Graco LubeMaster Instructions Manual

Instructions

®

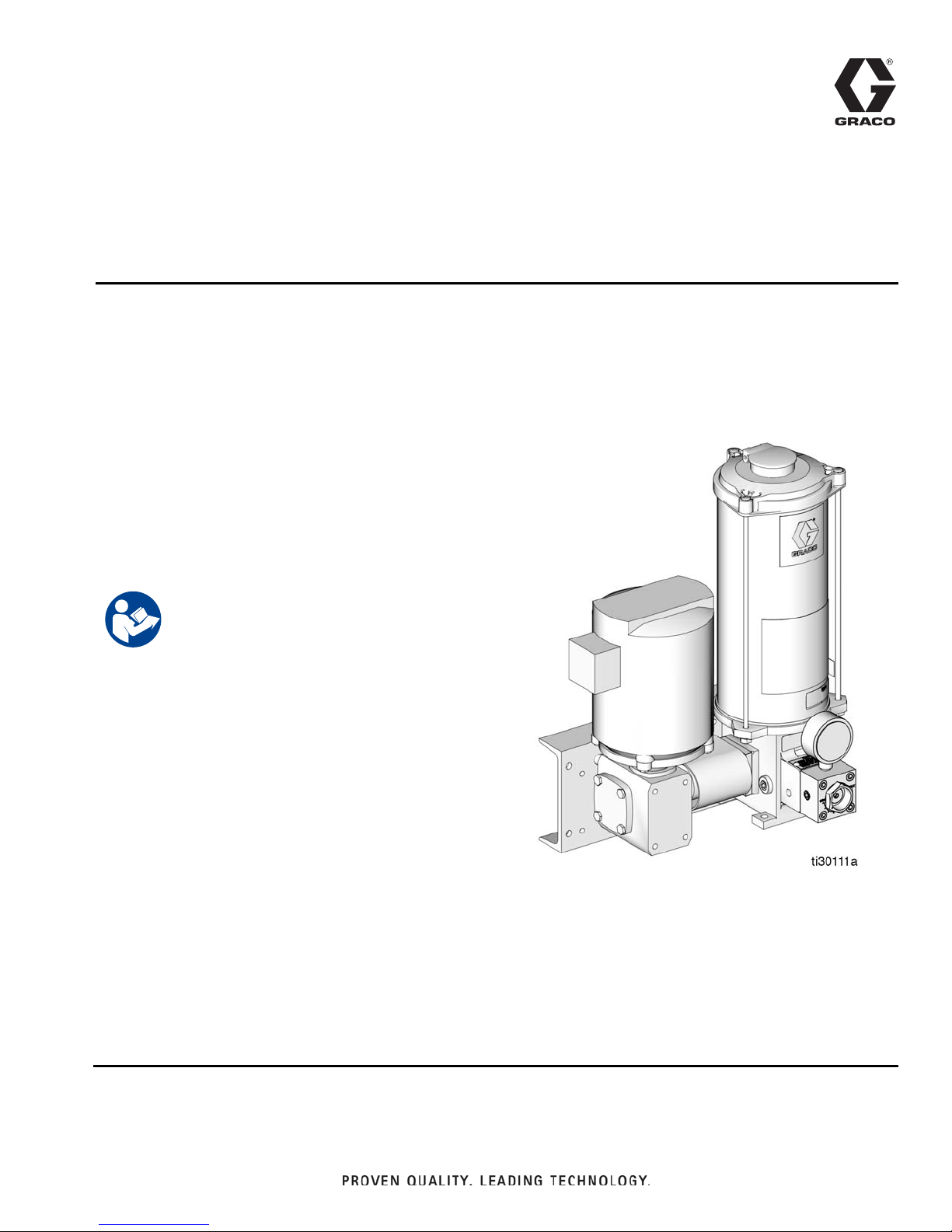

LubeMaster

Floor

Mount or Wall Mount

3A2781A

Pump Package

Provides a constant supply of lubrication to pump components. For professional use only.

Maximum Working Pressure: 5000 psi (340 bar, 34.0 MPa)

The LubeMaster Pump Package includes the following

components:

• Reservoir

• Oil or Grease Pump

EN

See page 6 for part number information.

Important Safety Instructions

Read all warnings and instructions in this manual. Save

these instructions.

Table of Contents

Table of Contents

Part Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Identification . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Reservoirs - Oil or Grease . . . . . . . . . . . . . . . . . 7

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Motors and Drives . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Instructions . . . . . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Relief Valves . . . . . . . . . . . . . . . . . . . . 8

Choosing an Installation Location . . . . . . . . . . . . 8

Pump Installation Procedure . . . . . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Filling the Reservoir . . . . . . . . . . . . . . . . . . . . . . 9

System Filling . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Manifold Bleeding . . . . . . . . . . . . . . . . . . . . . . . 11

Adjusting the Clutch Drive . . . . . . . . . . . . . . . . . 11

Standard Pump Adjustment . . . . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure Relief Procedure . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance and Repair . . . . . . . . . . . . . . . . . . . . 17

Pumps: Oil and Grease Models . . . . . . . . . . . . 17

Grease Reservoirs . . . . . . . . . . . . . . . . . . . . . . 18

Low-Level Switch Assemblies . . . . . . . . . . . . . . 19

Oil Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation After Maintenance . . . . . . . . . . . . . . 24

Drive and Motor . . . . . . . . . . . . . . . . . . . . . . . . . 24

Recommended Lubricants for Enclosed Gear

Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Alternative AGMA Lubricants . . . . . . . . . . . . . . 24

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Grease Reservoirs . . . . . . . . . . . . . . . . . . . . . . . 25

Oil Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Overhead Supply Adapter Assembly . . . . . . . . . 27

Pump Body Assembly . . . . . . . . . . . . . . . . . . . . 28

Clutch Drive Assembly . . . . . . . . . . . . . . . . . . . 29

LubeMaster Pump . . . . . . . . . . . . . . . . . . . . . . . 30

Motorized LubeMaster Pump with Gear Reducer

and Motor (Up to 20 lbs):

