Page 1

Instructions-Parts

3A0420T

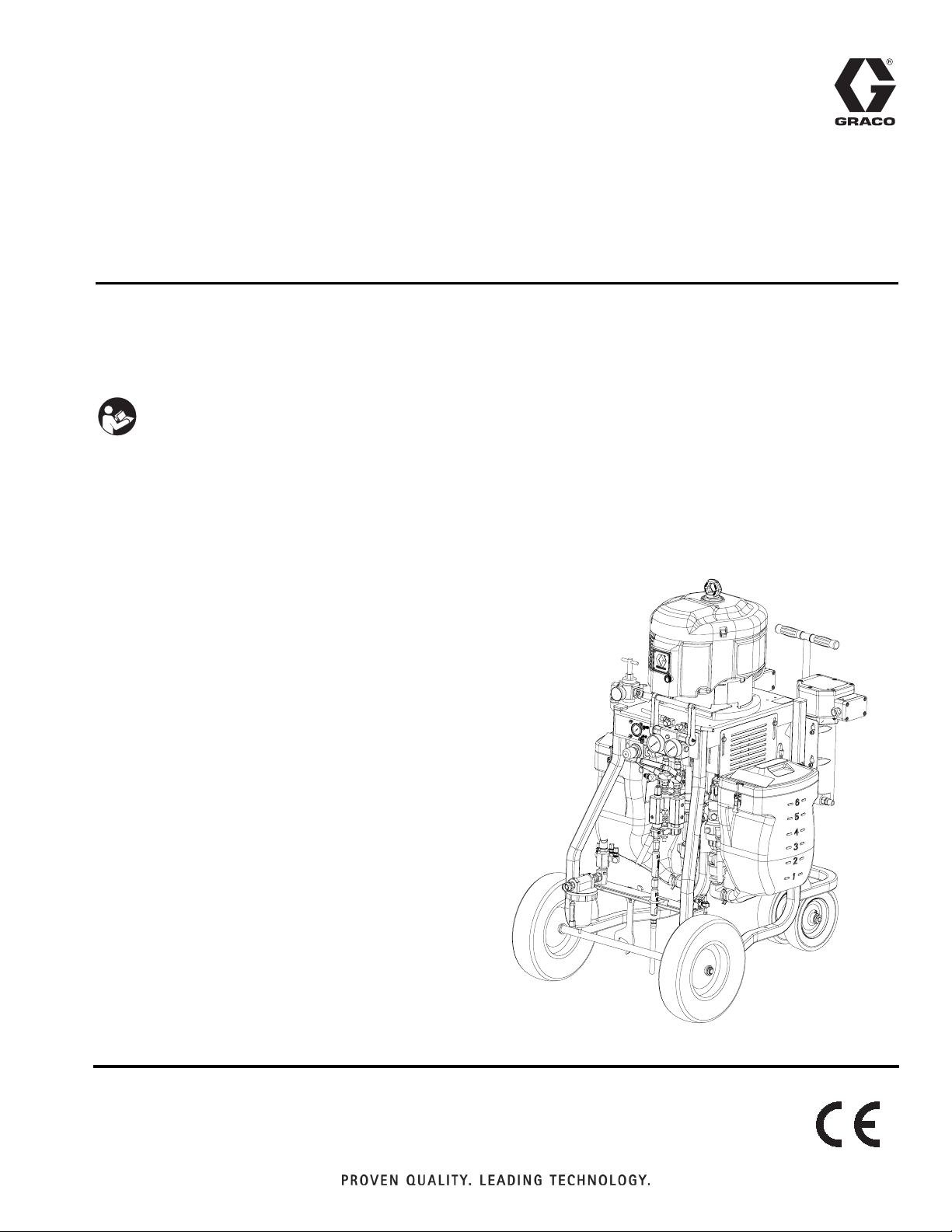

XP Proportioners

Mechanically linked fixed ratio plural-component system used for proportioning, mixing,

and spraying two component coatings. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

See page 11 for maximum working pressure and model

information.

XP70 system shown with hoppers and optional

solvent flush pump and heaters.

EN

r_571100_3A0420A_1a-2

Page 2

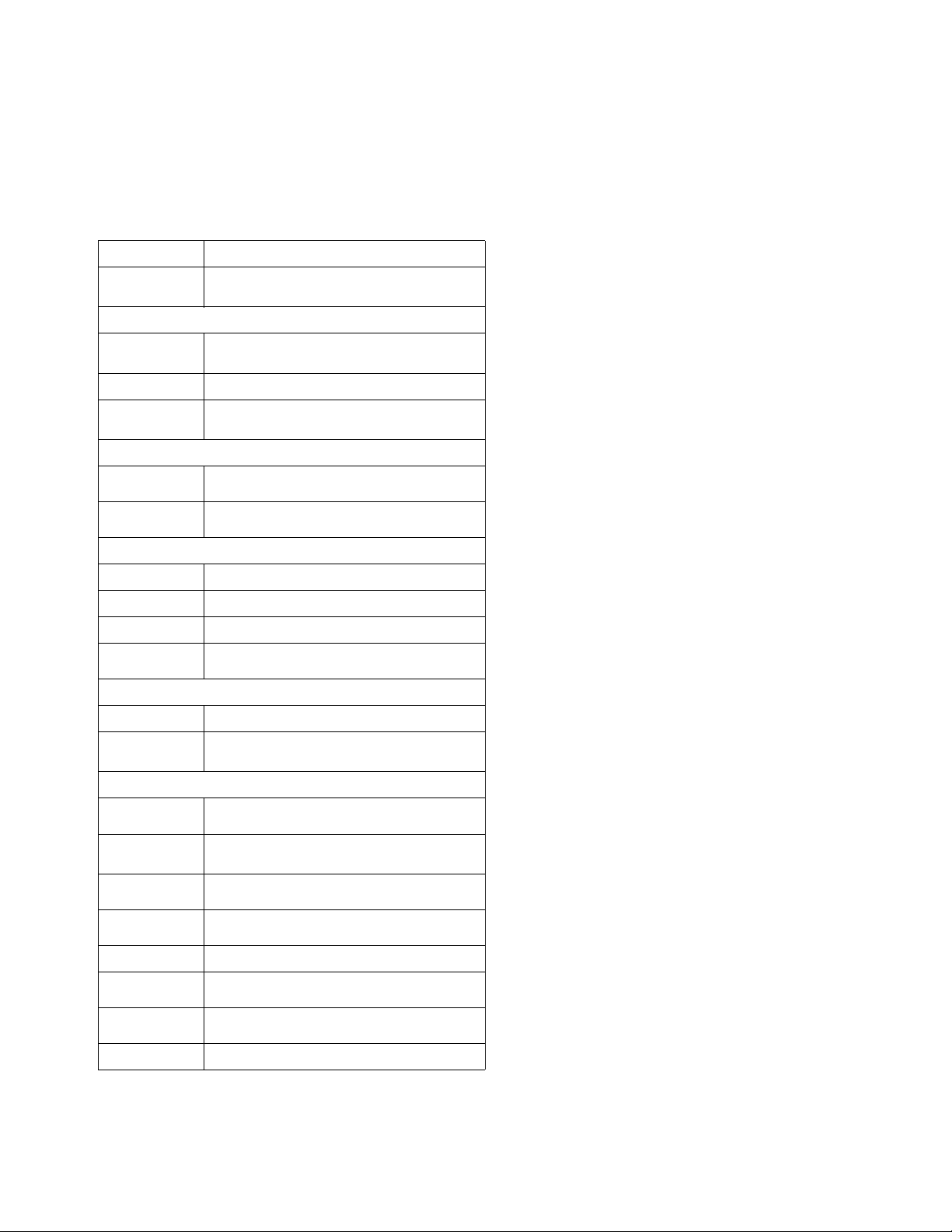

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Two-Component Material Information . 7

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 7

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 7

Keep Components A and B Separate . . . . . . . . . 7

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 7

Foam Resins with 245 fa Blowing Agents . . . . . . 7

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 8

A and B Component Designations . . . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Over Pressure Protection . . . . . . . . . . . . . . . . . . 9

Initial System Setup . . . . . . . . . . . . . . . . . . . . . . . 10

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cart-Mounted Systems . . . . . . . . . . . . . . . . . . . 11

Bare Proportioning Pump Packages . . . . . . . . . 13

Component Identification . . . . . . . . . . . . . . . . . . . 14

Fluid Control Assembly . . . . . . . . . . . . . . . . . . . 15

Main Air Controls . . . . . . . . . . . . . . . . . . . . . . . 15

45:1 Solvent Flush Pump Kit 262393 (optional) 16

Air Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fluid Line Accessories . . . . . . . . . . . . . . . . . . . 17

Flush Before Using Equipment . . . . . . . . . . . . . 17

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wire Systems with Explosion-Proof Heaters . . . 19

Motor Position . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connect Air Supply . . . . . . . . . . . . . . . . . . . . . . 21

Connect Static Mixers, Gun, and Hoses . . . . . . 21

Connect Fluid Hose Bundles (Remote Mix Manifold

Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 22

Prime Empty System . . . . . . . . . . . . . . . . . . . . . . . 23

Prime A and B Fluids . . . . . . . . . . . . . . . . . . . . 23

Prime Solvent Flush Pump . . . . . . . . . . . . . . . . 24

Recirculate Prior to Spraying or Re-Prime After a

Pump Runs Dry . . . . . . . . . . . . . . . . . . . . . 25

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

B Side Mix Manifold Restriction . . . . . . . . . . . . . . 27

Flush Mixed Material . . . . . . . . . . . . . . . . . . . . . . . 28

Flush Mix Manifold, Hose, and Spray Gun . . . . 28

Empty and Flush Entire System

(new system or end of job) . . . . . . . . . . . . . . 29

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Park . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

System Verification . . . . . . . . . . . . . . . . . . . . . . . . 31

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Hose Electrical Resistance . . . . . . . . . . . . . . . . 32

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . 32

Recommended Spare Parts . . . . . . . . . . . . . . . 32

Change the Mix Ratio . . . . . . . . . . . . . . . . . . . . 32

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pump Troubleshooting . . . . . . . . . . . . . . . . . . . 34

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 35

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Mix Manifold Assembly . . . . . . . . . . . . . . . . . . . 38

Fluid Circulation Manifold with Over Pressure Relief

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hoppers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Optional Solvent Pump . . . . . . . . . . . . . . . . . . . 40

