Page 1

Ignite

LIVE PRODUCTION CONTROL SYSTEM

SDC/HDC Robotic Camera

Instruction Manual

071849200

SEPTEMBER 2006

Page 2

Affiliate with the N.V. KEMA in The Netherlands

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley, Inc.

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

10 Presidential Way

rd

3

Floor, Suite 300

Woburn, MA 01801

United States

Nederland B.V.

4800 RP BREDA

The Netherlands

Technopole Brest Iroise

CS 73808

29238 Brest Cedex 3

France

7140 Baymeadows Way

Suite 101

Jacksonville, FL 32256

United States

Weiterstadt, Germany

Brunnenweg 9

D-64331 Weiterstadt

Germany

17 rue du Petit Albi-BP 8244

95801 Cergy Pontoise

Cergy, France

Rennes, France

Rue du Clos Courtel

Cesson-Sevigne, Cedex

France

2300 South Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope:

The design, manufacture and support of video hardware and software products and

related systems.

This Certificate is valid until: June 14, 2009

This Certificate is valid as of: August 30, 2006

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms

And Conditions For Quality And Environmental Management Systems Certifications.

Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 073004

Accredited By:

ANAB

Page 3

Ignite

LIVE PRODUCTION CONTROL SYSTEM

SDC/HDC Robotic Camera

Instruction Manual

071849200

SEPTEMBER 2006

Page 4

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Grass Valley. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 95959-7900

USA

www.thomsongrassvalley.com

Software Downloads — Software updates, drivers, and patches can be down-

loaded.

4 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 5

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Summary

Regulatory Notices

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Standard Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Other Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terms in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 1 — Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Additional Equipment (Required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SHOT Director Robotics/Camera Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ethernet Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optional Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Robotic Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Robotic Camera and SHOT Director . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Robotic Camera and Ignite Automated Production Control System . . . . . . . . 21

Section 2 — Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Robotic Pan/Tilt Head Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Prompter Adapter Plate (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Camera/Lens Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Prompter (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Robotic Pan/Tilt Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Camera/Lens Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Prompter (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ignite SDC/HDC Robotic Camera Instruction Manual 5

Page 6

Contents

Section 3 — Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Section 4 — Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Appendix A — SD (NTSC) Camera Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Menu Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Use Mode Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Halogen mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Fluorescent mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Outdoor mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

User mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Setting by Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Menu Item Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Changing the Language Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Submenus Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Brightness Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Color Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

G/L, Color Bar Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sharpness (DTL) Setting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Other Settings Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

User Mode Submenus Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Iris, Shutter, Gain Settings Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Color Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

G/L, Color Bar Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Detail Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Color Matrix Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Other Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

to Return to Initial Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Appendix B — SD (PAL) Camera Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Menu Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Use Mode Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Halogen mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fluorescent mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Outdoor mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

User mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Setting by Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Menu Item Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Submenus Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Brightness Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Color Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

G/L Adjustment Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Sharpness (DTL) Setting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Other Settings Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

User Mode Submenus Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 7

Contents

Iris, Shutter, Gain Settings Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Color Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

G/L Adjustment Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Detail Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Color Matrix Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Other Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Initial Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Appendix C — HD Camera Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Menu Selections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Setting by Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Black Shading Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Pedestal, Gamma Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Flare Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Knee, White Clip Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

R/B Gain Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Detail Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Skin Tone Detail Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Gain, Auto Iris Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Super Gain Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Frame Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Matrix Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Color Correction Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Setting Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Mode Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Shutter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Gen-Lock Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Pix Defect Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Protocol Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Camera ID Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

File Operation Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Time Code Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Shooting Mode Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

White Balance Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Black Balance Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Gen-lock Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Appendix D — Robotic (Pan/Tilt Head) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Default and Recommended Camera ID and IP addresses . . . . . . . . . . . . . . . . . . 108

Setting Soft Stops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Ignite SDC/HDC Robotic Camera Instruction Manual 7

Page 8

Contents

8 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 9

Preface

About This Manual

This manual is for technical personnel responsible for installation, setup,

and operation of an Ignite SDC/HDC robotic camera.

This manual is for camera models SDC-3100P/-3110P/-3100N/-3110N and

HDC-3200/-3210/-3300/-3310.

Standard Documentation

The standard Ignite SDC/HDC robotic camera documentation set comprises:

• SDC/HDC Robotic Camera Instruction Manual

• JSC-2300 SHOT Director™ Robotics/Camera Controller Instruction

Manual

Other Documentation

The flexible design of the Ignite SDC/HDC robotic camera allows operation in stand-alone manual control (ProAV) environments, or as an integrated component of a fully automated Ignite Live Production Control

System. This manual provides information to install and operate the

camera in either environment. For specific details about Ignite systems,

refer to the Ignite Live Production Control System documentation listed

below:

• Installation Planning Guide

• Installation and Service Manual

•User Manual

• Release Notes

Note The Ignite Live Production Control System documentation describes periph-

eral components as they relate to the Ignite system. For any other peripheral

component information, refer to the respective support documentation.

Ignite SDC/HDC Robotic Camera Instruction Manual 9

Page 10

Preface

10 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 11

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

Terms on the Product

The following terms may appear on the product:

DANGER — A personal injury hazard is immediately accessible as you read

the marking.

WARNING — A personal injury hazard exists but is not immediately acces-

sible as you read the marking.

CAUTION — A hazard to property, product, and other equipment is present.

Ignite SDC/HDC Robotic Camera Instruction Manual 11

Page 12

Safety Summary

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground prior to making any other equipment

connections.

Warnings

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or

replacing components.

Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

Use proper power cord — Use only the power cord supplied or specified for

this product.

Ground product — Connect the grounding conductor of the power cord to

earth ground.

12 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 13

Cautions

Safety Summary

Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

Use only in dry environment — Do not operate in wet or damp conditions.

Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

High leakage current may be present — Earth connection of product is essential

before connecting power.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

Use correct voltage setting — If this product lacks auto-ranging power sup-

plies, before applying power ensure that the each power supply is set to

match the power source.

Do not operate with suspected equipment failure — If you suspect product damage

or equipment failure, have the equipment inspected by qualified service

personnel.

Ensure mains disconnect — If mains switch is not provided, the power cord(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly — Route power cords and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Do not disassemble the camera — There are no user-serviceable parts inside.

Refer any servicing to qualified service personnel.

Do not abuse camera — Handle the camera with care. Avoid striking, shaking,

etc. The camera contains sensitive components which could be damaged by

improper handling or storage.

Ignite SDC/HDC Robotic Camera Instruction Manual 13

Page 14

Safety Summary

Cap the lens when camera is not in use — Protect the precision made lens by

placing the lens cap over the lens when the camera is not in use. If the lens

is not installed, protect the surface of the prism by placing the body cap into

the lens mount hole. Use a mild blower or lens cleaning tissue designed for

coated lenses, to clean the surface of the lens or prism in the event that it

should become dirty. Do not touch the surface of the lens or prism.

Do not aim the camera toward the sun — Even with power off, the camera optics

could be damaged. Use caution when operating the camera in the vicinity

of spot lights or bright lights, as well as light reflecting objects and surfaces.

Do not use the camera in high temperatures or high humidity environments — Use the

camera in an environment where the temperature is within 32 °F (0 °C) to

+104 °F (+40 °C), and the relative humidity is within 30% to 90% (no condensation).

Do not leave the camera turned on when not in use.

Do not turn camera power on and off repeatedly.

Do not block the ventilation slots — Internal heat buildup can cause a fire.

14 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 15

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

For products that comply with Class A. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

Ignite SDC/HDC Robotic Camera Instruction Manual 15

Page 16

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

Certification

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

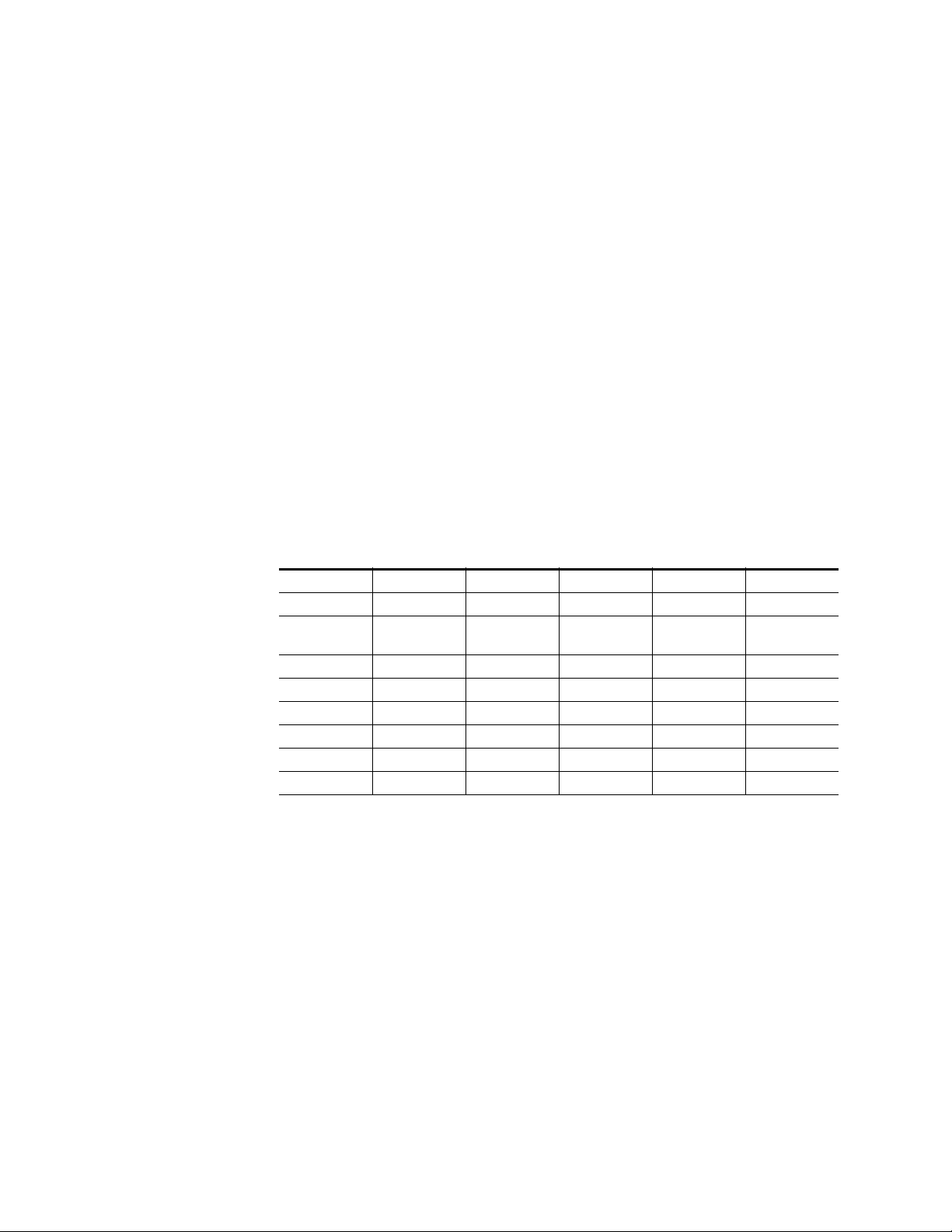

Category Standard Designed/tested for compliance with:

Safety UL1950 Safety of Information Technology Equipment, including Electrical Busi-

ness Equipment (Second edition, 1993).

