Gradall 534B Service Manual

®

SERVICE MANUAL

®

534B

®

CORPORATE OFFICE

9103-1390

July 2002

Starting S/N

8744110 thru 0144859

Also S/N 8744079 &

(534B-9) S/N 0144860

thru S/N 0144899

GRADALL DIVISION

JLG INDUSTRIES, INC.

1 JLG DRIVE

McConnellsburg, PA

17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

JLG INDUSTRIES, INC.

406 Mill Avenue S.W.

New Philadelphia, OH

44663

USA

Telephone: (330) 339-2211

Fax: (330) 339-8458

®

®

OPERATION & LUBRICATION MANUAL

®

534B

Form #48729

CORPORATE OFFICE

9103-1380

July 2002

Starting S/N

8744110

Also Covers

S/N 8744079

Original Issue 4/87

GRADALL DIVISION

JLG INDUSTRIES, INC.

1 JLG DRIVE

McConnellsburg, PA

17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

JLG INDUSTRIES, INC.

406 Mill Avenue S.W.

New Philadelphia, OH

44663

USA

Telephone: (330) 339-2211

Fax: (330) 339-8458

IMPORTANT SAFETY NOTICE

Safe operation depends on reliable equipment and proper operating

procedures. Performing the checks and services described in this manual will

help to keep your Gradall Material Handler in reliable condition and use of

the recommended operating procedures can help you avoid accidents.

Because some procedures may be new to even the experienced operator we

recommend that this manual be read, understood and followed by all who

operate the unit.

Danger, Warning and Caution notes in this manual and the FIEI Rough Terrain

Forklift Safety Manual will help you avoid injury and damage to the equipment.

These notes are not intended to cover all eventualities; it would be impossible to

anticipate and evaluate all possible applications and methods of operation for

this equipment.

Any procedure not specifically recommended by The Gradall Company must

be thoroughly evaluated from the standpoint of safety before it is placed in

practice. If you aren’t sure, contact your Gradall Material Handler

Distributor before operating.

Do not modify this machine without written permission from The Gradall

Company.

NOTICE

The Gradall Company retains all

proprietary rights to the information contained in this manual.

The Company also reserves the

right to change specifications without notice.

Gradall is a registered trademark for

hydraulic excavators, hydraulic material handlers and attachments manufactured by The Gradall Company.

Form No. 48729

The Gradall Company

406 Mill Avenue, S.W., New Philadelphia, Ohio 44663

INTRODUCTION

General

The manual provides important information

familiarize you with safe operating procedures and

operator maintenance requirements for the Gradall/

534-B Material Handler.

If you have any questions regarding the material

handler, contact your Gradall Material Handler

Distributor.

Operator Qualifications

Operators of the material handler must be in good

physical and mental condition, have normal reflexes

and reaction time good vision and depth perception

and normal hearing. He/she* must not be using

medication which could impair his abilities nor be

under the influence of alcohol or any other drug

during the work shift.

The operator should also possess a valid, applicable

driver’s license and must have completed a course of

training in the safe operation of this type of material

handling equipment.

Related Manuals & Decals

Separate publication are furnished with the

material handler to provide information

concerning safety, replacement parte, maintenance

procedures, theory of operation and vendor

components. Replacement manuals, decals and

instructions plates can be ordered from your Gradall

Material Handler Distributor.

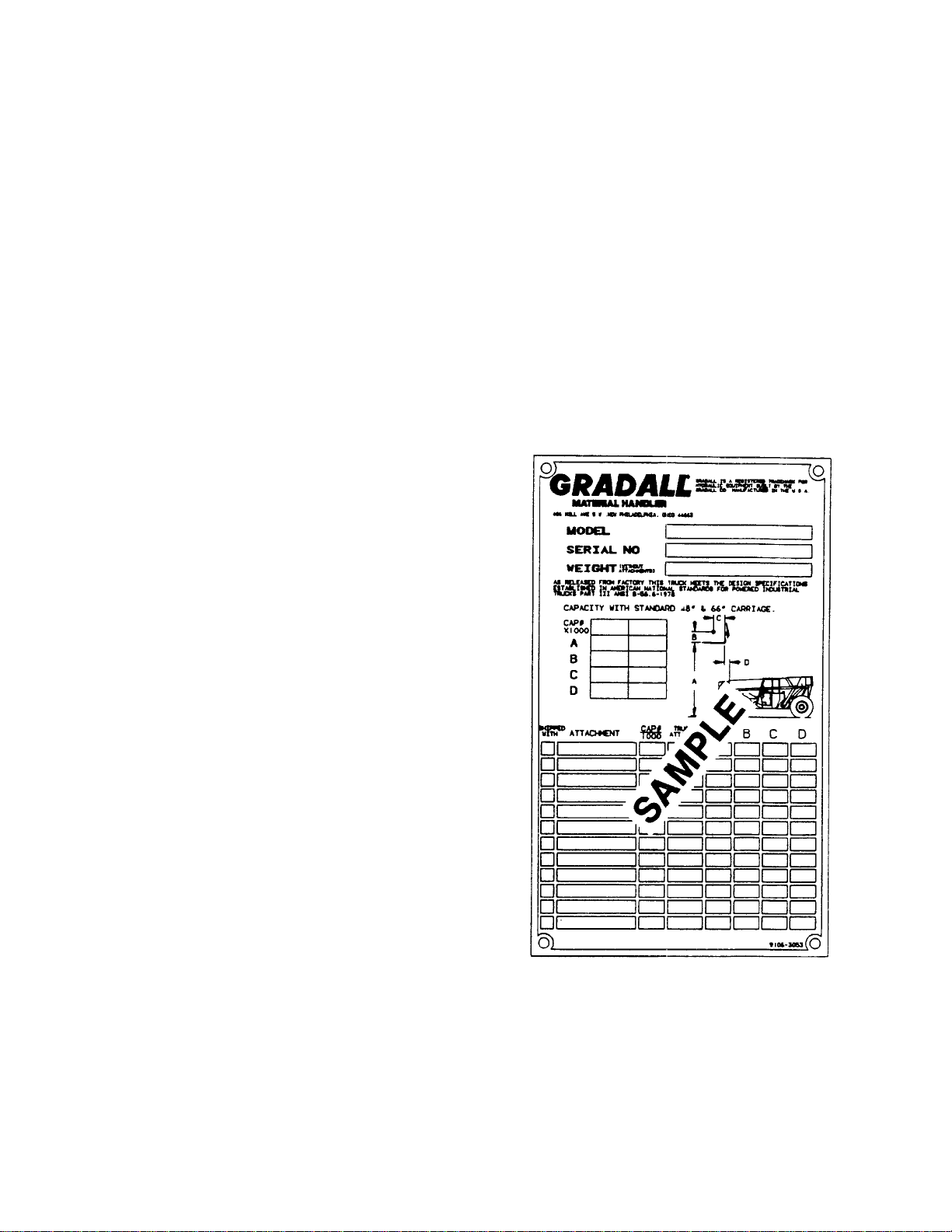

Serial Number Location

Specify Model and Serial Numbers when ordering

parts and when discussing specific applications and

procedures with your distributor. The model/serial

number plate located on the cate wall to the right

of the Operator’s seat pedestal.

In addition, the operator must read, understand and

comply with instructions contained in the following

material furnished with the material handler:

This Operator’s Manual

FIEI Rough T errain Forklift Safety Manual

Gradall Material Handler Safety Manual

All instruction decals and plates

Any optional equipment instructions furnished

The operator must also read, understand and

comply with all applicable Employer, Industry and

Governmental rules, standards and regulations.

Regardless of previous experience operating similar

equipment, the operator must be given sufficient

opportunity to practice with the 534-B Material

Handler in a safe, open area (not hazardous to people

or property) to develop the skills and “feel” required

for safe, efficient operation.

¬

Though no offense or discrimination is intended,

only the masculine pronouns will be used

throughout the remainder of this manual.

Orientation

When used to describe location of componente in

the material handler, the directions front, rear,

right and left relate to the orientation of a person

sitting in the operator’s seat.

