Page 1

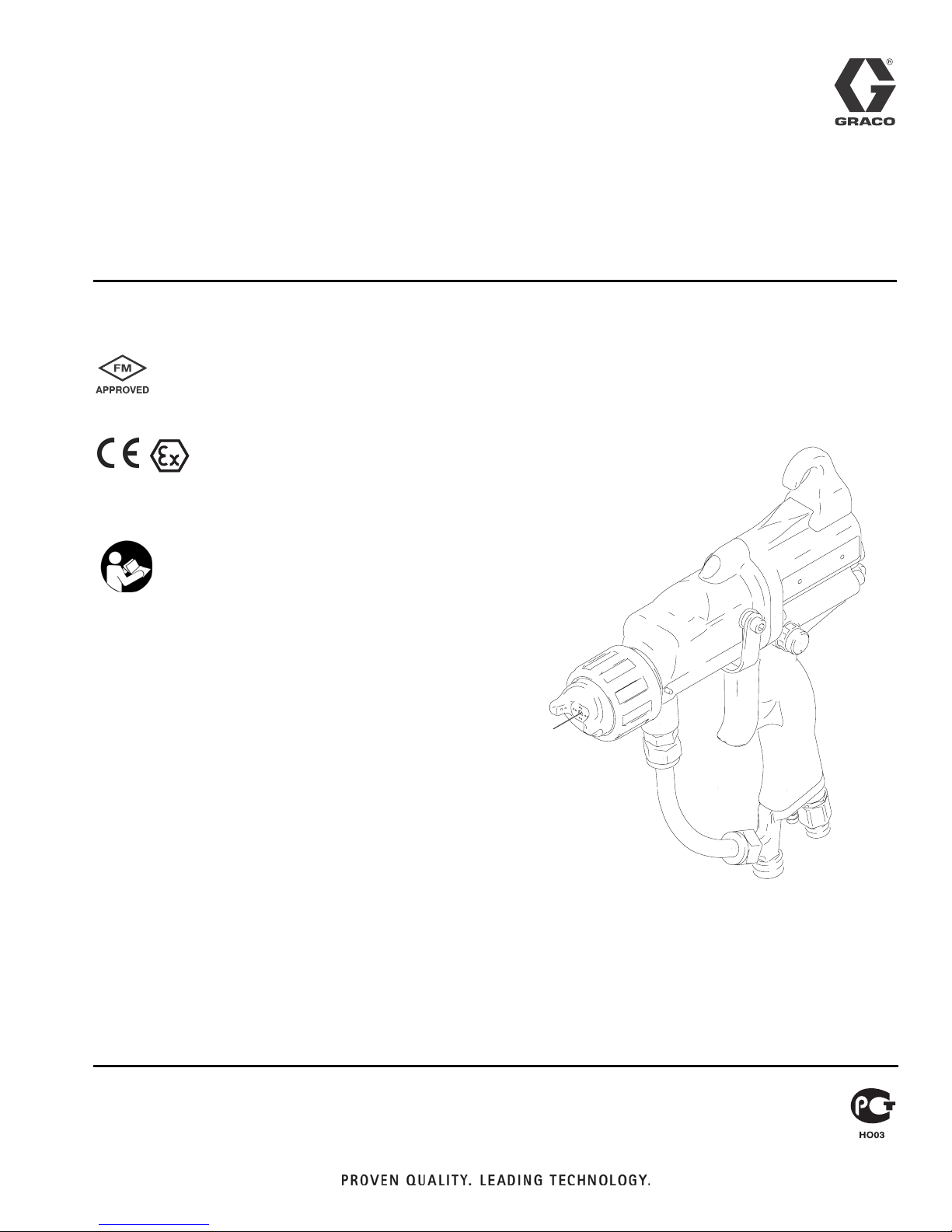

Instructions - Parts List

MANUAL ELECTROSTATIC

PRO™ Xs2

Air Spray Gun

For use in Class I, Div. I hazardous locations using Group D spray materials.

#53

For use in Group II, Zone 1 areas using Group IIA spray materials.

II 2 G EEx 0.24 mJ

For Professional Use ONLY.

309291P

ENG

Important Safety Instructions:

Read all warnings and instructions in this manual.

Save these instructions.

See page for 2 Table of Conte nts and List of Models.

Part No. 244399, Series C

See page 2 for Model 244399 information.

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

100 psi (0.7 MPa, 7 bar) Maximum Working Fluid Pressure

US Patents 6758424 and 7,226,004

U.S. Patents 6758424 and 7,226,004

ti1295a

Page 2

Table of Contents

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How the Electrostatic Spray Gun Works . . . . . . . 5

Gun Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Install the System . . . . . . . . . . . . . . . . . . . . . . . . 6

Warning Sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilate the Spray Booth . . . . . . . . . . . . . . . . . . 6

Connect the Air Line . . . . . . . . . . . . . . . . . . . . . . 8

Connect the Exhaust Tube . . . . . . . . . . . . . . . . . 8

Select a Fluid Nozzle and Air Cap . . . . . . . . . . . 9

Connect the Fluid Line . . . . . . . . . . . . . . . . . . . 10

Filter the Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Check Electrical Grounding . . . . . . . . . . . . . . . . 12

Check Fluid Resistivity . . . . . . . . . . . . . . . . . . . 13

Check Fluid Viscosity . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flush the Spray Gun . . . . . . . . . . . . . . . . . . . . . 15

Electrical Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Test Gun Resistance . . . . . . . . . . . . . . . . . . . . . 17

Test Power Supply Resistance . . . . . . . . . . . . . 18

Test Electrode Resistance . . . . . . . . . . . . . . . . . 19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Spray Pattern Troubleshooting . . . . . . . . . . . . . 20

Gun Operation Troubleshooting . . . . . . . . . . . . 21

Electrical Troubleshooting . . . . . . . . . . . . . . . . . 22

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Pressure Relief Procedure . . . . . . . . . . . . . . . . 23

Prepare the Gun for Service . . . . . . . . . . . . . . . 24

Air Cap/Nozzle Replacement . . . . . . . . . . . . . . 25

Electrode Replacement . . . . . . . . . . . . . . . . . . . 26

Fluid Packing Removal . . . . . . . . . . . . . . . . . . . 27

Packing Rod Repair . . . . . . . . . . . . . . . . . . . . . . 28

Barrel Removal . . . . . . . . . . . . . . . . . . . . . . . . . 29

Barrel Installation . . . . . . . . . . . . . . . . . . . . . . . . 29

Power Supply Removal and Replacement . . . . 30

Turbine Alternator Removal and Replacement . 31

Fan Air Adjustment Valve Repair . . . . . . . . . . . . 32

Fluid Adjustment Valve Repair . . . . . . . . . . . . . 33

Air Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . 33

Atomizing Air Restrictor Valve Removal and

Replacement . . . . . . . . . . . . . . . . . . . . . . . . 34

ES ON/OFF Valve Repair . . . . . . . . . . . . . . . . . 35

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . 39

Fluid Line Accessories . . . . . . . . . . . . . . . . . . . 39

Gun Accessories . . . . . . . . . . . . . . . . . . . . . . . . 39

Miscellaneous Accessories . . . . . . . . . . . . . . . . 40

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 42

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 42

Model Information

Part No. Model

244399 PRO Xs2

2 309291P

Type of Coatings

Standard High Conductivity

XX

Operation Manual

309294/3W9294/3Z9294

Page 3

Warnings

Warnings

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious injury

or death if you do not follow the instructions.

WARNING

Fire, Explosion, and Electric Shock Hazard

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Electrostatic equipment must be used only by trained, qualified personnel who understand the

requirements of this manual.

• Ground equipment, personnel, object being sprayed, and conductive objects in work area. See

Grounding instructions.

• Only use grounded Graco conductive air supply hoses.

• Check gun and hose resistance and electrical grounding daily.

• Use and clean equipment only in well ventilated area.

• Interlock the gun air supply to prevent operation unless ventilating fans are on.

• Use cleaning solvents with highest possible flash point when flushing or cleaning equipment.

• Always turn the electrostatics off when flushing, cleaning or servicing equipment.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equip-

ment until you identify and correct the problem.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths (potential static arc).

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Keep work area free of debris, including solvent, rags and gasoline.

• Keep a working fire extinguisher in the work area.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to or

destruction of equipment if you do not follow the instructions.

Toxic Fluid Hazard

Hazardous fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on

the skin, swallowed, or inhaled.

• Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

• Store hazardous fluid in an approved container. Dispose of the hazardous fluid according to all

local, state, and national guidelines.

• Wear appropriate protective clothing, gloves, eyewear, and respirator.

309291P 3

Page 4

Warnings

WARNING

Equipment Misuse Hazard

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and

result in a serious injury.

• This equipment is for professional use only.

• Read all manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are uncertain, call your Graco distribu-

tor.

• Do not alter or modify equipment. Use only genuine Graco parts and accessories.

• Check the equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum working pressure of the lowest rated system component. Maxi-

mum working air and fluid pressure of this equipment is 100 psi (0.7 MPa, 7.0 bar).

• Use fluids and solvents that are compatible with the equipment wetted parts. See the Techni-

cal Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warn-

ings.

• Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180°F (82°C) or below -40°F (-40°C).

• Do not kink or overbend hoses or use hoses to pull equipment.

• Wear hearing protection when operating this equipment.

