the RS-422 board

• RS-422 Breakout Box assembly

System Requirements

The PC you use to run IngestStation should conform to these requirements:

• Intel compatible CPU with a minimum of 800 MHz and 256 MB RAM

• Windows 2000 Pro or XP Pro with current service packs

Kit Contents

• Minimum 1024x768 SVGA display adapter

• 20GB HDD

• CD-ROM drive for installation

• Two available PCI slots for the video capture and RS-422 boards

• 100BaseTX Ethernet interface

Digital News Production

15

Page 18

Chapter 1 Introducing IngestStation

Tour of the IngestStation Window

The IngestStation window consists of one to six channel windows, a viewing

window, and a dynamic clip record area that changes depending on which mode

you are using. Both the recording area and the channel window contents change

depending on which mode you are using—VTR Mode or Feed Mode.

Dynamic Clip

Recording Area

Viewing Window

Channel Windows

16

Digital News Production

Page 19

Channel Window Toolbar

The Toolbar lets you perform common IngestStation functions:

Icon Function

Toggles the currently selected channel between VTR Mode and Feed

Mode for recording clips.

Displays channel status—A green icon indicates status is OK; a red

icon indicates a problem. Click on this icon to see status for the VTR,

Primary Server, and Backup Server.

Deletes the selected clip.

Clears the batch capture list.

Organizes the clips in order of timecode. (VTR Mode only)

Moves the selected clip up in the list. (VTR Mode only)

Moves the selected clip down in the list. (VTR Mode only)

Channel Window Toolbar

Digital News Production 17

Page 20

Chapter 1 Introducing IngestStation

VTR Mode

You use VTR Mode to create a batch list of clips, which you then record to your

Media Server.

Channel Columns

Each channel window displays information about the clips in the batch list:

Column Description

Clip Name The name of the clip placeholder.

Duration The duration of the clip.

Status The current status of the clip:

Ready = The clip is ready to record.

Cuing = The clip is preparing to record.

Recording = The clip is currently recording to the server.

Done = The clip has finished recording.

Failed = The clip could not record. Check the Error Message field for more

information.

Mark In The mark points for the clip.

Mark Out

In Handle The amount of handle material in the clip.

Out Handle

Clip ID The automatically-generated identification for the clip.

Description The description of the clip.

Error Message Any error messages describing why the clip was not recorded to the server.

