Page 1

Instructions

InvisiPac®

InvisiPac® InvisiPac®

Hot

Hot Hot

For

For For

Not

Not Not

See page 6 for models, approval

information and working pressure

ratings.

Melt

Melt Melt

dispensing

dispensing dispensing

approved

approved approved

Important

Important Important

Readallwarningsandinstructionsinthismanualandinrelated

manuals.Savetheseinstructions.

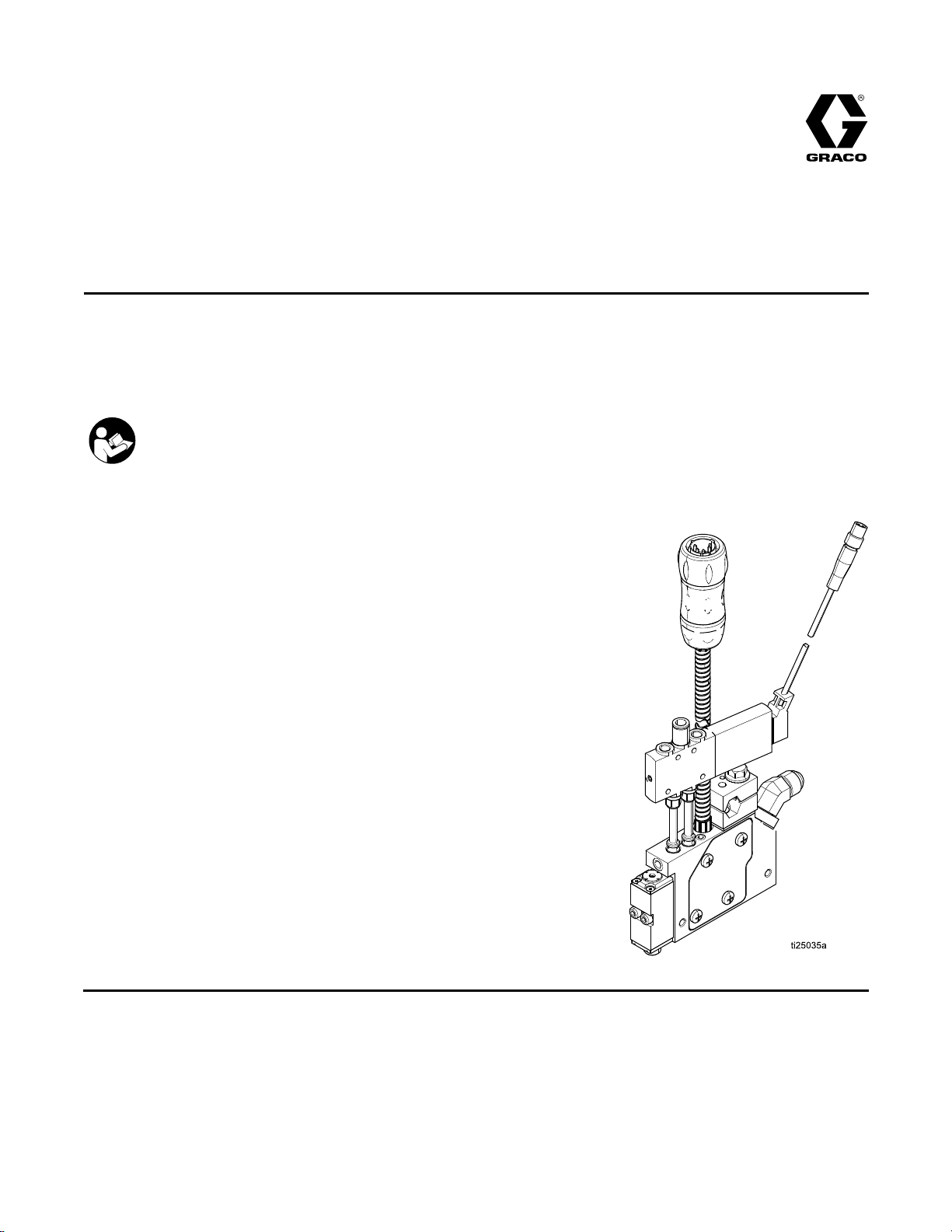

GM100

GM100 GM100

Applicator

Applicator Applicator

hot

melt

hot hot

for

use

for for

use use

Safety

Safety Safety

adhesive.

melt melt

adhesive. adhesive.

explosive

in ininexplosive explosive

Instructions

Instructions Instructions

Plug

Plug Plug

Free™

- --Free™ Free™

334627D

EN

For

professional

For For

professional professional

atmospheres

atmospheres atmospheres

use

only.

use use

only. only.

or

hazardous

or or

hazardous hazardous

locations.

locations. locations.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Warnings...........................................................3

Models...............................................................6

WorkingPressure........................................6

ModelApprovals..........................................6

ComponentIdentication.....................................7

Overview............................................................8

Grounding..........................................................8

Installation..........................................................9

Mounting.....................................................9

ConnectHeatedHose..................................9

RecommendedAirSetup..............................9

ConnectSolenoidValve...............................10

ConnectTriggeringDevice...........................10

BeforeUsingEquipment...............................10

Flush...........................................................11

InstallNozzle...............................................11

SelectRTD..................................................11

Operation...........................................................12

PressureReliefProcedure............................12

Maintenance......................................................13

ReplaceInletFilter.......................................13

FilterMaintenanceGuidelines.......................13

Troubleshooting..................................................14

CheckModule..............................................17

CheckNozzleandModule............................17

CheckHeater..............................................18

CheckRTD..................................................19

CheckThermalCutoff..................................19

Repair................................................................20

RequiredTools............................................20

BeforeBeginningRepair...............................20

ReplaceHeaterCartridge.............................20

ReplaceRTD...............................................21

ReplaceThermalCutoff................................21

ReplaceCordset..........................................23

ReplaceSolenoidValve...............................24

ReplaceModule...........................................24

ReplaceApplicator.......................................24

Notes................................................................25

Parts..................................................................26

SolenoidValveKits.............................................36

KitsandAccessories...........................................37

Dimensions........................................................40

TechnicalData...................................................45

GracoExtendedWarranty...................................46

2

334627D

Page 3

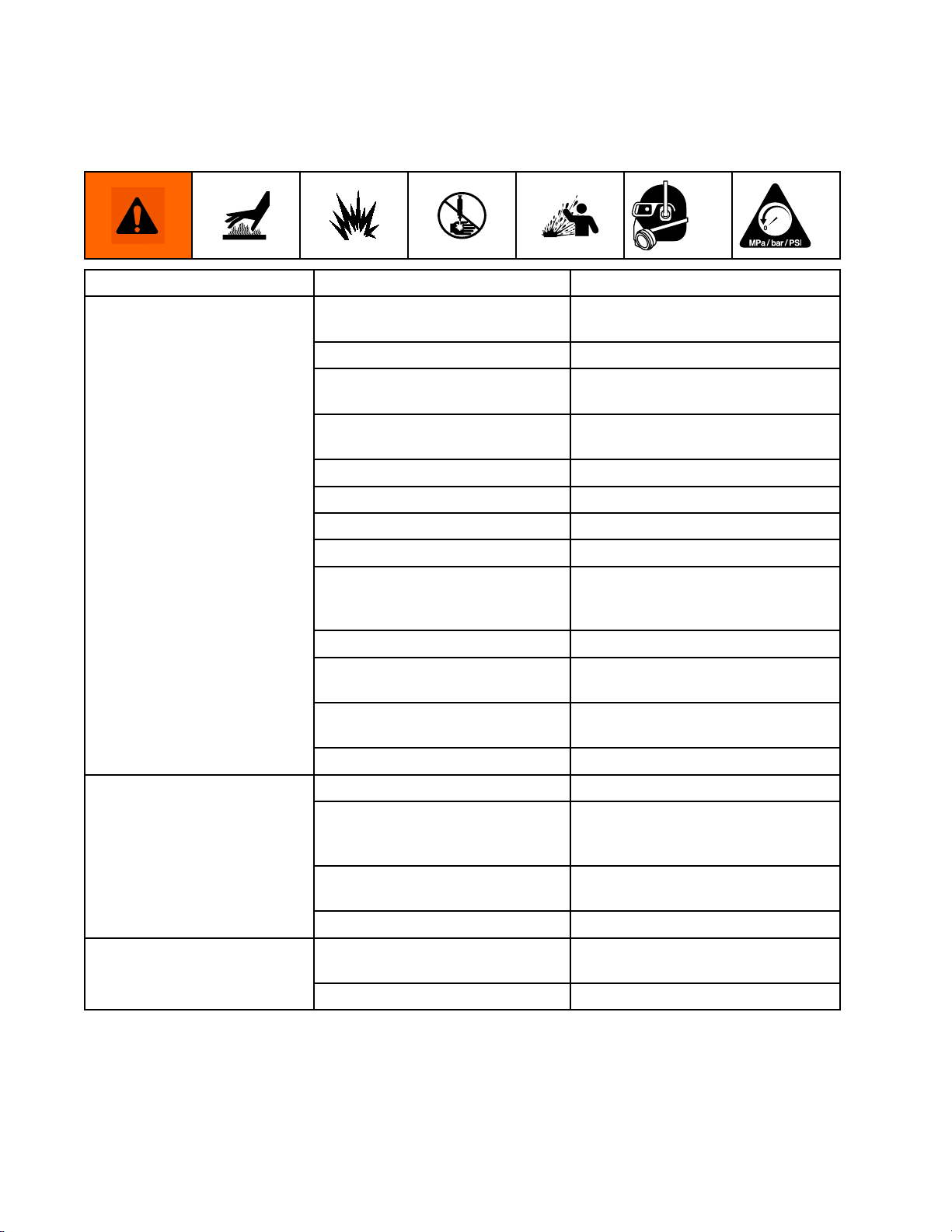

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

BURN

BURN BURN

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

ELECTRIC

ELECTRIC ELECTRIC

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

HAZARD

HAZARD HAZARD

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

Warnings

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

SKIN

INJECTION

SKIN SKIN

INJECTION INJECTION

High-pressureuidfromdispensingdevice,hoseleaks,orrupturedcomponentswillpierce

skin.Thismaylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

immediate

immediate immediate

•Donotpointdispensingdeviceatanyoneoratanypartofthebody.

•Donotputyourhandovertheuidoutlet.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

surgical

surgical surgical

HAZARD

HAZARD HAZARD

treatment.

treatment. treatment.

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

whenyoustopdispensingandbeforecleaning,

Get

334627D 3

Page 4

Warnings

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Useonlygroundedhoses.

•Holdapplicatorrmlytosideofgroundedpailwhentriggeringintopail.Donotusepail

linersunlesstheyareantistaticorconductive.

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

EQUIPMENT

EQUIPMENT EQUIPMENT

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

immediately

immediately immediately

MISUSE

MISUSE MISUSE

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Tohelp

Grounding

ifstaticsparkingoccursoryoufeelashock. ..Donotuse

HAZARD

HAZARD HAZARD

instructions.

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

FLUID

FLUID FLUID

OR

FUMES

OR OR

FUMES FUMES

Technical

HAZARD

HAZARD HAZARD

Data

Data Data

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Procedure

Procedure Procedure

whenequipmentisnotinuse.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

4

334627D

Page 5

WARNING

WARNING WARNING

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

PROTECTIVE

PROTECTIVE PROTECTIVE

EQUIPMENT

EQUIPMENT EQUIPMENT

Warnings

334627D 5

Page 6

Models

Models

Models Models

Allmodelsusea240Vheater.

Low

Prole

Low Low

Prole Prole

Dual

- --Dual Dual

ApplicatorswithNi120RTDtypescomewitha6–pin

rectangularcordset(24X040forslim,24X761for

standardDual,and24W088forallothermodels).

