Page 1

Instructions-Parts

Air Controls

Integrated and 2-Button Interlock Air Controls for use with Supply Systems.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for Model information.

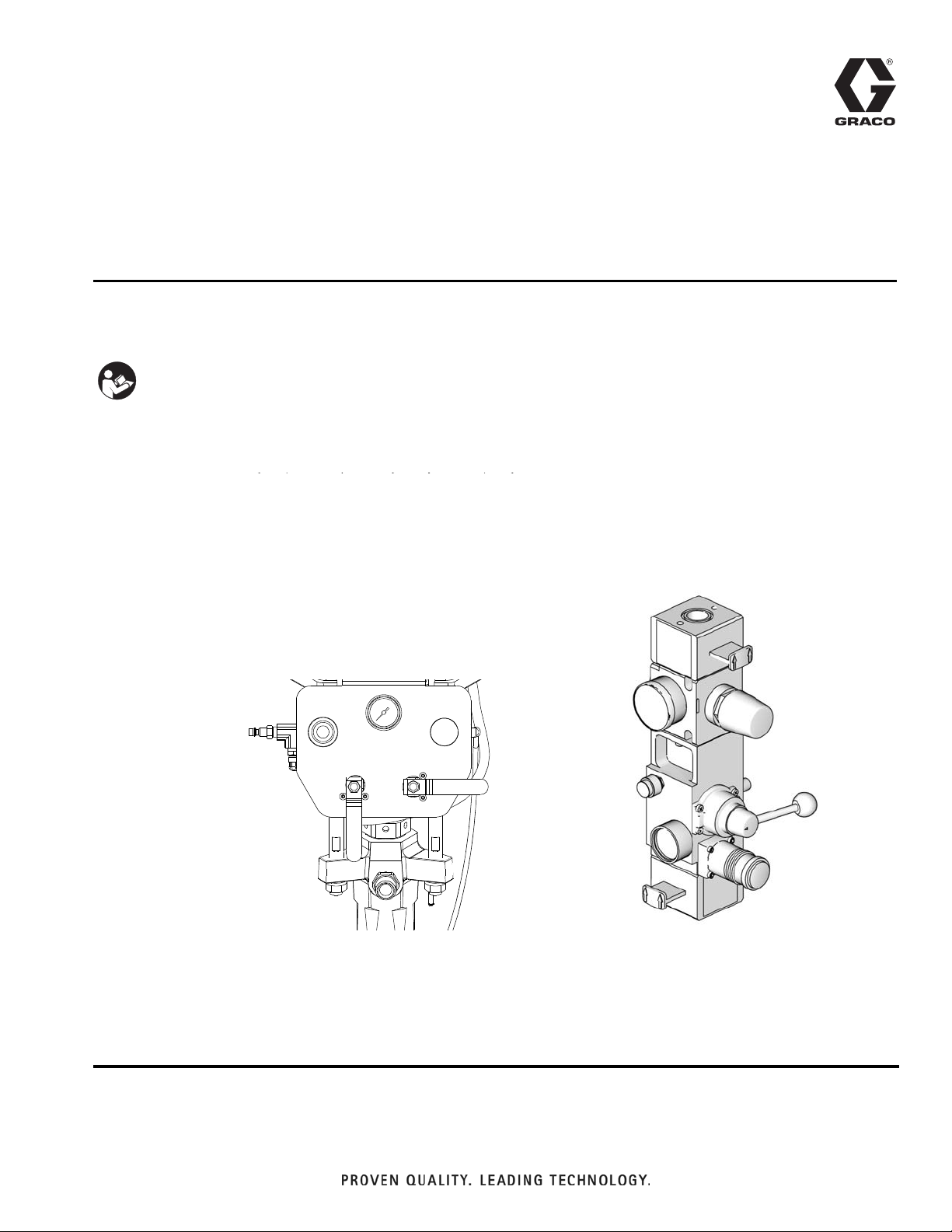

Integrated Air Controls

L20c Air Controls

312374H

EN

r_257302_312376_2e

ti10438a

Page 2

Contents

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Integrated Air Controls . . . . . . . . . . . . . . . . . . . . . . 3

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 3

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Replace Director Valve . . . . . . . . . . . . . . . . . . . . 4

Replace Air Motor Regulator . . . . . . . . . . . . . . . . 4

Replace Ram Air Regulator . . . . . . . . . . . . . . . . 5

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-Button Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Attach Roller Switch and Actuator . . . . . . . . . . . 6

Attach 2-Button Interlock Assembly . . . . . . . . . . 7

Models

L20c Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 9

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replace Air Motor Regulator . . . . . . . . . . . . . . . . 9

Replace Air Motor Shutoff Valve and Ram Shutoff

Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Remove Blowoff Push Button . . . . . . . . . . . . . . . 9

