Gradall 534B Operation Manual

IMPORTANT SAFETY NOTICE

Safe operation depends on reliable equipment and proper operating

procedures. Performing the checks and services described in this manual will

help to keep your Gradall Materials Handler in reliable condition and use of

the recommended operating procedures can help you avoid accidents.

Because some procedures may be new to even the experienced operator we

recommend that this manual be read, understood and followed by all who

operate the unit.

Danger, Warning and Caution notes in this manual and the Gradall Materials

Handler Safety Manual will help you avoid injury and damage to the

equipment. These notes are not intended to cover all eventualities; it would

be impossible to anticipate and evaluate all possible applications and

methods of operation for this equipment.

Any procedure not specifically recommended by The Gradall Company must

be thoroughly evaluated from the standpoint of safety before it is placed in

practice. If you aren’t sure, contact your Gradall Materials Handler

Distributor before operating.

Do not modify this machine without written permission from The Gradall

Company.

NOTICE

The Gradall Company retains all

proprietary rights to the information contained in this manual

The Company also reserves the

right to change specifications without notice

Form No. 8496 12/84

The Gradall Company

406 Mill Avenue, S.W., New Philadelphia, Ohio 44663

INTRODUCTION

General

This manual provides important information to

familiarize you with safe operating procedures and

operator maintenance requirements for the

Gradall Loed 534B Materials Handler.

If you have any questions regarding the materials

handler, contact your Gradall Materials Handler

Distributor.

Operator Qualifications

Operators of the materials handler must be in good

physical and mental condition, have normal reflexes

and reaction time. good vision and depth perception

and normal hearing. He / she* must not be using

medication which could impair his abilities nor be

under the influence of alcohol or any other drug

during the work shift.

The operator should also posses a valid, applicable

driver’s license and must have completed a course of

training in the safe operation of this type of material

handling equipment.

Related Manuals & Decals

Sublications are furnished with the

materials handler to provide information

concerning safety, replacement parts, maintenance

procedures, theory of operation and vendor

components. Replacement manuals, decals and

instruction plates can be ordered from your Gradall

Materials Handler Distributor.

Serial Number Location

Specify Model and Serial Numbers when ordering

parts and when discussing specific applications and

procedures with your distributor. The model/seria

number plate is located on the cab wall to the right

of the operator’s seat pedestal.

In addition, the operator must read, understand and

comply with instructions contained in the following

material furnished with the materials handler:

This Operator’s Manual

Gradall Materials Handler Safety Manual

All instruction decals and plates

Any optional equipment instructions furnished

The operator must also read, understand and

comply with all applicable Employer, Industry and

Governmental rules, standards and regulations.

Regardless of previous experience operating similar

equipment, the operator must be given sufficient

opportunity to practice with the 534B Materials

Handler in a safe, open area (not hazardous to

people or property) to develop the skills and “feel”

required for safe, efficient operation.

*Though no offense or discrimination is intended,

only the masculine pronouns will be used

throughout the remainder of this manual.

Orientation

When used to describe location of components in

the materials handler, the directions front, rear,

right and left relate to the orientation of a person

sitting in the operator’s seat.

