Graco SP, SPX, NOVApro, NOVA, SuperNOVApro Repair Manual

REPAIR

SP, SPX

Airless Paint Sprayers

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

3000 psi (207 bar, 20.7 MPa) Maximum Working Pressure

120 Vac

826031, A

826032, A

309711

Rev. B

Related manuals

Table of Contents

Component Function and Identification 3. . . . . . . . . . . .

Grounding 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Repair Information 4. . . . . . . . . . . . . . . . . . . . . .

Spin Test 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Brush Replacement 10. . . . . . . . . . . . . . . . . . . . .

On/Off Switch Replacement 12. . . . . . . . . . . . . . . . . . . .

826031

309665. . . . . . .

309045; SP. . . . . . .

309639; SPX. . . . . . .

309716. . . . . . .

Pressure Control Repair 14. . . . . . . . . . . . . . . . . . . . . . .

Drive Housing Replacement 17. . . . . . . . . . . . . . . . . . . .

Motor Replacement 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement Pump Replacement 19. . . . . . . . . . . . . . .

Technical Data 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 20. . . . . . . . . . . . . . . . . . . . . . . . . .

309060; SP. . . . . . .

309053; SPX. . . . . . .

TI0051c

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 2003, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

WARNING

Fire and explosion hazard: Solvent and paint fumes can ignite or

explode.

To help prevent a fire and explosion:

Use only in an extremely well ventilated area.

Eliminate all ignition sources; such as pilot lights, cigarettes and

static arcs from plastic drop cloths. Do not plug or unplug power

cords or turn lights on or off in spray area.

Ground Sprayer, object being sprayed, paint and solvent pails.

Hold gun firmly to side of grounded pail when triggering into pail.

Use only conductive airless paint hose.

Do not use 1,1,1–trichloroethane, methylene chloride, other

halogenated hydrocarbon solvents or fluids containing such

solvents in pressurized aluminum equipment. Such use could

result in a chemical reaction, with the possibility of explosion.

ADVERTÊNCIA

Poderá ocorrer incêndio e explosão quando for pulverizado ou injetado

líquido inflamável numa área onde houver má circulação de ar; vapores

inflamáveis poderão incendiar-se a partir de uma chama ou fagulhas a

descoberto.

Para ajudar a evitar incêndio e explosão:

Utilize no exterior ou numa área muito bem ventilada.

Não utilize 1,1,1–tricloroetano, cloreto de metileno, outros solventes de

hidrocarbonetos halogenados ou líquidos contendo tais solventes em

equipamento de alumínio pressurizado. Tal utilização poderá resultar

numa reação química, com possibilidade de explosão.

Retire, elimine ou desligue todas as fontes de ignição; coloque fita

adesiva na tomada da parede. Não fume na área de pulverização.

Nunca abasteça o depósito de combustível com o motor em funciona-

mento ou quente.

Ponha em contato com a terra o pulverizador, o objeto a ser pulveriza-

do, e os baldes de tinta e de solventes.

Segure a pistola firmemente de encontro ao lado de um balde em contato

com a terra, quando estiver descarregando para dentro do mesmo.

Utilize somente tubos flexíveis condutores para pintura a alta pressão.

Nunca faça funcionar o motor numa área fechada.

Fluid injection and high pressure hazard: High pressure spray or

leaks can inject fluid into the body.

To help prevent injection, always:

Engage trigger safety latch when not spraying.

Keep clear of nozzle and leaks.

Never spray without a tip guard.

Do PRESSURE RELIEF if you stop spraying or begin servicing

sprayer.

Do not use components rated less than sprayer Maximum

Working Pressure

Never allow children to use this unit.

If high pressure fluid pierces your skin, the injury might look like

“just a cut”. But it is a serious wound! Get immediate medical attention.

MISE EN GARDE

Risque d’incendie et d’explosion imminent pendant la pulvérisation

ou le rinçage à pression de fluides inflammables dans une zone à mauvaise circulation d’air et en présence de gaz inflammables pouvant

s’allumer par une flamme nue ou des étincelles.