Floor Mounting . . . . . . . . . . . . . . . . . . . . . . 31

Motorized LubeMaster Pump with Gear Reducer

and Motor (Up to 20 lbs):

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . 32

Oil Reservoir 15 Amp Low-Level Assemblies . . 33

Oil Reservoir 10-Watt Low-Level Assemblies . . 33

Grease Reservoir Low-Level Assembly . . . . . . . 34

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Clutch Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Clutch Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Motorized LubeMaster (Up to 20lbs):

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . 41

Motorized LubeMaster (Up to 20lbs):

Floor Mounting . . . . . . . . . . . . . . . . . . . . . . 42

Motorized LubeMaster (Up to 20lbs) . . . . . . . . . 43

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 44

2 3A2781A

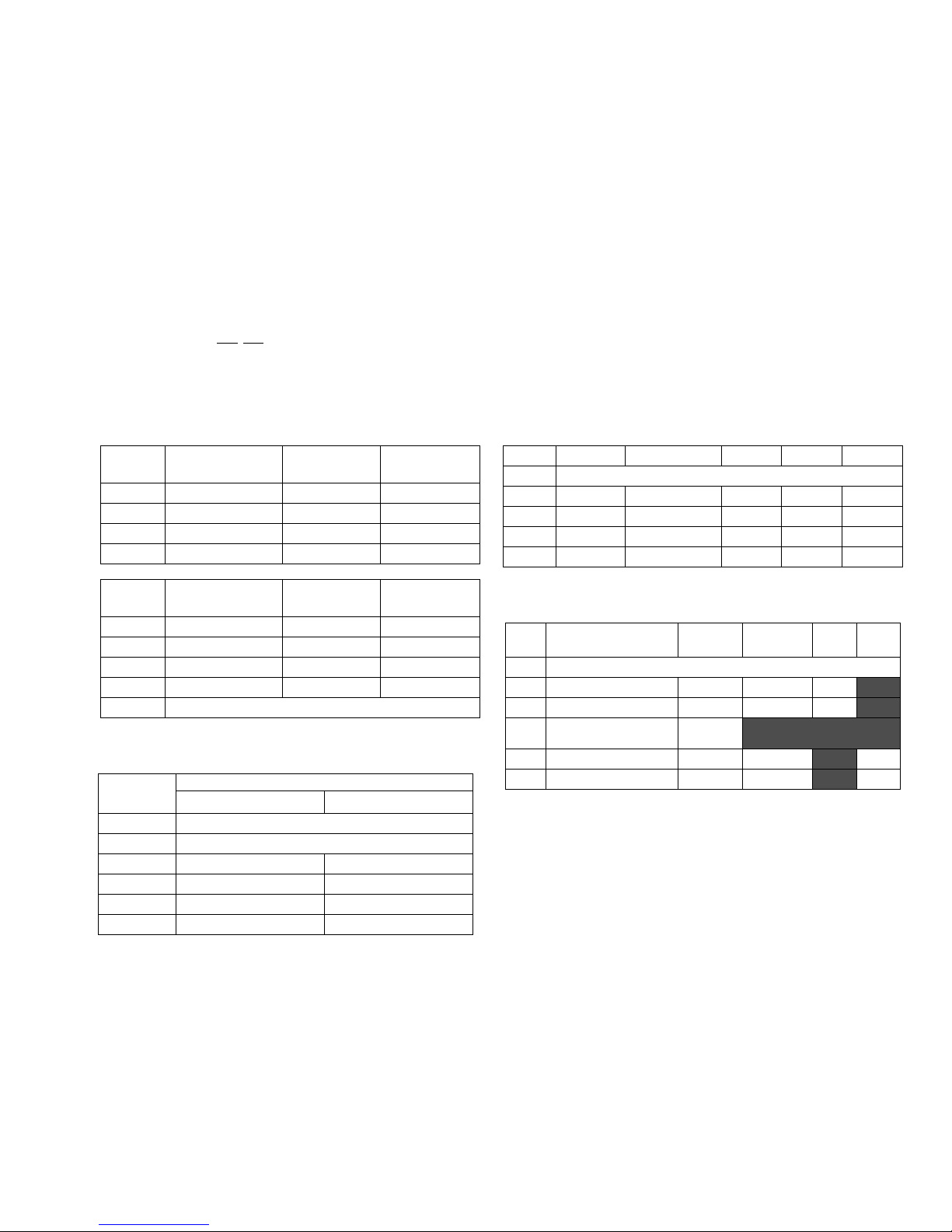

Part Number

Part Number

Use the Part Number Key provided below to identify each component included in your LubeMaster Pumping System Part Number.

The Codes associated with each Option (A-D) that make up the Part Number are provided in the tables below. For example, Part

Number - LM1321 is a LubeMaster pump system with a 12 pint plastic oil reservoir. It has a 10:1 reduction ratio and is floor

mounted. It is powered with a 115/230V, 1/2 hp, 1 PH, 60 hz, 1725 RPM motor and does not have a low level switch.

NOTE: Some part number configurations are not available. Contact Graco Customer Service or your local Graco distributor for

assistance.

Par t Key: LM A - B - C - D

Part Example: LM 1 3 2 1

LM = LubeMaster

Option A: Reservoir Options

Code

Code

Reservoir Size:

pints (liters)

1 12 (5.68) Oil Plastic

2 20 (9.46) Oil Plastic

3 12 (5.68) Oil Metal

4 20 (9.46) Oil Metal

Reservoir Size:

pounds (kg)

5 12 (5.44) Grease Plastic

6 20 (9.07) Grease Plastic

7 12 (5.44) Grease Metal

8 20 (9.46 L) Grease Metal

9 No Reservoir, Overhead Supply

Oil or Grease

Oil or Grease

Plastic or

Metal

Plastic or

Metal

Option B: Drive Options

Code

1None

2 Clutch Drive With Arm

3 10:1 Floor Mounting

4 10:1 Wall Mounting

5 60:1 Floor Mounting

6 60:1 Wall Mounting

Reduction Ratio Mounting Option

Description

Option C: Motor Options

Code Voltage Horsepower PH Hz RPM

1None

2 115/230 1/2 1 60 1725

3 230/460 1/2 3 60 1725

4 115/230 1/2 1 60 1140

5 230/460 1/2 3 60 1140

Option D: Low Level Switch Options

Code Size

1

2 12 (5.68 L) Oil X 15

3 20 (9.46 L) Oil X 15

12 and 20 pounds

4

(5.44 and 9.07 kg)

