Page 1

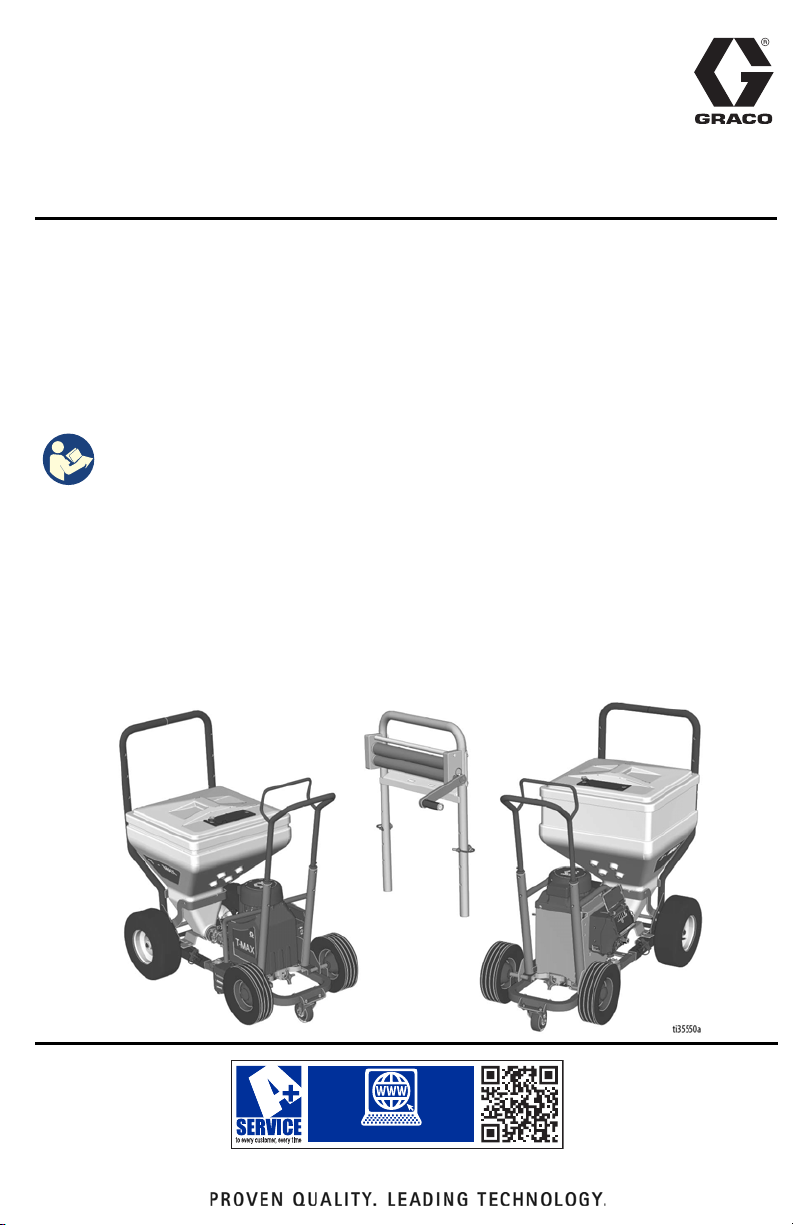

Operation, Repair, Parts

www.graco.com/techsupport

?? ??

T-Max™ 506/657/6912

3A6748B

Texture Sprayer

For portable spraying of water-based materials. Can be used for application of

solvent-based materials only when solvent compatible seals are installed and

solvent compatible, conductive hoses are used. For professional use only.

Not approved for use in European explosive atmosphere locations.

T-Max 506: 50 bar (5 MPa, 725 psi) Maximum Working Pressure

T-Max 657: 65 bar (6.5 MPa, 940 psi) Maximum Working Pressure

T-Max 6912: 69 bar (6.9 MPa, 1000 psi) Maximum Working Pressure

See page 4-6 for model information.

Important Safety Instructions

Read all warnings and instructions in this manual and related manuals before using

the equipment. Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

STX Trigger Gun 3A6746 Bag Roller Kits 312790, 3A4995

T-Max Remote Switch Kit 3A6784 T-Max Applicator 312879

PrimeValve Accessory Kit 3A6785 Free Flow Applicator 313537

Vibra-Flo T-Max 3A6909 Inline Applicator 309495

Air Manifold Kit 3A6839

Related Manuals

EN

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification 506 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Component Identification 657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Component Identification 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pump Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

T-Max 506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

T-Max 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Solvent-Based Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Amp Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mixing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hose Lubrication Mixing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Start Up - Airless . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Spray Tip Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Clear Spray Tip Clog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Start Up - Air Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Start Up - Air Assist STX Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Board Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Board Removal 506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Board Installation 506, 657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Control Board Removal 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Control Board Installation 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Pump Repair 506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Pump Repair 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cross-Section Reference / Pump Ball Identification 6912 . . . . . . . . . . . 63

Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Motor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Recycling and Disposal at End of Life . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2 3A6748B

Page 3

Parts - Hopper Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Parts List - Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Parts - Power Module 506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Parts List - Power Module 506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Parts - Power Module 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Parts List - Power Module 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Parts - Pump 289555 (506) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Parts List - Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Parts - Pump 289556 (657) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Parts List - Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Parts - Pump 25E668 (6912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Parts List - Pump 25E668 (6912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Parts - Control Box 506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Parts List - Control Box 506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Parts - Control Box 6912 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Parts List - Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

506/657 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6912 - US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6912 - UK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

CALIFORNIA PROPOSITION 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3A6748B 3

Page 4

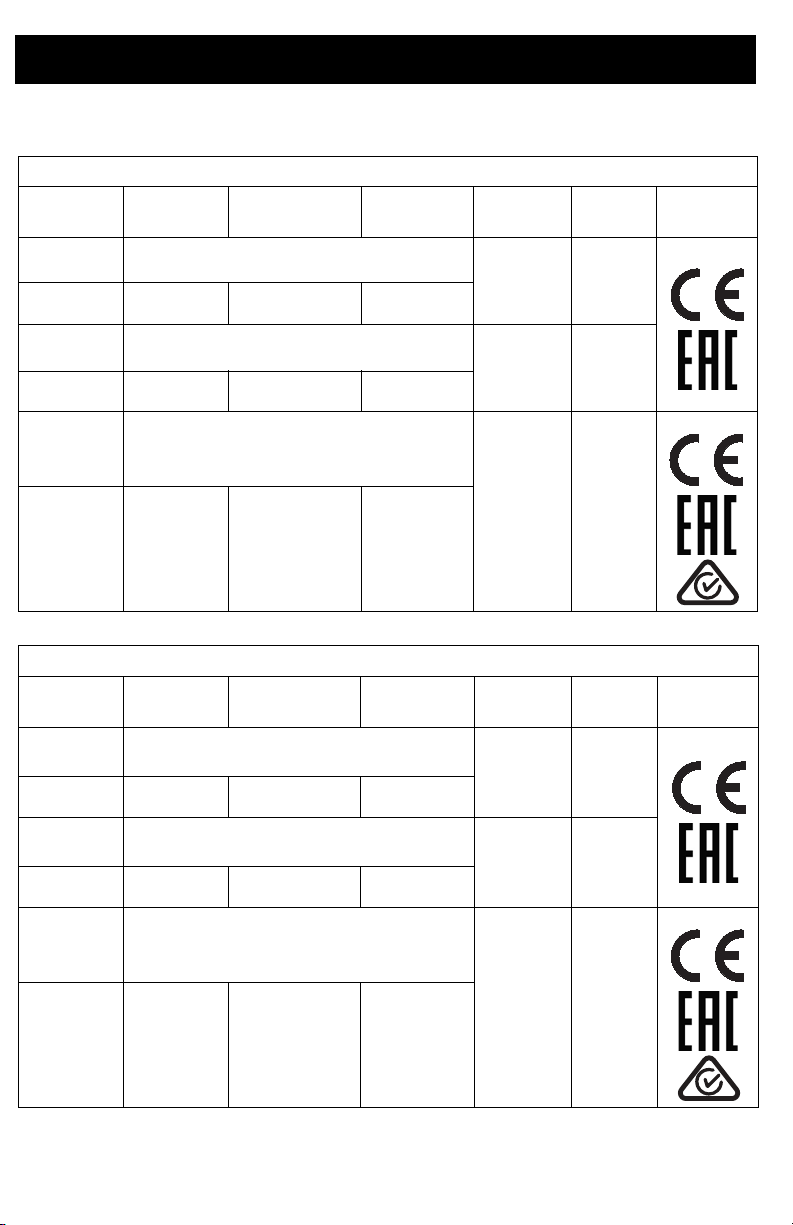

Models

Models

Model Hoses Applicator

T-MAX 506

17 Gallon

Hopper

Power

Cord

VAC

17Z169

17X980

17Z170

17X982

17Z291 Bare Unit

17X981

3m whip

5m

3m whip

5m

3m whip

5m

Bare Unit

T-Max Applicator

Bare Unit

T-Max Applicator

T-Max Applicator

Model Hoses Applicator

17Z171

17X983

17Z172

17X985

3m whip

5m

3m whip

5m

Bare Unit

T-Max Applicator

Bare Unit

T-Max Applicator

T-MAX 657

17 Gallon

Hopper

CEE 7/7

UK

Multi-Cord

Power

Cord

CEE 7/7

UK

230VAC

110VAC

230VAC

VAC

230VAC

110VAC

17Z292 Bare Unit

230VAC

17X984

3m whip

5m

T-Max Applicator

Multi-Cord

4 3A6748B

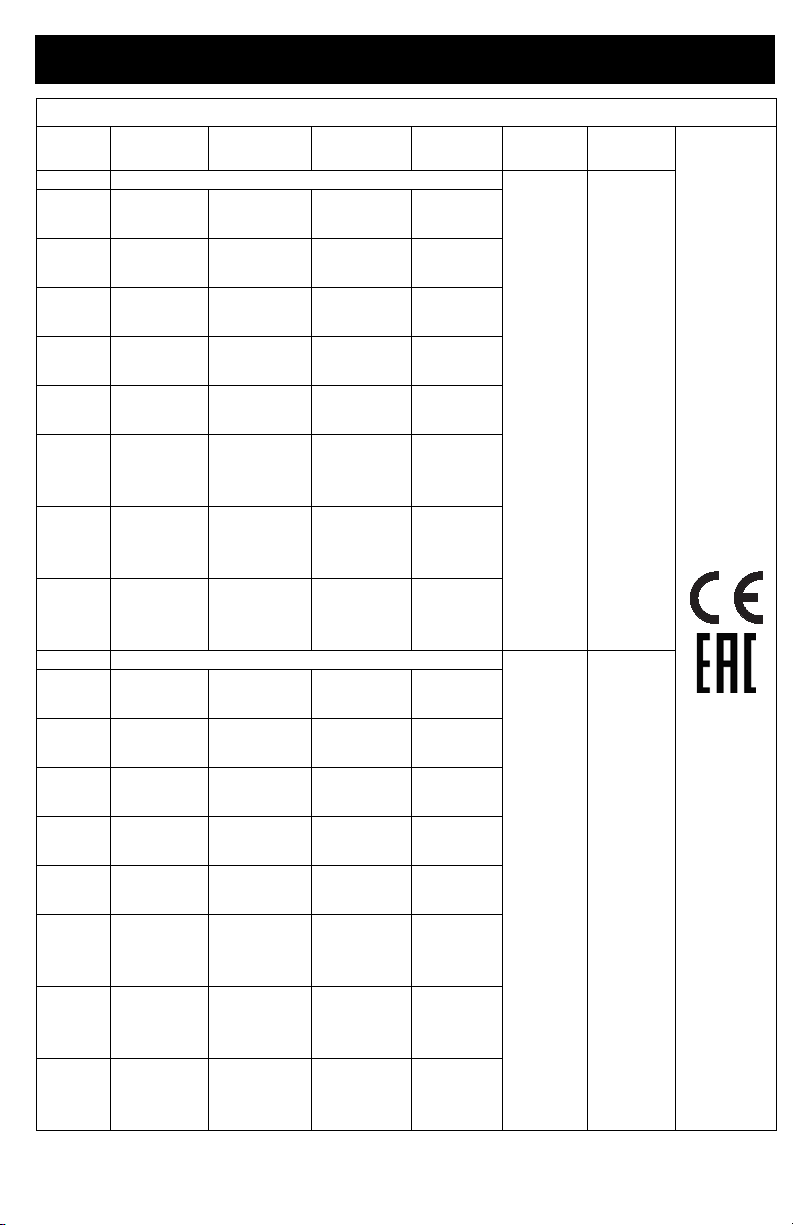

Page 5

Model Hoses Applicator

17Z173 Bare Unit

17Z626

17X986

17Z532

17X990

17X993

17Z285

17Z288

17Z529

17Z174 Bare Unit

17Z629

17X988

17Z534

17X992

17Z282

17Z287

17Z290

17Z531

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

T-Max

Applicator

Inline

Applicator

Free-Flow

Applicator

STX

Spray Gun

T-Max

Applicator

Free-Flow

Applicator

T-Max

Applicator

STX

Spray Gun

T-Max

Applicator

Pole

Applicator

T-Max

Applicator

Inline

Applicator

Free-Flow

Applicator

STX

Spray Gun

T-Max

Applicator

Free-Flow

Applicator

T-Max

Applicator

STX

Spray Gun

T-Max

Applicator

Pole

Applicator

T-MAX 6912

25 Gallon

Hopper

Air

Manifold

Power

Cord

CEE 7/7

UK

Models

VAC

230VAC

110VAC

3A6748B 5

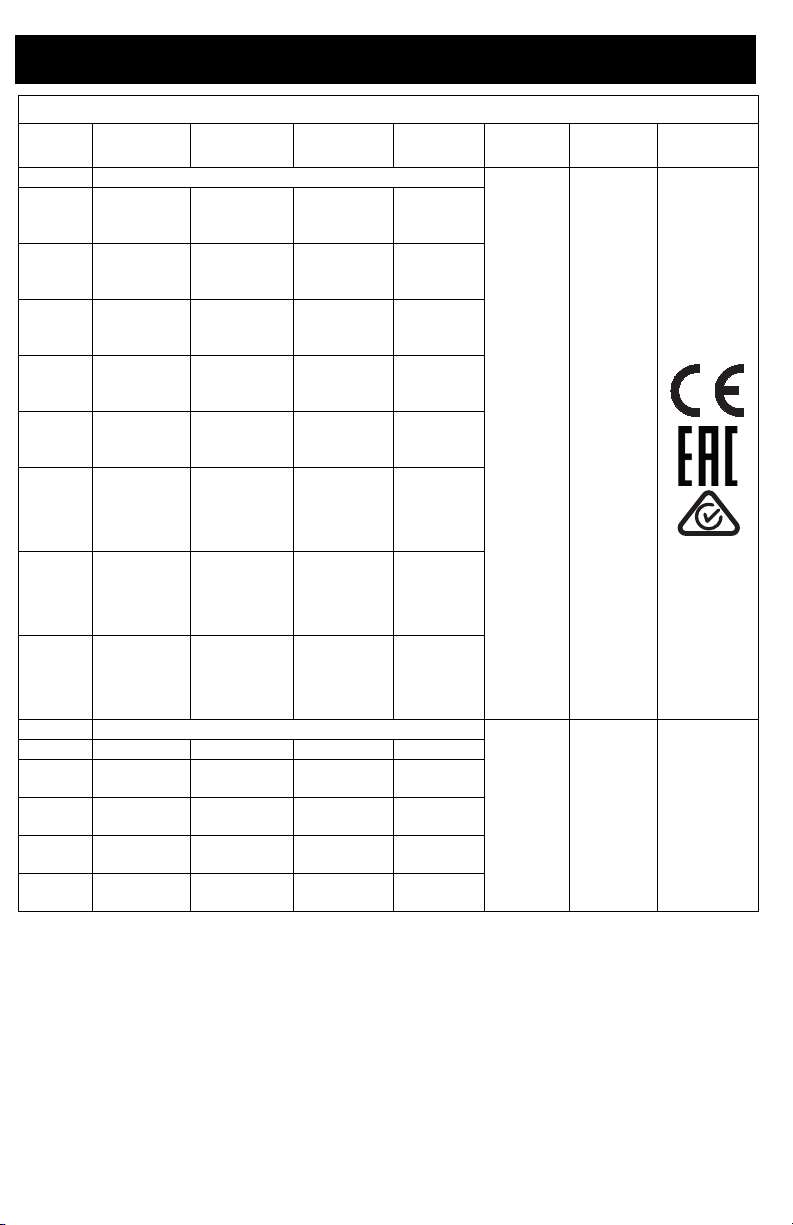

Page 6

Models

T-MAX 6912 continued

Model Hoses Applicator

17Z293 Bare Unit

17Z628

17X987

17Z533

17X991

17X994

17Z286

17Z289

17Z530

17Z175

17Z630

17X989

17Z283

17Z284

17Z703

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

3m whip

5m

10m

50’