Optional Fluid Heaters . . . . . . . . . . . . . . . . . . . . 41

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cart-Mounted System . . . . . . . . . . . . . . . . . . . . 42

Bare Proportioning Pump Package . . . . . . . . . . 50

Air Controls, 258983 . . . . . . . . . . . . . . . . . . . . . 52

Fluid Circulation Manifold with Over Pressure Relief

Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Recommended Spare Parts . . . . . . . . . . . . . . . . . 54

Accessories and Kits . . . . . . . . . . . . . . . . . . . . . . . 55

Acceptable For Use in Explosive Atmospheres . 55

Not Approved For Explosive Atmospheres . . . . 56

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Bare Proportioner Mounting Hole Dimensions . 60

Wall Mount Bracket 262812 Dimensions . . . . . . 61

Floor Stand 24M281 Dimensions . . . . . . . . . . . 62

Hydraulic Unit Dimensions . . . . . . . . . . . . . . . . 62

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 64

2 3A0420T

Page 3

Related Manuals

Manuals are available at www.graco.com. Component

manuals in English:

Manual Description

™

XTR

312145

Pump Package Components

307158

311238

311762

312747

406860

309524

309525 Heated Hose Kit, Instructions-Parts

5 and XTR™ 7 Spray Guns

Instructions-Parts

Viscount

®

II Hydraulic Motor Instruc-

tions-Parts

®

NXT

Air Motor Instructions-Parts

Xtreme

®

Displacement Pumps

Instructions-Parts

Hopper Kits

20 Gallon Double Wall Hopper Kit

Instructions-Parts

7 Gallon Hopper Installation Kit Instructions-Parts

Heating

Viscon

®

HP Heater Instructions-Parts

Related Manuals

313259 Hopper or Hose Heat Circulation Kit

406861

Viscon HP Heater Adapter Kit, Instructions-Parts

Solvent Flush

310863 Feed and Solvent Flush Kits

312794

Merkur

Instructions-Parts

®

Pump Assembly

Accessories and Kits

309852

311486

312769

339361

Polyurethane Circulation and Return

Tube Kits, Instructions-Parts

™

DataTrak

Conversion Kit, Instruc-

tions-Parts

Feed Pump and Agitator Kits

Instructions-Parts

High Pressure Hose and Accessories

Brochure

3A0421 Ratio Check Kit, Instructions-Parts

3A0590

3A2573

Mix Manifold, Quickset Mix Manifold

Instructions-Parts

Gun Splitter Valve with Independent

Flush, Instructions-Parts

406739 Desiccant Kit Instructions-Parts

3A0420T 3

Page 4

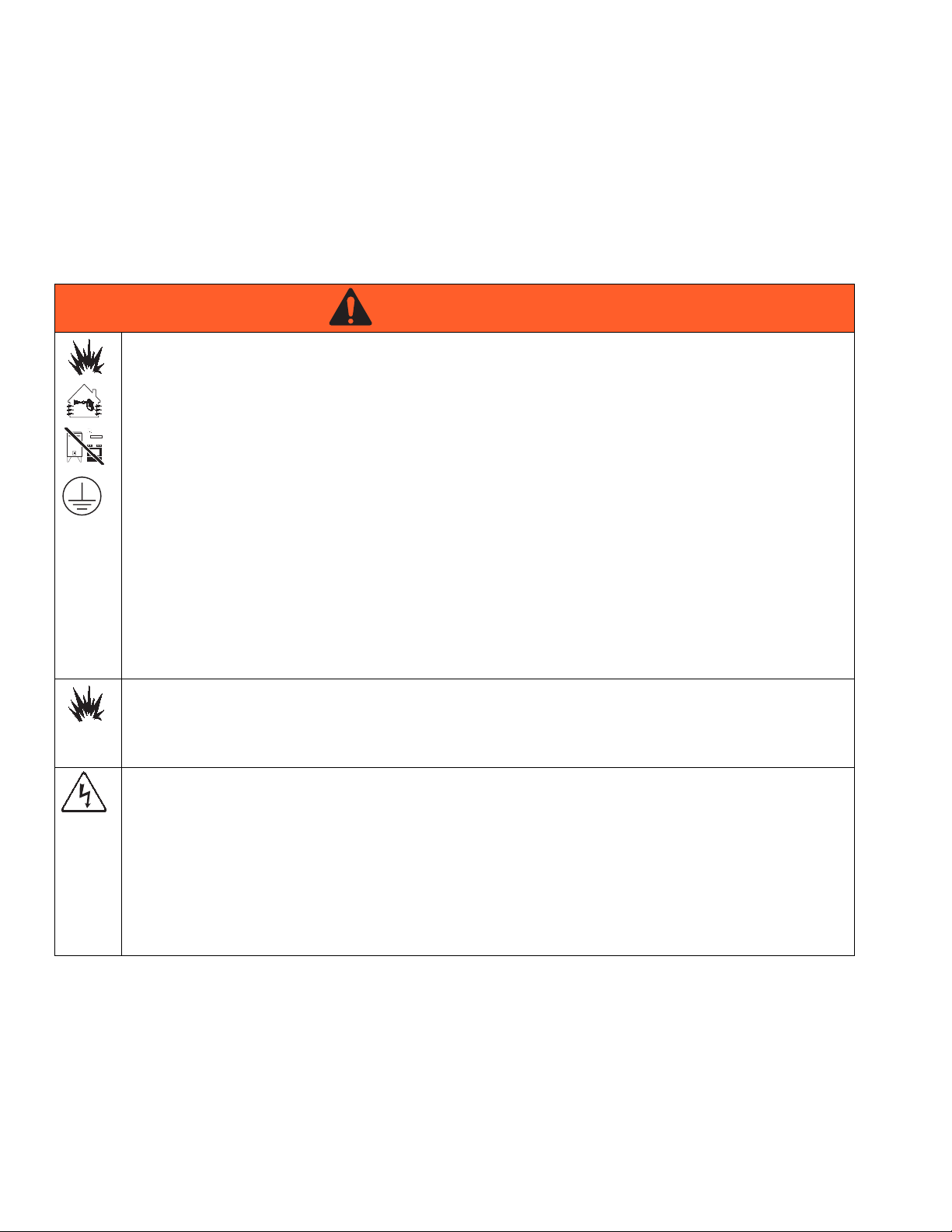

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SPECIAL CONDITIONS FOR SAFE USE

• To prevent the risk of electrostatic sparking, the equipment’s non-metallic parts must be cleaned with

only a damp cloth.

• Refer to the Viscon HP Heater manual for special conditions for safe use.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

4 3A0420T

Page 5

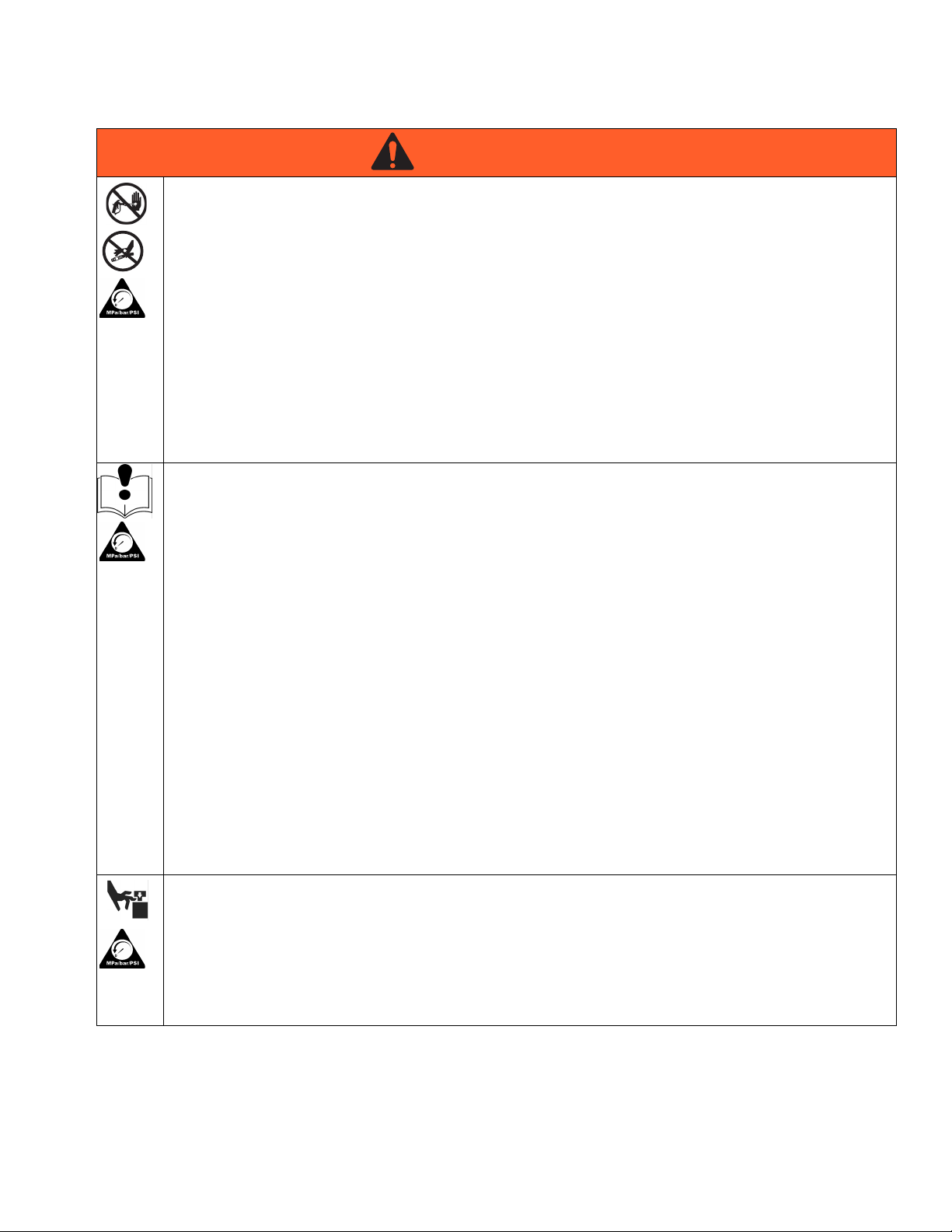

Warnings

WARNING

WARNINGWARNINGWARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system com-

ponent. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

3A0420T 5

Page 6

Warnings

WARNING

WARNINGWARNINGWARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

6 3A0420T

Page 7

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation is

not available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings and

material MSDS.