Pour éviter les risques d’incendie et d’explosion:

Manipuler les fluides à l’air libre ou dans une zone extrêmement

bien aérée.

Ne jamais utiliser de trichloroéthane 1,1,1, de chlorure de méthylène,

d’autres solvants à base d’hydrocarbures halogénés, ni de produits

contenant de tels solvants dans un équipement sous pression en

aluminium. Cela pourrait provoquer une réaction chimique avec risque

d’explosion.

Retirer, éteindre ou déboucher toute source d’inflammation, recouvrir

tout interrupteur mural avec du ruban adhésif. Ne pas fumer dans la

zone de pulvérisation.

Ne jamais remplir le réservoir d’essence lorsque le moteur est chaud

ou en marche.

Mettre à la terre le pulvérisateur, l’objet à pulvériser ainsi que les

seaux de peinture et de solvants.

Tenir le pistolet fermement contre la paroi d’un seau mis à la

terre lorsqu’on pulvérise dans le seau.

N’utiliser qu’un flexible pour peinture pulvérisée sans air.

Ne jamais mettre en marche un moteur dans une zone fermée.

A injeção de líquido é um ferimento grave! Se o líquido a alta pressão penetrar na sua pele, o ferimento poderá parecer “simplesmente

um corte”. Mas é um ferimento grave! Procure o médico imediatamente.

Para ajudar a evitar injeção de líquido, faça sempre o seguinte:

Engate o trinco de segurança do gatilho quando não estiver pulveri-

zando.

Sempre aponte a pistola para longe de você mesmo(a) ou de outras

pessoas.

Alivie a pressão antes de verificar ou reparar qualquer vazamento.

Alivie a pressão quando desligar o pulverizador ou parar de pulverizar.

Não utilize componentes classificados para uma pressão nominal

inferior à pressão máxima de trabalho dos sistemas.

Nunca permita que crianças utilizem esta unidade. Se sofrer algum

ferimento durante a utilização deste equipamento, procure o médico

imediatamente.

ADVERTENCIA

Pueden ocurrir incendios y explosiones cuando se pulveriza fluido inflamable o cuando se lava con este tipo de fluido en un área donde la

circulación de aire es deficiente y los vapores inflamables se pueden encender al contacto con el fuego o chispas.

Para prevenir incendios y explosiones:

Use en espacios abiertos o en un área muy bien ventilada.

No utilice nunca tricloretano–1,1,1, cloruro de metileno, u otros di-

solventes a base de hidrocarburos halógenos o fluidos que contengan

tales disolventes en un equipo a presión de aluminio. El uso de estas

sustancias puede provocar una intensa reacción química, con riesgos

de explosión.

Retire, apague o desconecte todas las fuentes de ignición; asegure el

interruptor de la pared con cinta. No fume en el área de pulverización.

Nunca llene el estanque de combustible mientras el motor esté en

marcha o caliente.

Ponga a tierra el pulverizador, el objeto que recibe el chorro pulverizado,

las cubetas de pintura y disolvente.

Sostenga firmemente la pistola a un lado de la cubeta puesta a

tierra cuando dispare dentro de ella.

Use solamente mangueras para pintura conductora sin aire.

Nunca haga andar el motor dentro de un área cerrada.

L’injection de fluide constitue une lésion grave! Si un fluide haute

pression perce la peau, la blessure peut paraître comme une

«simple coupure». Mais il s’agit bien d’une lésion grave! Consulter

immédiatement un médecin.

Pour éviter les risques d’injection, toujours:

Bloquer le loquet de sécurité de la gâchette à la fin de la pulvérisation.

Pointer le pistolet loin de soi-même et toute autre personne à proximité

Décharger la pression avant de vérifier ou réparer une fuite.

Décharger la pression après la mise hors tension du pulvérisateur ou

à la fin de la pulvérisation.

Ne pas utiliser de composants dont la pression nominale est inférieure

à la pression maximale de service du système.

Ne jamais permettre aux enfants d’utiliser cet appareil. En cas de blessure pour avoir utilisé cet appareil, consulter immédiatement un médecin.

