INSTRUCTIONS-PARTS

LIST

308–125

This

manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

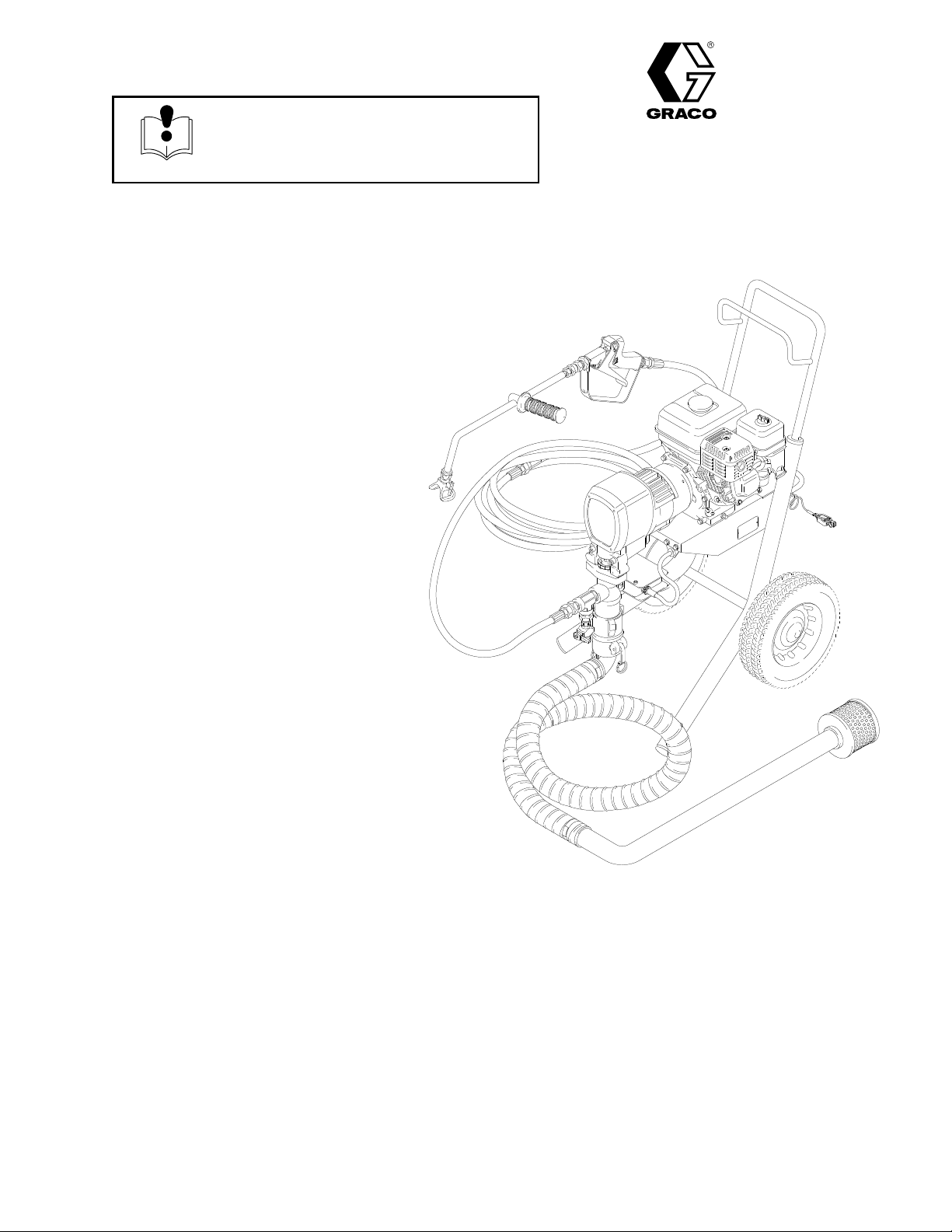

Roof Rigs

GM 1230

GASOLINE-POWERED

1200

psi (8.3 MPa, 83 bar) MAXIMUM

WORKING PRESSURE

Model 231–148

With

one gun, Heavy Duty RAC IV

DripLess T

and 861 size tip,

90 foot (28 m) hose

ip Guard,

AIRLESS SPRA

YER

First

choice when

quality counts.

Supersedes Rev. B

and PCN D

Rev. D

Model 224–483, Series A

Without

hose or gun

0394A

GRACO INC. P.O. BOX 1441

http://www.graco.com

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

MINNEAPOLIS, MN

1991, GRACO INC.

55440–1441

Table

of Contents

Warnings 3.

Setup 8

Fueling 9

Start

Flushing

Spray T

Spray Techniques 14.

Maintenance 15

Troubleshooting 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines

ip and T

. . . . . . . . . . . . . . . . . . . . . . . . . .

ip Guard

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.

12.

13.

Service

Removing

Displacement Pump

Bearing

Drive

Pinion

Clutch 26

and Installing a Displacement Pump

. . . . . . . . . . . . . . . . . . . . . .

Housing and Connecting Rod

Housing

Housing

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

19.

22.

23.

24.

Engine 27

Field

Clamp 29

Clutch

Reassembly 30

Parts

Lists and Drawings

Displacement Pump

Pinion

Complete

Suction

Roofing

Drive

Accessories 38

Technical

Warranty 40

Phone

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and Wiring Harness

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Housing

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

Assembly

Sprayer

Kit

Pump and Pressure Control Kit

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.

29.

32.

33.

34.

35.

35.

36.

39.

40.

NOTE: This

sprayer in other languages. Before operating the sprayer

is an example of the English language DANGER label on your sprayer. This label is supplied with the

, apply a DANGER label in the appropriate language for

your operators, according to the separate instructions supplied with it.

FIRE

AND

EXPLOSION HAZARD

Liquids

Spray

painting, flushing or cleaning equipment with flammable liquids in

confined

Use outdoors or in extremely well ventilated areas. Ground equipment,

hoses,

A

cloths,

arcs

switches on and of

Failure to follow this warning can result in death or serious injury

areas can result in fire or explosion.

containers and objects being sprayed.

void all ignition sources such as static electricity from plastic drop

open flames

from connecting or disconnecting power cords or turning light

such as pilot lights, hot objects such as cigarettes,

f.

.

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

can be injected into the body by high pressure airless spray or

leaks

– especially hose leaks.

Keep body clear of the nozzle. Never stop leaks with any part of the

body

. Drain all pressure before removing parts.A

ing of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical T

Failure to follow this warning can result in amputation or serious

injury.

reatment”.

SKIN INJECTION

HAZARD

void accidental trigger

-

Symbols

Warning Symbol

WARNING

This

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

FIRE AND EXPLOSION HAZARD

Improper

result in a fire or explosion and serious injury

grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

If there is any static sparking or you feel an electric shock while using this equipment,

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Disconnect all electrical equipment in the spray area.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

equipment if you do not follow the instructions.

.

stop spray-

Extinguish all open flames or pilot lights in the spray area.

Do not smoke in the spray area.

Do not turn on or of

Do not operate a gasoline engine in the spray area.

Ground the sprayer to a true earth ground with the ground wire and clamp (supplied).

Use only electrically conductive hoses.

f any light switch in the spray area while operating or if fumes are present.

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment

This equipment is for professional use only

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor

Do not alter or modify this equipment. Use only genuine Graco parts.

Check equipment daily

Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

T

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

nical Data

Do not use hoses to pull equipment.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82C (180F) or below –40C (–40

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

misuse can cause the equipment to rupture or malfunction and result in serious injury

.

echnical Data

section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

. Repair or replace worn or damaged parts immediately

on page 39 for the maximum working pressure of this equipment.

.

F).

.

.

Tech-

W

ear hearing protection when operating this equipment.

Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

MOVING PARTS HAZARD

Moving

parts can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the sprayer

Before servicing the equipment, follow the

equipment from starting unexpectedly

Pressure Relief Procedure

.

.

on page 8 to prevent the

WARNING

INJECTION HAZARD

Spray

from the gun, leaks or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury

Fluid injected into the skin may look like just a cut, but it is a serious injury. Get immediate medi

cal attention.

Do not point the gun at anyone or at any part of the body

Do not put your hand or fingers over the spray tip.

Do not stop or deflect leaks with your hand, body

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard and the trigger guard on the gun when spraying.

Check the gun dif

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

.

fuser operation weekly

.

, glove or rag.

. Refer to the gun manual.

-

Follow the

checking or servicing the equipment.

T

ighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily

repair high pressure couplings; you must replace the entire hose.

Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

Pressure Relief Procedure

on page 8 if the spray tip clogs and before cleaning,

. Replace worn or damaged parts immediately

TOXIC FLUID HAZARD

Hazardous

inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container

state and national guidelines.

Always wear protective eyewear

solvent manufacturer

fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

. Dispose of hazardous fluid according to all local,

, gloves, clothing and respirator as recommended by the fluid and

.