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

L20c Air Controls, 257613 . . . . . . . . . . . . . . . . . 10

Integrated Air Controls . . . . . . . . . . . . . . . . . . . . 11

Integrated Air Controls . . . . . . . . . . . . . . . . . . . . 12

2-Button Interlock Kit . . . . . . . . . . . . . . . . . . . . . 13

Pneumatic Schematic . . . . . . . . . . . . . . . . . . . . . . 14

Integrated Air Control Module . . . . . . . . . . . . . . 14

Integrated Air Control Module with Optional

2-Button Interlock . . . . . . . . . . . . . . . . . . . . 15

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 16

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air Controls

Model

No. Description

255650

24C824

257612

257613

Integrated Air Controls for D60, D200, and

D200s

Integrated Air Controls for D200 and D200s

(Ram only, no pump control)

Air Controls, For S20 3 in., 5 Gallon (20 Liter)

Supply Systems

Air Controls, For L20c 3 in., 5 Gallon (20

Liter) Supply Systems

2-Button Interlock

Model

No. Description

257615

255719

255720

Two-Button Interlock, For D60 3 in., 16 Gallon (60 Liter) Supply Systems

Two-Button Interlock, For D200 3 in., 55 Gallon (200 Liter) Supply Systems

Two-Button Interlock, For D200s 6.5 in., 55 Gallon (200 Liter) Supply Systems

Maximum

Regulated

Working

Pressure

psi (MPa, bar) Air Inlet Size

150 (0.69, 6.9) 3/4 npt(f) 255719

150 (0.69, 6.9) 3/4 npt(f) 255719

150 (0.69, 6.9) 1/2 npt(f) NA

100 (0.7, 7) 1/2 npsm(f) 255615

Compatible

2-Button Interlock

Model

255720

255720

2 312374H

Page 3

Integrated Air Controls

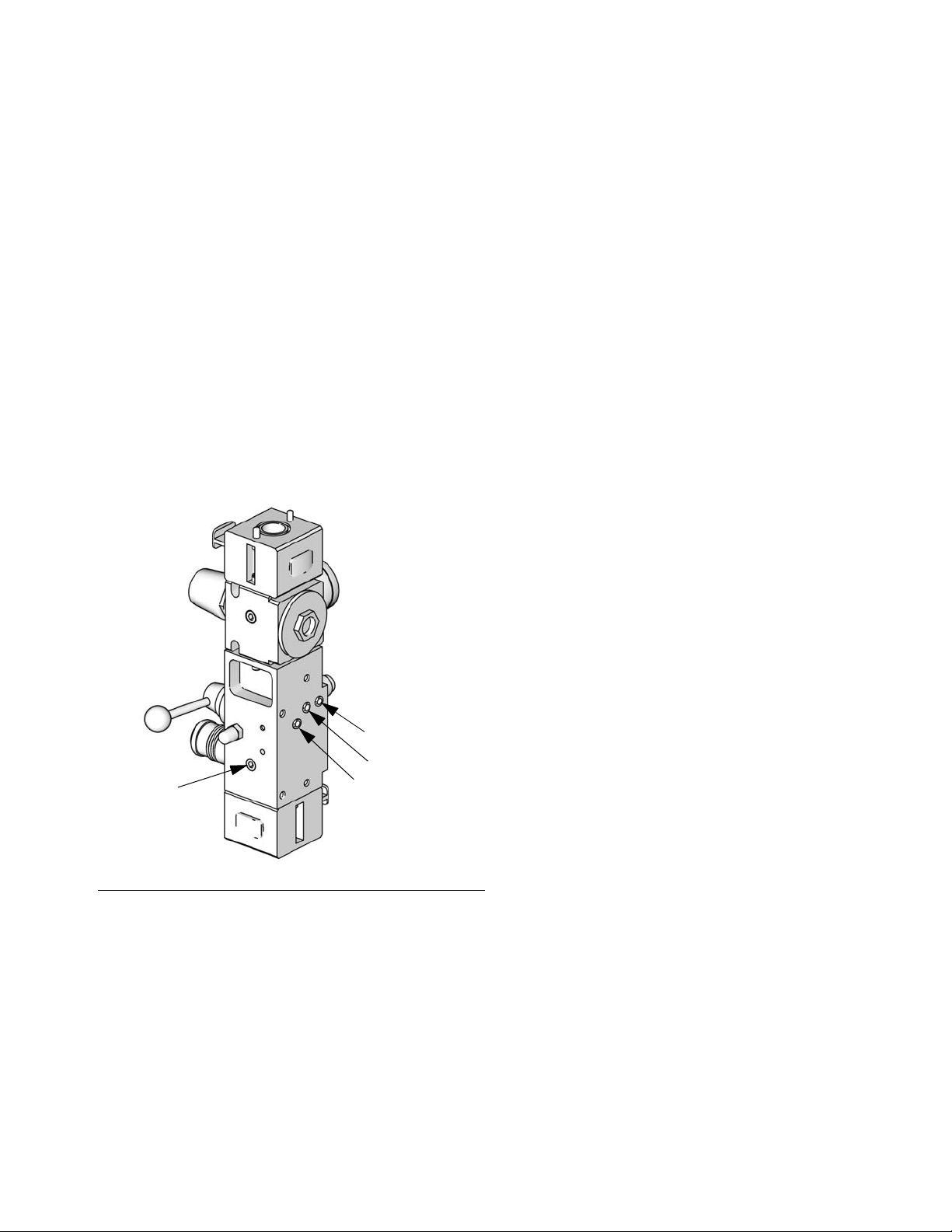

Integrated Air Controls

255650 (shown)

To reduce the risk of serious injury whenever you are

instructed to relieve the pressure, follow the Pressure

Relief Procedure.

Pressure Relief Procedure

1. Close the air motor slider valve (E) and the main air

slider valve (F).

2. Set the ram director valve to DOWN. The ram will

slowly drop.

3. Jog the director valve up and down to bleed air from

ram cylinders.

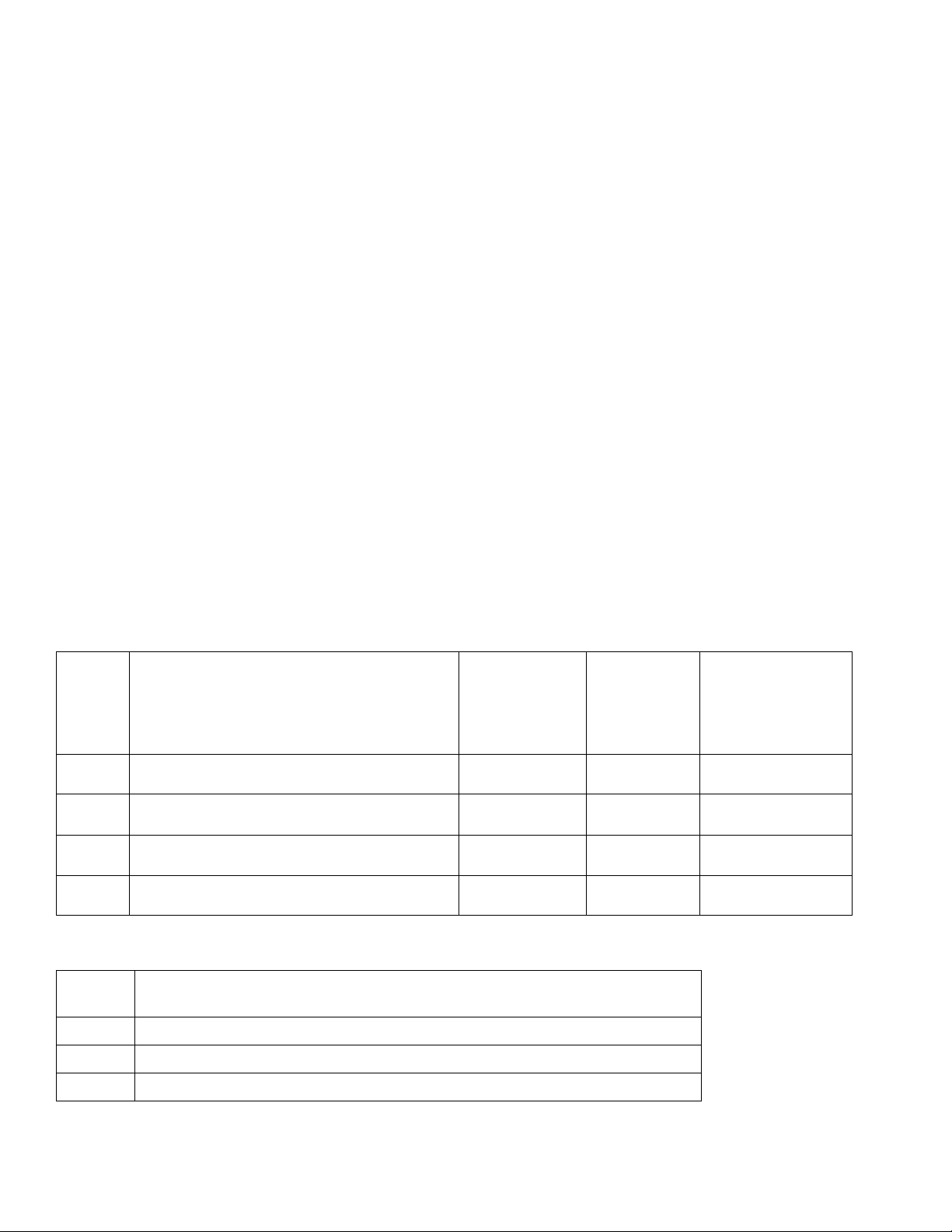

Disassembly

1. For Supply Systems with Shrouds: Remove

shrouds. Loosen six captive screws (A) and disassemble shrouds (B) from supply system.

