Page 1

Instructions-Parts

Integrated Air

311239H

Control Modules

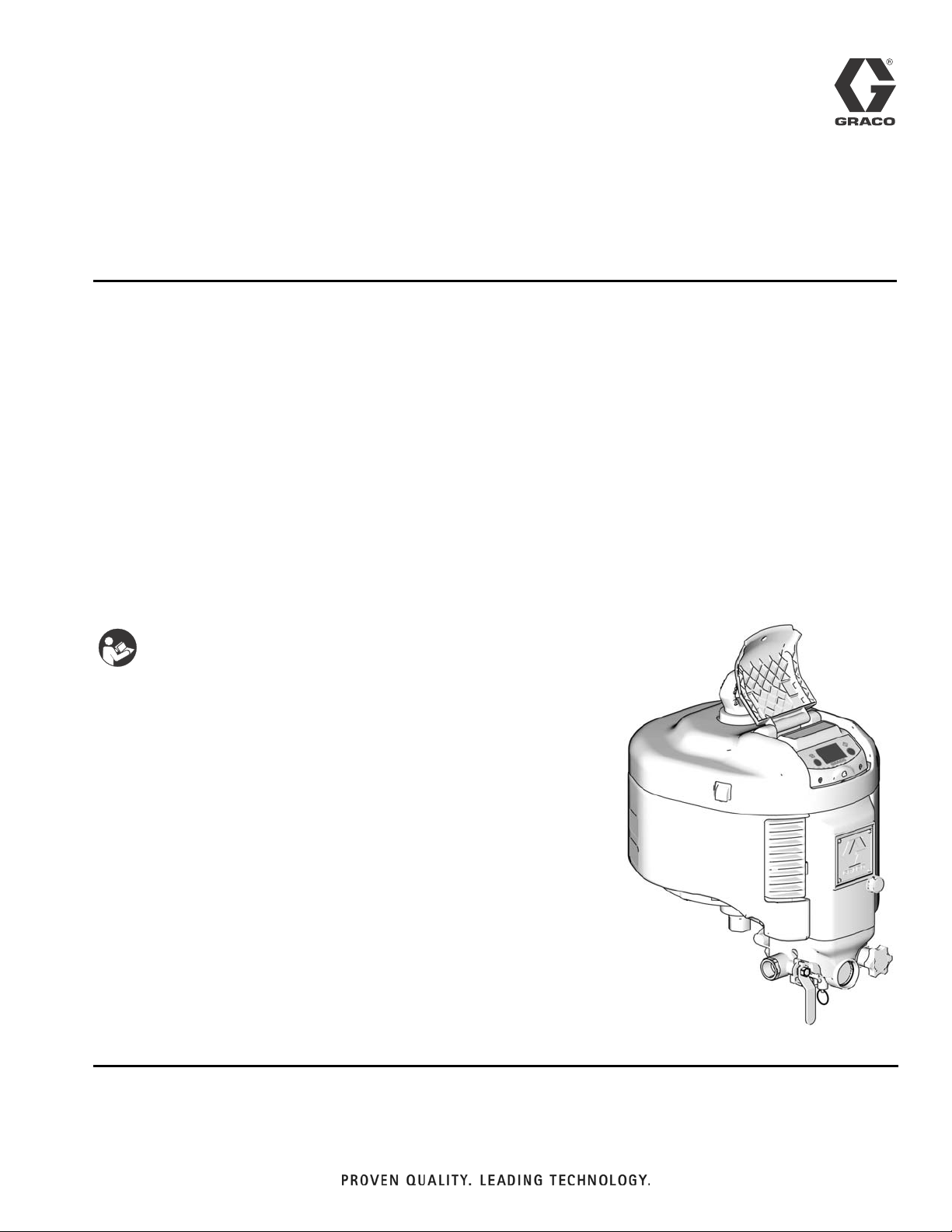

Integrated air controls for use with NXT® Model 2200, 3400, and 6500 Air Motors. For

professional use only.

