Page 1

INSTRUCTIONS-PARTS

LIST

.e

307m4=

Rev.

C

ORAC0

.

SUPERSEDES A

This

manual contains

IMPORTANT

WARNINGS

and

INSTRUCTIONS

READ AND RETAIN FOR REFERENCE

Gna

Powered

Airless

SUDD~V

Pump

45~W

psi

(310

bar)

MAXIMUM

WORKING PRESSURE

Model

226-961

Series

B

Less

hose,

swivel,

gun

and

tip.

.

..

.,

,.

'..

..

.

.:

GRACO INC. P.O.

Box

1441

MINNEAPOLIS,

MN

55440-1444

@COPYRIGHT

1981

GRACO

INC.

Page 2

WA

RNlNG

HIGH

PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR

PROFESSIONAL

USE

ONLY.

OBSERVE

ALL

WARNINGS.

Read

and

understand.all

instruction

manuals

before

operating

equipment.

'

INJECTION HAZARD

Fluids under high pressure from spray

or

leaks

can

penetrate the skin

and cause extremely serious injury, Including the need for

amputation.

NEVER

point the spray gun et anyone

or

any part

of

the body

NEVER

put hand or fingers over the spray tip.

NEVER

try to stop

or

deflect leaks with your hand or body

ALWAYS

have the tip guard in place when spraying.

MEDICAL TREATMENT

If

any fluid appears to penetrate your skin, get

EMERGENCY MEDICAL CARE AT ONCE.

DO

NOT TREAT AS A SIMPLE CUT.

Tell the doctor exactly what fluid was iniected. For treatment instruc-

-.

~~~

tions have your doctor

call

the

NATIONAL POISON CENTER NETWORK

i4121681-6669

USE EXTREME CARE WHEN CLEANING TIPS AND

SERVICING.

Always follow this pressure relief procedure when shutting

off

the unit

for any reason: shut

off

the engine. trigger the spray gun. engage fhe

trigger EafeQ, close the en ine fuel cock and

0

en the drain

VE~VE.

SPRAY GUN SAFETY

When spray gun or dispensing valve is not ECtUaib spraying. ahays

set the gun safeQ latch

in

the Closed or "SAFE position, making the

trigger inoperative.

00

NOT REMOVE

OR

MODIFY any

part

of the gun.

Check diffuser operation by using the lowest Pmible spray pressure

with spray tip removed. Trigger gun end maintain firm metal to metal

contact belwean aun and metal waste container. Fluid emitted should

be diffused into

ai

irregular streern

CHECK OPERATION OF ALL GUN SAFETY DEVICES BEFORE

EACH USE.

AVOID COMPONENT RUPTURE

Always be sure that all components used with this unit have e max-

mum working pressure rating of at

least

4500

pai

(310 barl. which is

the maximum working pressure of the GH

723.

NEVER

alter

or

modify the equipment.

Before each use, check hoses for weak, worn or damaged conditions

that may be caused by traffic, sharp corners, pinching, kinking end

general wear. Tighten all fluid connections securely before each use.

REPLACEany damaged hose.

NEVER

use tape

or

any device to mend

the hose.

PREVENT STATIC SPARKING

Always be sure

all

equipment end objects being sprayed are Properly

grounded. This

unit

is equipped with a grounding wire end clamp. The

fire

or

explosion.

high Velocity flow of fluid creates static electricity. Sparks may cause

Useonly conductiveor grounded fluid hoses. Be sure gun is grounded

through hose connections. Check ground continuity

in

hose end

equipment once e week. Overall (end to end) resistance of unpressurized hose must not exceed

29

megohms for any coupled

length or Combination of hose lengths.

When flushing equipment, remove spray tip,

use

the lowest possible

pressure, end maintain firm metal to metal contact between gun and

metal waste container. This reduces the chance of static sparking.

GAS ENGINE PRECAUTIONS

ALWAYS

locate unit et least

20

feet awayfrom spraying area because

of possible sparking hazard from gasoline engine.

NEVER

fill

fuel tank while engine is running or hot. Avoid the possibil-

ky

of spilled fuel causing a fire. Always refuel slowly to avoid spillage.

NEVER

operate engine

in

e closed building

unless

the exhaust is piped

outside. The exhaust contains carbon monoxide, a poisonous,

possible death.

odorless and invisible gas, which

if

breathed causes serious illness end

Always close the fuel cock and remove the ignition cable from the

spark plug before adjusting

or

servicing any mechanical parts of the

the mechanical parts end

C~USE

serious injury to the operator.

unit. Operating

E

mechanical pert by hand could start the engine and

NEVER

alter the throttle setting.

about

390

psi

(245

bar) working pressure.

.

Precaution is the best insurance against

en

accident. When starting

engine. maintain a safe disfence from moving pem of equipment.

The maximum full loEd engine speed is

28W

RPM

which occurs

Et

IMPORTANT

United States Government safer, standards have been adopted under the Occupational SafeQ End Health Act. These standards-perticulerb the

General Standards, Pert 1910, end the Constructon Standards, PaR 1926-should be consulted.

307-465

3

Page 3

GElTlNG READY

NOTE:

Reference numbers and letters .in parentheses

in

the text refer to the Typical Installa-

tion; Figures 1 through

9,

and the Parts

Drawing.

Refer to back page for the available Graco accessories.

ing heavy fluids andlor when very long hose lengths are

Install a check valve near the pump outlet when pump-

used.

See

ACCESSORIES.

Install an accessory material handling hose

and

applica-

tion valve to the

1

in.

npt(f) tee (141) of the displace.

ment pump (105). Refer to the Parts Drawing. Do not

install the spray tip on the gun yet; wait until the pump

has been flushed.

See

page

5.

the sprayer are secure. Refer to the Typical Installation

Be sure that the fittings on all of the hose connections

in

and the Parts Drawing.

Seal Liquid (TSL)

so

it

is about 1/2 full. Refer to Fig

9,

Fill the wet-cuplpacking

nut

1106) with Graco Throat

page 10.

Lubrication

CAUTION

I

Check the hydraulic oil and engine oil levels before

operating the sprayer. Add the appropriate oil,

if

necessaw.

I

-~

~-

filter (9). If there is enough hydraulic oil in the system,

Check the hydraulic oil. Unscrew the cap of the intake

there should be

1

in.

(25 mml of oil visible in the bottom

approved hydraulic oil to the proper level. A completely

of the filter screen.

See

Fig

1.

If necessary add Graco-

full hydraulic system contains approximately 5 gallons

(18.9 liters)

of

oil.

See

the ACCESSORIES section for

Graco-approved hydraulic oil.

9

Fig

1

Check

the

engine oil. Unscrew the oil fill plug (C); the

dipstick is attached.

See

Fig

2.

Without threading the

plug into place, check the oil level. The oil should be up.'

to the top mark on the dipstick. Add fresh oil if

necessaw.

RECOMMENDED LUBRICATING OIL: Use a high quali-

ty,

detergent oil classified "FOR SERVICE SD or

SF',

for regular use and for the breaking-in of a new engine.

I

GRADE

OF

OIL CHART

3

SEASON

OR

TEMPERATURE

SAE 30

Spring, Summer, Autumn

GRADE OF OIL

1

34PF

toO°F

Winter

SAE 1OW-30

I

Below

Oo

I

SAE

5W-20

Crankcase capacity: 2 quarts (1.9 liters)

Fuel

Fill the fuel tank

(D)

with clean, fresh gasoline. Refer

to

liters). Use only reputable, well-known brands of

Fig

2.

The tank holds approximately 1.5 gallons

(5.7

unleaded Regular Grade gasoline. The minimum octane

tane elsewhere. At the maximum operating speed of

requirements are

86

octane in the U.S.A., and 96 oc-

2800 RPM, the gasoline consumption is about 1.3

gallonslhour (4.9 liters/hourl.

WARNING

Always shut

off

the engine and let

it

cool before

refilling the fuel tank. Close the fuel cock (E).

Refer to Fig

2.

Be sure that the air vent

in

the tank

fill

cap IF) is not plugged

so

that

fuel

can flow to

the carburetor. Refer to Fig 6, page 6. Then

fill

the tank.

a fire.

Be careful not to spill any fuel, which could cause

Grounding

Connect the grounding clamp (138) to a good ground

such as a steel water pipe. Check your local codes for

regulations concerning electrical grounding.