• Comply with all applicable local, state, and national fire, electrical, and other safety regula-

tions.

Pressurized Equipment Hazard

Spray from the gun, hose leaks, or ruptured components can splash fluid in the eyes or on the skin

and cause serious injury.

• Do not point the spray gun at anyone or at any part of the body.

• Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure on page 23 when you stop spraying and before clean-

ing, checking, or repairing equipment.

• Check hoses and couplings daily. Replace worn, damaged, or loose parts immediately.

• Tighten all fluid connections before each use.

4 309291P

Page 5

Introduction

Introduction

How the Electrostatic Spray Gun

Works

The air hose supplies air to the spray gun. Part of the air

operates the turbine and the rest of the air atomizes the

fluid being sprayed. The turbine generates power, which

is converted by the power cartridge to supply high voltage current to the gun’s electrode.

The pump supplies fluid to the hose and gun, where the

fluid is electrostatically charged as it passes the electrode. The charged fluid is attracted to the grounded

workpiece, wrapping around and evenly coating all surfaces.

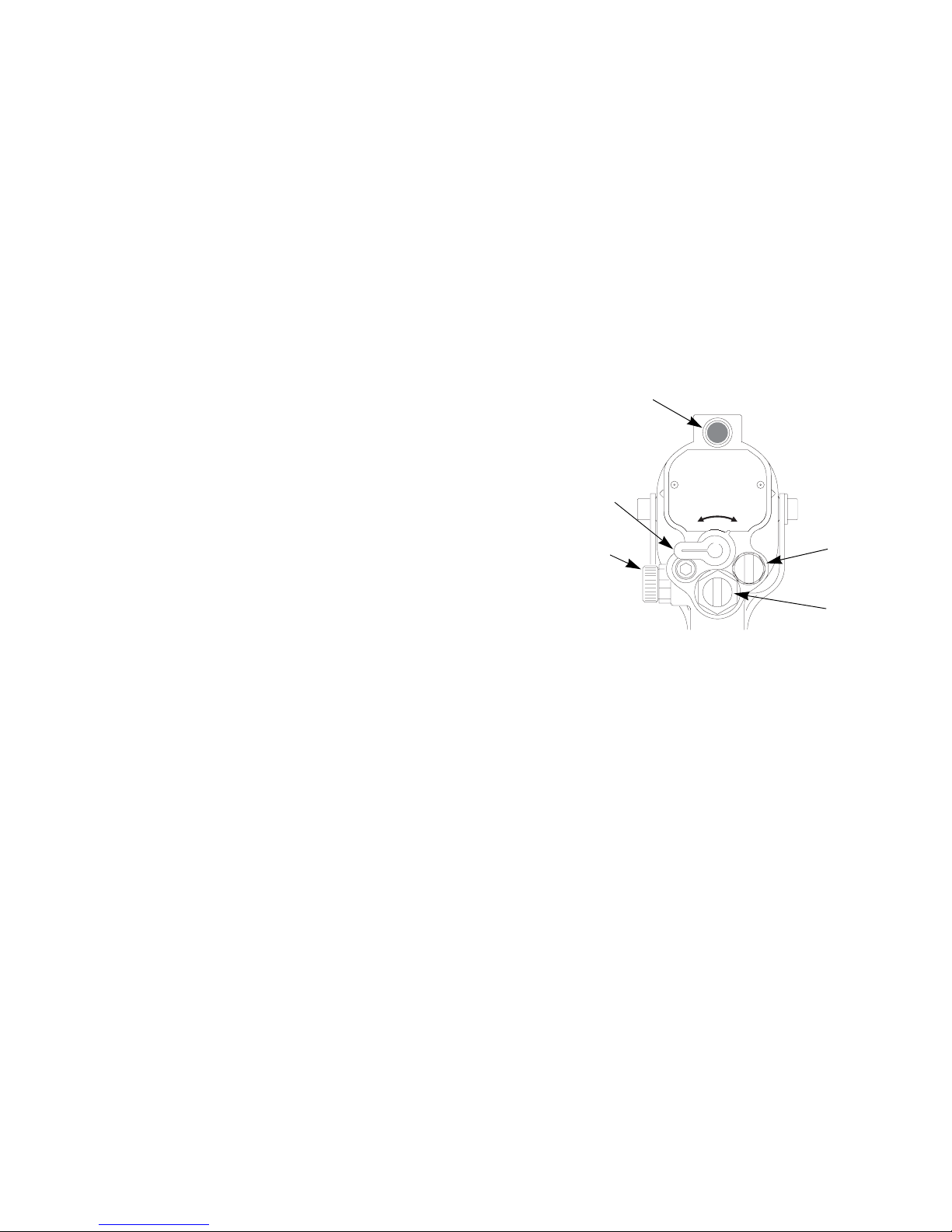

Gun Overview

The electrostatic gun includes the following controls

(see F

IG. 1).

• FLUID adjustment valve. Adjusts fluid rod travel.

Use only in low flow conditions, to reduce wear.

• Atomizing air RESTRICTOR valve. Restricts

atomizing air flow. Replace with plug (included) if

desired.

• ES ON/OFF valve. Turns electrostatics ON (I) or

OFF (0).

• ES INDICATOR. Green when ES is ON (I).

ES INDICATOR

ES ON/OFF

ES

I O

RESTRICTOR

ti1266a

AIR

FLUID

• Fan AIR adjustment valve. Adjusts fan size and

shape.

Fig. 1 Gun Overview

309291P 5

Page 6

Installation

Installation

Install the System

WARNING

Fire, Explosion, and Electric Shock Hazard

Installing and servicing this equipment

requires access to parts which may cause

electric shock or other serious injury if work

is not performed properly.

•Do not install or service this equipment

unless you are trained and qualified.

•Be sure your installation complies with

National, State and Local codes for the

installation of electrical apparatus in a

Class I, Div. I, Group D or a Group II,

Category 2G Hazardous Location.

•Comply with all applicable local, state, and

national fire, electrical, and other safety regulations.