C

D

r_289105_312375_2a

IG

. 2

F

255650 (shown)

E

1

F

E

B

B

255650 (shown)

A

r_289105_312375_a

F

IG

. 1

2. Disconnect all hoses and tubing from existing air

control.

3. Remove four screws (C) from the mounting bracket

(D) and remove the integrated air controls from the

supply system.

C

D

r_289105_312375_3a

IG

. 3

F

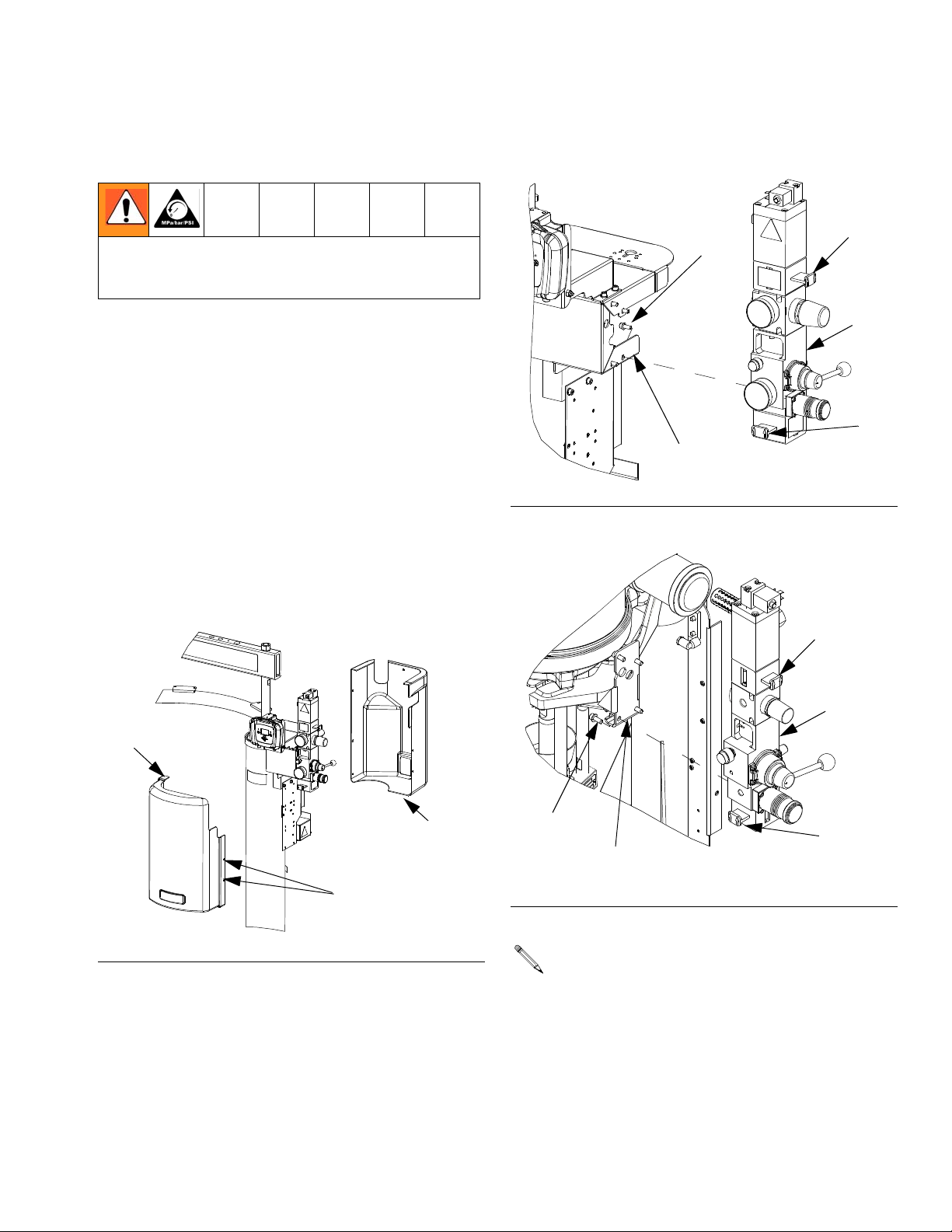

If you are not replacing the manifold (1), you may

prefer to remove the bracket from the ram and

leave it attached to the integrated air controls

because the screws are easier to reach. See F

1

F

IG

. 4.

