Page 1

Service Instructions

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

t

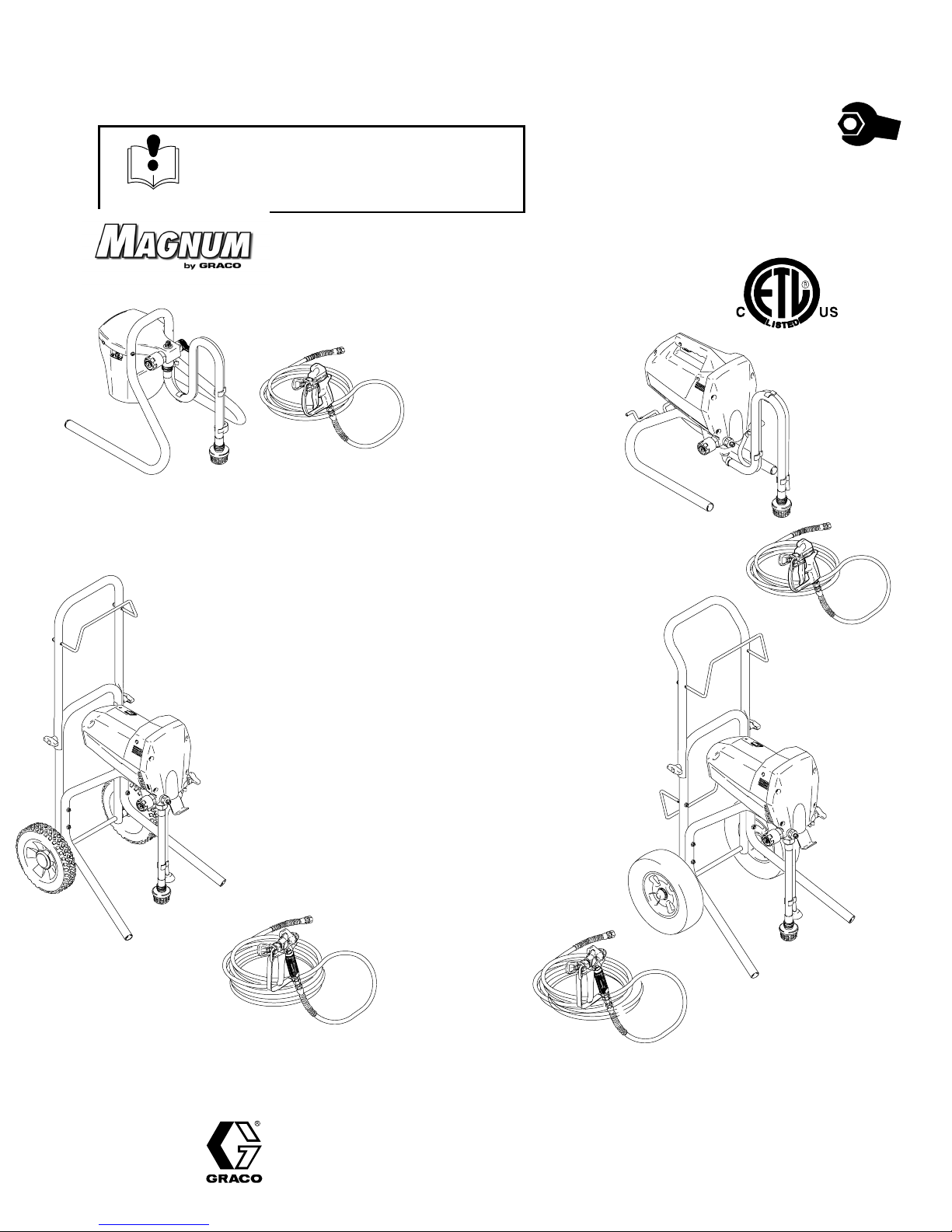

Airless Sprayers

MAGNUM DX

Model 232735

MAGNUM DX, Model 232735, Series A

0.24 gpm (0.91 lpm) stand–mount sprayer, 25 ft (7.6 m)

3/16” hose and SG1t–EF spray gun with reversible spray

tip and guard.

2800 psi (19 MPa, 193 bar) Maximum Working Pressure

MAGNUM XR5

Model 232740

Form No. 309226

Rev. A

This manual contains service

instructions only. See manual

309316 Operators Quick Guide and

309225 Operating Instructions for

complete operating instructions.

9558A

MAGNUM XR7

Model 232745

M

AGNUM XR5, Model 232740, Series A

0.27 gpm (1.02 lpm) stand–mount sprayer, 25 ft (7.6 m)

1/4” hose and SG1–EF spray gun with reversible spray tip

and guard.

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

MAGNUM XR7, Model 232745, Series A

0.31 gpm (1.17 lpm) stand–mount sprayer, 50 ft (15.2 m)

1/4” hose and SG2t metal spray gun with reversible spray

tip and guard.

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

MAGNUM XR9, Model 232750, Series A

0.38 gpm (1.44 lpm) stand–mount sprayer, 50 ft (15.2 m)

1/4” hose and SG3t pro metal spray gun with reversible

spray tip and guard.

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

9558A

9559A

MAGNUM XR9

Model 232750

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 2001, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification and Function 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding and Electrical Requirements 6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Repair Information 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Troubleshooting 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Kits 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Diagnostics 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Board Diagnostics 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Diagnostics 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

Model 232735 DX Magnum Sprayer 24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 232740 XR5 Magnum Sprayer 24. . . . . . . . . . . . . . . . . . . . . . . . . .

Model 232745 XR7 Magnum Sprayer 26. . . . . . . . . . . . . . . . . . . . . . . . . .

Model 232750 XR9 Magnum Sprayer 28. . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 309226

Page 3

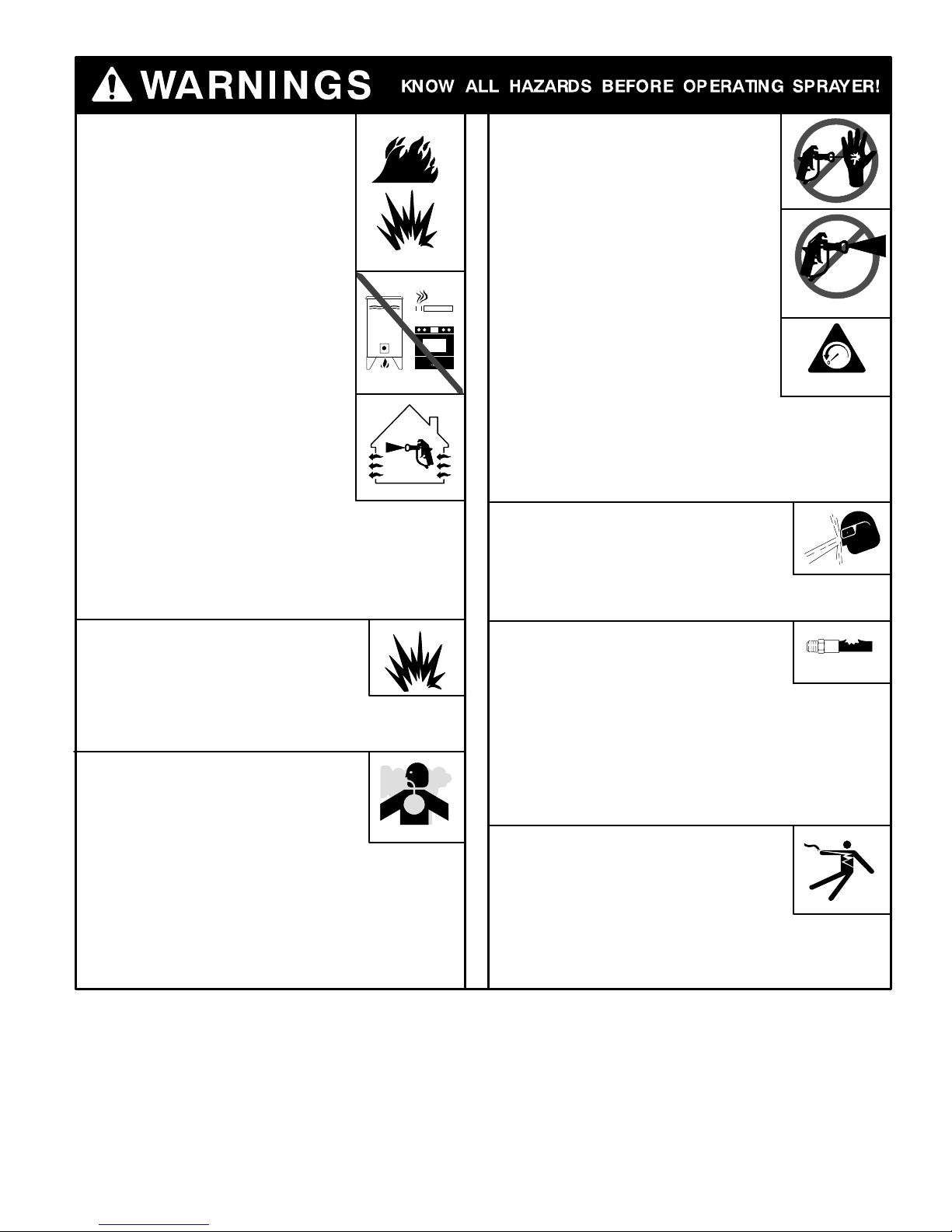

FIRE AND EXPLOSION HAZARD

A Fire and explosion hazard exists

any time you spray or flush flammable fluids.

To help prevent fire or explosion when

spraying flammable fluids

D Be sure sprayer is adequately grounded

through electrical outlet as follows:

– Use only grounded electrical outlets.

– Use only 3-wire extension cords.

– Make sure ground prongs are intact

on sprayer and extension cords.

D Motor in this sprayer is a source of

sparks. Keep sprayer in well-ventilated

area, at least 20 feet (6 meters) away

from gun when spraying or flushing.