~~~~~

4

307-465

Page 4

OPERATION

Starting the Engine

CAUTION

Always open the bypass valve

(78)

before starting

the engine.

Open the bypass valve

(78)

and the fuel cock

(E).

The

bypass valve is open when the lever is parallel to the

screwed out as far as

it

will go. See Fig

3.

body of the valve. The fuel cock is open when

it

is

Fig

3

,'

w

pull the rope firmly and rapidly to start the engine. If the

engine does not start after one or

two

attempts, try

opening the choke a little further. If the engine floods,

open the choke all the way and continue pulling the

rope.

After the engine has warmed 'up, gradually open the

choke lever

(GI

and close the bypass valve

(78).

See

Fig 3 and

4.

Raise the foot brace and engage the hitch

(34).

In

cold weather, run the engine for about 15 minutes

before starting the material pump. This helps to make

sure the hydraulic motor does not stall.

Stopping the Engine

Open the bypass valve

(78)

and depress the stop button

(J),

holding the button down until the engine stops.

Close the fuel cock

(E).

See

Fig

3.

Flush the Material Pump

Your new

unit

was tested

in

oil and the oil was

left

in

to

protect the material pump parts. Before using the

sprayer, flush the pump as instructed below.

1. Pour enough clean, compatible solvent to fill the

system into a large empty metal pail.

2.

Place the suction tube into the pail, or

tilt

the unit

back

(it

will support itself), place the pail under the

pump, then

tilt

the unit forward to lower the pump

into the pail.

Lower the foot brace by disengaging

it

from the hitch

(34).

Refer to Fig

3.

3.

Be sure the bypass valve (78) and fuel cock

(E)

are

oDen. Turn the Dressure control knob

(F)

all

the way

.If the engine is cold, close the choke by turning the lever counterclockwise to keep pump from operating.

or the air temperature is high, open the choke half way

(G)

so

it

is horizontal.

See

Fig

4.

If the engine is warm, See Fig

3.

Start the engine.

or completely.

4.

Close the bypass valve

(78).

Point the gun into a

metal waste container, holding a metal part of the

gun firmly against the metal pail. See Fig 5.

Squeeze the trigger. At the same time, slowly turn

the pressure control knob (F) clockwise just enough

to operate the pump. Always use the lowest possi-

ble pressure when flushing the unit. Operate the

pump until clean solvent comes from the gun. Then

release the trigger and engage the trigger safety.

Fig

4

Fig

5

starter rope.

Brace one foot against the foot brace and pull the

CAUTION

Always hold on to the starter rope while pulling or

,rewinding

it.

If the rope rewinds too quickly,

it

can

jam the starter assembly.

~

then let the rope rewind slowly into the starter. Then

Pull the engine over against the compression stroke and

5. Check all hose connections and fittings for leakage.

If there are any leaks, shut

off

the engine and

relieve the fluid pressure before tightening the fit-

tings. Then turn the

unit

on and check to be.sure

the leaks have stopped.