IEC 950 Safety of Information Technology Equipment, including Electrical Busi-

ness Equipment (Second edition, 1991).

CAN/CSA C22.2, No. 950-93 Safety of Information Technology Equipment, including Electrical Busi-

ness Equipment.

EN60950 Safety of Information Technology Equipment, including Electrical Busi-

ness Equipment.

16 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 17

Overview

Introduction

Section 1

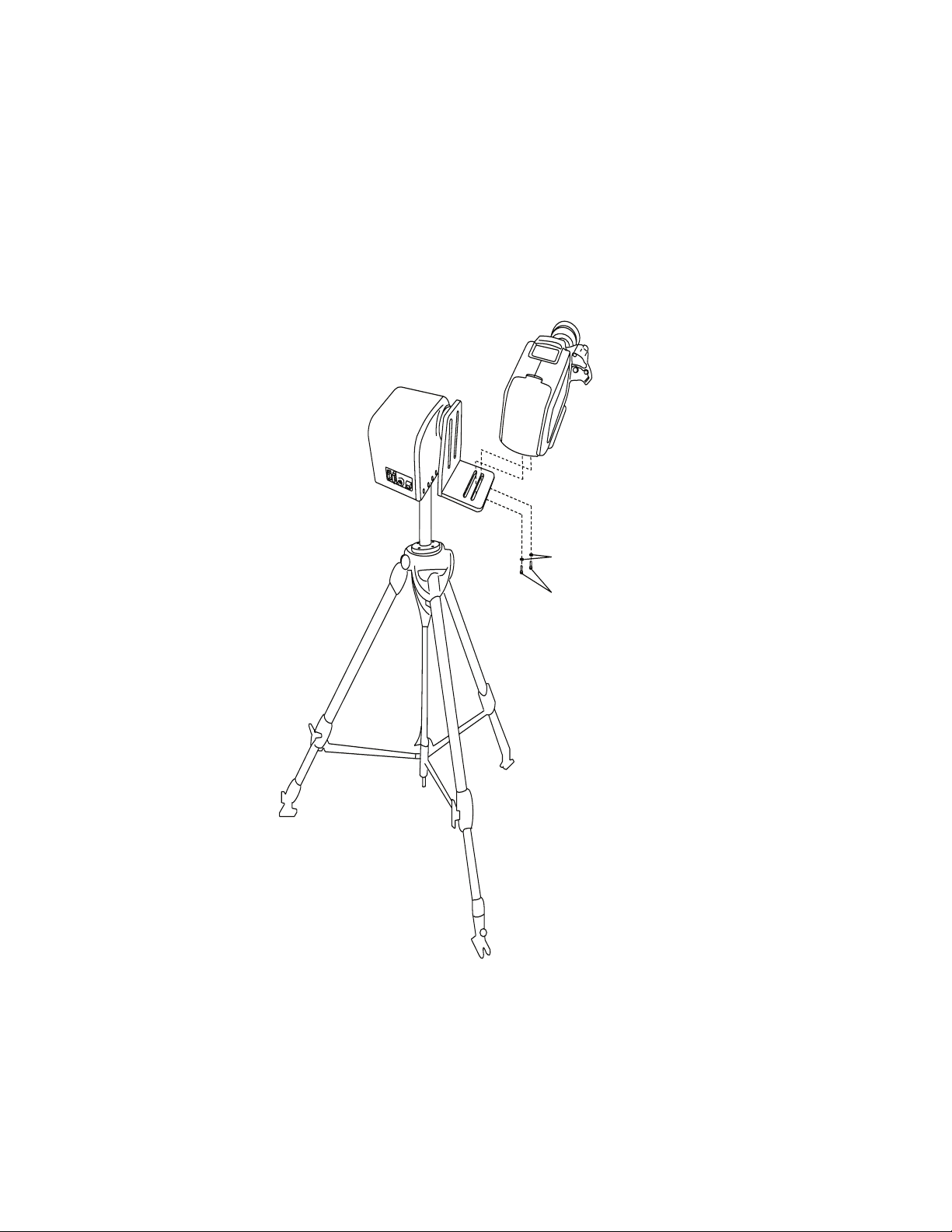

The Ignite SDC/HDC robotic camera (Figure 1) is a compact, fully-integrated, remote-control camera designed for worldwide Broadcast and

high-end ProAV applications.

Figure 1. Ignite SDC/HDC Robotic Camera

8492_01_r0

Both SDC and HDC models feature internet protocol (IP) control, converged pan/tilt/focus/zoom operation for seamless on-air movements,

fast pan and tilt speed (90°/s maximum), 300 location presets, 600 seconds

of movement recalls, super-quiet operation <30 dBm @ 1 m, integrated

dual-color light-emitting diode (LED) tally light, optional JSC-2300 SHOT

Director™ robotics/camera controller, optional 17” high-brightness

through-the-lens (TTL) prompter assembly, and optional inverted

mounting for ceiling and track installations.

The SDC (standard definition camera) model features three 2/3” interline,

supersensitive charge-coupled devices (CCD), switchable 4:3/16:9 aspect

ratio, serial digital interface (SDI) and analog composite video outputs, 850

lines of resolution, and 62 dB NTSC/61 dB PAL S/N ratio.

Ignite SDC/HDC Robotic Camera Instruction Manual 17

Page 18

Section 1 — Overview

The HDC (high definition camera) model features three high-sensitivity

2/3” interline transfer - charge-coupled devices (IT-CCD), switchable

720p/1080i support for global HD formats (1080/60i/59.94i/50i/30p/

25p/24p and 720/60p/59.94p/50p), multi-mode (NTSC/PAL) support,

sensitivity of F10.0 at 2,000 lux, and S/N ratio of 54 dB.

Hardware Description

Note To order SDC/HDC Robotic Camera hardware and accessories listed in this

manual, refer to Contacting Grass Valley on page 4.

SDC/HDC robotic cameras contain a camera block with integrated tally

light, mounted on a robotic pan/tilt head and pedestal mount. HDC

models come with either premium or standard lens. A TTL prompter is also

provided with select SDC/HDC models.

Ignite SDC/HDC robotic camera models and their features are listed in

Tabl e 1.

Table 1. SDC/HDC Robotic Camera Models

Model Definition Format Lens Prompter Tally

SDC-3100N Standard NTSC Standard Not Included Yes

SDC-3110N Standard NTSC Standard

SDC-3100P Standard PAL Standard Not Included Yes

SDC-3110P Standard PAL Standard TTL Yes

HDC-3200 High-Definition Multi Standard Not Included Yes

HDC-3210 High-Definition Multi Standard TTL Yes

HDC-3300 High-Definition Multi Premium Not Included Yes

HDC-3310 High-Definition Multi Premium TTL Yes

Additional Equipment (Required)

SHOT Director Robotics/Camera Controller

The JSC-2300 SHOT Director™ robotics/camera controller is a unique,

multiple-camera control device combining pan/tilt and CCU control. The

SHOT Director provides professional-quality, fingertip control of up to 16

Ignite SDC/HDC robotic cameras.

Through-The-

Lens (TTL)

Yes

Note At least one JSC-2300 SHOT Director™ robotics/camera controller is

required to operate up to 16 cameras.

18 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 19

Ethernet Hub

An Ethernet hub, (10/100/1000 Base TX, auto-sensing) is required to

connect up to 16 Ignite SDC/HDC robotic cameras to a JSC-2300 SHOT

Director robotics/camera controller.

Optional Mounting Hardware

The following optional mounting hardware is recommended for use with

Ignite SDC/HDC robotic cameras.