D Do not use plastic drop cloths when

spraying or flushing flammable fluids.

D Avoid all ignition sources, such as pilot

lights, cigarettes, and plastic drop cloths

(static arc hazard). Do not plug in or

unplug power cords or turn lights on or

off in spray area.

D Tape wall switches to prevent them from being turned

off or on.

D Do not smoke in spray area.

D Use only M

D Use outdoors or in a well-ventilated area.

EQUIPMENT MISUSE HAZARD

Do not use 1,1,1–trichloroethane, methylene

chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents

in pressurized aluminum equipment such as

this sprayer and gun. Such use could result in

chemical reaction and possible explosion.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause

serious injury or death if splashed in eyes

eyes or on skin, inhaled, or swallowed.

To help prevent injury or death from

toxic fluids

D Know specific hazards of fluid you are using; store

hazardous fluid in approved tub; dispose of

hazardous fluid according to all local, state, and

national guidelines.

D Always wear protective eyewear, gloves, clothing, and

respirator as recommended by fluid and solvent

manufacturer.

AGNUM or Graco airless paint hoses.

FLUID INJECTION HAZARD

If high-pressure fluid pierces skin,

the injury might look like “just a cut”

but is a serious wound. Get

immediate medical attention.

To help prevent injection

D Always put trigger safety lever in SAFETY

ON position when not spraying.

D Always shut off power and relieve pressure

when you stop spraying and before you

service or clean sprayer, remove parts, or

repair leaks. See Pressure Relief

Procedure below.

D Do not allow children to use this equipment.

D Keep clear of tip, and never point gun at

yourself or anyone else.

STARTUP HAZARD AFTER THERMAL OVERLOAD

Motor has thermal overload switch to

shut itself down if overheated. To reduce risk of injury

from motor restarting unexpectedly when it cools, always

turn Power switch OFF if motor shuts down.

FLUID SPLASHBACK HAZARD

Wear protective eyewear at all times.

To avoid splashing fluid when spraying

into pail, always aim at inside wall of pail.

Make sure gun is assembled with correct

gasket for fluid being sprayed. See Installing Tip &

Guard in enclosed Operator’s Quick Guide.

PRESSURIZED EQUIPMENT HAZARD

M

AGNUM sprayers are capable of

producing up to 3000 psi (21 MPa, 207 bar)

maximum working pressure. To avoid

component rupture and injury, do not operate sprayer

with components rated less than pressure of sprayer.

Sprayer is equipped with a pressure drain that

automatically relieves overpressure in the event of a fault

condition. This automatic pressure relief may cause

splashing of fluid. Correct fault before you resume spraying.

NOTE: Inadequate flushing and/or dried paint in drain

system may prevent proper overpressure relief.

ELECTRIC SHOCK HAZARD

Gun, hose, and sprayer are grounded

through electrical cord of sprayer.

To help prevent electric shock

D Use only grounded electrical outlets.

D Only use 3-wire extension cords.

D Make sure ground prongs are intact on sprayer and

extension cords.

D Keep electrical connections and inside of shroud dry.

SAFETY ON

pressure

309226 3

Page 4

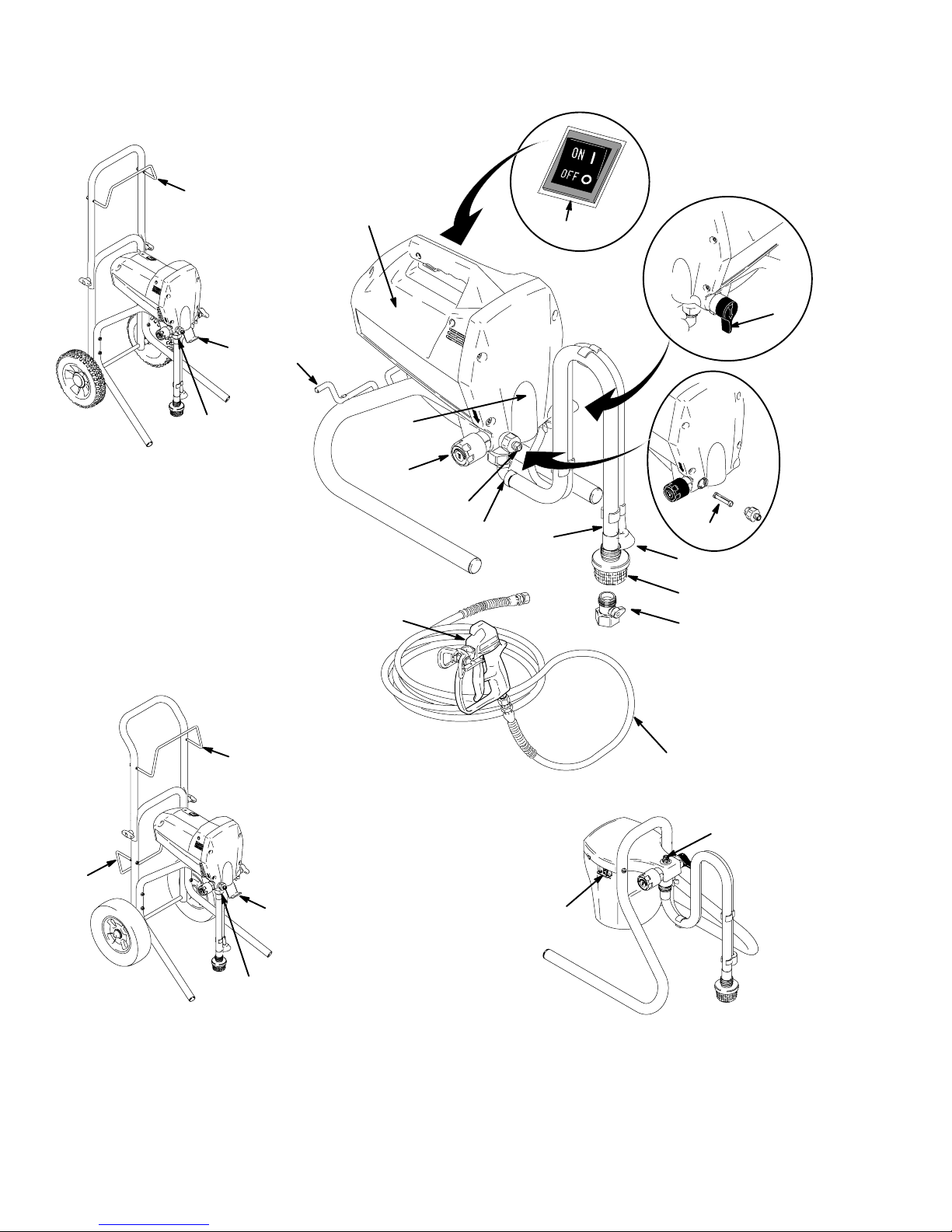

Component Identification and Function

W

A

B

X

N

J

MAGNUM XR7

9558A

K

MAGNUM XR5

W

F

C

D

K

P

G

E

H

L

Y

9560A

M

D

W

X

9559A

K

MAGNUM XR9

4 309226

B

MAGNUM DX

Page 5

Component Identification and Function

9

A Electric motor (inside of enclosures) Provides mechanical power to pump

B Power switch For manually turning on/off electrical power to motor (“I” is ON / “0” is OFF)

C Pressure Control knob For manually increasing (turn clockwise) and decreasing (turn

counter-clockwise) fluid pressure in pump, hose, and spray gun

D Pump fluid outlet fitting Threaded connection for paint hose

E InstaCleant fluid filter (XR models

only)

F Power-Pistont pump (behind Easy

Access door)

G Suction tube Draws fluid from paint pail into pump

H Prime tube (with diffuser) Drains fluid in system during priming and pressure relief

J Spray/Prime/Drain valve control D Directs pressurized fluid to paint hose in SPRAY position (pointing forward)

K Fluid inlet connection and inlet valve Where suction tube connects to pump and inlet valve

L Inlet screen Prevents debris from entering pump

M Paint hose Transports high-pressure fluid from pump to spray gun

N Cord wrap bracket Stows electrical cord (XR5 model only)

P Airless spray gun Manually-controlled, hand-held on/off device for fluid being sprayed

Q Tip guard Reduces risk of fluid injection injury

R Reversible spray tip D Atomizes fluid being sprayed, forms spray pattern, and controls fluid flow

S Trigger safety lever Prevents accidental triggering of spray gun

T Gun fluid inlet fitting Threaded connection for paint hose

U Smooth Glidet swivel

(SG3 spray gun only)

V Gun fluid filter (in handle) Filters fluid entering spray gun to reduce tip plugging and improve finish

W Hose/Cord wrap bracket Stows paint hose and electrical cord (MAGNUM XR7 and XR9 only)

X Pail hanger For transporting pail by its handle (MAGNUM XR7 and XR9 only)

Y Power Flush attachment (included) Connects garden hose to suction tube for power flushing water-base fluids

D Filters fluid coming out of pump to reduce tip plugging and improve finish

D Self cleans during pressure relief

Pumps and pressurizes fluid and delivers it to paint hose If necessary, Easy

Access door permits quick removal of outlet valve.

