Page 1

DENSITÉ series

FIO-1901-TT

3G/HD/SD Electrical to Fiber Optic Converter

Guide to Installation and Operation

M927-0200-100

14 Apr 2011

Miranda

Technologies Inc.

3499 Douglas-B.-Floreani

St-Laurent, Québec, Canada H4S 2C6

Tel. 514-333-1772

www.miranda.com

© 2011 Miranda Technologies Inc..

Fax. 514-333-9828

Page 2

GUIDE TO INSTALLATION AND OPERATION

Electromagnetic Compatibility

This equipment has been tested for verification of compliance with FCC Part 15, Subpart B requirements for

Class A digital devices.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

This equipment has been tested and found to comply with the requirements of the EMC directiv e

2004/108/CE:

• EN 55022 Class A radiated and conducted emissions

• EN 55024 Immunity of Information Technology Equipment

• EN 61000-3-2 Harmonic current injection

• EN 61000-3-3 Limitation of voltage changes, voltage fluctuations and flicker

• EN 61000-4-2 Electrostatic discharge immunity

• EN 61000-4-3 Radiated electromagnetic field immunity – radio frequencies

• EN 61000-4-5 Surge immunity

• EN 61000-4-11 Voltage dips, short interruptions and voltage variations immunity

Laser Safety

The single mode transceiver in the SFP module is a Class 1 laser product. It complies with IEC-60825 and FDA 21

CFR 1040.10 and 1040.11. The transceiver must be operated within the specified temperature and voltage limits. The

optical ports of the module shall be terminated with an optical connector or with a dust plug.

How to contact us:

For technical assistance, please contact the Miranda Technical support centre nearest you:

Americas

Telephone:

+1-800-224-7882

e-mail:

techsupp@miranda.com

China

Visit our web site at www.miranda.com

Asia

Telephone:

+852-2539-6987

e-mail:

asiatech@miranda.com

Telephone:

+86-10-5873-1814

e-mail:

asiatech@miranda.com

Europe, Middle East, Africa, UK

Telephone:

+44 (0) 1491 820222

e-mail:

eurotech@miranda.com

France (only)

Telephone:

+33 (0) 1 55 86 87 88

e-mail:

eurotech@miranda.com

FIO-1901-TT

Page 3

GUIDE TO INSTALLATION AND OPERATION

Table of Contents

1 FIO-1901-TT 3G/HD/SD Electrical to Fiber Optic Converter ................................................... 1

1.1 Introduction ......................................................................................................................................... 1

1.2 Features .............................................................................................................................................. 1

1.3 Block Diagram ..................................................................................................................................... 2

1.4 Front Card-edge Interface ................................................................................................................... 2

2 Installation .................................................................................................................................. 3

2.1 Installation in a Densité-2 frame ......................................................................................................... 3

2.2 Installation in a Densité-3 Frame ........................................................................................................ 4

2.3 Rear Connector Panel ........................................................................................................................ 6

2.4 SFP Modules ....................................................................................................................................... 6

3 Operation .................................................................................................................................... 7

3.1 Card-Edge Status LED ....................................................................................................................... 7

3.2 Local control using the Densité frame control panel ........................................................................... 7

3.2.1 Overview ................................................................................................................................ 7

3.2.2 Menu for local control ............................................................................................................. 8

3.2.3 Detailed Operating Procedure ............................................................................................... 8

3.2.3.1 Fail Over ................................................................................................................ 9

3.2.3.2 Output Configuration ............................................................................................. 9

3.2.3.3 Optical Transmitter Status ..................................................................................... 9

3.2.3.4 Reclocker ............................................................................................................... 9

3.2.3.5 User Presets .......................................................................................................... 9

3.2.3.6 Alarm configuration ............................................................................................... 9

3.3 Remote control using iControl ........................................................................................................... 10

3.3.1 The iControl graphic interface window ................................................................................. 10

3.3.2 The Status panel .................................................................................................................. 12

3.3.3 The Reclocker panel ............................................................................................................ 13

3.3.4 The Output & Optical panel .................................................................................................. 13

3.3.5 The Fail Over panel ............................................................................................................. 14

3.3.6 The Factory/Presets panel ................................................................................................... 14

3.3.7 The Alarm Config panel ....................................................................................................... 15

3.3.8 The Info panel ...................................................................................................................... 18

4 Specifications ........................................................................................................................... 20

ANNEX 1 – FIO-1901-TT User Interface (local menu structure) ................................................. 21

ANNEX 2 – Installing the Optical Interface .................................................................................. 22

FIO-1901-TT

Page 4

GUIDE TO INSTALLATION AND OPERATION

FIO-1901-TT

Page 5

GUIDE TO INSTALLATION AND OPERATION

1 FIO-1901-TT 3G/HD/SD Electrical to Fiber Optic Converter

1.1 Introduction

The FIO-1901 series are flexible serial digital video To/From Fiber Optic converters for the Densité frames. The FIO1901 series are designed for SD, HD and 3G serial video as well as compressed bit-streams (DVB-ASI). The series

supports any data rate within the range of 19.4 Mbps to 2.97 Gbps and provides a reclocked serial digital video from

270Mbps to 2.97 Gbps. The FIO-1901 series offer five different configurations: Single or dual fiber Tx, single or dual

fiber Rx and a bi-directional fiber Rx/Tx. The series is based on SFP modules that provide easy product maintenance

and flexibility when multiple wavelengths are needed (as for CWDM). The SFP Modules are also hot-swappable.

The FIO-1901 can be installed in the same chassis as a series of interface modules, providing a wide variety of video,

audio and data conversion and multiplexing functions.

The FIO-1901-TT version incorporates dual optical transmitters, and is also available in a WDM version for use with a

single optical fiber.

1.2 Features

• Supports any serial data rate from 19.4 Mbps (ATSC) to 2.97 Gbps (3G SDI)

• Reclocked serial digital video for 270 Mbps, 1.49 Gbps, and 2.97 Gbps

• Provides unidirectional interface between serial digital and fiber optic

• Supports Multiple wavelength from the standard 1310 nm, 1550 nm to multiple CWDM wavelengths

• WDM (1310/1550) solution for dual Tx cards

• Possible to set the Dual Tx modules in a change over mode.

