Graco GH 130, GH 200, GH 230, GH 300, dutymax gh 230 Repair Manual

...

334654B

EN

Repair

GH™130/200/230/300 and

DutyMax GH/EH™230/300 Displacement Pump

For professional use only.

Not approved for use in explosive atmosphere or hazardous locations.

For portable airless spraying of architectural paints and coatings.

Models: 24B748, 24W995, 24W996, 24W997, 24W998, 24W999, 24X001

Important Safety Instructions

Read all warnings and instructions in this manual and related manuals.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

24X00124W999

24W996

24W998

ti25242a

24B748

24W997

24W995

Table of Contents

2 334654B

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disassemble Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assemble Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pump 24B748 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pump 24W995 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pump 24W996 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pump 24W997 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pump 24W998 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pump 24W999 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pump 24X001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Warnings

334654B 3

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manua l

where applicable.

SKIN INJECTION HAZ ARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the

event that injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop

leaks with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs

while spraying, follow the Pressure Relief Procedure for turning off the unit and relieving

the pressure before removing the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment

energized or under pressure while unattended. Follow the Pressure Relief Procedure

when the equipment is unattended or not in use, and before servicing, cleaning, or

removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi. Use Graco replacement parts or accessories

that are rated a minimum of 3300 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning

properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the

controls.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your

material supplier for compatibility.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eye wear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects

or other reproductive harm. Wash hands after handling.