•Tripod

•Tripod mounting plate

• Wall mount

• Environmental dome

Optional Mounting Hardware

Functional Description

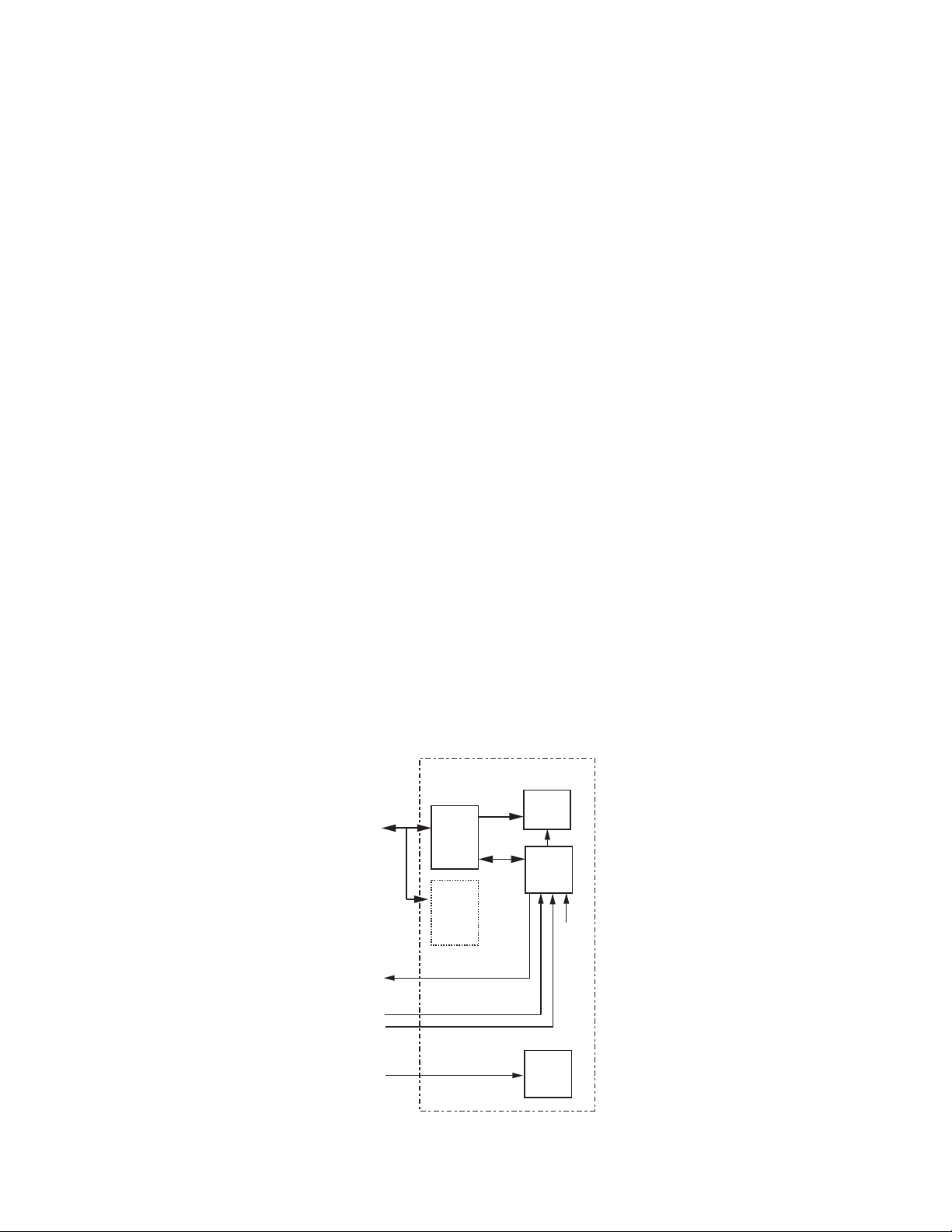

Robotic Camera

The SDC/HDC robotic camera receives TCP/IP control inputs (pan/tilt/

zoom/focus) from the JSC-2300 SHOT Director robotics/camera controller

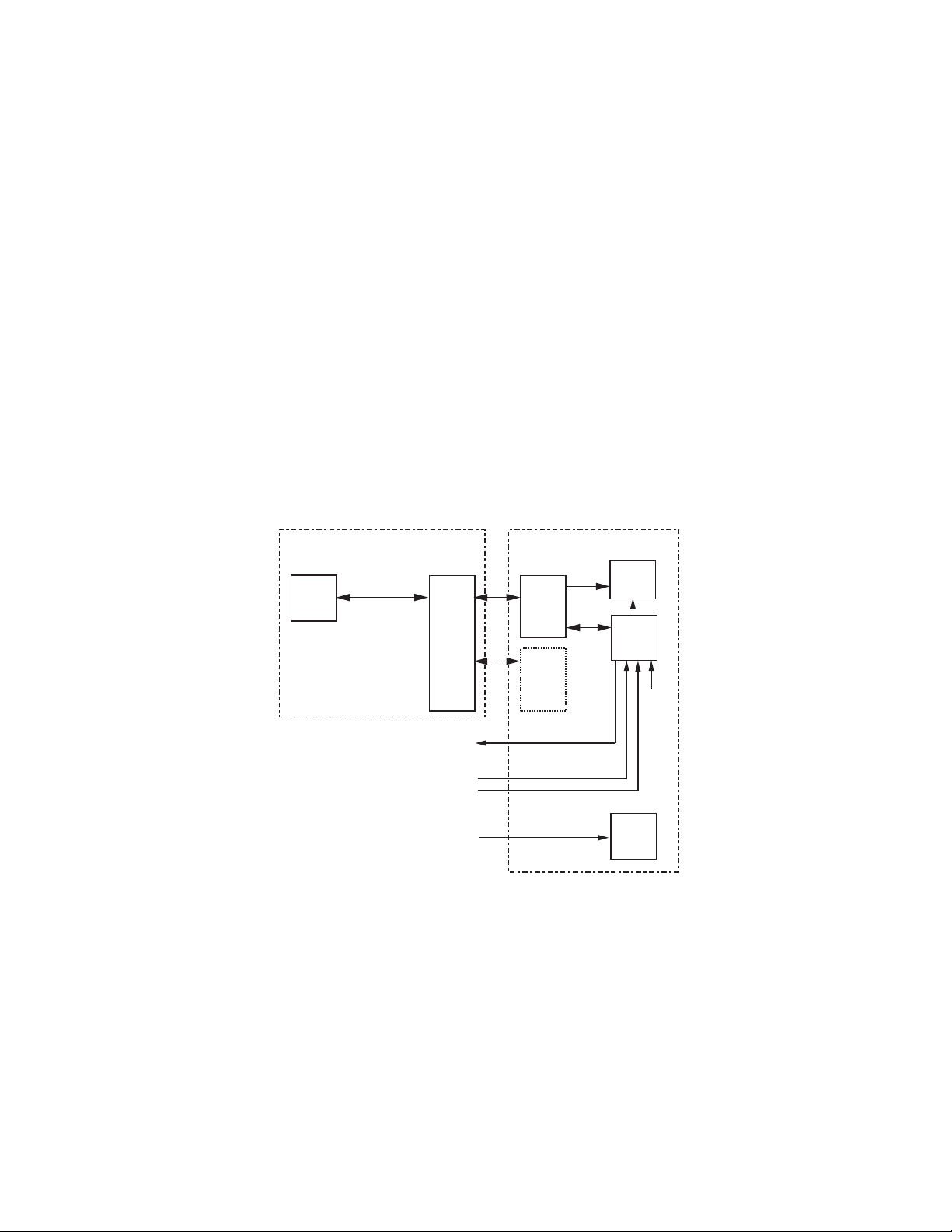

(Figure 2).

Figure 2. SDC/HDC Robotic Camera Functional Block Diagram

SDC/HDC

ROBOTIC CAMERA

LENS

ZOOM,

JSC-2300

SHOT DIRECTOR

ROBOTIC/CAMERA

CONTROL

VIDEO

EQUIPMENT

TCP/IP

PAN/TILT

ROBOTIC

HEAD

UP TO 15

ADDED

CAMERAS

SDI VIDEO

FOCUS

CTRL,

PWR

SDC/HDC

CAMERA

BLOCK

IRIS

G/L, SYNC

(FROM

FACILITY)

TALLY

CONTROL

SCRIPT

SERVER

RED TALLY (ON AIR)

AMBER TALLY (NEXT CAM)

VGA

PROMPTER

8492_02_r0

Ignite SDC/HDC Robotic Camera Instruction Manual 19

Page 20

Section 1 — Overview

Robotic Camera and SHOT Director

The robotic head processes the pan and tilt inputs and moves the camera to

the commanded location. It passes zoom and focus commands to the lens

assembly. It also provides a communication path between the camera head

and SHOT Director (for configuration and status monitoring), and provides 12 V dc to power the camera block.

The camera block receives 12 V dc power from the robotic head, tally (red

and amber) dry contact control from a tally controller, and facility supplied

gen-lock (sync). The camera provides iris control to the lens assembly,

status and configuration menu access to the SHOT Director (through the

robotic head assembly), and produces SDI video out to station switching

and processing equipment.