. Do not

Notes

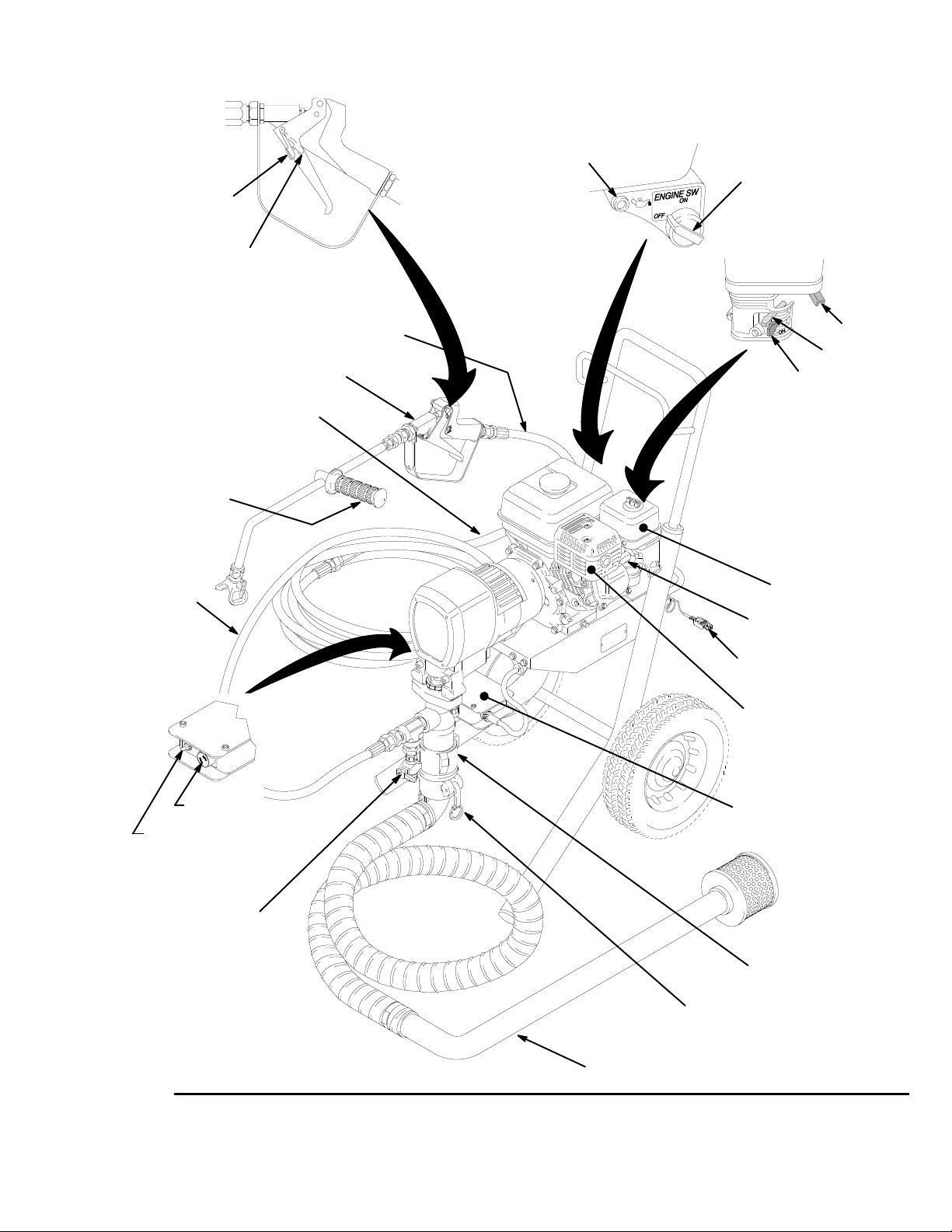

Setup

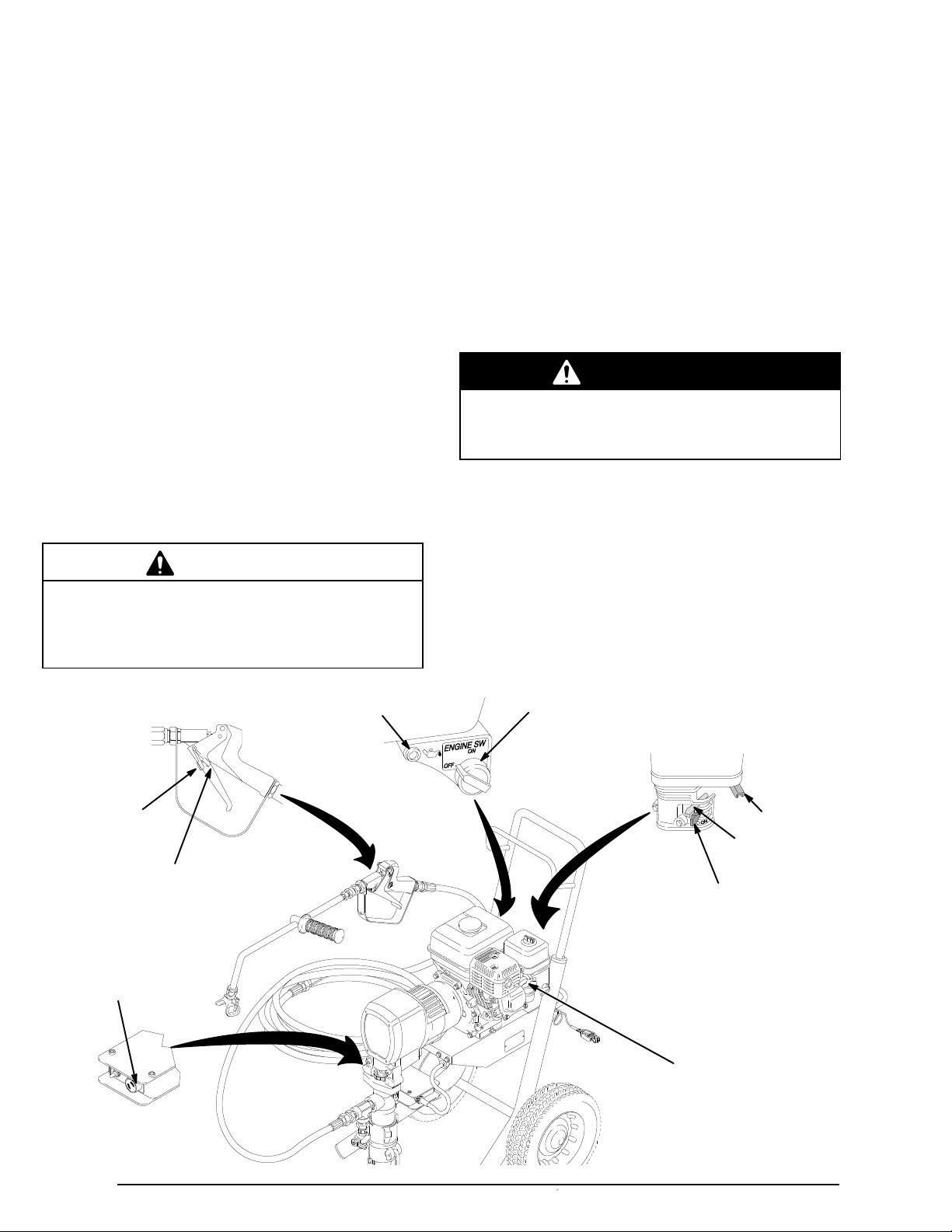

E

TRIGGER LOCK

SHOWN IN

ENGAGED OR

“SAFE” POSITION

TRIGGER LOCK

SHOWN IN

DISENGAGED OR

“OFF–SAFE” POSITION

40 ft (12 m) HOSE

WAND HANDLE

50 ft. (15 m)

MAIN HOSE

40 ft (12 m) HOSE

SPRAY GUN

ENGINE

OIL LIGHT

0015

ENGINE

ON/OFF

SWITCH

0016

FUEL

SHUTOFF

LEVER

AIR CLEANER

SP

ARK PLUG CABLE

THROTTL

CHOKE

PRESSURE

CONTROL KNOB

PRESSURE CONTROL

ON/OFF SWITCH

PRESSURE

RELIEF V

shown in closed

position

Fig.

1

0398

ALVE

SIPHON TUBE

GROUNDING CLAMP

MUFFLER

PRESSURE CONTROL

DISPLACEMENT PUMP

QUICK DISCONNECT ELBOW

0394A

Setup

General Information

NOTE:

in the text refer to the callouts in the figures and the

parts drawing.

Reference numbers and letters in parentheses

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below

the section

ARD

FIRE OR EXPLOSION HAZ

on page 3.

Grounding

1.

Sprayer

cord into a properly grounded outlet. Do not use an

adapter

and be rated for 15 amps.

2.

Fluid hoses:

maximum of 150 m combined hose length to

ensure grounding continuity

Spray gun:

3.

a properly grounded fluid hose and sprayer

: plug the power supply cord, or extension

. All extension cords must have three wires

use only grounded hoses with a

.

obtain grounding through connection to

. Also read

.

Pressure Relief Procedure

WARNING

INJECTION

Fluid under high pressure can be in

jected through the skin and cause seri

ous injury

from injection, splashing fluid, or moving parts, fol

-

low the

1.

2. T

3.

4.

Pressure Relief Procedure

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tips.

Engage the gun safety latch.

urn the ON/OFF switch to OFF

Unplug the power supply cord.

Disengage the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail, and trigger the gun to relieve pressure.

HAZARD

. T

o reduce the risk of an injury

whenever you:

.

-

-

-

4.

Object being sprayed:

5.

Fluid supply container:

6.

All solvent pails used when flushing,

local code. Use only metal pails, which are con

ductive. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which inter

rupts the grounding continuity

T

o maintain grounding continuity when flushing or

7.

relieving pressure

gun firmly to the side of a grounded metal pail,

then trigger the gun.

according to local code.

according to local code.

according to

.

, always hold a metal part of the

5.

Engage the gun safety latch.

6.

Open the pressure drain valve, having a container

ready to catch the drainage. Leave the valve open

until you are ready to spray again.

-

7.

Disconnect the spark plug cable.

-

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above

tip guard retaining nut or hose end coupling and very

slowly loosen the part to relieve pressure gradually

Now clear the tip or hose.

, wrap a rag around the

.

Setup

1. Read and follow the warnings on pages 3–3

before setting up or operating this sprayer

2. Install the hoses and gun.

3. Clamp the siphon hose to the pump.

gasket

is in the quick

prevent

4. Check

gine manual, supplied. In summary: remove one oil

fill plug – the oil should be almost overflowing. See

Fig.

NANCE

Recommended

gent oil, SAE 10W–40, classified “FOR SERVICE

SE

5. Ground the sprayer before operating it. Connect

the

low the FIRE OR EXPLOSION HAZARD on page

3.

priming.

the engine oil level.

1. Add oil as necessary

section on page 15.

or SF”.

grounding clamp (32) to a true earth ground.

disconnect elbow; air leaks will

Refer to the Honda en

. Also read the MAINTE-

engine

oil: Use a high–quality

.

Be sure

, deter

the

Fol

Fueling

6. Fill the gas tank.

7. Flush the pump to remove the protective lightweight oil. See FLUSHING GUIDELINES on page

12.

8. AGITATE OR MIX THE MATERIAL THOROUGH-

Make sure the heavier material on the bottom of

LY!

-

the

container is completely mixed in.

9.

Start the sprayer. See page 10.

See FUELING, below

CAUTION

-

-

T

o avoid damaging the pressure control, follow these

precautions.

1.

Always use spray hose at least 90 ft. (27 m)

long.

2.

Do not allow water or water-base material to

freeze in the pressure control.

.

WARNING

Gasoline is extremely flammable and explosive

under certain conditions. T

or explosion:

1.

Always shut of

2.

Refuel in a well-ventilated area.

3.

Do not smoke or allow flames or sparks in the

area where the engine is refueled or where the

gasoline is stored.

4.

Do not overfill the tank. Make sure the filler cap

is securely closed after refueling.

5.

Fuel vapor or spilled fuel can ignite. If any fuel

is spilled during refueling, make sure the are is

dry before starting the engine.