312374H 3

Page 4

Integrated Air Controls

r_289105_312375_4a

F

IG

. 4

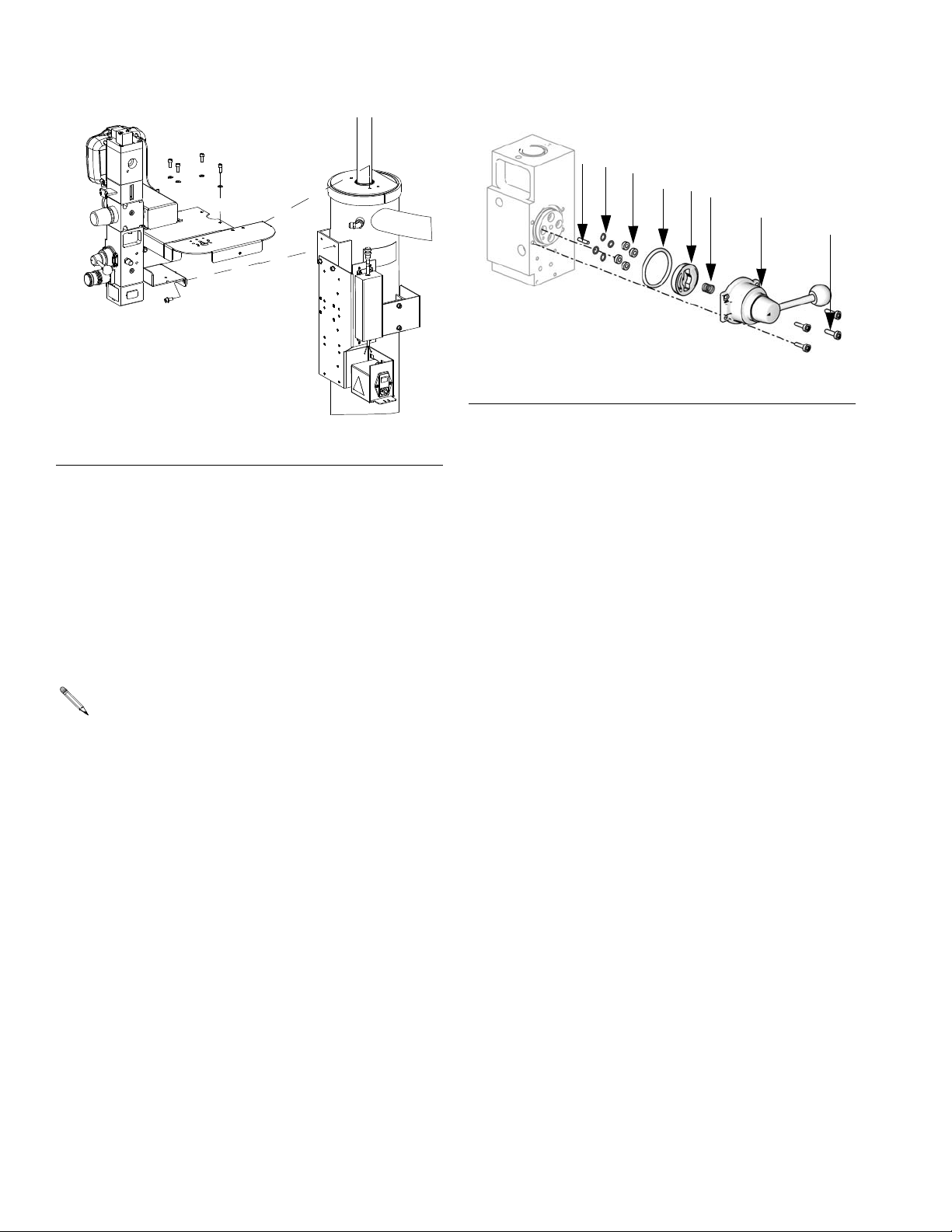

Replace Director Valve

Numbers in parentheses refer to FIG. 5.

1. Relieve pressure.

2. Remove screws (4a) and take off director valve.

3. Remove spring (4c), valve plate (4d), and o-ring

(4b)

.

4g

4f

4e

4b

4d

4c

4

4a

ti10952a

FIG. 5

Replace Air Motor Regulator

Numbers in parentheses refer to Parts, page 11. Air

motor regulator not included with 24C824 integrated air

controls.

1. Relieve pressure.

2. Disconnect air motor hosing and fittings.

3. Remove two screws (9) and take off the shutoff

valve (3) at top of module. If your supply system has

an air solenoid, it can remain attached to the shutoff

valve.