• Ideal for long video run with “Hum” immunity

• Presence/loss of signal alarm – iControl, on board LED and Densité Control Panel

• SFP Optical power monitoring and repo rt

• Internal SFP temperature alarms on the iControl interface and on the Densité Control Panel

• SFP Module type detections and report mismatch

• Remote monitoring and control

• Convenient front loading design

• The cards and the SFP modules are fully hot swap pable

FIO-1901-TT | 1

Page 6

GUIDE TO INSTALLATION AND OPERATION

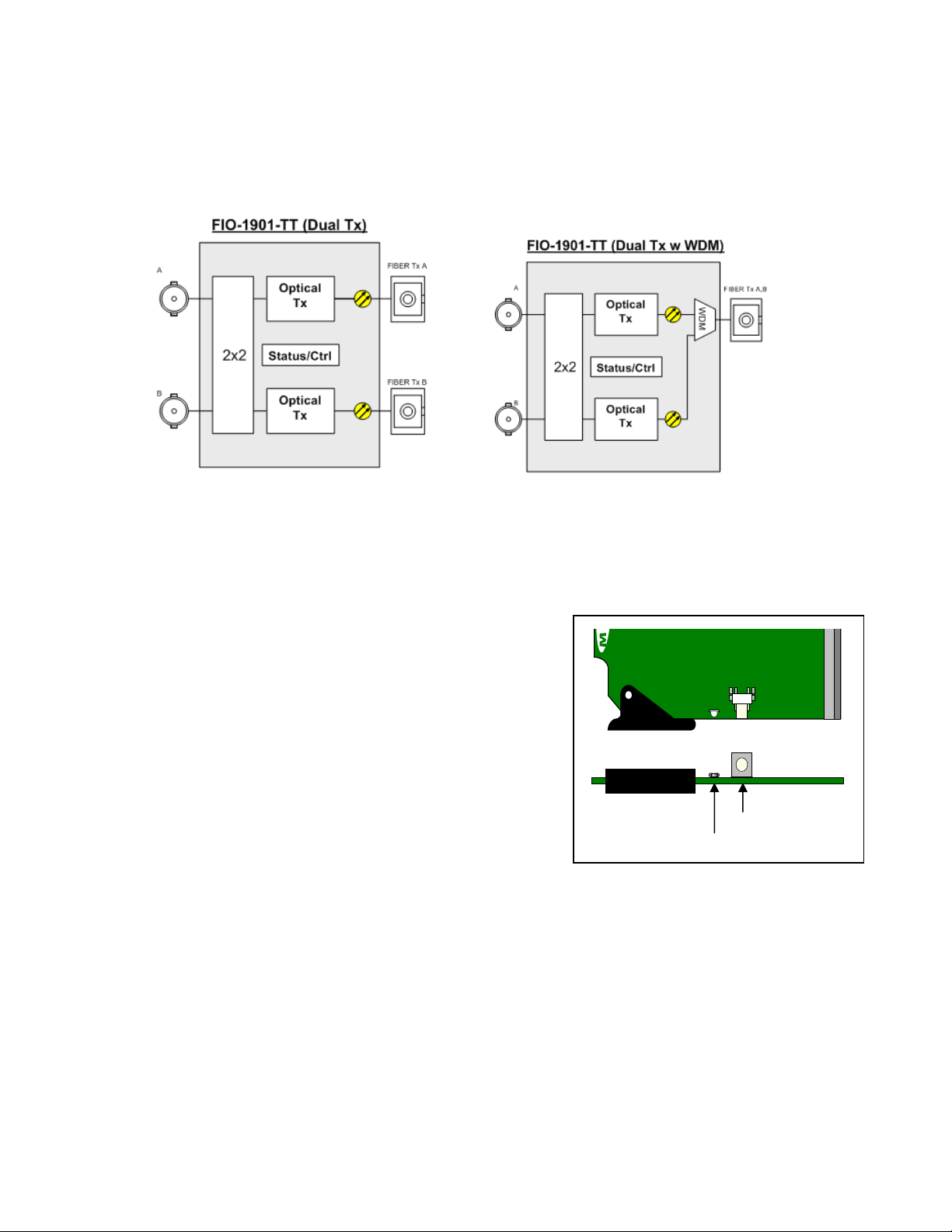

1.3 Block Diagram

The following block diagrams show the functionality of the FIO-1901-TT. Both versions of the card (Dual Tx, and Dual

Tx with WDM) are illustrated.

Figure 1.1 Functional block diagram of the FIO-1901-TT

1.4 Front Card-edge Interface

The front card-edge of the FIO-1901-TT incorporates two elements:

• Status LED (see section 3.1)

• Select Button (see section 3.2)

FIO-1901-TT

Figure 1.2 Front card-edge layout

Select

Status

Select Button

Status LED

2 | FIO-1901-TT

Page 7

GUIDE TO INSTALLATION AND OPERATION

2 Installation

Miranda Densité-series cards are each associated with a rear connector panel, which must be installed in the Densité

frame before the card can be inserted.

The FIO-1901-TT card is sized to fit into Miranda’s Densité-2 frame. One rear connector panel is available to fit the

Densité 2 frame:

• FIO-1901-TT-SRP – 1 fiber input and 2 electrical outputs

See section 2.1 below for installation instructions.

With the use of available adapters, the FIO-1901-TT and its rear panel can also be installed in a Densité-3 frame. See

section 2.2 below for details.

2.1 Installation in a Densité-2 frame

All cards and rear panels can be installed with the frame power on. The card has connectors which plug into a midframe mother board for distribution of power and for connection to the controller card, and a second connector which

plugs directly into the rear connector panel for input and output.

The rear connector panel must be installed with the card out of the frame.

- To remove an existing card from the slot, tilt up the swivel handle on the front of the card to lever the connectors

apart, then use the handle to pull the card straight out of the slot.

Installing the connector panel:

1. If a card is installed in the slot whose rear panel is being changed, remove it as described above.

2. Remove the existing panel (either blank or belonging to an existing card that is being changed) by releasing the

captive screw(s) at the bottom.

3. Position the new panel and secure it in place with the captive screw(s) at the bottom.

Densité-2 frame – rear panel installation

FIO-1901-TT | 3

Page 8

GUIDE TO INSTALLATION AND OPERATION

Installing the card

Once a matching rear connector panel has been installed, install the FIO-1901-TT card as follows:

1. Open the front panel of the frame.

2. Slide the FIO-1901-TT card into the slot with the swivel handle at the top, and push gently on the handle to seat

the connectors.