1 Fuel specifications. Use automotive gasoline with

a

pump octane number of 86 or higher

knocks

fuel

2 Gasolines containing alcohol (gasohol). Do not

use

does

for

do not use the gasohol if it contains more than

5%

or pings, use a higher octane fuel.

minimizes combustion chamber deposits.

gasohol which contains methanol, if the gasohol

not contain cosolvents and corrosion inhibitors

methanol. Even if it does contain such

methanol.

f the engine before refueling.

o reduce the risk of a fire

. If the engine

Unleaded

additives,

3. General. Do not use oil and gasoline mixtures or

contaminated gasoline. Avoid getting dirt, dust or

in the fuel tank.

water

4. Tank

5. Shut off the engine switch before refueling.

6. After refueling, tighten the fuel tank cap firmly.

capacity:

(13

mm) at the top of the tank for gas expansion.

0.95 gallons (3.6 liter).

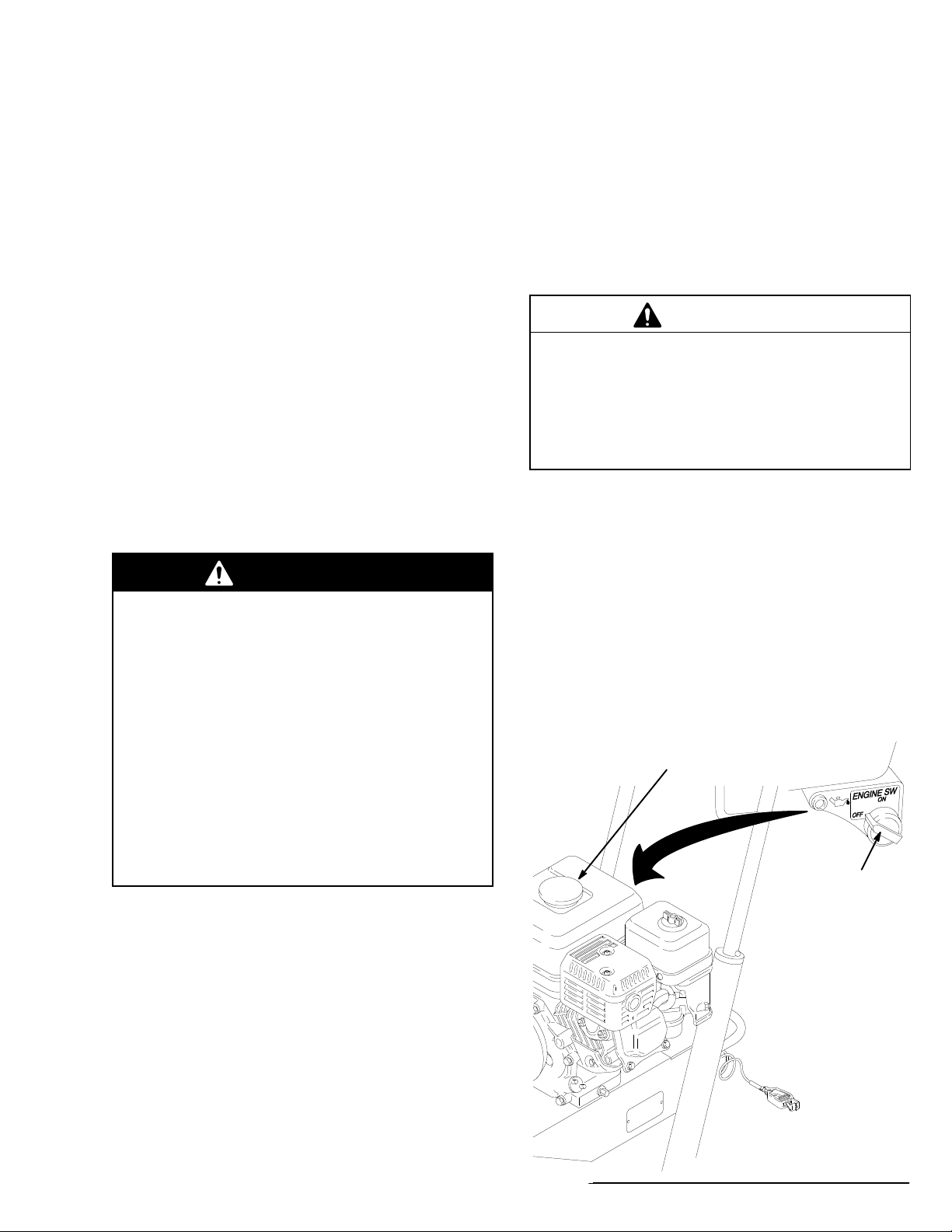

FILL

CAP

Leave 1/2 in.

ENGINE

ON/OFF

SWITCH

NOTE: The HONDA engine warranty does not cover

damage

taining

for

resulting from the use of gasolines con

alcohol.

more information.

See the HONDA engine manual

-

Fig.

2

0015

0141D

Start

Before You Start The Sprayer

1 See FLUSHING GUIDELINES, page 12, to deter-

mine

if the unit should be flushed.

2 Be sure the gas tank is full.

3 Check the engine oil level.

NOTE: The

4 Push the spark plug cable firmly onto the spark

plug.

5 If

Refer

engine stops automatically

if

it is low on oil. If you try to start it again without

adding

more oil,

switch

glows as you pull the starter rope.

a red light near the engine on/of

the sprayer in not primed, remove

to Fig. 3 as you start the sprayer

, or will not start,

the spray tip.

.

Up

3. T

urn OFF the pressure control switch.

4. To start the engine:

a. Turn the pressure adjusting knob all the way

counterclockwise

b. Slide the metal throttle lever away from the fuel

tank

c. If

f

the engine is cold, close the

the

the engine is warm, close the

If

the

d. T

urn ON the engine switch.

to the lowest pressure setting.

to the maximum position (fully left).

choke by moving

gray lever

.

choke by moving

gray lever only half way or not at all.

WARNING

Start Up

1. Place the siphon tube into the coating, water or

solvent container, depending on whether you are

flushing

or are ready to spray

.

2. Open the black fuel shutoff lever by pushing it in

direction of the arrow

the

.

CAUTION

Never start the engine unless fluid pressure is re

lieved and the pressure control switch is turned OFF

Attempting to start the engine when it is pressurized

could damage the recoil system.

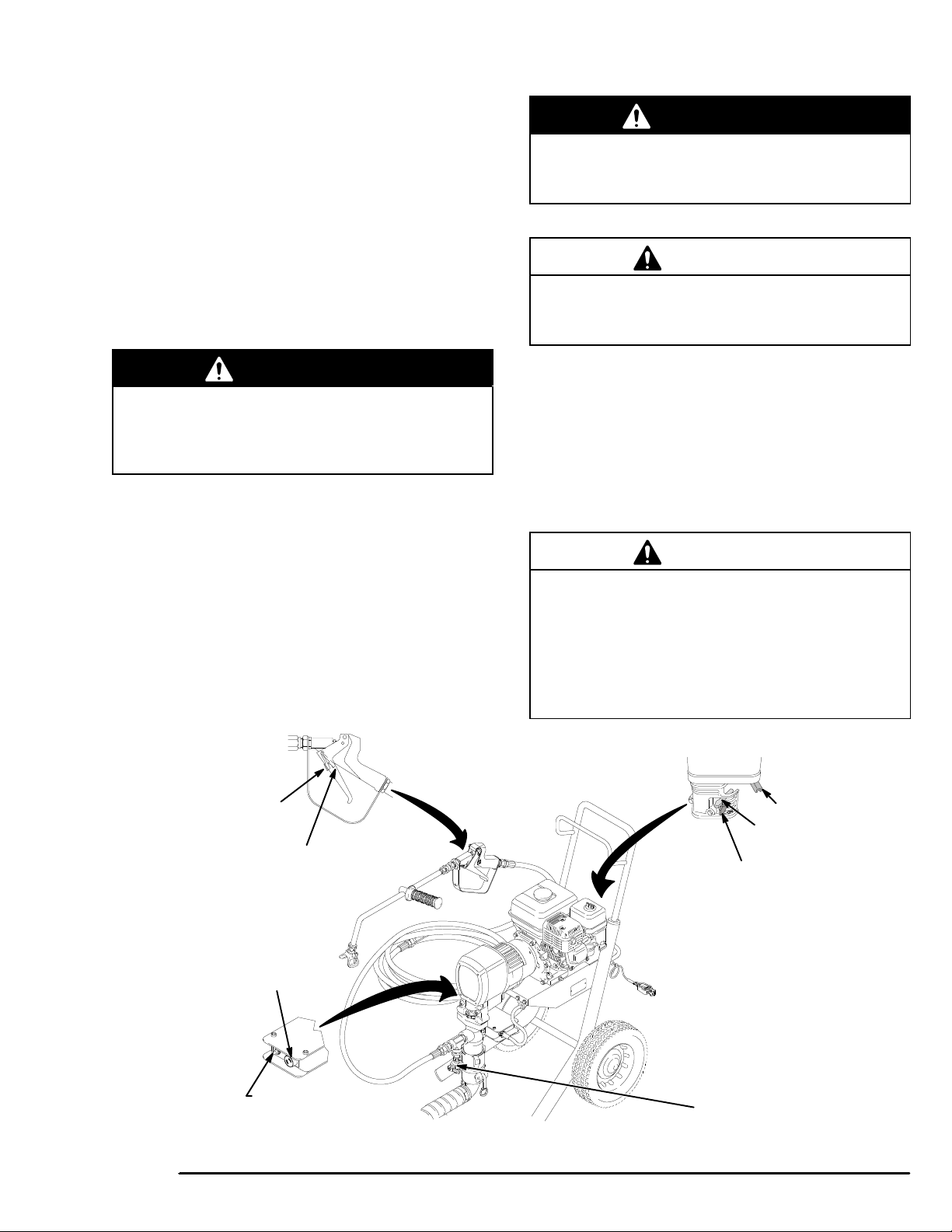

ENGINE

OIL LIGHT

TRIGGER LOCK

shown in

engaged or

“safe” position

TRIGGER LOCK

shown in

disengaged or

“off–safe” position

.

A starter rope that recoils too quickly may hit

someone and cause serious injury

also jam in the recoil assembly

e. Hold

f. Open

the frame of the sprayer with one hand

pull

the starter rope rapidly

holding

turn

the rope as you let it return.

the rope until the engine starts.

the choke as soon as the engine starts, ex

. The rope could

.

and firmly

cept in cold weather. In cold weather, leave the

choke

5. Engage

gun

0015

closed for 10 to 30

it to keep the engine running.

ing

the gun trigger safety latch

forward.

