Page 1

Operation, Parts

695 / 795 / 1095 / 1595 / Mark IV HD/ Mark V

HD/ Mark VII HD/ Mark X HD Electric Airless

Sprayers

For professional use only. Not approved for use in explosive atmospheres or

hazardous locations. For portable airless spraying of architectural paints and

coatings.

Models: 695 / 795 / 1095 / 1595 / Mark IV HD/ Mark V HD/ Mark VII HD/ Mark X HD

3300 psi (228 bar, 22.8 MPa) Maximum Working Pressure

See page 4 for additional model information.

Important Safety Instructions

Read all warnings and instructions in this manual and in Related Manuals listed on

page 2 before using the equipment. Be familiar with the controls and the proper usage

of the equipment. Save all instructions.

3A6342F

EN

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Page 2

Before You Spray

Before You Spray

Review Warnings for Important Safety Information

Important! Read carefully and practice good safety habits.

Related Manuals

3A6285 Contractor PC Spray Gun

311254 Flex Plus Spray Gun

309495 Heavy-Duty InLine Spray Gun

308491 Heavy-Duty Texture Spray Gun

3A6584 Displacement Pump

3A6583

ProConnect™ Displacement

Pump

Manuals can also be found at www.graco.com

2 3A6342F

Page 3

Contents

Contents

Before You Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Know Your Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Know Your Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Assemble Your Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

QuikReel™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10/16 Amp Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

15/20 Amp Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Flush Storage Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Strain the Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fill Pump (Prime Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fill Spray Gun and Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Refilling Paint Pail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

WatchDog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

BlueLink™ App . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

695/795 Lo-Boy Standard Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

695/795/Mark IV HD Hi-Boy Standard Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1095/1595/Mark V HD/Mark VII HD Hi-Boy Standard Parts . . . . . . . . . . . . . . . . . . . . 54

Mark X HD Standard Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

695/795/Mark IV HD ProContractor Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1095/1595/Mark V HD/Mark VII HD ProContractor Parts . . . . . . . . . . . . . . . . . . . . . . 60

Mark X HD ProContractor Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1095/1595/Mark V HD /Mark VII HD IronMan Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Mark X HD IronMan Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

ProContractor QuikReel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Spray Gun and Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Radio Frequency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

California Proposition 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3A6342F 3

Page 4

Models

Models

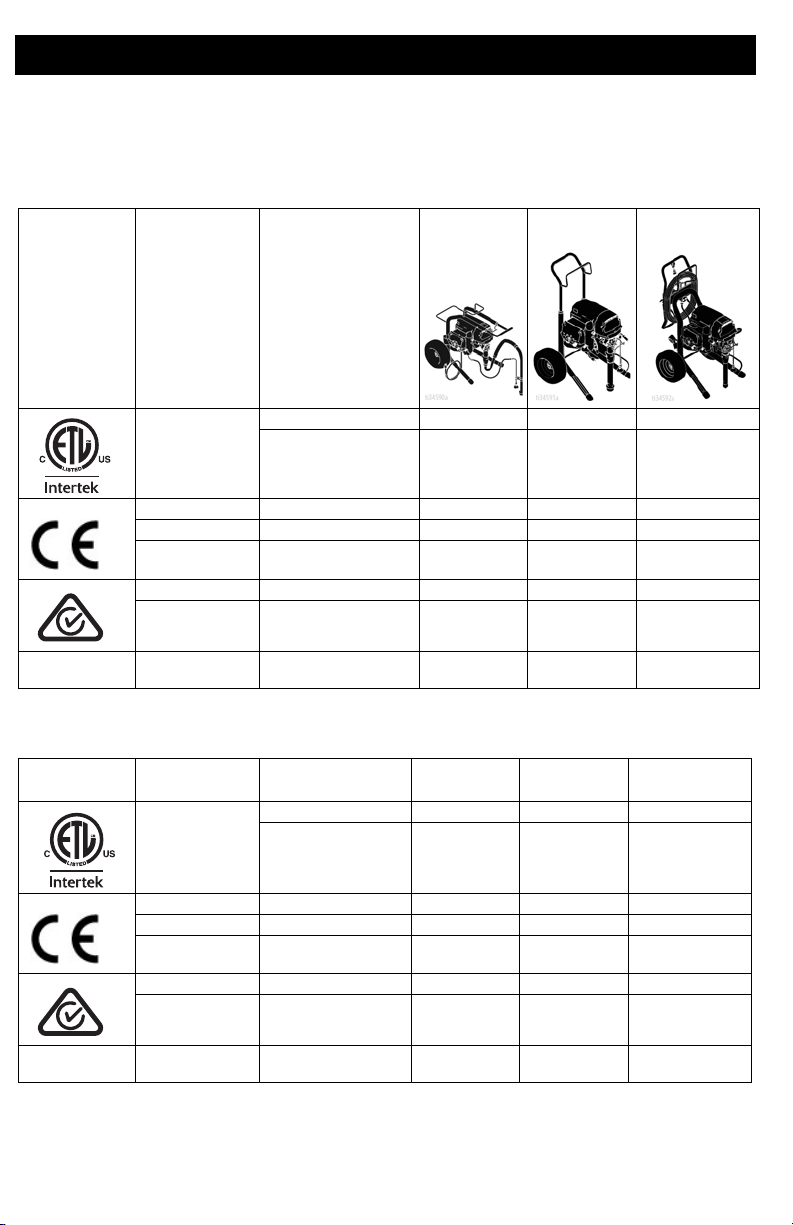

695 Models

Voltage Model

Ultra Max II 695

120

NEMA 5-15

Ultimate MX II 695

Standard

Hi-Boy

ProContractor

Standard

Lo-Boy

17E572 17E574 17E577

826222 826223 826224

230 CEE 7/7 Ultra Max II 695

230 Europe Multi Ultra Max II 695

230 ANZ/KR Ultra Max II 695

Japan/Taiwan

795 Models

230 CEE 7/7 Ultra Max II 795 17E639 17E642

230 Europe Multi Ultra Max II 795

230 ANZ/KR Ultra Max II 795

Japan/Taiwan

110 UK Ultra Max II 695

230 AP Ultra Max II 695

100

Ultra Max II 695

Voltage Model

Ultra Max II 795

120

NEMA 5-15

110 UK Ultra Max II 795

230 AP Ultra Max II 795

100

Ultimate MX II 795

Ultra Max II 795

17E632 17E635

17E633 17E636

17E634 17E637

17E610 17E613 17E614

26C981

26C982 26C983

Standard

Lo-Boy

17E616 17E617 17E619

Standard

Hi-Boy

17E579 17E582

826225 826226

17E640 17E643

17E641 17E644

26C985 26C986

ProContractor

26C984

4 3A6342F

Page 5

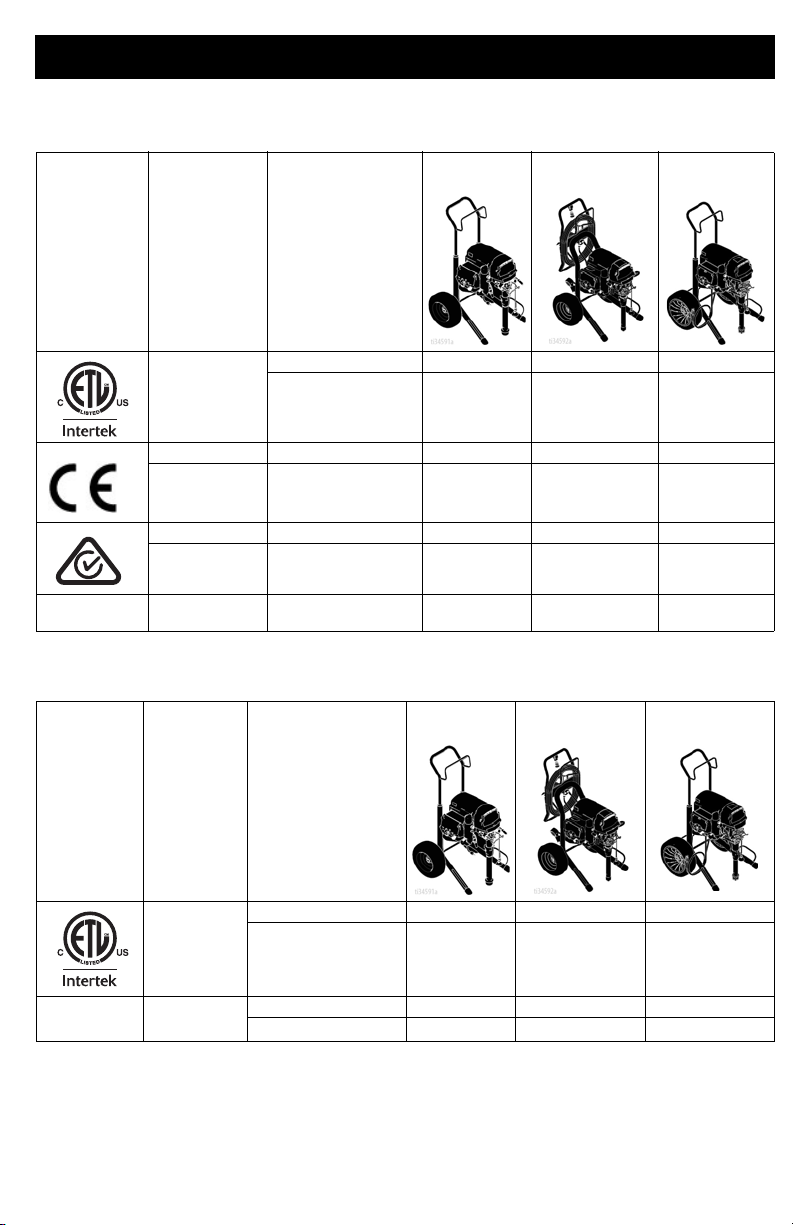

1095 Models

Voltage Model

NEMA 5-15

120

Ultra Max II 1095

Ultimate MX II 1095

Models

Standard

Hi-Boy

17E583 17E585 17E586

826227 826228 826229

ProContractor

IronMan

230 CEE 7/7 Ultra Max II 1095

230 Europe Multi Ultra Max II 1095

230 ANZ/KR Ultra Max II 1095

230 AP Ultra Max II 1095

Japan/Taiwan

1595 Models

Voltage Model

120

NEMA 5-20

120

NEMA 5-15

100

Ultra Max II 1095

Ultimate MX II 1595

Ultra Max II 1595

Ultra Max II 1595

Ultimate MX II 1595

17E646 17E647 17E650

17E648

17E620 17E621 17E623

26C987

26C988 26C989

Standard

Hi-Boy

17E589 17E596 17E594

826230 826232 826234

ProContractor

826233

17E593

IronMan

3A6342F 5

Page 6

Models

Mark HD Models

Voltage Model

120

NEMA 5-15

120

NEMA 5-20

120

NEMA 5-15

230

NEMA L6-30

230 CEE 7/7

230 Europe

Multi

110 UK Mark V HD

230 ANZ/KR

230 AP

100

Japan/Taiwan

Standard

Hi-Boy

Mark IV HD

Mark V HD

Mark V HD

Mark X HD

Mark IV HD

Mark V HD

Mark VII HD

Mark X HD

Mark IV HD

Mark V HD

Mark VII HD

Mark XHD

Mark V HD

Mark VII HD

Mark X HD

Mark IV HD 17E624

Mark V HD

Mark VII HD

Mark X HD

Mark V HD

17E603 17E604

17E605 17E606 17E607

17E608 17E609

17E651 17E653

17E655 17E660 17E664

17E665 17E667 17H895

17E669 17E671 17H897

17E652 17E654

17E666 17E668 17H896

17E670 17E672 17H898

17E659 17E662

17E657 26C990

26C992

17E673 26C995

ProContractor

17E628

17E661

17E663 17E629

26C993

17E674

26C991

IronMan

6 3A6342F

Page 7

Warnings

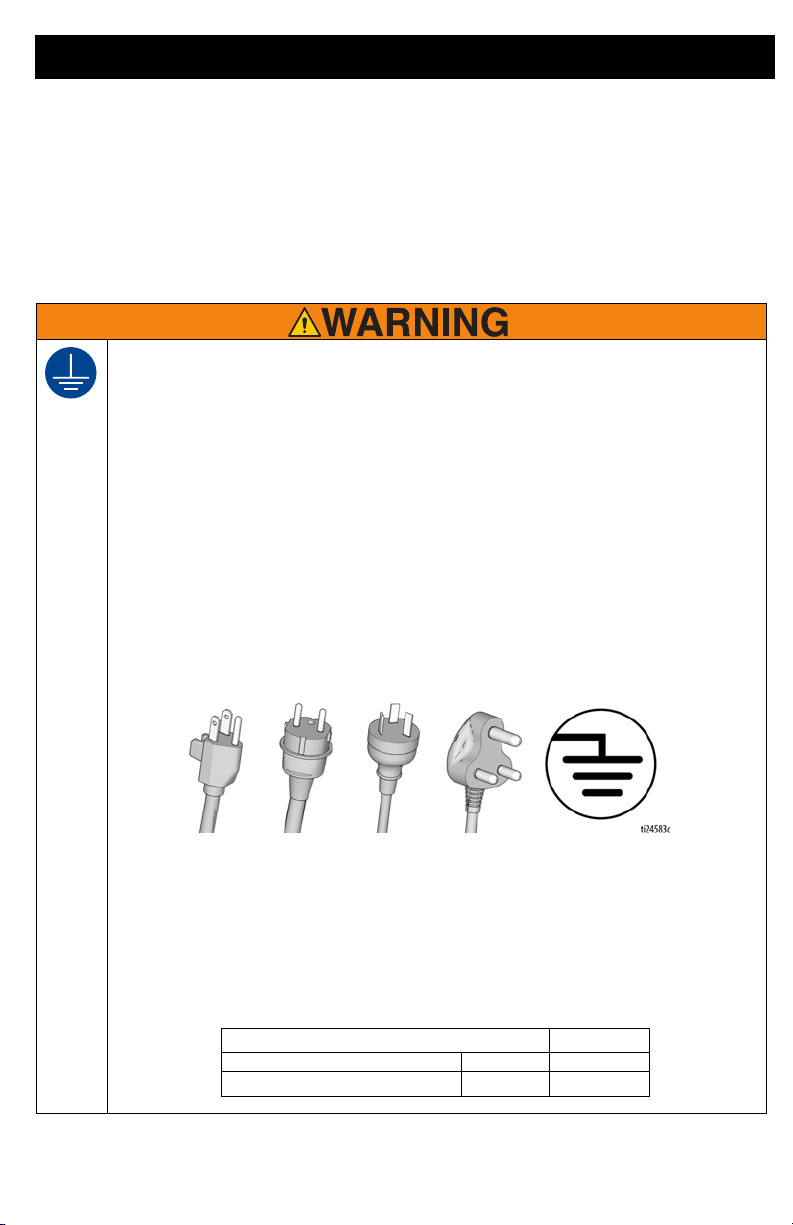

120V US 230V

230V ANZ 230V India

Conductor Size Length

AWG (American Wire Gauge) Metric Maximum

12

2.5 mm

2

50 ft. (15 m)

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual

where applicable.