3. Close the front panel of the frame.

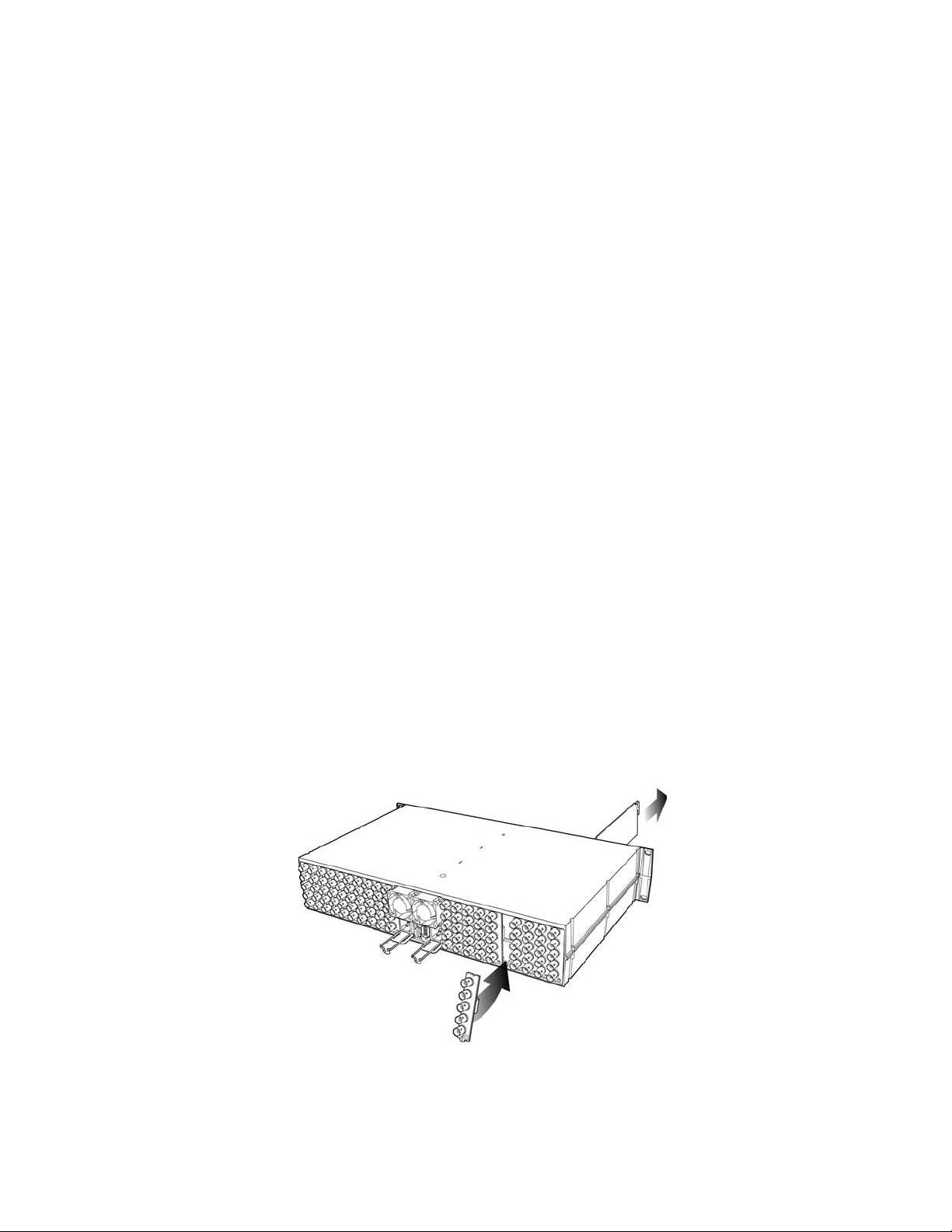

2.2 Installation in a Densité-3 Frame

All cards and rear panels can be installed with the frame power on. The card has connectors which plug into a midframe mother board for distribution of power and for connection to the controller card, and a second connector which

plugs directly into the rear connector panel for input and output.

The rear connector panel must be installed with the card out of the frame.

• To remove an existing card from the slot, tilt up the swivel handle on the front of the card to lever the connectors

apart, then use the handle to pull the card straight out of the slot.

The Densité-3 frame supports many Miranda Densité-2 series cards, including the FIO-1901 -TT. Should you wish to

install the FIO-1901-TT card in your Densité-3 frame, you will need an adapter for the card as well as an adapter for

the rear panel. These adapters extend the height of the Densité-2 devices so that they will fit into the slots of the 3 RU

Densité-3 frame.

Card adapter:

There are 3 different types of adapters available,

depending on the Densité 2 card geometry, so be

sure to order the adapter designed to fit the FIO1901-TT card:

Densité 3 – EXT A

Install the adapter on the FIO-1901-TT as follows:

1. Fit the top edge of the card into the holding

slot along the bottom edge of the adapter.

2. Align the holes in the top of the card with the

holes on the adapter, and secure them

together with the two provided screws and

lock washers, as shown in the figure.