Repair

4 334654B

Repair

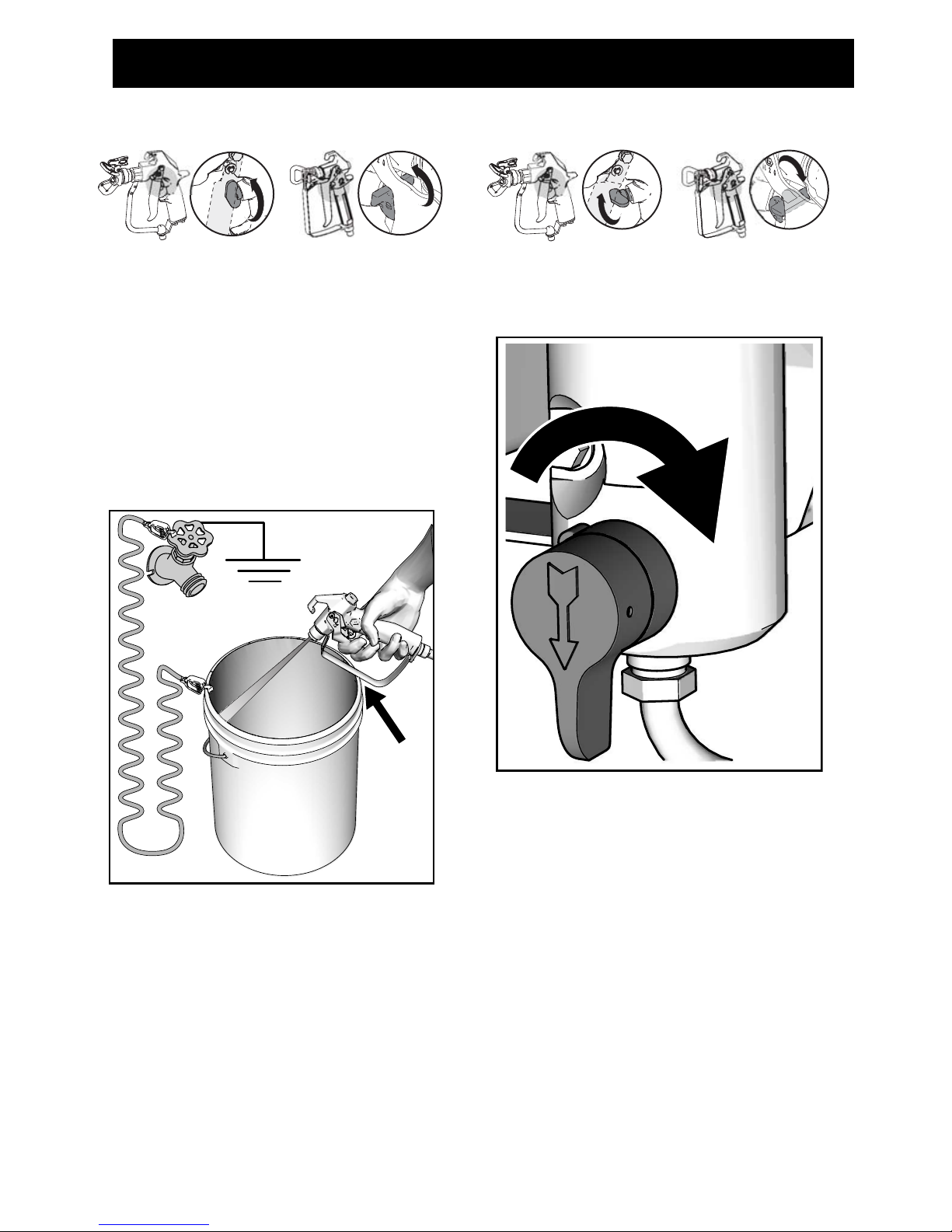

Trigger Lock

Always engage the trigger lock when sprayer

is stopped to prevent the gun from being

triggered accidentally by hand or if droppe d

or bumped.

Pressure Relief Procedure

1. Engage trigger lock.

2. If applicable, turn electric motor ON/OFF

switch to OFF position. Wait 7 seconds

for power to dissipate.

3. Unplug power cord or shut engine off.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection, splashed fluid

and moving parts, follow the Pressure

Relief Procedure whenever sprayer is

stopped and before sprayer is cleaned or

checked, and before equipment is

serviced.

ti24612a

ti24851a

OI

I

O

t

ti24853a

ti18812a

ti7529a

Repair

334654B 5

4. Disengage trigger lock.

5. Hold a metal part of the gun firmly to a

grounded metal pail. Trigger the gun to

relieve pressure.

Solvent and oil-based fluids: follow

local code. Use only conductive metal

pails, placed on a grounded surface

such as concrete.

Do not place pail on a non-conductive

surface such as paper or cardboard

which interrupts grounding continuity.

6. Engage trigger lock.

7. Open any fluid drain valves in system.

Leave drain valves open until ready to

spray again.

