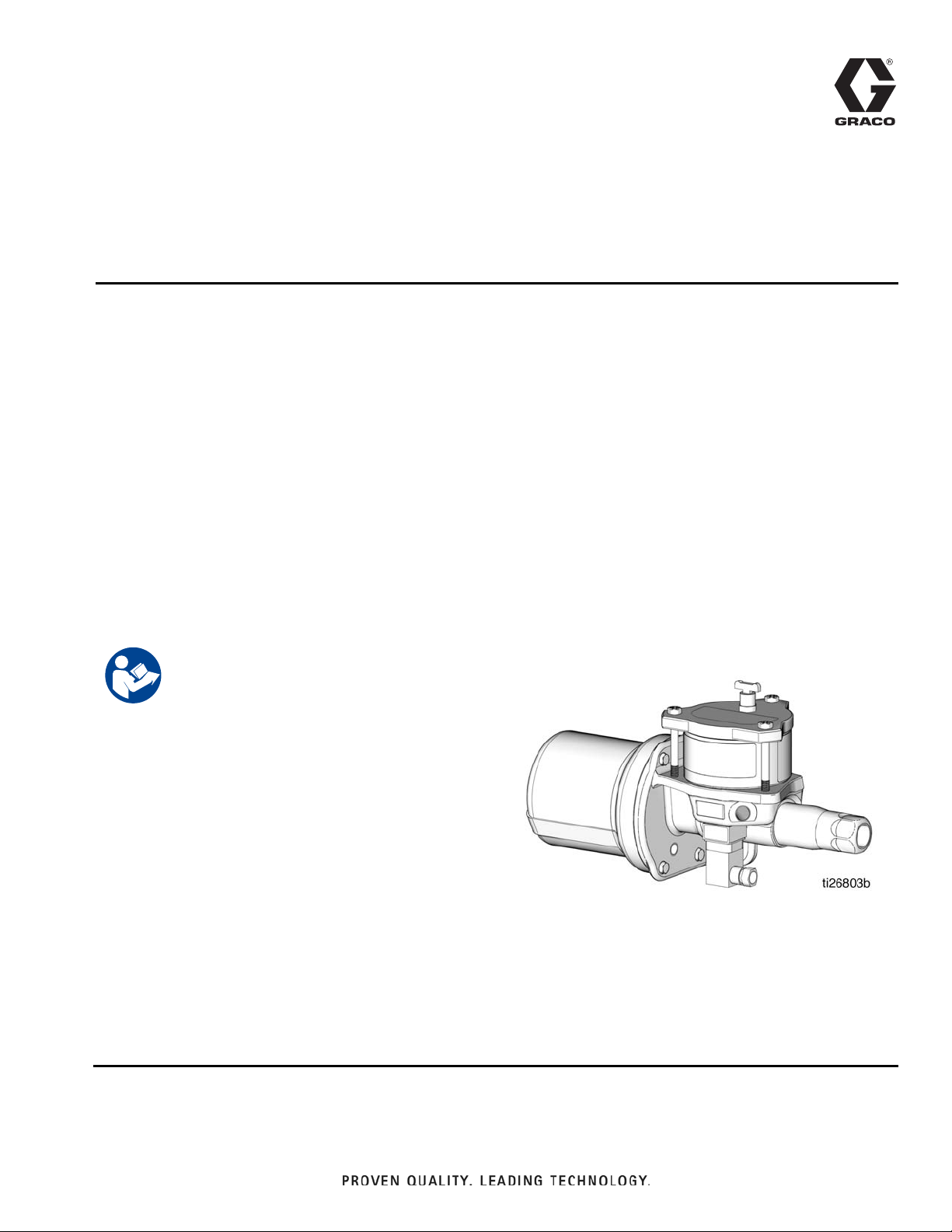

Graco LubePro H1900, LubePro 24Y498, LubePro 24Y499, LubePro 25Y499, LubePro 25Y498 Instructions Manual

Instructions

™

H1900 LubePro

3A3169E

Oil Pump

For pumping non-corrosive and non-abrasive lubricants only. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

Model No.

24Y498 - 19:1 Oil pump without Low Level

24Y499 - 19:1 Oil pump with Low Level

25Y498- 19:1 Oil pump without Low Level, includes BSPP adapter

25Y499 - 19:1 Oil pump with Low Level, includes BSPP adapter

EN

80 psi (0.55 MPa, 5.5 bar) Maximum Oil Input Pressure

3500 psi (24 MPa, 241 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Warnings

WARNING

WARNINGWARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

PRESSURIZED EQUIPMENT HAZARD

Over-pressurization can result in equipment rupture and serious injury.

• Do not exceed the maximum oil inlet pressure.

• Do not exceed the maximum air input pressure.

• Use tubing, hoses and other components with pressure ratings equal to or higher than the pump

rating.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgi-

cal treatment.

• Do not point dispensing device at anyone or at any part of the body

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in

all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

2 3A3169E

Warnings

WARNING

WARNINGWARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A3169E 3

Installation

J

B2

B1

F

B3

C

D

H

K

G

L

A

M

E

N

R

P

S

T

W

U

AA

V

Y

CC

EE

DD

UU

UU

UU

BB

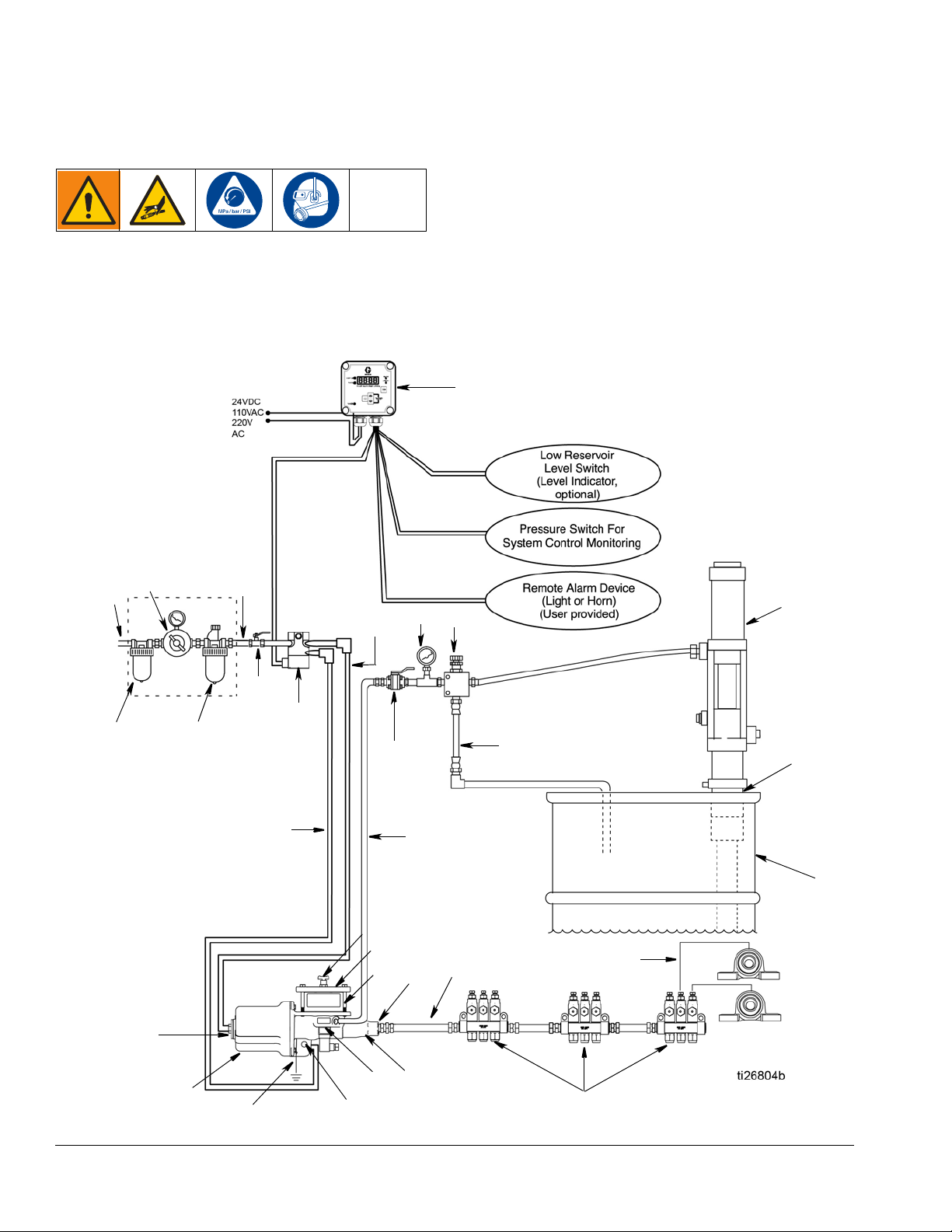

Installation

Typical Installation

Throughout this manual, reference letters used in the instructions, refer to the reference letters used in the Typical

Installation illustration shown in F

IG. 1.