4 | FIO-1901-TT

Page 9

GUIDE TO INSTALLATION AND OPERATION

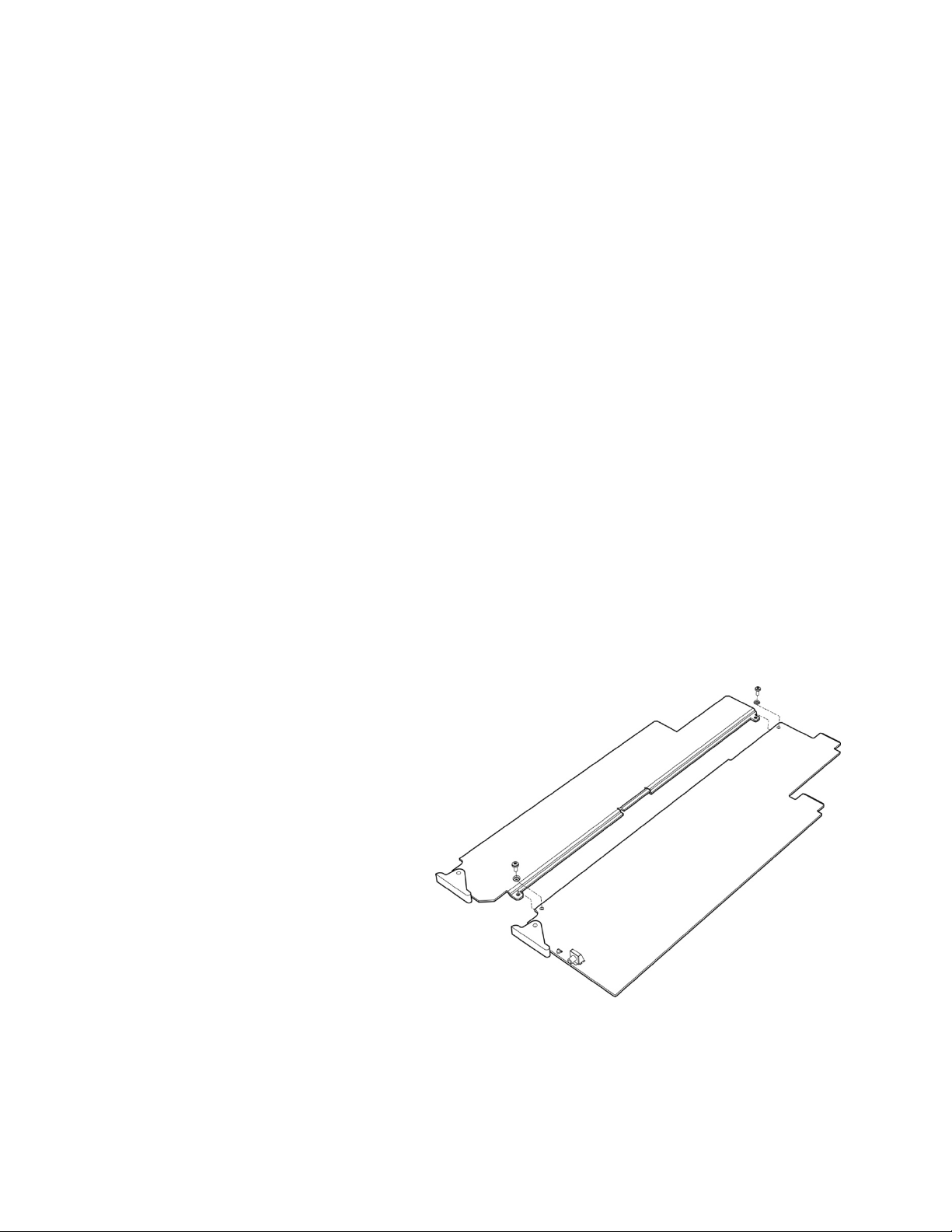

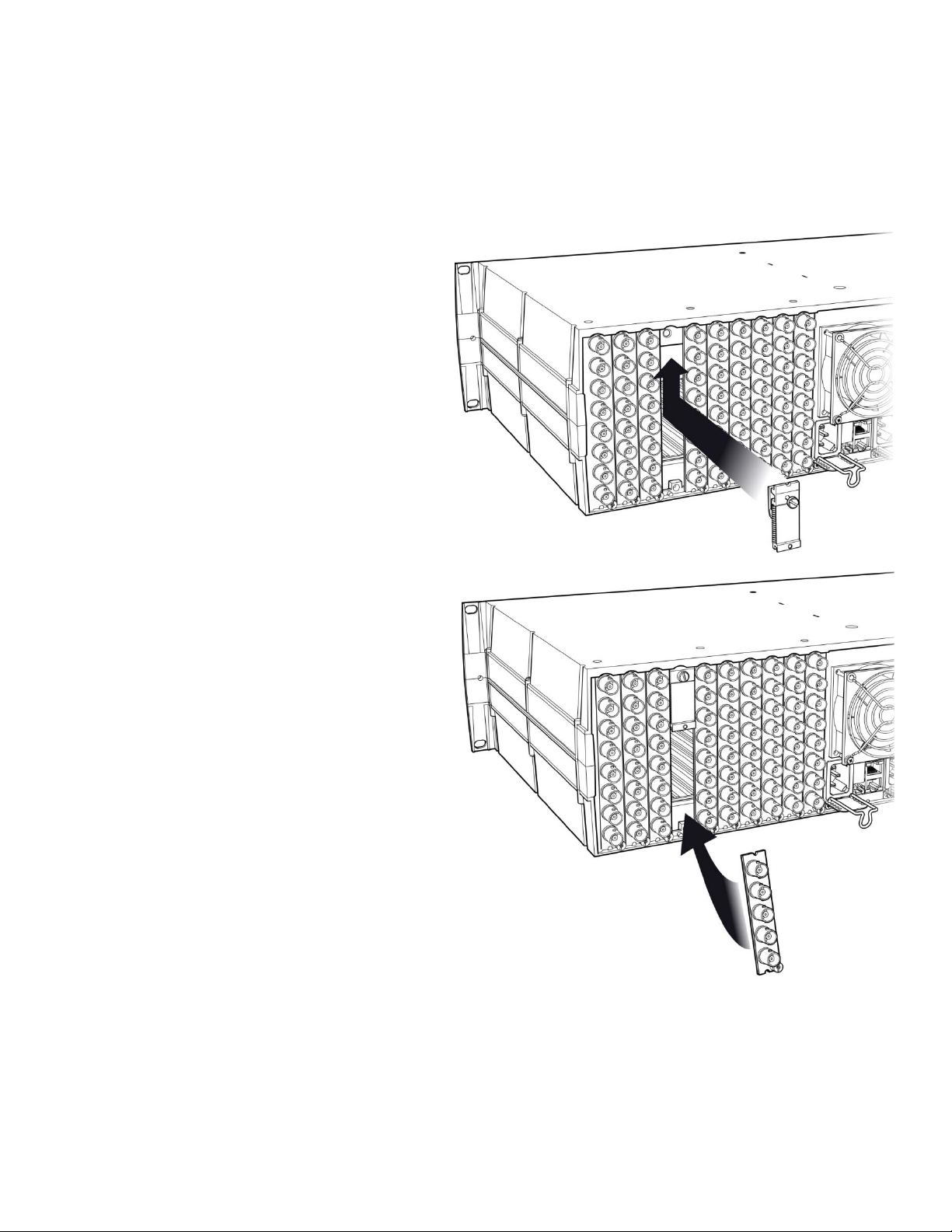

Rear adapter:

The FIO-1901-TT-SRP rear panel requires the following adapter for use in a Densité-3 frame:

DENSITE SRP-3RU

Installing the adapter and connector panel

Install the adapter and the rear panel as follows:

1. Position the adapter at the top of the empty

slot on the rear of the frame.

2. Use the captive screw in the adapter to

fasten it securely in position.

3. Slip the top of the rear panel into the slot at

the bottom of the adapter, and secure it to the

frame using the captive screw at the bottom of

the panel.

Installing the card

Once the rear connector panel has been installed,

insert the FIO-1901-TT card with attached adapter

as follows:

1. Open the front panel of the Densité-3 frame.

2. Slide the FIO-1901-TT card into the slot with

the swivel handle at the top, and push gently

on the handle to seat the connectors.

3. Close the front panel of the frame.

FIO-1901-TT | 5

Page 10

GUIDE TO INSTALLATION AND OPERATION

l

2.3 Rear Connector Panel

The FIO-1901-TT-SRP single-slot rear panel, mounted in a Densité 2 or Densité 3 frame, incorporates these

connectors:

• One socket for inserting a fiber transmitter SFP module – see the li st of supported modules below.

• Two BNC connectors for the 3G/HD/SD SDI inputs.

Figure 2.1 FIO-1901-TT-SRP Rear Panel

2.4 SFP Modules

The FIO-1901-TT supports the following SFP optical interface modules:

FIO-1901-TT Model # Description of associated SFP module

FIO-1901-TT-C27C29-LC Dual 3G/HD/SD optical CWDM Tx, 1271/1291 nm, LC/PC connector

FIO-1901-TT-C31C33-LC Dual 3G/HD/SD optical CWDM Tx, 1311/1331 nm, LC/PC connector

FIO-1901-TT-C35C37-LC Dual 3G/HD/SD optical CWDM Tx, 1351/1371 nm, LC/PC connector

FIO-1901-TT-C39C41-LC Dual 3G/HD/SD optical CWDM Tx, 1391/1411 nm, LC/PC connector

FIO-1901-TT-C43C45-LC Dual 3G/HD/SD optical CWDM Tx, 1431/1451 nm, LC/PC connector

FIO-1901-TT-C47C49-LC Dual 3G/HD/SD optical CWDM Tx, 1471/1491 nm, LC/PC connector

FIO-1901-TT-C51C53-LC Dual 3G/HD/SD optical CWDM Tx, 1511/1531 nm, LC/PC connector

FIO-1901-TT-C55C57-LC Dual 3G/HD/SD optical CWDM Tx, 1551/1571 nm, LC/PC connector

FIO-1901-TT-C59C61-LC Dual 3G/HD/SD optical CWDM Tx, 1591/1611 nm, LC/PC connector

FIO-1901-THTH-C27C29-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1271/1291 nm, LC/PC connector

FIO-1901-THTH-C31C33-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1311/1331 nm, LC/PC connector

FIO-1901-THTH-C35C37-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1351/1371 nm, LC/PC connector

FIO-1901-THTH-C39C41-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1391/1411 nm, LC/PC connector

FIO-1901-THTH-C43C45-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1431/1451 nm, LC/PC connector

FIO-1901-THTH-C47C49-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1471/1491 nm, LC/PC connector

FIO-1901-THTH-C51C53-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1511/1531 nm, LC/PC connector

FIO-1901-THTH-C55C57-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1551/1571 nm, LC/PC connector

FIO-1901-THTH-C59C61-LC High Power Dual 3G/HD/SD optical CWDM Tx, 1591/1611 nm, LC/PC connector

FIO-1901-TT-S13S13-LC Dual 3G/HD/SD Optical Transmitters 1310nm LC/PC Connectors

FIO-1901-TT-W13W15-LC Dual 3G/HD/SD Optical Transmitter 1310nm & 1550nm WDM - LC/PC Connector

See ANNEX 2 – Installing the Optical Interface on page 22 for instructions on installing and removing SFP modules.

