Page 1

INSTRUCTIONS-PARTS LIST

308–082

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

GM 3500

GASOLINE-POWERED AIRLESS LINESTRIPER

LineLazer

3000 psi (210 bar, 21.0 MPa)

Maximum Working Pressure

Model 231–132, Series A

With one gun, RAC IVR DripLesst Tip guard,

Size 317 LineLazer Tip & Size 517 SwitchTipt,

and 50 foot (15 m) hose.

Model 231–140

Same as 231–132, except includes

Second Gun Kit, 224–097

First choice when

quality counts.

t

Rev. W

Supersedes Rev. V

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

0001F

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

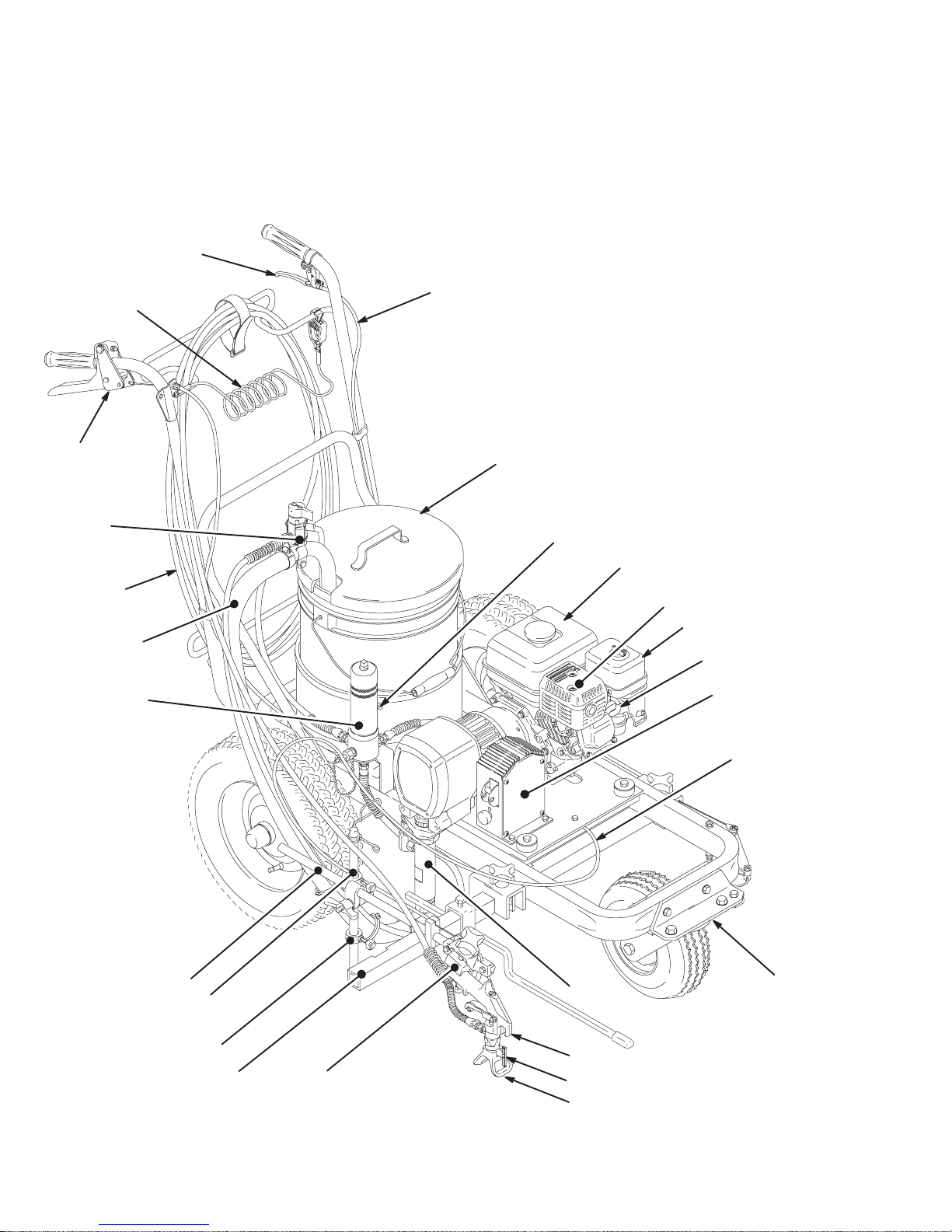

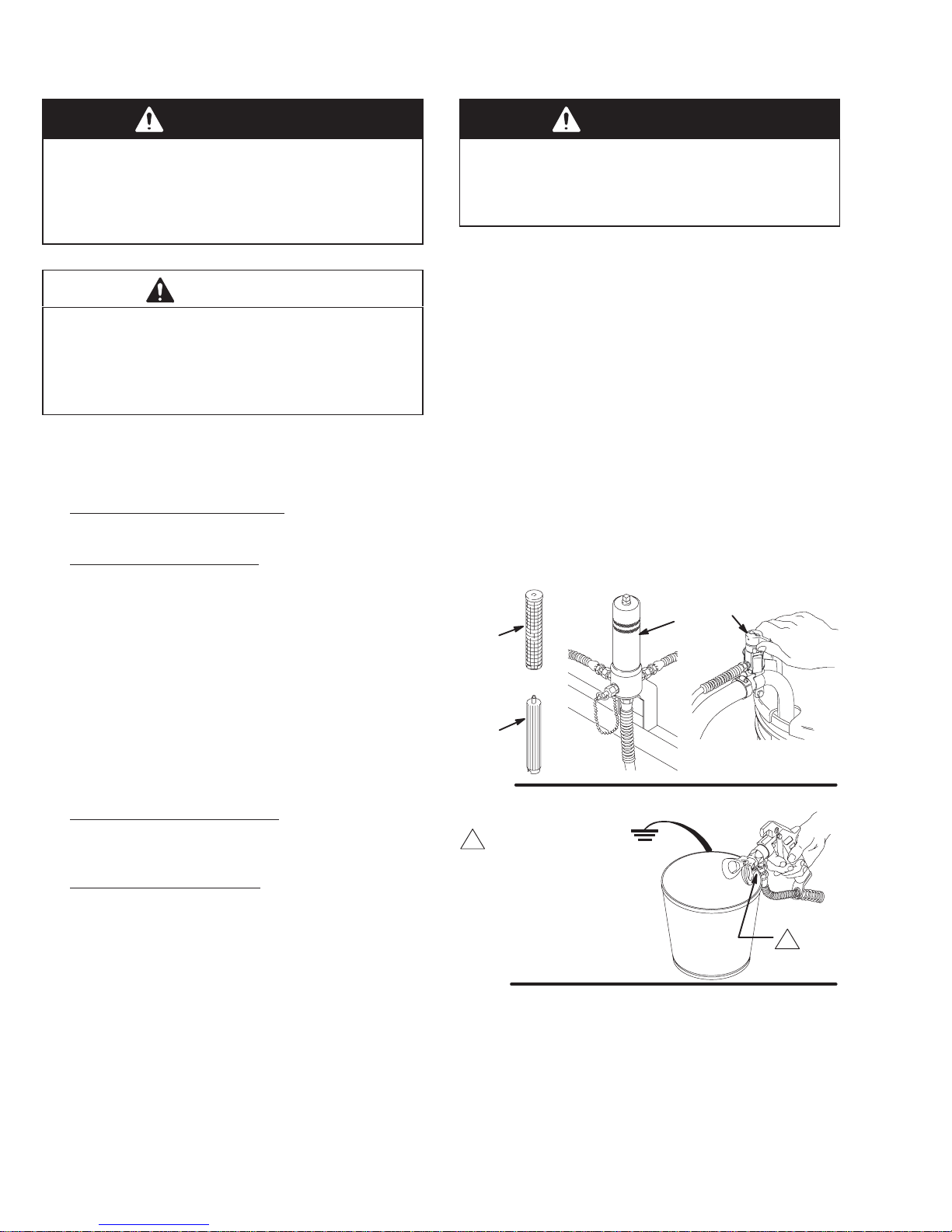

Part Identification

Key

A Caster lever

B Dual gun selector

C Main hose

D Suction hose

E Fluid filter

F Pressure drain valve

G Arm

H Post

A

Z

B

Y

X

F

J Carriage bar

K Gun holder

L Rac IV tip guard

M Switch T ip

N Flex gun

O Displacement pump

P Caster

Q Dual gun selector cable

R Pressure control

S Spark plug cable

T Air Cleaner

U Muffler

V Fuel T ank

W Hook eyelet (use to strap

pail or pail cover to cart)

X Pail cover

Y Caster Cable

Z Grounding cable and

clamp

AA Collar

W

V

C

U

T

D

S

R

E

Q

G

H

O

P

AA

J

K

2 308-082

N

M

L

0001F

Page 3

Table of Contents

Warnings 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fueling 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Second Gun and Hose Installation 11. . . . . . . . . . . . . . .

Flushing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Tip and Tip Guard 15. . . . . . . . . . . . . . . . . . . . . . .

Gasket Selection 15. . . . . . . . . . . . . . . . . . . . . . .

Installation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing a Clogged Tip 15. . . . . . . . . . . . . . . . . .

Maintenance 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Tip Selection 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Tip Application Recommendations 16. .

Spray Techniques 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Width Adjustment 16. . . . . . . . . . . . . . . . . .

Positioning the Gun Arm Assembly 17. . . . . . . . . . . . . .

Vertical position of the first or second gun 17.

Horizontal position of the first gun 17. . . . . . . .

Horizontal position of the second gun 17. . . . .

Mount guns on the engine side of the cart 18.

Setup for spraying arcs 18. . . . . . . . . . . . . . . . .

Adjust Simultaneous Gun Triggering 18. . . . . . . . . . . . .

Gun Arm Positions 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Lever & Cable Operation 20. . . . . . . . . . . . . . . . .

Operation 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Tire Replacement 20. . . . . . . . . . . . . . . .

Caster Cable Tension Adjustment 20. . . . . . . .

Caster Alignment 20. . . . . . . . . . . . . . . . . . . . . . .

How to Mount the Gun 20. . . . . . . . . . . . . . . . . . . . . . . . .

Gun Cable & Dual Gun Selector Operation 21. . . . . . . .

How the Dual Gun Selector Works 21. . . . . . . .

How to Release the Selector Cable 21. . . . . . .

Adjust the Trigger Cable Tension 22. . . . . . . . .

Maintenance 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair or Replacement

Pressure Control 26. . . . . . . . . . . . . . . . . . . . . . .

Pressure Control Adjustment 27. . . . . . . . . . . .

Bearing Housing and Connecting Rod 28. . . . .

Drive Housing 29. . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Housing 30. . . . . . . . . . . . . . . . . . . . . . . . .

Clutch 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field & Wiring Harness 34. . . . . . . . . . . . . . . . . .

Clamp 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Housing Removal 35. . . . . . . . . . . . . . . .

Reassembly 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

Pressure Control Parts 39. . . . . . . . . . . . . . . . . .

Cart Parts 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Parts 42. . . . . . . . . . . . . . . . . . . . . . .

Gun Mounting Parts 44. . . . . . . . . . . . . . . . . . . .

Pinion Parts 45. . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Change Summary

This manual has been updated to add items 194 – 196 and change item 2 to 240–484 from 238–361.