Keep Components A and B

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO pump wetcup or reservoir (if installed)

filled with Graco Throat Seal Liquid (TSL

206995. The lubricant creates a barrier between the

ISO and the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with TSL or grease

when reassembling.

™

), Part

Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or

damage equipment. To prevent cross-contamination

of the equipment’s wetted parts, never interchange

component A (isocyanate) and component B (resin)

parts.

3A0420T 7

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Page 8

Important Two-Component Material Information

Changing Materials

• Changing material types used in your system

requires special attention to avoid equipment damage and downtime.

• Always clean the fluid inlet strainers after flushing.

• When changing between epoxies and urethanes or

polyureas, disassemble and clean all fluid components and changes hose sets.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

A and B Component Designations

Material suppliers and markets refer to plural component materials differently. The table below summarizes the different designations for the components used in various machines.

Market Equipment Designations

Foam and Polyurea, and

Urethane Pour

Epoxy and Urethane

Protective Coatings

Epoxy, Silicone, Ure-

thanes, and other mate-

rials

All Reactors, HFR

®

, Xtreme-

™

and PR

™

and VRM

Hydra-Cat

™

, XM™, and XP

Mix

PR70

Letter

Color

™

,

Component Names

Major or Minor Component

(when not 1:1 mix)

Letter

Color

Component Names

Major or Minor Component

(when not 1:1 mix)

Letter

Color

Component Names

Major or Minor Component

(when not 1:1 mix)

Machine Left

Side

AB

Red Blue

ISO, Hardener,

Catalyst

Low Volume

Side

AB

Blue Green

Resin, Base

High Volume

Side

AB

Red Blue

Polyol, Resin,

Base

High Volume

Side

Machine Right

Side

Polyol, Resin,

Base

High Volume

Side

Hardener, Cata-

lyst

Low Volume

Side

ISO, Hardener,

Catalyst

Low Volume

Side

8 3A0420T

Page 9

Overview

Overview

Usage

The XP is a mechanically linked fixed ratio system that

can mix and spray most two-component epoxy and urethane protective coatings. When using quick-setting

material (less than 10 minute pot life) a remote mix manifold must be used or materials must mix at the gun.

Quickset manifold 24M398 is recommended for

quick-setting material.

The two pumps are carbide seat severe duty positive

displacement pumps that displace fluid on both strokes.

The XP systems are not approved for use in hazardous locations unless the base model, all accessories,

all kits, and all wiring meet local, state, and national

codes. See Important Two-Component Material

Information, page 7, to determine the appropriate

location for your particular XP model.

Over Pressure Protection

Mechanically linked pumps can create excessive fluid

pressure if the full motor force is applied to only one

of the fluid pumps.

• Cart-Mounted Systems Only: Maximum air pres-

sure set point blow off valves are provided to limit

maximum fluid pressure. Do not remove these

valves.

• Color coded automatic over pressure relief

valves are used on cart-mounted systems to

dump excess fluid pressure back to the supply.

Never plug these return hoses. See Fluid Circu-

lation Manifold with Over Pressure Relief

Valves on page 38.

• When using an XP bare pump package to build a

system, use the over pressure relief valves referenced above.

• Never install individual shut off valves on the “A”

and “B” lines. On cart-mounted systems, common handles link the fluid control valves.

• On models other than 1:1 mix ratio, a rupture disc

is provided on the small side fluid pump (pumps

72cc and smaller) as a back-up to the over pressure relief valve. If the rupture disc ever opens,

do not operate the machine until the over pressure valve and the rupture disc have been

replaced.

• If changing pump lowers or motor on your system, use the correct over pressure relief valves

from the chart on page 39.

3A0420T 9

Page 10

Initial System Setup

Initial System Setup

1. Check the shipment for accuracy. Ensure you have

received everything you ordered. See Component

Identification, page 14.

2. Check for loose fittings and fasteners.

3. Install optional solvent flush pump kit 262393, if

ordered. See manual 310863 for instructions.

4. Mount and connect optional heaters, if ordered. See

the heater adapter kit manual 406861 for instructions and the heater manual 309524.

5. Install desiccant kits if using polyurethane isocyanates in hoppers. See manual 406739 for instructions.

6. Install circulation and return tube kits if you are feeding material from drums or remote hoppers. See

manual 309852 if you are feeding urethane material.

7. Install hopper or hose heat circulation kit 24M224, if

ordered. See 313259 for instructions.

NOTE: Supply return lines must be used.

8. Connect the feed pumps, fluid strainers, and air

hoses as necessary. If your system does not use

hoppers, then see manual 312769.

9. Connect the air supply line. See Connect Air Sup-

ply, page 21.

10. Connect the fluid hose assembly, including the

static mixers, whip hose and gun. See Pressure

Relief Procedure, page 22.

11. Flush test oil from system as needed. See Empty

and Flush Entire System (new system or end of

job), page 29.

10 3A0420T

Page 11

Models

The XP systems are approved for use in hazardous

locations only if the base model, all accessories, all

kits, and all wiring meet local, state, and national

codes.

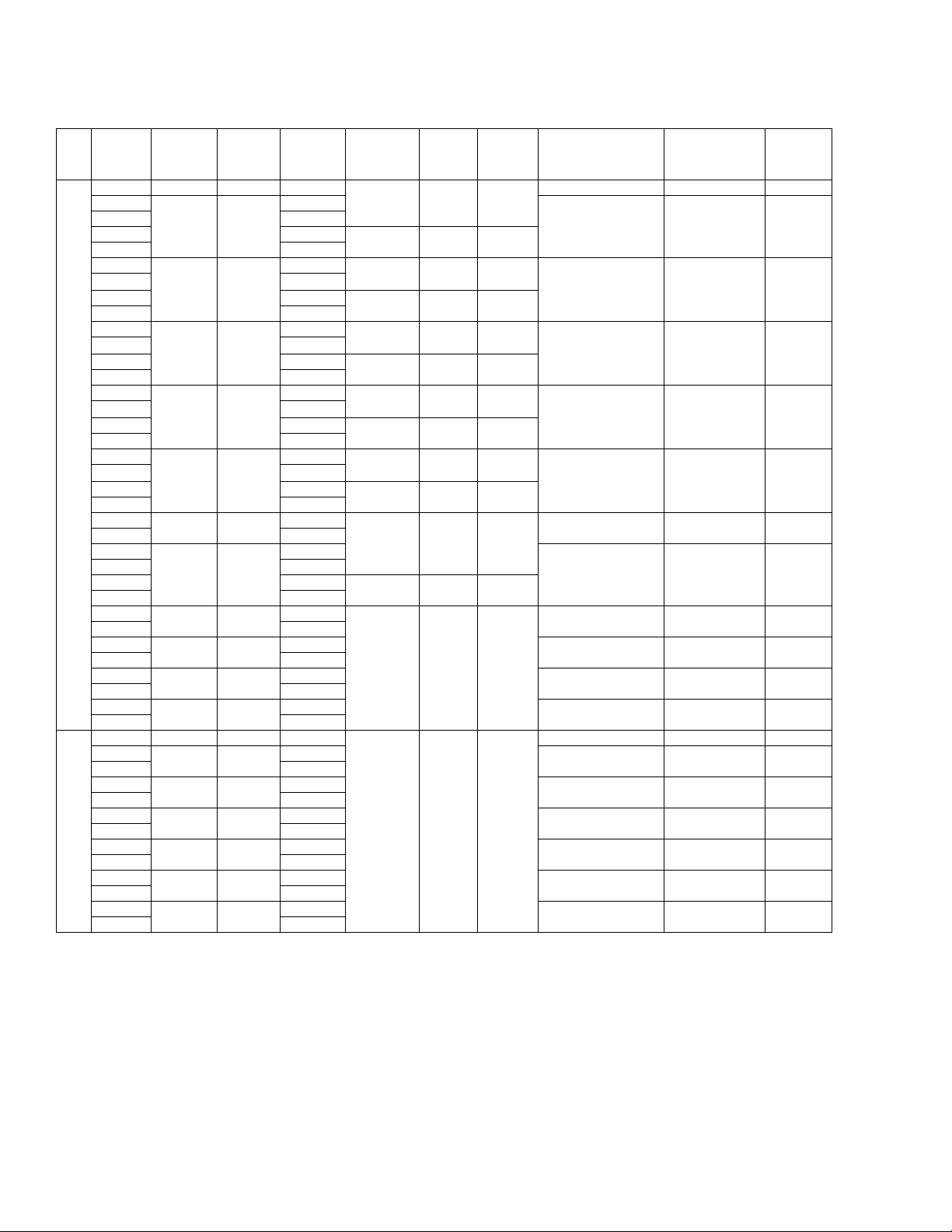

Cart-Mounted Systems

Models

NOTE: All cart-mounted systems listed are Ex rated:

II 2 G

c IIA T2

See Accessories and Kits on page 55 for a list of all optional accessories.

NOTE: The “Standard” mix manifold selection means the mix manifold is mounted on the cart and comes with mix-

ers, 25 ft of 3/8 in. mix hose, and 10 ft of 1/4 in. whip hose. The “Quickset” mix manifold selection means the manifold

has dual flush valves, is mounted on a remote carriage, and comes with mixers and 10 ft of 1/4 in. whip hose. When

ordering the Quickset configuration, A and B hoses from the sprayer to the mix manifold must be ordered separately.