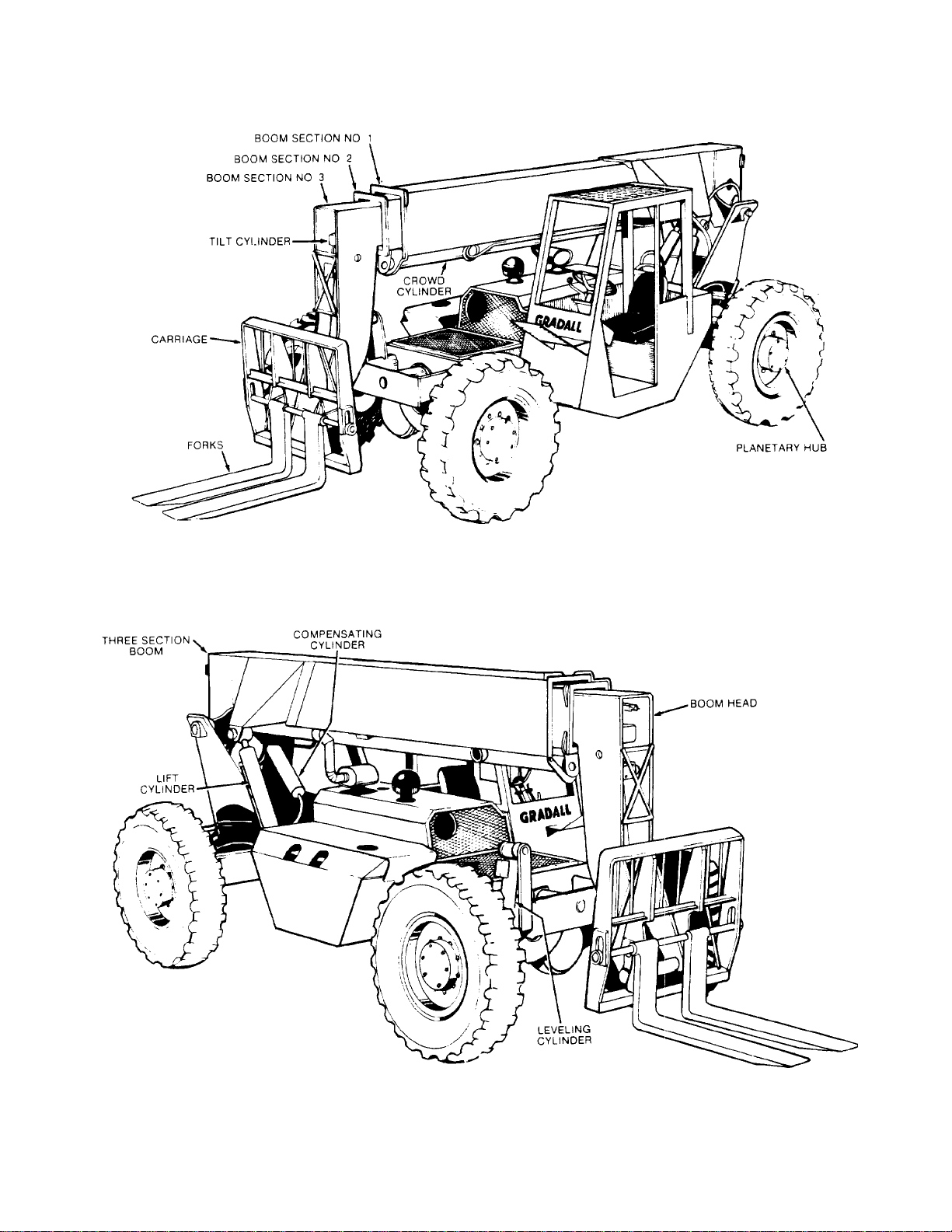

Nomenclature

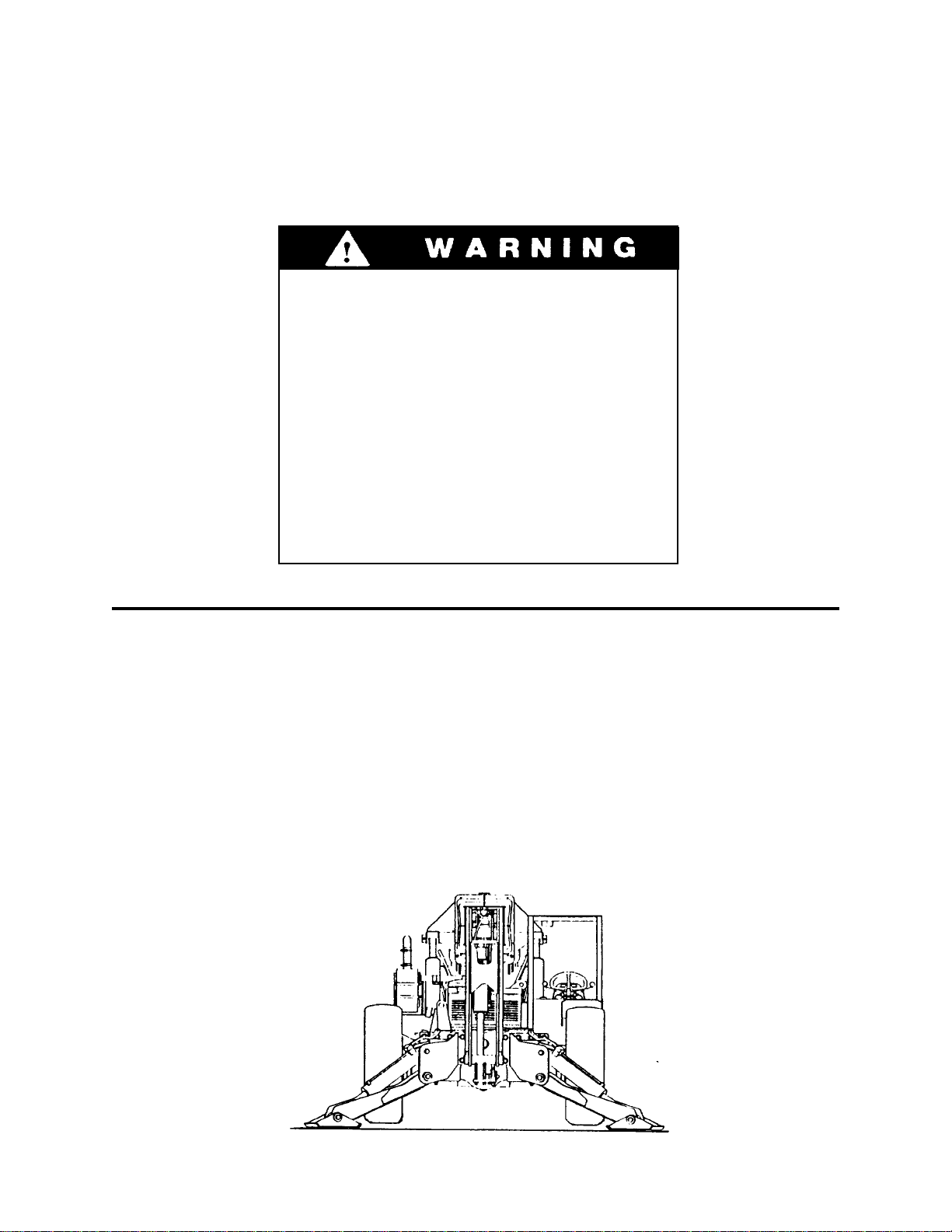

The illustrations on page 3 include nomenclature

applied to major components of the material handler.

The term “handler” will be used throughout the

balance of this manual in place of the words “material

handler”.

2

NOMENCLATURE

3

SAFETY HIGHLIGHTS

Read and understand this manual, the Gradall Material Handler Safety Manual and all instructional

decals and plates before starting, operating or performing maintenance procedures on this equipment.

Most safety notes included in this manual involve

characteristics of the Model 534-B Material

Refer to the FIEI Rough Terrain Forklift Safety

Manual and the Gradall Material Handler Safety

Manual for safety precautions relating to general

material handling procedures and practices.

Handler.

Watch for these symbols; they are used

to call your attention to safety notices.

Operators of this equipment must have successfully

completed a training program in the safe operation

of this type of material handling equipment.

Regardless of previous experience operating similar

equipment, the proper operator must be given

opportunity to practice with the 534-B Material

Handler in a safe open area (not hazardous to

or property) to develop the skills and “feel” re

for safe, efficient operation.

sufficient

people

quired

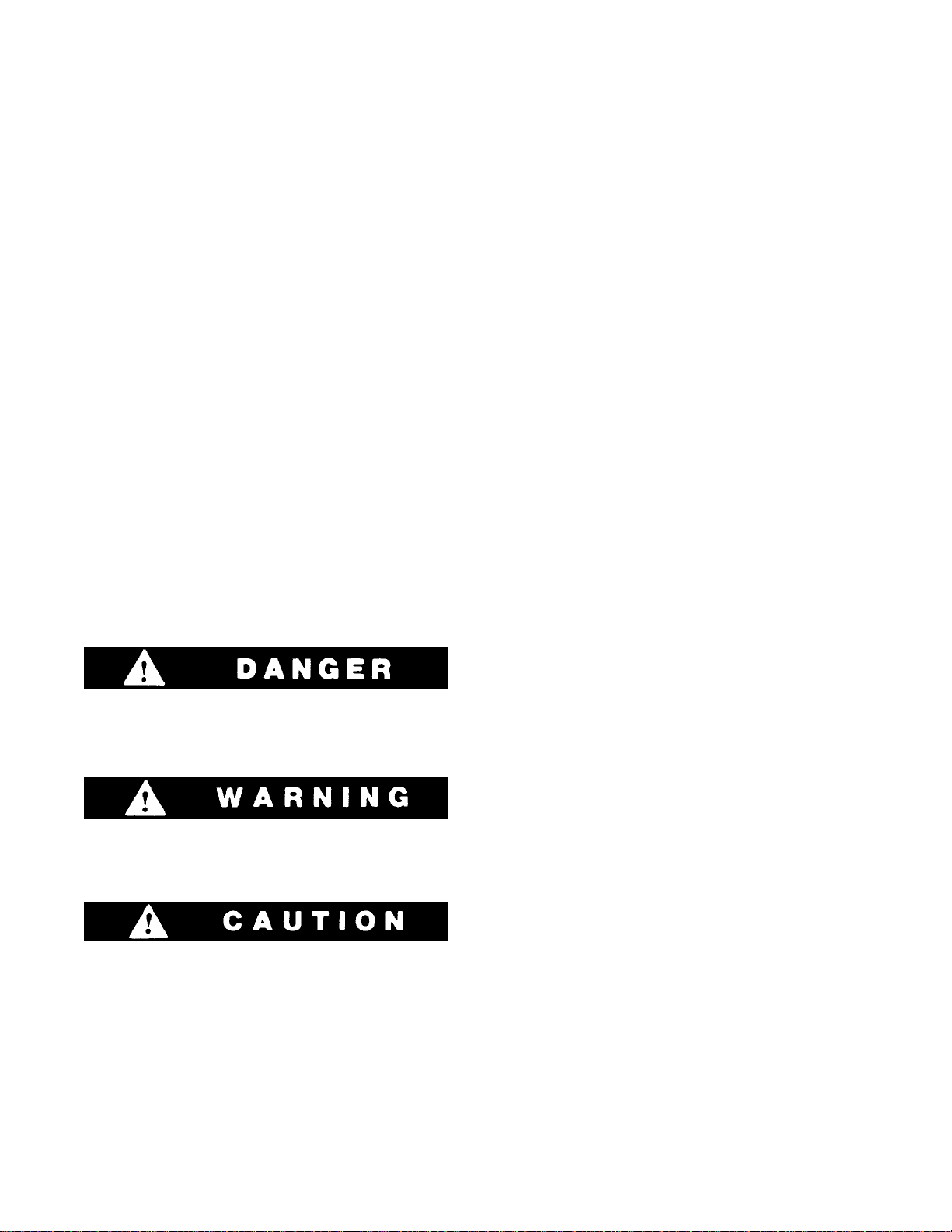

DANGER

This symbol indicates a hazard which could

would result in high probability of death or

serious injury if proper precautions are not

taken.

This symbol indicates a hazard which could

result in death or serious if proper

precautions are not taken.

This symbol indicates a hazard which could

result in injury or damage to equipment or

property if proper precautions are not taken.