3308-082

Page 4

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

equipment if you do not follow the instructions.

D Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 46 for the maximum working pressure of this equipment.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F).

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Wear hearing protection when operating this equipment.

D Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

4 308-082

Page 5

WARNING

INJECTION HAZARD

Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury.

Fluid injected into the skin may look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

Do not point the gun at anyone or at any part of the body.

Do not put your hand or fingers over the spray tip.

Do not stop or deflect leaks with your hand, body, glove or rag.

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard and the trigger guard on the gun when spraying.

Check the gun diffuser operation weekly. Refer to the gun manual.

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

Follow the Pressure Relief Procedure on page 7 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

Tighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do not

repair high pressure couplings; you must replace the entire hose.

Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

FUEL HAZARD

The fuel used in this unit is combustible and when spilled on a hot surface can ignite and cause a fire.

Do not fill the fuel tank while the engine is running or hot.

EXHAUST HAZARD

The exhaust contains poisonous carbon dioxide which is colorless and odorless.

Do not operate this equipment in a closed building.

5308-082

Page 6

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Disconnect all electrical equipment in the spray area.

Extinguish all open flames or pilot lights in the spray area.

Do not smoke in the spray area.

Do not turn on or off any light switch in the spray area while operating or if fumes are present.

Do not operate a gasoline engine in the spray area.

Ground the sprayer to a true earth ground with the ground wire and clamp (supplied).

Use only electrically conductive hoses.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the sprayer.

Before servicing the equipment, follow the Pressure Relief Procedure on page 7 to prevent the

equipment from starting unexpectedly.

FIRE AND

EXPLOSION HAZARD

Spray painting, flushing or cleaning equipment with flammable

liquids in confined areas can result in fire or explosion.

Use outdoors or in extremely well ventilated areas. Ground

equipment, hoses, containers and objects being sprayed.

Avoid all ignition sources such as static electricity from plastic

drop cloths, open flames such as pilot lights, hot objects such as

cigarettes, arcs from connecting or disconnecting power cords

or turning light switches on and off.

Failure to follow this warning can result in death or serious injury.

READ AND UNDERST AND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

SKIN INJECTION

HAZARD

Liquids can be injected into the body by high pressure airless

spray or leaks – especially hose leaks.

Keep body clear of the nozzle. Never stop leaks with any part of the

body . Drain all pressure before removing parts.Avoid accidental

triggering of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical Treatment”.

Failure to follow this warning can result in amputation or serious

injury .

6 308-082

Page 7

Setup

General Information

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

NOTE: Always use Genuine Graco Parts and Accessories, available from your Graco distributor.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below. Also read

the section FIRE OR EXPLOSION HAZ-

ARD on page 6.

1.

Sprayer:

contacts the ground while the unit is moving. See

page 42. For stationary spraying, connect a

ground wire and clamp (159) to a true earth

ground.

2.

Fluid hoses:

maximum of 500 ft. (150 m) combined hose

length to ensure grounding continuity.

3.

Spray gun:

a properly grounded fluid hose and sprayer.

4.

Object being sprayed:

5.

Fluid supply container:

6.

Solvent pails used when flushing:

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the

pail on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding continuity.

7.

To maintain grounding continuity when flushing or

relieving pressure

gun firmly to the side of a grounded

then trigger the gun.

make sure the grounding chain (106)

use only grounded hoses with a

obtain grounding through connection to

according to local code.

follow your local code.

follow your local

, hold a metal part of the spray

metal

pail,

Pressure Relief Procedure

WARNING

INJECTION HAZARD

Fluid under high pressure can be injected through the skin and cause seri-

ous injury. To reduce the risk of an injury

from injection, splashing fluid, or moving parts, follow the Pressure Relief Procedure whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tips.

1. Engage the spray gun safety latch.

2. Turn the ON/OFF switch to OFF.

3. Flip the pressure control switch to OFF.

4. Disengage the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail, and trigger the gun to relieve pressure.

5. Engage the gun safety latch.

6. Hold the pressure relief tube firmly to the side of a

grounded metal pail, and open the pressure relief

valve. Leave the valve open until you are ready to

spray again.

7. Disconnect the spark plug cable to prevent the

system from starting unexpectedly.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, very slowly

tip guard retaining nut or hose end coupling and relieve

pressure gradually, then loosen completely. Now clear

the tip or hose.

Valve shown in

CLOSED position.

Pressure

Valve shown

in OPEN position.

Hose

loosen the

159

Fig. 1

Fig. 2

Suction

Tube

Pressure

Relief Tube

06877

7308-082

Page 8

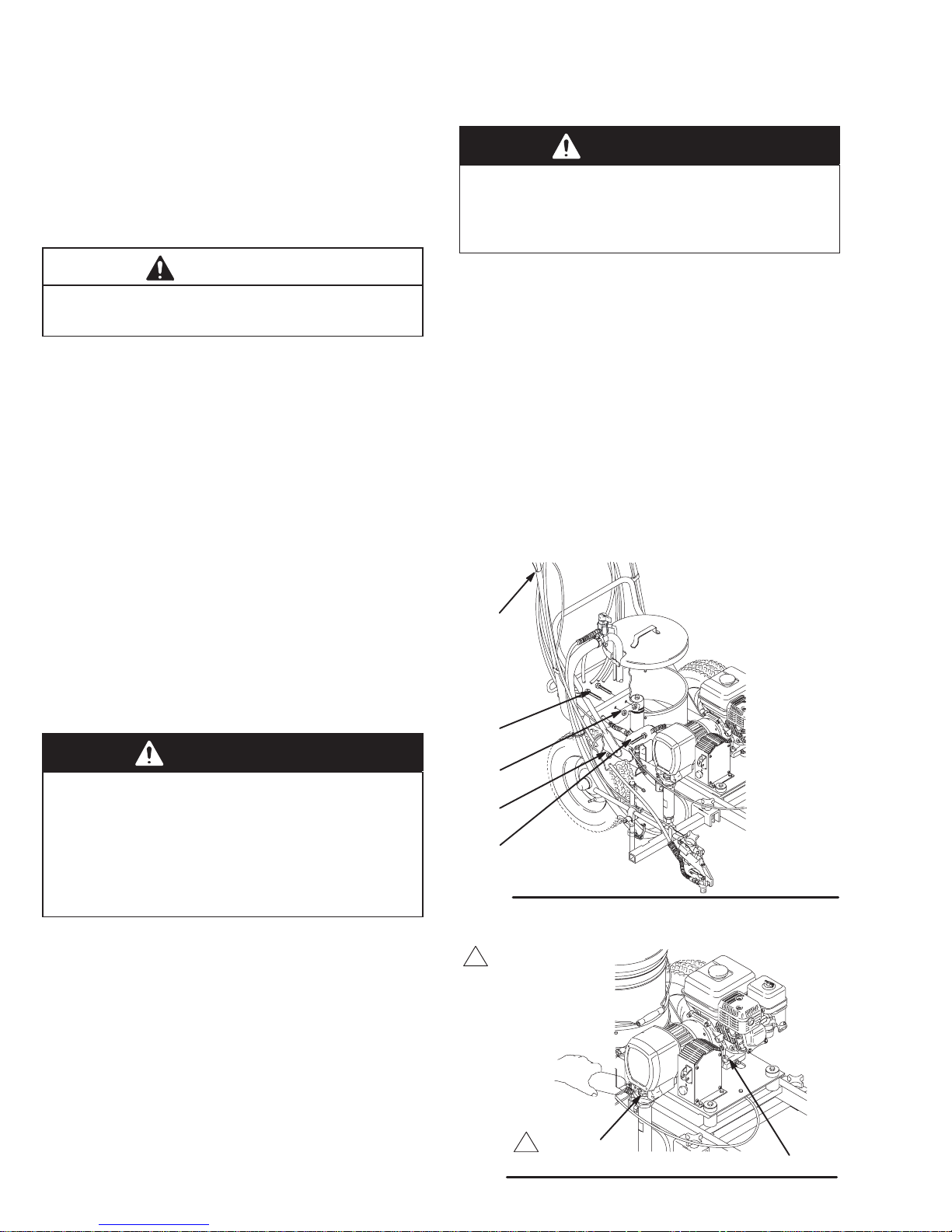

Setup

1. Read and follow the warnings on pages 4 and 6

before installing or operating this sprayer.

2. Unpack the LineLazer Carefully raise the handle (19)

to a vertical position. Four screws (39) and locknuts

(40) are packed in a bag. Install the two rear screws

(39A) and finger tighten the nuts (40A). Install one

screw (39B) and nut (40B) on each side of the handle. Firmly tighten all four nuts. See Fig. 3.

CAUTION

When raising the cart handle (19), be sure no cables

are caught on the frame or become kinked.

3. To install a second gun and hose, see page 11.

4. Fill the packing nut/wet–cup (216) 1/3 full with

Graco Throat Seal Liquid (TSL), supplied, and

keep it filled, to help extend the pump life. See

Fig. 4.

5. Check the engine oil level. Refer to the Honda

engine manual, supplied. This is a summary of the

information: Remove one of the oil fill plugs (A);

the oil should be almost overflowing. See Fig. 4.

Add oil as necessary. Also read the Maintenance

section on page 23.

7. Provide adequate ventilation when spraying indoors.

WARNING

If the LineLazer is used indoors, you must vent the

exhaust to the outdoors or provide adequate ventilation as specified by you local code. This is to

reduce the risk of carbon monoxide poisoning.

8. Fill the gas tank. See Fueling on page 10.

9. Flush the pump to remove the lightweight oil which

was left in the pump to protect it from rust. Follow the

Flushing on page 12.

10. Prepare the paint according to the manufacturer ’s

recommendations. Remove any skin that may have

formed. Stir the paint to mix pigments.

Strain the paint through a fine nylon mesh bag (available at most paint dealers) to remove particles that

could clog the filter or spray tip. This is an important

step toward trouble–free spraying.

Recommended engine oil: Use a high–quality , detergent oil, SAE 10W–40, classified “FOR SERVICE

SE or SF”.

6. Ground the sprayer. Proper grounding is essential to

maintaining an electrically safe system. Also read

and follow FIRE OR EXPLOSION HAZARD on page

6.

WARNING

Ground the sprayer whenever it is used indoors,

either as a moving line striper or as a stationary

sprayer. Floors in most factories are coated, which

causes them to be poor electrical conductors. This

increases the risk of hazardous static electric

discharge, which can result in serious injury, fire, or

explosion and property damage.

Whenever you flush: connect the ground clamp

(159) to a true earth ground.

Using as an outdoor striper: Be sure the static

chain attached to the bottom of the cart drags on the

ground to help dissipate static electricity . Ground the

sprayer to a true earth ground if specified by your

local electrical code.

Indoor spraying: Ground the sprayer whenever the

sprayer is used indoors. The ground wire supplied

with the sprayer is not long enough to allow much

operator movement. Therefore, the operator must

provide a longer ground wire or provide some other

method of effective electrical grounding as specified

by your local electrical code.

8 308-082

19

39A

40A

40B

39B

Fig. 3

Keep filled with TSL

Fig. 4

0007D

216

A

0008

Page 9

Setup

11. Observe the following cautions to avoid pressure

control damage.