Slim

Slim Slim

Dual

Dual Dual

Quad

Quad Quad

(Single)

(Single) (Single)

24UPart

24UPart 24UPart

25B021

25B024Ni120

Part

Part Part

25B075

25B301Ni120

Part

Part Part

25B077

25B303Ni120

RTD

Type

RTD RTD

Type Type

Pt100(385)24VDC

RTD

Type

RTD RTD

Type Type

Pt100(385)24VDC

RTD

Type

RTD RTD

Type Type

Pt100(385)24VDC

Solenoid

Solenoid Solenoid

24VDC

Solenoid

Solenoid Solenoid

24VDC

Solenoid

Solenoid Solenoid

24VDC

Part

Part Part

25B027

25B030Ni120

Related

Related Related

Valve

Valve Valve

Valve

Valve Valve

Valve

Valve Valve

Manual

Manual Manual

332072InvisiPacHeatedHose

333347InvisiPacHM25

Working

Working Working

Maximum

Maximum Maximum

1500psi(10.3MPa,103bar)

Maximum

Maximum Maximum

80psi(0.5MPa,5.5bar)

Minimum

Minimum Minimum

65psi(0.44MPa,4.4Bar)

Number

Number Number

Working

Working Working

Working

Working Working

Working

Working Working

RTD

RTD RTD

Pt100(385)24VDC

Manuals

Manuals Manuals

Pressure

Pressure Pressure

Fluid

Fluid Fluid

Air

Air Air

Air

Air Air

Type

Type Type

Pressure:

Pressure: Pressure:

Pressure:

Pressure: Pressure:

Pressure:

Pressure: Pressure:

Solenoid

Solenoid Solenoid

24VDC

Description

Description Description

Instructions-Parts

Tank-FreeHotMelt

DeliverySystem

Valve

Valve Valve

Low

Prole

Low Low

Prole Prole

Part

Part Part

25B033

25B036Ni120

Quad

- --Quad Quad

RTD

Type

RTD RTD

Type Type

Pt100(385)24VDC

Model

Model Model

Solenoid

Solenoid Solenoid

24VDC

Valve

Valve Valve

Approvals

Approvals Approvals

6 334627D

Page 7

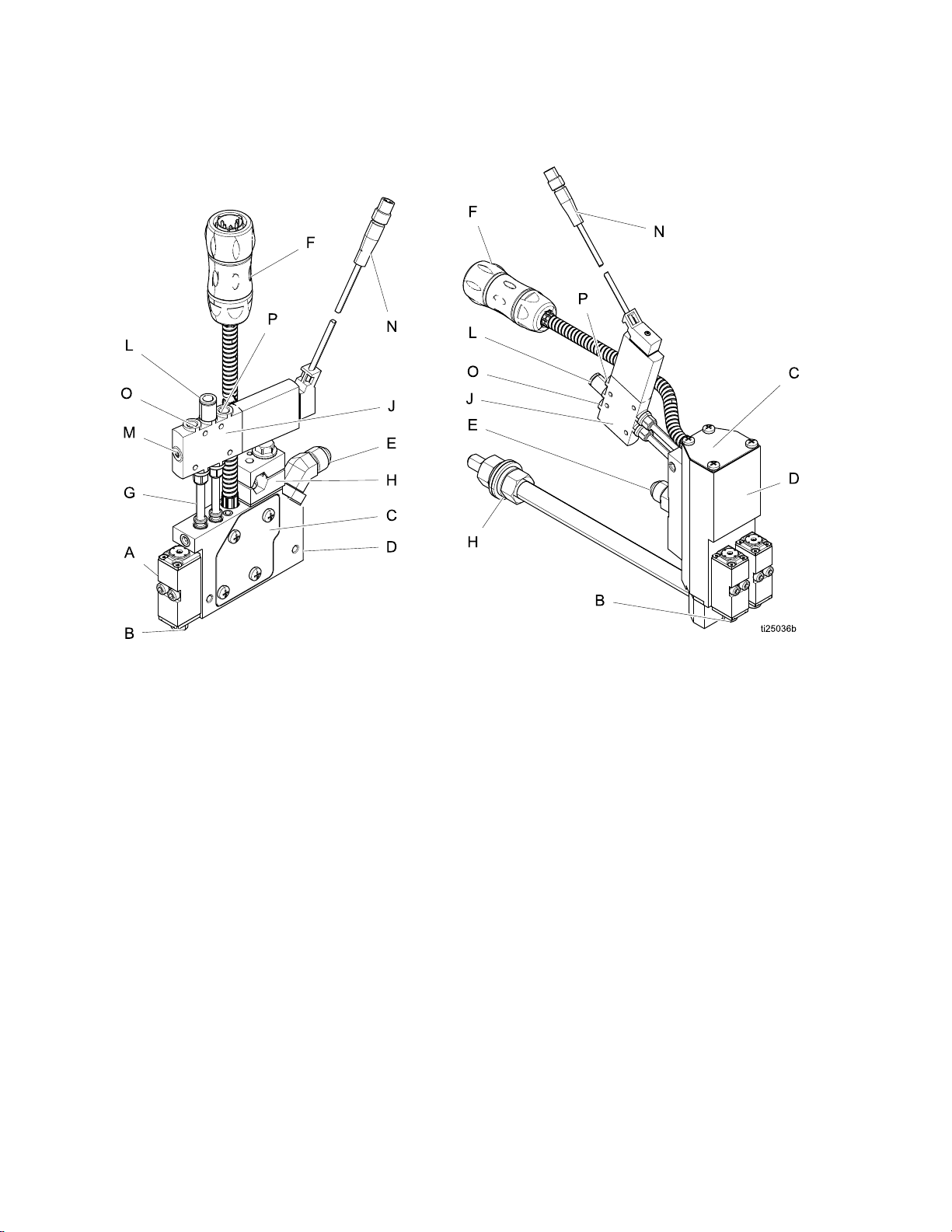

ComponentIdentication

Component

Component Component

Identication

Identication Identication

Figure1SlimModelShownonLeft,DualLowProle

ModelShownonRight

AModule

BFluidoutlet

CFluidlter

D

E

F

Manifold

Fluidinlet(9/16–18,—6JIC,37°are)

Cordset

G

H

J

L

MManualoverrideswitch

N

OAirCloseExhaustPort

P

Airtubes

Mountingclamp(1/2in.diameterbar)

Solenoidvalve(24VDC)

Airinlet(1/4in.diametertubing)

M8Solenoidvalveelectricalconnector

AirOpenExhaustPort

334627D

7

Page 8

Overview

Overview

Overview Overview

Theapplicatorusestheair-opened,airclosedmode

ofoperation.Itusesave-wayexhaustingsolenoid

tocontrolthepistoninsidethevalve.Fluidisltered

throughthemanifoldlter(C)beforeenteringthe

valveuidinletport.Thentheuidislteredonenal

timethroughthemodulelter,whichislocatedin

eachmodule,directlybeforetheballandseat.

Whenairmovesthepistonandrodfromitsseat,

itopenstheuidoutlet.Toturnofftheuid,the

solenoidredirectsairtothetopofthepiston.The

airandspringworktogethertopushthepistonand

rodintotheseat.

Theapplicatorshouldberigidlymountedand

remotelyoperatedbyameltersystemandtriggering

device.Themeltersystemprovidespressurizeduid

tothevalve.Thetriggeringdevicecontrolstheuid

owbyopeningandclosingthesolenoidvalve.

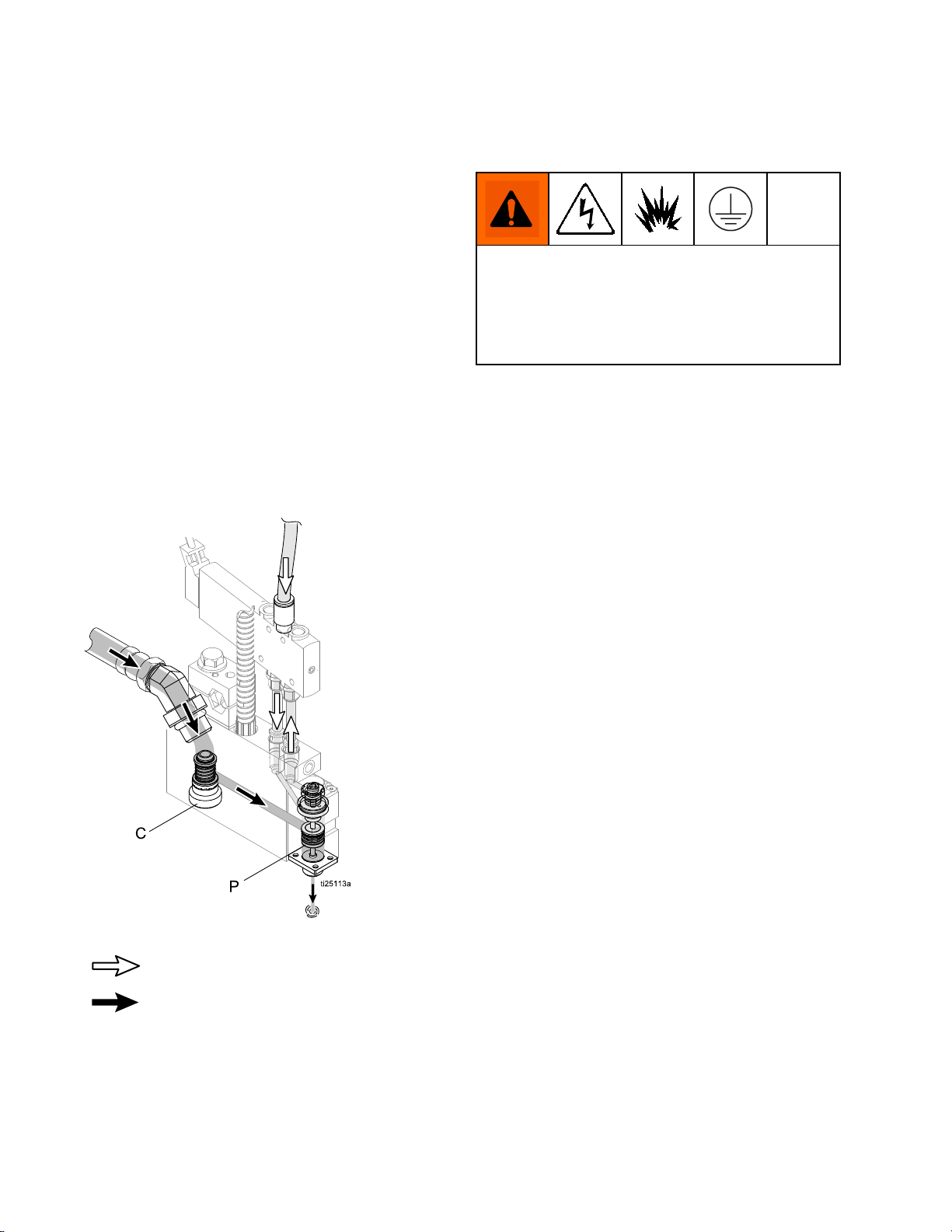

Grounding

Grounding Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

Pump:

•Pump: Pump:

Applicator:

•Applicator: Applicator:

Air

•Air Air

recommendations.

Fluid

•Fluid Fluid

Solvent

•Solvent Solvent

code.Useonlyconductivemetalpails,placed

onagroundedsurface.Donotplacethepail

onanon-conductivesurface,suchaspaperor

cardboard,whichinterruptsgroundingcontinuity.

followmanufacturer’srecommendations.

groundedthroughelectricalconnection.

compressor:

compressor: compressor:

supply

supply supply

pails

pails pails

followmanufacturer’s

container:

container: container:

used

used used

when

when when

followlocalcode.

ushing:

ushing: ushing:

followlocal

Figure2AirandFluidFlow

Air

Air Air

Fluid

Fluid Fluid

To

maintain

•To To

maintain maintain

relieving

relieving relieving

electricalpowerconnectoraregroundedproperly.