FIG. 1: Typical Installation

4 3A3169E

Installation

RT

GW

GS

Typical Installation Key:

A Main air supply

B Filter/Regulator/Lubricator Assembly

B1 - Air Filter

B2 - Air Regulator

B3 - Air Lubricator

C Air solenoid valve (4-way)

D Pump module

E Pump outlet

F Bleed-type master air valve (required)

G High pressure lubricant supply lines (user supplied)

HInjector

J Lubricator controller

K Pump reservoir

L Pump reservoir cover

M Ground

N Pump outlet check body

P Pump air inlet - forward stroke

R Pump air inlet - return stroke

S Feeder lines

TLow level

U Pressure reducing valve (required in systems over 80 psi

(0.55 MPa, 5.5 bar)

V Supply line shut-off valve (required)

WDrum

Y Pressure gauge

AA Bung adapter

BB Cock valve

CC Oil input supply line

DD Oil input supply pump/system

EE Drain hose

UU Air supply lines

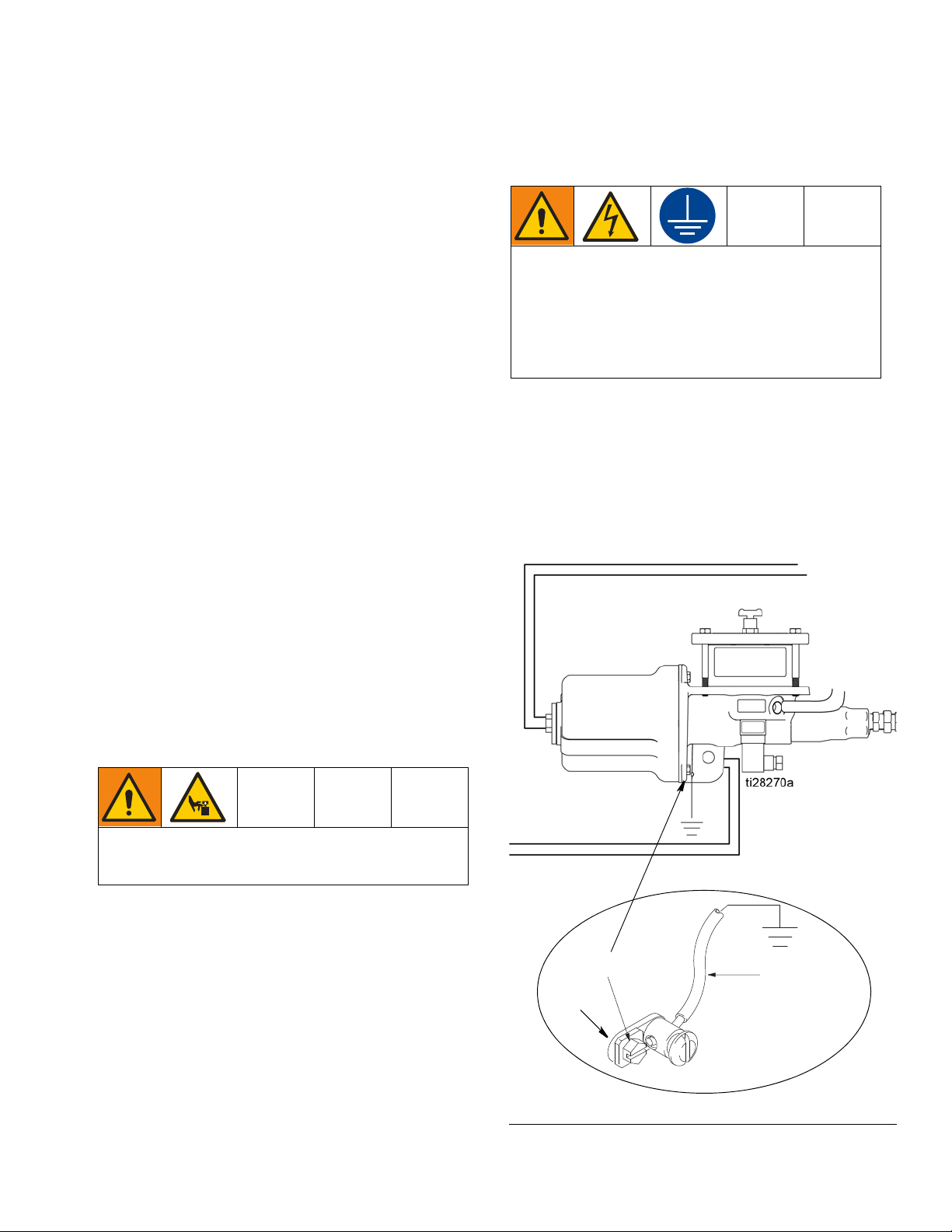

Grounding

Grounding is necessary when voltages above 30

VAC or 42 VDC are used for the low level switch or

for an air valve attached to the pump. Improper

grounding can cause electric shock. Grounding

reduces the risk of electric shock by providing an

escape wire for the electric current in the event of

malfunction or breakdown.

To ground the pump: Remove the ground screw (GS)

located on the back of the pump base and insert it

through the eye of the ring terminal (RT) at end of

ground wire (GW). Fasten the ground screw (GS) back

onto the pump and tighten securely. Connect the other

end of the ground wire to a true earth ground. See F

2.

IG.

Mounting

Mount pump securely so it cannot move around

during operation. Failure to do so could result in personal injury and/or equipment damage.

Install the pump in a location that will adequately support the weight of pump when filled with lubricant and

also provides easy operator access to the pump air controls. Pump must be mounted in a vertical position with

the reservoir up.

See Technical Data, page 31 for pump weight information and the Dimensions and Mounting layout, page 30.

