Gradall 544B Operation Manual

1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

0

0

0

0

0

0

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

IMPORT ANT SAFETY NOTICE

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456

Safe operation depends upon reliable equipment and proper operating

procdures. Performing the checks and services described in this manual

will help to keep your Gradall® Material Handler in reliable condition and use

of the recommended operating procedures can help you avoid accidents.

Because some procedures may be new to even the experienced operator,

we recommend that this manual be read, understood and followed by all

who operate the unit.

Strict attention to, and compliance with instructions provided in this manual,

the EMI Rough Terrain Forklift Safety Manual, the Gradall Material Handler

Safety Manual, as well as instructional decals and plates affixed to the

machine, will help you avoid personal injury and damage to the equipment.

The information provided is not intended to cover all situations; it would be

impossible to anticipate and evaluate all possible applications and methods

of operation for this equipment.

Any procedure not specifically recommended by The Gradall Company

must be thoroughly evaluated from the standpoint of safety before it is

placed in practice. If you aren’t sure, contact your Gradall Material Handler

Distributor before operating.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

Do not modify this machine without written

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

permission from The Gradall Company. Use

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

only genuine Gradall replacement parts.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901

23456789012345678901234567890121234567890123456789

23456789012345678901234567890121234567890123456789

23456789012345678901234567890121234567890123456789

23456789012345678901234567890121234567890123456789

23456789012345678901234567890121234567890123456789

OTHER NOTICES

23456789012345678901234567890121234567890123456789

The Gradall company retains all

proprietary rights to the information

contained in this manual.

The Company also reserves the right to

change specifications without notice.

Gradall is a registered trademark for

hydraulic excavators, hydraulic material

handlers and attachments manufactured

by The Gradall Company.

The Gradall Company

406 Mill Avenue, S.W ., New Philadelphia, Ohio 44663

Form No. 29027 - Revised 1/95

INTRODUCTION

General

The manual provides important information to

familiarize you with safe operating procedures and

operator maintenance requirements for the Gradall/

544B Material Handler.

If you have any questions regarding the material

handler, contact your Gradall Material Handler

Distributor.

Operator Qualifications

Operators of the material handler must be in good

physical and mental condition, have normal reflexes

and reaction time, good vision and depth perception

and normal hearing. He/she* must not be using

medications which could impair his abilities nor be

under the influence of alcohol or any other drug

during the work shift.

The operator should also possess a valid, applicable

driver’s license and must have completed a course of

training in the safe operation of this type of material

handling equipment.

In addition, the operator must read, understand and

comply with instructions contained in the following

material furnished with the material handler:

This Operator’s Manual

FIEI Rough T errain Forklift Safety Manual

Gradall Material Handler Safety Manual

All instruction decals and plates

Any optional equipment instructions furnished

Related Manuals & Decals

Separate publications are furnished with the

material handler to provide information

concerning safety, replacement parte, maintenance

components. Replacement manuals, decals and

instruction plates can be ordered from your Gradall

Material Handler Distributor.