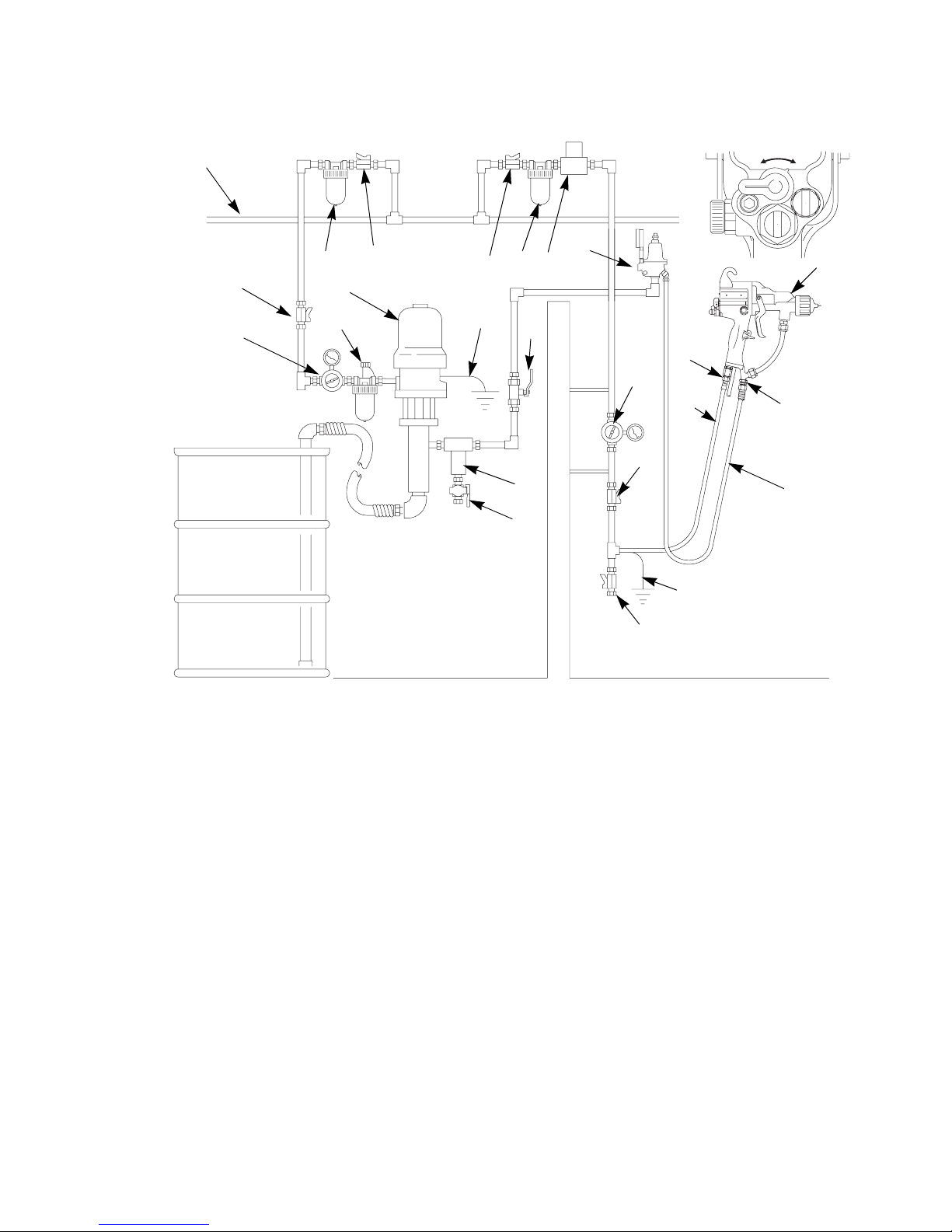

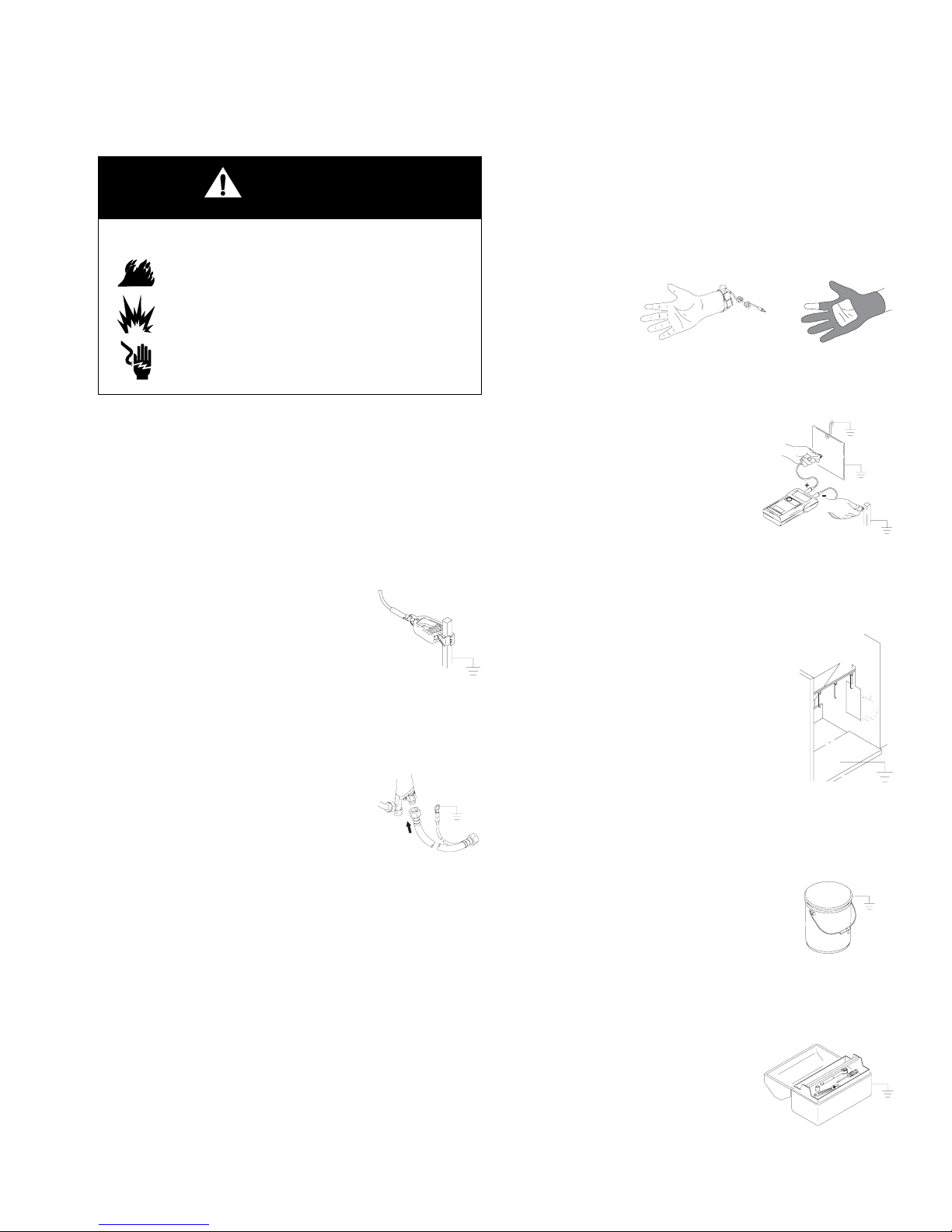

FIG. 2. shows a typical electrostatic air spray system. It

is not an actual system design. For assistance in

designing a system to suit your particular needs, contact

your Graco distributor.

Warning Sign

Mount warning signs in the spray area where they can

easily be seen and read by all operators. An English

Warning Sign is provided with the gun.

Ventilate the Spray Booth

WARNING

Flammable or Toxic Vapor Hazard

Provide fresh air ventilation to avoid the

buildup of flammable or toxic vapors when

spraying, flushing, or cleaning the gun. Do

not operate the gun unless ventilation fans

are operating.

Electrically interlock the gun air supply with the ventilators to prevent gun operation without ventilating fans

operating. Check and follow all National, State, and

Local codes regarding air exhaust velocity requirements.

High velocity air exhaust will decrease the operating efficiency of the electrostatic system. Air exhaust velocity of

100 ft/min (31 linear meters/minute) should be sufficient.

6 309291P

Page 7

Installation

ES ON/OFF valve: I is ON, 0 is OFF

A

M

B*

*E

G

C*D

O

C

H

F

J*

L

ES

I O

S

V

G

*R

W

P

K

U*

The air supply to the

gun must be electrically interlocked with

the ventilators to pre-

Q*

vent the power supply

from operating without

T

ventilating fans on.

N

Non-Hazardous Hazardous Area

Fig. 2. Typical Installation

Key

A Main Air Supply Line

B* Ventilation Fan Interlock Solenoid Valve

C* Main Air Supply Shutoff Valve (bleed-type)

D Pump Air Line Filter/Water Separator

E* Pump Air Supply Shutoff Valve (bleed-type)

F Air Line Lubricator

G Air Pressure Regulator

HPump

J* Pump Ground Wire

K Fluid Filter

L Fluid Supply Line Shutoff Valve

M Fluid Pressure Regulator

TI1531a

N Fluid Supply Line

O Gun Air Line Filter/Water Separator

P Gun Air Supply Line Shutoff Valve

Q* Air Hose Ground Wire

R* Graco Grounded Air Hose

S Electrostatic Air Spray Gun

T Air Line Drain Valve

U* Fluid Drain Valve

VGun Air Inlet

W Gun Fluid Inlet

* Required for safe operation. Must be purchased

separately. NOTE: Solenoid valve (B) is not

offered as a Graco accessory.

309291P 7

Page 8

Installation

Connect the Air Line

WARNING

Electric Shock Hazard

To reduce the risk of electric shock or other

serious injury, the air supply hose must be

electrically connected to a true earth

ground. Use only Graco Grounded Air

Supply Hose.

1. Connect the Graco Grounded Air Supply Hose (R)

between the air supply line and the gun's air inlet

(V). The gun air inlet fitting has a left-hand thread.

Connect the air supply hose ground wire (Q) to a

true earth ground.

2. Install an air line filter/water separator (O) on the

gun air line to ensure a dry, clean air supply to the

gun. Dirt and moisture can ruin the appearance of

your finished workpiece and can cause the gun to

malfunction.

3. Install a bleed-type air regulator (G) on the pump

and gun air supply lines to control air pressure to the

pump and gun.

4. Install a bleed-type air valve (E) on the pump air line

to shut off air to the pump. Install an additional

bleed-type air valve (C) on the main air line (A) to

isolate the accessories for servicing.

WARNING

Pressurized Equipment Hazard

The bleed-type air valve (E) is required in

your system to relieve air trapped between

the valve and the pump after the air regulator is shut off. Trapped air can cause the

pump to cycle unexpectedly, which can

result in serious injury, including splashing

fluid in the eyes or on the skin.

5. Install an air shutoff valve ( P) on each gun air supply line to shut off air to the gun(s).

Connect the Exhaust Tube

Press the exhaust tube (38) onto the barbed adapter on

the bottom of the gun handle. Secure the tube with the

clamp (39).

8 309291P

Page 9

Installation

Select a Fluid Nozzle and Air

Cap

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 23

before removing or installing a fluid nozzle

and/or air cap.

The gun is supplied with Part No. 197266 Nozzle and

24A376 Air Cap. If you require a different size, refer to

Table 1 and Table 2 , and instruction manual 309419, or

consult with your Graco distributor. See Air Cap/Nozzle

Replacement on page 25.

A wide pattern kit (P/N 24A431) is included with the gun

and if installed, will provide more fan air for wider spray

patterns. (If pattern becomes split, use the fan air valve

to reduce the amount of fan air.)

Table 1: Fluid Nozzles

Part No. Orifice Size

197263 0.75 mm (.030 in.)

197264 1.0 mm (.042 in.)

197265 1.2 mm (.047 in.)

197266 1.5 mm (.055 in.)

197267 1.8 mm (.070 in.)

197268† 2.0 mm (.080 in.)

249920* 0.75 mm (.030 in.)

249921* 1.0 mm (.042 in.)

249922* 1.2 mm (.047 in.)

249923* 1.5 mm (.055 in.)

249924* 1.8 mm (.070 in.)

249925*† 2.0 mm (.080 in.)

Table 2: Air Caps

Pattern Shape

Part No.

24A438

24A279

24A376*

24A274

24A439

24A275

*Also available in the following colors:

24A276 - blue

24A277 - red

24A278 - green

and Length in.