D Directs fluid to drain tube in PRIME/DRAIN position (pointing down)

D Automatically relieves system pressure in overpressure situations

according to hole size

D Reverses for unplugging without disassembly

Allows spray gun to swivel without twisting paint hose

S

R

Q

T

SG1–EF Spray Gun

included with

AGNUM DX and XR5

M

V

Q

SG2 Spray Gun

9561A

T

included with

AGNUM XR7

M

S

R

S

R

Q

V

U

T

SG3 Spray Gun

included with

AGNUM XR9

M

309226 5

Page 6

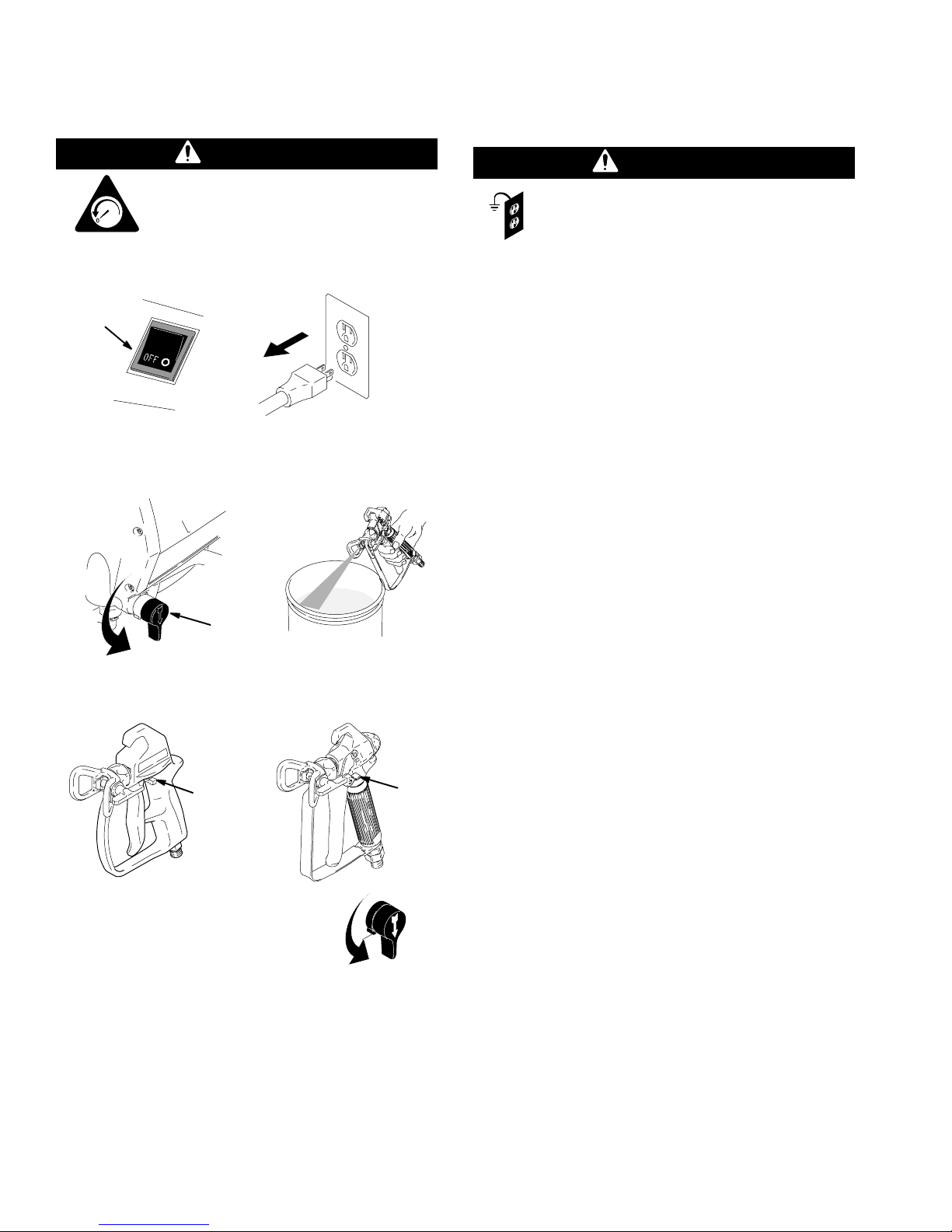

Pressure Relief

Grounding and

Procedure

WARNING

To help prevent injection injuries, follow

this procedure when you stop spraying

and before you service or clean the

psi/MPa/bar

1. Turn Power switch (B) to OFF, and unplug sprayer.

B

2. Turn Spray–Prime/Drain valve (J) to PRIME/

DRAIN to relieve pressure. Trigger gun to relieve

pressure that might be in hose.

sprayer, remove parts, or repair leaks.

9565A

Electrical Requirements

WARNING

This sprayer requires a 120V AC, 60 Hz, 15A

circuit with a grounding receptacle. Never use

an outlet that is not grounded. Do not use the

sprayer if the electrical cord has a damaged ground

prong. Use only an extension cord with an

undamaged, 3-prong plug.

Recommended extension cords for use with this

sprayer are

D 25 ft (7.6 m) 18 AWG

D 50 ft (15.2 m) 16 AWG

D 100 ft (30.5 m) 14 AWG

D 150 ft (45.7 m) 12 AWG

NOTE: Smaller-gauge or longer extension cords may

reduce sprayer performance.

J

3. Put trigger safety (S) in SAFETY ON position.

SG1–EF

S

NOTE: Leave Spray–Prime/Drain

valve in the PRIME/DRAIN position

until you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY loos-

en the tip guard retaining nut or hose end coupling to

relieve pressure gradually. Then loosen it completely.

Then clear the tip or hose obstruction.

SG2 / SG3

9565A

S

9565A

6 309226

Page 7

General Repair Information

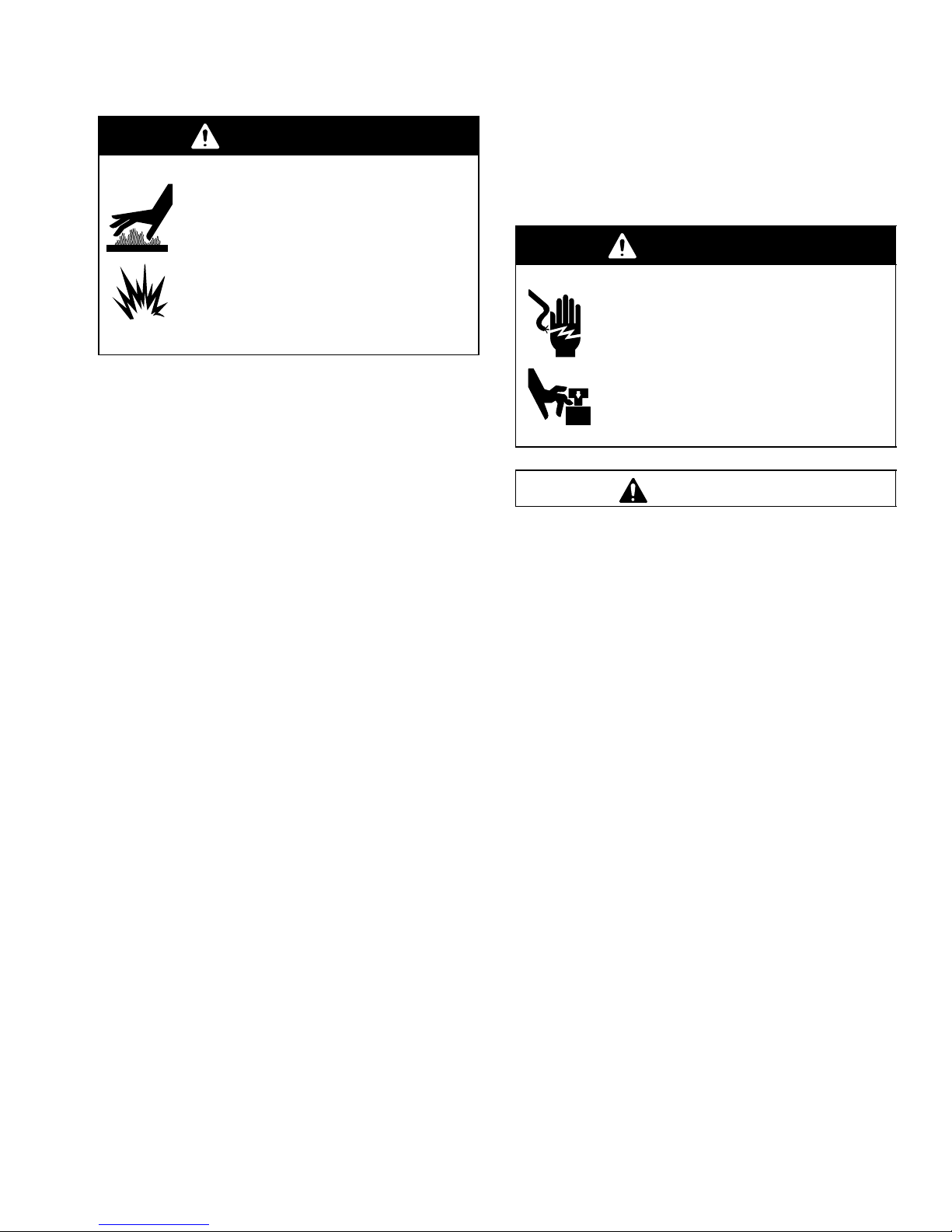

WARNING

HOT SURFACES HAZARD

EXPLOSION HAZARD

Motor and drive housing may be very hot

during operation and could burn skin if

touched.

Flammable materials spilled on hot, bare

motor could cause fire or explosion.

Have enclosures in place during

operation to reduce risk of burns, fire, or

explosion.

D Keep all screws, nuts, washers, gaskets, and

electrical fittings that you remove during repair

procedures. These parts are not normally provided

with replacement assemblies.

Do not operate the sprayer without the enclosure.

Replace if damaged. Enclosures direct cooling air

around the motor to prevent overheating. They also

reduce the risk of burns, fire or explosion. Read the

following WARNING.

WARNING

ELECTRIC SHOCK HAZARD

MOVING PARTS HAZARD

To reduce risk of serious injury, including

electric shock, do not touch moving or

electrical parts with fingers or tools while

testing repair. Unplug sprayer when power

is not required for testing. Install all

covers, gaskets, screws, and washers

before you operate sprayer.

CAUTION

D Test repairs after problems are corrected.

D If the sprayer does not operate properly, review

the repair procedure to verify that you did it correctly. See Troubleshooting on page 8 and

Advanced Troubleshooting on page 10.