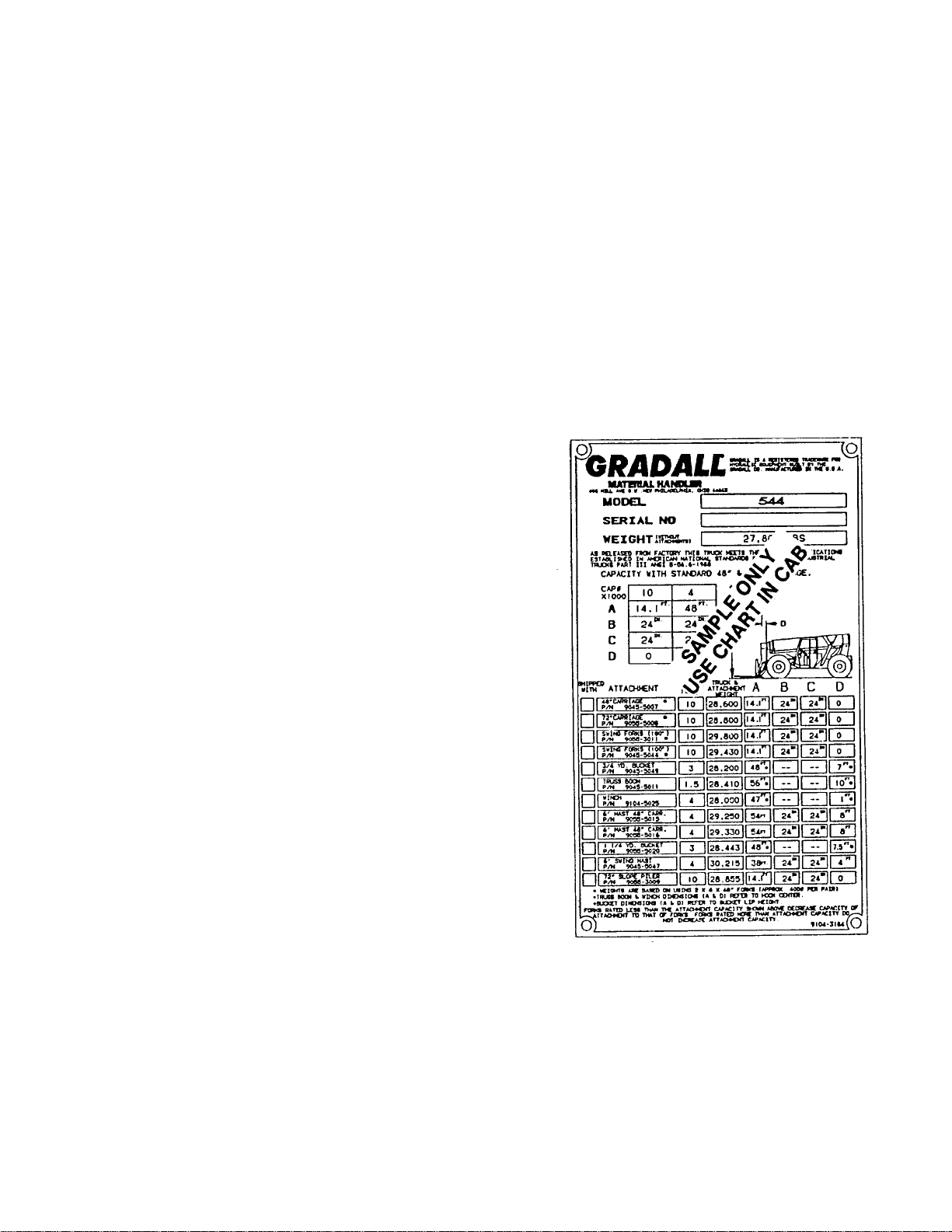

Serial Number Location

Specify Model and Serial Numbers when ordering

parts and when discussing specific applications and

procedures with your distributor. The model/serial

number plate is located on the right cab wall.

The operator must also read, understand and

comply with all applicable Employer, Industry and

Governmental rules standards and regulations.

Regardless of previous experience operating similar

equipment, the operator must be given sufficient

opportunity to practice with the 544B Material

Handler in a safe, open area (not hazardous to people

or property) to develop the skills and “feel” required

for safe, efficient operation

*Though no offense or discrimination is intended,

only the masculine pronouns will be used

throughout the remainder of this manual.

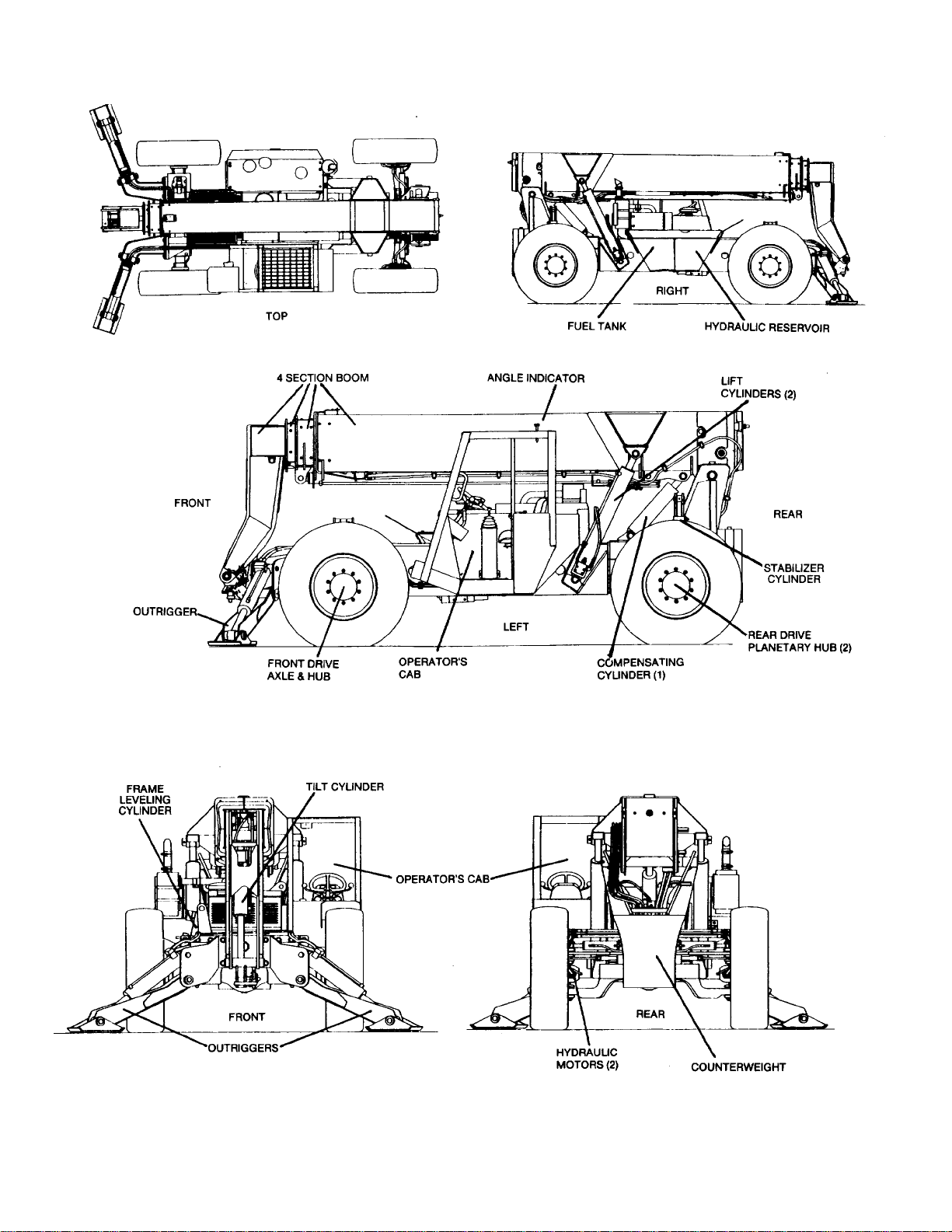

Orientation

When used to describe location of components in

the material handler, the directions front, rear,

right and left relate to the orientation of a person

sitting in the operator’s seat.

Nomenclature

The illustrations on page 3 include nomenclature

applied to major components of the material handler.

The term “handler” will be used throughout the

balance of this manual in place of the words “material

handler”.

2

NOMENCLATURE

3

SAFETY HIGHLIGHTS

Read and understand this manual, the Gradall Material Handler Safety Manual and all instructional

decals and plates before starting, operating or performing maintenance procedures on this equipment.

Most safety notes included in this manual involve

characteristics of the Model 544B Material Handler.

Refer to the FIEI Rough Terrain Forklift Safety

Manual and the Gradall Material Handler Safety

Manual for safety precautions relating to general

material handling procedures and practices.