3A3169E 5

FIG. 2

Installation

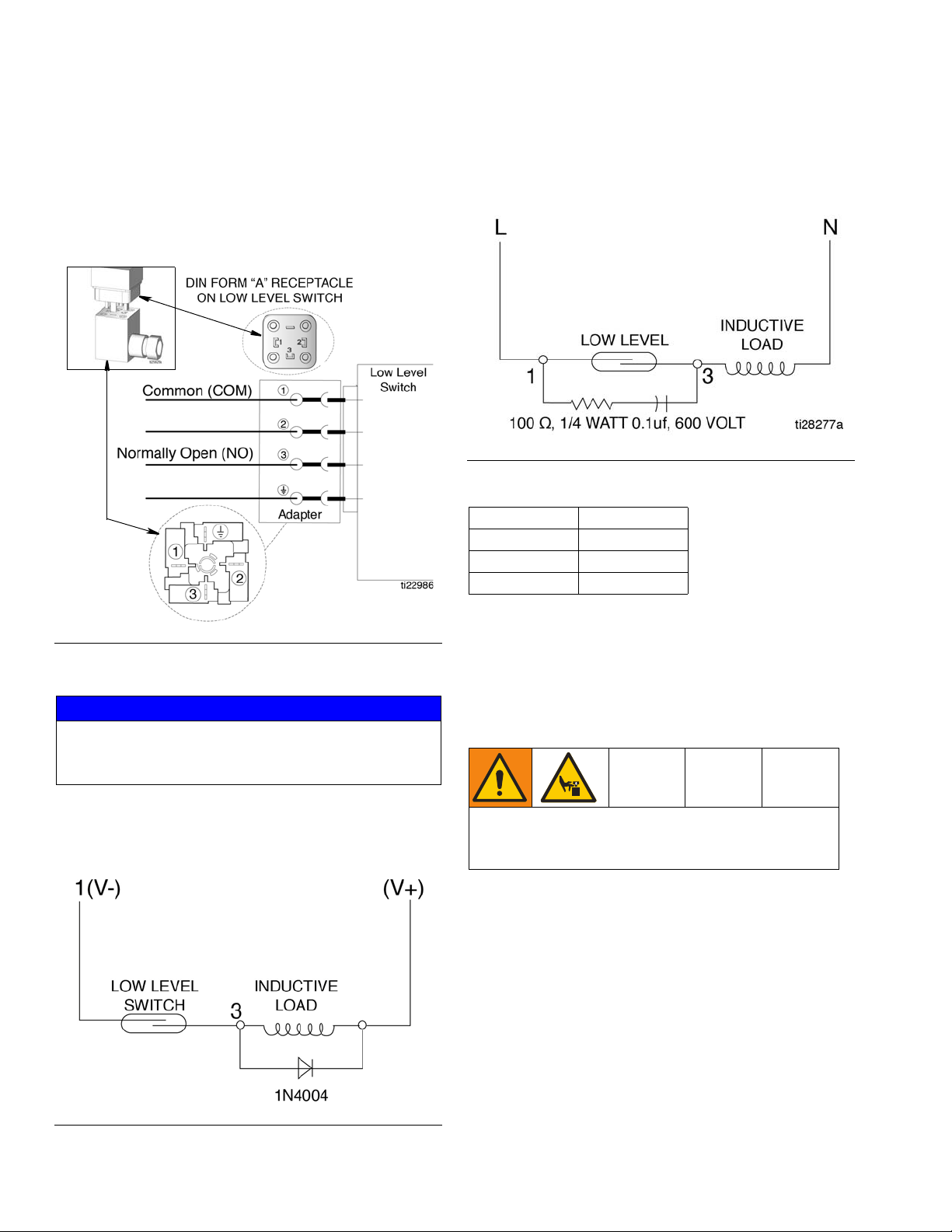

Low Level Models Only

DIN Connector

Connection is made to PINS 1 and 3 of the DIN Field

Wireable Connector. See F

page 31 for electrical ratings.

IG. 3. See Technical Data,

AC Voltage - A resistor and capacitor (high impedance

60 hertz) connected in parallel with the switch, as shown

in F

IG. 5, is recommended.

FIG. 5

Switch Ratings

Volts Amps

30 0.3

120 0.13

240 0.06

FIG. 3

Recommended Protection

NOTICE

Connecting the low level switch directly to the load

may weld the contacts or erode the contact surface,

resulting in a shorter switch life.

DC Voltage - A 1N4004 diode (or equivalent) connected

cathode-to-positive, shown in F

IG. 4, is recommended.

Air and Fluid Line Accessories

Install the air line accessories in the order shown in FIG.

1, page 4.

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

Bleed-type master air valve (F): required in your system to relieve air trapped between it and the pump.

Air line filter (B1): removes harmful dirt and moisture

from compressed air supply.

Pump air regulator (B2): to control pump speed and

outlet pressure. Locate it close to the pump.

FIG. 4

6 3A3169E

Installation

NOTICE

Do not mount the air accessories directly on the solenoid valve air inlet. The air inlet and fittings are not

strong enough to support the accessories and may

break. Provide a bracket on which to mount the

accessories.

1. Install a bleed-type master air valve (F) to relieve

air trapped between it and the pump. Install the

valve in a location that is easily accessible from the

pump and located downstream of the air regulator.

2. Install an air line filter (B1) to remove harmful dirt

and contaminants from the compressed air supply

3. Install the air regulator (B2) to control pressure.

4. Install an air line lubricator (B3) to lubricate the air

cylinder.

5. Install the (4-way) air solenoid valve (C) for control

of the pump forward and return strokes.

The maximum working pressure of each component

in the system may not be the same. To reduce the

risk of over-pressurizing any part of your system,

know the maximum working pressure rating of each

component and its connected components. Never

exceed the maximum working pressure of the lowest

rated components connected to a particular pump.

Oil Input Supply System

To reduce the risk of over-pressurizing the LubePro

Single Stroke Pump which could cause a rupture and

serious injury, including fluid injection, an oil input

supply system must have a means to limit the incoming fluid pressure to the LubePro Single Stroke Pump

to a maximum of 80 psi (0.55 MPa, 5.5 bar).

The oil input supply pump/system (DD) must have a

pressure reducing valve (U).

Oil Input Lines

Shut-off Valve (V): Allows isolation of the LubePro

pump from the incoming oil supply line (CC).

Required on the oil input supply pump/system (DD).

Hoses: Use a minimum 3/8 inch supply line (S).

Pressure Reducing Valve (U): circulates excess oil

pressure back to the tank. Install this valve (U) in the

supply line with a drain hose (EE). Limit supply pressure to a maximum 80 psi (0.55 MPa, 5.5 bar)).

Fluid-filled Pressure Gauge (Y): monitors hydraulic

pressure to the LubePro Single Stroke Pump during

startup.

To use the air regulator reading to determine the fluid

output pressure, multiply the ratio of the pump (19:1) by

the air pressure shown on the regulator gauge or see

Table 1: Lubricant Output - PSI or Table 2: Lubricant

Output - MPa (bar), provided on page 12.

Limit the air to the pump so that no air line or fluid line

component or accessory is over pressurized.

Air Supply Lines (UU)

1. Install two air supply lines (UU) between the air

solenoid valve outlets (C) and the pump (D) as

shown in the Typical Installation, page 4.

2. Install an air supply line (UU) between the air solenoid valve inlet (C) and the Filter/Regulator/Lubricator Assembly (B) as shown in the Typical

Installation, page 4.

