Page 1

12.56

(319)

3.31

(84.1)

2.50

(63.5)

12.83

(326)

F

DA

ADJUSTMENT

CAP

ADJUSTMENT

SCREW

LUBE

OUTLET

A

C

E

D

B1

LUBE

INLET

C

SA

TOP VIEW

OF SECTION

INDICATED

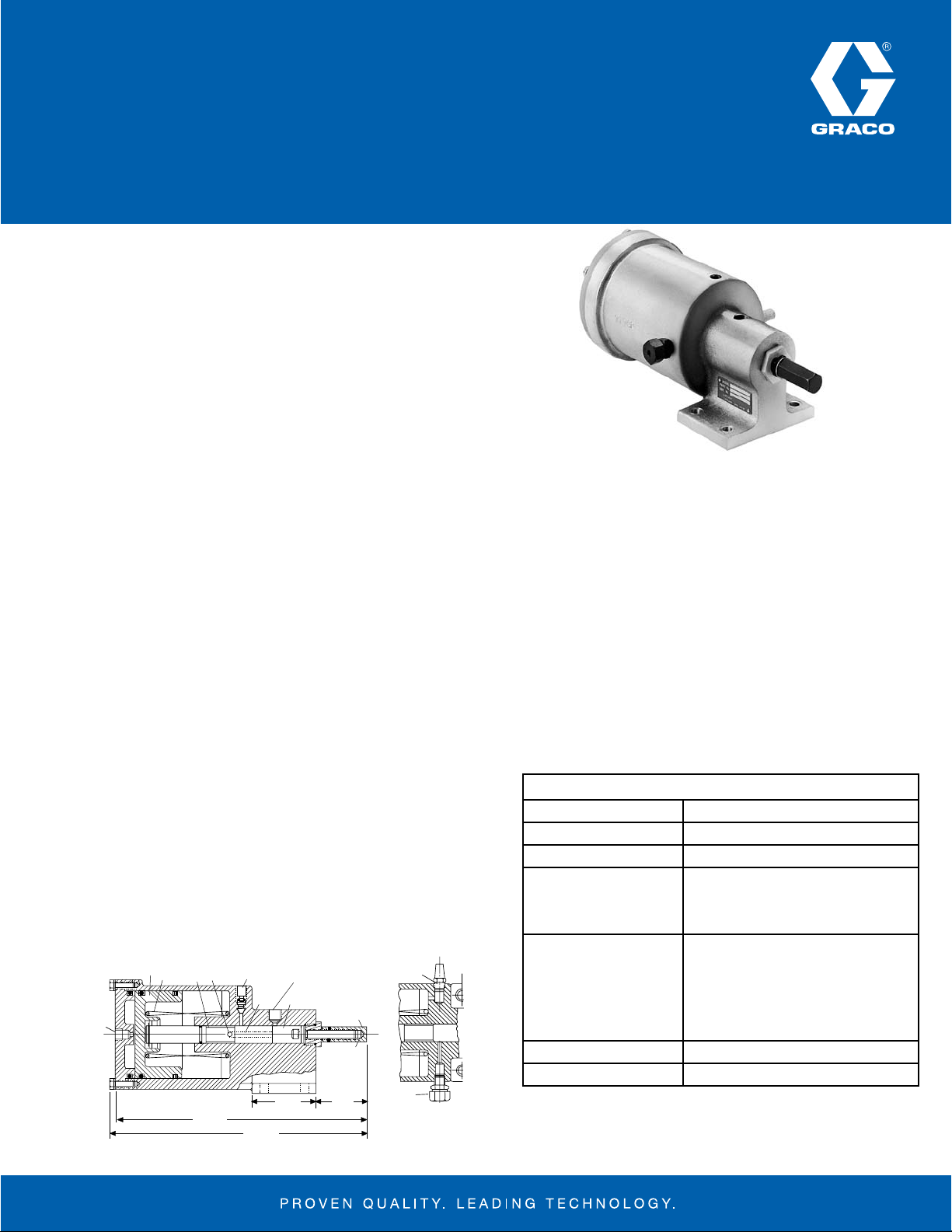

MSA-100 Air Operated Pump

DESCRIPTION

The MSA-100 is an air-operated pump with an ad justable volume

output. It is designed to be used in series progressive oil or grease

lubrication systems.

