Page 1

LC-1000 Lube System Controller

The Trabon microprocessor based LC-1000 Controller

is a multi-use solid state controller that is dedicated to

the operation and monitoring of intermittent operating series and parallel centralized lubrication systems

equipped with a cycle or pressure switch for cycle

completion feed back.

The LC-1000 monitors and schedules lubrication intervals in either time or stroke/cycle basis in values ranging from 1 to 9999. Pump may be self cycling or single

cycle type requiring a pulsed output.

Four units are available for 12 VDC, 24 VDC, 115

VAC, or 230 VAC operation. The LC-1000 is easy to

program in the fi eld using four mini push-buttons. The

programming requires no special knowledge or training

of computer language. During power down or outage,

all data is saved in EEPROM (Electrically Erasable Programming Read Only Memory). As power is restored,

counting and pump status are restored to values prior

to the loss of power.

SPECIFICATIONS

Power Supply

115 VAC + 10%, 50/60 Hz, 1 ph

230 VAC + 10%, 50/60 Hz, 1 ph

12 VDC + 10%

24 VDC + 10%

Output Loading

Main Pump Load: ..........12 VDC – 230 VAC, 50/60 Hz

10 Amp Relay Output (External Fused by User)

Fault Output Signal: ........12 VDC – 230 VAC, 50/60 Hz

1 Amp Resistive Max. (N.O.) Dry Isolated Contact

(External Fused by User)

Temperature Range

Do Not Locate unit in Direct Sunlight

Operating:: -20OC to 50OC (-4OF to 122OF)

Storage: -25OC to 60OC (-13OF to 140OF)

Enclosure

Plastic with Clear Cover, NEMA 4X, IP 66

Display

Supertwist LCD

Annotated 4 Digit

4 LED’s: PWR (GN), LUBE (YW), FAULT (RD),

CYCLE (YW)

Stroke Input

Maximum Input Rate: 10 hz (600 CPM)

Nominal 12 Volts for 12 VDC Version

Nominal 24 Volts for 24 VDC, 115 VAC, 230 VAC

Versions

Selectable for either Source or Sink Solid State

Proximity Switch or Dry Contact 10 mA Max.

Other Inputs

Cycle Switch: ........12 Volts, Dry Contact, 2.5 mA Max.

Counts Half Cycles

Programming Selection

Output ON: ...................... 1 to 9999 Seconds, Minutes,

Hours, Counts

Output OFF:..................... 1 to 9999 Seconds, Minutes,

Hours, Counts

Cycle Counter: .............................Half Counts (0 to 99)

Pump: ....................................... Steady State or Pulsed

Pulse Off Time (Prime) – 3 Seconds Fixed

Pulse On Programmable - 0 to 99 Seconds

(Pre-Lube function is not available)