4

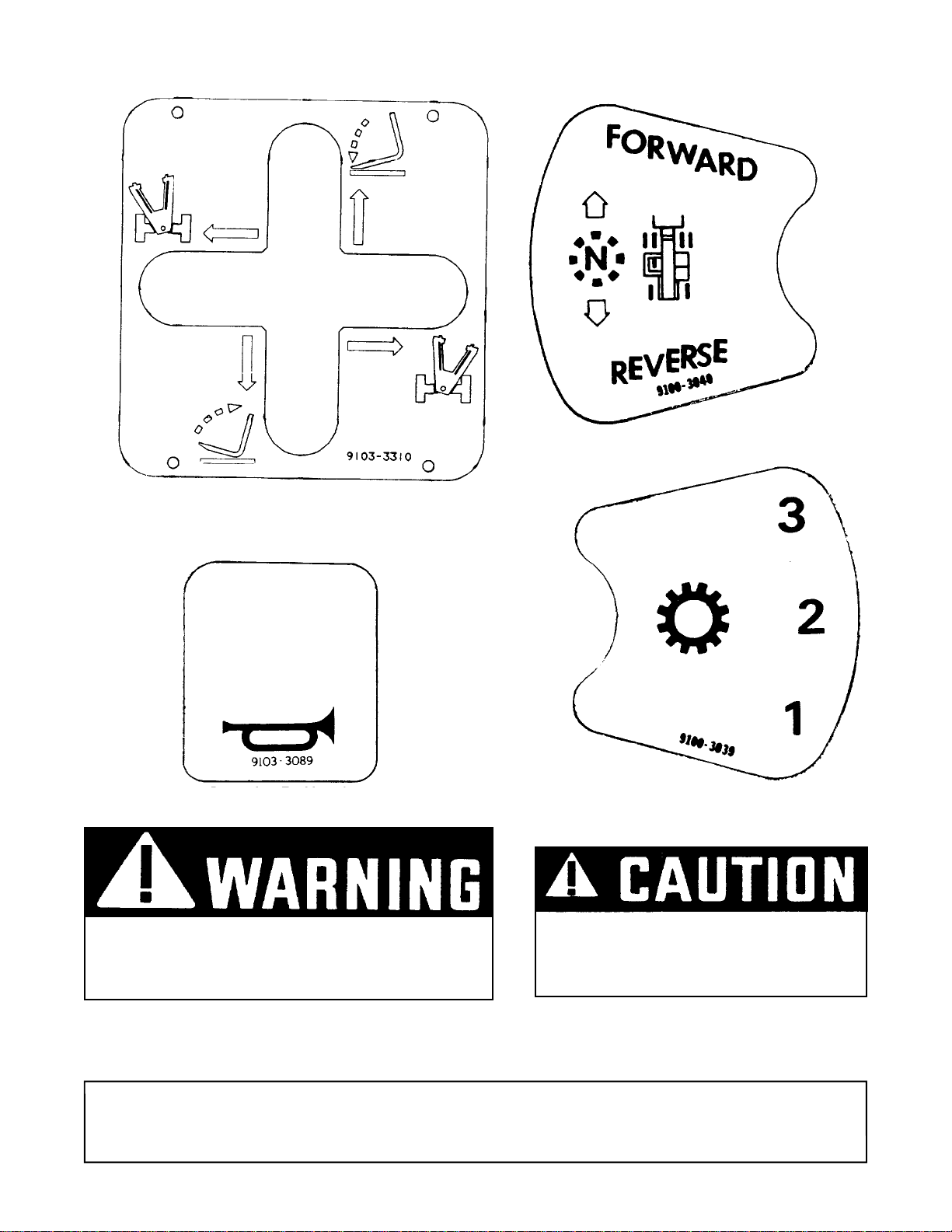

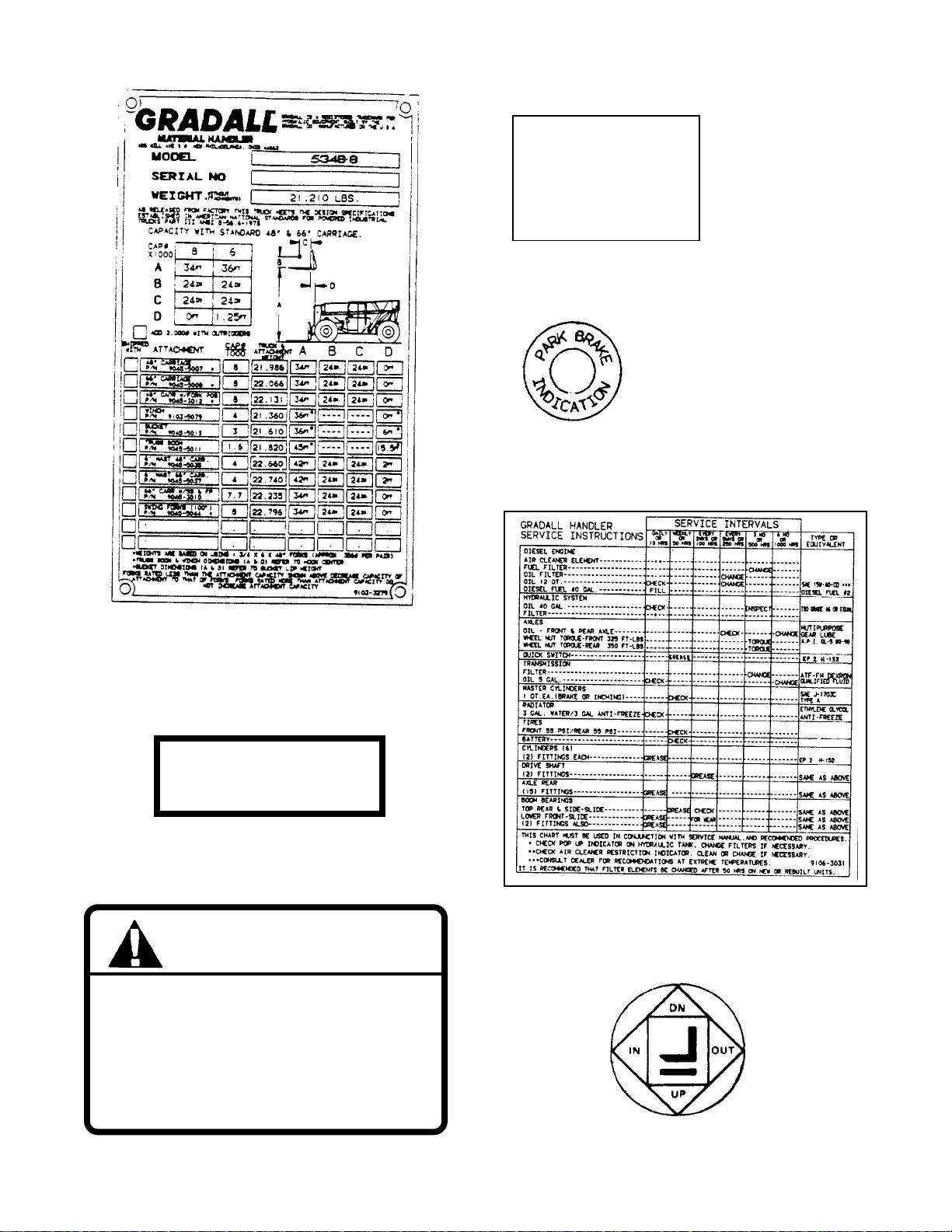

Decals Inside Cab

Located on Dashboard

Part No. 9100-3040

Located on Dashboard

9103-3310

Located on Dashboard

Part No.9103-3089

DO NOT OPERATE MACHINE

WITHOUT PROPER CAPACITY

CHART IN PLACE

Located on Dashboard

Part No. 9100-3039

TO PREVENT ENGINE RING GEAR DAMAGE,

WAIT 10 SECONDS AFTER ENGINE

ROTA TION STOPS BEFORE A T A TTEMPTING

TO RESTART .

W ARNING!

Located on Firewall

Part No. 9103-3010

Located on Dashboard

Part No. 9103-3157

LEVEL GRADALL HANDLER BEFORE LIFTING

ANY LOAD ABOVE 4 FEET

5

Located on Dashboard

Part No.9103-3014

Decals Inside Cab (cont.)

9100-3041

Located on Dashboard

Part No. 9100-3041

BRAKING CAPACITY IS

REDUCED WHEN ENGINE

IS NOT RUNNING.

9103-3135

Located on Dashboard

Part No. 9103-3135

9103-3244

Located on Dashboard

Part No. 9103-3244

W ARNING:

SHUT OFF ENGINE AND SET BRAKES BEFORE

LEAVING GRADALL HANDLER UNATTENDED

Located on Firewall

Part No. 9100-3029

WARNING:

ON GRADES AND UNEVEN GROUND PLACE FORKS

IN CARRY POSITION (APPROX. 12" ABOVE GROUND)

BEFORE MOVING GRADALL HANDLER

Located on Firewall

Part No. 9100-3050

WARNING:

OPERATOR PROTECTION (SUCH AS HARD HATS,

SAFETY GLASSES AND/OR EAR MUFFS) SHOULD BE

WORN WHEN JOB CONDITIONS WARRANT

Located on Firewall

Part No. 9100-3036

9100-3050

9100-3036

6

Decals Inside Cab (cont.)

PARK BRAKE

PULL TO SET

PUSH TO RELEASE

LIGHT IDENTIFICA TION

P ARK BRAKE

INSTRUCTIONS

P ARKING BRAKE

Located on Firewall

Part No. 9103-3279

START

9104-

BUTTON

Located on Front Face of Dashboard

Part NO. 9104-3207

3207

WARNING

DO NOT OPERATE THIS MACHINE

WITHOUT FIRST READING THE

OPERA T OR’S MANUAL. IF A

MANUAL IS NOT A V AILABLE,

REFER TO AN AUTHORIZED

GRADALL DEALER.

9103-3103

Located on Manual Holder

Part No. 9103-3103

Located on Manual Holder

Part No. 9106-3031

Located on Boom Lever Knob

Part No. 9100-3044

7

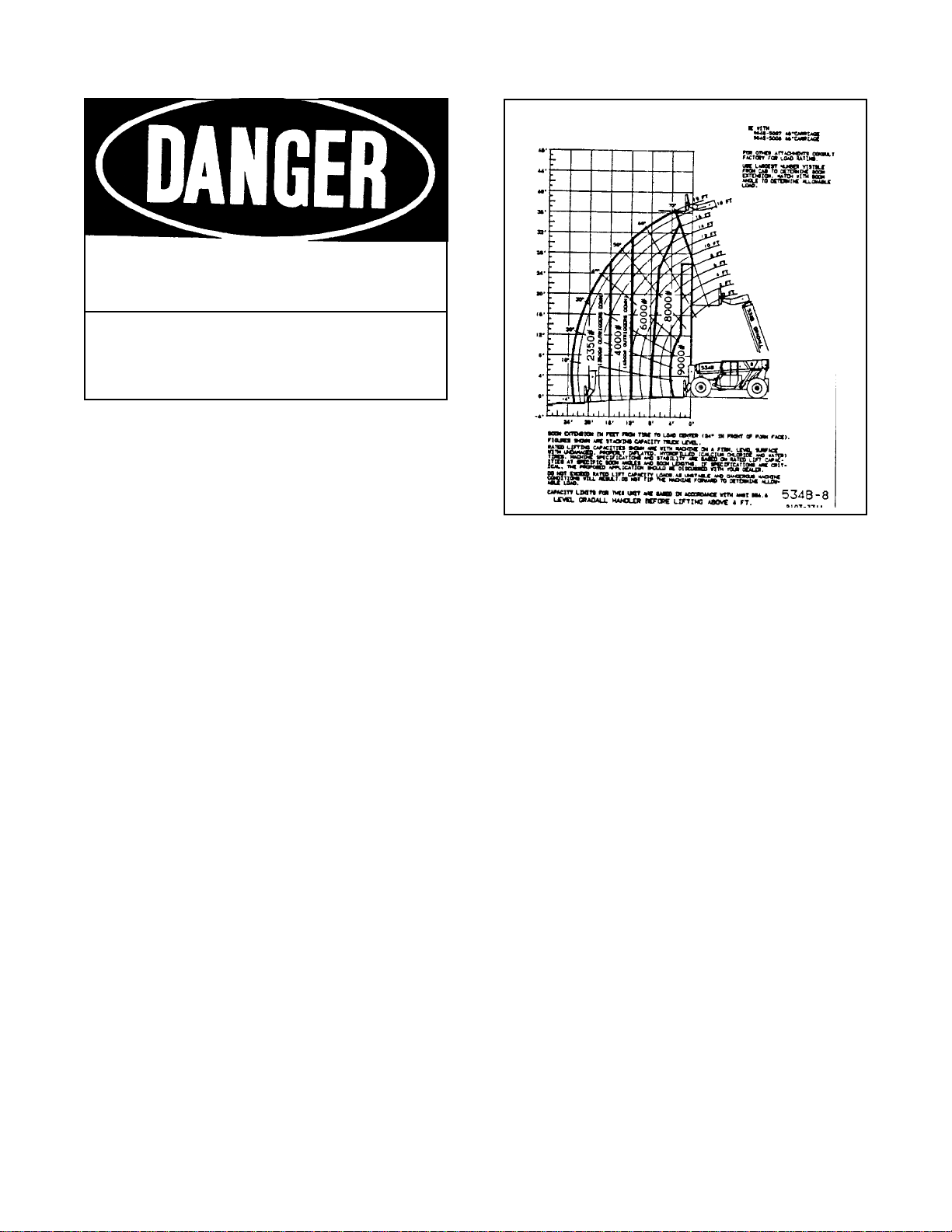

GFHGHGFH

Decals Inside Cab (cont.)

CAPACITY CHART: MODEL 5348-8

RA TED CAPACITY 2 FT . LOAD CENTER

DEATH

UNLAWFUL

FOR MINIMUM CLEARANCES OF HIGH VOLT AGE LINES IN EXCESS OF 50,000 VOL TS, SEE

YOUR LOCAL STA TE ANDFEDERAL REGULA TIONS DO NOT DEFACE OR REMOVED THIS

SIGN FROM THIS MACHINE

OR INJURY MAY RESULT FROM

CONT ACTING ELECTRICAL LINES.

TO PLACE ANY PART OF THIS

MACHINE OR LOAD WITHIN 10

FEET OF HIGH VOLTAGE LINES

OF UP TO 50,000 VOL TS.

Located on Mudguard

Part No. 8360-1011

88

9

9103-3311

Located on Dashboard

Part No. 9106-3034

Optional Lift Capacity Charts are

located on Firewall.

8

Decals Outside Cab

FUEL - DIESEL

EXTINGUISH ALL OPEN FLAME

AND SMOKING MA TERIALS

WHEN REFUELING.