3A3169E 7

Installation

Oil

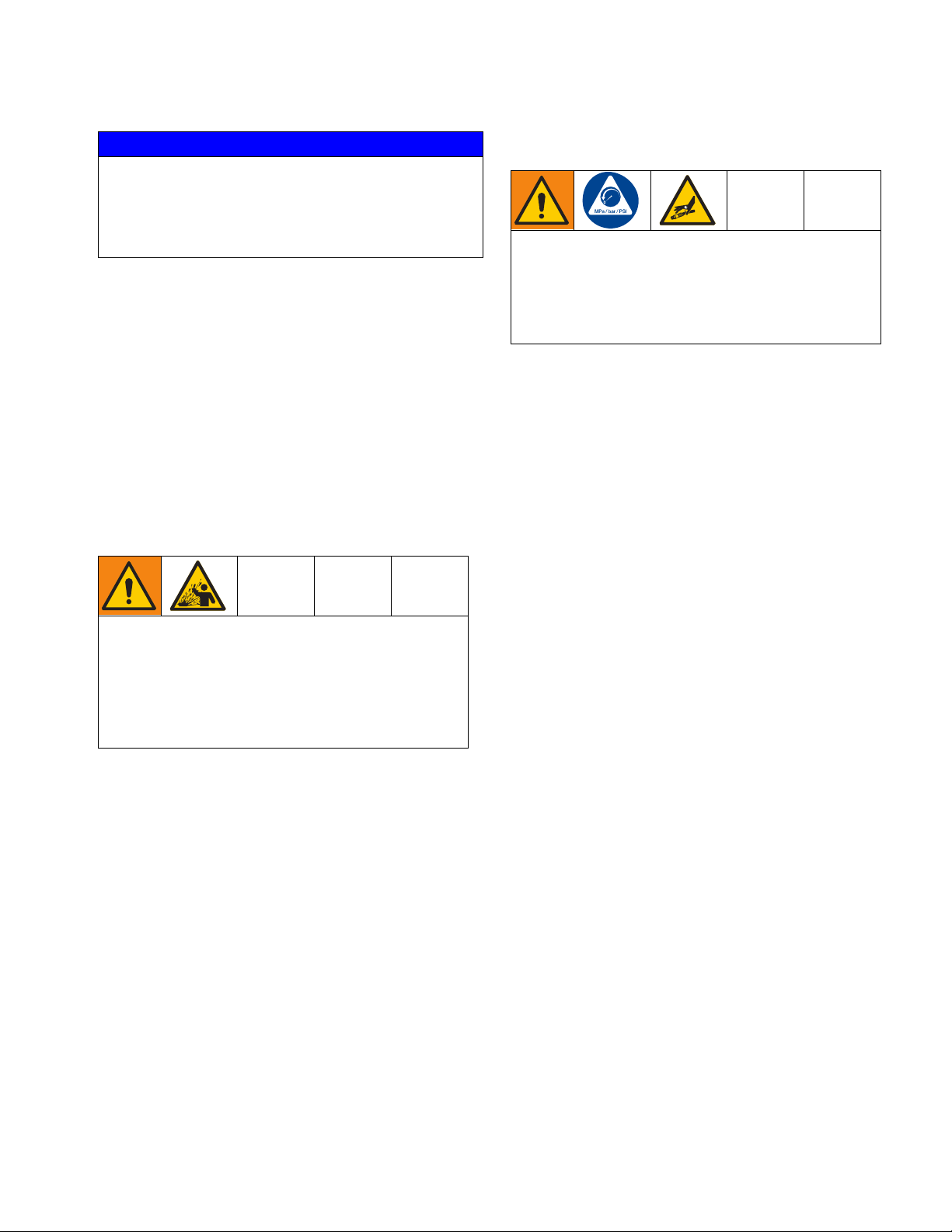

Starting Pump

1. Make sure the supply line (G) is connected and

there are no open lines for oil to leak out of the

pump outlet (E).

2. Close the oil supply shut-off valve (V).

3. Turn on the oil input supply pump/system (DD).

4. Adjust pressure reducing valve (U) to limit the oil

inlet pressure to 80 psi (0.55 MPa, 5.5 bar).

5. Slowly open the oil supply shut-off valve (V).

6. Remove the trapped air in the pump reservoir (K) by

slowly opening the cock valve (BB) until oil can be

seen coming out after all the air is released as

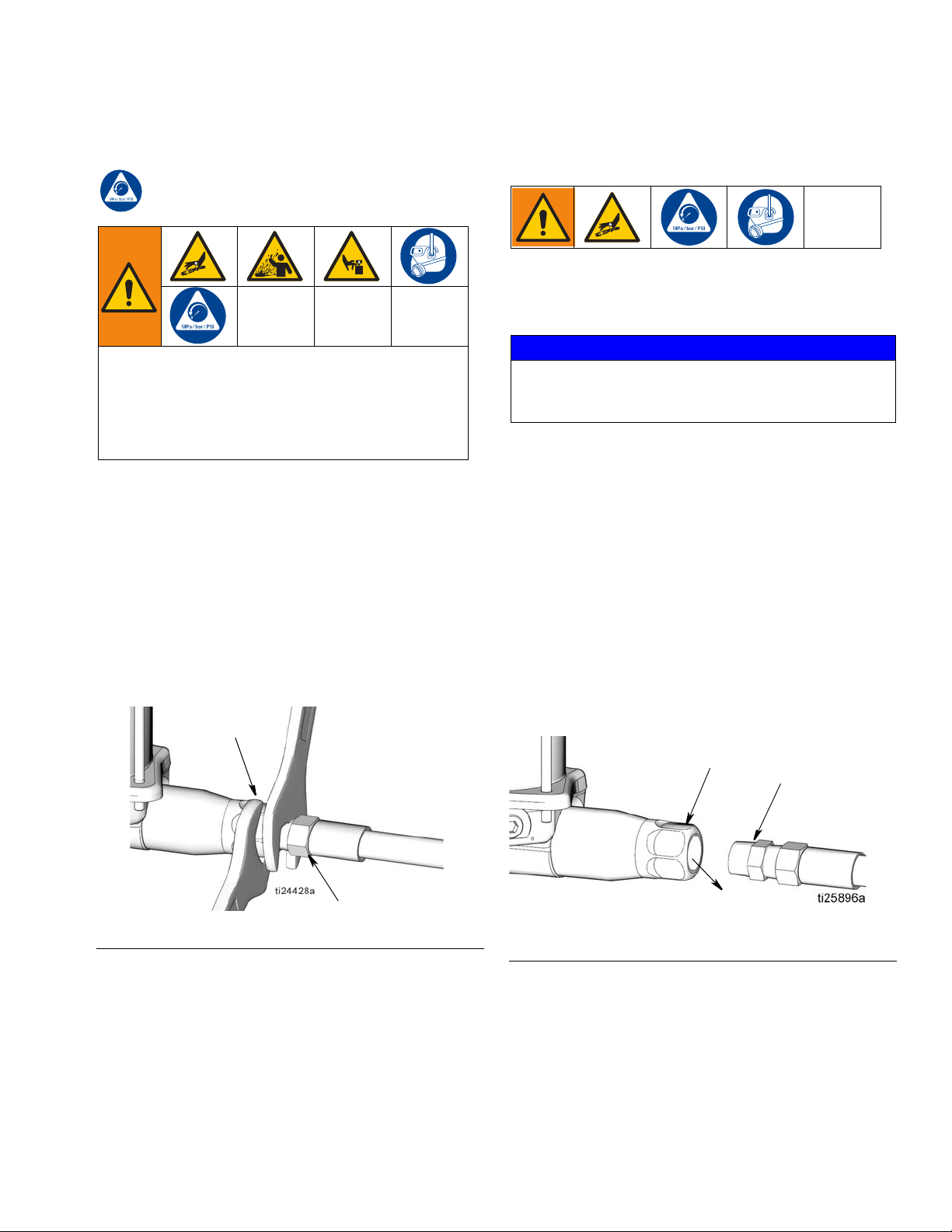

shown in F

IG. 6.

Supply Lines

1. If there are multiple pumps on the air line, close the

air regulators (B2) and bleed-type master air

valves (F) to all but one the pumps. If there is only

one pump, open its air regulator and bleed-type

master air valve.

2. Open the master air valve (F).

3. Set the air pressure to each pump at the lowest

pressure needed to get the desired results. See

Recommended Pressure provided in Tabl e 1:

Lubricant Output and Pressure - US or Tab l e 2 :

Lubricant Output and Pressure - Metric provided

on page 12.

4. Remove trapped air in the supply line (G) by

removing a plug or opening a fitting on the furthest

end of the supply line. Run the pump until oil comes

out. After oil free of air comes out, close the line.

Feeder Lines (S)

Fill each feeder line (S) with lubricant prior to connecting lines to the injector outlet.

FIG. 6

7. Close the cock valve (BB).

NOTICE

Always use lowest pressure possible to obtain desired

results.

Injectors (H)

For the following instructions, refer to Typical Installations, F

1. Check each injector (H) for proper operation. The

2. Adjust the injector output if needed to ensure that

IG. 1, page 4, for the following instructions.

injector stem should move when lubricant is discharged.

the output volume discharged is sufficient.