100 psi (0.69 MPa, 6.9 bar) Maximum Regulated Working Pressure

NXT011, Series E

With locking air regulator and 110 psi (0.76 MPa, 7.6 bar) relief valve

NXT021, Series E

With non-locking air regulator and 110 psi (0.76 MPa, 7.6 bar) relief valve

EN

NXT031, Series E

With locking air regulator and 85 psi (0.58 MPa, 5.8 bar) relief valve

Important Safety Instructions

Read all warnings and instructions in this manual

and in NXT air motor manual 311238. Save these

instructions.

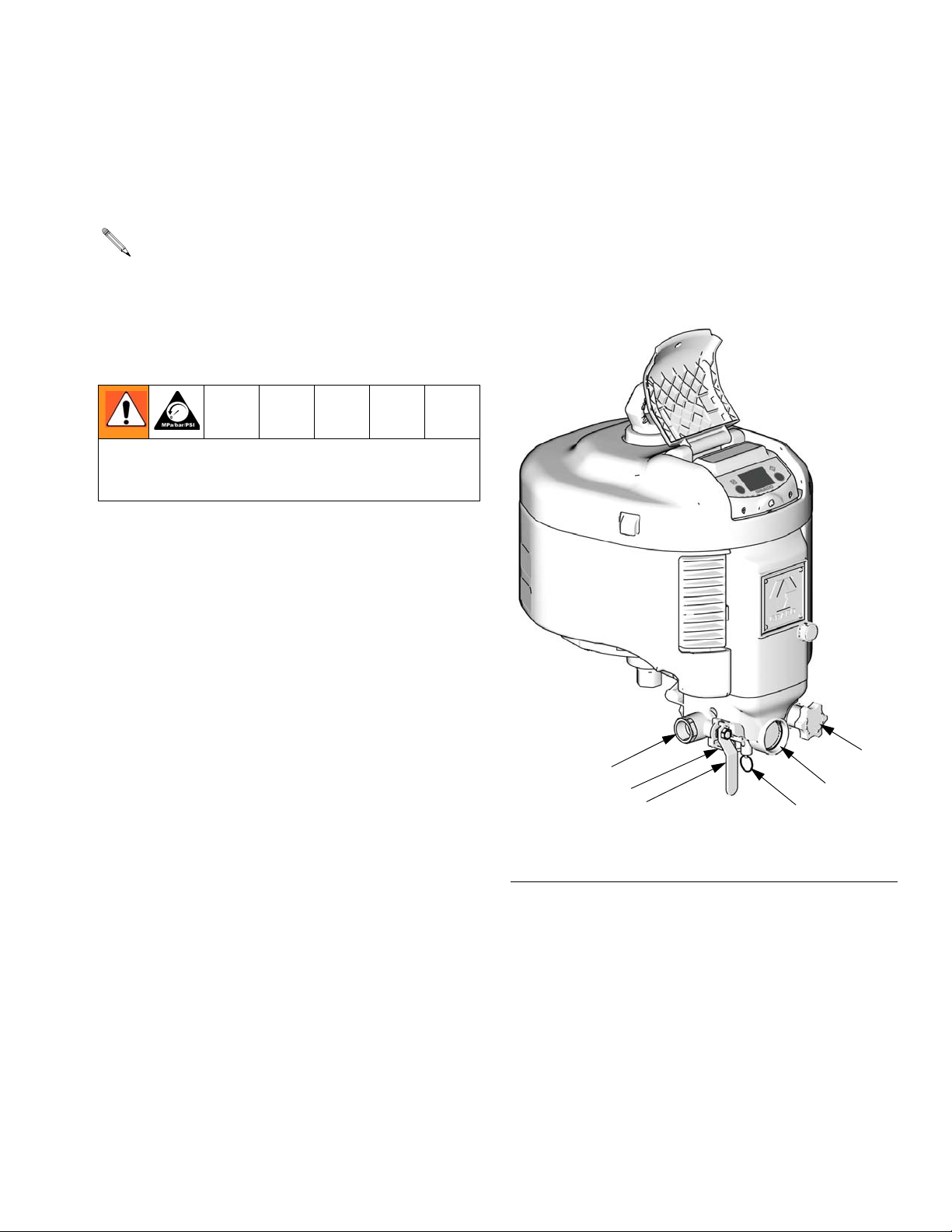

Integrated Air Control Module shown

mounted on an NXT Air Motor

TI8233c

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related Manuals

Manuals are available at www.graco.com.