Located on Fuel Tank

Part No.9100-3052

DO NOT INSERT HAND IN

OPENING WHILE ENGINE

IS RUNNING

Located on Radiator

Part No 9103-3011

9100-3052

9103-3011

NO RIDERS

9104-3211

Located on Hydraulic Reservoir & Left of Cab Door

Part No. 9104-3211

COOLANT

9100-3032

Located on Radiator

Part No. 9100-3032

DIESEL FUEL

7702-3308

CHECK TO ASSURE QUICK SWITCH

PIN IS FULL Y ENGAGED AND LOCKED

AFTER A TTACHMENT CHANGE

Located on Boom Head

Part No. 9103-3023

2-9103-3023

USE TWO

HANDS WHEN

Located on Fuel Tank

Part No. 7702-3308

TIRE PRESSURE

55 PSI

Located on Wheel Rims REAR: 55 psi

Part No. 9105-9104 FRONT: 65 psi

HYDRAULIC OIL

7702-3006

Located on Hydraulic Reservoir

Part No. 7702-3006

CLIMBING ON

MACHINE.

Located Left of Cab Door

Part No. 7702-3003

7702-3003

Located on Boom

Part No. 9100-3031

9

Decals Outside Cab (cont.)

DO NOT USE THIS MACHINE

FOR LIFTING PERSONNEL.

9104-3215

Located on Mudguard

Part No. 9104-3215

DO NOT STAND UNDER

LOAD OR BOOM

9104-3217

Located on Boom

Part No. 9104-3217

PINCH POINT AREA

TO PREVENT INJURY, KEEP

CLEAR ANYTIME MACHINE

IS RUNNING

Located Below Boom Pivot

Part No. 9104-3209

DO NOT USE BOOM

AS WALKAWAY

Located on Boom

Part No. 9104-3216

9104-3209

9104-3216

HOT EXHAUST

Located on Exhaust Guard

Part No. 7734-3018

PRESSURIZED-

COOLING SYSTEM

REMOVE CAP

SLOWL Y

9104-3210

Located on Radiator

Part No. 9104-3210

10

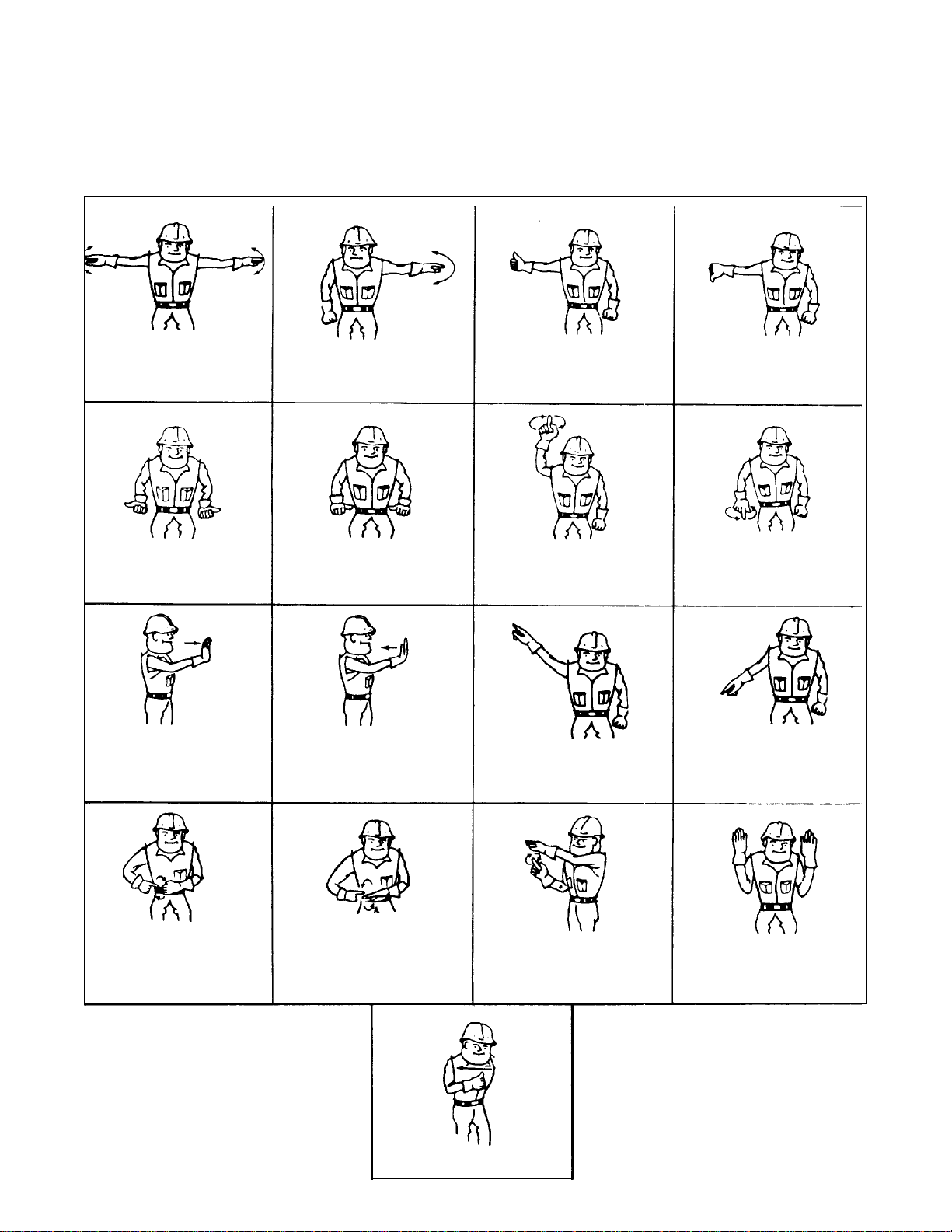

Standard Signals - When handler work conditions

require hand signals, they shall be provided or

posted conspicuously for the use of both signalman

and operator. No handler motions shall be made

unless signals are clearly understood by both

signalman and operator.

EMERGENCY STOP - With both

arms extended laterally hands open

downward, move arms back and

forth.

STOP - With either arm extended

laterally, hand open downward,

move arm back and forth.

Special Signals - When signals for auxiliary

equipment functions or conditions not covered are

required, they shall be agreed upon in advance by

the operator and signalman.

RAISED BOOM - With either arm

extended horizontally, finger

closed, point thumb upward.

HAND SIGNALS

Instructions - When it desired to give instructions

to the operator other than provided by the

established signal system all handler motions shall

first be stopped.

LOWER BOOM - With either arm

extended horizontally, fingers

closed, point thumb downward.

EXTEND TELESCOPIC BOOM With both hands clenched, point

thumbs outward.

MOVE LOAD OUT HORIZONTALLY

With either arm extended, hand

raised and open toward direction of

movement, move hand in direction of

required movement.

CLOSE BUCKET - Hold one hand

closed and stationary. Rotate other

hand in small vertical circle with

forefinger pointing horizontally at

closed hand.

RETRACT TELESCOPIC BOOM With both hands clenched, point

thumbs inward.

MOVE LOAD HORIZONTALLY With either arm extended, hand

raised and open toward direction of

movement, move hand in direction of

required movement.

OPEN BUCKET - Hold one hand

open and stationary. Rotate other

hand in small vertical circle with

forefinger pointing horizontally at

open hand.

RAISED LOAD VERTICALL Y - With

either forearm vertical, forefinger

pointing up, mover hand in small

horizontal circle.

TILT FORKS UP - With one arm held

at side, extend other arm upward at

about 45°.

MOVE SLOWLY - Place one hand

motionless in front of hand giving

motion signal. (Raise load slowly is

shown.)

LOWER LOAD VERTICALLY - With

either arm extended downward

forefinger pointing down, move hand

in small horizontal circle.

TILT FORKS DOWN - With one arm

held at side, extend other arm

downward at about 45°

THIS FAR TO GO - With hands raised

and open inward, move hands

laterally, indicating distance to go.

STOP ENGINE - Draw thumb or

forefinger across throat.

11

The standard cab is open on three sides and includes

an overhead guard to provide protection from

falling objects.

Never operate the handler unless the

overhead guard is in place and in good

condition.

A fully enclosed cab with Plexiglass windows and a

lokable door is available as an option. The cab

door can be secured in the fully opened or closed

position. Be sure the door is fully secured when

operating the handler.

The operator’s seat is equipped with a seat belt and

includes fore and aft adjustment to compensate for

OPERA TOR’S CAB

variations in operator size. The adjustment

release/lock lever is located beneath front edge of

seat belt at all times.

An optional windshield wiper is available for use

with enclosed cabs. An ON/OFF control switch is

located on the wiper motor.

A variable speed defroster fan is available for use

with enclosed cabs. An On/Off control switch and

speed control are located on the base of the fan.

A variable speed heater fan is available for use with

units equipped with a heater. An ON/OFF/SPEED

CONTROL knob is located on the dashboard. Hot

water to the heater can be controlled by a valve at

the engine.

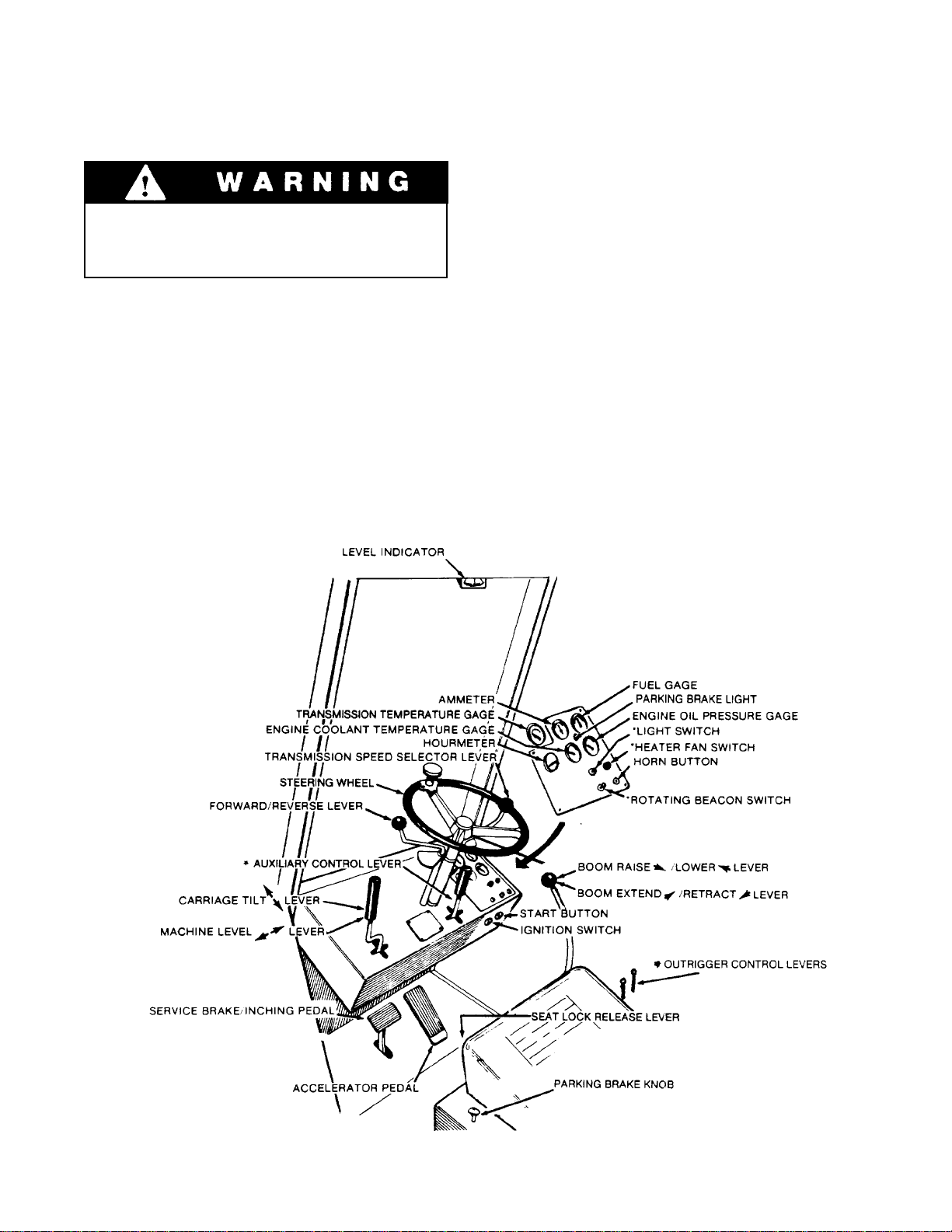

CONTROL AND INSTRUMENT IDENTIFICATION

*Items preceded by an asterisk and may not be furnished on your handler.