6.

Remove the pump or suction hose from the solvent

pail. Trigger the gun to force the solvent out of the

engine. Engage the trigger safety.

hose. Open the bypass valve

(78)

and shut

off

the

30745'

5

Page 5

Prepare the Material end Prime the Pump

Prepare your material according to the manufacturer's

instructions.

Place the displacement pump or the suction tube into

the material supply container. Install a spray tip in the

gun

(see

the gun instru,ct#on manual), and

start

the

engine. Trigger

the

gun Into a metal waste container,

holding a metal part.of the gun firmly against the metal

container. Refer to Fig

5.

Hold the gun trigger open until

all

air

is

forced out of the system. Release the trigger,

engage the trigger safety, and let the pump

stall.

NOTE:

The GH

733

can be tilted backwards and will

support itself while placing

a

5

gallon pail

under the material pump.

Adjusting the Pressure

Turn the pressure control knob IF) to adjust the fluid

pressure.

See

Fig

6.

Turn the knob clockwise to

in-

crease the pressure and counterclockwise

to

decrease

to completely atomize the material. Check

the spray

the

pressure. Always use the lowest pressure

necessary

pattern. The tip size and angle determines the panern

width and flow rate. Don't

try

to get more coverage by

increasing the pressure; use a larger tip instead.

See

the

separate instruction manual

306-997

for the correct

method'of airless spraying.

-H

-

:leaning a Clogged Tip

Pressure Relief Procedure

WARNING

Always relieve system pressure whenever you are

done spraying for a while and before installing,

removing or cleaning any parts to avoid possible

injury from high pressure fluid in the system.

Always

follow

this procedure: shut

off

the engine

by depressing the stop bunon

(J),

trigger the

spray gun, engage the trigger safety, close the

engine fuel cock

(E),

and slowly open the dram

valve

(143).

Leave the drain valve open until you

are ready to use the unit again.

Clean out the front of the tip frequently during the day's

operation with a solvent soaked brush. This helps to

prevent material build up and tip clogging.

If the spray tip clogs while spraying, follow the Pressure

Relief Procedure, above. Loosen the tip guard slowly

before removing

it

completely. Remove the tip and put

it

and the nozzle of the gun in solvent. Let the tip soak

long enough to dissolve the obstruction, or blow

it

out

with

air

through the front of the'tip. If the

air

and

sol-

vent does not loosen the obstruction, tap the back of

the tip against a flat surface to jar

it

out.

Shutdown and Care

pressure according to the Pressure Relief Procedure,

If you stop spraying for a short time, relieve system

the gun and the tip in solvent.

above. Remove the tip from the gun. Place the nozzle of

overnight in the unit, and for weekend or longer shut-

Flush the unit

if

the material you are pumping will dry

downs. Flush the unit with a compatible solvent, then

leave mineral spirits in the pump during storage to help

prevent corrosion of material pump.

Whenever

it

is possible, park the unit

in

the shade or in a

relatively cool area to reduce the possibility of

overheating.

Remove and clean the gun tip

at

least twice a day when

spraying. Always stop the pump

at

the bonom of

its

stroke when you are through spraying for the day.

periodically and tighten

it

if necessary. Refer

to Fig

9.

Check the tightness

of

the wet-cuplpacking

nut

(106)

page

10.

The nut should be tight enough

to

stop

leakage, but no tighter. Always relieve the system

pressure according to the Pressure Relief Procedure

(see

above) before adjusting the packing nut.

Check the hydraulic oil level occasionally. Unscrew the

cap of the intake

filter

(9);

there should be 1 in.

(25

mm)

of

oil visible in the bottom of the filter screen. Refer to

Fig

7,

page

7.

Use Graco-approved oil only.

See

AC-

CESSORIES.

the filter after every

500

hours

of operation or every

6

Inspect the return line filter

(3)

frequently, and replace

months, whichever comes first.

Refer

to Fig

7,

page 7.

A

clogged filter can cause the cooler to leak or to fail.

6

307-465

Page 6

Change the hydraulic oil after every

ZOO0

hours of

CAUTION

operation or every

12

months, whichever comes first.

For continuous operation

in

temperatures above

85O

F

2800

RPM.

6 months of use.

(30°

C), change the oil after every

1000

hours or

CAUTION

Cleanliness is essential when servicing hydraulic

systems.

Use

special care to avoid getting dust or

dirt into the hydraulic system.

To change the hydraulic

oil

or the filter

(3).

follow the

waste container under the bypass valve (78). be sure the

Pressure Relief Procedure warning on page 6. Place a

valve is closed, and unscrew the swivel union (761. See

Fig 7. Open the valve

and

allow the oil to drain. Remove

the 18 screws

(2)

and the reservoir cover. Remove the

assembly.

Secure the new filter'with the

seal

nut

(13)

return line

filter

(3)

and replace

it

with a new filter

screwed firmly to the elbow fitting

(14).

Inspect the inlet

strainer

(15)

and replace

it

if necessary.

See

Fig 7. Close

the bypass valve, install the reservoir cover,

and

pour

5

gallons (19 liters) of approved hydraulic oil into the

reservoir, through the intake filter cap

(9).

NOTE:

Whenever the reservoir cover

(10)

is

remov-

ed,

put

silicon sealant on the threads of the

screws

(2)

when reassembling the cover.

..

.

Periodically,. or if the engine is overheating, follow the

Pressure Relief Procedure Warning on page 6. Clean all

dirt,

dust, etc.,

off

the fan blades, motor

and

cooler

grill.

Fig

7

The unit should be level whenever you are checking the

hydraulic oil or the engine oil and when replacing

or

refilling these oils. Refer to the section on "Lubrication"

on

page

4.

