Gradall D174 Specification

D 174

CROSSOVER

HYDRAULIC

EXCAVATOR

SPECIFICATIONS

D174 CROSSOVER HYDRAULIC EXCAVATOR

Engine

• Cummins ISB 6.7. 660 ft lb Torque @

1600 rpm. 300 hp @ 1600 rpm

Intake: Electric grid air warmer

Air Filter

• 2-stage dry type with safety element,

ejector valve and service indicator

Electrical System

• 12 volt, 160 amp alternator with integral

voltage regulator. 2 SAE Group 31 1900

CCA batteries

Fuel Tank Capacity: 80 gal (303 L)

DEF Tank Capacity: 13 gal (49 L)

Gear Speeds (with 11R22.5 tires)

Gear 1 2 3 4 5 REV

MPH 10. 6 21.7 31.6 48.7 60 9. 74

Km/hr (17.0 ) (34.9) (50.9) (78.4) (97) (15. 2)

Upperstructure Cab

• All-weather cab isolated from frame on

rubber mounts

• Tinted safety glass windows

• Skylight

• Acoustical lining

• Four-way adjustable seat

• Dome light

• Filtered air heater and defroster

• Air conditioning

• AM/FM radio

• Heat source is provided by a fast response,

closed circuit hydraulic heater with 20,000

BTU/Hr. capacity

• Front window slides to overhead storage

• Rearview mirrors on right and left sides of

the machine

• Windshield wiper and washer

• Operator’s seat belt

Upperstructure Controls

• Two electronic joysticks control (hoist,

bucket, telescope and swing)

• One rocker switch (tilt) control

• Joysticks are mounted on arm pods that

are adjustable for individual operator

comfort and convenience

• Quick change joystick pattern using

interactive display

• Two foot pedals for remote control of

undercarriage travel and brakes

• Steering is handled with a rocker switch on

top of the lef t hand joystick

• Self-centering joysticks and panels; when

controls are released, power for movement

disengages and swing and travel brakes

set automatically

System Monitor

• Top selector buttons include

- Joystick pattern, hour meter and

indicator lamps

• Bottom selector buttons include

- Engine speed control, auto idle select

- A/C on select and heater

temperature control

The display shows as follows

• Park brake

• Low air brake pressure

• Malfunction indicator lamp (mil)

• Hydraulic oil level warning

• Hydraulic oil filter warning

• Engine stop lamp

• Amber warning lamp (engine)

• Wait to start lamp

• Diesel particulate filter lamp

• High exhaust system temperature

• Engine speed

• Fuel level

• DEF level

• Transmission gear request

• Transmission gear status

• Transmission oil temp

• Hydraulic oil temp

• Mode status (travel/remote)

• Check transmission lamp and

cab blower fan

Boom

• Two piece triangular telescoping boom

• Adjustable boom rollers with eccentric

shafts

• 220° boom tilt

• 105° boom pivot angle

Hydraulic System

Pumps

• One load-sensing bent axis piston pump;

0-58 GPM (0-219 L/min) total

SYSTEM SPECIFICATIONS

Four Double Acting Cylinders

• 2 hoist cylinders: 3.25” bore x 2.25” rod x

28.5” stroke (83 mm x 57 mm x 724 mm)

• 1 tool cylinder: 4.5” bore x 2.5” rod x 18.88”

stroke (114 mm x 63.5 mm x 479 mm)

• 1 boom cylinder: 3.25” bore x 2.25” rod x

123” stroke (83 mm x 57 mm x 3124 mm)

Two Hydraulic Motors

• Swing, 51 hp (38kW); Tilt, 21 hp (16kW)

Operating Pressures

• Hoist .....................................................3,800 psi (262 BAR)

• Tilt .............................................................2,500 psi (172 BAR)

• Swing .................................................. 3,800 psi (262 BAR)

• Tool ........................................................ 3,800 psi (262 BAR)

• Telescope .....................................3,800 psi (262 BAR)

• Pilot system ......................................550 psi (38 BAR)

Oil Capacity

• Reservoir 62 gallons (235 L )

• System 68 gallons (257 L)

• Pressurized reservoir with visual

oil level gauge

Filtration System

• 5 micron return filter

• 10 micron pilot filter

• Fin and tube-type oil cooler with

thermostatically controlled cooling fan

• Pressure-compensated, load-sensing

valves with circuit reliefs in all circuits

Undercarriage

• 4 x 4

• Wheelbase: 190” (4.83 m)

• Width 102” (2.6 m)

Transmission

• Allison 3500 RDS automatic

Gross Vehicle Axle Weight Rating

• 36,200 lb (16,420 kg))

Front Axles

• 13,200 lb (5,987 kg) rating

Rear Axle

• 23,000 lb (10,433 kg) rating 6.43 ratio

• Single reduction with driver controlled

differential lock.