ti22700a

ti24608a

ti24585a

Repair

6 334654B

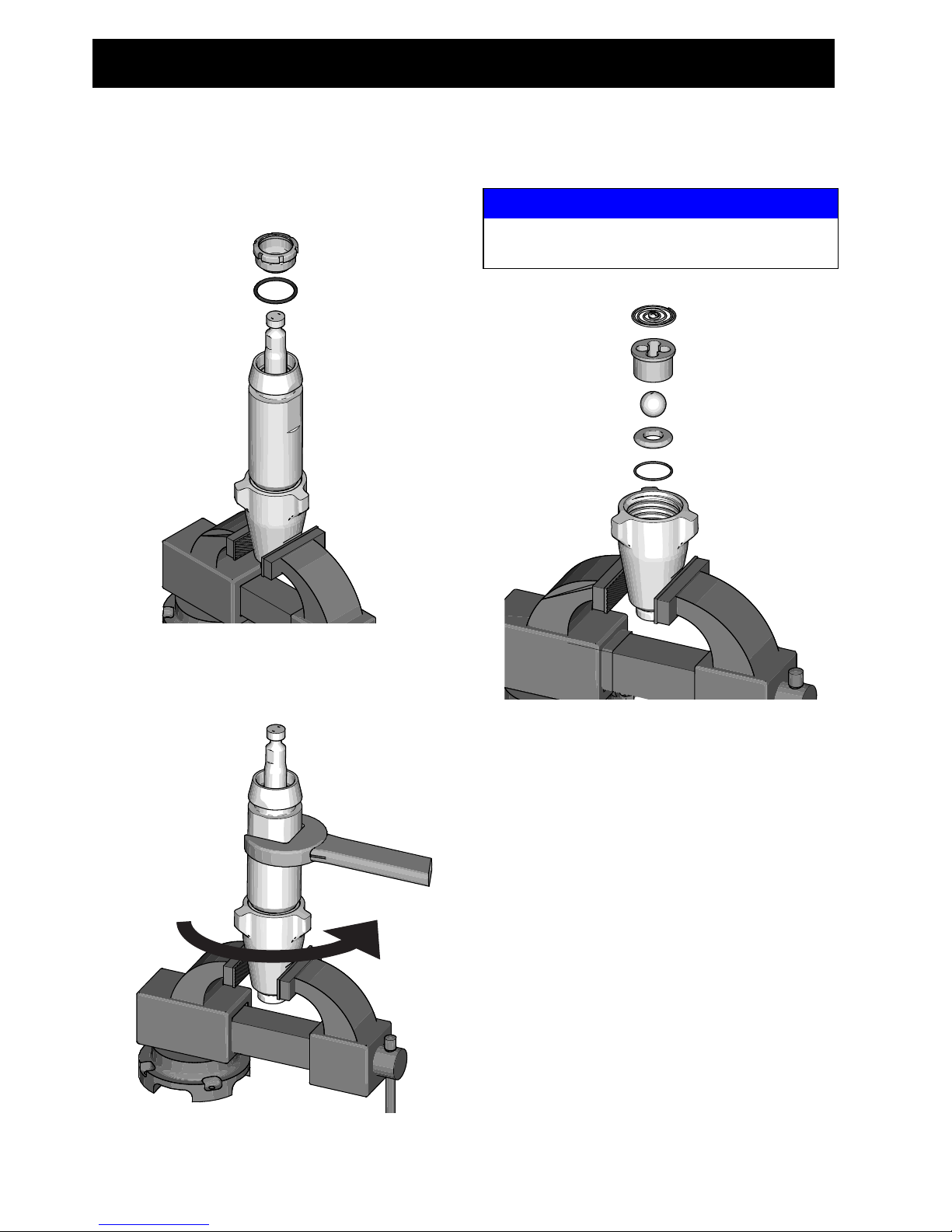

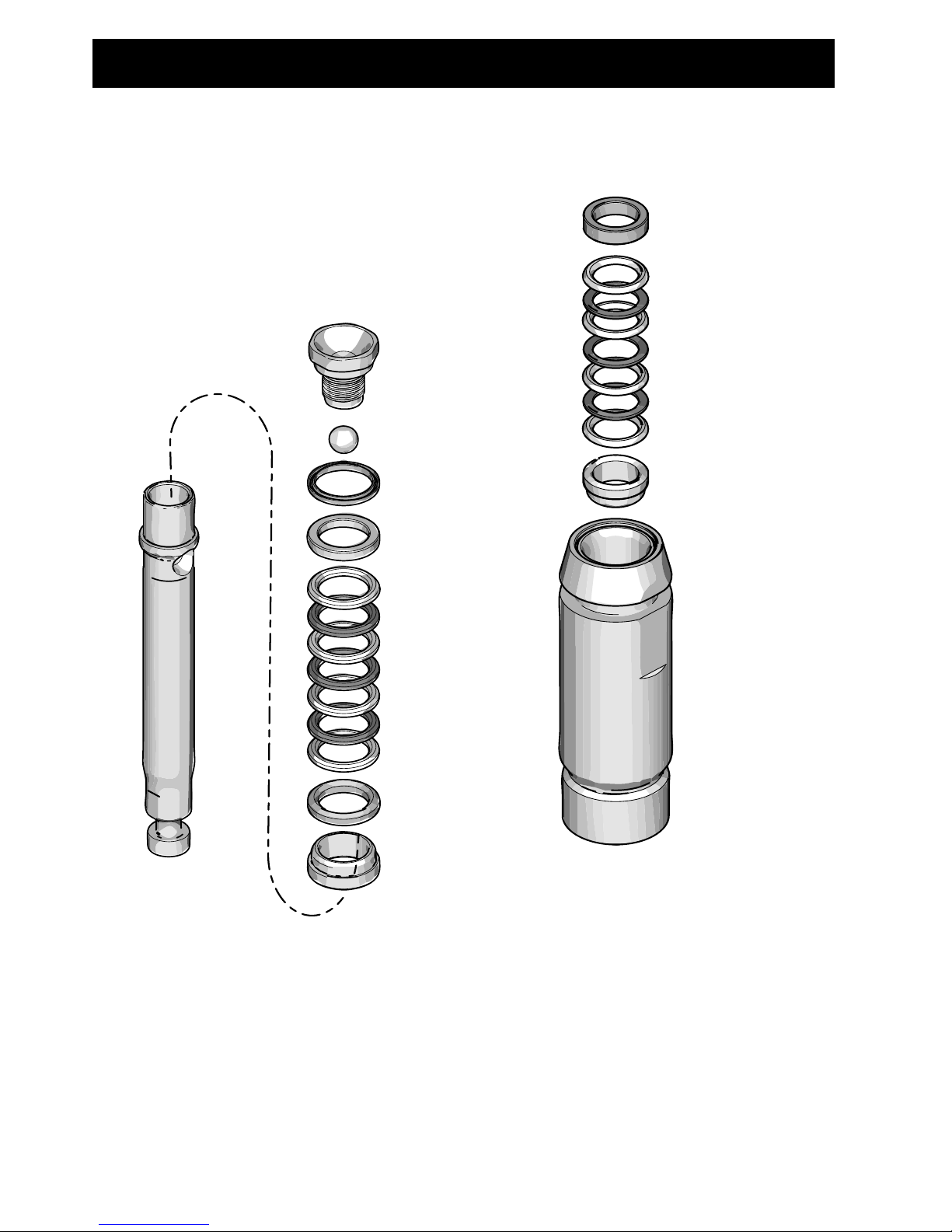

Disassemble Pump

1. Remove packing nut and throat

adjustment spacer.