Note that when WDM (Wavelength Division Multiplexing) or CWDM modules are installed, the outputs of the two

optical transmitters (operating at the wavelengths indicated in the chart) are multiplexed onto a single optical fiber.

6 | FIO-1901-TT

Page 11

GUIDE TO INSTALLATION AND OPERATION

3 Operation

3.1 Card-Edge Status LED

The status monitor LED is located on the front card-edge of the FIO-1901-TT, a nd is visible through the front access

door of the DENSITÉ frame. This multi-color LED indicates the status of the FIO-1901-TT by color, and by

flashing/steady illumination.

The chart shows how the various error conditions that can be flagged on the FIO-1901-TT affect the LED status.

• If a cell is gray, the error condition cannot cause the LED to assume that status

• If more than one LED status is possible for a particular error condition, the status is configurable.

See Sections 3.2.3.6 and 3.3.7 for details.

• The factory default status is shown by a

The LED will always show the most severe detected error status that it is configured to display, and in the chart error

severity increases from left to right, with green representing no error/disabled, and flashing red the most severe error.

Error Condition

No errors

No input signal presence (A or B)

No lock on input signal (A or B)

No SFP module present

Card / Rear panel / SFP module mismatch

No Rear

SFP Temperature

Card is selected for local control

Firmware Update

Green Yellow Red

If the LED is Flashing Yellow, it means that the card is selected for local control using the Densité frame’s control

panel, or that the card is booting up. See Section 3.2 for details.

3.2 Local control using the Densité frame control panel

Card-edge LED Status

Flashing

Yellow

Flashing

Red

3.2.1 Overview

Push the SELECT button on the FIO-1901-TT card edge (see Section 1.4) to assign the local control panel to operate

the FIO-1901-TT. Use the control panel buttons to navigate through the menu, as described below.

All of the cards installed in a Densité frame are connected to the frame’s controller card, which handles all interaction

between the cards and the outside world. There are no operating controls located on the cards themselves. The

controller supports remote operation via its Ethernet ports, and local operation using its integrated control panel.

FIO-1901-TT | 7

Page 12

GUIDE TO INSTALLATION AND OPERATION

The local control panel is fastened to the controller card by a hinged

connector, and when installed is located in the front center of the

frame, positioned in front of the power supplies. The panel consists

of a display unit capable of displaying two lines of text, each 16

characters in length, and five pushbuttons.

The panel is assigned to operate any card in the frame by pushing

the SELECT button on the front edge of that card.

ESC

+

-

CONTROLLER

SELECT

• Pushing the CONTROLLER button on the control panel

selects the Controller card itself.

Figure 3.1 Densité Frame local control panel

• The STATUS LED on the selected card flashes yellow.

The local control panel displays a menu that can be navigated using the four pushbuttons located beneath the display.

The functionality of the pushbuttons is as follows:

[+] [–] Used for menu navigation and value modification

[SELECT] Gives access to the next menu level. When a parameter value is shown, pushing this button once

enables modification of the value using the [+] and [–] buttons; a second push confirms the new value

[ESC] Cancels the effect of parameter value changes that have not been confirmed; pushing [ESC] causes the

parameter to revert to its former value.

Pushing [ESC] moves the user back up to the previous menu level. At the main menu, [ESC] does not

exit the menu system. To exit, re-push the [SELECT] button for the card being controlled.

If no controls are operated for 30 seconds, the controller reverts to it s normal standby status, and the selected card’s

STATUS LED reverts to its normal operating mode. If a parameter was changed on the card but not submitt ed

(SELECT was not pressed) and the 30 second timeout occurs, the parameters will be confirmed as if the SELECT key

had been pressed.

3.2.2 Menu for local control

The FIO-1901-TT has operating parameters which may be adjusted locally at the controlle r card interface.

• Press the SELECT button on the FIO-1901-TT front card edge to assign the Densité frame’s local control

panel to the FIO-1901-TT

• Use the keys on the local control panel to step through the displayed menu to configure and adjust the FIO1901-TT

The complete menu structure is shown in the Annex to this document, beginning on page 21.

3.2.3 Detailed Operating Procedure

The basic operating characteristics of the FIO-1901-TT can be adju sted u sing th e local control panel.

• Refer to the menu on page 21 for help in accessing the indicated items.

• In all sets of optional values for a parameter, the underlined

value is the default value.

8 | FIO-1901-TT

Page 13

GUIDE TO INSTALLATION AND OPERATION

3.2.3.1 Fail Over

When Failover mode is activated, the FIO-1901-TT is configured with Electrical In A as the source for both outputs,

and Electrical In B as the backup. If Electrical In A fails, the outputs will be switched over to Electrical In B (if it is

valid), after a defined delay. The delay can be set between 0 and 15 seconds, in order to accommodate deliberate or

anticipated breaks in the input data stream.

Mode: [OFF

Fail Delay: [0, 1, 2, 3

, ON]

, 4, …, 15] seconds

3.2.3.2 Output Configuration

Manually configure the input-to-output connections. Each of the two optical outputs can be connected to either of the

two electrical inputs. The default is A-to-A and B-to-B.

• When Failover is ON, the configuration is fixed and the settings made here are overridden.

Output TxA [Electrical In A

Output TxB [Electrical In A, Electrical In B

, Electrical In B]

]

3.2.3.3 Optical Transmitter Status

Turn each of the optical transmitters ON or OFF independently.

Optical TxA: [OFF, ON

Optical TxB: [OFF, ON

]

]

3.2.3.4 Reclocker

Enable reclocking of the video data stream on each of the electrical inputs independently. The reclocker operates at

the video standard rates of SD (270Mbps), HD (1.49Gbp), and 3G (2.97Gbps).

Electrical IN A: [ON

Electrical IN B: [ON

, BYPASS]

, BYPASS]

3.2.3.5 User Presets

The FIO-1901-TT has five data storage registers that can save the device configuration. Each register can be saved

independently by the user, and the device can be reconfigured from the contents of any of the registers by the user.