2 309711

¡La inyección de fluido en la piel es una lesión seria! Si fluido de

alta presión le penetra la piel, la lesión podría parecer “sólo un

corte”. ¡Es una lesión seria! Consulte de inmediato al médico.

Para prevenir la inyección en la piel, siempre:

Enganche el seguro del gatillo cuando no use el pulverizador.

No apunte la pistola ni a sí mismo ni a los demás.

Alivie la presión antes de inspeccionar o reparar cualquier filtración.

Alivie la presión cuando apague el pulverizador o deje de usarlo.

No use componentes cuya capacidad nominal sea inferior a la

presión máxima de operación del sistema.

No permita que niños usen esta unidad. Si se lesiona usando este

equipo, sométase de inmediato a tratamiento médico.

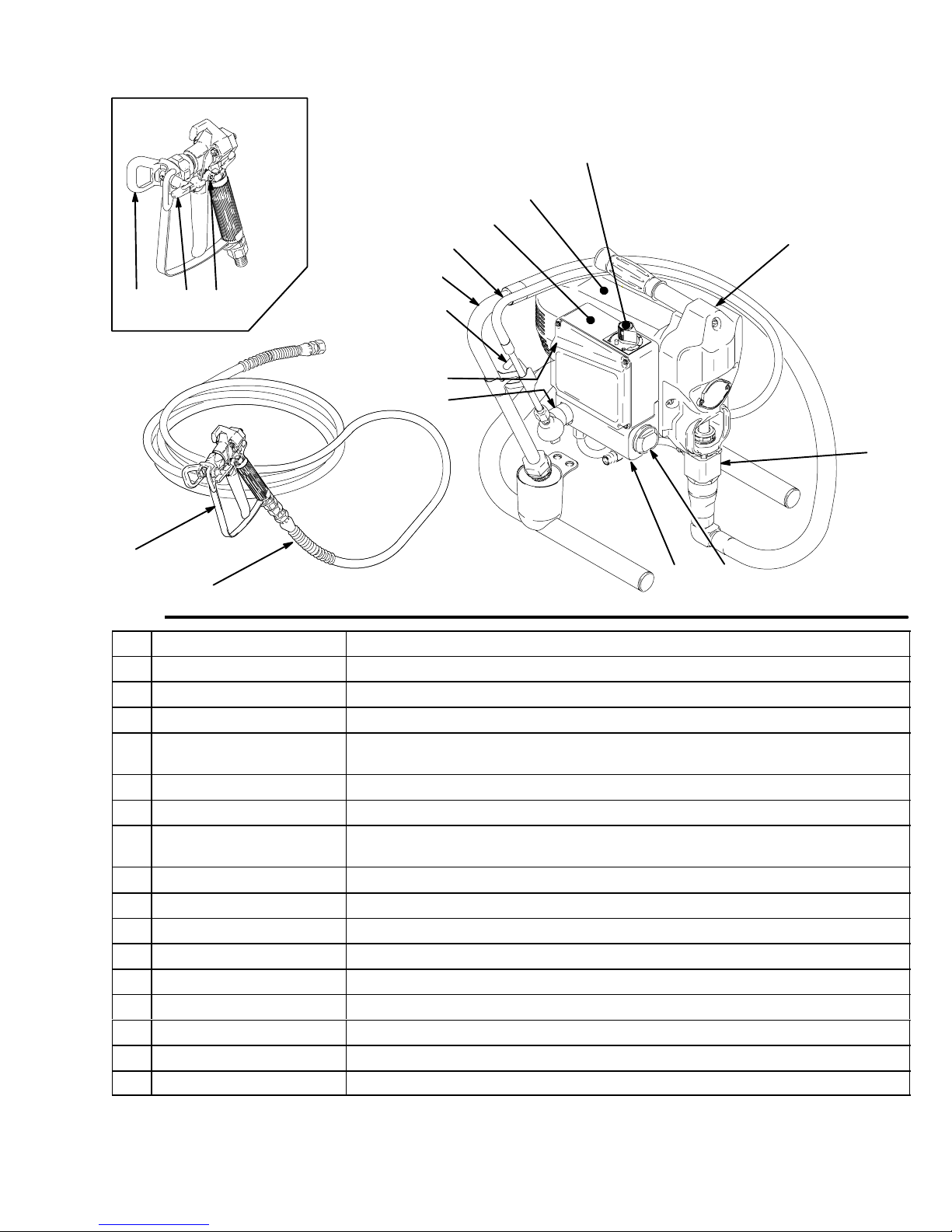

Component Identification and Function

H

A

J

V

U

PR

S

T

K

F

B

D

N

E

G

M

TI0051

Fig. 1

A Motor DC motor, permanent magnet, fan cooled

B Drive Assembly Transfers power from DC motor to displacement pump

D Displacement Pump Transfers fluid to be sprayed from source through spray gun

E Fluid Outlet Spray gun is connected here

F Prime Valve Used to prime and drain sprayer (also relieves fluid outlet pressure) when

open

G Fluid Filter (optional) Final filter of fluid to spray gun

H Pressure Adjusting Knob Controls fluid outlet pressure

J Pressure Control Controls motor speed to maintain fluid outlet pressure at displacement pump

outlet. Works with pressure adjusting knob.

K ON/OFF Switch Power switch that controls main power to sprayer

M 50 ft (15 m) Main Hose 1/4 in. ID, grounded, nylon hose with spring guards on both ends

N Spray Gun High pressure spray gun with gun safety latch

P RAC IV Switch Tip Uses high pressure fluid to clear tip clogs without removing tip from spray gun

R Tip Guard Tip guard reduces risk of injection injury

S Gun Safety Latch Gun safety latch inhibits accidental triggering of spray gun

T Power Cord Rack Holds wrapped power cord for storage

U Suction Hose Transfers fluid to be sprayed from source to pump

V Drain Tube Fluid outlet used to drain and prime the sprayer

8050A

3309711

General Repair Information

Pressure Relief Procedure

WARNING

INJECTION HAZARD

System pressure must be manually

relieved to prevent system from starting

or spraying accidentally. Fluid under high

pressure can be injected through skin and cause