SERVICE INFORMATION

Final

Assy.

DELETED 1121

2

103-813 Screw

o

Series

B

OLD

106W

Nut

DELETED 100-020

,

Lockwasher

I

NEW 13 105-430 Nut

OLD

NEW

106-065 Elbow

43

106268 Elbow

OLD 177-662 Cooler

Listed below by the assembly changed are OLD, NEW,

ADDED and DELETED parts.

ANGED STATUS

NO.

NO.

SSEMBLY PART

-

REF PART

NAME

OLD

177640

Hose

NEW

OLD

51 061-215

HOSE

106457

Elbow

-

"

."

ADDED I11

78

210-658

Ball

Valve

NEW

68

106048 Elbow

OLD

NFW

~ ~~

217-018

Hose

00

17&M6

Hme

DELETED

ADDED121 138 103-927 Clamp

178478 Label

ADDED

139

217-202 Tube

DELETEDIl)

49

101418 Clamp

ADDED

ADDED

140 106-645 Elbow

141

106-646

Tee

ADDED

142

106-466

Reducer

ADDED

ADDED

143

100-001

Screw

144

100-057

Screw

.

.

. .

.

-. .

~~~~

r

-I

INTERCHANGEABILITY NOTE NEW parts replace

OLD parts listed directly above them. Numbers

in

parentheses

in

the Status column indicate quantity

change.

307-465

7

Page 7

r-

SERVICE

WARNING

Always relieve system pressure whenever you are

Pressure Relief Procedure

done spraying for a while and before installing,

injury from high pressure fluid In the system.

removing or cleaning any parts to avoid possible

A/ways

follow

this

procedure:

shut

off

the unit by

depressing the enginestop button (J-see Fig

6).

trigger the spray gun, engage the trigger safety,

close the fuel 'cock (E-see Fig

6).

and slowly

open the drain valve

(78).

Leave the drain valve

open until you are ready to

use

the unit again.

TROUBLESHOOTING CHART

PROBLEM

properly.

The gas engine operates, but the

paint pump doesn't operate.

The displacement pump operates,

but the output

is

low on the

upstroke.

The displacement pump operates

but the outwt is low on the

downstroke andlor on both

strokes.

There is excessive leakage around

the hydraulic motor piston rod

Paint leaks into the wet-cup.

There are excessive surges

at

the

dispensing valve.

CAUSE

The hydraulic motor has stalled.

The pressure setting is too low.

The displacement pump outlet

filter (if used) is dirty or

clogged.

The tip or tip filter (if used) is

clogged.

The hydraulic fluid

is

too low.

The hydraulic pump is worn or

damaged.

The hydraulic motor

is

worn

01

damaged.

The displacement pump rod

is

seized by dried paint.

The piston ball check

is

not

seating properly.

The piston packings are worn or

damaged.

The piston packings are worn or

damaged.

The intake valve ball check

is

not seating properly.

The piston rod or seal

is

worn

or damaged.

The throat packings are worn or

damaged.

The displacement pump Outlet

filter

(if

used) is dirty or

clogged.

The spray tip

is

too big or

it

is

worn.

SOLUTION

Consult the engine manual.

See "Starting the Engine" on

page

5.

page

6.

Increase the pressure. See

Clean the filter.

Remove the tip and/or the filter

and clean them.

Shut

off

the unit and add fluid

immediately:

See

page

4.

Replace the pump. Refer to page

11.

Service the motor. See manual

Service the pump. See page 10,

307-158.

Service the piston ball check.

See

page

10.

Replace the packings. See

page 10.

~~

Replace the packings. See

page

10.

~~ ~

Service the intake valve ball

check. See page

10.

Replace these parts.

See

manual

~~

307-158.

Replace the packings.

See

page 10.

Clean the filter.

Change or replace the tip.

8

307-465

Page 8

PROBLEM

The fluid delivery is low.

The material coating is too thick.

There

is

spitting from the

dispensing valve.

CAUSE

The pressure setting

is

too low.

The pump outlet filter (if used)

is

dirty or clogged.

The hydraulic pump isworn or

damaged.

The hydraulic motor

is

worn or

damaged.

There

is

a large pressure drop in

the material handling hose.

The spray tip is too big or

it

is

worn.

The paint supply is low or

The dispensing valve

is

not

closing properly.

empty.

Check everything in the Troubleshooting Chart before

disassembling the unit.

*Check the hydraulic fluid level often.

Do

not

allow

it

to

fluid;

see

the ACCESSORIES section.

become too low.

Use

only Gmco approved hydraulic

Solvent flush the material from the pump, if possible.

Then shut

off

the engine, trigger the spray gun and

engage the trigger safety to relieve the fluid pressure.

Hydraulic

Motor

CAUTION

Cleanliness is essential when repairing hydraulic

dirt into the motor during servicing.

motors.

Use

special care to avoid getting dust or

See instruction manual 307-158 for motor service.

To remove the hydraulic motor, disconnect

all

hoses

the hoses to keep dirt out. Remove the three

tie

rod

(84,86,88)

from the motor.

See

Fig

8.

Plug the ends of

nuts (101). Support the displacement pump and

ter pin

(99)

and remove the pump. Unscrew the five

unscrew the connecting rod nut

(100).

Remove the cot-

frame (17). Lift the motor straight up. The

tie

rods (133)

capscrews

(36.95)

from the bottom side of the pump

will pass through the holes in the frame's mounting

plate.

See

Fig

8.

CAUTION

Support the engine on

2

x

4's

when removing the

motor to prevent the unit from tipping.

SOLUTION

Increase the pressure.

Clean the filter.

Replace the pump. See page 11.

Service the motor.

See

manual

307-158.

Use a larger diameter hose.

Change the tip.

Refill the supply container.

Service the valve.

Fig

8

307465

9

Page 9