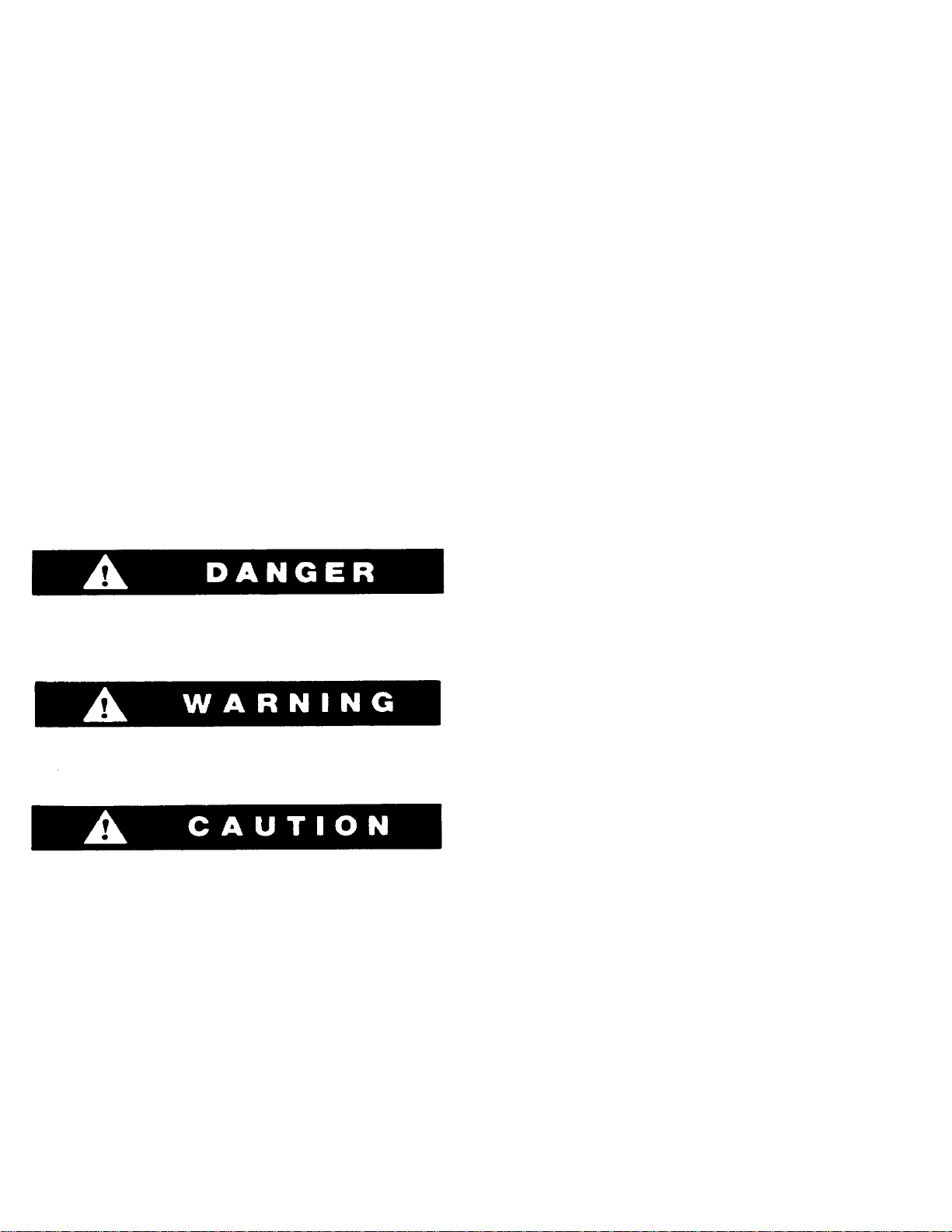

Watch for these symbols; they are used

to call your attention to safety notices.

Operators of this equipment must have successfully

completed a training program in the safe operation of

this type of material handling equipment.

Regardless of previous experience operating similar

equipment, the operator must be given sufficient

opportunity to practice with the 544B Material

Handler in a safe open area (not hazardous to people

or property) to develop the skills and “feel” required

for safe, efficient operation.