serious injury. To reduce risk of injury from injection, splashing fluid, or moving parts, follow Pres-

sure Relief Procedure whenever you:

are instructed to relieve pressure,

stop spraying,

check or service any system equipment,

or install or clean spray tip.

1. Lock gun safety latch.

2. Turn ON/OFF switch to OFF.

3. Unplug power supply cord.

4. Unlock gun safety latch. Hold metal part of gun

firmly to grounded metal pail. Trigger gun to relieve

pressure.

5. Lock gun safety latch.

6. Open pressure drain valve. Leave pressure drain

valve open until ready to spray again.

If suspected that spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Now clear

tip or hose obstruction.

1. Keep all screws, nuts, washers, gaskets, and

electrical fittings removed during repair procedures. These parts are not normally provided with

replacement assemblies.

WARNING

ELECTRIC SHOCK HAZARD

MOVING PARTS HAZARD

To reduce risk of serious injury, including

electric shock, do not touch moving or

electrical parts with fingers or tools while

testing repair. Shut off and unplug sprayer when inspection is complete. Install all

covers, gaskets, screws and washers

before operating sprayer.

2. Test repair after problem is corrected.

3. If sprayer does not operate properly, review

repair procedure to verify procedure was done

correctly. If necessary, see Troubleshooting Guide,

pages 5 – 9, for other possible solutions.

WARNING

HOT SURFACES HAZARD

EXPLOSION HAZARD

Motor and drive housing may be very hot

during operation and could burn skin if

touched.

Flammable materials spilled on hot, bare

motor could cause fire or explosion.

Have motor shroud in place during

operation to reduce risk of burns, fire or

explosion.

CAUTION

To reduce risk of pressure control malfunction:

Use needle nose pliers to disconnect wire. Never

pull on wire, pull on connector.

Mate wire connectors properly. Center flat blade of

insulated male connector in female connector.

Route wires carefully to avoid interference with

other connections of pressure control. Do not pinch

wires between cover and control box.

4 309711

CAUTION

Do not run sprayer dry for more than 30 seconds to

avoid damaging pump packings.

4. Install motor shroud before operation of sprayer and replace if damaged. Motor shroud prevents

overheating, and protects operator from possible

electrical shock by touching terminals of capacitor.

