Graco D Series, B Series, Glutton 218-061, Glutton 218-062, Glutton 218-060 Instructions And Parts List

...Page 1

INSTRUCTIONS-PARTS LIST

..........................................................................................................................................................................

This manual contains IMPORTANT

WARNINGS and INSTRUCTIONS

READ AND RETAIN FOR REFERENCE

THE GLUTTON@

U.S. PATENT NO. 4,029,442; 4,036,109;

AIR POWERED PUMPS

AND OTHER PATENT PENDING

@ 307-610

G

ORACO

Rev L

SUPERSEDES K

lay) psi (7 bad MAXIMUM AIR SUPPL Y PRESSURE

4’h:l RATIO PUMP

450 psi (31 bar) MAXIMUM WORKING PRESSURE

Model 218490 Series D

For use with abrasive, oil-based fluids

Model 231-019 Series B

For use with abrasive, water-based fluids

12:l RATIO PUMP

1200 psi (83 bar) MAXIMUM WORKING PRESSURE

Model 218461 Series D

23:l RATIO PUMP

231x) psi (15.9 bar) MAXIMUM WORKING PRESSURE

Model 218462 Series D

TABLE OF CONTENTS

WARNINGS

INSTALLATION..

Installing the Pump

Grounding

OPERATION

Flush the Pump Before Using

Pump Start Up

Pump

SERVICE

Troubleshooting Chart

Disassembling the Pump

Disassembling the Air Motor and Plston Rods

Assembling the Air Motor and Piston Rods..

Assembling the Pump

Servicing the Air Control Valve..

PUMP PARTS DRAWING..

PUMP PARTS LIST

AIR CONTROL VALVE PARTS DRAWING AND LIST

PACKING AND CONVERSION KITS

HOW TO ORDER REPLACEMENT PARTS

ACCESSORIES

TECHNICAL DATA.. ......................................................................................................

MOUNTING HOLE LAYOUT

DIMENSIONS

WARRANTY

.................................................................................................................................

..........................................................................................................................

....................................................................................................................

................................................................................................................................

................................................................................................................................

..........................................................................................................................

Shutdown..

.....................................................................................................................................

.....................................................................................................................

......................................................................................................................

...........................................................................................................................

...............................................................................................................

.................................................................................................................

......................................................................................................

...............................................................................................................

............................................................................................................ 8

......

..........

......

................................................................................................ 11

...........................................................................................................

..............................................................................................

...................................................................................... 16

............................................................................................ Back Cover

FOREIGN PATENTS PENDING

............................................................................... 6

.......................................................................

Back

Back Cover

Back Cover

.X

12

13

14

16

15

Cover

2

4

4

4

5

5

6

6

6

6

WARNING

Aluminum and Zinc Material Hazard

Never use 1 ,l ,l -trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing

such solvents in this equipment. Such use could result in a serious chemical reaction, with the possibility of explosion, which could cause death, serious bodily injury and/or substantial propem/ damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum and zinc parts.

GRACO INC. P.O. Box 1441 MINNEAPOLIS, MN 554404444

@COPYRIGHT 1963 GRACO INC.

Page 2

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS.

Read and understand all instruction manuals before operating equipment.

FLU/D /NJECT/ON HAZARD

WARNING

General Safety

This eauipment aenerates very high fluid pressure. Sprav from

the gun; leaks-or ruptured. components can inject fluid

through your skin and into your body and cause extremely

serious bodily injury, including the need for amputation. Also,

fluid injected or splashed into the eyes or on the skin can

cause serious damage.

NEVER point the spray gun or dispensing valve at anyone or at

any part of the body. NEVER put hand or fingers over the

spray tip or nozzle. NEVER try to “blow back” paint; this is

NOT an air spray system.

ALWAYS have the tip guard in place on the spray gun when

spraying.

ALWAYS follow the Pressure Relief Procedure, below,

before cleaning or removing the spray tip or nozzle or servicing

any system equipment.

NEVER try to stop or deflect leaks with your hand or body.

Be sure the equipment safety devices are operating properly

before each use.

Medical Alert -Airless Spray Wounds

If any fluid appears to penetrate your skin, get

MEDICAL CARE AT ONCE. DO NOT TREAT AS A

SIMPLE CUT. Tell the doctor exactly what fluid was injected.

Note to Physician:

jury. It is important to treat the injury surgically as soon

as

possible. Do not delay treatment to research toxicity.

Toxicity is a concern with some exotic coatings injected

directly into the blood stream. Consultation with a plastic

surgeon or reconstructive hand surgeon may be advisable.

Pressure Relief Procedure

To reduce the risk of serious bodilv iniury, includinq fluid iniection, splashing in the eyes or on the skin, or injury from moving parts, always follow this procedure whenever you shut off

the pump, when checking or servicing any part of the spray

system, when installing, cleaning or changing spray tips or

nozzles, and whenever you stop spraying.

Engage the gun safety latch.

::

Shut off the air to the motor.

Close the bleed-type master air valve (required).

::

Disengage the gun safety latch.

5.

Hold a metal part of the gun firmly to the side of a grounded metal pail and trigger the gun to relieve pressure.

Engage the gun safety latch.

7:

Open the drain valve (required) and/or the pump bleeder

valve, having a container ready to catch the drainage.

Leave the drain valve open until you are ready to spray

8.

again.

If you suspect that the spray tip/nozzle or hose is completely

clogged, or that pressure has not been fully relieved after

following the steps above, VERY SLOWLY loosen the retain-

ing nut or hose end coupling and relieve pressure gradually,

then loosen completely. Now clear the tip or hose obstruction.

Injection in the skin is a traumatic in-

EMERGENCY

Spray Gun and Dispensing Valve Safety Devices

Be sure all gun or dispensing valve safety devices are

operating properly before each use. Do not remove or modify

any part of the gun or dispensing valve; this can cause a

malfunction and result in serious bodily injury.

Safety Latch

Whenever you stop spraying, even for a moment, always set

the oun or dispensina valve safetv latch in the closed or “safe”

po&on, making the gun or dispensing valve inoperative.

Failure to set the safety latch can result in accidental triggering

of the gun or dispensing valve.

Diffuser /only on spray guns)

The gun diffuser breaks up spray and reduces the risk of fluid

injection when the tip is not installed. Check the diffuser

operation regularly. Follow the Pressure Relief Procedure,

at the left, then remove the spray tip. Aim the gun into a

grounded metal pail, holding the gun firmly to the pail. Using

the lowest possible pressure, trigger the gun. If the fluid emit-

ted is not diffused into an irregular stream, replace the diffuser

immediately.

Tip Guard (only on spray guns)

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you to the fluid injection hazard

and helps reduce, but does not prevent, the risk of accidental-

ly placing your fingers or any part of your body close to the

spray tip.

Trigger Guard (only on spray guns)

NEVER operate the gun with the trigger guard removed. The

trigger guard reduces the risk of accidentally triggering the

gun if it is dropped or bumped.

Spray Tip and Nozzle Safety

Use extreme caution when cleaning or changing spray tips or

nozzles. If the sorav tip or nozzle clogs while spraying, engage

the gun or dispensing valve safety latc‘h immediately.

ALWAYS follow the Pressure Relief Procedure, at the left,

and then-remove the spray tip or nozzle to clean it.

NEVER wipe off build-up around the spray tip or nozzle until

pressure is fully relieved and the gun or dispensing valve safety

latch is engaged.

MOVlNG PARTS HAZARD

Moving parts can pinch or amputate your fingers or other

body parts. KEEP CLEAR of moving parts when starting or

operating the pump. Follow the Pressure Relief Procedure,

at the left, before checking or servicing the pump to prevent it

from starting accidentally. NEVER operate the motor with the

pump housing removed.

SUCTlON HAZARD

NEVER place your hands on or near the pump suction inlet.

Powerful suction could cause serious bodily injury.