This manual is available in the following languages:

Manual Language

3A0081 Chinese

3A0082 Danish

3A0083 French

3A0084 Finnish

3A0085 German

3A0086 Greek

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . 14

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 16

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 16

3A0087 Italian

3A0088 Japanese

3A0089 Korean

3A0090 Norwegian

3A0091 Polish

3A0092 Portuguese

312917 Russian

313800 Spanish

3A0093 Swedish

3A0094 Turkish

2 311239H

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. Refer

back to these Warnings. Additional, product-specific warnings may be found throughout the body of this manual

where applicable.

WARNING

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine Graco

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

311239H 3

Page 4

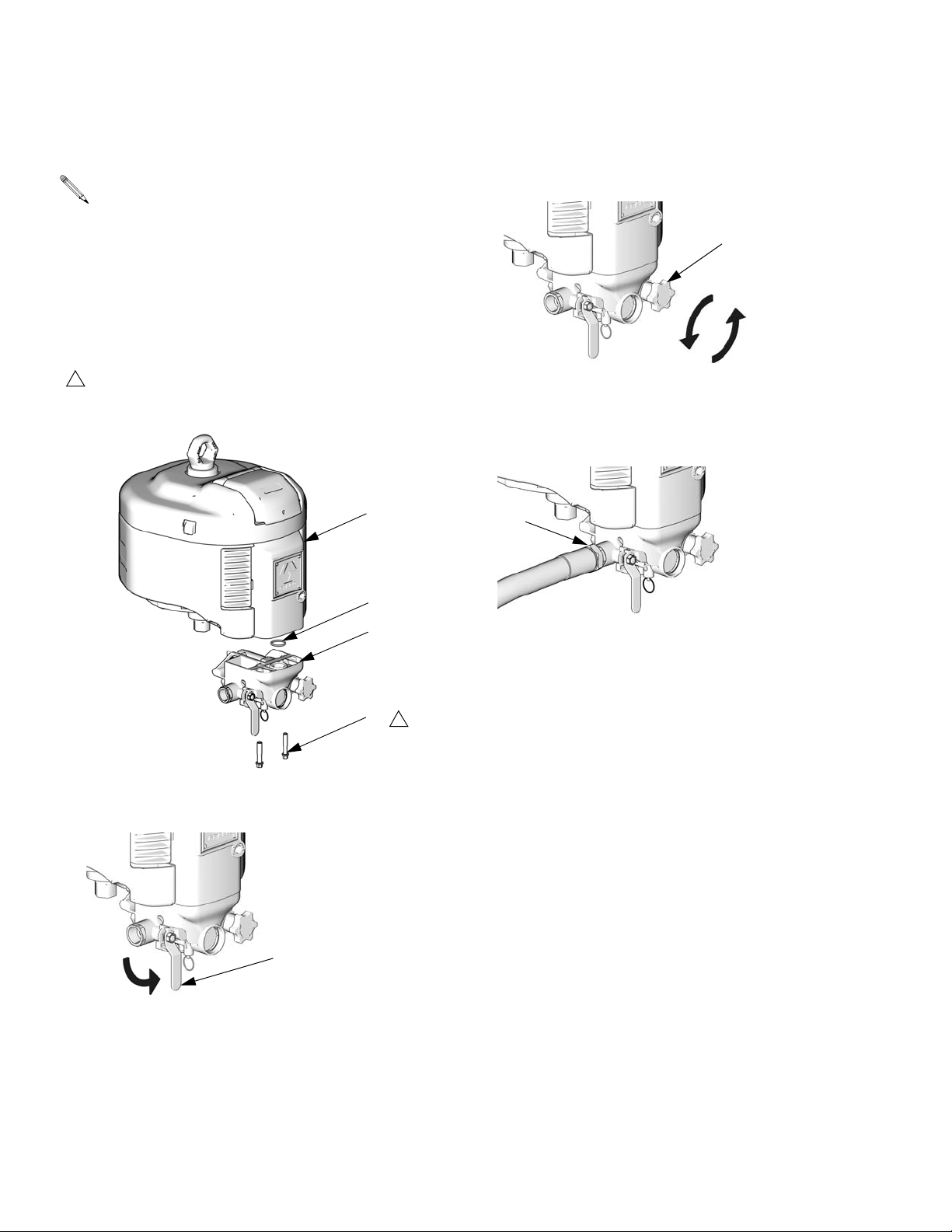

Installation

Installation

Air Control Modules NXT011 and NXT031 (locking

air regulator) and NXT021 (non-locking air regulator) are available.

1. Install supplied o-ring (43) into counterbore on upper

side of air control module (D). Fasten module to air

motor (M) with two supplied screws (44). Start

threading screws by hand before using a tool.

Torque to 20 ft-lb (27.1 N•m).

1

Screws are thread-forming. Start threading by hand

before using a tool. Torque to 20 ft-lb (27.1 N•m).

M

43

3. Turn air regulator knob (C) fully counterclockwise.

C

TI8322c

4. Hold the 3/4 npt(f) air inlet fitting (A) with a 1-5/16 in.

wrench to prevent it from turning while securely connecting the air supply hose.

A

TI8235c

2. Close bleed-type master air valve (B).

B

D

44

1

TI8323c

TI8322c

4 311239H

Page 5

Operation

Operation

Component Identification

Air Control Modules NXT011 and NXT031 (locking