9’ whip

50’

9’ whip

100’

9’ whip

100’

9’ whip

T-Max

Applicator

Inline

Applicator

Free-Flow

Applicator

STX Spray

Gun

T-Max

Applicator

Free-Flow

Applicator

T-Max

Applicator

STX SPray

Gun

T-Max

Applicator

Pole

Applicator

Bare Unit

T-Max

Applicator

STX Spray

Gun

STX Spray

Gun

STX Spray

Gun

25 Gallon

Hopper

Air

Manifold

Power

Cord

Multi-Cord

NA

VAC

230VAC

120VAC

6 3A6748B

Page 7

Warnings

WARNING

230V

110V UK

120V

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual

where applicable.

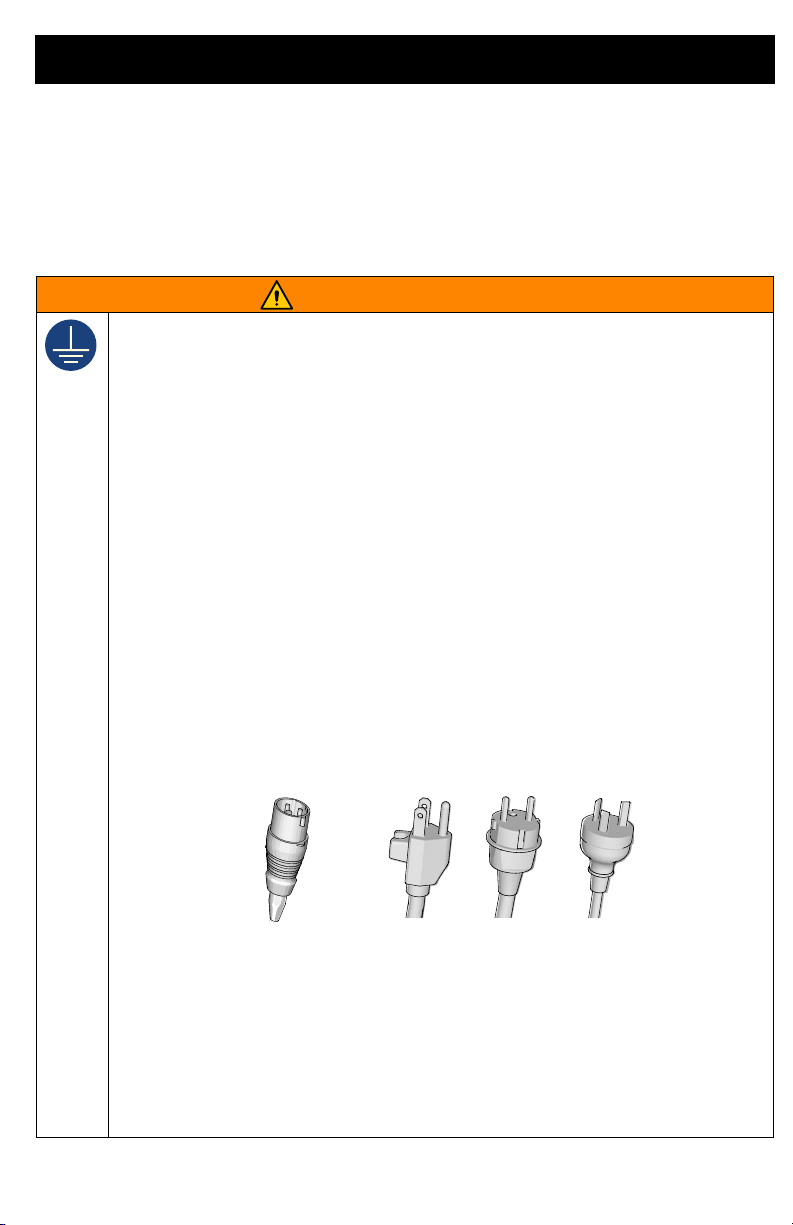

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electric shock by providing an escape wire for the electric current.

This product is equipped with a cord having a grounding wire with an appropriate

grounding plug. The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric

shock.

• When repair or replacement of the cord or plug is required, do not connect the

grounding wire to either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without

yellow stripes is the grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions

are not completely understood, or when in doubt as to whether the product is

properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet

installed by a qualified electrician.

• This product is for use on a nominal 110V or 230V circuit and has a grounding

plug similar to the plugs illustrated in the figure below.

ti24583a

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

•

Use only a 3-wire extension cord that has a grounding plug and a grounding

receptacle that accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary

use 12 AWG (2.5mm) minimum to carry the current that the product draws.

• An undersized cord results in a drop in line voltage and loss of power and

overheating.

3A6748B 7

Page 8

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and material fumes, in work area can ignite or

explode. To help prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources

of ignition such as cigarettes, motors, and electrical equipment.

• Material or solvent flowing through the equipment is able to result in static

electricity. Static electricity creates a risk of fire or explosion in the presence of

material or solvent fumes. All parts of the spray system, including the pump, hose

assembly, spray gun, and objects in and around the spray area shall be properly

grounded to protect against static discharge and sparks. Use Graco conductive

or grounded high-pressure airless material sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static

discharge. Do not use pail liners unless they are anti-static or conductive.

• Connect to a grounded outlet and use grounded extensions cords. Do not use

a 3-to-2 adapter.

• Do not use a material or a solvent containing halogenated hydrocarbons.

• Do not spray flammable or combustible liquids in a confined area.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through

the area.

• Sprayer generates sparks. Keep pump assembly in a well ventilated area a least

20 feet (6.1 m) from the spray area when spraying, flushing, cleaning, or

servicing. Do not spray pump assembly.

• Do not smoke in the spray area or spray where sparks or flame is present.

• Do not operate light switches, engines, or similar spark producing products in the

spray area.

• Keep area clean and free of material or solvent containers, rags, and other

flammable materials.

• Know the contents of the materials and solvents being sprayed. Read all Safety

Data Sheets (SDSs) and container labels provided with the materials and

solvents. Follow the material and solvents manufacturer’s safety instructions.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the

system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

• Wait five minutes after disconnecting power cord before servicing.

8 3A6748B

Page 9

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious injury

that can result in amputation. In the event that injection occurs, get immediate

surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not

try to stop leaks with any part of the body.

• Always use the spray tip guard. Do not spray without spray tip guard in place.

• Use Graco spray tips.

• Use caution when cleaning and changing spray tips. In the case where the spray

tip clogs while spraying, follow the Pressure Relief Procedure for turning off the

unit and relieving the pressure before removing the spray tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the

equipment energized or under pressure while unattended. Follow the Pressure

Relief Procedure when the equipment is unattended or not in use, and before

servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or

parts.

• This system is capable of producing 1000 psi (69 bar, 6.9 MPa). Use Graco parts

or accessories that are rated a minimum of 1000 psi (69 bar, 6.9 MPa).

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with

the controls.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can

cause serious chemical reaction and equipment rupture. Failure to follow this

warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated

hydrocarbon solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact

your material supplier for compatibility.

3A6748B 9

Page 10

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the

lowest rated system component. See Technical Specifications in all

equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See

Technical Specifications in all equipment manuals. Read fluid and solvent

manufacturer’s warnings. For complete information about your material, request

Safety Data Sheets (SDSs) from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when

equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately

with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency

approvals and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you

are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and

hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut, or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing

equipment, follow the Pressure Relief Procedure and disconnect all power

sources.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent

serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns.

This protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and

solvent manufacturer.

10 3A6748B

Page 11

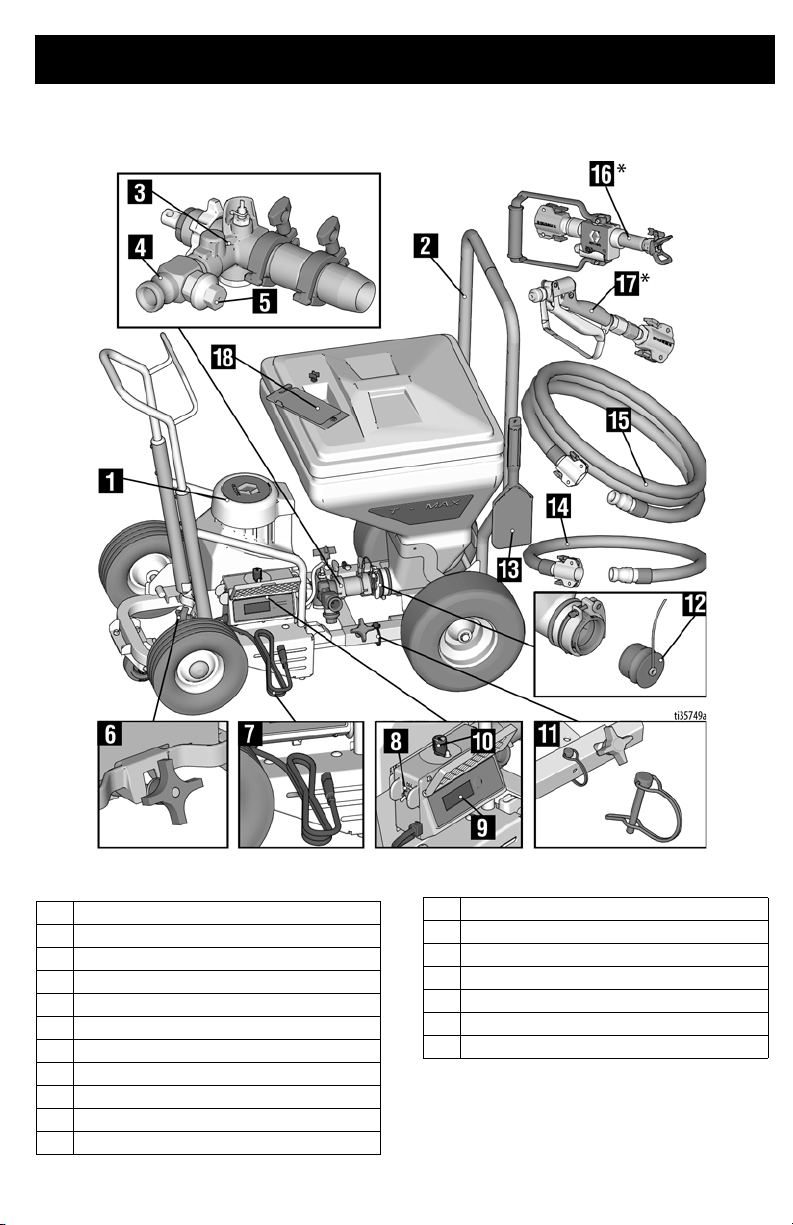

Component Identification 506

Component Identification 506

1 Pump Module

2 Hopper Frame

3Pump

4 Pump Outlet

5 Pressure Relief Valve

6 Module Securing Clamp

7 Power Cord

8 ON/OFF Switch

9 Display

10 Pressure Control Knob

11 Locking Pin

3A6748B 11

12 Hopper Plug

13 Scraper Tool

14 Whip Hose

15 Material Hose

16 T-Max Applicator

17 Inline Applicator

18 Tool Box

NOTE: All hoses sent with the unit are for

water-based material application only.

* See page14 for all applicators.