ENGINE

ON/OFF

SWITCH

seconds before open

0016

FUEL SHUT

LEVER

shown in off position

and

. Continue

Pull and re

by tipping the

THROTTLE

CHOKE

shown in

choked position

OFF

-

-

-

PRESSURE

CONTROL KNOB

Fig.

3

0398

SP

ARK PLUG CABLE

0394A

6. To start the pump:

a. Place

b. Reduce the engine speed by moving the metal

c. T

d. T

e. Turn the pressure control knob 1/4 turn from

f.

a container under the pressure drain valve

and

open the valve.

throttle lever away from the fuel tank about half

way

to the left.

urn the pressure control knob to minimum.

urn ON the pressure control switch.

minimum pressure. Run the pump until fluid

flows

smoothly from the pressure drain valve.

Close the pressure drain valve.

Start

Up

WARNING

T

o reduce the risk of serious injury from fluid injec

tion, never operate the spray gun with the tip guard

removed.

8. Install the tip guard and spray tip.

CAUTION

Use the lowest fluid pressure and the lowest throttle

setting needed. Higher settings cause excessive

clutch cycling and premature tip and pump wear

See page 13.

-

.

WARNING

Hold the handle of the wand firmly when triggering

the gun to reduce the risk of it kicking back from

the surge of pressure, which could cause serious

injury.

g. Disengage the gun safety latch. Hold a metal

part of the gun firmly against a grounded metal

container. Holding the gun firmly with both

hands,

squeeze the trigger until

the gun.

h.

Release the trigger

7. If you have not primed the unit with the coating

yet, move the siphon tube to the coating container.

Release

the water/solvent pail just until coating appears. Tip

the gun forward and fully release the trigger to engage

the trigger safety

the trigger safety latch.

TRIGGER LOCK

shown in

engaged or

“safe” position

TRIGGER LOCK

disengaged or

“off–safe” position

. Engage the safety latch.

latch. T

shown in

fluid flows from

rigger the gun into

9. Adjust

fore transporting the hoses to the roof. Trigger

the

and atomization. Turn the pressure adjusting knob

until you get a good pattern. Then slowly lower the

throttle

spray

10.

Read SPRA

the engine speed and pump pressure be

gun onto a test paper to check the spray pattern

setting as far as

pattern (the clutch does not cycle).

Y TECHNIQUES on page 14.

you can without changing the

CAUTION

Close the black fuel shutof

transporting the sprayer to prevent fuel from flooding

the engine.

Keep the sprayer upright and level when operating it

and when transporting it. This prevents crankcase oil

from leaking into the combustion chamber

makes start up very dif

f lever whenever you are

, which

ficult.

0016

THROTTLE

CHOKE

choked position

FUEL SHUT

LEVER

shown in off position

shown in

OFF

-

Fig.

PRESSURE

CONTROL KNOB

4

0398

PRESSURE CONTROL

ON/OFF SWITCH

PRESSURE DRAIN V

ALVE

0394A

Flushing

Guidelines

WARNING

To

reduce the risk of serious injury

injection, always follow the

dure W

ing, cleaning, or shutting down the sprayer

arning

on page 8 before checking, adjust

Pressure Relief Proce

When To Flush

1. Flush

2. Changing coatings.

3. Changing from water–base to oil–base coating.

4. Changing from oil–base to water–base coating.

a new sprayer

Before using water–base coating, flush with a compatible solvent, then warm, soapy water, and then

water

clean

Before using oil–base coating,

ible

solvent.

Flush

solvent.

Flush with a compatible solvent, then warm, soapy

water,

.

with warm, soapy water

and then clean water

to remove the protective oil.

Use a compatible solvent.

, including fluid

.

flush with a compat-

, and then a

.

compatible

-

-

2. Put

3. Start the sprayer. Trigger the gun into the coating

4. Move the gun to the grounded flushing container.

5. Check all fluid connections for leaks. Relieve pres-

6. Remove

the siphon tube in a grounded metal pail of water

or

compatible solvent.

just

container

nozzle.

Trigger the gun until clean water or solvent comes

from the it. See Fig. 6. Release the trigger and en-

the safety latch. Open the drain valve to clean

gage

it.

sure before tightening any connections. Start the

sprayer.

gage the gun safety latch. Trigger the gun to force

or solvent from the hose. Do not let the pump

water

run

dry for more than 30 seconds to avoid damaging

the

pump packings! Relieve pressure.

until water or solvent comes from the

Release the trigger

Recheck the connections for leaks.

the siphon tube from the solvent pail.

.

Disen

-

5. Storage.

Flush the pump only with a compatible solvent, fol-

lowed

by an oil–base solvent, such as mineral spirits.

Leave the drain valve open!

6.

Startup after storage.

Before

using water–base coating, flush out the com

solvent with warm, soapy water, and then with

patible

clean

water

.

using oil–based coating, flush out the compat

When

solvent with the coating to be sprayed.

ible

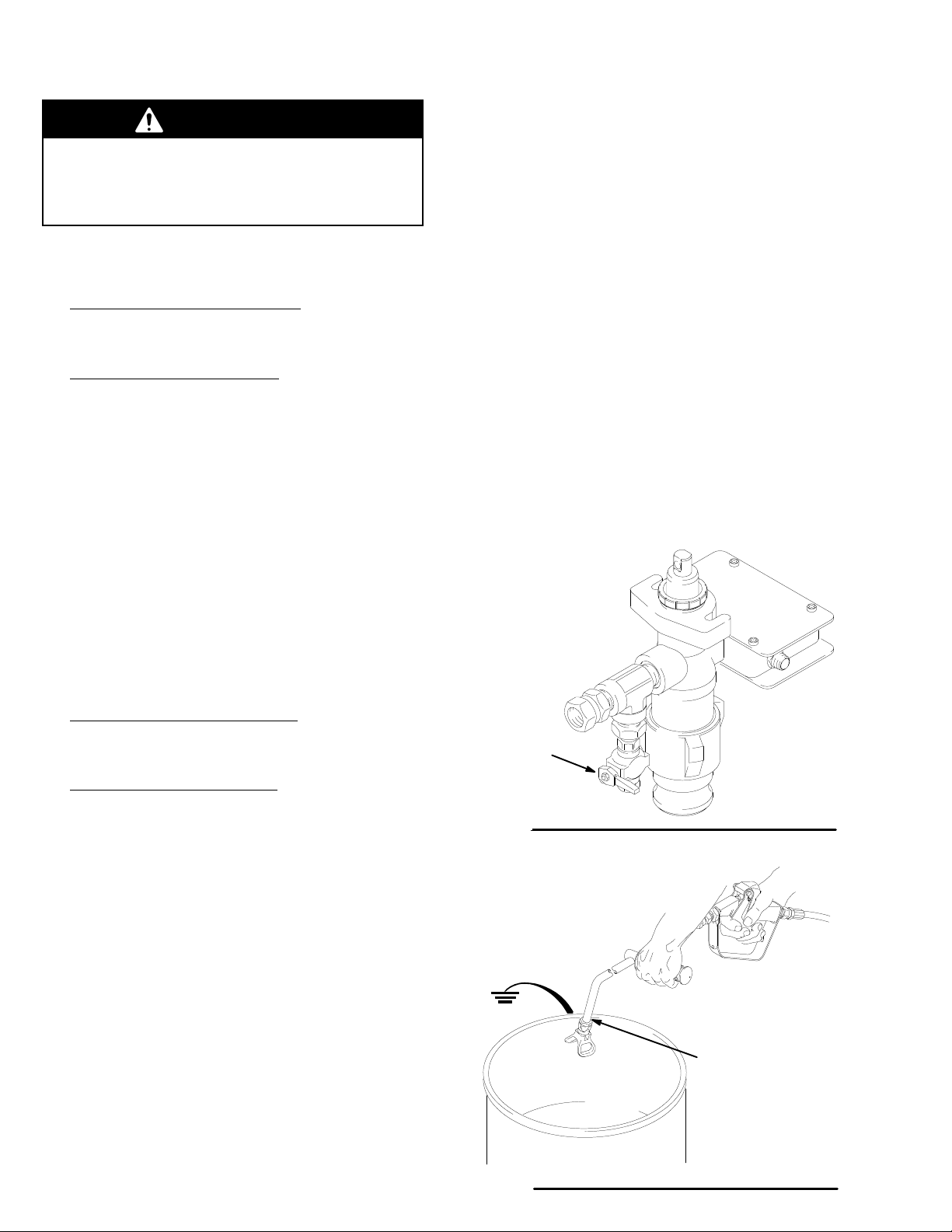

How To Flush The Pump Only

1. Relieve pressure. Leave the drain valve open. See

5.

Fig.

2.

Disconnect the siphon assembly

3. Put the pump in a grounded metal pail of water or

compatible

4. Start the sprayer – see page 10. Flush until the ball

in the foot valve is clean and moves up and down

easily.

solvent.

.

How To Flush The Entire Fluid System

-

-

PRESSURE

DRAIN VALVE

shown in closed

position

Fig.

5

0553

Maintain

metal-to-metal

when

reduce the chance of

static sparking and

splashing.

firm

flushing to

contact

1. Relieve pressure. Leave the drain valve open. See

Fig.

5.

Fig.

6

0406

Spray

T

ip and T

WARNING

To

reduce the risk of fluid injection or splashing in

the eyes or on the skin, completely relieve the fluid

pressure before installing, cleaning, or changing

tips. See the

8.

Pressure Relief Procedure

on page

ip Guard

RETAINING

Fig.

7

NUT

HOUSING

0464

Installation

1. Insert

2. Install the metal seal in the housing, flat side first.

3. Install

4. Snap

the housing through the back

nut

and pull it forward. See Fig. 7.

Fig. 8.

See

the cylinder tip in the housing so its small ori

faces front. See Fig. 9.

fice

on

the tip guard. Install the screw and the white

gasket.

See Fig. 10.

of the retaining

Operation

Be

sure the tip arrow handle is in the FULL SPRA

tion

before operating the gun. See Fig. 10.

Y posi

WARNING

Keep clear of the nozzle. High pressure fluid from

leaks or spray can penetrate the skin and cause

extremely serious injury

amputation. The tip guard provides extra protection

against injection, but does not prevent it. Never cut

of

f the tip guard.

, including the need for

-

-

RETAINING

HOUSING

SEAL

Fig.