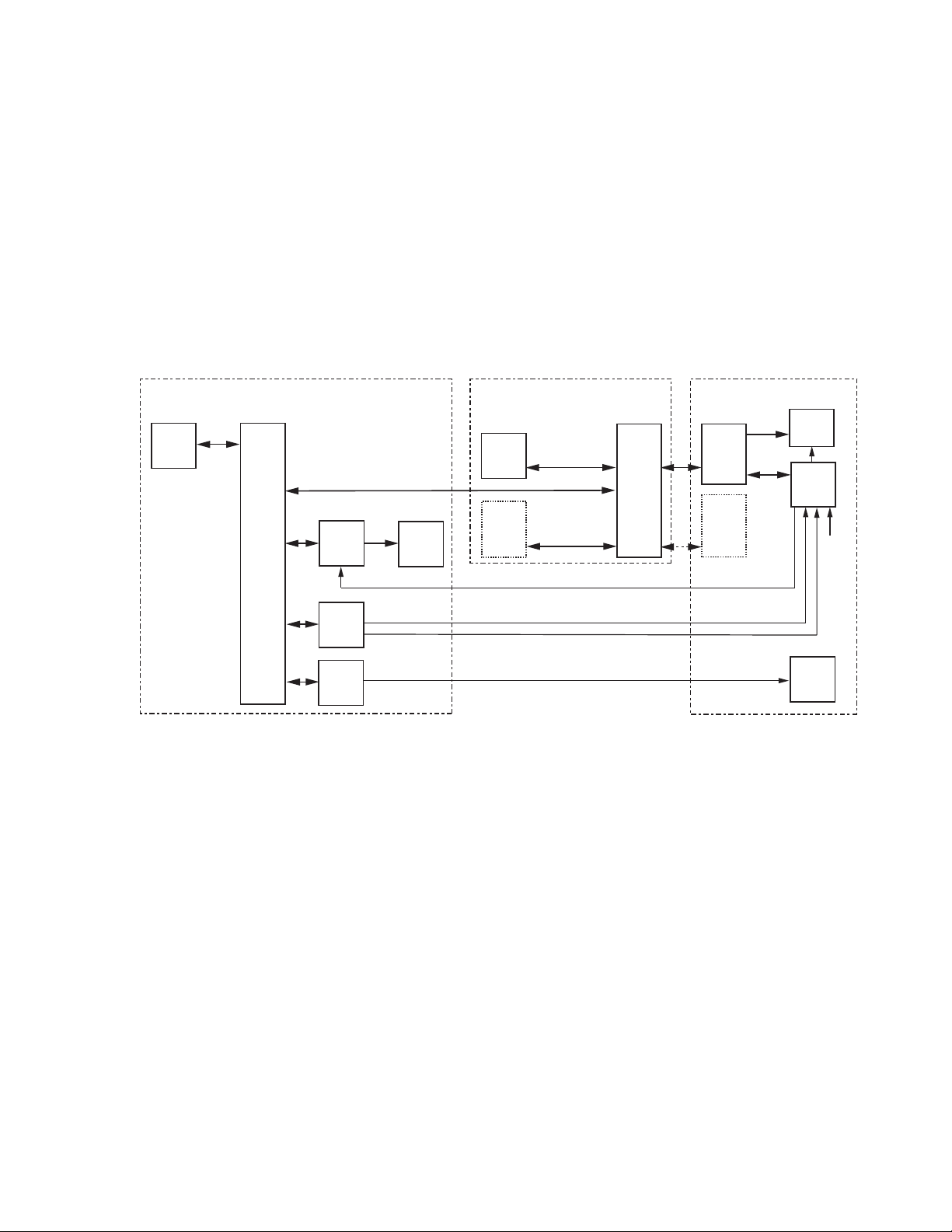

Robotic camera control requires connection to a JSC-2300 SHOT Director

robotics/camera controller through a network hub. (Figure 3)

Figure 3. SDC/HDC Robotic Camera and JSC-2300 SHOT Director Functional Block Diagram

SHOT DIRECTOR

ROBOTIC/CAMERA

CONTRO L

JSC-2300

SHOT

DIRECTOR

CAM SETTINGS MENU

CAM TRIG,

PRESETS,

MANUAL

PAN/TILT/

ZOOM/FOCUS

SUBNET

HUB

VIDEO

EQUIPMENT

TAL LY

CONTRO L

SDC/HDC

ROBOTIC CAMERA

ZOOM,

PAN/TILT

ROBOTIC

HEAD

UP TO 15

ADDED

CAMERAS

(16 TOTAL)

SDI VIDEO

RED TALLY (ON AIR)

AMBER TALLY (NEXT CAM)

FOCUS

CTRL,

PWR

LENS

SDC/HDC

CAMERA

BLOCK

IRIS

G/L, SYNC

(FROM

FACILITY)

SCRIPT

SERVER

VGA

PROMPTER

8492_03_r0

The SHOT Director can control up to 16 cameras. It provides the camera

trigger and preset/manual control commands (pan/tilt/zoom/focus) to

the robotic head. Camera presets are created and stored in the SHOT

Director. You can also access and make configuration changes to the

camera block settings menu with the SHOT Director.

20 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 21

Functional Description

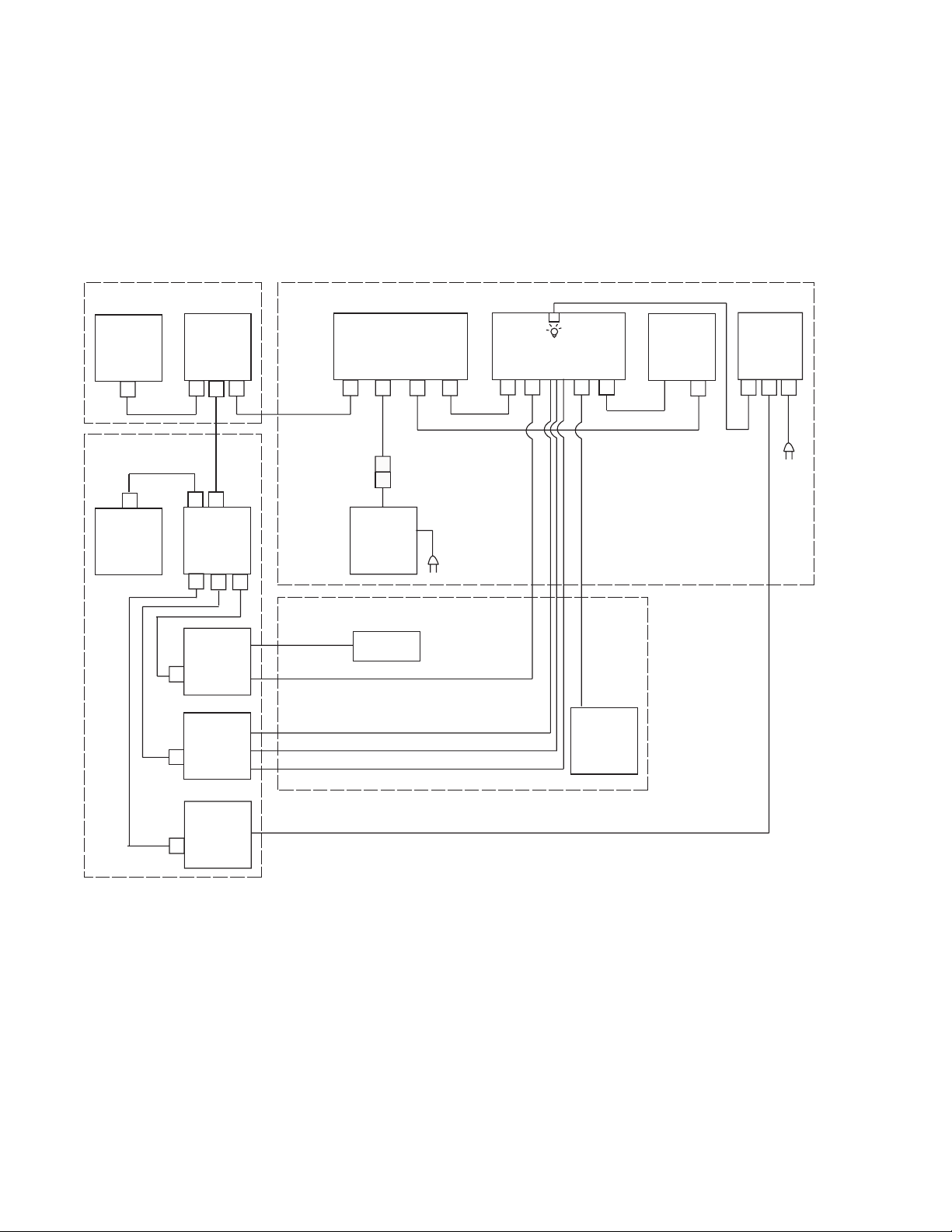

Robotic Camera and Ignite Automated Production Control System

The SDC/HDC robotic camera was designed to operate as an integrated

part of an Ignite automated production control system. (Figure 4).

The Ignite system provides TCP/IP automation control to the JSC-2300

SHOT Director robotics/camera controller, video switcher, tally controller,

and optional Script Viewer devices.

Note Up to six SHOT Directors and sixteen cameras can be used in an Ignite

system.

Figure 4. Ignite SDC/HDC Robotic Camera Functional Block Diagram

IGNITE

AUTOMATED PRODUCTION CONTROL SYSTEM

(COMPLETE SYSTEM NOT SHOWN)

TCP/IP

IGNITE

CPU

CONTRO L

NETWORK

HUB

(16 PORT)

CONTROL, MOVE CAMERA,

PRESET DATA, STATUS

KAYAK

VIDEO

SWITCHER

VIDEO

SDI VIDEO

VIDEO

MONITOR

SHOT DIRECTOR

ROBOTIC/CAMERA

CONTRO L

JSC-2300

SHOT

DIRECTOR

UP TO 5

ADDED

SHOT

DIRECTORS

(6 TOTAL)

CAM SETTINGS MENU

CAM SETTINGS MENU

CAM TRIG, PRESETS,

MANUAL PAN/TILT/

ZOOM/FOCUS

CAM TRIG, PRESETS,

MANUAL PAN/TILT/

ZOOM/FOCUS

SUBNET

HUB

SDC/HDC

ROBOTIC CAMERA

PAN/TILT

ROBOTIC

HEAD

UP TO 15

ADDED

CAMERAS

(16 TOTAL)

SDI VIDEO

ZOOM,

FOCUS

CTRL,

PWR

LENS

SDC/HDC

CAMERA

BLOCK

IRIS

G/L, SYNC

(FROM

FACILITY)

TALLY

CONTRO L

(GPI DRY

CONTACT )

SCRIPT

VIEWER

(OPTIONAL)

RED TALLY (ON AIR)

AMBER TALLY (NEXT CAM)

VGA

RED TALLY (ON AIR)

AMBER TALLY (NEXT CAM)

VGA

PROMPTER

8492_04_r0

Ignite SDC/HDC Robotic Camera Instruction Manual 21

Page 22

Section 1 — Overview

22 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 23

Installation

Unpacking

Check all parts received against the packing list enclosed with your shipment, and examine the equipment for any shipping damage. Immediately

report any missing or damaged items to the carrier and to your Grass

Valley Service Representative (See Contacting Grass Valley on page 4).

Keep all manuals supplied with your equipment. You will need them to

complete the installation procedures.

Installation Procedures

Section 2

General

Before you can use your Ignite SDC/HDC robotic camera, you must:

1. Mount the robotic assembly onto a tripod (or other mounting surface).

2. Install the optional prompter onto the robotic pan/tilt head assembly.

3. Install the camera/lens assembly onto the prompter, or directly onto

the robotic pan/tilt head (if the optional prompter was not purchased).

4. Connect cables.

Ignite SDC/HDC Robotic Camera Instruction Manual 23

Page 24

Section 2 — Installation

Robotic Pan/Tilt Head Assembly

Note Ignite SDC/HDC robotic cameras are suitable for inverted mounting.