(mm)

Round end;

15-17 (381-432)

Round end;

14-16 (356-406)

Tapered end;

17-19 (432-483)

Tapered end;

12-14 (305-356)

Round end;

11-13 (279-330)

Tapered end;

14-16 (356-406)

Recommended Fluids and

Production Rates

Light to medium viscosity.

Up to 15 oz/min (450 cc/min)

Medium to high viscosity and

high solids.

Up to 15 oz/min (450 cc/min)

Light to medium viscosity.

Up to 15 oz/min (450 cc/min)

Light to medium viscosity.

Up to 15 oz/min (450 cc/min)

Medium to high viscosity and

high solids.

Up to 15 oz/min (450 cc/min)

For use with 2.0 mm nozzle.

Light to medium viscosity and

high solids.

Aerospace coatings.

Up to 25 oz/min (750 cc/min).

* Glass-reinforced acetal construction.

† Air cap 24A439 must be used with a 2.0 mm (0.80 in.)

nozzle.

309291P 9

Page 10

Installation

Connect the Fluid Line

1. Before connecting the fluid line (N), blow it out with

air and flush it with solvent. Use solvent which is

compatible with the fluid to be sprayed.

2. Install a fluid regulator (M) on the fluid line to control

fluid pressure to the gun.

3. Install a fluid filter (K) and drain valve (U) at the

pump outlet.

WARNING

Pressurized Equipment Hazard

The fluid drain valve (U) is required in your

system to assist in relieving fluid pressure in

the displacement pump, hose, and gun.

Triggering the gun to relieve pressure may

not be sufficient. Install a drain valve close

to the pump's fluid outlet. The drain valve

reduces the risk of serious injury, including

splashing in the eyes or on the skin.

4. Connect the fluid line to the 3/8 npsm gun fluid inlet

(W).

5. Before running any paint through the spray gun,

flush it out with a compatible solvent.

Filter the Fluid

Install a fluid filter (K) to remove particles and sediment

which could clog the spray nozzle.

10 309291P

Page 11

Installation

Grounding

WARNING

Fire, Explosion, and Electric Shock Hazard

When operating the electrostatic gun, any

ungrounded objects in the spray area (people, containers, tools, etc.) can become

electrically charged. Improper grounding

can result in static sparking, which can

cause a fire, explosion, or electric shock.

Follow the grounding instructions below.

The following are minimum grounding requirements for

a basic electrostatic system. Your system may include

other equipment or objects which must be grounded.

Check your local electrical code for detailed grounding

instructions. Your system must be connected to a true

earth ground.

• Pump: ground the pump by connecting a ground

wire and clamp as described in your separate pump

instruction manual.

• All persons entering the spray area: shoes must

have conductive soles, such as leather, or personal

grounding straps must be worn. Do not wear shoes

with non-conductive soles such as rubber or plastic.

If gloves are necessary, wear the conductive gloves

that are supplied with the gun. If non-Graco gloves

are worn, cut off fingers or palm area of glove, to

ensure your hand contacts the grounded gun handle.

• Object being sprayed: keep the workpiece hangers

clean and grounded at all times. Resistance must

not exceed 1 megohm.

• The floor of the spray area: must be electrically con-

ductive and grounded. Do not cover the floor with

cardboard or any non-conductive material which

would interrupt grounding continuity.

• Electrostatic Air Spray Gun: ground the gun by con-

necting the Graco Grounded Air Hose and connecting the air hose ground wire to a true earth ground.

See Check Electrical Grounding, page 12.

ti1259a

• Air compressors: ground the equipment according

to the manufacturer's recommendations.

• All air and fluid lines must be properly grounded.

Use only grounded hoses with a maximum of 100

feet (30.5 m) combined hose length to ensure

grounding continuity.

• Flammable liquids in the spray area: must be kept in

approved, grounded containers. Do not use plastic

containers. Do not store more than the quantity

needed for one shift.

• All electrically conductive objects or devices in the

spray area: including fluid containers and wash

cans, must be properly grounded.

309291P 11

Page 12

Installation

Check Electrical Grounding

WARNING

Fire, Explosion, and Electric Shock Hazard

Megohmmeter Part No. 241079 (AA-see

F

IG. 3.) is not approved for use in a hazard-

ous area. To reduce the risk of sparking, do

not use the megohmmeter to check electrical grounding unless:

•The gun has been removed from the hazardous area;

•Or all spraying devices in the hazardous

area are turned off, ventilation fans in the

hazardous area are operating, and there

are no flammable vapors in the area (such

as open solvent containers or fumes from

spraying).

Failure to follow this warning could cause

fire, explosion, and electric shock and result

in serious injury and property damage.

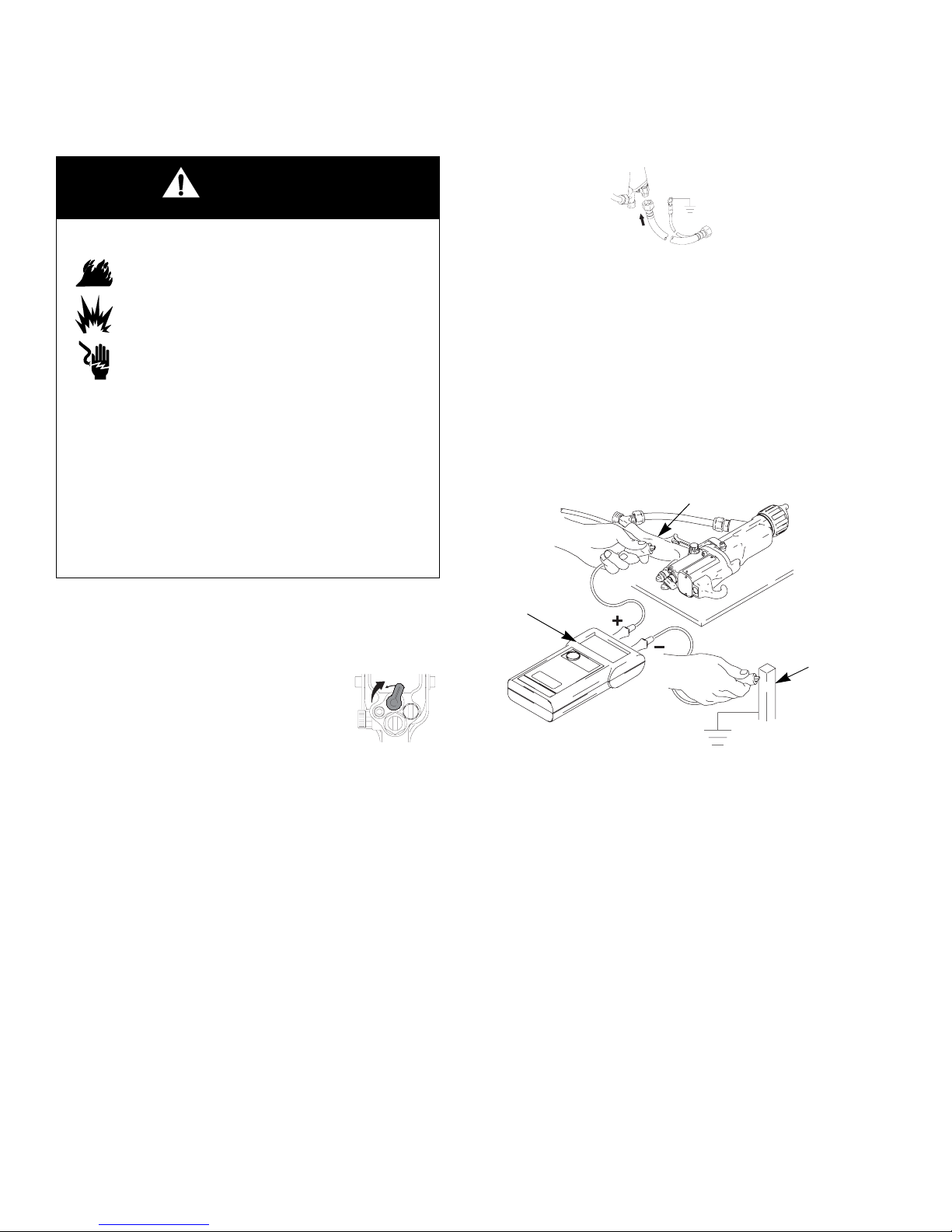

4. Make sure the grounded air hose (R) is connected

and the hose ground wire is connected to a true

earth ground.

ti1259a

5. Measure the resistance between the gun handle

(BB) and a true earth ground (CC). Use an applied

voltage of 500 minimum to 1000 volts maximum.

The resistance should not exceed 1 megohm. See

F

IG. 3..

6. If the resistance is greater than 1 megohm, check

the tightness of the ground connections and be sure

the air hose ground wire is connected to a true earth

ground. If the resistance is still too high, replace the

air hose.

BB

1. Have a qualified electrician check the electrical

grounding continuity of the spray gun and air hose.

2. Turn the ES ON/OFF valve OFF.

ES

I O

ti1273a

3. Turn off the air and fluid supply to the gun. The fluid

hose must not have any fluid in it.

AA

CC

ti1274a

Fig. 3. Check Gun Grounding

12 309291P

Page 13

Installation

Check Fluid Resistivity

WARNING

Fire, Explosion, and Electric Shock Hazard

Check the fluid resistivity in a non-hazardous area only. Resistance Meter 722886

and Probe 722860 are not approved for use

in a hazardous area.