grounding

grounding grounding

pressure:

pressure: pressure:

continuity

continuity continuity

ensuremountingmanifoldand

when

ushing

when when

ushing ushing

or

or or

8 334627D

Page 9

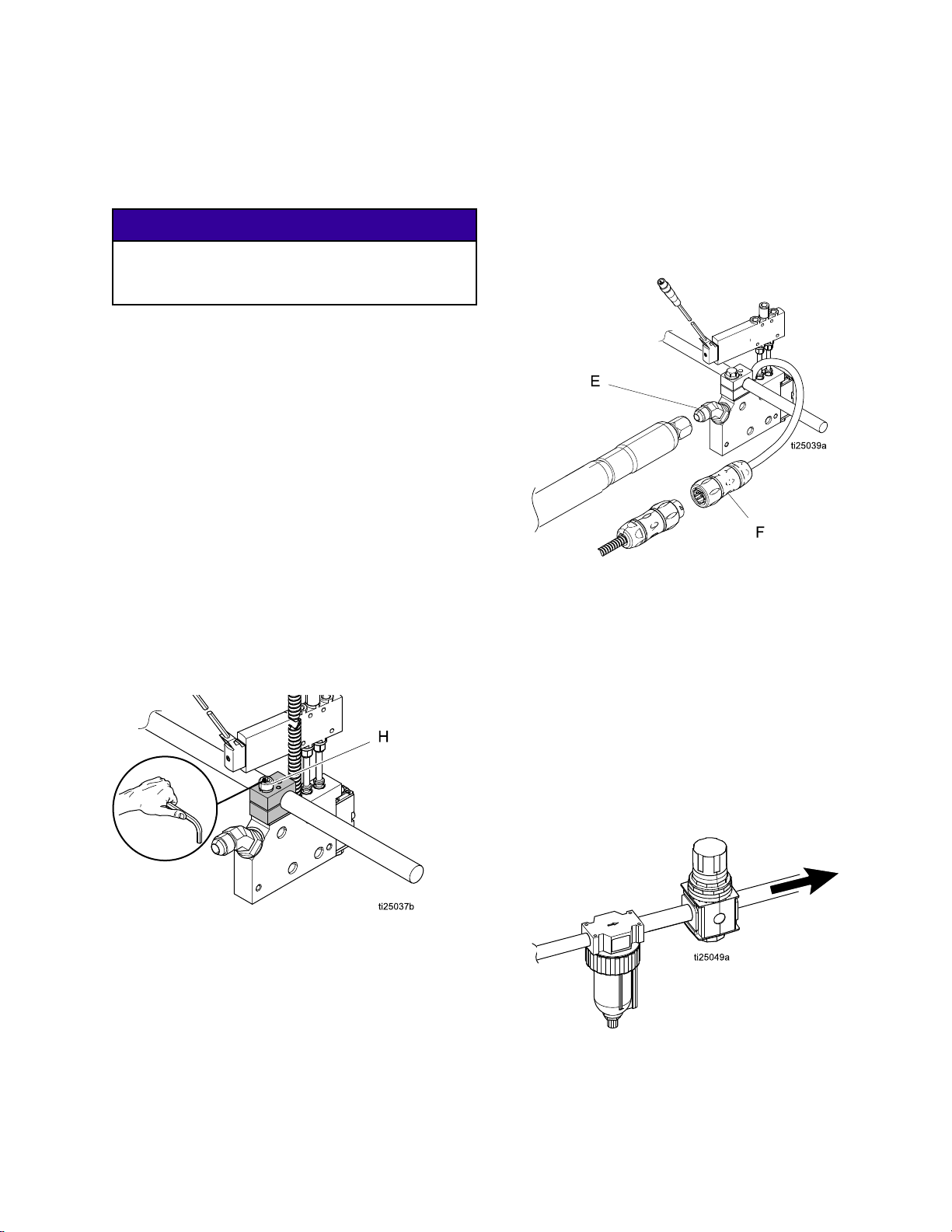

Installation

Installation

Installation Installation

Mounting

Mounting Mounting

NOTICE

NOTICE NOTICE

Topreventheattransferringintoothercomponents

ofthepackagingline,ensurethattheinsulatoris

installed.

Low

Prole

Low Low

Prole Prole

toadjustnutsthatcontrolpositionofapplicatoron

threadedrod.

All

Other

All All

Other Other

Mountmanifoldonuptoa1/2in.(12mm)diameter

barusingmountingclamp(H)toholdtheapplicator

inplaceandensureadhesiveisappliedproperly.

Foroptimalmountingstrengthofaslimmodel,use

a7/16hexbar.

NOTE:

NOTE: NOTE:

modelsusea5mmAllenwrench.

1.Useanappropriatewrenchtoloosenthe

mountingclampandslidetheapplicatoronthe

mountingbar.

2.Tightenthemountingclamp.Torqueto144in-lb

(16.2N•m).

NOTE:

NOTE: NOTE:

applicatorformaintenanceandrepair.

Models:

Models: Models:

Models:

Models: Models:

SlimStandardDualandStandardQuad

Provideenoughroomtoaccesssidesof

Usea3/4in.(19mm)wrench

Seethefollowinginstructions.

Connect

Connect Connect

1.Connectthehoseuidoutlettothemanifolduid

inlet(E).Usetwo11/16in.wrenchestotighten

thehosetting.

Figure4ConnecttheHeatedHose

2.Connectthecordset(F)tothehose.

3.Connectthehoseinlettothemeltersystem

outlet.Seetheheatedhosemanualfor

installationguidelines.

4.Connectthehosecordsettomelter.Seethe

heatedhosemanualforinstallationguidelines.

Heated

Heated Heated

Hose

Hose Hose

Recommended

Recommended Recommended

1.Connecttubingfromtheairlter(Gracopart

106148)totheairregulator.

Figure3MountingClamp

Figure5ConnecttheAirSupply

2.Settheairregulatorto80psi(5.5Bar,0.5MPa).

3.Connecttubingfromtheairregulatortothe

applicatorsolenoid.

334627D 9

Air

Setup

Air Air

Setup Setup

Page 10

Installation

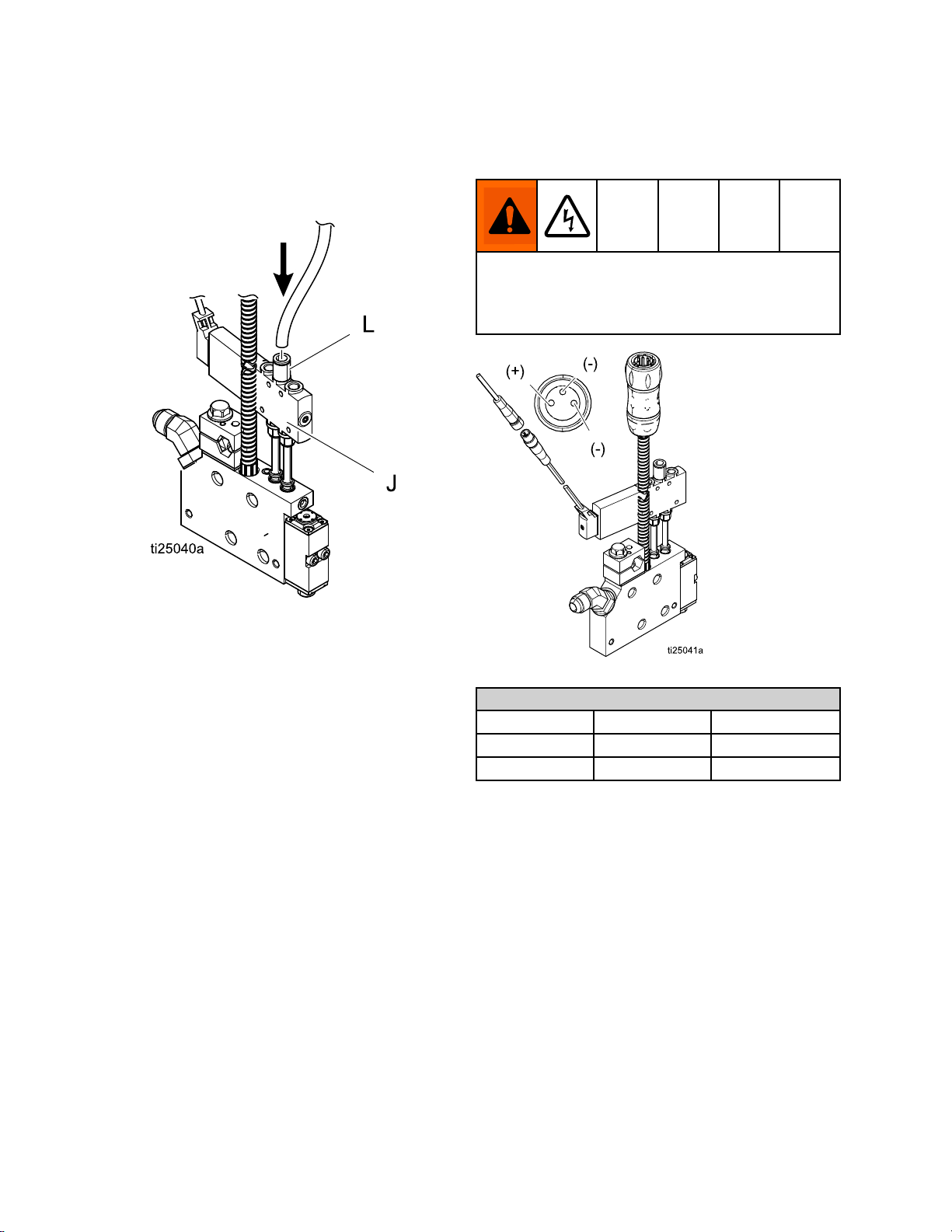

Connect

Connect Connect

1.Connect1/4in.diameterairsupplytubingtoa

clean,dry,andnon-lubricatedairsupplyandto

thepush-to-connectairinlettting(L).

Solenoid

Solenoid Solenoid

Valve

Valve Valve

Connect

Connect Connect

AllGM100valvesusea24VDCsolenoidvalve.

Improperelectricalconnectioncanresultinelectric

shock.Allelectricalwiringmustbedonebya

qualiedelectricianandcomplywithalllocalcodes

andregulations.

Triggering

Triggering Triggering

Device

Device Device

Figure6AirInletFitting

2.Connectsolenoidvalve(J)to24VDCsignal.

SeeConnectTriggeringDevice,page10.

NOTE:

NOTE: NOTE:

applicator.Thettingcanbechangedusinga5

mmAllenwrench.

A6mmtubettingisincludedwiththe

Figure7SolenoidValveElectricalConnector

Standard

Standard Standard

Terminal

Terminal Terminal

Plus(+)24VSupply

Minus(-)

Before

Before Before

Theequipmentwastestedwithcanolaoil,whichis

leftintheuidpassagestoprotectparts.Toavoid

contaminatingyouruidwithoil,primetheequipment

withhotmeltuntilalloftheoilispushedoutbefore

usingtheequipment.SeeFlush,page11.

Cable

Cable Cable

ReturnBlue/Black

Using

Using Using

Wiring

Wiring Wiring

Function

Function Function

Equipment

Equipment Equipment

Colors

Colors Colors

M8

M8 M8

Brown

10 334627D

Page 11

Installation

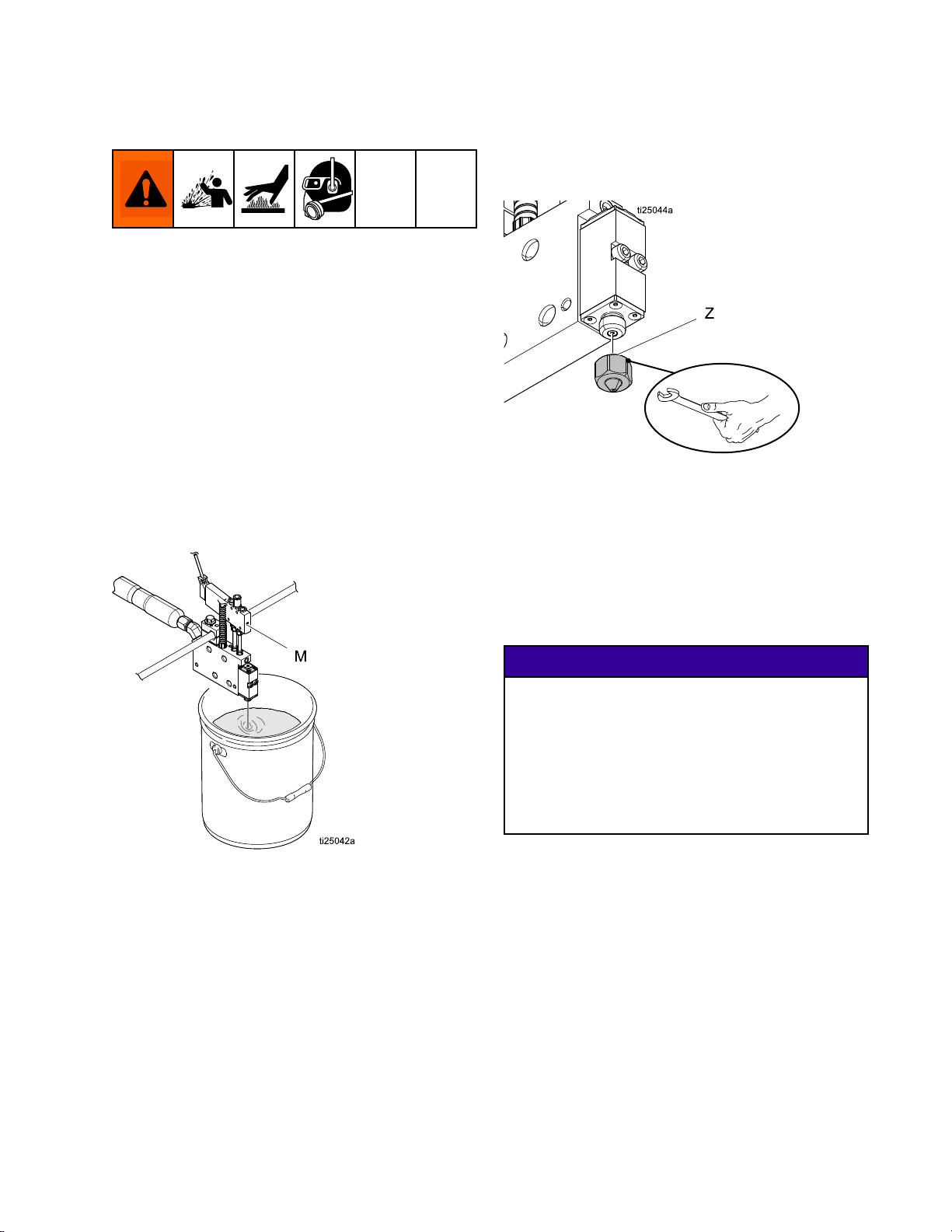

Flush

Flush Flush

NOTE:

NOTE: NOTE:

temperaturesetpointhasbeenachieved.Cycling

themodulebelowthetemperaturesetpointmay

causeprematuresealleakage.