Program Entry

4 Mini Push Buttons – Program, Increase, Shift, Enter

EEPROM

Electrically Erasable Programming Read Only Memory

Page 2

LC-1000 Lube System Controller

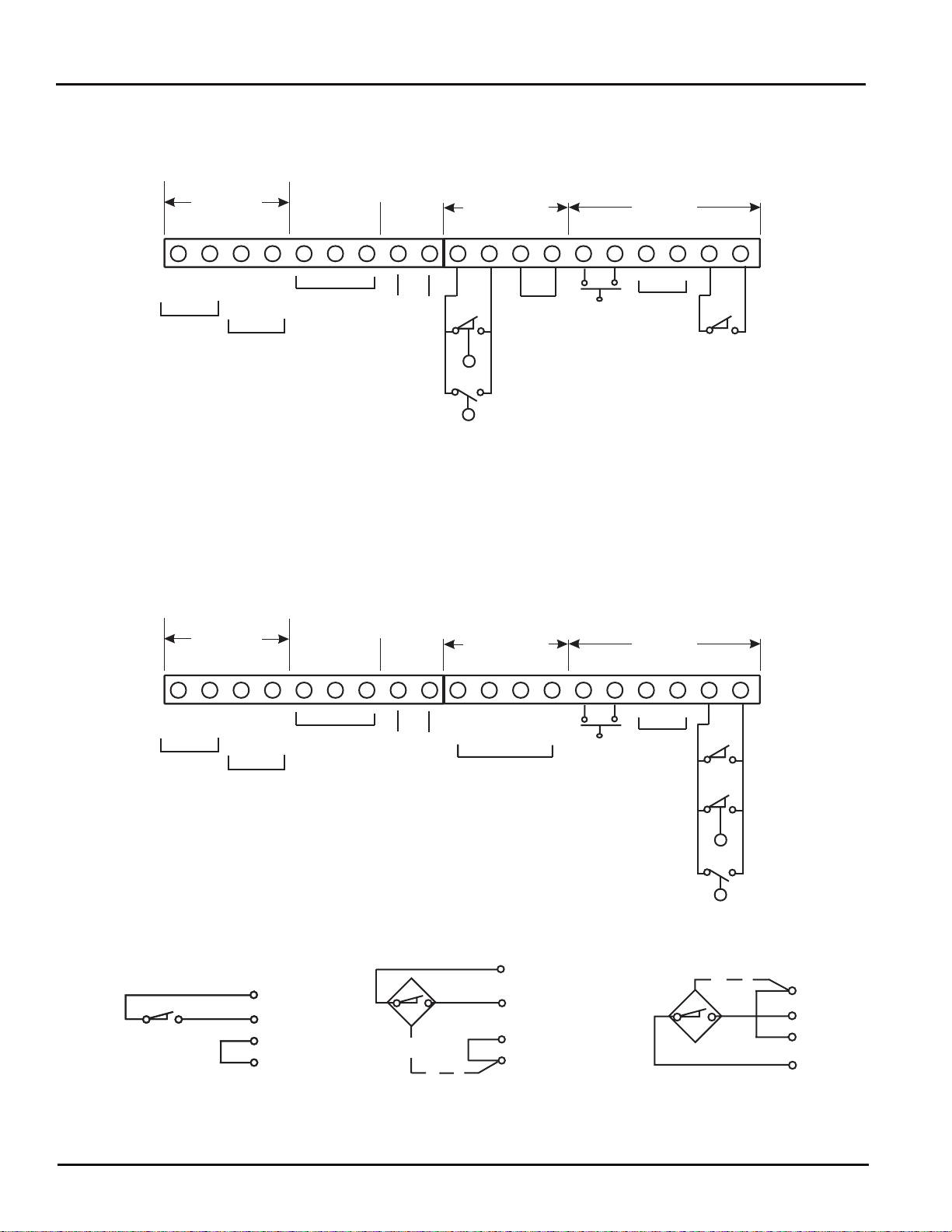

WIRING INFORMATION

Option for units built after February 1, 1999 that are programmed in time mode.

14540

INPUT

VOLTAGE

1234567

DRY

CONTACT

9

8

FIG 1

+

HOT

INPUT

-

NEU

-

+

PUMP

OUTPUT

DO NOT USE

PUMP

OPTIONAL

LOW-LEVEL SWITCH

AND/OR HIGH PRESSURE

SWITCH. BOTH MUST BE

OPEN DURING NORMAL

SYSTEM OPERATION.

CLOSURE OF SWITCH CONTACTS

CAUSES LC-1000 TO INDICATEA FAULT

CONDITION. BUT PUMP WILL CONTINUE

TO OPERATE.

FAULT

WIRING INFORMATION

All units programmed in machine count mode, or any units built prior to Februay 1, 1999.

Option for units built after February 1, 1999 that are programmed in time mode.

INPUT

VOLTAGE

1234567

FIG 2

-

+

NEU

HOT

INPUT

Figure 3, 4 and 5 refer to machine count input only.