Page 12

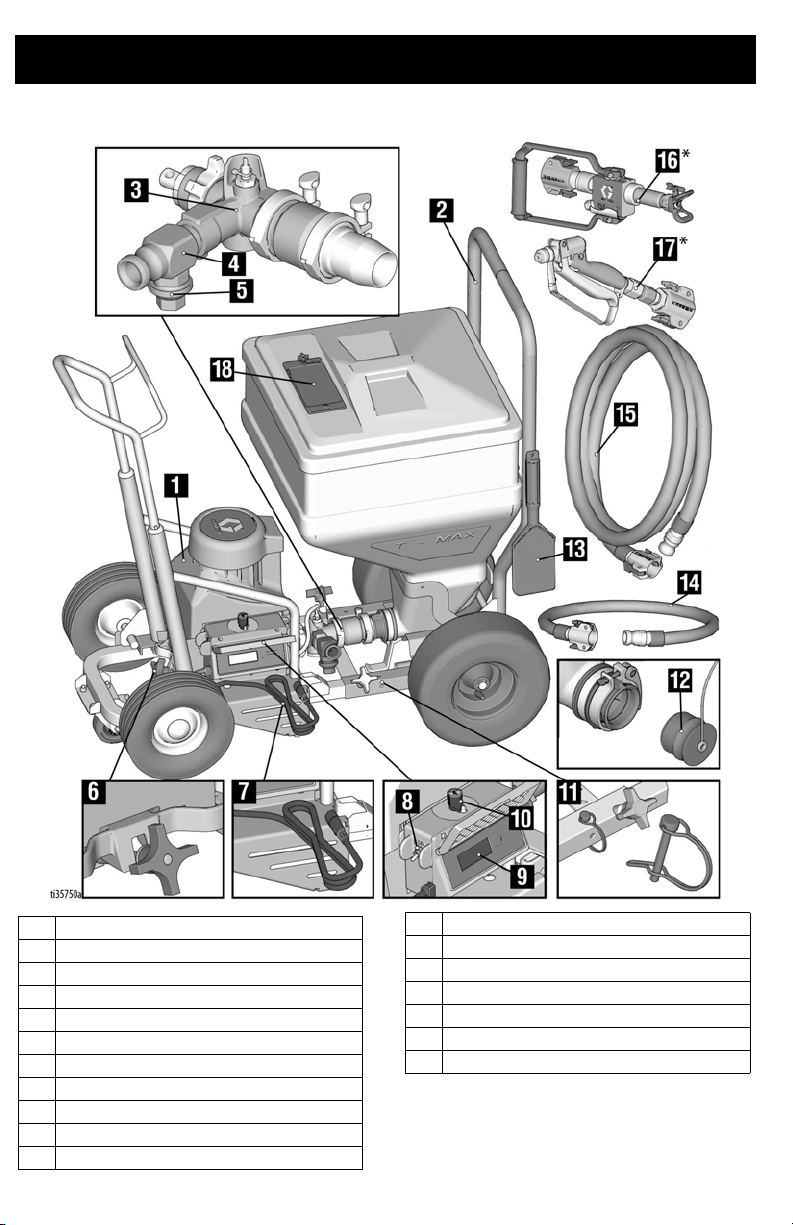

Component Identification 657

Component Identification 657

1 Pump Module

2 Hopper Frame

3Pump

4 Pump Outlet

5 Pressure Relief Valve

6 Module Securing Clamp

7 Power Cord

8 ON/OFF Switch

9 Display

10 Pressure Control Knob

11 Locking Pins

12 3A6748B

12 Hopper Plug

13 Scraper Tool

14 Whip Hose

15 Material Hose

16 T-Max Applicator

17 Inline Gun

18 Tool Box

NOTE: All hoses sent with the unit are for

water-based material application only.

* See page14 for all applicators.

Page 13

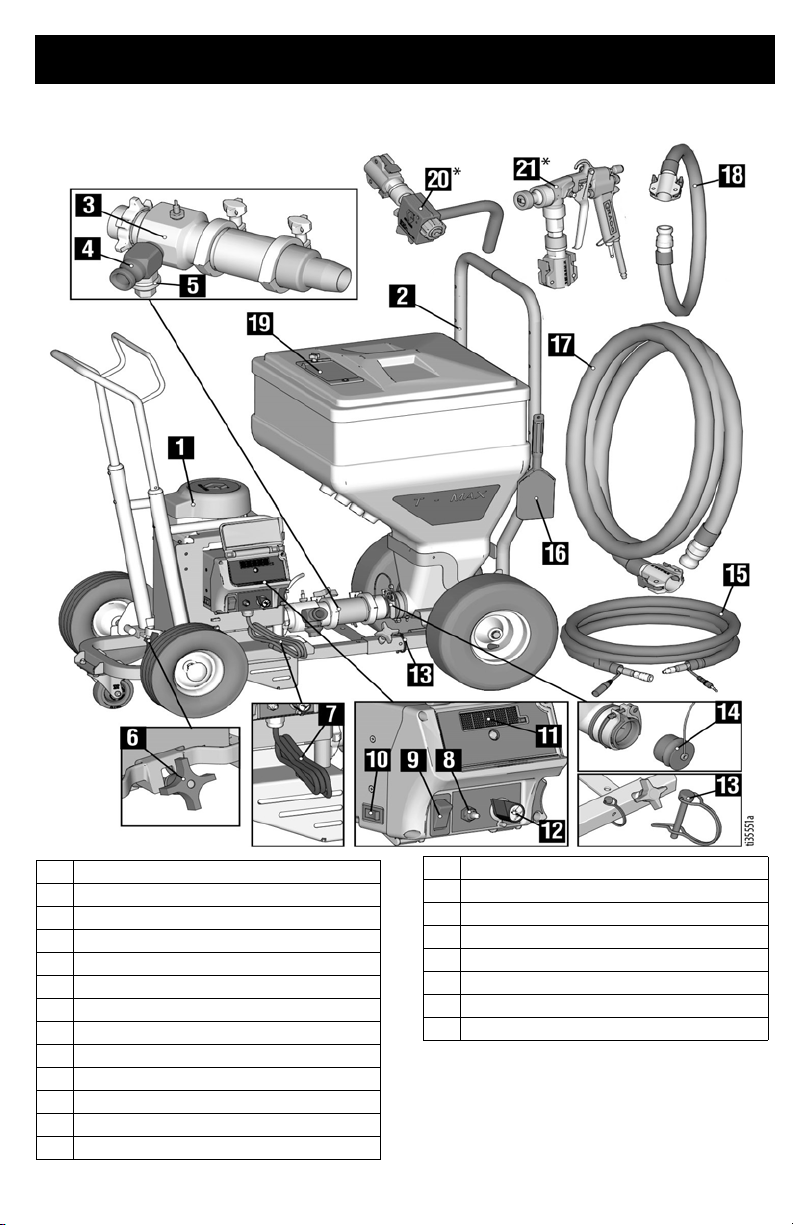

Component Identification 6912

Component Identification 6912

1 Pump Module

2 Hopper Frame

3Pump

4 Pump Outlet

5 Pressure Relief Valve

6 Module Securing Clamp

7 Power Cord

8 Pump Mode Switch

9 ON/OFF Switch

10 Amp Switch

11 Display

12 Pressure Control Knob

13 Locking Pins

3A6748B 13

14 Hopper Plug

15 Signal / Air Hose

16 Scraper Tool

17 Material Hose

18 Whip Hose

19 Tool Box

20 Free Flow Applicator

21 STX Spray Gun

NOTE: All hoses sent with the unit are for

water-based material application only.

* See page14 for all applicators.

Page 14

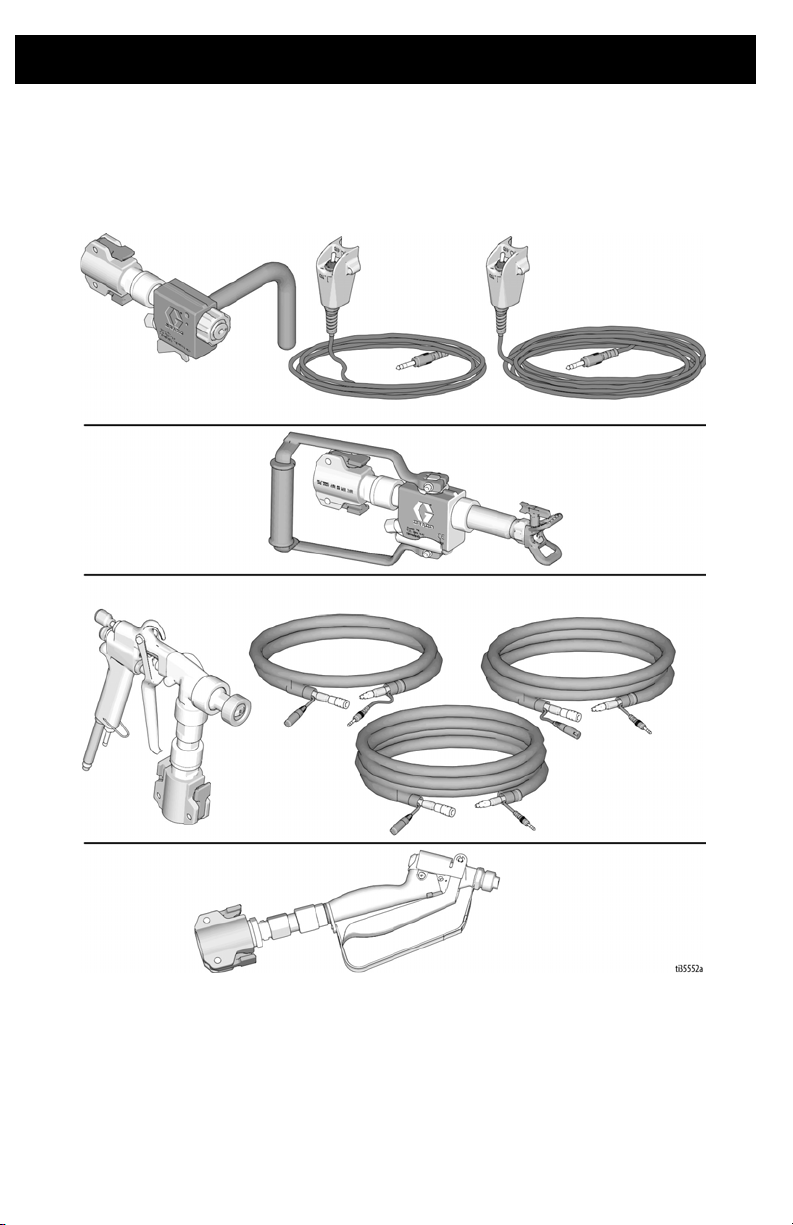

Component Identification

Free Flow

Applicator (17Z128)

T-Max Applicator

(17Z054)

STX Spray Gun

(17Y910)

18m Remote

Switch (17Z157)

30m Remote

Switch (17Z158)

13m Signal/Air

Hose (17Z144)

18m Signal/Air

Hose (17Z148)

33m Signal/Air

Hose (17Z151)

Inline Applicator

(17Y907)

Component Identification

14 3A6748B

Page 15

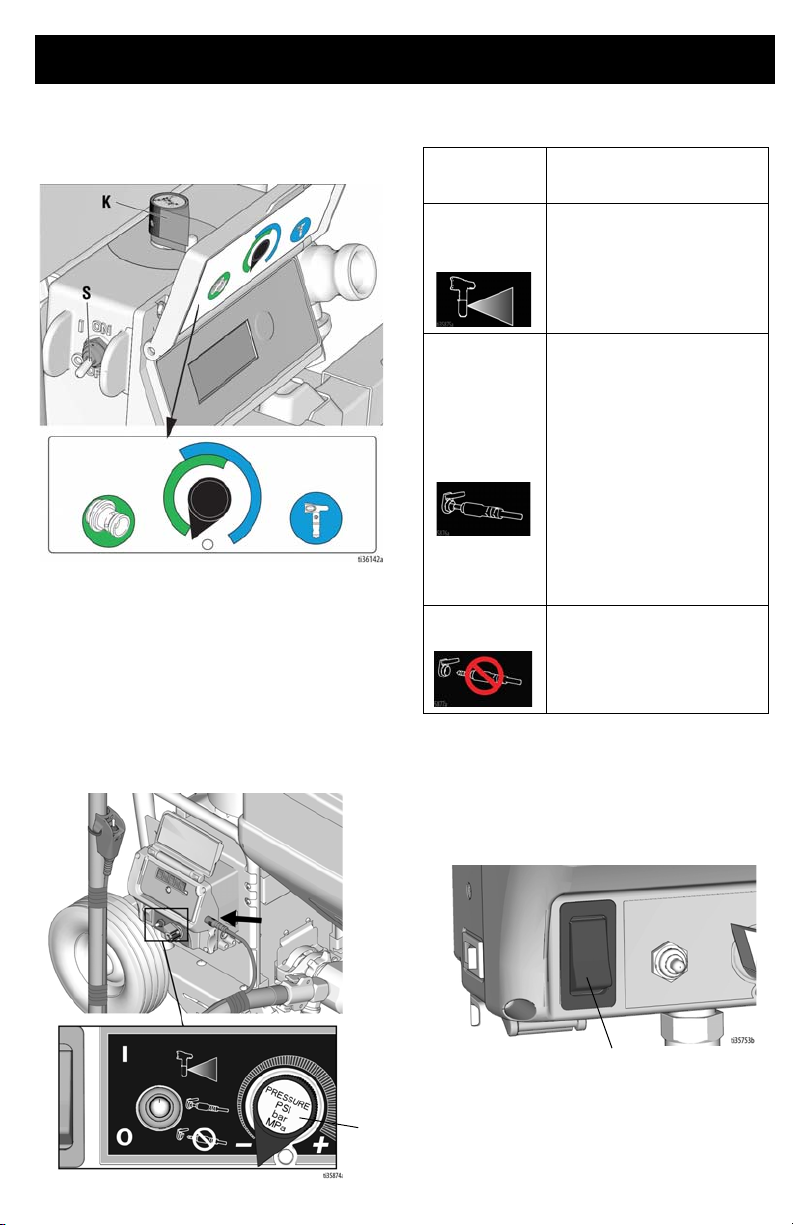

Pump Control Settings

K

S

Pump Control Settings

T-Max 506/657

Flow Mode (first half of Pressure Control

Knob):

The motor will run continuously at the

speed determined by the Pressure Control

Knob (K). 0-100%

Pressure Mode (second half of Pressure

Control Knob):

pressure determined by the Pressure Control

Knob (K).

The motor will run to meet the

Pump Control

Setting Description

Pressure

Mode

Flow Mode

with Remote

Control

Flow Mode

The motor will run to meet the

pressure determined by the

Pressure Control Knob (K).

The “Flow Mode with Remote

Control” setting allows the

user to control ON/OFF

functionality of the pump

through the remote toggle

switch or the STX Spray

Gun. When the remote toggle

switch or the STX Spray Gun

is installed and the pump

control settings are set to

“Flow Mode with Remote

Control”, they can be used to

turn the pump ON and OFF.

The motor will run

continuously at the speed

determined by the Pressure

Control Knob (K). 0-100%

T-Max 6912

Operation

The motor power switch (S) must be

ON for the sprayer to pump material.

3A6748B 15

Page 16

Preparation

Preparation

Grounding

The equipment must be grounded to

reduce the risk of static sparking and

electric shock. An electric or static spark

can cause fumes to ignite or explode. An

improper ground can cause electric shock.

A good ground provides an escape wire for

the electric current.

This product is equipped with a cord having

a grounding wire with an appropriate

grounding plug. The plug must be plugged

into an outlet that is properly installed and

grounded in accordance with all local codes

and ordinances.

Do not modify the plug provided; if it does not

fit the outlet, have the proper outlet installed

by a qualified electrician.

Solvent-Based Materials

NOTE: All hoses sent with the unit are for

water-based material application only.

Solvent compatible hoses and applicators

must be used.

Flush the Equipment

• Flush with a fluid that is compatible with

the fluid being dispensed and the

equipment wetted parts.

• Flush at the lowest pressure possible.

Check connectors for leaks and tighten

as necessary.

1. Follow Pressure Relief Procedure,

page 19.