8

HOUSING

CYLINDER

SMALL ORIFICE

Fig.

9

SCREW

TIP GUARD

Fig.

10

NUT

0465

TIP

0466

GASKET

0467

Clearing a clogged spray tip See

Engage the trigger safety latch.

1.

2. Turn

3. Disengage

4. Engage the trigger safety latch. Return the arrow

the arrow handle to the FULL CLEAN position.

the

trigger safety latch and trigger the gun

into

the waste container

handle

to the FULL SPRA

.

Y position.

Fig. 1

1.

Maintenance

Replace

these

the gasket and seal

parts wear at about the same rate.

whenever you replace a tip;

GUN NOZZLE

RAC IV

DripLess

TIP GUARD

FULL SPRA

Fig. 11

SwitchTip

HANDLE

Y POSITION

FULL

CLEAN POSITION

0093

Spray

T

echniques

MOVE HORIZONT

A

T A STEADY RA

Fig. 12

Type of Coating

Primers N/A

Aluminum Solvent–Base

Aluminum Emulsion

Asphalt Solvent–Base

Asphalt Emulsion

Aluminum Solvent–Base

Aluminum Emulsion

Asphalt Emulsion

1

Roof coatings vary greatly. The formulas, batch,

temperature,

cosity. If the sprayer does not atomize the coating

well, thinning and/or agitating it should help. Apply

thinned

thickness.

should

2

A 0.061 tip is standard with the sprayer

coating more heavily to get an equal dry film

be applied about 10% thicker

ALLY

TE

1

and age of the coating all af

For example, coating that is thinned 10%

Fibered? Recommended

No

No

No 0.051

No 0.051

Yes 0.061

Yes 0.061

Yes 0.061

Tip Size

0.031 or larger

0.041 or larger

0.051 or larger

2

fect its vis

.

.

HOLD THE GUN PERPENDICULAR T

AND 24” (610 MM) ABOVE THE SURF

OVERLAP

the spray stroke 24” (610

Start

and pull the trigger

face

the gun is still moving, and as you approach the other

edge, release the trigger. This method avoids excess

material

Do not try to increase coverage by increasing the fluid

pressure!

necessary

the life of your sprayer and minimizes coating lost by

overspray.

there

If

minimize

build-up at the end of each stroke.

Use a slower

to get the results you want; this helps prolong

is a wind, angle the spray pattern into the wind to

drifting.

EACH STROKE BY 50%

mm) above the target sur

as the

gun is moving.

stroke. Use the lowest pressure

The best way to control the rate of coverage is with the

tip size.

gun

er tip orifice applies more coating. The width of the pat-

depends on the fan pattern of the tip you choose.

tern

A small tip orifice applies less coating. A larg

O

ACE

0551

-

Then, while

-

Maintenance

WARNING

T

o reduce the risk of serious injury

the

Pressure Relief Procedure

checking, adjusting, cleaning, or shutting down the

sprayer.

, always follow

on page 8 before

CAUTION

For detailed engine maintenance and specifications,

refer to the HONDA engine manual.

CAUTION

Close the black fuel shutof

transporting the sprayer to prevent fuel from flooding

the engine.

Keep the sprayer upright and level when operating it

and when transporting it. This prevents crankcase oil

from leaking into the combustion chamber

makes startup very dif

f lever whenever you are

, which

ficult.

DAILY: Check

DAILY: Check

AFTER THE FIRST 20 HOURS OF OPERATION AND

100 HOURS THEREAFTER:

EACH

WEEKLY: Remove

ment. In very dusty environments, check the filter daily.

Replace

can

SP

plug.

Always

the element as needed. Replacement elements

be purchased from your local HONDA dealer

ARK PLUG:

Gap the plug to 0.025 to 0.030 in. (0.7 to 0.8

use a spark plug wrench.

the engine oil level and

and fill the gas tank.

the air filter cover and clean the ele

Use only a (NGK)

fill as necessary

Change the oil.

BP6ES or BPR6ES

.

mm).

.

-

Troubleshooting

WARNING

Check everything in the guide before disassembling

the sprayer

.

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

PROBLEM CAUSE SOLUTION

Engine/sprayer won’t start

Engine won’t “fire” or

“pull over”

Engine operates, but

displacement pump doesn’t

Also see manual 308–126.

on page 8.

Engine switch not on

Out of gas

Engine oil level low

Spark plug cable disconnected or

spark plug damaged

Adjusting the pressure control knob

doesn’t

Oil seepage into combustion

chamber

Pressure control switch turned OFFTurn on pressure control switch.

Pressure setting too low

T

start pump

ip clogged

Relieve the pressure before disassembling the spray

er.

T

urn on engine switch.

Refill gas tank.

Try

starting engine. If light on

glows,

replenish oil.

Connect cable on top of engine or replace

spark

plug.

Return pressure control to authorized Graco dealer for repair.

Remove

times. Clean and replace plug. Try to start.

Keep

Increase pressure.

Clean tip.

spark plug. Pull starter rope 3 or 4

sprayer upright to avoid oil seepage.

-

rear of engine

Displacement pump rod seized by

dry coating

Connecting rod worn or damaged

Drive housing worn or damaged

Electrical power not energizing field

Clutch worn or damaged

Pinion assembly worn or damaged

Service pump. See page 19.

Replace connecting rod. See page 22.

Replace drive housing. See page 23.

Check wiring connections. See page 28.

With pressure control switch ON and pressure

turned to MAXIMUM, use a test light

check continuity across black and white

wires

from pressure control.

Have pressure control checked by authorized

Graco dealer

Service clutch. See page 26.

Service pinion assembly

.

. See page 24.

to

PROBLEM CAUSE SOLUTION

Engine starts but dies

Displacement

on

upstroke

Displacement

on

downstroke or both strokes

Coating leaks into wet–cup

Low fluid delivery

pump output low

pump output low

Oil level drops below oil sensor

Siphon hose strainer is clogged

Piston ball check not seating

Piston packings worn or damaged

Sleeve o–ring in displacement pump

worn or damaged

Siphon hose strainer is clogged

Piston packings worn or damaged

Intake valve ball check not seating

properly

Clutch

worn or damaged

Loose wet–cup

Throat packings worn or damaged

Displacement rod worn or damaged

Siphon hose strainer is clogged.

Add oil.

Clean strainer

Service piston ball check. See page 19.

Replace packings. See page 19.

Replace o–ring gasket. See page 19.

Clean strainer

Replace packings. See page 19.

Clean and service intake valve. See page

19.

Replace clutch. See page 26.

T

ighten wet–cup just enough to stop

leakage.

Replace packings. See page 19.

Replace displacement rod. See page 19.

Clean strainer

.

.

.

Pressure setting too low

Engine RPM too low

Large pressure drop in hose

Spitting from gun Air in fluid pump or hose

Fluid supply is low or empty

Increase pressure. See

Step 9, page 1

Increase throttle setting. See

Steps 4b and 9, pages 10 and 1

Use larger diameter hose.

Change

nect coupling, if worn or missing. Replace

pump cylinder o–ring. Then prime the

pump.

See

Refill and prime the pump. See Startup,

page

10. Check fluid supply often to prevent

running

the pump dry

1.

gasket in siphon hose quick discon

Startup

Startup,

Startup,

1.

, page 10.

.

-

Removing

and I

nstallin

g a D

isplacemen

t P

ump

Removal

WARNING

To

reduce the risk of serious injury

the

Pressure Relief Procedure

repairing the sprayer

1. Flush

the sprayer

.

. Remove the suction

, always follow

on page 8 before

hose, if used.

WARNING

To

reduce the risk of pinching or amputating a

finger

, keep your fingers away from the area of the

connection rod and pin while jogging the engine.

2.

Start the engine. Jog the pressure control ON/OFF

switch

until the connecting link stops near the bottom

of

the stroke and is fully exposed. See Fig. 13. Shut

off

the engine.

3. Unscrew

plug

4. Relieve

5. Remove the outlet hose. Slightly loosen the two

mounting

6. Use a small screwdriver to push in the connecting

link

up from the back of the connecting link. Then push

the

the collar

the cord from the pressure control. See Fig. 14.

the pressure

screws. See Fig. 13.

pin just until you can gently pry the retaining ring

pin in so it falls out the back.

of the power supply cord and un

.

7. Remove the two mounting screws while supporting

weight of the pump with your free hand.

the

Installation

1. Push

2. Pull the displacement rod out of the pump 2 to 3 in.

3. Align the flats of the pump piston rod and the pump

the pin just barely into the connecting link, but

not

into the mating hole of the displacement pump.

(50–75 mm).

outlet.

Lift the pump into position and gently push on

the pin while moving the pump slightly until the pin

slips into the hole. Be sure the retaining ring snaps

over the end of the pin.

down

WARNING

Be sure the retaining spring is firmly in the groove

of the connecting link, all the way around, to pre

vent it from working loose due to vibration. See Fig.

-

13.

If the pin work loose, it or other parts could break

of

f due to the force of the pumping action and

result in serious injury or property damage, includ

ing damage to the pump, connecting link or bearing

housing.

Procedure continued on page 19.

-

-

Fig.

13

FRONT VIEW OF PUMP AND

SPRA

YER CONNECTING LINK

PIN

BEARING HOUSING

RETAINING RING

CONNECTING LINK

MOUNTING SCREWS

T

orque to

20 ft–lb (27 N.m)

CUTAWA

SHOWS HOW PIN GOES

THROUGH CONNECTING ROD

PIN

PUMP PIST

CONNECTING LINK

RETAINING RING

ON ROD

Y VIEW

BACK

OF PUMP

FRONT OF PUMP

0407

Removing

and I

nstallin

g A D

isplacemen

t P

ump

4. Check

5. Lift

6. Plug

the back of the bearing housing to be sure the

parts

are installed properly

the pump to align the mounting holes and install

the mounting screws. IMPORTANT – torque the

screws

the

Fig. 14.

to 20 ft-lb (27 N.m). See Fig. 13.

in the power cord so the notch in the collar and

tab in the socket align. Screw on the collar

.

Displacement

WARNING

To

reduce the risk of serious injury

the

Pressure Relief Procedure

repairing the sprayer

.

, always follow

on page 8 before

. See

Fig.

14

Pump

423

401

420

PRESSURE CONTROL

TAB

NOTCH

COLLAR

0408

416

414

415*

406*

Disassemble the pump

1

See page 18 for how to remove the pump.

2 Use a hard rubber mallet on the tabs of the lug nut

to loosen the foot valve housing.