5 12 (5.68 L) Oil X 10

6 20 (9.46 L) Oil X

Oil or

Grease

No low level switch

Grease

SPDT Amps Watts

10

3A2781A 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Ground all equipment in the work area.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

4 3A2781A

Warnings

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A2781A 5

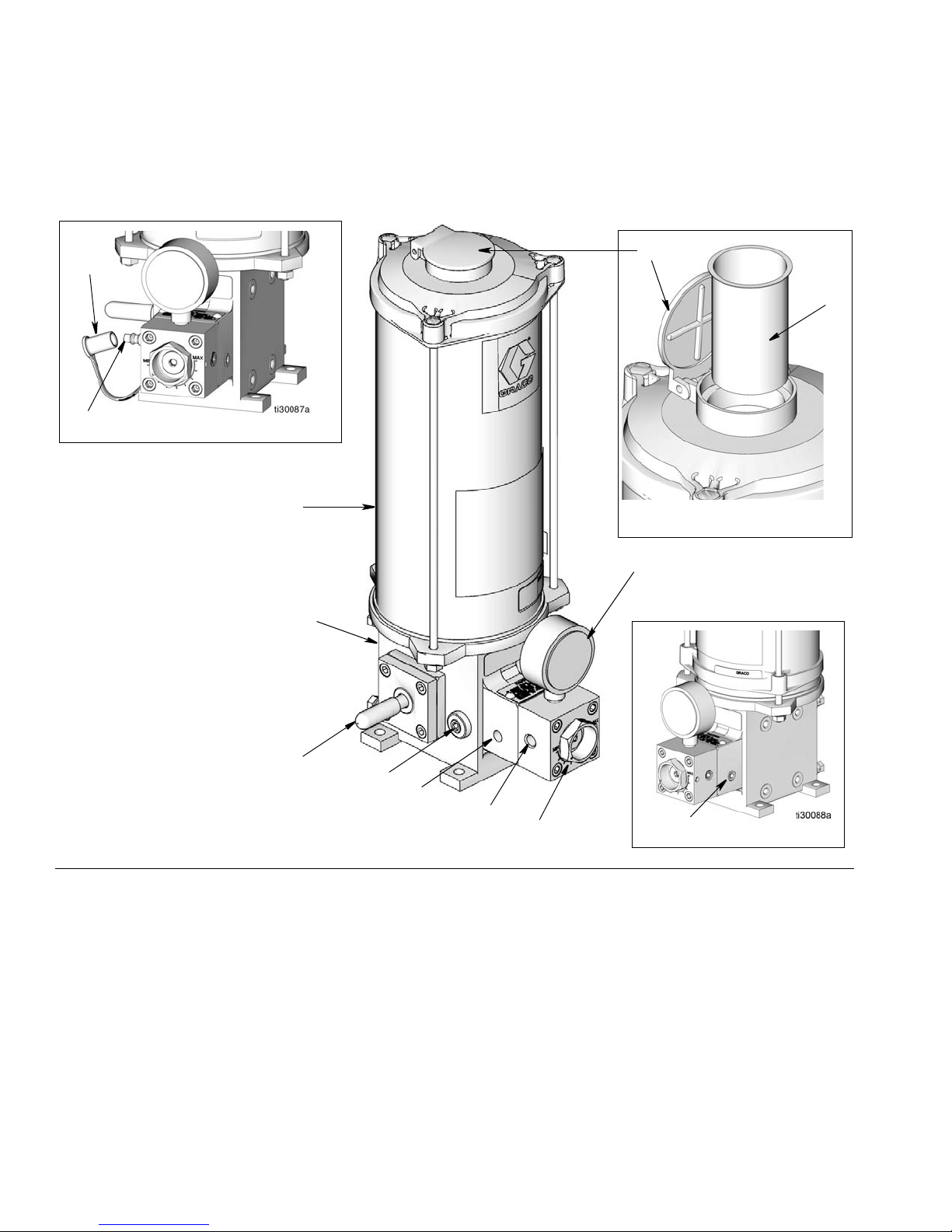

System Identification

11

Oil Model

Grease Model

A

D

B

30

31

C

101

E

F

E

13

12

Side View

System Identification

(Floor Mount Model Shown)

FIG. 1

A Pump Adjustment Nut

B Pump Inlet

CDrive Shaft

D Pressure Gauge

E Drain and Drain Plug (Oil Models: one on each side of

base); (Grease Models: one on the opposite side of the

base from the fill stud (13)