D Overspray may build up in the air passages.

Remove any overspray and residue from the air

passages and openings in the enclosures whenever

you service the sprayer.

Do not run sprayer dry for more than 30 seconds.

Doing so could damage pump packings.

Protect the internal drive parts of this sprayer

from water. Openings in the enclosures allow for air

cooling of the mechanical parts and electronics

inside. If water gets into these openings, the sprayer

could malfunction or be permanently damaged.

Prevent pump corrosion and damage from freezing. Never leave water or water-base paint in

the sprayer when it is not in use in cold weather.

Freezing fluids can seriously damage the sprayer.

Store the sprayer with mineral spirits/paint thinner or

Graco Pump Armor to protect equipment during

storage.

309226 7

Page 8

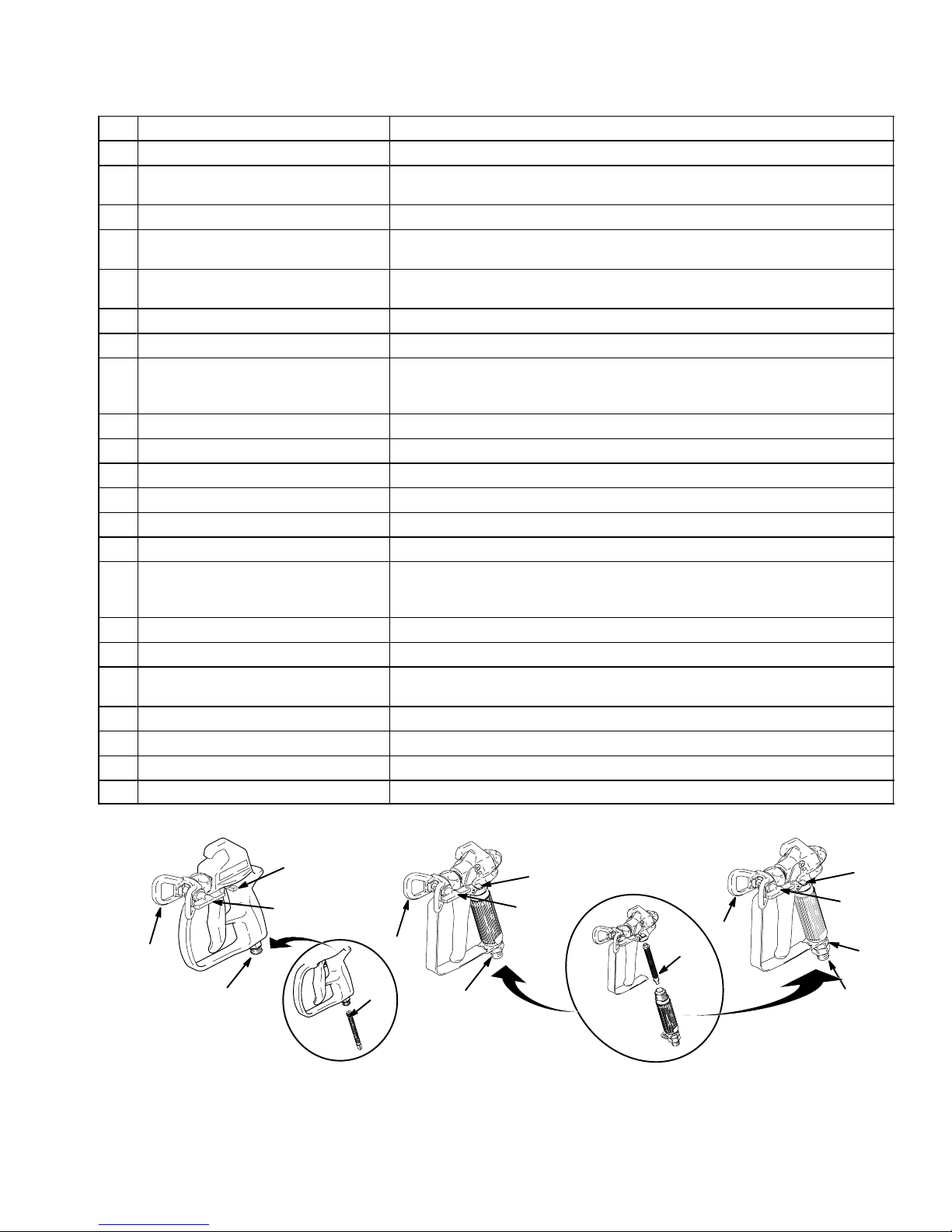

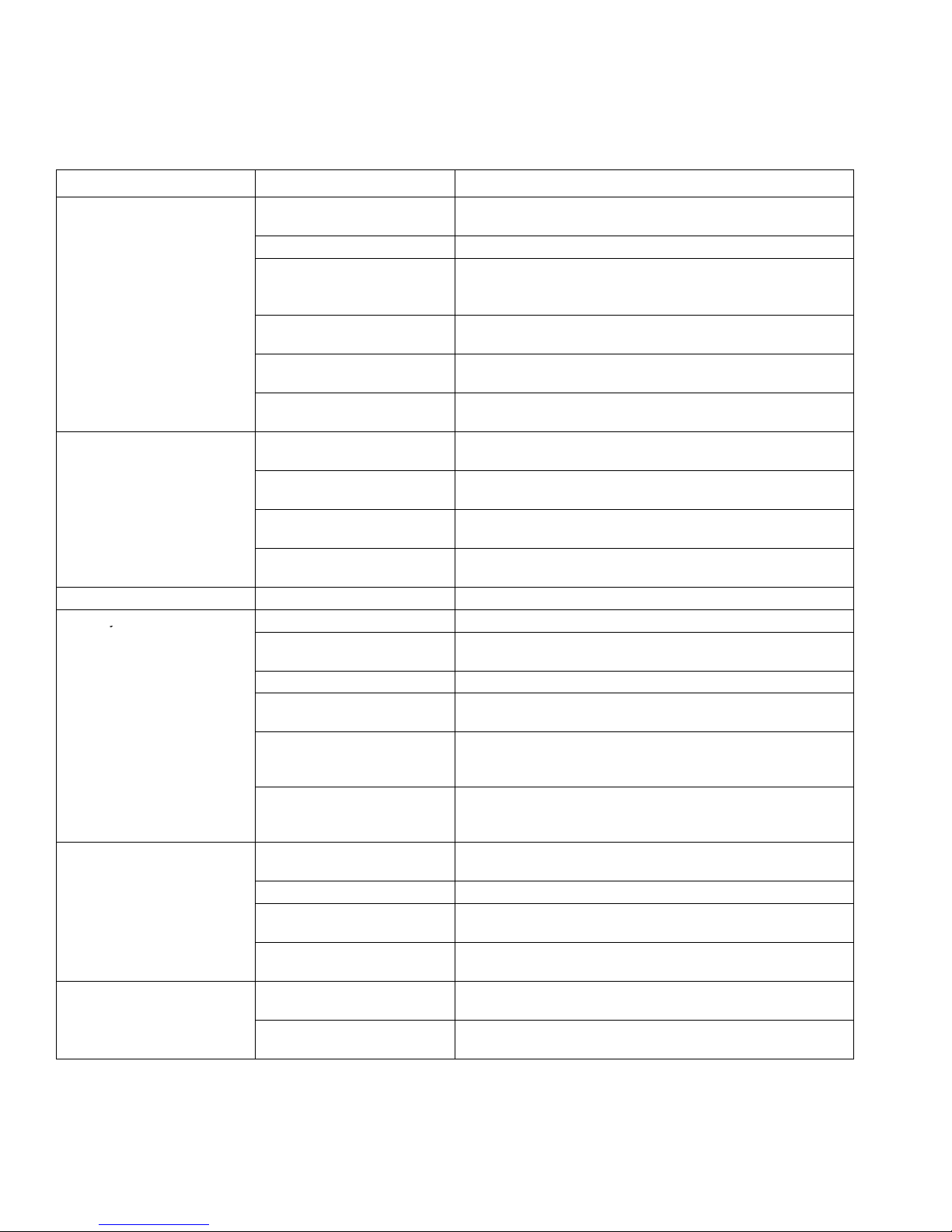

Basic Troubleshooting

does not cycle

does not cycle

y

The following troubleshooting guidelines from the Operating Instructions manual are included here as preemptive

measures against Advanced Troubleshooting on page 10.

PROBLEM CAUSE SOLUTION

Power switch is on and

sprayer is plugged in, but

motor does not run, and pump

.

.

Pump does not prime. Spray–Prime/Drain valve is in

Spray gun stopped spraying. Spray tip is plugged. Unplug spray tip. See manual 309225 Operating Instructions.

Pump cycles but does not

build up pressure.

Pump cycles, but paint only

dribbles or spurts when spray

gun is triggered.

Spray pattern is inconsistent

or is leaving stripes.

Pressure is set at zero

pressure.

Motor or control is damaged. See Motor Does Not Operate on page 10.

Electrical outlet is not

providing power.

Extension cord is damaged. Replace extension cord. See Grounding and Electrical

Sprayer electrical cord is

damaged.

Paint is frozen or hardened in

pump.

SPRAY position.

Inlet screen is clogged, or

suction tube is not immersed.

Balls in check valve are stuck,

or check valves are damaged.

Suction tube is leaking. Tighten suction tube connection (K). Inspect for other cracks

Pump is not primed. Prime pump.

Inlet screen is clogged, or

suction tube is not immersed.

Paint pail is empty. Refill paint pail, and reprime sprayer.

Suction tube is leaking. Tighten suction tube connection (K). Inspect for other cracks

Pump check valves are dirty

or damaged. (Usually only

one valve)

Spray–Prime/Drain valve is

worn or obstructed with debris

Pressure is set too low. Slowly turn Pressure Control knob (C) clockwise to Increase

Spray tip is plugged. Unplug spray tip. See manual 309225 Operating Instructions.