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces

the risk of electric shock by providing an escape wire for the electric current. This product is

equipped with a cord having a grounding wire with an appropriate grounding plug. The plug

must be plugged into an outlet that is properly installed and grounded in accordance with all

local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding

wire to either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes

is the grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not

completely understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed

by a qualified electrician.

• This product is for use on a nominal 120 V or 230 V circuit and has a grounding plug similar

to the plugs illustrated in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use a 3-to-2 adapter with this product.

Extension Cords:

•

Use only a 3-wire extension cord that has a grounding plug and a grounding receptacle

that accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary use 12

AWG (2.5mm

2

) minimum to carry the current that the product draws.

• An undersized cord results in a drop in line voltage and loss of power and overheating.

3A6342F 7

Page 8

Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To

help prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition

such as cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static

electricity creates a risk of fire or explosion in the presence of paint or solvent fumes. All

parts of the spray system, including the pump, Hose assembly, Spray Gun, and objects

in and around the spray area shall be properly grounded to protect against static discharge

and sparks. Use Graco conductive or grounded high-pressure airless paint sprayer

hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

Do not use pail liners unless they are anti-static or conductive.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2

adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Do not spray flammable or combustible liquids in a confined area.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

• Sprayer generates sparks. Keep pump assembly in a well ventilated area a least 20 feet

(6.1 m) from the spray area when spraying, flushing, cleaning, or servicing. Do not spray

pump assembly.

• Do not smoke in the spray area or spray where sparks or flame is present.

• Do not operate light switches, engines, or similar spark producing products in the spray

area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable

materials.

• Know the contents of the paints and solvents being sprayed. Read all Safety Data Sheets

(SDSs) and container labels provided with the paints and solvents. Follow the paint and

solvents manufacturer’s safety instructions.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

• Wait five minutes after disconnecting power cord before servicing.

8 3A6342F

Page 9

Warnings

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In

the event that injection occurs, get immediate surgical treatment.

• Do not aim the Spray Gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop

leaks with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip

clogs while spraying, follow the Pressure Relief Procedure for turning off the unit and

relieving the pressure before removing the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment

energized or under pressure while unattended. Follow the Pressure Relief Procedure

when the equipment is unattended or not in use, and before servicing, cleaning, or

removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3000 psi (207 bar, 20.7 MPa). Use Graco

replacement parts or accessories that are rated a minimum of 3000 psi (207 bar, 20.7

MPa).

• Always engage the Trigger Lock when not spraying. Verify the Trigger Lock is functioning

properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the

controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at

all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the Hose.

• Do not expose the Hose to temperatures or to pressures in excess of those specified by

Graco.

• Do not use the Hose as a strength member to pull or lift the equipment.

• Do not spray with a Hose shorter than 25 feet.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in w hich you are using

it.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your

material supplier for compatibility.

3A6342F 9

Page 10

Warnings

MOVING PARTS HAZARD

Moving parts can pinch, cut, or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

10 3A6342F

Page 11

Know Your Sprayer

Know Your Sprayer

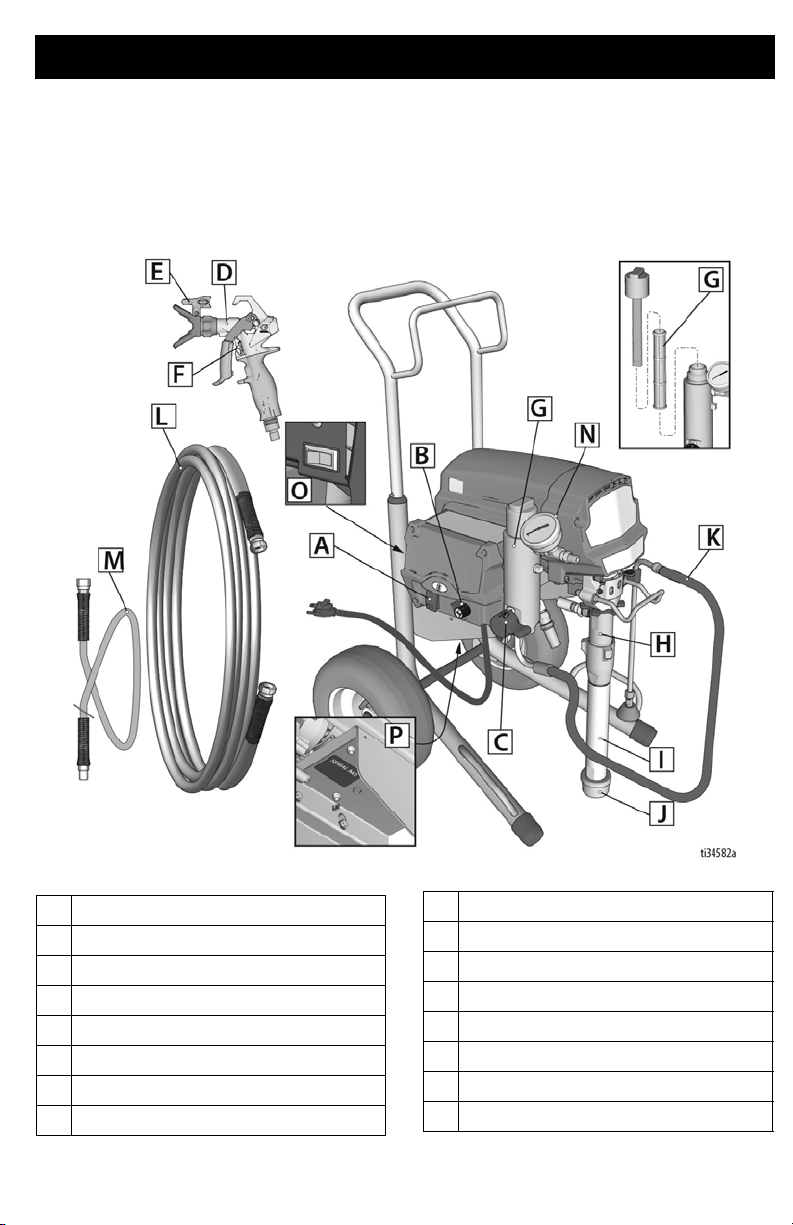

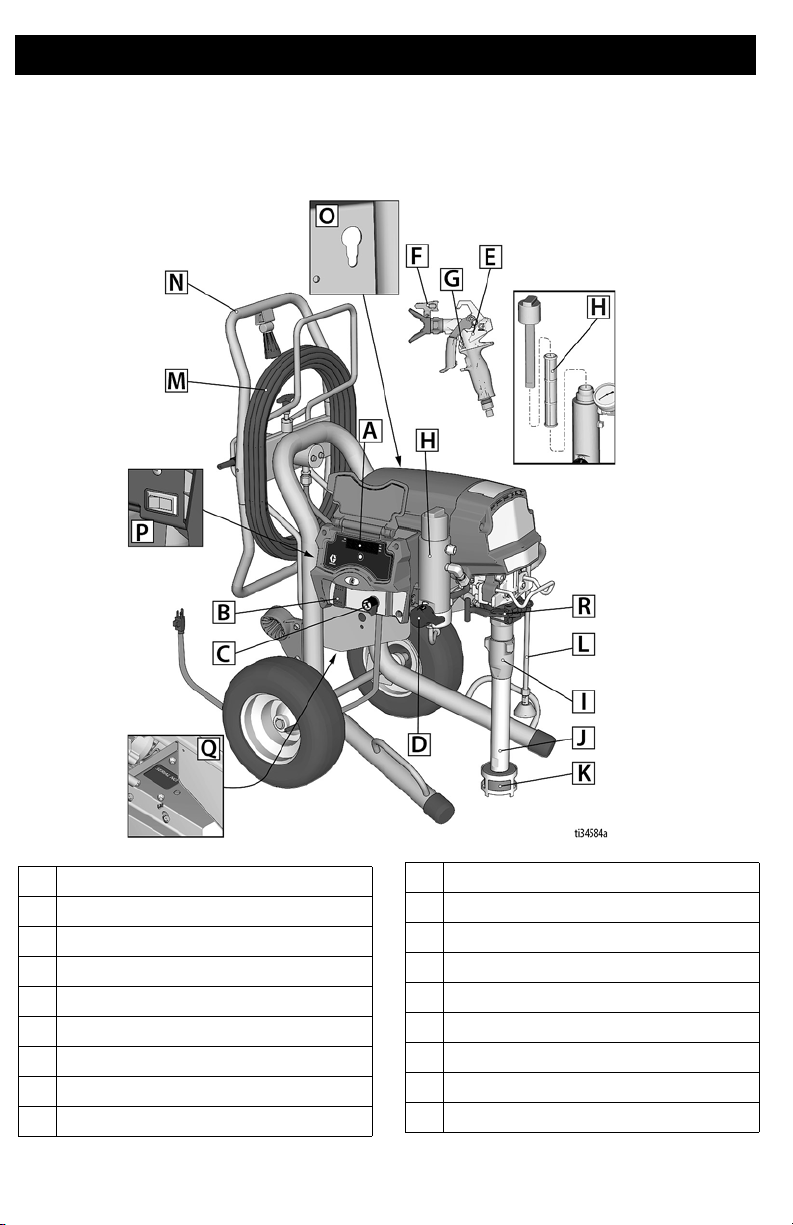

695 / 795 / 1095 / 1595 / Mark IV HD/ Mark V HD/ Mark VII HD/ Mark X HD Standard Models:

AON/OFF Switch

B Pressure Control Knob

C Prime / Spray Valve

D Spray Gun

E Spray Tip

F Trigger Lock

GFilter

HPump

3A6342F 11

I Suction Tube

J Inlet Strainer

KDrain Tube

LHose

M Whip Hose (not included on all models)

N Pressure Gauge (not included on all units)

O Amp Switch (not equipped on all units)

P Unit/Serial Tag

Page 12

Know Your Sprayer

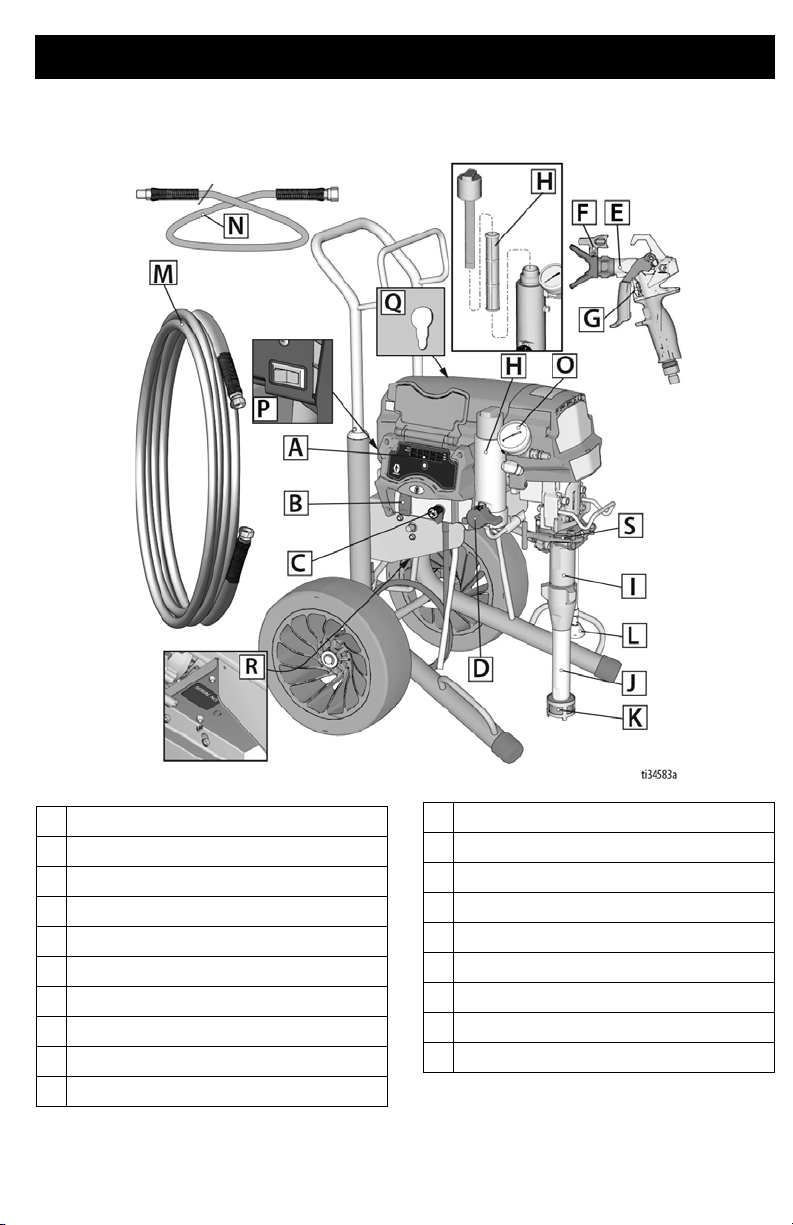

695 / 795 / 1095 / 1595 Mark IV HD/ Mark V HD/ Mark VII HD/ Mark X HD ProContractor Models:

A LED Display (not included on all units)

BON/OFF Switch

C Pressure Control Knob

D Prime / Spray Valve

ESpray Gun

FSpray Tip

G Trigger Lock

HFilter

IPump

12 3A6342F

J Suction Tube

K Inlet Strainer

L Drain Tube

MHose

NQuikReel™

O ProConnect Pump Rod Pull Feature

P Amp Switch (not equipped on all units)

Q Unit/Serial Tag

R ProConnect II

Page 13

Know Your Sprayer

1095 / 1595 / Mark V HD IronMan Models:

A LED Display (not included on all units)

BON/OFF Switch

C Pressure Control Knob

D Prime / Spray Valve

ESpray Gun

FSpray Tip

G Trigger Lock

HFilter

IPump

J Suction Tube

K Inlet Strainer

L Drain Tube

MHose

N Whip Hose (not included on all models)

O Pressure Gauge (not included on all units)

P Amp Switch (not equipped on all units)