(421)

3

Disassemble the pump, but do not disassemble the

piston

rod (401) from the piston housing (416)

one

of those needs to be replaced. Due to the highstrength

the joint must be heated before disassembly. Refer

to

Clean and inspect all parts

1 Use a compatible solvent to thoroughly clean all

parts

2. Inspect the parts, including seats, for nicks and

scratches. Replace worn or damaged parts as they

cause the packings to wear more quickly and/or result

Loctite used at the joint of these two parts,

Fig. 15.

and remove all traces of sealant.

in poor pump performance.

unless

*419

*403

417

*404

*405

*404

*407

418**402

413*

412*

408*

422

410

411*

409

421

Continued on page 20.

Fig. 15

0412

Displacement

2

Pump

Repair

1A

2 Parts

Reassemble the pump

NOTE: Refer to Fig. 13 for reassembly except where

NOTE: Grease

1. Install the ball guide (409), ball (411*) and intake

2.

3. On the piston seat (422), install the u–cup seal

4. Install the nut (414) on the piston seat (422). Hand

NOTE: If

Kit

Packing Repair Kit, Part No. 224–523, is

Use

all the parts in the kit for the best results.

included in the kit are marked with an asterisk

in

the text and drawings. For example, 408*.

noted.

all packings and o–rings before installing

them.

housing

Place new o–rings (404*) on the cylinder (405).

(408*), lips down. Install the female gland (412*).

With

install

stall

tighten

(410) in the lug nut (421).

the lips of the v–packings facing up, alternately

the leather (407*)

the male gland (406*).

the nut very firmly

you disassembled the piston rod

ton

housing (416), clean the threads

Apply red Loctite and torque to 35–50 ft–lb

(47–68

N.m).

and poly packings (413*). In

.

available.

(401) and pis

thoroughly

7. From the top of the pump housing (417), install the

gland (403). With the lips of the v–packings

male

ing down, alternately install the leather packings

(418*), and poly packings (402*). Install the female

(419*).

gland

8. Screw

9. Grease the o–rings on the cylinder (405). Slide the

10. Grease the piston rod (401) and piston packings.

11. Align the holes in the top of the piston rod with the

NOTE: If

-

12.

13. Install

.

in the packing nut (420) loosely

after the pump is installed and operating.

ened

cylinder

Slide

cylinder so it extends out of the piston housing 2–3

in.

ings.

pump

Install the intake valve housing and tighten firmly

(20)

into the bottom of the pump housing (417).

the piston rod assembly into the bottom of the

(50–75 mm). Be careful not to damage any pack

outlet.

you push the piston rod too far out of the pump

housing, using a hard rubber mallet (ONLY!) to

tap

it down.

If

the piston rod does not extend out far enough,

remove

and tighten it just enough to prevent leakage.

the foot valve and tap the piston up.

the pump and prime

it. Check the packing nut

. It will be

fac

tight

.

-

-

-

5. Apply

Loctite green (supplied in the repair kit) to the

piston

seat (422) threads. Install the ball (415*).

CAUTION

Before assembling the piston, not that the top of the

piston seat (422) has four flutes (B) and that the

piston housing (416) has four holes (A). T

these flutes and holes provide the fluid flow path.

Failure to align the parts properly

Step 6, will result in poor pump performance.

6. Back off the piston housing just until the holes and

flutes (B) mentioned in the CAUTION are perfectly

aligned,

through

ton housing (416) down to the nut (414) and torque

to

and the tips

the holes (A). See Fig 20–1. Screw the pis

90–125 ft–lb (122–170 N.m).

(B) are not visible when you look

, as instructed in

ogether

416

HOLE

FLUTE

TIP

-

Fig. 16

422

055

Displacement

Pump

20

V–P

ACKINGS MUST

FACE DOWN

LEATHER

LIPS OF

V–PACKINGS

F

ACE UP

U–CUP

LIPS MUST

FACE DOWN

LIPS

*

4

5

*15

*13

MUST

*12

*

8

SEAL

*

2

POLY

OF

19*

18*

LEATHER

LIPS OF V–P

MUST F

ACE DOWN

3*

1

16

14

6*

7*

POLY

LIPS

OF V–P

MUST F

ACE UP

21

4*

ACKINGS

T

ORQUE ROD (1) T

HOUSING (16) T

34–50 FT–LB

(44–68 N.m)

TORQUE

T

T

(150 N.m)

NUT (14)

O HOUSING (16)

O 1

10 FT–LB

ACKINGS

O

O

Fig.

17

10

0411

Bearing

Housing and Connecting Rod

WARNING

To

reduce the risk of serious injury

the

Pressure Relief Procedure

repairing the sprayer

.

, always follow

on page 8 before

9. Install the screws (48) and lockwashers (49) on the

bearing housing. Tighten the screws evenly to

ft–lb (34 N.m).

25

10.

Refer to

Installing the pump

on page 18.

NOTE:

1.

2. Remove

3. While

4. Inspect

5. Evenly

6. Assemble

7. Clean the mating surfaces of the bearing (23) and

Steps 1 to 10 refer to Fig. 18.

Refer to

the

one hand, lightly tap the lower rear of the bearing

housing

drive

connecting

the

in

necting rod link (D), with high–quality motor oil (do

not

in the connecting rod assembly (22) with bearing

grease

ing (23).

drive

Removing the pump

the screws

bearing housing (23).

pulling the

(23)

with a plastic mallet to loosen it from the

housing (20). Pull the bearing housing and the

rod assembly of

the crank (A) for excessive

drive housing. See page 23.

lubricate the inside of the bronze bearing

the bearing housing (23), and the inside of the con

use grease). Liberally pack the

(20d), supplied.

the connecting rod (22)

(20) housings.

(48) and lockwashers (49) from

connecting rod assembly (22) with

on page 18.

f the drive housing.

wear and replace

(C)

roller bearing (E)

and bearing hous

20

A

E

49

D

22

23

B

C

TORQUE TO

25 ft–lb

(34 N.m)

48

-

-

8. Align

the connecting rod with the crank (A) and care

fully align the locating pins (B) in the drive housing

with the holes in the bearing housing (23). Push

(20)

the bearing housing onto the drive housing or tap it

place with a plastic mallet.

into

CAUTION

DO

NOT use the bearing housing screws (48) to align

or seat it with the drive housing. These parts must be

aligned

ture

using the locating pins (B), to help avoid

bearing wear

.

prema

-

-

Fig.

18

0400

Drive

Housing

WARNING

To

reduce the risk of serious injury

the

Pressure Relief Procedure

repairing the sprayer

NOTE:

1. Disconnect the suction hose (A). Disconnect the

2. Disconnect

3. Remove the four screws (48) and lockwashers (49)

4. Lightly

5. Remove the bearing housing screws (41) and the

6. Lightly

Refer to Fig. 19 for this procedure.

pressure control cord (62). Remove the front cover

(21).

the pump outlet hose.

the bearing housing (23).

from

tap the back of the bearing

a plastic mallet. Pull the pump, bearing housing and

connecting

one

assembly

pinion

tic

mallet to loosen it from the pinion housing (19p).

rod away from the drive housing (20)

housing screws (3).

tap around the drive housing (20) with a plas

.

.

, always follow

on page 8 before

housing (23) with

as

20

CAUTION

Do not drop the gear cluster (1) when removing the

drive

housing (20). The

The

gear may

or

the pinion housing.

Do not lose the thrust balls (20c and 19k) located at

each

end of the gear cluster

ly covered with grease, usually stay in the shaft recesses,

between the gears and not

ously

damage

place, the bearings will wear prematurely

7. Liberally

gear cluster (1). Be sure the thrust balls (20c and

19k)

8. Place

silver–colored washer (20b) on the shaft protruding

from

the gears and push the new drive housing straight

onto

-

9. Reassemble the sprayer. Or, go to the next section

in

this manual if further service is needed.

B

20b

20a

stay engaged in either the drive housing

but they could be dislodged. If they are caught

the drive housing. If the balls are not in

apply bearing grease (20d,

are in place.

the bronze colored washer (20a)

the big bearing of the drive housing (20). Align

the pinion housing and locating pins (B).

gear cluster is easily damaged.

. The balls, which are

removed, the balls will seri

supplied) to the

heavi

.

and then the

-

-

TORQUE TO

40

21

48

25 ft–lb

(34 N.m)

49

23

41

2

62

20c

19p

3

2

19k

1

Fig.

19

A

0401

Pinion,

Disassembling these parts can start from the pinion

housing

or from the clutch, if no pinion service is

Clutch, Clamp, Field, and Engine

needed.

If starting from the pinion housing

1

to 6 of

ue

If starting from the clutch

DRIVE HOUSING

with the procedure below

, on page 23, and then contin

.

, see page .

, first follow Steps

Pinion

Removing the Pinion Housing

WARNING

To

reduce the risk of serious injury

the

Pressure Relief Procedure

repairing the sprayer

NOTE:

1 Remove

2 Pull the pinion housing (19p) away from the clutch

Refer to Fig. 20 for Steps 1 to 3.

the two bottom screws (3) first, and then re

the top three screws (3).

move

housing

(17). The armature (9b) will come with it.

.

, always follow

on page 8 before

-

Housing

-

3 Pull

Do

on

NOTE: To

the armature (9b) of

of

the pinion housing.

not lose the thrust ball (19k). Refer to the CAUTION

page 23 for more information.

disassemble the pinion, go to

Pinion, page 25. To disassemble more of the

sprayer,

er from this point, go to Reassembly, page 31,

7.

Step

f the hub (19j –

CAUTION

go to page 27. T

see Fig.

Repairing the

o reassemble the spray

21)

-

19p

19k

Fig.

20

3

2

17

9b

3

2

SEE PAGE 26 FOR PINION

0171

Pinion

Housing

CUTAWA

PINION HOUSING (19a)

Fig.

Y VIEW OF

0041

Lubricate exterior

21

Repairing the Pinion

NOTE: Refer

NOTE: A

to Fig. 21 except where noted.

hydraulic press is required

pinion parts individually.Otherwise, use Repair

Kit No. 221–032, which includes the shaft and

bearings

pre–assembled and lubricated.

BACK OF PINION HOUSING (19a)

PRESS PINION ASSEMBL

IN HERE

19a

Y

19b

19c

19d

19c

Lubricate exterior

if you purchase the

19k

19m**

19j**

19h**

Lubricate inner and

outer diameters

19g**

Lubricate teeth

19f**

Lubricate

outer diameters

**Included in Repair Kit 221–032

inner and

0169

If purchasing parts separately, use these instructions.

Disassemble as far as needed for the parts being

replaced.