InstaClean fluid filter is

clogged. (XR models only)

Spray gun fluid filter is

clogged.

Pressure is set too low. Turn Pressure Control knob (C) clockwise to increase

Spray tip is worn beyond

capability of sprayer.

Turn Pressure Control knob (C) clockwise to increase

pressure setting.

D Try a different outlet, or plug in something that you know is

working to test outlet.

D Reset building circuit breaker, or replace fuse.

Requirements on page 6.

Check for broken insulation or wires. Replace electrical cord if

damaged.

See Motor Does Not Operate on page 10.

Turn Spray–Prime/Drain valve (J) to PRIME/DRAIN position

(pointing down).

Clean debris off inlet screen (L), and make sure suction tube

(G) is at bottom of paint pail.

Clean or replace check valves. See Pump Service on page

20. Do not store in water.

or vacuum leaks.

Clean debris off inlet screen (L), and make sure suction tube

(G) is at bottom of paint pail.

or vacuum leaks.

Clean or replace check valves. See Pump Service on page

20.

Check Spray–Prime/Drain valve for debris trapped on seat

and worn parts. Torque to 185 in-lb (21 NSm). Replace if parts

are worn.

pressure setting to check if sprayer develops more pressure.

Clean or replace InstaClean fluid filter (E).

Clean or replace spray gun fluid filter (V).

pressure.

Replace spray tip.

8 309226

Page 9

Basic Troubleshooting

g

intermittentl

NOTE: This is a thermal

WARNINGS section on

OR

PROBLEM CAUSE SOLUTION

Pressure is set at maximum,

but cannot achieve a good

spray pattern.

Motor is hot and runs

y.

NOTE: This is a thermal

overload condition. Motor

automatically shuts off due to

excessive heat.

See Startup Hazard After

Thermal Overload in the

page 3. Damage can occur if

cause is not corrected.

Building circuit breaker opens

after sprayer operates for 5 to

10 minutes.

OR

Building circuit breaker opens

as soon as sprayer is plugged

into outlet, and sprayer is

turned on.

Fan pattern varies

dramatically while spraying

OR

Sprayer does not turn on

promptly when resuming

spraying.

Cannot trigger spray gun. Spray gun trigger safety lever

Spray comes out of spray gun

in two thick streams.

Paint is coming out of

pressure control switch.

Spray–Prime/Drain valve

actuates automatically,

relieving pressure through

drain tube.

Paint leaks down outside of

pump.

Spray tip is too big for

sprayer.

Spray tip is worn beyond

capability of sprayer.

Extension cord is too long or

not a heavy enough gauge.

Spray gun fluid filter is

clogged.

InstaClean fluid filter is

clogged. (XR models only)

Inlet screen is clogged. Clean debris off inlet screen (L).

Pump valves are worn. See Output is Low or Fluctuating on page 13.

Vent holes in enclosures are

p

plugged, or sprayer is

covered.

Extension cord is too long or

not a heavy enough gauge.

Unregulated electrical

generator being used has

excessive voltage.

Sprayer was operated at high

pressure with very small tip,

which causes frequent motor

starts and excessive heat

build up.

Too many appliances are

plugged in on same circuit.

Sprayer electrical cord is

damaged.

Pressure control switch is

worn and causing excessive

pressure variation.

is in SAFETY ON position.

Reversible spray tip is in

UNCLOG position.

Pressure control switch is

worn.

System is overpressurizing. See Excessive Pressure is Building Up on page 16.

Pump packings are worn. Replace pump packings. See Pump Service on page20.

p

Select a smaller spray tip.

Replace spray tip.

Replace extension cord. See Grounding and Electrical

Requirements on page 6.

Clean or replace spray gun fluid filter (V).

Clean or replace InstaClean fluid filter (E).

Keep vent holes clear of obstructions and overspray, and keep

p

sprayer open to air.

Replace extension cord. See Grounding and Electrical

Requirements on page 6.

Use electrical generator with a proper voltage regulator.

Sprayer requires a 120V AC, 60 Hz, 1500-Watt generator.

Decrease pressure setting or increase tip size.

Free up circuit (unplug things), or use a less busy circuit.

Check for broken insulation or wires. Replace electrical cord if

damaged.

Replace Pressure Control knob using Pressure Control

Switch Kit 244266 for DX models or 244267 for XR models.

Rotate trigger safety lever (S) to SAFETY OFF position.

Rotate arrow-shaped handle on spray tip so it points forward in

SPRAY position.

Replace Pressure Control knob using Pressure Control

Switch Kit 244266 for DX models or 244267 for XR models.

p

309226 9

Page 10

Advanced Troubleshooting

t

See Electric Shock Hazard on

page 7.

See Pressure Relief

Procedure on page 6.

NOTE: See Basic Troubleshooting on page 8 for the problems that are more easily remedied.

General Problem: Motor Does Not Operate

SPECIFIC PROBLEM CAUSE SOLUTION

Power switch is on and

p

sprayer is plugged in, bu

pump does not cycle.

Basic Mechanical

Problems

Basic Electrical Problems Motor is overheated. Allow to cool for 30 minutes. Retry.

p

See Basic Troubleshooting page 8.

Paint is frozen or hardened in pump. Unplug sprayer from electrical outlet.

NOTE: If frozen, do not try to start sprayer

until completely thawed, or damage to motor,

control board, and/or drivetrain may occur.

Make sure power switch (B) is OFF. Place

sprayer in warm area for several hours, then

plug in and turn on. Slowly increase pressure

setting to see if motor starts.

If paint hardened in sprayer, replace pump

packings and remove all residue from valves.

See Pump Service on page20.

Motor is damaged. Remove gear, and try to rotate motor shaft by

hand. See Motor Diagnostics on page 19. If

shaft will not turn, replace motor using Motor

Kit 245080 for DX models or 243236 for XR

models.

Yoke is broken, because pump is locked up by

dried paint or worn packings. (XR models only)

Electrical outlet is damaged. Reset building circuit breaker or replace

Control board leads are improperly fastened or

improperly mated.

Motor brushes are worn.

NOTE: Brushes do not wear at the same rate on

both sides of motor. Check both brushes.

Motor armature commutator is damaged. Check for burn spots, gouges and extreme

Repair as necessary or replace using

Gear/Yoke Repair Kit 243230.

building fuse. Try another outlet.

Check electric supply with volt meter. Meter

must read 85 to 130V AC. If voltage is too

high, do not plug sprayer in until outlet is

corrected.

Replace any loose terminals. Make sure all

leads and harnesses are firmly connected.

Check pressure control harness connection on

front side of drive housing.

Clean control board terminals. Securely

reconnect leads.

Check length of brushes. Brush length must

be 0.25 in. (6.4 mm) minimum. If brushes are

worn, replace motor using Motor Kit 245080

for DX models or 243236 for XR models.

roughness. Have motor shop resurface

commutator if possible, or replace motor using

Motor Kit 245080 for DX models or 243236 for

XR models.

10 309226

Page 11

Advanced Troubleshooting

General Problem: Motor Does Not Operate (continued)

SPECIFIC PROBLEM CAUSE SOLUTION

Basic Electrical Problems

(Continued)

Motor armature is shorting. Check for shorts using armature tester (growler), or perform

spin test (see Motor Diagnostics on page 19). If shorts are

evident, replace motor using Motor Kit 245080 for DX

models or 243236 for XR models.

Sprayer Wiring Problems

NOTE: Remove right

enclosure mounting

screws, and pull right

enclosure away from drive

housing. Take care to not

pull on the leads from

the electrical cord and

the Power switch (B).

Control board is damaged.

CAUTION: Do not perform control

board diagnostics until you have

determined that the armature is good.

A bad motor armature can burn out a

good control board.

Sprayer electrical cord is damaged. Unplug sprayer electrical cord. Disconnect black electrical

Sprayer power switch (B) is damaged. Unplug sprayer electrical cord. Disconnect black control

Thermal overload cutoff switch is

damaged.

See Startup Hazard After Thermal

Overload in the WARNINGS section

on page 3.

Terminals are damaged or loose. Replace any damaged terminals, and make sure all

See Control Board Diagnostics on page 19, and replace

control board if damaged using Control Board Kit 245079

for DX models, 243228 for XR5 and XR7 models, or

243229 for XR9 models.

cord wire at Power switch (B), and unplug in-line connection

of white electrical cord wire. Plug in electrical cord, and test

voltage between black and white electrical cord wires.

Meter must read 85 to130V AC.

Replace electrical cord if no voltage.

board wire at Power switch (B), and unplug in-line

connection of white electrical cord wire. Plug in electrical

cord, turn Power switch ON, and test voltage between open

terminal of Power switch and white electrical cord wire.

Meter must read 85 to130V AC.

Replace Power switch (B) if no voltage.

Unplug sprayer electrical cord. Remove motor harness from

control card, and check for continuity between yellow leads

of motor harness. If thermal relief switch is open (no

continuity), allow motor to cool. If switch remains open after

motor cools, replace motor using Motor Kit 245080 for DX

models or 243236 for XR models.

If thermal relief switch closes after motor cools, find and

correct cause of overheating.

terminal connections are tight.

309226 11

Page 12

Advanced Troubleshooting

g

General Problem: Circuit Breaker is Tripping

SPECIFIC PROBLEM CAUSE SOLUTION

Building circuit breaker opens

as soon as sprayer is turned on.

Sprayer electrical wiring is pinched, or insulation

is damaged.

Wires between pressure control switch and

control board are pinched.

Motor armature is shorting. Check for shorts using armature tester

Repair or replace any damaged wiring or

terminals. Securely reconnect all wires.

(growler), or perform spin test (see Motor

Diagnostics on page 19). If shorts are

evident, replace motor using Motor Kit

245080 for DX models or 243236 for XR

models.

Building circuit breaker opens

as soon as sprayer is plugged

into outlet, and sprayer is NOT

turned on.