CAUTION

To avoid damaging the pressure control, follow these

precautions.

Allow the main hose to act as a pulsation damp-

ener: Always use nylon spray hose at least 50 ft.

(15 m) long for the main gun; Never use a wire

braid hose; it is too rigid.

Never install a ball valve or shutoff device be-

tween the filter and the 50 ft. (15 m) hose.

Do not allow water or water-base material to

freeze in the pressure control.

CAUTION

Close the black fuel shutoff lever whenever you are

transporting the sprayer to prevent fuel from flooding

the engine.

12. To use the wheel brake, lift the brake handle (A–

bottom rear of cart) to engage the brake. Lower

the handle to disengage the break. See Fig. 5. For

positive break engagement, be sure there is

proper tire pressure and that tire wear is not

excessive.

13. For how to operate and adjust the various features

of the LineLazer see pages 11 – 22.

14. Start the sprayer. See page 13.

A

Keep the sprayer upright and level when operating it

and transporting it. This prevents crankcase oil from

leaking into the combustion chamber, which makes

startup very difficult.

Fig. 5

03586

9308-082

Page 10

Fueling

WARNING

Gasoline is extremely flammable and explosive

under certain conditions. To reduce the risk or a fire

or explosion:

1. Always shut off the engine before refueling.

NOTE: The HONDA engine warranty does not cover

damage resulting from the use of gasolines containing alcohol. See the HONDA engine manual for more information.

3. General. Do not use oil and gasoline mixtures or contaminated gasoline. Avoid getting dirt, dust or water

in the fuel tank.

2. Refuel in a well-ventilated area.

3. Do not smoke or allow flames or sparks in the

area where the engine is refueled or where

gasoline is stored.

4. Do not overfill the tank. Make sure the filler cap

is securely closed after refueling.

5. Fuel vapor or spilled fuel can ignite. If any fuel

is spilled during refueling, make sure the area

is dry before starting the engine.

1. Fuel specifications. Use automotive gasoline with

a pump octane number of 86 or higher. If the

engine knocks or pings, use a higher octane fuel.

Unleaded fuel minimizes combustion chamber

deposits.

2. Gasolines containing alcohol (gasohol). Do not use

gasohol which contains methanol, if the gasohol

does not contain cosolvents and corrosion inhibitors for methanol. Even if it does contain such

additives, do not use the gasohol if it contains

more than 5% methanol.

4. Tank capacity: 0.66 gallons (2.5 liter). Leave 1/2 in.

(13 mm) at the top of the tank for gas expansion.

5. Shut off the engine switch (A) before refueling.

6. After refueling, tighten the fuel tank cap (B) firmly.

B

Fig. 6

A

0009

10 308-082

Page 11

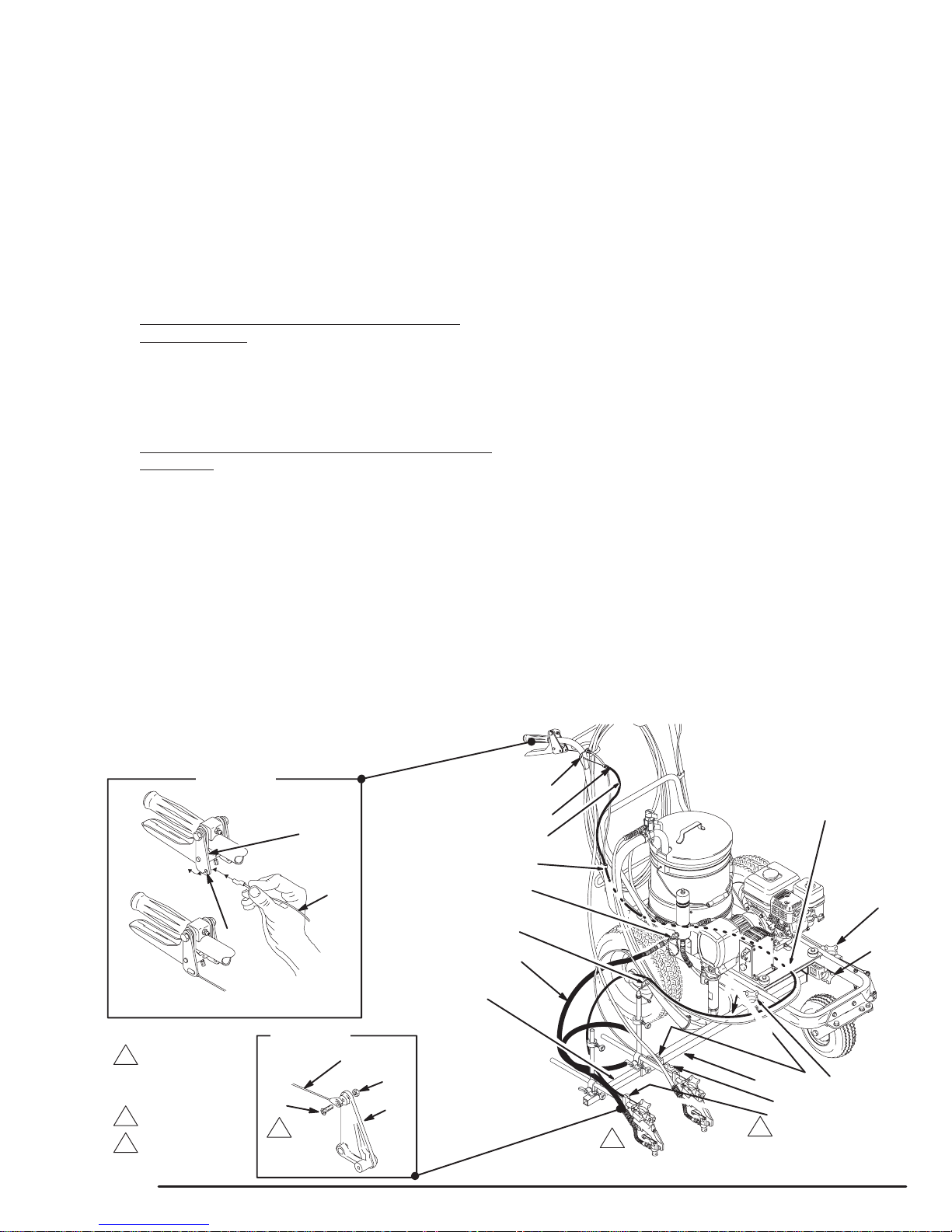

Second Gun and Hose Installation

NOTE: Fig. 7 represents the installation at Step 3.

NOTE: To switch the gun assemblies to the engine side

of the cart, refer to the instructions on page 17 before installing the second gun kit.

1. Disengage the trigger cable from the block (48) of

the unit’s existing gun. See page 21. Engage the

gun’s trigger safety latch.

2. Loosen the carriage clamps (B, C). Slide the

carriage bar (4) off the cart.

3. For mounting the second gun bar on the pump

side of the cart: Slide a clamp (405A) onto the

carriage bar (4). Slide the carriage bar through the

pump-side carriage clamp (B) and into the center

of the cart. Now slide another clamp (405B) onto

the carriage bar. See Fig. 7.

For mounting the second gun bar on the engine side

of the cart: Follow Step 3, except slide the carriage

bar through the engine-side carriage clamp (C) and

the into the center of the cart. The knobs of the

clamps (405A, 405B) must face back toward the

handle bars.

4. Slide the carriage bar (4) through to the opposite carriage clamp. Tighten the carriage clamps (B,C).

5. Slide the second gun bar (404) far enough into the

carriage bar that the clamp (405B) engages the bar.

Position the clamps (405A, 405B) over the notches

(A) in the carriage bar (4) and tighten the clamps.

6. Disconnect the trigger cable from the second gun at

the screw (34). See Fig. 7 DETAIL B.

7. Unscrew the filter’s second outlet cap (14). Screw

the short hose (403) onto the filter nipple.

8. Remove the guide clamp screw (27).

9. Snap the cable bushing (E) into the guide plate (D).

Route the trigger cable (402) parallel with the main

gun cable, separating the guide clamp (104) to feed

the cable through it. Install and tighten the clamp

screw (27). Route the cable through the cable guide

(7) and to the second gun.

10. Slide the hooked end of the cable (402) through the

hole (F) in the lever plate (122). Rotate and slide the

hook back until it engages the plate. See DET AIL A.

11. Reconnect the trigger cable to the second gun at

screw (34). Torque the screw to 15 in–lb (1.7 N.m),

back it off 1/16 to 1/8 turn and then tighten the jam

nut (99) while holding the screw (34). Be sure the

plate (94) moves freely.

12. Install the clip (401) to hold the cable onto the frame.

13. Connect both trigger cables to the blocks (48). Then

adjust the cable tension. See pages 20 and 22.

14. Do not install the spray tip until the system is primed.

15. Adjust simultaneous gun triggering. See page 18.

NOTE: For stable gun operation, the second

gun bar (404) has a maximum recommended

extension from the carriage bar of about

11-1/4” (286 mm).

DETAIL A

HOW TO INSTALL CABLE

122

F

CORRECTL Y INSTALLED CABLE

T orque to 15 in–lb

(1.7 N.m)

and then back up

1/16 to 1/8 turn

First gun

Second gun

DETAIL B

34

Fig. 7

402

402

99

94

404

403

402

401

14

7

D

E

27,104

C

405B

4

A

B

405A

48

02490C

11308-082

Page 12

Flushing

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

Be sure the pump is properly grounded.

CAUTION

Never leave water in the sprayer if the is any chance

it could freeze. Push the water out with compatible

solvent. Water frozen in the pressure control tube

prevents the sprayer from being started, and causes

serious damage to the pressure control.

When to Flush

1. Flush a new sprayer to remove the protective oil.

Before using water–base paint, use compatible sol-

vent, then soapy water, and then clean water.

Before using oil–base paint, use compatible solvent.

WARNING

To reduce the risk of static sparking and splashing

when flushing, always remove the spray tip from

the gun, and hold a metal part of the gun firmly to

the side of, and aimed into, a grounded metal pail.

6. Follow Startup on page 13. Keep the gun triggered

until clean water or solvent comes from the nozzle.

See Fig. 9. Release the trigger and engage the gun

safety latch.

NOTE: If you have two guns, release the trigger safety

latch on the second gun and trigger that gun until clean

water or solvent comes from the nozzle. To ensure that

the hoses are well-flushed, flush the first gun and then the

second gun at least one more time.

7. Check all fluid connections for leaks. Relieve pressure before tightening any connections. Start the

sprayer. Recheck the connections for leaks.

8. Remove the suction tube from the solvent pail. Disengage the gun safety latch. T rigger the gun to force

water or solvent from the hose. Do not let the pump

run dry for more than 30 seconds to avoid damaging

the pump packings! Relieve pressure.

2. Changing colors. Use a compatible solvent.

3. Changing from water–base to oil–base paint. Use

warm, soapy water, and then a compatible solvent.

4. Changing from oil–base to water–base paint. Use a

compatible solvent, then warm, soapy water, and

then clean water.

5. Storage. After the compatible solvent flush, relieve

pressure, but do not drain the compatible solvent.

6. Startup after storage.

Before using water–base paint, flush out the compatible solvent with soapy water, and then with clean

water.