2. Set pump to lowest possible fluid

pressure, and start pump.

3. Hold a metal part of the gun firmly to a

grounded metal pail. Trigger the gun

until clean solvent dispenses.

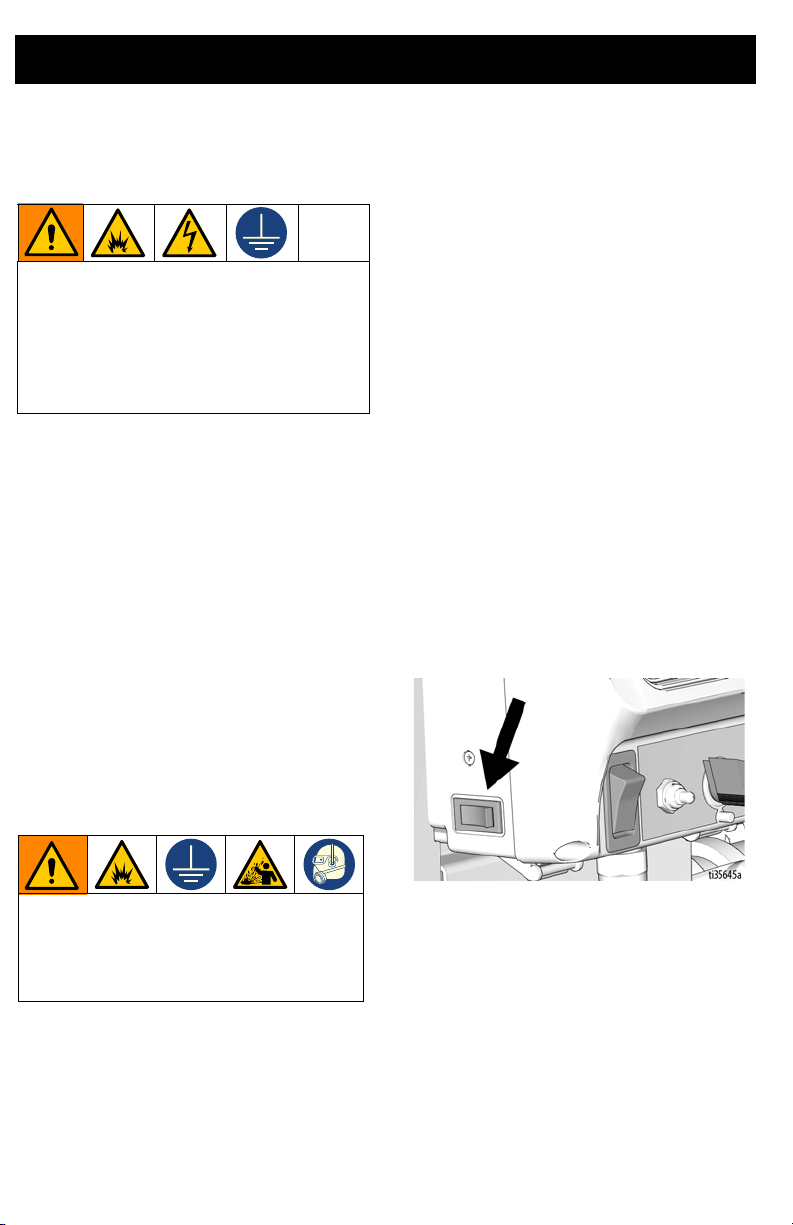

Amp Switch

Select 15A or 20A depending on your circuit

rating. 110V units require 100-120 VAC,

50/60 Hz, 15 – 20A, 1 phase

Select 10A or 16A depending on your circuit

rating. 230V units require 220-240 VAC,

50/60 Hz, 10 – 16A, 1 phase

To avoid fire and explosion, always

ground equipment and waste container.

To avoid static sparking and injury from

splashing, always flush at the lowest

possible pressure.

Flush before changing materials, before

•

fluid can dry or cure in the equipment, at

the end of the day, before storing, and

before repairing equipment.

16 3A6748B

Page 17

Preparation

ti2496c

40 lb.

TEXTURE MIX

5 GAL

PREMIX

5

GAL

ti2493b

Extension Cords

Use an extension cord with an undamaged

ground contact. If an extension cord is

necessary, use a 3-wire, 12 AWG (2.5 mm2)

minimum.

NOTE: Lighter gauge or longer extension

cords may reduce sprayer performance.

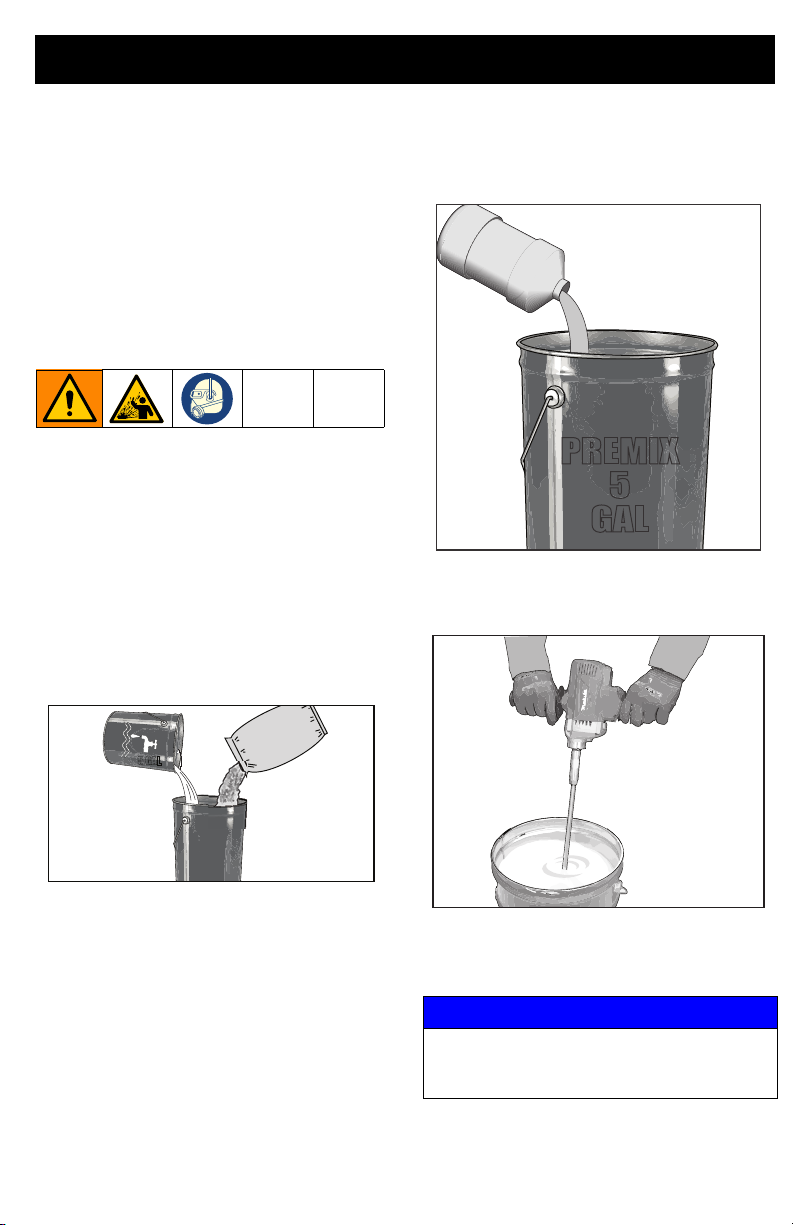

Mixing Material

NOTE: Correct material mixture is essential.

The pump and spray gun will not operate if

the mixture is too thick. Use water-based

materials only.

1. Mix the material and water in a

separate container.

Dry Mix

Carefully mix texture material and water

according to manufacturer instructions

on bag.

Premix

Slowly add water to a 5 gallon (18.9 liter)

bucket of premix.

2. Agitate to mix with mixing paddle, to a

smooth, lump-free consistency.

3. Make certain all dry powder clumps are

mixed throughly before pouring mixture

into the sprayer hopper.

NOTICE

Failure to make certain that all dry powder

is throughly mixed may cause tip or pump

clogging.

3A6748B 17

ti30766a

Page 18

Preparation

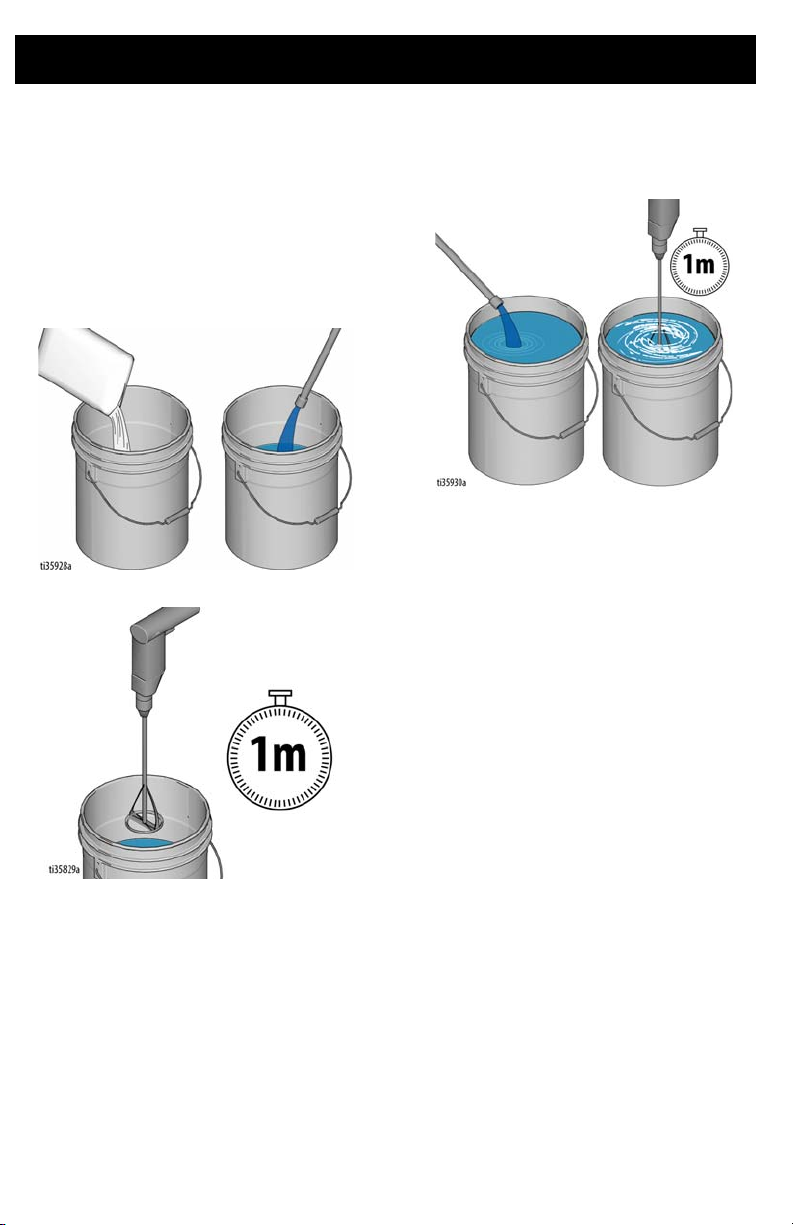

Hose Lubrication Mixing Instructions

Hose lubrication (17Z224) is used to lube the

pump and hose passages to reduce the risk

of packout when priming aggregate material.

NOTE: If using other hose lubricants, follow

manufacturer’s mixing instructions.

1. Empty one bag of hose lubricant into

five-gallon bucket and half fill with water.

2. Stir for one minute.

3. Fill remainder of bucket with water. Stir

for one minute.

4. Let mix stand for at least five minutes or

until a slick-like texture develops.

18 3A6748B

Page 19

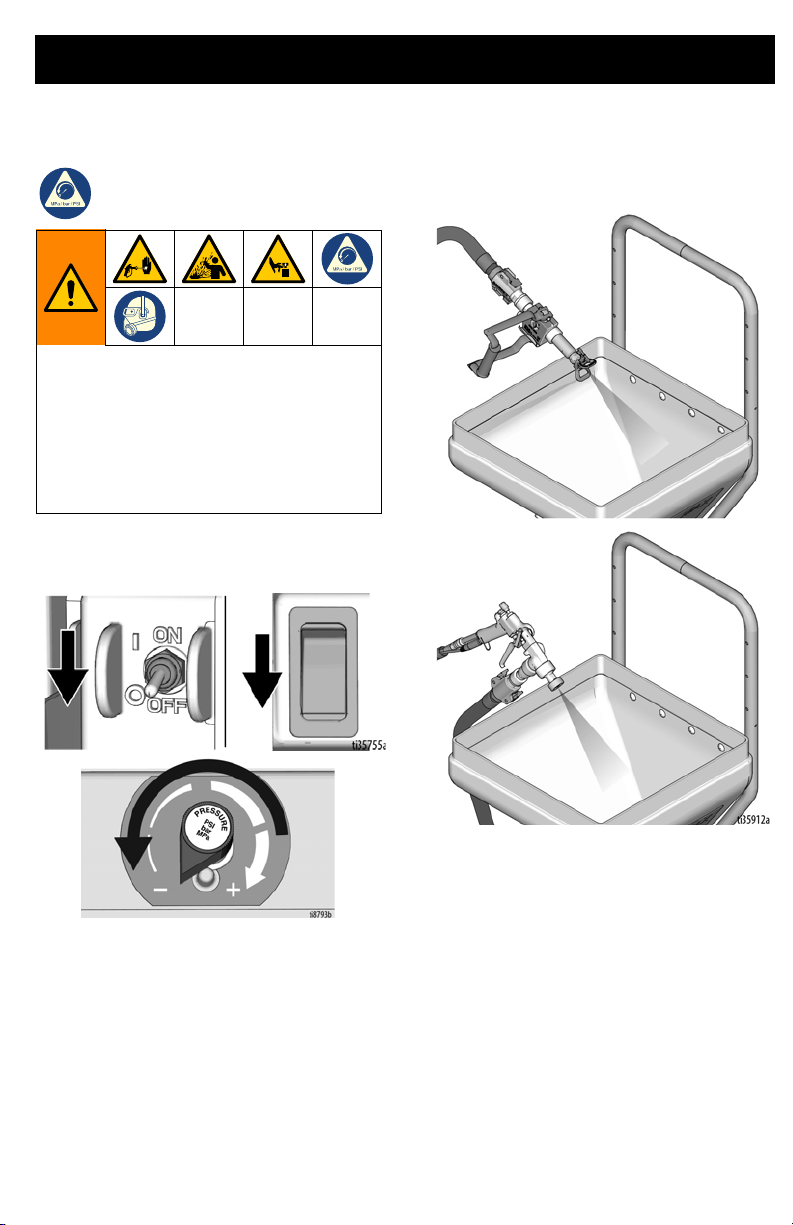

Pressure Relief Procedure

Preparation

Follow the Pressure Relief

Procedure whenever you see this

symbol.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection, splashing fluid

and moving parts, follow the Pressure

Relief Procedure when you stop spraying

and before cleaning, checking, or

servicing the equipment.