FIG 3

DRY CONTACT SWITCH

-

+

PUMP

OUTPUT

10

10

11

11

12

12

13

13

DO NOT USE

PUMP

DRY

CONTACT

9

8

FAULT

FIG 4

SOURCE SWITCH 2 OR 3 WIRE TYPE

(SEE NOTE 1)

10

11 12 13 14 15 16

FAULT

Note 1: 12 VDC with 12 VDC Input Voltage

Note 2: Piston Distributor or Injector System will use a Pressure Switch.

(SEE NOTE 1)

10

11 12 13 14 15 16

+

SW

SW IN

FAULT

MACHINE COUNT

(SEE FIG 3 THRU 5)

CLOSURE OF SWITCH CONTACTS

CAUSES LC-1000 TO INDICATEA FAULT

CONDITION. ON EXPIRATION OF THE

NEXT ON (MONITOR) PERIOD.

SUSPENDING OPERATION OF THE PUMP.

12 VDC

18

17

JUMPER

INSTALLED

24 VDC with 24 VDC, 115 VAC and 230 VAC Input Voltage

MANUAL

RUN

DO NOT

USE

12 VDC

17

19

CYCLE

SWITCH

(SEE NOTE 2)

18

19

-

10

SENSE

SW

MANUAL

RUN

OPTIONAL

LOW-LEVEL SWITCH

AND/OR HIGH PRESSURE

SWITCH. BOTH MUST BE

OPEN DURING NORMAL

SYSTEM OPERATION.

DO NOT

USE

CYCLE

SWITCH

(SEE NOTE 2)

FIG 5

11

12

13

SINK SWITCH -

2 OR 3 WIRE TYPE

10

11

12

13

Page 2

Page 3

LC-1000 Lube System Controller

DIMENSIONS mm / (Inches)

14540

114.3

(4.50)

TIME COUNTS REMAINING

114.3

127.0

(5.00)

(4.50)

PRGM

RUN BUTTON

S

MANUAL RUN

MODEL LC-1000

MANUAL

ORDERING INFORMATION

LC-1000 Controller

VOLTAGE PART NUMBER

12 VDC 163-400-050

24 VDC 163-400-051

115 VAC, 50/60 Hz 163-400-052

230 VAC 50/60 Hz 163-400-053

Replacement Board

VOLTAGE PART NUMBER

12 VDC 572-144-644

24 VDC 572-144-645

115 VAC, 50/60 Hz 572-144-646

230 VAC 50/60 Hz 572-144-647

X

127.0

(5.00)

LUBE SYSTEM

CONTROLLER

ENTER

76.2

(3.00)

POWER

LUBE

FAULT

CYCLE

4.8 (.19)

PUSH BUTTONS:

There are four mini push buttons;

PRGM - Initiate Program mode, or alternate between

settings for:

ON (Monitor Time)

OFF (Pause Time)

CYCLE (Switch Transitions)

PUMP (Pulsed On Time)

S - Increase digit

X - Next digit select

ENTER - Enter (save) new setting and advance to

next program step.

PROGRAMMING INSTRUCTIONS

The LC-1000 Controller has icons in the display to indicate if the unit is in a lube ON cycle or OFF cycle and to

show the timing mode. They are also used to indicate

which counter is being adjusted when programming new

parameters. The LCD four digit display is used to show

the remaining time left in either an ON or OFF cycle, as

indicated by the icons. Timing can be done in seconds,

minutes, hours or counts. A fl ashing LCD character

indicates that the timer is in the Programming mode.

Page 3

Page 4

LC-1000 Lube System Controller

14540

OPERATION

When power is applied, the green “POWER LED”lights

and the LC-1000 counts down alternately from the

programmed “OFF/ON” Times/Counts to zero.

In the “ON” (Monitor) mode, the ” PUMP LED” lights.

