Page 1

Manzel® Model 88 Pump

DESCRIPTION

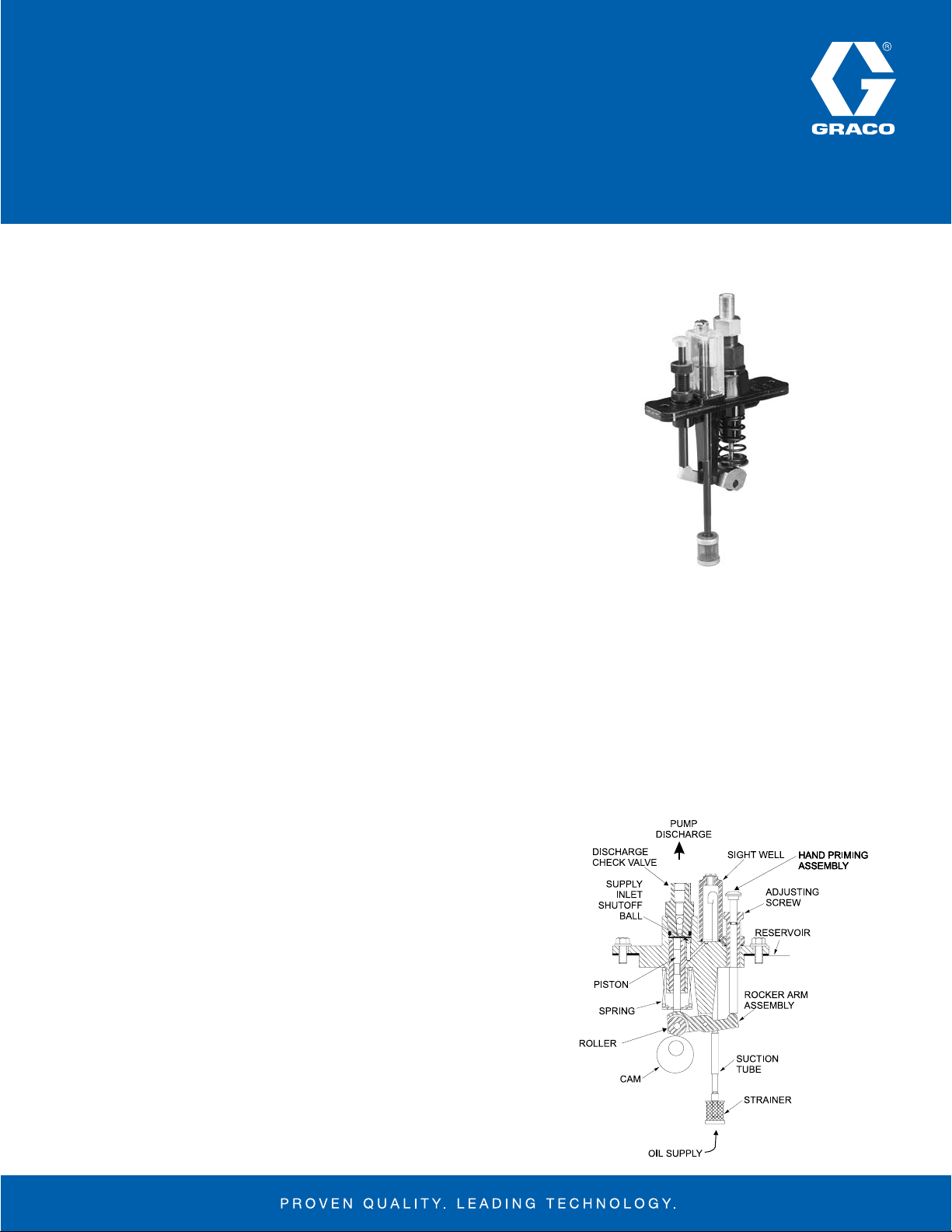

The Model 88 Pump is a heavy-duty precision metering pump

capable of accurately pumping small flows of either mineral or

synthetic oil to machinery injection points. The single-piston

pump is mechanically driven from a camshaft in the reservoir

and is adjustable from 1 to 27 drops per stroke, depending on

the piston size. The pump can develop pressures up to 7500

psi, depending on the piston size. All working parts are totally

enclosed away from dirt, water, and impurities and self-lubricated

at all times by the fluid in the reservoir.

