Page 1

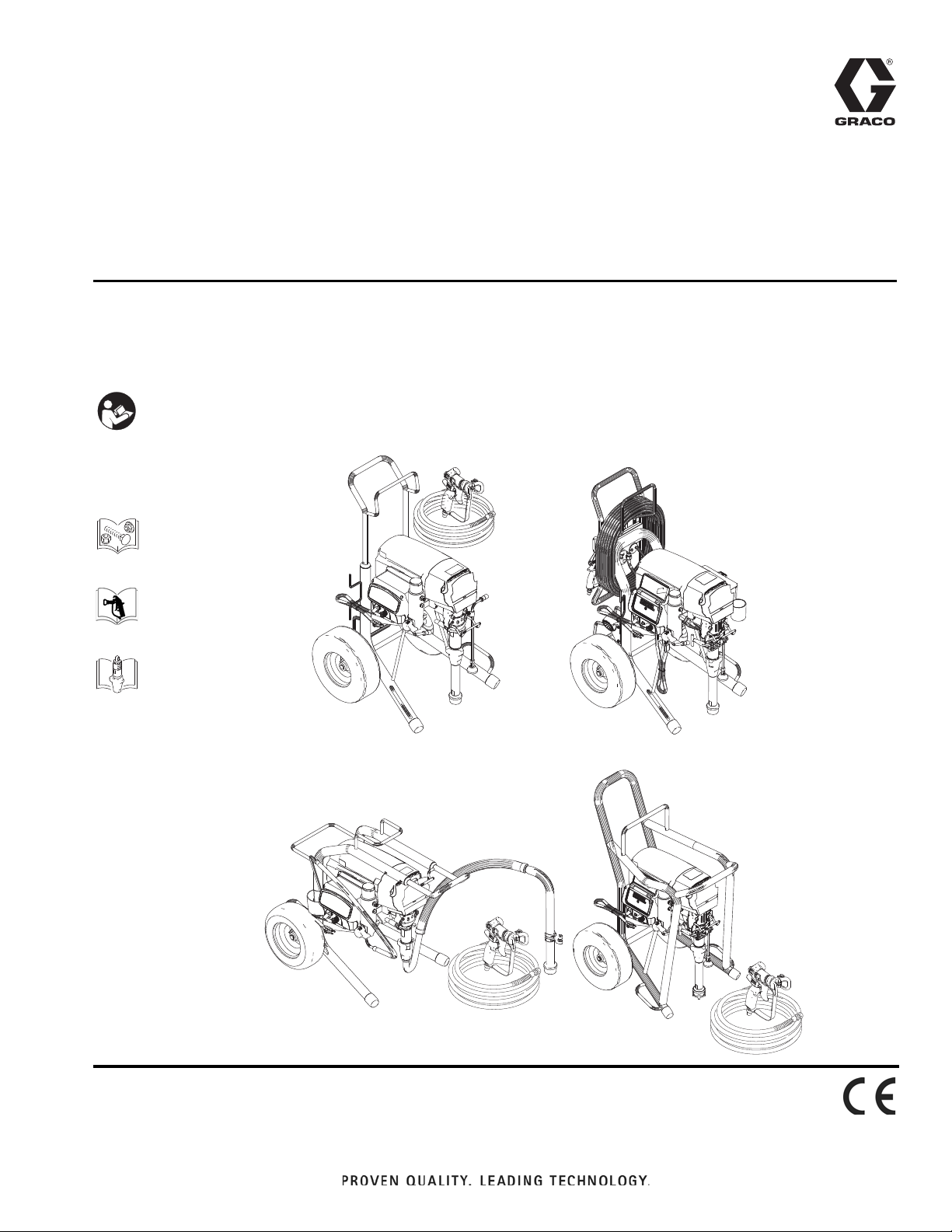

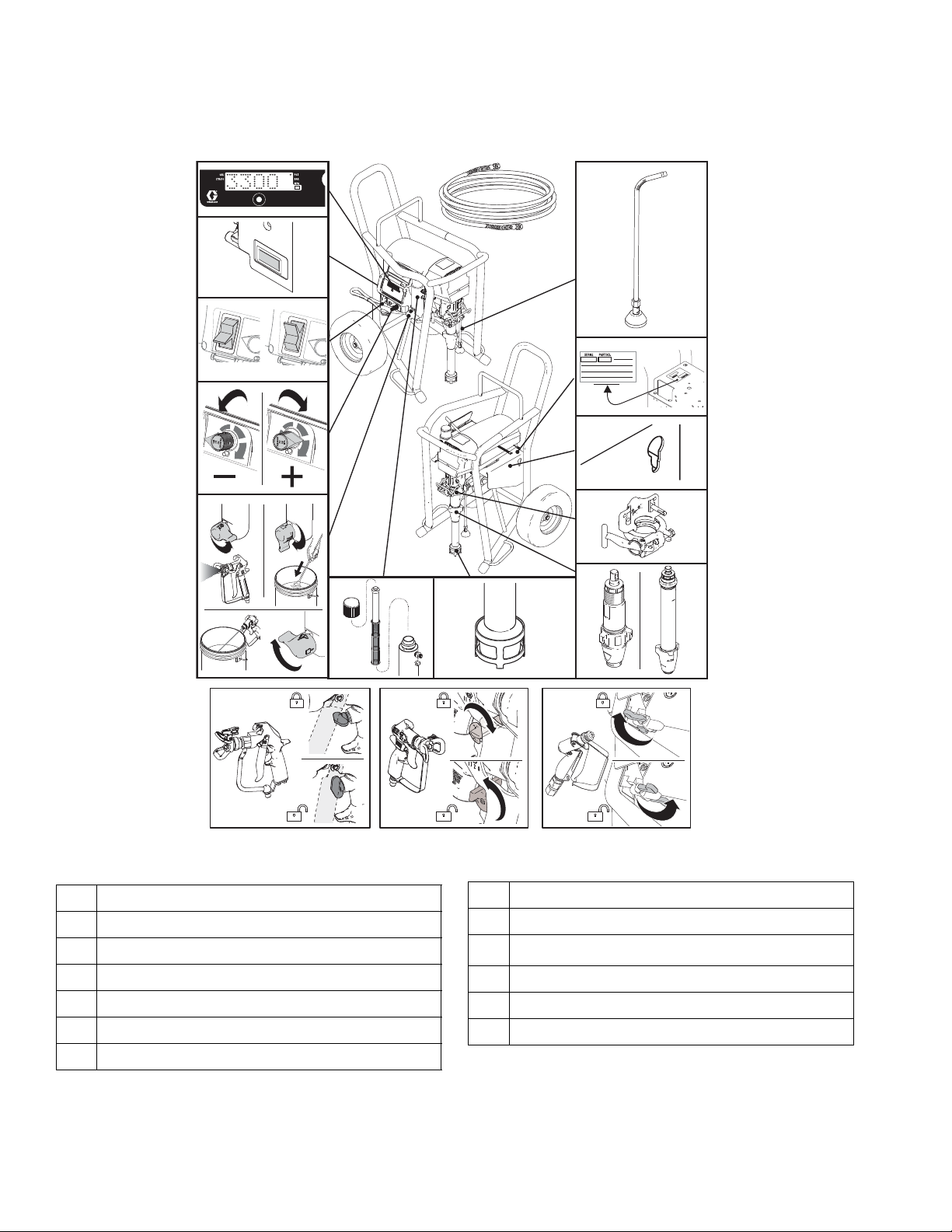

Operation

ti22882a

Standard Hi-Boy Series

ProContractor Series

IronMan Series

Standard Lo-Boy Series

695 / 795 / 1095 / 1595 / Mark IV / Mark V / Mark VII / Mark X

332916C

Electric Airless Sprayers

For Portable Airless Spraying of Architectural Coatings and Paints.

For professional use only. Not approved for use in European explosive atmosphere locations.

3300 psi (227 bar, 22.7 MPa) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Related Manuals:

332918

333281

309495

308491

311861

311254

333028

332922

EN

Page 2

Table of Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

UltraMax II, Ultimate Max II Models: . . . . . . . . . . 3

TexSpray Models: . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . . . 8

695 / 795 / 1095 / 1595 / Mark IV / Mark V / Mark VII

/ Mark X

Standard Models: . . . . . . . . . . . . . . . . . . . . . 8

695 / 795 / 1095 / 1595 Mark IV / Mark V / Mark VII /

Mark X ProContractor Models: . . . . . . . . . . . 9

1095 / 1595 / Mark V IronMan Models: . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Requirements . . . . . . . . . . . . . . . . . . . . 11

Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . 11

Pails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10/16 Amp Switch . . . . . . . . . . . . . . . . . . . . . . . . . 12

15/20 Amp Switch . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 13

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Switch Tip Installation . . . . . . . . . . . . . . . . . . . . . . 16

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Clearing Tip Clog . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fast Flush

(ProContractor and IronMan models only) . . 17

WatchDog

(ProContractor and IronMan models only) . . 17

ProGuard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Standard Models . . . . . . . . . . . . . . . . . . . . . . . . 18

ProContractor and IronMan Models . . . . . . . . . 18

Hose Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

(ProContractor models only) . . . . . . . . . . . . . . . 19

Digital Tracking System

(ProContractor and IronMan models only) . . 20

Operation Main Menu . . . . . . . . . . . . . . . . . . . . 20

Change Display Units . . . . . . . . . . . . . . . . . . . . 20

Job Gallons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Lifetime Gallons . . . . . . . . . . . . . . . . . . . . . . . . . 20

Secondary Menu - Stored Data . . . . . . . . . . . . . 21

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mechanical/Fluid Flow . . . . . . . . . . . . . . . . . . . . 24