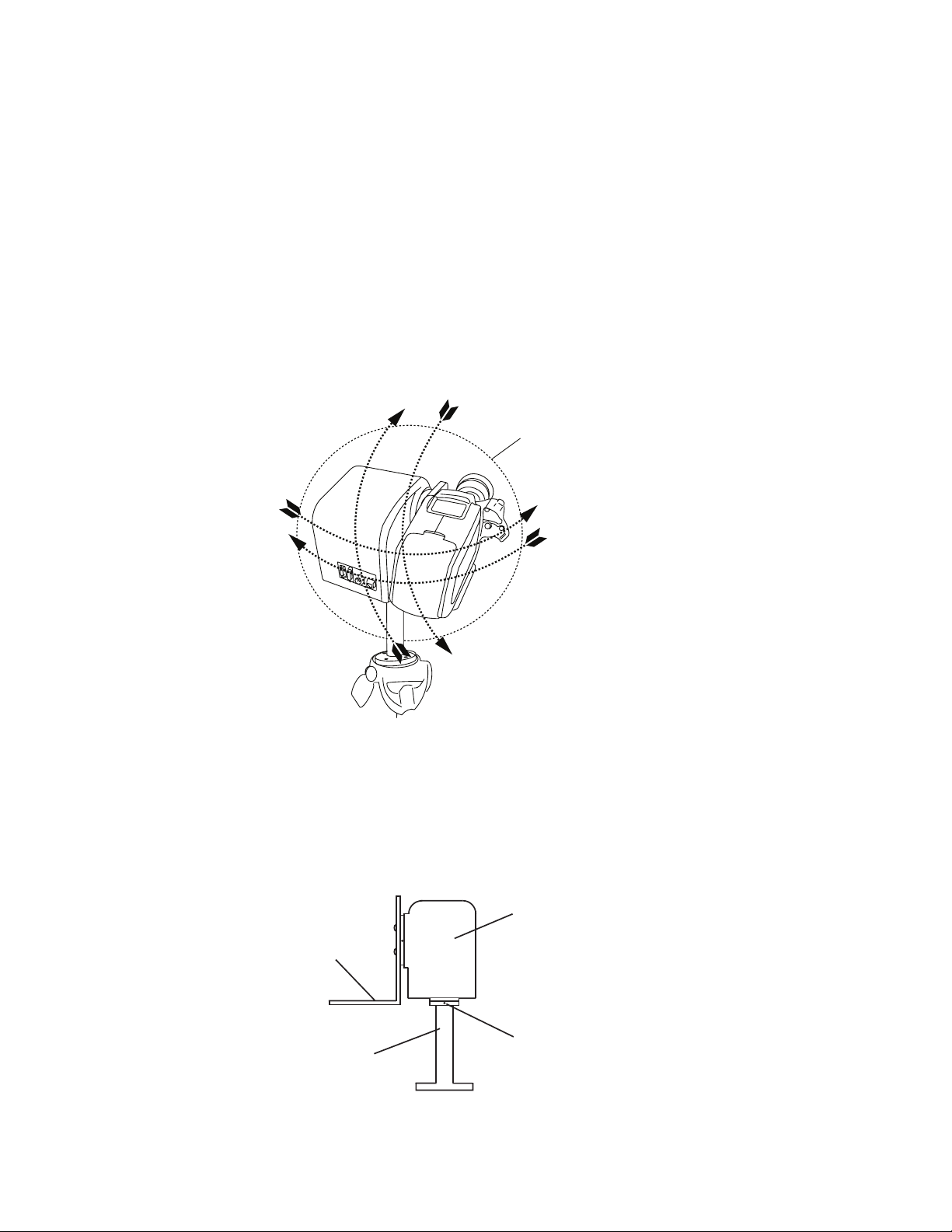

1. Check the selected camera location to ensure that there is enough

clearance (Figure 5) for the fully assembled camera, prompter, and

cables to pan and tilt without obstruction.

If necessary, you can limit pan and/or tilt movement by adjusting the

pan/tilt head soft stops via the SHOT Director controller. Refer to the

JSC-2300 SHOT Director Robotics/Camera Controller Instruction

Manual.

Figure 5. Clearance Diagram

Diameter: 24” (0.61 m)

48” (1.22 m) with prompter

8492_06_r0

2. On the stationary ring at the top of the pedestal mount (Figure 6), locate

the zero-degree (pan) position labeled FRONT. Point the FRONT label

in the direction that best reflects the center of travel in which the camera

will be used (usually the center of the room).

Figure 6. Robotic Pan/Tilt Head Assembly

Front

Robotic

pan/tilt

Camera mount

L-bracket

8” Pedestal

mount

head

Zero degree

(Pan)

reference

492_05_r0

24 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 25

Installation Procedures

CAUTION Ensure that the selected mounting surface and hardware can safely support

the weight of a fully assembled unit (approximately 55 lbs (29.95 kg)).

3. If ceiling/inverted mounting is required:

• Remove the L-bracket, rotate it 180 degrees, then re-attach it to the

robotic pan/tilt head.

• Attach a safety wire or chain, that can support the

weight of the fully assembled unit to one of the bolts in the pedestal

mount flange and secure the other end to a rigid part of the ceiling/

mounting location.

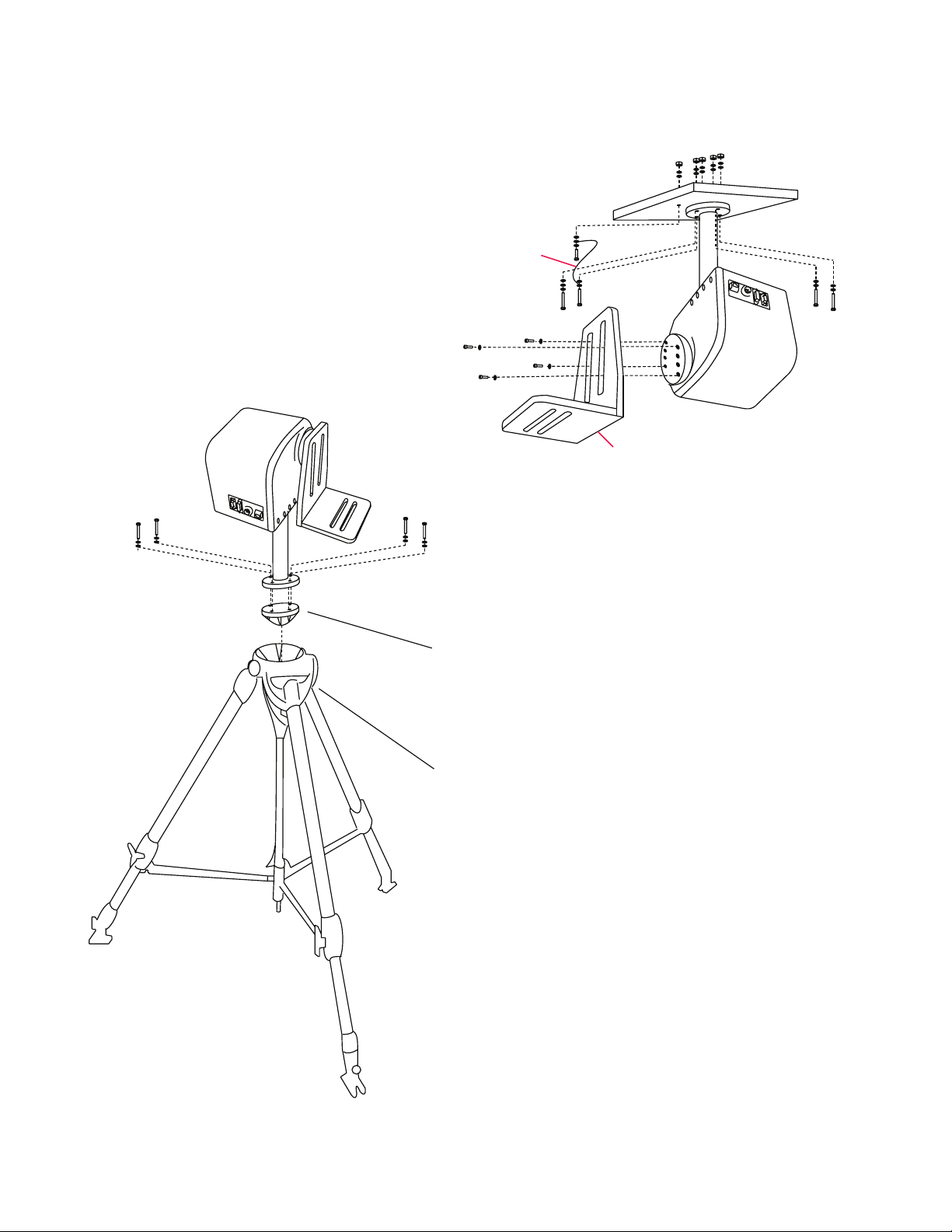

4. Attach the robotic pan/tilt head assembly to the selected mounting

location. Use the four mounting holes in the pedestal mount flange as

shown in Figure 7.

55 lb (29.95 kg)

Ignite SDC/HDC Robotic Camera Instruction Manual 25

Page 26

Section 2 — Installation

Safety Wire

L-bracket must be inverted

Figure 7. Robotic Pan/Tilt Head Mounting

Ceiling Mount

Safety Wire

Tripod Mount

L-bracket must be inverted

Tripod

adapter

plate

Tripod

26 Ignite SDC/HDC Robotic Camera Instruction Manual

8492_07_r0

Page 27

Prompter Adapter Plate (Optional)

Note The prompter assembly is supported by a mounting plate that sits beneath

the camera assembly.

1. Attach camera adapter plate to prompter adapter plate (Figure 8).

Figure 8. Prompter and Camera Adapter Plates

Camera

adapter

Mounting

plate

rods

plate

Front

Installation Procedures

Prompter

adapter

plate

8492_08_r0

2. Attach the main body of the prompter adapter plate to the robotic pan/

tilt head assembly L-bracket so that the T-bolt end of the two rods

attached to the mounting plate extend to the front of the robotic pan/

tilt head assembly.