The pump is activated and both the “ON and “RUN”

icons are displayed. If the programmed number of

cycle switch transitions (1/2 cycles) are received before expiration of the “ON” (Monitor) period, the PUMP

OUTPUT, “PUMP” LED, “ON” and “RUN” icons turn

off and the “OFF” icon will display. If the programmed

number of cycle switch transitions (1/2 cycles) are

not received before expiration of the “ON” (Monitor)

period, a “Fault” will be registered. This suspends

pump operation, turns off the ” PUMP” LED, the “ON

and “RUN” icons, turns on the red “FAULT” LED and

closes the fault output contacts.

If a pulsed output to the pump is required, a “PUMP

ON” time may be programmed from 0 to 99 seconds.

Setting this value to zero will provide a steady state

output. “PUMP OFF” is fi xed at 3 seconds.

The “RUN” icon will display anytime the pump output is energized. During pulsed pump operation, the

“RUN” icon will fl ash on and off in sequence with the

pump. During continuous running, the “RUN” icon will

not fl ash.

The Controller is programmed to retain the Time/Count

in memory when power is turned off. This feature prevents excessive lubrication in start/stop applications

and retains information for cycle to be completed when

power is restored.

CHANGING SETTINGS

From the Timer display mode, pressing the “PRGM”

button will allow you to review or change between the

set “ON” (Monitor), “OFF”, “CYCLE, “PUMP” (Pulsed

On Time) and “DISPLAY” modes. When in the programming mode, the icons/digits will blink. When in

the display mode, the icons/digits do not blink.

1. To set a new “ON” (Monitor) Time/Count, press

the “PRGM” key until the “ON” icon blinks. The

current “ON” (Monitor) Time/Count will be

displayed.

a) Press the “ENTER” key. The “ON” (Monitor)

Time/Count digit will blink.

b) Change the value using the S key and X

key.

c) Press the “ENTER” key to accept the new

value. The “SEC/MIN/HR/CNT” icon will blink

d) Press “ENTER” to accept the time base or the

S key to scroll through the timing choices.

e) Press “ENTER” to complete the process (Note:

Monitor period is normally set 2 times the

actual time required for the pump to satisfy the

system cycle requirements).

2. The “OFF” icon will now be blinking.

a) Repeat above process until all “OFF”

options have been programmed.

b) Press “ENTER” to accept the new values.

3. The “CYCLE” icon will now be blinking

a) Press “ENTER” and the cycle value

(1/2 cycles) will blink.

b) Using the S and X keys set the cycle

value as follows:

Series Progressive: ...............02 (1 divider cycle),

04 (2 divider cycles), 06 (3 divider cycles), etc.

Dual Line: ................. 01 (half cycle) 02 (full cycle)

Piston Distributor or Injector: .........................01

c) Press “ENTER” to register the new value.

4. The “PUMP” icon will now blink.

a) Press “ENTER” again and the pump

pulsed “ON” time will blink.

b) Using the S key and X key, set the value

(seconds) as follows:

Self-Cycling Pump

(Motor Driven, or Reciprocating Barrel): ...... 00

Single Shot Pump

(Piston Distributor, or Injector): ................... 00

Single Shot Pump

(Recycle for Series Progressive): ........03 to 10

c) Press "ENTER" to accept the new values.

NOTE: In the Recycle mode, PUMP “OFF” time is

fi xed at 3 seconds. Press “ENTER” to register

the new value and return to the “DISPLAY”

mode.

NOTE: Scrolling through the modes using the“PRGM”

key only will allow the review of the current

settings without changing any of the values or

timing. It is recommended that programming

not be attempted while a lube cycle is in

process. After making any change in settings,

activate a manual run to initiate the change.

NOTE: Programming examples for specifi c types of

systems are shown on pages 5, 6 and 7.

MANUAL RUN / RESET

A manual-run lubrication cycle may be initiated by

pressing the manual run button, located on the left

underside of the unit, OR by shorting terminals 14

and 15 together, such as with a remote push-button

momentary switch. Manual run may also be initiated

by pressing S and "ENTER" keys together. Manul run

is also used to reset the controlelr and to clear faults.