NOTE: The

old

bearings (19h and 19f) will be damaged

when

removed.

need

to remove them for any reason.

Have extra ones on hand if you

If using Repair Kit 221–032, follow Steps 1 to 5, below

1. Remove

the small ring (19m**) from the hub (19j) and

the large ring (19k) from the bearing recess of the

pinion

housing (19a).

2. Push on the front of the shaft (19g**) to force the

bearing

and hub assembly out of the housing (19a).

3. Install the new shaft assembly into the pinion housing,

pushing it to the shoulder of the housing (19a).

4.

Install the rings (19k and 19m**).

5. Go

to

Reassembly

page

26.

PLACEMENT OF STEEL BLOCKS WHEN

PRESSING OFF LARGE BEARING (19h)

ROUND STEEL

BAR T

O PUSH

ON SHAFT

(19g)

LARGE

BEARING

(19h)

, page 31, Step 7, or continue on

HYDRAULIC

PRESS

HUB (19J)

STEEL BAR

STOCK

TWO STEEL

BLOCKS

(only one shown)

.

1.

Remove the small ring (19m) from the hub (19j).

2. Remove

of

3. Push

ing

4.

Using a hydraulic press,

stock

the snap ring (19k) from the bearing recess

the pinion housing (19a).

on the front of the shaft (19g) to force the bear

(19h) and hub (19j) assembly out of the housing.

place pieces of steel bar

on the inner race of the large bearing (19h) and

press the shaft through the hub and bearing. Then

turn over the shaft and press out the small bearing

(19f).

See Fig. 22.

5.

Apply lubricant to the parts as shown in Fig. 21.

6. Press fit the following parts: Large bearing (19h) to

the

large shoulder of the shaft (19g).

Small

(19f) to the shoulder of the shaft (19g). Hub (19j)

onto the shaft (19g) all the way to the large bearing

(19h).

7. Install

the shaft assembly

of

the housing (19a).

, pushing it

to the shoulder

8. Install the snap ring (19k). Install the small ring

(19m).

-

bearing

Fig.

22

PRESS PLA

TFORM

0043

9. Go

page

to

Reassembly

26.

, page 31, Step 7, or continue on

Clutch

NOTE: The clutch assembly (9) includes the armature

and rotor (9a). The armature and rotor must

(9b)

be

replaced together so they wear evenly

.

NOTE: If the pinion assembly (19) is not yet separated

from the clutch housing, follow Steps 1 to 4.

Otherwise,

1.

Relieve the pressure.

start at Step 5.

2. Disconnect the hose from the displacement pump.

Disconnect the cord set (62) from the pressure

control.

3. Remove the bottom two screws (3) from the clutch

housing (17) and then remove the remaining three

screws (3).

4. Tap lightly on the back of the bearing housing (23)

with

a plastic

mallet to loosen the assembly (D) from

the clutch housing (17). Pull the assembly away; the

armature

(9b) will come with it.

5.

Remove the armature from the pinion.

6.

There are two ways to remove the rotor (9a):

a. Remove

Install

the

the

the capscrews (4) and lockwashers (2).

two of the screws in the threaded holes in

rotor (9a). Alternately tighten the screws until

rotor comes of

f. See Fig. 23.

b. Use a standard steering wheel puller (A) with two

1/4–28

short

x 3 or 4 in. long screws (B). Replace

screws of the steering wheel puller with the

longer screws. Turn the screws (B) into the

threaded

holes of the

rotor (9a). T

ighten the cap

screw (C) of the tool until the rotor comes off.

Detail in Fig. 23.

See

7. Skip

ahead to

tinue

on page 27.

Reassembly, page 31, Step 6, or con

the

-

-

Fig. 23

TORQUE TO 7 ft–lb (9.5 N.m)

19

23

D

9b

3

2

17

9a

2

4

3

2

THREADED

HOLES

PINION SHAFT

INSIDE THIS

HOUSING

A

B

C

62

USE A STEERING WHEEL

PULLER T

O REMOVE ROT

OR

Ref

9a

0402

Engine

1 Working

move

See

under the mounting plate

(A) of the cart, re

the screw (5), lockwasher (6) and washer (7).

Fig. 24.

2 Remove the engine-mounting locknuts (43) and

screws

(42). Disconnect

the mating black, white and

green wires. Pull the wires carefully through the

grommets

(8) before removing the engine. See Fig.

24 and 25.

3 Lift

4 Remove

5Go

the

engine carefully and place it on a work bench.

the

Field

and W

Clutch

Housing

to

Reassembly, page 30, Step 1.

, as instructed

iring Harness, Clamp

on pages 28 and 29.

and

NOTE: All service to the engine must be performed by

authorized HONDA dealer

an

.

-

A

GREEN W/RED COVER

WHITE

RED

Fig. 24

FROM ENGINE

42

B

7

8

6

5

T

O FIELD

43

0153

62

Fig.

25

BLACK

VIEW

FROM UNDER ENGINE MOUNTING PLA

TE

0405

Field

and W

iring Harness

NOTE: Refer

1

Remove the engine. See page 27.

2 Loosen the setscrews (16). Unplug the wiring har-

ness

the

to Fig. 26.

(69) from under

field out to expose the black and white wires.

the engine mounting plate. Pull

16

3 Pull the caps (A) off the wire screws (57) in both

places on the field. Loosen the screws and release

wires of the harness (69).

the

4

Go to

Reassembly, page 30, Step 4.

Fig. 26

57

69

A

0046

Clamp

NOTE: A

NOTE:

1 Loosen

2 Install two screws (B) of the tool (A) in two of the

3 Go to Reassembly, page 30, Step 3, or continue

standard steering wheel puller and two1/4–28

x 3 or 4 in. long screws are required to remove

clamp.

the

Refer to Fig. 27.

the two screws (4) on the clamp (15), work

through the slot at the bottom of the clutch hous

ing

ing (17).

threaded holes in the clamp. Tighten the screw (C)

the clamp comes of

until

below.

f.

Fig.

-

-

27

17

A

B

C

4

TORQUE TO

125 in–lb

15

(14 N.m)

0155

NOTE: Refer

1

Remove the capscrews (1

lockwashers (12) which hold the

clutch housing (17) to the engine (45).

2

Remove the engine key (14).

3

Pull of

4

Go to

to Fig 29–2.

1) and

f the clutch housing (17).

Reassembly, page 30, Step 1.

Clutch

Housing

45

14

17

12

11

Fig. 28

0156

Reassembly

1. Install

2.

the

clutch housing (17)

lockwashers

(12) on the engine. See Fig. 29.

Install the engine shaft

key (14).

, capscrews (1

See Fig. 29.

1) and

3. Install the clamp (15) onto the engine shaft (A).

Maintain

shown

in Fig. 30.

the 1.99 in.

+/– 0.01 (50.54 mm) dimension

To check the dimension, place a rigid, straight steel

bar (B) across the face of the clutch housing (17).

Use an accurate measuring device to measure the

distance between the inside of the bar and the face

the clamp. Adjust the clamp as necessary. T

of

two screws (4) to 125 in–lb (14 N.m).

the

T

ORQUE OPPOSITEL

AND EVENL

Y T

25 in–lb

(2.8 N.m)

Y

O

14

A

orque

16

4. Connect

(57)

the wires of the harness (69) to the

in both places on the field. Pull the plastic caps

(C) up and snap them over the screws. Guide the

wires

of

the harness (69) through the slot in the clutch

housing.

setscrew

Slide the

field (10)

into the clutch. Align the

chamfers in the field and the clutch housing

(17). Tighten the setscrews (16) oppositely and

evenly,

to 25 in–lb (2.8 N.m). See Fig. 29.

17

FACE

OF

HOUSING

1.99”

(50.54

mm)

screws

10

Fig.

15

29

11

12

17

D

4

TORQUE T

125 in–lb (14 N.m)

CONNECT

(69) HERE BEFORE SLIDING

FIELD (10) INT

O

WIRING HARNESS

O HOUSING (17)

57

B

A

4

TORQUE TO

125 in–lb

(14 N.m)

69

C

0049

SIDE CUTAWAY VIEW OF CLUTCH HOUSING

Fig.

30

0050

Reassembly

NOTE:

5. Place

Refer to Fig. 31 for Steps 5–9.

the

engine (45)

on the cart. Align the mount

ing holes. Guide the engine wire (A) and wiring har

(69) through the mounting

ness

Install

the screws (42) and nuts (43) and torque to 15

plate grommets (8).

ft–lb (20 N.m). Install the capscrews (5), lockwash-

(6) and washer (7) from under the engine

ers

plate

ing

the

to secure the clutch housing (17). Connect

like-colored wires as shown in the Detail A.

mount

6. Be sure the face of the rotor (9a) and the field (10)

is free of all oil and contaminants. Install the rotor,

lockwashers

screws

to 7 ft–lb (9.5 N.m).

(2) and capscrews (4). T

orque the cap

After installing the rotor (9a), pull the engine recoil

to assure that the engine turns freely and there

rope

is

no friction between the rotor (9a) and the field (10).

If

there is friction, loosen the setscrews (16) and re

position the field (10) as necessary. Tighten the

setscrews oppositely and evenly to 25 in–lb

N.m). Also make sure there are no burrs on the

(2.8

outside

edge of the rotor

.

17

10

9a

TORQUE TO

7 ft–lb (9.5 N.m)

12

4

7. Be sure the face of the armature (9b) is clean. As-

-

-

semble

ing (C). A retaining ring located within the armature

makes it difficult to assemble these parts. For the

best

the armature to the shaft in

results, first

engage a few splines of both parts,

the pinion hous

then use a screwdriver to gently push the retaining

into the armature, and then engage the remain

-

ring

splines. Push the armature onto the shaft until it

ing

contacts the ring.

8. Assemble the drive/pinion housing (C) to the

-

clutch housing, using the capscrews (3) and lockwashers (2).

Connect the cord set (62) to the pressure control.

9.

-

45

3

2

16

-

-

42

0403

19n,19k

B

FACES

MUST

BE

CLEAN

9b

C

DETAIL

VIEW FROM UNDER ENGINE MOUNTING PLA

62

WHITE

A

GREEN W/

RED COVER

69

7

6

5

RED

FROM ENGINE

A

8

43

TORQUE TO

15 ft–lb (20.4 N.m)

TE

T

O FIELD

62

Fig.