Ignite SDC/HDC Robotic Camera Instruction Manual 27

Page 28

Section 2 — Installation

Camera/Lens Assembly

1. Ensure camera/lens assembly is oriented toward the front of the pan/

tilt head assembly.

2. Mount the camera/lens assembly to the camera adapter plate (if

installing prompter), or directly to the robotic pan/tilt head assembly

L-bracket with two 3/8-16 x 0.5” socket head screws.

Figure 9. Camera/Lens Assembly Mounting

Flat washers

Camera mounting screws

(3/8-16 x 0.5” socket head)

8492_70_r0

28 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 29

Prompter (Optional)

1. Slide extrusion slots onto mounting plate rods and rotate rods to

tighten (Figure 10). Mounting plate rods slide into the back of the

extrusion where two slots provide alternative vertical positions for the

prompter. The rods attach to the extrusion using a T-bolt that is

tightened by turning the rod.

Figure 10. Extrusion

Installation Procedures

92_09_r0

2. Rotate the drop plates to the orientation shown in Figure 11.

Figure 11. Drop Plates

92_10_r0

3. Attach drop plates to extrusion and tighten red fixing screws. A choice

of mounting holes are provided to raise and lower the monitor in

relation to the hood to prevent the outer edge of the TFT screen from

appearing in the shot.

4. Attach the hood to the extrusion and rotate hood columns to tighten.

5. Move prompter unit back on the support rods until the lens is nearly

touching the glass and lock in position with small locking levers.

6. Slide the whole prompter assembly back on the mounting plate rods to

obtain best possible balance of the pan/tilt L-bracket. Attach

counterweights if necessary.

Ignite SDC/HDC Robotic Camera Instruction Manual 29

Page 30

Section 2 — Installation

System Interconnection

Use Figure 12 and the following steps to connect the camera, lens, pan/tilt

head, and prompter assemblies to a JSC 2300 SHOT Director controller and

an Ignite system. If you are not connecting to an Ignite system use the following steps and Figure 13.

Figure 12. Interconnect (with Ignite) Diagram

SHOT

DIRECTOR

SHOT

DIRECTOR

CAT-5

IP CONTROL

P/O IGNITE LIVE

PRODUCTION CONTROL

IP CONTROL

SYSTEM

CAT-5

IGNITE

CPU

IP CONTROL

IP CONTROL

IP CONTROL

SUBNET

HUB

CAT-5

IP CONTROL

CAT-5

ENET HUB

CAT-5

KAYAK

VIDEO

SWITCHER

CAT-5

TALLY

CTRLR

CAT-5

CAT-5

CAT-5

CAT-5

AUX

OUT

VIDEO

PROG

COM

PREV

SDC/HDC ROBOTIC CAMERA

DB15

CAM

CTRL/PWR

CAMERA

BLOCK

HD15/

SCSI-50

PAN/TILT

HEAD

CAT-5

IP CONTROL

CAT-5

FACILITY PROVIDED

EQUIPMENT

VIDEO

VIDEO

RED (PROGRAM) TALLY

TALLY COMMON

AMBER (PREVIEW) TALLY

AMP CIRC

CAT-5

POWER

HARD

48 VDC PWR

SUPPLY

VIDEO

MONITOR

DB9

ZOOM/FOCUS

DIN8

WIRED

RED TALLY OPTICAL SENSOR

VID OUT

HARD

WRED

GEN-LOCK

GEN-LOCK

(FACILITY

PROVIDED)

G/L BNC

HIROSE CIRC

IRIS

ZOOM/FOCUS

LENS

HARD

WRED

HIROSE CIRC

PROMPTER

SENSOR IN

VGA IN

MAINS

POWER

SCRIPT

VIEWER

VGA

OUT

CAT-5

8492_11_r0

30 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 31

SHOT

DIRECTOR

SHOT

DIRECTOR

SUBNET

HUB

Figure 13. Interconnect (without Iignite System) Diagram

SDC/HDC ROBOTIC CAMERA

PAN/TILT

HEAD

CAMERA

BLOCK

System Interconnection

RED TALLY OPTICAL SENSOR

LENS

PROMPTER

CAT-5

IP CONTROL

DB9

DB15

CAM

CTRL/PWR

ZOOM/FOCUS

VIDEO

MONITOR

AMP CIRC

AUX

OUT

VIDEO

PROG

COM

PREV

VGA

OUT

CAT-5

POWER

HARD

WIRED

48 VDC PWR

SUPPLY

VIDEO

VIDEO

RED (PROGRAM) TALLY

TALLY COMMON

AMBER (PREVIEW) TALLY

DIN8

CAT-5

CAT-5

IP CONTROL

FACILITY PROVIDED

EQUIPMENT

VIDEO

SWITCH

TAL LY

CTRLR

SCRIPT

VIEWER

HD15/

SCSI-50

VID OUT

HARD

G/L BNC

WRED

GEN-LOCK

GEN-LOCK

(FACILITY

PROVIDED)

HIROSE CIRC

IRIS

ZOOM/FOCUS

HARD

WRED

HIROSE CIRC

VGA IN

SENSOR IN

MAINS

POWER

WARNING Ensure mains power is OFF before connecting or disconnecting any

cables, cords, or wires.

Robotic Pan/Tilt Head

1. Connect a CAT-5 cable (not supplied) between the pan/tilt head

assembly and the subnet hub.

2. Connect the zoom/focus cable hirose circular connector to the lens

assembly and the DB-9 connector to the pan/tilt head.

Camera/Lens Assembly

1. Connect the camera control and power harness from the camera block

to the pan/tilt head (DB15).

Ignite SDC/HDC Robotic Camera Instruction Manual 31

8492_11_r0

Page 32

Section 2 — Installation

Prompter (Optional)

2. Connect an SDI video cable (not supplied) from the camera block to a

studio monitor or video switcher (with studio monitor output).

3. If using a video switcher, connect genlock to the camera block.

4. Connect the Iris control cable from the lens assembly to the camera

block.

5. Connect the unterminated tally wires from the camera block to a tally

controller using 16AWG wire, or provide contact closure control. Tally

control wiring should not exceed 200’ (60.96 m).

1. Connect a VGA video cable (not supplied) between the prompter and

the script generator.

2. Attach the prompter tally optical sensor to the camera block tally light

cover.

Power

1. Connect the 48 V dc power cord to the pan/tilt head assembly

(Amphenol circular) and the 48 V dc power supply (DIN8). Then

connect the power supply to Mains power.

2. Attach the Mains power cord to the prompter.

32 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 33

Operation

Operating Procedure

Section 3

1. Turn on all equipment power.

WARNING Ensure personnel and obstacles are clear of the camera during power-up.

The robotic head will automatically rotate to the preset zero degree pan

and tilt location.

Note The camera robotics may make some noise for the first few hours of opera-

tion. This is due to a special type of grease that will seat into the gears to

provide long life lubrication of the mechanical components. The noise should

abate soon after the camera is put into operation.

2. Adjust the camera.

Use the SHOT Director to adjust the camera.

Refer to the JSC-2300 SHOT Director Robotics/Camera Controller

Instruction Manual for procedures and Appendix A-SD (NTSC) Camera

Block, Appendix B-SD (PAL) Camera Block, or Appendix C-HD Camera

Block for adjustment options.

You should adjust the following items the first time the camera is used.

a. Camera ID and IP address.

The pan/tilt head and JSC-2300 SHOT Director are factory set to

default IP addresses to allow the units to communicate initially. If

you are connecting multiple cameras, you will need to set each

camera to a unique ID and IP address using the JSC-2300 SHOT

Director. Refer to Appendix D-Robotic (Pan/Tilt Head) for default and

recommended IP addresses and camera IDs.

b. White balance adjustment.

This adjustment is needed when the camera is used for the first

time, after leaving it unused for a long time, or when the lighting

condition or brightness change.

Note After adjusting the white balance, re-adjustment is not needed under the

same conditions.

Ignite SDC/HDC Robotic Camera Instruction Manual 33

Page 34

Section 3 — Operation

c. Black balance adjustment.

This adjustment is needed when the camera is used for the first

time, after being unused for a long time, or when the ambient temperature changes significantly (i.e. seasonal changes).

Note After adjusting the black balance, re-adjustment is not needed under the

same conditions.

d. Flange back adjustment for zoom lens

This adjustment is used to set the focus range of the zoom lens from

maximum (telephoto) to wide angle.

Note This adjustment is performed at the factory and will typically not need to be

performed in the field, unless it is necessary to change the lens.

• Fully open the iris by shooting a dark object from a distance of

at least 6.6 ft (2 m).

• Loosen the flange back fixing knob.

Figure 14. Zoom Lens Adjustments

Focus ring Flange back xing knob

Flange back adjust ring

• Set the lens to maximum zoom and adjust the focus by turning

the focus ring.

• Set the lens to widest angle and adjust the focus by turning the

flange back adjust ring.

• Repeat adjustment of focus ring and flang back adjust ring until

the focus is adjusted through the entire zoom range.

• Tighten the flange back fixing knob.

e. Gen-lock adjustment.

When multiple cameras are used, or the camera is combined with

other equipment, do the following.

• Connect an external gen-lock synchronization signal (black

burst output) to the camera G/L input.

34 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 35

Operating Procedure

Note The HDC camera accepts SD and HD synchronizing signals. HD synchro-

nizing signals may require different test equipment and may display differently than signals shown in Figure 15.

• Using a two-channel oscilloscope, observe the gen-lock input

and camera video output waveforms.

• Match the horizontal phases of the gen-lock in and video out

signals (Figure 15), by adjusting the camera H-Phase setting of

the GEN-LOCK or G/L menu.

Figure 15. Gen-Lock Horizontal Phase Adjustment Waveform

Gen-lock signal

Video signal

Horizontal phase

3. Adjust the lighting for the object.

4. Start shooting.

8492_71_r0

• Refer to the Ignite Live Production Control System User Manual for

automated camera control procedures.