Volume

Typ

eModel

281000 --- --281101

281102 ✔

281105

281106 ✔

281201

281202 ✔

281205

281206 ✔

262804

281252 ✔

281255

281256 ✔

281301

281302 ✔

281305

XP35 with NXT 3400 Air Motor

281306 ✔

281401

281402 ✔

281405

281406 ✔

Pump

Package

281100 1.0:1 3500 (24, 241) 95 (0.65, 6.5) 38:1

281200 2.0:1

262803 2.5:1

281300 3.0:1

281400 4.0:1

Ratio

Mix

7 Gallon

Hoppers

Mix

Manifold Hose Gun

Standard

--- --- ---

Standard

--- --- ---

Standard

--- --- ---

Standard

--- --- ---

Standard

--- --- ---

35 ft

(10.7 m)

35 ft

(10.7 m)

35 ft

(10.7 m)

35 ft

(10.7 m)

35 ft

(10.7 m)

XTR5

XTR5

XTR5

XTR5

XTR5

Max Fluid

Working Pressure

psi (MPa, bar)

--- --- ---

3500 (24, 241) 85 (0.59, 5.9) 40:1

3500 (24, 241) 90 (0.62, 6.2) 34:1

3500 (24, 241) 100 (0.7, 7) 36:1

3500 (24, 241) 95 (0.65, 6.5) 38:1

Max Air

Pressure

psi (MPa, bar)

Pressure

Ratio

3A0420T 11

Page 12

Models

Volume

Typ

e Model

282000 --- --282101

282102 ✔

282105

282106 ✔

282151

282152 ✔

282155

282156 ✔

282201

282202 ✔

282205

282206 ✔

282251

282252 ✔

282255

282256 ✔

282301

282302 ✔

282305

282306 ✔

282331

XP50 with 6500 Air Motor

282332 ✔

282401

282402 ✔

282405

282406 ✔

283101

283102 ✔

283201

283202 ✔

283301

283302 ✔

283401

283402 ✔

571000 --- --571101

571102 ✔

571151

571152 ✔

571201

571202 ✔

571251

571252 ✔

571301

571302 ✔

571401

XP70 with NXT 6500 Air Motor

571402 ✔

Pump

Package

282100 1.0:1 4500 (31, 310) 100 (0.7, 7) 45:1

282150 1.5:1

282200 2.0:1

282250 2.5:1

282300 3.0:1

282330 3.3:1

282400 4.0:1 4800 (33, 331) 100 (0.7, 7) 48:1

282100 1.0:1

282200 2.0:1 4800 (33, 331) 100 (0.7, 7) 48:1

282300 3.0:1 4500 (31, 310) 100 (0.7, 7) 45:1

282400 4.0:1 4800 (33, 331) 100 (0.7, 7) 48:1

571100 1.0:1 7250 (50, 500) 95 (0.65, 6.5) 76:1

571150 1.5:1 7250 (50, 500) 80 (0.5, 5.5) 91:1

571200 2.0:1 7250 (50, 500) 95 (0.65, 6.5) 76:1

571250 2.5:1 6500 (45, 448) 100 (0.7, 7) 65:1

571300 3.0:1 6800 (47, 469) 100 (0.7, 7) 68:1

571400 4.0:1 7250 (50, 500) 100 (0.7, 7) 73:1

Ratio

Mix

7 Gallon

Hoppers

Mix

Manifold Hose Gun

Standard

--- --- ---

Standard

--- --- ---

Standard

--- --- ---

Standard

--- --- ---

Standard

--- --- ---

Standard

--- --- ---

Quickset

Standard

35 ft

(10.7 m)

35 ft

(10.7 m)

35 ft

(10.7 m)

35 ft

(10.7 m)

35 ft

(10.7 m)

35 ft

(10.7 m)

10 ft

(3.0 m)

35 ft

(10.7 m)

XTR5

XTR5

XTR5

XTR5

XTR5

XTR5

FlexPlus

XTR7

Max Fluid

Working Pressure

psi (MPa, bar)

--- --- ---

5000 (34, 344) 90 (0.62, 6.2) 55:1

4500 (31, 310) 100 (0.7, 7) 48:1

5000 (34, 344) 95 (0.65, 6.5) 52:1

4500 (31, 310) 100 (0.7, 7) 45:1

5000 (34, 344) 90 (0.62, 6.2) 56:1

4500 (31, 310) 100 (0.7, 7) 45:1

--- --- ---

Max Air

Pressure

psi (MPa, bar)

Pressure

Ratio

12 3A0420T

Page 13

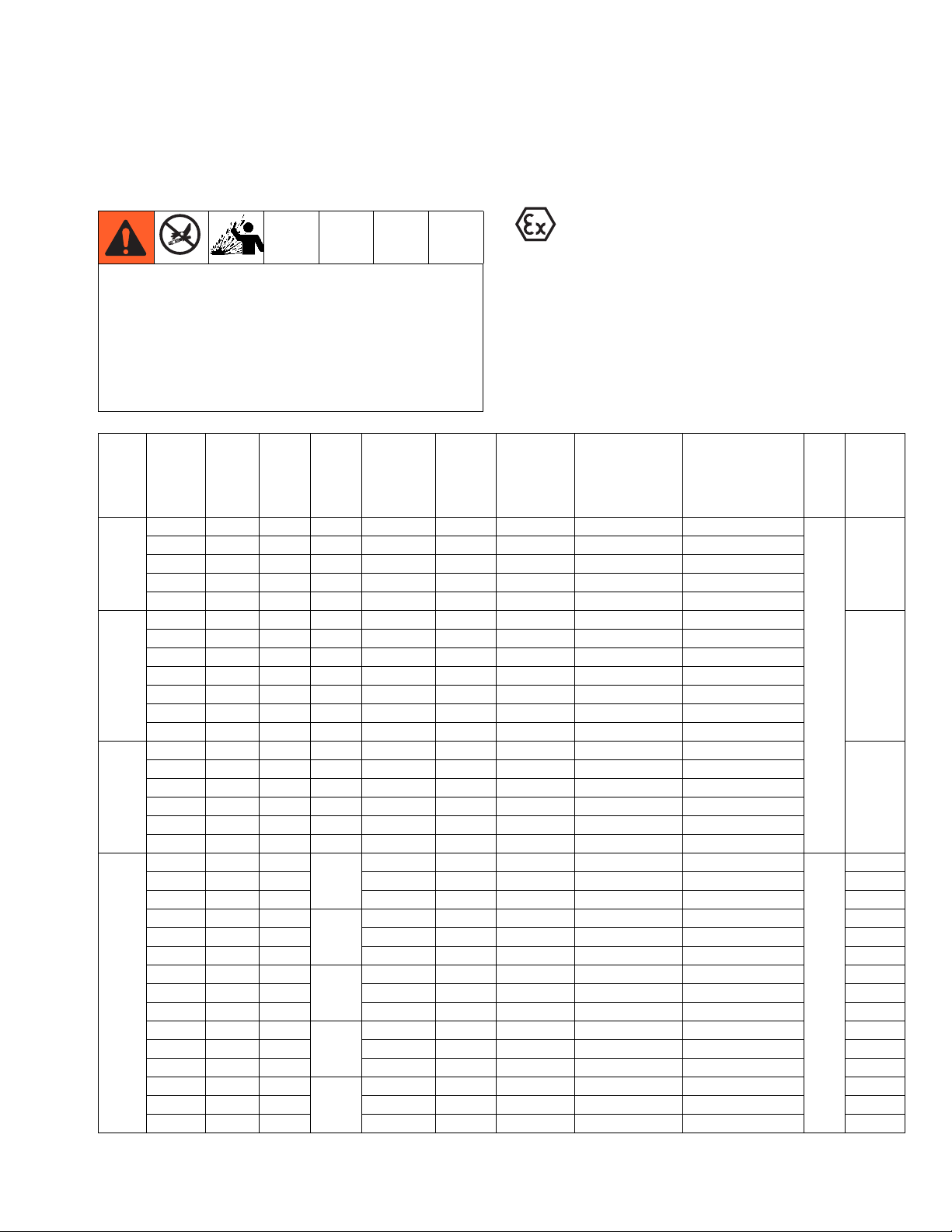

Bare Proportioning Pump Packages

Models

Packages include motor, pump lowers, and all connection hardware.

Building systems with bare proportioning pump

packages:

• Over Pressure Protection must be used, see

page 9. See chart on page 39 to identify the over

pressure relief valves to use with your system.

• All components must meet or exceed maximum

working pressures.