12

A brief description of controls and Instruments is provided here as a convenience for

the operator. These descriptions DO NOT

provide complete operating instructions.

Read and understand this manual and the

FIEI Rough Terrain Forklift Safety Manual

before operating the handler.

Engine Oil Pressure Gage: This gage displays engine

oil pressure. Normal operating pressure is 35-50 psi

(241-345 kPa).

Forward/Reverse Lever: This lever engages forward

or reverse travel. Push lever fully forward for forward

travel; pull lever fully to rear for reverse travel or

Read and understand this manual and the

move lever to centered position for neutral.

Fuel Gage: This gage displays level of fuel in fuel

tank.

NOTE: These descriptions are provided in alphabetical sequence in accordance with the nomenclature shown on the facing page.

Accelerator Pedal: The accelerator pedal is connected to the engine speed control by a cable to

provide accurate engine speed control. Depress pedal

to increase speed and release pedal to decrease speed.

Ammeter: The ammeter indicates the charge/discharge rate of the battery charging system. With the

engine running, a discharge reading or a continuing

high charge rate indicates a problem in the system.

Auxiliary Control Lever (optional): This lever is used

to control optional hydraulic attachments. Follow

decal instructions for lever handler movements.

Boom Extend/Retract Lever: This lever controls

boom extension and retraction. Speed is proportional

to lever actuation. Move lever to right to extend

boom or to left to retract boom.

Boom Raise/Lower Lever: This lever controls raising

and lowering the boom. Speed is proportional to lever

actuation. Pull lever to rear to raise boom or push

lever forward to lower boom.

Brake/Inching Pedal: The brake/inching pedal provides service brake control and inching control. To

activate the brakes, push the pedal down. To release

the brakes, remove foot from pedal. When full brakes

are applied, the rear hydraulic drive is disconnected.

When partial brake/inching pedal movement is used,

the front wheel drive is disconnected from the

transmission. The inching feature of the rear wheel

drive system provides for smooth machine operation

at low speeds and high engine rpm.

Heater Fan Switch (optional): This rotary switch

controls heater fan. Rotate clockwise to start fan.

Continued clockwise rotation controls fan speed.

Horn Button: Depress button to sound horn.

Hourmeter: This meter indicates total time of engine

operation in hours and tenths of hours.

Ignition Switch: This switch is actuated by a key. In

ON position (turned clockwise) voltage is available

for all electrical functions. Turn key counterclockwise to stop engine and remove voltage from all

electrical functions.

Level indicator: This indicator (a bubble level)

enables the operator to determine the left to right

level condition of the handler.

Light Switch (optional): This switch controls optional

lighting which may be provided with the handler.

Machine Level lever: This lever controls the vertical

relationship of the handler frame to the front axle.

Move the lever to the right to tilt frame to right or

move lever to left to tilt frame to left.

Rotating Beacon Switch (optional): This switch

controls operation of rotating beacon.

Seat Lock Release Lewer: This lever unlocks and

locks seat position adjustment. Lift lever to unlock

and release lever to lock adjustment.

Start Button: The start button controls operation of

the engine starter motor. With ignition switch in ON

position, depress start button to actuate starter motor.

Release button to disengage starter motor.

Park Brake Control Knob: The park brake control

knob is located to the left of the operator and is used

to apply and release the parking brake. To apply the

parking brake, pull the knob up. To release the

parking brake, push the knob down.

Carriage Tilt Lever: This lever controls tilt of the

fork carriage. Speed is proportional to lever actuation. Push lever forward to tilt down or pull lever to

rear to tilt up.

Engine Coolant Temperature Gage: This gage displays engine coolant temperature. Normal operating

temperature is 180-200°F . (82-93°C.)

Steering Wheel: The steering wheel controls the

angle of rear axle wheels. Turning the steering wheel

to the right causes a right turn by angling rear wheels

to left. A left turn is caused by angling rear wheels to

right.

Transmission Speed Selector Lever: This lever permits selection of three speed ranges for forward and

reverse travel.

Transmission Temperature Gage: This gage displays

temperature of transmission fluid. Normal operating

temperature is 180-200°F . (82-93°C.).

13

CHECKS AND SERVICES BEFORE STARTING ENGINE

(To be performed at beginning of each work shift)

Use extreme caution when checking items

beyond your normal reach. Use an

approved safety ladder.

enter these ports, it can shorten the life of o-rings,

seals, packings and bearings.

When adding fluids or changing filter elements,

refer to the lubrication section of this manual to

determine the proper type to be used.

Before removing filler caps or fill plugs, wipe all dirt

and grease away from the ports. If dirt is allowed to

Complete all required maintenance before operating unit.

Service the unit in accordance with the lubrication

and maintenance schedule.

If spark arrestors are required, be sure they are in

place and in good working order.

Inspect all structural members, including attachment, for signs of damage.

Inspect unit for obvious damage, vandalism

and needed maintenance. Check for signs of fuel,

lubricant, coolant and hydraulic leaks. Open all

access doors and look for loose fittings, clamps,

components and attaching hardware. Replace

hydraulic lines that are cracked, brittle, cut or show

signs of abrasion.

14

ENGINE OPERATION

NOTE: If engine is being started at beginning of work shift be sure to perform all “CHECKS AND

SERVICES BEFORE ST AR TING ENGINE” (page 6).

Starting Engine

1. Check to be sure that all controls are in neutral

and that all electrical components (lights, heater,

defroster, etc.) are turned off. Set parking brake.

2. Insert ignition key and turn clockwise to ON

position.

3. Depress accelerator pedal approximately 1/4 to

1/3 of travel from top.

Depressing start button while engine fly wheel is rotating can cause serious damage

to engine and/or starting motor.

NOTE: If temperature requires the use of a starting

aid, and if your handler is equipped with a factoryinstalled ether starting aid, depress cold weather

button one time only before starting engine. If you

use a different starting aid, be sure to follow

manufacturer’s instructions carefully. Excessive ether

may damage engine.

Depress start button to engage starting motor.

4.

Release button immediately when engine starts. If

engine fails to start within 20 seconds, release

button and allow starting motor to cool for a few

minutes before trying again.

After engine starts, observe oil pressure gage. If

5.

gage remains on zero for more than ten seconds,

stop engine and determine cause. Correct cause

of malfunctioning before restarting engine.

Normal engine oil pressure should be in range of

35 - 50 psi (241 - 345 kPa).

Warm up engine at approximately 1/2 throttle

6.

until engine coolant temperature reaches

operating range of 180 - 200°F. (82 - 93°C.).

Cold Weather Starting Aids

Diesel engine ignition is accomplished by heat

generated when fuel/air mixture is compressed

within the cylinders. Because this heat may be

insufficient to start a cold engine in cold weather,

the use of starting aids has become common practice.

Because of the wide variety of starting aids available

it would be impractical to attempt to provide,

Normal Engine Operation

Observe gages frequently to be sure all engine

systems are tunctioning properly.

The ammeter shows the charge/ discharge rate of the

battery charging system. With the engine running, a

discharge reading (-) or a continuing high charge

reading (+) indicates a problem in the battery

charging system.

specific instructions for their use in this manual.

Carefully follow instructions furnished with your

starting aid.

If you use a starting aid employing ether or a

similar substance pay particular attention to

manutacturer’s warnings.

Avoid prolonged idling. Idling causes engine

temperature to drop and this permits formation of

heavy carbon deposits and dilution of lubricating oil

by imcompletely burned fuel. If the engine is not

being used, turn it off.

Be alert for unusual noises or vibration. When

an unusual condition is noticed, stop machine in a

safe position and shut off engine. Determine cause

and correct problem before continuing.

Always keep engine covers closed while

engine is running (it furnished).

15

Stopping the Engine

Operate engine at idle speed for a few minutes

before turning it off. This allows engine coolant

and lubricating oil to carry excessive heat away

from critical engine areas.

Do not “gun” engine before shut down; this

practice causes raw fuel to remove oil film from

cylinder walls and dilute lubricant in crankcase.

To stop the engine, allow engine to run at idle for a

few minutes, this is to allow the turbo components

to cool. Turn key counter clockwise to stop position.

Be sure to remove key from ignition switch before

leaving cab.

WARM UP & OPERATIONAL CHECKS

(To be performed at beginning of each work shift)

Complete all required maintenance before operating unit

The safety efficiency and service life of your unit

will be increased by performing the operational

checks listed below. Items preceded by an asterisk

(*) are optional and may not be furnished on your

machine. Check items during warm-up period.

*

Heater defroster and windshield wiper

1.

Forward and reverse travel in all gears

6.

“Inching” travel - should be smooth through

7.

full pedal travel

Horn and back-up alarm

8.

*

Operating lights and rotating beacon

2.

Low brake pressure light - should go out with

3.

engine running above idle

Ammeter - should show low charging rate after

4.

charging system has replaced starting drain

When engine warms to operating range, check

the following items:

Service brake, parking brake and parking brake

5.

lock.

Continued operation with hydraulic fluid

by-passing the filter (yellow flag

showing) can cause severe damage to

hydraulic system components.

All boom and attachment functions - full stroke

9

in both directions

Hydraulic Filter Condition Indicator - observe

10.

torque converter temperature gage after starting

normal operation. When needle has been in

operating range for an hour or so, stop handler in

a safe area and set parking brake. With engine

running at full RPM check hydraulic filter

condition indicator. When yellow flag fills

indicator window filter is clogged and hydraulic

oil is bypassing filter. Filter must be changed

before reaching bypass condition (change before

yellow flag reaches midpoint of window).

16

BRAKE SYSTEM

Service Brakes

General

The brake system furnished on the handler includes a

service brake, inching brake and parking brake.

Because service braking and “inching” (slow travel)

functions overlap, some features of inching will be

discussed here. Refer to Drive Train Section for

additional information on inching travel.

Inching Travel

Overlap between service braking and inching occurs

because the same foot pedal controls both functions,

and also because both functions control travel speed.

However, the methods of controlling travel speed are

quite different: service braking involves a controlled

stopping force applied to the front wheels while,

inching involves a controlled driving force applied to

the rear wheels.