NOTE: Remove right

enclosure mounting screws,

and pull right enclosure away

from drive housing. Take care

to not pull on the leads from

the electrical cord and the

Power switch (B).

Control board is damaged.

CAUTION: Do not perform control board

diagnostics until you have determined that the

armature is good. A bad motor armature can burn

out a good control board.

Sprayer electrical cord is damaged. Unplug sprayer electrical cord. Disconnect

Sprayer Power switch (B) is damaged. Unplug sprayer electrical cord, and

See also “Basic Electrical Problems” on page 10 and “Sprayer Wiring Problems” on page 11.

See Control Board Diagnostics on page

19, and replace control board if damaged

using Control Board Kit 245079 for DX

models, 243228 for XR5 and XR7 models, or

243229 for XR9 models.

black electrical cord wire at Power switch (B),

and unplug in-line connection of white

electrical cord wire. Plug in electrical cord,

and test voltage between black and white

electrical cord wires. Meter must read

85 to130V AC.

Replace electrical cord if no voltage.

disconnect wires from Power switch (B).

Check resistance of switch with ohmmeter.

Reading must be infinity with Power switch

OFF, and zero with Power switch ON.

Replace Power switch if damaged.

12 309226

Page 13

Advanced Troubleshooting

General Problem: Motor Operation is Erratic

SPECIFIC PROBLEM CAUSE SOLUTION

Sprayer quits after running for 5 to 10 minutes. Electrical outlet is damaged or

supplying the wrong voltage.

See also “Basic Electrical Problems” on page 10 and “Sprayer Wiring

Problems” on page 11.

Motor is hot and runs intermittently.

NOTE: This is a thermal overload condition.

Motor automatically shuts off due to excessive

heat.

See Startup Hazard After Thermal Overload

in the WARNINGS section on page 3.

Damage can occur if cause is not corrected.

See Basic Troubleshooting page 9.

General Problem: Output is Low or Fluctuating

Reset building circuit breaker or

replace building fuse. Try another

outlet.

Check electric supply with volt meter.

Meter must read 85 to 130V AC. If

voltage is too high, do not use outlet

until corrected.

pp

SPECIFIC PROBLEM CAUSE SOLUTION

Pump cycles, but output is low

or surging.

See Basic Troubleshooting page 8.

Pump valves are worn or obstructed by debris. Check for worn pump valves as follows:

Prime sprayer with paint. Trigger spray gun

momentarily. When spray gun trigger is

released, pump should cycle momentarily

and stop. If pump continues to cycle, pump

valves may be worn or obstructed.

See Pump Service on page 20.

Spray–Prime/Drain valve is leaking. Check Spray–Prime/Drain valve for debris

trapped on seat and for worn parts. Torque to

185 in-lb (21 NSm). Replace if parts are worn

using Spray–Prime/Drain Valve Kit 235014.

Voltage from electrical outlet is too low. Low

voltages reduce sprayer performance.

Extension cord is too long or not a heavy enough

gauge.

Leads from motor to control board are damaged,

loose, or overheated.

Check voltage of outlet. Meter must read

85 to 130V AC.

Reset building circuit breaker or replace

building fuse.

Repair electrical outlet or try another outlet.

Replace extension cord.

See Grounding and Electrical

Requirements on page 6.

Be sure terminals are centered and firmly

connected. Inspect wiring insulation and

terminals for signs of overheating, and

replace any loose terminals or damaged

wiring. Securely reconnect terminals.

309226 13

Page 14

Advanced Troubleshooting

General Problem: Output is Low or Fluctuating

SPECIFIC PROBLEM CAUSE SOLUTION

Motor brushes are worn.

NOTE: Brushes do not wear at the same rate on

both sides of motor. Check both brushes.

Motor brush springs are broken. If springs are broken, replace motor using

Motor brushes are binding in brush holders. Clean brush holders, remove carbon dust

Motor stops before sprayer reaches correct

pressure (stall pressure is too low).

Check length of brushes. Brush length must

be 0.25 in. (6.4 mm) minimum. If brushes

are worn, replace motor using Motor Kit

245080 for DX models or 243236 for XR

models.

Motor Kit 245080 for DX models or 243236

for XR models.

with small cleaning brush.

Replace Pressure Control knob using

Pressure Control Switch Kit 244266 for DX

models or 244267 for XR models.

General Problem: Output is Low or Fluctuating

SPECIFIC PROBLEM CAUSE SOLUTION

Motor armature is shorting. Check for shorts using armature tester

(growler), or perform spin test (see Motor

Diagnostics on page 19). If shorts are

evident, replace motor using Motor Kit

245080 for DX models or 243236 for XR

models.

Control board is damaged.

CAUTION: Do not perform control board

diagnostics until you have determined that the

armature is good. A bad motor armature can burn

out a good control board.

See Control Board Diagnostics on page

19, and if damaged, replace control board

using Control Board Kit 245079 for DX

models, 243228 for XR5 and XR7 models, or

243229 for XR9 models.

General Problem: Output is Low or Fluctuating (continued)

SPECIFIC PROBLEM CAUSE SOLUTION

Motor runs and pump

cycles, but pressure does

not build up.

Intake valve ball or outlet valve ball is not

seating properly.

Pump packings are worn or damaged. Check for leaking around throat packing nut.

Spray–Prime/Drain valve is leaking.

Remove and clean valves, and check balls and

seats for nicks; replace if necessary. Strain paint

before spraying to remove particles that could clog

pump.

See Pump Service on page 20.

Replace pump packings if there are leaks.

See Pump Service on page 20.

Check Spray–Prime/Drain valve for debris trapped

on seat and for worn parts. Torque to 185 in-lb

(21 NSm). If parts are worn, replace valve using

Spray–Prime/Drain Valve Kit 235014.

14 309226

Page 15

Advanced Troubleshooting

t

General Problem: Output is Low or Fluctuating (continued)

SPECIFIC PROBLEM CAUSE SOLUTION

Spray pattern has

variations, pressure

fluctuates excessively, or

motor runs very slowly.

Leads from motor to control board are

damaged, loose, or overheated.

Pressure control switch leads are pinched

between pump and drive housing or between

front cover and drive housing.

Control board is damaged.

CAUTION: Do not perform control board

diagnostics until you have determined that the

armature is good. A bad motor armature can

burn out a good control board.

Pressure control switch is damaged or worn

out.

Be sure terminals are centered and firmly

connected. Inspect wiring insulation and terminals

for signs of overheating, and replace any loose

terminals or damaged wiring. Securely reconnect

terminals.

Make sure pressure control harness is routed

behind pump, through retention clip, and

connected to control board connector at back of

drive housing (connected with tab to the right).

See Control Board Diagnostics on page 19. If

damaged, replace control board using Control

Board Kit 245079 for DX models, 243228 for XR5

and XR7 models, or 243229 for XR9 models.

Replace pressure control switch using Pressure

Control Switch Kit 244266 for DX models or

244267 for XR models.

General Problem: There is No Output

SPECIFIC PROBLEM CAUSE SOLUTION

Power switch is on and

p

sprayer is plugged in, bu

pump does not cycle.

Motor runs, but pump does not

cycle.

Motor does not run. Water or paint entered pressure control

p

See Basic Troubleshooting page 8.

Gear and/or yoke are damaged. Replace gear and yoke using Gear/Yoke Repair

Kit 243230.

Clean out and/or dry out, and retry. Replace if

switch or shorted control board.

necessary using Pressure Control Switch Kit

244266 for DX models or 244267 for XR models.

309226 15

Page 16

Advanced Troubleshooting

General Problem: Excessive Pressure is Building Up

SPECIFIC PROBLEM CAUSE SOLUTION

Spray–Prime/Drain valve

actuates automatically,

relieving pressure

through drain tube.

Pressure control switch is worn. Replace pressure control switch using Pressure

Control Switch Kit 244266 for DX models or

244267 for XR models.

Water or paint entered pressure control switch

or shorted control board.

Control board has failed. See Control Board Diagnostics on page 19, and

Clean out and/or dry out, and retry. Replace if

necessary using Pressure Control Switch Kit

244266 for DX models or 244267 for XR models.

replace control board if damaged using Control

Board Kit 245079 for DX models, 243228 for XR5

and XR7 models, or 243229 for XR9 models.

16 309226

Page 17

List of Kits

Kit Number Models/Series Kit Description

235014 XR/All Spray–Prime/Drain Valve

243082 XR/All Inlet Strainer (for inlet of suction tube)

243090 XR/All Pump Repair (pump packing module)

245077 DX Pump Inlet Valve Module

243093 XR/All Pump Inlet Valve Module (1/2” NPT bottom port)

245070 XR/All Pump Inlet Valve Module (intergral hose barb)

195750 XR5/All Suction Tube (inlet valve with 1/2” NPT bottom port;

115628 plastic elbow)

197607 XR5/All Suction Tube (inlet valve with intergral hose barb; no el-

bow)

195883 XR7 & XR9/All Suction Tube (inlet valve with 1/2” NPT bottom port)

197608 XR7 & XR9/All Suction Tube (inlet valve with intergral hose barb

245076 DX Pump Outlet Valve Module

243094 XR/All Pump Outlet Valve Module

244035 DX Drain Tube Diffuser

243096 XR/All Drain Tube Diffuser

244266 DX & XR5/A Pressure Control Switch

244267 XR5/B & C;

XR7 & XR9/All

245079 DX Control Board

243228 XR5 & XR7/All Control Board

243229 XR9/All Control Board

XR5/XR7/XR9 Pressure Control Switch

(continued)

309226 17

Page 18

List of Kits

Kit Number Models/Series Kit Description

245109 XR/All Combo Kit (Motor/Gear/Front Cover for 3/8” bronze bear-

ing configuration)

243231 XR/All Fan/Shroud/Brace

243230 XR5/A & B;

XR7/A; XR9/A

245062 XR5/C; XR7/B;

XR9/B

243237 XR5/A & B;

XR7A; XR9A

245064 XR5/C; XR7B;

XR9B

243236 XR5/ A & B;

XR7/A; XR9/A

245063 XR5/C; XR7/B;

XR9/B

243232 XR5/All Enclosure (includes both sides, labels, and screws)

243234 XR7 & XR9/All Enclosure (includes both sides, labels, and screws)

245078 DX Pump Repair

245080 DX Motor Repair

245078 DX DX Pump Repair

243533 XR/All XR Pump Replacement (complete pump*)

10mm Shaft Gear/Yoke/Guides (ball bearing equipped

cover and motor castings)

3/8” Shaft Gear/Yoke/Guides (bronze bearing equipped

cover and motor castings)

Front Cover (10mm ball bearing)

Front Cover (3/8” bronze bearing)

Motor/Drive Housing (10mm ball bearing motor casting)

Motor/Drive Housing (3/8” bronze bearing motor casting)

* Does not include Pressure Control Switch 244267 . Re-use

pressure control switch from pump being replaced, or order

separately.