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 44

™

Protection System

2 332916C

Page 3

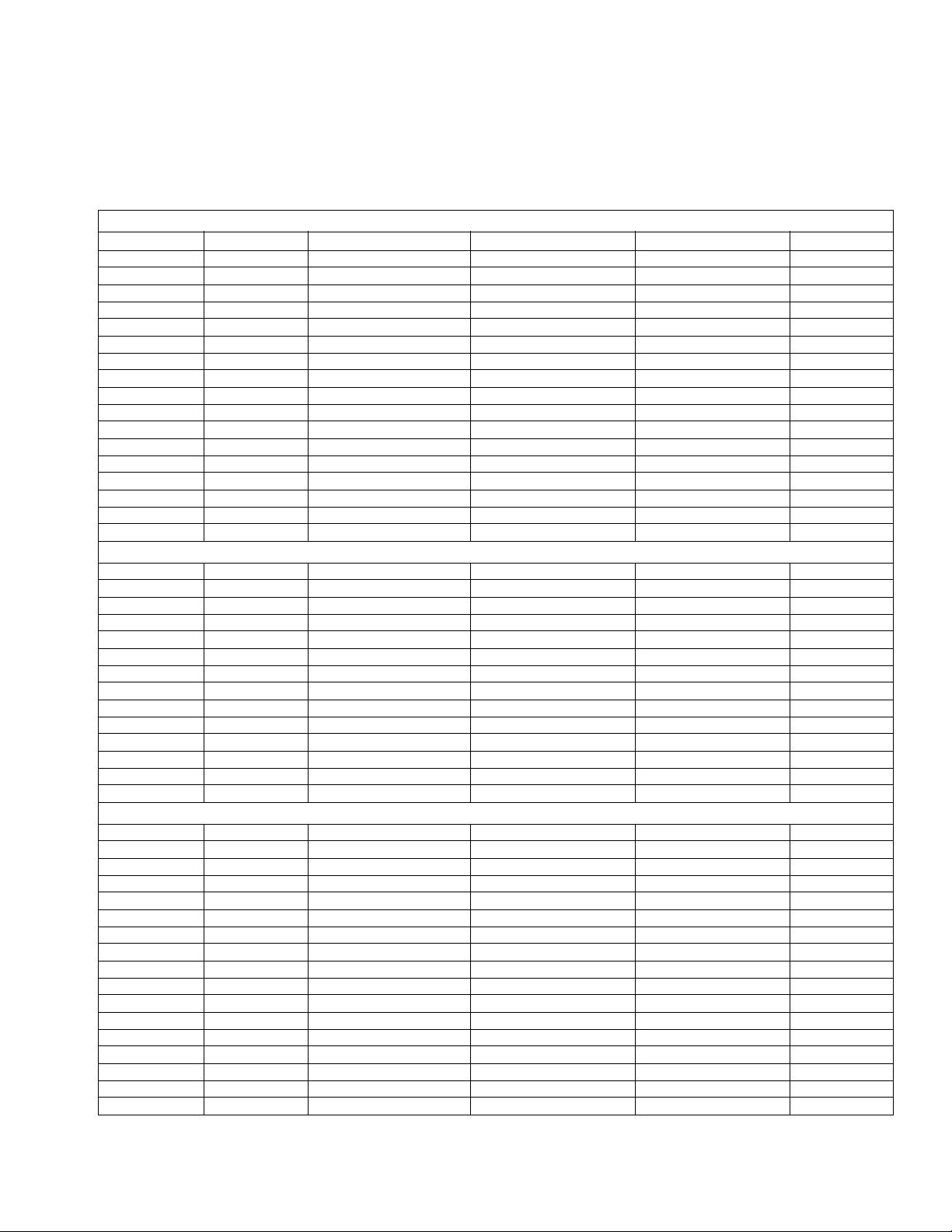

Models

UltraMax II, Ultimate Max II Models:

695 UltraMax, Standard, ProContractor, IronMan Models

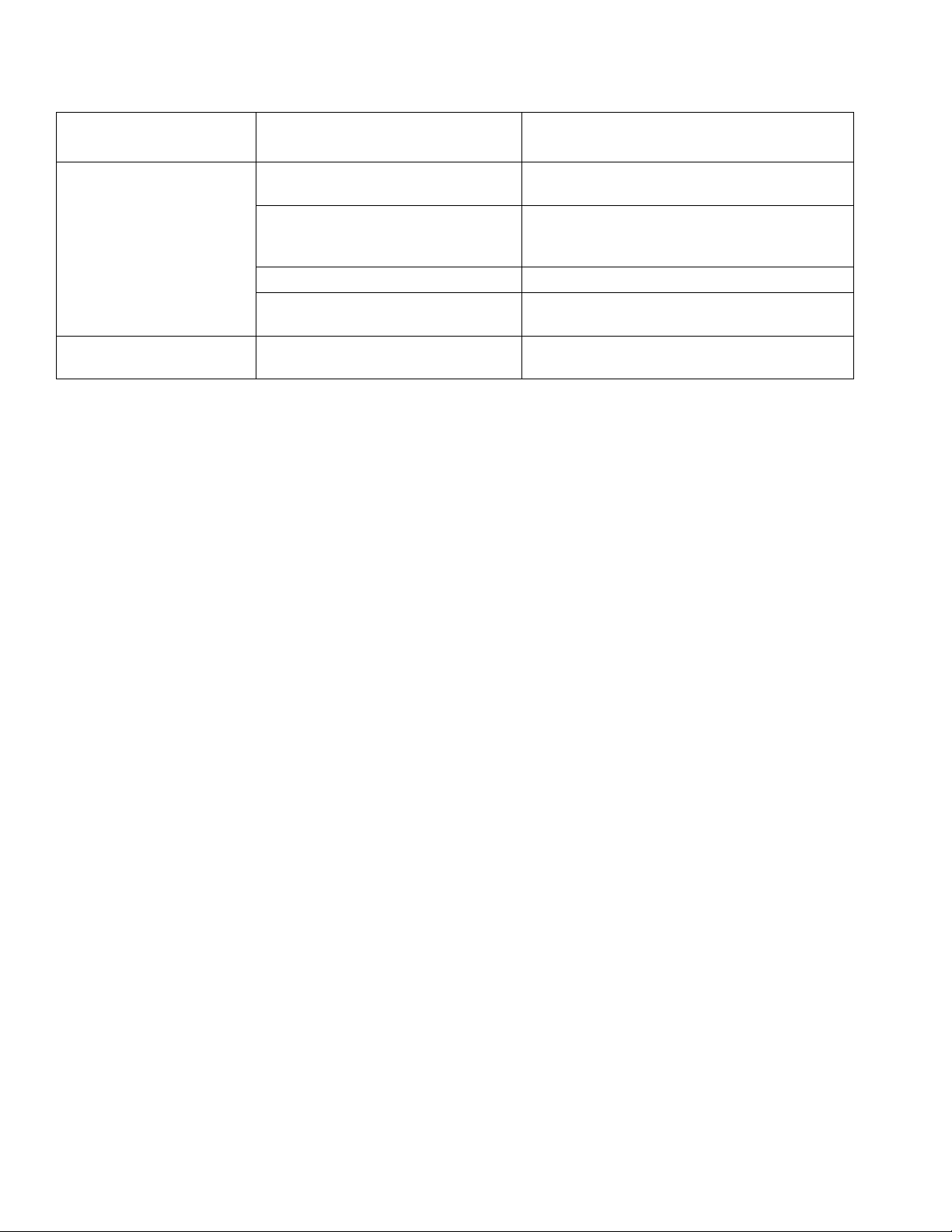

Model Voltage Standard Hi-Boy Standard Lo-Boy ProContractor IronMan

16W892 120

16W893 120

16W894 120

826177 120

826178 120

826179 120

16X656 230

16X657 230

16X658 120

16X659 120

16X660 230

16X811 120

16X812 230

16Y635 230

16Y637 230

16Y638 120

16Y639 230

795 UltraMax, Standard, ProContractor, IronMan Models

16W895 120

16W896 120

826180 120

826181 120

16X813 230

16X870 230

16X871 230

16X872 120

16X873 230

16Y895 230

16Y896 230

16Y897 230

16Y898 120

16Y899 120

1095 UltraMax, Standard, ProContractor, IronMan Models

16W899 120

16W900 120

16W901 120

826182 120

826183 120

826184 120

16X874 230

16X875 230

16X881 230

16X882 120

16Y829 230

16Y830 230

16Y831 120

16Y832 230

16Y833 120

16Y869 230

16Y871 230

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

Models

✓

✓

✓

✓

332916C 3

Page 4

Models

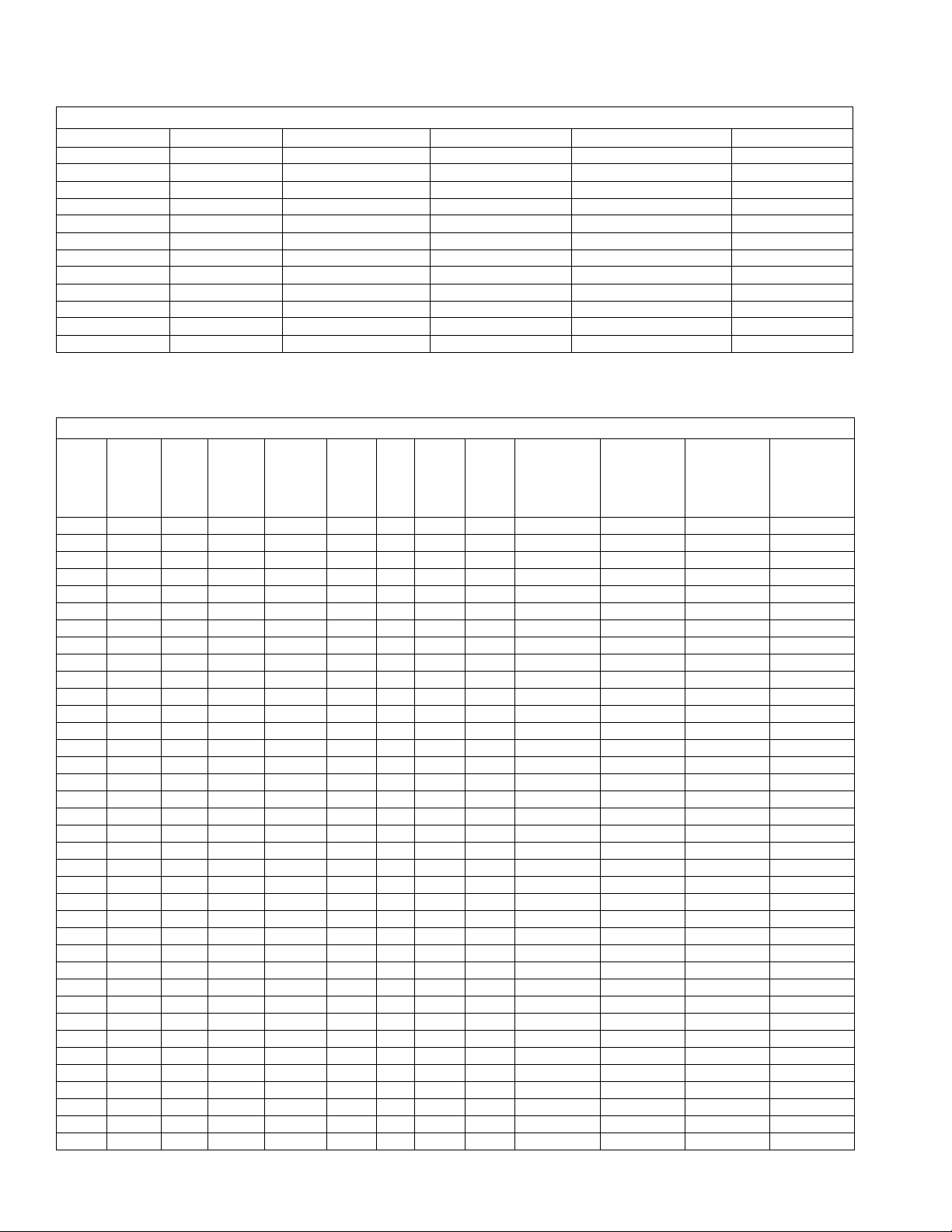

1595 UltraMax, Standard, ProContractor, IronMan Models

Model Voltage Standard Hi-Boy Standard Lo-Boy ProContractor IronMan

16W902 120

16W903 120

16W907 120

16W936 120

16W937 120

16W938 120

826185 120

826186 120

826187 120

826188 120

826189 120

826190 120

✓

✓

✓

✓

✓

✓

✓

✓

TexSpray Models:

Mark IV / Mark V / Mark VII / Mark X Standard, ProContractor, IronMan Models

Model

Number

16W897 Mark IV 120

16W898 Mark IV 120

16X953 Mark IV 230

16X954 Mark IV 230

16X956 Mark IV 230

16Y892 Mark IV 230

16Y893 Mark IV 230

16Y894 Mark IV 230

16W905 Mark V 120

16W906 Mark V 120

16W939 Mark V 120

16W940 Mark V 120

16X944 Mark V 230

16X947 Mark V 120

16X965 Mark V 230

16X966 Mark V 120

16X967 Mark V 230

16Y533 Mark V 120

16Y864 Mark V 230

16Y865 Mark V 230

16Y866 Mark V 120

16Y867 Mark V 230

16Y868 Mark V 120

16Y872 Mark V 230

16Y874 Mark V 230

16Y763 Mark VII 230

16Y919 Mark VII 230

16Y920 Mark VII 230

16Y921 Mark VII 230

16W908 Mark X 230

16X099 Mark X 230

16Y534 Mark X 230

16Y535 Mark X 230

16Y536 Mark X 230

16Y910 Mark X 230

16Y912 Mark X 230

16Y913 Mark X 230

Model Voltage

3/8 in. x 50ft +

HD

Standard

Hi-Boy

Pro

Contractor

IronMan

Flex

Plus

Gun

Blue

Texture

Gun

Inline

Texture

Gun

1/4 in. x 3 ft

whip

(9.5mm x 15m

+ 6.4mm x

0.9m whip)

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓✓

✓✓ ✓

✓✓✓

✓✓ ✓

✓✓✓

✓✓ ✓

✓✓✓

✓✓✓

✓✓✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

✓✓✓

✓✓✓

✓✓ ✓

✓✓ ✓

✓✓✓

✓✓ ✓

✓✓✓

✓✓✓

✓✓✓

✓✓ ✓

✓✓ ✓

✓✓ ✓

3/8 in. x 100 ft

+ 1/4 in. x 3 ft

whip

(9.5mm x 30m

+ 6.4mm x

0.9m whip)

1/2 in. x 50 ft +

3/8 in. x 12 ft

whip

(12.7mm x 15m

+ 9.5mm x

3.7m whip)

✓

✓

✓

✓

1/2 in. x 100 ft

+ 3/8 in. x 12 ft

whip

(12.7mm x 30m

+ 9.5mm x

3.7m whip)

4 332916C

Page 5

Warnings

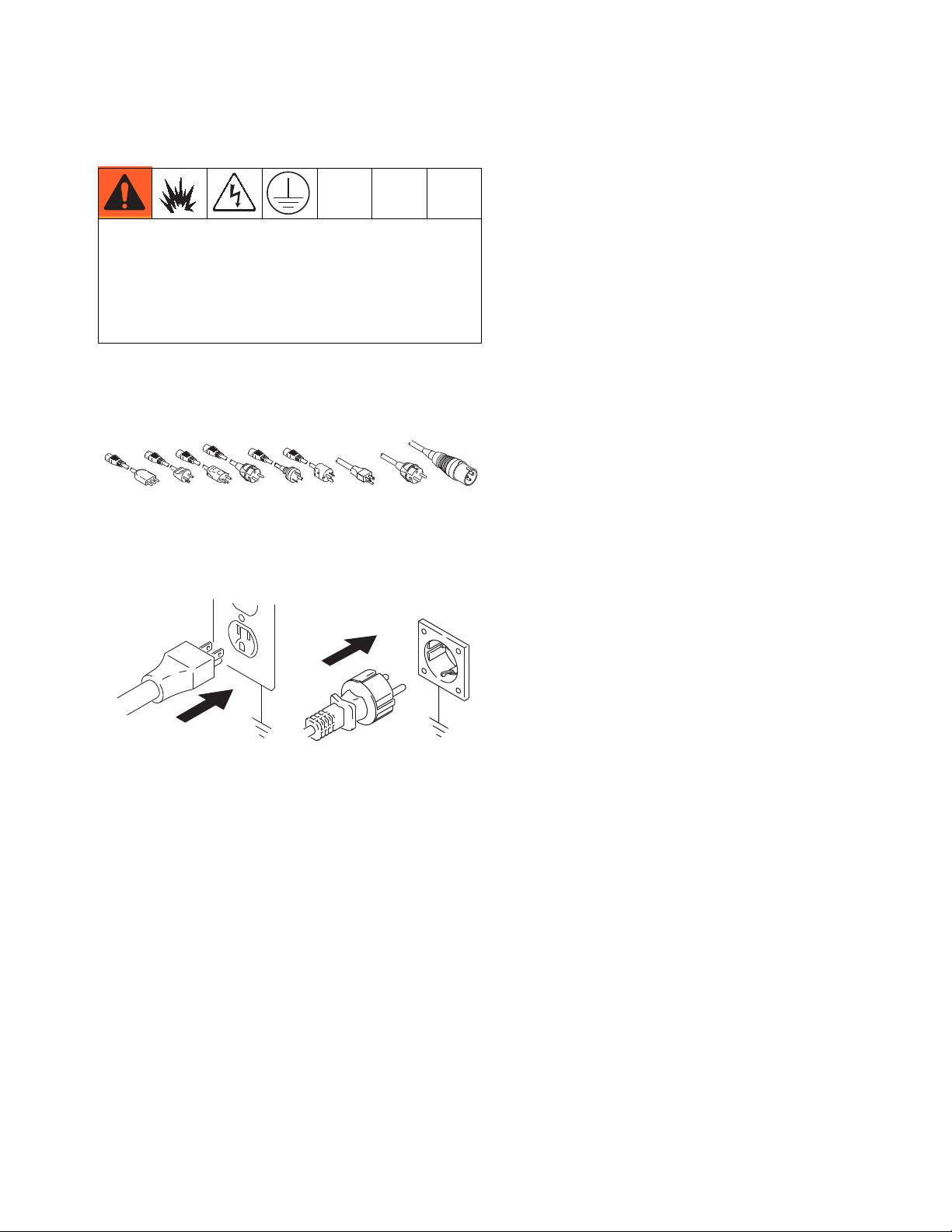

WARNING

120V US

230V

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

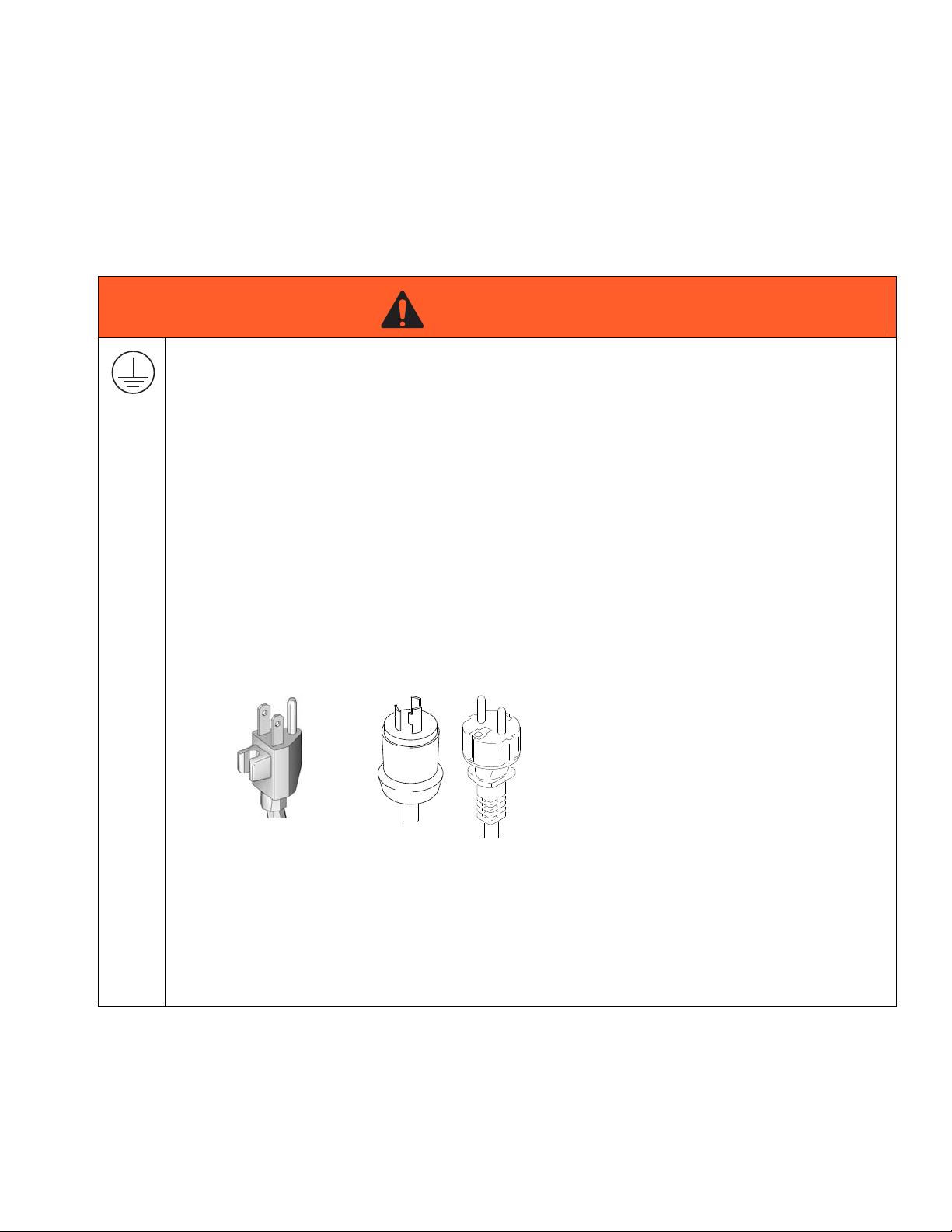

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to

either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician.

• This product is for use on a nominal 120V or 230V circuit and has a grounding plug similar to the

plugs illustrated in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a grounding plug and a grounding receptacle that accepts

the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG

(2.5 mm

• An undersized cord results in a drop in line voltage and loss of power and overheating.