2. Unscrew cylinder from intake valve.

3. Disassemble intake valve. Clean and

inspect. O-ring may require a pick for

removal.

ti25168a

ti25169a

NOTICE

If using a pick to remove the O-ring use care

to avoid damage to the machined surfaces.

ti25170a

Repair

334654B 7

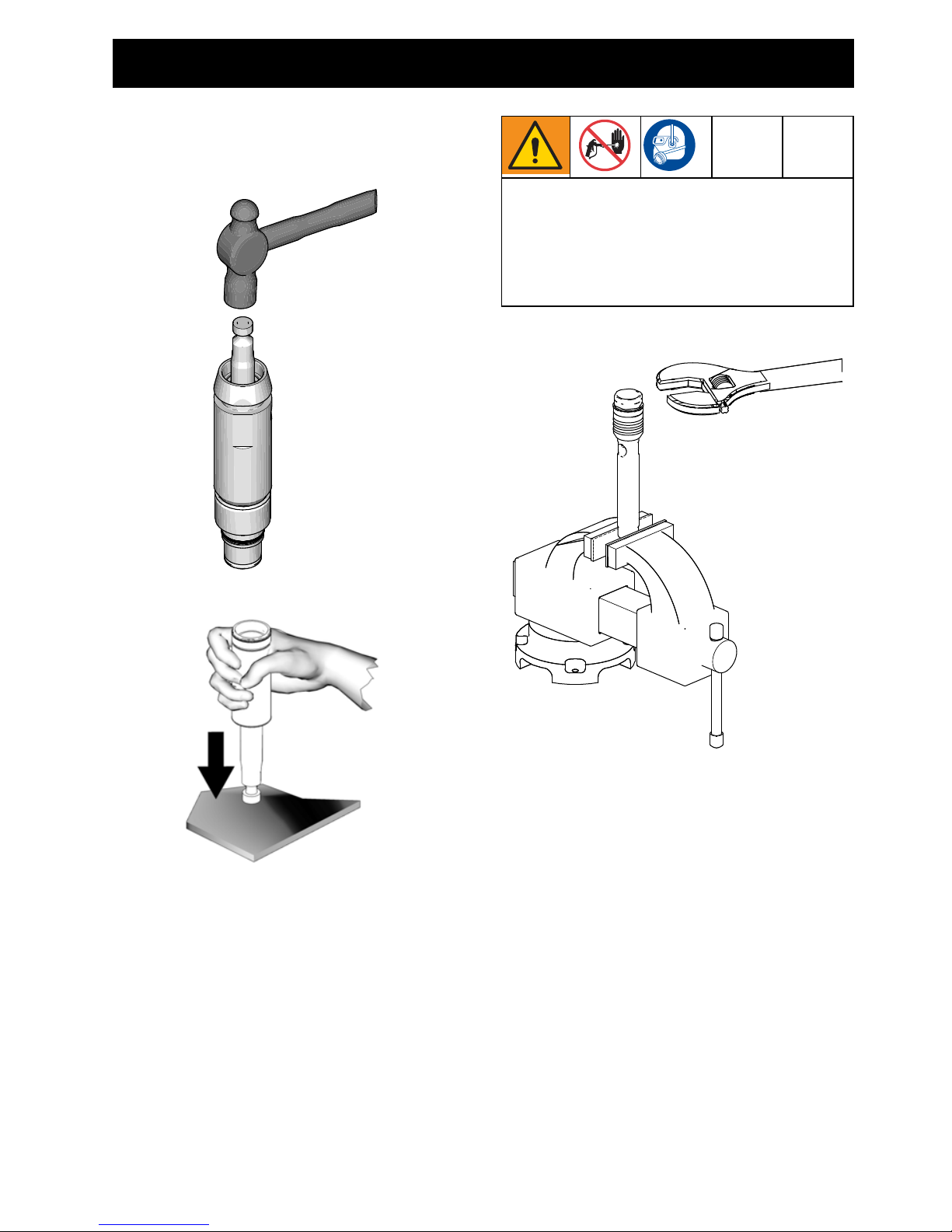

4. Tap piston rod out of cylinder with a

hammer or flip over and tap piston rod

out against a bench.

5. Remove piston rod from sleeve.

6. Unscrew piston valve from piston rod.

ti25171a

ti8849a

Do not clean or wipe the piston valve

threads. Cleaning the piston valve threads

could destroy the special sealing patch and

cause the piston valve to come loose

during operation, causing a pump burst

and possible serious bodily injury.