Page 4

Page 5

LC-1000 Lube System Controller

Sample LC-1000 Program for Series Progressive,

31 Point Series Progressive System

DESCRIPTION

■

System Lube Volume: 6.0 cu in (99 cc) per hour

■

AL-50 Pump Used: .24 cu in per stroke (3.9 cc)

■

Master Divider Volume per Cycle: .15 cu in (2.4

cc)

■

Cycle Interval 15 Minute (1/4 hour) Used

■

Volume per Lube Cycle: 6.0 cu in/4 = 1.5 cu in/15

min.

■

Master Divider Cycles/Lube Cycle: 1.5 cu in/.15

cu in = 10 cycles

■

Cycle Switch Transitions (2 transitions/cycle) x 10

= 20

■

Pump Strokes per Lube Cycle: 1.5 cu in/.24 cu in

= 6.3 (use 7)

■

Monitor Time: 7 Strokes x 6 seconds/stroke (3

second "ON", 3 second "OFF") = 42 second x 2

(safety factor) = 84 seconds.

SECONDARY DIVIDER

14540

PUMP AND RESERVOIR

MASTER DIVIDER VALVE

CYCLE SWITCH

LARGE BEARINGS

VALVES

PROGRAMMING

1. Initiate Programming Mode

a) Press “PRGM” Key – “ON” Icon blinks

2. “ON” (Monitor Period)

a) Press “ENTER” Key – ON TIME/COUNT

blinks

b) Use S Key and X Key to set Monitor

(“ON”) Time to 0084

c) Press “ENTER” Key to accept value;

“SEC/MIN/HR/CNT” blinks

d) Use S Key to scroll through choices;

select ” SEC”

e) Press “ENTER” Key to accept choice;

“OFF” Icon blinks

3. “OFF” (Pause Time)

a) Press “ENTER” Key –

OFF TIME/COUNTblinks

b) Use S Key and X Key to set

“OFF TIME” to 0015

c) Press “ENTER" Key to accept value;

"SEC/MIN/HR/CNT" blinks

d) Use S Key to scroll through choices;

select “MIN”

e) Press “ENTER” Key to accept choice;

“CYCLE” Icon blinks

4. “CYCLE” (Cycle Switch Transitions)

a) Press “ENTER” Key; CYCLE

(switch transitions) blinks

b) Use S Key and X Key to select 20 (20

cycle switch transitions = 10 Divider cycles)

c) Press “ENTER” Key to accept value;

”PUMP” Icon blinks

5. “PUMP ON” (Pump Duty-Pulsed/Non-Pulsed)

a) Press “ENTER” Key –

“PUMP” (pulsed on time) blinks

b) Use S Key and X Key to set ” ON TIME”

TO 03 (3 sec pulsed output)

c) Press “ENTER” Key to accept value;

LCD returns to “DISPLAY” mode

Programming is now complete. To verify lube sequence, initiate a manual lube cycle by pressing

“MANUAL RUN” button.

NOTE: If an electric motor driven pump or self cycling

barrel pump is used, enter “00” in Step 5b for

non-pulsed output.

Page 5

Page 6

LC-1000 Lube System Controller

Sample LC-1000 Program for Piston Distributor or Injector Systems

31 Point Piston Distributor System

DESCRIPTION

System Lube Volume: 99 cc (6.0 cu in) per hour

■

EO-3 Motor Driven Pump: 140 cc/min (8.5 cu in)

■

Total Piston Distributor Displacement: 4.62 cc/cycle

■

(.28 cu in)

Cycle Interval: 99 cc / 4.62 cc = 21.4 cycles/hr

■

60 min/21.4 cyc = 2.8 min (168 sec) per cycle

■

Cycle Switch (Pressure Switch) Transitions:

■

(1 transition/cycle) x 1 = 1

Pump Run Time: 4.62cc/140cc = .033min

■

(1.98 second)

Monitor Time: 1.98 sec x 2 (safety factor) = 3.96

■

seconds

Note: Due to the very short calculated pump run time,

use a 20 second monitor time.