7

SO7-610

Page 3

EQUIPMENT MISUSE HAZARD

General Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible fluids,

or using worn or damaged parts, can cause them to rupture

and result in fluid injection or other serious bodily injury, fire,

explosion or property damage.

NEVER alter or modify any part of this equipment; doing so

could cause it to malfunction.

CHECK all spray equipment regularly and repair or replace

worn or damaged parts immediately.

Read and follow the fluid and solvent manufacturer’s recommendations for use of protective clothing and equipment.

System Pressure

The 4-l/2:1 ratio pump can develop 450 psi (31 bar) MAX-

IMUM WORKING PRESSUREat 100 psi (7 bar) maximum incoming air pressure.

The 12:l ratio pump can develop 7200 psi (83 bar) MAXIMUM WORKING PRESSURE at 100 psi (7 bar) maximum incoming air pressure.

The 23:l ratio pump can develop 2300 psi (15.9 bar) MAXIMUM WORKING PRESSUREat 100 psi (7 bar) maximum incoming air pressure.

Be sure that all spray equipment and accessories are rated to

withstand the maximum working pressure of this pump. DO

NOT exceed the maximum working pressure of any component or accessory used in the system.

Fluid Compatibility

BE SURE that all fluids and solvents used are chemically com-

patible with the wetted parts shown in the TECHNICAL DATA

on the back cover. Always read the fluid manufacturer’s

literature before using them in this pump.

HOSE SAFETY

High pressure fluid in the hoses can be very dangerous. If the

hose develops a leak, split or rupture due to any kind of wear,

damage or misuse, the high pressure spray emitted from it can

cause a fluid injection injury or other serious bodily injury or

property damage.

ALL FLUID HOSES MUST HAVE SPRING GUARDS ON

BOTH ENDS! The sorina auards helo orotect the hose from

kinks or bends at or &OS; 6 the cou&g which can result in

hose rupture.

TIGHTEN all fluid connections securely before each use. High

pressure fluid can dislodge a loose coupling or allow high

pressure spray to be emitted from the coupling.

NEVER use a damaged hose. Before each use, check the entire hose for cuts, leaks, abrasion, bulging cover, or damage or

movement of the hose couplings. If any of these conditions

exist, replace the hose immediately. DO NOT try to recouple

high pressure hose or mend it with tape or any other device. A

repaired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY. Do not pull on

the hoses to move the equipment. Do not use fluids which are

not compatible with the inner tube and cover of the hose. DO

NOT expose Grace hose to temperatures above 1WF W°C)

or below -40°F (-4O“C).

Hose Grounding Continuity

Proper hose grounding continuity is essential to maintaining a

grounded spray system. Check the electrical resistance of your

air and fluid hoses at least once a week. If your hose does not

have a tag on it which specifies the maximum electrical

resistance, contact the hose supplier or manufacturer for the

maximum resistance limits. Use a resistance meter in the ap-

propriate range for your hose to check the resistance. If the

resistance exceeds the recommended limits, replace it im-

mediately. An ungrounded or poorly grounded hose can make

your system hazardous. Also, read FIRE OR EXPLOSION

HAZARD, below.

F/f?E OR EXPLOSION HAZARD

Static electricity is created by the flow of fluid through the

pump and hose. If every part of the spray equipment is not

properly grounded, sparking may occur, and the system may

become hazardous. Sparking may also occur when plugging

in or unplugging a power supply cord. Sparks can ignite fumes

from solvents and the fluid being sprayed, dust particles and

other flammable substances, whether you are spraying indoors or outdoors, and can cause a fire or explosion and

serious bodily injury and property damage. Do not plug in or

unplug any power supply cords in the spray area when there is

any chance of igniting fumes still in the air.

If you experience any static sparking or even a slight shock

while using this equipment, STOP SPRAYING IMME-

DIATELY. Check the entire system for proper grounding. Do

not use the system again until the problem has been identified

and corrected.

Grounding

To reduce the risk of static soarkina, nround the Dump and all

other spray equipment used or l&%ed in the’ spray area.

CHECK your local electrical code for detailed grounding instructions for your area and type of equipment. BE SURE to

ground all of this spray equipment:

1. Pump: by connecting a ground wire and clamp to a true

earth ground. See the procedure on page 4.

2. Air and fluid hoses: use only grounded hoses with a maximum of 500 feet (150 m) combined hose lenath to ensure grounding continuity. Refer to Hose Giounding

Continuity, above.

3.

Spray gun: obtain grounding through the connection to a

properly grounded fluid hose and pump.

4.

Air compressor: according to the manufacturer’s recommendations.

5.

Fluid supply container: according to the local code.

6.

Object being sprayed: according to the local code.

7.

All solvent pails used when flushing: according to the

local code. Use only metalpails which are conductive. Do

not place the pail on a nonconductive surface, such as

paper or cardboard,

continuity.

To maintain grounding continuity when flushing or reiiev-

8.

ingpressure, always hold a metal part of the gun firmly to

the side of a grounded metal pail, then trigger the gun.

Flushing Safety

Before flushina, be sure the entire system and flushina pails

are properly giounded. Refer to Grounding, to the ‘left.

Follow the Pressure Relief Procedure on oaoe 2. and

remove the spray tip from the gun. Always use ihe lbwest

possible fluid pressure, and maintain firm metal-to-metal contact between the gun and a grounded metal pail during

flushing to reduce the risk of fluid injection injury, static sparking and splashing.

which interrupts grounding

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards-particularly the General Standards, Part 1910, and the Construction Standards, Part 1926-should be consulted.

307-610

3

Page 4

NOTES:

1. Reference numbers and letters in parentheses in the

text refer to the figure illustrations and the Parts

Drawings.

2. Dimensions, port sizes, and technical data are on

the back page.