Dis lacement Pump Service

NO+E:

Repair

Kit

NO.

207-966

is

available for SeN-

icing the pump. Use

all

the new parts in the

kit, even

if

the old ones look good. The old

servicing sooner.

parts will wear faster and the pump will need

To remove the pump, remove the three

tie

rod nuts

(101).

support the pump, remove the cotter pin

(99).

unscrew the connecting rod nut

194)

and remove the

pump.

IntakeValva

Screw the intake valve

(127)

out of the pump housing

(1131.

If the valve is stuck in the housing, squirt

around the housing with a hammer to loosen

it.

See

penetrating oil around the threads and gent& tap

Fig

9.

O-ring

(126).

guide

(124)

and ball

(125).

See Fig

9.

Clean

Remove the ball stop pin

(123).

O-ring retainer

(122).

all

the parts and inspect them for wear or damage.

Reassemble the valve with new parts, if necessary, and

screw

it

into the pump housing.

Screw the intake valve

1127)

out of the pump housing

Piston, Cylinder, or Displacement

Rod

(113).

Unscrew the coupling nut

194).

Screw the

locknut

(100)

up and remove the lower cotter pin

(112).

ting rod

(97).

Loosen the packing nut

(106)

and push the

Unscrew the displacement rod

(116)

from the connec-

displacement rod down and out of the housing. Secure

the rod in a vise and screw the piston

(121)

out of the

displacement rod. Remove the ball

11191.

washer

11M).

packings

(108,109)

and glands

1107.110).

Refer to

Fig

9.

Clean

all

parts and inspect them carefully for signs of

wear or damage. Check the rod carefully for nicks,

and

any other new parts needed and reassemble the

scratches or wear. Use the new parts from the repair kit

Torque the piston

1121)

to

150-175

ft-lb

(203-237

Nm)

piston, packings, and ball into the displacement rod.

is compatible to the material being pumped. Always

use

Lubricate the outside

of

the packings with a grease that

new glands with new packings. Inspect the inside of the

cylinder

(115)

for score marks. If

it

needs to be replaced,

be sure to install the new cylinder with the tapered end

down. If you can't remove

it

easily from the housing,

contact your nearest Graco Factory Branch or Service

Depot.

Throat Packings

Screw the intake valve

(1271

out of the housing and

screw the packing nut

(105)

out of the housing

(113)

remove the piston and rod as explained above. Then

and remove the packings

(108,109)

and glands

side of the new packings with a grease that

is

compati-

(107,110)

from the cavity. See Fig

9.

Lubricate the in-

glands with new packings.

ble to the material being pumped. Always use new

disassembly. Check the

tie

rods

(133)

to be sure that

Reassemble the pump in the reverse order

of

they are tightened securely into the hydraulic motor

base. Assemble the connecting rod

(97)

to the hydraulic

motor and screw the locknuts

(101)

loosely onto the

tie

rods. Screw the packing nut

(106)

loosely in place.

Finish tightening the locknuts evenly to

35-50

ft-lb

to stop leakage, but no tighter. Start the pump and

147-68

N.m).

Then tighten the packing nut just enough

operate

it

at

a

slow speed to check the

tie

rods for signs

of binding. Adjust the

tie

rod locknuts if necessary.

10

307-465

f

Fig

9

Page 10

Hydraulic Pump

WARNING

.

I

The hydraulic pump and the pressure control knob

are sold as a complete assembly only. Do not at-

tempt to service these parts yourself. Send them

to an authorized Graco service center for replace-

I

ment or repair.

I

ICAUT1ON1

Cleanliness is essential when repairing hydraulic

systems. Use special care to avoid getting dust or

dirt

into

the

pump

during servicing.

~~ ~~~ ~~~~~

Unscrew the swivel (76). point the bypass valve (78)

down into a waste container and open the bypass valve

to drain the reservoir (121. Refer

to

Fig

10.

the hydraulic motor

(89).

Be careful

not

to

turn

the

Disconnect the hose

(881

between the cooler

(47)

and

elbow

(431.

Loosen the hose clamp

(49)

nearest to the

cooler on the short section

of

hose (51

that

is located

between the reservoir and the cooler.

See

Fig 10.

to the. fan shield

(521.

Remove the cooler. Remove the

Remove the six screws (2) holding the cooler assembly

fan.

Unscrew the hose coupling stud

(60)

to disconnect the

suction hose

(59)

between the reservoir and the

hydraulic pump.

from the elbow

(681

and disconnect the pressure hose

Disconnect the case drain hose (55) coupling stud (671

(84)

from the tee

(75)

in

the outlet of the hydraulic

pump

169).

flange

(64).

Remove plate

(631.

loosen the setscrew on

Remove the two screws (711 from the pump

(691

and

the coupling

(66)

and pull the pump

(69)

out.

~~~

installing the fan

(50).

slide

it

about

1

in.

(25

mml

onto

Reassemble

,in

the reverse order

of

disassembly. When

the pump

(691

shaft and tighten the setscrews.

NOTE:

Whenever the reservoir cover

(10)

is removed, put silicone sealant on the threads of the

screws

(2)

when reassembling the cover.

CAUTION

The alignment of the engine mounting flange

(641

to the engine and the alignment of the coupler

(661

which connects the hydraulic

pump

1691 shaft

and the engine shaft are critical. If the coupler has

failed, Graco recommends that you contact your

~

nearest factory branch or the Graco Service

Department for detailed service information.