F Pump Outlet

11 Reservoir Assembly (Oil or Grease)

12 Fill Cap (Grease Only)

13 Fill Stud (Grease Only)

30 Fill Cap (Oil Only)

31 Filter Screen (Oil Only)

101 Pump Body

6 3A2781A

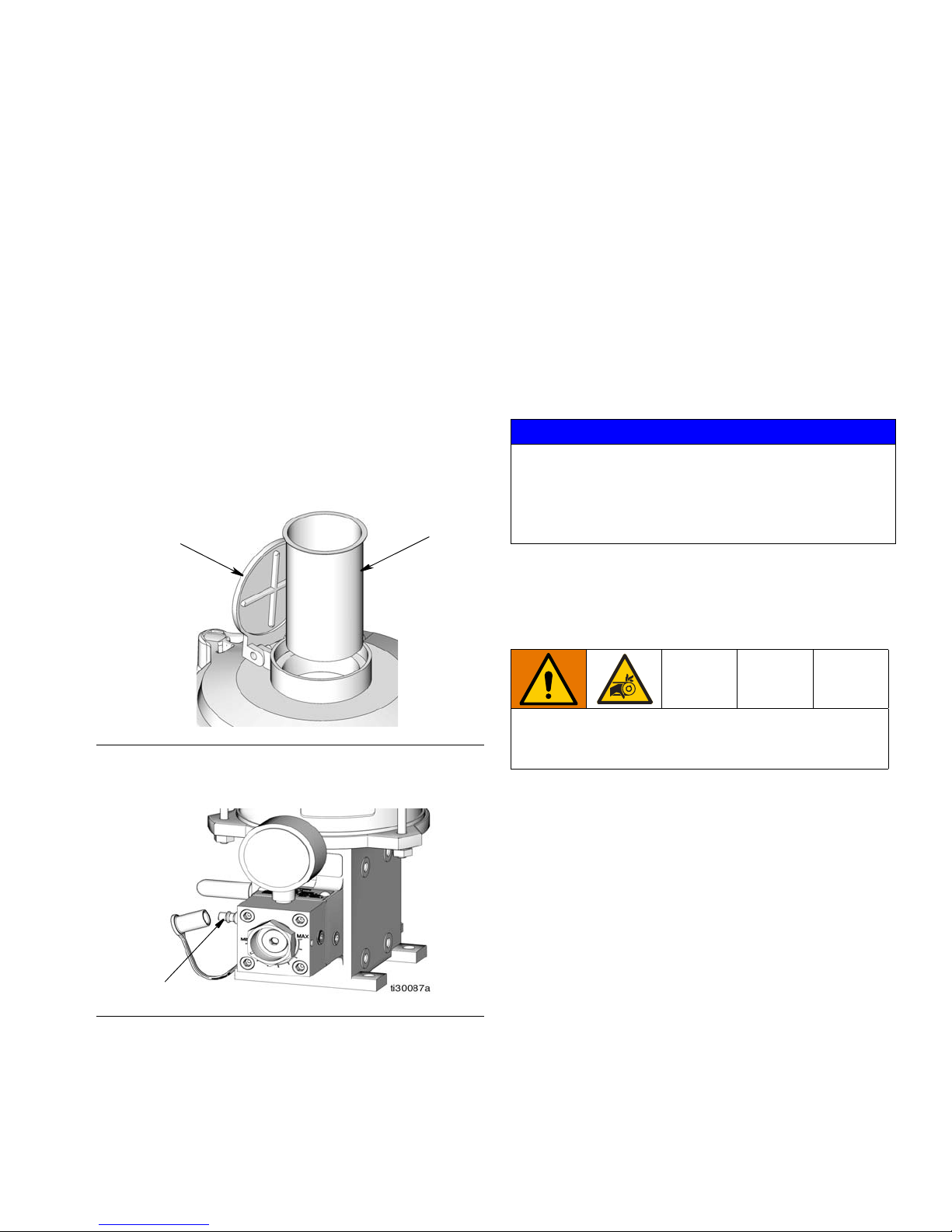

Component Identification

31

30

13

Component Identification

All LubeMaster Pump Packages include the following

components:

• A reservoir (11) for holding the lubricant.

• A standard pump (101).

Reservoirs (11) - Oil or Grease

• Container for holding oil or grease.

• Grease models include a follower plate.

• The reservoir mounts directly to LubeMaster pump.

Oil Reservoirs

• Reservoirs for oil models have a fill cap (30) and

screen (31), located on top (F

IG. 2).

Pump (101)

• The pump can be driven by an electric motor or by a

rotating or oscillating machine motion.

• The pump must always be installed with the reservoir (11) in a vertical position to ensure proper operation.

• Always use lockwashers with mounting bolts and

make certain that the bolts are properly torqued.