Q ProConnect Pump Rod Pull Feature

R Unit/Serial Tag

S ProConnect II

3A6342F 13

Page 14

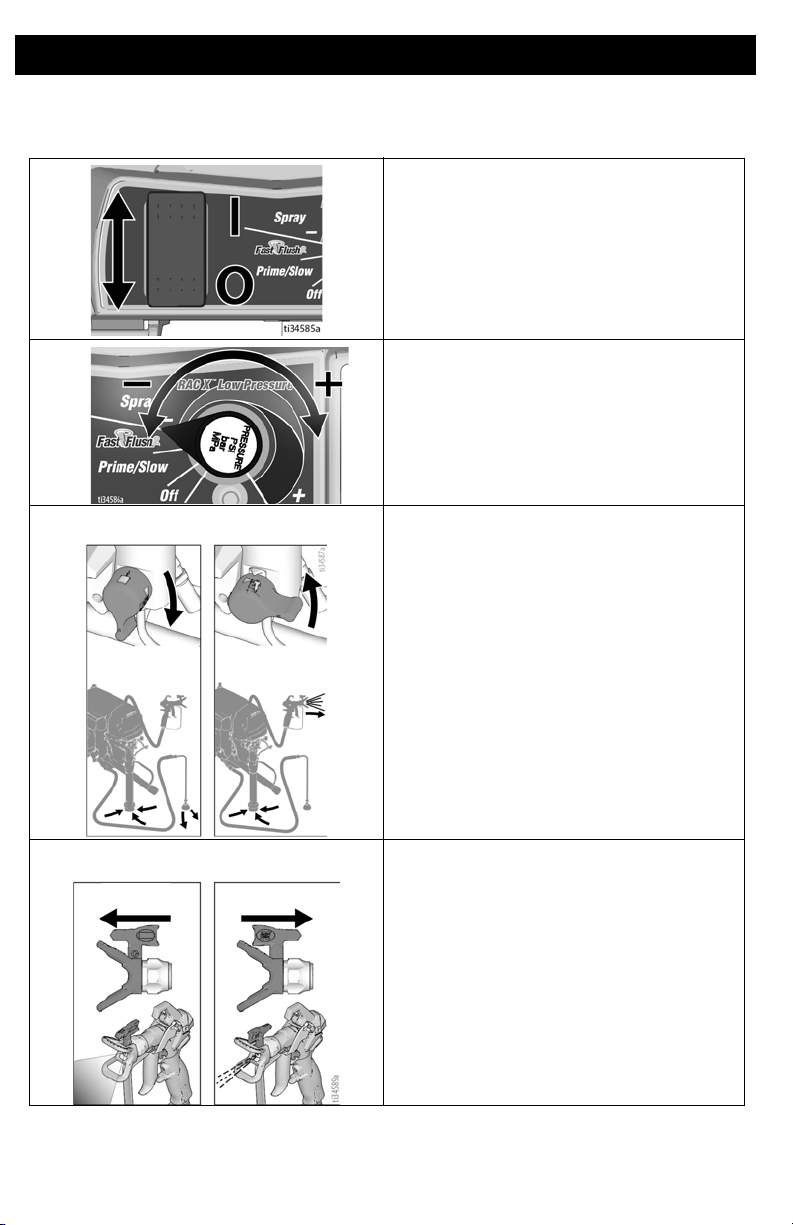

Know Your Controls

PRIME/SPRAY

Prime

Spray

SPRAY TIP

Spray

Unclog

Know Your Controls

The ON/OFF power switch controls the

power to your sprayer.

The Pressure Control Knob increases or

decreases the pressure. It also has a setting

for Prime/Slow and FastFlush™.

The Prime/Spray Valve directs the fluid to

either the Drain Tube or the Hose and Spray

Gun. It is used to prime the sprayer, which

means to evacuate the air out of the pump,

Hose, and Spray Gun.

Your Spray Gun will not spray if there is air in

the system. It is necessary to prime the

pump, Hose, and Spray Gun any time air

enters the Suction Tube.

14 3A6342F

The Spray Tip is the key to airless spray

technology. High pressure paint pumped

through the very small hole in the Spray Tip

comes out as a spray.

The Spray Tip has the ability to be reversed

and quickly clear clogs.

Page 15

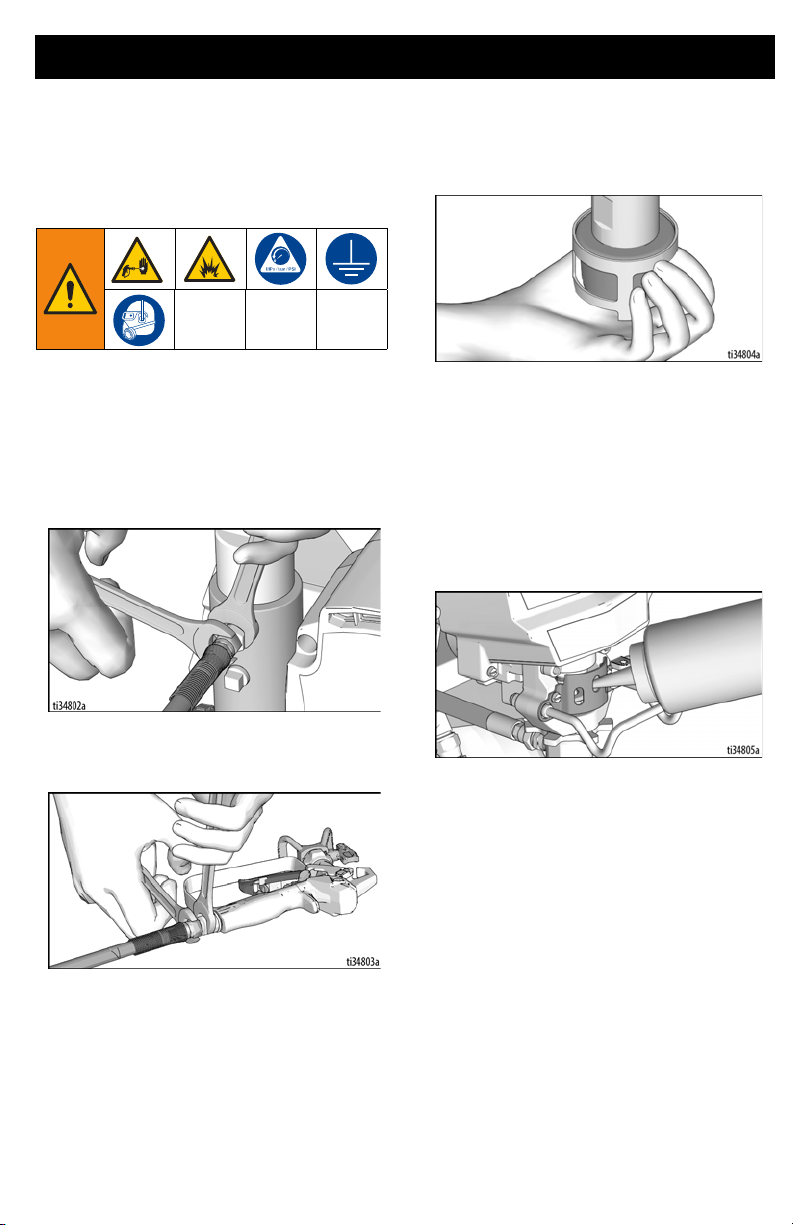

Setup

Setup

Assemble Your Sprayer

When unpacking sprayer for the first time or

after long term storage perform setup

procedure.

1. All sprayers except ProContractor:

Connect Graco airless Hose to sprayer.

If whip Hose is included, attach to end of

airless Hose. Use wrenches to tighten

securely.

3. When unpacking sprayer for the first

time remove packaging materials from

inlet strainer. After long term storage

check inlet strainer for clogs and debris.

4. Fill throat packing nut with Graco TSL™

to prevent premature packing wear. Do

this each time you spray.

a. Place the TSL bottle nozzle into the

top center opening in the grill at the

front of the sprayer.

b. Squeeze bottle to dispense enough

TSL to fill the space between the

pump rod and packing nut seal.

2. Connect Spray Gun to other end of

Hose. Use wrenches to tighten

securely.

3A6342F 15

5. Ensure Spray Tip is properly inserted

into the Spray Tip Guard, and the Spray

Tip Guard assembly is tightened

securely to the Spray Gun. Refer to

separate Spray Gun manual.

6. Perform the Pressure Relief Proce-

dure, page 18.

Page 16

Setup

QuikReel™

(ProContractor models only)

Moving parts can pinch, cut or amputate

fingers and other body parts. To avoid

injury from moving parts, be sure to keep

your head clear of QuikReel while winding

up Hose.

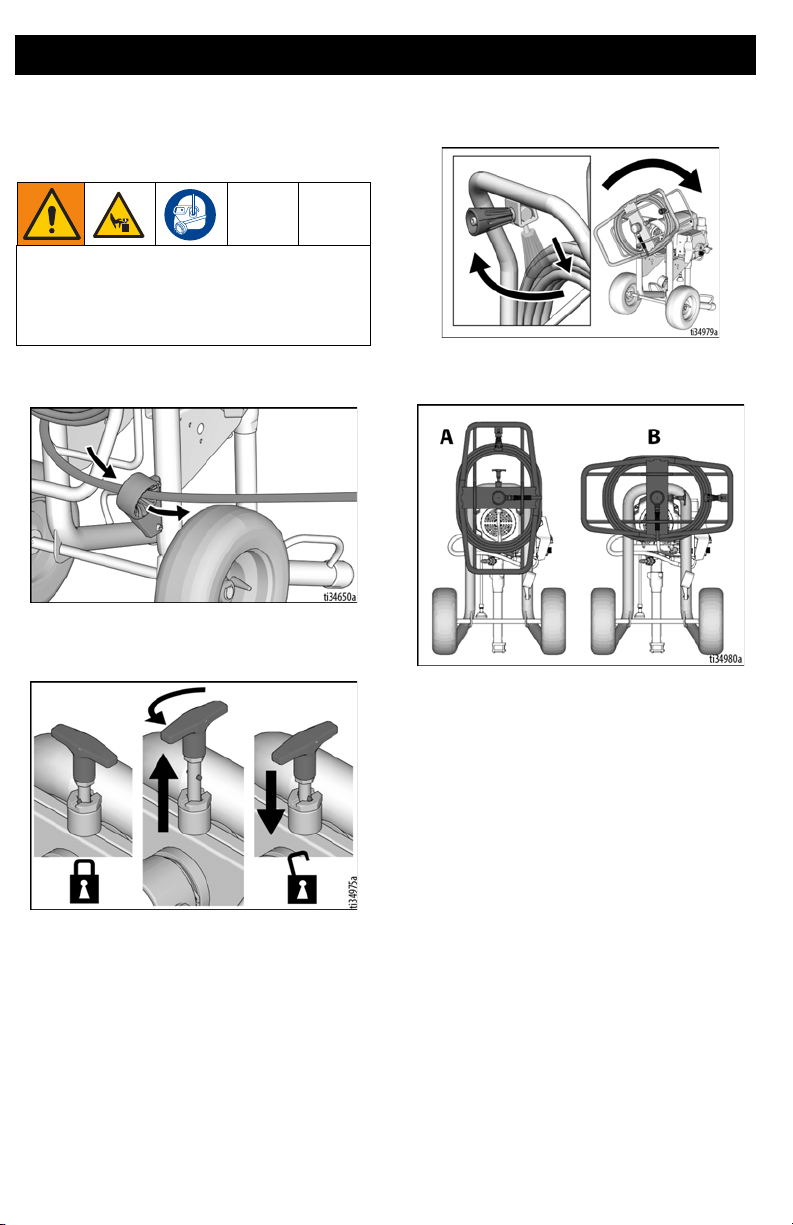

1. Make sure Hose is routed through hose

guide.

2. Lift and turn pivot lock 90° to unlock

Hose Reel. Pull on Hose to remove it

from Hose Reel.

3. Pull reel handle down and out. Turn

clockwise to reel in Hose.

NOTE: QuikReel can be locked into two

positions: Usage (A) and Storage (B).

16 3A6342F

Page 17

Setup

ti24584a

Grounding

The equipment must be grounded to

reduce the risk of static sparking and

electric shock. An electric or static spark

can cause fumes to ignite or explode. An

improper ground can cause electric shock.

A good ground provides an escape wire for

the electric current.

This sprayer is equipped with a power cord

that has a ground wire and an appropriate

grounding plug.

The plug must be plugged into an outlet that

is properly installed and grounded in

accordance with all local codes and

ordinances.

Do not modify the plug provided; if it does not

fit the outlet, have the proper outlet installed

by a qualified electrician.

Power Requirements

• 100-120V units require 100-120 VAC,

50/60 Hz, 15A, 1 phase.

• 230V units require 230 VAC, 50/60 HZ,

10A-16A, 1 phase.

Extension Cords

Use an extension cord with an undamaged

ground contact. If an extension cord is

necessary, use a 3-wire, 12 AWG (2.5 mm2)

minimum.

NOTE: Smaller gauge or longer extension

cords may reduce sprayer performance.

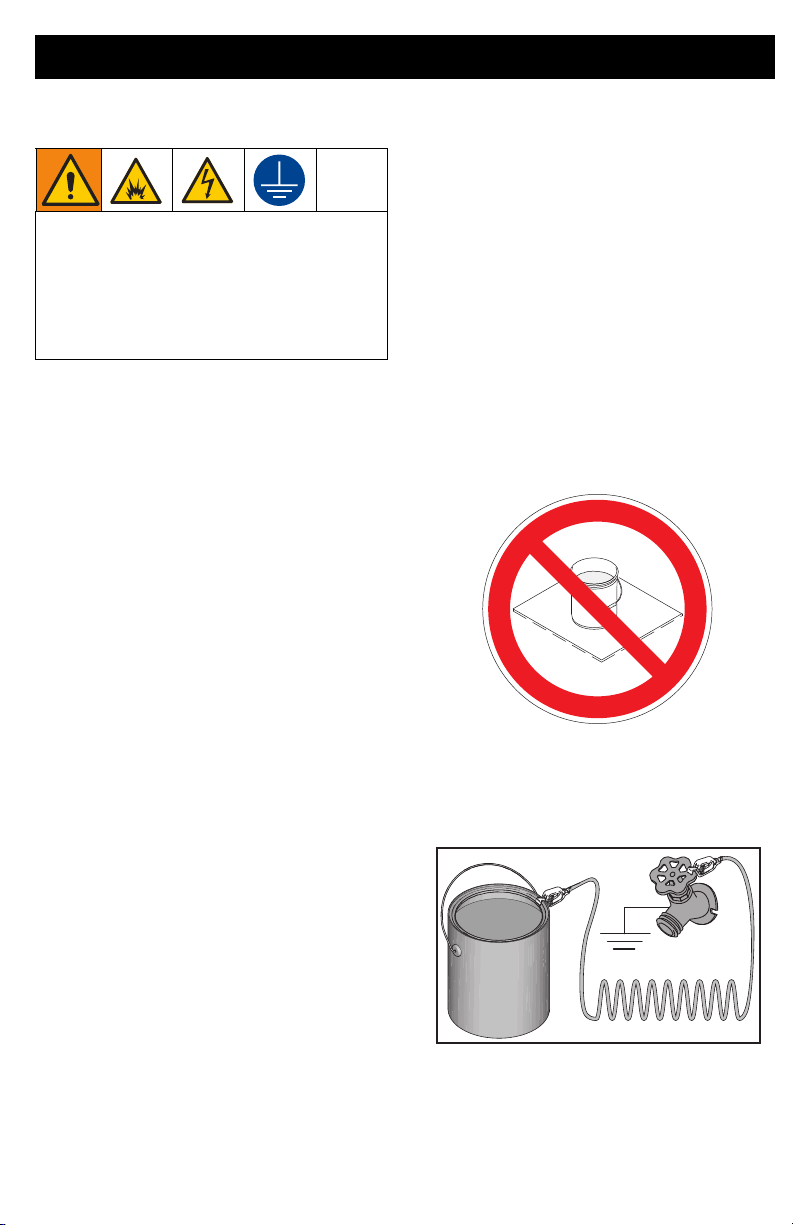

Pails

Solvent and oil-based fluids: follow local

code. Use only conductive metal pails,

placed on a grounded surface such as

concrete.