Repair

8 334654B

7. Clean and inspect parts. (The piston has

a special thread locking/sealing patch.

Do not remove the patch. The patch

allows for disassembly/assembly

procedures before it is necessary to

apply thread sealant to the threads. On

fifth assembly apply thread sealant to

threads.

8. Remove and discard throat packing and

glands from the cylinder.

ti25172a

ti25173a

Repair

334654B 9

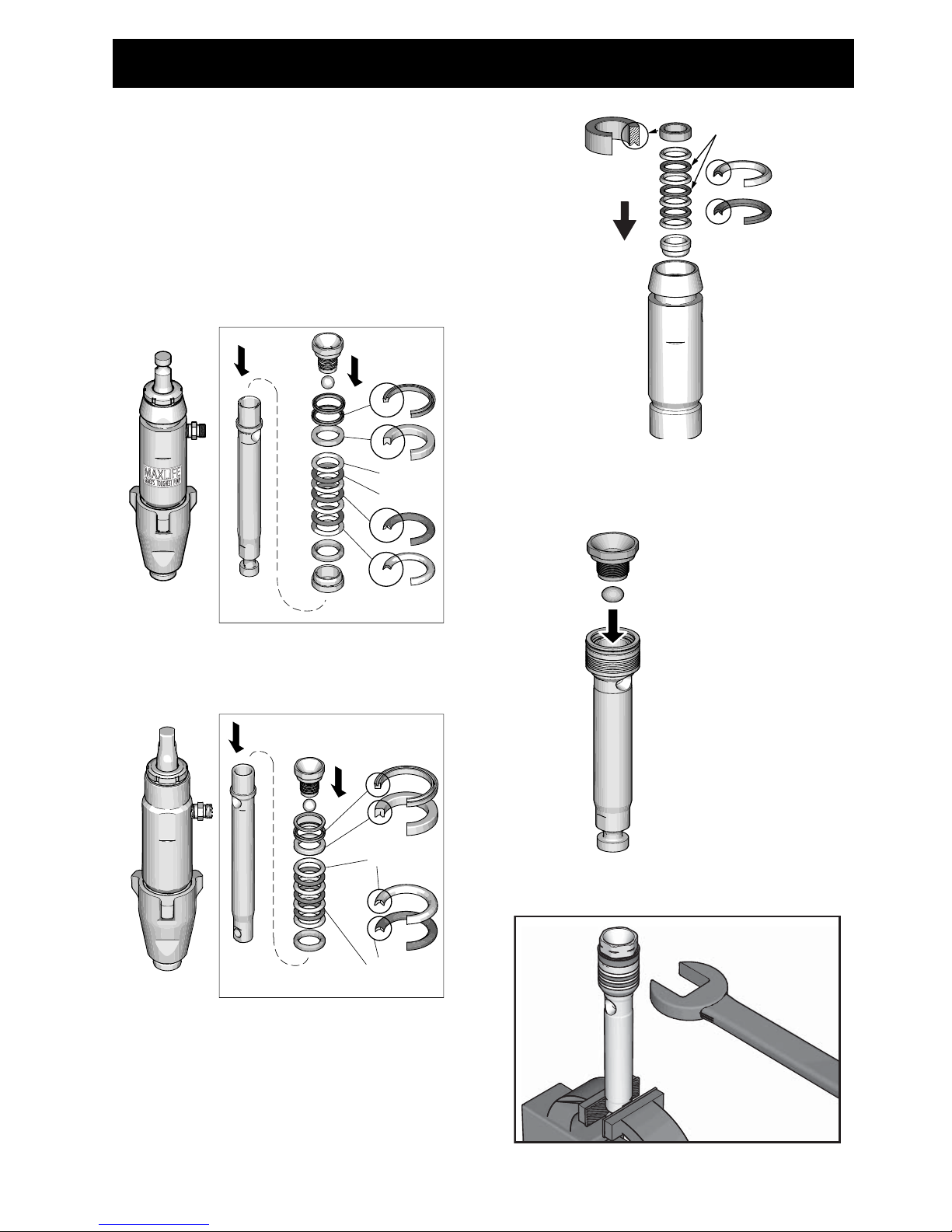

Assemble Pump

1. If applicable, soak leather packings in

SAE 30W oil for one hour before

assembly.

2. Install ball in piston rod. Apply thread

sealant to piston valve threads; ensure

that none gets on the ball.

3. Torque to 55 ± 3 ft-lb (75 ± 4 N•m).

Leather

Packings

Blue

Brown

Blue

ti25174a

Leather

Packings

ti25175a

ti25176a

ti24892a

Loading...

Loading...