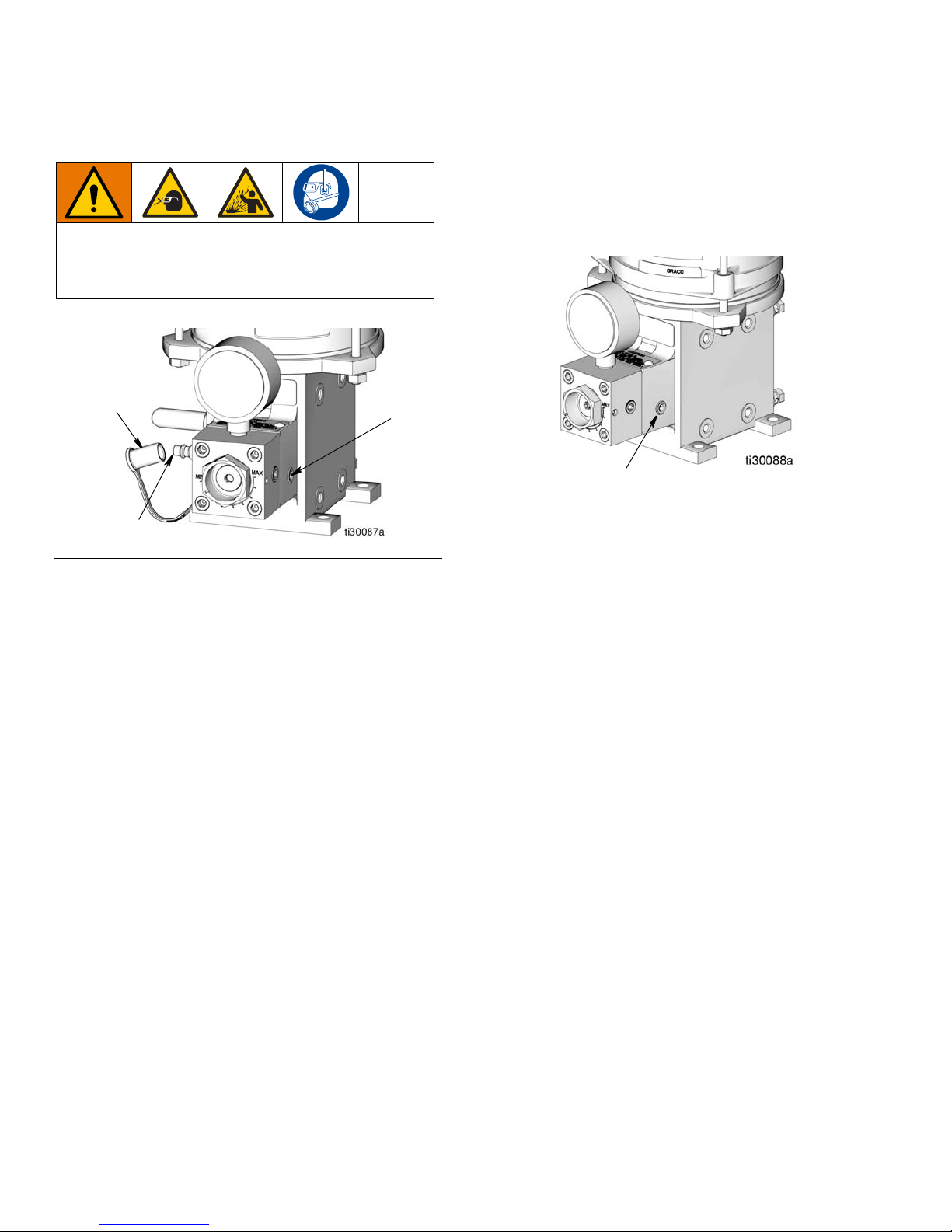

Motors and Drives

Gear Reducer

NOTICE

Gear reducer units are shipped without lubricant.

Before operating, always check lubricant level and fill

per manufacturers instructions. Operation without lubricant will damage the gear reducer. A table of suggested lubricants is provided on page 24.

Gear reducers have either a 10:1 or 60:1 reduction or an

oscillating clutch drive that can be activated by a

machine motion.

FIG. 2

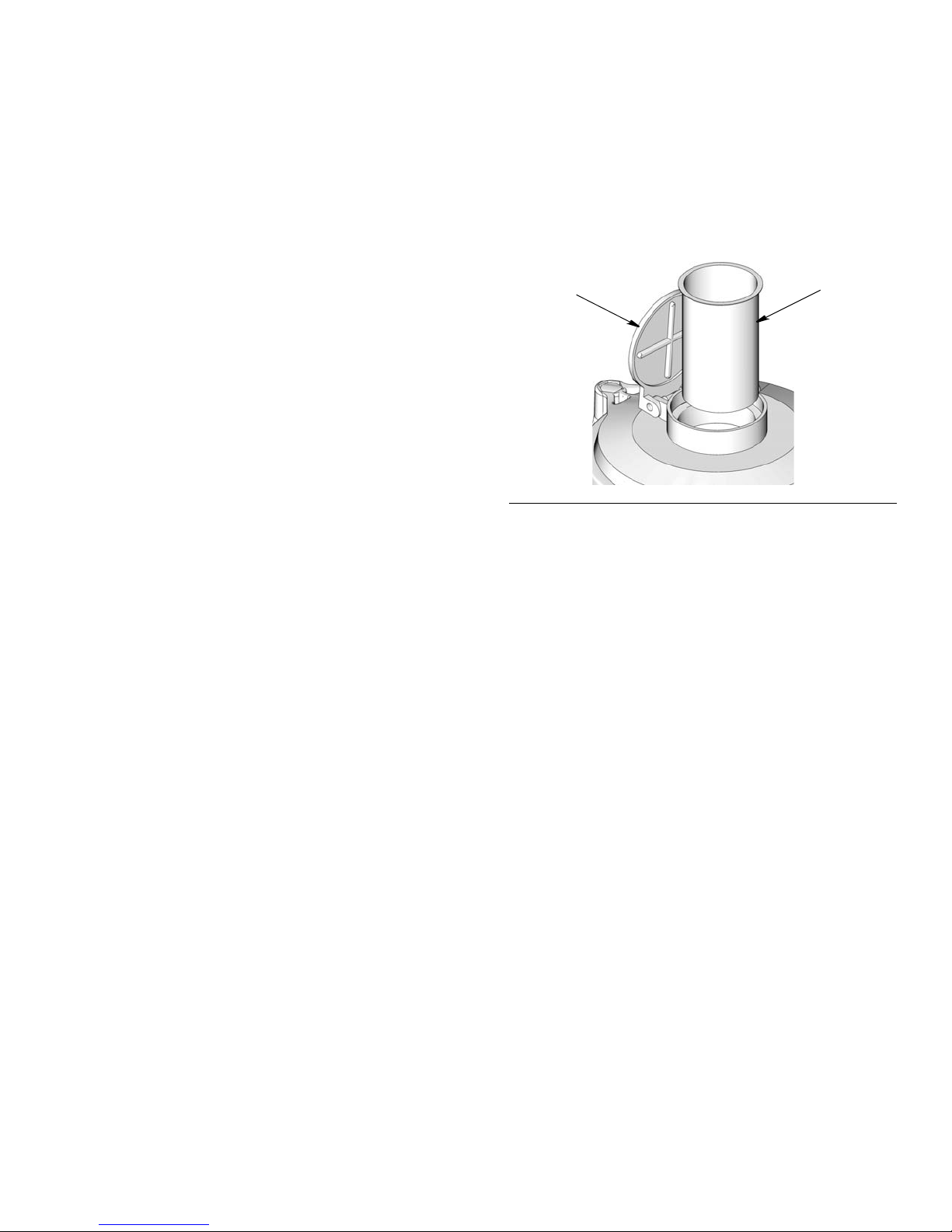

Grease Reservoirs

FIG. 3

• Grease reservoirs require an external air-free supply source connected to the fill stud (13).

ENTANGLEMENT HAZARD

An exposed drive shaft must be guarded to enclose

the shaft.

• A shaft guard is included if the pump is configured

with a gear reducer.

• The user must provide a guard for any other configuration.

Low-Level Switch

Low-level switches protect the system against excessive

pressure and low lubricant levels. The switch provides

an electrical signal when the lubricant level in the reservoir is low.

3A2781A 7

Installation Instructions

Installation Instructions

The reference letters and numbers used in the following

sections, refer to F

Components are completely assembled when you first

receive the LubeMaster Pump Package from the factory.

Reassembly instructions for these components are provided in the Maintenance and Repair section of this

manual, beginning on page 17.

IG. 1.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Install a 12 gauge (1.5 mm) minimum ground wire

between the LubeMaster pump package and a true

earth ground.