Note the orientation of the director valve plate when

you remove it. The opening should be on the opposite side (left) of the lever.

4. Remove and discard pin (4g) and four valve seats

(4e) with o-rings (4f).

5. Insert new valve seats (4e) with o-rings (4f) and new

pin.

6. Insert new director valve plate (4d, see Note above)

spring (4c), and o-ring (4b).

7. Attach new director valve with screws (4a). Tighten

screws until snug.

4. Remove two screws (9) and take off the air motor

regulator (6).

5. Attach new regulator to manifold. Orient so the

gauge lines up with the gauge on the ram air regulator and the direction of flow arrow points up. Tighten

screws until snug. Recommend using thread locker

Loctite 220 or equivalent.

6. Reattach shutoff valve (3) at top of regulator. Make

sure that o-ring (5) is in place on valve (3).

4 312374H

Page 5

Replace Ram Air Regulator

Numbers in parentheses refer to Parts, page 10.

1. Relieve pressure.

2. Remove four screws (7a) and take off the ram air

regulator (7).

3. Replace o-rings (7b) on back side of regulator.

4. Attach new air regulator to manifold. Use index pin

for correct orientation. Tighten screws until snug.

Reassembly

1. Using four screws, attach the integrated air controls

to the mounting bracket. See F

2. Attach the ram up, ram down, and blowoff air lines

as shown in Figure F

255650 (shown)

IG

. 6.

IG

. 2.

Integrated Air Controls

Not included

with 24C824

}

Ram up

Blowoff

Auxiliary

air supply port

ti10778a

IG

. 6

F

3. Attach all other hoses and replace shrouds.

Ram down

312374H 5

Page 6

2-Button Interlock

2-Button Interlock

To reduce the risk of serious injury whenever you are

instructed to relieve the pressure, follow the Pressure

Relief Procedure, page 3.

Attach Roller Switch and Actuator

1. Attach roller switch (133) to bracket (132). Position

roller switch to far back position on the bracket and

leave mounting screws (144) loose.

2. Attach bracket (132) to ram with screws (105) and

washers (106). Leave screws loose. See F

F

IG

. 8.

IG

. 7 and

3. Raise platen to top of drum.

4. Attach actuator bracket.

a.

For D200 and D200s supply systems

actuator bracket (138) near bottom of lift rod so

it engages the roller switch when the platen

reaches the top of the drum.

139

140

: Attach

F

IG

. 7: D200 and D200s Bracket

105

106

132

150

ti10844a

144

133

144

133

105

132

106

138

ti10848a

IG

. 9

F

b. For D60 supply systems: Loosen one screw

(151a) and remove one screw (152b). Align

actuator rod (151) on piston rod so it touches

the air motor mounting bracket. Tighten actuator rod to piston rod with four screws (140).

151b

151a

151

138

139

152

153

ti10847a

r_289105_312375_5a

IG

. 8: D60 Bracket

F

6 312374H

F

IG

. 10

140

r_289105_312375_5a

Page 7

5. Tighten actuator bracket to rod using 4 screws (140)

and bracket clamps (139).

6. Adjust the roller switch (133) out so it contacts actuator bracket (138), then tighten screws (144).

7. Tighten bracket (132) to ram with screws (105) and

washers (106).

8. Connect main air (S1) to port (S1) on roller switch

(133) with 15 in. of tubing (146).

9. Connect switch signal air (S2) to port (S2) on roller

switch (133) with 15 in. of tubing (146).

10.

For D60 supply systems

: Install two fittings (150)

into (S1) and (S2).

S2

S1

2-Button Interlock

130

145

ti10843a

FIG. 12

133

ti10844a2

F

IG

. 11:

Attach 2-Button Interlock Assembly

See FIG. 12.

1. Relieve pressure.

2. Remove shrouds. See F

3. Disconnect air lines.

4. Remove integrated air controls from bracket. See

Disassembly, page 3.

5. Remove back cover from 2-button interlock assembly (130).

6. Position 2-button interlock assembly between air

control bracket and air controls. The screws that

attach the integrated air controls to the supply system also attach the 2-button interlock assembly.

IG

. 1.

7. Reattach integrated air controls. See Reassembly,

page 5.

8. Insert cap screw (145) through integrated air controls into 2-button interlock module. See F

IG

. 12.

312374H 7

Page 8

2-Button Interlock

See FIG. 13 for steps 9 - 14.

9. Inside 2-button interlock module, disconnect elbow

fitting (6) and push fittings (7) from tee fitting (5).

Remove plug (8) from auxiliary air supply port on

back of integrated air controls. Install tee fitting (5)

through into the port and through the opening in the

bracket. Reconnect elbow fitting (6) and push fittings (7). Reinstall plug (8) at top of tee fitting (5).