3. Accessories are shown on page 15.

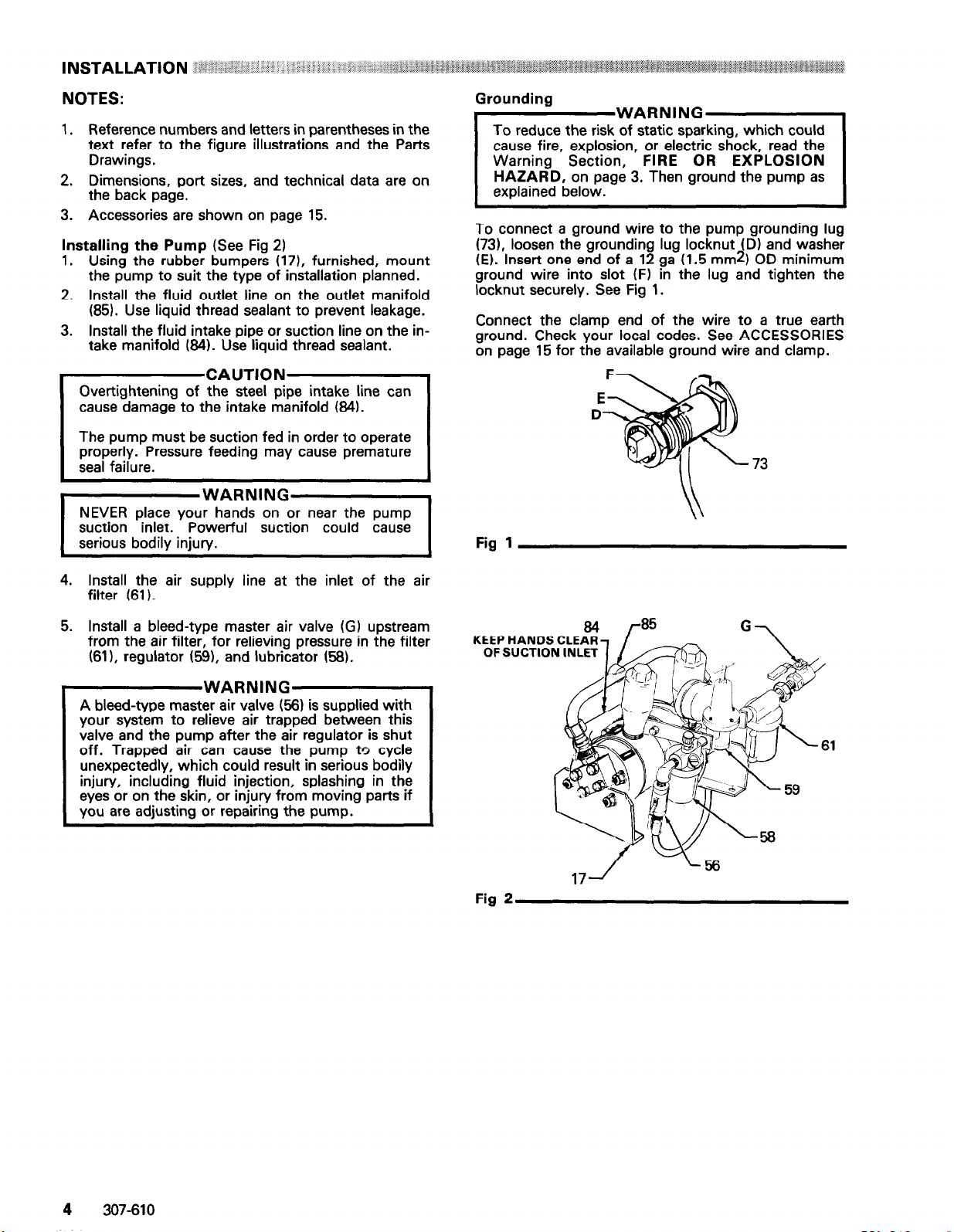

Installing the Pump (See Fig 2)

1. Using the rubber bumpers (171, furnished, mount

the pump to suit the type of installation planned.

2. Install the fluid outlet line on the outlet manifold

(85). Use liquid thread sealant to prevent leakage.

3. Install the fluid intake pipe or suction line on the in-

take manifold (64). Use liquid thread sealant.

Overtightening of the steel pipe intake line can

cause damage to the intake manifold (64).

The pump must be suction fed in order to operate

properly. Pressure feeding may cause premature

WARNING

NEVER place your hands on or near the pump

suction inlet. Powerful suction could cause

serious bodily injury.

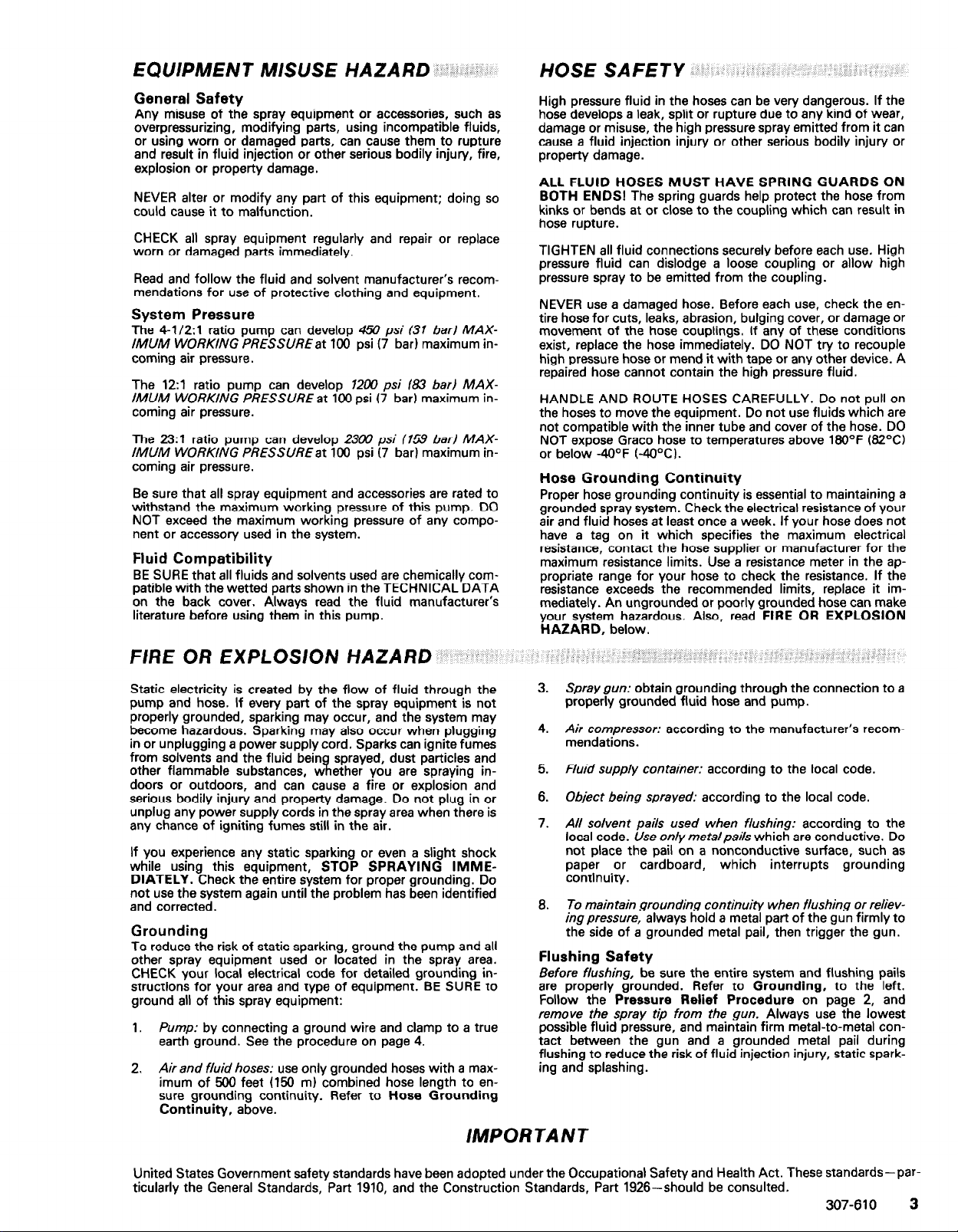

Grounding

WARNING

of static sparking, which could

cause fire, explosion, or electric shock, read the

Warning Section, FIRE OR EXPLOSION

HAZARD, on page 3. Then ground the pump as

explained below.

To connect a ground wire to the pump grounding lug

(731, loosen the grounding lug locknut (D) and washer

(El. Insert one end of a 12 ga (1.5 mm21 OD minimum

ground wire into slot (F) in the lug and tighten the

locknut securely. See Fig 1.

Connect the clamp end of the wire to a true earth

ground. Check your local codes. See ACCESSORIES

on page 15 for the available ground wire and clamp.

Fig 1

4. Install the air supply line at the inlet of the air

filter (61).

5. Install a bleed-type master air valve (G) upstream

from the air filter, for relieving pressure in the filter

(611, regulator (591, and lubricator (56).

WARNING

A bleed-type master air valve (56) is supplied with

your system to relieve air trapped between this

valve and the pump after the air regulator is shut

off. Trapped air can cause the pump to cycle

unexpectedly, which could result in serious bodily

injury, including fluid injection, splashing in the

eyes or on the skin, or injury from moving parts if

you are adjusting or repairing the pump.

84 1-85 G-i

Fig 2

4

307-610

Page 5

WAHNINb

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including fluid injection, splashing in the eyes or on

the skin, or injury from moving parts, always

follow this procedure whenever you

shut off

the

pump, when checking or servicing any part of the

spray system, when installing, cleaning or changing spray, tips or nozzles, and whenever you stop

spraying.

1. Engage the gun safety latch.

2. Shut

off the air to the motor.

3. Close the bleed-type master air valve

(required).

4. Disengage the gun safety latch.

5. Hold a metal part of the gun firmly to the side of

a grounded metal pail and trigger the gun to

relieve pressure.

6. Engage the gun safety latch.

7. Open the drain valve (required) and/or the

pump bleeder valve, having a container ready

to catch the drainage.