18 Digital News Production

Page 21

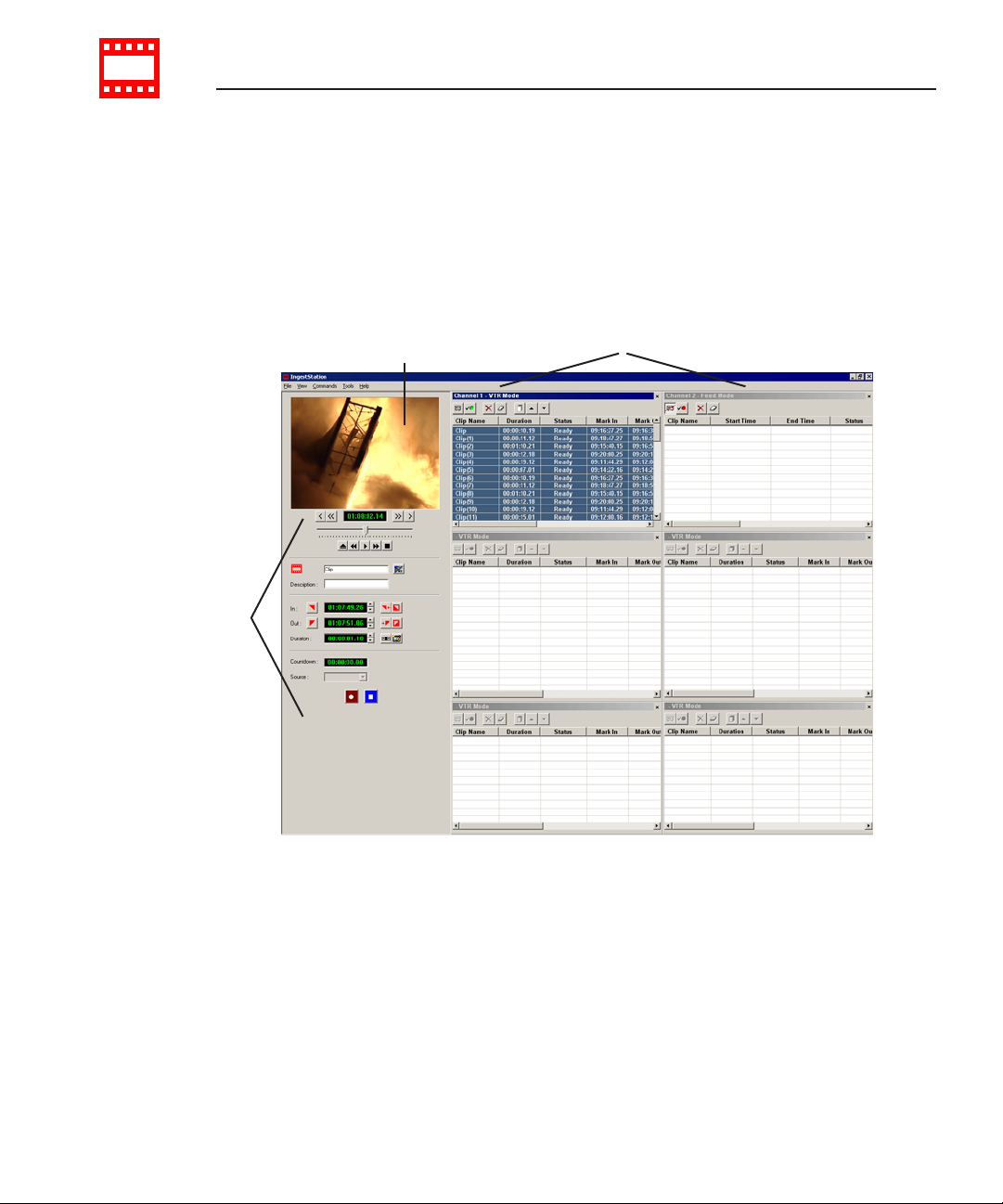

Clip Record Area

VTR controls

VTR Mode

Clip name and

description

Mark point area

Recording countdown

Link to

NewsQ Pro

placeholder

Record buttons

Digital News Production 19

Page 22

Chapter 1 Introducing IngestStation

Feed Mode

You use Feed Mode to record a source from a router as one long clip.

Channel Columns

Each channel window displays information about the feed:

Column Description

Clip Name The name of the feed placeholder.

Start Time The beginning and ending time for the feed.

End Time

Status The current status of the feed:

Ready = The feed is ready to record.

Cuing = The feed is preparing to record.

Recording = The feed is currently recording to the server.

Done = The feed has finished recording.

Failed = The feed could not record. Check the Error Message field for more

information.

Router Source The router source selected for this feed.

In Handle The amount of handle material in the feed.

Out Handle

Clip ID The automatically-generated identification for the feed.

Description The description of the feed.

Error Message Any error messages describing why the feed was not recorded to the server.

20 Digital News Production

Page 23

Feed Record Area

Feed Mode

Feed name and

description

Recording countdown

Link to

NewsQ Pro

placeholder

Record buttons

Digital News Production 21

Page 24

Chapter 1 Introducing IngestStation

22 Digital News Production

Page 25

Chapter

22

Installing IngestStation

The IngestStation system consists of two boards you install in your computer, a

VTR, an optional router, the IngestStation software, and your Profile Media

Server or M-Series iVDR.

This chapter discusses how to:

• Install the IngestStation hardware

• Install the IngestStation software

• Obtain a Software License number

Digital News Production 23

Page 26

Chapter 2 Installing IngestStation

Installing the IngestStation Hardware

To install the IngestStation hardware:

1. Install the video capture board in your computer and install the driver for the

board.