332916C 5

2

) minimum to carry the current that the product draws.

Page 6

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as

cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity

creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray system, including the pump, hose assembly, spray gun, and objects in and around the spray area shall

be properly grounded to protect against static discharge and sparks. Use Graco conductive or

grounded high-pressure airless paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge. Do not

use pail liners unless they are are antistatic or conductive.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep

pump assembly in a well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets

(MSDS) and container labels provided with the paints and solvents. Follow the paint and solvents

manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or

cleaning, keep sprayer at least 20 feet (6 m) away from explosive vapors.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event

that injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks

with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while

spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure

before removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure for turning off the unit.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi (227 bar, 22.7 MPa). Use Graco replacement parts or

accessories that are rated a minimum of 3300 psi (227 bar, 22.7 MPa).

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

6 332916C

Page 7

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure for turning off the unit.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

• Do not spray with a hose shorter than 25 feet.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

• Wait five minutes after disconnecting power cord before servicing large capacitor units.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

332916C 7

Page 8

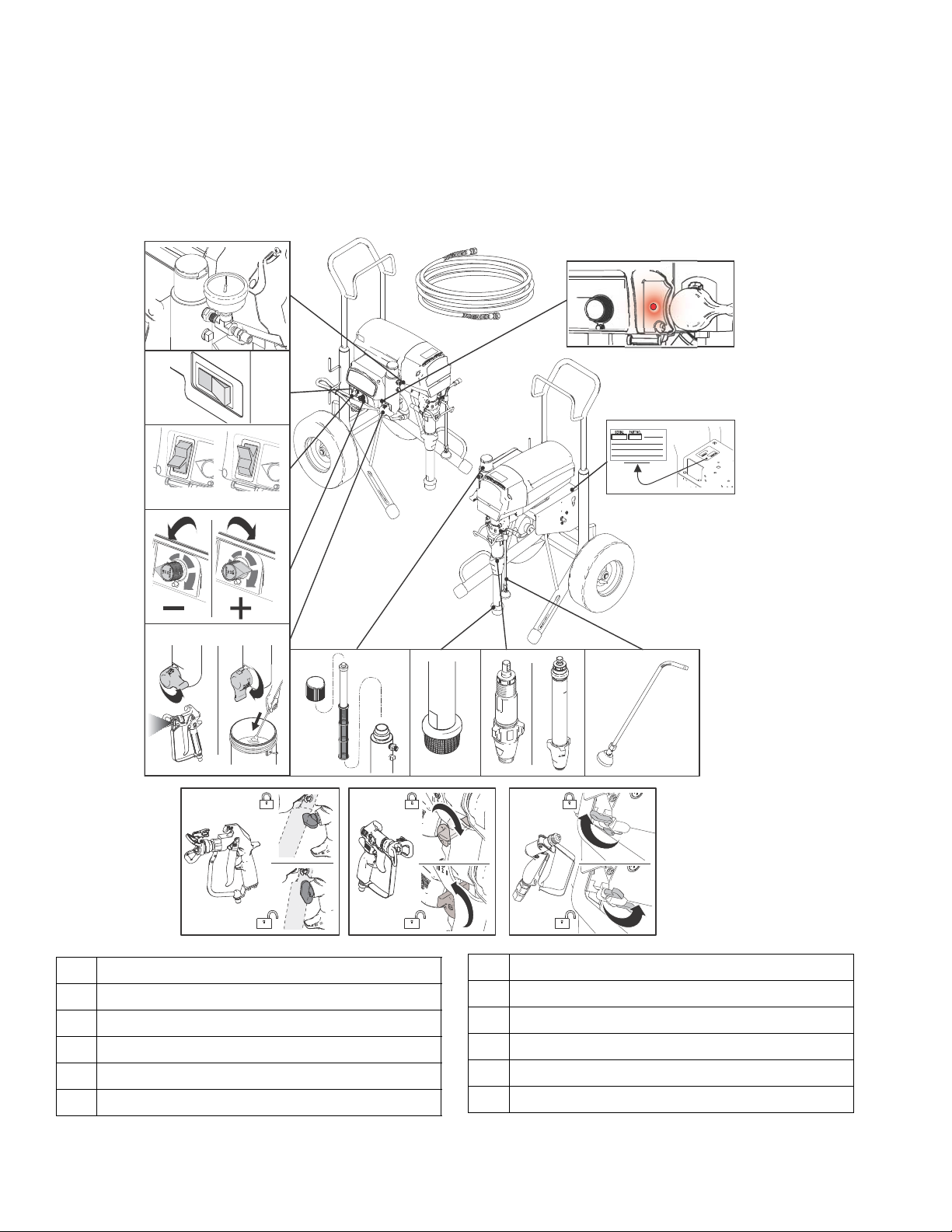

Component Identification

ONOFF

ti14839c

A

GH J K

L

B

C

D

E

F

M

Component Identification

695 / 795 / 1095 / 1595 / Mark IV / Mark V / Mark VII / Mark X

Standard Models:

A Pressure Gauge (not available on all units)

B Amp Switch (not available on all units)

C ON/OFF Switch

D Pressure Control

E Prime / Spray Valve

F Trigger Lock

GFilter

H Strainer

JPump

K Drain Tube

L Model/Serial Tag

M ProGuard Status Light

8 332916C

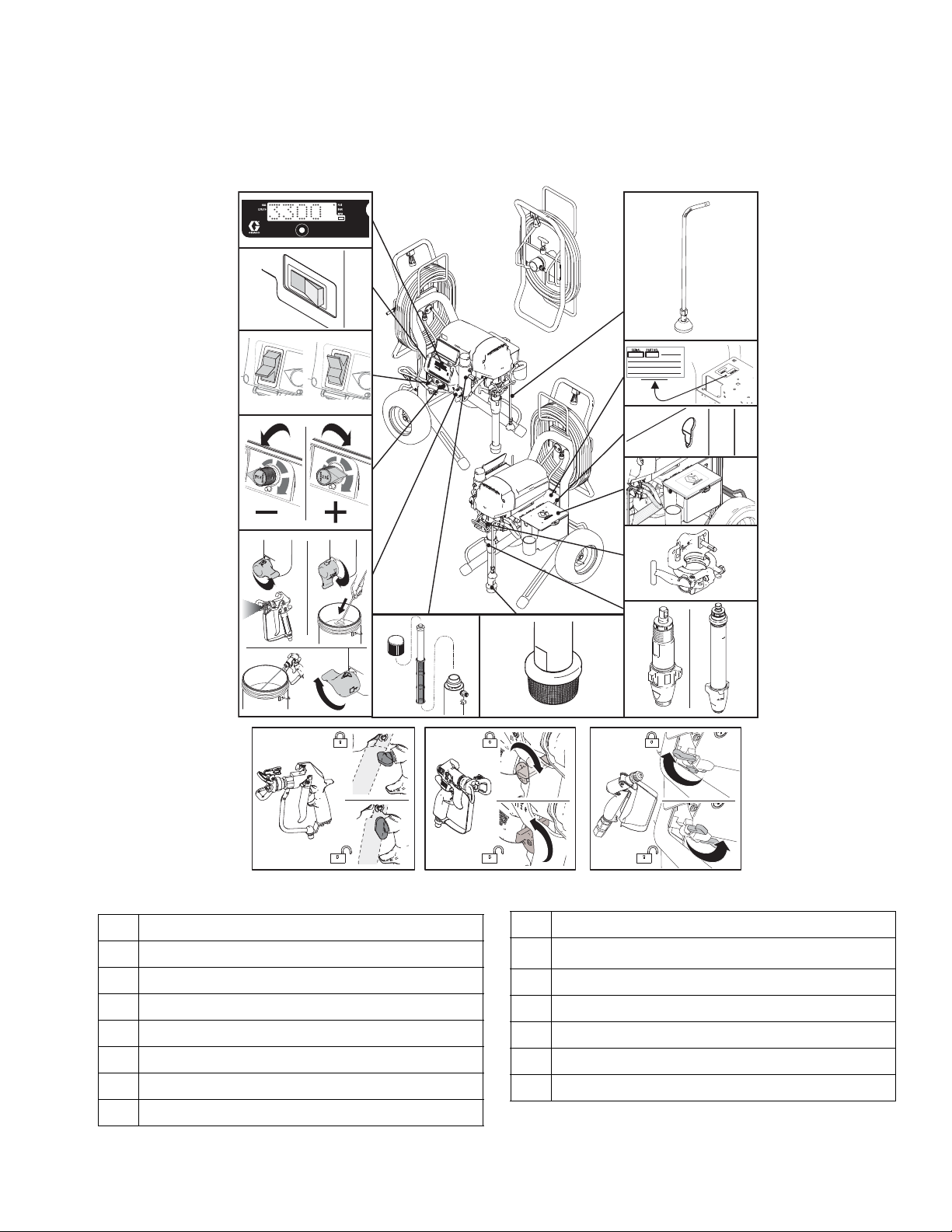

Page 9

Component Identification

ONOFF

ti18239b

P

N

M

L

G

A

B

R

K

J

H

C

D

E

F

F

695 / 795 / 1095 / 1595 Mark IV / Mark V / Mark VII / Mark X

ProContractor Models:

A Smart Control 3.0 Display

B Amp Switch (not available on all units)

C ON/OFF Switch

D Pressure Control

E Spray / Prime / Fast Flush

F Trigger Lock

GFilter

H Strainer

JPump

K

ProConnect

LTool Box

M Rod Pull Feature

N Unit / Serial Tag

P Drain Tube

RQuikReel

™

II

332916C 9

Page 10

Component Identification

ONOFF

ti22935a

N

M

L

G

A

B

K

J

H

C

D

E

F

1095 / 1595 / Mark V IronMan Models:

A Smart Control 3.0 Display

B Amp Switch (not available on all units)

C ON/OFF Switch

D Pressure Control

E Spray / Prime / Fast Flush

F Trigger Lock

GFilter

H Strainer

JPump

K

ProConnect

™

II

L Rod Pull Feature

M Unit / Serial Tag

N Drain Tube

10 332916C

Page 11

Grounding

ti7528b

ti7529b

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

The sprayer cord includes a grounding wire with an

appropriate grounding contact. Do not use the sprayer if

the electrical cord has a damaged ground contact.

The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Grounding

Do not modify plug! If it will not fit in outlet, have

grounded outlet installed by a qualified electrician. Do

not use an adapter.

Power Requirements

• 100-120V units require 100-120 VAC, 50/60 Hz,

15A, 1 phase

• 230V units require 220-240 VAC, 50/60 Hz,

10A-16A

Extension Cords

Use an extension cord with an undamaged ground

contact.

If an extension cord is necessary, use a 3-wire, 12 AWG

(2.5 mm

cords reduce sprayer performance.