8. Leave the drain valve open until you are ready

to spray again.

If you suspect that the spray tip/nozzle or hose is

completely clogged, or that pressure has not been

fully relieved after following the steps above,

VERY SLOWLY loosen the retaining nut or hose

end coupling and relieve pressure gradually, then

loosen completely, Now clear the tip or hose

obstruction.

Flush the Pump Before Using

The pumps are tested with hydraulic oil, which is left in

to protect the pump parts. Read and follow Flushing

Safety under FIRE OR EXPLOSION HAZARD

on

page 3. Then flush the pump with a compatible solvent.

If the pump is being used in a circulating system, allow

the solvent to circulate long enough to thoroughly flush

the pump and the fluid lines.

Puma Start Up

1.

check and- service the lubricator, regulator, and

filter according to the instructions supplied with

them.

Open the bleed-type master air valves.

2.

Open the air regulator slowly. Adjust it until the

3.

pump runs smoothly.

4.

If you are using this pump to spray fluid, trigger the

gun to prime the hose. Adjust the pump pressure

just enough to completely atomize the fluid. Higher

pressures cause premature spray tip and pump

wear.

5.

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a

high speed, possibly damaging itself. If your pump

accelerates quickly, or is running too fast, stop it

immediately and check the fluid supply. If the supply container is empty and air has been pumped into the lines, refill the container and prime the pump

and lines with the fluid, or flush and leave filled with

a compatible solvent. Be sure to eliminate all air

from the fluid system.

Pump Shutdown

1.

Close the bleed-type master air valves.

2.

If you are using a gun or a dispensing valve, relieve

the system pressure by following the Pressure

Relief Procedure Warning at the left. If you are

not using a gun or a dispensing valve, relieve the

system pressure by opening the fluid outlet valve.

3.

Always flush the pump before the fluid dries in it.

Read and follow Flushing Safety under FIRE OR

EXPLOSION HAZARD on page 3. If the pump is

to be stored for any period of time, and you are

pumping water-based fluid, first, flush the pump

with water and then with mineral spirits or a com-

patible solvent to protect the pump parts. Leave the

mineral spirits or an oil-based solvent in the pump

to prevent corrosion.

307-610 5

Page 6

To reduce the risk of serious bodily injury, ineluding fluid injection, splashing in the eyes or on

the skin, or injury from moving parts, always

follow this procedure whenever you shut off the

pump, when checking or servicing any part of the

spray system, when installing, cleaning or changing spray tips or nozzles, and whenever you stop

spraying.

1. Engage the gun safety latch.

2. Shut off the air to the motor.

3. Close the bleed-type master air valve

(required).

4. Disengage the gun safety latch.

5. Hold a metal part of the gun firmly to the side of

a grounded metal pail and trigger the gun to

relieve pressure.

6. Engage the gun safety latch.

7. Open the drain valve (required) and/or the

pump bleeder valve, having a container ready

to catch the drainage.

8. Leave the drain valve open until you are ready

to spray again.

if you suspect that the spray tip/nozzle or hose is

completely clogged, or

fully relieved after following the steps above,

that

pressure has not been

VERY SLOWLY loosen the retaining nut or hose

end coupling and relieve the pressure gradually,

then loosen completely. Now clear the tip or hose

obstruction.

SYMPTOM

1. Pump will not

prime

2. Pump will not run

PROBABLE CAUSE TEST PROCEDURE REMEDY

Air is getting into the intake

housing:

a) Porous accumulator or poor

seal on the accumulator accumulator

threads

b) Defective o-ring on intake

manifold

cl Intake manifold not sealed

a) Tighten or replace

b) Replace o-ring

c) Tighten or add sealant to

threads of intake manifold;

replace intake

necessary

a)

Air supply turned off

b) Fluid valve turned off b)

c) Air pressure regulator set

too low

c) Minimum air pressure on

regulator 35 psi (2.4 bar)

(depending on fluid being

a) Turn air supply on

Turn fluid supply valve on

c) Increase air pressure

regulator adjustment

pumped I

e) Pilot valve assemblies (41

worn

e) Remove tube ends (18 Et 88) e) Replace pilot valve

from hose studs We); with assembly (4)

air supply on, alternately

plug tube ends; if pump

runs, remove pilot valves

and inspect

manifold if

6

307-610

f) Air control valve (531

defective

g) Air piston seal (2) worn

h) Air control valve spool h1 Check for exhaust at

g) Check for air coming

from exhaust when pump is seal (2)

not running

centered in valve block both mufflers at same time

f) Repair or replace air

control valve 63)

g) Replace air piston

hl Remove one muffler and

momentarily cover hole

Page 7

TROUBLESHOOTING CHART ‘: T il’ ’

:

SYMPTOM

L Pump runs but

does not maintain

constant pressure

PROBABLE CAUSE

a) Air in fluid line a) Check for spitting at

b) Dirty or worn check valve

assemblies (Items 12, 26, 27, continues to run, check seat (391, ball (261, spring

33, 39, Et 971

c) Pilot valve assemblies (4) c) Remove tube ends (18 Et 96) c)

worn

d) Worn piston (40) and/or

piston seal (24)

f) Air control valve mufflers

(78) plugged

g) Air control valve (53)

dirty or worn

h) Lack of lubrication

Dirty air passages

il

TEST PROCEDURE

fluid line outlet

b) Shut off fluid valve; if pump b)

valve may be dirty or worn (271, and ball guide (97);

from hose studs Me); with assembly (4)

air supply on, alternately

plug tube ends; if pump

keeps running, remove and

inspect pilot valve

assemblies

d) Shut off fluid valve; if pump d)

keeps running, piston MO)

and/or seal (24) may be

worn

f) Check for slow air flow

at mufflers (78) mufflers (78)

h) Pump reacts slowly h) Adjust lubricator

Check for sluggish air con-

il

trol valve operation

REMEDY

a) Bleed fluid line until

constant flow is obtained

Remove, clean, and inspect

replace if worn

Replace pilot valve

Replace piston and/or

seal (24)

f) Remove and clean

g) Repair or replace air

control valve (63)

il Clean air passages; (do not

enlarge orifices); empty air

line filter

1. Pump continues to a) Dirty or worn check

run with fluid valve assemblies (Items

supply valve shut

Off

i.

Paint dripping from a)

drain slot on

external side of air

motor

12, 26, 27,

b) Worn piston (40) and/or

piston seal (241

Ruptured bellows seal (8)

33, 39, Et 971

a) Shut off fluid valve; if

pump continues to run, inspect seat (391, ball

check valves may be worn

or dirty

b) Same as above

a) Check for presence

of paint on outside

of air motor

a) Remove, clean, and

126), spring (27), and ball

guide (97); replace if worn

b) Replace piston MO1

and/or piston seal (241

a) Replace bellows seal (8)

NOTE: Pressure feeding the

pump may damage bellows

seal. Be sure to suction feet

the pump.

307-610 7

Page 8

Disassembling the Pump

cluding fluid injection, splashing in the eyes or on

the skin, or injury from moving parts, ALWAYS

follow the Pressure Relief Procedure Warning

on page 6 before servicing the pump.

NOTES:

If you are using a repair kit to service the

pump, use all the new parts, even if the old

ones look good. Old parts do not seal well

with new ones, and the pump may leak.

WARNING

Certain steps in the disassembly procedure require

the use of low pressure air injected into the air

motor intake ports to move the pistons (fluid and

air) from one end of their stroke to the other.

To reduce the risk of serious bodily injury, including amputation, keep your hands clear of all

moving parts while moving the pistons with low

pressure air.

?fer to the Parts Drawing on page 12.

1. Relieve system pressure by following the Pressure

Relief Procedure Warning on page 6.

2. Disconnect the air and fluid lines, remove the pump

from its mounting and place it on a bench.

3. Loosen the two nuts on each side of the outlet

manifold (85) and remove it.