2. If necessary, install the RS-422 board in your computer and install the driver

for the board.

3. If you are going to be connecting several VTRs to IngestStation, you may

want to install and use the RS-422 breakout box, which connects to the

RS-422 board in the IngestStation computer.

4. Connect the video capture board’s S-Video Input connector to the device

you’re using for on-screen video display (VTR, router, or switch box).

5. Connect the VTR(s) to the computer via RS-422 (either directly to the board

or through the breakout box).

Installing the IngestStation Software

To install the IngestStation software on your computer, insert the IngestStation

CD-ROM into the machine’s CD-ROM drive and follow these instructions:

On this screen... Do this...

Welcome Click Next.

Choose Destination

Location

Select Server Type Select the type of media server you are using with IngestStation—

Select Program

Manager Group

Start Installation Click

Installation Complete Click

24 Digital News Production

Click

Next.

MSeries or Profile.

Click

Next.

Install.

Finish.

Page 27

Obtaining a Software License Number

Obtaining a Software License Number

Once you’ve installed the IngestStation software, you need to get a License

Number from Grass Valley.

To obtain a License Number:

1. Open Windows Explorer and browse to

C: | Program Files | IngestStation | Utilities.

2. Double-click the file License.exe to open it.

The Software License Utility opens:

System

Identification

Number

Your System Identification Number appears in the bottom field of the

window.

3. Call Grass Valley Product Support at 1-800-547-8949 and provide the

customer service representative with your System Identification Number, as

well as the software version and the original order number for the system.

4. Enter the License Number provided to you by Grass Valley Product Support

and click

OK.

Digital News Production 25

Page 28

Chapter 2 Installing IngestStation

26 Digital News Production

Page 29

Chapter

33

Configuring Your System

Once you’ve cabled IngestStation and installed software, you need to configure

your system for your particular newsroom equipment and workflow.

This chapter discusses how to:

• Set up your media server for IngestStation

• Configure IngestStation

Digital News Production 27

Page 30

Chapter 3 Configuring Your System

Setting Up Your Media Server

You need to configure your Media Server to work with IngestStation. Follow

the instructions below for your type of server.

M-Series iVDR

If you are using an M-Series iVDR as your media server with IngestStation, you

need to configure it as follows:

• Set up record channels to use Advanced Media Protocol (AMP).

• Configure channels to use LTC input (IngestStation only supports LTC

input).

See your M-Series iVDR documentation for instructions.

Profile Media Server

You configure the Profile Server differently for IngestStation depending on

they type of communication you’re using for the server—DCOM or RS-422.

DCOM

If you are using DCOM, see your Profile documentation and set up the server

as follows:

• Set up record channels using the Configuration Manager.

• Configure channels to use LTC input (IngestStation only supports LTC

input).

• When you connect, it is imperative that you don’t launch any of the Profile

interfaces; you can’t have any channels open in either the VdrPanel or the

AMP Application.

RS-422

If you are using RS-422, see your Profile documentation and set up the server

as follows:

• Set up record channels using the Configuration Manager.

• Configure channels to use LTC input (IngestStation only supports LTC

input).

• Use the AMP Client Application to configure channels for control by AMP.

28 Digital News Production

Page 31

Configuring IngestStation

You need to configure IngestStation options for your particular newsroom

equipment and workflow.

To set IngestStation options:

Configuring IngestStation

1. Choose

Tools | Options.

2. Go through each Options tab to set options.

The following sections describe each tab in the Options window.

3. Click

OK when you are done adjusting options.

Configuring Recording Settings

Setting Options Description

In Handle Handles allow you to have additional frames to use while

Out Handle

Pre-roll Duration Enter the number of seconds of pre-roll you want to use when

Video Standard

NTSC drop frame

NTSC non-drop frame

PAL

editing. Enter the duration you want for the In and Out

Handles. The default duration is 0 seconds.

recording clips. The default duration is 5 seconds.

Select the video standard used in your newsroom.