1. Turn ON/OFF Switch to OFF and turn

Pressure Control Knob fully

counterclockwise to OFF.

2. Point applicator into hopper. Turn

applicator ON.

3A6748B 19

Page 20

Preparation

3. If you suspect the spray tip or hose is

clogged or that pressure has not been

fully relieved:

a. If installed, turn prime valve down to

prime position.

b. VERY SLOWLY loosen the

retaining ring, hose end coupling, or

pressure relief valve to relieve

pressure gradually.

c. Loosen the retaining nut or the

coupling completely.

d. Clear the obstruction in the hose or

tip.

NOTE: If pressure relief valve was used to

relieve pressure, be sure to disassemble and

clean thoroughly.

20 3A6748B

Page 21

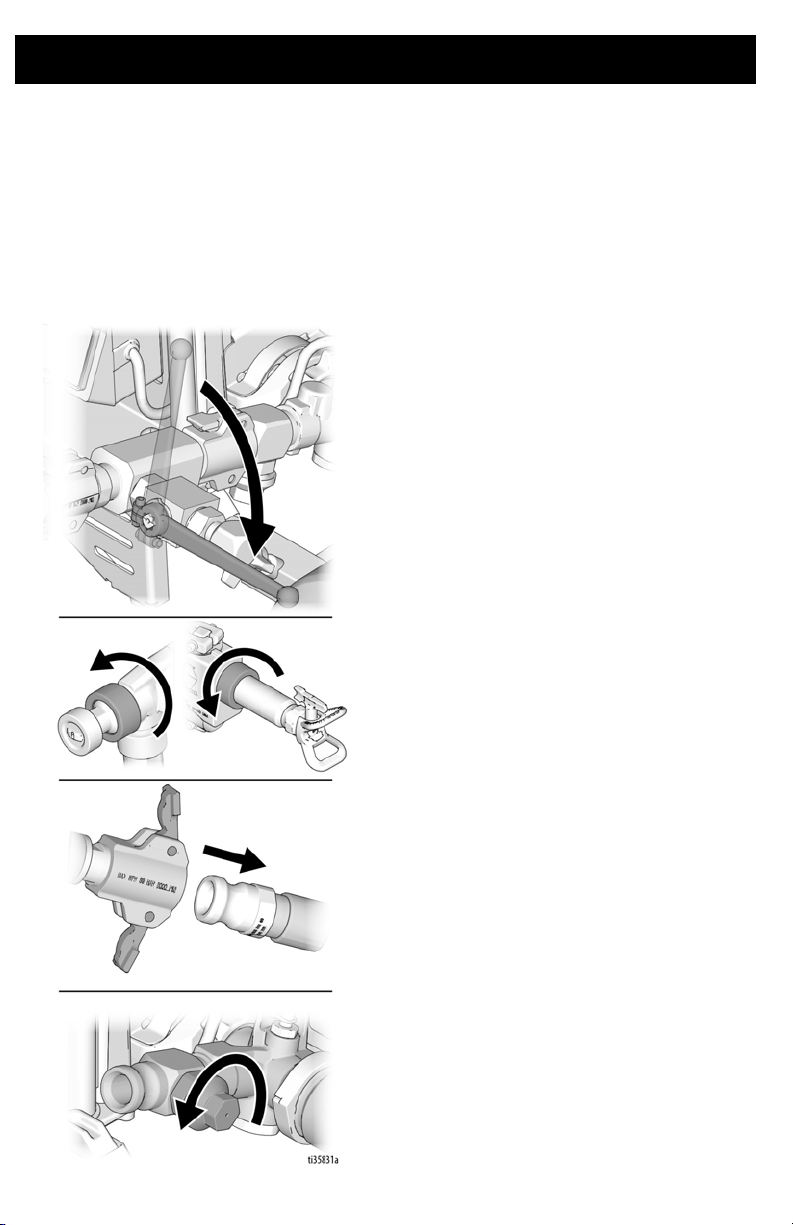

Setup

When unpacking sprayer for the first time or

after long term storage perform setup

procedure. When first setup is performed

remove shipping plug from fluid outlet.

1. Loosen knobs on hopper frame and pull

out pins. Adjust hopper frame to fit the

506/657 (shortest frame position) or the

6912 (longest frame position).

Setup

Depending on materials being sprayed with

the T-Max 6912, different pump setups might

be desired. For disassembly instructions, see

Pump Repair, page 60.

a. Smooth materials: Use steel inlet

ball with spring and steel outlet ball

with spring. This is how the unit is

shipped.

b. Some aggregates: To help prevent

packout, use a rubber inlet ball with

spring and a steel outlet ball with

spring. NOTE: Sometimes it is

necessary to remove spring from

outlet if packout occurs. See Part C.

3A6748B 21

Page 22

Setup

c. To remove outlet spring, remove

pump inlet and pump cylinder. Then

remove spring from the piston.

2. Lock front caster.

4. Move module securing clamp down.

5. Connect pump module to hopper frame.

3. Release hopper clamp.

22 3A6748B

Page 23

Setup

6. If hopper and pump do not align, loosen

four nuts on back of hopper. Make sure

hopper and pump are aligned and then

tighten four nuts.

7. Turn ON/OFF Switch to OFF. Connect

power cord.

8. Remove pump plug. Connect material

hose to pump outlet.

3A6748B 23

Page 24

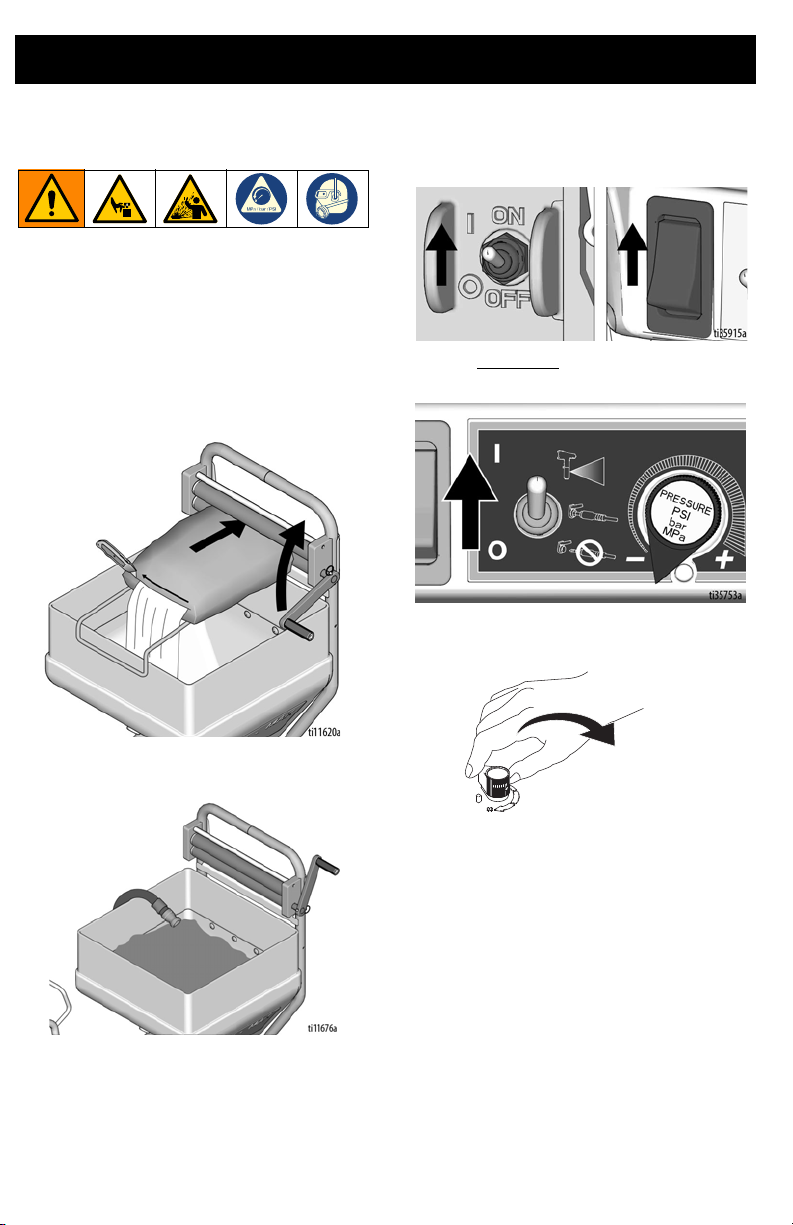

Start Up - Airless

Start Up - Airless

Perform the start up procedure each time the

sprayer is started for the first time after it has

been cleaned or stored.

1. Perform Pressure Relief Procedure,

page 19.

2. Fill material hopper with pre-mixed

texture material. Bag roller sold

separately.

b. Turn ON/OFF Switch to ON.

c. 6912 only

Switch in up position.

d. Turn Pressure Control Knob

clockwise 1/4 turn.

: Place Pump Mode

3. Prime pump.

a. Place material hose in hopper.

24 3A6748B

Page 25

Start Up - Airless

ti11697a

ti8794a

e. Once a steady stream flows from

the material hose, run for an

additional 30 seconds.

f. Turn ON/OFF Switch to OFF.

4. Install filter or air passage plug and tip

extension. Material consistency and tip

size will determine which filter size to

use. In certain instances, air passage

plug with no screen is needed with large

tips to successfully spray materials with

sand or rock.

5. Connect applicator to material hose.

6. Turn ON/OFF Switch to ON.

7. Turn applicator ON. Turn Pressure

Control Knob clockwise until desired

material delivery rate is achieved. Run

for 15 seconds.

3A6748B 25

Page 26

Start Up - Airless

ti29242a

Spray Tip Installation

To avoid serious injury from skin injection

do not put your hand in front of the spray tip

when installing or removing the spray tip

and tip guard.

1. Perform Pressure Relief Procedure,

page 19.

2. Verify spray tip and tip guard parts are

assembled in the order shown.

c. Assemble retaining ring on tip guard

adapter then assemble tip guard.

3. Turn the arrow shaped handle on the

spray tip forward to the spray position.

a. Use spray tip to align gasket and

seal in the tip guard.

4. Screw spray tip and tip guard assembly

onto the gun and tighten.

b. Spray tip must be pushed all the

way into the tip guard. Turn spray tip

to push down.

26 3A6748B

Page 27

Start Up - Airless

ti11714a

ti11794a

ti11715a

ti11793a

Clear Spray Tip Clog

To avoid tip clogs:

• When the applicator is not in use for

extended periods of time, keep the tip

“wet” and perform Pressure Relief

Procedure, page 19.

• Keep spray tip clean and free of material.

1. Rotate spray tip to unclog position. Aim

applicator at floor and turn applicator

ON. When clog clears, turn applicator

OFF.

UNCLOG

2. Rotate spray tip back to spray position.

Turn applicator ON. Spray test pattern.

SPRAY

NOTE: When spraying, if the applicator is not

used for a significant period of time be sure to

clean the sprayer, or keep the gun “wet” by

placing in water or wrapping with a wet cloth.

This reduces the potential of the material

drying in the gun causing pack-out of the gun.

3A6748B 27

Page 28

Start Up - Air Assist

Start Up - Air Assist

Perform the start up procedure each time the

sprayer is started for the first time after it has

been cleaned or stored.

1. Perform Pressure Relief Procedure,

page 19.

2. To help prevent packout, fill material

hopper with hose lubrication. See Hose

Lubrication Mixing Instructions, page

18, then follow prime instructions. Pump

all hose lube through hose back into a

bucket then continue with the material

prime.

If spraying large aggregates, use rubber inlet

ball with spring and steel outlet ball with

spring.

To prime without outlet spring, remove hose

and pour water into the outlet. Place unit in

“flow mode” and turn Pressure Control Knob

clockwise until material comes out of the

pump outlet. Turn pressure control

counterclockwise until flow stops, then

connect material hose. If applicable, connect

a prime valve to the outlet, then connect

material hose. Open prime valve and slowly

turn the pressure control knob clockwise until

material comes out the prime valve.

Close prime valve and allow the hose to fill

(prime valve sold separately).

3. Fill hopper with mixed texture material.

NOTE: While priming material, allow residual

hose lube to flow into a bucket until material

starts to comes out.

NOTE: If having packout issues in the pump,

remove the outlet spring and run without it.

28 3A6748B

Page 29

Start Up - Air Assist

4. Prime pump.

a. Place material hose in hopper.

b. Turn ON/OFF Switch to ON.

c. Place Pump Mode Switch in down

position. Turn Pressure Control

Knob clockwise 1/4 turn.

d. Once a steady stream flows from

the material hose, run for an

additional 30 seconds.

ti11697a

e. Turn ON/OFF Switch to OFF.

3A6748B 29

Page 30

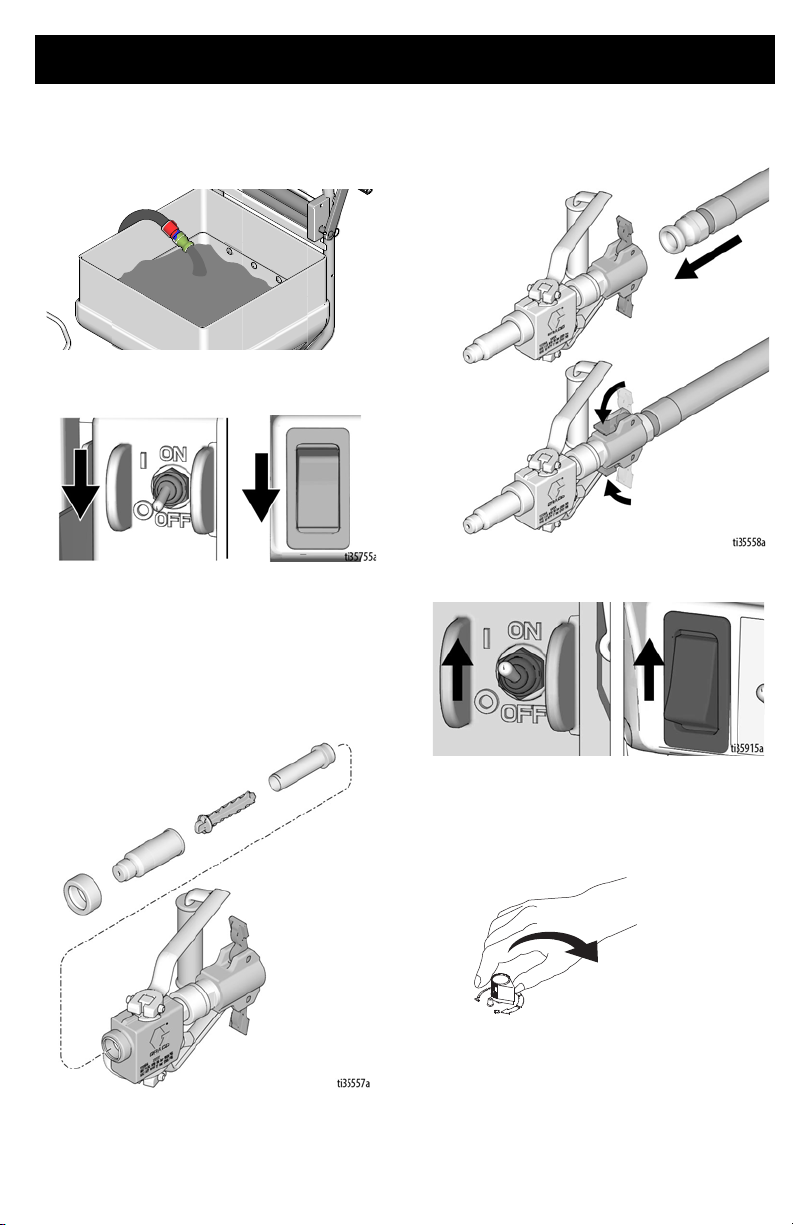

Start Up - Air Assist STX Gun

Start Up - Air Assist STX Gun

1. Turn air needle valve to low setting.

Connect applicator to material hose.