4. Remove the intake manifold (84) by removing the

nuts

(89) and washers (88) from each manifold

flange (81). Remove the screws (87).

5. Remove the four hex head bolts (50) and

lockwashers, the check valve housing (30), ball

guide (97), ball stop (33), spring (27), ball (26), seat

(39), and o-ring (12) from one end of the pump.

6. Remove two hex nuts (45) and lockwashers and the

support bracket (28). Remove the two remaining

hex nuts, lockwashers, and the pump housing (25).

7. Repeat steps 5 and 6 working on the opposite end

of the pump.

8. Remove the tube ends (18 & 96) from the hose

studs (4e) on each end of the air motor.

9. Disconnect the hose (55) from the air control

valve (53).

10. Position the pump to gain access to the air control

valve (53), located on the bottom of the pump.

Remove the four socket head machine screws (52),

and remove the air control valve from the pump.

11. Use an air blow gun to apply low pressure air f25 psi

(1.75 bar) maximum] to one of the air motor intake

ports (located at the air control valve mounting) to

move one of the pistons (40) to the full “in” position.

NOTE:

For ease of assembly, the accumulator (37)

and the intake fitting (83) should never be

removed from the pump housing (22) unless

specific repairs to the accumulator or the

pump housing are required.

13. Repeat steps 11 and 12, working on the opposite

end of the pump.

14. Remove the piston hex head bolt (44) using a

socket head breaker bar.

breaker bar using a soft mallet

Apply a sharp blow to the

to loosen the hex

bolt. Be sure you loosen the hex bolt and not the

piston stud (47).

15. Remove the piston (40) by grasping it with your

hands and pulling with a rocking motion to free it

from the piston rod.

16. Remove the bellows seal (8), [with the intake plate

(21). Models 218-060, 231-019 and 218-061 only].

Then remove the centering ring (36).

17. Repeat steps 14-16 working on the opposite end of

the pump.

Disassembling the Air Motor and Piston Rods

To remove the piston rods, the air motor must be

disassembled:

1. Remove two machine screws (43) and the pilot

valve assembly (4), from each end of the air motor.

2. If replacing the valve stem (4i) and rod seal (4h),

remove the stem from the air motor plate. Use the

end of the valve stem to pry the seal out of the air

motor plate. Do the same on the other end of the air

motor.

3. Remove the four hex head bolts (41) and the lockwashers. Remove the mounting bracket (34) with

the filter/lubricator/regulator assembly (55-62).

Remove the sixteen remaining hex bolts (41) and

both air motor plates (19, 20).

4. Remove the air motor piston (10) with the piston

rods (11) from the air motor by pushing the piston

out through the motor ring (16).

5. Using the packing nut wrench (179901, see ACCESSORIES on page 15). remove the bearing (91)

and the u-cup packing (90) from each air motor

plate (19, 20).

6. With the wrenches on the flats of the piston rods

(1 1), unscrew and disconnect the piston rods from

the air motor piston (IO) and piston stud (47).

NOTE:

DO NOT disassemble the piston rods unless

replacement is needed, as a high strength

adhesive thread sealant was used on the

threads. Heating the joint to 3OOOF will ease

disassembly if removal is necessary.

12. Working on one end of the pump with the piston at

the full “in” position, remove the piston seal (24),

piston guide (23), and the pump housing (22).

R

2n7-610

Assembling the Air Motor and Piston Rods

NOTE:

Lubricate all the packings, seals, and mating

surfaces with lithium base grease before

assembling, except the piston seal (24).

Page 9

1. Apply high strength adhesive thread sealant to the

IcAyT’oNl

piston stud (47). Partially thread one piston rod (11)

onto the piston stud.

Over-tightening of the piston rods (11) can shear

IIheAIfudT’ON -1

NOTE:

2. Install the o-ring (1) on the outside face of the air

3. Install the u-cup packing (901, lips down, into the

4. Install the valve stem (4i) and rod seal (4h) in the

5. Turn the motor ring/motor plate assembly over and

6. Insert the piston rod/piston stud assembly

7. Generously coat the inside of the air motor ring (16)

8. Install the u-cup packing (90), lips down, into the

9. Install the o-ring (1) on the outside face of the

10. Slide the left motor plate (20) onto the piston rod

11. Install the valve stem (4i) and rod seal (4h), with the

NOTE:

The piston stud threads should extend into

the piston rod about 5/16 in. (7.93 mm).

motor ring (16). Place the right motor plate (19) on

the face of the motor ring. Align the motor plate

with the motor ring by aligning the machined flats

on the outside diameter of both pieces. Install eight

hex bolts (411, with lockwashers, in the motor plate

and tighten until snug. Alternately and progressively, tighten the hex bolts and torque to lo-20 ft-lb

(13.5-27.0 N-m).

motor plate (19). Screw in the bearing (911, using

the packing nut wrench (179901, see AC-

CESSORIES). Torque the bearing to lo-20 ft-lb

(13.5-27 N.m).

motor plate (19). Then install the pilot valve

assembly (4) on the motor plate, using the two

machine screws (43).

set it on blocks.

(assembled in step 1) through the hole in the air

motor piston (10). Apply high strength adhesive

thread sealant to the exposed threads of the piston

stud (47). Then thread the other piston rod (11) onto the piston stud and hand tighten. Install the

quad-ring (2) in the groove of the air motor piston.

and the quad-ring (2) on the air motor piston (10)

with lithium base grease. Lower the piston rod/air

piston assembly (assembled in step 6) into the air

motor ring (16) until the piston rests on the motor

ring.

Using a soft mallet, lightly

of the air motor piston until it enters the motor ring.

motor plate (20). Screw in the bearing (911, using

the packing nut wrench, 179901. Torque the bear-

ing to lo-20 ft-lb (13.5-27 N.m).

motor ring (16). Apply lithium base grease to the in-

side of the motor ring where the piston (10) has

scraped the ring clear of grease during installation.

(11) and the motor ring (16). Align the motor plate

with the motor ring by aligning the machined flats

on the outside diameter of both pieces. Install eight

hex bolts (41) with lockwashers in the motor plate

and tighten until snug. Alternately and progressively, tighten eight hex bolts and torque to lo-20 ft-lb

(13.5-27.0 N-m). (The four remaining hex bolts are

used to mount the filter/lubricator/regulator

assembly in step 13.1

sealing lips down, in the motor plate (20). Then in-

stall the pilot valve assembly (4) on the motor plate,

using the two machine screws (43).

When installing the trigger valve assembly,

be sure the hose studs Me) in the housing

(4c) face away from the front of the pump to

ease tube connection.

tap around the top

13. Install the filter/lubricator/regulator assembly using

the four remaining hex bolts (41) with lockwashers.

Torque to lo-20 ft-lb (13.5-27.0 N-m). Connect the

hose (55) to the air control valve (53).

14. Connect the tubes (96) between each pilot valve’s

inlet hose stud (4e) (the hose stud farthest from the

air motor) and a manifold hose stud (95).

Assembling the Pump

1. Using an air blow gun, slowly apply low pressure air

125 psi (1.75 bar) maximum] to one of the air motor

intake ports, located on the machined flats of the

motor plates (19,201, to move either piston rod (11)

to the full “out” position.

To reduce the risk of serious bodily injury, in-

NOTE:

2. Install the centering ring (36) down along the piston

3. Coat the inside of the bellows seal (8) with lithium

DO NOT force the small end of the bellows seal (8)

onto the piston rod (11) or damage to bellows will

occur. lnstallrng the piston (40) will clamp the

bellows seal onto the piston rod.