Failure to follow this warning could cause

fire, explosion, or electric shock and result

in serious injury and property damage.

Graco Part No. 722886 Resistance Meter and 722860

Probe are available as accessories to check that the

resistivity of the fluid being sprayed meets the requirements of an electrostatic air spray system.

Follow the instructions included with the meter and

probe. Readings of 25 megohms-cm and above provide

the best electrostatic results.

Check Fluid Viscosity

To check fluid viscosity you will need:

• a viscosity cup

• a stopwatch.

1. Completely submerge the viscosity cup in the fluid.

Lift the cup out quickly, starting the stopwatch as

soon as the cup is completely removed.

2. Watch the stream of fluid coming from the bottom of

the cup. As soon as there is a break in the stream,

shut off the stopwatch.

3. Record the fluid type, elapsed time, and size of the

viscosity cup.

4. If the viscosity is too high or too low, contact the

material supplier. Adjust as necessary.

309291P 13

Page 14

Operation

Operation

Refer to the gun operation manual

(supplied) for Setup, Shutdown, and

Daily Care procedures.

INSTRUCTIONS

14 309291P

Page 15

Maintenance

INSTRUCTIONS

Flush the Spray Gun

Maintenance

Refer to the gun operation manual

(supplied) for Daily Care and Cleaning

procedures.

Flush the gun before changing colors, at the end of the

day, before storing, and before repairing the gun.

WARNING

Fire, Explosion, and Electric Shock Hazard

To reduce the risk of fire, explosion, or electric shock, turn the ES ON/OFF valve OFF

before flushing the gun.

CAUTION

Flush the gun with a non-conductive, compatible

solvent. Conductive solvents can cause the gun to

malfunction.

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 23

whenever you are instructed to relieve the

pressure.

2. Relieve the pressure.

ti1276a

3. Change the fluid source to solvent, or disconnect

the fluid line and connect a solvent supply line to the

gun.

4. Point the gun into a grounded metal pail. Flush until

clean solvent flows from the gun.

Do not use methylene chloride as a flushing or

cleaning solvent with this gun as it will damage

nylon components.

1. Turn the ES ON/OFF valve OFF.

309291P 15

ES

I O

ti1276a

5. Relieve the pressure.

ti1276a

ti1273a

Page 16

Maintenance

6. Shut off or disconnect the solvent line.

7. Hang the gun from its hook, with the nozzle pointing

down.

ti1288a

8. When ready to spray again, reconnect the fluid supply line. Follow the Setup procedure in the Operation Manual.

16 309291P

Page 17

Electrical Tests

Electrical Tests

Electrical components inside the gun affect performance

and safety. The following procedures test the condition

of the power supply (18) and electrode (29), and electrical continuity between components.

Use megohmmeter Part No. 241079 (AA) and an

applied voltage of 500 V. Connect the leads as shown.

WARNING

Fire, Explosion, and Electric Shock Hazard

Megohmmeter Part No. 241079 (AA-see

F

IG. 4.) is not approved for use in a hazard-

ous area. To reduce the risk of sparking, do

not use the megohmmeter to check electrical grounding unless:

•The gun has been removed from the hazardous area;

•Or all spraying devices in the hazardous

area are turned off, ventilation fans in the

hazardous area are operating, and there

are no flammable vapors in the area (such

as open solvent containers or fumes from

spraying).

Test Gun Resistance

1. Flush and dry the fluid passage.

2. Measure resistance between the electrode needle

tip (29) and the air swivel (35); it should be 101-121

megohms. If outside this range, go to the next test. If

in range, refer to Electrical Troubleshooting on

page 22, for other possible causes of poor performance.

AA

29

Failure to follow this warning could cause

fire, explosion, and electric shock and result

in serious injury and property damage.

35

TI1468A

Fig. 4. Test Gun Resistance

309291P 17

Page 18

Electrical Tests

Test Power Supply Resistance

1. Remove the power supply (18), page 29.

2. Remove the turbine alternator (19) from the power

supply, page 30.

3. Measure resistance from the power supply's ground

strips (EE) to the spring (18b). See F

IG. 5..

4. The resistance should be 75-85 megohms. If outside this range, replace the power supply. If in

range, proceed to the next test.

5. If you still have problems, refer to Electrical Trou-

bleshooting on page 22 for other possible causes

of poor performance, or contact your Graco distributor.

6. Be sure the spring (18b) is in place before reinstalling the power supply.

18b

ti1500a

EE

Fig. 5. Test Power Supply Resistance

18 309291P

Page 19

Test Electrode Resistance

1. Insert a conductive rod (B) into the gun barrel

(removed for the power supply test) and against the

metal contact (C) in the front of the barrel.

2. Measure the resistance between the conductive rod

(B) and the electrode (29). The resistance should be

20-30 megohms. See F

IG. 6..

Electrical Tests

3. If in range, refer to Electrical Troubleshooting on

page 22 for other possible causes of poor performance, or contact your Graco distributor.

4. Remove the electrode (29), page 26. Measure the

resistance between the contact (E) and the electrode wire (F). The resistance should be 20-30 megohms. If out of range, replace the electrode. See

F

IG. 7..

5. Make sure the metal contact (C) in the barrel, the

nozzle contact ring (7a, F

IG. 8.), and the electrode

contact (E) are clean and undamaged.

C

29

B

ti1499a

F29E

ti1548a

Fig. 7. Electrode

7a

ti1513a

Fig. 8. Nozzle Conductive O-Ring

Fig. 6. Test Electrode Resistance

309291P 19

Page 20

Troubleshooting

Troubleshooting

WARNING

Electric Shock Hazard

Installing and servicing this equipment

requires access to parts which may cause

an electric shock or other serious injury if

the work is not performed properly. Do not install or

repair this equipment unless you are trained and

qualified.

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 23

whenever you are instructed to relieve the

pressure.

Check all possible remedies in the Troubleshooting

Chart before disassembling the gun.

WARNING

Spray Pattern Troubleshooting

Some spray pattern problems are caused by the improper balance between air and fluid.

Problem Cause Solution

Fluttering or spitting spray. No fluid. Refill supply.

Loose, dirty, damaged nozzle/seat. Clean or replace nozzle, page 25.

Air in fluid supply. Check fluid source. Refill.

Improper spray pattern. Damaged nozzle or air cap. Replace, page 25.

Fluid buildup on air cap or nozzle. Clean. See Operation Manual.

Fan air pressure too high. Decrease.

Fluid too thin. Increase viscosity.

Fluid pressure too low. Increase.

Fan air pressure too low. Increase.

Fluid too thick. Reduce viscosity.

Too much fluid. Decrease flow.

Streaks. Did not apply 50% overlap. Overlap strokes 50%.

Dirty or damaged air cap. Clean or replace, page 25.

20 309291P

Page 21

Troubleshooting

Gun Operation Troubleshooting

Problem Cause Solution

Excessive spray fog. Atomizing air pressure too high. Close restrictor valve some, or

decrease air pressure as low as possible; minimum 40 psi (0.28 MPa, 2.8

bar) needed at gun for full voltage.

Fluid too thin. Increase viscosity.

“Orange Peel” finish. Atomizing air pressure too low. Open atomizing air valve more or

increase gun air inlet pressure; use

lowest air pressure necessary.

Poorly mixed or filtered fluid. Remix or refilter fluid.

Fluid too thick. Reduce viscosity.

Fluid leaks from the fluid packing

area

Air leaks from the front of the gun Air valve (21) is not seating properly. Clean and service air valve; see

Fluid leakage from the front of the

gun

Gun does not spray Low fluid supply. Add fluid if necessary.

Dirty air cap Misaligned air cap (9) and fluid noz-

Worn packings or rod. Replace packings or rod; see page

28.

page 33.

Worn or damaged packing rod (26). Replace; see page 28

Worn fluid seat. Replace fluid nozzle and/or electrode

needle; see pages 25 to 26.

Loose fluid nozzle (7). Tighten; see page 25.

Damaged nozzle o-ring (7b). Replace; see page 25.

Damaged air cap (9). Replace; see page 25.

Dirty or clogged fluid nozzle (7). Clean; see page 25.

Damaged fluid nozzle (7). Replace; see page 25.

Damaged fluid adjustment valve (25). Replace; see page 33.

Clean fluid buildup off air cap and

zle (7).

fluid nozzle seat; see page 25.

309291P 21

Page 22

Troubleshooting

Electrical Troubleshooting

Problem Cause Solution

Poor wrap. ES ON/OFF valve OFF (0).* Turn ON (I).

Gun air pressure too low. Check air pressure to gun; minimum

40 psi (0.28 MPa, 2.8 bar) needed at

gun for full voltage.

Atomizing air pressure too high. Decrease.

Fluid pressure too high. Decrease.

Incorrect distance from gun to part. Should be 8-12 in. (200-300 mm).

Poorly grounded parts. Resistance must be 1 megohm or

less. Clean workpiece hangers.

Faulty gun resistance. See Test Gun Resistance on page

17.

Low fluid resistivity. Check fluid resistivity, page 13.

Fluid leaks from the packing (26d)

and causes a short.

Faulty turbine alternator. Be sure the plug is in place on the

ES indicator or voltage/current display is not lit.

Operator gets mild shock. Operator not grounded or is near

Operator gets shock from workpiece. Workpiece not grounded. Resistance must be 1 megohm or

ES ON/OFF valve OFF (0).* Turn ON (I).