Pressure Relief Valves

Pressure Relief Valves

Choosing an Installation

Location

AUTOMATIC SYSTEM ACTIVATION HAZARD

The system is equipped with an automatic timer that

activates the pump lubrication system. Unexpected

activation of the system could occur and result in

serious injury, including skin injection and amputation.

Before you install or remove the lubrication pump

from the system, disconnect and isolate all power

supplies and relieve all pressure.

• Select a location that will adequately support

the weight of the pump and lubricant, as well as

all plumbing and electrical connections.

• Refer to the mounting hole layouts provided in

the Dimensions section of this manual beginning on page 37. No other installation configuration should be used.

• Use designated mounting holes and provided

configurations only.

• Use fasteners that are strong enough to support

the weight of the pump and lubricant when

securing the pump to the mounting surface.

To prevent over-pressurization, which can result in

equipment rupture and serious injury, a pressure

relief valve appropriate for the lubrication system

must be installed close to every pump outlet to alleviate unintended pressure rises in the system and protect the pump from damage.

• Only use a pressure relief valve that is rated for no

more than the working pressure of any component

installed in the system. See Technical Data, page

35.

• Install a pressure relief valve close to every pump

outlet and before any auxiliary fitting.

8 3A2781A

Pump Installation Procedure

1. Secure with attaching hardware to installation location. Make certain all fasteners are tightened to the

proper torque.

2. Install all guards and mechanical linkages or connections removed at the pump drive shaft.

3. Install the reservoir.

4. Electrically reconnect the pump drive.

5. Fill system with lubricant. See Filling the Reservoir

instructions, beginning on page 9.

Setup

31

30

Setup

Filling the Reservoir

Material Cleanliness

Make sure that lubricant used to fill the system is clean.

If there is doubt about cleanliness, lubricant should be

filtered before being introduced into the system. System

life and consistent operation will both be improved by

using clean lubricant.

After filtering the lubricant, make sure the lubricant supply is protected from debris.

On all pumps, the lube piston diameter is very close to

the diameter of the chamber in the pump body. Contaminants in the lubricant could cause scoring in this area,

resulting in erratic pump operation and costly parts

replacement.

Temperature Effects

Flow characteristics of the lubricant may change if the

area the unit is used in goes through drastic temperature changes. Choose a lubricant that will flow properly

at all temperatures expected in the system environment.

Overhead Supply Adapter Assemblies Only

Filling Oil Reservoirs

Oil reservoirs have a fill cap (30) and filter (31).

FIG. 4

1. Wipe the area around the fill cup to avoid contamination during filling.

2. Open the fill cap (30) and slowly pour oil into the

reservoir (11) through the filter screen (31).

NOTE: The filter screen (31) will remove large particles which may be present in the oil.

The recommended inlet pressure is 15 psi (0.103 MPa,

1.03 bar) or less.

3. When filling is complete, close fill cap (30) and wipe

any spillage.

3A2781A 9

Setup

12

E

13

E

Filling Grease Reservoirs

OVER PRESSURIZATION HAZARD

Over pressurization can result in equipment rupture

and serious injury. Fill slowly to avoid over pressurizing the reservoir.

FIG. 5

• Filling grease reservoirs requires an external,

air-free supply source be connected to the fill stud

(13).

• To avoid introducing air into the system, make sure

there is enough grease in the supply source to fill

the reservoir without being disconnected.

• Operate the supply source at a steady speed to

allow air-free filling of the reservoir. Filling the reservoir too fast may result in air pockets.

1. Remove cover (12)

2. Connect grease supply source to fill stud (13).

3. Loosen the drain plug (E) (located on the opposite

side of the base from the fill stud (13) (F

IG. 6).

FIG. 6

4. Slowly begin to fill the reservoir, allowing air trapped

under follower to exhaust out the open drain plug.

5. When grease free of air flows from the drain, tighten

the plug (E) and continue to fill the reservoir until follower is at the vent hole in reservoir tube (any

remaining air and small amount of grease will exit

drain).

6. When filling is complete, turn off the supply source

and disconnect if from the fill stud (13). Replace the

cover (12).

NOTE: A check valve in the fill stud will prevent

lubricant from being forced back out.

• The level of grease is checked by visual means.

- In reservoirs with plastic cylinders, the grease level

can be viewed through the cylinder.

10 3A2781A

7. Loosen system mainline connection at pump outlet.

8. Operate pump until lubricant free of air flows from

outlet port.

9. Tighten mainline connection at pump. Pump is now

free of air.

NOTE: If the pump will not take a prime, it may be

helpful to inject several ounces of heavy oil through

the fill stud. The pump will then prime on oil pulling

the grease behind it. If it becomes necessary to use

this method, all injected oil should be discharged at

the loosened system mainline connection along with

any air.

Setup

System Filling

After the reservoir is filled as described in Filling the

Reservoir, page 9, fill the remainder of the system by

attaching a hand pump to the system downstream from

the pump manifold block assembly and cycle the hand

pump until the system is filled.

Manifold Bleeding

Proper filling of the system will reduce the chance of air

entrapment. The pump block manifold assembly (117,

page 28) must be bled to remove air which will be

trapped inside the pump. Cycle the pump several times

until air-free lubricant is dispensed.

NOTE: Manual air bleeding procedures are necessary

in the event any system components are loosened, disconnected or otherwise removed after their initial installation.