Lubricant can be supplied to the MSA-100 pump by either a

gravity feed reservoir or a pressurized source such as a bulk

header that exerts up to 500 psi at the pump inlet. This pressure

handling capability results from the valve action of the MSA-100.

Its piston prevents lubricant from flowing into the lube system

when the piston is in the priming position.

The MSA-100 is supplied as a single-acting pump. However, it can

be easily field-converted to double- acting by simply removing the

air breather from the double-acting port and installing an air line.

FEATURES

Adjustable lube output, from .400 to .800 cubic inches per •

stroke, permits a broad range of applications.

The MSA-100 is ideal for bulk header lube systems because it •

can handle up to 500 psi inlet pressure.

Single-or double-acting air cylinder provides wide choice of •

controls.

Ability to pump either oil or grease expands the opportunity to •

standardize on the MSA-100 through out the plant or shop.

High pressure relief protection reduces chance of damage to the •

lube system in case of blockage.

Can be piped to standard Trabon reservoirs (Refer to bulletin •

L12000 for reservoirs).

OPERATION

When air is supplied in the single-acting port (SA), the pump

piston (A) is moved forward. The lube inlet is closed by the piston

(B1). The lubricant in the chamber (C) is forced into a channel in

the middle of the piston (B1). An outlet hole (D) from that channel

opens into an undercut (E) on the piston. When the undercut opens

to the lube outlet, the lubricant flows, under pressure, to the lube

system. If a blockage occurs in the lube system, the rupture to

atmosphere indicator (F) ruptures and the pressure is relieved.

When the air has been vented from the single-acting inlet, the

piston return spring (G) returns the piston to its original position,

reopening the lube inlet and allowing new lubricant to enter

chamber (C) for the next cycle.

If the pump is double-acting, air will be supplied in the doubleacting air inlet (DA) as air is vented from the single-acting port to

return the piston to its original position.

SPECIFICATIONS

Material Aluminum

Seals Buna-N and Viton

3

Output per Stroke .400-.800 cu.in (6.566-13.112 cm

Max Pump Stokes per Min

Single-Acting 15

Double-Acting 30

Operating Pressure

Air Inlet 60-140 psi (4-10 bar)

*Max Lube Inlet 500 psi (35 bar)

Max Lube Outlet

3000 psi (207 bar), supplied with 1450 psi

Rupture-To-Atmosphere Indicator

Lubricant Oil or Grease

Air to Lube 25:1

*When connected to pressurized supply, back-flow to supply must be

permitted; alternatively, a small accumulator or 3 ft of 1/2 in ID hose can

be connected to lube inlet of pump.

)

Page 2

12.56

(319)

3.31

(84.1)

2.50

(63.5)

12.83

(326)