Digital News Production 29

Page 32

Chapter 3 Configuring Your System

Configuring the Router

If you are using a SMS7000 or Encore router as part of your news station, you

can configure IngestStation to use sources from the router to record clips.

To configure a router for use with IngestStation:

1. Enter the IP address of the router in the Router Machine field and press

Connect.

IngestStation connects to the router, queries the list of sources, and displays

the available sources in the window.

2. Check the

Use Router checkbox.

3. For each source you want to use in IngestStation, check the box in the

column.

4. Click on the Source Name field for each checked source and enter a name

for that source. Checked sources display in the feed recording source list

using the Source Name you entered.

5. Click

30 Digital News Production

Apply to save changes.

Use

Page 33

Configuring Channels

With IngestStation, you can have between one and six channels. The number of

channels you have depends on how IngestStation is licensed. You need to

configure each channel in order to record clips.

Configuring Channels

Digital News Production 31

Page 34

Chapter 3 Configuring Your System

Setting Options Description

Select Channel Select the channel you want to configure from the list.

Channel Channel Name Enter a name for the channel. This name identifies the

IngestStation Channel Window.

On-Screen Video Source If using a router, select the router destination source; this is the

destination for video input to the video capture board.

VTR VTR Port Select the COM port for controlling the VTR

Router Source If using a router, select the router source for the VTR.

Main Recording Channel: Select DCOM or RS422 for the type of connection you have.

DCOM Media Server Enter the name or IP address of the M-Series or Profile server.

Recording Channel Name Enter the name of the channel you are using to record; for an

M-Series server, enter

0 or 2; for a Profile server, enter the

name of the channel, such as vtr1.

Record Destination If using a router, select the router destination that is physically

connected to the Media Server’s recorder channel.

RS422 Recording Control Port Select the COM port for the recording channel.

Record Destination If using a router, select the router destination that is physically

connected to the Media Server’s recorder channel.

Use Backup Check this box if you are using a backup channel for recording.

Backup Recording Channel:

DCOM Media Server Enter the name or IP address of the M-Series or Profile server.

Recording Channel Name Enter the name of the channel you are using to record; for an

Record Destination If using a router, select the router destination that is physically

RS422 Recording Control Port Select the COM port for the recording channel.

Record Destination If using a router, select the router destination that is physically

32 Digital News Production

M-Series server, enter

0 or 2; for a Profile server, enter the

name of the channel, such as vtr1.

connected to the Media Server’s recorder channel.

connected to the Media Server’s recorder channel.

Page 35

Configuring NewsQ Pro Settings

If you are using NewsQ Pro to playout clips to air, set these options; otherwise,

leave these fields blank. Setting this option allows you to associate clips you

record using IngestStation with a NewsQ Pro placeholder.

Setting Description

Configuring NewsQ Pro Settings

Database Server Enter the name of the server where the NewsQ Pro database resides

Backup Database Server If you are using a backup database server, enter the name of the server

(primary SDB Server).

where the backup NewsQ Pro database resides (hot-standby SDB

Server).

Digital News Production 33

Page 36

Chapter 3 Configuring Your System

34 Digital News Production

Page 37

Chapter

44

Using IngestStation

With IngestStation, you can record clips in two ways—from a VTR tape or a

router feed. Recorded clips are saved on your Media Server for later use in a

newscast. If you have NewsQ Pro as part of your newsroom, you can also link

clips to NewsQ Pro placeholders.

This chapter discusses how to:

• Record clips from a VTR tape

• Record feeds

• Link clips to NewsQ Pro placeholders

Digital News Production 35

Page 38

Chapter 4 Using IngestStation

Recording Clips from a VTR Tape

You can record a list of clips from a single videotape in a Channel Window.

To record clips from a VTR:

1. Decide if you want to add handles to your clips.

2. Create a batch list or import an EDL.

3. Rearrange the batch list if you need to.

4. Record the batch list to your Media Server.

The following sections describe each step in detail.

Adding Handles

If you add handles to your clips, you will have additional frames to choose from

when trimming your clips.

To use handles:

• Click the

To set the duration of the handles, see “Configuring Recording Settings” on

page 29.