2

) minimum. Longer cords and higher gauge

332916C 11

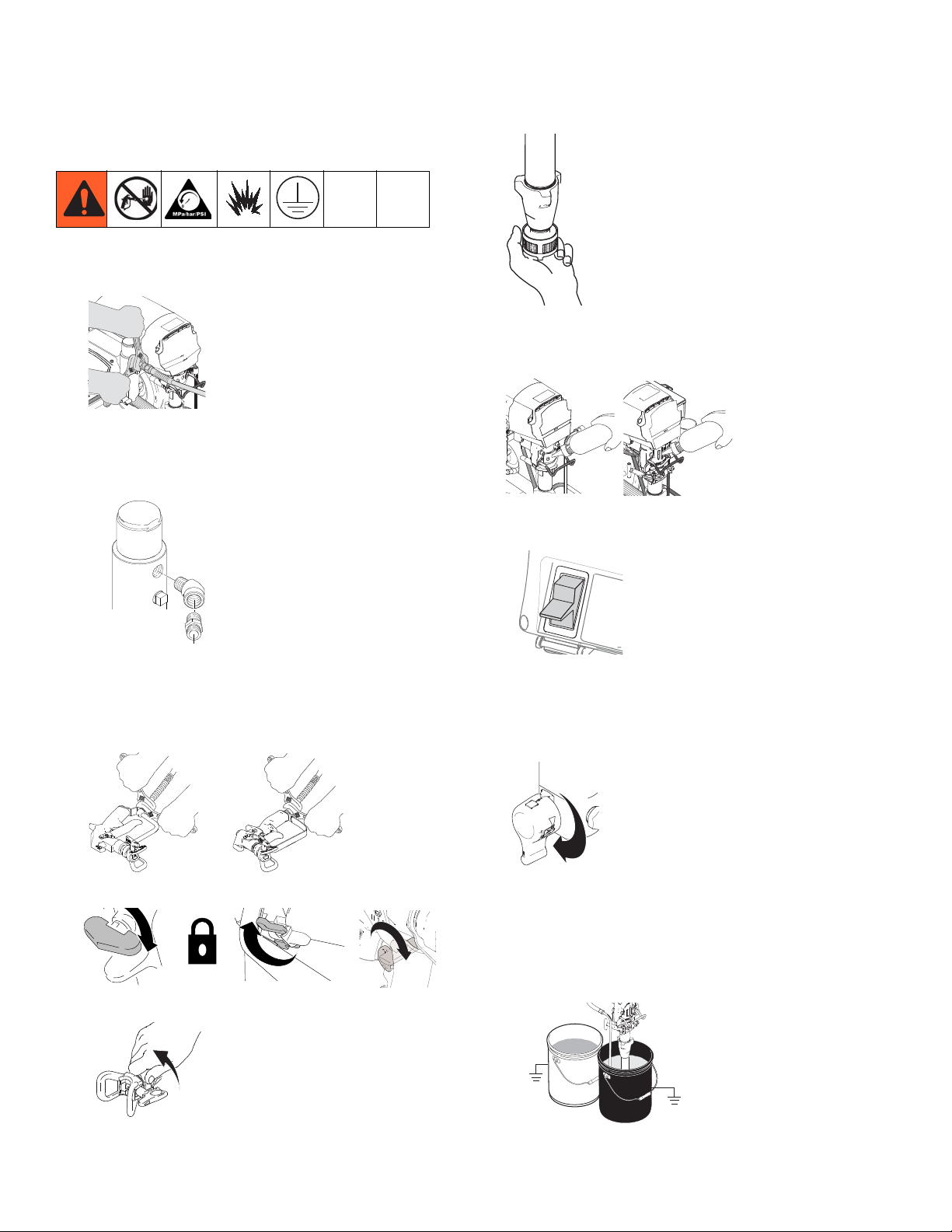

Page 12

10/16 Amp Switch

ti5850b

ti14840a

ti18247b

ti22874a

ti22936a

Pails

Solvent and oil/based fluids: follow local code. Use

only conductive metal pails, placed on a grounded surface such as concrete.

Do not place pail on a nonconductive surface such as

paper or cardboard which interrupts grounding

continuity.

Grounding a metal pail: connect a ground wire to the

pail by clamping one end to pail and other end to a true

earth ground.

10/16 Amp Switch

(Mark VII and Mark X units)

Select 10A or 16A setting based on your circuit rating.

15/20 Amp Switch

(120V 1595 and Mark V units)

Select 15A or 20A setting based on your circuit rating.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of spray gun firmly

to side of a grounded metal pail. Then trigger gun.

12 332916C

Page 13

Pressure Relief Procedure

ti18199a

ti2769a

ti22937a

ti2595a

ti14842a

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Turn power OFF. Wait 7 seconds for power to

dissipate.

4. Turn pressure to lowest setting. Trigger gun to

relieve pressure.

5. Put drain tube in pail. Turn prime valve down to

DRAIN position. Leave prime valve in DRAIN position until you are ready to spray again.

2. Engage trigger lock.

3. Remove guard and SwitchTip.

6. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

332916C 13

Page 14

Setup

ti22875a

ti18631a

ti18195a

ti18199a

ti2769a

ti17608b

ti18421b

ti22950a

ti14842a

ti18245b

Setup

1. All sprayers except ProContractor: Connect

Graco airless hose to sprayer. Tighten securely.

If using the optional hopper, remove the nipple fitting from the filter. Install 45° elbow (from parts box)

into filter and install nipple fitting into elbow. Then

connect the hose to the nipple.

5. Check inlet strainer for clogs and debris.

6. Fill throat packing nut with Graco TSL to prevent

premature packing wear. Do this each time you

spray.

7. Turn power OFF.

NOTE: Make sure nipple fitting is angled away from

hopper so the hose can be easily installed.

2. Connect whip hose (if applicable) and gun to other

end of hose. Tighten securely.

3. Engage trigger lock.

4. Remove tip guard.

8. Plug power supply cord into a properly grounded

electrical outlet.

9. Turn prime valve down to DRAIN position.

10. Place pump in grounded metal pail partially filled

with flushing fluid. Attach ground wire to pail and

to true earth ground. Perform steps 1 - 5 of Startup

to flush out storage oil shipped in sprayer. Use

water to flush water-base paint and mineral spirits to

flush oil-base paint and storage oil.

14 332916C

Page 15

Startup

ti13670b

ti4266b

1/2

15sec

.

ti14845a

ti18198a

ti22949a

ti18244b

ti18248a

ti18199a

1. Perform Pressure Relief Procedure, page 13.

2. Turn pressure control to lowest pressure.

Startup

6. Hold gun against grounded metal flushing pail. Trigger gun and increase fluid pressure 1/2 turn. Flush

1 minute.

3. Turn power ON.

4. Increase pressure 1/2 turn to start motor and allow

fluid to circulate through drain tube for 15 seconds;

turn pressure down.

5. Turn prime valve forward to SPRAY position. Disengage trigger lock.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. Do not stop

leaks with hand or rag.

7. Inspect for leaks. If leaks occur, perform Pressure

Relief Procedure, page 13. Tighten fittings. Perform Startup, steps 1 - 5. If no leaks, proceed to

step 7.

8. Place pump in paint pail.

9. Trigger gun again into flushing pail until paint

appears. Move gun to paint pail and trigger for 20

seconds.

10. Engage trigger lock. Assemble tip and guard, see

instructions on next page.

332916C 15

Page 16

Switch Tip Installation

ti13023a

C

A

B

ti13024a

ti2710a

ti18243a

ti18242a

ti13033a

ti13034a

Switch Tip Installation

1. Perform Pressure Relief Procedure, page 13.

™

2. Use spray tip (A) to insert OneSeal

guard (C).

3. Insert Switch Tip.

(B) into

Spray

1. Spray test pattern. Increase pressure to eliminate

heavy edges. Use smaller tip size if pressure adjustment can not eliminate heavy edges.

2. Hold gun perpendicular, 10-12 in. (25-30 cm) from

surface. Spray back and forth. Overlap by 50%.

Trigger gun after moving and release before stopping.

4. Screw assembly onto gun. Tighten.

Clearing Tip Clog

SKIN INJECTION HAZARD

Never point gun at your hand or into a rag!

1. Release trigger, engage trigger lock. Rotate

SwitchTip. Disengage trigger lock. Trigger gun to

clear clog.

2. Engage trigger lock. Return SwitchTip to original

position. Disengage trigger lock and continue spraying.

16 332916C

Page 17

Fast Flush (ProContractor and IronMan models only)

ti22940a

ti22938a

ti22033a

ti22939a

Fast Flush

(ProContractor and IronMan models only)

To flush the hose and gun at an accelerated speed, perform the following steps:

1. Perform steps 1 - 3 of Cleanup, page 22.

2. Squeeze gun trigger and turn prime valve down to

DRAIN position and then over to FAST FLUSH.

3. Continue flushing system until fluid appears clear.

WatchDog™ Protection System

(ProContractor and IronMan models only)

Pump stops automatically when material pail is empty.

To Activate:

1. Perform Startup.

2. Turn WatchDog switch ON and WD ON displays.

EMPTY displays/flashes and pump stops when

Watchdog protection system detects an empty

material pail.

3. Turn WatchDog switch OFF. Add material or reprime sprayer. Turn pump switch OFF and ON to

reset WatchDog protection system. Turn WatchDog

switch back ON to continue to monitor material

level.