No power. Replace power supply. See page 30.

ungrounded object.

Gun not grounded. See Check Electrical Grounding on

Clean the packing rod cavity.

Replace the packing rod. See page

28.

back of the turbine alternator housing. Remove and test the turbine

alternator. See page 31.

See Grounding on page 11.

page 12 and Test Gun Resistance

on page 17.

less. Clean workpiece hangers.

* ES indicator light is off when the gun is triggered.

22 309291P

Page 23

Repair

Repair

Pressure Relief Procedure

WARNING

Pressurized Equipment Hazard

The system pressure must be manually

relieved to prevent the system from starting

or spraying accidentally. To reduce the risk

of an injury from electric shock, accidental spray from

the gun, splashing fluid, or moving parts, follow the

Pressure Relief Procedure whenever you:

• are instructed to relieve the pressure

• stop spraying

• check or service any of the system equipment

• or install or clean the fluid nozzle.

1. Turn the ES ON/OFF valve OFF.

ES

I O

3. Trigger the gun into a grounded metal waste container to relieve the fluid pressure.

ti1276a

4. Open the pump drain valve, having a waste container ready to catch the drainage. Leave the pump

drain valve open until you are ready to spray again.

ti1290a

5. If the nozzle or hose is completely clogged or pressure is not fully relieved, slowly loosen the hose end

coupling. Now clear the nozzle or hose.

ti1273a

2. Turn off the air bleed valves to the fluid source and

to the gun.

ti1289a

t

309291P 23

Page 24

Repair

Prepare the Gun for Service

WARNING

Electric Shock Hazard

Installing and repairing this equipment

requires access to parts that may cause

electric shock or other serious injury if the

work is not performed properly. Do not install or service this equipment unless you are trained and qualified.

WARNING

Pressurized Equipment Hazard

To reduce the risk of injury, follow the Pres-

sure Relief Procedure on page 23 before

checking or servicing any part of the system

and whenever you are instructed to relieve the pressure.

• Check all possible remedies in Troubleshooting

before disassembling the gun.

• Use a vise with padded jaws to prevent damage to

plastic parts.

• Lubricate the power supply o-ring (18a) and some

packing rod parts (26) with dielectric grease (40), as

specified in the text.

• Lightly lubricate o-rings and seals with non-silicone

grease. Order Part No. 111265 Lubricant. Do not

over-lubricate.

• Only use genuine Graco parts. Do not mix or use

parts from other PRO Gun models.

• Air Seal Repair Kit 244781 is available. The kit must

be purchased separately. Kit parts are marked with

an asterisk, for example (6*).

• Fluid Seal Repair Kit 244911 is available. The kit

must be purchased separately. Kit parts are marked

with a double asterisk, for example (5**).

1. Flush the gun, page 15.

2. Relieve the pressure, page 23.

3. Disconnect the gun air and fluid lines.

4. Remove the gun from worksite. Repair area must be

clean.

24 309291P

Page 25

Air Cap/Nozzle Replacement

Repair

WARNING

CAUTION

Hold the front end of the gun up and trigger the gun

while removing the nozzle to help drain the gun and

prevent any paint or solvent left in the gun from

entering the air passages.

1. Prepare gun for service, page 24.

2. Remove the retaining ring (27) and air cap (9). See

F

IG. 9..

3. Point gun up and squeeze trigger while removing

the fluid nozzle (7) assembly with the multi-tool (37).

27

27a*

9

Fire, Explosion, and Electric Shock Hazard

The nozzle contact ring (7a) is a conductive

contact ring, not a sealing o-ring. To reduce

the risk of sparking or electric shock, do not

remove the nozzle contact ring (7a) except

to replace it and never operate the gun without the contact ring in place. Do not replace

the contact ring with anything but a genuine

Graco part.

Use non-silicone grease, Part No. 111265, on the small

o-ring (7b). Do not over-lubricate. Do not lubricate the

contact ring (7a).

4. Lightly lubricate the o-ring (7b). . Install it and the

contact ring (7a) on the nozzle (7).

Make sure the electrode needle (29) is finger-tight (page

26).

5. Trigger gun while installing the fluid nozzle (7) with

the multi-tool (37). Tighten until the fluid nozzle

seats in the gun barrel (1/8 to 1/4 turn past

hand-tight).

Fig. 9. Air Cap/Nozzle Replacement

7b

ti1501a

7a

37

7

6. Install the air cap (9) and retaining ring (27). Make

sure the u-cup (27a*) is in place with the lips facing

forward.

7. Test gun resistance, page 17.

309291P 25

Page 26

Repair

Electrode Replacement

1. Prepare the gun for service, page 24.

2. Remove the air cap and nozzle, page 25.

3. Unscrew the electrode (29) with the multi-tool (37).

Hold the packing rod end (26h) to prevent it from

turning. See F

IG. 10..

CAUTION

To avoid damaging the plastic threads, be very

careful when installing the electrode.

37

4. Apply low-strength (purple) Loctite

®

or equivalent

thread sealant to the electrode and packing rod

threads. Install the electrode finger-tight. Do not

overtighten.

5. Install the fluid nozzle and air cap, page 25.

6. Test gun resistance, page 17.

ti1502a

Fig. 10. Electrode Replacement

26 309291P

Page 27

Fluid Packing Removal

1. Prepare the gun for service, page 24.

2. Remove the air cap and fluid nozzle, page 25.

3. Remove the electrode, page 26.

4. Remove the trigger screws (8) and trigger (30). See

F

IG. 11.

5. Remove the packing rod (26), using the multi-tool

(37).

CAUTION

Clean all parts in non-conductive solvent compatible with the fluid being used, such as xylol or mineral spirits. Use of conductive solvents can cause

the gun to malfunction.

Repair

37

30

8

6. Check all parts for wear or damage and replace if

necessary.

TI1549A

Fig. 11. Fluid Packing Removal

309291P 27

Page 28

Repair

Packing Rod Repair

You may replace the packing rod as individual parts or

as an assembly. The assembly is pre-adjusted at the

factory.

Before installing the fluid packing rod into the gun barrel,

make sure the internal surfaces of the barrel are clean.

Remove any residue with a soft brush or cloth. Check

the inside of the barrel for marks from high voltage arcing. If marks are present, replace the barrel.

To assemble the individual parts:

1. Place the packing nut (26e) and seal (26b**) on the

fluid rod (26h). Flats on the packing nut must face

the back of the fluid rod. The seal o-ring must face

away from the packing nut. See F

2. Fill the inner cavity of the spacer (26g**) with dielectric grease (40). Place the spacer on the fluid rod

(26h) in the direction shown. Generously apply

dielectric grease to the outside of the spacer.

IG. 12.

4. Lightly tighten the packing nut (26e). The packing

nut is properly tightened when there is 3 lb (13.3 N)

of drag force when sliding the packing housing (26f)

assembly along the rod. Tighten or loosen the packing nut as needed.

5. Install the o-ring (26a**) on the outside of housing

(26f). Lubricate the o-ring with non-silicone grease,

Part No. 111265. Do not over-lubricate.

6. Install the spring (4) against the nut (E) as shown.

7. Install the packing rod assembly (26) into the gun

barrel. Using the multi-tool (37), tighten the assembly until just snug.

8. Install the trigger (30) and screws (8).

9. Install the electrode, page 26.

10. Install the nozzle and air cap, page 25.

11. Test gun resistance, page 17.

3. Place the fluid packing (26c**), rod packing (26d**),

and housing (26f) on the packing rod (26h) .

**26b

**26g

**26c

**26d

26f

**26a

4

E

26h

TI1550A

26e

Fig. 12. Packing Rod

28 309291P

Page 29

Repair

Barrel Removal

1. Prepare the gun for service, page 24.

2. Carefully loosen the nut (32) from the bracket fluid

fitting (13). Pull the tube (14) out of the fitting. Make

sure both ferrules and the nut stay with the tube.

3. Loosen the three screws (11).

CAUTION

To avoid damaging the power supply (18), pull the

gun barrel straight away from the gun handle. If

necessary, gently move the gun barrel from side to

side to free it from the gun handle.

4. Hold the gun handle (17) with one hand and pull the

barrel (16) straight off the handle. See F

14

32

13

11

IG. 13..

16

Barrel Installation

1. Be sure the gasket (10*) is in place. Make sure the

air holes are aligned properly. Replace if damaged.

See F

IG. 14..

2. Place the barrel (16) over the power supply (18) and

onto the gun handle (17).

3. Tighten the three screws (11) oppositely and evenly

(about a half turn past snug).

CAUTION

Do not over-tighten the screws (11).

4. Assemble the fluid tube (14) into the bracket fitting

(13). Ensure that the ferrules are in place. Tighten

the nut (32).

5. Test gun resistance, page 17.

*10

18

11

ti1503a

17

Fig. 13. Barrel Removal

16

ti1535a

ti1504a

Fig. 14. Barrel Installation

309291P 29

Page 30

Repair

Power Supply Removal and

Replacement

• Inspect the gun handle power supply cavity for dirt

or moisture. Clean with a clean, dry rag.

• Do not expose gasket (10) to solvents.

1. Prepare gun for service, page 24.

2. Remove the barrel (16), page 29.

CAUTION

Be careful when handling the power supply (18) to

avoid damaging it.