air regulator) and NXT021 (non-locking air regulator) include air line components in an integrated

assembly. See F

Bleed-type Master Air Valve (B)

Trapped air can cause the pump to cycle unexpectedly,

which could result in serious injury from splashing or

moving parts.

The bleed-type master air valve is required in your system to relieve air trapped between it and the air motor

when the valve is closed.

Air Regulator (C)

IG. 1.

Key for F

A Air Inlet, 3/4 npt(f)

B Bleed-type Master Air Valve

C Air Regulator Adjustment Knob (locking or non-locking)

D Air Pressure Gauge

E Air Filter (partially hidden)

F Safety Relief Valve

IG. 1

Adjusts air pressure to the motor and fluid outlet pressure of pump. View the gauge (D) to read air pressure.

Air Filter (E)

Removes harmful contaminants from entering the air

control module and air motor.

Safety Relief Valve (F)

Automatically opens to relieve air pressure, to prevent

pump overpressurization.

A

E

B

FIG. 1: Air Control Module Mounted on NXT Air Motor

F

C

D

TI8233c

311239H 5

Page 6

Operation

Startup Locking Regulator (NXT011 and

1. Turn air regulator knob (C) fully counterclockwise.

C

TI8322c

A small amount of air venting

through knob assembly (18) is

normal.

2. Open bleed-type master air valve (B).

NXT031 only)

1. To lock pressure setpoint, push knob (C) in.

C

TI8236c

2. Pull knob out to unlock, then adjust regulator to

desired pressure setpoint.

C

TI8236c

B

TI8236c

3. Turn air regulator knob (C) clockwise until air pressure reaches desired setpoint.

C

TI8236c

Shutdown

Close bleed-type master air valve (B).

B

TI8235c

6 311239H

Page 7

Troubleshooting

Problem Cause Solution

Troubleshooting

Excess air leaking from regulator

housing, or gauge shows unstable

regulated pressure.

Air leaking from quick exhaust vent

hole.