8 3A3169E

Installation

E

G

E

G

ol

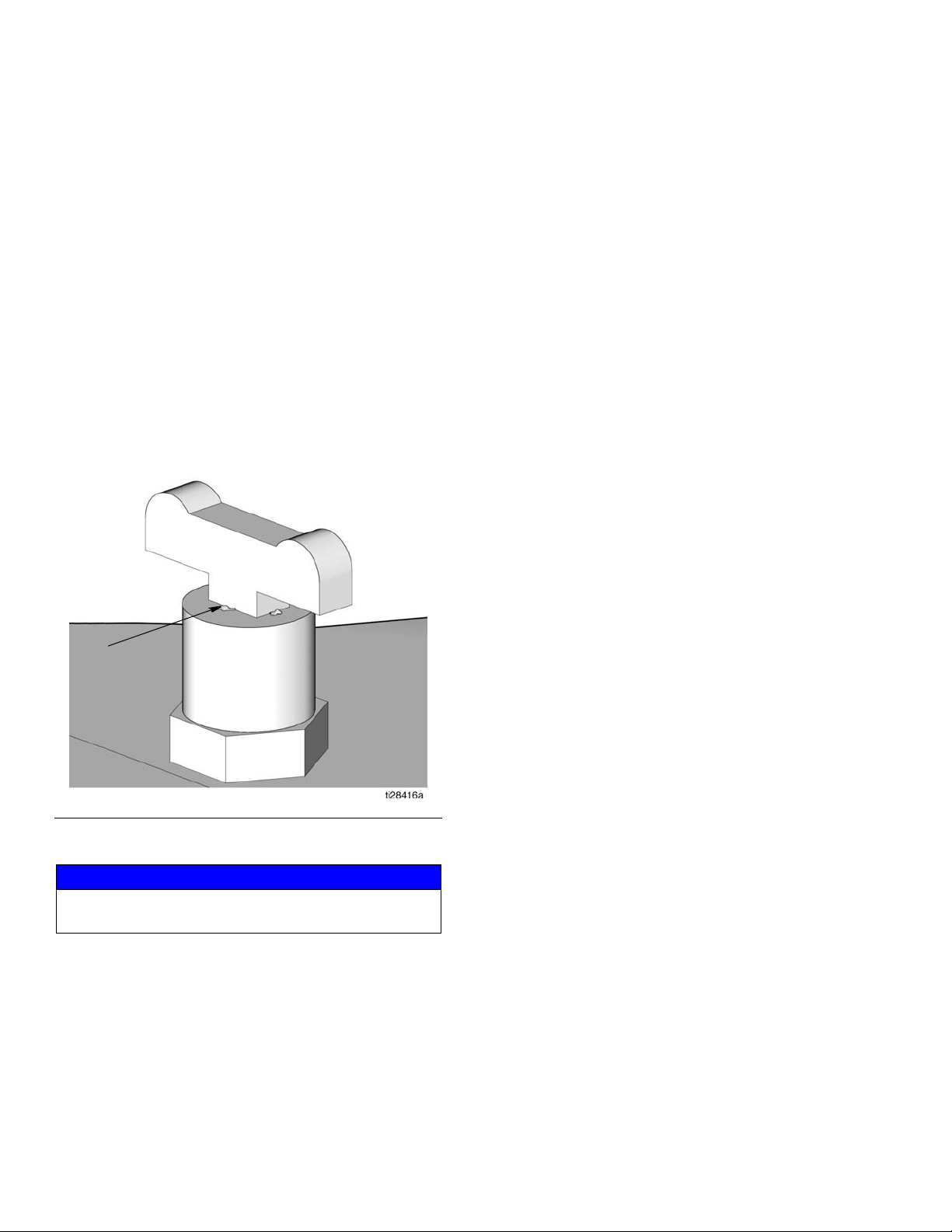

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. Close the bleed-type master air valve (F) (required

in the system).

2. Close the shut-off valve (V) on the oil input sup-

ply pump/system (DD).

3. Relieve pressure in system using two wrenches

working in opposite directions on the pump outlet

(E) and lubrication line fitting (G) to slowly

loosen the fitting until it is loose and no more lubri-

cant or air is leaking out of the fitting (F

IG. 7).

Air Lock Procedure

An air lock occurs when a bubble or pocket of air prevents the normal flow of the lubricant.

NOTICE

Running the pump dry will cause an air lock. To prevent

an air lock, do not run the pump without lubricant.

Always refill the pump before it is empty.

If there is an air lock, first:

• Check that input supply oil line (CC) is connected

and that the oil flow is continuous to reservoir (K).

• Loosen the cock valve (BB) from the pump reser-

voir cover (L) to bleed out the air.

If the air lock persists:

1. Relieve pressure. See Pressure Relief Procedure,

page 9.

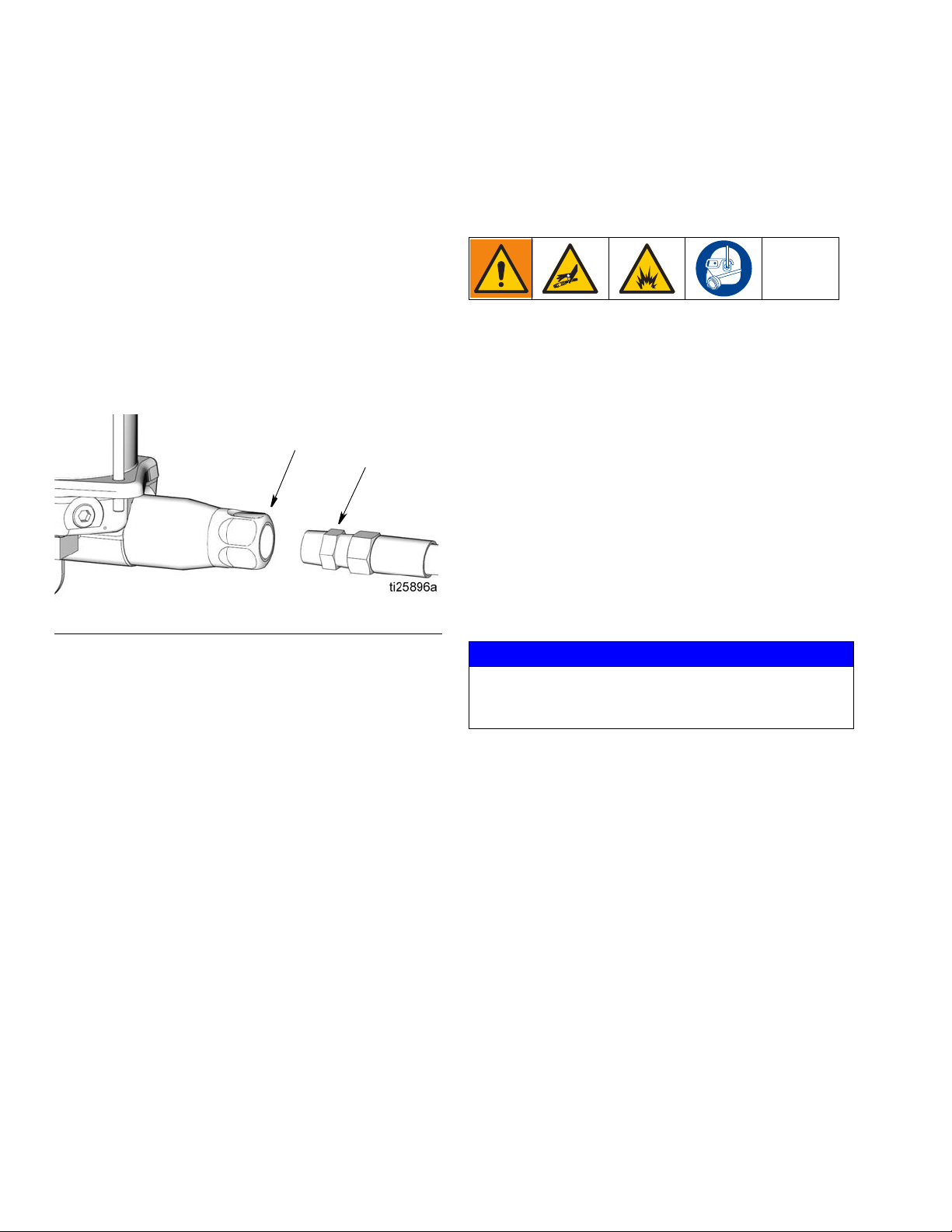

2. Disconnect the lubricant supply line (G) from the

pump outlet (E) (F

IG. 8).

