Page 1

M680™ Mortar Pump Resurfaces

Wastewater Transfer Station

CASE STUDY

Challenge:

Commonwealth Epoxy Coatings, Inc., of Newport News, VA, won the contract

to resurface a wastewater transfer station for a regional water and sewer

authority in North Carolina. The specs called for two cementitious materials of

different viscosities.

Commonwealth had never before sprayed the heavier of the two materials and

recognized that their existing equipment wasn’t capable of handling it. That left

them with two immediate options - double their timeline and hand-trowel the

material, or rent large, difficult-to-maneuver shotcrete equipment and absorb

the extra expense. Neither option appealed to them.

Solution:

Fortunately, Commonwealth had enough time to explore a third option: the Graco

™

M680

Mortar Pump. The M680 is capable of handling a range of materials of

varying viscosities at low pressures (typically 200 to 500 psi/13.7 to 34.5 bar).

It is easy to use, which enabled Commonwealth to begin spraying quickly, and

the spray provided excellent thickness control, producing a consistent layer

of material.

Results:

The project took 30 kits to complete. In terms of Commonwealth’s expectations,

the Graco M680 exceeded all of them. According to Vice President Jeff White,

the Graco M680 cut project time in half, reduced costs by one-third and made

it possible for them to spray a new material.

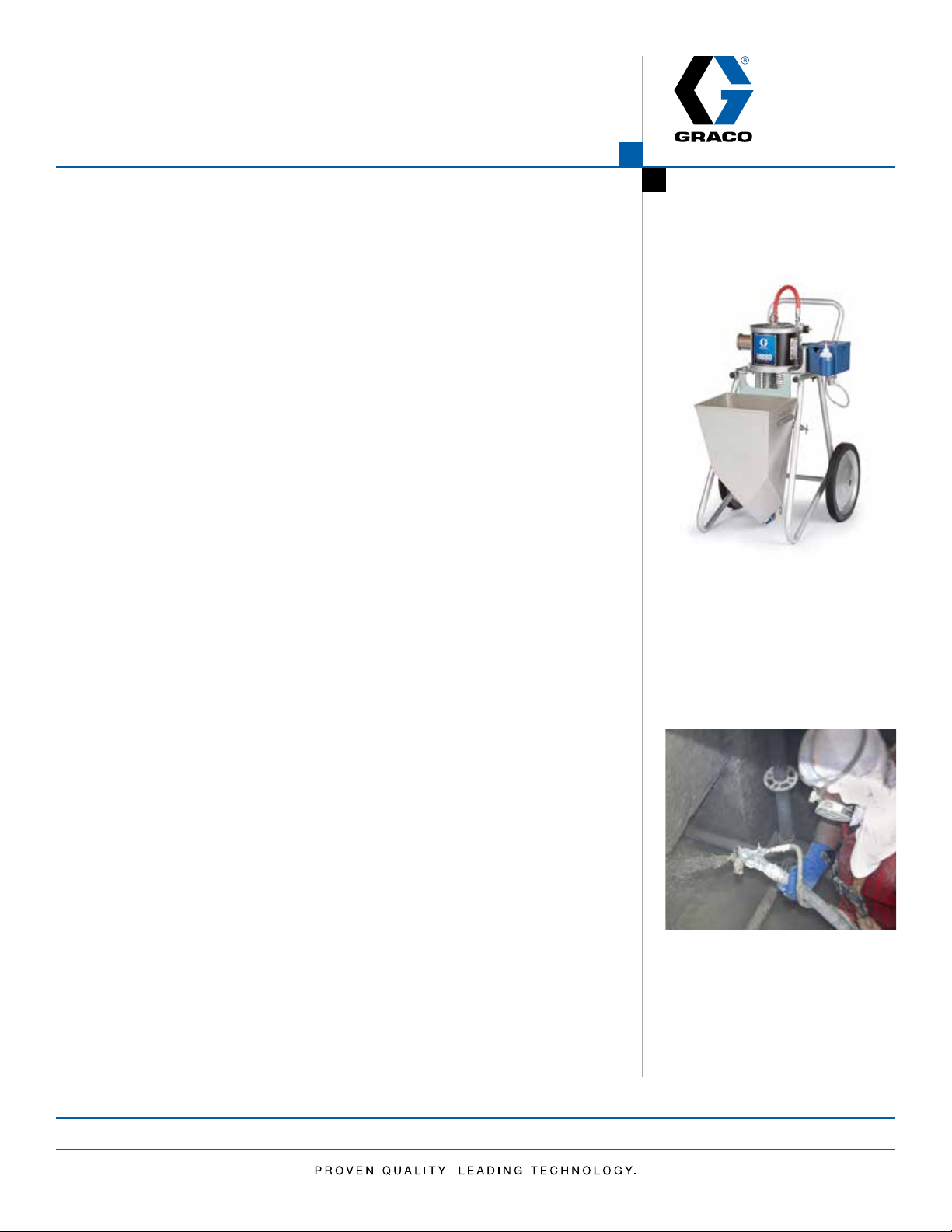

Graco M680 Mortar Pump

Because the Graco M680 is easy to use

and maneuverable, Commonwealth

Epoxy Coatings, Inc. was able to spray

in tight spaces rather than hand-finish,

which Commonwealth estimates cut

the project time in half and reduced

costs by one-third.

For more information, contact us at 1-800-746-0883 or info@graco.com. Visit us at www.graco.com

Page 2

SPECIFICATIONS

END USER

Commonwealth Epoxy Inc.

INDUSTRY

Wastewater

APPLICATION

Resurfacing a transfer station

Material Specs:

• Name of Material –

Series 218 MortarClad

Series 217 MortarCrete

• Material Supplier –

Tnemec Company, Inc.

• Feed Method – Hopper

• Components –

MortarClad: A + B liquid, C dry mix

MortarCrete: A liquid, B dry mix

• Chemistry –

MortarClad: Epoxy modified

cementitious mortar;

MortarCrete: Cementitious

repair mortar

™

™

GRACO EQUIPMENT

• M680 Mortar Pump

CONFIGURATION

• Part Number: 24T834

• Hose: 1 in x 25 ft fluid hose

(25 mm x 12.6 m); .75 in x 10 ft ship

(19 mm x 3 m)

• Applicator: Flex Hose applicator

with #6 Nozzle

• Atomization type: Air atomization

Graco Inc.

P.O. Box 1441

Minneapolis, MN 55440-1441

© 2014 Graco Inc. 349203 Rev. A 4/14 All written and visual data contained in this document

are based on the latest product information available at the time of publication. Graco reserves

the right to make changes at any time without notice. All other brand names or marks are used

for identification purposes and are trademarks of their respective owners.

Loading...

Loading...