It can also reduce risk of burns, fire or explosion;

see preceding WARNING.

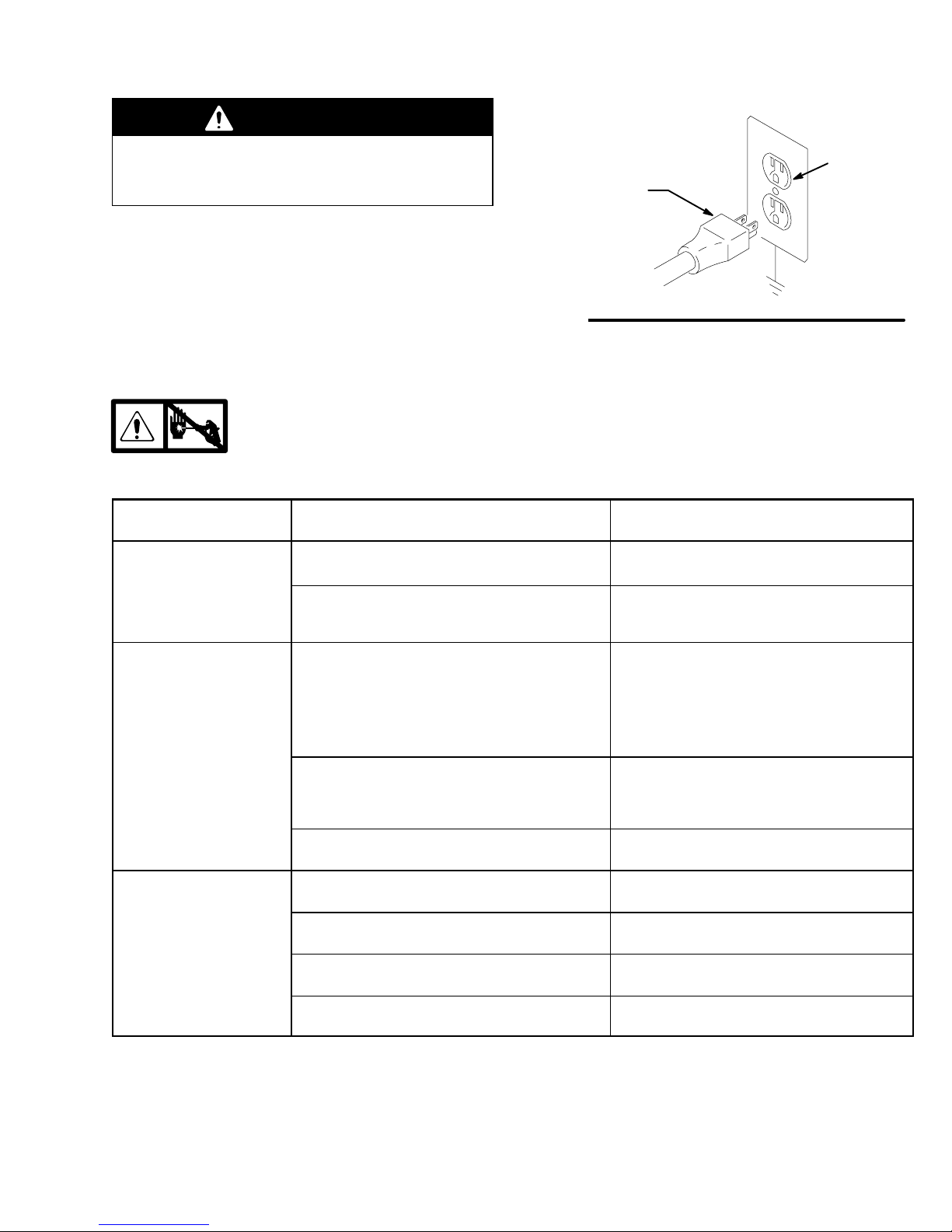

WARNING

Grounding

Improper installation or alteration of grounding plug

results in risk of electric shock, fire or explosion

that could cause serious injury or death.