36 Digital News Production

Add Handles button.

Page 39

Creating a Batch List

VTR controls

Creating a Batch List

Clip name and

description

Mark point area

Recording countdown

Record buttons

To create a batch list:

1. Play through the videotape to get the footage you need (see “Controlling the

VTR with IngestStation” on page 38).

2. Mark an In and Out point for the clip (see “Marking In and Out Points” on

page 39).

3. Name the clip and add a description, if you want to.

Link to

NewsQ Pro

placeholder

4. Click

Add Clip to Batch List or press C on your keyboard.

5. Repeat steps 1-4 for additional clips.

Digital News Production 37

Page 40

Chapter 4 Using IngestStation

Controlling the VTR with IngestStation

To get the footage you need to create clips, you need to play through the

videotape in the VTR. IngestStation provides transport control buttons like

those on a tape deck. Use these controls to locate the material you want to

record as a clip. The deck controls are:

Button Function

Ejects the tape.

Rewinds the tape.

Plays the tape.

Fast forwards the tape.

Stops the tape.

Jogs one frame back.

38 Digital News Production

Jogs 10 frames back.

Jogs one frame forward.

Jogs 10 frames forward.

Page 41

Marking In and Out Points

Mark points are used to determine the length of a clip.

Creating a Batch List

Sets a

Mark In

Point

Sets a

Mark Out

Point

Shows

Duration

of Clip

Moves to

Mark In

Point

Clears

Mark In

Point

Clears

Mark Out

Point

To set Mark In and Out Points:

1. Find the spot on the videotape where you want your clip to begin.

2. Mark an In Point using any of the following methods:

- Press

- Click the

I on your keyboard.

Mark In button on the IngestStation window.

- Type the timecode in the In field.

Moves to

Mark Out

Point

- Create a Mark In on the VTR.

3. Play through the tape until you reach the point where you want the clip to

end.

4. Mark an Out Point using any of these methods:

- Press

- Click the

O on your keyboard.

Mark Out button on the IngestStation window.

- Use the up or down arrows to find the correct timecode.

- Type the ending timecode in the Out field.

- Create a Mark Out on the VTR.

Digital News Production 39

Page 42

Chapter 4 Using IngestStation

Importing an EDL

You can also use an Edit Decision List (EDL) as your batch list. Supported

EDL formats are .ale, .edl, and .xml.

NOTE: IngestStation does not currently support EDLs that contain

clips from multiple tapes within a single batch list.

To import an EDL:

1. Choose

The Open window appears:

2. Navigate to the correct folder, select the EDL you want, and click

The clips in the EDL appear in the batch list for the selected channel and are

ready to record:

File | Import EDL.

Open.

3. Record your clips to the media server.

40 Digital News Production

Page 43

Rearranging the Batch List

Rearranging the Batch List

If you need to, you can rearrange clips on the batch list:

Button Function Other Ways to Access

Deletes the selected clip. Right-click in batch list and select Delete.

Clears the batch list. Right-click in batch list and select

Organizes the clips in order of timecode. N/A

Moves the selected clip up in the list. N/A

Moves the selected clip down in the list. N/A

Clear All.

If you have a clip that failed to record for some reason, you can change its status

back to Ready by highlighting the clip, right-clicking and selecting

Ready.

Digital News Production 41

Mark

Page 44

Chapter 4 Using IngestStation

Recording Clips to the Media Server

After you’ve created a batch list, you can record the clips to your Media Server.

To batch record:

1. Make sure the Channel Window is selected.

2. Click

Record.

IngestStation records the clips from the VTR tape to the server for later use

in a news story. Clip status changes from Ready -> Cuing -> Recording ->

Done. If the clip didn’t record for some reason, status shows as Failed.

42 Digital News Production

Page 45

Recording a Feed

With IngestStation, you can record a feed from a router source. In order to

record a feed, you need to have IngestStation configured for your router and a

specific IngestStation channel configured as well. See “Configuring the

Router” on page 30 for instructions.