3. Grasp the power supply (18) with your hand. With a

gentle side to side motion, free the power supply/alternator assembly from the gun handle (17),

then carefully pull it straight out. See F

IG. 15..

7. Lubricate the alternator o-ring (19a*) with non-silicone grease, Part No. 111265. Do not over-lubricate.

8. Lubricate the power supply o-ring (18a*) with dielectric grease (40).

9. Insert the power supply/alternator assembly in the

gun handle (17). Make sure the ground strips make

contact with the handle.

10. Install the barrel (16), page 29.

11. Test gun resistance, page 17.

*10

*19a

19

19e

GG

4. Disconnect the 3-wire connector (GG) from the

power supply. Slide the alternator up and off the

power supply. Inspect the power supply and alternator for damage.

5. Check the power supply resistance, page 18.

Replace if necessary.

Before installing the power supply, make sure the

o-rings (18a*, 19a*), spring (18b), and pads (19e) are in

place.

6. Connect the 3-wire connector (GG). Slide the alternator (19) down onto the power supply (18).

ti1534a

18

16

18b

*18a

Fig. 15. Power Supply

30 309291P

Page 31

Repair

Turbine Alternator Removal and

Replacement

Replace turbine alternator bearings after 2000 hours of

operation. Order Part No. 223688 Bearing Kit.

1. Prepare gun for service, page 24.

2. Remove the power supply/alternator assembly,

page 30.

3. Disconnect the alternator from the power supply,

page 30.

4. Measure resistance between the two outer terminals of the 3-wire connector (GG); it should be

2.5-3.5 ohms. If outside this range, replace the alternator coil.

5. Follow the bearing replacement procedure in the

bearing kit manual 308034.

6. Install the alternator on the power supply, page 30.

7. Install the power supply/alternator assembly, page

30.

309291P 31

Page 32

Repair

Fan Air Adjustment Valve Repair

1. Prepare the gun for service, page 24.

2. Place a wrench on the flats of the valve assembly

(20) and unscrew it from the handle (17).

You may replace the valve as an assembly (go to

step 9) or as individual parts (steps 3-9).

3. Remove the retaining ring (20a). See F

4. Turn the valve stem (20d) counterclockwise until it

comes free from the valve housing (20c).

5. Remove the o-ring (20b).

IG. 16..

6. Clean all parts and inspect for wear or damage.

Use non-silicone grease, Part No. 111265. Do not

over-lubricate.

7. When reassembling the fan air valve (20), lightly

lubricate the valve threads and screw the stem (20d)

fully into the housing (20c) until bottomed. Install the

o-ring (20b*), lubricate, and unscrew the valve stem

until the o-ring enters the housing.

8. Reassemble the retaining ring (20a). Unscrew the

valve stem from the housing until it is stopped by the

retaining ring.

9. Screw the valve assembly (20) into the gun handle,

using a wrench on the flats of the housing. Torque to

15-25 in-lb (1.7-2.8 N•m).

20d

TI1487A

20c

20a

Fig. 16. Fan Air Adjustment Valve

20b*

32 309291P

Page 33

Repair

Fluid Adjustment Valve Repair

1. Prepare the gun for service, page 24.

2. Remove the fluid adjustment valve (25). It can only

be replaced as a complete assembly. See F

3. Screw the valve (25) into the gun handle. Torque to

15-25 in-lb (1.7-2.8 N•m).

TI1536A

IG. 17..

25

4. Remove the air valve (21) with a pliers. Inspect the

rubber sealing surface and replace the air valve if

damaged.

CAUTION

When removing the air valve (21) be careful not to

damage the seat area.The rubber seal is not

removable.

5. Inspect the u-cup (6*). Do not remove the u-cup

unless damaged. If removed, install the new one

with its lips facing into the gun handle (17).

6. Install the air valve (21) and spring (15) into the gun

handle (17).

7. Install the fluid adjustment valve (25). Torque to

15-25 in-lb (1.7-2.8 N•m).

8. Install the barrel, page 29.

Fig. 17. Fluid Adjustment Valve

Air Valve Repair

1. Prepare the gun for service, page 24.

2. Remove the barrel, page 29.

3. Remove the fluid adjustment valve (25) from the

handle (17). Remove the spring (15). See FIG. 18..

CAUTION

Clean all parts in non-conductive solvent compatible with the fluid being used, such as xylol or mineral spirits. Use of conductive solvents can cause

the gun to malfunction.

25

15

21

17

*6

TI1551A

Fig. 18. Air Valve

309291P 33

Page 34

Repair

Atomizing Air Restrictor Valve

Removal and Replacement

1. Prepare the gun for service, page 24.

2. Remove the atomizing air restrictor valve (23).

Inspect the o-ring (23c*). Replace if necessary. See

F

IG. 19..

3. Install a new atomizing air restrictor valve (23), or

disassemble and replace parts individually. The

valve protrusion must be oriented to clear the air

valve (21) shaft.

If the atomizing air valve is not desired, install the supplied plug (47).

4. Torque the valve housing (23a) to 15-20 in-lb

(1.7-2.3 N•m).

23c*

23a

23d

TI1533A

Fig. 19. Atomizing Air Valve

47

23b

34 309291P

Page 35

Repair

ES ON/OFF Valve Repair

1. Prepare the gun for service, page 24.

2. Loosen the screw (48). Remove the valve.

3. Lubricate the o-rings (22a* and 22b*) with non-silicone grease, Part No. 111265. Do not over-lubricate.

CAUTION

Do not over-lubricate parts. Excessive lubricant on

the o-rings can be pushed into the gun air passage

and blemish the finish on the workpiece.

4. Clean and inspect parts for damage. Replace if necessary.

The protrusion on the retainer plate (22d) must point

upward.

5. Reinstall the valve. Torque the screw (48) to 15-25

in-lb (1.7-2.8 N•m).

22d

22e

22b*

22c

22a*

TI1488A

Fig. 20. ES ON/OFF Valve

22f

22g

48

309291P 35

Page 36

Parts

Parts

Part No. 244399 20 kV Electrostatic Gun, Series C

See page 37 for detail views of the alternator (19), fan adjustment

valve (20), ES ON/OFF valve (22), and packing rod (26).

22

18

20

11

19e

19

19a*

I O

25 (Ref)

ES

ti1266a

18b

*18a

28

17

25

15

21***

11

23c*

23a

29

27

26

27a*

16

4

*10

*6

8

**5

30

23d

24a*

24

13

47

23b

35

1

**31

7b

32

7a

38

39

7

14

9

36

ti1496b

37

36 309291P

Page 37

Parts

Ref. No. 20: Fan Adjustment ValveRef. No. 19: Alternator

19a*

19b

19b

19e

19d

19c

Ref. No. 22: ES ON/OFF Valve

22g

22f

22d

TI1481a

20b*

20c

20a

Ref. No. 26: Packing Rod

**26b

26c**

26d**

26f

20d

TI1487A

TI1497a

26e

26h

22c

TI1488A

22a*

22b*

22e

26g**

48

26a**

309291P 37

Page 38

Parts

Ref.

No. Part No. Description Qty

1 110078 FITTING, tube, fluid; includes one

each of items 31 and 32

4 185111 SPRING, compression 1

5** 185120 SPACER, fluid; nylon 1

6* 188749 PACKING, u-cup, air valve;

UHMWPE

7 197266 NOZZLE; 1.5 mm orifice; includes

items 7a and 7b

7a 111261 .O-RING, conductive 1

7b 111507 .O-RING; fluoroelastomer 1

8 197369 SCREW, trigger 2

9 24A376 AIR CAP 1

10* 197517 GASKET, barrel 1

11 197518 SCREW; socket-hd;

10-24 x 3/4 in. (19 mm)

13 15M678 BRACKET, inlet, fluid 1

14 197589 TUBE, fluid 1

15 185116 SPRING, compression 1

16 244396 BARREL, gun 1

17 245289 HANDLE, gun (includes item 28) 1

18 244539 POWER SUPPLY, 20 kV; includes

items 18a-18b

18a* 103337 .O-RING; fluoroelastomer 1

18b 197624 .SPRING, compression 1

19 244555 TURBINE, alternator; includes

items 19a-19e

19a* 110073 .O-RING; fluoroelastomer 1

19b 223688 .BEARING KIT; includes front and

rear bearings and fan

19c 244577 .COIL 1

19d 111745 .RING, retaining 1

19e 198821 .PAD, pressure 2

20 244556 VALVE, adjustment, fan; includes

items 20a-20d

20a 101021 .RING, retaining 1

20b* 106560 .O-RING; fluorocarbon 1

20c 197566 .HOUSING, fan valve 1

20d 197567 .STEM, fan valve 1

21*** 244557 VALVE, air 1

22 244558 VALVE, electrostatics, ON/OFF;

includes items 22a-22g

22a* 111516 .O-RING; CV75 1

22b* 113137 .O-RING; fluoroelastomer 1

22c 198403 .SHAFT, valve 1

22d 198404 .PLATE, retaining 1

22e 198453 .WASHER 1

22f 198464 .PIN 1

22g 276753 .KNOB 1

23 244559 VALVE, air, atomizing; includes

items 23a-23d

23a 197594 .HOUSING, valve 1

23b 197591 .SHAFT 1

Ref.