Cooler

Special care must be used if the return tube 1139). the

9oo

elbow

(43)

or the hose

(88)

leading

into

the elbow

are removed from the cooler (47). The return tube and

elbow each connects to a hex-shaped male adapter

(K)

which is part of the cooler core assembly.

See

Fig 10.

The adapter is made of aluminum and can be easily

damaged.

So,

whenever

you

are working on these

adapter. Remove and replace the necessary cooler parts

parts, hold a wrench stationary on the hex of the male

as instructed

in

paragraphs 2 and 3 of the Hydraulic

Pump section (column

1

).

Reassemble the cooler in the

elbow, use a liquid sealant on the threads and screw the

reverse order of disassembly. When installing the

elbow~onto the adapter by hand. Tighten the nuts (L).

Refer to Fig 10.

Motor

Mounts

If the motor mounts (32) must be replaced, be careful to

install them correctly and evenly. The

nut

(30) must be

screwed onto the capscrew (31)

so

the first thread of

the screw is just flush with the top of the nut. Refer to

the Parts Drawing, page 14.

Page 11

lef

No.

105Displacement Pump

lcludes

items

106-127

Page 12

307-465

13

Page 13

14 307-465

Page 14

.

..

.

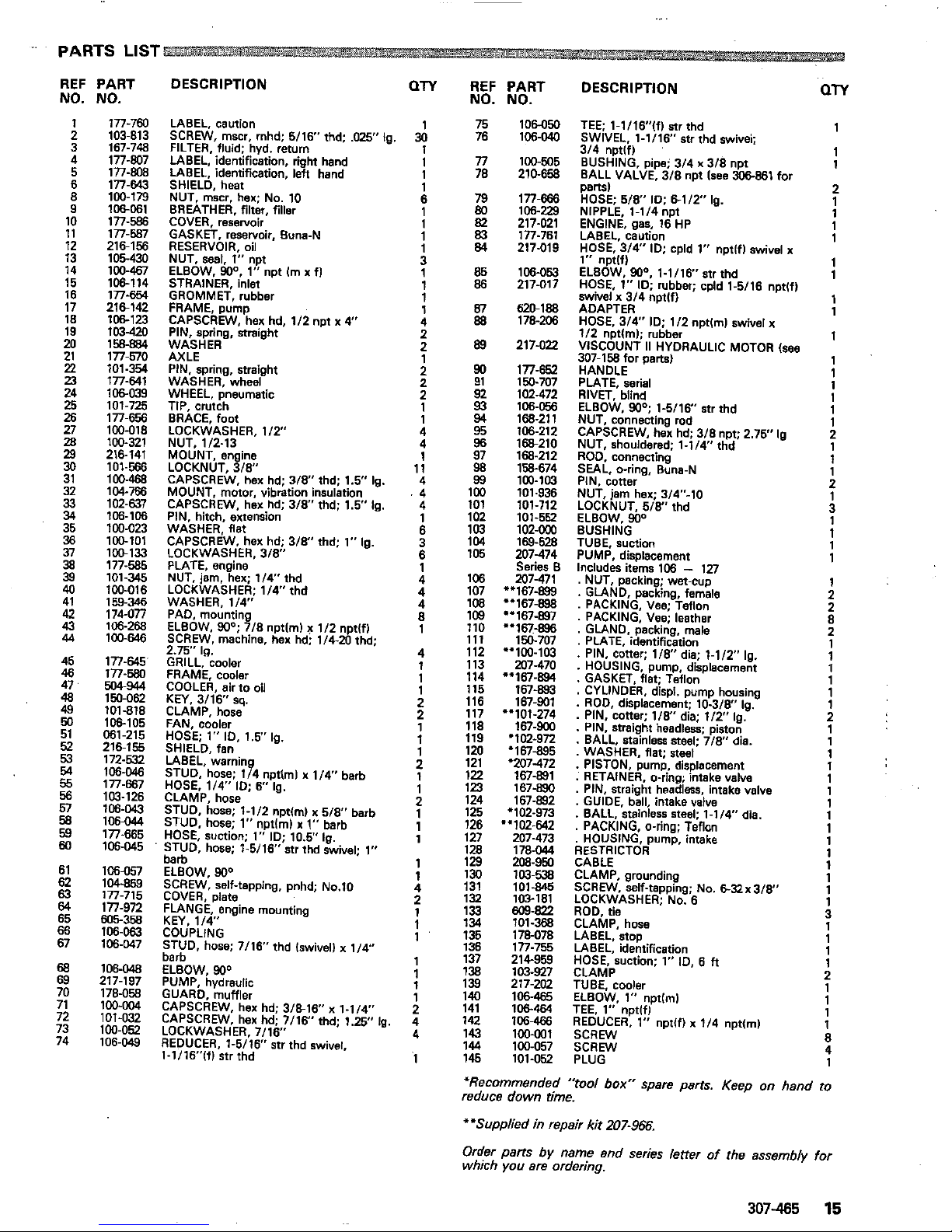

PARTS

LIST

REF

PART DESCRIPTION

NO.

NO.

an

REF

PART

DESCRIPTION

NO.

NO.

QTY

1

1

1

2

1

3

4

5

6

8

9

10

12

11

13

14

15

16

17

18

19

21

22

23

24

26

25

28

29

30

32

31

33

34

35

36

38

37

39

40

42

41

43

44

20

n

177-760

103-813

167-748

177.807

177-ma

in-w

1w-179

106061

177.586

177-587

216-156

105-430

100-457

106114

216142

106123

103-420

158-884

101-354

rn-570

106.039

101-725

177-656

100418

177-6w

in-641

LABEL, caution

SCREW, rnscr, rnhd;

5/16

thd;

,025"

Ig.