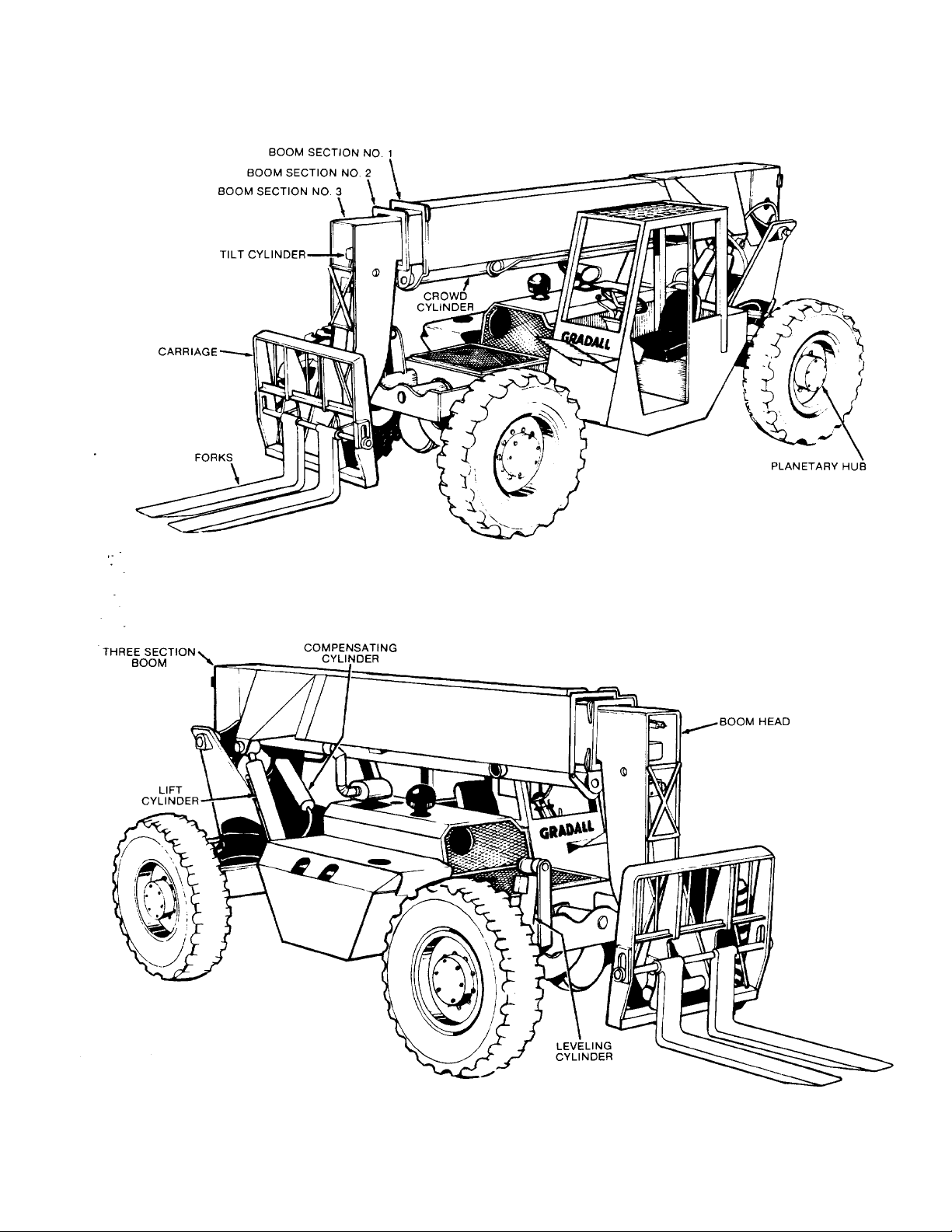

Nomenclature

The illustrations on page 3 include nomenclature

applied to major components of the material

handler. The term “handler” will be used

throughout the balance of this manual in place of

the words “materials handler”.

2

3

SAFETY HIGHLIGHTS

Read and understand this manual, the Gradall

Loed/Materials Handler Safety Manual and all

instructional decals and plates before starting,

operating or performing maintenance procedures

on this equipment.

Most safety notes included in this manual involve

characteristics of the Model 534B Loed/Materials

Handler. Refer to the Gradall/Loed Materials

Handler Safety Manual for safety precautions

relating to general material handling procedures

and practices.