When using oil–based paint, flush out the compatible

solvent with the paint to be sprayed.

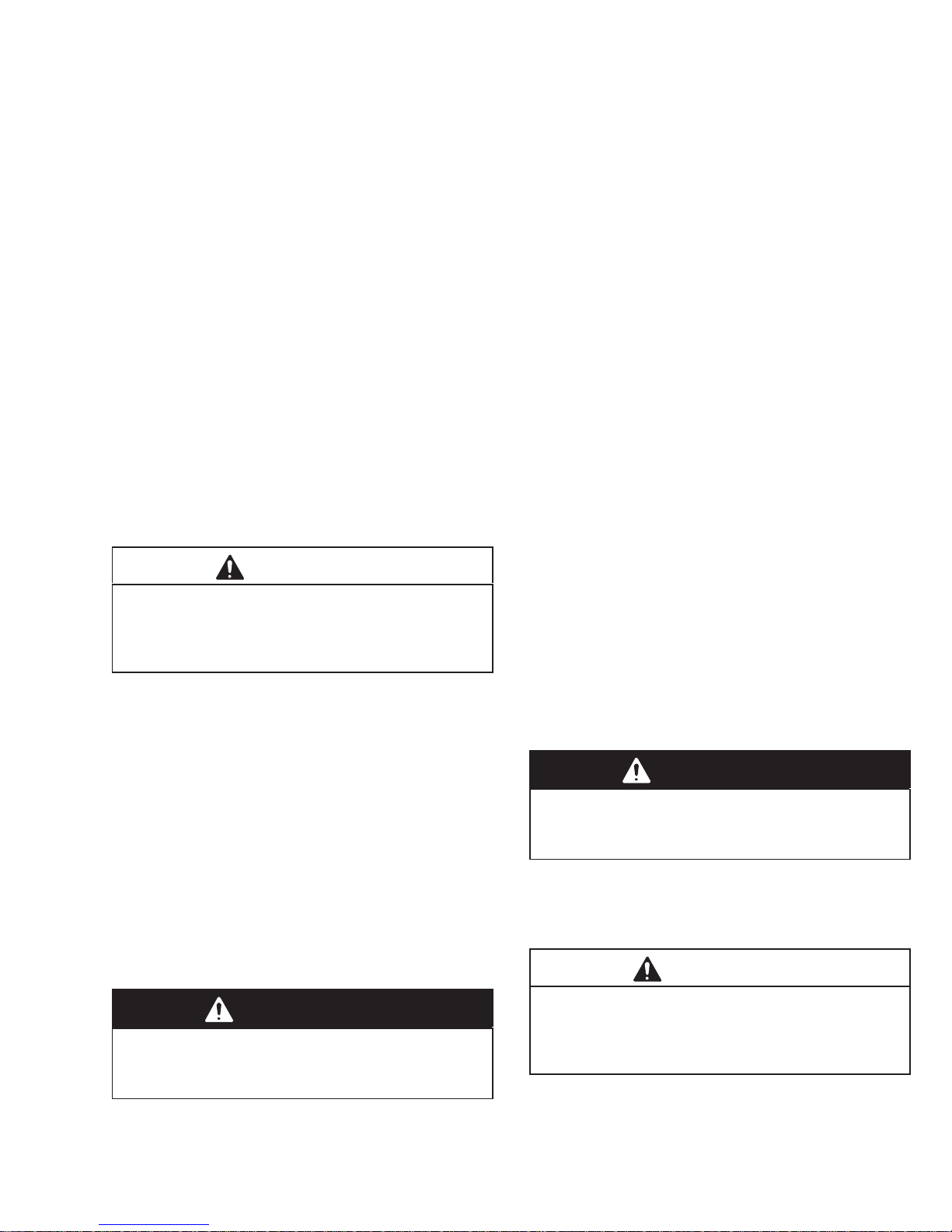

How to Flush

1. Relieve pressure.

2. Remove the filter bowl (A) and screen (B); see manual 307–273. Install the bowl and support (C), without

the screen, to flush it. Clean the screen separately.

See Fig. 8.

3. Close the pressure drain valve (13).

4. Put the suction tube in a grounded pail of water or

solvent.

13

A

B

C

Fig. 8

Maintain firm metal-

to-metal contact

when flushing to

reduce the chance

of static sparking

and splashing.

Fig. 9

9. If you have been spraying paint, remove the strainer,

suction tube and suction hose and clean them separately to be sure all paint sediment is removed. Dried

paint in the suction tube assembly can build up and

cause performance problems later on.

10. Install the clean filter screen. Install the filter bowl and

hand tighten.

0013

0014

5. Remove the gun(s) from the holder. Remove the

spray tip(s) to prevent splashing.

12 308-082

11. See Storage or Changing Colors, above. Relieve

pressure.

Page 13

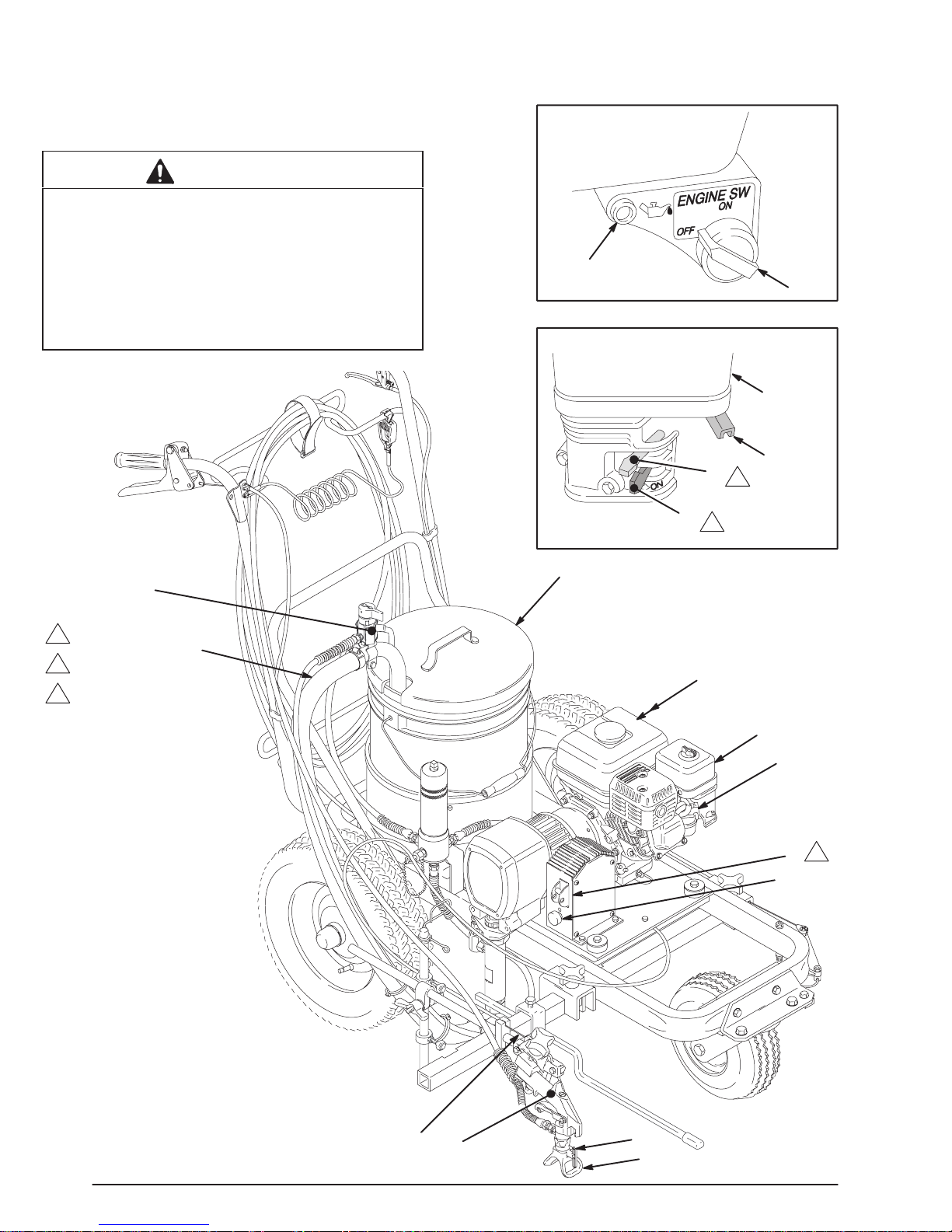

Startup

Before You Start the Linestriper

1. See Flushing, page 12, to determine if the Line Lazer

should be flushed.

2. Be sure the gas tank is full.

3. Check the engine oil level.

NOTE: The engine stops automatically, or will not start,

if it is low on oil. If you try to start it again without adding

more oil, a red light (A) near the engine on/off switch

glows as you pull the starter rope.

4. Be sure the spark plug cable (J) is firmly pushed onto

the spark plug.

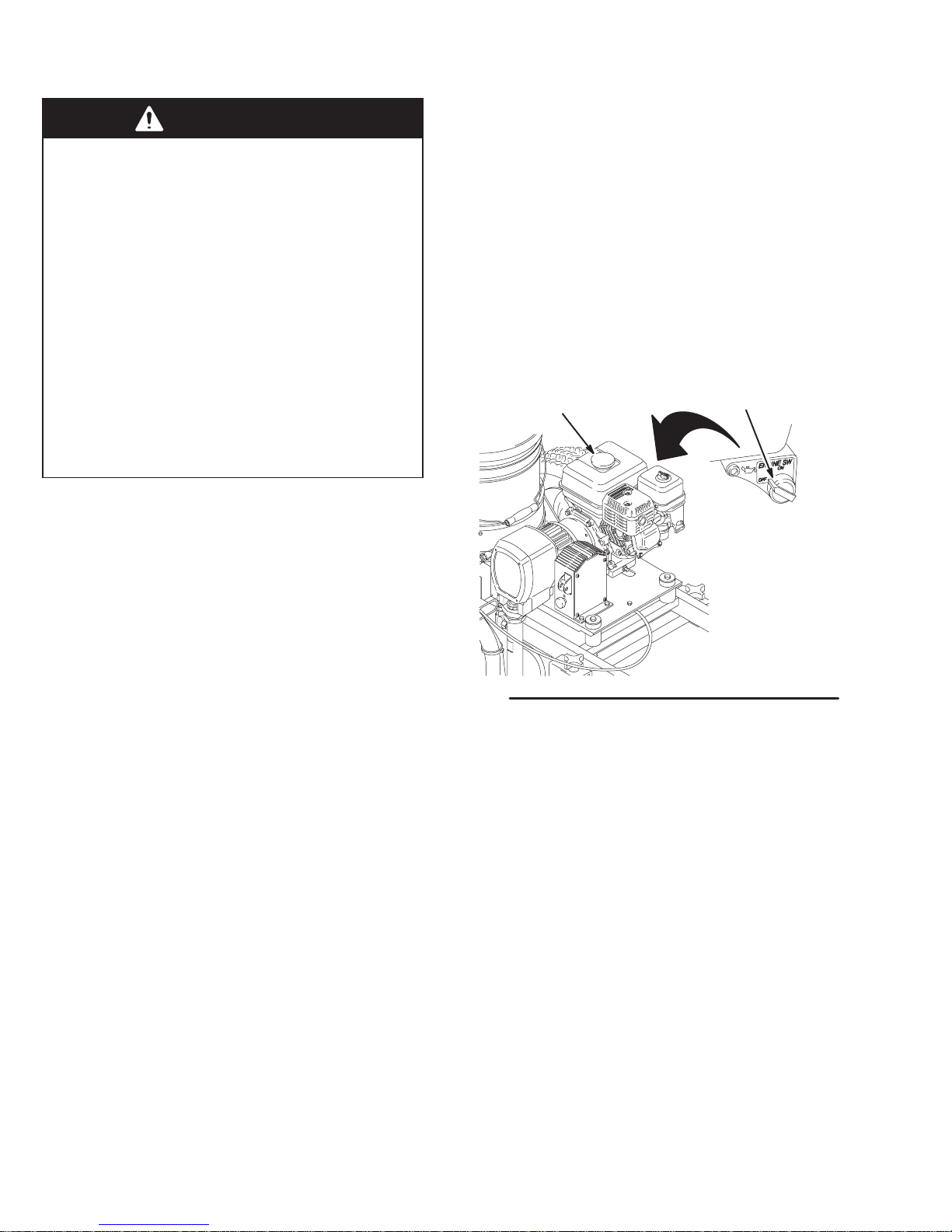

Startup See Fig. 10

1. When starting a sprayer that IS NOT PRIMED, remove the spray tip.

2. Place the suction tube (S) into the paint, water or solvent container, depending on whether you are flushing or are ready to spray.