• Refer to the JSC-2300 SHOT Director Robotics/Camera Controller

Instruction Manual if you want to:

• Control the camera manually

• Create and save presets

• Change camera settings

5. After shooting, turn off all equipment power.

Ignite SDC/HDC Robotic Camera Instruction Manual 35

Page 36

Section 3 — Operation

36 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 37

Service

General

Troubleshooting

Section 4

Ignite SDC/HDC robotic cameras contain no user-serviceable parts. Refer

any servicing to qualified service personnel.

Should problems occur with the Ignite SDC/HDC robotic camera, please

refer to the following troubleshooting matrix (Tabl e 2). If questions or

problems still exist after troubleshooting, please contact your authorized

Grass Valley reseller or contact Grass Valley Customer Support directly.

(See Contacting Grass Valley on page 4.).

Table 2. Troubleshooting (Problem/Cause/Solution) Matrix

Problem Cause Solution

Power Mains power OFF. Energize Mains power

Power supply not connected to Mains Connect power supply to Mains

Power supply failure If power supply LED is NOT illumi-

Power supply not connected to pan/

tilt head.

Pan/tilt head failure. Use the SHOT Director to pan/tilt the

Pan/tilt head not connected to camera

block.

Camera block failure. If the camera block POWER LED is not

Communication No power to SHOT Director, network

hub, pan/tilt head, or camera.

nated, replace the power supply.

Ensure power supply is properly connected to the pan/tilt head amphenol

circular connector.

camera.

If the pan/tilt head responds properly,

continue to the next possible cause.

If the pan/tilt head does not respond,

replace the pan/tilt head.

Ensure the DB15 connector on the

pan/tilt head is connected to the

HD15 or SCSI-50 connector on the

camera block.

illuminated, replace the camera/lens

assembly.

Ensure all devices are powered.

Ignite SDC/HDC Robotic Camera Instruction Manual 37

Page 38

Section 4 — Service

Table 2. Troubleshooting (Problem/Cause/Solution) Matrix

Problem Cause Solution

SHOT Director or hub communication

failure.

No traffic indicated on the network

hub front panel LEDs.

Pan/tilt head communication failure. Ensure all devices are powered,

CAUTION Contact Customer Service before pressing

the RESET switch on the pan/tilt head.

Ensure all devices are powered.

Check CAT5 cable between SHOT

Director and hub.

Use crossover cable between SHOT

Director and pan/tilt head (no hub).

Troubleshoot SHOT Director and/or

hub. (Refer to JSC-2300 SHOT Director Robotics Controller Instruction

Manual).

Verify that pan/tilt head does not

respond to pan, tilt, zoom, or focus

commands,

Verify traffic indicated on network hub

front panel LEDs

Check CAT5 cable between hub and

pan/tilt head.

Verify correct IP address setup for

pan/tilt head and SHOT Director

(Refer to JSC-2300 SHOT Director

Robotics Controller Instruction Manual).

Press the pan/tilt head RESET switch

(Item 2, Figure 74 on page 107) to set

the pan/tilt factory default IP address

(192.168.0.126) and subnet mask

(255.255.255.0). Then set the SHOT

Director to default address

192.168.0.100 (Refer to JSC-2300

SHOT Director Robotics Controller

Instruction Manual).

Replace pan/tilt head.

Camera block communication failure. Ensure the DB15 connector on the

Robotics Pan/tilt head will not pan, tilt or both. Verify that the pan/tilt head searches

Video No video Check video cable connected to back

pan/tilt head is connected to the

HD15 or SCSI-50 connector on the

camera block.

(HDC Only).

Access the Setting menu using the

menu switch on the back of the HD

camera block (Appendix C-HD Cam-

era Block). Ensure that the protocol is

set to 4.

Replace camera/lens assembly.

for home (zero pan and zero tilt) at

power up.

Replace pan/tilt head.

of camera block.

Replace camera/lens assembly.

38 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 39

Tr ou b l es ho ot in g

Table 2. Troubleshooting (Problem/Cause/Solution) Matrix

Problem Cause Solution

Poor quality video Check video cable connected to back

Tally Tally does not illuminate Ensure the tally light is properly con-

of camera block.

Ensure DB9 connector at pan/tilt head

is connected and that the zoom/focus

cable is connected to the lens assembly.

Ensure the Iris cable from the lens

assembly is connected to the hirose

circular connector at the back of the

camera block.

Use the SHOT Director to access the

camera Settings menu and verify all

menu selections. Refer to the JSC2300 SHOT Director Robotics Controller Instruction Manual and

Appendix A-SD (NTSC) Camera

Block, Appendix B-SD (PAL) Camera

Block, or Appendix C-HD Camera

Block.

Replace camera/lens assembly.

nect to a tally controller.

Replace camera/lens assembly.

Ignite SDC/HDC Robotic Camera Instruction Manual 39

Page 40

Section 4 — Service

40 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 41

SD (NTSC) Camera Block

Controls and Indicators

SD (NTSC) camera controls and indicators are shown in Figure 16 and

described in Tabl e 3.

Figure 16. SD Camera Controls and Indicators

FRONT

1

2

3

14

13

12

11

Appendix A

REAR

ZOOM/FOCUS

SDI

OUT

1

SDI

OUT

2

4

5

6

7

Table 3. SD Camera Controls and Indicators

Item Name Description

1 Lens mount

2 Lens fixing ring knob

3 Zoom/Focus connector

Video Output connector

4

(VIDEO OUT)

G/L Input connector

5

(G/L IN)

I/F Remote connector

6

(I/F REMOTE)

7 Iris connector (IRIS)

DC 12 V input connector

8

(DC 12V IN)

9 Power indicator

2/3” Standard bayonet type (B4) mount.

Rotate the lens fixing ring knob counterclockwise and remove the lens mount

cap. Mount the lens on the camera and rotate the lens fixing ring knob clockwise in order to fix the lens securely.

Not Used.

Composite video output.

Gen-lock input.

Input terminal dedicated to control signals from an optional remote control

box.

Input terminal for lens with an iris control function.

12 V dc input.

Red LED lamp lights when DC power is supplied to the camera.

10

9

8

8492_12_r0

Ignite SDC/HDC Robotic Camera Instruction Manual 41

Page 42

Appendix A — SD (NTSC) Camera Block

Table 3. SD Camera Controls and Indicators

Item Name Description

10 SDI OUT 1 and 2

11 NO/BAR switch (NO/BAR/–)

YES/ABC switch

12

(YES/ABC/+)

ITEM/AWC switch

13

(ITEM/AWC/S)

14 MENU switch (MENU/A)

Tally light (located on top of

15

camera body, but not illustrated)

SDI video outputs (SDI Option card)

When the camera is in shooting mode (menu not displayed), the color bar and

shooting conditions are alternately indicated by pressing the switch.

With the Main Menu displayed, you can scroll down to any Sub Menu.

With a Sub Menu displayed, you can reduce the value of any setting.

When the camera is in shooting mode (menu not displayed), the automatic

black balance control can be set with this switch.

With the Main Menu displayed, you can scroll up to any Sub Menu.

With a Sub Menu displayed, you can increase the value of any setting.

When the camera is in shooting mode (menu not displayed), the automatic

white balance control can be set with this switch.

With a menu displayed, any item can be selected by pressing this switch.

A menu will appear on the monitor screen when this switch is pressed for

about 5 seconds. This item can be selected by pressing the switch while the

menu is on the screen.

Dual-color LED

Red - On Air

Amber - Next Camera

Requires dry contact tally control

Menu Selections

You can adjust camera settings via on-screen menus by using the controls

on the back of the camera block or by using the JSC-2300 SHOT Director

robotics/camera controller. These adjustments should be performed by

qualified technical personnel only. If your system includes a JSC-2300

SHOT Director, always use the JSC-2300 SHOT Director LCD menus to

make these adjustments.

Use Mode Setting

The camera has four use modes, and various functions for four use modes

have been preset. Functions can be set as best suited to each use mode.

Note Cameras come from the factory set in User Mode, which allows the greatest

Halogen mode

Suited to indoor shooting, such as at weddings, parties, lecture meetings,

events, etc. Settings can be changed using a simple menu.

flexibility of settings. Other modes have many of the settings pre-determined

which may or may not work in a particular application.

42 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 43

Fluorescent mode

Suited to indoor shooting under fluorescent lighting. Settings can be

changed using a simple menu.

Outdoor mode

Suited to outdoor shooting. Settings can be changed using a simple menu.

User mode

Settings can be changed using a detail menu.

Setting by Camera

1. Turn the camera on while keeping the MENU switch (Figure 16)

depressed.

2. The use mode setting menu (Figure 17) appears on the monitor screen

and one of the use mode blinks .

Menu Selections

Figure 17. Use Mode Setting Menu

8492_13_r0

3. Press the MENU switch, ITEM/AWC switch, or NO/BAR switch to let

the desired use mode blink.

• MENU switch: The blinking item moves up one.

• ITEM/AWC switch, NO/BAR switch: The blinking item moves down

one.

4. Press the YES/ABC switch. The blinking use mode comes into effect.

After the use mode setting menu is shown for about 5 seconds, the

camera returns to ready and operates in the selected use mode.

Ignite SDC/HDC Robotic Camera Instruction Manual 43

Page 44

Appendix A — SD (NTSC) Camera Block

Menu Item Setting

Each of the four use modes of the camera has a main menu (example shown

in Figure 18).

Figure 18. Main Menu - Halogen, Fluorescent, Outdoor Mode

• Each item of the main menu has a submenu, which consists of several

settings.

• These settings have been preset to the optimum values to suit each use

mode, and can be changed to suit actual shooting conditions.

Use mode

Blinking

8492_14_r0

1. Keep the MENU switch depressed for 5 seconds or more. The main

menu appears on the monitor screen.

2. Each time the MENU switch, ITEM/AWC switch, or NO/BAR switch

is pressed, the blinking item moves up or down.