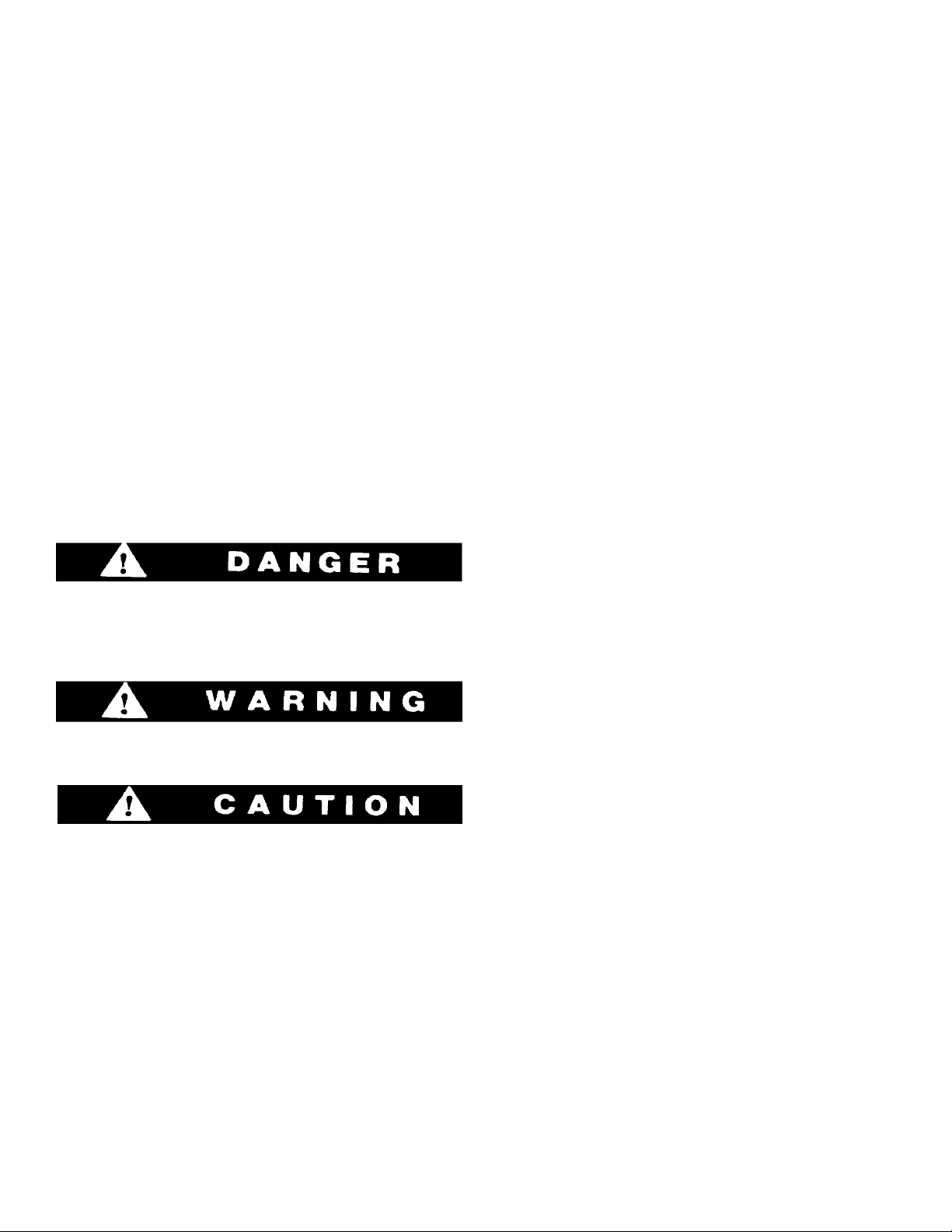

Watch for these symbols; they are used

to call your attention to safety notices.

Operators of this equipment must have successfully,

completed a training program in the safe operation

of this type of material handling equipment.

Regardless of previous experience operating similar

equipment, the operator must be given sufficient

opportunity to practice with the 534B Materials

Handler in a safe open area (not hazardous to

people or property) to develop the skills and “feel”

required for safe, efficient operation.

This symbol indicates an extreme hazard which

would result in high probability of death or

serious Injury if proper precautions are not

taken.

This symbol indicates a hazard which could

result in death or serious injury if proper

precautions are not taken.

This symbol indicates a hazard which could

result in injury or damage to equipment or

property if proper precautions are not taken.