LOAD: [USER1, USER2, USER3, USER4, USER5] Load the contents of the preset into the FIO-1901-TT

SAVE: [USER1, USER2, USER3, USER4, USER5] Save the configuration of the FIO-1901-TT into the preset

3.2.3.6 Alarm configuration

The following configurable alarms are listed in the menu:

ELE.A NO LOCK (Electrical input A not locked)

ELE.A NO SIGNAL (Electrical input A no signal)

ELE.B NO LOCK (Electrical input B not locked)

ELE.B NO SIGNAL (Electrical input B no signal)

SFP TEMPERATURE (temperature on the SFP module)

R/SFP MISMATCH (any mismatch between the card type / rear panel type / installed SFP module type)

NO SFP (no SFP module installed)

FIO-1901-TT | 9

Page 14

GUIDE TO INSTALLATION AND OPERATION

For each alarm, select how it will be displayed on the card-edge Status LED.

Alarm level: [GREEN, YELLOW, RED, FLASH RED]

For each alarm, select whether it will be reported on the GPI output of the frame controller.

Alarm report: [NONE, GPI]

3.3 Remote control using iControl

The operation of the FIO-1901-TT may be controlled using Miranda’s iControl system.

• This manual describes the control panels associated with the FIO-1901-TT and their use.

• Please consult the iControl User’s Guide for information about setting up and operating iControl.

In iControl Navigator or iControl Websites, double-click on the FIO-1901-TT icon to open the control panel.

3.3.1 The iControl graphic interface window

The basic window structure for the FIO-1901-TT is shown in figure 3.2. The window identification line gives the card

type and the slot number where the card is installed in its Densité frame.

There are three main sections in the window itself, identified in figure 3.2:

Figure 3.2 FIO-1901-TT iControl graphic interface window

10 | FIO-1901-TT

Page 15

GUIDE TO INSTALLATION AND OPERATION

1. The top section displays icons on the left. These icons report the

status of some parameters associated with this FIO-1901-TT. Figure

3.3 shows the three icons that appear.

Move the mouse over an icon and a status message appears below the

icon providing additional information.

If there is an error, the error status message appears in the message

area without mouse-over.

Icon # 1 2 3

• If there are multiple errors, the error messages cycle

• The icon whose status or error message is shown is highlighted

with a mauve background

Figure 3.3 iControl Status Icons

The table below lists the various status icons that can appear, and how

they are to be interpreted.

• In cases where there is more than one possible interpretation, read the error message in the iControl window to

see which applies.

Table – iControl Status Icon interpretation

Icon #1 – Manual Card Configuration

Remote card control activated. The iControl interface can be used to operate the card

(green)

Local card control active, The card is being controlled using the Densité frame control

panel, as described in section 3.2. Any changes made using the iControl interface will have

(yellow)

no effect on the card.

Icon #2 – In A status

Signal detected and valid.

(green)

Input signal error

(red)

No rear

No electrical input

(grey)

Icon #3 – In B status

Signal detected and valid.

(green)

Input signal error

(red)

No rear

(grey)

No electrical input

FIO-1901-TT | 11

Page 16

GUIDE TO INSTALLATION AND OPERATION

Section 2. The left portion of the window contains access buttons for all the parameter groups, which become

highlighted when they are selected; the main panel (3) then displays the group’s set of parameters. Each of the

groups is described in detail below.

Section 3. The main panel contains all the parameters specific to the group selected.

Each of the panels associated with the groups accessed from the buttons in Section 2, and shown in Section 3, is

described individually in the following sections.

3.3.2 The Status panel

This panel reports the status of this FIO-1901-TT card, its

rear panel, its SFP module, and the signals arriving at the

electrical inputs on the rear panel.

ELECTRICAL IN A and ELECTRICAL IN B

• Shows the incoming data rate when a signal is

successfully received (green icons)

• Identifies No Signal or No Lock conditions (red icons)

Rear Type – the data box identifies the rear panel installed

in the Densité frame for this FIO-1901-TT.

Rear mismatch – the icon is green when a compatible rear

panel is installed and red when an incompatible rear panel is

installed.

SFP - the data box identifies the SFP module installed in the

rear panel for this FIO-1901-TT.

SFP mismatch – the icon is green when a compatible SFP

module is installed and red when an incompatible SFP

module is installed.

SFP Info – the data boxes in this section give information

about the SFP module itself, and measured data about the operating status of the two transmitters TX-A and TX-B

Figure 3.4 Status panel

12 | FIO-1901-TT

Page 17

3.3.3 The Reclocker panel

Use the radio buttons to enable reclocking of the video data

stream on each of the electrical inputs independently.

The reclocker operates at the video standard rates of

SD (270 Mbps), HD (1.485 Gbps), and 3G (2.97 Gbps):

ON – reclock the data before passing it to the output

BYPASS – pass the data stream through without reclocking

GUIDE TO INSTALLATION AND OPERATION

Figure 3.5 Reclocker panel

3.3.4 The Output & Optical panel

Output Config

Manually configure the input-to-output connections. Each of

the two optical outputs can be connected to either of the two

electrical inputs. The default is A-to-A and B-to-B.

• When Fail Over is ON, the configuration is fixed and

the settings made here are overridden. See section

3.3.5 below.

Optical Config

Use the radio buttons to switch the two optical transmitters

ON or OFF independently.

Figure 3.6 Output & Optical panel

FIO-1901-TT | 13

Page 18

GUIDE TO INSTALLATION AND OPERATION

3.3.5 The Fail Over panel

When Fail Over mode is activated, the FIO-1901-TT is

configured with Electrical In A as the source for both

outputs, and Electrical In B as the backup. If Electrical In A

fails, the outputs will be switched over to Electrical In B (if it

is valid), after a defined delay. The delay can be set

between 0 and 15 seconds, in order to accommodate

deliberate or anticipated breaks in the input data stream.

Mode: Use the radio buttons to set the Fail Over

operating mode to OFF or ON

Fail Delay: Use the slider to set the delay between the

detection of a failure on Electrical In A and the

switchover to Electrical In B (range is 0 to 15

seconds)

Note that turning this mode ON overrides the output

configuration set in the Output & Optical panel. See

section 3.3.4 above.

Figure 3.7 Fail Over panel

3.3.6 The Factory/Presets panel

Click the Load Factory button to reset all parameters on

this FIO-1901-TT card to factory default values.

• The factory default values are shown underlined

menu found in the Annex to this document, beginning

on page 21.

User Presets

The FIO-1901-TT has memory registers which can hold up

to 5 user-defined parameter settings.

Select any one of the five presets using the pull-down list.

The name of the currently-selected User Preset is shown on

the name bar.

Click Load to load the contents of the selected User Preset

into the FIO-1901-TT. All parameter settings and values will

be replaced by the contents of the selected User Preset.

Click Save to store the current parameter settings and

values from the FIO-1901-TT into the selected User Preset.

The existing contents of the preset will be overwritten

without asking for confirmation.

in the

Figure 3.8 Factory / Presets panel

14 | FIO-1901-TT

Page 19

GUIDE TO INSTALLATION AND OPERATION

3.3.7 The Alarm Config panel

This panel allows the alarm

reporting of the FIO-1901-TT

to be configured.

Click on the Alarm Config

button to open the Alarm

Configuration window.

