Page 1

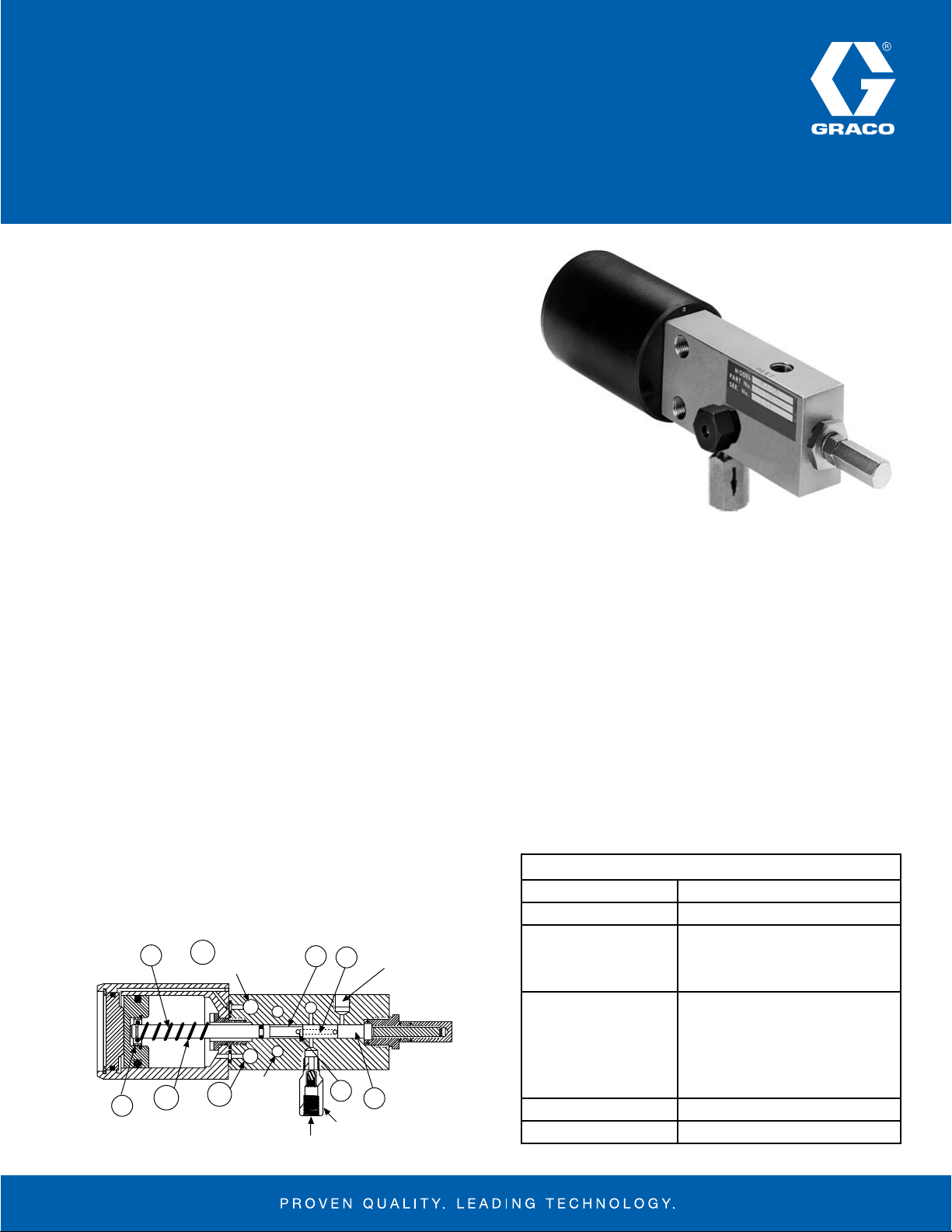

DA

D

C

AB

B1

E

SA

G

A

1/4-18

N.P.S.F.

DOUBLE

ACTING PORT

.34(8.7) DIA.

2 MOUNTING

HOLES

LUBE OUTLET

1/4-18 N.P.S.F.

1/4-18 N.P.S.F.

SINGLE

ACTING PORT

14-18 N.P.S.F.