Do not place pail on a non-conductive surface

such as paper or cardboard which interrupts

grounding continuity.

Always ground a metal pail: connect a

ground wire to the pail. Clamp one end to the

pail and the other end to a true earth ground

such as a water pipe.

3A6342F 17

Page 18

Start Up

Start Up

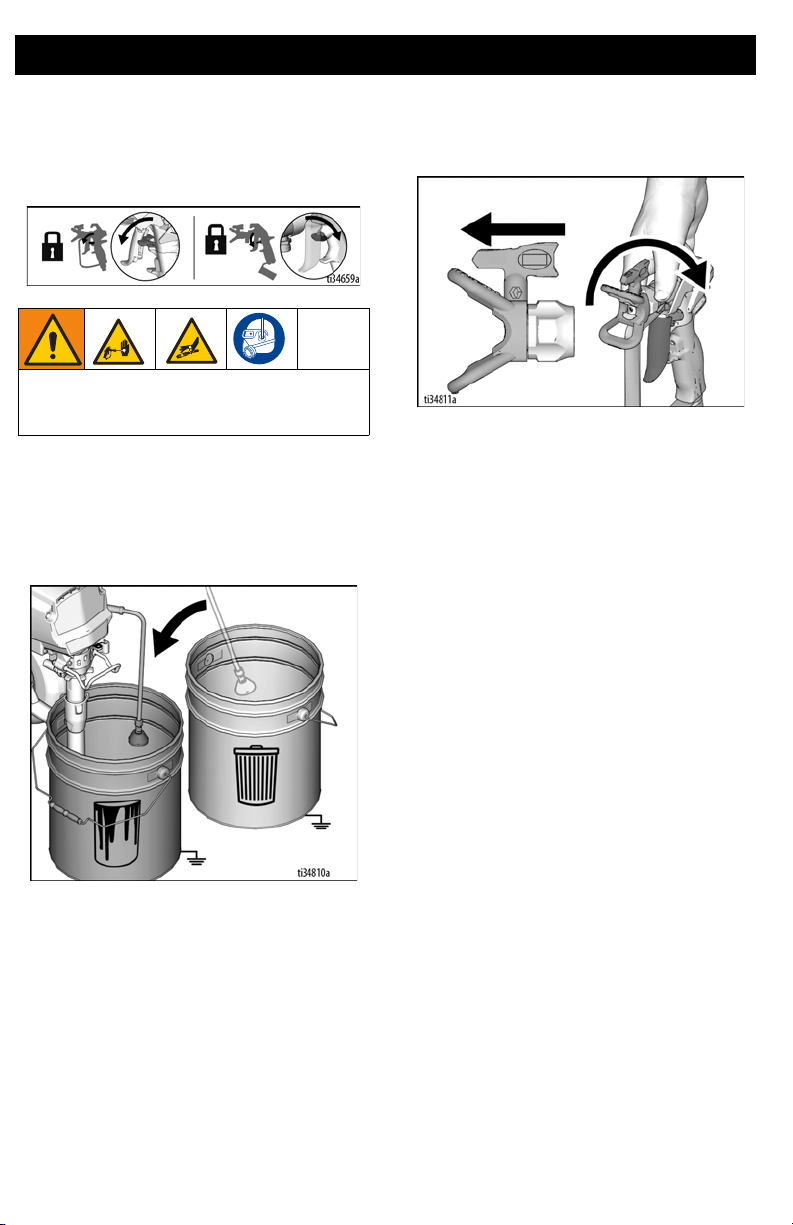

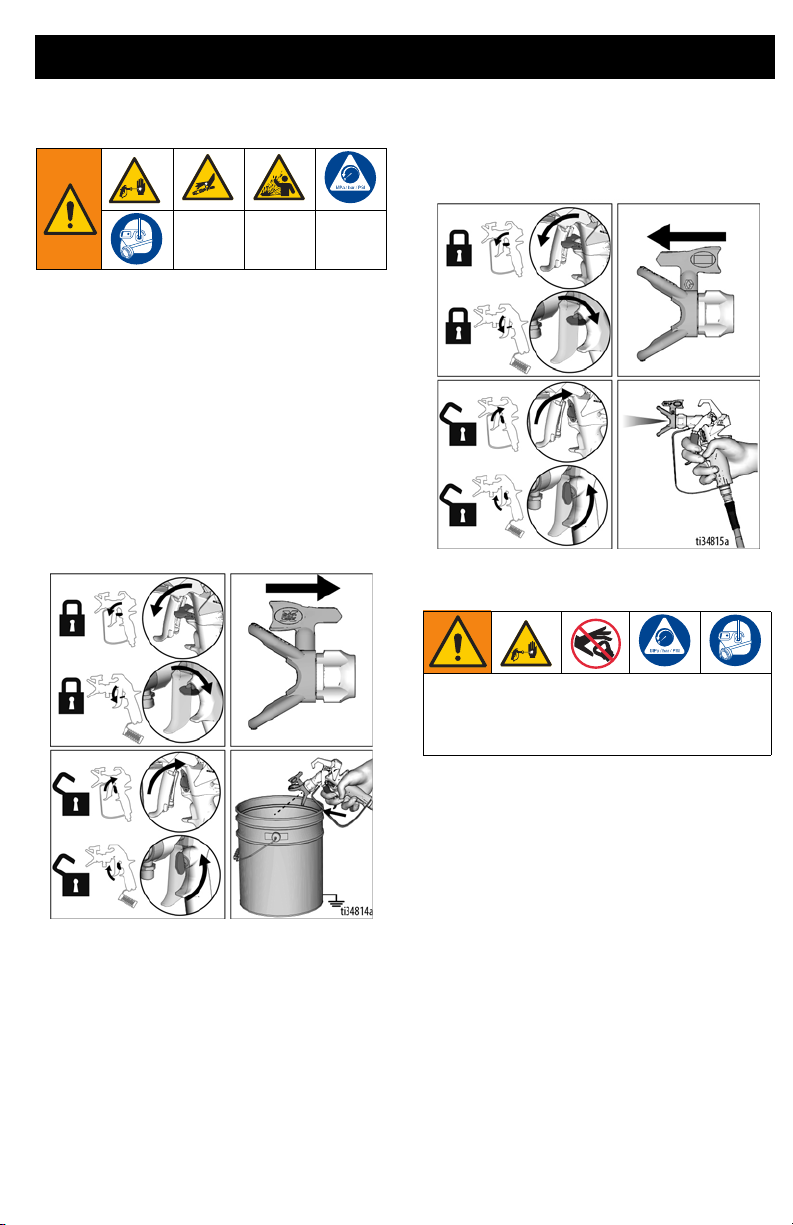

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection or splashed

fluid, follow the Pressure Relief

Procedure whenever sprayer is stopped

and before sprayer is cleaned or checked,

and before equipment is serviced.

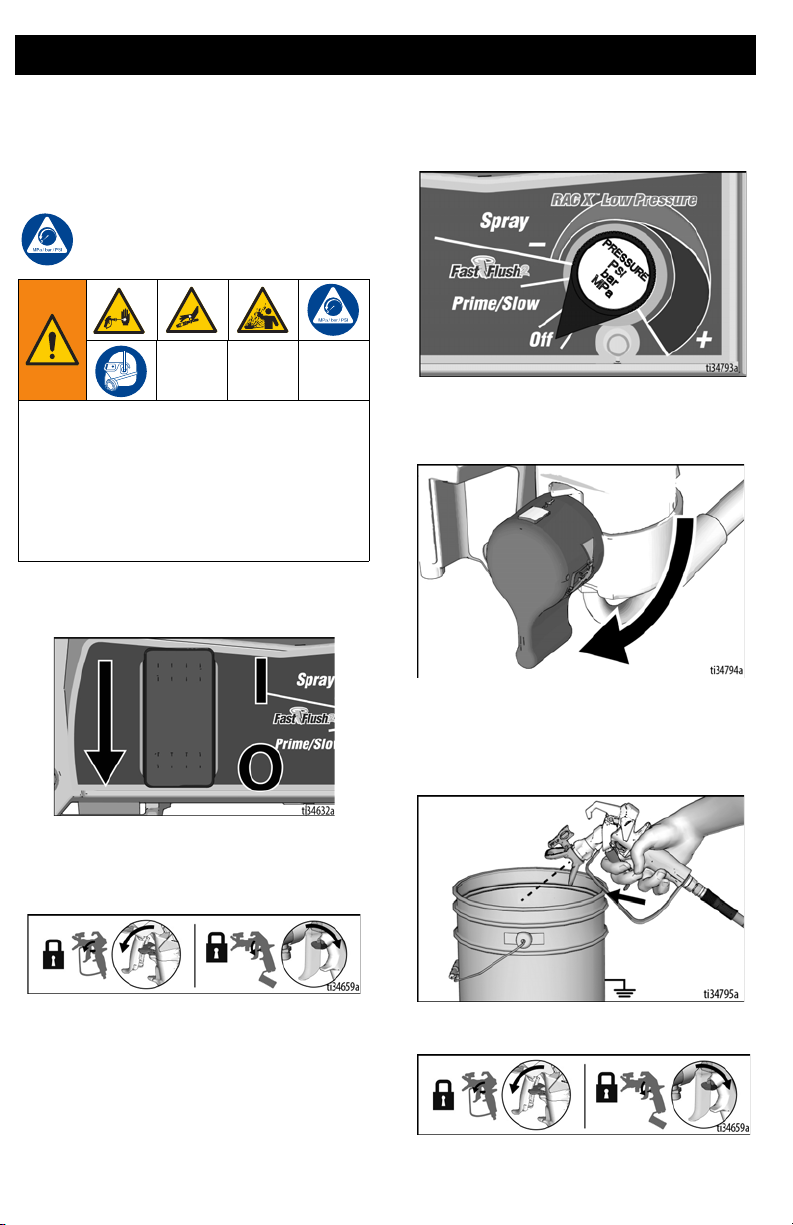

1. Turn ON/OFF switch to the OFF

position.

2. Engage the Trigger Lock. Always

engage the Trigger Lock when sprayer

is stopped to prevent the Spray Gun

from being triggered accidentally.

4. Put Drain Tube into a waste pail and

turn Prime/Spray Valve down to PRIME

position to relieve pressure.

5. Hold the Spray Gun firmly to a

grounded pail. Point Spray Gun into

pail. Disengage the Trigger Lock and

trigger the Spray Gun to relieve

pressure.

3. Turn Pressure Control Knob to OFF (all

the way counterclockwise).

18 3A6342F

6. Engage the Trigger Lock.

Page 19

Start Up

7. If you suspect the spray tip or Hose is

clogged or that pressure has not been

fully relieved:

a. VERY SLOWLY loosen the tip

guard retaining nut or the Hose end

coupling to relieve pressure

gradually.

b. Loosen the nut or coupling

completely.

c. Clear Hose or tip obstruction.

NOTE: Leave Prime/Spray Valve in the

PRIME position until you are ready to spray.

10/16 Amp Switch

(230V Mark VII and Mark X units)

15/20 Amp Switch

(120V 1595 and Mark V units)

Use 20A setting if 20A circuit is available for

maximum sprayer performance. Otherwise,

use 15A setting.

Flush Storage Fluid

It is important that you flush storage fluid

from the sprayer before using it.

1. Make certain ON/OFF switch is OFF.

2. Separate Drain Tube (smaller) from

Suction Tube (larger). Place Drain

Tube in a waste pail.

3. Submerge Suction Tube into grounded

pail filled with appropriate flushing fluid.

Use 16A setting if 16A circuit is available for

maximum sprayer performance. Otherwise,

use 10A setting.

3A6342F 19

Page 20

Start Up

4. Make certain Prime/Spray Valve is

down in the PRIME position.

5. Make certain the Pressure Control

Knob is set to OFF (all the way

counterclockwise).

6. Plug power cord into a properly

grounded electrical outlet.

7. Turn ON/OFF switch to ON position.

8. Turn Pressure Control Knob to

Prime/Slow in order to start the motor.

Flushing fluid will flow up the Suction

Tube and out the Drain Tube into the

waste pail.

10. Turn the ON/OFF switch to OFF

position.

Strain the Paint

Disposable paint strainer bags are used to

remove coarse particles and debris from

new or previously opened paint or stain, and

are available where paint is sold. To avoid

priming problems and Spray Tip clogs it is

recommended to strain all paints and stains

before spraying. Stretch a disposable paint

strainer bag over a clean pail and pour the

paint through the strainer.

ti26894a

High-pressure spray is able to inject toxins

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

9. When you see flushing fluid exiting the

Drain Tube, turn Pressure Control Knob

to FastFlush setting and allow unit to

flush for 30-60 seconds.