332916C 17

Page 18

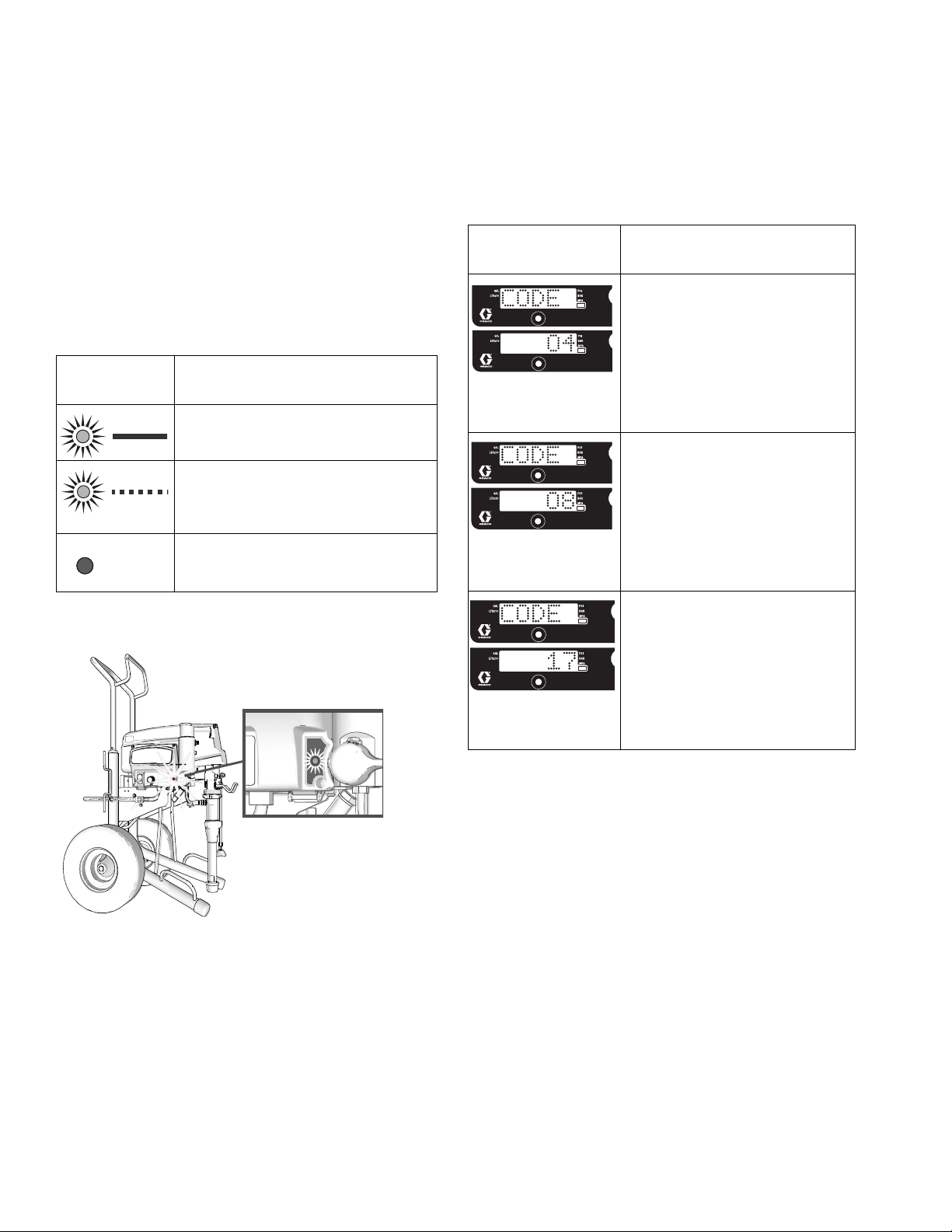

ProGuard

ProGuard

Status Indicator Light

ProGuard

This sprayer protects itself against high and low voltage.

If the sprayer is plugged into a power source that is too

low or too high the sprayer will stop operating.

Standard Models

Standard models come equipped with a ProGuard status indicator light. This light has three different states of

operation: ON, blink, and OFF.

Error

Code

Light is ON

Unit is powered and operating normally.

Light is Blinking

Voltage supply is too low or too high for

sprayer and will not run until it is plugged

into a good power supply.

Light is OFF

No power to sprayer, or there is another

error other than the voltage supply.

See Troubleshooting (page 24) to determine the cause

of any errors.

Definition

ProContractor and IronMan Models

One of three error codes will be displayed:

Error

Code

Multiple incoming voltage surges

detected - unplug sprayer and

locate good voltage supply to

prevent damage to electronics.

Typical cause of this error is plugging

into a circuit that is higher than the

rated voltage of the sprayer. Find a

circuit that supplies the correct

voltage.

Incoming voltage too low for

sprayer operation - unplug sprayer

and locate good voltage supply to

prevent damage to electronics.

Typical cause of this error is other

equipment on the same circuit or

generator frequently turning on/off

under load. Find a circuit that is

dedicated to the sprayer.

Sprayer plugged into wrong

voltage - unplug sprayer and

locate correct voltage supply.

Typical cause of this error is a GFCI

box that is wired for the wrong

voltage (240V vs. 120V). No damage

has occurred to the sprayer. Find a

circuit with the correct voltage and

the sprayer will run correctly.

Definition

18 332916C

Page 19

Hose Reel

ti18241a

ti13501c

ti13503b

ti13502b

(A)

(B)

ti13563b

Hose Reel

(ProContractor models only)

Moving parts can pinch, cut or amputate fingers and

other body parts. To avoid injury from moving parts, be

sure to keep your head clear of hose reel while winding

up hose.

1. Make sure hose is routed through hose guide.

2. Lift and turn pivot lock 90° to unlock hose reel. Pull

on hose to remove it from hose reel.

3. Pull reel handle up and turn clockwise to reel in

hose.

NOTE: The hose reel can be locked into two positions:

Usage (A) and Storage (B).

332916C 19

Page 20

Digital Tracking System (ProContractor and IronMan models only)

ti22719a

ti22941a

ti22942a

ti22876a

ti22717a

ti22718a

Digital Tracking System

(ProContractor and IronMan models only)

Operation Main Menu

Short press to move to next display. Press and hold (5

seconds) to change units or reset data.

1. Turn pressure to lowest setting. Trigger gun to

relieve pressure. Turn prime valve down to DRAIN

position.

Job Gallons

1. Short press DTS button to move to Job Gallons (or

liters x 10).

NOTE: JOB scrolls past, then the number of gallons

sprayed above 400 psi (28 bar, 2.8 MPa) for Mark

VII and Mark X displays; 1000 psi (70 bar, 7 MPa)

for all other models.

2. Press and hold to reset to zero.

Lifetime Gallons

1. Short press DTS button to move to Lifetime Gallons

(or liters x 10).

2. Turn power ON. Pressure display appears. Dashes

will not appear unless pressure is less than 200 psi

(14 bar, 1,4 MPa).

Change Display Units

Press and hold DTS button for 5 seconds to change

pressure units (psi, bar, MPa) to desired units. Selection of bar or MPa changes gallons to liters x 10. To

change display units DTS must be in pressure display

mode and pressure must be at zero.

NOTE: LIFE scrolls briefly, then the number of gallons sprayed above 400 psi (28 bar, 2.8 MPa) for

Mark VII and Mark X displays; 1000 psi (70 bar, 7

MPa) for all other models.

20 332916C

Page 21

Digital Tracking System (ProContractor and IronMan models only)

ti22881a

ti22720a

ti22721a

ti22722a

ti22723a

ti22724a

ti22725a

Secondary Menu - Stored Data

1. Perform Pressure Relief, steps 1 - 4 if they have not

already been done.

2. Turn power switch on while holding DTS button down.

3. SERIAL NUMBER scrolls past and then serial number

(e.g. 00001) displays.

4. Short press DTS button and MOTOR HOURS scrolls past

and then total motor run hours are displayed.

5. Short press DTS button. LAST CODE scrolls by and last

code is displayed; e.g. E=07 (see Repair manual).

7. Short press DTS button. W-DOG scrolls past then OFF

displays if watchdog switch is OFF. ON displays if Watch-

dog switch is ON.

8. Press and hold (8 seconds) DTS button to move to

WatchDog Trigger % menu. Continue to hold DTS button

and Watchdog can be set to trigger at 30, 40, 50, or 60%

of current sprayer pressure setting. Release DTS button

when desired % is displayed. Default is 50%.

9. Short press to move to SOFTWARE REV.

10. Short press DTS button. MOTOR ID RESISTOR scrolls

by and model code number (see below).

Motor ID Number Models

0695

2 795 / Mark IV

4 1095 / 230V Mark V

6 1595 / 120V Mark V / MARK VII

10 Mark X

6. Press and hold DTS button to clear code to zero.

332916C 21

Page 22

Cleanup

ti22943a

ti18249a

ti22944a

ti18248a

ti22945a

ti22946a

ti18248a

ti22947a

ti22945a

Cleanup

1. Perform Pressure Relief Procedure (page 13),

steps 1 - 4. Remove tip guard from gun.

NOTE: Use water for water-base material, mineral

spirits for oil-base material, or other solvents recommended by manufacturer.

5. Turn prime valve down to DRAIN position and allow

flushing fluid to circulate until flushing fluid appears

clear.

2. Turn power ON. Turn prime valve forward to

SPRAY position.

3. Increase pressure to 1/2. Hold gun against pail. Disengage trigger lock. Trigger gun until flushing fluid

appears.

4. Move gun to waste pail, hold gun against pail, trigger gun to thoroughly flush system. Release trigger

and engage trigger lock.

6. Turn prime valve forward to SPRAY position. Trigger gun into flushing pail to purge fluid from hose.

7. Raise pump above flushing fluid and run sprayer for

15 to 30 seconds to drain fluid. Turn power OFF.

8. Turn prime valve down DRAIN position. Unplug

sprayer.

22 332916C

Page 23

Cleanup

ti13454a

ti15018a

ti2895a

Pump Armor

ti2776a

9. Remove filters from gun and sprayer, if installed.

Clean and inspect. Install filters.

10. If flushing with water, flush again with mineral spirits, or Pump Armor, to leave a protective coating to

prevent freezing or corrosion.

11. Wipe sprayer, hose and gun with a rag soaked in

water or mineral spirits.

332916C 23

Page 24

Troubleshooting

Troubleshooting

Mechanical/Fluid Flow

Perform Pressure Relief Procedure; page 13.

WHAT TO CHECK

TYPE OF PROBLEM

For units with display:

CODE XX is displayed.

For units with no display:

ProGuard status light is

blinking or the light is off

and there is power to the

sprayer.

Pump output is low Spray tip worn Follow Pressure Relief Procedure on page

If check is OK, go to next check

Fault condition exists Determine fault correction from table,

Spray tip clogged Relieve pressure. Check and clean spray tip.

Paint supply Refill and reprime pump.

Intake strainer clogged Remove and clean, then reinstall

Intake valve ball and piston ball are

not seating properly

Fluid filter, tip filter, or tip is clogged

or dirty.

Prime valve leaking Relieve pressure. Repair prime valve.

Verify pump does not continue to

stroke when gun trigger is released.

(Prime valve not leaking.)

Leaking around throat packing nut

which may indicate worn or damaged

packings.

When check is not OK, refer to this column

page 27.

13, then replace tip. See your separate gun or

tip manual.

Remove intake valve and clean. Check balls

and seats for nicks; replace if necessary; see

pump manual. Strain paint before using to

remove particles that could clog pump.

Clean filter; see operation manual.

Service pump; see pump manual.

Replace packings; see pump manual. Also

check piston valve seat for hardened paint or

nicks and replace if necessary. Tighten packing nut/wet-cup.

WHAT TO DO

24 332916C

Page 25

Troubleshooting

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

When check is not OK, refer to this column

WHAT TO DO

Pump output is low Pump rod damage Repair pump. See pump manual.

Low stall pressure Turn pressure knob fully clockwise. Make sure

pressure control knob is properly installed to

allow full clockwise position. If problem persists, replace pressure transducer.

Piston packings are worn or dam-

Replace packings; see pump manual.

aged

O-ring in pump is worn or damaged Replace o-ring; see pump manual.