The Alarm Configuration

window is organized in

columns

Status/Name

This contains an expandable tree listing all the alarms reported by this FIO-1901-TT card.

• Each alarm name includes an icon that shows its current status

The Card LED, Overall alarm and GSM contribution columns contain pulldown lists that allow the level of

contribution of each individual alarm to the alarm named in the column heading to be set.

Figure 3.9 Alarm Configuration panel

¾ Click on the alarm icon to see the available levels; then click on one to select it

Card LED

This column allows configuration of the contribution of each individual alarm to the status reported by the Status

LED on the front edge of the FIO-1901-TT card, visible through the front door of the Densité frame.

Overall Alarm

This column allows configuration of the contribution of each individual alarm to the Overall Alarm associated with

this card. The Overall Alarm is shown in the upper left corner of the iControl panel, and also appears at the bottom

of the Status/Name column.

GSM Contribution

This column allows configuration of the contribution of each individual alarm to the GSM Alarm Status associated

with this card. GSM is a dynamic register of all iControl system alarms, and is also an alarm provider for external

applications. The possible values for this contribution are related to the Overall alarm contri bution:

FIO-1901-TT | 15

Page 20

GUIDE TO INSTALLATION AND OPERATION

• If the Overall alarm contribution is selected as Disabled, the GSM alarm contribution can be set to any available

value

• If the Overall alarm contribution is selected as any level other than disabled, the GSM contribution is forced to

follow the Overall Alarm.

Levels associated with these alarms:

The pulldown lists may contain some or all of the following options:

The alarm makes no contribution (black icon)

The alarm is of minor importance (yellow icon)

The alarm is of major importance (orange icon)

The alarm is of critical importance (red icon)

The alarm exists but has no effect (used for text and composite alarms)

Shortcut: if you click on one of the “Set All” boxes in the Card LED, Overall Alarm or GSM Contribution columns,

you will open a pulldown that lets you assign a level to all alarms in that section of the column simultaneously.

Log Events

iControl maintains a log of alarm events associated with the card. The log is useful for troubleshooting and identifying

event sequences. Click in the checkbox to enable logging of alarm events for each individual alarm.

At the bottom of the window are several other controls.

Overall alarm and GSM contribution follow card LED

Click in the checkbox to force the Overall alarm and GSM contribution to be identical to the Card LED status

• All Overall alarms and GSM contributio ns for which there is a Card LED alarm will be forced to match the Card

LED alarm

• All Overall Alarms and GSM contributions for which there is no Card LED alarm will be forced to Disabled

A warning box will open allowing you to confirm the action,

since it will result in changes to the configuration and there

is no undo function.

Figure 3.10 Warning for Follow LED change

16 | FIO-1901-TT

Page 21

GUIDE TO INSTALLATION AND OPERATION

Copy to other cards

Click this button to open a panel that allows the

alarm configuration set for this card to be copied

into another FIO-1901-TT card.

• Select one or more destination cards from

the list in the window by clicking in the

checkboxes, or all of them by clicking in the

All checkbox

Figure 3.11 Copy to Other Cards

Get alarm keys

Click this button to open a save dialog where you

can save a file containing a list of all alarms on

this card and their current values, along with an

Alarm Key for each. The alarm keys are useful for

system integration and troubleshooting.

• The file is saved in .csv format

Figure 3.12 Save dialog for Get Alarm Keys

OK, Apply, Cancel

• OK accepts the settings and closes the window once the card confirms that ther e are no errors.

• Apply accepts the settings, but leaves the window open

• Cancel closes the window without applying any changes, and leaves the previous settings intact.

FIO-1901-TT | 17

Page 22

GUIDE TO INSTALLATION AND OPERATION

3.3.8 The Info panel

When the FIO-1901-TT is included in an iControl

environment, certain information about the card should be

available to the iControl system. The user can enter labels

and comments that will make this card easy to identify in a

complex setup. This information is entered into data boxes in

this panel.

Label: type the label that is shown for this FIO-1901-

TT when it appears in iControl applications

Short Label type the short-form label that iControl uses in

some cases (8 characters)

Source ID type a descriptive name for this FIO-1901-TT

Comments: type any desired text

The remaining data boxes show manufacturing information

about this card.

Three buttons in the panel give access to other information.

• Details…: Reports the Firmware version, service version,

and panel version for this card

• Advanced…: Shows the Miranda LongID for this card. The

Miranda LongID is the address of this FIO-1901-TT in the iControl

network.

Figure 3.13 Info panel

Figure 3.14 Details window

Figure 3.15 Advanced window

18 | FIO-1901-TT

Page 23

GUIDE TO INSTALLATION AND OPERATION

• Remote System Administration – opens the Joining Locators window,

which lists remote lookup services to which this FIO-1901-TT is

registered.

Add: Force the iControl service for this FIO-1901-TT to register itself

on a user-specified Jini lookup service, using the following syntax in

the data box:

jini://<ip_address>

where <ip_address> is the ip address of the server running the

lookup service, e.g.:

Figure 3.16 Joining Locators window

Remove: select one of the services listed in the window by clicking on it, and click Remove t o open a q uery

box allowing you to delete it from the window.

FIO-1901-TT | 19

Page 24

GUIDE TO INSTALLATION AND OPERATION

4 Specifications

ELECTRICAL INPUT (2)

Signal: 3G/HD/SD SDI SMPTE 424M, 292M, and 259M-C compliant

Supported data rates:

Reclocker bypassed – all rates between 19.4 Mbps and 3 Gbps

Reclocked data at 270, 1483.5, 1485, 2967, 2970 Mbps

EN50 83-9 DVB-ASI 270 Mbps

Cable length: (Belden1694A): 3G: 70 m (180’) @ 3 Gbps

HD: 130 m (400’) @ 1.5 Gbps

SD: 380 m (1000’) @ 270 Mbps

Return loss: 15 dB up to 1.5 GHz

10 dB from 1.5 GHz to 3 GHz

OPTICAL OUTPUT (2)

Optical: SMPTE-297M-2006 compliant

TX CHANNEL

Wavelength: 1310 nm single mode on LC Connectors

1310 nm & 1550nm single mode on LC Connectors

Tx Power: Min

Max

SFP-TT-S13S13-LC: -5 dBm 0 dBm

SFP-TT-CXXCYY-LC -6 dBm -3 dBm (DFB laser)

SFP-THTH-CXXCYY-LC 0 dbm 4 dBm (DFB laser)

SFP-TT-W13W15-LC -5 dBm 0 dBm @1310 nm (Fabry-Perot laser)

-6 dBm -3 dBm @1550 nm (DFB laser)

PROCESSING PERFORMANCE

Signal path: 10 bits

Latency: < 6 ns

Power: < 5W

20 | FIO-1901-TT

Page 25

GUIDE TO INSTALLATION AND OPERATION

pp

ANNEX 1 – FIO-1901-TT User Interface (local menu structure)