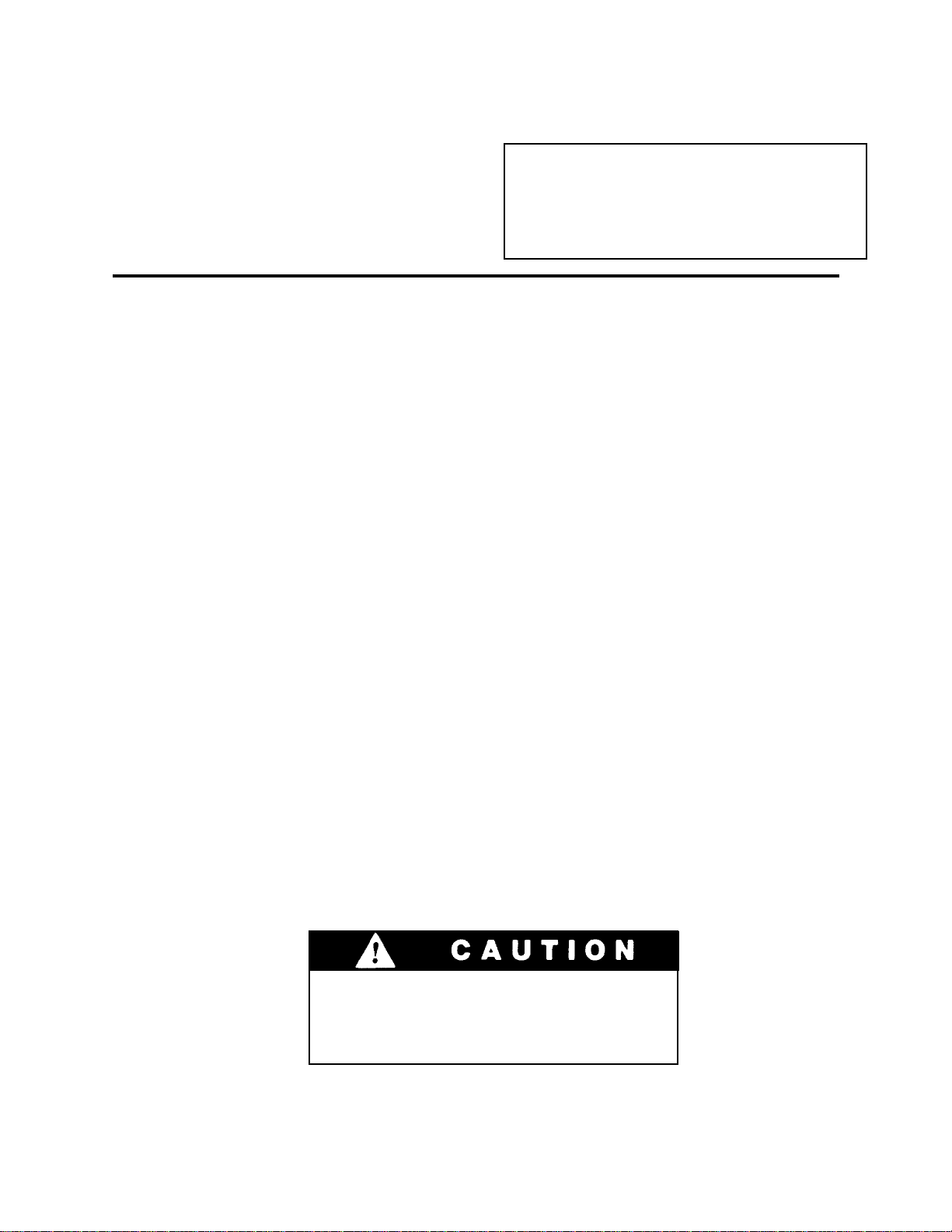

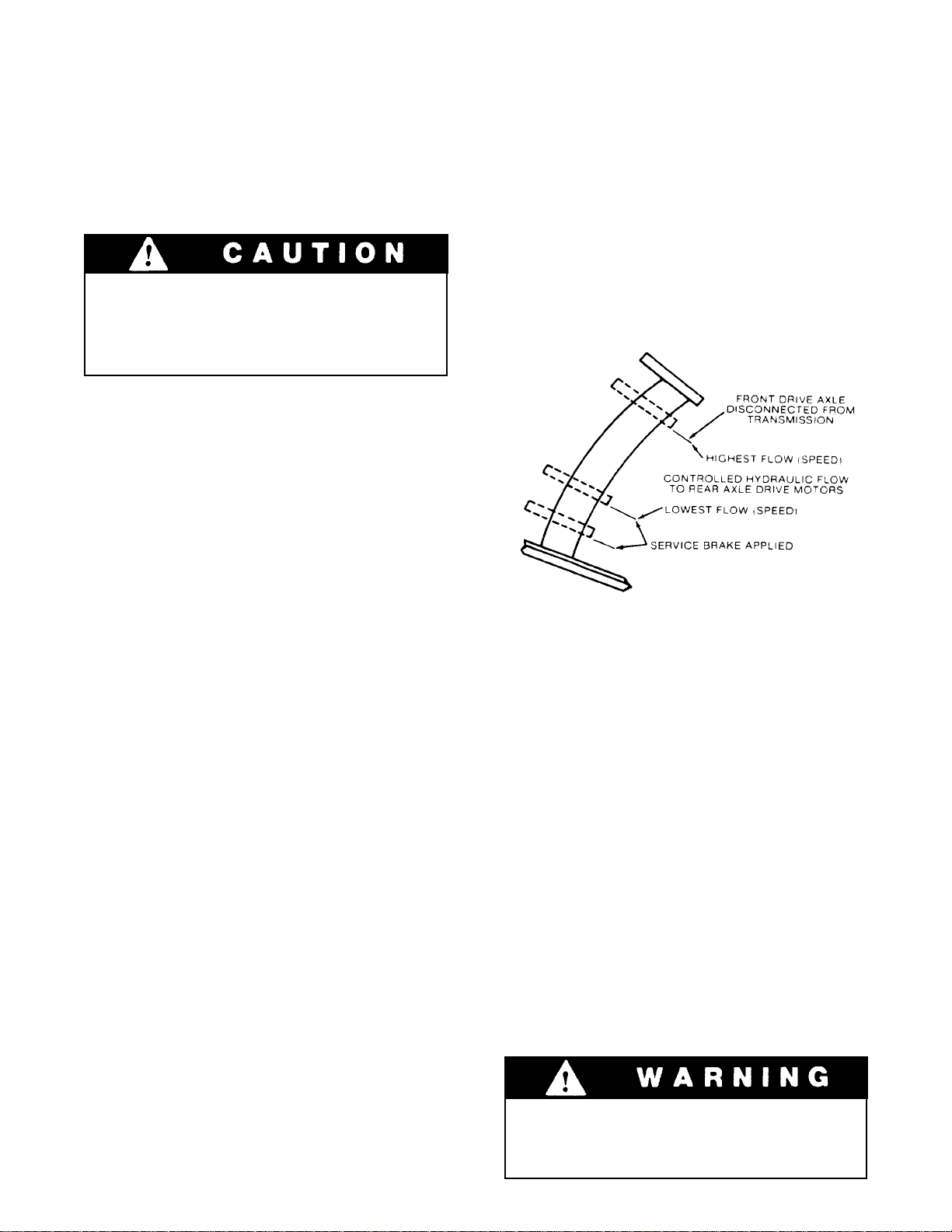

The service brake/inching pedal has three separate

It disconnects front drive axle from transmission.

1.

functions:

The service brake is applied to the front wheels of the

handler.

Oil for the brakes comes from the pilot circuit pump,

thru an accumulator charging valve and the accumulator. When the service/inching brake pedal is depressed far enough to actuate the brake valve, the

hydraulic oil flows to the wet disc brakes in both front

wheel hubs. The pressure compresses the brake discs.

It controls hydraulic flow to rear axle drive motors

2.

(hydraulic flow regulates speed).

It applies service brake.

3.

As illustrated, the three functions occur in sequence

as service brake/inching pedal is depressed from top

to bottom of stroke.

Parking Brakes

The parking brakes are also applied at the wet disc

brakes in the front axles.

TO APPLY THE PARKING BRAKE, pull up on the

parking brake knob located to the left of the operator’s seat. This opens the parking brake circuit to

dump, allowing a spring in the wet disc brake

assembly to compress the discs, applying the brakes.

TO RELEASE THE PARKING BRAKE, push down

on the parking brake knob.

When the handler is not being used, with the engine

shut off, the parking brakes must be applied.

Practice inching/braking in a safe, open

area until you are thoroughly familiar with

response of machine to pedal travel.

17

STEERING SYSTEM

Ninety degree rear wheel power steering is provided

to reduce operator fatigue and to permit high

maneuverability in close quarters.

Be alert for any increase in eftort needed to

steer. It any difference is noted, notify

maintenance personnel immediately for

correction. It power assist feature should

fail for any reason IT WOULD BECOME

VERY DIFFICULT TO STEER. For this

reason it is extremely important that you

NEVER TURN ENGINE OFF WHILE

TRAVELING.

In the event power steering tails, stop as

soon as possible. Do not drive unit until

problem has been corrected.

It is important that the operator practice

maneuvering the handler in a safe, open area until

he becomes thoroughly familiar with steering

response and clearance required for tailswing and

load when turning.

FRONT OUTRIGGERS (2) (OPTIONAL)

Front outriggers are provided in order to raise the

front tires off of the ground level while working, thus

improving the overall stability of the handler .

Two outrigger control levers are located to the right

hand side of the operator’s seat. Pushing forward on

the lever lowers the outriggers, and pulling back on

the lever raises them.

18

DRIVE TRAIN

General

The drive train provides two and four wheel drive

and includes the engine, torque converter

transmission, drive shaft and front and rear driving

axles.

Inching travel is directly related to drive train

functions and will be discussed in this section.

Two & Four Wheel Drive

The drive train is designed to provide two wheel

drive (front axle driving) or four wheel drive (both)

front and rear axles driving.

Under certain conditions, changing from four wheel

drive to two wheel drive may cause a difference in

the way the machine responds to steering, braking

and drive controls. Always be aware of which travel

mode you are using.

There are two ways to disengage rear wheel

drive:

Shift to third gear (rear axle drive is engaged only

1.

in first and second gears)

Disengage rear planetary hubs (refer to Rear

2.

Drive Axle heading in this section)

NOTE: Rear drive axle can also be disengaged in

response to overload in associated electrical

circuitry causing automatic reset type circuit

breaker to trip (open). Breaker will close again in

approximately ten seconds.

Torque Converter

There are no operator controls for the torque

converter. It functions automatically to permit

starting from a standstill in any transmission speed

range.

An oil temperature gage is provided to indicate

operating temperature of torque converter/transmission. Normal operating temperature is 180200°F. (82- 93°C.). If overheating occurs, attempt

to lower temperature by traveling in a lower gear. If

necessary, stop and allow torque converter to cool

with engine running and gear selector in neutral. Be

sure radiator fins are clean.