FILTER, fluid; hyd. return

LABEL, identification, right hand

LABEL, identification, left hand

SHIELD, heat

NUT, rnscr. hex; No.

10

COVER, reservoir

BREATHER, filter, filler

GASKET, reservoir,

Buna-N

RESERVOIR, oil

NUT,

seal.

1"

npt

ELBOW,

90O.

1"

npt

Irn

x

fl

STRAINER, inlet

GROMMET, rubber

CAPSCREW, hex hd,

1/2

npt

x

4"

FRAME, pump

PIN, spring, straight

WASHER

AXLE

PIN, spring, straight

WASHER, wheal

WHEEL, pneumatic

TIP, crutch

BRACE, foot

NUT,

112-13

LOCKWASHER,

112"

MOUNT, engine

LOCKNUT,

318"

CAPSCREW, hex hd:

3/8"

thd:

1.5

Ig.

MOUNT, motor, vibration insulation

CAPSCREW, hex hd;

318"

thd;

1.5

Ig.

WASHER,

flat

PIN, hitch, extension

CAPSCREW, hex hd;

318"

thd;

1"

Ig.

PLATE, engine

LOCKWASHER,

3/6

NUT, jam. hex;

114"

thd

WASHER,

114"

LOCKWASHER;

114"

thd

PAD, mounting

ELBOW.

90':

7/8

nptlrnl

x

112

nptlf)

2.75'

Ig.

SCREW. machine. hex hd;

1/4-20

thd;

GRILL, cooler

FRAME, cooler

COOLER, air to oil

KEY.

3116

sq.

CLAMP, hose

FAN, cooler

HOSE;

1"

ID,

1.5"

Ig.

SHIELD, fan

STUD. hose;

114

nptlrnl x

114"

barb

LABEL, warning

CLAMP, hose

HOSE,

114"

IO; 6 Ig.

STUD, hose;

1"

nptlrn)

x

1"

barb

STUD. hose:

1-112

nptlrn)

x

5/8"

barb

STUD, hose:

1-5/16''

str thd swivel;

1"

HOSE, suction;

1"

ID;

10.5"

10.

ham

30

1

1

1

1

75

76

1M50

1o6-040

210-658

100-505

77

78

6

i

1

79

&I

82

E3

84

177-666

106229

217-021

1

1

217419

177-761

".

3

1

1

i

85

86

217-017

106453

620-188

178-206

i

1

4

2

2

1

2

2

2

1

4

1

4

11

1

4

.4

4

1

6

3

6

1

87

88

1

89

217422

90

92

91

93

94

95

96

97

98

99

100

1

02

101

103

104

105

177-652

150-707

102-472

106-056

168-211

168210

106-212

168-212

158674

101-936

100-103

101-712

216141

101-566

100-468

104-766

102-637

106-106

100423

1w-101

1Oa32i

3

101-552

102-ooo

207474

169-528

Series

E

207-471

**167-899

"57-898

"167-898

*'167-897

150-707

"00-103

207-470

"67-894

167-893

"101-274

167-901

V02-972

167-900

'167-895

'207-472

167-891

167-890

*102-973

167-892

"102-642

207-473

208.950

..

178044

103-538

CLAMP, grounding

101-845

SCREW, self-tapping; No.

632x3/8"

609-822

ROD, tie

103-181

LOCKWASHER: No.

6

101-368

CLAMP, hose

178478

LABEL, stop

214-959

HOSE, suction:

1"

ID,

6

ft

177-755

LABEL. identification

217-202

TUBE, cooler

103-927

CLAMP

106465

ELBOW,

1"

nptlrnl

106464

TEE,

1"

nptlfl

106-466

REDUCER,

1"

nptlf)

x

1/4

nptlm)

109-001

SCRFW

100-057

101-052

.. . . .-

100-133

177-585

100416

101.345

159.346

174.077

106-268

100-646

~~ ~~

1

106

107

108

109

110

111

112

113

i

4

4

E

1

4

1

1

45

46

47

48

49

50

51

52

53

55

54

177.645

177-580

504944

150-062

106105

216-155

061-215

172-532

177-667

106046

103-126

106-043

177-665

106044

106-045

to1a18

114

. ._

115

116

117

119

118

1

20

121

123

122

1

24

125

1

27

128

129

131

130

132

133

134

135

136

1

37

138

139

140

141

1

42

143

144

145

. ..

1m

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

57

56

58

59

M)

..

1

1

61

62

63

64

106457

104-869

177-715

177-972

605-358

106-047

106-063

106"R

SCREW, self-tapping, pnhd;

No.10

ELBOW.

90O

COVER, piate

FLANGE, engine mounting

KEY

l/d"

4

2

1

65

66

67

i

1

COUPLING

barb

STUD. hose;

7/16'.

thd (swivel)

x

114"

ELBOW,

90O

GUARD, muffler

PUMP. hydraulic

CAPSCREW, hex hd;

3/816

x

1.114"

CAPSCREW, hex hd;

7/16

thd;

1.25

Ig.

REDUCER,

1-5/16

str

lhd swivel,

LOCKWASHER,

7/16

1-1/16lfl

str

thd

.

. - .

.

. , .

1

1

68

69

70

71

72

73

74

1

217-197

178-058

100-004

101-032

100-052

~~

.

..

1

1

2

d

1

8

4

1

4

'1

106-049

SCREW

PLUG

- -

. .

-

. .

reduce down time.

*Recommended "tool box" spare parts. Keep on hand to

**Supplied in repair kit

207-966

Order Pam by name and series letter

of

the assembly for

which you are ordering.