Air leaking from ball valve vent hole. Loose inlet fitting (32a). Tighten inlet fitting. See page 11.

Regulator does not regulate pressure.

Loose or worn diaphragm (17d). Tighten housing or repair regulator

using repair kit NXT095. See page

10.

Worn seat (17e) or poppet (17f). Repair regulator using repair kit

NXT095. See page 10.

Main spool seals or relief valve worn. Replace with spool kit NXT098,

page 10.

Quick exhaust poppet (20b) or seat

(20a) worn.

Worn poppet o-ring (20c). Replace with quick exhaust repair kit

Quick exhaust poppet (20b) or seat

(20a) worn.

Worn valve seals (32b, 32d). Repair ball valve using repair kit

Worn spool o-rings or worn/damaged

diaphragm (17d).

Replace with quick exhaust repair kit

NXT099, page 10.

NXT099, page 10.

Replace with quick exhaust repair kit

NXT099, page 10.

NXT097. See page 11.

With air on and bleed-type master air

valve (B) open, unscrew the regulator

housing (19).

Gauge will not go to 0 when ball valve

is open and knob is turned counter-clockwise to 0.

• If pressure drops, diaphragm is

damaged. Install Repair Kit

NXT095, page 10.

• If air leaks out bottom orifice,

spool o-rings are worn. Install

Repair Kit NXT098, page 10.

Washer (17c) is on wrong side of diaphragm (17d).

Pilot air seat (17e) is not fully seated. Turn pilot air seat (17e) in until if fully

Seal (3) is too thin or damaged causing air to leak into pilot air chamber.

Move washer (17c) to spring side of

diaphragm.

seats.

Replace snail seal (3). Seal should

have a minimum thickness of 0.065

in. (1.65 mm).

311239H 7

Page 8

Troubleshooting

Problem Cause Solution

Gauge pressure increases above set

point pressure.

Air pressure drops when pump is

cycling.

Leak across rear spool (8) o-ring,

which raises pilot air pressure even

Replace spool assembly (8) with

spool kit NXT098.

while spraying.

Leak across front spool (8) o-ring,

which raises air motor pressure when

Replace spool assembly (8) with

spool kit NXT098.

stalled.

Spool assembly (8) sticking. Clean and lubricate spool (8). Add oil

to filter cup and run motor. Or, add a

lubricator to air supply.

Seal (3) leaking. Replace snail seal (3). Seal should

have a minimum thickness of 0.065

in. (1.65 mm).

Side hole or through vent plugged on

diaphragm tube (17d).

Air hose has too small of an inside

Clean through vent and side 0.015 in.

(0.381 mm) hole.

Use a 3/4 in. ID air hose.

diameter.

Air supply is not adequate. (Check

Use a larger air compressor.

gauge between hose and inlet.)

Air filter (6) is plugged. Replace air filter with kit NXT092. Or,

upgrade to a larger coalescing filter

with a manual drain (NXT094), or

with an automatic drain (NXT093).

See Accessories (page 13) and

manual 406659.

8 311239H

Page 9

Repair

Pressure Relief Procedure

Repair

Replace Filter Element

1. Relieve pressure, page 9.

Follow Pressure Relief Procedure when you stop

spraying and before cleaning, checking, or servicing

equipment.

1. Close bleed-type master air valve (B).

B

TI8235c

2. Make sure gauge (D) reads zero (0). If not, pull on

pressure relief ring to bleed off air pressure.

2. Remove filter bowl (E) with wrench. Remove filter

element (G).

3. Install new filter element (G) on boss within the bowl

(E). Reinstall bowl 1/4 turn past handtight.

G

E

TI8237b

Replace Gauge

1. Relieve pressure, page 9.

2. See Parts drawing, page 12. Using a 7/16 open-end

wrench on the flats, unscrew old gauge (31).

D

3. Turn air regulator knob (C) fully counterclockwise.

C

311239H 9

TI8235c

TI8322c

3. Apply PTFE tape to threads before installing new

gauge.