Combined

Fluid

Output

cc/cycle

435 1.75:1 4.6 (17.4) 3150 (22, 217) 1800 (12, 124) Purple

435 1.75:1 4.6 (17.4) 3150 (22, 217) 1800 (12, 124) Purple

407 1.88:1 4.3 (16.3) 3400 (23, 234) 1800 (12, 124) Purple

388 1.97:1 4.1 (15.5) 3500 (24, 241) 1800 (12, 124) Purple

360 2.10:1 3.8 (14.4) 3800 (26, 262) 1800 (12, 124) Purple

Pressure

Ratio

Type

XP35 with

XP50 with

XP70 with

XP-h with

Volume

Pump

Package

281100 L090C0 L090C0 1.0:1 180 38:1 1.9 (7.2) 3500 (24, 241) 95 (0.65, 6.5)

281200 L115C0 L058C0 2.0:1 173 40:1 1.8 (6.8) 3500 (24, 241) 85 (0.59, 5.9)

262803 L14AC0 L058C0 2.5:1 202 34:1 2.1 (7.9 3500 (24, 241) 100 (0.7, 7)

281300 L14AC0 L048C0 3.0:1 192 36:1 2.0 (7.6) 3400 (23, 234) 95 (0.65, 6.5)

Air Motor

NXT 3400

281400 L14AC0 L036C0 4.0:1 180 38:1 1.9 (7.2) 3500 (24, 241) 90 (0.62, 6.2)

282100 L14AC0 L14AC0 1.0:1 288 45:1 3.1 (11.7) 4500 (31, 310) 100 (0.7, 7)

282150 L14AC0 L097C0 1.5:1 240 55:1 2.6 (9.8) 5000 (34, 345) 90 (0.62, 6.2)

282200 L18AC0 L090C0 2.0:1 270 48:1 2.9 (11.0) 4800 (33, 331) 100 (0.7, 7)

282250 L18AC0 L072C0 2.5:1 252 52:1 2.7 (10.2) 5000 (34, 345) 95 (0.65, 6.5)

282300 L22AC0 L072C0 3.0:1 288 45:1 3.1 (11.7) 4500 (31, 310) 100 (0.7, 7)

Air Motor

NXT 6500

282330 L18AC0 L054C0 3.3:1 234 56:1 2.5 (9.5) 5000 (34, 345) 95 (0.65, 6.5)

282400 L22AC0 L054C0 4.0:1 270 48:1 2.9 (11.0) 4800 (33, 331) 100 (0.7, 7)

571100 L090C0 L090C0 1.0:1 180 72:1 1.9 (7.2) 7250 (50, 500) 100 (0.7, 7)

571150 L085C0 L058C0 1.5:1 144 91:1 1.5 (5.6) 7250 (50, 500) 80 (0.55, 5.5)

571200 L115C0 L058C0 2.0:1 174 76:1 1.8 (6.8) 7250 (50, 500) 95 (0.65, 6.5)

571250 L14AC0 L058C0 2.5:1 203 65:1 2.1 (7.9) 6500 (45, 448) 100 (0.7, 7)

Air Motor

NXT 6500

571300 L14AC0 L048C0 3.0:1 193 68:1 2.0 (7.5) 6500 (45, 448) 100 (0.7, 7)

571400 L14AC0 L036C0 4.0:1 181 73:1 1.9 (7.2) 7250 (50, 500) 100 (0.7, 7)

284101 L22AC0 L22AC0

284102 L14AC0 L14AC0 293 2.63:1 3.1 (11.7) 4700 (32, 324) 1800 (12, 124) Gold

284103 L090C0 L090C0 180 4.21:1 1.9 (7.2) 7150 (49, 493) 1700 (12, 117) Silver

284201 L29AC0 L14AC0

284202 L18AC0 L090C0 274 2.81:1 2.9 (11.0) 5050 (35, 348) 1800 (12, 124) Gold

284203 L115C0 L058C0 170 4.39:1 1.8 (6.8) 7200 (50, 496) 1650 (11, 114) Silver

284251 L29AC0 L115C0

284252 L18AC0 L072C0 255 3.02:1 2.7 (10.2) 5000 (34, 345) 1650 (11, 114) Gold

284253 L14AC0 L058C0 199 3.77:1 2.1 (7.9) 6800 (47, 469) 1800 (12, 124) Silver

Viscount II

284301 L29AC0 L097C0

Hydraulic Motor

284302 L22AC0 L072C0 293 2.63:1 3.1 (11.7) 4700 (32, 324) 1800 (12, 124) Gold

284303 L14AC0 L048C0 189 3.95:1 2.0 (7.6) 7100 (49, 490) 1800 (12, 124) Silver

284401 L29AC0 L072C0

284402 L22AC0 L054C0 274 2.80:1 2.9 (11.0) 5000 (34, 345) 1800 (12, 124) Gold

284403 L14AC0 L036C0 180 4.21:1 1.9 (7.2) 7150 (49, 493) 1700 (12, 117) Silver

A Side

Pump

B Side

Pump

Mix

Ratio

1.0:1

2.0:1

2.5:1

3.0:1

4.0:1

NOTE: All pump packages are Ex rated except for the

XP-h pump packages (284xxx):

II 2 G

c IIA T2

Hydraulically powered pump packages (XP-h) are not

available as complete systems. Refer to manual 307158

for hydraulic application information.

Pump sizes are marked on the pump cylinder; sizes are

nominal. See technical data in manual 311762 for actual

displacement.

Over

Fluid Flow

at 40 cpm

gpm (lpm)

Maximum Fluid

Working

Pressure

psi (MPa, bar)

Maximum Air/

Hydraulic Oil

Working Pressure

psi (MPa, bar)