Transmission

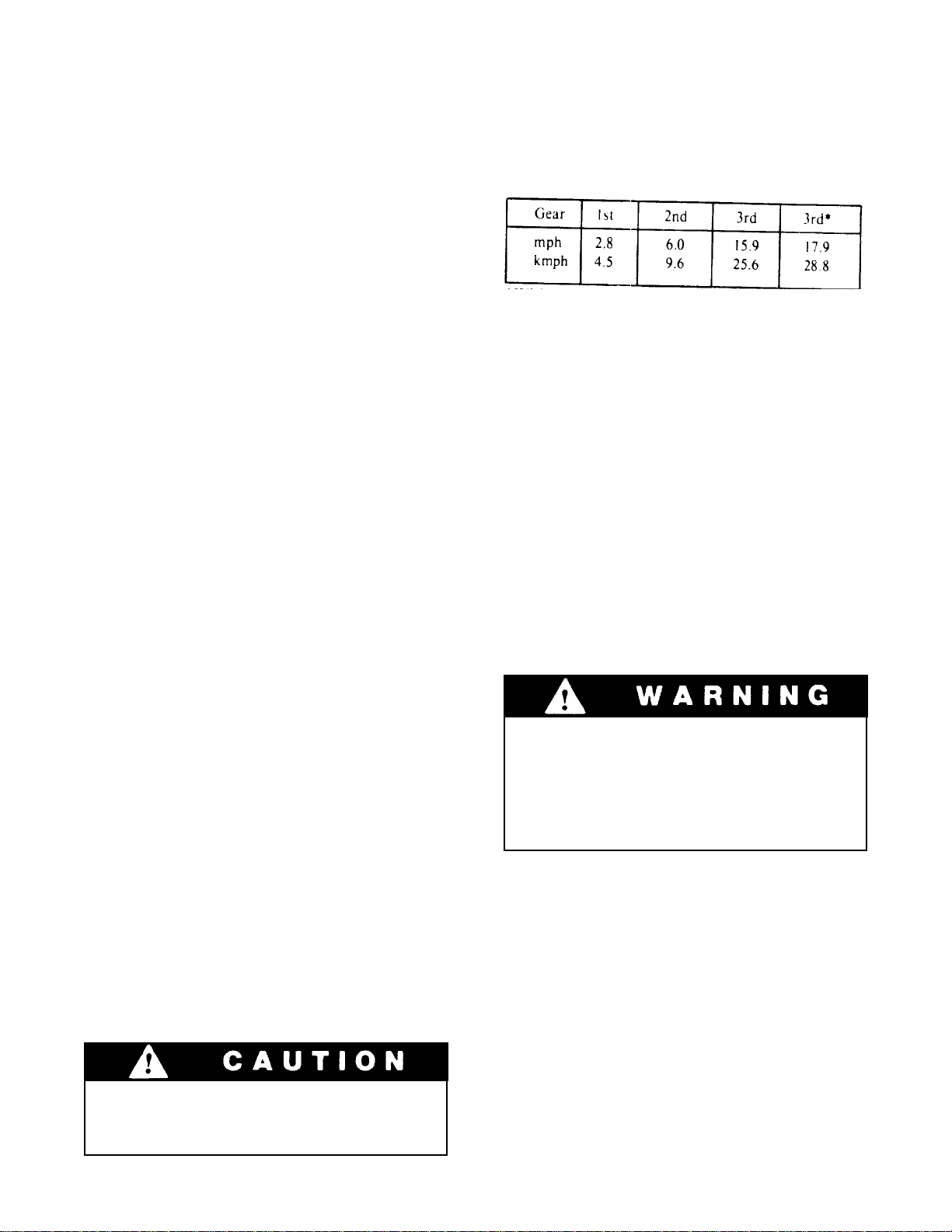

The transmission provides three speed ranges for

both forward and reverse travel.

*With rear planetary hubs disengaged

There are three operator controls for the

transmission:

Gear Selector Lever (for 1st, 2nd and 3rd gears)

1.

2.

Direction Selector lever (for forward, neutral

and reverse)

3.

Service Brake Inching Pedal (refer to Inching

Travel heading in this section)

T o Operate Transmission:

1.

Release parking brake and hold handler in

position using service brake.

2.

Move gear selector to appropriate speed range

(1st. 2nd or 3rd gear). The gear selector may be

shifted while traveling. When traveling downhill,

use the same gear needed to travel up the hill.

Never shift gear selector or direction

selector to cause a sudden change of

travel speed or direction. Such a change

could cause load to shift or machine to tip

over. Reversing direction while traveling

can also damage transmission.

3.

Move direction selector to forward or reverse

position.

Release service brake and depress accelerator to

4.

attain appropriate speed.

5.

Stop handler by releasing accelerator and

applying service brake.

6.

Move direction selector to neutral position.

Continued operation of overheated torque

converter/transmission can cause serious

damage to these components.

Apply parking brake.

7.

Front Driving Axle

The front driving axle includes a differential and

planetary drive hubs and is powered by a drive shaft

from the transmission. The service brake/inching

pedal is the only operator control for the front axle

(refer to Inching Travel heading).

19

continued...

Rear Driving Axle

The rear driving axle includes planetary hubs which

are powered by hydraulic motors mounted on the

inner face of the hubs. HYdraulic flow to drive

motors is provided only in first and second gear

speed ranges. Drive motors are free-floating in third

gear.

Continuous driving for two miles or more

in third gear, with rear driving hubs

engaged, can damage hydraulic drive

motors.

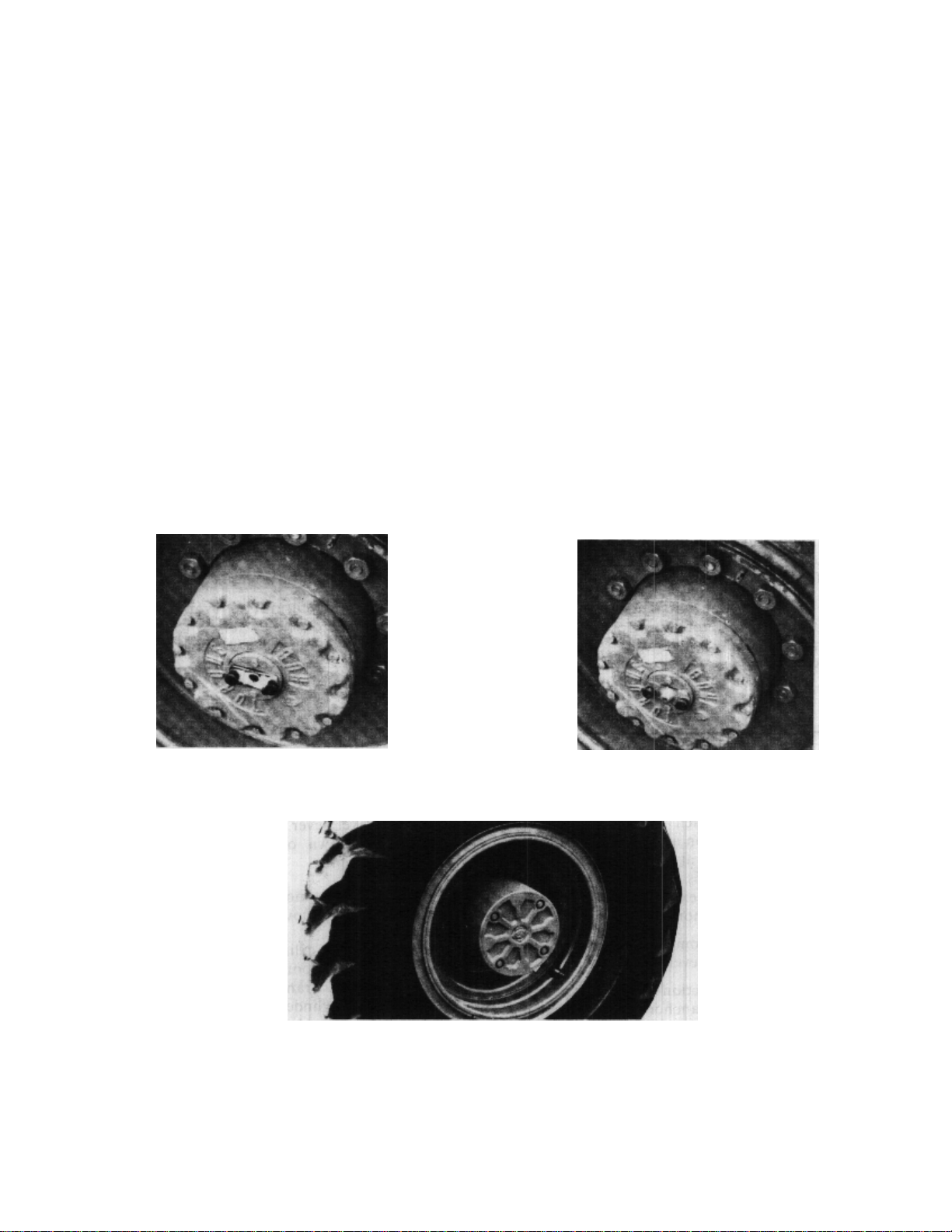

To Disengage Rear Driving Hubs:

Apply parking brake and remove key from

1.

ignition switch.

Remove thumb screws or hex head cap screws

2.

from keeper pin plate.

travel functions only in first and second gears. There

is no hydraulic flow to drive motors in third gear.

Inching travel is controlled by the service

brake/inching travel pedal. This pedal has three

separate functions:

It disconnects front drive axle from

1.

transmission.

It controls hydraulic flow to rear axle drive

2.

motors (hydraulic flow equals speed).

It applies service brake.

3.

Remove and rotate plate (cup out-engaged-cup

3.

in-disengaged).

Secure plate using thumb screws or hex head cap

4.

screws.

Repeat procedure for other hub.

5.

To Engage Rear Driving Hubs: Repeat procedure.

NOTE: If machine is moved with keeper pin plate

removed, input shaft pin will pop out.

Hydraulic flow to rear axle drive motors is

controlled electrically. An automatic reset type

breaker is included to prevent damage from

overload. If circuit breaker trips (opens) rear

axle drive will be inoperative for approximately

ten seconds until breaker resets. Notify

maintenance personnel if circuit breaker trips

repeatedly.

To determine whether circuit breaker has tripped,

attempt to move machine using inching travel. If

machine does not respond to inching travel pedal,

circuit breaker is open.

As illustrated, the three functions occur in sequence

as pedal is depressed from top to bottom of stroke.

To Engage Inching Travel:

Depress service brake/inching travel pedal

1.

approximately 1-1/2 inches to disengage front

driving axle from transmission. At this point rear

drive motors are receiving full flow and travel

speed will not have changed.

Continue to depress pedal to reduce speed-the

2.

more pedal travel, the less speed.

T o stop, depress pedal fully.

3.

OR

To resume normal travel release service brake/

inching travel pedal. Depress accelerator pedal to

attain appropriate speed.

Inching Travel

Inching travel is provided to permit very slow travel

while maintaining high engine speed for other

functions. Because inching travel depends on

hydraulic flow to rear axle drive motors, inching

Practice inching/braking in safe, open

area until you are thoroughly familiar with

response of machine to pedal travel.

20

MOVING HANDLER (Emergency Only)

If handler must be moved, when the engine is not

workable, extreme care should be used because:

1.

With the engine not operating there will be NO

steering.

2.

With the wheel hubs adjusted to permit movement, ther will be NO brakes.

If the handler is to be moved, do the following:

1.

Place blocks on wheels to prevent movement.

2.

On both rear axles, reverse the hub disengagement

caps.**

3.

Loosen front hub cover bolts equally until cover

moves 3/16" to 1/4". This released the wet disc

brakes. ***

We recommend that the unit be pushed, not towed

and that the unit be attached firmly to the pushing

vehicle because the handler brakes are released.

**In Disengaged **Out Engaged

** Back off 4 bolts

21

MATERIAL HANDLING

Leveling

The handler is designed to permit tilting main frame

eight degrees to left or right to compensate for

uneven ground conditions.

Raising the boom (loaded or unloaded)

when handler is leaning to the side can

cause machine to tip over with little or no

warning.

A level indicators located on upper portion of front

window frame to permit operator to determine that

machine is or is not level.

The rear axle pivots at the midpoint of the main

frame to help assure that wheels will remain in

contact with ground. A hydraulic cylinder provides

a rigid connection between front axle and main

frame to help assure a solid work platform and

permit tilting main frame to left or right.

NOTE:The frame leveling function is provided only

to level the machine before lifting or placing a load.

Do not attempt to use leveling feature to turn on or

travel across a slope.

To Level Handler:

Position machine in best location to lift or place

1.

load and apply brake.

Observe level indicator to determine whether

2.

machine must be leveled. Note position of

indicator for later realignment.

If necessary, position boom in carry position and

3.

move carriage tilt machine level lever to left or

right to level machine. Move lever to left to lower

left side of frame or move lever to right to lower

right side of frame.

Lift or place load as appropriate.

4.

Retract and lower boom to carry position.

5.

Realign frame to position noted in step 2.

6.

If handler cannot be leveled using leveling

system, do not attempt to raise or place

load. Have surface leveled.

Boom

The three section hydraulically operated boom

provides maximum reach of 36 feet above

horizontal at 70ø elevation and 21 feet forward of

forward edge of front tires at 0ø elevation (measured

to heel of standard forks mounted on standard

carriage). Boom travel extends from 4ø below

horizontal to 70ø above horizontal.