FIG. 7

3A3169E 9

FIG. 8

3. Open the bleed-type master air valve (F, page 4).

4. Open the shut-off valve (V).

Operation

E

G

5. Run the pump a few strokes until oil (ol), free of air,

comes out of the pump outlet (E) (F

• It may take up to 20 the pump strokes to expel the

air from the pump and deliver a continuous flow of

oil. This will depend on the viscosity of the lubricant

and temperature.

• Allow a minimum of 5 seconds ON time for the forward stroke and 5 seconds OFF time for the return

stroke.

6. Connect the pump outlet (E) to the lubrication line

(G) (F

IG. 9).

FIG. 9

IG. 8).

Operation

Start Up

1. Verify reservoir is filled with lubricant and system

has been Primed (see Prime System, page 8).

2. Turn on the lubrication controller (J) power switch.

3. Program the lubrication controller to actuate the

solenoid valve (C).

NOTE: See the lubrication controller instruction

manual included with the system for these instructions.

4. Open air regulators and master air valves.

NOTE: Never allow the pump to run dry of the material

being the pumped.

NOTICE

Running the pump dry will cause an air lock. To prevent

an air lock, do not run the pump without lubricant.

Always refill the pump before it is empty.

At the start of a the pump cycle:

a. The air solenoid (C) supplies air to the pump

air inlet (P).

b. On the pump forward stroke, lubricant is dis-

pensed to all the injectors.

c. The pump is supplied with air through the air

inlet (R).

d. The pump makes a return stroke, venting the

system pressure back to the pump and resetting

all of the injector.

10 3A3169E

Operation

llf

llf

Low Level Switch

When the oil reservoir is full, the low level float (llf) sits in

the high, raised position as shown in F

FIG. 10: Low level float in raised position

As oil is dispensed, the low level float begins to travel

down. When the oil in the reservoir reaches low level,

the fully traveled down float (shown in F

the normally open low level switch and a low level signal

is sent to the lubricator controller (J).

IG. 10.

IG. 11) closes

Shut Down

To shut down the system:

a. Close the bleed-type master air valve (F).

b. Turn off electrical supply to the lubrication con-

troller (J).

c. Close the shut-off valve (V) on the oil input

supply pump/system (DD).

FIG. 11: Low level float in fully traveled down

position

To clear the low level fault/error:

• Check that input supply oil line (CC) is connected

and that the oil flow is continuous to reservoir (K).

• Loosen the cock valve (BB) from the pump reser-

voir cover (L) to bleed out the air.

FIG. 12

3A3169E 11

Operation

Lubrication System Sizing and Calculation Guidelines

Table 1: Lubricant Output and Pressure - US

NOTE: The lubricant output per pump stroke must be less than the amount of lubricant discharged per pump stroke.

1 2 3 4 5 6 7

Max

Injector

Typ e

Injector

Output

cu. in.

GL-43 0.008 0.016

GL42 0.003 0.006

Injector

Volu m e t o

Dispense

and Charge

cu. in.

Table 2: Lubricant Output and Pressure - Metric

1 2 3 4 5 6 7

Max

Injector

Type

Injector

Output

cc

GL-43 0.131 0.262

GL42 0.049 0.098

Injector

Volume to

Dispense

and Charge

cc

Max Pump

Lubricant

Maximum Pressure

Minimum

Pressure

Recommended Pressure

Output /

Stroke

cu. in.

3.0 1000 53 750 39 850 45

Max Pump

Lubricant

Output PSI

Maximum Pressure

Required Air

PSI

Output PSI

Minimum

Pressure

Required

Air PSI

Output PSI

Required Air

Recommended Pressure

Output /

Stroke

cc

49.1 6.9 (68.9) 0.36 (3.6) 5.2 (51.7) 0.26 (2.7) 5.9 (58.6) 0.31 (3.1)

Output

MPA (bar)

Required Air

MPA (bar)

Output

MPA (bar)

Required Air

MPA (bar)

Output

MPA (bar)

Required Air

PSI

MPA (bar)

1. Total Injector Volume to Dispense and Charge

a. Add together the total number of injectors in the sys-

tem.

b. From Table 1 or Table 2 above, find your Injector Type

in the first column and the related Injector Volume to

Charge in the third column. Multiply this value by the

total number of injectors determined in Step a

(above).

2. Calculate the volume of lubricant in the Pipeline (G):

a. Use the pipe’s inside diameter (ID) measurement to

calculate the area of the pipe.

b. Measure the length of the pipe (G) only. Do not

include the feeder lines (S) in this calculation.

c. Multiply the area of the pipe (calculated in Step a) by

the length of the pipe (measured in Step b).

3. Calculate line expansion and fluid compression in the pipe

using the 10% Rule.

a. Multiply the volume calculated in Step 2 by 10%.

4. Calculate the Total System Volume required.

a. Add together the total from Step 1 and Step 3 ONLY.

Do NOT include Step 2.

b. The Total System Volume required must be less than

the Pump Lubricant Output / Stroke provided in the

fourth column of Table 1 or Table 2.

c. If the Total System Volume required is greater than

the Pump Lubricant Output / Stroke provided in the

fourth column of Table 1 or Table 2, split the system

into two or more systems.

12 3A3169E

Repair

Repair

Seal Replacement

NOTE: For most seal replacement procedures, the

pump should be completely removed from service and

clamped in a vise. If you are only replacing the reservoir

and/or reservoir seals, you do not have to remove the

pump from it’s service location. The following instructions cover the complete disassembly of the pump. Your

pump repair may not require total pump disassembly.

Disassembly

1. Turn off air supply and disconnect air lines to the

pump.

2. Disconnect electrical connections to lubrication controller.

3. Close shut-off valve (V) to turn off oil input supply

pump/system (DD).

4. Relieve pressure (page 9).

7. Remove mounting bolts (F

pump from service.

FIG. 14

8. Clamp the pump base in a vise as shown in F

Use a soft-jaw vise or place a rag in the vise jaws to

protect the surface of the pump base.

IG. 14) and remove the

IG. 15.

5. Disconnect supply line (G) from the pump outlet

(E).

6. Slowly loosen and remove oil input line from the

pump base and drain oil from the pump (F

NOTE: Removing the oil input line slowly will help

prevent splashing while the oil drains from the reservoir.

FIG. 13

IG. 13).

FIG. 15

9. Collect drained oil in a pail or waste container. Dispose of oil according to all regulations for proper disposal.

3A3169E 13

Repair

29

27

30

27

1

26

26

30

2

3

4

3

10. Use a wrench to remove tie rods (29). Loosen the

rods in a diagonal pattern, taking care to loosen

each rod gradually until all rods are completely loosened. Remove tie rods (29). See F

IG. 16.

FIG. 16

11. Remove cover (30) from reservoir (27) (F

IG. 16).

12. Remove reservoir (27) from the pump base (1) (F

17). If replacing reservoir o-rings (26), remove

o-rings from reservoir and cover. Dispose of o-rings

according to all regulations for proper disposal.

IG.

13. Remove piston stop nut (3) from top of the air cylinder (2) (F

IG. 18).

FIG. 18

14. Remove o-ring (4) from piston stop nut (3). Dispose

of o-ring according to all regulations for proper disposal.

FIG. 17

FIG. 19

14 3A3169E

Repair

33

2

1

33

13

6

2

13

5

6

41

13

15. Use a 3/8 inch socket to remove the 4 bolts (33)

holding the air cylinder (2) to the pump base (1)

(F

IG. 20). Remove air cylinder from the pump base.

FIG. 20

16. Piston Rod (13) and Piston (6)

a. Pull piston rod (13) and piston (6) out of air cyl-

inder (2) (F

IG. 22).

face of the piston and cause fluid leaks during

the pump operation. Only move the wrench

holding the nut (5) to loosen and remove the

nut.

FIG. 22

c. Remove o-ring (41) from the piston rod (13)

(F

IG. 23).

FIG. 23

FIG. 21

b. To separate piston rod (13) and piston (6) use

two wrenches, working in opposite directions.