Ex

Rated

✔

Pressure

Relief

Valve To

Use

Purple

Gold

Silver

3A0420T 13

Page 14

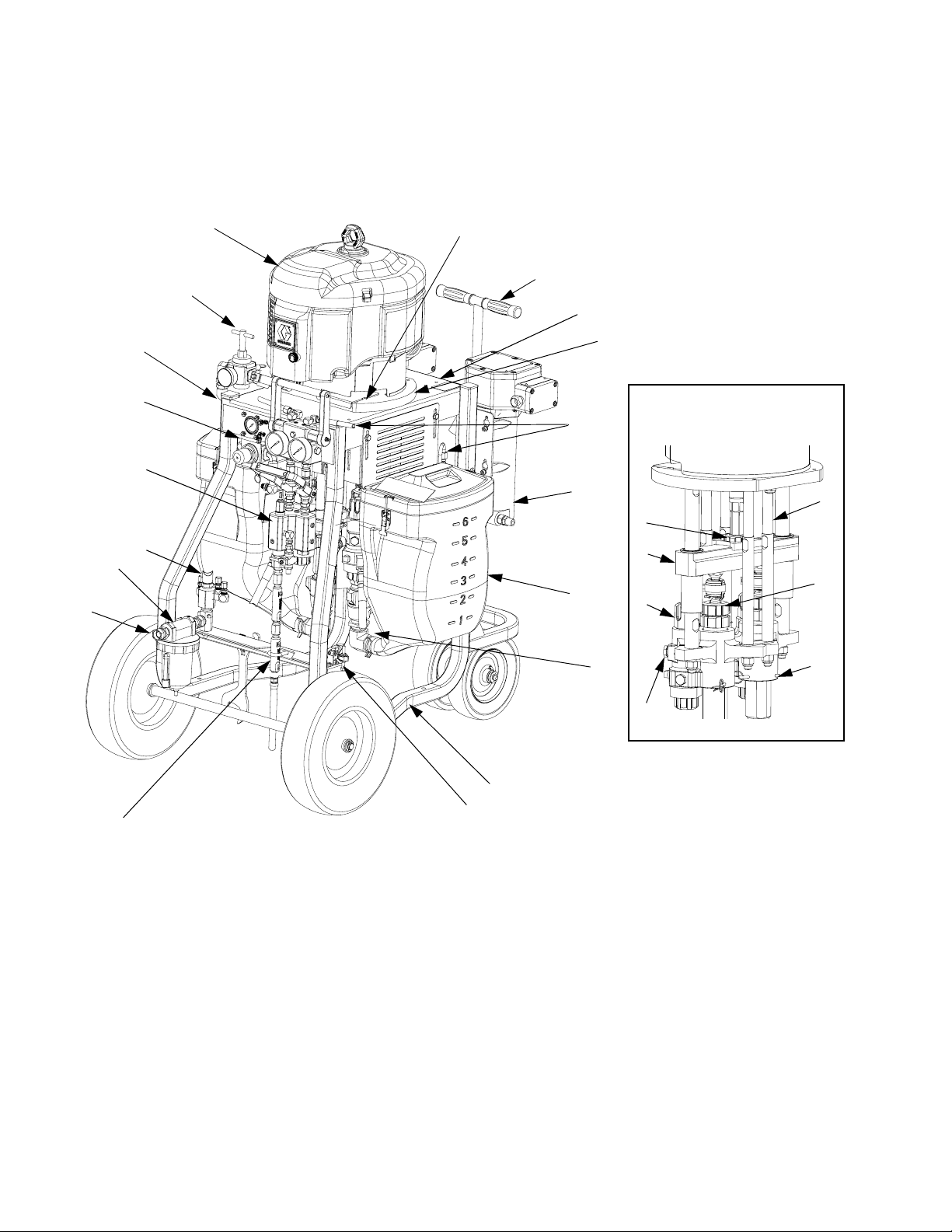

Component Identification

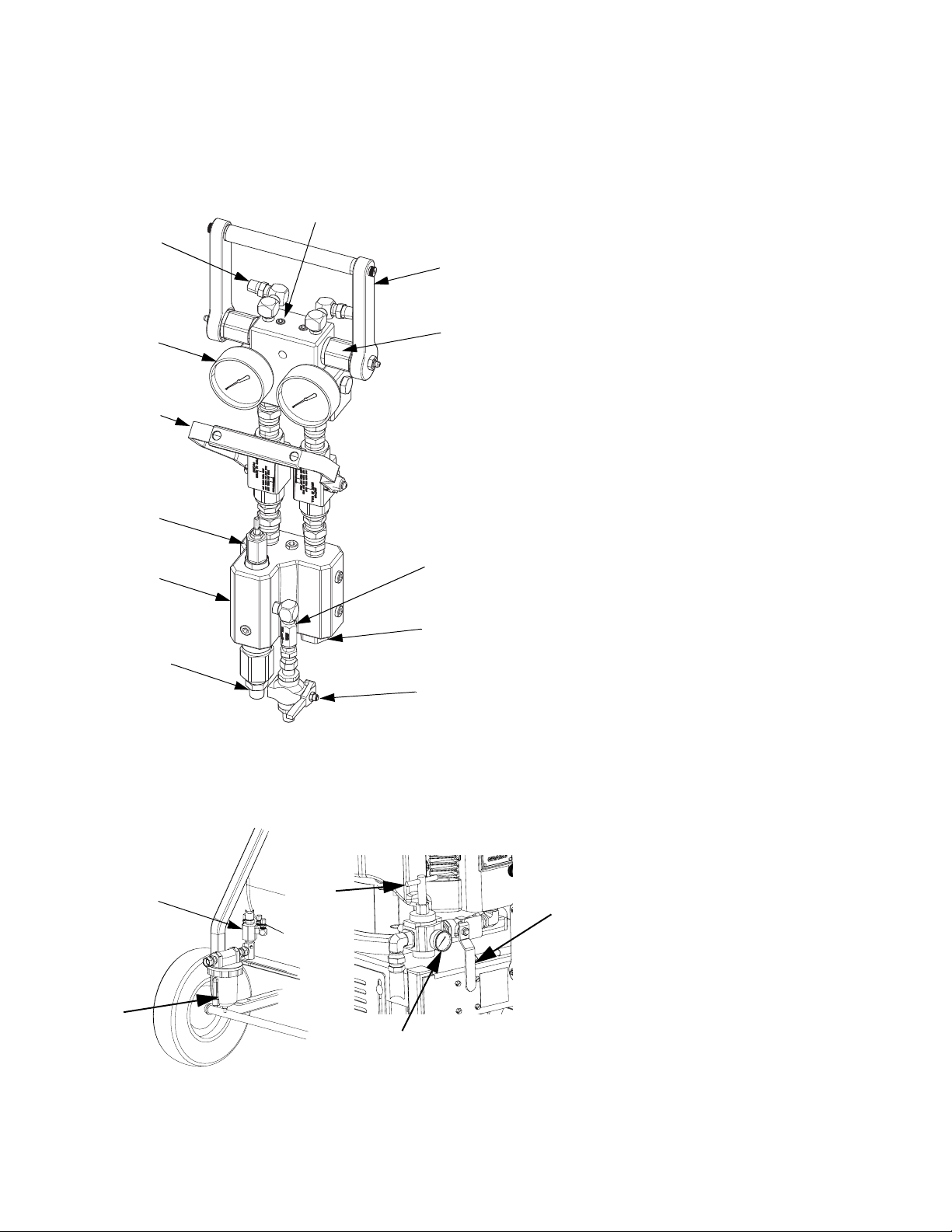

Component Identification

E

X

M

B

G

A

R

Mounting Components for

Pump Package

H

U

N

F

P

V

A

B

T

S

C

J

D

D

D

W

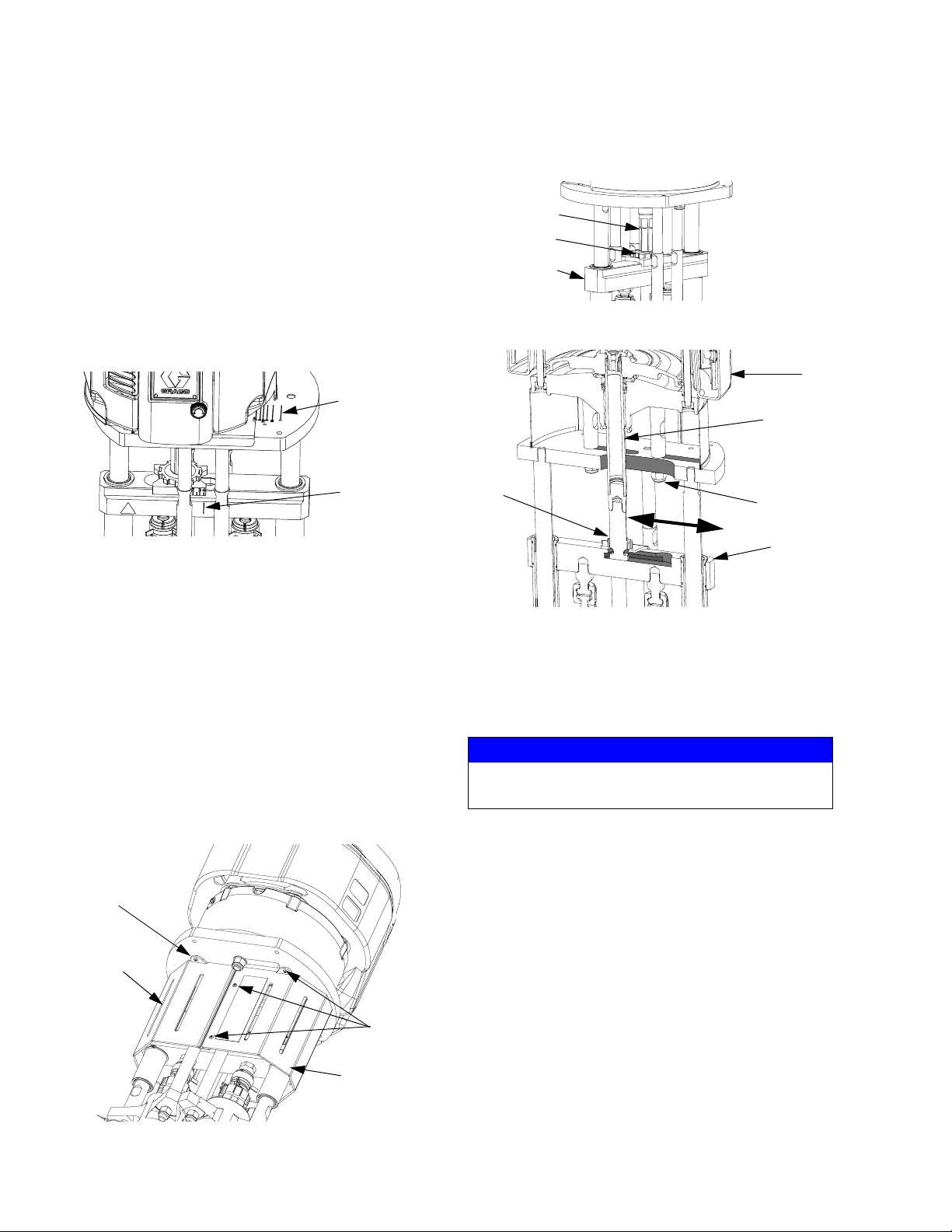

FIG. 1: XP70 system with optional accessories

Key:

A Air Supply Hose for Motor

B Main Air Controls; see page 15

C Air Inlet - 3/4 npsm(f)

D High Pressure Fluid Pump

EMotor

F Fluid Heater (optional)

G Solvent Flush Pump (optional); see page 16

H Solvent Flush Pump Air Controls; see page 16

J 7 Gallon Hoppers (optional)

KCart

L Brake

M Handle (lift to release)

Y

K

L

r_571101_3a0420a_1a-2

N Fluid Control Assembly; see page 15

P Tie Rods

R Motor Adapter Plate

S Adjustable Packing Nuts with Wet Cups

T Yoke With Rod Bearings

U Recirculation Lines

V Yoke Position Nut

W Static Mixer Tubes with Replacement Plastic Elements

X Motor Position Indicator Lines; see Motor Position on

page 20

Y Over Pressure Rupture Disc;

only 38cc, 48cc, 54cc, 58cc, and 72cc pumps

14 3A0420T

Page 15

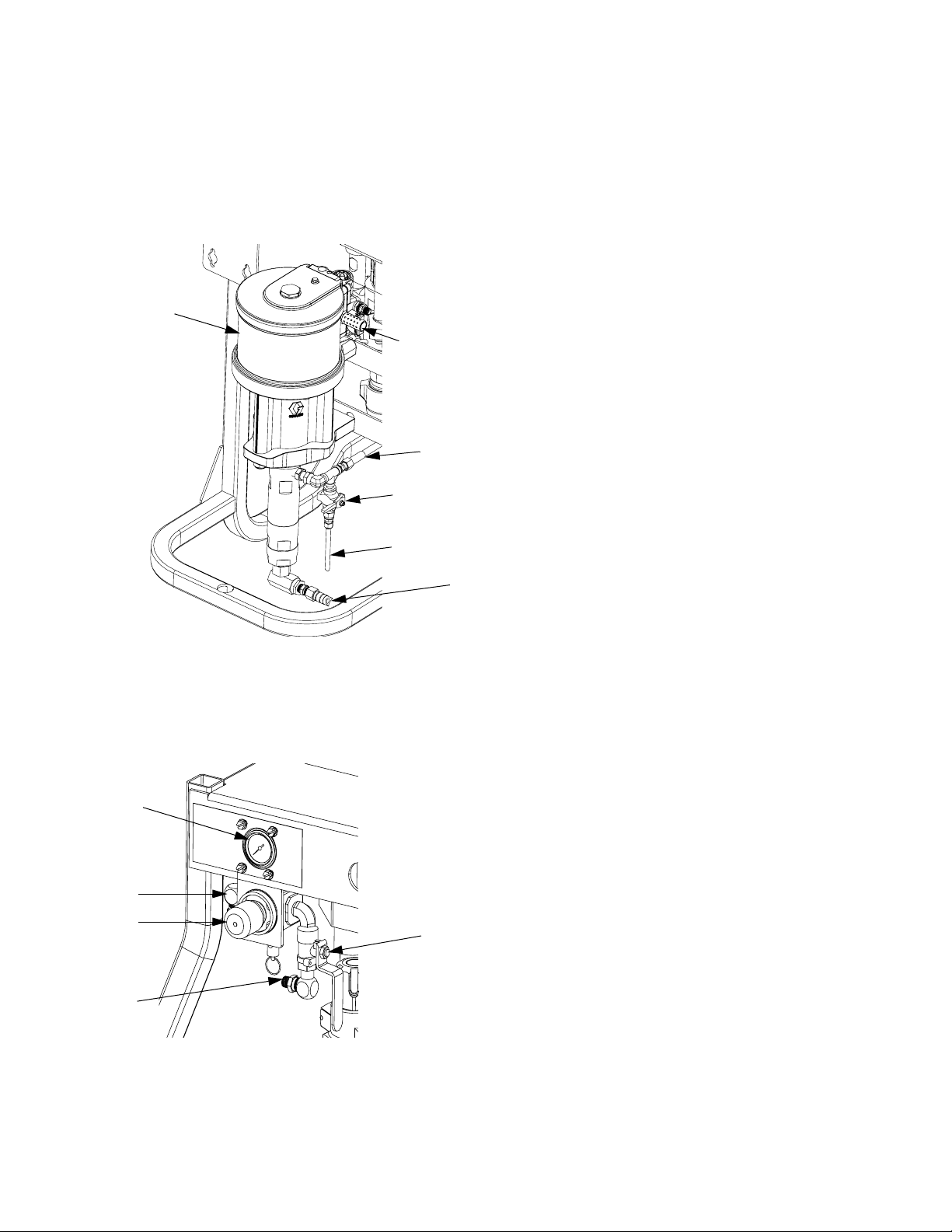

Fluid Control Assembly

Standard Mix Manifold shown

AA

AH

AF

AE

AJ

AB

AL

AC

AM

Component Identification

Key:

AA Fluid Manifold

AB Mix Manifold

AC Circulation Handle

AD Solvent Flush Valve

AE Dual Shutoff Handle

AF Fluid Pressure Gauges

AG Fluid Supply Inlet (Behind Fluid Manifold)

AH Fluid Circulation Fittings

AJ B Component Adjustable Fluid Restrictor; see

page 27

AK A and B Mix Manifold Check Valves

AL Solvent Inlet Check Valve

AM Automatic, Spring Loaded, Color-Coded Over

Pressure Relief Valves; with grease fittings; see

page 39

AN A and B Combined Outlet; 3/8 npt(m)

AN

FIG. 2

Main Air Controls

CE

CC

ti19167a

CB

CD

AK

AD

CA

Key:

CA Main Motor Shutoff Valve (Relieving)