Intake valve ball is packed with mate-

Clean intake valve; see pump manual.

rial

Pressure setting is too low Increase pressure; see pump manual.

Motor runs but pump does

not stroke

Large pressure drop in hose with

heavy materials

Check to see if Amp switch (10/16 or

15/20) is on low setting. Make sure

circuit is able to provide high setting.

Displacement pump pin damaged or

missing; see pump manual.

Use larger diameter hose and/or reduce overall

length of hose.

Switch to 16A or 20A setting. Change to circuit

that provides 16A or 20A. Change to less

loaded circuit.

Replace pump pin if missing. Be sure retainer

spring is fully in groove all around connecting

rod; see pump manual.

Connecting rod assembly damaged;

see pump manual.

Replace connecting rod assembly; see pump

manual.

Gears or drive housing damaged. Inspect drive housing assembly and gears for

damage and replace if necessary; see pump

manual.

Excessive paint leakage

into throat packing nut

Throat packing nut is loose Remove throat packing nut spacer. Tighten

throat packing nut just enough to stop leakage.

Throat packings are worn or dam-

Replace packings; see pump manual.

aged

Displacement rod is worn or dam-

Replace rod; see pump manual.

aged

Fluid is spitting from gun Air in pump or hose Check and tighten all fluid connections. Cycle

pump as slowly as possible during priming.

Tip is partially clogged Clear tip; see Operation manual.

Fluid supply is low or empty Refill fluid supply. Prime pump; see pump man-

ual. Check fluid supply often to prevent running

pump dry.

332916C 25

Page 26

Troubleshooting

TYPE OF PROBLEM

Pump is difficult to prime

No display, sprayer

operates

WHAT TO CHECK

If check is OK, go to next check

When check is not OK, refer to this column

WHAT TO DO

Air in pump or hose Check and tighten all fluid connections. Cycle

pump as slowly as possible during priming.

Intake valve is leaking Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well. Reassemble valve.

Pump packings are worn Replace pump packings; see pump manual.

Paint is too thick Thin the paint according to supplier recommen-

dations.

Display is damaged or has bad con-

Check connections. Replace display.

nection

26 332916C

Page 27

Electrical

D20

D20

ProGuard Status Light

Control Board Status Light

Symptom: Sprayer does not run, stops running, or will

not shut off.

Perform Pressure Relief Procedure; page 13.

Troubleshooting

1. Plug sprayer into correct voltage, grounded outlet.

2. Set power switch OFF for 30 seconds and then ON

again (this ensures sprayer is in normal run mode).

3. Turn pressure control knob clockwise 1/2 turn.

4. View digital displayy.

Keep clear of electrical and moving parts during troubleshooting procedures. To avoid electrical shock hazards when covers are removed for troubleshooting, wait

5 minutes after unplugging power cord for stored electricity to dissipate.

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all See flow chart, page 33.

Display is blank

ProGuard status light and

control board status light never

light

Sprayer does not run at all Check transducer or transducer

Display shows CODE 02

Control board status light blinks

2 times repeatedly

connections

For units without a display, see

ProGuard

(page 18). If

there is a voltage supply issue (CODE 04, 08, or 17), the

ProGuard status light will blink continuously when the

ON/OFF switch is ON. To determine which code (or any

other code besides voltage supply) refer to the control

board status light. Turn the ON/OFF switch OFF, remove

the control cover then turn power back ON. Observe the

status light. Blinking LED total count equals the error

code (for example: two blinks equals CODE 02).

1. Make sure there is no pressure in the system (see

13

Pressure Relief Procedure, page

path for clogs, such as clogged filter.

2. Use airless paint spray hose with no metal braid

1/4 in. x 50 ft minimum. Smaller hose or metal braid

hose may result in high-pressure spikes.

3. Set sprayer to OFF and disconnect power to

sprayer.

4. Check transducer and connections to control board.

5. Disconnect transducer from control board socket.

Check that transducer and control board contacts

are clean and secure.

6. Reconnect transducer to control board socket.

Connect power, set sprayer ON and control knob

1/2 turn clockwise. If sprayer does not run properly,

set sprayer to OFF and go to next step.

7. Install new transducer. Connect power, set sprayer

ON and control knob 1/2 turn clockwise. Replace

control board if sprayer does not run properly.

). Check fluid

332916C 27

Page 28

Troubleshooting

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Check transducer or transducer

Display shows CODE 03

Control board status light blinks

3 times repeatedly

Sprayer does not run at all

Display shows CODE 4

connections (control board is not

detecting a pressure signal).

Check voltage supply to the

sprayer (control board is

detecting a multiple voltage

surges).

1. Set sprayer to OFF and disconnect power to

sprayer.

2. Check transducer and connections to control board.

3. Disconnect transducer from control board socket.

Check to see if transducer and control board

contacts are clean and secure.

4. Reconnect transducer to control board socket.

Connect power, set sprayer ON and control knob

to 1/2 turn clockwise. If sprayer does not run,

set sprayer to OFF and go to next step.

5. Connect a confirmed working transducer to control

board socket.

6. Set sprayer ON and control knob to 1/2 turn

clockwise. If sprayer runs, install new transducer.

Replace control board if sprayer does not run.

7. Check transducer resistance with ohmmeter (less

than 9k ohm between red and black wires and 3-6k

ohm between green and yellow wires).

1. Set sprayer to OFF and disconnect power to

sprayer.

2. Locate a good voltage supply to prevent damage to

electronics.

Control board status light blinks

four times repeatedly

28 332916C

Page 29

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Green Blue Red Black

Green Blue Red Black

Green Blue Red Black

STEP 1:

STEP 2:

STEP 3:

Troubleshooting

Sprayer does not run at all Control is commanding motor to run

Display shows CODE 05

Control board status light blinks

5 times repeatedly

but motor shaft does not rotate.

Possibly locked rotor condition, an

open connection exists between

motor and control, there is a

problem with motor or control board,

or motor amp draw is excessive.

1. Remove pump and try to run sprayer. If motor runs,

check for locked or frozen pump or drive train.

If sprayer does not run, continue to step 2.

2. Set sprayer to OFF and disconnect power to

sprayer.

3. Disconnect motor connector(s) from control board

socket(s). Check that motor connector and control

board contacts are clean and secure. If contacts

are clean and secure, continue to step 4.

4. Set sprayer to OFF and spin motor fan 1/2 turn.

Restart sprayer. If sprayer runs, replace control

board. If sprayer does not run, continue to step 5.

5. Perform Spin Test: Test at large 4-pin motor field

connector. Disconnect fluid pump from sprayer. Test

motor by placing a jumper across pins 1 & 2. Rotate

motor fan at about 2 revolutions per second. A cogging

resistance to motion should be felt at the fan.

The motor should be replaced if no resistance is felt.

Repeat for pin combinations 1 & 3 and 2 & 3. Pin 4

(the green wire) is not used in this test. If all spin test

is positive, continue to step 6.

332916C 29

Page 30

Troubleshooting

Resistance Table:

695/240V Mark IV 0 ohms

795/120V Mark IV 2k ohms

1095/240V Mark V 3.9k ohms

1595/120V Mark V/MARK VII 6.2k ohms

MARK X 10.0k ohms

-

ti13140a

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Control is commanding motor to run

Display shows CODE 05

but motor shaft does not rotate.

Possibly locked rotor condition,

an open connection exists between

motor and control, there is a problem

with motor or control board, or

motor amp draw is excessive.

Control board status light blinks

5 times repeatedly

6. Perform Field Short Test: Test at large 4-pin motor

field connector. There should not be continuity from

pin 4, the ground wire, and any of the remaining

3 pins. If motor field connector tests fail,

replace motor.

7. Check Motor Thermal Switch: Unplug thermal

wires. Set meter to ohms. Meter should read the

proper resistance for each unit (see table below).

30 332916C

Page 31

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

-

ti13140a

Resistance Table:

695/240V Mark IV 0 ohms

795/120V Mark IV 2k ohms

1095/240V Mark V 3.9k ohms

1595/120V Mark V/MARK VII 6.2k ohms

MARK X 10.0k ohms

Troubleshooting

Sprayer does not run at all Allow sprayer to cool. If sprayer

Display shows CODE 06

runs when cool, correct cause of

overheating. Keep sprayer in cooler

location with good ventilation. Make

sure motor air intake is not blocked.

If sprayer still does not run, follow

Step 1.

Control board status light blinks

6 times repeatedly

NOTE: Motor must be cooled down for the test.

1. Check thermal device connector (yellow wires)

at control board.

2. Disconnect thermal device connector from control

board socket. Make sure contacts are clean and

secure. Measure resistance of the thermal device. If

reading is not correct, replace motor.

Check Motor Thermal Switch: Unplug thermal

wires. Set meter to ohms. Meter should read the

proper resistance for each unit (see table below).

Sprayer does not run at all Check voltage supply to the sprayer

Display shows CODE 08

Control board status light blinks

eight times repeatedly

Sprayer does not run at all Check to see if control board is over

Display shows CODE 10

Control board status light blinks

10 times repeatedly

332916C 31

(incoming voltage too low for

sprayer operation)

heating.

3. Reconnect thermal device connector to control

board socket. Connect power, turn sprayer ON and

control knob 1/2 turn clockwise. If sprayer does not

run, replace control board.

1. Set sprayer to OFF and disconnect power to

sprayer.

2. Remove other equipment that uses the same circuit.

3. Locate a good voltage supply to avoid damage to

electronics.

1. Make sure motor air intake is not blocked.

2. Make sure fan has not failed.

3. Make sure control board is properly connected

to back plate and that conductive thermal paste

is used on power components.

4. Replace control board.

5. Replace motor.

Page 32

Troubleshooting

ti18685a

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Excessive current protection

Display shows CODE 12

enabled

Control board status light blinks

12 times repeatedly

Sprayer does not run at all Check the connections above the

Display shows CODE 15

motor

Control board status light blinks

15 times repeatedly

Sprayer does not run at all Check the connections. Control

Digital display shows CODE 16

is not receiving a motor position

sensor signal

1. Cycle power on and off.

1. Set sprayer to OFF and disconnect power to

sprayer.

2. Remove motor shroud.

3. Disconnect motor control and inspect for damage at

connectors.

4. Reconnect motor control.

5. Turn power on. If code continues, replace motor.

1. Turn power OFF.

2. Disconnect motor position sensor and inspect for

damage at connectors.

Control board status light blinks

16 times repeatedly

3. Reconnect sensor.

4. Turn power ON. If code continues, replace motor.

Sprayer does not run at all Check voltage supply to the sprayer

Display shows CODE 17

(sprayer plugged into wrong

voltage)

1. Set sprayer to OFF and disconnect power to

sprayer.

2. Locate a good voltage supply to avoid damage to

electronics.

Control board status light blinks

17 times repeatedly

32 332916C

Page 33

Sprayer Will Not Run

Remove control box cover. Turn

sprayer ON. Observe control

board status light on control board

(see page 27).