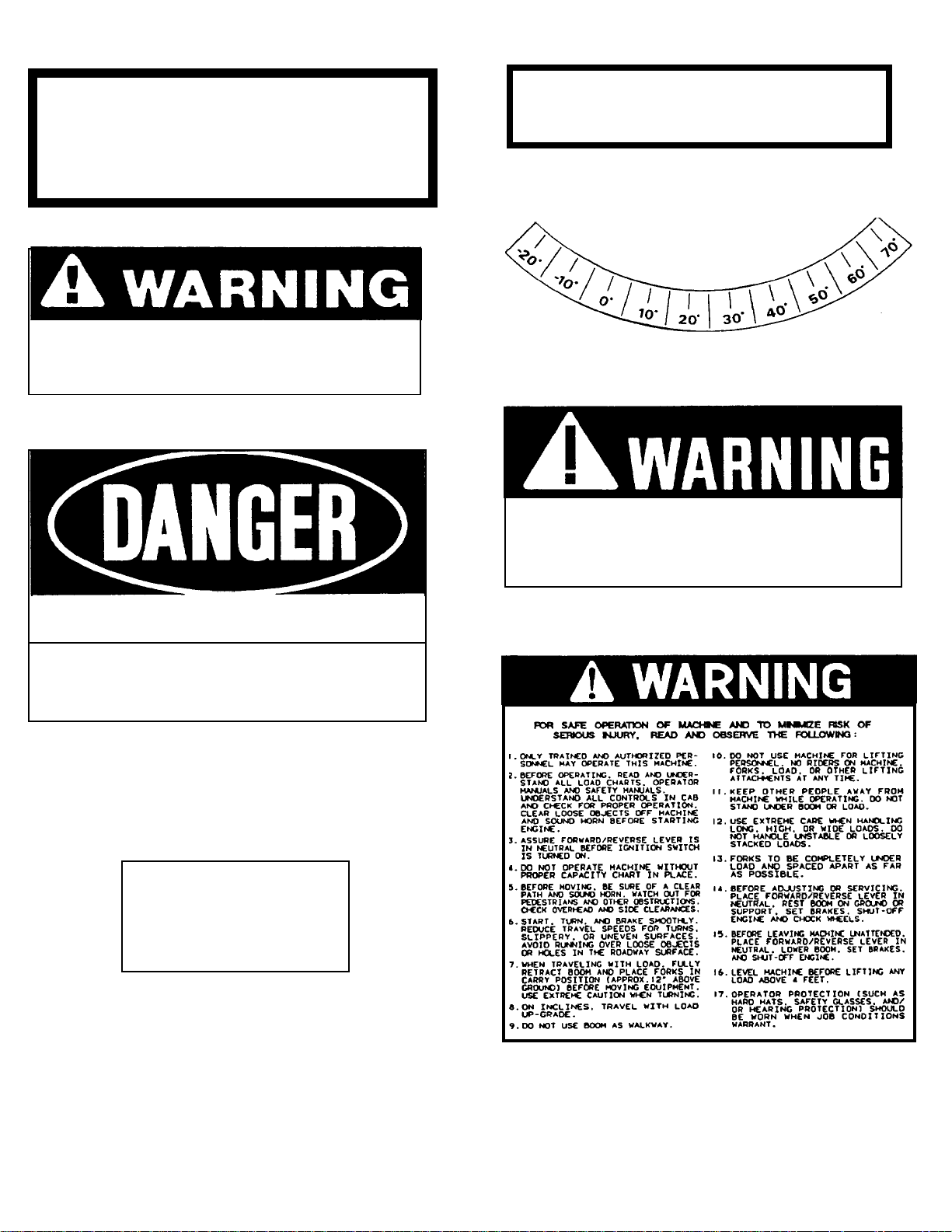

This symbol indicates an extreme hazard which

would result in high probability of death or

serious in|injury if proper precautions are not

taken.

This symbol indicates a hazard which could

result in death or serious injury it proper

precautions are not taken.

This symbol Indicates a hazard which could

result in injury or damage to equipment or

property it proper precautions are not taken.