Page 10

Repair

Spool Repair Kit NXT098

1. Relieve pressure, page 9.

2. See Parts drawing, page 12. Using a 1/4 in. drive

ratchet or a 3/8 in. deep well socket, remove 2

screws (37). Use a 3/8 in. open-end wrench to

remove the third screw (37) and disassemble front

cover (5) from housings (1, 2). Remove spring (16).

3. Pull the spool assembly (8) out of the housing (1).

Use a pliers to carefully pull the spool assembly out

by the tip.

4. Clean and lubricate the bore in the housing (1).

5. Install the new spool (8), spring (16), and o-ring (38).

Regulator Repair Kit NXT095

Quick Exhaust Repair Kit NXT099

1. Relieve pressure, page 9.

2. See Parts drawing, page 12. Using a 3/8 in. deep

well socket, remove 2 screws (37). Use a 3/8 in.

open-end wrench to remove the third screw (37) and

disassemble front cover (5) from housings (1, 2).

Remove spring (16).

3. Remove seat (20a) with large flat blade screwdriver.

Work out the poppet (20b) from the hole beneath the

poppet using an o-ring pick or an allen wrench.

4. Liberally grease housing threads to avoid damaging

o-ring (20c) on new poppet (20b). Install new poppet

with o-ring. Install new seat (20a) until it bottoms out

tight in the housing.

1. Relieve pressure, page 9.

2. See Parts drawing, page 12. Using a 1-3/8 in.

open-end wrench, unscrew the regulator housing

(19).

3. Remove adjustment screw (17a), spring (17b), slip

ring (17c), diaphragm (17d), and washer (48).

4. Using #2 Phillips screwdriver, remove valve seat

(17e) slowly to avoid damaging flutes. Remove valve

assembly (17f) and spring (17g).

5. Use all new parts in the kit. Reinstall the spring

(17g), valve assembly (17f), washer (48), and valve

seat (17e). Tighten seat slowly to avoid damaging

flutes.

6. Do not apply any lubricant on the seating area of the

diaphragm (17d). Reinstall diaphragm, slip ring

(17c), spring (17b), and adjustment screw (17a).

10 311239H

Page 11

Repair

Ball Valve Seal Repair Kit NXT097

1. Relieve pressure, page 9.

2. See Parts drawing, page 12. Remove the inlet fitting

(32a) using a 1 5/16 in. wrench.

3. See F

4. See F

IG. 2. Move the handle to the 7:30 position.

Remove the outboard seal (32b) with an o-ring pick.

IG. 2. Move the handle to the 6:00 position.

Remove the ball (32c) using adhesive tape. Remove

the inboard seal (32d) with an o-ring pick.

Use notes on page 12 as a guide while completing

step 5.

6. Install the new outboard seal (32b) and inlet

fitting (32a). Torque to 500 in-lb (56 N•m).

The stem seal components (32e-32k) do not need

replacement unless leakage is noted. If necessary,

replace parts as shown on page 12.

9:00

7:30

6:00

IG. 2. Valve Handle Positions

F

TI8803a

5. Install the new inboard seal (32d). Install the new

ball (32c) with the notch (N) facing the front of the

module, so it engages the valve stem (33). The flat

spot on the ball must face inward.

311239H 11

Page 12

Parts

Parts

NXT011 and NXT031 Locking Integrated Air Control Module

NXT021 Non-Locking Integrated Air Control Module

32e

32f

32g

32h

32j 32k

34 35 33

4

5

32a

37

1

2

32b

7

8

32c

8

20a 20b 20c

2

8

32d

3

1

37

N

1

8

17f†

17g†

17f†

48†

8

8

16

38

7

6

4

17e†

5

17d†

17c†

31

18

18

17a†

3

17b†

50

TI8234d

1

Torque to 140 in-lb (16 N•m).

2

Torque to 500 in-lb (56 N•m).

3

Torque to 240 in-lb (27 N•m).

4

43

44

6

TI8323b

12 311239H

Torque to 130 in-lb (15 N•m).