4. Models 218-090, 231-019, 218-081 only. Place the

5. Without forcing, place the piston (40) on top of the

6. Repeat steps l-5, working on the opposite end of

7. Using a socket and breaker bar on each piston bolt

Over-tightening of the piston bolts (44) can shear

(7PiTfOn.fYd(47;AUT’oN -1

Working on the end of the air motor with the

piston rod (1 I) in the full “out” position,

complete steps 2-5.

rod (11) and onto the motor plate so that the

grooves in the face of the ring are toward the air

motor.

base grease, and place it onto the piston rod so that

the large flange of the seal faces toward the motor.

intake plate (21) over the piston rod (11) and the

bellows seal (8) so the large flange of the seal enters

the counterbore in the intake plate. Do not force

the intake plate down onto the motor plate.

bellows seal (8) and the piston rod (11). Insert the

piston bolt (44) through the piston and thread it into

the piston rod. Tighten only until snug.

the pump.

(441, torque one piston bolt to 40-50 ft-lb

(54-68 N*m). Then reverse the procedure and tor-

que the other piston bolt in the same way.

J

12. With a wrench on the flat of each piston rod (111,

apply opposing force and tighten the piston rods

until snug.

307-610 9

Page 10

8. Using an air blow gun, slowly apply low pressure air

[25 psi (1.75 bar) maximum] to one of the air motor

intake ports [located on the machined flats of the

motor plates (19, 2011, moving either piston (40) to

the full “in” position.

To reduce the risk of serious bodily injury, in-

NOTE:

9. Models 218480, 231-019, 218081 only.

NOTE:

10. Model 218-080, 231-019 only.

Working on the end of the pump with the

piston (40) at the full “in” position, complete

steps 9 and 10.

Install the face seal (29) with the flat side against

the back of the shoulder of the intake plate (21).

Then install the pump housing (22) so the seal and

the intake plate seat in the shallow counterbore of

the pump housing.

Model 218482 only

Install the pump housing (22) over the bellows seal

(8) and the piston (40) and onto the motor plate so

the counterbore in the pump housing faces in

toward the air motor.

DO NOT use grease when installing the piston seal (24) because the seal may pull out of

the counterbore of the housing.

Install the o-ring 198) on the pump housing (22). In-

stall the piston guide (23) onto the alignment studs

(38) and up against the pump housing (22) so the

larger beveled opening of the piston guide faces in

toward the air motor. Install the piston seal (24) in

the shallow counterbore of the pump housing (25).

While holding the piston seal in place, slide the

pump housing with the seal onto the alignment

studs and up against the piston guide. Install the

support bracket (28) on the alignment studs. Install

the four hex nuts (45) with lockwashers. Alternately

and progressively, tighten the hex nuts and torque

them to 20-30 ft-lb (27-40 N.m).

Model 218-081 only.

Install the o-ring (98) on the shoulder of the piston

guide (23). Install the guide on the pump housing

(22) so the o-ring faces in toward the housing. Install the piston seal (24) in the shallow counterbore

of the pump housing (25). While holding the seal in

place, slide the pump housing onto the alignment

studs (38) and up against the pump housing. Install

the support bracket (28) and the hex nuts (45) with

lockwashers onto the alignment studs. Alternately

and progressively, tighten the hex nuts and torque

them to 20-30 ft-lb (27-40 N-m).

NOTE:

When repeating steps 8-10 on the opposite end of

11. Working on one end of the pump, install the check

NOTES:

12.

13.

14.

15.

16.

Repeat steps 8-10, working on the opposite

end of the pump.

valve seat (39) in the pump housing (25) so the

flange of the seat (39) faces

the pump. Place the o-ring (12) around the seat and

onto the pump housing. Install the spring (271, ball

stop (331, and ball guide (97) in the check valve

housing (30). Align the slot in the ball guide with

the pin in the check valve housing. Standing the

pump on end, place the ball (26) on the seat. Install

the check valve housing, with the spring and the

ball stop, onto the housing, using the hex nuts (50)

and lockwashers.

1. Do not completely tighten the bolts (50)

at this time.

2. Repeat step 11, working on the opposite

end of the pump.

Install the o-ring (82) in the groove in the intake fitting (831. Install the intake manifold (84) by inserting the screws (87) into the flanged ends of the

manifold. Insert the washers (88) and the nuts (89).

Fit the outlet manifold (85) into the connectors (86)

and tighten the nuts. Alternately and progressively,

tighten the bolts (50) on the check valve housings

(30) and torque them to lo-20 ft-lb (13.5-U N.m).

Position the pump to gain access to the air control

valve mounting location on the bottom of the

pump. Using the four socket machine screws (521,

install the air control valve (53). Alternately and progressively, tighten the machine screws. Torque/

them to 35-45 in-lbs (3.9-5.1 N-m).

Connect each

outlet hose stud Me) (the hose stud closest to the

air motor) and the control valve’s elbow (115). The

tube from the right side pilot valve must connect to

the left side elbow (115) and the tube from the left

side pilot valve must connect to the right side elbow

(the two tubes will cross each other). See Fig 3. If

the tubes are not connected to the correct side

of the control valve, the pump will not cycle.

Be sure to reconnect the ground wire before

operating the pump.

tube

(18) between the pilot valve’s

TOP VIEW

out

toward the end of

n

Model 218482 only.

Install the piston seal (241 into the counterbore of

the pump housing (25). Install the o-ring (99)

around the outside (not on the shoulder) of the

piston guide (23). Install the guide into the counter-

bore of the pump housing so the larger beveled

opening of the guide faces away from the pump

housing. Slide the pump housing with the guide

and the seal onto the alignment studs (38) and up

against the pump housing (221. Install the support

bracket (28) and the hex nuts (45) with the

lockwashers (46) on the alignment studs (38). Alter-

nately and progressively, tighten the hex nuts and

torque them to 20-30 ft-lb (27-40 N-m).

10

307-610

18

Fig

Page 11

Servicing The Air Control Valve

Refer to Parts Drawings on pages 12 and 14.

1.

Remove the tube ends (18) from the two end block

elbows (115).

2.

Remove four socket head machine screws (101)

and the end block (114) with the elbow (115) and

the muffler (78). Repeat the procedure on the op-

posite end of the air control valve.

With the valve spools (106) centered in the block

3.

(1101, apply opposing force with the wrenches on

the dalve spool flats, and unscrew the valve spools

from the spool stem (107). Remove the spools and

the stem from the center block.

4.

Unscrew the mufflers (78) and the lock rings (79)

from the end blocks (114).

Unscrew and remove the elbows (115) from the end

5.

blocks (114).

NOTE:

Apply lithium grease to all o-rings before

assembling and to the complete spool

assembly before installing it into the center

block (110).

6. Install the new o-rings (105,109,lll) on each spool

(106). Be sure the o-rings are seated properly in the

grooves.

9. Install a gasket (103) into each end block (114) and

then install an o-ring (104) on the shoulder of each

end block (114).

10. Install the end blocks (114) onto the center block

(110) using the socket head machine screws (101).

Torque the screws to 35-45 in-lbs (3.9-5.1 N-m).

11. Install the mufflers with the lock rings into the end

blocks.

CAUTION

Mufflers must be installed with the lock rings.

Failure to do so may result in damage to the spool

and the o-rings during operation.

12.

Install end block elbows (115) in the end blocks

(114).

13.

Connect the tubes (18) as instructed on page 10,

step 15.

14.

Install the o-rings (105) in the top of the center

block (110). Install the air control valve on the

pump. Torque the air valve mounting screws, alternately and progressively, to 35-45 in-lbs

(3.9-5.: N-m).

NOTE: O-ring (105) has an ID of 0.612 in. and

o-ring (109) has an ID of 0.549 in. Do not

switch them; the pump will not run.

7. Apply low strength adhesive thread sealant to only

the tips of the spool stem (107). Remove the excess

sealant.

8. Thread one spool (106) onto the stem (1071 and in-

sert it in the center block (1101. Then thread the

other spool (106) onto the stem (107). Apply opposing force with wrenches on the flats of the spools

(106) and tighten until snug.

307-610 11

Page 12

is

3

4

0

NOTE: Apply sealant to all nonswiveling npt threads.