Connect signal wire connector to gun

handle, then the air hose.

2. Place Pump Mode Switch in center

position for remote pump control.

3. Hold applicator over material hopper and

turn applicator ON.

4. Turn Pressure Control Knob clockwise

until desired material delivery rate is

achieved. Run 15 seconds.

30 3A6748B

Page 31

Start Up - Air Assist STX Gun

5. When done spraying, release trigger.

The fluid passage will stay open,

relieving pressure.

6. When pressure is relieved, press trigger

stop button to close fluid passage.

7. Spray test pattern. Aim applicator at

floor. Turn air valve ON. Turn applicator

ON and move application to spray

surface.

8. Adjust air needle valve and/or select

alternative nozzle size (4 - 12mm) for

desired finish.

9. If a fan pattern is desired, remove

retaining ring and add adapter housing,

disk, and retaining nut to the assembly.

10. Select alternative disk (W4 - WXL) for

desired finish.

3A6748B 31

Page 32

Operation

ti11848a

Operation

The system has thermal overload

protection that will automatically shut

down the sysem if it overheats. To reduce

the risk of bodily injury due to the system

restarting unexpectedly, always turn the

ON/OFF switch to OFF.

An external air compressor may be

connected to the applicator air line fitting.

This may be useful for the application of

decorative or hard-to-spray materials.

Overpressurizing the system may cause

component rupture and result in serious

injury. To reduce risk of overpressurizing

system:

• Do not use a compressor with an

output pressure greater than 125 psi

(0.86 MPa, 8.6 bar).

The system comes with the following hoses:

T-Max 506:

• Fluid Hose: 5 m of 25 mm ID & 3 m

of 19 mm ID

T-Max 657:

• Fluid Hose: 10 m of 25 mm ID & 3 m

of 19 mm ID

T-Max 6912:

• Fluid Hose: 5m, 10m, 15m, 30m of

25mm ID & 3m of 19mm ID

• Air Hose: If applicable, 18m or 33m

Hose Usage

Always attach 25 mm ID hose to pump outlet.

Other hoses may then be added up to the

maximum fluid hose lengths:

• Use shortest fluid hose length required

for the spray application (25 mm x 5 m)

minimum.

• Unnecessary hose length decreases

sprayer performance.

• Maximum fluid hose lengths:

T-Max 506:

• 15 m of 25 mm ID or 10 m of 25 mm

ID + 3 m of 19 mm ID

T-Max 657:

• 30 m of 25 mm ID or 25 m of 25 mm

ID + 3 m of 19 mm ID

NOTE:

T-Max 6912:

• 30 m of 25 mm ID + 3m of 19mm ID

NOTE: Use only one 3 m of 19 mm ID. Do not

exceed 1000 psi. Temperature usage range

0°F - 180°F. All hoses sent with the unit are

for water-based material application only.

32 3A6748B

Page 33

Cleanup

ti11732a

ti11731a

Cleanup

Storage less than 24 hours

1. Perform Pressure Relief Procedure,

page 19.

2. Remove applicator. Keep applicator

“wet” by placing in water or wrapping

with a wet cloth.

3. Remove hose and couple ends together.

4. Clean hopper sides to material level.

Cover material in hopper with hopper

cover.

5. Disconnect pump from hopper.

3A6748B 33

Page 34

Cleanup

ti11711a

ti11850a

6. Install hopper plug.

7. Install cap on pump inlet.

8. Install pump cap (sold separately) on

pump outlet.

Storage more than 24 hours

1. Perform Pressure Relief Procedure,

page 19.

2. Shut air OFF if spraying with air. Remove

applicator from material hose. Clean

applicator.

3. Turn Pressure Control Knob clockwise

and pump unused texture from material

hopper and hose.

34 3A6748B

Page 35

Cleanup

4. Scrape remaining texture in hopper into

pump to be pumped from sprayer.

5. Rotate pump control to shut pump OFF.

7. Insert two wet cleaning balls into pump

outlet. Connect material hose to pump

outlet.

8. Fill material hopper with water and clean

sides.

9. Rotate Pressure Control Knob clockwise

to start pump.

6. Disconnect material hose from pump

outlet.

3A6748B 35

Page 36

Cleanup

10. Run pump until cleaning balls exit

material hose. Hold material hose

securely while passing balls through it.

Pressure can build up and make hose

jump. Save cleaning balls.

11. Rotate Pressure Control Knob to shut

pump OFF.

12. Connect applicator to material hose.

13. Turn Pressure Control Knob clockwise

to start pump.

14. Run pump until clean water flows from

applicator. Continue until hopper is

empty.

15. Add additional water and repeat steps 13

- 14, if necessary.

NOTE: After flushing with water, flush again

with Pump Armor to leave a protective

coating to prevent freezing and corrosion.

36 3A6748B

Page 37

Cleanup

16. Rotate Pressure Control Knob to shut

pump off.

17. Disconnect pump from hopper.

19. Clean applicators, spray tips and guard

with brush.

18. Flush hopper with water. Clean and

install drain plug.

3A6748B 37

Page 38

Cleanup

ti11811a

ti11847a

20. Clean hardened material from applicator

nozzles with air nozzle cleaner.

NOTICE

Do not use air nozzle cleaner to clean

applicator check valve and spray tip. Doing

so will damage both items.

38 3A6748B

Page 39

Troubleshooting

Troubleshooting

1. Follow Pressure Relief Procedure,

page 19, before checking or repairing.

2. Check all possible problems and causes

before disassembling unit.

Motor Will Not Operate

Problem Cause Solution

Basic Fluid Pressure Problems Pressure control knob setting.

Basic Mechanical Problems Frozen or hardened paint. Thaw sprayer if water or

Motor will not run if at minimum

setting (fully counterclockwise).

Spray tip or fluid filter may be

clogged.

Pump mode switch is not in the

proper position (6912).

Builds pressure but material will not

come out.

Displacement pump connecting rod

pin. Pin must be completely pushed

into connecting rod and retaining

spring must be firmly in groove of

pump pin.

Motor. With machine unplugged,

remove drive housing assembly.

Try to rotate fan by hand.

Slowly increase pressure setting to

see if motor starts.

Relieve pressure and clear clog or

clean filter; refer to separate gun or

tip instruction manual.

Place the pump mode switch in

proper position for application.

Up: Pressure Mode

Middle: Remote Control

Down: Flow Mode

Perform Pressure Relief

Procedure, page 19. Check

applicator, hose, and pump for

packout. May need to remove outlet

spring if packout in pump is

reoccuring.

water-based paint has frozen in

sprayer. Place sprayer in warm area

to thaw. Do not start sprayer until

thawed completely. If paint

hardened (dried) in spr ayer, replace

pump packing. See Pump Repair,

page 58.

Push pin into place and secure with

spring retainer.

Replace motor if fan won't turn.

3A6748B 39

Page 40

Troubleshooting

Problem Cause Solution

Basic Electrical Problems Motor control board. Board shuts

Motor is Hot and Runs Intermittently

down and displays error code.

Electrical supply. Meter must read:

210-255 Vac for 220-240 Vac

models;

85-130 Vac for 100-120 Vac

models.

Extension cord. Check extension

cord continuity with volt meter.

Sprayer power supply cord. Inspect

for damage such as broken

insulation or wires.

Check that motor leads are securely

fastened and properly mated.

ON/OFF Switch. Connect volt mete r

between L1 and L2 terminal on

ON/OFF switch. Plug in sprayer and

turn ON. Meter must read:

210-255 Vac for 220-240V models

85-130 Vac for 100-120V models.

Check all terminals for damage or

loose fit.

See Control Board Diagnostics,

page 43.

Reset building circuit breaker;

replace building fuse. Try another

outlet.

Replace extension cord.

Replace power supply cord.

Replace loose terminals; crimp to

leads. Be sure terminals are firmly

connected. Clean circuit board

terminals. Securely reconnect

leads.

Replace ON/OFF switch.

Replace damaged terminals and

reconnect securely.

Problem Cause Solution

Motor is hot and runs intermittently. Determine if sprayer was operated

at high pressure with small tips,

which causes low motor RPM and

excessive heat build up

Be sure ambient temperature where

sprayer is located is no more than

90°F and sprayer is not located in

direct sun

Decrease pressure setting or

increase tip size.

Move sprayer to shaded, cooler

area if possible.

40 3A6748B

Page 41

Troubleshooting

Low or Fluctuating Output

Problem Cause Solution

Low Output Worn spray tip. Follow Pressure Relief Procedure

Verify pump does not continue to

stroke when applicator is turned off.

Filter clogged (If optional filter is

installed).

Material hose length. Longer hose

length reduces sprayer

performance.

Pump hopper adapter connections. Tighten any loose connections.

Electrical supply with volt meter.

Meter must read:

210-255 Vac for 220-240 Vac

models;

85-130 Vac for 100-120 Vac

models. Low voltages reduce

sprayer performance.

Extension cord size and length;

must be at least 2.05 mm2 (12 awg)

wire and no longer than 90 m (295

ft). Longer cord lengths reduce

sprayer performance.

Leads from motor to pressure

control circuit board for damaged or

loose wires or connectors. Inspect

wiring insulation and terminals for

signs of overheating.

Low stall pressure. Turn pressure control knob fully

Fluctuating Output Material supply. Refill hopper and reprime pump.

Loose fittings. Tighten; use thread sealant or

Intake valve ball and piston ball are

not seating properly.

Leaking around throat packing nut

which may indicate worn or

damaged packings.

Pump rod damage. Repair pump.

3A6748B 41

Warning, then replace tip. See your

separate gun or tip manual.

Service pump. Check piston and

intake valves for wear or

obstructions.

Relieve pressure. Check and clean

filter.

Replace with hose length less than

specified maximum.

Replace pump hopper adapter if

cracked or punctured.

Reset building circuit breaker;

replace building fuse. Repair

electrical outlet or try another outlet.

Replace with a correct, grounded

extension cord.

Be sure male terminal blades are

centered and firmly connected to

female terminals. Replace any

loose terminal or damaged wiring.

Securely reconnect terminals.

clockwise. Make sure pressure

control knob is properly installed to

allow full clockwise position. Try a

new transducer. Check pump

control mode. If used in middle

position, the pump is limited to 600

psi.

sealing tape on threads if

necessary.

Remove intake and piston valves

and clean. Check balls and seats for

nicks or obstructions; replace if

necessary, page 58. Clean hopper

before using to remove particles

that could clog pump. Switch to a

rubber inlet ball (6912).

Replace packing, page 58. Also

check piston valve seat for

hardened paint or nicks and replace

if necessary.

Page 42

Troubleshooting

Problem Cause Solution

Motor runs but pump does not

stroke

Electrical Short

NOTICE

A short in any part of the motor power circuit will

cause the control circuit to inhibit sprayer

operation. Correctly diagnose and repair all shorts

before checking and replacing control board.

Problem Cause Solution

Building circuit breaker opens as

soon as sprayer switch is turned

on.

Building circuit breaker opens as

soon as sprayer is plugged into

outlet and sprayer is NOT turned

on.

Sprayer quits after sprayer

operates for 5 to 10 minutes.

Pump pin damaged or missing. Replace pump pin if missing. Be

Connecting rod assembly is

damage.

Gears or drive housing. Inspect drive housing assembly and

All electrical wiring for damaged

insulation, and all terminals for

loose fit or damage. Also wires

between pressure control and

motor.

Motor armature for shorts. Inspect

windings for burns

Motor control board by performing

motor control board diagnostics. If

diagnostics indicate, substitute

with a good board.

Basic Electrical Problems on

page 41.

For damaged or pinched wires in

pressure

control.

Basic Electrical Problems. Perform necessary procedures.

Electrical supply with volt meter.

Meter must read:

210-255 Vac for 220-240 Vac

models;

85-130 Vac for 100-120 Vac

models.

sure retainer spring is fully in groove

all around connecting rod.

Replace connecting rod assembly.

gears for damage and replace if

necessary.

Repair or replace any damaged

wiring or terminals. Securely

reconnect all wires.

Replace motor.

Replace with a new motor control

board.

Perform necessary procedures.

Replace damaged parts.

If voltage is too high, do not

operate sprayer until corrected.

42 3A6748B

Page 43

Repair

Control Board Diagnostics

Repair

1. Perform Pressure Relief Procedure,

page 19.

NOTE: Do not allow sprayer to develop fluid

pressure without transducer installed. Leave

pump outlet open if test transducer is used.

Control

board status

Display

No Display Never blinks Spray stops. Power is not

psi/bar/MPa Once Sprayer is pressurized. Power is

E=02

CODE 02

E=03

CODE 03

E=04

CODE 04

E=05

CODE 05

E=06

CODE 06

LED Blinks

Two times

repeatedly

Three times

repeatedly

Four times

repeatedly

Five times

repeatedly

Six times

repeatedly

Spray Operation Indicates What to Do

applied. Sprayer must be

pressurized.

applied. (Pressure varies with tip

size and pressure control

setting.)

Sprayer may continue to run.

Power is applied.

Sprayer shuts down and LED

continues to blink three times

repeatedly

Sprayer does not operate. Control board is

Sprayer does not start or stops

and LED continues to blink five

times repeatedly. Power is

applied.

Sprayer stops and LED blinks six

times repeatedly. Power is

applied.

2. Observe display messages in the

following table.

3. Observe LED operation and reference

the following table.