3. Open the black fuel shutoff lever (E) by pushing it in

the direction of the arrow.

CAUTION

Never start the engine unless fluid pressure is relieved and the pressure control switch is turned OFF.

Attempting to start the engine when it is pressurized

could damage the electrical system.

4. Turn OFF the pressure control switch (K).

5. To start the engine:

g. Open the choke as soon as the engine starts,

except in cold weather. In cold weather, leave

the choke closed for 10 to 30 seconds before

opening it to keep the engine running.

6. Release the trigger cable and engage the gun trigger

safety latch. See page 21.

7. Remove the gun from the holder by unscrewing the

gun holder knob and lifting out the gun.

8. To start the pump:

NOTE: Lower the throttle setting for easier priming.

a. Open the pressure drain valve (R).

b. Turn ON the pressure control switch (K).

c. Turn the pressure control knob (L) about 1/4

turn from minimum pressure. Run the pump

until fluid is flowing smoothly from the pressure

drain valve, indicating the pump is fully primed.

d. Close the pressure drain valve (R).

e. Disengage the gun safety latch. Hold a metal

part of the gun firmly against a grounded metal

pail, squeeze the trigger until fluid flows from

the gun.

f. Release the trigger. Engage the safety latch.

NOTE: If you are using two guns, follow Step e and f,

above, for the second gun.

9. If you have not primed the sprayer with paint yet,

move the suction tube (S) to the paint container. Release the trigger safety latch. Trigger the gun into the

water/solvent pail just until paint appears. Release

the trigger and engage the trigger safety latch. Repeat for the second gun, if two guns are used.

10. Place the pail cover (F) on the pail.

a. Turn the pressure adjusting knob (L) all the

way counterclockwise to the lowest pressure

setting.

b. Slide the metal throttle lever (C) away from the

fuel tank to the maximum position (fully left).

c. If the engine is cold, close the choke by mov-

ing the gray lever (D).

d. If the engine is warm, close the choke by

moving the gray lever (D) only half way or not

at all.

e. Turn ON the engine switch (B).

WARNING

A rope that recoils too quickly may hit someone

and cause serious bodily injury. The rope could

also jam in the recoil assembly.

f. Hold the frame of the sprayer with one hand

and pull the starter rope (G) rapidly and firmly.

Continue holding the rope as you let it return.

Pull and return the rope until the engine starts.

WARNING

To reduce the risk or serious injury from fluid

injection, never operate the spray gun with the tip

guard removed.

11. Install the tip guard and spray tip (M). See page 15.

12. Mount the gun in the gun holder. See page 20.

13. Engage the trigger cable. See page 21.

CAUTION

Always use the lowest fluid pressure and the lowest

throttle setting needed. Higher settings cause excessive clutch cycling, premature tip wear and premature pump wear.

14. Adjust the engine speed and pump pressure. Trigger

the gun onto a test paper to check the spray pattern

and atomization. Turn the pressure adjusting knob

(L) until you get a good pattern. Then slowly lower the

throttle setting (C) as far as you can without changing

the spray pattern.

13308-082

Page 14

Startup

15. Read Spray Techniques on page 16.

CAUTION

Close the black fuel shutoff lever (E) whenever you

are transporting the sprayer to prevent fuel from

flooding the engine.

Keep the sprayer upright and level when operating it

and when transporting it. This prevents crankcase oil

from leaking into the combustion chamber, which

makes start up very difficult.

A

B

––AT REAR OF ENGINE––

H

R

Shown in

choked position

Shown off

Shown in

off position

KEY

A Engine Oil Light

B Engine On/Off Switch

C Throttle Lever

D Gray Choke Lever

E Black Fuel Shutoff Lever

F Pail Cover

G Starter Rope

H Air Cleaner

J Spark Plug Cable

K Pressure Control On/Off Switch

L Pressure Adjusting Knob

M SwitchT ip

N Rac IV Tip Guard

P Gun Trigger Safety Latch

Q Remote Trigger Cable

R Pressure Drain Valve

S Suction Tube

S

Fig. 10

14 308-082

D

E

F

G

H

J

C

K

L

Q

P

M

N

0001F

0001F

Page 15

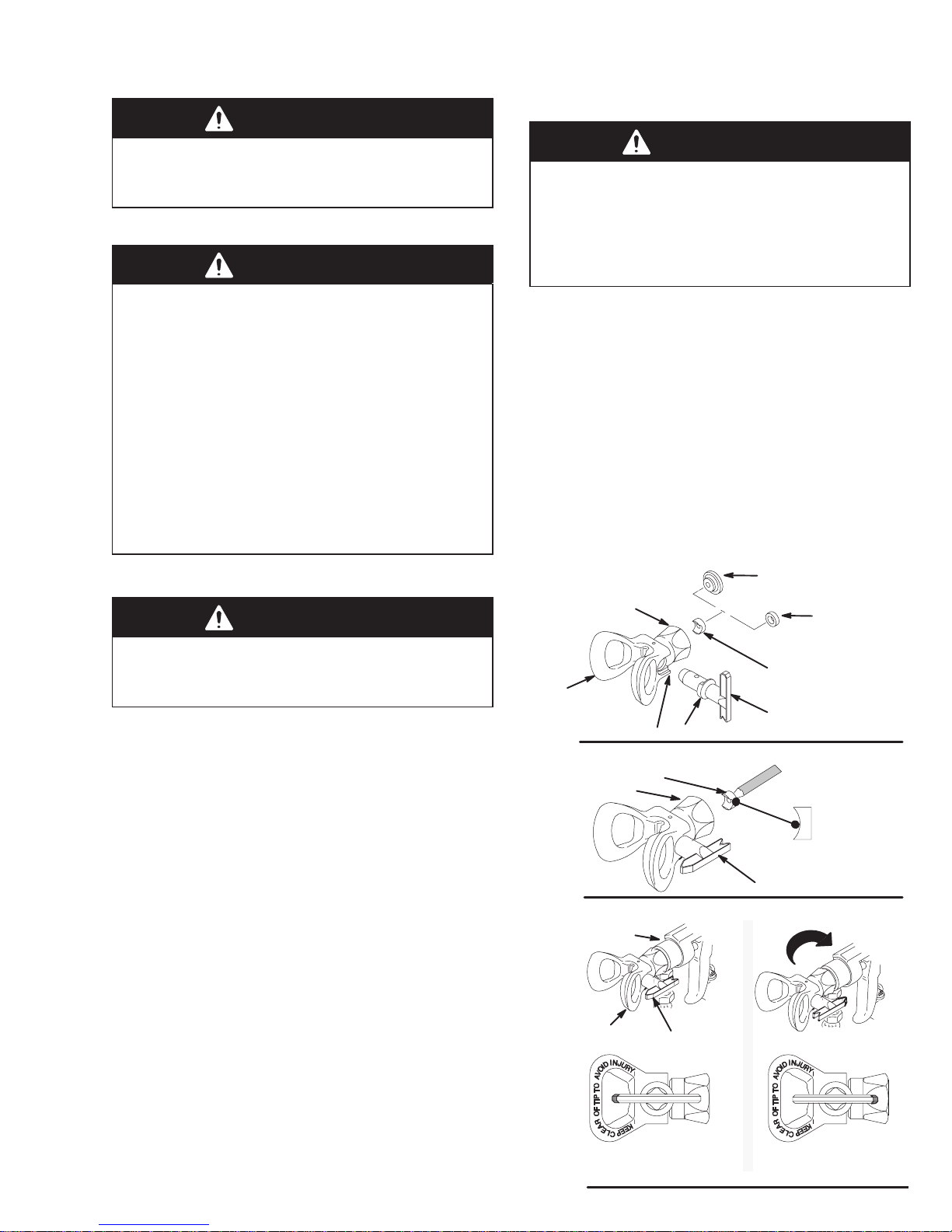

Spray Tip and Tip Guard

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

WARNING

Operation

WARNING

Keep clear of the nozzle! High pressure fluid from

leaks or spray can penetrate the skin and cause

extremely serious injury, including the need for

amputation. The spray tip guard provides extra

protection against injection, but does not prevent it!

Never cut off the spray tip guard.

Failure to install or use the RAC IV tip guard assembly correctly may result in an undirected spray

of paint into the eyes or on the skin of the operator.

Be sure you:

Use the appropriate gasket for the solvent used.

Fully insert the tip into the guard.

Fully tighten the guard onto the gun nozzle

using a wrench.

Turn the handle so it is parallel to the gun

nozzle.

When replacing a worn spray tip, always install

a new gasket and seat.

Gasket Selection

WARNING

To reduce the risk of fluid splashback into the eyes

or on the skin, use the appropriate gasket as

specified in the following text.

Use the black rubber gasket (D) ONLY with latex and

oil-based paints, stoddard solvents, mineral spirits, turpentine and water . When using this gasket, the spray tip

can be removed and replaced without using tools.

Use the red or yellow plastic gasket (C) with the same

fluids as above and with most other solvents, including

lacquer thinner, trichloroethylene, MEK, acetone, brush

cleaner, xylol. When using this gasket, loosen the RAC

IV retaining nut to remove the spray tip.

Installation

Relieve pressure. Install a tip (F) so the flange (G) on the

cylinder fits into the slots (H) at the base of the spray tip

guard (J). See Fig. 11.

Be sure the spray tip handle is in the FULL SPRA Y position before operating the gun. See Fig. 11.

Clearing a Clogged Spray Tip

Disengage the trigger cable(s). Engage the gun safety

latch. Turn the arrow handle to the FULL CLEAN position. See Fig. 13. Release the safety latch and trigger the

gun. Fluid pressure should force out the clog. Return the

arrow handle to the full spray position.

clogged

page 7 and remove the spray tip for cleaning.