Secure one open end wrench to flats of piston

rod and the second wrench is used to loosen

the nut (5) as shown in F

IG. 22.

NOTE: The open end wrench secured to the

flats of the piston rod is only used to hold the

rod securely, do not rotate this wrench. Moving

this wrench could scratch or damage the sur-

3A3169E 15

Repair

6

7

4

15

1

d. Remove o-ring (7) from piston (6) (FIG. 24).

FIG. 26

FIG. 24

e. Discard o-rings (7, 41) and nut (5) according to

all regulations for proper disposal

17. Remove the outlet check valve (15) from the pump

base (1) (F

IG. 25). Remove o-ring (4) from outlet

check valve. Dispose of o-ring according to all regulations for proper disposal.

FIG. 25

19. Throat Seal Kit

The Throat Seal Kit includes the following parts

(F

IG. 27):

• Retaining Ring (9)

• Tapered Spacer (10)

•Seal (11)

• Spacer (12)

• Retaining Ring (51)

• Spacer (12)

•Seal (11)

• Spacer (12)

18. Reposition the pump base (1) in the vise as shown

in F

IG. 26.

16 3A3169E

Repair

9

10

(install tapered side down)

11

(install lips up)

12

51

12

11

12

51*

(install lips down)

(do not remove from pump)

9

(te)

(ha)

53

(br)

c. Use the blade of a small, flat screw driver under

the tapered edge (fe) of retaining ring (51) to

remove the ring as shown in F

IG. 28 and remove

the retaining ring.

d. Remove spacer (12), seal (11), and spacer (12).

DO NOT REMOVE THE LAST RETAINING

RING (51).

e. Dispose of all parts according to all regulations

for proper disposal.

20. Use a soft brass rod (br) and hammer to gently tap

the pump element sleeve (53) out of the pump base

IG. 29).

(1) (F

Use your hand to catch the sleeve while tapping it

out of the pump base to make sure it does not drop

on the ground or table which could damage the

sleeve.

FIG. 27

*This part is shown for reference only. It is not included

in the Throat Seal Kit.

a. Slide the blade of a small, flat screw driver

under the tapered edge (te) of retaining ring (9)

and remove the ring as shown in F

IG. 28.

FIG. 29

NOTE: Be careful not to scratch or damage the sleeve

and/or the pump base housing (1) when tapping the

FIG. 28

b. Remove the tapered spacer (10), seal (11), and

spacer (12).

sleeve out of the pump base or when removing the

o-ring. A scratched or damaged sleeve and or pump

base housing (1) will result in fluid leaking during the

pump operation and will prevent the pump from operating correctly.

3A3169E 17

Repair

14

53

8

1

21. Remove o-ring (14). Dispose of o-ring according to

all regulations for proper disposal.

Reassembly

NOTE: Always use all new parts included in replace-

ment kits. Discard used parts according to all applicable

regulations for proper disposal.

1. Use a clean cloth to wipe down the pump base (1)

and remove any dirt or contaminants. Inspect surface for any scratches or damage. Replace the

pump if the pump base is damaged.

2. If necessary, reposition the pump base (1) in the

vise as shown in F

IG. 32.

FIG. 30

22. Remove square o-ring (8) from the pump base (1)

(F

IG. 31). Dispose of o-ring according to all regula-

tions for proper disposal

FIG. 31

FIG. 32

3. Throat Seal Installation

The Throat Seal Kit includes the following parts

(F

IG. 33):

• Retaining Ring (9)

• Tapered Spacer (10)

•Seal (11)

• Spacer (12)

• Retaining Ring (51)

• Spacer (12)

•Seal (11)

• Spacer (12)

18 3A3169E

Repair

9

10

(install tapered side down)

11

(install lips up)

12

51

12

11

12

51*

(install lips down)

(do not remove from pump)

12

(bb)

11

12

d. Install seal (11). Be sure the lips of the seal are

facing down as shown in F

IG. 35.

NOTE: Make sure the seal lip is not damaged

while pressing the seal through the clip grooves.

FIG. 35

FIG. 33

e. Install spacer (12) (F

IG. 36).

*This part is shown for reference only. It is not included

in the Throat Seal Kit.

a. Apply a thin layer of grease to all the seals

included in the kit and the pump base bore (bb).

b. Verify retaining ring (51) is in place in side the

pump base (1).

c. Install spacer (12) shown in F

IG. 34.

FIG. 36

FIG. 34

3A3169E 19

Repair

51

12

11

10

f. Install retaining clip (51) (FIG. 37). You should

hear a “click” when the retaining clip is correctly

seated in the groove.

FIG. 37

g. Install spacer (12) (F

IG. 38).

h. Install seal (11), with the lips facing up as shown

in F

IG. 39.

NOTE: Make sure the seal lip is not damaged

while pressing the seal through the clip grooves.

FIG. 39

i. Install the tapered spacer (10), tapered side fac-

ing down as shown in F

IG. 40.

FIG. 38

FIG. 40

20 3A3169E

Repair

9

53

14

j. Install clip (9) (FIG. 41). You should hear a “click”

when the retaining clip is correctly seated in the

groove.

FIG. 41

4. Reposition the pump base (1) in the vise as shown

in F

IG. 42.

5. Pump Element Sleeve (53)

a. Use a clean cloth to wipe down the pump ele-

ment sleeve (53) and remove any dirt or contaminants. Inspect surface for any scratches or

damage.

b. Apply a thin layer of grease to o-ring (14). Install

o-ring around the pump element sleeve (d) (F

43).

IG.

FIG. 42

FIG. 43

c. Install the pump element sleeve (53) in the

pump base (1). To determine the correct installation orientation, refer to F

IG. 44.

NOTE: When the sleeve is installed in the pump

base correctly, the notches (n) around the bottom of the sleeve will go into the pump base first

and the o-ring will be on the top.

3A3169E 21

Repair

53

1

(n)

53

1

4

15

FIG. 44

d. Use your thumbs to press the sleeve (53) into

the pump base (1). Then using a soft rod, press

the sleeve all the way down as far as possible

(F

IG. 45).

6. Outlet Check Valve (15)

a. Use a clean cloth to wipe down the outlet check

valve (15) and remove any dirt or contaminants.

Inspect surface for any scratches or damage.

Replace damaged parts.

NOTE: The outlet check valve consists of a ball

check inside the bore. It is not repairable. If

there is any damage or contamination in the

bore, replace the check valve.

b. Apply a thin layer of grease to o-ring (4). Install

o-ring around the outlet check valve (15) (F

46).

IG.

FIG. 45

NOTE: Be careful not to scratch or damage the

sleeve and/or the pump base housing (1) when

installing the sleeve in the pump base.

Scratched or damaged surfaces will create a

path for the fluid to leak during the pump operation and will prevent the pump from operating

correctly.

FIG. 46

c. Thread the outlet check valve (15) into the

pump base (1) (F

IG. 47). Tighten securely. Then

torque to 50 to 55 ft. lbs (67.8 to 74.5 N•m).

22 3A3169E

FIG. 47

15

1

8

1

13

41

6

13

7. Apply a thin layer of grease to square o-ring (8).

Install square o-ring (8) in groove in the pump base

(1) as shown in F

IG. 48.

8. Piston Rod (13) and Piston (6)

NOTE: Do not clamp piston rod (13) in vise.

a. Use a clean cloth to wipe down the piston rod

(13) and piston (6) and remove any dirt or contaminants. Inspect surfaces for any scratches or

damage. Replace damaged parts.

b. Apply a thin layer of grease to o-ring (41). Install

o-ring over the grooves of the piston rod (13)

(F

IG. 49).

NOTE: If needed, a pick can be used to help

seat the o-ring over the grooves of the piston

rod (13).

Repair

FIG. 49

c. Push piston (6) over end of piston rod (13) until

it is seated on the rod (F

IG. 50).

NOTE: You should hear a pop sound when it is

in place correctly.

FIG. 48

FIG. 50

3A3169E 23

Repair

13

6

5

7

6

13

1

2

6

1

d. Install nut (5) over the end of the piston rod (13).