10. Connect tubing (147) from ram down fitting on back

of air controls to fitting (D1) on right side of bottom

pilot valve. See F

IG

. 13.

11. Connect tubing from ram down fitting near top of

ram cylinder to fitting (D2) on left side of bottom pilot

valve. See F

IG

. 13.

S1

12. Connect tubing (147) from ram up fitting on back of

air controls to fitting (U1) on right side of top pilot

IG

valve. See F

. 13

13. Connect tubing from ram up fitting near bottom of

ram cylinder to fitting (U2) on left side of top solenoid.

14. Connect blowoff air (B1) to blowoff air connector on

platen.

15. Replace cover on 2-button interlock assembly.

It may be necessary to rearrange tubing so cover

will fit back on assembly.

16. Attach all other hoses and replace shrouds.

U2

B1

(blowoff)

U1

D2

D1

7

S2

6

F

IG

. 13

8

5

D1

(ram down)

U1

(ram up)

8 312374H

Page 9

L20c Air Controls

To reduce the risk of serious injury whenever you are

instructed to relieve the pressure, follow the Pressure

Relief Procedure.

L20c Air Controls

Replace Air Motor Shutoff Valve and Ram Shutoff Valve

See parts illustration on page 10.

1. Remove two screws (211) from air motor shutoff

valve and two screws (209) from ram shutoff valve.

Pressure Relief Procedure

1. Close the air motor shutoff valve (E) and remove air

line from air control coupling (x).

2. Set the elevator director valve to DOWN. The ram

will slowly drop.

Disassembly

1. Remove two screws that attach air control panel to

elevator.

2. Disconnect all hoses and tubing from existing air

control.

Replace Air Motor Regulator

1. Loosen swivel fitting (205) between regulator (206)

and air motor shutoff valve (203).

2. Remove nut (218) from front of regulator and pull

regulator out of panel (201).

2. Remove valve assemblies from panel.

Remove Blowoff Push Button

See parts illustration on page 10.

1. Hold button in place and remove screw.

2. Remove nut underneath button and push button

from panel (201).

Reassembly

1. Replace parts as needed and reassemble them in

the reverse order of disassembly.

2. Connect all hoses and tubing.

3. Install air controls on elevator with two screws and

lockwashers from kit 257613. See manual 313527.

206

218

205

203

F

IG

. 14

312374H 9

201

r_289105_312375_8a

Page 10

Parts

Parts

L20c Air Controls, 257613

Front View

218

211

212

209

r_289105_312375_9a

201

215

214

202

203

Back View

205

204

210

213

216

206, 218

207

208

217

219

r_289105_312375_9a2

Ref. Part Description Qty.

201 PANEL 1

202 517313 VALVE, 3 way 1

203 114362 VALVE, ball, air 2

204 FITTING, adapter 1

205 FITTING, 90° swivel 1

206 110318 REGULATOR 1

207 FITTING, tee 1

208 FITTING, line, air 1

209 SCREW, cap; 10-24 x 0.375 in. 2

210 FITTING, elbow 1

211 SCREW, cap; 10-24 x 0.625 in. 2

212 15T500 GAUGE 1

213 FITTING, 90° swivel 1

214 FITTING, elbow 2

215 FITTING, elbow 3

216 FITTING, elbow 1

217 FITTING, swivel 1

218 NUT, regulator 1

219 SAFETY, valve 1

Mounting screws and lockwashers are included with

kit 257613. See manual 313527.

10 312374H

Page 11

Parts

Integrated Air Controls

9

13

9

8

13

5

7b

3

5

1

10

9

Model 255650; D200s, D200, and D60

Model 257612; S20

3

5

6

11

4b

4

4a

7a

7

ti10774a

Ref. Part Description Qty.

1MANIFOLD 1

3 ★ 121108 VALVE, shutoff (includes o-rings

and screws)

◆ 121793 VALVE, shutoff (includes o-rings

and screws)

4 121107 VALVE, director (includes 4a and

4b, plus all parts shown in F

4a SCREW 4

4b O-RING 1

5 ★ 121110 O-RING, buna 3

◆ 102620 O-RING 3

6 ★ 255651 REGULATOR, air motor (includes

regulator, o-ring, and screws)

◆ 257614 REGULATOR, air motor (includes

regulator, o-ring, and screws)

7 121106 REGULATOR, ram (includes 7a

and 7b)

7a SCREWS 4

7b O-RING 2

8 121109 VALVE, blowoff (includes valve

and push button)

9 ★ 121112 SCREW, cap, socket head

1/4-20 x 5/8

◆ 121803 SCREW, cap, button head

10-32 x 1/2

10 517449 MUFFLER 1

11 100721 PLUG, pipe, auxiliary air supply 1

13 ★ 101689 GAUGE, air pressure, 0-200 psi

(0-1.4 MPa, 0-14 bar)

◆ 113911 GAUGE, air pressure, 0-160 psi

(0-1.1 MPa, 0-11 bar)

★

For D200s, D200, and D60 supply systems only.