18 309226

Page 19

Motor Diagnostics

Check for electrical continuity in the motor armature, windings, and brush as follows:

If Motor Diagnostics reveal a damaged motor, or if either of the motor brushes are shorter than 1/4 in. (6.4 mm),

or if the motor shaft cannot turn, replace the motor using Motor Kit 245080 for DX models or 243236 for XR models.

See Electric Shock Hazard on

page 7.

See Pressure Relief

Procedure

Setup

1. Unplug electrical cord, and relieve pressure.

2. Remove right enclosure, and disconnect motor

harness from control board.

3. Remove fan brace.

4. Remove the four cover screws and front cover.

5. Remove yoke and guide rods, and remove gear.

on page 6.

Armature Short Circuit Test (Spin Test) (XR Models

only)

Quickly turn motor fan by hand. If there are no electrical shorts, fan coasts two or three revolutions before

stopping. If fan does not spin freely, armature is

shorted. Replace motor using Motor Kit 245080 for

DX models or 243236 for XR models.

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity) (XR models only)

1. Connect red and black motor leads together with

test lead. Turn motor fan by hand at about two

revolutions per second.

2. If there is uneven resistance or no resistance,

replace motor using Motor Kit 245080 for DX

models or 243236 for XR models.

Control Board Diagnostics

Check for a damaged control board or pressure control switch as follows:

See Electric Shock Hazard on

page 7.

See Pressure Relief

Procedure

1. Unplug electrical cord, and relieve pressure.

2. Remove the four cover screws and front cover.

3. Remove yoke and guide rods, and remove gear.

4. Remove pressure control harness from control

board. Using fingernail or tip of small, flat-

blade screwdriver, press tab on right side

connector to release.

on page 6.

5. Attach to the control board a harness from a

pressure switch that you know is functioning

correctly.

NOTE: Pressure control switch does not have to

be installed in pump.

6. Turn pressure control adjustment knob to maximum pressure setting.

7. Plug electrical cord into 120V AC receptacle, and

turn Power switch (B) ON.

D If motor runs, replace pressure switch.

D If motor does not run, replace control board

and repeat test using Control Board Kit

245079 for DX models, 243228 for XR5 and

XR7 models, or 243229 for XR9 models.

309226 19

Page 20

Pump Diagnostics

All Models

CAUTION

When repairing or cleaning the pump, never submerge the pump in water or allow fluid to enter the pressure control.

When the pump packings wear, paint begins to leak down the outside of the pump. Replace the pump packings at

the first sign of leaking, or additional damage could occur. Use pump repair kit 245078 for DX models or 243090 for

XR models.

Pump Service

All Models

CAUTION

When repairing or cleaning the pump, never submerge the pump in water or allow fluid to enter the pressure control.

If the sprayer continues to cycle (motor and pump run) when the spray gun trigger is released, or if performance is

poor even with new spray tips and clean filters, the pump inlet or outlet valve my be obstructed or worn. If a pump

valve is worn, replace it.

Pump Service Kits

Model Description Kit

DX All 245078

XR Inlet Valves – 1/2” NPT bottom port 245093

XR Inlet Valves – integral hose barb 245070

XR Outlet Valves – All 243094

20 309226

Page 21

Technical Data

MAGNUM DX MAGNUM XR5 MAGNUM XR7 MAGNUM XR9

Working pressure

range

Electric motor

(open-frame,

permanent magnet DC)

Operating horsepower 3/8

Maximum delivery (with

tip)

Paint hose 25 ft (7.6 m) x 3/16 in.

Maximum tip hole size 0.015 in. (0.38 mm)

Weight, sprayer only 13 lb (6 kg)

Weight, sprayer, hose,

& gun

Dimensions 14.9 in. (37.8 cm) L

Power cord 16 AWG, 3 wire, 6 ft

Pump inlet fitting 3/4 in. internal thread (standard garden hose thread)

0 to 2800 psi

(0 to 19 MPa, 0 to 193

bar)

6.5 Amp

0.24 gpm (.91 lpm)

16 lb (7.25 kg)

15.0 in. (38.1 cm) W

15.6 in. (39.6cm) H

(1.8 m)

0 to 3000 psi

(0 to 21 MPa, 0 to 207

bar)

5.8 Amp

5/8

0.27 gpm (1.02 lpm)

25 ft (7.6 m) x 1/4 in.

0.015 in. (0.38 mm)

21 lb (10 kg)

24 lb (11 kg)

13.75 in. (34.9 cm) L

11 in. (27.9 cm) W

17 in. (43.2 cm) H

16 AWG, 3 wire, 6 ft

(1.8 m

0 to 3000 psi

(0 to 21 MPa, 0 to 207

bar)

5.8 Amp 4.9 Amp

3/4 7/8

0.31 gpm (1.17 lpm) 0.38 gpm (1.44 lpm)

50 ft (15.2 m) x 1/4 in. 50 ft (15.2 m) x 1/4 in.

0.017 in. (0.43 mm) 0.019 in. (0.48 mm)

31 lb (14 kg) 35 lb (16 kg)

36 lb (17 kg) 40 lb (18 kg)

19.5 in. (49.5 cm) L

17.25 in. (43.8 cm) W

40.75 in. (103.5 cm) H

Height with folded

handle is

26 in. (66 cm)

16 AWG, 3 wire, 6 ft

(1.8 m)

0 to 3000 psi

(0 to 21 MPa, 0 to 207

bar)

19.5 in. (49.5 cm) L

19 in. (48.3 cm) W

40 in. (101.6 cm) H

Height with folded

handle is

26 in. (66 cm)

16 AWG, 3 wire, 10 ft

(3 m)

Fluid outlet fitting 1/4 npsm external thread

Inlet screen on suction

tube

Wetted parts, pump &

hose

Wetted parts, gun SG1–EF: plated steel, nylon, aluminum, tungsten carbide, stainless steel, brass, viton

Generator requirement 1500 Watt minimum

Electrical power

requirement

Storage temperature

range * {

Operating temperature

range **

stainless steel, brass, leather, ultra-high molecular weight polyethylene (UHMWPE), carbide, nylon,

PVC, zinc-aluminum alloy, polypropylene

SG2 / SG3: aluminum, brass, carbide, nylon, plated steel, stainless steel, UHMWPE, zinc

14 mesh (1300 micron)

120V AC, 60 Hz, 1 phase, 15A

–30_ to 160_ F (–35_ to 71_ C)

40_ to 115_ F (4_ to 46_ C)

* When pump is stored with non-freezing fluid. Pump damage will occur if water or latex paint freezes in pump.

{ Damage to plastic parts may result if impact occurs in low-temperature conditions.

* * Changes in paint viscosity at very low or very high temperatures can affect sprayer performance.

309226 21

Page 22

Model 232735 DX Sprayer

50

57

52

23

Parts

54

55

42

44

45

53

31

13

4

58

40

51

12

7

5

13

2

3

59

1

56

22 309226

Page 23

Model 232735 DX Sprayer

Parts

Ref.

No. Part No. Description Qty.

1 196569 FRAME 1

2 243082 STRAINER 1

3 244035 DEFLECTOR, barbed 1

4 195400 CLIP, spring 2

5 196582 TUBE, suction 1

7 196586 COVER, switch 1

12 195084 TUBE, drain 1

13 115489 CLAMP, drain tube 2

23 244266 KIT, pressure switch, repair 1

31 235014 KIT, valve, repair 1

40 196566 HOUSING, pump 1

42 196567 COVER, housing 1

Ref.

No. Part No. Description Qty.

44 196577 GEAR, eccentric 1

45 196579 GEAR, combination 1

50 245078 KIT, pump repair 1

51 245079 KIT, control board 1

52 245080 KIT, motor, repair 1

53 245076 KIT, outlet valve 1

54 245077 KIT, inlet valve 1

55 116295 CLAMP, spring, .88 diameter 1

56 115478 SCREW, machine; pan head 2

57 196594 CORD, power 1

58 243954 HOSE, DuraFlex, 3/16 in. x 25 ft 1

(available from Service Center only)

59 243926 GUN, spray, SG1–EF 1

309226 23

Page 24

Model 232740 XR5 Sprayer

48

51

63

Parts

66

61

114

52

62

114

94

52

70

47

46

65

95

58

68

67

69

54

25

20

59

1

36

65

127

2

17

13

19

40

75

88

18

75

24 309226

93

72

90

73

76

74

81

Page 25

Model 232740 XR5 Sprayer

Parts

Ref.

No. Part No. Description Qty.