PRESSURE

SWITCH

PISTON

DISTRIBUTORS

VENT

VALVE

14540

LUBRICATION

POINTS

VENT LINE

PUMP AND

RESERVOIR

PROGRAMMING

1. Initiate Programming Mode

a) Press “PRGM” Key – “ON” Icon blinks

2. “ON” (Monitor Period)

a) Press “ENTER” Key – ON TIME/COUNT blinks

b) Use S Key and X Key to set Monitor (“ON”)

Time to 0020

c) Press “ENTER” Key to accept value;

“SEC/MIN/HR/CNT” blinks

d) Use S Key to scroll through choices;

select ” SEC”

e) Press “ENTER” Key to accept choice;

“OFF” Icon blinks

3. “OFF” (Pause Time)

a) Press “ENTER” Key –

OFF TIME/COUNT blinks

b) Use S Key and X Key to set

“OFF TIME” to 0168

c) Press “ENTER” Key to accept value;

"SEC/MIN/HR/CNT" blinks

d) Use S Key to scroll through choices;

select “SEC”

e) Press “ENTER” Key to accept choice;

“CYCLE” Icon blinks

4. “CYCLE” (Pressure Switch Transitions)

a) Press “ENTER” Key; CYCLE blinks

b) Use S Key and X Key to select 01

(1 pressure switch transition = 1 system cycle)

c) Press “ENTER” Key to accept value;

”PUMP” Icon blinks

5. “PUMP ON” (Pump Duty-Pulsed/Non-Pulsed)

a) Press “ENTER” Key;

"PUMP" (pulsed on time) blinks

b) Use S Key and X Key to set

”ON TIME” TO 00 (non-pulsed output)

c) Press “ENTER” Key to accept value;

LCD returns to “DISPLAY” mode

Programming is now complete. To verify lube sequence, initiate a manual lube cycle by pressing

“Manual Run” button.

Page 6

Page 7

LC-1000 Lube System Controller

Sample LC-1000 Program for Bi-Flo (Dual Line) Systems

31 Point Bi-Flo (Dual Line) System

DESCRIPTION

System Lube Volume: 6.0 cu in (99 cc) per hour

■

Bi-Flo Motor Driven Pump Used: 8.6 cu in (141 cc)

■

per minute.

Note 1: Requires a Motor Starter

Note 2: Requires a hydraulic reverser with

cycle switch.

Cycle Interval 15 Minute (1/4 hour) Used

■

Volume per Lube Cycle: 6.0 cu in/4 = 1.5 cu in/15

■

minute.

Cycle Switch Transitions (2 transitions/cycle)

■

x 1 = 2

Pump Run Time per Lube Cycle: 1.5 cu in/

■

8.6 cu in = .17 min (10.4 second)

Monitor Time: 10.4 sec x 2 (safety factor) = 20.8

■

second (use 21 second).

VENT LINE

REVERSER

CYCLE SWITCH

PUMP AND

RESERVOIR

BI-FLO

VALVES

14540

LUBRICATION

POINTS

INDICATORS

PROGRAMMING

1. Initiate Programming Mode

a) Press “PRGM” Key – “ON” Icon blinks

2. “ON” (Monitor Period)

a) Press “ENTER” Key – ON TIME/COUNT

blinks

b) Use S Key and X Key to set Monitor (“ON”)

Time to 0021

c) Press “ENTER” Key to accept value;

“SEC/MIN/HR/CNT” blinks

d) Use S Key to scroll through choices;

select ” SEC”

e) Press “ENTER” Key to accept choice;