◆

ForS20 supply systems only.

IG

. 5)

2

2

1

1

1

1

1

6

6

2

2

312374H 11

Page 12

Parts

Integrated Air Controls

1

10

8

13

5

7b

3

9

7

11

4b

7a

ti10774a

4a

Model 24C824; D200s and D200

Ref. Part Description Qty.

1MANIFOLD 1

3 121108 VALVE, shutoff (includes o-rings

and screws)

4 121107 VALVE, director (includes 4a and

IG

4

4a SCREW 4

4b O-RING 1

5 121110 O-RING, buna 3

7 121106 REGULATOR, ram (includes 7a

7a SCREWS 4

7b O-RING 2

8 121109 VALVE, blowoff (includes valve

9 121112 SCREW, cap, socket head

10 517449 MUFFLER 1

11 100721 PLUG, pipe, auxiliary air supply 1

13 101689 GAUGE, air pressure, 0-200 psi

4b, plus all parts shown in F

and 7b)

and push button)

1/4-20 x 5/8

(0-1.4 MPa, 0-14 bar)

. 5)

2

1

1

1

2

1

12 312374H

Page 13

Parts

2-Button Interlock Kit

Model 255719

(For D200 3-in., 55 gallon (200 liter) supply systems with

NXT 2200, 3400 and 6500 Air Motors only)

Model 255720

(For D200s 6.5-in., 55 gallon (200 liter) supply systems

with NXT 2200, 3400 and 6500 Air Motors only)

Model 257615

(For D60 3-in., 16 gallon (60 liter) supply systems)

Ref. Part Description Qty.

105 SCREW, cap, 1/4-20 x 5/8 2

106 WASHER, lock, 1/4 2

130 AIR CONTROL, 2-button interlock 1

132 BRACKET, switch, mounting 1

✿ BRACKET, switch, mounting 1

133 VALVE, roller operated 1

135 WASHER, no. 8 2

136 WASHER, lock, no. 8 2

137 NUT, hex, 8-32 2

138 BRACKET, actuator 1

139 BRACKET, actuator, mounting 2

140 SCREW, cap, 1/4-20 x 1 1/4 4

✿ SCREW, cap, 8/32 x 1 4

144 SCREW, panhead, 8-32 x 1 1/2 2

145 SCREW, cap, 1/4-20 x 2 1/2 1

146 TUBING, nylon, 5/32 in. (not shown) 30

147 TUBING, nylon, 1/4 in. (not shown 30

150✿ ELBOW, 90°; 5/32 tube x 5/32 OD 2

151✿ ACTUATOR, weldment 1

152✿ WASHER, plain- 4

153✿ NUT, hex; 8/32 4

144

133

105

106

132

135

136

137

1

Flip mounting bracket 132 on D60 supply systems.

ti10844a1

130

145

1

ti10843a1

✿

For D60 2-button interlock kit 257615 only.

Actuator Bracket (138) for 255719 and 255720

Actuator Bracket (138) for 257615

151

139

138

140

138

139

152

153

ti10848a

140

312374H 13

r_289105_312375_5a

Page 14

Pneumatic Schematic

Pneumatic Schematic

Integrated Air Control Module

INTEGRATED AIR

CONTROL MODULE

Pump Pressure

Regulator

Air Motor

Shutoff

MAIN

AIR IN

Air Pressure

Relief Valve

Ram Pressure

Regulator

Ram Directional

Control Valve

UP

DOWN

Pump Air

Motor

Ram Down

Blow Off

Valve

Platen

Ram Up

14 312374H

Page 15

Pneumatic Schematic

Integrated Air Control Module with Optional 2-Button Interlock

INTEGRATED AIR

CONTROL MODULE

Pump Pressure

Regulator

Air Motor

Shutoff

MAIN

AIR IN

Air Pressure

Relief Valve

Ram Interlock

Roller Valve

Ram Pressure

Regulator

OPTIONAL 2-BUTTON

INTERLOCK

Ram Directional

Control Valve

UP

DOWN

Pump Air

Motor

Blow Off

Valve

Platen

Ram Down Pilot

Interlock Valve

Ram Down

Ram Up Pilot

Interlock Valve

Interlock

Ram Up

Push buttons

P S

A

Synchronous

Input

Safety Valve

B

312374H 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER,

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions.

International Offices: Belgium, China, Japan, Korea

This manual contains English. MM 312374

Graco Headquarters: Minneapolis

www.graco.com

Revision H, September 2014

Loading...

Loading...