20 3A6342F

Page 21

Start Up

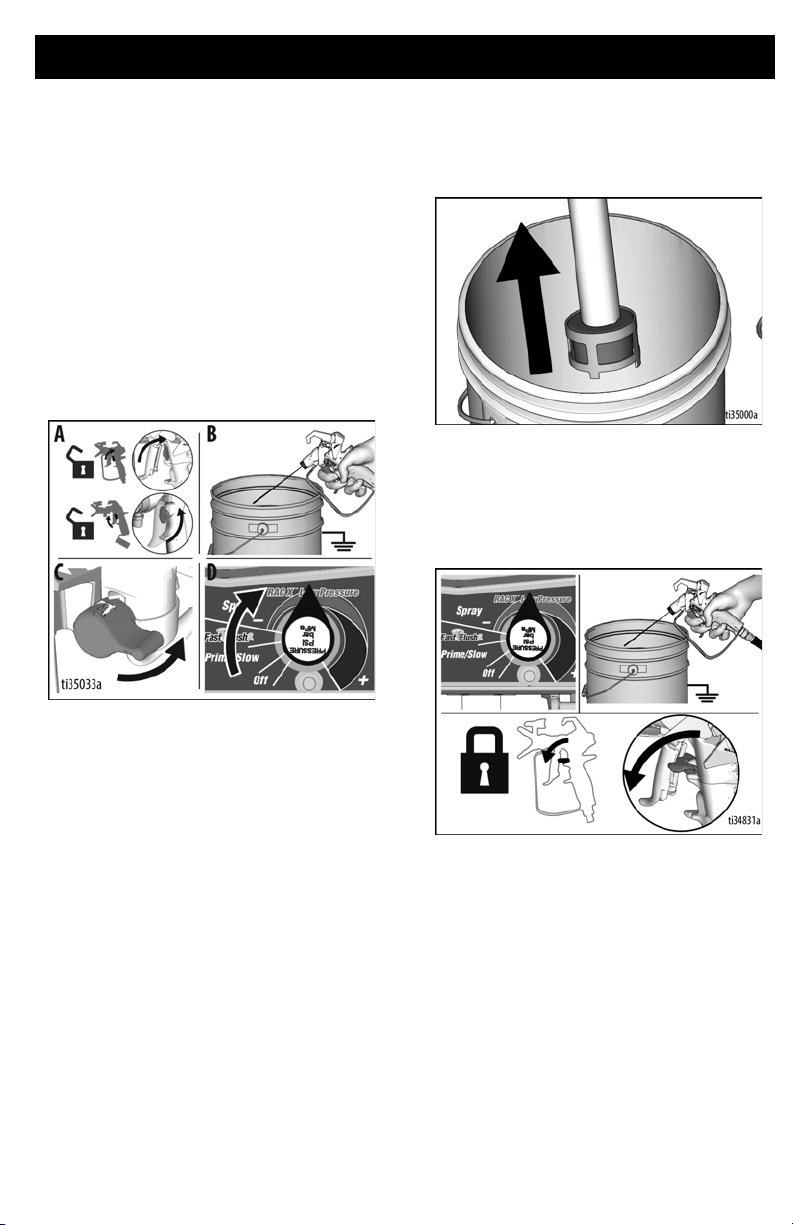

Fill Pump (Prime Pump)

The Prime/Spray Valve directs the fluid to

either the Drain Tube or the Hose and Spray

Gun. It is used to prime the sprayer, which

means to evacuate the air out of the pump,

Hose, and Spray Gun.

Your Spray Gun will not spray if there is air in

the system. It is necessary to prime the pump,

Hose, and Spray Gun any time air enters the

Suction Tube.

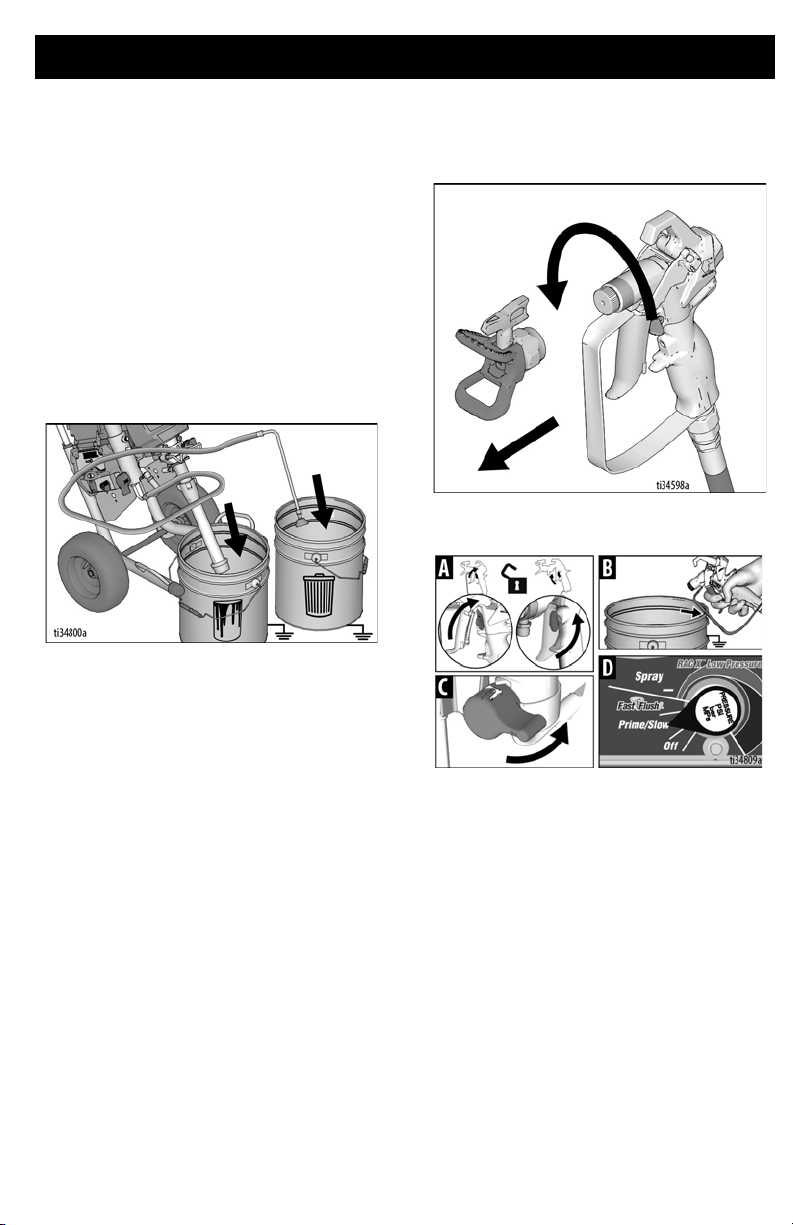

1. Move Suction Tube to paint pail and

submerge Suction Tube in paint. Place

Drain Tube in waste pail.

2. Turn Pressure Control Knob to

Prime/Slow.

3. Turn ON/OFF switch to ON position to

start motor.

4. Wait to see paint coming out of Drain

Tube.

5. Turn Pressure Control Knob to OFF (all

the way counterclockwise) to

disengage motor.

Fill Spray Gun and Hose

1. Remove Spray Tip Guard.

2. Hold Spray Gun against waste pail.

Point Spray Gun into waste pail.

a. Disengage Trigger Lock (A).

b. Pull and hold Spray Gun trigger (B).

c. Turn Prime/Spray Valve horizontal

to SPRAY position (C).

d. Turn Pressure Control Knob to

Prime/Slow (D).

3A6342F 21

Page 22

Start Up

Spray

3. Continue to trigger Spray Gun into

waste pail until only paint comes out of

the Spray Gun.

4. Release trigger. Engage Trigger Lock.

High-pressure spray is able to inject toxins

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

NOTE: Inspect for leaks. If leaking occurs,

perform Pressure Relief Procedure, page

18, then tighten all fittings and repeat Fill

Pump (Prime Pump), page 21.

5. Transfer Drain Tube to paint pail.

6. Install Spray Tip Guard. Rotate Spray

Tip back to SPRAY position and ensure

the Spray Tip Guard is tight.

You are now ready to spray!

NOTE: It is normal for the motor to stop once

the sprayer is primed and under pressure.

Refilling Paint Pail

When the paint pail runs low and the Spray

Gun stops spraying, refill the paint pail and

repeat the Fill Pump (Prime Pump)

procedure, then the Fill Spray Gun and

Hose procedure.

22 3A6342F

Page 23

Spraying

Good Spray Pattern

12 in. (30 cm)

from surface

TAILS - Gaps at edges

Pressure

too low

Tip Wear

Start

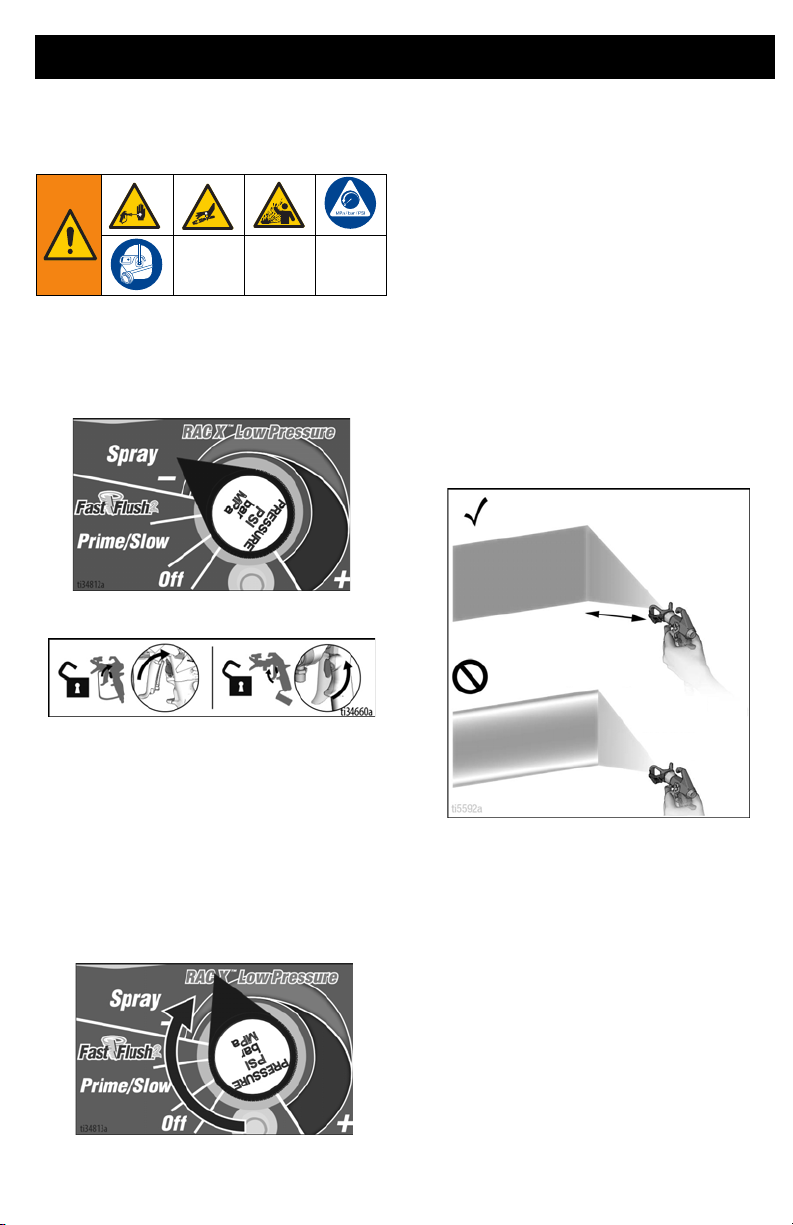

1. Turn pressure control knob to SPRAY

position.

2. Disengage Trigger Lock.

Spraying

Spray Pattern Quality

A good spray pattern is evenly distributed as

it hits the surface.

• Spray should be atomized (evenly

distributed, no gaps at edges).

• Increase Pressure Control Knob if

needed until spray is even and without

gaps at edges.

• Spray Tip may be worn or a smaller tip

may be needed.

• Material may need to be thinned. If

material needs to be thinned follow

manufacturer’s recommendations.

Adjust Pressure Control

1. For best spray results with lowest

overspray, begin with the Pressure

Control Knob adjusted to the lowest

spray setting.

2. If needed, increase Pressure Control

Knob setting to the lowest spray setting

that results in an acceptable spray

pattern.

3A6342F 23

Page 24

Spraying

EVEN FINISH

UNEVEN FINISH

even

finish

uneven

finish

EVEN FINISH

UNEVEN FINISH

thin

thick

thin

START

STROKE

TRIGGER

GUN

CONTINUE

STROKE

RELEASE

TRIGGER

END

STROKE

Horizontal Spray

Vertical

Spray

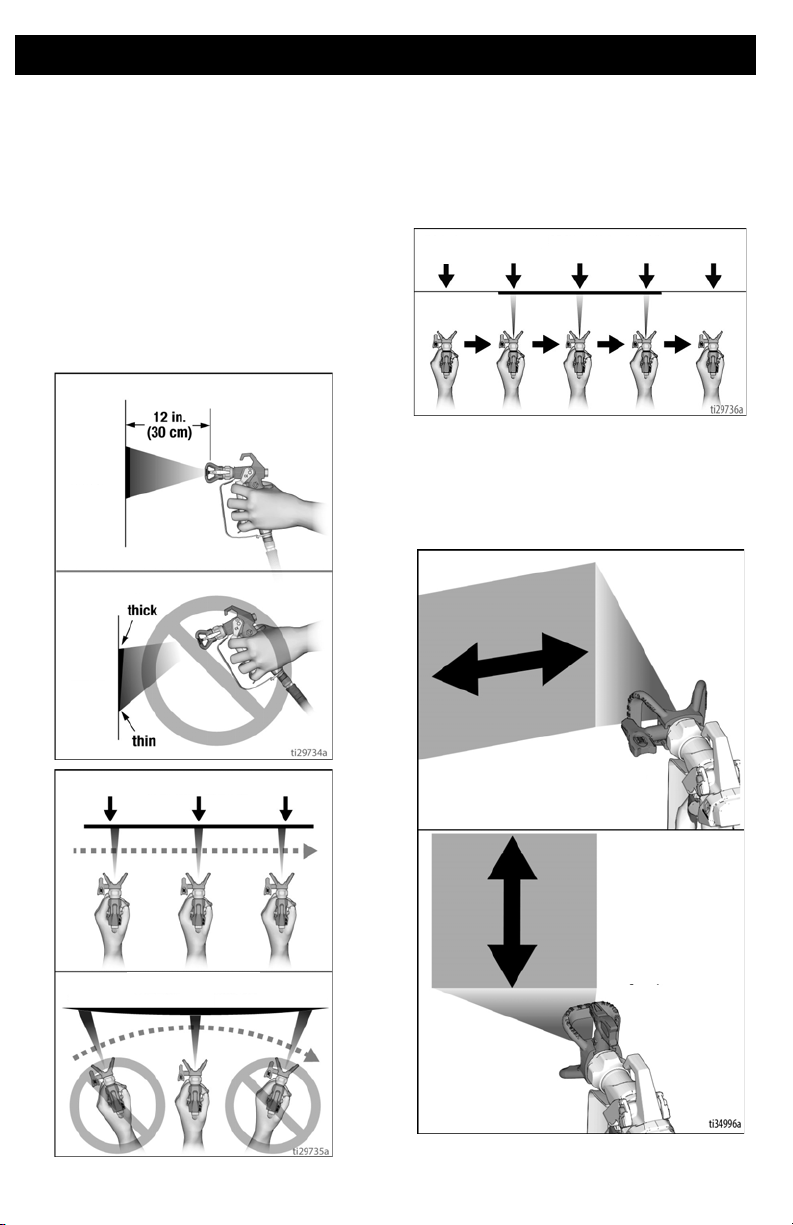

Spray Techniques

Use a piece of scrap cardboard to practice

these basic spraying techniques before you

begin spraying the surface.