1.Disconnectorturnoffthedevicewhichtriggers

2.Ensurethenozzle(Z)isremoved.

3.Heatthesystemtoworkingtemperature.

4.Placewastecontainerundertheapplicatorto

5.Pressthemanualoverrideswitch(M)tomanually

6.Dispensehotmelt(adhesive)untilitisclean.

DoNOTcyclethemoduleuntilthe

thesolenoidvalve.

catchtheadhesive.

triggerthesolenoidvalve.

Install

Install Install

Use1/2in.wrenchtoinstallnozzle.See

KitsandAccessories,page37.

Figure9InstallNozzle

Select

Select Select

NOTE:

NOTE: NOTE:

Nozzle

Nozzle Nozzle

RTD

RTD RTD

ForInvisiPacsystemsonly.

Figure8Flush

IdentifyRTDtypeusedinapplicatoronthesystem

AdvancedDisplayModule(ADM).TheRTDtypeis

listedonthemanifoldcoverplate.

NOTICE

NOTICE NOTICE

AnincorrectRTDsettingwillcausethesystem

tobeincapableofmaintainingthetemperature

setting.Theapplicatormayoverheatandtripthe

thermalcutoff,iftheapplicatorusesaPT100(385)

andNI120isselectedontheADMSetupscreen.

Theapplicatormayunder-heatiftheapplicator

usesaNI120andPT100(385)isselectedonthe

ADMSetupscreen.

•IfPT100(385)islisted,selectPT100(385)inthe

ADMSetupscreens.

•IfNI120islisted,selectNI120intheADMSetup

screens.

334627D

11

Page 12

Operation

Operation

Operation Operation

Pressure

Pressure Pressure

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchasskininjection,

andsplashinguid,followthePressureRelief

Procedurewhenyoustopsprayingandbefore

cleaning,checking,orservicingtheequipment.

1.Depressurizehotmeltsystem.

Relief

Relief Relief

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Procedure

Procedure Procedure

2.Closethebleed-typemasterairvalve.

3.Actuatetheapplicatorrepeatedlyuntilnouid

ows.

4.Ifyoususpectthemodulenozzleisclogged,

removenozzleandthenactuatethemoduleto

relievepressure.

5.Ifyoususpectthemoduleoruidhoseis

cloggedorthatpressurehasnotbeenfully

relievedafterfollowingthestepsabove,VERY

SLOWLYlooseninlettting,inletlter,orhose

endcouplingtorelievepressuregradually,

thenloosencompletely.Clearhoseormodule

obstruction.

6.Turnoffairpressuretothesolenoidvalve.

12

334627D

Page 13

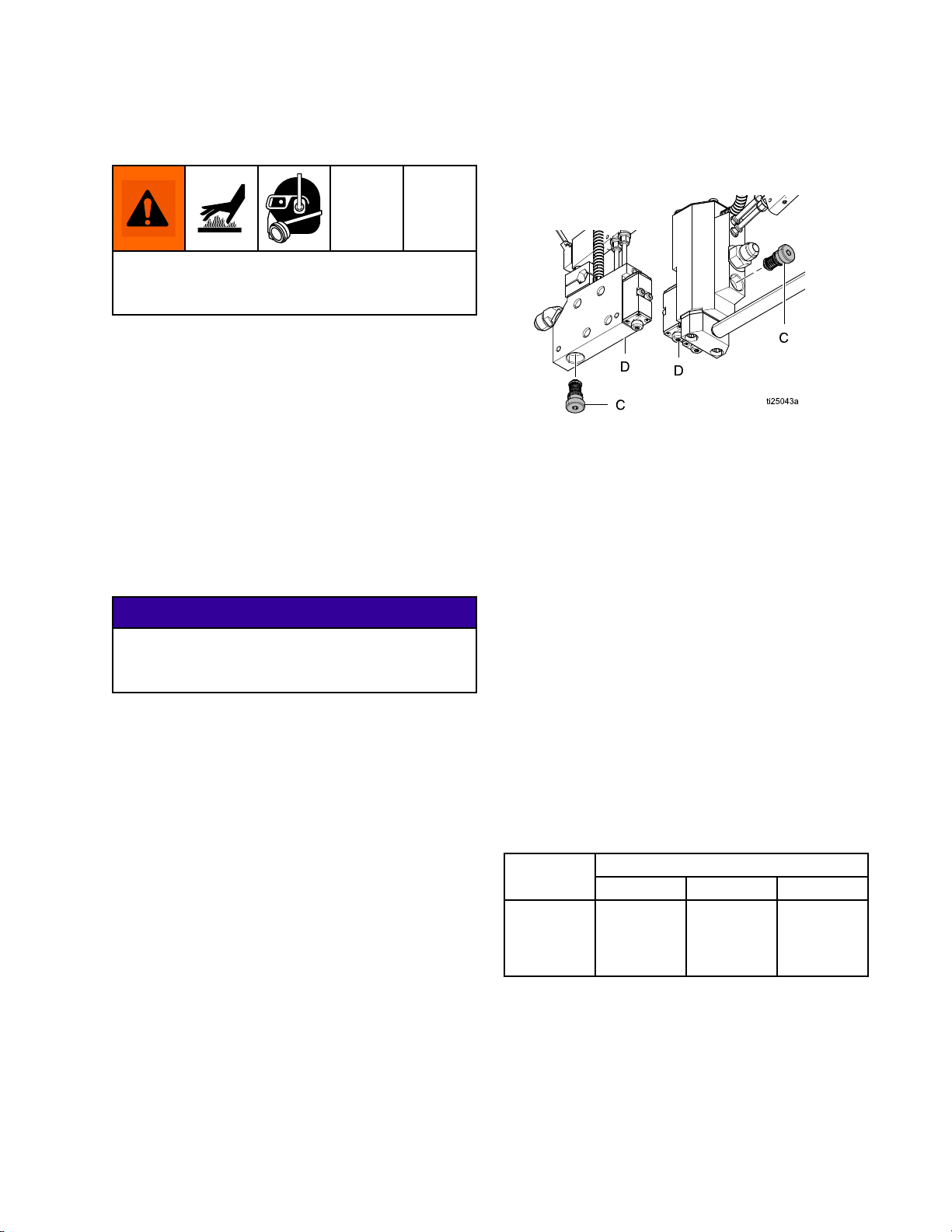

Maintenance

Maintenance Maintenance

Materialinsidetheapplicatorcanbenearsetpoint

temperature.Wearprotectiveclothingtoavoid

severeburns.

Daily:

Daily: Daily:

Cleanhotmeltfromexteriorofapplicator.

Weekly:

Weekly: Weekly:

Inspecttheapplicator,uidlines,cordset,

andsolenoidcableforwearordamage.See

Repair,page20forinstructions.

Maintenance

2.Removedirtylter(C)frommanifold(D).

Figure10InletFilter

3.Applyathincoatingofhigh-temperaturelubricant

tosealsonthenewlter(C)andinstallinthe

manifold(D).Torqueto30in.-lb(3.4N∙m),using

a5/32in.(4mm)Allenwrench.

Replace

Replace Replace

Removethelterwhentheapplicatorishot.Ifthe

applicatoriscold,theadhesivewillbehardandthe

ltermaybedifculttoremoveordamaged.

1.Disabletheapplicator.See

BeforeBeginningRepair,page20.

Inlet

Inlet Inlet

Filter

Filter Filter

NOTICE

NOTICE NOTICE

Filter

Filter Filter

These recommendations are service level guidelines

- actual service levels required in your factory

will vary based on environmental and operating

conditions. High or low volume adhesive usage, as

well as adhesives that contain a powdered release

agent or are otherwise dusty, will have an impact

on the frequency of lter maintenance. To establish

a preventative maintenance cycle tailored to your

environment, Graco recommends inspecting lters

every 4 weeks after installation and replacing when

necessary. Document replacement intervals and

use this as your preventative maintenance schedule

moving forward.

Manifold

lter

Maintenance

Maintenance Maintenance

Environment

Environment Environment

Clean

Clean Clean

Replace

lterevery

six

six six

months

Guidelines

Guidelines Guidelines

Classication

Classication Classication

Moderate

Moderate Moderate

everyfour four

Replace

lter

four

months

Replace

everytwo two

Dusty

Dusty Dusty

lter

months

two

334627D 13

Page 14

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

Problem

Problem Problem

Noadhesiveorincorrect

amountofadhesiveoutofall

moduleswhentriggered

Cause

Cause Cause

PluggedmanifoldlterReplacemanifoldlter.See

ReplaceInletFilter,page13.

CloggedhoseCleanorreplacehose.

Failedsolenoidvalve

Nosignaltosolenoidvalve

Incorrectsolenoidvalvewiring

Incorrectsignaltosolenoidvalve

SolenoidmuferpluggedCheckandreplacemufers.

NouidpressureCheckadhesivedeliverysystem.

Heaterfailure(coldapplicator)Checkandreplace

Noairtosolenoidvalve

DirtyorfaultytriggeringdeviceCheck,clean,orreplacetriggering

Solenoidvalveconnected

incorrectly

Checkforcorrectoperation.Clean

orreplace.

Checksolenoidvalveforcorrect

operation.

Checksolenoidvalvewiring.

Checkif24VDC.

heatercartridges.See

ReplaceHeaterCartridge,page20.

Checkairsupply.

device.

Checksolenoidvalveairconnections.

Solution

Solution Solution

Noadhesiveorincorrect

amountofadhesiveoutof

one/somemoduleswhen

triggered

Adhesiveoutofone/some

moduleswhennottriggered

14

CloggedmanifoldpassageCleanorreplacemanifold.

Pluggednozzle

Failedmoduleinclosedposition

PluggedmodulelterReplacemodule.See

CloggedmanifoldpassageCleanorreplacemanifold.

Failedmoduleinopenposition

Adhesivepressuretoohigh

Cleanorreplacenozzle.

Checkforcorrectoperation.

Cleanorreplace.See

CheckModule,page17.

ReplaceModule,page24.

Cleanorreplacemodule.See

ReplaceModule,page24.

Checkandreduceuidpressure.

334627D

Page 15

Troubleshooting

Problem

Problem Problem

Applicatorwillnotheat

Applicatoroverheats

Cause

Cause Cause

HeaterfailureCheckandreplace

heatercartridge.See

ReplaceHeaterCartridge,page20.

Loosecordsetconnection

RTDfailureCheckandreplaceRTD.See

IncorrectRTDforadhesivedelivery

system

ThermalcutofffailureCheckandreplace

WrongRTDtypeselected

HeaterfailureCheckandreplace

RTDfailureCheckandreplaceRTD.See

IncorrectRTDforadhesivedelivery

system

Checkconnection.

CheckRTD,page19.

CheckdeliverysystemRTD

requirement

thermalcutoff.See

ReplaceThermalCutoff,page21.

CheckRTDtypesettingsonthe

system.Changeifnecessary.See

SelectRTD,page11.

heatercartridge.See

ReplaceHeaterCartridge,page20.

CheckRTD,page19.

CheckdeliverysystemRTD

requirement.

Solution

Solution Solution

Applicatorunder-heats

Adhesiveleakingfrom

applicator

Incorrectpowertoheater

WrongRTDtypeselected

HeaterfailureCheckandreplace

RTDfailureCheckandreplaceRTD.

IncorrectRTDforadhesivedelivery

system

Incorrectpowertoheater

WrongRTDtypeselected

Moduleo-ringfailureCheckandreplaceo-ring.See

InletttinglooseTightentting.

Manifoldltero-ringfailureCheckandreplaceo-ring.

NozzlelooseTightennozzle.

Checkandcorrectpower.