“OFF” Icon blinks

3. “OFF” (Pause Time)

a) Press “ENTER” Key –

OFF TIME/COUNT blinks

b) Use S Key and X Key to set

“OFF TIME” to 0015

c) Press “ENTER” Key to accept value;

"SEC/MIN/HR/CNT" blinks

d) Use S Key to scroll through choices;

select “MIN”

e) Press “ENTER” Key to accept choice;

“CYCLE” Icon blinks

4. “CYCLE” (Cycle Switch Transitions)

a) Press “ENTER” Key;

CYCLE (switch transitions) blinks

b) Use S Key and X Key to select 02 (02

cycle switch transitions = 1 System cycle)

c) Press “ENTER” Key to accept value;

”PUMP” Icon blinks

5. “PUMP ON” (Pump Duty-Pulsed/Non-Pulsed)

a) Press “ENTER” Key

"PUMP" (pulsed on time) blinks

b) Use S Key and X Key to set

”ON TIME” TO 00 (Non- pulsed output)

c) Press “ENTER” Key to accept value;

LCD returns to “DISPLAY” mode

Programming is now complete. To verify lube sequence,

initiate a manual lube cycle by pressing “MANUAL RUN”

button.

NOTE 1: If half cycle Bi-Flo (Dual Line) operation is desired,

select 01 (one switch transition) in step 4b.

NOTE 2: If a single cycle pump is used in conjunction with a

Bi-Flo Reverser, enter “03” in Step 5b for pulsed

pump output (3 second "ON", 3 second "OFF").

Page 7

Page 8

Your Program Record

Company: _____________________________________ By: _______________________

Machine Identifi cation: __________________ Date: _____________________

System Type: Bi-Flo ___ Piston Distributor ___ Series ___ Other: _________________

On (Monitor) Value: Time/Count _____ Seconds ___ Minutes ____Hours ___ Counts _____

Off Value: Time/Count _______ Seconds ______ Minutes ______ Hours ____ Counts ______

Cycle Value (Switch Transitions): ______________________

Pump On (Pulsed/Non Pulsed): ____________ (00 is NonPulsed)

TROUBLESHOOTING

Symptom Cause Remedy

Blank Display, No LEDs

No Display or Black Display, but System Operates

Program Will Not Run

Can’t Change Program

Fault Light On

Failure to Indicate a Fault

No Power Check Wiring & Fuse-Repair as Required

Bad Circuit Board Replace Circuit Board

Temperature too High or too Low Move Controller to Location that is within

Temperature Limits

Bad Display Replace Circuit Board

Programming Error or Bad Circuit

Board

In Programming Mode Exit by Pressing PRGM

Programming Error or Bad

Circuit Board

Power Off Before Programming

Completed

No Cycle Input Check Cycle Switch & Wiring-Repair as Required

Level Sw. or HP Sw. Closed

(If Used)

System Blockage Correct Blockage (see Bul 30101)

No Pump Flow or Low Flow Check Reservoir Level & Pump

Main Line Leaks Check & Repair as Required

Plugged Filter/Strainer Clean or Repair as Required

Monitor Time too Short Increase Monitor Time

Cycle Count Set to 00 Set Cycle Count to Desired Number of Half-Cycles.

Programmed Machine Count

Mode, and Wire According to

Fig. 1

Review Instructions & Examples-Reprogram/

Replace Circuit Board as Required

Review Instructions & Examples-Reprogram/

Replace Circuit Board as Required

Complete the Programming Process Before

Removing Power

Check Reservoir Level and Operating PressureRefi ll/Repair as Required

Output-Refi ll/Repair as Required

Program On and Off in Time Mode, or Wire per

Fig. 2.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice

Call today for product information or to request a demonstration.

1.800.USA.LUBE

®2006 Graco Inc. Bulletin 14540, July 2000. Printed in U.S.A.

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

(1-800-872-5823) or visit us at www.lubriquip.graco.com.

Loading...

Loading...