, follow the Pressure Relief Procedure on

If it is still

Maintenance

Change the seat and gasket when the spray tip wears

out; these parts wear at about the same rate.

C

RED or YELLOW

J

Fig. 11

Fig. 12

GUN NOZZLE

A

E

F

G

H

E

A

F

D

BLACK

0091

0092

Place the seat (E) on a pencil, curved side out, as shown

in Fig. 12. Guide the seat into the retaining nut (A) and

turn the seat until it straddles the cylinder of the spray tip

(F). Drop in the appropriate gasket and press it down. If

using the red or yellow gasket (C), be sure the flat side

faces out of the retainer (A). See Fig. 11.

Screw the spray tip guard snugly onto the gun, holding

it in the desired position while tightening retaining nut (A).

NEVER use a wrench to turn the plastic tip guard (J), to

avoid damaging the guard.

RAC IV

DripLess

TIP GUARD

Fig. 13

TIP

HANDLE

FULL CLEAN POSITIONFULL SPRAY POSITION

0093

15308-082

Page 16

Spray Tip Selection

Spray Tip Application Recommendations

Lineal Feet/Minute

(rate at which unit is moved)

Based on 4” wide line and 15 mils of paint

Application 120 144 184 220 264 308 352 400

Parking Lot Lines

4” wide 217 LLT–317*{ 221* 223 224

6” wide 317 317* 321* 323 325

Long Lines,

4–6” wide 221* 223 225 227 228 231

Curbs 417* 419*

*

Tips can be used with two guns.

Fig. 14

{

Supplied with the Line Lazer.

Spray Techniques

These spray techniques discuss how to use and adjust

the features of the Line Lazer. Y ou must also consider operator technique, job site conditions and weather.

1. Use water rather than paint to practice spraying technique and positioning the guns.

2. Be sure the RAC IV Tip Guard is always parallel to

the ground and the “wings” of the spray tip guard face

the front and back of the unit, as shown in Fig. 15.

8. The spray tip size and the rate at which you move the

unit affect the coating thickness. Generally , the faster you move the unit, the larger the spray tip orifice

should be. The fan width of the spray tip indicates approximately how wide the line will be. See the chart

in Fig. 14 for spray tip application recommendations.

9. Position the guns to suit your requirements. See the

section below and pages 17 to 19.

Other Applications

Sport Court,

2” wide line LLT–213

Crosswalk,

12” wide line, 1 gun 621,

623, 625

Airport,

24” wide line, two guns 721

Stencils 417*, 419*

General Stationary

Painting 517

{

WARNING

To reduce the risk of a fluid injection injury, always

disengage the remote trigger cable to the gun(s)

and engage the gun trigger safety latch(es) before

moving or adjusting the spray tip guards, guns, or

gun arms. See Page 21.

3. Use the lowest pressure necessary for good atomization. High pressure may cause excessive paint

buildup and overspray.

4. Start moving the Line Lazer before triggering the gun

to prevent a build up of paint at the beginning of the

line. Release the trigger a second before stopping

the Line Lazer. Move at an even rate of speed.

5. Always check your gun adjustments on cardboard or

paper before starting each job. When painting curbs,

paint first in an area that is less frequently seen.

6. Keep in mind that many factors affect the straightness of a line, including uneven surfaces, potholes,

rocks and other debris and a clogged or worn spray

tip. See page 15 for how to clear or change a spray

tip.

7. To minimize the ef fect of bumps on the spray pattern,

keep the spray tip guard centered with the front

wheel axis.

16 308-082

10. Traffic paints may be formulated for air spray , airless

spray or have no formulation description.Generally,

air spray formulas are pre–thinned, and will work well

in the Line Lazer, but there may be more overspray.

Non–air spray formulas tend to deliver more lineal

feet of line per gallon with less overspray, since they

are less easily absorbed into the pavement.

1 1. If you use fast–draying traffic paint on a hot day , float

compatible solvent on top of the paint to prevent skin

from forming on it.

Line Width Adjustment

Several factors affect line width: vertical distance of the

spray tip to the spraying surface, spray tip fan pattern, using one or two guns, paint pressure, and a worn or

clogged spray tip.

The typical conditions for a 4 in. wide line are: 317 size

Line Lazer Tip (supplied), the gun positioned one inch

from the lowest vertical position, and just enough pressure to atomize the paint. Depending on the fan pattern

of the spray tip, use one gun to paint 2 to 12 in. wide lines,

and two guns to paint 12 to 24 in. wide lines.

T o decrease line width, lower the gun (if possible) or use

a tip with a narrower fan pattern.

To increase line width, raise the gun, or use a tip with a

wider fan pattern, or use two guns.

Page 17

Positioning the Gun Arm Assembly

PUMP SIDE

1

402

First gun

Second gun

F

Fig. 15

The gun arms can be positioned for a variety of spraying

needs. The drawings on page 19 primarily show the guns

mounted on the pump side of the Linestriper. However,

one or both guns may be mounted on the engine side.

“WINGS” OF TIP GUARD

Whenever You Move the Guns

ENGINE SIDE

D

405B

0012E

B

4

405A

93

404

E

B

A

DETAIL A

D

Horizontal Position of the First Gun

Method 1: Disengage the trigger cable. Loosen the carriage clamps (B,D) and slide the carriage bar (4) left or

right, so the gun will be outside the tire path. Tighten the

clamps. Engage the trigger cable.

CAUTION

Do not kink the cables, which could prevent them

from properly triggering the guns.

Disengage the trigger cables and engage the gun trigger

safety latch first. See page 21. Do not kink the trigger

cables. Pull out more of the 50 ft. hose, if necessary.

After moving the guns, reposition the spray tip guard so

it is parallel to the ground and its “wings” face the front

and back of the unit. Disengage the gun trigger safety

latch and engage the trigger cable.

V ertical Position of the First or Second Gun

Loosen the arm clamp (6) and move the gun up or down.

Tighten the clamp. Engage the trigger cable.

NOTE: See Fig. 15. Two collars (F) are located above

and below each gun. The collars can be adjusted to provide stops for preset spray width positions for each gun.

Method 2: Disengage the trigger cable. Loosen the arm

clamp (6) and rotate the gun out to the side. Tighten the

bolt. Engage the trigger cable.

NOTE: Use methods 1 and 2 together to obtain the maximum distance of one gun from the unit, which is helpful

when spraying around obstacles.

Horizontal Position of the Second Gun

Method 1: Disengage the trigger cable. Loosen the

clamps (405A, 405B). Slide the second gun bar (404)

horizontally, being sure both clamps engage the second

gun bar. Tighten the clamps. Engage the trigger cable.

Method 2: Disengage the trigger cable. Loosen the arm

clamp (6) and rotate the gun out to the side. Tighten the

bolt. Engage the trigger cable.

NOTE: Use methods 1 and 2 together to obtain the maximum distance of 33–1/2 in. (851 mm) between the center

of two guns.

17308-082

Page 18

Positioning the Gun Arm Assembly

Mount Guns on the Engine Side of the Cart

1. See Fig. 15. For both guns, disengage the trigger

cable and engage the trigger safety latch. See page

22.

2. Loosen the gun holder knobs (93) and remove the

gun. Lay the guns out of the way.

3. Remove the knobs (E) on both carriage clamps

(B,D); the carriage bar (4) and extension clamps (A)

will drop down.

4. Lift the front tire and rotate the carriage bar 180 under the cart and to the other side of it.

5. Position the carriage bar below the carriage clamps

(B,D). Align the holes in the top of the extension

clamps (A) with the holes in the carriage bar clamps

and install the knobs (E).

6. Loosen the post/arm clamps (6) and rotate the guns

forward. Retighten the clamps.

7. Install the guns. Note which gun and position on the

dual gun selector each of the cables (1 and 402)

goes. Route the hoses and cables to prevent kinking.

Position the spray tip guards. Disengage the gun trigger safety latches. Engage the trigger cables.

Setup for Spraying Arcs

1. See Fig. 16. Disengage the trigger cable (1) and engage the gun trigger safety latch. See page 21.

2. Loosen the arm clamp (6) and rotate the arm (A)

back near the rear tire and then position the arm so

the spray tip guard aligns with the back axle of the

unit. Retighten the clamp.

3. Extend the carriage bar (4) or second gun bar (404)

so you can easily watch the line you are painting and

also to avoid running over the paint line. See

page 17.

4. Adjust the vertical and horizontal position of the gun.

5. Spray the arc from the outside.

A

6

1

4

Fig. 16

Adjust Simultaneous Gun Triggering

WARNING

To reduce the risk of a fluid injection injury, always

disengage the trigger cable to the gun (s) and

engage the guns’ trigger safety latch before moving

or adjusting the guns or gun arms.

1. Align the front of the guns by adjusting the gun arms.

See page 17.

18 308-082

0002D

2. Position the dual gun selector to trigger both guns.

See page 21.

3. Start the sprayer, using water, or spray on cardboard. See page 13. Trigger the guns to see if the

lines begin at the same time and place.

If one gun triggers before the other gun, reduce the

cable tension of the gun that triggers first. See Ad-

just the trigger cable tension on page 22

If one line starts in front of the other, adjust the position of the guns. See page 17.

Trigger the guns to recheck the adjustments.

.

Page 19

Gun Arm Positions

ONE GUN CURBSINGLE LINE

DOUBLE LINE OR SINGLE LINE UP TO 24” WIDE TWO GUN CURB

SINGLE OR DOUBLE LINE; SPRA YING AROUND OBSTACLES

DOUBLE LINE OR SINGLE LINE UP TO 24”

0017A

WIDE

19308-082

Page 20

Caster Lever and Cable Operation

CAUTION

The AccuTrack caster is factory-adjusted to track

in a straight line. It should not require adjustment

unless it is replaced. If a line is tracking poorly, check

for the following items before aligning the caster.

1. Even back tire pressure.

2. Even tension on the rear tire bearings (adjust

nuts (10) as needed.) See page 40.

3. Even tightness of the caster screws (F). See

Fig. 18.

4. Uneven painting surface.

5. Operator technique.

Operation

Maintenance See Fig. 18

Paint builds up on the caster triggering mechanism. To

keep it operating properly , use a grease gun at the grease

zerks (32A, 32B) to flush out the buildup – two to four

times a month, depending on use.

Caster Tire Replacement See Fig. 18.

Remove the setscrews (F) from the caster fork (E). Remove screw (G) and the tire (114a). Install the new tire

and the setscrews (F). Tighten the setscrews equally so

the tire has no play in it, but turns freely.

Caster Cable T ension Adjustment See Fig. 18.

1. Loosen the nut (A) located just outside the carriage

clamp (B).

2. With the pin (D) fully engaged in the caster fork (E),

pull back on the cable (2) to increase the cable tension, or push it forward to reduce the tension. Finger

tighten the nut (H). Tighten the nut (A) firmly.

The normal operating mode of the AccuTrack caster is

locked in the straight forward position.

1. For a free moving caster: Squeeze and hold the caster lever (22).

2. To lock the caster in the free moving position,

squeeze the trigger, push in and hold the the button

(A) and release the trigger. See Fig. 17.

3. To return to the normal mode, squeeze and release

the caster lever and move the Line Lazer forward to

lock the caster in the straight position.