Loss of power. Check power source. Perform

Normal operation. Do nothing.

Run away pressure.

Pressure greater

than 1500 psi (103

bar, 10.3 MPa) or

damaged pressure

transducer.

Pressure transducer

is faulty or missing.

detecting multiple

voltage surges.

Motor fault. Check for locked rotor,

Motor is too hot or

there is a fault in

motor thermal

device.

Pressure Relief Procedure,

page 19, before repair or

disassembly.

Replace motor control board

or pressure transducer.

Check transducer connection.

Open drain valve. Substitute

new transducer for transducer

in sprayer. If sprayer runs,

replace transducer.

Check voltage switch, ensure

it is in the right voltage setting

for the voltage being used. Set

Sprayer to OFF and

disconnect power to sprayer.

Locate a good voltage supply

to prevent damage to

electronics.

shorted wiring or

disconnected motor. Repair or

replace failed parts.

Allow sprayer to cool. If

sprayer runs correctly when

cool, check motor fan function

and air flow. Keep sprayer in

cool location. If sprayer does

not run when cool and

continues to blink six times,

replace motor.

3A6748B 43

Page 44

Repair

Control

board status

Display

CODE 08 Eight times

CODE 10 Ten times

CODE 12 Twelve times

CODE 15 Fifteen times

CODE 16 Sixteen times

CODE 17 Seventeen

- - - Power is applied. Pressure less than

LED Blinks

repeatedly

repeatedly

repeatedly

repeatedly

repeatedly

times

repeatedly

Spray Operation Indicates What to Do

Sprayer does not operate. Voltage supply to

Sprayer does not operate. Overheating control

Sprayer does not operate. Excessive current

Sprayer does not operate. Motor connection

Sprayer does not operate. Control is not

Sprayer does not operate. Wrong voltage

low.

board

protection enabled.

problem.

receiving a motor

position signal.

detected.

60 psi (4.1 bar, 41

MPa).

Set sprayer to OFF and

disconnect power to sprayer

remove other equipment that

uses the same circuit. Locate

a good voltage supply to avoid

damage to electronics.

Make sure motor air intake is

not blocked. Make sure fan

has not failed. Make sure

control board is properly

connected to back plate and

that conductive thermal paste

is used on power

components. Replace control

board. Replace motor.

Cycle power on and off.

Set sprayer to OFF and

disconnect power to sprayer.

Remove motor shroud.

Disconnect motor control and

inspect for damge at

connectors.

Turn power OFF. Disconnect

motor position sensor and

inspect for damage at

connectors. Reconnect

sensor. Turn power on. If

problem continues, replace

motor.

Check voltage switch, ensure

it is in the right voltage setting

for the voltage being used. Set

Sprayer to OFF and

disconnect power to sprayer.

Locate a good voltage supply

to prevent damage to

electronics.

Increase pressure if desired.

Drain valve may be open.

44 3A6748B

Page 45

Repair

ti11854a

Control Board Removal 506/657

1. Perform Pressure Relief Procedure,

page 19. Unplug power cord to

disconnect power.

2. Separate pump from hopper.

3. Remove four screws and motor cover.

4. Remove four screws and control cover.

Disconnect display from control board.

3A6748B 45

Page 46

Repair

ti11853a

ti11856a

5. Reference Wiring Diagram, page 81.

Remove screw. Disconnect ground, blue

and brown leads.

6. Remove power cord from control box.

7. Remove filter board screws.

8. Remove ON/OFF switch toggle boot.

9. Disconnect black lead from control

board to filter board.

10. Remove filter board from control box.

46 3A6748B

Page 47

Repair

ti11864a

409

ti11862a

A

B

E

D

C

ti11863a

ti11863a

ti11862a

A

B

E

D

C

ti11864a

11. Remove screw from bottom of control

box.

12. Disconnect motor (A), thermister (B),

potentiometer (C) and transducer (D)

connectors. Remove grommet (E).

Control Board Installation 506, 657

1. Install control board with four screws.

2. Connect motor (A), thermister (B),

potentiometer (C) and transducer (D)

connectors. Install grommet (E).

13. Remove four screws and control board.

3. Install screw through bottom of control

box.

3A6748B 47

Page 48

Repair

ti11856a

412

ti11853a

4. Install filter board in control box.

5. Connect black lead from control board to

filter board.

6. Install ON/OFF switch toggle boot.

7. Install filter board screw.

8. Install power cord (C) in control box.

9. Reference Wiring Diagram, page 81.

Connect ground, blue and brown leads.

Install screw.

48 3A6748B

Page 49

Repair

ti11854a

ti11737a

10. Connect display to control board. Install

control cover with four screws.

11. Install motor cover with four screws.

Control Board Removal 6912

1. Perform Pressure Relief Procedure,

page 19. Unplug power cord to

disconnect power.

2. Separate pump from hopper.

3A6748B 49

Page 50

Repair

3. Remove four screws and motor cover. 4. Remove four screws and open cover.

5. Remove two screws and remove filter

board and amp switch.

50 3A6748B

Page 51

Repair

6. Reference Wiring Diagrams, page 82.

Disconnect mode switch (yellow and

black), transducer, potentiometer, amp

switch, LED display filter board (black,

blue). Remove front cover.

7. Disconnect motor leads, thermal switch,

and motor hall/encoder sensor. Remove

grommet.

8. Remove two screws from back of control

box and remove box.

Control Board Installation 6912

1. Install control box with two screws.

3A6748B 51

Page 52

Repair

2. Connect motor leads, thermal switch,

and motor hall/encoder sensor. Install

grommet.

3. Reference Wiring Diagrams, page 82.

Connect mode switch (yellow and

black), transducer, potentiometer, amp

switch, LED display filter board (black,

blue).

4. Install filter board in control box with two

screws. Install amp switch.

5. Close cover and install four screws.

52 3A6748B

Page 53

6. Install motor cover using four screws. 7. Connect pump to hopper.

Repair

3A6748B 53

Page 54

Repair

ti11854a

506/657

6912

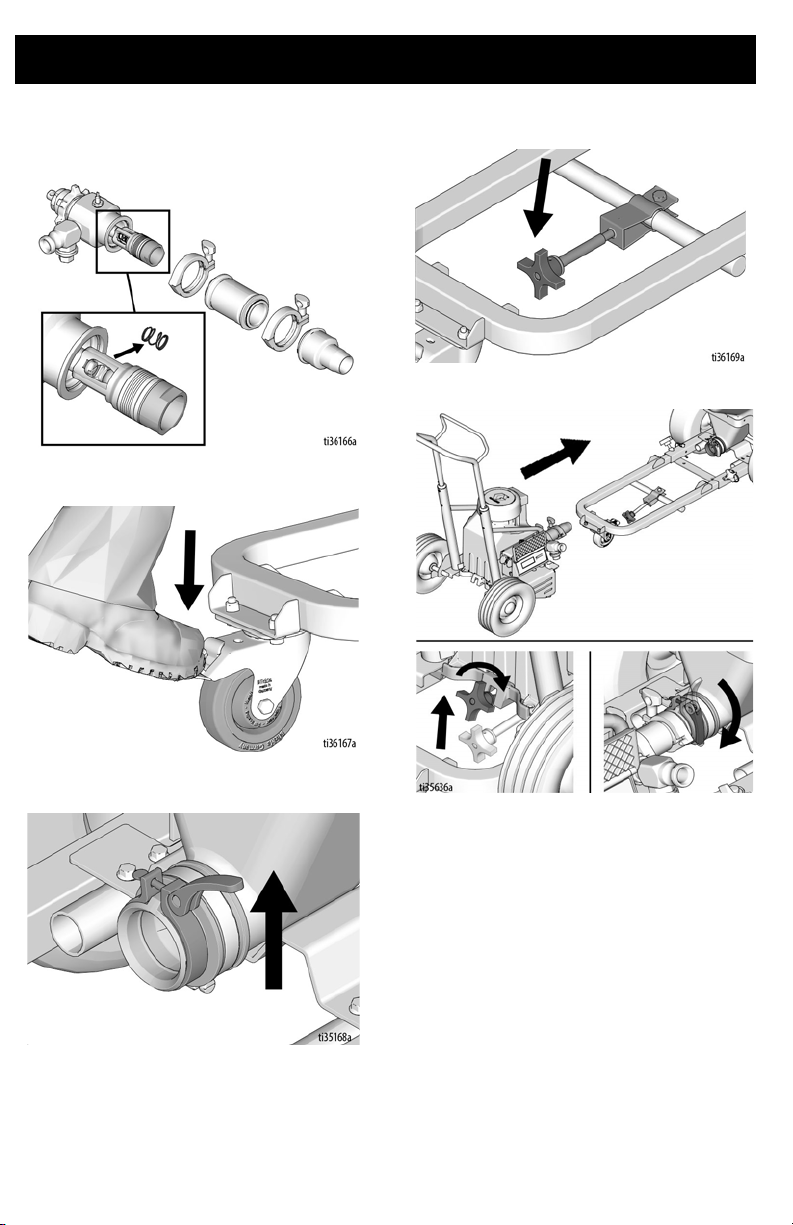

Pump Removal

1. Perform Pressure Relief Procedure,

page 19. Unplug power cord to

disconnect power.

2. Perform Storage more than 24 hours

procedure, page 34.

3. Separate pump from hopper.

4. Remove four screws and motor cover.

5. Remove four screws and control cover.

54 3A6748B

Page 55

Repair

ti11867a

ti11747a

6. Disconnect transducer from control

board. Remove transducer and strain

relief from control box.

7. Slowly rotate fan blade on motor until

connecting rod is at bottom of stroke.

9. Loosen retaining nut.

10. Unscrew pump from bearing housing.

8. Pry retaining spring up on connecting

rod toward motor. Push pump pin out

with a screwdriver.

3A6748B 55

Page 56

Repair

ti11879a

5

0

-

7

0

m

m

ti11747a

Pump Installation

1. Push piston rod out of pump 50 to 70 mm

(2 to 2.8 in.).

2. Screw retaining nut onto pump until it

stops. Screw pump into bearing housing

until pump stops. Unscrew pump until

pump outlet is 13° from horizontal,

but no more than one turn.

3. Tighten retaining nut.

If pump pin loosens, parts may break off

due to force of pumping action. Parts may

project through the air and result in serious

injury or property damage. Make sure

pump pin and retaining spring are properly

installed.

4. Push retaining spring up with a

screwdriver toward motor. Push in pump

pin. Push retaining spring down over

pump pin.

56 3A6748B

Page 57

Repair

ti11854b

506/657

6912

5. Install transducer and strain relief in

control box. Connect transducer to

control board.

6. Install control cover with four screws.

7. Install motor cover with four screws.

8. Connect pump module.

3A6748B 57

Page 58

Repair

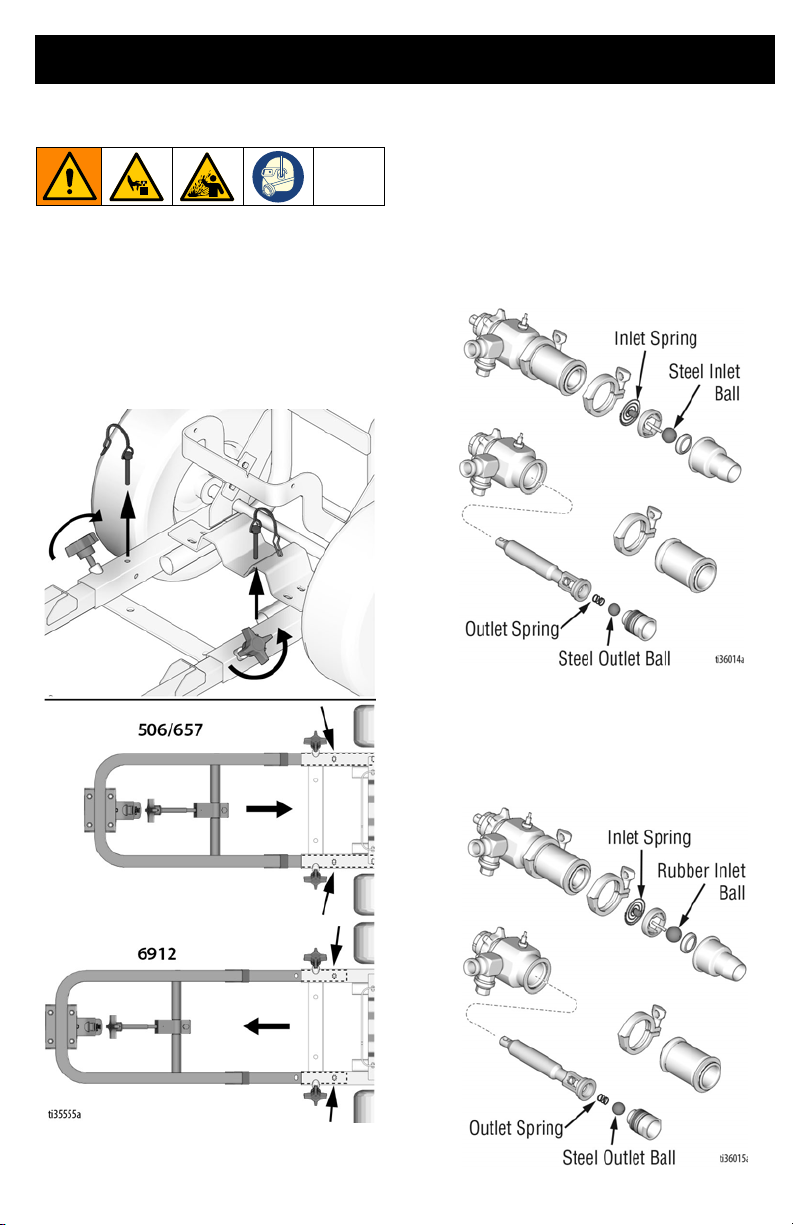

Pump Repair 506/657

Disassembly

NOTE: It may be easier to leave the pump

connected to the connecting rod and bearing

housing if the only assembies to be cleaned

and inspected are the intake housing or

piston valve.

1. Perform Pressure Relief Procedure,

page 19. Unplug power cord to

disconnect power.

2. Refer to Pump Removal, page 54, to

remove pump.

3. Remove clamp and intake housing.

4. Remove clamp and pump cylinder.

5. Remove packing nut. Push piston rod

from outlet housing.

6. Place end of piston rod in vise and

remove piston valve (12). Remove

piston seal (16). Inspect all parts for

nicks and scratches. Replace worn or

damaged parts as they may result in

poor pump performance.

58 3A6748B

Page 59

Repair

A

ti11755a

Assembly

1. Place end of piston rod in vise. Install

new piston seal. Torque piston valve to

27 ft-lb (36,6 N·m).