Use two wrenches, working in opposite directions to tighten the nut. Secure one open end

wrench to flats of piston rod and use the second

wrench to tighten the nut (5) as shown in F

IG.

51.

NOTE: The open end wrench secured to the

flats of the piston rod is only used to hold the

rod securely, do not rotate this wrench. Moving

this wrench could scratch or damage the surface of the piston and cause fluid leaks during

the pump operation. Only move the wrench

holding the nut (5) to tighten the nut. Torque nut

to 15 to 17 ft. lbs (20.3 to 23.1 N•m).

f. Apply a thin layer of grease around and along

the entire length of the piston rod (13). Gently

push the piston rod into the pump base (1)

using a push and turn motion to work the rod

through the previously installed, seals and spacers (F

IG. 53).

FIG. 53

9. Air Cylinder

FIG. 51

e. Apply a thin layer of grease to o-ring (7). Install

o-ring (7) around piston (6) as shown in F

IG. 52.

a. Use a clean cloth to wipe inside the air cylinder

(2) and remove any dirt or contaminants.

b. Apply a thin layer of grease to the inside sur-

faces of the air cylinder (2). Slide the air cylinder

(2) over the piston (6) and push it all the way

down until it is seated tightly to the pump base

(1). See F

IG. 54.

Make sure the Graco G in the air cylinder is facing out.

FIG. 54

FIG. 52

24 3A3169E

Repair

33

4

3

2

3

26

1

27

GL

c. Install 4 new bolts. Hand tighten the bolts (33)

evenly, each one a little at a time in a diagonal

pattern. Then torque diagonally to 10-13 ft. lbs.

(13.5-17.6 N•m). See F

IG. 55.

FIG. 55

d. Apply a thin layer of grease to o-ring (4). Install

o-ring to piston stop nut (3) (F

IG. 56).

e. Thread piston stop nut (3) into top of air cylinder

(2) as shown in F

IG. 57. Wrench tighten nut.

Then torque nut to 15 to 17 ft. lbs (20.3 to 23.1

N•m).

FIG. 56

FIG. 57

10. Apply a thing layer of grease to o-ring (26). Install

o-ring (26) into groove in the pump base (1) as

shown in F

IG. 58.

NOTE: This is the only correct way to install this

o-ring and ensure it will not slip out of place when

the reservoir is installed over the pump base.

3A3169E 25

FIG. 58

Repair

30

26

30

27

26

29

30

11. Install reservoir (27) into the pump base (1) with

Graco Identification label (GL) facing to the front of

the pump base as shown in F

IG. 58. Take care to not

pinch or move the o-ring.

12. Apply a thin layer of grease to o-ring (26). Install

o-ring inside groove in cover (30) as shown in (F

59).

NOTE: This is the only correct way to install this

o-ring and ensure it will not slip out of place when

the cover is installed on the reservoir.

14. Install tie rods (29) Evenly tighten tie rods in a diagonal pattern, a little at a time. Torque to 12-13 in.

lbs. (1.4 - 1.5 N•m). Take care not to over tighten

any of the rods.

IG.

FIG. 61

15. Reinstall the pump in the service location. See

Installation Instructions beginning on page 4.

FIG. 59

13. Position cover (30) over reservoir (27). Take care to

not pinch or move the o-ring (F

IG. 60).

FIG. 60

26 3A3169E

Troubleshooting

Problem Cause Solution

The pump is not operating. No lubricant

flow.

Injectors not cycling or only some of the

injectors are operating

Troubleshooting

No air 1. Adjust air pressure/supply.

2. Open bleed-type master air valve

(F) (page 4).

No lubricant in reservoir Check oil input supply system.

Losing prime

Remove trapped air (see Air Lock,

page 9).

No lubricant flow See Pump is not operating. No lubricant

flow in Troubleshooting table.

Low pressure or no pressure 1. Check piping for leaks. If a leak is

detected, repair or replace piping.

Pump seals are bad

2. Check injectors for leaks. If a leak is

detected, repair or replace injector.

3. If the total system volume is greater

than the Pump Lubricant Output provided in Table 1 or Table 2, split the

system into two or more systems.

Refer to Lubrication System Sizing

and Calculation Guidelines, page 28.

Replace seals. See Parts, page 29.

3A3169E 27

Parts

29

30

26

42

27

52

26

19

37

15

14

1

36

51

12

10

8

11

9

13

6

7

5

2

41

4

3

4

53

33

39

51

11

38

54

31

Parts

28 3A3169E

Parts

Parts

Ref Part No. Description Qty

1 PUMP BASE 1

2 160613 CYLINDER, air 1

3 NUT, piston stop 1

4

5

6PISTON, air 1

7

8

9

10

11

12

13 PISTON 1

14

15 17D305 VALVE, dual outlet check 1

19

26

27 RESERVOIR 1

29 ROD, tie, reservoir 3

30 COVER 1

156698

104095

PACKING, o-ring 2

NUT, hex, lock, nylon, thin 1

PACKING, o-ring 1

PACKING, square 1

RING, retaining internal 1

SPACER, seal. wedge 1

SEAL, oil 2

SPACER, seal 3

PACKING, o-ring 1

FLOAT, low level (model, 24Y499,

25Y499)

O-RING, reservoir 2

Ref Part No. Description Qty

31 VALVE, air cock, 1/4” NPT 1

33 101578 SCREW, cap, hex, hd 4

36

37 NUT, low level float mount 1

38 PACKING, o-ring 1

39

41 PACKING, o-ring 1

128434 LABEL, safety, warning 1

42

51 RING, snap 2

52 128433 LABEL, branding 1

53 SLEEVE, pump element 1

128625 LABEL, pressure rating 1

54

Replacement Danger and Warning labels, tags and cards

1

are available at no cost.

Included in Seal Replacement Kit 24X889.

NOTE: Only one (#51) is included in the kit.

SENSOR, low level with float (models

24Y499, 25Y499)

PLUG (models 24Y498, 25Y498) 1

CONNECTOR, DIN, Form A, 4-pin

(models 24Y499, 25Y499)

1

1

3A3169E 29

Dimensions and Mounting

Dimensions and Mounting

30 3A3169E

Technical Data

H1900 Single Stroke Pump, Oil

US Metric

Maximum fluid working pressure 3500 psi 24 MPa, 241 bar

Pressure ratio19:1 19:1

Pump output 3.0 cu. inch/stroke

Oil input supply pressure 80 psi 0.55 MPa, 5.5 bar

Maximum air inlet pressure 185 psi 1.27 MPa, 12.76 bar

Air inlet size 1/4 in. NPT

Fluid outlet size 3/4 in. NPT‡

Oil input supply size 3/8 in. NPT

Pump: high phosphorus electroless nickel plated dectile iron,

enamel painted dectile aluminum, zinc nickel coated steel, acetal

Wetted Parts

Approximate weight 22 lbs 9.9 kg

Operating temperature 14°F to 149°F -10°C to 65°C

Low Level

Switch Rating 30 Volts; 0.3 Amps

IP ratings IP65 when plugged and screwed down

Cable diameter 0.315 to 0.394 inches 8 to 10 mm

Wire size 20 to 16 AWG

plastic, 6061 aluminum alloy, enamel painted aluminum alloy 308,

aluminum alloy 308

Seals: Buna-N (nitrile)

120 Volts; 0.13 Amps

240 Volts; 0.06 Amps

0.5 to 1.5 mm

2

Technical Data

Models 25Y498 and 25Y499 are supplied with three, 1/4 in. NPT(m) x 1/4 in. BSPP(f) fittings as loose items. Two are supplied

for the air inlet and one for the pump outlet.

Models 25Y498 and 25Y499 are supplied with one, 3/8 in. NPT(m) x 3/8 in. BSPP(f) fitting as a loose item.

‡ All the pumps are supplied with 3/4 in. NPT(m) x 1/4 inch NPT(f) reducers if needed.

3A3169E 31

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2015, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A169

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised

March 2017

Loading...

Loading...