Suspension

• Front: leaf springs with automatic

lock-out cylinders

• Rear: solid mount

Brakes

• Front: Meritor “Q” Series

- Cam-Master Size: 16.5” x 5”

(419 mm x 127 mm)

- ABS Brakes

- Automatic slack adjusters.

• Rear: Meritor “P” Series

- Cam-Master Size: 16.5” x 7”

(419 mm x 178 mm)

- Automatic Slack Adjusters

• Spring brake system incorporates emergency

and parking brakes on the rear axle

Wheels

• Hub piloted disc 10-stud

• 11.25” (286 mm) bolt circle

Tires

• Front: M/S11R22.5 16-ply mud and snow

traction tread

• Rear: M/S11R22.5 16-ply mud and snow

traction tread

Steering

• Integral hydraulic power steering

Standard Chassis Equipment

• Halogen headlights

• Tail lights

• Back-up lights and alarm

• Stoplights

• Identification lights front and rear

• Directional lights

• Four-Way hazard lights

• Front tow hooks

• Desiccant type air dryer with automatic

purge valve

Chassis Cab

• Two-person cab

• Sun visor

• Gauges for oil pressure

• Coolant temperature

• Air tank pressures

• Fuel level

• Def level

• Voltmeter

• Speedometer with odometer

• Tachometer

• Hour meter

• Engine and transmission monitor lights

• Engine shutdown controlled by engine

electronics

• Indicator lights and controls for rear axle

differential lock

• Park brake control

• Tinted safety glass

• Roll up and down windows

• Instrument panel lights

• Windshield wiper/washer

• West coast style mirror system with plane

and convex mirrors

• Fresh air heater and defroster

• Thermostatically controlled heater

• Dome light

• Air suspension seat with seat belt both driver

and passenger

• Key ignition switch with neutral start

• AM/FM bluetooth radio

• Duel electric horns

• Center storage console

• 12 volt power supply in dash

• Aluminum kick plates on insides of

both chassis doors

Swing

• Priority swing circuit with axial piston motor

• Planetary transmission

Swing speed: 8 rpm

Swing Brake

• Automatic spring-set/hydraulic release

wet-disc parking brake

• Dynamic braking is provided by the

hydraulic system

Hydraulic Remote Control

• Upperstructure powered by chassis

hydraulics through PTO

• Travel and brake pedals in the

upperstructure cab

• Steering controlled with left hand joystick

• Digging brakes and front axle lockout

cylinders set automatically with travel

pedal in neutral

• Parking brakes controlled by toggle