CheckRTDtypesettingsonthe

system.Changeifnecessary.See

SelectRTD,page11.

heatercartridge.See

ReplaceHeaterCartridge,page20

CheckdeliverysystemRTD

requirement.

Checkandcorrectpower.

CheckRTDtypesettingsonthe

system.Changeifnecessary.See

SelectRTD,page11.

ReplaceModule,page24.

334627D 15

Page 16

Troubleshooting

Problem

Problem Problem

Speedhasreducedonone

module

Adhesiveoutofallmodules

whennottriggered

Cause

Cause Cause

Lowairpressuretosolenoidvalve

LowuidpressureCheckadhesivedeliverysystem

Lowapplicatortemperature

PluggedmanifoldlterReplacemanifoldlter(see

Modulepistonsealairleak

SolenoidvalvefailureCheckandreplacesolenoidvalve.

Adhesivepressuretoohigh

Solenoidvalveconnected

incorrectly

ModulefailureCheckandreplaceallmodules.See

Noairtosolenoidvalve

Checkairsupply

Checkheatoperation.See

“Applicatorwillnotheat”sectionin

Troubleshooting,page14.

ReplaceInletFilter,page13).

Checksolenoidaircloseexhaustport

(O).SeeReplaceModule,page24.

Checkandreduceuidpressure.

Checksolenoidvalveairconnections.

CheckModule,page17.

Checkairsupply.

Solution

Solution Solution

16 334627D

Page 17

Troubleshooting

Check

Check Check

Checkthemoduleoperationtoverifyifthemodule

hasfailedandneedstobereplaced.

1.Visuallycheckforthepresenceofglueinthe

2.Verifythattheairpressuretothesolenoidvalve

Module

Module Module

weephole(W).

NOTE:

NOTE: NOTE:

replaced.SeeReplaceModule,page24.

is65–80psi(4.4–5.5bar,0.44–0.55MPa).

Ifglueispresent,themoduleneedstobe

6.Removethenozzle.

7.Pressthemanualover-rideswitchtotriggerthe

module.Ifglueowsfromtheseat,themodule

isfunctioningproperly.

Check

Check Check

Triggertheapplicatorwithoutthenozzletodetermine

ifthenozzleormoduleisclogged.

1.Disableapplicatorassembly.See

2.Usea1/2in.wrenchtoloosenthenozzleand

Nozzle

Nozzle Nozzle

BeforeBeginningRepair,page20.

removebyhand.

and

Module

and and

Module Module

Figure11CheckModule

3.Verifythatthereisairpressuretothemotor,

whichwillverifythatthereisuidpressure.

4.Makesurethesystemisatthecorrect

temperature.

5.Whilelookingintheweepholepressthesolenoid

valvemanualoverrideswitch(M)tomanually

triggertheapplicator.

NOTE:

NOTE: NOTE:

movesthenthemoduleisfunctioningproperly.If

theroddoesnotmove,themoduleneedstobe

replaced.SeeReplaceModule,page24.

Lookthroughtheweephole.Iftherod

Figure12

3.Connectthepowerandsolenoidcable.

4.Returntheapplicatorbackintooperation.

5.Triggertheapplicator.

a.Ifadhesiveows,cleanthenozzleand

reinstallonthemodule.

b.Ifadhesivedoesnotow,themoduleis

cloggedandneedstobereplaced.See

ReplaceModule,page24.

334627D

17

Page 18

Troubleshooting

Check

Check Check

Checkthecontinuityoftheheatertoverifyproper

resistance.Ifthereisnocontinuity,theheaterhas

failedandneedstobereplaced.

1.Disableapplicator.See

2.Checkresistanceoftheheaterusinga

3.Replacetheheatercartridgeifthe

Cordset

Cordset Cordset

24W087,

24X039,

or24X760

Pt100

(385)RTD

Cordset

Heater

Heater Heater

BeforeBeginningRepair,page20.

multi-meterbetweenthepinsofthecordset

connector.Seeconnectorsillustrationsincordset

pintables.

resistancereadingisoutsidethe

rangeorifthereisnocontinuity.See

ReplaceHeaterCartridge,page20.

Check

Check Check

Pins

Pins Pins

AandC

Model

Model Model

SlimModels

DualandDual

LowProle

Models

Quadand

Quadlow

ProleModels

Table

Table Table

RTD

RTD RTD

Pin

Pin Pin

A

B

C

D

E

Table

Table Table

Cordset

Cordset Cordset

Pin

Pin Pin

Resis-

Resis- Resistance

tance tance

Values

Values Values

365–405

Ohms

180–200

Ohms

145–165

Ohms

1

2Heat-

3

5

GGround

24W087,

1 1124W087, 24W087,

Cordset

Cordset Cordset

Description

Description Description

ThermalCutoff

Ground

Heat

RTD(White)

RTD(Red)

24W088,

2 2224W088, 24W088,

Description

Description Description

ThermalCutoff

RTD(White)

RTD(Red)

24X039,

24X039, 24X039,

24X040,

24X040, 24X040,

24X760,

or oror24X760, 24X760,

24X761,

or oror24X761, 24X761,

Pt

100

Pt Pt

Ni

Ni Ni

(385)

100 100

(385) (385)

120

RTD

120 120

RTD RTD

24W088,

24X040,or

24X761Ni

120RTD

Cordset

1and2

SlimModels

DualandDual

LowProle

Models

Quadand

Quadlow

ProleModels

365–405

Ohms

180–200

Ohms

145–165

Ohms

18 334627D

Page 19

Troubleshooting

Check

Check Check

CheckthecontinuityoftheRTDtoverifyproper

resistance.Ifthereisnocontinuity,theRTDhas

failedandneedstobereplaced.

1.Disabletheapplicator.See

2.CheckresistanceoftheRTDusingamulti-meter

RTD

RTD RTD

BeforeBeginningRepair,page20.

betweenthepinsofthecordsetconnector.See

connectorsillustrationsincordsetpintables.

Cordset

Cordset Cordset

24W087,

24X039,or

24X760Pt

100(385)

RTDCordset

24W088,

24X040,or

24X761Ni

120RTD

Cordset

Check

Check Check

DandE107-115

3and5130-140

Pins

Pins Pins

Resistance

Resistance Resistance

Values

Values Values

At

At At

Temperature

Temperature Temperature

ohms

ohms

Check

Check Check

Ifworkingproperly,thecutoffwilltripat500°F(260°

C)andrestat420°F(216°C).Iffailureissuspected,

allowtheapplicatortocoolandthencheckthe

continuityofthethermalcutofftoverifyithasnot

failed.Ifthereisnocontinuity,thecutoffhasfailed

andneedstobereplaced.

1.Disabletheapplicator.See

2.Removecoverplate.

3.Checkforcontinuityusingamulti-meterbetween

Room

Room Room

Cordset

Cordset Cordset

24W087,24X039,or

24X760Pt100(385)

RTDCordset

24W088,24X040,or

24X761Ni120RTD

Cordset

Thermal

Thermal Thermal

BeforeBeginningRepair,page20.

pinofcordsetconnectorandthewirefromthe

thermalcutoffthatconnectstotheheaterlead.

Cutoff

Cutoff Cutoff

Check

Check Check

A

1

Pins

Pins Pins

3.ReplacetheRTDiftheresistancereadingis

outsidetherange,orifthereisnocontinuity.See

ReplaceRTD,page21.

334627D 19

Page 20

Repair

Repair

Repair Repair

Required

Required Required

•Phillipsscrewdriver

•Flatbladescrewdriver

•3mm,4mm,and5mmAllenwrenches

•10mm,1/2in.11/16in.,and3/4in.wrenches

•Torquewrenches

•Wastecontainer

•High-temperatureanaerobicthreadsealant

•High-temperaturelubricant

•Anti-seize

•Crimptool

Before

Before Before

Tools

Tools Tools

Beginning

Beginning Beginning

Repair

Repair Repair

Replace

Replace Replace

1.Disabletheapplicator.

SeeBeforeBeginningRepair,page20.

2.UseaPhillipsscrewdrivertoremovethefour

screws(15)andmanifoldcoverplate(18).

Heater

Heater Heater

Cartridge

Cartridge Cartridge

Materialinsidetheapplicatorcanbenearsetpoint

temperature.Wearprotectiveclothingtoavoid

severeburns.

1.Turnoffthemeltersystem.Seemeltermanual

forshutdowninstructions.

2.Relievepressure.See

PressureReliefProcedure,page12.

3.Disconnectthecordset(F)fromtheheatedhose.

Figure13DisconnectCordset

4.DisconnectM8solenoidelectricalconnector(N).

3.Removetheheatercartridges(3)fromthe

manifold(1).

NOTE:

NOTE: NOTE:

leadlengths.

4.Removebuttsplices(4)fromheaterwires(3),

thermalcutoff(29),andcordsetwireleads(17).

5.Crimpnewheaterwiresintonewsplices(4).See

wiringdiagram.

6.Insertthenewheatercartridges(3)intothe

manifold(1).

NOTE:

NOTE: NOTE:

cartridge.

7.Reinstallthemanifoldcoverplate(18).

8.Reconnectthecordset(17)totheheatedhose.

9.ReconnecttheM8solenoidelectricalconnector

(N).

Notetheplacementoftheheatersand

NOTICE

NOTICE NOTICE

Topreventashorttogroundandblowinga

MZLPfuse,ensurebarewiresarecovered

andberglasstapeandsleevesarecentered

oversplices.

Donotapplythermalgreasetotheheater

20 334627D

Page 21

Repair

Replace

Replace Replace

TheRTDisreplacedbyreplacingtheentirecordset.

SeeReplaceCordset,page23,forinstructions.

Replace

Replace Replace

1.Disabletheapplicator.See

BeforeBeginningRepair,page20.

2.UseaPhillipsscrewsdrivertoremovethefour

screws(15)andmanifoldcoverplate(18).

3.Removebuttsplices(4)fromheaterwires(3)

andcordsetwireleads(17).

4.Crimpwires.SeeWiringDiagram.

Topreventashorttogroundandblowinga

MZLPfuse,ensurebarewiresarecovered

withberglasstape(32)andsleeves(30)are

centeredoverbuttsplices(4).

RTD

RTD RTD

Thermal

Thermal Thermal

Cutoff

Cutoff Cutoff

NOTICE

NOTICE NOTICE

a.Crimpbuttspliceoncordsetheaterwires

(17)andheaterwires(3).Lightpullonsplice

toensureitiscrimped.

b.Slidesleeves(30)overeachpairofwires

beforecrimping.

c.Crimpwhitewiretoonethermalcutofflead

(29).

d.Crimpotherthermalcutofflead(29)toone

heaterwire(s)(3).

e.Crimpotherheaterwire(s)toblacklead(17).

f.Wrapashortpieceofberglasstapearound

eachsplice.

g.Centersleeves(30)overeachtapedsplice.

5.Gentlypresswiresintothemanifold.Instalplate

(18)andscrews(15).

334627D

21

Page 22

Repair

Wiring

Wiring Wiring

Thermal

Thermal Thermal

Diagram

Diagram Diagram

Cutoff

Cutoff Cutoff

NOTE:

NOTE: NOTE:

useoneheater(3).

22

Slim(25B021and25B024),Quad(25B077and25B303)andLowProleQuad(25B075and25B301)

334627D

Page 23

Repair

Replace

Replace Replace

SeeFig14,page23.

NOTE:

NOTE: NOTE:

24X039isforslim100OhmRTDcontrolled

applicators.

24X040isforslim120OhmRTDcontrolled

applicators.

24X760isfordual100OhmRTDcontrolled

applicators.

24X761isfordual120OhmRTDcontrolled

applicators.

24W087isforLowProleDual,LowProleQuad,

andQuad100OhmRTDcontrolledapplicators.

24W088isforLowProleDual,LowProleQuad,

andQuad120OhmRTDcontrolledapplicators.

Makesureyouhavethecorrectcordsetbefore

replacing.

1.Disabletheapplicator.See

BeforeBeginningRepair,page20.

2.UseaPhillipsscrewdrivertoremovethefour

screws(15)andmanifoldcoverplate(18).

Cordset

Cordset Cordset

Therearesixtypesofcordsets(17):

10.Reinstallthegroundleadontothemanifold(1).

NOTE:

NOTE: NOTE:

belowthegroundringterminal.

11.InserttheRTD(17a)andthermalcutoff(29)into

themanifoldports.SeeFig14.

NOTE:

NOTE: NOTE:

thermalcutoff.

12.Inserttheheatercartridges(3)inthemanifold(1).

13.Reinstallthemanifoldcoverplate(18).

14.Reconnectthecordset(17)totheheatedhose.