LUBE INLET

EXTERNAL

CHECK VALV E

MSA-10 Air Operated Pump

DESCRIPTION

The MSA-10 is an air-operated pump with an ad justable volume

output. It is designed to be used in series progressive oil or grease

lubrication systems. Lubricant can be supplied to the MSA-10

pump by either a gravity feed reservoir or a pressurized source

such as a bulk header that exerts up to 500 psi at the pump inlet.

This pressure handling capability is a result of the pump pistons

valving ac tion which prevents lubricant from flowing into the lube

system when the piston is in the priming position. The MSA-10 is

supplied as a single-acting pump. However, it can easily be fieldconverted to double-acting by removing the plastic vent plug from

the double-acting port and installing an air line.

FEATURES

Adjustable lube output, from .040 to .120 cubic inches per •

stroke, permits a broad range of applications.

The MSA-10 is ideal for bulk header lube systems because it •

can handle up to 500 psi inlet pressure.

Single-or double-acting air cylinder provides wide choice of •

controls.

Ability to pump either oil or grease expands the opportunity to •

standardize on the MSA-10 through out the plant or shop.

OPERATION

When air is supplied in the single-acting port (SA), the pump piston

(A) is moved forward. The lube inlet is closed by the piston (A/B). The

lubricant in the chamber (C) is forced into a channel in the middle

of the piston (B1). An outlet hole (D) from that channel opens into an

undercut (E) on the piston. When the undercut (E) opens to the lube

outlet, the lubricant from the chamber (C) flows, under pressure, to

the lube system. If a blockage occurs in the lube system, the rupture

indicator (not shown) opens and the pressure is vented. When the air

has been vented from the single-acting inlet, the piston return spring

(G) returns the piston to its original position. If the pump is doubleacting, air will be supplied in the double-acting inlet (DA) as air is

vented from the single-acting port.

High pressure relief protection reduces chance of damage to •

the lube system in case of blockage.

SPECIFICATIONS

Can be piped to standard Trabon reservoirs. (Refer to bulletin •

L12000 for reservoirs.)

Material Steel

Output per Stroke 0.040-0.120 cu.in. (0.66-1.97 cm

Max Pump Stroke per Min

Single-Acting 15

Double-Acting 60

Operating Pressure

Air Inlet 40-150 psi (275.8-1034.2 kPa)

Max Lube Inlet 500 psi (3447.5 kPa)

Max Lube Outlet

Lubricant Oil or Grease

Air to Lube 25:1

1450 psi (9997.7 kPa), w/Standard 1450

psi Rupture-To-Atmosphere Indicator

3

)