Model 88 Pumps are designed for use in Manzel® Model 55 and

76 Box Lubricators, and in Mega, Lincoln and Premier Model 55

Box Lubricators. The output ranges vary slightly depending on the

lubricator.

Model 88 Pumps are rugged, heavy duty units. Each pump

includes a precision machined steel sleeve fitted with an alloy

steel piston.

The pump is actuated by a hardened steel roller - rocker following

a cam for low wear and longer life. The visual sight well is onepiece injection molded material that is impervious to ultra-violet

rays, and mineral and synthetic oils.

Three (3) piston sizes are available to produce outputs up to 27

drops per stroke in Manzel Box Lubricators and up to 20 drops per

stroke in Mega, Lincoln and Premier Model 55 Box Lubricators.

FEATURES/BENEFITS

ball is concurrently unseated and lubricant is drawn into the piston

cylinder from the sight well. This action creates a pressure reduction

(vacuum) in the air- tight sight well, causing lubricant from the

reservoir to be drawn into the well until pressure is equalized. On

the piston upstroke, the oil in the piston cylinder reseats the inlet

shutoff ball and is forced out through the discharge check valve to the

machine injection point.

The number of drops seen falling in the sight well equals the amount

of oil discharged by the pump. Pump volume can be adjusted by

means of an external screw. This changes the length of the piston

stroke which changes the pump discharge volume.

Rugged construction for high performance and durability•

Suction and gravity/pressure feed models for application •

flexibility

Pump output is easily adjustable•

Hardened cam roller adds to pump and cam life•

One piece sight glass means fewer leak path and seal •

points

OPERATION

Pumps With Vacuum Feed

(Sight Glass Type)