15.ReconnecttheM8solenoidelectricalconnector..

Ensurethestarwasher(20)isplaced

DonotapplygreaseontheRTDor

NOTICE

NOTICE NOTICE

Donotpinchanywireswheninsertingwire

inthemanifold,topreventremovingwire

insulationordisconnectingwires.Ifwire

insulationisremoved,theRTDorheaters

couldshortoutandneedtobereplaced.

3.Usea2mmAllenwrenchtoremovetheset

screw(6)holdingthecordset(17)onthemanifold

(1).

4.UseaPhillipsscrewdrivertoremovetheground

leadandstarwasher(20)fromthemanifold(1).

Low

Prole

Low Low

Prole Prole

nexttoRTD.

5.RemovetheRTD(17a)fromthemanifold(1).

6.Disconnectthermalcutoff(29).

7.Removethecordset(17)fromthemanifold(1).

8.Installthenewcordset,RTD,andground(17)in

themanifold(1).Crimpthermalcutoffwires(29).

SeeWiringDiagram,page22forconnections.

NOTE:

NOTE: NOTE:

insertedintothemanifold.

9.Installsetscrew(6)againstthecordsetbushing

tosecurethecordset(17)tothemanifold(1).

Models

Models Models

Ensurethecordsetbushingisfully

only:

only: only:

RemovePhillipsscrew

Figure14RepairParts

334627D 23

Page 24

Repair

Replace

Replace Replace

1.Disabletheapplicator.See

BeforeBeginningRepair,page20.

2.Turnofftheairsupplytothesolenoidvalve.

3.DisconnecttheM8solenoidelectricalconnector

(N).

4.Disconnectairlinefromairtting(L).

Figure15ReplaceSolenoidValve

5.Loosenthesolenoidvalvesetscrewwitha3mm

Allenwrench,thenremovethesolenoidvalve(J).

6.Applyhightemperaturegreasetoo-ringson

solenoidtubes.

7.Installthenewsolenoidvalveintothemanifold,

thenusea3mmAllenwrenchtotightenthe

solenoidvalvesetscrew.

8.ConnecttheM8solenoidvalveelectrical

connector(N).

9.Connectthe1/4in.airlinetothesolenoid.Turn

airon.

Replace

Replace Replace

1.Disabletheapplicator.See

BeforeBeginningRepair,page20.

Solenoid

Solenoid Solenoid

Module

Module Module

Valve

Valve Valve

NOTICE

NOTICE NOTICE

Donotallowadhesivetoentertheairports,

toallowairtoowthroughvalve.Adhesivein

theairportswillobstructtheowofairand

damagethevalve.

Figure16RemoveModuleFromManifold

3.Verifythatnoglueispresentinthemanifoldair

ports.

4.Applyhightemperaturelubricanttoairsection

o-rings(2b)anduidsectiono-ring(2a)in

module(2).

NOTE:

NOTE: NOTE:

uidsectiono-ringisblack.Allo-ringsare

uoroelastomer.Thecolorisonlyusedtoidentify

thedifferenceinsize.

5.Applyanti-seizetotwoscrewthreads(22).Use

a3mmAllenwrenchtoinstallnewmodule(2)on

manifoldwithtwoscrews(22).Torqueto28–32

in.-lb(3.2–3.6N•m).

6.Connectcordset(17)totheheatedhose.

Replace

Replace Replace

1.Disabletheapplicator.See

BeforeBeginningRepair,page20.

2.Loosenthemountingbarclampandremovethe

applicatorfromthemountingbar.

3.Installnewapplicator.SeeInstallation,page9.

Airsectiono-ringsarebrownandthe

Applicator

Applicator Applicator

2.Usea3mmAllenwrenchtoremovethetwo

mountingscrews(22)andmodule(2)from

manifold(1).

24

334627D

Page 25

Notes

Notes

Notes Notes

334627D 25

Page 26

Parts

1

2

4

10

11

Parts

Parts Parts

SLIM

SLIM SLIM

(25B021,

(25B021, (25B021,

25B024)

25B024) 25B024)

Applyathincoatingoflubricanttoseals.

Applylubricanttotherst.05in.ofthethread

ofthebolts(22)beforeinstallingmodule(2).

Torqueto30+/-2in-lb(3.3+/-0.2N•m).

Torqueto15–20in-lb(1.7–2.2N•m).

26 334627D

Torqueto10–12in-lb(1.1–1.5N•m).

Torqueto144in–lb/12ft-lb(1.5N•m).

Page 27

Parts

Table

Table Table

Ref.

Ref. Ref.

1

225B241

3♦24X043

4◌

5▲

8124736

9☼24X038

10●

11●

12●

13102411

14●

15128306

16■

17

17a24X039

17b24X040

1817A518

1917B164

Slim

Parts

1 11Slim Slim

Part

Part Part

16K931

List

Parts Parts

List List

Description

Description Description

MANIFOLD,single

MODULE,AC,GM100

HEATER,rod

CONNECTOR,buttsplice

TAG,warning

SCREW,set,cup,M4x7x4

mm,sst

SOLENOID,quickdisconnect

INSULATOR,slim

CLAMP,bottom,hinged

BOLT,shcs,M6x35mm

PIN,spring,

SCREW,mach,hex,athd

SCREW,mach,phillips,pan

hd

FILTER,applicator,80mesh

CORD,set,240V,applicator,

mini

APPLICATOR,GM100,single,

24VDC,PT100(Model

25B021)

APPLICATOR,GM100,

single,24VDC,Ni120(Model

25B024)

PANEL,single

INSULATOR,electrical

Qty.

Qty. Qty.

1

1

1

3

1

1

1

1

2

1

1

1

5

1

1

Ref.

Part

Ref. Ref.

Part Part

20157021

22111119

2424P548

25103473

2616P285

2924X046

30◌

32◌

C33049

4024X456

41▲17F001

42●

●

Included in Slim Mounting Clamp Kit, see

Kits and Accessories, page 37 .

◌

Included with all Heater, Cordset, and Overtemp

Kits, see Kits and Accessories, page 37 .

♦

Included with Slim Heater Kit, see

Description

Description Description

WASHER,lock,int

SCREW,valve

FITTING,elbow,45,JIC06x

SEA06,mm

STRAP,tie,wire

SCREW,set,cup,sockethd

SWITCH,overtemp,500F,2

in.leads

SLEEVE,silicone,red,2in.

LGX,0.16in.OD

TAPE,adhesive,berglass

CABLE,M8,3–pin,5.0m

TAG,instruction

LOCKWASHER

Qty.

Qty. Qty.

1

2

1

1

1

1

3

0.25

1

1

1

Kits and Accessories, page 37 .

■

Included in Inlet Filter Kit options, see

Kits and Accessories, page 37 .

☼

For individual solenoid components, see

Solenoid Valve Kits, page 36 .

▲

1

1

Replacement Danger and Warning labels are

available at no cost.

334627D

27

Page 28

Parts

7

11

15

17

Dual

Dual Dual

(25B075,

(25B075, (25B075,

25B301)

25B301) 25B301)

Applyathincoatingoflubricanttoseals.

Applylubricanttotherst.05in.ofthethread

ofthebolts(22)beforeinstallingmodule(2).

Torqueto30+/-2in-lb(3.3+/-0.2N•m).

28 334627D

Torqueto10–12in-lb(1.1–1.5N•m).

Torqueto15–20in-lb(1.7–2.2N•m).

Page 29

Parts

Table

Table Table

Ref. Ref.

1

225B241

3♦24X242

4◌

5▲

617D782

7

8124736

9☼24X038

1124X046

12108050

13117030

1424P549

15128306

16■

17

17a24X760

17b24X761

Dual

Parts

2 22Dual Dual

Ref.

Part

Part Part

16K931

128220

List

Parts Parts

List List

Description

Description Description

MANIFOLD,dual,GM100,

machined

MODULE,AC,GM100

HEATER,rod

CONNECTOR,buttsplice

TAG,warning

PLATE,electrical,GM100,dual

INSULATOR,electrical,dual

SCREW,set,cup,M4x0.7x4

mm,sst

SOLENOID,quickdisconnect

SWITCH,overtemp,500F,with

2in.leads

WASHER,lock,spring

SCREW,shcs,M6x40

FITTING,elbow,45,JIC06x

SEA06,mm

SCREW,mach,phillips,panhd

FILTER,applicator,80mesh

CORD,set,240V,applicator,

dual,100

APPLICATOR,GM100,dual,

24VDC,PT100(Model25B075)

APPLICATOR,GM100,dual,

24VDC,Ni120(Model25B301)

Qty.

Qty. Qty.

1

2

2

3

1

1

1

1

1

1

2

2

1

6

1

1

Ref.

Part

Ref. Ref.

Part Part

20157021

22111119

26103473

27●16T205

28●16P848

2916P285

33◌

44◌

C33049

5224X456

53▲17F001

●

Included in Dual Mounting Clamp Kit, see

Kits and Accessories, page 37 .

◌

Included with all Heater, Cordset, and Overtemp

Kits, see Kits and Accessories, page 37 .

♦

Included with Dual Heater Kit, see

Kits and Accessories, page 37 .

■

Included in Inlet Filter Kit options, see

Kits and Accessories, page 37 .

☼

For individual solenoid components, see

Description

Description Description

WASHER,lock,int

SCREW,valve

STRAP,tie,wire

CLAMP,bar,housing,metric

INSULATOR,clamp,bar,

housing

SCREW,set,cup,sockethd

SLEEVE,silicone,red,2in.

LGX0.16in.OD

TAPE,adhesive,berglass

CABLE,M8,3–pin,5.0m

TAG,instruction

Qty.

Qty. Qty.

1

4

1

2

1

1

3

0.25

1

1

Solenoid Valve Kits, page 36 .

▲

Replacement Danger and Warning labels are

available at no cost.

334627D 29

Page 30

Parts

7

11

15

17

Quad

Quad Quad

(25B077,

(25B077, (25B077,

25B303)

25B303) 25B303)

Applyathincoatingoflubricanttoseals.

Applylubricanttotherst.05in.ofthethread

ofthebolts(22)beforeinstallingmodule(2).

Torqueto30+/-2in-lb(3.3+/-0.2N•m).

30 334627D

Torqueto10–12in-lb(1.1–1.5N•m).

Torqueto15–20in-lb(1.7–2.2N•m).

Page 31

Parts

Table

Table Table

Ref. Ref.

1

225B241

3♦24X758

4◌

5▲

617A618

7

8

9☼24X038

1124X046

12●108050

13●117030

1424P549

15128306

16■

17

17a24W087

17b24W088

Quad

Parts

3 33Quad Quad

Ref.

Part

Part Part

16K931

128219

124736

List

Parts Parts

List List

Description

Description Description

MANIFOLD,quad,mini,

machinehead

MODULE,AC,GM100

HEATER,240VAC,375W,8

mmdia.

CONNECTOR,buttsplice

TAG,warning,turbo

COVER,electric,GM100,quad

INSULATION,electrical,quad

SCREW,set,cup,M4x0.7x

4mm,sst

SOLENOID,quickdisconnect

SWITCH,overtemp,500Fwith

2in.leads

WASHER,lock,spring

SCREW,shcsM6X40

FITTING,elbow,45,JIC

06XSAE06,mm

SCREW,mach,phil,panhd

FILTER,applicator,80mesh

CORDSET,240V,applicator

APPLICATOR,GM100,quad,

24VDC,PT100(Model

25B077)

APPLICATOR,GM100,quad,

24VDC,Ni120(Model25B303)

Qty.

Qty. Qty.

1

4

1

3

1

1

1

1

1

1

Ref.

Part

Ref. Ref.

Part Part

20157021

22111119

26103473

27●16T205

28●16P848

2916P285

33◌

43102233

44◌

C33049

5224X456

53▲17F001

Description

Description Description

WASHER,lock,int

SCREW,valve

STRAP,tie,wire

CLAMP,bar,housing,metric

INSULATOR,clamp,bar,

housing

SCREW,set,cup,sockethd

SLEEVE,silicone,red,2in.

LGX16in.OD

BALL,stainlesssteel

TAPE,adhesive,berglass

CABLE,M8,3–pin,5.0m

TAG,instruction

Qty.

Qty. Qty.

1

8

1

2

1

1

3

2

1

1

2

●

2

Included in Quad Mounting Clamp Kit, see

Kits and Accessories, page 37 .

1

6

1

1

◌

Included with all Heater, Cordset, and Overtemp

Kits, see Kits and Accessories, page 37 .

♦

Included with Quad Heater Kit, see

Kits and Accessories, page 37 .

■

Included in Inlet Filter Kit options, see

Kits and Accessories, page 37 .