No. Part No. Description Qty

23c* 111504 .O-RING; fluoroelastomer 2

1

23d 101021 .RING, retaining 1

24 249323 VALVE, exhaust; includes item

24a

24a* 112085 .O-RING; fluorocarbon 1

1

25 244593 VALVE, adjustment, fluid 1

26 244598 ROD, packing; includes items

1

26a-26h

26a** 111316 .O-RING; fluoroelastomer 1

26b** 116905 .SEAL 1

26c** 178409 .PACKING, fluid; UHMWPE 1

26d** 178763 .PACKING, rod; acetal homopoly-

mer

26e 185488 .NUT, packing 1

3

26f 185495 .HOUSING, packing 1

26g** 186069 .SPACER, packing; acetal 1

26h 244694 .ROD, packing 1

27 244927 RING, retaining, air cap; includes

item 27a

27a* 198307 .PACKING, u-cup 1

28 276695 HOOK 1

1

29****276697 NEEDLE, electrode 1

30 276698 TRIGGER 1

31** 110077 FERRULE, tube, fluid 1

32 110079 NUT, tube, fluid 1

1

35 244834 SWIVEL, air; 1/4 npsm(m);

left-hand threads

36 107460 WRENCH, ball end 1

1

37 276741 MULTI-TOOL 1

38 185103 TUBE, exhaust 1

39 110231 CLAMP 1

40 116553 GREASE, dielectric, tube (not

1

41 244914 COVER, gun; box of 10 (not

shown)

shown)

42▲ 179791 TAG, warning (not shown) 1

43▲ 180060 SIGN, warning (not shown) 1

47 197967 PLUG 1

48 198058 SCREW, cap, socket hd 1

49 24A431 KIT, wide pattern (not shown) 1

1

* Included in Air Seal Repair Kit 244781.

** Included in Fluid Seal Repair Kit 244911.

*** Rubber seal is not removable.

**** Optional replacement Electrode Needle 277007 is

1

available for abrasive materials.

▲ Replacement Warning labels, signs, tags, and cards

are available at no cost.

1

1

1

1

1

1

1

38 309291P

Page 39

Accessories

Accessories

Air Line Accessories

AirFlex™ Flexible Grounded Air Hose

100 psi (7 bar, 0.7 MPa) Maximum Working Pressure

0.315 in. (8 mm) ID; 1/4 npsm(f) x 1/4 npsm(f) left-hand

thread. Use for maximum flexibility.

244963 6 ft (1.8 m)

244964 15 ft (4.6 m)

244965 25 ft (7.6 m)

244966 36 ft (11 m)

244967 50 ft (15 m)

244968 75 ft (23 m)

244969 100 ft (30.5 m)

Standard Grounded Air Hose

100 psi (7 bar, 0.7 MPa) Maximum Working Pressure

0.315 in. (8 mm) ID; 1/4 npsm(f) x 1/4 npsm(f) left-hand

thread

223068 6 ft (1.8 m)

223069 15 ft (4.6 m)

223070 25 ft (7.6 m)

223071 36 ft (11 m)

223072 50 ft (15 m)

223073 75 ft (23 m)

223074 100 ft (30.5 m)

Bleed-Type Master Air Valve

300 psi (21 bar, 2.1 MPa) Maximum Working Pressure

Relieves air trapped in the air line between this valve

and the pump air motor when closed.

107141 3/4 npt

Air Line Quick Disconnect

112534 Swiveling quick disconnect replaces stan-

dard air inlet swivel.

Air Hose Adapter Nipple

185493 Use to connect multiple air hoses. 1/4 npt x

1/4 npsm left-hand thread.

Non-Swivel Air Inlet Fitting

185105 Replaces standard swivel. Left-hand thread.

Extended Air Inlet Fitting

189191 Replaces standard swivel to provide

extended handle grip area. Left-hand

thread.

Fluid Line Accessories

Fluid Hose

225 psi (14 bar, 1.4 MPa) Maximum Working Pressure

FM Approved; nylon; 3/8 npsm(fbe)

215637 1/4 in. (6 mm) ID x 25 ft (7.6 m)

215638 1/4 in. (6 mm) ID x 50 ft (15.2 m)

Fluid Shutoff/Drain Valve

500 psi (35 bar, 3.5 MPa) Maximum Working Pressure

For turning fluid on or off to the gun and for relieving

fluid line pressure at the pump.

208630 1/2 npt(m) x 3/8 npt(f); carbon steel and

PTFE; for non-corrosive fluids

Air Line Shutoff Valve

150 psi (10 bar, 1.0 MPa) Maximum Working Pressure

For turning air to gun on or off.

224754 1/4 npsm(m) x 1/4 npsm(f) left-hand thread.

309291P 39

Fluid Swivel

5800 psi (405 bar, 40 MPa) Maximum Working Pressure

115898 1/4 npsm(m) x 1/4 npsm(f)

Page 40

Accessories

Gun Accessories

Gun Repair Kits

244781 Air Seal Repair Kit

244911 Fluid Seal Repair Kit

Round Pattern Kits

Consists of fluid tip, diffuser and air cap.

245217 4-6 in. (102-152 mm) diameter

245219 8-10 in. (203-254 mm) diameter

Adjustable Round Pattern Kit

277851 Slow velocity, bell shaped spray pattern for

excellent transfer efficiency. Pattern is

adjustable from 6-12 in.

Push/Pull Fan Air Valve

244912 For quick change of fan size.

ES Always On Kit

244913 Replaces inlet fitting with ball valve to shut

off air during flushing. Converts ES ON/OFF

valve to always ON condition.

Handle Grips

245263 Medium Grip

245264 Large Grip

Gun Washer Kit

245270 Use to convert Graco gun washers so they

can clean PRO Xs2 air spray guns.

Pressure Cups

Includes air regulators for gun atomization air and supply air to pressure cup.

244731 1 Quart (0.95 Liter)

244732 2 Quart (1.90 Liter)

Abrasive Material Electrode Needle

277007 Optional replacement Electrode Needle is

available for abrasive materials.

Miscellaneous Accessories

Ground Wire and Clamp

222011 For grounding pump and other components

and equipment in the spray area.

12 gauge, 25 ft (7.6 m).

Megohmmeter

241079 500 Volt output; 0.01-2000 megohms.

Not for use in hazardous areas.

Paint Resistance Meter

722886 Use with 722860 Paint Probe to measure

resistance of paint.

Not for use in hazardous areas.

Paint Probe

722860 Use with 722886 Paint Resistance Meter to

measure resistance of paint.

Not for use in hazardous areas.

Safety Warning Signs

180060 English Warning Sign. FM Approved. Avail-

able at no charge from Graco.

Instruction Signs

198309 English Setup Instructions.

198319 English Daily Care Instructions.

Electrostatic Conductive Gloves (box of 12)

117823 Small

117824 Medium

117825 Large

Gun Valve Lubricant

111265 4 oz (113 g) tube of sanitary (non-silicone)

lubricant for fluid seals and wear areas.

Alternator Bearing Kit

223688 To repair the turbine alternator.

Cleaning Brush

105749 For cleaning air cap and fluid nozzle.

40 309291P

Page 41

Technical Data

Technical Data

Category Data

Maximum Working Fluid Pressure 100 psi (0.7 MPa, 7 bar)

Maximum Working Air Pressure 100 psi (0.7 MPa, 7 bar)

Minimum Air Pressure at Gun Inlet 40 psi (0.28 MPa, 2.8 bar)

Maximum Fluid Operating Temperature 120°F (48°C)

Paint Resistivity Range 3 megohm-cm to infinity

Short Circuit Current Output 125 microamperes

Voltage Output 20 kV

Sound Power (measured per ISO Standard 9216) at 40 psi (0.28 MPa, 2.8 bar): 90.4 dB(A)

at 100 psi (0.7 MPa, 7 bar): 105.4 dB(A)

Sound Pressure (measured 1 m from gun) at 40 psi (0.28 MPa, 2.8 bar): 87 dB(A)

at 100 psi (0.7 MPa, 7 bar): 99 dB(A)

Air inlet fitting, left-hand thread 1/4 npsm(m)

Fluid inlet fitting 3/8 npsm(m)

Gun Weight 23.5 oz (668 g)

Gun Length 8.6 in. (21.8 cm)

Wetted Parts Stainless Steel, Nylon, Acetal, Ultra-High Molecular

Weight Polyethylene, Fluoroelastomer, PEEK, Tungsten

Wire, Polyethylene

Loctite® is a registered trademark of the Loctite Corporation.

309291P 41

Page 42

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship

on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twelve months or two thousand hours of operation from the date of sale, repair or replace any

part of the equipment determined by Graco to be defective. However, any deficiency in the barrel, handle, trigger, hook, internal

power supply, and alternator (excluding turbine bearings) will be repaired or replaced for thirty-six months or six thousand hours of

operation from the date of sale. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco's written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused

by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering,

or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by

Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts.

The equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose

any defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco's sole obligation and buyer's sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no

other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or

property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within

two (2) years of the date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not

manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer.

Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying

equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach

of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal

proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les

parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et

procédures judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les

procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1-800-328-0211Toll Free • 612-623-6921 • 612-378-3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2001, Graco Inc. is registered to ISO 9001

This manual contains English. MM 309291

Graco Headquarters: Minneapolis

www.graco.com

Revised 10/2009

Loading...

Loading...