31

BLACK

0405

Parts

– Displacement Pump

Model 224–527, Series A

Includes

Ref

No. Part No. Description Qty

401 187–067 ROD, piston 1

402 187–071* V–PACKING, poly 3

403 187–069*

404 111–486* O–RING 2

405 187–066 CYLINDER 1

406 187–074*

407 187–072* V–PACKING, poly 2

408 187–102* U–CUP SEAL 1

409 187–064

410 224–407 HOUSING, pump intake 1

411 102–973*

412 187–073*

413 187–078* V–P

414 187–077 NUT

415 101–859*

416 187–076 HOUSING, piston 1

417 186–951 HOUSING, outlet 1

418 187–079* V–P

419 187–070*

420 187–068 PACKING NUT 1

421 187–065 LUG NUT 1

422 224–408 PISTON SEAT 1

423 183–210 PIN 1

*These

Packing Repair Kit 224–523.

Keep a kit on hand to reduce down time.

items 401–423

GLAND, male, steel

GLAND, male

GUIDE, ball 1

BALL, intake

GLAND, female

ACKING, leather

, 1-1/4–18

BALL, piston

ACKING, leather

GLAND, female

parts also included in

1

423

1

401

416

414

415*

1

1

2

1

1

420

406*

*419

2

1

*407

413*

412*

*402

*403

418*

408*

417

*404

*405

*404

422

409

411*

410

421

0412

Ref No. 19

Pinion Housing

Includes items 19a to 19f

Parts

– Pinion Assembly

REF

NO. PART NO. DESCRIPTION QTY

19a 221–032 PINION SHAFT ASSEMBLY

19b 183–395 .SHAFT

19c 108–797 .BEARING, ball 1

19d 108–798 .BEARING, ball 1

19e 108–796

19f 183–396

Includes items 19b to 19f

, pinion

.RING, retaining, external

.HUB, armature

19a

19n

19p

19h

Lubricate

exterior

REF

NO. PART NO. DESCRIPTION QTY

NOTE:

1

19h 108–692

1

19j 107–088

19k 100–069 BALL, sst 1

19m 108–799

19n 105–489

1

1

19p 183–394 HOUSING, pinion 1

Items 19h to 19p are not included in a kit. Order them

separately as needed.

BEARING, needle, roller

BEARING, needle, needle

RING, retaining, internal

PIN, dowel

19m

19f

19d

19b

Lubricate teeth

Lubricate

outer

inner

diameters

1

1

1

2

19e

and

19k

19j

Lubricate exterior

19c

Lubricate

outer

inner

diameters

and

0042

Parts

– Complete Sprayer

COMPLETE

SPRA

YER

Model 231–148

Includes items 101 to 104

Ref

No. Part No. Description Qty

101 224–439

102 224–472 MASTIC FLOW VALVE

103 224–440

HOSE, coupled 3/4 npt(m) x

3/4 nspm(f) swivel, 3/4” ID,

50 ft (15 m) long

See manual 308–124 for parts

HOSE, coupled 3/4 npt x 1/2 npt (mbe),

5/8” ID, 40 ft. (12 m) long

102

See manual 308–124

Ref

No. Part No. Description Qty

104 224–483 BASIC SPRAYER

104a 224–442 . 55 GALLON SUCTION KIT

1

104b 224–528 . ROOFING PUMP and

1

1

104c 224–482 . SPRAYER DRIVE ASSEMBLY

Includes items 104a – 104c

See parts on page 35

PRESSURE CONTROL KIT

See parts on page 35

See parts on page 36

103

1

1

1

1

101

104c

See parts on page

36.

104b

See

parts on page 32 and 35.

104a

See parts on page

35.

0395A

Parts

– Suction Kit and Roofing Pump

SUCTION

KIT

Model 224–442

Includes items 301 to 306

Ref

No. Part No. Description Qty

301 111–338 COUPLER, 90

302 187–123 HOSE, 2” ID 1

303 187–131 SUCTION TUBE 1

304 187–119 STRAINER 1

305 –

306 111–340 GASKET 1

CLAMP

requires special tool; use radiator

clamp as alternative)

, quick disconnect 1

(clamp supplied with sprayer

305

303

ROOFING

PUMP AND PRESSURE CONTROL KIT

Model 224–528

Includes items 201 to 212

Ref

No. Part No. Description Qty

201 187–181

202 187–184 COVER PLATE 2

203 224–711 PRESSURE CONTROL, 1200 PSI

203a 155–463 . O–RING 1

204 110–885 SCREW

205 224–527 ROOFING PUMP

2

206 183–210

209 157–785 UNION, swivel, 3/4 npt(m) x

210 111–337

211 100–505

212 224–441

LABEL,

Includes

See parts on page 32

PIN, straight

3/4 npsm(f)

TEE, 3/4 npt(m) X 3/4 npt(f) x 3/4 npt(f)

BUSHING, 3/4 npt(m) x 3/8 npt(f)

BALL VALVE

ON/OFF & PRES. ADJ.

replaceable part 203a

, mach, pnh, 10–24 x 3/8”

, 3 GPM

See 306–861 for parts

206

1

1

8

1

1

1

1

1

1

201

LABEL

204

203

304

209

211

212

210

202

204

203a

205

306

301

305

302

0396

ID

LABEL

40

21

DANGER LABEL

48

56

49

41

22

Parts

20b

20a

39

20

2

– Drive

3

2

36

33

Ref

37

29

28

35

Ref 34

SEE P

ON P

19

ARTS

AGE 33

19K

1

20c

38

WARNING

LABEL

WARNING

LABEL

23

61

SEE PARTS ON

AGE 33

P

68

60

9b

45

37

16

59

14

SEE

DETAIL

ABOVE

34

42

31

32

13

15

11

12

ID LABEL

2

17

3

10

9a

2

4

4

57

69

2

67

65

8

64

43

63

7

6

5

62

66

44

26

25

24

27

0397A

Parts

– Drive

SPRAYER

DRIVE ASSEMBL

Y

Model 224–482, Series A

Includes items 1 to 69

REF

NO. PART NO. DESCRIPTION QTY

1 220–919 GEAR REDUCER 1

2 105–510 LOCKWASHER, 1/4” 17

3 100–644 CAPSCREW

4 108–803 CAPSCREW

5 100–469 CAPSCREW

6 100–133 LOCKWASHER, 3/8” 1

7 108–851 W

8 108–805 BUSHING, snap 2

9 221–031 CLUTCH ASSEMBLY

9a 183–399 .ROTOR 1

9b 108–806 .ARMATURE 1

10 183–400 FIELD 1

11 108–842 CAPSCREW

12 100–214 LOCKWASHER, 5/16” 4

13 108–800

14 183–401 KEY

15 183–517 CLAMP

16 108–801 SETSCREW

17 183–397 HOUSING, clutch 1

19 220–920 PINION HOUSING

20 220–638 DRIVE HOUSING

20a 106–227 .W

20b 183–209 .WASHER, silver colored 1

20c 100–069 .BALL 1

20d 110–293

21 183–168 COVER, drive housing 1

22 224–560 CONNECTING ROD 1

23 224–484 BEARING HOUSING 1

24 101–242 RETAINING RING, ext 2

25 154–636 WASHER 2

26 179–811 WHEEL 2

27 104–811 HUBCAP 2

28 108–068

29 183–350 WASHER 2

x 3/4”

ASHER, plain, 3/8”

Includes items 9a and 9b

PIN, dowel; 5/16 x 1”

, shaft

x 5/16” long, cone point

See parts on page 33

Includes items 20a – 20d

ASHER, bronze colored

.TUBE, grease

PIN, spring, straight, 3/16” x 1.25”

, hex sch; 1/4–20 x 3/4”

, hex sch; 1/4–28 x 1”

, hex hd; 3/8–16

, sch, 5/16–24 x 3/4”

, mounting, rotor

, 1/4–20

(not shown)

REF

NO. PART NO. DESCRIPTION QTY

31 112–798 SCREW

32 237–686 GROUNDING CLAMP

9

6

33 179–777 BUTTON, snap 2

34 224–002 CART 1

1

35 108–795 SCREW

1

36 185–188 BUSHING 2

37 220–918 HANDLE w/hose rack 1

38 181–867

1

39 185–953

40 108–850 SCREW,

41 108–849 CAPSCREW

42 110–837 SCREW

4

43 110–838 LOCKNUT

1

44 108–794

1

45 108–802

1

48 110–616 CAPSCREW, sch;

4

49 106–115 LOCKW

56 187–120

57 108–860 SCREW

1

59 187–121

1

60 187–111 SCREW, quick disconnect 2

1

61 183–169

62 224–538 CORD SET 1

63 111–348 BUSHING, strain relief 1

1

64 108–868 CLAMP

65 187–182 BRACKET

66 110–963 SCREW

67 110–996 NUT

68 187–240

69 220–980 ELECTRICAL HARNESS 1

2

Replacement W

able at no charge.

No. 8–32 x 3/8”

w/25 ft (7.6 m) wire

LABEL, W

LABEL, DANGER

5/16–18 x 1–1/2”2

PLUG, tubing

ENGINE, gasoline, 5 HP

3/8–16 x 1–1/2” (special) 4

LABEL, ID

8–32 x 1/4”

LABEL, ID

SPRING, retaining

5/16–18 x 3/4”

LABEL, warning

arning and Danger Labels and tags avail

, mach, hex washer hd,

, mach, pnh, 10–32 x 0.312

ARNING

mach, filh; 8–32 x 1–1/4”4

, serrated flange, hex hd,

, 5/16”

ASHER, 3/8”, high collar

, mach, slotted, bdgh

, wire

, power cord

, serrated flange, hex hd,

, flanged, hex hd

on

engine

on

drive housing

, hex sch; 1/4–20 x 3”

1

1

4

1

1

2

4

2

1

4

1

2

1

1

2

1

2

2

1

-

Accessories

USE ONL

DANGER

The English language DANGER label shown on

page

who

labels to apply to your sprayer.

shows the best placement of these labels for good

visibility. Order the labels directly from Graco, free

of

charge.

T

oll Free:

French 185–956

Spanish 185–961

German 186–041

Greek 186–045

Korean 186–049

English 185–953

2 GPM PUMP KIT

1900 ps

LABELS

1 is also on your

do not read English, order one of the following

1–800–328–0211

i (

13.

2 M

Pa

Apply

language

, 1

3

2 b

sprayer

other

here

ar

Y

GENUINE GRACO

. If you have painters

The drawing below

) M

aximu

m W

orkin

238–053

g P

ressure

P

AR

TS AND ACCESSORIES

HIGH PRESSURE DISPLACEMENT PUMP

PRESSURE CONTROL, AND FIL