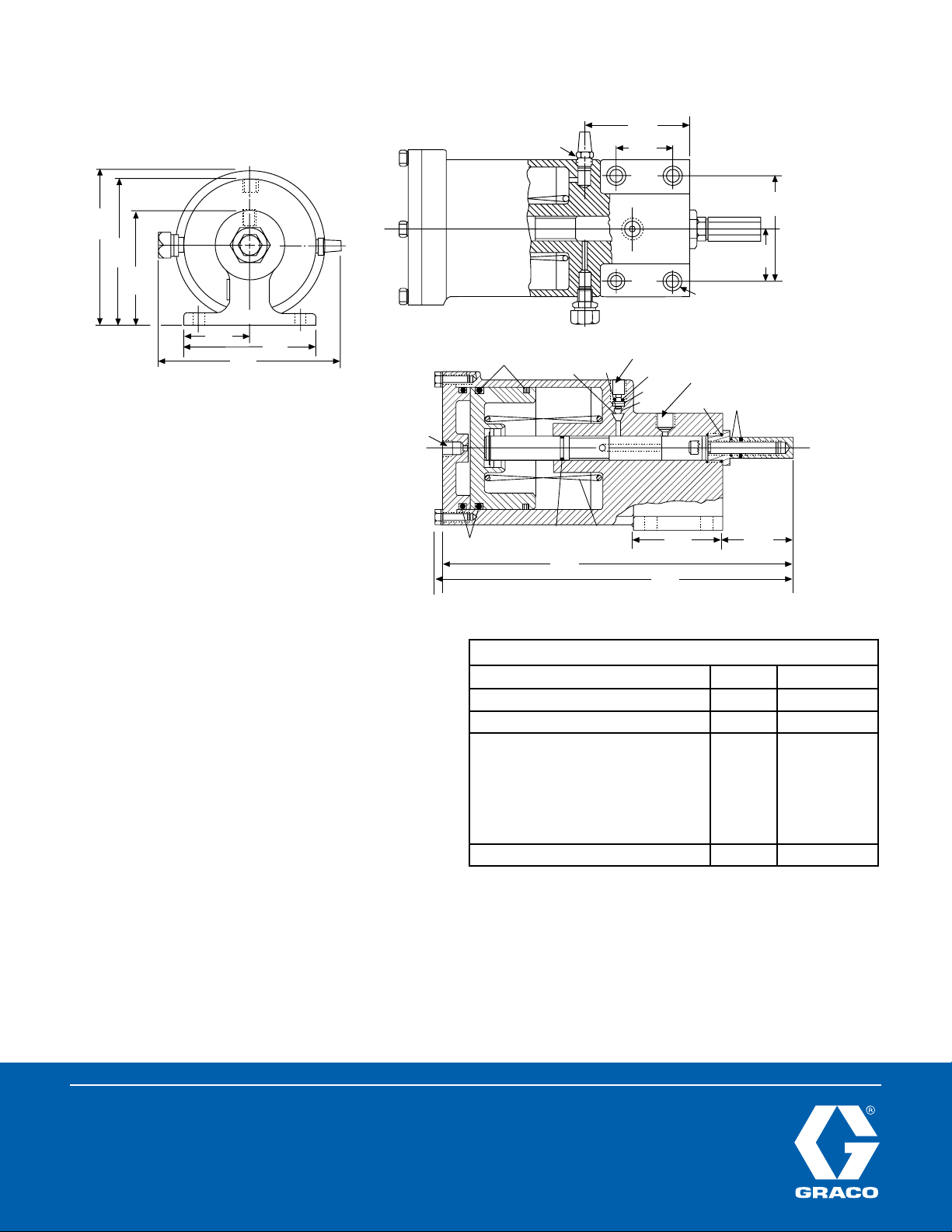

1/4 NPSF

AIR (SA)

LUBE INLET

3/8 NPSF

LUBE OUTLET

1/4 NPSF

5.69

(144)

5.38

(137)

4.19

(106)

2.44

(61.9)

6.94

(176)

4.88

(124)

4 MTG. HOLES

.406 DIA. (10.03)

1.88

(47.6)

3.75

(93.3)

3.75

(95.3)

2.00

(50.8)

1/4 NPSF

AIR (DA)

1

9

2

3

4

6

7

5

8

10

11

DIMENSIONS Inches (mm)

INSTALLATION INSTRUCTIONS

Mount pump, using all four mounting holes.1.

If you intend the MSA-100 to operate as a double-acting pump, 2.

remove the vent plug from the double-acting inlet port and

install the air line to that inlet.

Seal all pipe connections. DO NOT USE PTFE TYPE TAPE.3.

Cycle the pump until all air is removed and lubri cant runs clear 4.

at the outlet.

To adjust pump output, remove adjustment screw cap and turn 5.

the screw clockwise to reduce output, or counter clockwise to

increase output.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

ORDERING INSTRUCTIONS

Description Part No. Old Part No.

MSA-100 Pump 562855 140-000-171

1450 psi Rupture-To-Atmosphere Indicator – 511-839-100

*Repair Parts Kit: four O-Rings (1,5 & 6),

Keeper (2), Check Valve Spring (3), 3/8

in Viton Ball (4), two Gaskets (7), Return

Spring (8), two Spiral Back-Up Rings (9),

Poppet (10), Spring Rest (11), Instructions

for Installation

Air Inlet Restrictor (not shown) 563072 463-410-080

For higher pressure rupture discs, refer to Bulletin L15401 or contact your

Trabon Distributor.

*(#) represent numbers marked out in diagram above.

563913 560-001-560

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L12851 Rev. B 2/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...