307-465

15

Page 15

~~ ~

~

ACCESSORIES (Must be purchased separately)

AIRLESS SPRAY GUN

0.090

in.

fluid passage orifice; 114 npsm

(m)

fluid inlet

XXWpsi(344bar) MAXIMUM WORKING PRESSURE

208-663

with three-fingertrigger

208-664

with four-finger

trigger

6wo

psi

(415

bar) MAXIMUM WORKING PRESSURE

For heavy materials. 112 npt(f) inlet.

FLO-GUN 207-945

50

DSi

(344

barl MAXIMUM WORKING

PRF.9.9lIRF

CHECK VALVE

217-286

1" npt. Installed after outlet elbow (Ref No. 140). and

followed by Accessory elbow 106-645 which is installed

before the tee (Ref

No.

141).

~ ~~ ~~

=-GAL. SUCTION TUBE 207-485

THE GRACO WARRANTY

Graco Inc. warrants all equipment manufactured by

it

and bearing

its

name to be free from defects

in

material and workmanship under

normal use and service. This warranty extends to. the original

purchaser for a period of

12

months from the date of purchase and ap-

accordance with written factory recommendations. This warranty

plies only

when the equipment is installed and operated

in

does not cover damage

or

wear which, in the reasonable judgment of

Graco. arises from misuse. abrasion, corrosion, negligence, accident,

substitution of non-Graco parts, faulty installation or tampering.

This warranty is conditioned upon the prepaid return of the equipment

claimed to be defective for examination by Graco to verify the claimed

defect. If the claimed defect is verified, Graco will repair or replace

free of charge. any defective park. The equipment will be returned to

the original purchaser transportation prepaid. If inspection of the

equipment does not disclose any defect in workmanship or material,

will be charged.

repairs will be made

at

a

reasonable charge and return transportation

THIS LIMITED WARRANTY

IS

EXCLUSIVE, AN0

IS

IN LIEU OF

ANY OTHER WARRANTIES (EXPRESS

OR

IMPLIED) INCLUDING

WARRANTY OF MERCHANTABILITY

OR

WARRANTY OF

CONTRACTUAL

LIABILITIES INCLUDING PRODUCT

LlABiLlTlES

FITNESS FOR A PARTiCULAR PURPOSE AND OF

ANY NON-

BASE0 ON NEGLIGENCE

OR

STRICT LIABILITY. EVERY FORM

OF

LIABILITY

FOR

DIRECT, SPECIAL

OR

CONSEQUENTIAL

DAMAGES

OR

LOSS

IS

EXPRESSLY EXCLUDED AN0 DENIED.

EQUIPMENT NOT COVERED

BY

GRACO WARRANTY. Accessories

or components of equipment sold by Graco

that

are not manufactured

by Graco lsuch as electric motors, switches, hose, etc.) are subject to

the warranty. if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making such claims.

HYDRA-MASTICSWIVELS

6wopsi(413bar) MAXIMUM WORKING PRESSURE

207-946 Straioht Swivel.

,a

318 npt(f) x llfnpsm

(f)

'

207-947 Straiaht Swivel,

207-948

90°

Swivel,

112npt(f)xl/2npsm(f)

5wopsi1344barl MAXIMUM WORKING PRESSURE

Clears tip stoppages by paint pressure

REVERSE-A-CLEAN

111

216-001

50

psi

(344

barl MAXIMUM WORKING PRESSURE

SURGE TANK 8 FILTER

214-625

Paint Filter,

60

mesh

(250

micron),

18

sq.

in. (120 cm2) filter screen

ELBOW

106-645

1"

npt. Required to install check valve217-286. Same

as

Ref No. 104.

HYDRAULIC FLUID 207-428

1 gallon (3.8 liter)

HIGH PRESSUREFLUID HOSE

50psi1344barl MAXIMUM WORKING PRESSURE

215441

loft

(3

m)

112in.

ID,

BunaN tube, coupled 112npthnbe)

215-442 15ft(4.5m)

215444 50ft(15.2m)

215-443 25ft (7.6

m)

314in.

ID,

Neoprene tube, coupled3/4npt(mbe)

215-238

lOft(3m)

215-239

15ft(4.5m)

215240 25ft(15.2m)

TECHNICAL DATA

Engine

Gasoline tank

Hydraulic pump

Hydraulic fluid sump

Hyd. pump suction filter

Hydraulic oil return filter

Material pump

Wetted parts

Dimensions

Weight

:

KOHLER. Model K341-T, 4 cycle,

single cylinder, air cooled,

16

HP

:

1.5

gallon

(5.7

liter) capacity; con-

112

kW)

:

9

GPM

134

literlmin) max. volume;

Sumes

1.3

gailhr

14.9

iiterlhour)

200-15w

psi

114-103

bar) pressure

range

:

5

gallon

(19

liter)

:

30

mesh screen

:

400

sq in

12580

cm*) surface area;

25

:4500

psi

(310

bar) max. working

micron filtration; disposable type

pressure; 3 GPM

(13

literlmin) out-

put;

15

cycleslgal

:Steel, Nitralloy, Tungsten Carbide,

Leather

:

350

Ib

I160

kg1

:Length:

48

in.

11.2

m)

Width:

29

in.

1736

mml

Height:

48

in.

11.2

ml

Subsidiary

and

Affiliate

Compen1as:Canada: England:

Switzerland; France: Germany; Hone Kona: JaDan

Factory

Branches:Atlante, Dallas, Detrolt,

Los

Angeles. West Caldwell

IN.J.1

GRACO INC. P.

0.

Box

1441

MINNEAPOLIS,

MN

55&0"1444-

PRINTED

IN

U.S.A.

307-465

581

Revised

162

PTFE

Loading...

Loading...