CB Main Motor Air Pressure Regulator

CC Air Filter with Auto Drain

CD Main Motor Air Pressure Gauge

CE Filtered Air Distribution Manifold

FIG. 3

3A0420T 15

Page 16

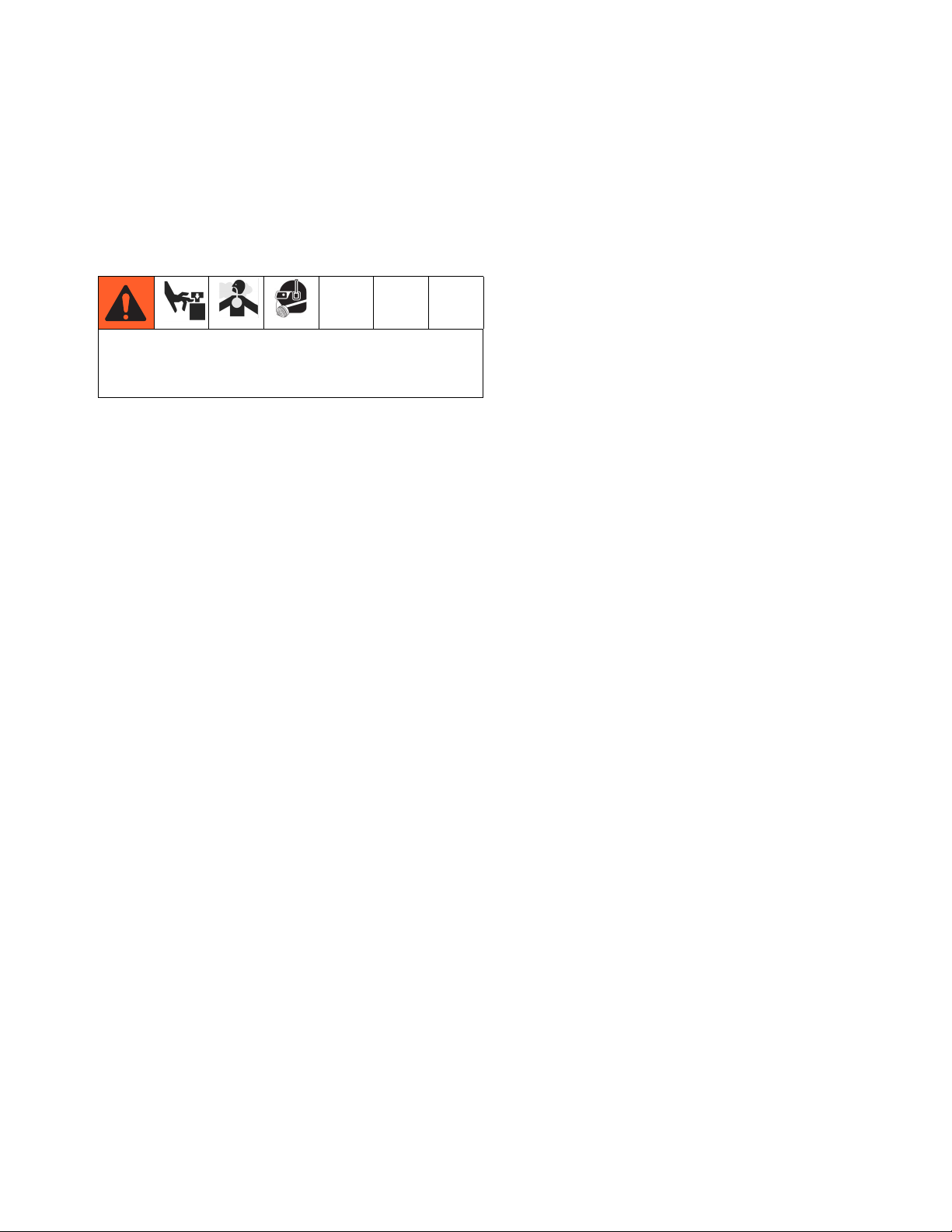

Component Identification

45:1 Solvent Flush Pump Kit 262393 (optional)

Pump

Key:

BA Solvent flush pump (Merkur Pump)

BA

BD

BF

BE

BB Fluid Inlet

BD Muffler

BE Prime/Flush/Sample valve

BF Fluid Outlet Hose

BG Circulation hose

FIG. 4

Air Controls

DC

DE

DB

BG

BB (suction hose not shown)

r_571100_3a0420a_4a-2

Key:

DA Solvent Pump Air Shutoff Valve (Relieving)

DB Solvent Pump Air Pressure Regulator

DC Solvent Pump Air Pressure Gauge

DD Air Outlet

DE Air Inlet

DA

DD

r_571101_3a0420a_5a-2

FIG. 5

16 3A0420T

Page 17

Component Identification

Air Line

• Bleed-type master air valve (CA): Required in

your system to relieve air trapped between it and

the air motor when the valve is closed. Be sure the

valve is easily accessible from the pump and

located downstream from the air regulator.

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

• Pump air regulator (CB): Controls pump speed

and outlet pressure.

• Air line filter (C): 40 micron filter removes harmful

dirt and moisture from compressed air supply. Accumulated water is automatically drained from the filter.

Fluid Line Accessories

Optional Accessories

• Optional Fluid Heaters (N): Heats the resin and

hardener before mixing. Improves the chemical

reaction and lowers viscosity to improve the spray

pattern.

• Optional Solvent Flush Kit (G): Flushes the mix

manifold. Includes a solvent pump, mounting hardware, and solvent supply hose.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Empty and Flush Entire System (new system or end

of job), page 29.

• Fluid Manifold (AA): Controls circulation and pump

priming.

• Mix Manifold (AB): Combines A and B fluid into

one fluid line.

• Circulation Handle (AC): Directs fluid flow for cir-

culation or mixing. Move to open position to relieve

fluid pressure, prime pumps, and circulate material

in hoppers. Move to closed position to spray mixed

material.

• Dual Shutoff Handle (AE): Controls A and B fluid

flow for mixing and dispensing. Close before flushing.

• Solvent Flush Valve (AD): Controls solvent flow to

the mix manifold, hose, and spray gun.

• Static mixer/gun hose kit: Thoroughly mixes the

two fluids and delivers the mixed fluid to the spray

gun. Includes static mixer and hoses to the spray

gun.

3A0420T 17

Page 18

Setup

Setup

Location

The XP35, XP50, and XP70 systems are approved

for use in hazardous locations only if the base model,

all accessories, all kits, and all wiring meet local,

state, and national codes.

1. Locate the proportioner on a level surface.

2. Position the proportioner for convenient operator

access and maintenance, safe routing of air and

fluid lines, and easy connection of components and

accessories.

3. For permanent mounting, remove wheels and

mount the frame to the floor. See Dimensions,

page 58.

4. Ensure that the cart brake (L) is in the locked position.

Grounding

Pump: use ground wire and clamp (supplied). Loosen

grounding lug locknut (W) and washer (X). Insert ground

wire end (Y) into lug (Z) slot and tighten locknut

securely. Connect ground clamp to a true earth ground.

Y

W, X, Z

Solvent Pump: use ground wire and clamp (supplied

with solvent pump). Follow instructions in pump manual.

Air and fluid hoses: use only static dissipation type

hoses with a maximum of 500 ft (150 m) combined hose

length to ensure grounding continuity. Check electrical

resistance of hoses regularly. If total resistance to

ground exceeds 29 megohms, replace hose immediately.

Air compressor: follow manufacturer’s recommendations.

Spray gun: ground through connection to a properly

grounded fluid hose and pump.

Fluid supply container: follow local code.

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by providing an escape wire for the electrical current due to

static build up.

18 3A0420T

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

Page 19

Wire Systems with Explosion-Proof Heaters

(Hazardous location systems only)

If your system is rated for hazardous areas, and you

have explosion-proof heaters, you must have a qualified electrician connect heater wiring. Ensure wiring

and installation comply with local electrical codes for

hazardous areas.

Improperly installed or connected equipment will create

a hazardous condition and cause fire, explosion, or

electric shock. Follow local regulations.

When explosion-proof heaters are used, ensure the wiring, wiring connections, switches, and electrical distribution panel all meet flame-proof (explosion-proof)

requirements.

Setup

Refer to the Viscon HP heater manual for electrical connection instructions and guidelines in hazardous locations.

3A0420T 19

Page 20

Setup

Motor Position

The motor position must be set for the volume mix ratio

of the system.

NOTE: Changing the motor position does not change

the mix ratio.

Check Motor Position

1. Verify that the correct pumps are mounted for your

mix ratio by volume. See chart in Bare Proportion-

ing Pump Packages on page 13.

indicator line

indicator line

Air Motor shown

FIG. 6: Ratio indicators

r_258914_3a0420a_10b

3. Place wrench on adapter rod (104) then use supplied tool to loosen the serrated yoke nut (V) above

the yoke (T).

104

Air Motor shown

V

T

r_571101_3a0420a_2a-2

4. Loosen the three nuts (P2) below the motor tie rods.

E

piston rod

V

P2

T

2. Verify that the motor position is adjusted correctly

for that mix ratio. See F

IG

. 6. If not, perform the fol-

lowing Change Motor Position procedure.

Change Motor Position

There are specific motor positions for each mix ratio setting. To adjust the position of the air motor:

1. Perform Check Motor Position procedure. If position is incorrect, continue to next step.

2. Loosen the eight fasteners and remove the two

pump guards.

Air Motor shown

fastener

pump guard

fastener

r_258914_3a0420a_5a

Air Motor shown

FIG. 7

5. Grab the piston rod and slide the position of the

motor (E) until the indicator lines are aligned with

your ratio. See F

IG

. 6 and FIG. 7.

NOTICE

Do not hit tie rods (P) with a steel hammer. Damage

to the air motor base may result.

6. Tighten the three nuts (P2) and yoke nut (V).

7. Use supplied tool to tighten the yoke nut.

8. Install the pump guards.

pump guard

r_258914_3a0420a_4a-1

20 3A0420T

Page 21

Setup

Connect Air Supply

1. Connect the air supply hose to the 3/4 npt(f) air filter

inlet (C).

NOTE: Use a 3/4 in. (19.1 mm) ID minimum air hose.

Air consumption is 75 cfm per gallon per minute

spraying. Do not use pin fitting type quick disconnects.

C plug

r_571100_3a0420a_10a-1

FIG. 8

2. Remove plugs as necessary for solvent pump and

feed supply pump air hoses. See pump manuals for

setup instructions. See F

IG

. 8.

Connect Fluid Hose Bundles (Remote Mix Manifold Only)

Connect additional fluid hoses to the fluid manifold (AA)

when the mix manifold (AB) is remote. Hoses must be

properly sized and balanced for your mix ratio. See mix

manifold manual for details.

1. Connect the resin and hardener hoses to the resin

and hardener outlets on the proportioner fluid manifold and resin and hardener inlets on the mix manifold.

AB

AN

W

Connect Static Mixers, Gun, and Hoses

NOTICE

To prevent creating a flare on the mixer tube, do not

use a union swivel end on the mix tube inlet.

1. Connect the outlet of the two primary static mixer

tubes with mixer elements (W) to the fluid mix

hose (25), cleanup mixer (27, 28), whip hose (30),

and spray gun (31). See F

2. Add mixed material hose as necessary between the

mix hose (25) and cleanup mixer (27, 28).