4

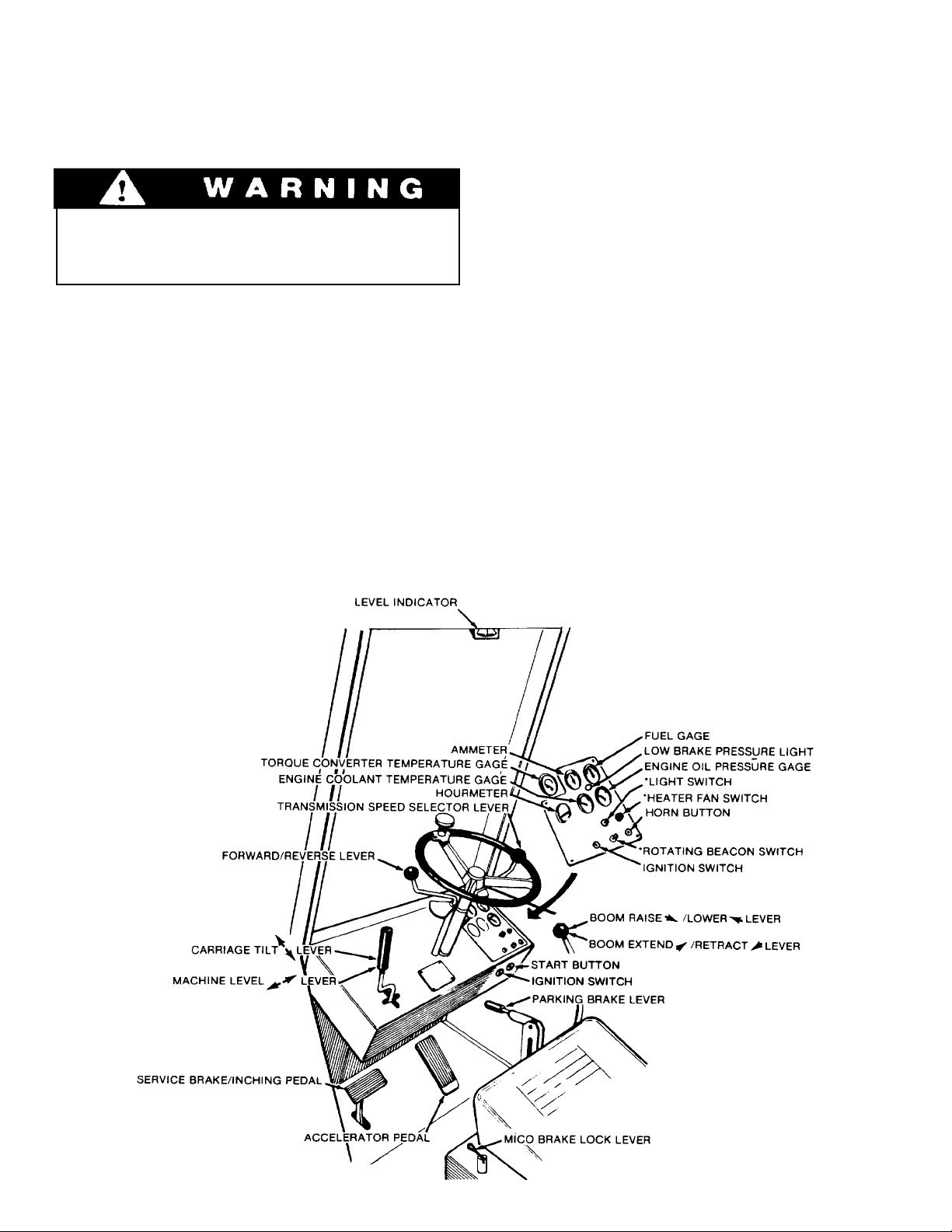

OPERA TOR’S CAB

The standard cab is open on three sides and includes

an overhead guard to provide protection from

falling objects.

Never operate the handler unless the

overhead guard is in place and in good

condition.

A fully enclosed cab with Plexiglass windows and a

lockable door is available as an option. The cab

door can be secured in the fully opened or closed

position. Be sure the door is fully secured when

operating the handler.

The operator’s seat is equipped with a seat belt and

includes fore and aft adjustment to compensate for

variations in operator size. The adjustment

release/lock lever is located beneath front edge of

seat. Wear seat belt at all times.

An optional windshield wiper is available for use

with enclosed cabs. An ON/OFF control switch is

located on the wiper motor.

A variable speed defroster fan is available for use

with enclosed cabs. An ON / OFF control switch and

speed control are located on the base of the fan.