1. Fig. 2. Both models require a 50/60 Hz, 15A circuit

with a grounding receptacle.

2. Do not alter ground prong or use adapter.

3. A 12 AWG, 3 wires with grounding prong, 300 ft

(90 m) extension cord may be used.

Troubleshooting

Relieve pressure; page 4.

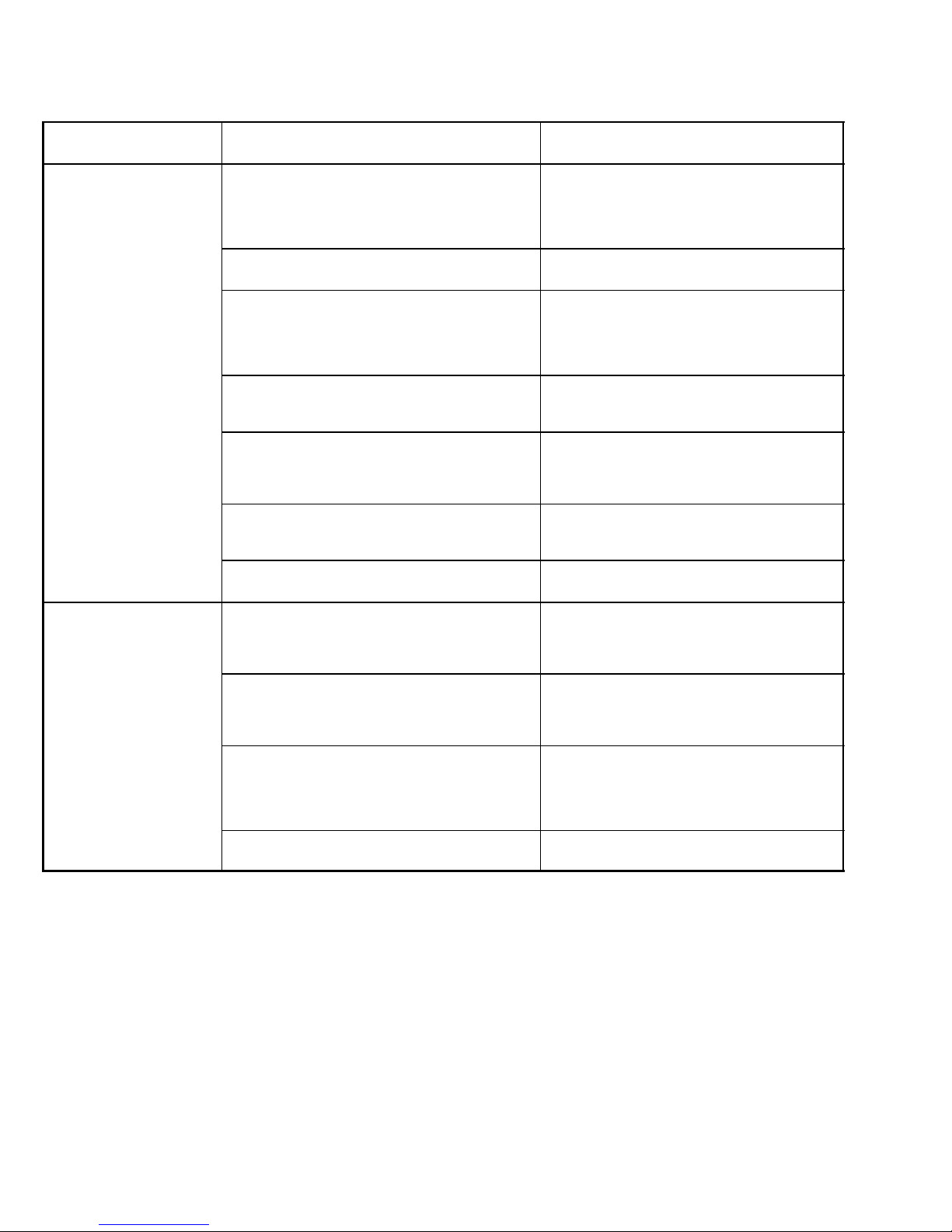

MOTOR WON’T OPERATE

TYPE OF PROBLEM

Basic Fluid Pressure

Problems

WHAT TO CHECK

If check is OK, go to next check

1. Pressure control knob setting. Motor will not run

if at minimum setting (fully counterclockwise).