Rotation of the lubricator cam actuates the pump rocker arm

assembly to operate the pump piston. On the piston downstroke,

spring force is exerted on the piston causing it to follow the cam. As

it moves down, a pressure reduction is created in the area between

the piston and the discharge check valve. The supply inlet shutoff

Page 2

Manzel

®

Model 88 Pump

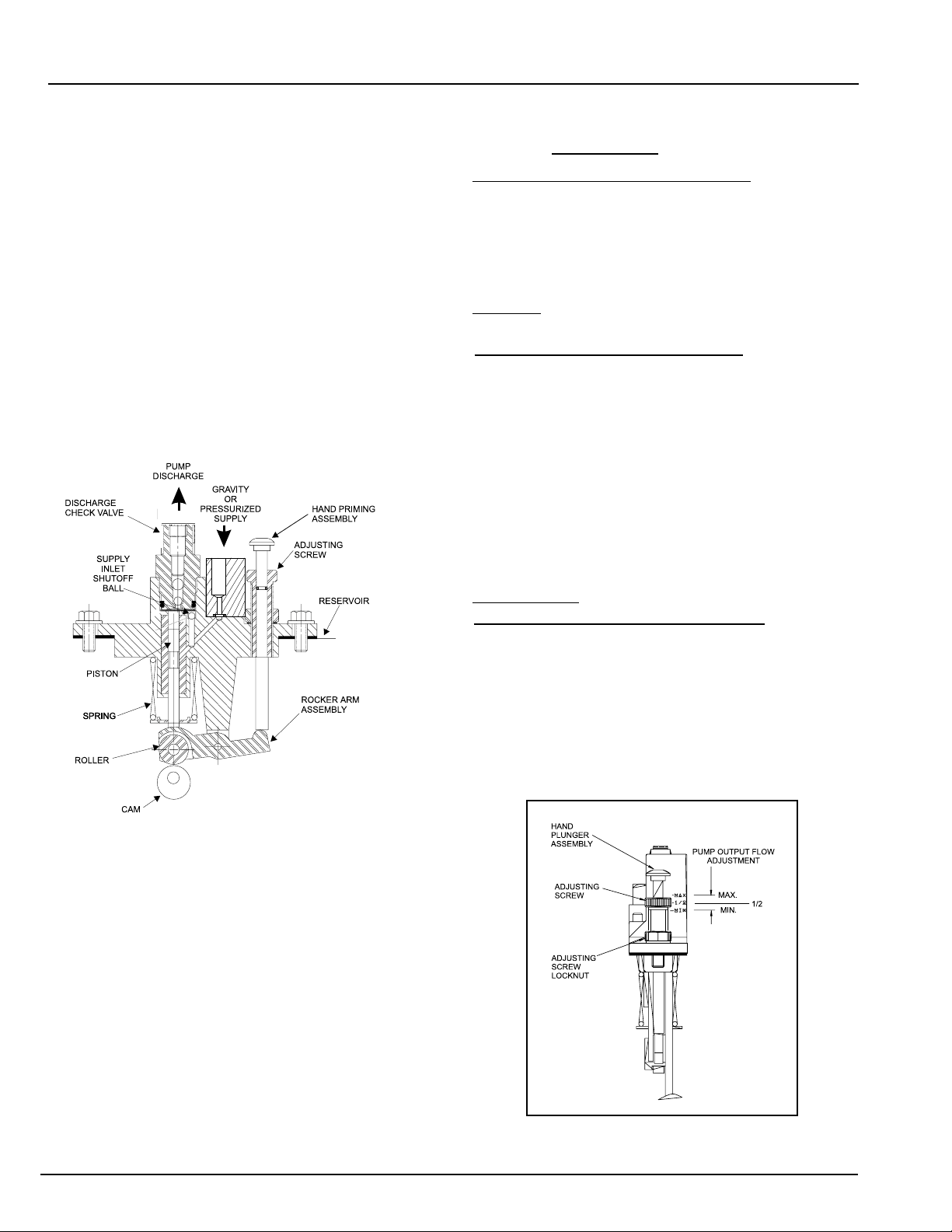

Pumps With Gravity Feed and Pressurized

Supplies

L51025

Calculate Pints Per Day As Follows:

Rotation of the lubricator cam actuates the pump rocker arm

assembly to operate the pump piston. On the piston downstroke,

spring force is exerted on the piston causing it to follow the cam.

As it moves down, a pressure reduction is created in the area

between the piston and the discharge check valve. The gravity

feed or pressurized supply unseats the supply inlet shutoff ball

and fills the piston bore with lubricant. On the piston upstroke, the

oil in the piston cylinder reseats the inlet shutoff ball and is forced

out through the discharge check valve to the machine injection

point. Pump volume can be adjusted by means of an external

screw. This changes the length of the piston stroke which

changes the pump discharge volume.

Number of Drops/Min. X 1440 (Minutes in a Day) = Pints/Day

14115 (Number of drops in a Pint)

Calculate Minimum or Maximum Pump

Output Capacity

Input Speed X Pump Output X 1440

Gear Ratio (Min. or Max. (Min./day)

drops/stroke*)

14115 (Number of Drops in a Pint)

* Minimum and Maximum Drops Per Stroke Listed in

Specifications on the next page.

NOTE: For proper sizing select the appropriate

lubricator brand. Brand as well as piston

size will effect minimum and maximum

pump capacity.

The following example is a Manzel lubricator, electric motor driven,

300:1 internal ratio, 1/4" pump model 88. Solve for maximum flow:

1725 Motor Speed X Max. 12 drops X 1440 Min.

300:1 Gear Ratio per stroke

14115 (Number of Drops in a Pint)

Min. or Max. Pump Output

=

(Pints Per Day)

Max. 7.04

=

Pints/day

ADJUSTMENT

Pump discharge (output flow) can be adjusted within the min./

max. ranges as shown in the illustration. The adjustment is

linear. Therefore, positioning the screw midway will produce

one-half of the pump capacity. To adjust the flow, proceed as

follows:

Loosen adjusting screw locknut.1.

Turn the adjusting screw to the desired position and, with 2.

the pump operating, count the drops falling in the sight well

for a one-minute interval.

Tighten adjusting screw locknut.3.

To Calculate Minimum: Replace the maximum 12 drops per stroke

with the minimum 2 drops per stroke: (1.17 minimum pints per day)

*Should not reciprocate up and down as pump operates, on

pumps built beginning in January 1997.

Page 2

Page 3

Manzel

®

Model 88 Pump

SPECIFICATIONS

1&2

Cu.In./Stroke Cu.Cm/Stroke Stroke/Minute Stroke

Pump Model

In Manzel

Lubricator

(55 and 76)

In Mega,

Lincoln or

Premier

Lubricators

Based on 500 SUS oil at 701.

When approaching maximum outputs, some oils will stream rather than form drops in sight glass. 2.

For operating pressures over 50% of the rated maximum , consult the factory.3.

Allowable viscosity range independent of temperature: 80-5000 SUS.4.

Maximum allowable inlet pressure: Pressurized pump, 100 PSI; Pressurized pump with sight glass, 10 PSI.5.