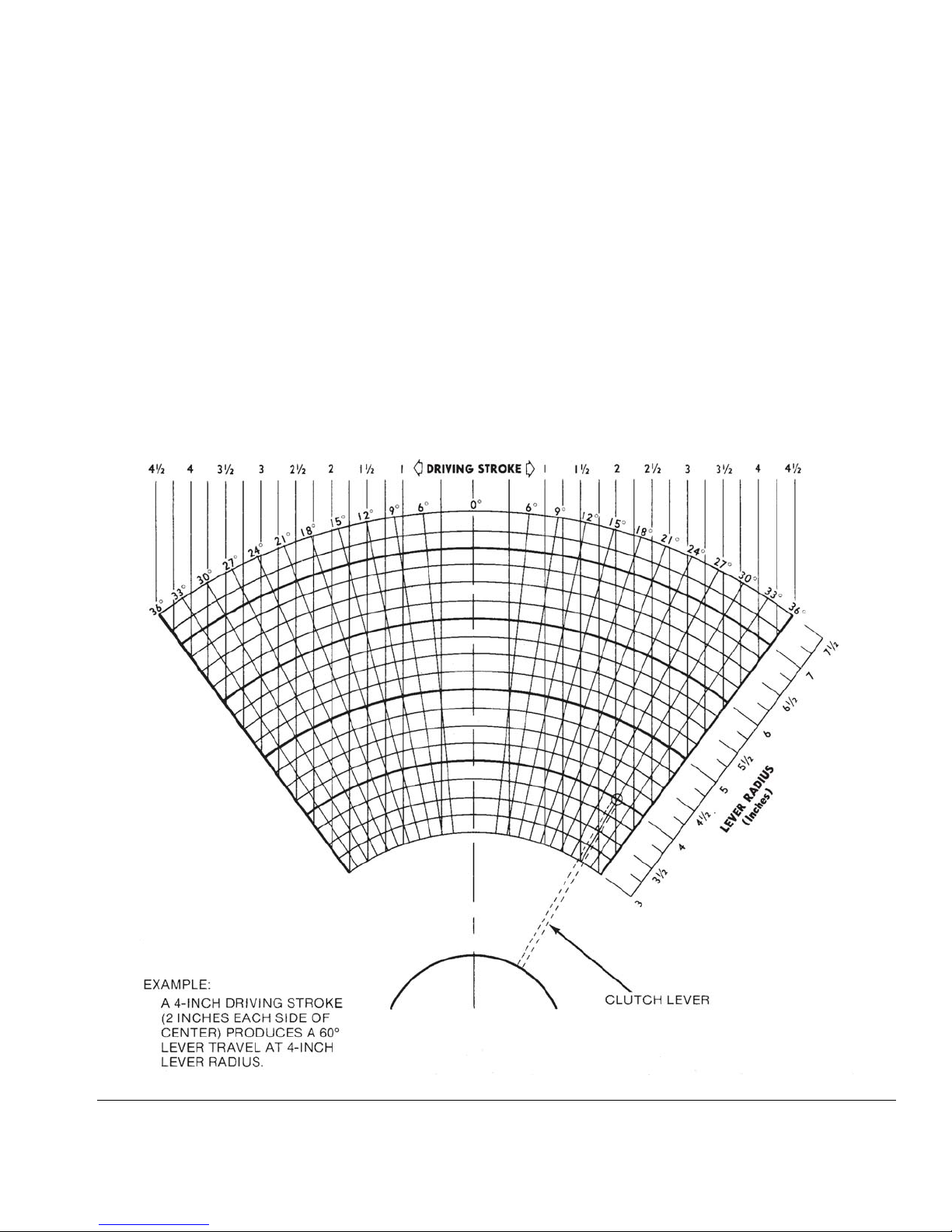

Adjusting the Clutch Drive

The degrees of throw of the clutch lever is adjustable

from 12 to 60 degrees. Table 1 (page 12) provides the

minimum/maximum pump outputs. The actual pump

output for your installation may be computed by using

the Calculating Pump Output procedure (page 12).

Using the clutch lever diagram provided in F

mine the anticipated clutch lever throw angle.

IG. 7 deter-

FIG. 7

3A2781A 11

Setup

Clutch Drive - Calculating Pump Output

The standard pump output can be varied, from 0.010 to 0.050 cubic inches (0.1639 to 0.8195 cu. cm) per cycle, by

changing the position of the pump adjustment sleeve (2) (F

high volume pump has a fixed output.

To calculate the pump output per hour, use the following formulas:

IG. 1, page 6) located below the pressure gauge (3). The

360°

Degrees of Throw

* Degrees of Throw can be found by using clutch lever diagram (F

IMPULSES/HOUR

RATIO

Pump strokes per hour x 0.010 = Minimum Pump Output per Hour

Pump strokes per hour x 0.050 = Maximum Pump Output per Hour

= Effective Ratio

IG. 7, page 11)

PUMP STROKE PER HOUR

=

Table 1: Minimum / Maximum Pump Output

Degrees of

Throw

Effective Ratio Impulses Per

Minute

Output Per Hour

Pump Strokes Per

Cubic Inches (Cubic Centimeters)/hour

Minimum Maximum

Hour

12 30:1 5 Minimum 10 0.100 (1.639) 0.500 (8.195)

60 6:1 150 Maximum 1500 15.00 (245.8) 75.00 (1229)