4

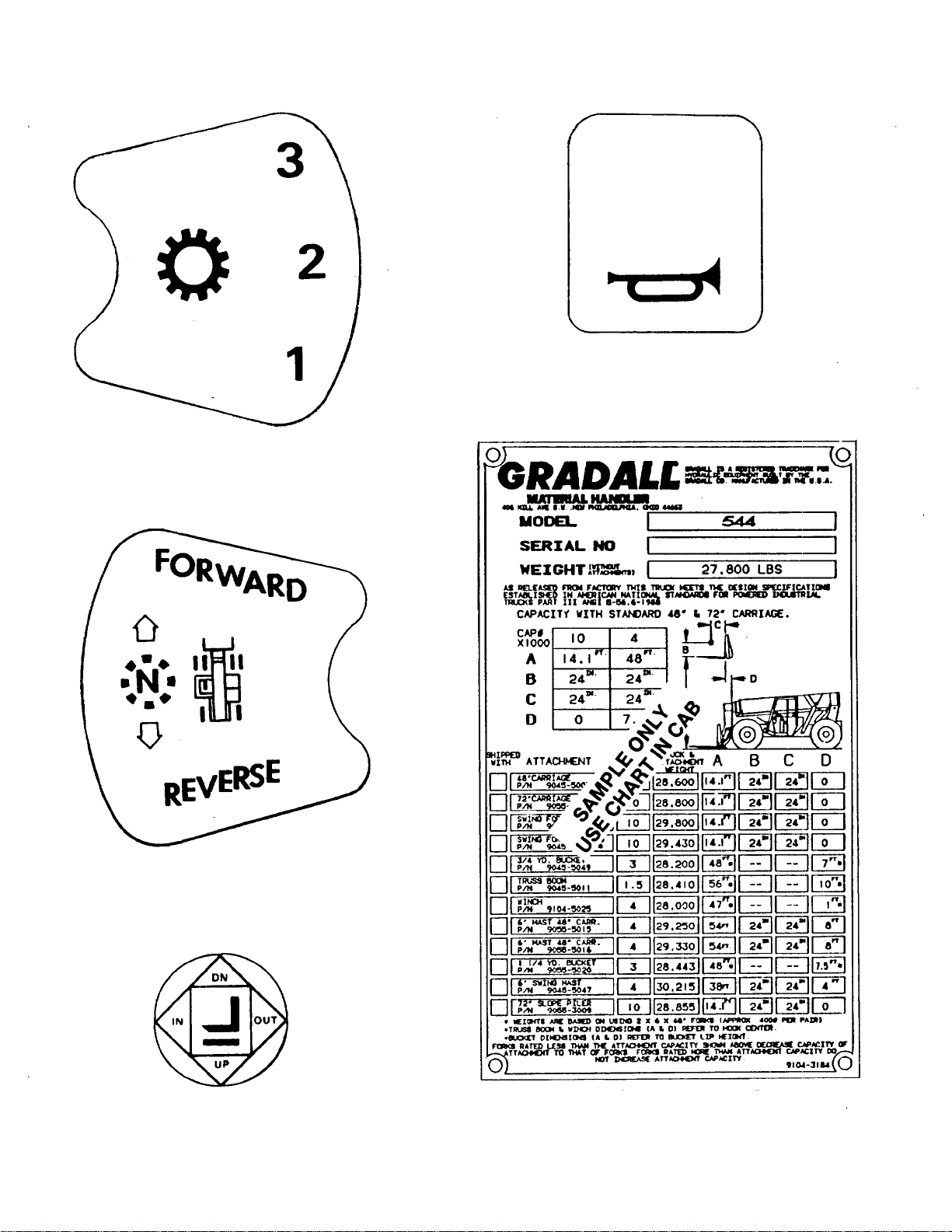

9100-3039

Located on Dashboard

Part No.9100-3039

Decals

9103-3089

Located on Dashboard

Part No. 9103-3089

9100-3040

Located on Dashboard

Part No. 9100-3040

Located on Boom Lever Knob

Part No. 9100-3400

Located on Right Cab Wall

Part No. 9104-3184

5

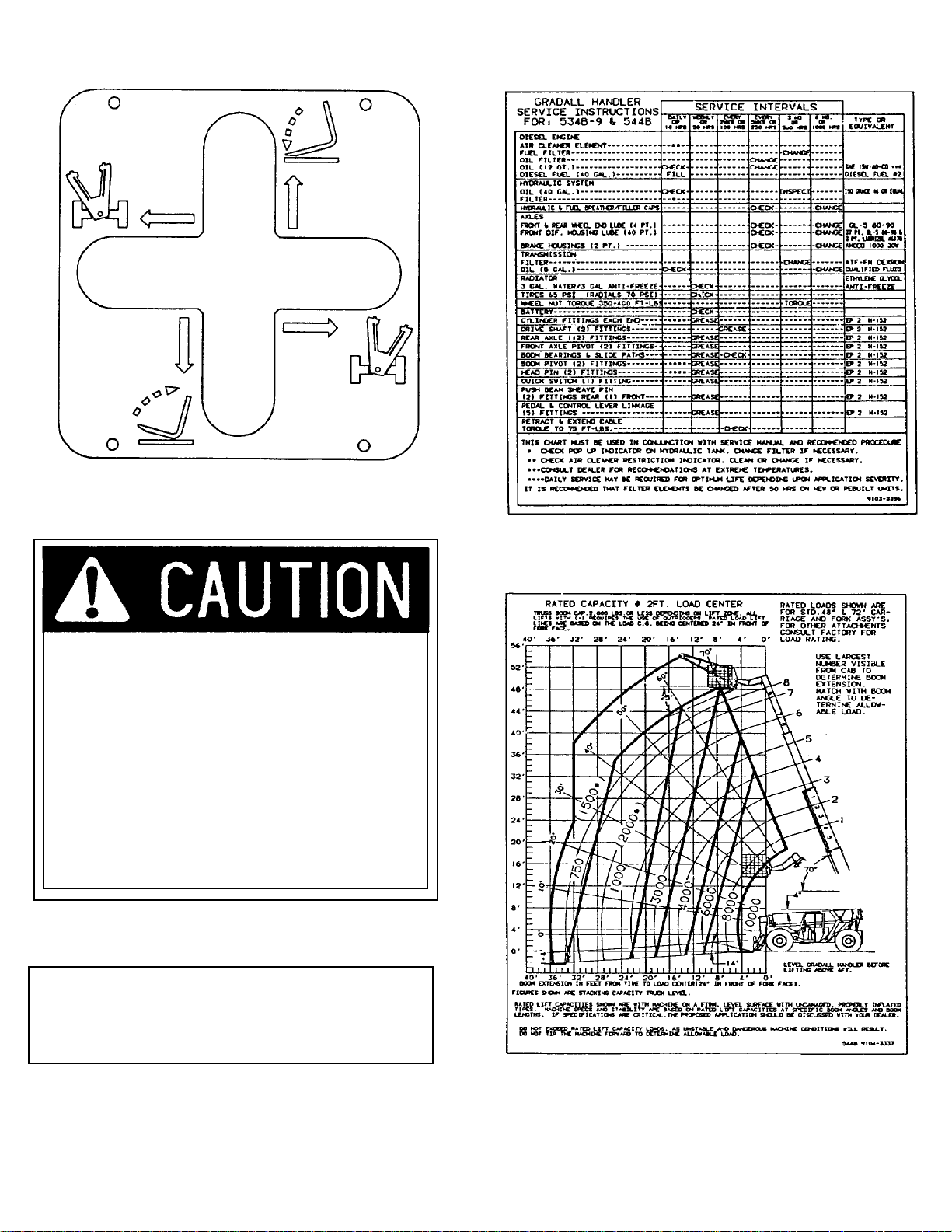

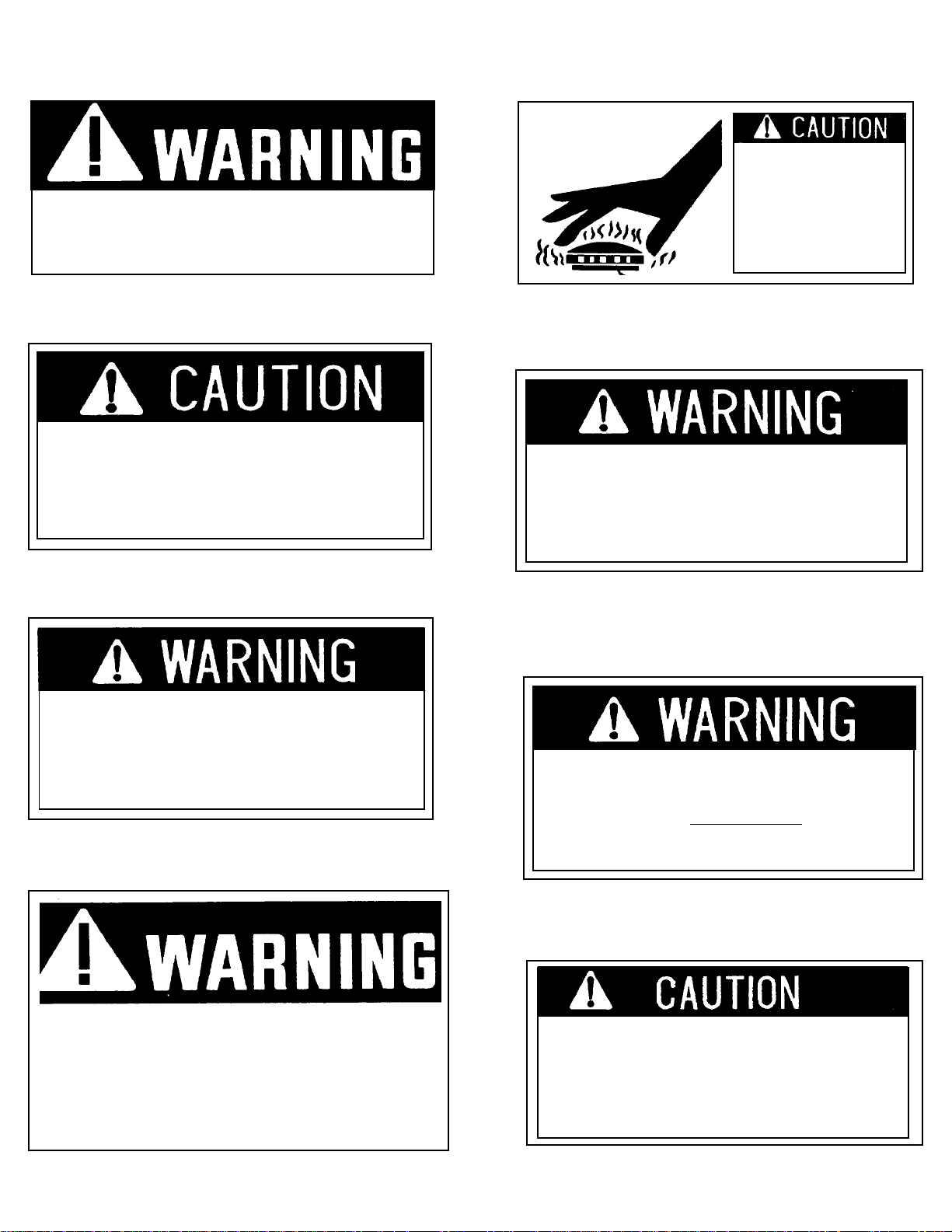

Located on Dashboard

Part No. 9103-3341

Decals (cont.)

FOR LONGER TURBOCHARGER

LIFE, IDLE ENGINE AT LEAST

1 MINUTE AFTER START-UP

AND BEFORE SHUT DOWN.

TO PREVENT ENGINE RING

GEAR DAMAGE, WAIT 10

SECONDS AFTER ENGINE

STOPS BEFORE ATTEMPTING

TO RESTART.

FOR OPTIMUM CONTROL AND BRAKE

LIFE. USE LOW GEAR WHEN

DESCENDING STEEP GRADES.

Located on Dashboard

Part No. 9103-3443

Located on Left Cab Wall

Part No. 9103-3396

WHEN TRA VELING AT HIGH SPEEDS

FOR OVER 2 MILES, DISENGAGE

REAR HUBS BY REVERSING SMALL

COVER PLA TE AT HUB CENTER.

Located on Dashboard

9103-3418

9103-3418

Located on Mudguard

Part No. 9103-3395

6

Decals (cont.)

IMPORTANT

To prevent damage to the electrical system when

using booster battery or charger, always connect

( + ) POSITIVE TO POSITIVE

( - ) NEGA TIVE TO NEGA TIVE

Located on Battery Cover

Part No. 7702-3007

HOT EXHAUST

Located on Engine Cover

Part No.7734-3018

HYDRAULIC OIL

Located on Hydraulic T ank

Park No. 7702-3006

Located on Side of Boom

Part No. 9100-3031

DEATH

UNLAWFUL

PARK BRAKE

PULL TO SET

PUSH TO RELEASE

OR INJURY MAY RESULT FROM

CONTACTING ELECTRICAL LINES.

TO PLACE ANY PART OF THIS

MACHINE OR LOAD WITHIN 10

FEET OF HIGH VOLTAGE LINES

OF UP TO 50,000 VOLTS.