22

A

Fig. 17

0018

Shown removed only

for visual purposes

Tighten equally so tire

has no play in it but

turns freely

Fig. 18

A

2

32A

114a

G

H

B

D

87

32B

D

E

F

0019

Caster Alignment

Do this adjustment only if the caster or tire is replaced,

or if no other solutions to poor tracking are found.

1. Loosen the two capscrews (87), grasp the tire and

visually align it. Tighten the capscrews evenly . Move

the unit forward. If the caster appears straight, start

the unit (use water) and spray along a true straight

line. Continue adjusting as necessary. See Fig. 18.

How To Mount the Gun

1. Relieve pressure. See page 7.

2. Disengage the trigger cable. See page 21. Engage

the gun’s trigger safety latch (B).

3. Loosen the gun holder knob (93).

4. Position the gun so the gun trigger is resting on the

remote trigger lever (A).

5. Be sure that the gun is mounted straight and then

tighten the knob (93) firmly.

6. Disengage the gun safety latch. Engage the remote

trigger cable. See page 21.

20 308-082

Fig. 19

95

93

B

A

0020B

Page 21

Gun Cable & Dual Gun Selector Operation

Shown in

three positions

A

B

118d

1 or 402

Fig. 20

C

0021

How the Dual Gun Selector Works See Fig. 20.

The gun is remotely triggered with the dual gun selector

on the right handlebar . The gun is mounted in the holder

so its trigger rests on a trigger lever which is connected

to the dual gun selector by a trigger cable.

The main gun cable is black. In a two–gun operation, the

second gun cable (402) is black with a light red cover at

each end. Use the color coding to determine how each

trigger cable is routed to the dual gun selector.

How to Release the Dual Gun Selector

Cable

WARNING

The gun is remotely triggered with a dual gun

selector on the handle bar.

To reduce the risk of an injection injury due to

remotely triggering the gun by accident, always

disengage the trigger cable from the block before

handling the gun. See Fig. 21 DETAIL A. The gun

will trigger briefly when releasing the cable!

Before you remove the gun from the holder, engage the gun’s trigger safety latch.

1. To disengage the cable, grasp the cable (1or 402)

just behind the block (48). Pull the cable back about

1/2 inch (13 mm) and then up and out of the block.

The gun will trigger briefly! See Fig. 21.

2. To engage the cable, slide the cable (1) into the block

(48), making sure the end of the cable jacket seats

firmly in the seat of the block. The gun will trigger

briefly! See Fig. 21.

CAUTION

Always note to which gun and position on the dual

gun selector (C) each of the cables goes so that the

correct gun is triggered.

T o trigger the main gun only, move the selector (C) left until the spool (118d) protrudes through the plate (B) and

disengages from the other plate (A).

To trigger the optional second gun only, move the selector (C) right until the spool protrudes through the plate (A)

and disengages from the other plate (B).

To trigger both guns, center the selector (C).

CAUTION

Keep the seat in the gun cable block (48) and the

end of the cable jacket clean at all times to be sure

the cable functions properly.

CAUTION

A loose cable prevents the gun from being fully

triggered causing premature wear of the gun needle.

A tight cable prevents the full trigger release of the

gun resulting in dripping and premature tip wear.

Follow Trigger cable tension adjustment on page

22.

21308-082

Page 22

Trigger Cable & Dual Gun

Selector Operation

Trigger Cable Tension Adjustment See Fig. 21

1. Relieve pressure. See page 7.

2. Be sure the gun is properly mounted in the holder as

instructed on page 20.

3. Pull the actuator lever (94) forward and hold it. Lift up

on the gun trigger (A) until there is slight resistance.

Visually check to see if there is about 1/32 to 1/16 in.

gap between the trigger lever (B) and where the gun

trigger touches the bar.

4. To adjust the tension, loosen the screw (C) in the

block (48). Slide the block forward to increase the

gap and backward to decrease the gap. Tighten the

screw.

5. Recheck the gap and adjust as needed.

CAUTION

Do not allow the cable (402) to rub against the

outside edges of the slot (H) in the block (48), to

prevent premature wear of the cable. Rotate the

block slightly to eliminate rubbing. See Fig. 21

DETAIL A.

FORWARD

DETAIL A

48

Fig. 21

1 or 402

94

A

48

C

45

45

1/32 – 1/16”

(1–2 mm)

0023

0024

B

Be sure end jacket of cable

seats here. keep jacket and

seat clean

1 or 402

22 308-082

Page 23

WARNING

Maintenance

After the first 20 hours of operation and each 100

hours thereafter: Change the oil.

To reduce the risk of serious injury always follow

the Pressure Relief Procedure on page 7,

before checking, adjusting, cleaning, or shutting

down the LineLazer.

CAUTION

For detailed engine maintenance and specifications,

refer to the separate HONDA engine manual.

Daily: Check the engine oil level and fill as necessary.

Daily: Check and fill the gas tank.

1

Weekly: Remove the air filter cover and clean the element. In very dusty environments, check the filter daily.

Replace the element as needed. Replacement elements

can be purchased from your local HONDA dealer.

Weekly: Check the level of the TSL in the displacement pump packing nut. Fill the nut, if necessary. Keep

TSL in the nut to help lubricate the pump packings. See

page 8.

Weekly: Use a grease gun to grease the zerks (32) on

this unit. The grease purges pivot areas of paint buildup.

See Fig. 22.

Spark plug: Use only a (NGK) BP6ES or BPR6ES

plug. Gap the plug to 0.025 to 0.030 in. (0.7 to 0.8 mm).

Always use a spark plug wrench.

One zerk on dual gun selector

1

2

One zerk on each gun holder

3

One zerk on caster lever

4

One zerk on caster latch

One zerk on wheel

5

Fig. 22

3

4

2

5

23308-082

Page 24

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

Check everything in the chart before disassembling the sprayer.

PROBLEM CAUSE SOLUTION

Engine/sprayer won’t start Engine switch not on Turn on engine switch.

Out of gas Refill gas tank.

Engine oil level low Try starting engine. If light on rear of engine

Spark plug cable disconnected or

spark plug damaged

Water frozen in pressure control Return pressure control to authorized Graco

Engine won’t “fire” Oil seepage into combustion

Engine operates, but displacement

pump doesn’t

chamber

Pressure control switch turned OFF Turn on pressure control switch.

Pressure setting too low Increase pressure.

Displacement pump outlet filter dirty Clean filter.

Tip or tip filter clogged Clean tip or tip filter.

Displacement pump rod seized by

dry paint

Connecting rod worn or damaged Replace connecting rod. See page 28.

Drive housing worn or damaged Replace drive housing. See page 29.

Electrical power not energizing field Check wiring connections. See page 34.

glows, replenish oil.

Connect cable on top of engine or replace spark

plug.

dealer for repair.

Remove spark plug. Pull starter rope 3 or 4 times.

Clean and replace plug. Try to start. Keep sprayer upright to avoid oil seepage.

Service pump. See page NO TAG.

With pressure control switch ON and pressure

turned to MAXIMUM, use a test light to check

continuity across black and white wires from

pressure control.

Have pressure control checked by authorized

Graco dealer.

Clutch worn or damaged Service clutch. See page 32.

Pinion assembly worn or damaged Service pinion assembly. See page 30.

Engine starts but dies Oil level drops below oil sensor Add oil.

Displacement pump output low on

upstroke

Pump inlet screen clogged Clean screen.

Piston ball check not seating Service piston ball check. See page NO TAG.

Piston packings worn or damaged Replace packings. See page NO TAG.

Sleeve gasket in displacement pump

worn or damaged

24 308-082

Replace sleeve gasket. See page NO TAG.

Page 25

Troubleshooting

PROBLEM CAUSE SOLUTION

Displacement pump output low on

downstroke or both strokes

Paint leaks into wet–cup Loose wet–cup Tighten wet–cup just enough to stop leakage.

Spitting from gun Air in fluid pump or hose Check for loose connections at pump intake and

Pump inlet screen clogged Clean screen.

Pressure setting too low Increase pressure. See Startup,

Dirty outlet filter , tip filter or tip Clean filters and/or tips.

Piston packings worn or damaged Replace packings. See page NO TAG.

Intake valve ball check not seating

properly

Engine RPM too low Increase throttle setting. See Startup,

Clutch worn or damaged Replace clutch. See page 32.

Partially clogged suction tube assembly Remove and clean suction tube. During normal

Large pressure drop in hose Use larger diameter hose.

Throat packings worn or damaged Replace packings. See page NO TAG.

Displacement rod worn or damaged Replace displacement rod. See page NO TAG.

Step 14, page 13.

Clean and service intake valve. See page

NO T AG.

Steps 5b and 14, page 13.

flushing remove and clean the suction tube assembly separately to prevent further clogging.

tighten. Them prime the pump.

See Startup, page 13.

Tip partially clogged Clear tip clog. See page 15.

Fluid supply is low or empty Refill and prime the pump. See Startup, page 13.

Dried paint particles from a poorly cleaned

suction tube assembly

Check fluid supply often to prevent running the

pump dry.

Remove and clean suction tube. During normal

flushing remove and clean the suction tube as-

sembly separately to prevent further clogging.

25308-082

Page 26

Pressure Control

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

1. Disconnect both hoses (133) at the pressure control

swivel unions (108). Note the original location of

each hose to be sure you reassemble them correctly

at the end of this procedure. See Fig. 23.

2. Working under the engine mounting plate of the cart,

disconnect the pressure control wires at A. Remove

the four nuts (40) and related hardware from the

capscrews (91 & 87).

3. Remove the pressure control covers (89). See Fig.

23.

4. Disconnect the red, black and white wires from the

rectifier (307) which are sheathed with the conductor

(309). Unscrew the connector (313) from the pressure control, pulling the conductor and wires out with

it. See Fig. 24.

5. Use a wrench to hold the hex of the adapters (C)

while removing the swivel unions (108). See Fig. 24.

W ARNING

To reduce the risk of electric shock, be sure all

grounding features of the pressure control are

properly assembled:

Ground wire (308) connected in pressure con-

trol.

Serrated flange capscrews to mount the pres-

sure control to the cart.

Grounding chain (106) connected by the long

pressure control mounting capscrew (87).

6. Reassemble the pressure control in the reverse order. Use the long pressure control mounting screw

(87) in hole B. From below the mounting plate (25)

assemble the grounding chain (106), washer (105)

and nut (40) to the screw. See Fig. 23.

7. Perform the Pressure Control Adjustment on

page 27 before regular operation of the sprayer.

106

105

40

TO ENGINE

108

WHITE

RED

109

B

91,87

309

89

309

40

307

313

BLACK

C

RECTIFIER (307) CONNECTIONS

A

~

BLACKRED

-

0033

TO FIL TER

Fig. 23

TO PUMP

26 308-082

133

0032

Fig. 24

+

WHITE

~

GROUND

0034

Page 27

Pressure Control Adjustment

WARNING

Use extreme caution when performing this calibration procedure to reduce the risk of a fluid injection in-

jury or other serious bodily injury , which can result from

component rupture, electric shock, fire, explosion or

moving parts.

This procedure sets the sprayer to 2600–3000 psi

(190–210 bar, 19.0–21.0 MPa) Maximum Working

Pressure.

Perform this procedure whenever the pressure control

assembly is removed and reinstalled, or replaced, to be

sure the sprayer is properly calibrated.