• Hold Spray Gun 12 in. (30 cm) from

surface and aim straight at surface.

Tilting Spray Gun to direct spray angle

causes an uneven finish.

• Flex wrist to keep Spray Gun pointed

straight. Fanning Spray Gun to direct

spray at angle causes uneven finish.

Triggering Spray Gun

Pull trigger after starting stroke. Release

trigger before end of stroke. Spray Gun must

be moving when trigger is pulled and

released.

Aiming Spray Gun

Aim center of spray of Spray Gun at bottom

edge of previous stroke, overlapping each

stroke by half.

24 3A6342F

Page 25

Spraying

UNCLOG

SPRAY

Clear Spray Tip Clog

In the event that particles or debris clog the

Spray Tip, the Spray Tip can be reversed to

quickly and easily clear particles without

disassembling the sprayer.

See Strain the Paint, page 20, for additional

information.

1. Engage Trigger Lock. Rotate Spray Tip

to UNCLOG position. Ensure spray tip

remains fully seated, pushed all the way

into the Spray Tip Guard. Disengage

Trigger Lock. Trigger Spray Gun at

waste area to clear clog.

2. Engage Trigger Lock. Rotate Spray Tip

back to SPRAY position. Disengage

Trigger Lock and continue spraying.

Spray Tip Installation

To avoid serious injury from skin injection

do not put your hand in front of the spray tip

when installing or removing the spray tip

and spray tip guard.

To prevent Spray Tip leaks make certain

Spray Tip and Spray Tip Guard are installed

properly. Refer to separate Spray Gun

manual for procedure to remove and install

NOTE: If Spray Tip is difficult to rotate when

turning to the UNCLOG position perform,

Pressure Relief Procedure, page 18, then

turn Prime/Spray Valve horizontal to SPRAY

position and repeat step 1.

3A6342F 25

Spray Tip, Seal, and Spray Tip Guard.

Page 26

Cleanup

ti24592a

Cleanup

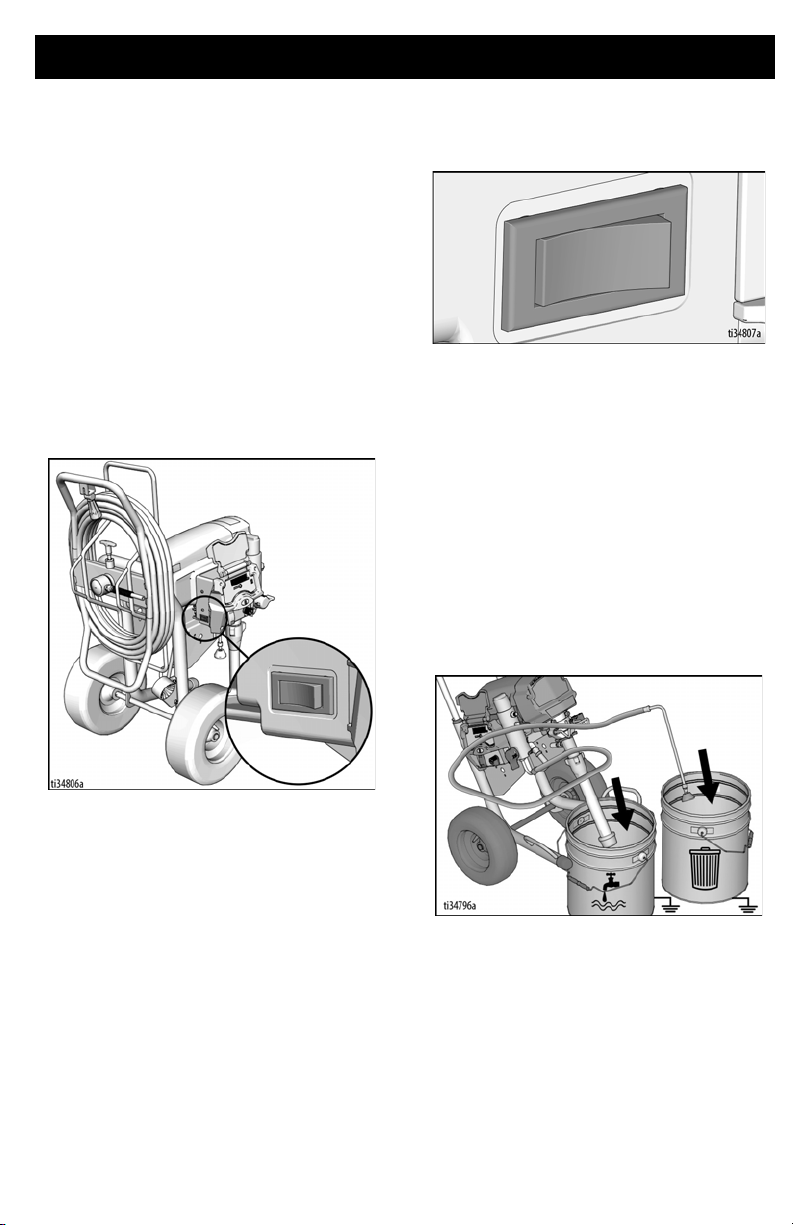

1. Perform Pressure Relief Procedure,

page 18.

2. Remove Spray Tip Guard and Spray Tip.

For additional information, see separate

Spray Gun manual.

4. Place Suction Tube in appropriate

flushing fluid. Place Drain Tube in waste

pail.

5. To flush Drain Tube and pump turn

Prime/Spray Valve down to PRIME

position.

6. Turn pressure control to Prime/Slow and

turn ON/OFF switch to ON position to

start the motor. Flushing fluid will flow up

the Suction Tube and out the Drain Tube

into the waste pail. Allow flushing fluid to

Clean Drain Tube

3. Remove Suction Tube and Drain Tube

from paint; wipe excess paint off outside

of Suction Tube.

26 3A6342F

flow out of Drain Tube for 5 seconds.

7. Turn Pressure Control Knob to OFF

setting (all the way counterclockwise).

Page 27

Cleanup

Clean Hose and Spray Gun

8. Hold Spray Gun against a grounded

metal waste pail. Point Spray Gun into

waste pail.

a. Disengage Trigger Lock (A).

b. Pull and hold Spray Gun trigger (B).

c. Turn Prime/Spray Valve horizontal

to SPRAY position (C).

d. Turn pressure control to 12 o’ clock

position to begin flushing (D). (For

optimal cleaning performance, the

Pressure Control Knob can be

turned to the FastFlush setting.)

12. Remove Suction Tube from flushing fluid

so that air can enter the pump and push

flushing fluid out of the Hose and Spray

Gun.

13. Trigger Spray Gun into flushing pail and

turn Pressure Control Knob to 12 o’ clock

position to purge fluid from Hose.

14. When flushing fluid has been purged,

release trigger. Engage Trigger Lock.

9. Continue flushing until flushing fluid

appears clear.

10. Turn Pressure Control Knob to OFF (all

the way counterclockwise).

11. Stop triggering Spray Gun.

3A6342F 27

Page 28

Cleanup

15. Turn Pressure Control Knob to OFF and

turn ON/OFF switch to OFF position.

Disconnect power to sprayer.

16. Turn Prime/Spray Valve down to PRIME

position.

17. Remove Spray Tip and Spray Tip Guard

from Spray Gun. Remove filter from

Spray Gun. Clean and inspect. Reinstall.

See separate Spray Gun manual for

more information.

18. Remove filter from sprayer. Clean and

inspect. Reinstall.

NOTE: If flushing with water, flush again with

mineral spirits or Pump Armor™ to leave a

protective coating to prevent freezing or

corrosion for longterm storage.

19. Wipe sprayer, Hose and Spray Gun with

a rag soaked in water or mineral spirits.

28 3A6342F

Page 29

WatchDog

WatchDog

Your sprayer is equipped with WatchDog™,

which automatically stops and protects the

pump when the sprayer runs out of paint.

Enabling or Disabling WatchDog

By default, WatchDog is disabled. To enable

or disable WatchDog, use the Graco

BlueLink™ app. See page 30 for instructions

to download the Graco BlueLink app.

Alternatively, you can enable or disable

WatchDog using the LED Display (if

equipped). See page 34 for instructions to

enable or disable WatchDog using the LED

Display.

Adjusting WatchDog Sensitivity

WatchDog can be set to LOW, MEDIUM, or

HIGH sensitivity when detecting if the sprayer

has run out of paint. By default, WatchDog

sensitivity is set to MEDIUM. WatchDog

sensitivity can be adjusted using the Graco

BlueLink app or by using the LED Display, as

described above.

Refilling Paint and Resuming

When you run out of paint and WatchDog

stops the pump, perform the following steps

to resume spraying.

1. Turn the ON/OFF switch to the OFF

position.

2. Perform Pressure Relief Procedure,

page 18.

3. Refill the paint pail.

4. Perform the Fill Pump (Prime Pump),

page 21, then the Fill Spray Gun and

Hose, page 21.

3A6342F 29

Page 30

BlueLink™ App

BlueLink™ App

Download the Graco BlueLink app from the

Apple App Store, Google Play, or other

available application stores to connect to the

paint sprayer via Bluetooth

The BlueLink app allows you to access

sprayer information, settings, statistics, and

provides access to useful features such as

WatchDog™, improved maintenance

tracking, sprayer tracking, and job tracking.

Find the Graco BlueLink App at:

https://www.graco.com/BlueLink

Further instructions can be accessed within

the app. Instructions can also be accessed

online at:

https://www.graco.com/BlueLinkSupport

®

.

Enabling or Disabling BlueLink

1. Turn the ON/OFF switch to the OFF

position. Turn the Pressure Control

Knob all the way counterclockwise to the

OFF position.

2. Unplug sprayer from power outlet and

allow power to dissipate for 5 minutes.

3. Remove control box cover.

4. Locate the Bluetooth transmitter power

switch (S2) on the control board. Using

a ballpoint pen, DISABLE BlueLink by

moving the switch to the left, or

ENABLE BlueLink by moving the

switch to the right.

The Graco BlueLink system uses Bluetooth

to communicate between the sprayer’s

control board and a mobile phone. To disable

BlueLink by shutting off the Bluetooth

transmitter, perform the following steps.

5. Reassemble control box cover.

30 3A6342F

Page 31

Replacing BlueLink Battery

BlueLink™ App

In order to keep your sprayer synced, your

unit has a small battery built-in. If you receive

the following message, the battery will need

to be replaced.

3. Remove black battery cover with a

philips screwdriver.

4. Slide battery out of the holder, to the

left.

5. Replace battery with a new CR2032

battery.

6. Place the battery cover back on the

unit.

7. Hook the clip under the control board.

NOTE: The cover should not move.

8. Tighten the screw back into place on

the battery cover.

1. Turn sprayer OFF and disconnect

power.

2. Remove the control box cover.

9. Close and screw the control box cover

back on the unit.

3A6342F 31

Page 32

LED Display

LED Display

(not included on all models)

Operation Main Menu

Short press

next display. Press and hold to change

units or reset data.

1. Perform the Pressure Relief

Procedure, page 18.

2. Turn power ON. LED Display will show

dashes if pressure is less than 200 psi

(14 bar, 1,4 MPa).

DISPLAY

button to move to

Change Display Units

Press and hold the DISPLAY button for

5 seconds to change pressure units

(psi, bar, MPa) to desired units.

Selection of bar or MPa changes

gallons to liters x 10. To change

display units LED Display must be in

pressure display mode and pressure

must be at zero (dashes displayed).

32 3A6342F

Page 33

LED Display

Job Gallons

1. Short press DISPLAY button to move to

Job Gallons (or liters x 10).

2. Press and hold the DISPLAY

button to reset to zero.

Lifetime Gallons

1. Short press DISPLAY button to move to

Lifetime Gallons (or liters x 10).

2. Turn power switch on while holding

DISPLAY button down.

3. SERIAL NUMBER scrolls past on the

display.

4. Short press DISPLAY button to move

to MOTOR HOURS. The total motor

run hours are displayed.

5. Short press DISPLAY button. LAST

CODE scrolls by and last code is

displayed; e.g. CODE 06 MOTOR

THERMAL PROTECTION ENABLED

(see Repair manual).

Secondary Menu - Stored Data

1. Perform Pressure Relief Procedure,

page 18, steps 1 - 4 if they have not

already been done.

3A6342F 33

Page 34

LED Display

6. Press and hold DISPLAY button

to clear code. NO CODE STORED will

be displayed after clearing the code

7. Short press

displayed then

is OFF. ON displays if Watchdog is ON.

8. Short press DISPLAY button to move

to WatchDog sensitivity menu. Press

and hold DISPLAY button and Watch-

dog can be set to low, medium, or high

sensitivity. Release DISPLAY button

when desired sensitivity setting is displayed. Default is medium.

DISPLAY

button.

OFF

displays if watchdog

W-DOG

11. Short press DISPLAY button to move

to Pressure Control Knob Calibration.

KNOB displays. If you wish to calibrate

the Pressure Control Knob, follow the

procedure below. Otherwise, short

press the DISPLAY button to return to

SERIAL NUMBER.

is

a. Align the Pressure Control Knob to

the line between Fast Flush and the

minus (-) symbol.

b. Press and hold DISPLAY button to

calibrate the Pressure Control

Knob. PASS is displayed if the knob

is aligned correctly, then the menu

returns to SERIAL NUMBER. Knob

calibration is complete.

9. Short press DISPLAY button to move

to SOFTWARE REV.

10. Short press DISPLAY button. MOTOR

ID RESISTOR scrolls by and model

code number (see below).

Motor ID

Number Models

0 695/230V Mark IV

2 795 / 120V Mark IV

4 1095 / 230V Mark V

6 1595 / 120V Mark V / Mark VII

10 Mark X

34 3A6342F

NOTE: If the knob is not aligned correctly,

FAIL displays, then KNOB displays again.

Ensure the Pressure Control Knob is aligned

correctly, then try the calibration procedure

again.

Page 35

Maintenance

Maintenance

Routine maintenance is important to ensure proper operation of your sprayer. Maintenance

includes performing routine actions which keep your sprayer in operation and prevents trouble

in the future.

Perform Pressure Relief Procedure, page 18, before performing maintenance.

Activity Interval

Inspect/clean sprayer filter, fluid inlet strainer, and Spray Gun

filter.

Inspect motor shield vents for blockage.