Located on Mud Guard

Part No. 8360-1011

FUEL-DIESEL

EXTINGUISH ALL OPEN FLAME

AND SMOKING MA TERIALS

WHEN REFUELING

Located on Fuel T ank

Part No. 9100-3052

Located on Seat Pedestal

Part No. 9104-3129

Located Inside Cab

Part No. 9106-3047

7

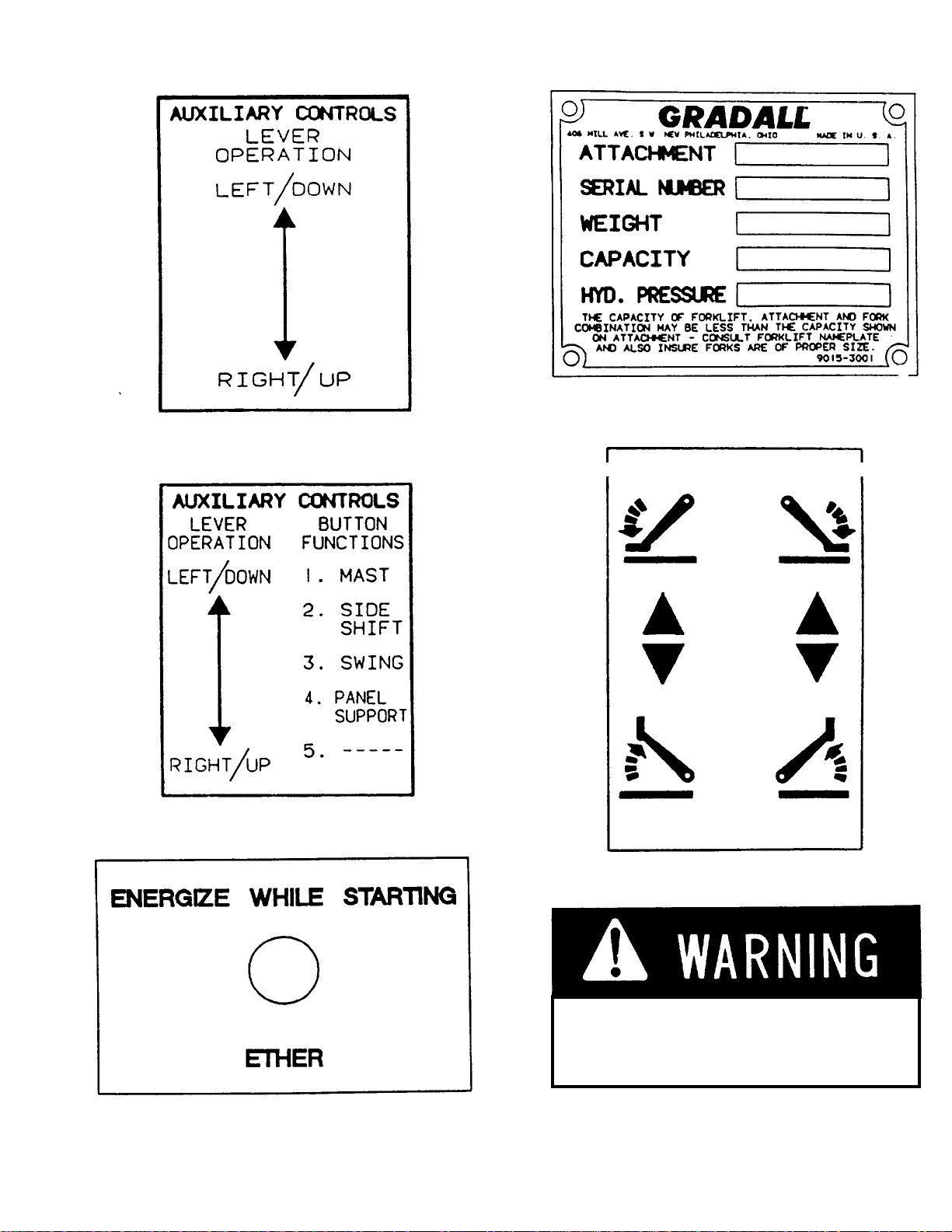

DO NOT INSERT HAND IN

OPENING WHILE ENGINE

IS RUNNING

Located on Engine Cover

Part No. 9103-3011

DO NOT USE OXYGENDO NOT USE OXYGEN

DO NOT USE OXYGEN

DO NOT USE OXYGENDO NOT USE OXYGEN

USE “OIL PUMPED OR DRY NITROGEN.”USE “OIL PUMPED OR DRY NITROGEN.”

USE “OIL PUMPED OR DRY NITROGEN.”

USE “OIL PUMPED OR DRY NITROGEN.”USE “OIL PUMPED OR DRY NITROGEN.”

CONSULT DEALER BEFORE CHARGING ACCUMULATORCONSULT DEALER BEFORE CHARGING ACCUMULATOR

CONSULT DEALER BEFORE CHARGING ACCUMULATOR

CONSULT DEALER BEFORE CHARGING ACCUMULATORCONSULT DEALER BEFORE CHARGING ACCUMULATOR

9104-3206

Decals (cont.)

9103-3011

PRESSURIZED-PRESSURIZED-

PRESSURIZED-

PRESSURIZED-PRESSURIZED-

COOLING SYSTEMCOOLING SYSTEM

COOLING SYSTEM

COOLING SYSTEMCOOLING SYSTEM

REMOVE CAPREMOVE CAP

REMOVE CAP

REMOVE CAPREMOVE CAP

SLOWLYSLOWLY

SLOWLY

SLOWLYSLOWLY

9104-3210

Located on Engine Cover

Part No. 9104-3210

NO RIDERS

Located on Accumulator

Part No. 9104-3206

PINCH POINT AREAPINCH POINT AREA

PINCH POINT AREA

PINCH POINT AREAPINCH POINT AREA

TO PREVENT INJURY, KEEPTO PREVENT INJURY, KEEP

TO PREVENT INJURY, KEEP

TO PREVENT INJURY, KEEPTO PREVENT INJURY, KEEP

CLEAR ANYTIME MACHINECLEAR ANYTIME MACHINE

CLEAR ANYTIME MACHINE

CLEAR ANYTIME MACHINECLEAR ANYTIME MACHINE

IS RUNNING.IS RUNNING.

IS RUNNING.

IS RUNNING.IS RUNNING.

Located on Rear of Frame

Part No. 9104-3209

9104-3209

9104-3211

Located at Cab Entrance &

on Engine Cover

Part No. 914-3211

DO NOT USE THIS MACHINE

FOR LIFTING PERSONEL.

9104-3215

Located on Mudgaurd

Part No. 9104-3215

TT

O PREVENTO PREVENT

T

O PREVENT

TT

O PREVENTO PREVENT

INJURINJUR

INJUR

INJURINJUR

OUT OF BOOMOUT OF BOOM

OUT OF BOOM

OUT OF BOOMOUT OF BOOM

HOLES.HOLES.

HOLES.

HOLES.HOLES.

Located on each side of boom

Part No. 7702-3009

YY

,,

KEEP KEEP

Y

,

KEEP

YY

,,

KEEP KEEP

7702-3009

INSURE FORKS ARE LEVEL AND

LOAD IS SECURE BEFORE ROTATING

LOAD WHEN EQUIPPED WITH SWING

FORKS. BOOM SHOULD BE PROPERLY

SHIMMED TO MINIMIZE TWIST.

LOSS OF LOAD WILL RESULT FROM

MISUSE OF SWING FORKS.