5

Install bowl 1/4 turn past handtight.

6

Screws are thread-forming. Start

threading by hand before using a tool.

Torque to 20 ft-lb (27.1 N•m).

7

Apply blue thread lock sealant.

8

Apply lithium grease.

Page 13

Accessories

Ref.

No. Part No. Description Qty

1 15G298 HOUSING, right 1

2 15G299 HOUSING, left 1

3* 15G439 GASKET; nitrile 1

4 277109 BOWL, filter 1

5 277107 COVER, front 1

6 NXT092 ELEMENT, filter, 40 micron; pack-

age of 10

7* 103209 O-RING; fluoroelastomer 1

8 NXT098 SPOOL, valve 1

16 119987 SPRING, compression 1

17† NXT095 KIT, repair, regulator; includes

items 17a-17g

18 NXT090 KNOB ASSEMBLY, regulator, lock-

ing; NXT011 and NXT031

NXT091 KNOB ASSEMBLY, regulator,

non-locking; NXT021

20 NXT099 KIT, relief valve; includes items

20a-20c

31 108190 GAUGE, pressure, air 1

32 NXT097 KIT, repair, ball valve; 3/4 npt(f)

inlet; includes items 32a-32k

33 15F726 STEM, ball valve 1

34 15F727 INSERT, threaded, ball valve 1

35* C20145 O-RING; buna-N 1

37 119426 SCREW, machine, hex washer hd,

thread-forming; 1/4-20 x 1 in. (25

mm)

38* 115078 O-RING; nitrile 1

43 110782 O-RING; buna-N 1

44 120089 SCREW; 3/8-16 x 1-3/4 in. (44 mm) 2

48† 187509 WASHER, flat 1

50 113498 RELIEF VALVE, safety; 110 psi

(0.76 MPa, 7.6 bar); NXT011 and

NXT021

108124 RELIEF VALVE, safety; 75 psi (0.51

MPa, 5.1 bar); NXT031

Accessories

Kit Description

NXT090 Locking knob kit

NXT091 Non-locking knob kit

1

1

1

1

1

1

7

1

1

NXT092 Filter element, 40 micron, package of 10

NXT093 Coalescing filter with automatic drain

NXT094 Coalescing filter with manual drain

NXT095 Regulator repair kit

NXT096 Seal repair kit

NXT097 Ball valve repair kit

NXT098 Spool valve kit

NXT099 Relief valve kit

116635 Element replacement kit. For use with

kits NXT093 and NXT094.

* Parts included in Seal Repair Kit NXT096 (purchase

separately).

Recommended spare parts. Keep on hand to avoid

downtime.

† Parts included in Air Regulator Repair Kit NXT095

(purchase separately.)

311239H 13

Page 14

Schematic Diagram

Schematic Diagram

Bleed-Type Ball Valve

Air Filter

Pilot Valve

Pilot Vent

Diaphragm

AIR IN

Quick Air Purge

ATMOSPHERE

TO MOTOR

Air Pressure

Gauge

Spool

Overpressure Safety

Relief Valve

Atmosphere

Air Regulator

Adjustment Knob

Supply Pressure

Regulated Pressure

Pilot Pressure

14 311239H

Page 15

Technical Data

Technical Data

Maximum air inlet pressure 140 psi (0.97 MPa, 9.7 bar)

Maximum regulated working pressure 100 psi (0.69 MPa, 6.9 bar)

Maximum operating temperature 140°F (60°C)

Air Inlet Size 3/4 npt(f)

Air Gauge Port Size 1/8 npt(m)

Height 6.5 in. (165 mm)

Width 6.75 in. (171 mm)

Depth 4.75 in. (121 mm)

Weight 5.1 lb (2.3 kg)

Materials of construction Chrome, brass, aluminum, acetal, fluorocarbon rubber,

nylon, nitrile rubber, fluoroelastomer

311239H 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2006, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 311239

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 07/2011

Loading...

Loading...