Piston Dia

4

88B, F, J 3/16 7500 6 1 0.013 0.002 0.213 0.033 50 3

88E, H, L 3/8 2500 27 4 0.055 0.004 0.901 0.131 50 3

88B, F, J 3/16 7500 5 1 0.009 0.002 0.148 0.033 50 3

88E, H, L 3/8 2500 20 4 0.041 0.004 0.672 0.131 50 3

NOTE: Any static positive pressure applied to the pump inlet has the potential to cause leakage flow through a pump at rest or adjusted for zero stroke unless offset by a check valve

of comparable pressure rating located at the pump outlet. The "discharge check valve" pictured has no spring and is rated at zero PSI. The "outlet check valve" pictured in

phantom in view at bottom of next page is rated at 35 PSI.

(inches)

0

F ambient. Heavier oil will produce fewer but larger drops.

Max

Pressure 3

(psi)

Drops/Stroke

Max Min Max Min Max Min Max Min

ORDERING INFORMATION

5

Pump

Piston Size

Model Part No. Old Part No. Model Part No. Old Part No. Model Part No. Old Part No.

Vacuum Feed Pump Gravity Feed Pump & Pressurized Pump

3/16 in 88B 562954 376-000-001 88F 562962 376-000-121 88J 564011 376-000-530

1/4 in 88C 562956 376-000-011 88G 562964 376-000-131 88K 562967 376-000-540

3/8 in 88E 562958 376-000-031 88H 562966 376-000-151 88L 562968 376-000-560

Gravity Feed Pump w/Sight Glass

L51025

Length

(inches)

1/288C, G, K 1/4 6000 12 2 0.024 0.004 0.393 0.066 50 3

3/888C, G, K 1/4 6000 9 2 0.018 0.004 0.295 0.066 50 3

5

Model 88 Pumps Configured for Mega, Lincoln and Premier Box Lubricator, and for Manzel Model 55

Lubricator

Model 88 Pumps are interchangeable with Mega, Lincoln and Premier Model 55 Pumps. Use the following table to determine the appropriate part

number.

ORDERING INFORMATION

Description Pump Size Part No. Old Part No. Mega Part No. Premier Part No. Lincoln Part No.

*Vacuum Pumps (B) 3/16 562954 **376-000-001 – – –

*Vacuum Pumps (C) 1/4 562956 **376-000-011 039315 91200/91220 880187/880550

*Vacuum Pumps (E) 3/8 562958 **376-000-031 039308 91201/91221 880330/880560

Press Supply (F) 3/16 562962 376-000-121 – – –

Press Supply (G) 1/4 562964 376-000-131 039488 91202 880453/880552

Press Supply (H) 3/8 562966 376-000-151 039489 91203 880454

Press Supply w/Sight Glass (J) 3/16 564011 376-000-530 – – –

Press Supply w/Sight Glass (K) 1/4 562967 376-000-540 – – –

Press Supply w/Sight Glass (L) 3/8 562968 376-000-560 – – –

Press Supply to Front 3/16 562962 †376-000-121 – – –

Press Supply to Front 1/4 562964 †376-000-131 038704 91208 880087-X

Press Supply to Front 3/8 562966 † 376-000-151 038705 91209 880402-X

Press Supply to Rear 3/16 562962 †376-000-121 – – –

Press Supply to Rear 1/4 562964 †376-000-131 038702 91206 880087-CL

Press Supply to Rear 3/8 562966 † 376-000-151 038703 91207 880402-CL

Press Supply w/Shutoff 3/16 562962 †376-000-121 – – –

Press Supply w/Shutoff 1/4 562964 †376-000-131 039425 91204 880087

Press Supply w/Shutoff 3/8 562966 † 376-000-151 038153 91205 880402

*When configured from the factory to fit into Model 55, Mega, Lincoln or Premier Box Lubricators, the vacuum pump has a 0.875 in shortened suction tube.

**Model 88B, C and E pumps can be field modified to fit Mega, Lincoln and Premier Box Lubricators. Remove the strainer, break off the suction tube at the V-groove, and

replace the strainer.

†Graco will provide pump replacement only, customer to supply tubing and fittings for rear, front and shutoff pumps.

Page 3

Page 4

MANZEL MODEL 88 PUMP OPERATING INSTRUCTIONS

Fill the box lubricator reservoir, to the top of the sight level gauge, 1.

with oil, filtered through a 25 micron nominal strainer. (Machine

requirements may dictate a higher oil cleanliness level.)