Located on left cab wall

8

Part No. 9104-3173

9104-3173

Optional Equipment Decals

9103-3417

Located on Instrument Console

Part No. 9103-3417

9103-3394

Located on Instrument Console

Part No. 9103-3394

Located on Attachment

Part No. 9015-3001

9102-3006

Located on Dashboard

Part No. 9108-3363

Located on Seat Pedestal

Part No. 9102-3006

CHECK TO ASSURE QUICK SWITCHCHECK TO ASSURE QUICK SWITCH

CHECK TO ASSURE QUICK SWITCH

CHECK TO ASSURE QUICK SWITCHCHECK TO ASSURE QUICK SWITCH

PIN IS FULLY ENGAGED AND LOCKEDPIN IS FULLY ENGAGED AND LOCKED

PIN IS FULLY ENGAGED AND LOCKED

PIN IS FULLY ENGAGED AND LOCKEDPIN IS FULLY ENGAGED AND LOCKED

AFTER ATTACHMENT CHANGE.AFTER ATTACHMENT CHANGE.

AFTER ATTACHMENT CHANGE.

AFTER ATTACHMENT CHANGE.AFTER ATTACHMENT CHANGE.

2-9103-3023

Located on Boom Head

Part No. 9103-3023

9

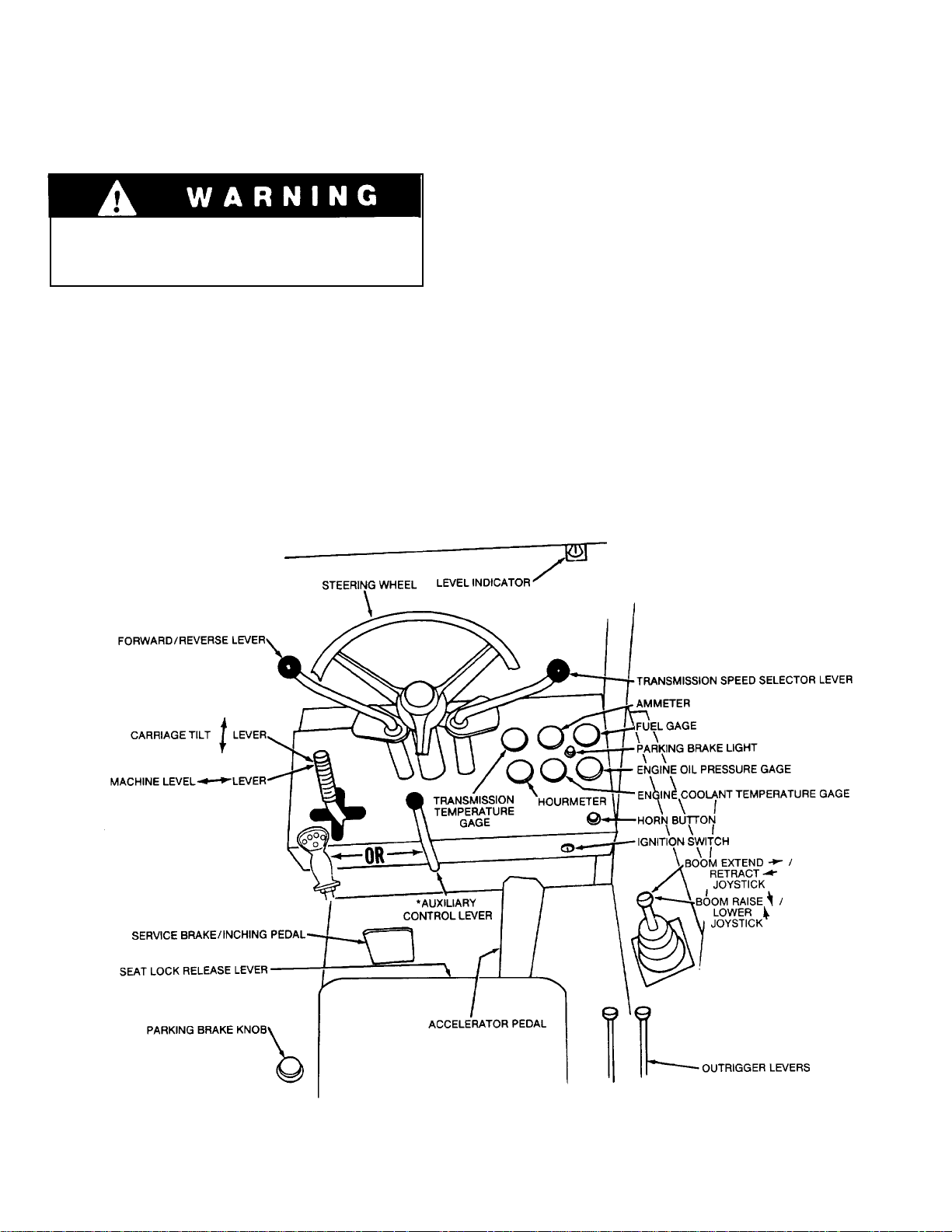

OPERA TOR’S CAB

The standard cate is open on three sides and includes

an overhead guard to provide protection from

falling objects.

Never operate the handler unless the

overhead guard is in place and in good

condition.

A fully enclosed cate with windows and a lockable

door is available as an option. The cab door can be

secured in the fully opened or closed position. Be

sure the door is fully secured when operating the

handler.

The operator’s seat is equipped with a seat belt and

includes fore and aft adjustment to compensate for

CONTROL AND INSTRUMENT IDENTIFICATION

variations in operator size. The adjustment

release/lock lever is located beneath front edge of

seat. Wear set belt at all times.

An optional windshield wiper is available for use

with enclosed cabs. An ON/OFF control switch is

Located on the wiper motor.

A variable speed defroster fan is available for use

with enclosed cabs. An ON/OFF control switch and

speed control are located on the base of the fan.

An optional variable speed heater fan is available for

use with units equipped with a heater. An ON/OFF/

SPEED CONTROL knob is located on the dashboard. Hot water to the heater can be controlled by a

valve at the engine.

*Items preceded by an asterisk are optional and may not be furnished on your handler

10

Loading...

Loading...