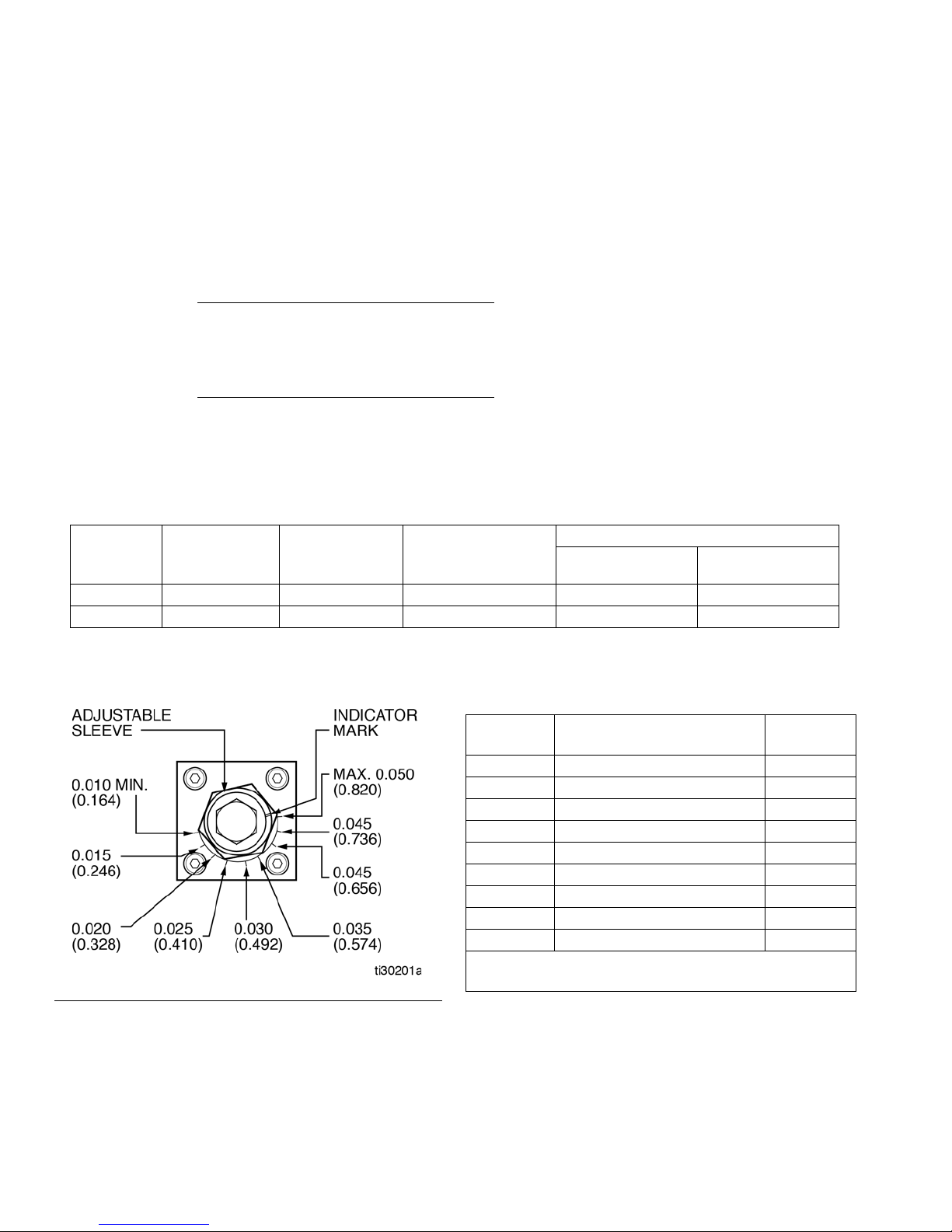

Standard Pump Adjustment

Table 2: Standard Output/Stroke Adjustment

Percent of

Output

100 0.050 (0.820) Max.

90 0.045 (0.737) *1st

80 0.040 (0.656) *2nd

70 0.035 (0.574) *3rd

60 0.030 (0.492) *4th

50 0.025 (0.410) *5th

40 0.020 (0.328) *6th

30 0.015 (0.246) *7th

20 0.010 (0.164) Min.

* All marks are counting clockwise from the maximum

setting.

FIG. 8

Output Per Stroke Cubic

Inches (Cubic Centimeters)

Adjustment

Mark

12 3A2781A

Operation

a

Operation

Startup

Before attempting to operate any system, check the

following:

• Ensure the reservoir is securely fastened to the

pump and that the fill cap or grease-fill fitting is easily reached.

• Check that the pump is securely fastened in place.

• Check that gear reducer has been filled with proper

lubricant.

• Check all electrical connections to any controllers,

level switches or pressure switches used on the system.

While the system is operating, periodically check

the following components:

• Check that the pump is cycling according to schedule.

• Visually check the unit for leaks and loose fittings.

Make sure that hoses do not become kinked and

are not rubbing on anything.

• If the reservoir is not equipped with a low-level

switch, visually check the lubricant level and refill

before all lubricant is used.

NOTE: If the reservoir is allowed to run dry, excess

air will be introduced into the system, requiring that

the system be bled.

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

• Check that all accessories plumbed into the output

manifold block assembly are secure.

• Make sure all hose or tubing connections are tight.

• Check that the reservoir is filled with lubricant. See

Filling the Reservoir, page 9.

• Check that all filling and bleeding steps have been

completed.

• Check the output of the lubricant pump. Adjust the

output as described in the Clutch Drive - Calculating

Pump Output, page 12.

• If the pump is equipped with a clutch drive, verify it

is properly adjusted as described in the Adjusting

the Clutch Drive section, page 11.

The unit is now ready to run. The pump is cycled by an

external source, such as a timer, counter, control package, or customer-supplied drive. Once this external

source is engaged, the unit will cycle as programmed.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or servicing the equipment.

1. Verify pump is stopped and disconnected from

power source.

2. Using a wrench, slowly loosen the outlet fitting (a,

F

IG. 9) connected to the pump block manifold

assembly until the fitting is loose and no more lubricant or air is leaking from the fitting.

3A2781A 13

FIG. 9

Troubleshooting

Troubleshooting

Many system problems may be caused by loose connections or trapped air in the system. Before removing system

components, check all connections to make sure they are tight. Also make sure the system is properly bled.

Problem Cause Solution

No lubrication is dispensed from

pump, but pump is rotating

Pump is Not Running or Requires

Service

No lubrication is dispensed from

pump and drive shaft is not rotating

Motor is Not Running

No Gear Reducer Output

Reservoir is empty

Check valve is defective

Adjustment sleeve seals are defective

Problem is in the pump

Yoke connector pin and piston are

defective

Sheared drive motor key Replace key.

Broken pump drive shaft

Piston is not engaged in sleeve

Motor is not running

No gear reducer output

Defective pump input shaft

Power is off Turn power on.

Electric connections to motor or timer

are loose

Timer/controller is set incorrectly or

defective

Key is sheared or missing at coupling Replace key.

Defective gearbox

Refill as required. See Filling The

Reservoir, page 9.

Clean and install seal repair kit.

See Pump is Not Running or

Requires Servicing section of this

Troubleshooting Table.

Replace defective parts using Pump

Drive Repair Kit.

Replace defective parts using Pump

Drive Repair Kit.

Replace defective parts using Output Manifold Kit.

Refer to Motor is Not Running section

of this Troubleshooting Table.

Refer to No Gear Reducer Output

section of this Troubleshooting Table.

Replace defective parts using Pump

Drive Repair Kit.

Check all connections and tighten

securely.

Set timer/controller to correct setting.

If unit is still not functioning, repair or

replace timer/controller.

Gearbox must be replaced. For this

repair unit must be returned to an

authorized Graco repair facility.

14 3A2781A

Loading...

Loading...