A variable speed heater fan is available for use with

units equipped with a heater. An ON/OFF/SPEED

CONTROL knob is located on the dashboard. Hot

water to the heater can be controlled by a valve at

the engine.

CONTROL AND INSTRUMENT IDENTIFICATION

* Items preceded by an asterisk are optional and may not be furnished on your handler.

CHECKS AND SERVICES BEFORE STARTING ENGINE

(T o be performed at beginning of each work shift)

enter these ports, it can shorten the life of o-rings.

seals, packings and bearings.

Use extreme caution when checking items

beyond your normal reach. Use an

approved safety ladder.

Before removing filler caps or fill plugs, wipe all dirt

and grease away from the ports. If dirt is allowed to

Complete all required maintenance before operating unit.

When adding fluids or changing filter elements,

refer to the lubrication section of this manual to

determine the proper type to be used.

If spark arrestors are required, be sure they are in

place and in good working order.

Service the unit in accordance with the lubrication

and maintenance schedule.

Inspect unit for obvious damage, vandalism

and needed maintenance. Check for signs of fuel,

lubricant, coolant and hydraulic leaks. Open all

access doors and look for loose fittings, clamps,

components and attaching hardware. Replace

hydraulic lines that are cracked, brittle, cut or show

signs of abrasion.

Inspect all structural members, including attachment, for signs of damage.

Check to be sure rear planetary hubs are properly

set for the type of travel expected.

6

ENGINE OPERATION

NOTE: If engine is being started at beginning of work shift be sure to perform all “ CHECKS AND

SERVICES BEFORE STARTING ENGINE” (Page 6).

Starting Engine

Check to be sure that all controls are in neutral

1.

and that all electrical components (lights, heater,

defroster, etc.) are turned off. Set parking brake.

Insert ignition key and turn clockwise to ON

2.

position. Low brake pressure light should glow

and continue to glow until brake system

accumulator is fully charged.

Depress accelerator pedal approximately 1/4 to

3.

1/3 of travel from top.

Turning ignition switch to START position

while engine flywheel is rotating can cause

serious damage to engine and/or starting

motor.

NOTE: If temperature requires the use of a starting

aid, and if your handler is equipped with a factory-

installed ether starting aid, fully raise and depress

starting aid knob one time only before cranking

engine. If you use a different starting aid, be sure to

follow manufacturer’s instructions carefully.

Excessive ether may damage engine.

Turn ignition key clockwise to on position and

4.

depress start button to engage starting motor.

Release button immediately when engine starts.

If engine fails to start within 20 seconds, release

button and allow starting motor to cool for a few

minutes before trying again.

After engine starts, observe oil pressure gage. If

5.

gage remains on zero for more than ten seconds,

stop engine and determine cause. Correct cause

of malfunctioning before restarting engine.

Normal engine oil pressure should be in range of

35 - 50 psi (241 - 345 kPa).

Warm up engine at approximately 1/2 throttle

6.

until engine coolant temperature reaches

operating range of 180 - 200°F. (82 - 93°C.).

Cold Weather Starting Aids

Diesel engine ignition is accomplished by heat

generated when fuel/air mixture is compressed

within the cylinders. Because this heat may be

insufficient to start a cold engine in cold weather,

the use of starting aids has become common practice.

Because of the wide variety of starting aids available

it would be impractical to attempt to provide

Normal Engine Operation

Observe gages frequently to be sure all engine

systems are functioning properly.

The ammeter shows the charge/discharge rate of the

battery charging system. With the engine running, a

discharge reading (-) or a continuing high charge

reading (+) indicates a problem in the battery

charging system.

Be alert for unusual noises or vibration. When

an unusual condition is noticed, stop machine in a

safe position and shut off engine. Determine cause

and correct problem before continuing.

specific instructions for their use in this manual.

Carefully follow instructions furnished with your

starting aid.

If you use a starting aid employing ether or a

similar substance pay particular attention to

manufacturer’s warnings.

Avoid prolonged idling. Idling causes engine

temperature to drop and this permits formation of

heavy carbon deposits and dilution of lubricating oil

by incompletely burned fuel. If the engine is not

being used, turn it off.

Always keep engine covers closed while

engine is running.

continued...

7

Loading...

Loading...