Fill TSL by adding through TSL fill point.

Check sprayer stall.

With sprayer Spray Gun NOT triggered, sprayer motor should

stall and not restart until Spray Gun is triggered again.

If sprayer starts again with Spray Gun NOT triggered, inspect

pump for internal/external leaks and check prime valve for leaks.

Throat packing adjustment

When pump packing begins to leak after extended use, tighten

packing nut down until leakage stops or lessens. This allows

approximately 100 gallons of additional operation before a

repacking is required. Packing nut can be tightened without

0-ring removal.

Daily or each time you spray

Daily or each time you spray

Daily or each time you spray

Every 1000 gallons (3785 liters)

As necessary based on usage

Maintenance can be scheduled and tracked

via the Graco BlueLink app. See

Maintenance, page 35, for more information.

Recycling and Disposal at End of Life

At the end of the product’s useful life,

dismantle and recycle it in a responsible

manner.

Preparation:

•

Perform the Pressure Relief

Procedure, page 18.

• Drain and dispose of fluids according to

applicable regulations. Refer to the

material manufacturer’s Safety Data

Sheet.

3A6342F 35

Dismantle and recycle:

•

Remove motors, circuit boards,

displays, and other electronic

components. Remove the coin-cell

battery from the battery holder on the

control board. Recycle according to

applicable regulations.

• Do not dispose of electronic

components with household or

commercial waste.

• Deliver remaining product to a recycling

facility.

Page 36

Troubleshooting

Troubleshooting

Mechanical/Fluid Flow

1. Perform Pressure Relief Procedure,

page 18, before checking or repairing.

2. Solutions listed at the beginning of each

problem are the most common.

Problem Cause Solution

Paint does not come out

of the Spray Gun or you

suspect pressure has not

been fully relieved.

Pump output is low

There is a blockage in the

pump Hose or Spray Gun.

Spray tip worn Follow Pressure Relief Procedure, page

Spray tip clogged Refer to Clear Spray Tip Clog, page 25.

Paint supply is empty Refill and reprime pump.

Suction Tube strainer clogged Remove and clean, then reinstall.

Intake valve ball and piston

ball are not seating properly

Sprayer filter or Spray Gun

filter is clogged or dirty.

Prime valve leaking Follow Pressure Relief Procedure, page

Pump is worn. Service pump; see pump manual.

1. VERY SLOWLY loosen the Hose

connection to the Spray Gun and

disconnect the airless spray Hose from

the Spray Gun.

2. Turn Prime/Spray Valve horizontal to

SPRAY position.

3. While holding Hose firmly, point end of

Hose into paint pail. Turn ON/OFF

switch to ON position and turn Pressure Control Knob to PRIME/SLOW.

a. If fluid does not flow out of Hose,

b. If fluid flows out of Hose, see

4. Reassemble the Hose and Spray Gun,

and repeat Fill Spray Gun and Hose,

page 21.

18, then replace tip. See your separate

Spray Gun or tip manual.

Remove intake valve and clean. Inspect

balls and seats for nicks; replace if

necessary; see pump manual. Strain paint

before using to remove particles that could

clog pump.

Clean or replace filter.

18. Replace prime valve.

replace the Hose and continue to

step 4.

Clean the Spray Gun and Spray

Gun Filter, page 31.

36 3A6342F

Page 37

Troubleshooting

Problem Cause Solution

Pump output is low

(continued)

Fluid is spitting from

Spray Gun

Pump is difficult to prime

Pump throat packings are

worn.

Intake valve ball is packed

with material

Pressure setting is too low Turn Pressure Control Knob clockwise to

Material is too thick for a small

diameter Hose, or Hose is too

long.

Amp switch is on low setting.

(10A or 15A setting)

Tip is partially clogged Refer to Clear Spray Tip Clog, page 25.

Material supply low, or air was

not properly purged during

priming.

Intake valve is stuck to seat. Remove foot valve. Clean and inspect intake

Suction tube o-ring on foot

valve is damaged or missing.

Air in pump Refer to Fill Pump (Prime Pump), page 21.

Intake valve is leaking Clean intake valve. Be sure ball seat is not

Pump packings are worn Replace pump packings; see pump manual.

Tighten packing nut/wet cup. If leakage

continues, replace packings; see pump

manual. Also check piston valve seat for

hardened paint or nicks and replace if

necessary. Tighten packing nut/wet-cup.

Clean intake valve; see pump manual.

increase pressure.

Use larger diameter Hose and/or reduce

overall length of Hose.

Switch to 16A or 20A setting.

Refill fluid supply. Refer to Fill Pump (Prime

Pump), page 21. Then Fill Spray Gun and

Hose, page 21. Check fluid supply often to

prevent running pump dry.

valve.

Replace Suction Tube o-ring.

Then Fill Spray Gun and Hose, page 21.

nicked or worn and that ball seats well.

Reassemble valve.

Motor does not run

Motor runs but pump does

not stroke

Pressure Control Knob is set

too low

Spray tip clogged Refer to Clear Spray Tip Clog, page 25.

Displacement pump pin

damaged or missing; see

pump manual.

Connecting rod assembly

damaged; see pump manual.

Gears or drive housing

damaged.

Increase pressure by turning Pressure

Control Knob clockwise.

Replace pump pin if missing. Be sure

retainer spring is fully in groove all around

connecting rod; see pump manual.

Replace connecting rod assembly; see

pump manual.

Inspect drive housing assembly and gears

for damage and replace if necessary; see

pump manual.

3A6342F 37

Page 38

Troubleshooting

Electrical

Keep clear of electrical and moving parts

during troubleshooting procedures. To

avoid electrical shock hazards when

covers are removed for troubleshooting,

wait 5 minutes after unplugging power cord

for stored electricity to dissipate.

If sprayer does not run or does not shut off,

follow the steps below before beginning to

troubleshoot electrical issues.

1. Perform Pressure Relief Procedure,

page 18.

2. Plug sprayer into correct voltage,

grounded outlet.

3. Set power switch OFF for 30 seconds

and then ON again (this ensures

sprayer is in normal run mode).

4. Turn pressure control knob clockwise

1/2 turn.

5. Observe BlueLink status light to diagnose and resolve error codes in the following Troubleshooting chart.

Blinking red LED total count equals the error

code (for example: two blinks equals CODE

02).

NOTE: Use BlueLink app for more

information about error codes.

38 3A6342F

Page 39

Problem Cause Solution

•

Sprayer does not run at all

• Display is blank

• BlueLink status light never lights up

Sprayer will not shut off

• Sprayer does not run at all

• Display shows CODE 02

• BlueLink status light blinks 2 times

repeatedly

• Sprayer does not run at all

• Display shows CODE 03

• BlueLink status light blinks 3 times

repeatedly

Multiple electrical

issues.

Multiple electrical

issues.

Transducer or

transducer

connection issue.

Transducer

connection issue

(control board is

not detecting a

pressure signal).

Troubleshooting

See flow chart, page 46.

See flow chart, page 48.

1. Make sure there is no pressure in the

system (see Pressure Relief

Procedure, page 18). Check fluid path

for clogs, such as clogged filter.

2. Use airless paint spray Hose with no

metal braid 1/4 in. x 50 ft minimum.

Smaller Hose or metal braid Hose may

result in high-pressure spikes.

3. Set sprayer to OFF and disconnect

power to sprayer.

4. Check transducer and connections to

control board.

5. Disconnect transducer from control

board socket. Check that transducer

and control board contacts are clean

and secure.

6. Reconnect transducer to control board

socket. Connect power, set sprayer

ON and control knob 1/2 turn clockwise. If sprayer does not run properly,

set sprayer to OFF and go to next step.

7. Install new transducer. Connect power,

set sprayer ON and control knob 1/2

turn clockwise. Replace control board

if sprayer does not run properly.

1. Set sprayer to OFF and disconnect

power to sprayer.

2. Check transducer and connections to

control board.

3. Disconnect transducer from control

board socket. Check to see if transducer and control board contacts are

clean and secure.

4. Reconnect transducer to control board

socket. Connect power, set sprayer

ON and control knob to 1/2 turn clockwise. If sprayer does not run,

set sprayer to OFF and go to next

step.

5. Connect a confirmed working transducer to control board socket.

6. Set sprayer ON and control knob to 1/2

turn clockwise. If sprayer runs, install

new transducer. Replace control board

if sprayer does not run.

7. Check transducer resistance with ohmmeter (less than 9k ohm between red

and black wires and 3-6k ohm between

green and yellow wires).

3A6342F 39

Page 40

Troubleshooting

Problem Cause Solution

• Sprayer does not run at all

• Display shows CODE 4

• BlueLink status light blinks four

times repeatedly

• Sprayer does not run at all

• Display shows CODE 05

• BlueLink status light blinks 5 times

repeatedly

Control board

detected voltage

surges.

Control is

commanding

motor to run but

motor shaft does

not rotate.

Set sprayer to OFF and disconnect power

to sprayer.

Locate a good voltage supply to prevent

damage to electronics.

1. Remove pump and try to run sprayer. If

motor runs, check for locked or frozen

pump or drive train. If sprayer does not

run, continue to step 2.

2. Set sprayer to OFF and disconnect

power to sprayer.

3. Remove motor cover.

4. Disconnect motor connector(s) above

motor. Check that connectors are

clean. Reconnect connectors. Check

that connectors are fully seated and

secure.

5. Set sprayer to OFF and spin motor fan

1/2 turn. Restart sprayer. If sprayer

runs, replace control board. If sprayer

does not run, continue to step 5.

6. Perform Spin Test: Test at large 4-pin

motor field connector. Disconnect fluid

pump from sprayer. Test motor by

placing a jumper across pins 1 & 2.

Rotate motor fan at about 2 revolutions

per second. A cogging resistance to

motion should be felt at the fan.

The motor should be replaced if no

resistance is felt. Repeat for pin combinations 1 & 3 and 2 & 3. Pin 4 (the

green wire) is not used in this test. If all

spin test is positive, continue to step 6.

See connections on next page:

40 3A6342F

Page 41

Troubleshooting

Green Blue Red Black

Green Blue Red Black

Green Blue Red Black

STEP 1:

STEP 2:

STEP 3:

Problem Cause Solution

3A6342F 41

Page 42

Troubleshooting

-

ti13140a

Resistance Table:

695/240V Mark IV 0 ohms

795/120V Mark IV 2k ohms

1095/230V Mark V 3.9k ohms

1595/120V Mark

V/Mark VII

6.2k ohms

Mark X 10.0k ohms

Problem Cause Solution

• Sprayer does not run at all

• Display shows CODE 05

• BlueLink status light blinks 5 times

repeatedly

Control is

commanding

motor to run but

motor shaft does

not rotate.

7. Perform Field Short Test: Test at

large 4-pin motor field connector.

There should not be continuity from pin

4, the ground wire, and any of the

remaining 3 pins. If motor field connector tests fail, replace motor.

8. Check Motor Thermal Switch:

Unplug thermal wires. Set meter to

ohms. Meter should read the proper

resistance for each unit (see table

below).

42 3A6342F

Page 43

Problem Cause Solution

-

ti13140a

Resistance Table:

695/240V Mark IV 0 ohms

795/120V Mark IV 2k ohms

1095/240V Mark V 3.9k ohms

1595/120V Mark V/Mark VII 6.2k ohms

Mark X 10.0k ohms

• Sprayer does not run at all

• Display shows CODE 06

• BlueLink status light blinks 6 times

repeatedly

Troubleshooting

Motor overheated NOTE: Motor must be cooled down for the

test.

1. Keep sprayer in cooler location with

good ventilation. Make sure motor air

intake is not blocked.

2. Remove motor cover. Ensure fan is

securely attached to motor shaft.

3. Check thermal switch connector (yellow wires) above motor.

4. Disconnect thermal switch connector

above motor. Make sure contacts are

clean and secure. Measure resistance

of the thermal switch. If reading is not

correct, replace motor.

Check Motor Thermal Switch: Unplug

thermal wires. Set meter to ohms. Meter

should read the proper resistance for each

unit (see table below).

5. Reconnect thermal switch connector

to control board socket. Connect

power, turn sprayer ON and turn pressure control knob 1/2 turn clockwise. If

sprayer does not run, replace control

board.

3A6342F 43

Page 44

Troubleshooting

Problem Cause Solution

• Sprayer does not run at all

• Display shows CODE 08

• BlueLink status light blinks eight

times repeatedly

• Sprayer does not run at all

• Display shows CODE 10

• BlueLink status light blinks 10 times

repeatedly

• Sprayer does not run at all

• Display shows CODE 12

Incoming voltage

too low for sprayer

operation

Control board is

over heating.

Excessive current

protection enabled

1. Set sprayer to OFF and disconnect

power to sprayer.

2. Remove other equipment that uses the

same circuit.

3. Locate a good voltage supply to avoid

damage to electronics.

1. Make sure motor air intake is not

blocked.

2. Make sure fan is securely attached to

motor shaft.

3. Replace control board.

4. Replace motor.

Cycle power on and off.

• BlueLink status light blinks 12 times

repeatedly

• Sprayer does not run at all

• Display shows CODE 15

Motor not spinning

(no current to

motor)

1. Set sprayer to OFF and disconnect

power to sprayer.

2. Remove motor cover.

3. Disconnect motor control and inspect

for damage at connectors.

4. Reconnect motor control.

5. Turn power on. If code continues,

replace control board.

• BlueLink status light blinks 15 times

repeatedly

44 3A6342F

Page 45

Problem Cause Solution

ti18685a

• Sprayer does not run at all

• LED Display shows CODE 16

• BlueLink status light blinks 16 times

repeatedly

• Sprayer does not run at all

• Display shows CODE 17

Motor position

sensor not working

Sprayer plugged

into wrong voltage

Troubleshooting

1. Set sprayer to OFF and disconnect

power to sprayer.

2. Remove motor cover.

3. Disconnect motor position sensor and

inspect for damage at connectors.

4. Reconnect sensor.

5. Turn power ON. If code continues,

replace motor.

1. Set sprayer to OFF and disconnect

power to sprayer.

2. Locate a good voltage supply to avoid

damage to electronics.

• BlueLink status light blinks 17 times

repeatedly

• Error appears in Graco Bluelink App

3A6342F 45

Battery depleted See Replacing BlueLink Battery, page 31.

Page 46

Troubleshooting

Remove control box cover. Turn

sprayer ON. Observe control

board status light on control board

(see below).

No light

Once Normal

operation

Light on

Continuously

Control board

commanding

motor to run

Flashing See Code

section for

further

troubleshooting

Connect a test

transducer to the

board. Does the

motor run?

Replace

potentiometer.

See step 2. Is the

proper reading

present through the

thermal switch

wires?

See step 3. Does

the motor run?