Recording a Feed

Digital News Production 43

Page 46

Chapter 4 Using IngestStation

To record a feed:

1. Select the channel window where you want to record the feed.

2. Click

Toggle Mode to switch the channel to feed mode.

The icon changes to this:

3. Enter a name for the clip.

4. Enter a description for the clip, if you want to.

5. Select the router source from the Source drop-down list.

IngestStation switches the router source to the router destination for the onscreen video source, main record channel and backup record channel.

6. Click

Record.

The clip is added to the batch list. IngestStation switches the router source to

the router destination for the main recording channel record destination and

backup record channel destination. After a short time the clip begins

recording.

7. When you are done recording, click

Stop Record.

Recording stops and the clip status changes to Done.

44 Digital News Production

Page 47

Linking Clips to NewsQ Pro Placeholders

Linking Clips to NewsQ Pro Placeholders

If you are using NewsQ Pro for playout, you can link clips you record with

IngestStation to placeholders in NewsQ Pro. You can link clips for both the

VTR Mode and Feed Mode using NewsQ Pro’s Assignment List Manager. In

VTR Mode, you can link a placeholder to any of the individual clips in the batch

list. In Feed Mode, you link the placeholder to the entire feed, and for playout,

you’ll need to jog/shuttle using NewsQ Pro to cue the piece accurately to the

start point.

Tour of the Assignment List Manager

The list of assignments shows each clip placeholder and its properties:

Column Description

Clip Name The name of the clip placeholder.

Duration The length of the clip.

Editorial

Duration

Category The category assigned to the clip; you can assign categories based on the editor

Type The type of story or sequence an editor needs to create: Voice Over (VO),

Description Brief description of the clip an editor needs to create.

Clip ID The clip ID, which is automatically defined when the placeholder is created.

Date The date the placeholder was created.

The duration of the clip set when the placeholder was created. This estimated

value will be changed later when media is associated with the placeholder.

to receive the assignment, for instance.

Sound on Tape (SOT), or other types set in News Q Pro’s SDB Server Options.

Digital News Production 45

Page 48

Chapter 4 Using IngestStation

Linking Clips

To link an ingested clip to a NewsQ Pro placeholder:

1. In VTR Mode, mark an In and Out point to create a clip; in Feed Mode, select

your feed source.

2. In the left pane of IngestStation, click

The Assignment List Manager opens.

3. Select a placeholder to link to and click

The placeholder name and description fill in on IngestStation.

4. In VTR Mode, click

The ingested clip or feed is now associated with the NewsQ Pro placeholder.

Add Clip to Batch List; in Feed Mode, click Record.

Creating New Placeholders

If you need to, you can create additional placeholders for clips you want to link

to NewsQ Pro.

To create a new placeholder for a clip:

1. Click

New.

The New Clip Entry window appears:

Assignment List Manager.

OK.

46 Digital News Production

Page 49

Creating New Placeholders

2. Enter the clip information:

Clip Name — Enter a name for the placeholder. The name identifies the

placeholder in your Assignment List Manager, the Assignment List

Plug-in on the ENPS system, and the NewsQ Pro playlist.

- Story Type — Select a Story Type from the drop-down menu. Story types

are set in the NewsQ Pro application in SDB Server Options. Default story

types are SOT (Sound on Tape) or VO (Voice Over). You can also leave

this field blank.

Category — Select a category from the drop-down menu. The category

determines who receives the placeholder as an assignment. Selecting

makes the placeholder accessible to all editors who select

Assignment List Manager.

Editorial Duration — If desired, enter an estimated duration for the story

or select one from the drop-down list. Once the clip is created the duration

is automatically adjusted to the clip length. The editor can also enter an

editorial duration that is less than the clip length, which is sent back to the

NCS for show timing.

-

Description — Enter a description for the placeholder to help identify the

clip you need to create.

ALL in their

ALL

Protected — Check this box to prevent the clip from being deleted from

the database.

Being Edited — Check this box to show that the clip for a placeholder is

being edited. This field allows editors to easily see that a clip is already

being worked on in another edit room.