87

\

TORQUE TO

4MO ft-lb

(52-82 N.m)

ALTERNATE

PROGRESSI’

TOM

‘$-bTo

10-20

1 :13.5-27 N.rnI

LYEt

VELY

I”..--- - -

a-30 ft-I b

(27-40 N.m)

I

ALIGN SLOT

IN GUIDE (97)

WITH PIN IN

HOUSING (30)

TsClf Fb’ 0

(3.9-5.1 N.ml

I

Ref. No. 4 Includes items 4a-4i

Ref. No. 21, 29

Models 218-060,

hf.

NO.

53 See Daw

Et 95

231-019

14 for oafls

B

218461

only

Page 13

GLUlTON PUMP

Model 218-080, 231-019, 218-081, Et 218-082

REF PART

NO. NO.

+107-159

:

‘107-160

4

218-956

101-435

2

105-745

181-131

2

108-383

181-138

181-133

:

107-161

4i

181-132

1:

11

l2 r 179-821

16

17

18

19

2

22

23 179-848

24

25 179850

26

z

29

30

E

:

38

39

40

179-815

179-817

179-818

179-845

i

-*157-195

179-846

I-

107-166

181-135

179-823

179-824

179-825

179-826

179-847

179-854

i

179-627

179-855

iI

181-266

* 179-828

*179-849

“179-856

181-267

i

179-829

179-857

-I

181-268

107-167

108-286

i

179830

179831

l

181-313

224-603

179-833

179-834

179-835

179-636

179-837

I

179-858

I- 179438

-I-

220-002

r 179839

-L

179-851

179-858

DESCRIPTION

O-RING; nitrile rubber

QUAD-RING; nitrile rubber

PILOT VALVE ASSY.

(Includes items 4a-4i)

.BALL, valve, pilot

*SPRING, valve

.HOUSING, valve

.STUD, hose

.GASKET; polyethylene

.CAP, valve

.SEAL, rod

.-STEM, valve

SEAL, bellows

PISTON, motor, air

ROD, piston (Models 218-060 &

231-019)

ROD, piston (Models

218-061 Et 218-062)

O-RING; nitrile rubber

RING, motor (Models 218-060 Et

231-019)

RING, motor (Models

218-061 Et 218-062)

BUMPER

TUBE; nylon, 0.225” O.D. x 0.125”

ID, 13” (330 mm) long

PLATE, motor, riaht

PLATE; motor; le’ft

PLATE. intake (Models

218-066, 231-019 & 218-061)

HOUSING, pump (Models 218-060 B

231-019)

HOUSING, pump (Model 218-061)

HOUSING, pump (Model 218-062)

GUIDE, piston (Model 218-060)

GUIDE, piston (Model 218-061)

GUIDE, piston (Model 218-062)

GUIDE, piston (Model 231-019)

SEAL, piston (Model 218-060)

SEAL, piston (Model 218-061)

SEAL, piston (Model 218-062)

SEAL, piston (Model 231-019)

HOUSING, pump (Model 218-060

HOUSING, pump (Model 218061)

HOUSING, pump (Model 218-062)

HOUSING, pump (Model 231-019)

BALL, valve; SST, 1” dia. (Models

218-060. 218-061 Et 218-062)

BALL, valve; tungsten carbide, 1”

dia. (Model 231-019)

SPRING, compression

BRACKET, support

SEAL, face; UHMW polyethylene

(Models 218-060, 231-019 & 218-061)

HOUSING, valve, check

STOP, ball

BRACKET, mounting

RING, centering

ACCUMULATOR

STUD, alignment

(Models 218-060, 231-019 8 218-0611

STUD, alignment (Model 218-062)

SEAT. valve. check (Models 218-060.

218-061 Et 2i8%62)

SEAT, valve, check (Model 231-019)

PISTON, fluid (Models 218-060 Et

231-019)

PISTON, fluid (Model 218-061)

PISTON, fluid (Model 218-062)

REF PART

NO. NO.

45 100-321

46

2

4iJ

50 107-175

E

55 218-093

56

z 214848 100-l 19

ii 206-197 101-180

: 106-149 107-311

66 179-842

72 179-885

73 104-029

75 179-944

77 164-259

598 107-190 107-189

80 156-684

ii 180-766

83 180-767

84- r

100-018

179-840

loo-077

101344

107-176

107-142

“108-103

218-722

218-723

85

L 108-104

86

ii

89

90

ii;

2

96

z

98

100

““Refer to page 14 for Parts List and Parts Drawing.

See “How To Order Replacement Parts” on page 15.

108-105

i

102-269

:g:g

*108-158

* 180-997

104582

181-134

108-383

181-136

181-264

“102-778

“107-179

*107-180

150-287

“Included in Repair Kit. Refer to page 15.

DESCRIPTION

NUT, hex; l/2-13 thd

WASHER. lock: l/2”

STUD, piston

NUT. hex: 5/16-18 thd

SCRiW, mounting; 5/16-18x 318”

BOLT, machine; 3/8-16 x 3”

WASHER

SCREW, machine; lo-24 x 2”

VALVE, control, air

(Models 218-061 Et 218-062)

VALVE, control, air (Models 218-060

Et 231-019)

HOSE, coupled; l/2 npt(m), l/2”

ID, 18” (457 mm) long, buna-N,

Static free

VALVE, ball; l/2-14 npt

ELBOW, street; 90°, l/2 npt

LUBRICATOR, air

REGULATOR, air

GAUGE, pressure

FILTER, air

NIPPLE, hex; l/2” x l-5/8”

LABEL, warning, hhc :

LABEL, warning 1

LUG, grounding

LABEL, warning ;

ELBOW, street;

l/4 nptff) x 3/8 npt(m)

MUFFLER

RING, lock f

ADAPTER, union; l/2 npt(m) x

l/2 npt(f) swivel

FLANGE, manifold :

O-RING; Vito@

FITTING; intake

MANIFOLD, intake (Model 218-061)

MANIFOLD, intake (Models 218-060

8 231-019)

MANIFOLD, intake (Model 218-062) ;

MANIFOLD, outlet (Model 218-062)

MANIFOLD, outlet (Model 218-061)

MANIFOLD, outlet (Models 218-060

& 231-019) 1

CONNECTOR, male; l-1/16-12 thread

(Model 218-062) 2

CONNECTOR, male; l-5/16-12 thread

(Models 218660, 23i-019 Et 218-061)

SCREW. cao hex: 5/16-18x 1.250”

WASHER ’

NUT, heavy hex; 5/16-18 thread 44

U-CUP PACKING; buna-N

BEARING, shaft

WASHER, tab

MANIFOLD; l/2-14 npt

STUD, hose :

TUBE; nylon, 0.225” OD x 0.125” ID,

20” (505 mm) long

GUIDE, ball ;

O-RING; nitrile rubber (Models 218-060

& 231-019)

O-RING; nitrile rubber (Model 218-061)

O-RING; nitrile rubber (Model 218-062)

COUPLING; l/4 npt(m) x 3/8 npt(f)

QTY

4

8

:

1

1

1

:

1

:

1

;

1

1

1

2

4

2

2

1

;

:

ii

44

107-171 103846

107-174

BOLT, machine, hex; 5/16-18x l-1/2”

SCREW, machine; lo-24 x l/2”

BOLT, hex; SST, l/2-20 x l-l /4”

307-610

13

Page 14

AIR CONTROL VALVE

Model 218-083

AIR CONTROL VALVE

Model 218-084

REF PART

NO. NO.

101 107-m

163 ‘181-464

104 l 107-185

105 ‘107-186

:iY 179-862 179-865

109 ‘107-187

110 179-867

111 l 107-188

114 179-864

115 107-163

116 100403

*Supplied in repair kit 2 18-W

See ‘Wow To Order Replacement Parts” on page 15.