See step 1. Do

you have over

100 VAC

(220 VAC for

230V units)?

Repair or

replace

power cord.

If motor is hot, let cool

and retest. If step 2 still

shows incorrect

resistance, replace

motor. The motor has

a defective thermal

device.

Replace the

transducer

Replace the

control board.

YES

YES

NO

NO

NO

YES

YES

NO

Electrical cont...

Sprayer does not run at all, display is blank, or BlueLink status light never lights up.

(See following page for steps)

46 3A6342F

Page 47

STEP 1:

Plug power cord in and turn switch ON. Connect

probes to on/off switch. Turn meter to AC Volts.

STEP 2:

Check motor thermal switch. Unplug yellow wires

above motor. Meter should read according to

Resistance Table on page 42. NOTE: Motor

should be cool during reading.

STEP 3:

Plug power cord in and turn switch ON. Disconnect

potentiometer.

Troubleshooting

3A6342F 47

Page 48

Troubleshooting

Plumb pressure gauge into paint

Hose, plug sprayer in, and turn power

switch ON. Does sprayer reach or

exceed its maximum pressure?

Unplug the transducer from control

board. Does motor stop running?

Bad transducer. Replace and test

with a new one.

Replace the control board.

Mechanical problem: See the proper

fluid pump manual for the sprayer for

further trouble shooting procedures.

NO

NO

YES

YES

Electrical cont...

Sprayer Will Not Shut Off

1. Perform Pressure Relief Procedure,

page 18. Leave prime valve open, turn

power switch OFF, and unplug sprayer

from power outlet.

2. Follow the troubleshooting

procedure below.

48 3A6342F

Page 49

Notes

Notes

3A6342F 49

Page 50

695/795 Lo-Boy Standard Parts

2

8

4

5

6

9

6

1

3

9

3

7

Ref. Torque

40-45 in-lb (4.5 - 5.0 N•m)

9-11 in-lb (1.0 - 1.2 N•m)

200-230 in-lb (22.6 - 25.9 N•m)

190-210 in-lb (21.4 - 23.7 N•m)

22-28 in-lb (2.4 - 3.1 N•m)

25-30 ft-lb (33.8 - 40.6 N•m)

70-80 ft-lb (94.9 - 108.4 N•m)

130-150 in-lb (14.6 - 16.9 N•m)

65-85 in-lb (7.3 - 9.6 N•m)

12345

678

9

See pages 70-72.

695/795 Lo-Boy Standard Parts

50 3A6342F

Page 51

695/795 Lo-Boy Standard Parts

695/795 Lo-Boy Standard Parts List

Ref. Part Description Qty.

6 15C753 SCREW, mach, torx, hex 5

8 15E891 CLIP, retaining 2

10 156306 WASHER, flat 2

11* 119420 WHEEL, pneumatic 2

12 106115 WASH, lock, spring 4

14 17E788 SCREW, cap, socket hd 4

17 15C871 CAP, leg 2

18 109032 SCREW, mach, pnh 4

22 116038 WASHER, wave spring 2

24 111040 NUT, hex, flanged 4

28 114672 WASHER, thrust 2

30 114699 WASHER, thrust 1

31 118444 SCREW, machine, hex

36 116191 WASHER, thrust 1

37 100057 SCREW, cap, hex hd 4

41 196178 FITTING 1

43 176817 SPRING, retaining 1

44 176818 PIN, str, hdls 1

48 189920 STRAINER, (1-11 1/2

51 24V023 COVER, drive, plastic,

56 17A257 NUT, retaining 1

58 287281 695 SHIELD, motor,

62 24Y424 FRAME, cart 1

71 LABEL, front 1

17E728 Ultra 695

17E730 Ultra 795

17E736 Ultimate 695

72 LABEL, side 1

17E729 Ultra 695

17E731 Ultra 795

17E737 Ultimate 695

76 248216 HOSE, suction;

77 15D000 CLIP, drain line 1

83 24V026

84 257185

85 241008 ROD, connecting;

washer hd

NPSM)

painted; includes 31

painted; includes 123, 124

includes 109, 138, 139,

140, 141

HOUSING, bearing;

includes 12, 14, 31, 108,

117

MOTOR, electric; includes

126, 127

includes 43

Ref. Part Description Qty.

87 241920 DEFLECTOR, threaded 1

89 287289 GEAR, combination;

90 287283 HOUSING, drive

90a 107089 WASHER, race, thrust 1

91 16Y598 PUMP, displacement

93 248217 HOSE, drain; includes 87 1

94 16X904 HOSE, coupled, 3/8 x

99 24A249 HANDLE, cart 1

105 276975 CUP, drain 1

6

106 15F952 BRACKET, drain cup 1

107 114423 SCREW, mach, hex hd 2

108 16X770 SHIELD, pump rod 1

109 115099 WASHER, garden Hose 1

110 LABEL, Standard Series 1

17E924 Ultra

1

1

1

1

1

1

1

17G987 Ultimate

117 187437 LABEL, torque 1

123 276980 GROMMET, cover 2

124 119250 SCREW, shoulder, hex

126 15D088 FAN, motor 1

127 115477 SCREW, mach, torx, pan hd1

128 TAG, WARNING (not

222385 English, French, Spanish

17A134 English, Chinese, Korean

17R476 English, Spanish,

138 117559 O-RING 2

139 118505 RING, retaining, external 1

140 15C980 NUT, jam 1

141 15C981 WASHER, suction swivel 1

159 278075 BAFFLE 1

160 15Y118 LABEL, Made in USA 1

* 253132 KIT, repair, tube, 11 in.

Replacement safety labels, tags, and cards are

available at no cost.

includes 28, 30

includes 6, 36, 90a

695/795

19.5

washer

shown)

Portuguese

1

1

1

1

2

1

3A6342F 51

Page 52

695/795/Mark IV HD Hi-Boy Standard Parts

1

1

9

9

1

2

9

3

3

4

5

6

6

7

8

Ref. Torque

40-45 in-lb (4.5 - 5.0 N•m)

9-11 in-lb (1.0 - 1.2 N•m)

200-230 in-lb (22.6 - 25.9 N•m)

190-210 in-lb (21.4 - 23.7 N•m)

22-28 in-lb (2.4 - 3.1 N•m)

25-30 ft-lb (33.8 - 40.6 N•m)

70-80 ft-lb (94.9 - 108.4 N•m)

130-150 in-lb (14.6 - 16.9 N•m)

65-85 in-lb (7.3 - 9.6 N•m)

123456789

9

See pages

70-72.

695/795/Mark IV HD Hi-Boy Standard Parts

52 3A6342F

Page 53

695/795/Mark IV HD Hi-Boy Standard Parts

695/795/Mark IV HD Hi-Boy Standard Parts List

Ref. Part Description Qty.

6 15C753 SCREW, mach, torx, hex 5

8 15E891 CLIP, retaining 2

10 156306 WASHER, flat 2

11* 119420 WHEEL, pneumatic 2

12 106115 WASH, lock, spring 4

14 17E788 SCREW, cap, socket hd 4

17 15C871 CAP, leg 2

18 109032 SCREW, mach, pnh 4

22 116038 WASHER, wave spring 2

24 111040 NUT, hex, flanged 6

28 114672 WASHER, thrust 2

30 114699 WASHER, thrust 1

31 118444 SCREW, machine, hex

36 116191 WASHER, thrust 1

37 100057 SCREW, cap, hex hd 4

41 196178 FITTING 1

43 176817 SPRING, retaining 1

44 176818 PIN, str, hdls 1

48 189920 STRAINER, (1-11 1/2

51 24V023 COVER, drive, plastic,

55 16C457 HANGER, pail 1

56 17A257 NUT, retaining 1

58

287281 695/Mark IV 230V

287282 795/Mark IV 120V

62 24Y429 FRAME, cart 1

71 LABEL, front 1

17E728 Ultra 695

17E730 Ultra 795

17E736 Ultimate 695

17E738 Ultimate 795

17E745 Mark IV HD

72 LABEL, side 1

17E729 Ultra 695

17E731 Ultra 795

17E737 Ultimate 695

17E739 Ultimate 795

17E744 Mark IV HD 230V

17E746 Mark IV HD 120V

76 248214 TUBE, intake; includes

77 278204 CLIP, spring 1

83 24V026

84 MOTOR, electric;

washer hd

NPSM)

painted; includes 31

SHIELD, motor, painted;

includes 123, 124

109

HOUSING, bearing;

includes 12, 14, 24, 31, 55,

77, 108, 117

includes 106, 127

Ref. Part Description Qty.

257185 695/Mark IV HD 230V

257186 795/Mark IV HD 120V

85 241008 ROD, connecting;

87 241920 DEFLECTOR, threaded 1

89 287289 GEAR, combination;

90 HOUSING, drive;

287283 695/Mark IV 230V

287284 795/Mark IV 120V

90a 107089 WASHER, race, thrust 1

6

91 PUMP, displacement;

16Y598 695/795

17H828 Mark IV HD

93 244240 HOSE, coupled; includes 871

94 16X904 HOSE, coupled, 3/8 x

1

99 287489 HANDLE, cart 1

1

105 16X695 HANGER, stand, cart 1

106 15C982 CAM, cart 2

107 114531 SCREW, mach, hex

1

108 16X770 SHIELD, pump rod 1

109 118494 PACKING, o-ring 1

110 LABEL, Standard Series 1

17E924 Ultra/Mark

17G987 Ultimate

117 187437 LABEL, torque 1

123 276980 GROMMET, cover 2

124 119250 SCREW, shoulder, hex,

126 15D088 FAN, motor 1

127 115477 SCREW, mach, torx, pan, hd1

128

222385 English, French, Spanish

17A134 English, Chinese, Korean

17R476 English, Spanish,

1

159 278075 BAFFLE 1

160 15Y118 LABEL, Made in USA 1

1

* 253132 KIT, repair, tube, 11 in.

Replacement safety labels, tags, and cards

1

are available at no cost.

includes 43

includes 28, 30

includes 6, 36, 90a

includes 41, 109

19.5

washer

washer

TAG, WARNING (not

shown)

Portuguese

1

1

1

1

1

4

2

1

3A6342F 53

Page 54

1095/1595/Mark V HD/Mark VII HD Hi-Boy

9

9

1

1

2

3

3

9

3

4

5

8

6

6

7

Ref. Torque

40-45 in-lb (4.5 - 5.0 N•m)

9-11 in-lb (1.0 - 1.2 N•m)

200-230 in-lb (22.6 - 25.9 N•m)

190-210 in-lb (21.4 - 23.7 N•m)

22-28 in-lb (2.4 - 3.1 N•m)

25-30 ft-lb (33.8 - 40.6 N•m)

70-80 ft-lb (94.9 - 108.4 N•m)

130-150 in-lb (14.6 - 16.9 N•m)

65-85 in-lb (7.3 - 9.6 N•m)

123456789

See pages 70-72.

1095/1595/Mark V HD/Mark VII HD Hi-Boy Standard Parts

54 3A6342F

Page 55

1095/1595/Mark V HD/Mark VII HD Hi-Boy

1095/1595/Mark V HD Hi-Boy Standard Parts List

Ref. Part Description Qty.

6 15C753 SCREW, mach, torx, hex 5

8 15E891 CLIP, retaining 2

10 156306 WASHER, flat 2

11* 119509 WHEEL, pneumatic 2

12 106115 WASH, lock, spring 4

14 17E789 SCREW, cap, socket hd 4

17 276974 CAP, leg 2

18 108795 SCREW, mach, pnh 4

19 102982 PACKING, o-ring (Mark

22 116038 WASHER, wave spring 2

23 117791 SCREW, cap, flng hd 2

24 111040 NUT, hex, flanged 6

28 114672 WASHER, thrust 2

30 114699 WASHER, thrust 1

31 118444 SCREW, machine, hex

36 116192 WASHER, thrust 1

37 100057 SCREW, cap, hex hd 4

41 FITTING, pump, quick disc 1

196178 1095/1595

16X834 Mark V HD / Mark VII HD

43 119778 SPRING, retaining 1

44 183210 PIN, pump 1

48 189920 STRAINER, (1-11 1/2

51 24V024 COVER, drive, plastic,

55 16C457 HANGER, pail 1

56 193031 NUT, retaining 1

58 287282 SHIELD, motor, painted;

62 24Y428 FRAME, cart 1095/1595 1

71 LABEL, UltraMax 1

17E732 Ultra 1095

17E734 Ultra 1595

17E740 Ultimate 1095

17E742 Ultimate 1595

17E747 Mark V HD

17E749 Mark VII HD

72 LABEL, UltraMax II

17E733 Ultra 1095

17E735 Ultra 1595

17E741 Ultimate 1095

17E743 Ultimate 1595

17E748 Mark V HD

17E750 Mark VII HD

76 248215 TUBE, intake; includes 109 1

77 278204 CLIP, drain line 1

83 24V027 HOUSING, bearing;

84 MOTOR, electric;

V/Mark VII)

washer hd

NPSM)

painted;

includes 31

includes 123, 124

1095/1595

includes 12, 14, 24, 31, 55,

77, 108, 113, 117

includes 126, 127

Ref. Part Description Qty.

257187 1095/Mark V 230V/Mark V

257188 1595/Mark V 120V/UK

85 24V021 ROD, connecting; includes

87 241920 DEFLECTOR, threaded 1

89 287290 GEAR, combination;

1

90 HOUSING, drive

287294 1095 110V/120V

287295 1095 230V/1595/Mark V

24M417 Mark VII

90a 194173 WASHER, race, thrust 1

91 PUMP, displacement;

8

1

1

1

1

1

16Y706 1095/1595

17H829 Mark V

17H830 Mark VII

93 244240 HOSE, drain; includes 87 1

94 HOSE, coupled 3/8 x 15.75 1

16X904 1095/1595

24V029 Mark V/Mark VII; includes

99 24A250 HANDLE, cart 1

105 16X696 HANGER, stand, cart 1

106 15C982 CAM, cart 2

107 114531 SCREW, mach, hex

108 16X770 PUMP, shield rod 1

109 118494 PACKING, o-ring 1

110 LABEL, Standard Series 1

17E924 Ultra/Mark

17G987 Ultimate

113 15C762 SHIELD, pump rod 1

117 187437 LABEL, torque 1

123 276980 GROMMET, cover 2

124 119250 SCREW, shoulder, hex,

126 15D088 FAN, motor 1

127 115477 SCREW, mach, torx, pan, hd1

128 TAG, WARNING (not

222385 English, French, Spanish

17A134 English, Chinese, Korean

17R476 English, Spanish,

159 278075 BAFFLE 1

160 15Y118 LABEL, Made in USA 1

161 110476 FITTING, Mark VII 1

* 253132 KIT, repair, tube, 11 in.

1

Replacement safety labels, tags, and cards are