Improper calibration can cause the sprayer to over–

pressurize and result in component rupture, fire or ex-

plosion. It may also prevent the sprayer from obtaining

the maximum working pressure, resulting in poor

sprayer performance.

NEVER attempt to increase the fluid outlet pressure by

performing these calibrations in any other way. Never

Exceed 3000 Psi (210 Bar, 21.0 MPa) Maximum

Working Pressure. Normal operation of the sprayer at

higher pressures could result in component rupture,

fire or explosion.

AL WA YS use a

new

50 foot (15.2 m) spray hose, rated

for at least 3000 psi (210 bar, 21.0 MPa) Maximum

Working Pressure, when performing this procedure. A

used, under–rated hose could develop a high pressure

leak or rupture.

Service Tools Needed:

New 50 foot (15.2 m), 3000 psi (210 bar, 21.0 MPa),

flexible nylon airless spray hose, Part No. 223–541

0–5000 psi (0–345 bar, 34.5 MPa) fluid–filled pressure

gauge,

Part No. 102–814

New spray tip, size 0.025 to 0.029

3/8 in. ignition wrench or nut driver

5 gallon pail of water or mineral spirits

Swivel, 156–823

Nipple, 162–453

Tee, 104–984

Set Up

1. Follow the Pressure Relief Procedure Warning on

page 7.

2. Set up the system as shown in Fig. 25.

Set the Dead Band (Pressure Differential)

1. Remove the pressure control cover.

NOTE: Do not alter this adjustment if the wheel is already

set as shown in Fig. 26.

2. Set the white differential wheel (A) on the microswitch. Turn the wheel so the letter F is concealed

behind the switch and the letter E is the first letter

seen.

Fig. 25

Inside pressure

control looking up

at differential wheel

Fig. 26

102–814

156–823

104–984

162–453

223–541

0035

A

0036

Pressure Up

1. Start the sprayer and prime it.

2. Adjust the pressure to 2600 psi (180 bar, 18.0 MPa).

3. Shut off the engine. If the pressure drops after the engine is shut off, replace the pump packings before

proceeding. See page NO TAG.

Adjust the Pressure

1. Remove the plug (320) in the bottom of the control.

2. Turn and hold the pressure control knob (B) at the

maximum pressure.

3. Engage the nut (C): Insert the nut driver through the

pressure control hole (D), or use an ignition wrench

inserted from the front of the pressure control.

See Fig. 27.

D

B

320

Fig. 27

C

0037

a. Loosen the nut just until you hear a click. Stop.

b. Slowly tighten the nut just until another click is

heard. Stop.

4. Replace the plug (320) and the pressure control

cover.

27308-082

Page 28

Bearing Housing and Connecting Rod

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

NOTE: Steps 1 to 10 refer to Fig. 28.

9. Install the screws (81) and lockwashers (46) on the

bearing housing. Tighten the screws evenly to 175

in–lb (20 N.m).

10. Refer to Installing the pump on page NO TAG.

T orque to 175 in–lb (20 N.m)

1. Refer to Removing the Pump on page NO TAG.

2. Remove the four screws (81) and lockwashers (46)

from the bearing housing (76).

3. While pulling the connecting rod assembly (79) with

one hand, lightly tap the lower rear of the bearing

housing (76) with a plastic mallet to loosen it from the

drive housing (77). Pull the bearing housing and the

connecting rod assembly off the drive housing.

4. Inspect the crank (A) for excessive wear and replace

parts as needed.

5. Evenly lubricate the inside of the bronze bearing (D)

in the bearing housing (76), and the inside of the connecting rod link (C), with high–quality motor oil. Liberally pack the roller bearing (B) in the connecting rod

assembly (79) with bearing grease (77d), supplied.

6. Assemble the connecting rod (79) and bearing housing (76).

7. Clean the mating surfaces of the bearing and drive

housings.

8. Align the connecting rod with the crank (A) and carefully align the locating pins (E) in the drive housing

(77) with the holes in the bearing housing (76). Push

the bearing housing onto the drive housing or tap it

into place with a plastic mallet.

81,46

59

73

72

74

80,59

15

71

79

77

B

C

A

E

D

76

75

137

54

CAUTION

Do not use the bearing housing screw (81) to align or

seat the bearing housing with the drive housing.

These parts must be aligned using the locating pins

(E) to help avoid premature bearing wear.

28 308-082

Fig. 28

53

0038A

Page 29

Drive Housing

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

NOTE: Refer to Fig. 29 for this procedure.

1. Remove the front cover (74).

2. Disconnect the pump outlet hose (133).

3. Remove the four screws (81) and lockwashers (46)

from the bearing housing (76).

4. Lightly tap the back of the bearing housing (76) with

a plastic mallet. Pull the pump, bearing housing and

connecting rod away from the drive housing as one

assembly.

5. Remove the two bearing housing screws (80) and

lockwashers (59). Remove the four pinion housing

screws (67) and lockwashers (59).

6. Lightly tap around the drive housing (77) with a plastic mallet to loosen it from the pinion housing (138p).

CAUTION

Do not drop the gear cluster (78) when removing the

drive housing (77). The gear cluster is easily damaged. The gear may stay engaged in either the drive

housing or the pinion housing.

Do not lose the thrust balls (77c and 138k) located at

each end of the gear cluster. The balls, which are

heavily covered with grease, usually stay in the shaft

recesses, but they could be dislodged. If they are

caught between the gears and not removed, the balls

will seriously damage the drive housing. If the balls

are not in place, the bearings will wear prematurely.

7. Liberally apply bearing grease (77d, supplied) to the

gear cluster (78). Be sure the thrust balls (77c and

138k) are in place.

8. Place the bronze colored washer (77a) and then the

silver–colored washer (77b) on the shaft protruding

from the big bearing of the drive housing (77). Align

the gears and push the new drive housing straight

onto the pinion housing and locating pins (B).

9. Starting at Step 5, work backwards to reassemble

the sprayer. Or, move ahead to the next section in

this manual if further service is needed.

67

59

T orque to 175 in–lb (20 N.m)

74

73

133

76

79

B

138p

77b

77a

77

67

59

138k

78

77c

59

80

46

81

Fig. 29

0039A

29308-082

Page 30

Pinion, Clutch, Clamp, Field, & Engine

Disassembling these parts can start from the pinion

housing or from the clutch, if no pinion service is

needed.

Pinion Housing

Removing the Pinion Housing

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

NOTE: Refer to Fig. 30 for Steps 1 to 3.

1. Remove the two bottom screws (67) first, and then

remove the top three screws (67).

2. Pull the pinion housing (138p) away from the clutch

housing (61). The armature (55a) will come with it.

3. Pull out the armature (55a).

CAUTION

If starting from the pinion housing

1 to 6 of DRIVE HOUSING, on page 29, and then contin-

ue with the procedure below.

If starting from the clutch

2. Push on the front of the shaft (138b) to force the

bearing and hub assembly out of the housing

(138p).

3. Install the new shaft assembly (138a), pushing it to

the shoulder of the pinion housing (138p).

4. Install the rings (138e and 138m).

5. Skip ahead to Reassembly, page 37, Step 7, or

continue on page 32.

See page 31

, see page 32.

, first follow Steps

Do not lose the thrust ball (138k). Refer to the CAU-

TION on page 29 for more information.

NOTE: To disassemble the pinion, continue with Repair-

ing the Pinion, below. To disassemble more of the

sprayer, go to page 32. To reassemble the sprayer from

this point, skip ahead to Reassembly, page 37, Step 8.

Repairing the Pinion

NOTE: A hydraulic press is required for disassembly and

reassembly if you purchase the pinion parts individually.

If you do not have such a press, use Repair Kit No.

223–189, which includes the shaft and bearings pre–assembled and lubricated.

NOTE: Refer to Fig. 31 except where noted.

If using Repair Kit 221–032, follow steps 1 to 5 below.

1. Remove the small ring (138e) from the hub (138f)

and the large ring (138m) from the bearing recess

of the pinion housing (138p).

Fig. 30

55a

61

138k

59

67

138p

67

59

0040

30 308-082

Page 31

Pinion Housing

0041

DETAIL A

CUTAWAY VIEW OF PINION

HOUSING (138p)

Fig. 31

138p

2

3

1

138h

138k

Back of pinion housing

1

Press fit small bearing (138c) and roller clutch (138g) in here

2

Lubricate exterior

3

Lubricate inner and outer diameters

4

5

Lubricate teeth

138m

138a

138n

138c

138j

3

138g

4

138b

138d

5

138f

138e

4

0042

If you purchased parts separately, use the following instructions. Disassemble only as far as needed for the

parts being replaced.

NOTE: The old bearing (138d) will be damaged when removed. Have an extra one on hand if you need to remove

it for any reason.

1. If replacing the small bearing (138c) or roller clutch

(138g), press the old ones out of the pinion housing (138p).

2. Remove the small ring (138e) from the hub (138f).

Remove the snap ring (138m) from the bearing

recess of the housing (138p).

3. Push on the front of the shaft (138b) to force the

bearing and hub assembly out of the housing

(138p).

6

Round steel bar to

1

push on shaft (138b)

2

Large bearing

Hub

3

Steel bar stock

4

Two steel blocks

5

Hydraulic press

6

7

Press platform

2

1

138d

138f

3

4

5

4.

Using a hydraulic press,

place pieces of steel

bar stock on the inner race of the large bearing

(138d) and press the shaft through the hub and

bearing. See Fig. 31.

5. Apply lubricant to the parts as shown in Fig. 31.

CAUTION

The arrow on the roller clutch (138g) must point

toward the small bearing (138c) for the shaft (138b)

to rotate in the right direction.

6. Press fit the following parts:

Small bearing (138c) and then the roller clutch

(138g), with its arrow pointing to the bearing,

into the rear of the housing (138n). See Detail A

in Fig. 31.

Large bearing (138d) to the shoulder of the shaft

(138b).

Hub (138f) onto the shaft (138b) all the way to

the large bearing (138d).

7. Install the shaft assembly (138a), pushing it to the

shoulder of the housing (138p).

PLACEMENT OF STEEL BLOCKS AND BAR

Fig. 32

STOCK WHEN PRESSING OFF LARGE BEARING

7

0043

8. Install the rings (138e and 138m).

9. Skip ahead to Reassembly, page 37, Step 7, or

continue on the next page.

31308-082

Page 32

Clutch

NOTE: The clutch assembly (55) includes the armature

(55a) and rotor (55b). The armature and rotor must be replaced together so they wear evenly.

NOTE: If the pinion assembly (138) is not yet separated

from the clutch housing, follow Steps 1 to 4. Otherwise,

start at Step 5.

1. Follow the Pressure Relief Procedure Warning on

page 7.

2. Disconnect the hose (133) from the displacement

pump.

3. Remove the bottom two screws (67) from the clutch

housing (61) and then remove the remaining three

screws (67).

Torque to 7 ft–lb (9.5 N.m)

Pinion shaft

Threaded holes

55b

156

157

55a

4. Tap lightly on the back of the drive housing (77) with

a plastic mallet to loosen the assembly (D) from the

clutch housing (61). Pull the assembly away; the armature (55a) will come with it.

5. Remove the armature from the pinion shaft.