1 195126 PUMP, housing 1

2 243090 KIT, pump repair 1

13 243094 KIT, outlet valve (includes #17) 1

17 103338 PACKING, o–ring 1

18 195947 FILTER, adapter 1

19 243070 PUMP, filter, InstaClean 1

20 243093 KIT, inlet valve, 1/2” NPT

(includes #25) 1

245070 KIT, inlet valve, intergral hose barb

(includes #25) 1

25 103413 PACKING, o–ring, inlet valve 1

36 244266 KIT, pressure switch, repair, Series A 1

244267 KIT, pressure switch, repair,

Series B & C 1

40 235014 KIT, valve, repair 1

46 114687 CLIP, retainer 1

47 243236 KIT, motor repair, Series A & B

(includes fan kit #48) 1

245063 KIT, motor repair, Series C

(includes fan kit #48) 1

48 243231 KIT, fan and shield 1

51 243228 CONTROL BOARD, XR5 1

52 115477 SCREW, machine 10

54 243230 KIT, gear, yoke, guide, repair,

Series A & B 1

245062 KIT, gear, yoke, guide, repair,

Series C 1

Ref.

No. Part No. Description Qty.

55 116295 CLAMP, spring, .88 diameter 1

58 194507 DOWEL, pin 5/16 2

61 115642 BUSHING, strain relief 1

62 243237 COVER with label, Series A & B 1

245064 COVER with label, Series C 1

63 195110 CORD, power 1

65 115478 SCREW, torx/slt pan hd, 1/4” 8

66 115499 SWITCH, rocker 1

67 195431 LEG, left 1

68 195430 LEG, right 1

69 105521 PLUG 2

70 195432 HANGER, cord 1

72 197607 TUBE, suction, 90_ bend

(includes #90) 1

73 243082 STRAINER 1

74 195084 TUBE, drain 1

75 115489 CLAMP, drain tube 2

76 195400 CLIP, spring 3

81 244035 DEFLECTOR, barbed 1

88 115719 O–RING, filter adapter 1

90 115099 WASHER, inlet strainer 1

93 102473 CLAMP, hose, 1

94 243022 HOSE, 1/4 in. x 25 ft 1

95 243926 GUN, spray, SGI–EF 1

114 243232 ENCLOSURE, (includes label and

screws) 1

127 243533 PUMP, replacement (includes #1, 2,

13, 17, 18, 19, 20, 40. Item #36 must

be purchased separately.) 1

309226 25

Page 26

Model 232745 XR7 Sprayer

Parts

63

96

95

113

70

73

69

72

75

71

48

72

125

47

51

52

46

61

58

54

66

52

2

125

52

62

65

81

127

13

17

26 309226

77 76

74

68

79

80

65

67

79

Alternate Config.

20

26

84

36

19

20

85

84

86

1

25

102

40

88

18

87

88

89

94

Page 27

Model 232745 XR7 Sprayer

Parts

Ref.

No. Part No. Description Qty.

1 195126 PUMP, housing 1

2 243090 KIT, pump repair 1

13 243094 KIT, outlet valve (includes #17) 1

17 103338 PACKING, o–ring 1

18 195947 FILTER, adapter 1

19 243070 PUMP, filter, InstaClean 1

20 243093 KIT, inlet valve, 1/2” NPT

(includes #25) 1

245070 KIT, inlet valve, intergral hose barb

(includes #25) 1

25 103413 PACKING, o–ring, inlet valve 1

26 116295 CLAMP, spring, .88 diameter 1

36 244267 KIT, pressure switch, repair 1

40 235014 KIT, drain/prime, valve repair 1

46 114687 CLIP, retainer 1

47 243236 KIT, motor, repair, Series A

(includes #48) 1

245063 KIT, motor, repair, Series B

(includes #48) 1

48 243231 KIT, fan and shield 1

51 243228 CONTROL BOARD, XR7 1

52 115477 SCREW, thread forming, #8 11

54 243230 KIT, gear, yoke, guide, repair, Series A 1

245062 KIT, gear, yoke, guide, repair, Series B 1

58 194507 DOWEL, pin 5/16 2

61 111348 BUSHING, strain relief 1

62 243237 COVER with label, Series A 1

245064 COVER with label, Series B 1

63 115603 CORD, power 1

65 115478 SCREW, torx/slt pan hd, 1/4” 8

66 115499 SWITCH, rocker 1

67 195433 SUPPORT, right 1

Ref.

No. Part No. Description Qty.

68 195434 SUPPORT, left 1

69 195436 FRAME, cart 1

70 195435 HANDLE, cart 1

71 195440 HOSE RACK 1

72 115097 SCREW, curved head 2

73 115480 KNOB, t–handle 2

74 197285 AXLE 1

75 195367 SPACER 2

76 115095 WHEEL, 9” 2

77 112612 CAP 2

79 105221 PLUG 2

80 102040 NUT, lock 4

81 195105 HANGAR, pail 1

84 115099 WASHER, inlet strainer 1

85 195883 TUBE, suction, 1/2” NPT(m) fitting

(includes washer 84) 1

197608 TUBE, suction, barb,

(includes washer 84) 1

86 243082 STRAINER 1

87 195108 TUBE, drain 1

88 115489 CLAMP, drain tube 2

89 195400 CLIP, spring 1

94 244035 DEFLECTOR, barbed 1

95 243024 HOSE, 1/4 in. x 50 ft. 1

96 243011 GUN, spray, SG2 1

102 115719 PACKING, o–ring, filter adapter 1

113 115651 NUT,acorn 2

125 243234 ENCLOSURE, with label and screws 1

127 243533 PUMP, replacement (includes 1, 2, 13

17, 18, 19, 20,40. Item #36 must

be purchased separately.) 1

309226 27

Page 28

Model 232750 XR9 Sprayer

Parts

63

95

96

112

70

73

71

72

69

75

71

48

72

112

124

47

51

52

46

61

58

54

66

124

52

62

65

80

127

52

13

2

17

28 309226

77

76

74

68

79

78

65

67

78

Alternate Config.

20

26

84

36

101

19

25

20

84

83

85

1

18

88

40

87

86

88

94

Page 29

Model 232750 XR9 Sprayer

Parts

Ref.

No. Part No. Description Qty.

1 195126 PUMP, housing 1

2 243090 KIT, pump repair 1

13 243094 KIT, outlet valve (includes #17) 1

17 103338 PACKING, o–ring, outlet valve 1

18 195947 FILTER, adapter 1

19 243070 PUMP, filter, InstaClean 1

20 243093 KIT, inlet valve, 1/2” NPT

(includes #25) 1

245070 KIT, inlet valve, intergral hose barb

(includes #25) 1

25 103413 PACKING, o–ring, inlet valve 1

26 116295 CLAMP, spring .88 diameter 1

36 244267 KIT, pressure switch, repair 1

40 235014 KIT, drain/prime valve repair 1

46 114687 CLIP, retainer 1

47 243236 KIT, motor repair, Series A

(includes #48) 1

245063 KIT, motor, repair, Series B

(includes #48) 1

48 243231 KIT, fan and shield 1

51 243229 CONTROL BOARD XR9 1

52 115477 SCREW, thread forming, #8 11

54 243230 KIT, gear, yoke, guide, repair, Series A 1

245062 KIT, gear, yoke, guide, repair, Series B 1

58 194507 DOWEL, pin 5/16 2

61 111348 BUSHING, strain relief 1

62 243237 COVER with label, Series A 1

245064 COVER with label, Series B 1

63 115604 CORD, power 1

65 115478 SCREW, torx/slt, 1/4” 8

66 115499 SWITCH, rocker 1

Ref.

No. Part No. Description Qty.

67 195433 SUPPORT, right 1

68 195434 SUPPORT, left 1

69 195439 FRAME, cart 1

70 195438 HANDLE, cart 1

71 195440 HOSE RACK 2

72 115097 SCREW, curved head 6

73 115480 KNOB, t–handle 2

74 195366 AXLE 1

75 195367 SPACER 2

76 115094 WHEEL, 10” 2

77 112612 CAP 2

78 105221 PLUG 2

80 195105 HANGAR, pail 1

83 115099 WASHER, inlet strainer 1

84 195883 TUBE, suction, 1/2” NPT(m) fitting

(includes washer #83) 1

197608 TUBE, suction, barb,

(includes washer 84) 1

85 243082 STRAINER 1

86 195108 TUBE, drain 1

87 115489 CLAMP, drain tube 1

88 195400 CLIP, spring 1

94 244035 DEFLECTOR, barbed 1

95 243024 HOSE, 1/4 in. x 50 ft 1

96 243012 GUN, spray, contractor, SG3 1

101 115719 PACKING, o–ring, filter, adapter 1

112 115651 NUT, hex, 5/16” 4

124 243234 ENCLOSURE with label and screws 1

127 243533 PUMP, replacement (includes 1, 2, 13,

17, 18, 19, 20,40. Item #36 must

be purchased separately.) 1

309226 29

Page 30

Limited Warranty

Graco Inc. warrants to the original retail purchaser (other than for purposes of resale or rental) all equipment

manufactured by Graco and bearing its name to be free from defects in material and workmanship if operated

in accordance with Graco’s printed recommendations and instructions. This warranty applies for one year from

the date of purchase.

This warranty does not cover and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by improper use, accidents, user negligence, use of non-Graco component parts or

service or repair performed by anyone other than a Graco authorized service center.

IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE.

GRACO SHALL NOT IN ANY EVENT BE LIABLE FOR ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL

LOSS, DAMAGE OR EXPENSE OF ANY KIND, WHETHER FROM BREACH OF THIS WARRANTY OR ANY

OTHER REASON. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you.

To make a claim under this warranty, return the product with proof of purchase, transportation prepaid, to any

Authorized Graco Service Center. Graco’s Authorized Service Center, at its option, will either repair or replace

the product and return it to you, postage prepaid. A listing of Authorized Graco Service Centers is enclosed

with this product. You may also find the nearest Authorized Graco Service Center by calling 1–888–541–9788

or by visiting our website at www.graco.com.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to

state.

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

30 309226

www.graco.com

PRINTED IN USA 309226 03/2001

Loading...

Loading...