Raise boom by pulling boom lever to rear and lower

boom by pushing boom lever forward.

Boom extension and retraction is accomplished by a

hydraulic crowd cylinder anchored at rear of boom

section no. 1 and at front of boom section no. 2 and

also by a cable and push beam arrangement within

the boom sections. Extension or retraction of attachment

boom section no. 2 is always equaled by a

corresponding movement of boom section no.

3

A hydraulic cylinder is located within the boom

head to tilt the fork carriage or other attachment

back and forth as required.

The tilt cylinder is controlled by carriage tilt/

machine level lever. Push lever forward to tilt

attachment down or pull lever to rear to tilt

attachment up.

Extend boom by moving boom lever to right and

retract boom by moving boom lever to left.

A compensating cylinder is pinned to main frame

and to base of boom section no. 1. As boom is

raised, oil is transferred from rod end of

compensating cylinder to rod end of attachment tilt

cylinder. Lowering boom causes transfer of oil from

barrel end of compensating cylinder to barrel end of

attachment tilt cylinder. This transfer of oil causes

extension and retraction of tilt cylinder to maintain

angle of attachment as boom is raised and lowered.

All cylinders related to boom (attachment tilt, raise/

lower and extend/retract) are protected by pilot

operated check valves which prevent load from

falling in event of a broken hydraulic hose or tube.

22

Attachments

Although the carriage/fork combination is most

frequently used, a number of other attachments

available for use with the handler. 180ø and 100ø

swing forks are available. A material bucket can be

provided for light duty work. A truss boom is

available to extend maximum reach and height and

can be fitted with a winch when required. Consult

your Gradall Material Handler Dealer for information on attachments designed to solve special

material handling problems.

Attachments Capacities

The Rated Capacity Chart located on left side of

dashboard indicates maximum capacities for

handlers equipped with standard carriage/fork

combination. These capacities apply only to

standard carriage, fork combination and cannot be

used for other attachments.

A serial number plate Is attached to all attachments

and indicates maximum capacity for that

attachment. However, the capacity shown on

this plate may be incorrect in relation to your

machine.

Refer to Attachment Capacity Plate located below

Serial Number Plate on right cab wall for correct

maximum capacity for all attachments furnished

with your machine. If attachment in question is not

listed on this plate contact factory for maximum

capacity.

Refer to Operating Procedures and Techniques

section for instructions on proper use of

information shown on capacity plates.

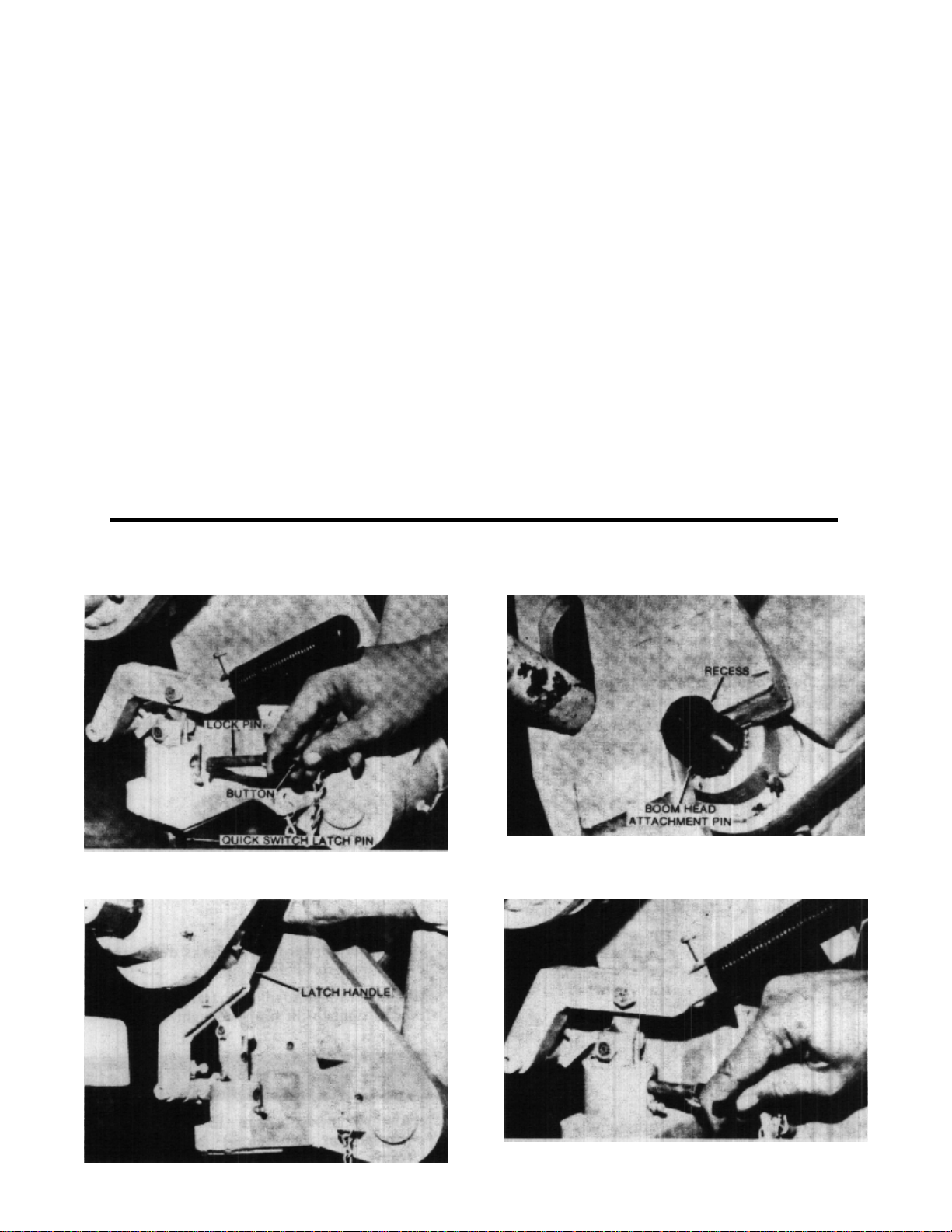

Attachment Installation

1.

Depress button and remove lock pin from quick

switch latch pin.

Position boom head attachment pin fully in recess

3.

of attachment. Tilt upward slightly to assure full

engagement.

2.

Raise handle to retract latch pin fully .

23

4.

Depress handle fully to engage latch pin in

attachment and install lock pin in latch.

OPERATING PROCEDURES & TECHNIQUES

This section highlights some common procedures

and discusses areas which may be new to even the

experienced operator.

Hydraulic Controls

All boom and attachment movements are governed

by hydraulic controls. Rapid, jerky operation of

hydraulic controls will cause rapid, jerky movement

of the load. Such movements can cause the load to

shift or fall or may cause the machine to top over.

Feathering

Feathering is a control operation technique used for

smooth load handling. To feather controls, move

control lever very slowly until load begins to move,

then gradually move lever further until load is

moving at desired speed. Gradually move lever

toward neutral as load approaches destination.

Continue to reduce load speed to bring load to a

smooth stop. Feathering effect can be increased by

lowering engine speed at beginning and near end of

load movement.

With boom raised above horizontal, forks can be

removed from a load by moving boom control lever

back and to the left until forks move rearward

horizontally.

With boom lowered below horizontal, forks can be

inserted under a load by moving boom control lever

back and to the right until forks move forward

horizontally.

With boom lowered below horizontal, forks can be

removed from a load by moving boom control lever

forward and to the left until forks move rearward

horizontally.

The closer the boom to horizontal, the less boom

raise/lower movement required for inserting and

removing forks.

Carriage Tilt/Machine Level Lever

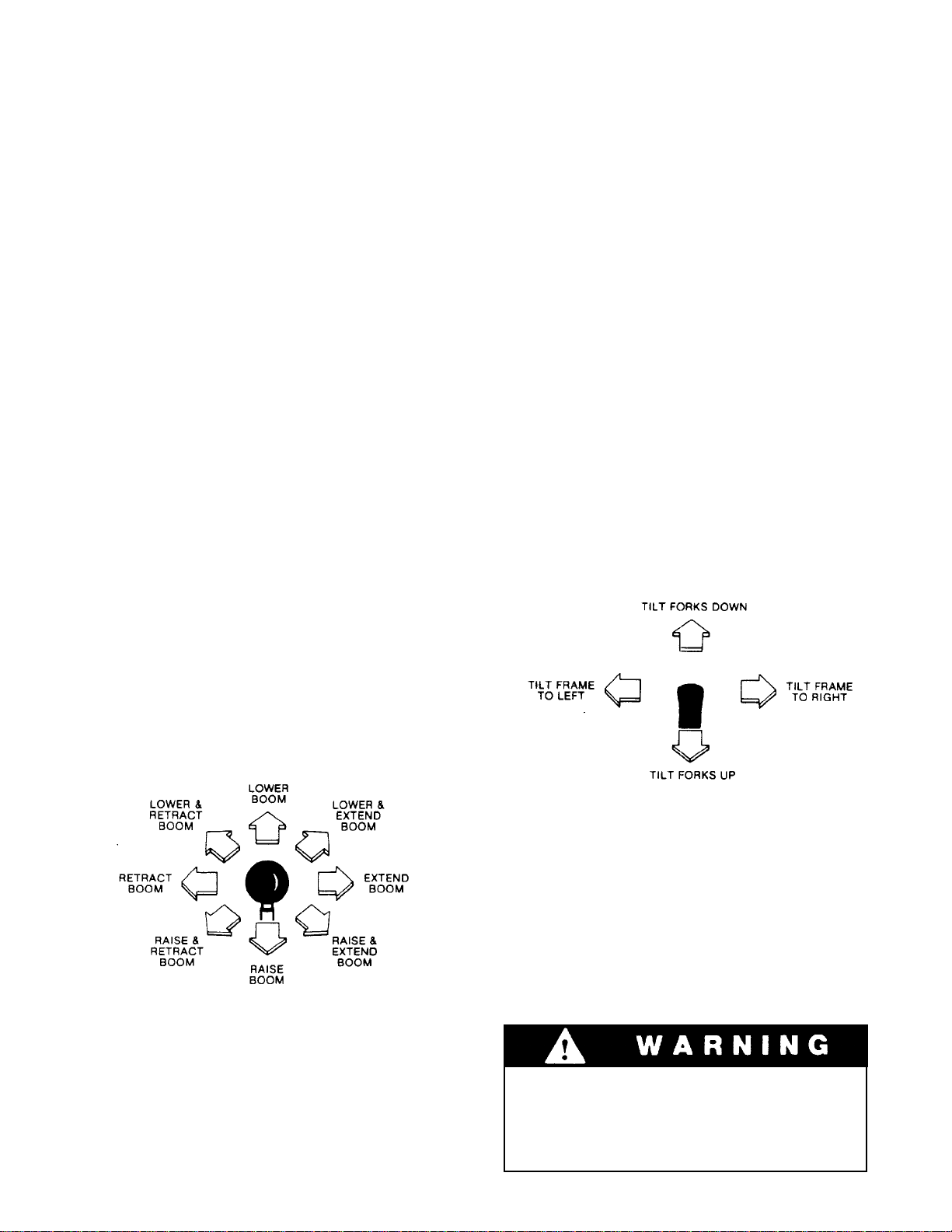

Boom Control Lever

The boom control lever can be positioned to cause

individual boom movements or combinations of

boom movements as illustrated.

Move lever to left to the tilt forks down and move

lever to rear to tilt forks up.

Move lever to left to tilt main frame to left and move

lever to right to tilt frame to right.

With boom raised above horizontal, forks can be

inserted under a load by moving boom control lever

forward and to the right until forks move forward

horizontally.

Always move boom to carry position

(horizontal or below before leveling

frame. Attempting to level machine with

boom raised may caused it to tip over.

24

Loading...

Loading...