2. Install packing nut. Hand tighten then tap

with screw driver. Push piston rod into

outlet housing. Extend piston rod 50 - 75

mm (A) out of outlet housing.

3A6748B 59

Page 60

Repair

ti11752a

3. Install clamp on pump cylinder. Torque

clamp to 100in-lb (11.3 Nm).

4. Install clamp on intake housing. Torque

clamp to 100in-lb (11.3 Nm).

Pump Repair 6912

Disassembly

NOTE: It may be easier to leave the pump

connected to the connecting rod and bearing

housing if the only assembies to be cleaned

and inspected are the intake housing or

piston valve.

1. Perform Pressure Relief Procedure,

page 19. Unplug power cord to

disconnect power.

2. Refer to Pump Removal, page 54, to

remove pump.

3. Remove clamp and intake housing.

5. Refer to Pump Installation, page 56, to

install pump.

4. Disassemble intake valve.

60 3A6748B

Page 61

5. Remove clamp and pump cylinder.

6. Remove packing nut. Push piston rod

from outlet housing. Remove throat

packings and glands from cylinder.

Discard throat packings and glands.

Repair

7. Place cage of piston rod in vise and

remove piston valve. Remove piston

seal. Remove packings and glands from

piston rod. Inspect all parts for nicks and

scratches. Replace worn or damaged

parts as they may result in poor pump

performance.

3A6748B 61

Page 62

Repair

Assembly

1. Place cage of piston rod in vise. Install

new piston seal. Torque piston valve to

90 ft-lb (122 N·m). Install piston wiper

(note orientation, page 63) and backup

washer on piston valve, threads are

good for four repackings. Use thread

sealant on piston valve threads after four

repackings. Stack male gland on piston

rod. Alternately stack light and dark

packings (note orientation, page 63) on

piston rod. Install female gland.

2. Install packing nut. Hand tighten then tap

with screw driver. Push piston rod into

outlet housing. Extend piston rod 50 - 75

mm (A) out of outlet housing.

62 3A6748B

Page 63

Repair

Cross-Section Reference / Pump Ball Identification 6912

3A6748B 63

Page 64

Repair

Motor Removal

1. Perform Pressure Relief Procedure,

page 19. Unplug power cord to

disconnect power.

2. Remove pump. See Pump Removal,

page 54.

3. Tip unit on back.

4. While supporting motor/drive housing,

remove two screws from base.

5. Remove four screws, washers and

bearing housing.

NOTE: Do not drop gear cluster when

removing drive housing. Gear cluster may

stay engaged in motor front end bell or drive

housing.

6. Remove three screws and drive

housing.

7. Remove screw and fan.

64 3A6748B

Page 65

Repair

Motor Installation

NOTICE

When installing motor, carefully align gears

to avoid damaging mating parts.

1. Install drive housing with three screws.

2. Install bearing housing with four screws

and washers. Torque to 25 - 30 ft-lbs

(33.9 - 40.67 N·m).

3. Install motor with two screws. Torque to

200 - 220 in-lbs (22.6 - 24.9 N·m).

4. Install fan with screw. Torque 11 - 13

in-lb (1.24 - 1.46 N·m).

5. Install pump. See Pump Installation,

page 56.

3A6748B 65

Page 66

Repair

Recycling and Disposal at End of Life

At the end of the product’s useful life,

dismantle and recycle it in a responsible

manner.

Preparation:

• Perform the Pressure Relief

Procedure.

• Drain and dispose of fluids according to

applicable regulations. Refer to the

material manufacturer’s Safety Data

Sheet.

Dismantle and recycle:

• Remove motors, circuit boards, LCDs

(liquid crystal displays), and other

electronic components. Recycle

according to applicable regulations.

• Do not dispose of electronic components

with household or commercial waste.

• Deliver remaining product to a recycling

facility.

66 3A6748B

Page 67

Notes

Notes

3A6748B 67

Page 68

Parts - Hopper Frame

b

a

Parts - Hopper Frame

68 3A6748B

Page 69

Parts List - Frame

Parts - Hopper Frame

Ref. Part

1 19A673 FRAME, hopper, Tmax 1

2 156306 WASHER, flat 2

3 116038 WASHER, wave spring 2

4 119509 WHEEL, pneumatic 2

5 120211 RING, retaining, e-ring 2

6 19A675 BRACKET, support,

7 129335 SCREW, hex, serrated,

8 102040 NUT, lock, hex 9

9 25E625 FRAME, mounting, power

10 17N602 CASTER, swivel 1

11 110963 SCREW, cap, hex hd 4

12 111040 NUT, lock , insert, nylock

13 15C797 BRACKET, swivel 1

14 101566 NUT, lock 1

15 100004 SCREW, cap, hex hd 1

16 104430 PIN, cotter 1

17 15C799 ROD, clamp 1

Description Qty

hopper

1/4-20 x 2.00

module

5/16

Ref. Part

18 19A674 BRACKET, guide, hopper 1

19 113796 SCREW, flanged, hex hd 4

20 HOPPER, material

20a 25E541 17 gallon 1

20b 25E542 25 gallon 1

21 404533 BOLT, carriage 4

1

22 112958 NUT, hex, flanged 3/8 -16 4

23 121313 PIN, locking, 1-4” 2

4

24 111145 KNOB, pronged 2

27 15D306 PLUG, adapter, hopper 1

30 234188 CLAMP, quick release 1

1

31 19A646 TOOL, scraper 1

32 130878 BOLT, hook, 1/4-20 x

34 15D561 COVER, tool tray 1

4

35 115814 WASHER, flat, sst 2

36 551787 SCREW, cap 1

37 19A714 KNOB, stuf, #10-32 x .44 1

38 120481 SLEEVE, oval 4

39 120483 CABLE 2.5

50 19A748 LABEL, brand, Tmax, left 1

51 19A749 LABEL, brand, Tmax, right 1

Description Qty

1-5/8 thd

1

3A6748B 69

Page 70

Parts - Power Module 506/657

PAGE 78

PAGES 74, 75

Parts - Power Module 506/657

70 3A6748B

Page 71

Parts - Power Module 506/657

Parts List - Power Module 506/657

Ref. Part

1 287234 HOUSING, drive, Tmax

287235 HOUSING, drive, Tmax

2 116192 WASHER, thrust 1

3 114672 WASHER, thrust 2

4 114699 WASHER, thrust 1

5 243951 GEAR, cobination 1

6 289570 MOTOR 1

7 15C753 SCREW, mach, hex

8 240724 HOUSING, bearing 1

9 287395 ROD, connecting 1

10 106115 WASHER, lock 4

11 114666 SCREW, cap, socket

12 19A690 BASE, drive module,

13 120981 SCREW, mach, hex

14 119778 SPRING, retaining 1

17 15F856 PIN, pump 1

18 19A585 GUIDE, power module 2

19 100023 WASHER, flat 4

20 112746 NUT, lock, nylon 4

21 19A669 FRAME, right, Tmax,

22 19A670 FRAME, left, Tmax,

23 107129 BOLT, round head 4

35 15D088 FAN, motor 1

36 115477 SCREW, mach, torx

Description Qty

506

657

wash hd

head

machined

washer hd

painted

painted

pan hd

Ref. Part

42 19A713 BUMPER, rubber 1

1

43 115483 NUT, lock 2

44 103374 SCREw, mach, rhd 2

45 106062 WHEEL, semi-

46 101242 RING, retaining 2

47 104811 CAP, hub 2

51 100016 WASHER, lock 2

52 110298 SCREW, cap, sch 2

91 15R741 SHIELD, Tmax, painted 1

3

92 118444 SCREW, mach, slot hex

93 15T629 SHIELD, pump rod 1

97 287489 HANDLE, assy, hi cart 1

98 109032 SCREW, mach, pnh 2

4

191 187437 LABEL, torque 1

1

193 19A814 LABEL, brand, Tmax

2

1

1

19A815 LABEL, brand, Tmax

194 15U014 LABEL, brand, Tmax

195 17P925 LABEL, A+ Service 1

196 15Y118 LABEL, made in USA 1

197 15H108 LABEL, safety, warning,

198 17Z485 LABEL, safety 1

16C681 LABEL, notice 1

199

Description Qty

pneumatic

wash hd

506

657

cap

pinch

Replacement safety labels, tags, and

cards are available at no cost.

1

2

6

1

1

1

1

3A6748B 71

Page 72

Parts - Power Module 6912

PAGE 80

PAGE 76

Parts - Power Module 6912

72 3A6748B

Page 73

Parts - Power Module 6912

Parts List - Power Module 6912

Ref. Part

1 24M008 HOUSING, drive 1

2 116192 WASHER, thrust 1

3 114672 WASHER, thrust 2

4 114699 WASHER, thrust 1

5 243951 GEAR, combination 1

6 25P037 KIT, repair, motor 1

7 15C753 SCREW, mach, hex

8 245795 HOUSING, bearing 1

9 287395 ROD, connecting 1

10 106115 WASHER, lock 4

11 114666 SCREW, cap, socket,

12 19A690 BASE, drive module 1

13 120981 SCREW, mach, hex

14 17Z347 SPRING, retaining 1

17 15F856 PIN, pump 1

18 19A585 GUIDE, power module 2

19 100023 WASHER, flat 4

20 112746 NUT, lock, nylon 4

21 19A671 FRAME, right, Tmax,

22 19A672 FRAME, left, Tmax,

23 107129 BOLT, round head 4

24 117791 SCREW, cap 2

35* 15D088 FAN, motor 1

36* 115U77 SCREW 1

42 19A713 BUMPER, rubber 2

Description Qty

wash hd

head

washer hd

painted

painted

Ref. Part

43 115483 NUT, lock 2

44 103374 SCREW, mach 2

45 106062 WHEEL, semi-

46 101242 RING, retaining 2

47 104811 CAP, hub 2

3

4

2

1

1

49 19A738 GROMMET 1

91 19A676 COVER, motor, Tmax,

92 118444 SCREW, mach, slot hex

93 19A666 SHIELD, assy w/

94 15T629 SHIELD, pump rod 1

95 19A715 BRACE, front 1

96 126687 SCREW, mach, pnh 4

97 287489 HANDLE, assy, hi cart 1

98 109032 SCREW, mach, pnh 4

191 187437 LABEL, torque 1

193 19A750 LABEL, 6912 brand 1

194 15U014 LABEL, cap brand 1

195 17P925 LABEL, A+ service 1

196 15Y118 LABEL, made in USA 1

15H108 LABEL, pinch 1

197

16G596 LABEL, safety 1

198

16C681 LABEL, notice 1

199

* Included in Motor Repair Kit 25P037

Description Qty

2

pneumatic

1

painted

10

wash hd

1

shroud, painted

Replacement safety labels, tags, and

cards are available at no cost.

3A6748B 73

Page 74

Parts - Pump 289555 (506)

Parts - Pump 289555 (506)

Parts List - Pump

Ref. Part Description Qty

1 15D117 TUBE, fiber, pump 1

2 107185 PACKING, o-ring 1

3 118597 PACKING, u-cup 1

4 15R739 HOUSING, outlet,

machining

5 118598 CLAMP, sanitary, 1.5 in. 2

6 15R740 CYLINDER, pump 1

7 248232 VALVE, piston 1

248530 KIT, repair, seal, piston,

includes 7, 13, 15, 16

8 248162 SPRING, Intake ball 1

9 193395 SEAT, carbide 1

10 107098 PACKING, o-ring 1

11 15R620 ROD, pump 1

12 15D112 NUT, packing 1

74 3A6748B

Ref. Part Description Qty

13 501095 SPRING, ball check 1

14 121588 O-RING 2

15 101822 BALL, bearing 1

16 15D116 SEAL, piston 1

1

17 15D115 GUIDE, ball 1

18 107167 BALL, sst 1

19 248769 HOUSING, intake 1

37 111457 O-RING 1

38 289672 TRANSDUCER 1

1

40 17Z238 OUTLET 1

41 17Y930 RELIEF, pressure 1

48 17Z345 PLUG 1

49 121429 O-RING 1

50 193031 NUT, retaining 1

51 248530 KIT, valve, piston

includes 7, 13, 15, 16

1

Page 75

Parts - Pump 289556 (657)

Parts - Pump 289556 (657)

Parts List - Pump

Ref. Part Description Qty

1 15D117 TUBE, fiber, pump 1

2 107185 PACKING, o-ring 1

3 118597 PACKING, u-cup 1

4 15R621 HOUSING, outlet,

machining

5 500984 CLAMP 2

6 15R619 CYLINDER, pump 1

7 248232 VALVE, piston 1

248530 KIT, repair, seal, piston,

includes 7, 13, 15, 16

8 248162 SPRING, Intake ball 1

9 193395 SEAT, carbide 1

10 107098 PACKING, o-ring 1

11 15R620 ROD, pump 1

12 15D112 NUT, packing

248529 KIT, repair, throat seal

includes 1, 2, 3, 12

3A6748B 75

Ref. Part Description Qty

13 501095 SPRING, ball check 1

14 121587 O-RING 2

15 101822 BALL, bearing 1

16 15D116 SEAL, piston 1

1

17 15D115 GUIDE, ball 1

18 107167 BALL, sst 1

19 289941 HOUSING, intake 1

37 111457 O-RING 1

38 289672 TRANSDUCER 1

1

40 17Z238 OUTLET 1

41 17Y930 RELIEF, pressure 1

48 17Z345 PLUG 1

49 121429 O-RING 1

50 193031 NUT, retaining 1

51 248530 KIT, valve, piston

1

includes 7, 13, 15, 16

1

Page 76

Parts - Pump 25E668 (6912)

Parts - Pump 25E668 (6912)

76 3A6748B

Page 77

Parts - Pump 25E668 (6912)

Parts List - Pump 25E668 (6912)

Ref. Part Description Qty

1 19A610 HOUSING, outlet,

machining

2† 187939 GLAND, male 1

3† 187071 PACKING, vee 3

4† 188560 PACKING 2

5† 187070 GLAND, female 1

6† 19A625 WIPER, fiber, pump rod 1

7 19A685 NUT, packing 1

8 25E669 ROD, pump 1

8a 19A686 ROD, pump 1

8b 19A689 HOUSING, piston pump 1

8c 19A691 BALL, stop 1

8d 130862 SPRING, compression 1

8e 107167 BALL, sst 1

8g† 188432 GLAND, packing, male 1

8h† 187072 PACKING 3

8j† 188561 PACKING, throat 2

8k† 188433 GLAND, packing, female 1

8m† 188558 SEAL, u-cup 1

8n† 188627 WASHER, back-up 1

8o 17Z242 VALVE, piston, assy 1

9 19A609 CYLINDER, pump 1

Ref. Part Description Qty

10† 130792 O-RING 2

11 620223 CLAMP 2

12 17Z241 HOUSING, intake ball 1

13 235962 SEAL, foot valve 1

14 19A692 GUIDE, ball, inlet 1