3. Click OK.

The Clip ID and Date are automatically set when you create the placeholder.

Digital News Production 47

Page 50

Chapter 4 Using IngestStation

48 Digital News Production

Page 51

Appendix

A

The IngestStation Keyboard

This appendix lists all of the keyboard functions that control IngestStation,

including key combinations using the Control keys.

Digital News Production 49

Page 52

Appendix The IngestStation Keyboard

Icon Key Name Function

F12 Record Starts recording the clips in the batch list or the feed

Ctrl + Q Eject Ejects tape from tape deck.

W Play Plays the tape or feed.

E Rewind Rewinds the tape or feed.

R Fast Forward Fast Forwards the tape or feed.

I Mark In Marks an In point.

Ctrl + I Go to Mark In Moves to the Mark In point.

O Mark Out Marks an Out point.

from the router source.

Ctrl + O Go to Mark Out Moves to the Mark Out point.

P Clear Mark In Clears the In point.

[ Clear Mark Out Clears the Out point.

A Back 1 Frame Moves cursor one frame back on the Timeline.

50 Digital News Production

Page 53

Icon Key Name Function

S Forward 1 Frame Moves cursor one frame forward on the Timeline.

D Back 10 Frames Moves cursor 10 frames back on the Timeline.

F Forward 10 Frames Moves cursor 10 frames forward on the Timeline.

C Add Clip to Batch List Adds marked clip to batch list.

Space Bar Stop Toggles between recording and stopping recording.

Digital News Production 51

Page 54

Appendix The IngestStation Keyboard

52 Digital News Production

Page 55

Index

A

Assignment List Manager 45

B

batch list

creating 37

importing EDL 40

rearranging 41

C

channel

columns 18, 20

configuration 31

window toolbar 17

clip record area 19

clips

linking in NewsQ Pro 45, 46

recording to server 42

configuration

channels 31

IngestStation 29

Media Server 28

M-Series iVDR 28

NewsQ Pro 33

Profile Media Server 28

recording settings 29

router 30

controlling a VTR with IngestStation 38

creating

batch list 37

new placeholders 46

D

description of IngestStation 14

E

EDL, importing into IngestStation 40

F

Feed Mode

channel columns 20

description of 20

feed record area 21

recording 43

feed record area 21

G

guidelines, safety 7

H

handles, adding 36

hardware, installing 24

Digital News Production 53

Page 56

Index

I

importing EDL 40

IngestStation

configuring 29

controlling a VTR 38

description of 14

Feed Mode 20

importing EDL 40

installing

hardware 24

software 24

kit contents 15

linking clips to NewsQ Pro place-

holders 45

recording clips 42

software license 25

system requirements 15

VTR Mode 18

windows 16

installation

hardware 24

software 24

K

keyboard, description of keys 50

kit, IngestStation 15

L

linking clips in NewsQ Pro 46

M

Mark Points

description 39

setting 39

Media Server

configuring 28

recording clips 42

M-Series iVDR, configuring for Ingest-

Station 28

N

NewsQ Pro

Assignment List Manager 45

configuring for IngestStation 33

creating new placeholders 46

linking clips 46

linking clips to placeholders 45

O

organizing clips 41

P

PC requirements for IngestStation 15

placeholders

creating 46

linking clips to 45

precautions 7, 8

product support 5

Profile Media Server, configuring 28

54 Digital News Production

Page 57

Index

R

rearranging batch list 41

recording

clips 42

clips from VTR tape 36

feed 43

recording settings, configuring 29

router, configuring for IngestStation 30

S

safety guidelines 7

service safety 9

setting Mark Points 39

setting up Media Server 28

software

installation 24

license number 25

support 5

system requirements 15

T

technical support 5

toolbar, channel window 17

W

windows in IngestStation 16

V

VTR Mode

adding handles 36

channel columns 18

clip record area 19

controlling VTR 38

creating batch list 37

description of 18

VTR, recording from 36

Digital News Production 55

Page 58

Index

56 Digital News Production

Loading...

Loading...