No light

Once Normal operation

Light on

Continuously

Control board

commanding

motor to run

Flashing See Code section

for further

troubleshooting

Connect a test

transducer to the

board. Does the

motor run?

Replace

potentiometer.

See Step 3. Is the

proper reading

present through the

thermal switch

wires?

Replace the

ON/OFF switch.

See step 4. Does

the motor run?

See Step 1. Do

you have over

100 VAC

(220 VAC for

230V units)?

See Step 2. Do

you have over

100 VAC

(220 VAC for

230V units)?

Repair or

replace

power cord.

If motor is hot, let cool and

retest. If Step 3 still shows

incorrect resistance, replace

motor. The motor has

a defective thermal device.

Replace the

transducer

Replace the

control board.

YES

YES

YES

NO

NO

NO

NO

YES

YES

NO

(See following page for steps)

Troubleshooting

332916C 33

Page 34

Troubleshooting

-

V

--

200-240V

200-240V

100k ohm

STEP 1:

Plug power cord in

and turn switch ON.

Connect probes to

on/off switch. Turn

meter to AC Volts.

STEP 2:

Plug power cord in

and turn switch ON.

Connect probes to

on/off switch. Turn

meter to AC Volts.

STEP 3:

Check motor thermal switch.

Unplug yellow wires. Meter

should read according to

Resistance Table on page 30.

NOTE: Motor should be cool

during reading.

STEP 4:

Plug power cord

in and turn switch

ON. Disconnect

potentiometer.

34 332916C

Page 35

Sprayer Will Not Shut Off

Plumb pressure gauge into paint

hose, plug sprayer in, and turn power

switch ON. Does sprayer reach or

exceed its maximum pressure?

Unplug the transducer from control

board. Does motor stop running?

Bad transducer. Replace and test

with a new one.

Replace the control board.

Mechanical problem: See the proper

fluid pump manual for the sprayer for

further trouble shooting procedures.

NO

NO

YES

YES

Troubleshooting

1. Perform Pressure Relief Procedure; page 13.

Leave prime valve open and power switch OFF.

Troubleshooting Procedure

2. Remove control box cover so the control board

status light can be viewed if available.

332916C 35

Page 36

Technical Data

Technical Data

695 Sprayers

U.S. Metric

Sprayer

Maximum Delivery

North American Models 0.95 gpm 3.6 lpm

International Models 0.75 gpm 2.8 lpm

Maximum Tip Size 0.031 0.031

Fluid Outlet npsm 1/4 in. 1/4 in.

Cycles 226 per gallon 60 per liter

Generator Minimum 5000 W 5000 W

120V, A, Hz 14.8, 50/60 14.8, 8, 50/60

230V, A, Hz 9, 50/60 9, 50/60

Dimensions

Weight:

Standard Series Lo-Boy 94 lb 43 kg

Standard Series Hi-Boy 94 lb 43 kg

ProContractor 111 lb 50 kg

Height:

Standard Series Lo-Boy 27.5 in. 69.9 cm

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

Length:

Standard Series Lo-Boy 37 in. 94 cm

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 29.5 in. 75 cm

Width: 22.5 in. 57.2 cm

28.5 in. (Handle down)

38.75 in. (Handle up)

72.4 cm (Handle down)

98.4 cm (Handle up)

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

36 332916C

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

Page 37

795 Sprayers

U.S. Metric

Sprayer

Maximum Delivery

North American Models 1.1 gpm 4.2 lpm

International Models 0.95 gpm 3.6 lpm

Maximum Tip Size 0.033 0.033

Fluid Outlet npsm 1/4 in. 1/4 in.

Cycles 195 per gallon 52 per liter

Generator Minimum 5000 W 5000 W

120V, A, Hz 15, 50/60 15, 50/60

230V, A, Hz 10, 50/60 10, 50/60

Dimensions

Weight:

Standard Series Lo-Boy 98 lb 45 kg

Standard Series Hi-Boy 98 lb 45 kg

ProContractor 115 lb 52 kg

Height:

Standard Series Lo-Boy 27.5 in. 69.9 cm

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

Length:

Standard Series Lo-Boy 37 in. 94 cm

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 29.5 in. 75 cm

Width: 22.5 in. 57.2 cm

28.5 in. (Handle down)

38.75 in. (Handle up)

72.4 cm (Handle down)

98.4 cm (Handle up)

Technical Data

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

332916C 37

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

Page 38

Technical Data

1095 Sprayers

U.S. Metric

Sprayer

Maximum Delivery

North American Models 1.2 gpm 4.5 lpm

International Models 1.1 gpm 4.1 lpm

Maximum Tip Size 0.035 0.035

Fluid Outlet npsm 1/4 in. 1/4 in.

Cycles 123 per gallon 33 per liter

Generator Minimum 5000 W 5000 W

120V, A, Hz 15, 50/60 15, 50/60

230V, A, Hz 10, 50/60 10, 50/60

Dimensions

Weight:

Standard Series Hi-Boy 120 lb 55 kg

ProContractor 141 lb 64 kg

IronMan 127 lb 58 kg

Height:

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

IronMan 40.2 in. 102 cm

Length:

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 28 in. 71 cm

IronMan 29.9 in. 76 cm

Width:

Standard Series Hi-Boy 24 in. 61 cm

ProContractor 24 in. 61 cm

IronMan 24.4 in. 62 cm

29.5 in. (Handle down)

38.5 in. (Handle up)

74.9 cm (Handle down)

97.8 cm (Handle up)

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

38 332916C

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

Page 39

1595 Sprayers

U.S. Metric

Sprayer

Maximum Delivery 1.35 gpm 5.1 lpm

Maximum Tip Size 0.039 0.039

Fluid Outlet npsm 1/4 in. 1/4 in.

Cycles 110 per gallon 29 per liter

Generator Minimum 5000 W 5000 W

120V, A, Hz 20/15, 50/60 20/15, 50/60

Dimensions

Weight:

Standard Series Hi-Boy 125 lb 57 kg

ProContractor 146 lb 66 kg

IronMan 132 lb 60 kg

Height:

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

IronMan 40.2 in. 102 cm

Length:

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 28 in. 71 cm

IronMan 29.9 in. 76 cm

Width:

Standard Series Hi-Boy 24 in. 61 cm

ProContractor 24 in. 61 cm

IronMan 24.4 in. 62 cm

29.5 in. (Handle down)

38.5 in. (Handle up)

74.9 cm (Handle down)

97.8 cm (Handle up)

Technical Data

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

332916C 39

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

Page 40

Technical Data

Mark IV Sprayers

U.S. Metric

Sprayer

Maximum Delivery

North American Models 1.1 gpm 4.2 lpm

International Models 0.95 gpm 3.6 lpm

Maximum Tip Size

North American Models 0.033 0.033

International Models 0.031 0.031

Fluid Outlet npsm 3/8 in. 3/8 in.

Cycles 195 per gallon 52 per liter

Generator Minimum 5000 W 5000 W

120V, A, Hz 15, 50/60 15, 50/60

230V, A, Hz 10, 50/60 10, 50/60

Dimensions

Weight:

Standard Series Hi-Boy 98 lb 45 kg

ProContractor 119 lb 54 kg

Height:

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

Length:

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 29.5 in. 75 cm

Width: 22.5 in. 57.2 cm

28.5 in. (Handle down)

38.75 in. (Handle up)

72.4 cm (Handle down)

98.4 cm (Handle up)

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

40 332916C

Page 41

Mark V Sprayers

U.S. Metric

Sprayer

Maximum Delivery

North American and UK Models 1.35 gpm 5.1 lpm

International Models 1.2 gpm 4.5 lpm

Maximum Tip Size

North American and UK Models 0.039 0.039

International Models 0.035 0.035

Fluid Outlet npsm 3/8 in. 3/8 in.

Cycles 110 per gallon 29 per liter

Generator Minimum 5000 W 5000 W

120V, A, Hz 20/15, 50/60 20/15, 50/60

230V, A, Hz 10, 50/60 10, 50/60

Dimensions

Weight:

Standard Series Hi-Boy 130 lb 59 kg

ProContractor 151 lb 68 kg

IronMan 137 lb 62 kg

Height:

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

IronMan 40.2 in. 102 cm

Length:

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 28 in. 71 cm

IronMan 29.9 in. 76 cm

Width:

Standard Series Hi-Boy 24 in. 61 cm

ProContractor 24 in. 61 cm

IronMan 24.4 in. 62 cm

29.5 in. (Handle down)

38.5 in. (Handle up)

74.9 cm (Handle down)

97.8 cm (Handle up)

Technical Data

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

332916C 41

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

Page 42

Technical Data

Mark VII Sprayers

U.S. Metric

Sprayer

Maximum Delivery 1.58 gpm 6.0 lpm

Maximum Tip Size 0.041 in. 0.041 in.

Fluid Outlet npsm 1/2 in. 1/2 in.

Cycles 97 per gallon 26 per liter

Generator Minimum 5000 W 5000 W

230V, A, Hz 16, 50/60 16, 50/60

Dimensions

Weight:

Standard Series Hi-Boy 139 lb 63 kg

ProContractor 160 lb 73 kg

Height:

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

Length:

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 28 in. 71 cm

Width: 24 in. 61 cm

29.5 in. (Handle down)

38.5 in. (Handle up)

74.9 cm (Handle down)

97.8 cm (Handle up)

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

42 332916C

Page 43

Mark X Sprayers

U.S. Metric

Sprayer

Maximum Delivery 2.1 gpm 8.0 lpm

Maximum Tip Size 0.045 in. 0.045 in.

Fluid Outlet npsm 1/2 in. 1/2 in.

Cycles 70 per gallon 19 per liter

Generator Minimum 5000 W 5000 W

230V, A, Hz 16, 50/60

Dimensions

Weight:

Standard Series Hi-Boy 154 lb 70 kg

ProContractor 178 lb 81 kg

Height:

Standard Series Hi-Boy

ProContractor 39 in. 99 cm

Length:

Standard Series Hi-Boy 26 in. 66 cm

ProContractor 30 in. 75 cm

Width: 24 in. 61 cm

29.9 in. (Handle down)

40.1 in. (Handle up)

76 cm (Handle down)

102 cm (Handle up)

Technical Data

Wetted parts

Noise Level:

Sound Power 91 dBa* 91 dBa*

Sound Pressure 82 dBa* 82 dBa*

zinc- and nickel-plated carbon steel, nylon, stainless steel, PTFE, Acetal,

leather, UHMWPE, aluminum, tungsten carbide, PEEK, brass

*per ISO 3744; measured at 3.1 ft *per ISO 3744; measured at 1 m

332916C 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissen

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

t avoir convenu que la

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2014, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions.

This manual contains English. MM 332916

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision C - March 2014

Loading...

Loading...