Expel all air from the pump. 2. NOTE: Do not connect the oil line to the

pump outlet or lube point until all air has been expelled. To Expel Air

From The Pump:

Remove the sight well plug.a.

Fill the sight well to the top with filtered oil.b.

Operate the hand priming assembly until the oil level c.

drops below the end of the drip tube.

Replace the sight well plug.d.

Continue to hand prime until oil from the drip tube is free e.

of air.

If all oil is evacuated from sight well, repeat steps (a) through f.

(e) as often as necessary, until all air has been expelled.

Connect the tubing to the pump outlet.4.

Hand prime the pump until clean, air-free oil is flowing through the 5.

lube line.

Connect the tubing to the lube point.6.

The lubricator is now ready to operate. After start-up, the lubricator 7.

may require adjustment of the individual pumps to meet required

flow rates.

To adjust The Pump:8.

Loosen the adjusting screw lock nut.a.

Turn the adjusting screw clockwise or counterclockwise b.

to decrease or increase flow.

With the lubricator operating, count the drops falling into c.

the sight well for one minute.

If any further adjustment is necessary, turn the d.

adjustment screw; 1) counterclockwise to increase flow

(drops per minute); or 2) clockwise to decrease flow

(drops per minute).

PUMP DIMENSIONS

Repeat (7-c) to assure that the pump is adjusted to the proper e.

specification.

Once the pump has been adjusted to the proper specification, f.

tighten the adjusting screw locknut.

The recommended minimum flow rate is 2 drops per stroke. Operators 9.

are cautioned against decreasing the oil flow below this rate, as a pump

malfunction may occur.

The minimum recommended strokes per minute is 3. The maximum 10.

recommended strokes per minute is 50. NOTE: To maximize pump life,

it is recommended that the pump not exceed 20 strokes per minute.

Oil level in the sight well will stabilize promptly, then rise and fall slightly 11.

during pump operation. Should oil level in the sight well rise above the

drip tube:

Remove the sight well plug.a.

Allow the pump to continue to operate until the oil level has b.

dropped below the drip tube.

Replace the sight well plug. c. NOTE: This condition is not

uncommon for a vacuum type pump. However it could be an

indication of a problem with the supply inlet shutoff ball/seat.

If this condition persists, check the ball and seat. If there are

no apparent problems there, the piston and bore are worn

and the pump should be replaced.

Should oil level in the sight well fall below the pump body surface:12.

Remove the sight well plug.a.

Allow the pump to continue to operate, and manually fill the b.

sight well with filtered oil to below the end of the drip tube.

Replace the sight well plug. c. NOTE: This condition could be an

indication of a problem with the seal between the sight glass

and pump body surface, or with the sight well plug. Check

parts for nicks, cuts and sealing capability. Replace parts

using Repair Kit Part No. 564437 (560-001-860) if needed.

The MANZEL MODEL 88 PUMP will operate in a Manzel, Mega, Lincoln, 13.

or Premier lubricator. For more information about the Manzel Force Feed

Box Lubricator, refer to Manzel Bulletin L51020 and/or L51040.

PUMP REPAIR KITS

Pump repair kits are the same for both vacuum feed and gravity •

feed with sight glass pumps in all pump sizes. Repair kits may

be ordered by part number 564437 (560-001-860) and contain

only parts necessary to replace the pump sight glass.

` DIMENSION INCHES MILLIMETERS

A 2.31 58.7

B

B

C 5.375 136.5

D 0.75 19.1

E 1.50 38.1

F 3.00 76.2

G

G

H

H

J

K

1

4.625 117.5

2

4.406 111.9

1

8.53 216.7

2

7.75 196.8

1

5.53 140.5

2

4.75 120.6

2.625 66.7

1.00 25.4

B1/G1/H1 - in Manzel "76" Lubricator; B2/G2/H2 - in Manzel "55"

Mega, Lincoln and Premier Lubricator.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Body/sleeve and piston subassembly is not sold separately.•

FLUID MEASUREMENT CONVERSION DATA

1 Drop approx 0.002 cu.in.

14,115 Drops 1 pint

28.89 cu.in. 1 pint

490 Drops 1 cu.in.

10 Drops/Min 1 pint/24 hours

30 Drops 1cc

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L51025 Rev. B 4/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...