☼

For individual solenoid components, see

Solenoid Valve Kits, page 36 .

▲

Replacement Danger and Warning labels are

available at no cost.

334627D 31

Page 32

Parts

7

8

11

17

18

Low

Prole

Low Low

Prole Prole

Quad

Quad Quad

(25B033,

(25B033, (25B033,

25B036)

25B036) 25B036)

Applyathincoatingoflubricanttoseals.

Applysealanttothreads.Theheadofthe

plugneedstobeushwiththehousing.

Applylubricanttotherst.05in.ofthethread

ofthebolts(22)beforeinstallingmodule(2).

Torqueto30+/-2in-lb(3.3+/-0.2N•m).

32 334627D

Torqueto15–20in-lb(1.7–2.2N•m).

Torqueto20–30in-lb(2.2–3.3N•m).

Page 33

Parts

Table

Table Table

Ref. Ref.

1

225B241

3♦24X758

4◌

5▲

617B968

7

8124736

9☼24X038

1124X046

12●108050

13●117029

1424P615

15128306

16■

17

17a24W087

17b24W088

1817D216

20157021

21103147

22111119

Low

Prole

Quad

Parts

4 44Low Low

Prole Prole

Quad Quad

Description

Ref.

Part

Part Part

Description Description

MANIFOLD,quad,LP,mini,

machined

MODULE,AC,GM100

HEATER,240VAC,375W,8

mmdiameter

CONNECTOR,buttsplice

16K931

TAG,warning

PLATE,side,quad,LP,

GM100

128007

INSULATOR,electrical,side

plate

SCREW,set,cup,M4x0.7x

4mm,sst

SOLENOID,quickdisconnect

SWITCH,overtemp,500F,

with2in.leads

WASHER,lock,spring

SCREW,shcs,M6X25

FITTING,adapter,JIC06x

SEA06,mm

SCREW,mach,phillips,pan

hd

FILTER,applicator,mesh80

CORD,set,240V,applicator

APPLICATOR,GM100,dual,

LP,24VDC,PT100(Model

25B033)

APPLICATOR,GM100,dual,

LP,24VDC,Ni120(Model

25B036)

PLATE,back,quad,LP,

GM100

WASHER,lock,int

PLUG,pipe

SCREW,valve

List

Parts Parts

List List

Qty.

Qty. Qty.

1

4

1

3

1

Ref.

Part

Ref. Ref.

Part Part

26103473

2916P285

33◌

35●

36●

1

37●

1

1

1

38●102598

39●109570

40●100020

41●100018

1

2

2

1

10

1

1

42●100321

43102233

44◌

C33049

46128008

5224X456

53▲17F001

●

Included in Quad Mounting Clamp Kit, see

Description

Description Description

STRAP,tie,wire

SCREW,set,cup,sockethd

SLEEVE,silicone,red,2in.

LGX0.16in.OD

INSULATOR,clamp,GM100,

quad,LP

BLOCK,mounting,GM100,

quad,LP

ROD,mtg,threaded,low

prole

SCREW,cap,sockethead

WASHER,plain

WASHER,lock

WASHER,lock,spring

NUT

BALL,stainlesssteel

TAPE,adhesive,berglass

INSULATOR,electrical,back

plate

CABLE,M8,3–pin,5.0M

TAG,instructions

Qty.

Qty. Qty.

1

1

3

1

1

1

1

2

1

2

2

4

0.25

1

1

1

Kits and Accessories, page 37 .

◌

Included with all Heater, Cordset, and Overtemp

Kits, see Kits and Accessories, page 37 .

♦

Included with Quad Heater Kit, see

Kits and Accessories, page 37 .

■

Included in Inlet Filter Kit options, see

1

1

1

8

Kits and Accessories, page 37 .

☼

For individual solenoid components, see

Solenoid Valve Kits, page 36 .

▲

Replacement Danger and Warning labels are

available at no cost.

334627D 33

Page 34

Parts

7

8

11

15

17

18

Low

Prole

Low Low

Prole Prole

Dual

Dual Dual

(25B027,

(25B027, (25B027,

25B030)

25B030) 25B030)

Applyathincoatingoflubricanttoseals.

Applysealanttothreads.Theheadofthe

plugneedstobeushwiththehousing.

Applylubricanttotherst.05in.ofthethread

ofthebolts(22)beforeinstallingmodule(2).

Torqueto30+/-2in-lb(3.3+/-0.2N•m).

34 334627D

Torqueto10–12in-lb(1.1–1.5N•m).

Torqueto15–20in-lb(1.7–2.2N•m).

Torqueto20–30in-lb(2.2–3.3N•m).

Page 35

Parts

Table

Table Table

Ref. Ref.

1

225B241

3♦24X242

4◌

5▲

8124736

9☼24X038

1124X046

12●108050

13●127941

1424P615

15128306

16■

17

17a24W087

17b24W088

18

20157021

21103147

22111119

26103473

2916P285

Low

Prole

Dual

Parts

5 55Low Low

Prole Prole

Dual Dual

Description

Ref.

Part

Part Part

Description Description

MANIFOLD,dual,LP,mini,

machined

MODULE,AC,GM100

HEATER,rod

CONNECTOR,buttsplice

16K931

TAG,warning

SCREW,set,cup,M4x0.7x

4mm,sst

SOLENOID,quickdisconnect

SWITCH,overtemp,500F,

with2in.leads

WASHER,lock,spring

SCREW,shcs,M5x25

FITTING,adapter,JIC06x

SEA06,mm

SCREW,mach,phillips,pan

hd

FILTER,applicator,80mesh

CORD,set,240V,applicator

APPLICATOR,GM100,dual,

LP,24VDC,PT100(Model

25B027)

APPLICATOR,GM100,dual,

LP,24VDC,Ni120(Model

25B030)

17C165

PLATE,electrical,GM100,

dual,LP

WASHER,lock,int

PLUG,pipe

SCREW,valve

STRAP,tie,wire

SCREW,set,cup,sockethd

List

Parts Parts

List List

Qty.

Qty. Qty.

1

2

Ref.

Part

Ref. Ref.

Part Part

33◌

35●

17C164

2

36●

3

1

1

1

1

2

2

17C163

37●16V783

38●102598

39●109570

40●100020

41●100018

42●100321

43102233

1

6

1

1

44◌

C33049

46127943

5224X456

53▲17F001

●

Included in Quad Mounting Clamp Kit, see

Description

Description Description

SLEEVE,silicone,red,2in.

LGX0.16in.OD

INSULATOR,clamp,GM100,

dualLP

BLOCK,mounting,GM100,

dual,LP

ROD,mtg,threaded,low

prole

SCREW,cap,sockethead

WASHER,plain

WASHER,lock

WASHER,lock,spring

NUT

BALL,stainlesssteel

TAPE,adhesive,berglass

INSULATOR,electrical

CABLE,M8,3–pin,5.0m

TAG,instructions

Qty.

Qty. Qty.

3

1

1

1

1

2

1

2

2

2

0.25

1

1

1

Kits and Accessories, page 37 .

◌

Included with all Heater, Cordset, and Overtemp

Kits, see Kits and Accessories, page 37 .

♦

Included with Quad Heater Kit, see

Kits and Accessories, page 37 .

1

1

1

4

1

■

Included in Inlet Filter Kit options, see

Kits and Accessories, page 37 .

☼

For individual solenoid components, see

Solenoid Valve Kits, page 36 .

▲

Replacement Danger and Warning labels are

available at no cost.

1

334627D 35

Page 36

SolenoidValveKits

Ref.

Solenoid

Solenoid Solenoid

24X038,

24X038, 24X038,

Valve

Valve Valve

24

VDC

24 24

VDC VDC

Solenoid Solenoid

Kits

Kits Kits

Solenoid

Valve

Valve Valve

Ref. Ref.

1

*2

*3

*4

*5

*6

Part

Part Part

---

24X044KIT,solenoidtubewith

106560

295685

17A633

24X045KIT,solenoidcable1

Description

Description Description

VALVE,solenoid,5w,sr,

24VDC

o-rings

O-RING,packing

O-RING

FITTING,1/4

push-to-connect,M7

Qty.

Qty. Qty.

1

1

1

1

1

36 334627D

Page 37

KitsandAccessories

Kits

Kits Kits

Module

Module Module

25B241

25B241 25B241

Part

Part Part

----

111119

24R835

24T179

24X834

Cordsets

Cordsets Cordsets

CordsetsincludetheRTD.Usecrimptoolkit24W086

(purchaseseparately).

Kit

Kit Kit

24X039

24X040

24X760

24X761

24W087AllothermodelsPlatinum100

24W088Allothermodels

and

and and

Replacement Replacement

Accessories

Accessories Accessories

Replacement

Description

Description Description

MODULE

SCREW,valve

O-RING(10pack)Fluid

LUBRICANT,anti-seize

AirO-RING(10pack)

Model

Model Model

Slim

SlimNickel120Ohm

StandardDual

StandardDualNickel120Ohm

RTD

RTD RTD

Platinum100

Ohm

Platinum100

Ohm

Ohm

Nickel120Ohm

Anti

Seize

Anti Anti

- --Seize Seize

24T179

24T179 24T179

Qty.

Qty. Qty.

1

2

1

1

2

Type

Type Type

Tubewith0.5ozofanti-seizeforuseonmodule

mountingscrewsinInvisiPacapplicators.

Mufers

Mufers Mufers

24X037

24X037 24X037

Includestwomufersthatcanbeusedwithsolenoid

valvekits.

Blanking

Blanking Blanking

24W017

24W017 24W017

Usetoruntwoorthreemodulesonaquadapplicator

oronemoduleonadualapplicator.

Inlet

Inlet Inlet

Kit

Kit Kit

24P275

24P8023Pack

Plate

Plate Plate

Filter

Filter Filter

Qty.

Qty. Qty.

Single

Kit

Kit Kit

Heater

Heater Heater

Heatercartridgesforsingle,dual,andquadmodels.

Kit

Kit Kit

24X043

24X242DualLow

24X758

High

High High

24T156

24T156 24T156

Packetwith3–gramsofhightemperaturelubricant.

ForuseonsealsinInvisiPacapplicators.

334627D 37

Cartridges

Cartridges Cartridges

Model

Model Model

Slim1.75in.(44mm)

Proleand

Dual

QuadLow

Proleand

Quad

Temperature

Temperature Temperature

Length

Length Length

1.75in.(44mm)

3.1in.(79mm)

Lubricant

Lubricant Lubricant

Material

Material Material

Single

Single Single

Qty.

Qty. Qty.

1

2

1

24P615

24P548

24P547

Thermal

Thermal Thermal

Kit

Kit Kit

24X046

Inlet

Inlet Inlet

Kit

Kit Kit

Fittings

Fittings Fittings

Description

Description Description

Straight

45°

90°

Cutoff

Cutoff Cutoff

Description

Description Description

Standard

Replacement

Replacement Replacement

Kits

Kits Kits

Page 38

KitsandAccessories

Mounting

Mounting Mounting

(Slim

24X042)

(Slim (Slim

24X042) 24X042)

Ref

Ref Ref

1017A496

11

12108050

13112674

14106371

24X243

24X243 24X243

Ref

Ref Ref

1024P276

11

12108050

13117029

44

45

46

47

48

49

24P277

24P277 24P277

Ref.

Ref. Ref.

116T205

2108050

3117030

416P848

Clamp

Clamp Clamp

Part

Part Part

---

(Dual

Low

(Dual (Dual

Low Low

Part

Part Part

---

---

---

---

---

---

---

(Dual

and

(Dual (Dual

and and

Part

Part Part

Kits

Kits Kits

Description

Description Description

INSULATOR,clamp,bar,

housing

CLAMP,barhousing

WASHER,lock,spring

SCREW,shcs,M6x35

SCREW,athead

Prole)

Prole) Prole)

Description

Description Description

INSULATOR,clamp,bar,

housing

BLOCK,mating,low

prole

WASHER,lock,spring

SCREW,shcs,M6x25

ROD

SCREW,cap,sockethead

WASHER,lock

WASHER,plain

WASHER,lock,spring

NUT,1/2–132

Quad)

Quad) Quad)

Description

Description Description

CLAMP,bar,housing,

metric

WASHER,lock,spring

SCREW,shcs,M6x40

INSULATOR,clamp,bar,

housing

Qty.

Qty. Qty.

Qty.

Qty. Qty.

Qty.

Qty. Qty.

24X835

24X835 24X835

Ref.

Ref. Ref.