3. When the YES/ABC switch is pressed after selecting the desired item

to blink, the submenu for the selected item appears on the screen.

4. Select the desired item to be changed in its settings using the MENU

switch and ITEM/AWC switch.

5. Press the YES/ABC switch or NO/BAR switch to change the settings.

6. Select [Return] using the MENU switch and ITEM/AWC, then press

the YES/ABC switch to return to the main menu.

7. After changing the settings, take the following steps. Select [End] using

the MENU switch and ITEM/AWC switch and press the YES/ABC

switch.

Changing the Language Setting

The language on the menu screen can be changed from English to Japanese.

(Factory setting: English)

• Halogen, Fluorescent, Outdoor Mode – Select Japanese in the Language

setting in Other Set submenu.

• Use Mode – Select Japanese in the Language setting in Other Set2 submenu.

44 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 45

Submenus Overview

The following submenus are for Halogen Mode, Fluorescent Mode, and

Outdoor Mode on the NTSC version of the SD camera.

For User Mode submenus, refer to User Mode Submenus Overview on

page 50.

Brightness Setting

Figure 19. Brightness Setting Submenu

Menu Selections

Table 4.

Brightness Settings

Selection

Picture Level

Light PEAK/AVG

Light Area

Auto ND (ELC)

Auto Gain Up

AGC Max Gain

8492_15_r0

Description

(-50 to +50) Convergence level of AUTO IRIS/AUTO GAIN UP/ AUTO ND

(ELC) can be adjusted.

(P50 to A50) The ratio of AUTO IRIS/AUTO GAIN up/AUTO ND (ELC)

detected peak to average can be adjusted within a predetermined range.

A photometric measurement method can be selected for AUTO IRIS/AUTO

GAIN UP/AUTO ND (ELC).

ALL: All the screen area is measured.

Center: The screen is measured mainly in the center area, about

one-third of both the top and bottom and one-third of both the right

and left portions of the screen are excluded from measurement.

Top Cut: About one-third of the top part of the screen is excluded

from measurement.

BTM Cut: About one-third of the bottom portion of the screen is

excluded from measurement.

R/L Cut: About one-third of both the right and left portions of the

screen are excluded from measurement.

OFF: Luminance is not automatically adjusted by the electronic shutter.

ON: The electronic shutter is controlled to automatically adjust the luminance.

*ON is automatically selected when the Shutter Speed on the submenu

[Other Set] is set to [Auto ND].

OFF is selected when other than [Auto ND] is selected.

OFF: The light quantity is not adjusted automatically.

ON: The light quantity is adjusted automatically. The maximum to

which the gain can be increased using the Auto Gain Up function is

selected by the AGC Max Gain setting.

(6dB, 12dB, 18dB, 24dB, N/Eye L, N/Eye H) This is used to set the maximum amount to which the gain can be increased when “ON” has been

selected as the Auto Gain Up setting.

Ignite SDC/HDC Robotic Camera Instruction Manual 45

Page 46

Appendix A — SD (NTSC) Camera Block

Table 4. Brightness Settings

Selection

Manu Gain Up

Pedestal

Color Setting

Figure 20. Color Setting Submenu

Description

Manual setting is possible only when the Auto Gain Up setting is “OFF”.

0 dB: 0 dB should be selected in normal cases.

1 dB - 30 dB: Use this range if sufficient video output cannot be obtained

even when the lens iris is opened in shooting dark scenes.

N/Eye L (Night Eye L): Use this mode if sufficient video output can not be

obtained even if 30 dB gain up should be selected.

N/Eye H (Night Eye H): Use this setting if it is not possible to achieve a satisfactory video output even at the Night Eye L setting.

(-150 to +150) The black level (pedestal) of the luminance (Y) signal can

be set. Used in adjusting the black levels of two or more cameras.

Table 5. Color Settings

Selection

Chroma Level

Flesh Tone

White Bal

ATW Speed

8492_16_r0

Description

(-3 to +3) Chroma Level can be decreased or increased to any of three levels each.

(-3 to +3) Skin color can be decreased or increased to any of three levels

each.

ATW: The white balance is automatically adjusted to be always right.

AWC A, AWC B: Once the white balance is adjusted with the ITEM/

AWC switch on the back of the camera, it is no longer necessary to

set the white balance again if you simply select AWC A or AWC B,

provided that the camera is used under the same conditions. Fine

color adjustment can be made after setting AWC by red/blue gain

adjustment in user mode.

P SET 3200 K: The white balance is adjusted to 3200 K illumination.

P SET 5600 K: The white balance is adjusted to 5600 K illumination.

(Slow 2, Slow 1, Mid, Fast 1, Fast 2) ATW Speed can be set.

46 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 47

G/L, Color Bar Setting

Figure 21. GL, Color Bar Setting Submenu

Table 6. Color Bar Settings

Selection

H Phase

SC Coarse

SC Fine

Color Bar Set

Color Bar Set2

Menu Selections

8492_17_r0

Description

(-206 to +49) Horizontal phase can be adjusted when a genlock signal is

supplied.

(1, 2, 3, 4) Coarse adjustment of sub carrier phase can be made when a

genlock signal is supplied.

(-511 to +511) Fine adjustment of sub carrier phase can be made when a

genlock signal is supplied.

(0.0 IRE, 7.5 IRE) The setup level of color bar can be adjusted.

(0.0 IRE, 7.5 IRE) Set 0.0 IRE for the SDI card.

Sharpness (DTL) Setting Overview

Figure 22. Sharpness (DTL) Settings Submenu

Table 7. Sharpness (DTL) Settings

Selection

DTL Select

Level

Noise Suppress

Description

(Sharpness, Super DTL) If contour correction is not sufficient at the Sharpness position when Detail Level setting is set to Low or High, select the

Super DTL position.

*Neither Sharpness nor Super DTL is valid for contour correction if Detail

Level setting is in the OFF position.

(OFF, Low, High) Detail level can be adjusted when Detail Select setting is

at Sharpness. Super DTL level can be adjusted when it is at Super DTL.

(OFF, Low, High) Screen noise can be reduced when Detail Level setting is

at High or Low.

8492_18_r0

Ignite SDC/HDC Robotic Camera Instruction Manual 47

Page 48

Appendix A — SD (NTSC) Camera Block

Table 7. Sharpness (DTL) Settings

Selection

Clean DNR

Flesh Noise Sup.

Other Settings Overview

Figure 23. Other Settings Submenu

Description

(OFF, Low, High) This enables the clean DNR effect to be selected.

(OFF, Low, High) Flesh noise is suppressed in two steps when the Level

setting is at High or Low.

8492_19_r0

Table 8. Other Settings

Selection

Contrast (Gamma)

Shutter Speed

Description

(Low, Mid, High) Contrast can be adjusted to any of three levels.

OFF: Electronic shutter is turned off.

1/100, 1/250, 1/500, 1/1000, 1/2000, 1/4000, 1/10000:

Electronic shutter operates at one of these speeds as selected.

S/Scan (Synchro Scan): Electronic shutter operates at the speed set with

the Synchro Scan setting.

Auto ND: Electronic shutter is controlled to automatically adjust the luminance.

*Flickering may increase at Auto ND under fluorescent lights. *Auto ND is

automatically selected if Auto ND (ELC) setting is set to ON.

48 Ignite SDC/HDC Robotic Camera Instruction Manual

Page 49

Table 8. Other Settings

Selection

Menu Selections

Description

(60.34 Hz to 15.75 kHz) This setting is possible only when the Shutter

Speed setting is at S/Scan.

Horizontal bar noise can be reduced by synchro-scan adjustment in shooting workstation scenes, for example.

*For luminance settings at each shutter speed and synchro-scan shutter

speed, refer to the following table.

Synchro Scan

V Resolution

Baud Rate

Component

Aspect Ratio

Fan SW

Language

Shutter

Speed

OFF - 1

1/100 100.3 Hz 2

1/250 250.0 Hz 4

1/500 492.2 Hz 8

1/1000 984.4 Hz 16

1/2000 1.969 kHz 32

1/4000 3.938 kHz 64

1/10000 7.875 kHz 160

Normal: Normal image. (CCD storage will be by field storage. Recommended for general use because sensitivity will decrease at the Fine setting.

Fine: Vertical resolution increases. (Vertical resolution is raised without

increasing residual images by frame storage and electronic shutter.)

(1200bps, 2400bps, 4800bps, 9600bps)

Select a communication speed in controlling the camera from the computer.

This enables RGB, Y/Pr/Pb or Y/C to be selected as the component signals

which are to be output from the I/F REMOTE connector.

Aspect ratio can be selected from 16:9 or 4:3.

OFF: Select this setting to stop the fan when its operating sound is found to

be bothersome in a studio or other such environment.

Auto: The temperature is detected automatically, and the fan starts operating when the temperature exceeds approx. 95 ºF (35 ºC). Under normal circumstances, the “Auto” setting is used.

English: Menu screen is displayed in English.Japanese: Menu screen is

displayed in Japanese.

Synchro

Scan

Required

Luminance

Ratio

Ignite SDC/HDC Robotic Camera Instruction Manual 49

Page 50

Appendix A — SD (NTSC) Camera Block

User Mode Submenus Overview

Iris, Shutter, Gain Settings Overview

Figure 24. Iris, Shutter, Gain Settings Submenu

Table 9. Iris, Shutter, Gain Settings

Selection

Picture Level

Light PEAK/AVG

Light Area

Auto Iris Adjust

Shutter Mode

8492_20_r0

Description

(-50 to +50) Convergence level of AUTO IRIS, AUTO GAIN UP, ELC can be

adjusted.

(P50 to A50) The ratio of AUTO IRIS, AUTO GAIN UP, ELC detected peak to

average can be adjusted within a range.

A photometric measurement method can be selected for AUTO IRIS, AUTO

GAIN UP, ELC.

All: All the screen is measured.

Center: The screen is measured mainly in the center area, about one-third

of both the top and bottom and one-third of both the right and left portions

of the screen are excluded from measurement.

Top cut: About one-third of the top portion of the screen is excluded from

measurement.