STATUS NO REAR, FIO-1901-RR-SRP, FIO-1901-TT-SRP, FIO-1901-RT-SRP, FIO-1901-R-SFP, FIO-1901-T-SRP

REAR MISMATCH

ELE.INA NO LOCK, NOSIGNAL, 270 Mbps, 1.5 Gbps, 3 Gbps

ELE.INB NO LOCK, NOSIGNAL, 270 Mbps, 1.5 Gbps, 3 Gbps

NO SFP, SFP-RR-LC, SFP-TT-S13S13-LC, SFP-RT-S13-LC, SFP-R-LC, SFP-T-S13-LC,

SFP-RR-W-LC, SFP-TT-C27C29-LC, SFP-TT-C31C33-LC, SFP-TT-C35C37-LC, SFP-TT- C39C41-LC,

SFP-TT-C43C45-LC, SFP-TT-C47C49-LC, SFP-TT-C51C53-LC, SFP-TT-C55C57-LC,

SFP-TT-C59C61-LC, SFP-TT-W13W15-LC

SFP MISMATCH

SFP VENDOR NAME (ex: GENNUM, OE ELECTRONICS,…)

SFP PART NUMBER (ex GO2922)

SFP REVISION

SFP TEMPERATURE (ex: [TEMP: LOW, NORMAL, HIGH])

FAIL OVER MODE [OFF

FAIL DELAY [0,…,3

OUTPUT CONFIG OUTPUT TxA [ELECTRICAL IN A

OUTPUT TxB [ELECTRICAL IN A, ELECTRICAL IN B]

OPTICAL Tx OPTICAL TxA [OFF, ON]

OPTICAL TxB [OFF, ON]

RECLOCKER ELECTRICAL IN A [ON

ELECTRICAL IN B [ON, BYPASS]

USER PRESET LOAD [USER 1 ,USER 2, USER 3, USER 4, USER 5]

SAVE [USER 1 ,USER 2, USER 3, USER 4, USER 5]

CONFIG ALARMS ELE.A NO LOCK ALARM LEVEL [GREEN, YELLOW

ALARM REPORT [NONE, GPI]

ELE.A NO SIGNAL ALARM LEVE L [GREEN, YELLOW, RED

ALARM REPORT [NONE

ELE.B NO LOCK ALARM LEVEL [GREEN, YELLOW

ALARM REPORT [NONE

ELE.B NO SIGNAL ALARM LEVE L [GREEN, YELLOW, RED, FLASH RED]

ALARM REPORT [NONE

SFP TEMPERATURE ALARM LEVEL [GREEN, YELLOW, RED

ALARM REPORT [NONE

R./SFP MISMATCH ALARM LEVEL [GREEN, YELLOW, RED, FLASH RED]

ALARM REPORT [NONE

NO SFP ALARM LEVEL [GREEN, YELLOW, RED, FLASH RED

ALARM REPORT [NONE

VERSION FIO-19TT: XXX

CPU BUILD: YYY

This item does not a

This item does not appear if the SFP is matched to the card type and rear

, ON]

,…,14,15] seconds

, BYPASS]

ear if the rear is matched to the card type

Only if matched SFP present

, ELECTRICAL IN B]

, GPI]

, GPI]

, GPI]

, GPI]

, GPI]

, GPI]

Only if Fail Over mode is OFF

, RED, FLASH RED]

, FLASH RED]

, RED, FLASH RED]

, FLASH RED]

]

FIO-1901-TT | 21

Page 26

GUIDE TO INSTALLATION AND OPERATION

ANNEX 2 – Installing the Optical Interface

Installing and removing the Fiber I/O interface cartridge requires special care. This annex describes the process.

The FIO-1901-TT-SRP rear panel incorporates a fiber optic interface. The interface consists of two parts:

• A socket on the rear panel into which an SFP interface module is plugged

• An SFP (Small Form-factor Pluggable) module into which the optical fibers are plugged, and which incorporates

the optical/electrical interface

Cautions and Warnings

SFP Transmitter modules contain a class 1 laser, which emits invisible radiation whenever the module is

powered up. Because the SFP is hot-swappable, the module may be powered up as soon as it is installed.

DO NOT LOOK INTO AN OPERATING SFP MODULE’S CONNECTORS, AS EYE DAMAGE MAY RESULT.

The SFP module is sensitive to electrostatic discharge (ESD). It is recommended that you use an ESDpreventive wrist strap grounded to the Densité chassis while handling the SFP module.

SFP modules are subject to wear, and their useful lifetime is reduced each time they are inserted or removed.

Do not remove them more often than is absolutely necessary.

Never remove or install an SFP module with the fiber optic cables connected. Damage to the cables could

Installing an SFP module

result.

The presence of dust and debris can seriously degrade the performance of an op tical interface. It is

recommended that you insert a dust plug into the SFP module whenever a fiber optic cable is not connected.

1. Make sure that the bale clasp lever is in the closed position

2. Position the SFP module so that the recessed slot is lined up with the

tab side of the socket.

22 | FIO-1901-TT

Page 27

GUIDE TO INSTALLATION AND OPERATION

3. Slide the module straight into the socket, and push gently until it

clicks into position.

Connecting the fiber optic cables

1. Remove the dust plug from the SFP module if present

2. Verify that both the exposed end of the optical fiber in the LC connector and the fiber stub within the SFP

module are clean

• Carefully remove any debris if necessary – see the note below.

3. Plug the LC-terminated fiber optic cable into the SFP module

Keep the connection clean!

The physical interface between two optical fibers is the critical point in a fiber system. The two fibers must

be accurately aligned – that’s the job of the connector plugs and bulkheads – and be in intimate contact

with no obstructions. That’s the job of the user. The small size of the fiber, and the even smaller size of

the fiber core, means that even common dust particles can seriously impair the transfer of light from one

fiber to another.

There are a variety of cleaning solutions available to help the fiber user maintain good fiber network

performance. For best results, it should be possible for the user to perform a visual inspection of the fiber

ends to verify cleanliness.

Miranda strongly urges all users to select a cleaning method that meets their needs, and to use it

rigorously and consistently.

A few tips:

• Always use a dust plug in an empty fiber receptacle, to keep airborne particles from settling on the

fiber end

• Keep your dust plugs clean – a sealed container is a must.

• Always follow the instructions carefully when cleaning – abrasions on the fiber ends can degrade

system performance significantly

• A visual inspection will ensure that particles and liquid residue have been removed

• If it’s still dirty, clean it again.

FIO-1901-TT | 23

Page 28

GUIDE TO INSTALLATION AND OPERATION

Removing the fiber optic cables

1. Grasp the LC fiber optic connector that is plugged into the SFP module, and pull it straight out to disengage

the optical fiber from the SFP.

• Never pull the fiber optic cable itself, as catastrophic damage may occur.

2. Insert a dust plug into the SFP module.

Removing the SFP module

1. Move the bale clasp lever to the open position.

2. Grasp the SFP module between your thumb and forefinger, and

pull it straight out of the slot.

• Do NOT pull on the bale clasp lever to remove the module, as

it is easily damaged

• You may find that you need to wiggle the module, or perhaps

push it into the slot a bit, before it will release and slide out.

3. Insert a dust plug into the SFP module.

24 | FIO-1901-TT

Loading...

Loading...