Page 2

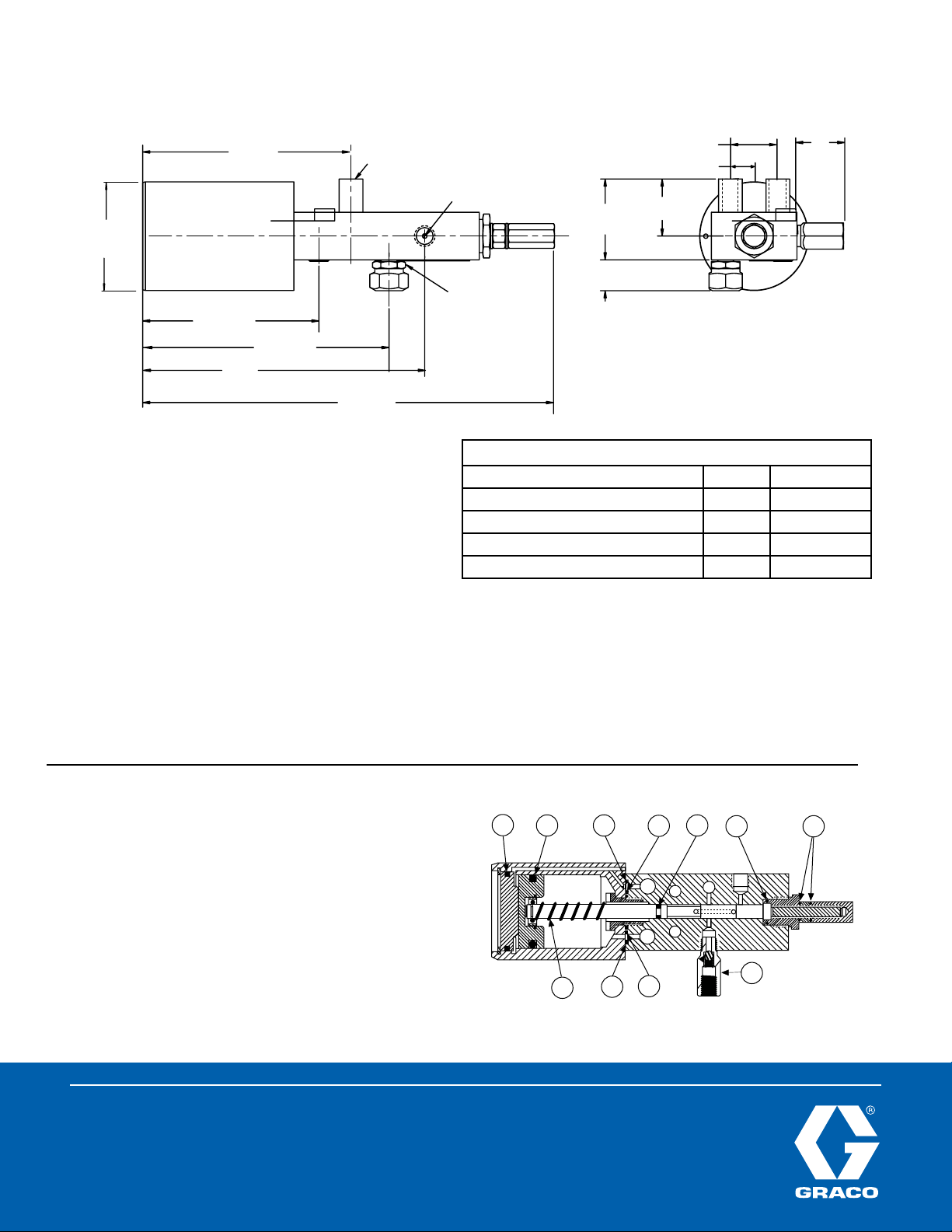

DIMENSIONS

9

3

4

8

7

6

5

4

3

2

1

2.87 Dia.

(73.0)

4.64

(117.7)

6.48

(164.6)

10.75

(273.0)

RUPTURE-TOATMOSPHERE

INDICATOR

1/4 - 8 N.P.S.F.

LUBE INLET

(2) .34 DIA.

MOUNTING

HOLES

2.12

(54.0)

1.50

(38.1)

.81

(20.6)

1.45

(36.8)

7.42

(188.4)

5.50

(139.7)

Dimension to centerline

single- and double-acting ports

.75

(19.0)

1.25

(31.8)

Inches (mm)

INSTALLATION INSTRUCTIONS

Mount pump using both mounting holes.1.

Seal all pipe connections. 2. DO NOT USE PTFE TYPE TAPE.

Cycle the pump until all air is removed and lubricant runs clear 3.

at the outlet.

If you intend the MSA-10 to operate as a double-acting pump, 4.

remove the plastic vent orifice plug from the double-acting inlet

port and install the air line to that inlet.

To adjust pump output, remove adjustment screw cap and turn 5.

the screw clockwise to reduce output, or counterclockwise to

increase output.

SPARE PARTS KIT

A handy spare parts kit is available and includes:

Appropriate O-rings (1, 2, 3, 4, 5, and 6); two gaskets (7): external

check valve (for replacement of both external and internal types) (8);

piston return spring (9); and complete instructions for installations.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L12850 Rev. B 2/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

ORDERING INFORMATION

Description Part No. Old Part No.

MSA-10 Air Operated Pump 562854 140-000-111

1450 psi Rupture-To-Atmosphere Indicator – 511-839-100

Spare Parts Kit 563912 560-001-550

Air Inlet Restrictor Valve 563072 463-410-080

For MAS-10 pumps with higher max psi, refer to Bulletin L15401 or consult

your Trabon distributor or the factory.

Loading...

Loading...