2. Spray tip or fluid filter may be clogged. 2. Relieve pressure and clear clog or clean fil-

Grounding Plug

Fig. 2

Grounded

Outlets

WHAT TO DO

When check is not OK refer to this column

1. Slowly increase pressure setting to see if motor starts.

ter; refer to separate gun or tip instruction

manual.

Basic Mechanical

Problems

Basic Electrical Problems

1. Pump (13) for frozen or hardened paint. 1. Thaw sprayer if water or water-based paint

2. Displacement pump connecting rod pin (9a).

Pin must be completely pushed into connecting

rod (9) and retaining spring (9b) must be firmly

in groove of pump pin. See Fig. 10.

3. Motor (1). Remove drive housing assembly

(10). See page 17. Try to rotate fan by hand.

1. Motor control board. Board shuts down and displays error code.

2. Electrical supply:

Meter must read 85–130 Vac

3. Extension cord. Check extension cord continuity with volt meter.

4. Sprayer power supply cord (79). Inspect for

damage such as broken insulation or wires.

has frozen in sprayer. Place sprayer in warm

area to thaw. Do not start sprayer until

thawed completely. If paint hardened (dried)

in sprayer, replace pump packings. See

page 19 (Displacement Pump Replace-

ment).

2. Push pin into place and secure with spring retainer.

3. Replace motor (1) if fan won’t turn. See page

18.

1. See Motor Control Board Diagnostics,

page 14.

2. Reset building circuit breaker; replace building fuse. Try another outlet.

3. Replace extension cord.

4. Replace power supply cord.

5309711

Troubleshooting

MOTOR WON’T OPERATE (Continued)

TYPE OF PROBLEM

Basic Electrical Problems

(continued)

WHAT TO CHECK

If check is OK, go to next check

5. That motor leads are securely fastened and

properly mated.

6. For loose motor brush lead connections and terminals. See page 10.

7. Brush length which must be 1/2 in. minimum.

See page 10.

NOTE: Brushes do not wear at the same rate on

both sides of motor. Check both brushes.

8. For broken or misaligned motor brush springs.

Rolled portion of spring must rest squarely on

top of brush. See page 10.

9. Motor brushes may be binding in brush holders.

See page 10.

10.Motor armature commutator for burn spots,

gouges and extreme roughness.

See page 10.

11. Motor armature for shorts using armature tester

(growler) or perform spin test. See page 10.

WHAT TO DO

When check is not OK refer to this column

5. Replace loose terminals; crimp to leads. Be

sure terminals are firmly connected.

Clean circuit board terminals. Securely reconnect leads.

6. Tighten terminal screws. Replace brushes if

leads are damaged. See page 10.

7. Replace brushes. See page 10.

8. Replace spring if broken. Realign spring with

brush. See page 10.

9. Clean brush holders. Remove carbon with

small cleaning brush. Align brush leads with

slot in brush holder to assure free vertical

brush movement.

10.Remove motor and have motor shop resurface commutator if possible. See page 18.

11. Replace motor. See page 18.

Refer to wiring diagram on

page 13, to identify test

points (TP).

1. Power supply cord (79). Connect volt meter between N (neutral) and TP1.

Plug in sprayer. Meter must read: 85–130 Vac.

Unplug sprayer.

2. ON/OFF switch (23). Connect volt meter between L and N terminal on ON/OFF switch. Plug

in sprayer and turn ON.

Meter must read 85–130 Vac

3. Motor thermal cutoff switch. Turn sprayer OFF.

Check for continuity between TO1 and TO2 with

ohmmeter.

4. All terminals for damage or loose fit. 4. Replace damaged terminals and reconnect

1. Replace power supply cord.

2. Replace ON/OFF switch. See page 12.

3. If thermal switch is open (no continuity), allow

motor to cool. If switch remains open after

motor cools, replace motor. If thermal switch

closes after motor cools, correct cause of

overheating.

securely.

6 309711

Loading...

Loading...