1100018

2100020

1

2

1

1

1

1

1

2

2

1

1

1

2

2

2

2

2

1

3100321NUT2

4102598

5

6

7

816V783

9

10

Solenoid

Solenoid Solenoid

24X456

24X45710m

Remote

Remote Remote

NOTE:

NOTE: NOTE:

increases.

24X049

24X050Metric

(Low

Prole

(Low (Low

Prole Prole

Part

Part Part

108050

17C203BLOCK,mounting,

17C204INSULATOR,clamp,

Extension

Extension Extension

5m

Mounting

Mounting Mounting

Performanceisdecreasedastubelength

Standard

Quad)

Quad) Quad)

Description

Description Description

WASHER,lock,spring

WASHER,lock

SCREW,cap,socket

head

WASHER,lock,spring

WASHER,plain

SCREW,shcsM5x25

ROD,mtg,threaded,low

prole

GM100,quad,lp

GM100,quad,lp

Cables

Cables Cables

Kit

Kit Kit

Qty.

Qty. Qty.

2

1

1

2

2

2

1

1

1

38 334627D

Page 39

KitsandAccessories

Nozzles

Nozzles Nozzles

Single

Single Single

24P63624P7940.008straight

24P63724P7950.010straight

24P63824P7960.012straight

24P63924P7970.016straight

24P64024P7980.018straight

24P64124P7990.020straight

24P64224P8000.024straight

24P64324P803

24P64424P804

24P64524P805

24P64624P806

24P64724P807

24P64824P808

24P64924P809

(Single

(Single (Single

Orice)

Orice) Orice)

Pack

5 55Pack Pack

Description

Description Description

0.00890°

0.01090°

0.01290°

0.01690°

0.01890°

0.02090°

0.02490°

334627D 39

Page 40

Dimensions

(151.79 mm)

5.976

(64.95 mm)

2.557

(77.90 mm)

3.067

(95.86 mm)

3.774

(69.47 mm)

2.735

(57.15 mm)

2.250

(129.08 mm)

5.082

(19.02 mm)

.749

(101.57 mm)

3.999

(17.78 mm)

.700

(8.89 mm)

.350

(27.305 mm)

1.075

Dimensions

Dimensions Dimensions

Slim

Slim Slim

(25B021,

(25B021, (25B021,

25B024)

25B024) 25B024)

40 334627D

Page 41

Dimensions

3.29

(83.57 mm)

2.01

(51.05 mm)

1.58

(40.13 mm)

.88

(22.35 mm)

.79

(20.07 mm)

6.14

(155.96 mm)

2.72

(69.09 mm)

.75

(19.05 mm)

3.68

(93.47 mm)

4.49

(114.05 mm)

4.22

(107.19 mm)

.37

(9.40 mm)

Dual

Dual Dual

(25B075,

(25B075, (25B075,

25B301)

25B301) 25B301)

334627D

41

Page 42

Dimensions

2.01

(51.05 mm)

3.29

(83.57 mm)

3.27

(83.06 mm)

.88

(22.35 mm)

.88

(22.35 mm)

.88

(22.35 mm)

.79

(20.07 mm)

4.49

(114.05 mm)

3.73

(94.74 mm)

4.19

(106.43 mm)

.37

(9.40 mm)

.75

(19.05 mm)

6.14

(155.96 mm)

2.72

(69.09 mm)

Quad

Quad Quad

(25B077,

(25B077, (25B077,

25B303)

25B303) 25B303)

42

334627D

Page 43

Dimensions

.88

(22.35 mm)

.88

(22.35 mm)

.88

(22.35 mm)

.82

(20.83 mm)

1.94

(49.28 mm)

10.76

(273.30 mm)

2.72

(69.09 mm)

3.598

(91.39 mm)

7.17

(182.12 mm)

4.93

(125.22 mm)

1.14

(28.96 mm)

.13

(3.30 mm)

3.27

(83.06 mm)

Low

Prole

Low Low

Prole Prole

Quad

Quad Quad

(25B033,

(25B033, (25B033,

25B036)

25B036) 25B036)

334627D 43

Page 44

Dimensions

(22.35 mm)

.88

(44.45 mm)

1.75

(30.48 mm)

1.20

(20.07 mm)

.79

(3.30 mm)

.13

(132.59 mm)

5.22

(69.34 mm)

2.73

(264.16 mm)

10.40

(191.77 mm)

7.55

(91.70 mm)

3.61

Low

Prole

Low Low

Prole Prole

Dual

Dual Dual

(25B027,

(25B027, (25B027,

25B030)

25B030) 25B030)

44

334627D

Page 45

TechnicalData

Technical

Technical Technical

Data

Data Data

334627D 45

Page 46

Graco

Graco Graco

GracowarrantsallequipmentreferencedinthisdocumentwhichismanufacturedbyGracoandbearingits

nametobefreefromdefectsinmaterialandworkmanshiponthedateofsaletotheoriginalpurchaserforuse.

Withtheexceptionofanyspecial,extended,orlimitedwarrantypublishedbyGraco,Gracowill,foraperiodof

eighteenmonthsfromthedateofsale,repairorreplaceanypartoftheequipmentdeterminedbyGracotobe

defective.Thiswarrantyappliesonlywhentheequipmentisinstalled,operatedandmaintainedinaccordance

withGraco’swrittenrecommendations.

GracowarrantsallequipmentreferencedinthisdocumentwhichismanufacturedbyGracoandbearingits

nametobefreefromdefectsinmaterialandworkmanshiponthedateofsaletotheoriginalpurchaserforuse.

Withtheexceptionofanyspecial,extended,orlimitedwarrantypublishedbyGraco,Gracowill,foraperiodof

twelvemonthsfromthedateofsale,repairorreplaceanypartoftheequipmentdeterminedbyGracotobe

defective.Thiswarrantyappliesonlywhentheequipmentisinstalled,operatedandmaintainedinaccordance

withGraco’swrittenrecommendations.

Thiswarrantydoesnotcover,andGracoshallnotbeliableforgeneralwearandtear,oranymalfunction,

damageorwearcausedbyfaultyinstallation,misapplication,abrasion,corrosion,inadequateorimproper

maintenance,negligence,accident,tampering,orsubstitutionofnon-Gracocomponentparts.NorshallGraco

beliableformalfunction,damageorwearcausedbytheincompatibilityofGracoequipmentwithstructures,

accessories,equipmentormaterialsnotsuppliedbyGraco,ortheimproperdesign,manufacture,installation,

operationormaintenanceofstructures,accessories,equipmentormaterialsnotsuppliedbyGraco.

Thiswarrantyisconditionedupontheprepaidreturnoftheequipmentclaimedtobedefectivetoanauthorized

Gracodistributorforvericationoftheclaimeddefect.Iftheclaimeddefectisveried,Gracowillrepairorreplace

freeofchargeanydefectiveparts.Theequipmentwillbereturnedtotheoriginalpurchasertransportation

prepaid.Ifinspectionoftheequipmentdoesnotdiscloseanydefectinmaterialorworkmanship,repairswillbe

madeatareasonablecharge,whichchargesmayincludethecostsofparts,labor,andtransportation.

THIS

WARRANTY

THIS THIS

WARRANTY WARRANTY

INCLUDING

INCLUDING INCLUDING

FOR

FOR FOR

A AAPARTICULAR PARTICULAR

Graco’ssoleobligationandbuyer’ssoleremedyforanybreachofwarrantyshallbeassetforthabove.The

buyeragreesthatnootherremedy(including,butnotlimitedto,incidentalorconsequentialdamagesforlost

prots,lostsales,injurytopersonorproperty,oranyotherincidentalorconsequentialloss)shallbeavailable.

Anyactionforbreachofwarrantymustbebroughtwithintwo(2)yearsofthedateofsale.

GRACO

GRACO GRACO

AND

FITNESS

AND AND

FITNESS FITNESS

MATERIALS

MATERIALS MATERIALS

manufacturedbyGraco(suchaselectricmotors,switches,hose,etc.),aresubjecttothewarranty,ifany,of

theirmanufacturer.Gracowillprovidepurchaserwithreasonableassistanceinmakinganyclaimforbreachof

thesewarranties.

InnoeventwillGracobeliableforindirect,incidental,specialorconsequentialdamagesresultingfromGraco

supplyingequipmenthereunder,orthefurnishing,performance,oruseofanyproductsorothergoodssold

hereto,whetherduetoabreachofcontract,breachofwarranty,thenegligenceofGraco,orotherwise.

FORGRACOCANADACUSTOMERS

ThePartiesacknowledgethattheyhaverequiredthatthepresentdocument,aswellasalldocuments,notices

andlegalproceedingsenteredinto,givenorinstitutedpursuantheretoorrelatingdirectlyorindirectlyhereto,be

drawnupinEnglish.Lespartiesreconnaissentavoirconvenuquelarédactionduprésentedocumentseraen

Anglais,ainsiquetousdocuments,avisetprocéduresjudiciairesexécutés,donnésouintentés,àlasuitedeou

enrapport,directementouindirectement,aveclesprocéduresconcernées.

Extended

Extended Extended

IS

EXCLUSIVE,

IS IS

BUT

BUT BUT

PARTICULAR

MAKES

MAKES MAKES

OR

OR OR

EXCLUSIVE, EXCLUSIVE,

NOT

LIMITED

NOT NOT

LIMITED LIMITED

PURPOSE.

PURPOSE. PURPOSE.

NO

WARRANTY,

NO NO

WARRANTY, WARRANTY,

FOR

FOR FOR

PARTICULAR

A AAPARTICULAR PARTICULAR

COMPONENTS

COMPONENTS COMPONENTS

Warranty

Warranty Warranty

AND

AND AND

TO

TO TO

AND

AND AND

SOLD

SOLD SOLD

IN

LIEU

OF

ANY

IS ISISIN IN

LIEU LIEU

WARRANTY

WARRANTY WARRANTY

DISCLAIMS

DISCLAIMS DISCLAIMS

PURPOSE,

PURPOSE, PURPOSE,

BUT

BUT BUT

OF OF

OF

MERCHANTABILITY

OF OF

MERCHANTABILITY MERCHANTABILITY

ALL

ALL ALL

IN

CONNECTION

IN IN

NOT

NOT NOT

CONNECTION CONNECTION

MANUFACTURED

MANUFACTURED MANUFACTURED

OTHER

ANY ANY

OTHER OTHER

IMPLIED

IMPLIED IMPLIED

WARRANTIES,

WARRANTIES, WARRANTIES,

OR

OR OR

WARRANTIES

WARRANTIES WARRANTIES

WITH

ACCESSORIES,

WITH WITH

ACCESSORIES, ACCESSORIES,

BY

GRACO.

BY BY

GRACO. GRACO.

EXPRESS

EXPRESS EXPRESS

WARRANTY

WARRANTY WARRANTY

OF

MERCHANTABILITY

OF OF

MERCHANTABILITY MERCHANTABILITY

EQUIPMENT,

Theseitemssold,butnot

EQUIPMENT, EQUIPMENT,

OR

IMPLIED,

OR OR

OF

OF OF

IMPLIED, IMPLIED,

FITNESS

FITNESS FITNESS

Graco

Graco Graco

FormoreinformationaboutInvisiPac,visitwww.InvisiPac.com.

To

To To

Fortechnicalassistanceorcustomerservice,calltollfree:1–800–458–2133.

Allwrittenandvisualdatacontainedinthisdocumentreectsthelatestproductinformationavailableatthetimeofpublication.

Information

Information Information

place

an

place place

order,

an an

order, order,

contactyourGracoDistributororcalltoidentifythenearestdistributor.

Gracoreservestherighttomakechangesatanytimewithoutnotice.

Forpatentinformation,seewww.graco.com/patents.

OriginalInstructions.ThismanualcontainsEnglish.MM334627

Graco

Headquarters:

Graco Graco

Headquarters: Headquarters:

International

International International

GRACO

GRACO GRACO

INC.

AND

INC. INC.

Copyright

Copyright Copyright

SUBSIDIARIES

AND AND

SUBSIDIARIES SUBSIDIARIES

2012,

Graco

2012, 2012,

Inc.

Graco Graco

Inc. Inc.

Ofces:

Ofces: Ofces:

• ••P.O. P.O.

All

Graco

All All

Graco Graco

RevisionD–May2015

Belgium,China,Japan,Korea

P.O.

BOX

BOX BOX

manufacturing

manufacturing manufacturing

www.graco.com

Minneapolis

1441

MINNEAPOLIS

1441 1441

• ••MINNEAPOLIS MINNEAPOLIS

locations

locations locations

MN

MN MN

are

registered

are are

registered registered

55440-1441

55440-1441 55440-1441

ISO

to totoISO ISO

USA

• ••USA USA

9001.

9001. 9001.

Loading...

Loading...