• Electrically operated alarm mounted

on undercarriage signal remote control

movement in either direction, reverse

movement when driven from

undercarriage cab

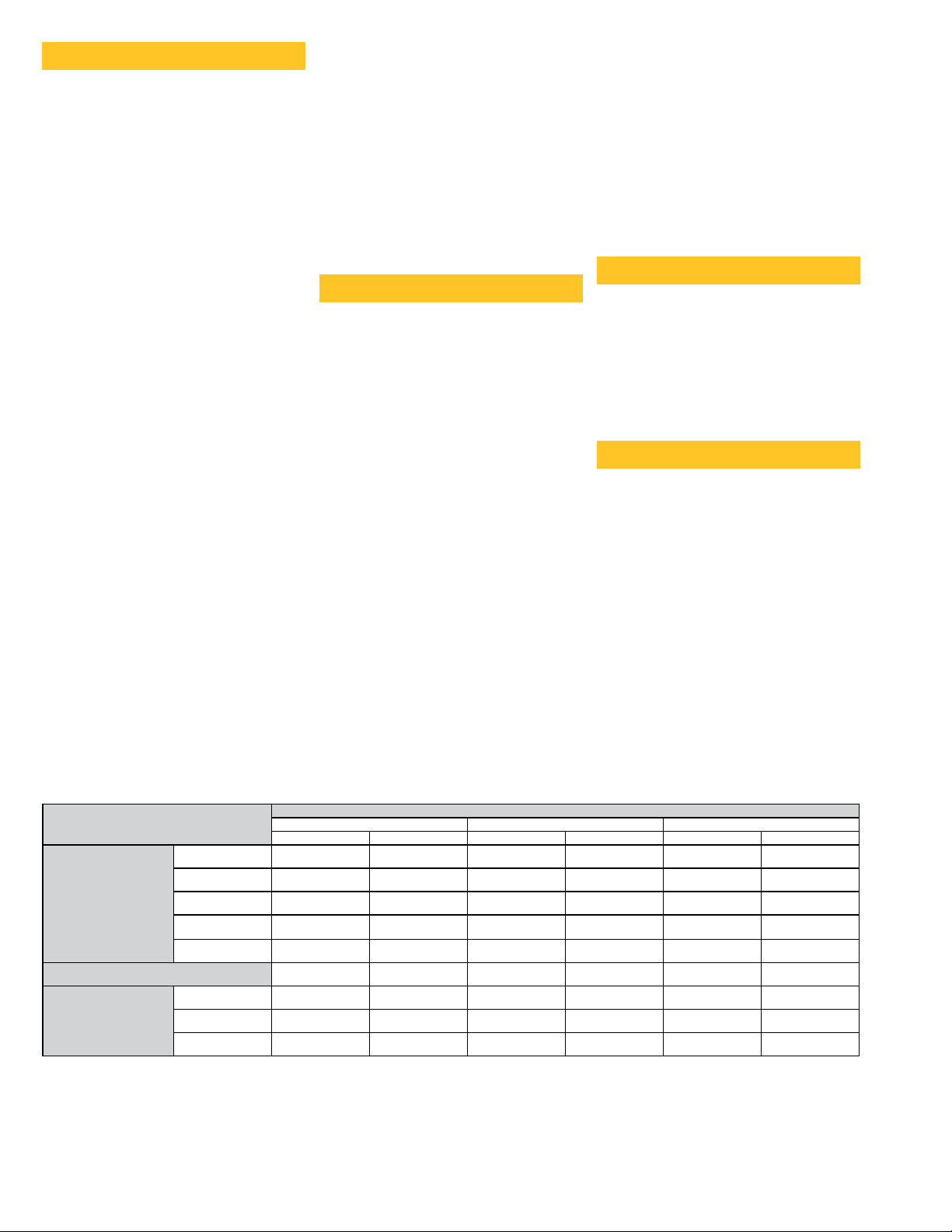

GRADALL Model D154 4x4 Lift Capacity Over Side or Rear - LB. (kg)

LOAD POINT HEIGHT

19’ 7” (6.0 m) 3000 (1360) 3000 (1360)

15’ 6” (4.7 m) 4660 (2115) 4660 (2115) 3180 (1440) 3180 (1440) 2880 (1305) 2880 (1305)

ABOVE GROUND LEVEL

AT GROUND L EVEL

BELOW GROUND LEVEL

10’ 6” (3.2 m) 5390 (2445) 5390 (2445) 3530 (1600) 3530 (1600) 2880 (1305) 2880 (1305)

BOOM LEVEL

9’ 2” (2.8 m)

5’ 6” (1.7 m) 5480 (2485) 5480 (2485) 3615 (1640) 3615 (1640) 2905 (1320) 2905 (1320)

4’ 6” (1.4 m) 3690 (1675) 3690 (1675) 2955 (1340) 2955 (1340)

9’ 6” (2.9 m) 2695 (1220) 2695 (1220) 2690 (1220) 2690 (1220)

10’ 3” (3.1 m) 2580 (1170) 2580 (1170)

NOTE: The above loads are in compliance with the SAE standard J1097 DEC2005.

They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity.

The rated lift capacity is based on the mac hine being equipped with 4,500 lb (20 41 kg)

counter weight, standard boom, standard tires, no auxiliary hydr aulics and no bucket.

NOTE: Bucket adjustment values are 87% of the actual buc ket weights .

The load p oint is located on the bucke t pivot point , including load listed fo r maximum radius.

Do not at tempt to lif t or hold any load greater tha n these rate d values at spe cified load radii and

heights. The weight of slings and any auxiliar y devices must be deduc ted from the rated load to

determine the net load that may be lif ted.

15’ 6” (4.7 m) 20’ 6” (6. 2 m) Maximum radius

Over End Over Side Over End Over Side Over End Over Side

5490 (2490) 5490 (2490) 3580 (1625) 3580 (1625) 2885 (1310) 2885 (1310)

4760 (2160) 4760 (2160) 3365 (1525) 3365 (1525) 2950 (1340) 2950 (1340)

ATTENTION: All rated loa ds are based o n the machine being stationary and level on a firm

suppor ting sur face. For safe working loads, the user must make allowance for his particular job

condit ions such as soft or uneven ground, ou t of level conditions, side loads, ha zardous

condit ions, expe rience of personnel , etc. The operator and ot her personnel must fully acquaint

themselves with the Operator’s Manual furnished by the manufacturer before operating this

machine . Rules for safe operation of equipment must be adher ed to at all time s.

LOAD RADIUS

Loading...

Loading...