DESCRIPTION

SCREW, machine, socket head,

10-24x2-1/2

GASKET; polyurethane

O-RING; nitrile rubber

O-RING; nitrile rubber

SPOOL, differential

STEM, spool

O-RING; nitrile rubber

CENTER BLOCK

O-RING; nitrile rubber

END BLOCK

ELBOW, male, mini barb;

PLUG, pipe; l/8 npt

9oof ‘I8

AIR CONTROL VALVE REPAIR KIT 218-084

Q-I-Y REF

8

2

2 :ii

4

:

1

;

npt :

Ref No.

103

104 ;

105

109

111 s

NO.

107-183

101

“181-464

“107-185

l

107-186

105

179-862

179-866

l

107-187

:: 169

110

179-868

111 114

l 1;EE

107-163

115

100-403

116

*Supplied

See “How To Order Replacement Parts” on page 15.

DESCRIPTION

SCREW, machine, socket head;

10-24x2-1/2

GASKET; polyurethane

O-RING; nitrile rubber

O-RING; nitrile rubber

SPOOL, differential

STEM, spool

O-RING; nitrile rubber

CENTER BLOCK

O-RING: nitrile rubber

END BLOCK

ELBOW male, mini barb; BOO, l/8 npt

PLUG, pipe; l/8 npt

in

repair kit 218-084.

Qw

4

QTY

8

f

4

2

:

:

s

1

Page 15

PACKING REPAIR AND CONVERSION KITS

(Must be purchased separately)

PACKING REPAIR KITS

INCLUDES 2

PUMP KIT

MODEL NO. NO.

following items (see

Parts List, page 13)

218-060 218-085 12, 24, 29, 82, 98

ea.

of

the

PACKING CONVERSION KITS

See Manual 307-736 for parts,

PUMP VITONO

MODEL

NO. KIT NO.

CONVERSION

ETHYLENE-PROPYLENI

CONVERSION KIT NO.

218-061 218-086 12, 24, 29, 82, 98

218-062 218-087 12, 24, 82, 99

231-019 231-021 12, 24, 29, 82, 98

AIR PISTON SEAL REPAIR KIT 218-885

Ref No.

QtY

2

:

1

E 22

VALVE CONVERSION KIT 218-888

For use with Zinc-rich fluids.

Two required. Includes:

Part No.

179-871

157-195

218-146

ACCESSORIES

Description

Spacer

O-ring

Valve Housing

(Must be purchased separately)

QTY

1

:

GROUND WIRE 288-958

(7.6 m) 25 f-t Ig

218-060 231-022 231-023

218-061 231-024

I

I

231-025

218-062 1 231-026 231-027

1 I

231-019 ] 231-022

VALVE SEAT CONVERSION KIT 231-028

For use with corrosrve ~IUICIS sucn as catalyzea var-

. r...

1

231-023

nishes. See Manual 307-736 for parts.

PUMP CONVERSION KIT 228-888

To convert Pump Model 218-060 to an abrasiveresistant pump. See Manual 307-736 for parts.

PILOT VALVE CONVERSION KIT 218959

For converting the Glutton Pump (Models 218-060,

218-061 and 218-062, Series A and B) from the old-style

pilot valve to the new-style pilot valve. See Manual

307-715 for parts.

BLEED-TYPE MASTER AIR VALVE

300 psi (21 barl MAXIMUM WORKING PRESSURE

Relieves air trapped in the air line between the pump air

inlet

and this valve when closed.

107-141 314 npt(m xf) inlet & outlet

107-142 l/2 npt(m x f) inlet & outlet

TOOLS 179-881

Packing Nut Wrench

INLET ADAPTERS

188-144 Bushing l-l /4-l l-l /2 npt(m) x 3/4-14 npt(f)

188-145 Nipple 314-14 npt(m) x l-1/4-11-1/2 npt(f)

HOW TO ORDER REPLACEMENT PARTS

1. To be sure you receive the correct replacement parts,

kit or accessories, always give all of the information

requested in the chart below.

2. Check the parts list to identify the correct part number;

do not use the ref. no. when ordering.

3. Order all parts from your nearest Grace distributor.

6 digit

PART

NUMBER QTY

PART DESCRIPTION

SERVICE INFORMATION

Listed below by the assembly changed are OLD, NEW,

and ADDED parts.

ASSEMBLY PART

CHANGED STATUS

218-060

231-01s

Pumps

All

Pumps

8 OLD

NEW

OLD

NEW

ADDED

\ITERCHANGEABILITY NOTE: NEW parts replace

ILD parts listed directly above them.

REF PART

NO. NO.

102-269 Screw

49 101-344 Screw

165641 Union

77 164-269 Elbow

100 150-267 Coupling

NAME

307-610 15

Page 16

TECHNICAL DATA

Recommended Air Operating Range : 35-100 psi (3-7 bar)

Maximum Recommended Pump Speed : 80 cycles per minute

Vito@ is a registered trademark of the Du Pont Company.

Loctite@ is a registered trademark of the Loctite Corporation.

MOUNTING

HOLE LAYOUT :

Fluid Outlet : 1 npt(f) (Models 218-060, 231-019, Et 218-061)

Fluid Inlet : l-1/4 npt(f)

Wetted Parts :

Weight : 86 Ibs (38.7 kg)

3/4 npt(f) (Model 218-062)

A// Models:

Carbon Steel, Aluminum, Nylon,

Polypropylene, buna-N, Vito@ , Stainless Steel,

UHMW Polyethylene

Model 231-019:

Also includes Polyurethane and

Tungsten Carbide

:,i

DIMENSIDNS

I; I,; i :.:! !:,.I::i.;j;y;!i

~1~

181/Z’ (419 mm) 16-3/4” (425 mm) l&3/4” (425

I

THE GRACO WARRANTY AND DISCLAIMERS

WARRANTY

Grace warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on the data of sale

by an authorized Grace distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty, Grace will, for a

period of twelve months from the date of sale, repair or replace any part of the equipment proven defective. This warranty applies only when the

equipment is installed, operated and maintained in accordance with Grace’s written recommendations.

This warranty does not cover, and Grace shall not be liable for, any malfunction, damage or wear caused by faulty installation, misapplication,

abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Grace component parts. Nor

shall Grace be liable for malfunction, damage or wear caused by the incompatibility with Grace equipment of structures, accessories, equipment or materials not supplied by Grace, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Grace.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective for examination by Grace to verify the claimed

defect. If the claimed defect is verified, Grace will repair or replace free of charge any defective parts. The equipment will be returned to the

original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be

made at a reasonable charge, which charges may include the the costs of parts, labor and transportation.

DISCLAIMERS AND LIMITATIONS

THE TERMS OF THIS WARRANTY CONSTITUTE PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND ARE IN LIEU OF ANY OTHER

WARRANTIES (EXPRESS OR IMPLIED). INCLUDING WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, AND OF ANY NON-CONTRACTUAL LIABILITIES, INCLUDING PRODUCT LIABILITIES, BASED ON NEGLIGENCE OR

STRICT LIABILITY. EVERY FORM OF LIABILITY FOR DIRECT, SPECIAL OR CONSEOUENTIAL DAMAGES OR LOSS IS EXPRESSLY EX-

CLUDED AND DENIED. IN NO CASE SHALL GRACO’S LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE. ANY ACTION FOR

BREACH OF WARRANTY MUST BE BROUGHT WITHIN TWO (2) YEARS OF THE DATE OF SALE.

EQUIPMENT NOT COVERED BY GRACO WARRANTY

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PAR-

TICULAR PURPOSE, WITH RESPECT TO ACCESSORIES, EQUIPMENT, MATERIALS, OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Grace (such as electric motor, switches, hose, etc.), are subject to the warran-

ty, if any, of their manufacturer. Grace will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

mm)

Subsidiary and Affiliate Companies:Canada; England; France; Germany; Hong Kong; Japan

Factory Branches:Atlanta, Dallas. Detroit. Los Angeles, West Caldwell (N.J.1

GRACO INC. P. 0. Box 1441 MINNEAPOLIS, MN 55440-1444

PRINTED IN U.S.A. 307-610 S-83

Revised

11-86

Loading...

Loading...