IG

. 9.

25

Standard Mix Manifold shown

FIG. 9

27, 28

30

31

r_571100_3a0420a_43a

3A0420T 21

Page 22

Pressure Relief Procedure

Pressure Relief Procedure

Follow Flush Mixed Material, page 28 when you

stop spraying or dispensing; and before cleaning,

checking, servicing, or transporting equipment.

8. Engage the trigger lock.

9. Close the dual shutoff handle (AE) and open the circulation handle (AC).

AC

Relieve A and B Fluid Pressure

1. Engage the trigger lock.

TI1949a

2. Close the main air shutoff valve (CA).

CA

r_571100_3A0420A_11a-1

3. Shut off heaters, if used.

4. Shut off feed pumps, if used.

5. Remove the spray tip and clean.

6. Disengage the trigger lock.

AE

r_571101_3A0420A_9a-2

10. Always flush the mix hose after relieving A and B

fluid pressure through the mix manifold. See Flush

Mixed Material, page 28.

11. Shutoff the solvent supply pump and repeat steps

6-8 to relieve solvent pressure.

If the mixed material has already been flushed, but

pressure remains on the A and B pumps, pressure

can be relieved back to the hoppers (J).

a. Close the main air shutoff valve (CA).

b. Open the circulation handle (AC).

NOTE: For longer valve life in abrasive fluids, it is

advisable to relieve high pressure out through the

gun when possible.

12. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, very slowly loosen tip guard

retaining nut or hose end coupling to relieve pressure gradually, then loosen completely. Clear hose

or tip obstruction.

13. If static mixer, whip hose, and gun cannot be

flushed because of mixed and cured material, very

slowly loosen static mixer tube from mix manifold

TI1950a

TI1953a

outlet to relieve pressure gradually, then loosen

completely. Replace or clean clogged components.

7. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure.

22 3A0420T

Page 23

Prime Empty System

Prime Empty System

Prime A and B Fluids

Wear gloves when using flush solvents and/or if the

fluid temperature exceeds 110°F (43°C).

NOTE: The equipment is tested with mineral oil at

the factory. If necessary, flush out the oil with a

compatible solvent before spraying. See Empty and

Flush Entire System (new system or end of job),

page 29.

Do not install the gun spray tip yet. To avoid splashing, use the lowest pressure possible to prime.

1. Condition the materials prior to adding to the hoppers (J). Ensure that the resin materials are thoroughly mixed, homogenous, and pourable prior to

adding to the hopper. Stir the hardeners back into

suspension prior to adding material to hopper.

2. Fill the A and B reservoirs with proper materials. Fill

the A side (blue) with major volume of material; fill

the B side (green) with minor volume of material

(unless 1:1 mix ratio).

3. Move the recirculation lines (U) to empty containers.

U

4. Close the dual shutoff handle (AE) and open the circulation handle (AC).

AC

AE

r_571101_3A0420A_9a-2

5. Open the main air shutoff valve (CA).

J

CA

6. Slowly open the air regulator (CB).

7. Dispense fluid into the containers until clean fluid

comes out of the A and B recirculation lines.

8. Decrease air pressure. Close the main air shutoff

valve (CA).

9. Move the recirculation lines (U) back to the correct

hopper (J).

10. If using heaters, heat fluid throughout system before

spraying. See Recirculate Prior to Spraying or

Re-Prime After a Pump Runs Dry, page 25.

3A0420T 23

Page 24

Prime Empty System

Prime Solvent Flush Pump

Follow instructions if the optional solvent flush pump kit

is used.

1. Connect the flush pail ground wire to a metal pail of

solvent.

2. Place the siphon tube and the solvent circulation

hose (BG) in the pail of solvent.

BG

BE

r_571101_3A0420A_5b-2

3. Open the solvent prime valve (BE) on the solvent

pump (BA) outlet.

4. Open the solvent pump air valve (DA). Slowly turn

the solvent pump air regulator (DB) clockwise to

prime the solvent pump and route solvent back to

the pail. Close the solvent pump fluid valve (BE) and

air valve (DA).

6. Ensure the trigger lock is engaged. Remove the

spray tip.

TI1949a

4)!

TI1948a

7. Disengage the trigger lock and trigger the gun into a

grounded pail. Use a pail lid with a hole to dispense

through. Seal around the hole and gun with a rag to

prevent splash back. Be careful to keep fingers

away from the front of the gun.

TI1950a

TI1953a

8. Open the solvent pump air valve (DA). Slowly turn

the solvent pump air regulator (DB) clockwise to

prime the solvent pump and push air out of the mix

hose and gun. Trigger the gun until all air is purged.

9. Close the solvent pump air valve (DA) and trigger

the gun to relieve pressure. Engage the trigger lock.

DB

DA

TI1949a

DA

r_571101_3A0420A_5a-2

5. Open the solvent flush valve (AD) on the mix manifold.

10. Close the solvent flush valve (AD).

NOTE: Solvent pump air and pressure may be left

r_571101_3A0420A_12a-2

on while spraying. Never spray mixed material without the solvent pump and hose primed with solvent.

AE

(closed)

AB

AD

24 3A0420T

Page 25

Prime Empty System

Recirculate Prior to Spraying or Re-Prime After a Pump Runs Dry

NOTE: Agitate, recirculate, and heat the material

only as necessary to avoid mixing air into the fluid.

Use the recirculation mode when heating the material is

required. Note the temperature at the top of the heater

(outgoing or back to the hopper). When the thermometer reaches operating temperature, the material is ready

to spray.

If using a system that does not require heat, recirculation is still required prior to spraying. Recirculation

ensures that any settled fillers are mixed in, the pump

lines are fully primed, and the pump check valves are

operating smoothly.

Recirculation also allows you to re-prime one side that

has run dry.

1. Follow Prime Empty System, page 23.

2. Close the dual shutoff handle (AE).

AC

5. Turn down the air pressure regulator (CB) and then

open the main air shutoff valve (CA). Use the air

pressure regulator to slowly increase the air pressure to the pumps until they start running slowly.

CB

CA

6. Run the pumps for a few minutes or until the material has reached the desired temperature. See Heat

Fluid.

7. Close the main air shutoff valve (CA).

CA

AE

r_571101_3A0420A_9a-2

3. Ensure the recirculation hoses (U) are in the correct

hoppers (J).

U

J

4. Open the circulation valve handle (AC).

r_571100_3A0420A_11a-1

8. See Spray, page 26.

Heat Fluid

To heat fluid evenly throughout the system:

1. Circulate the fluid at approximately 1/2 gpm

(10-20 cycles/min.) to raise the temperature of the

hoppers to 80-90° F (27-32° C).

2. Decrease the circulation rate to approximately

0.25 gpm (5 cycles/min.) to increase the heater outlet temperature to match the spray temperature.

NOTE: Circulating the fluid too quickly without

decreasing the circulation rate will increase only the

hopper temperature. Similarly, circulating fluid too

slowly will increase only the heater outlet temperature.

3A0420T 25

Page 26

Spray

Spray

Wear gloves when using flush solvents and/or if fluid

temperature exceeds 110°F (43°C).

5. Engage the trigger lock. Install the tip on the gun.

NOTE: After the first day of spraying follow Pressure Relief Procedure, page 22, and tighten the

throat packing nuts on both pumps.

1. If heaters are used, turn them on. To adjust the

heater temperature, refer to the Viscon HP manual

for instructions, and the Heat Fluid section, page

25. Circulate as necessary.

2. Close the circulation handle (AC) and the solvent

flush valve (AD). Open the dual shutoff handle (AE).

AC

AE

AD

3. Adjust the main air regulator (CB) to 30 psi

(0.21 MPa, 2.1 bar).

4. Remove tip. Disengage the trigger lock and trigger

the gun into a grounded metal pail. Use a metal pail

lid with a hole to dispense through to avoid splashing. Dispense out of the mix hose until a well mixed

coating flows from the gun.

TI1949a

6. Adjust the main pump air regulator (CB) to the necessary spraying pressure and apply a coating to a

test panel.

NOTE: Run system verification tests everyday. See

page 31.

7. Excess pressure increases overspray and pump

wear.

8. Check and record gauge readings frequently during

operation. A change in gauge readings indicates a

change in system performance.

NOTE:

• A pressure drop occurs during pump stroke

changeover. It should be quick and synchronous.

• Flush the mix manifold as necessary during the

day’s operation.

9. Follow Flush Mixed Material, page 28 when you

are finished spraying or before potlife expires.

NOTE: Mixed material potlife or working time

decreases with increased temperature. Pot life in

the hose is much shorter than the dry time of the

coating.

TI1950a

26 3A0420T

TI1953a

Page 27

B Side Mix Manifold Restriction

The B side restrictor (AJ) controls “lead/lag” ratio errors

of the A and B flow into the static mixer tubes. These

errors occur momentarily when the gun opens. The

error is caused by differences in viscosity, volume, and

hose expansion.

The restrictor is used primarily when the mix manifold is

positioned remote from the machine with a short mix

hose to the spray gun. It can also be used in the ratio

check procedure.

B Side Mix Manifold Restriction

AJ

AB

If the mix manifold (AB) is mounted on the machine, you

do not need to adjust the restrictor. Leave open two

turns minimum.

To Adjust the Restrictor:

Adjust the restrictor stem clockwise while spraying until

you see a slight rise in the B side pressure gauge. The

point where the pressure starts to rise is a good adjustment setting.

NOTE: Unless you are dispensing directly out of the

mix manifold and mixer, this is an approximate

adjustment.

See the mix manifold manual for more information.

3A0420T 27

Page 28

Flush Mixed Material

Flush Mixed Material

Flush the mix manifold when any of the following situations occur.

• breaks in spraying

• overnight shutdown

• mixed material in system approaching end of potlife

To flush the entire system, see Empty and Flush

Entire System (new system or end of job), page 29.

Flush Mix Manifold, Hose, and

4. Open the solvent flush valve (AD).

AB

AD

5. Disengage the trigger lock and trigger gun into a

grounded pail. Use a pail lid with a hole to dispense

through. Seal around the hole and gun with a rag to

prevent splash back. Be careful to keep fingers

away from the front of the gun. Continue flushing

until clean solvent dispenses.

Spray Gun

If your system doesn’t include a solvent flush pump, see

step 2 of Empty and Flush Entire System (new sys-

tem or end of job), page 29.

Turn off heaters. Allow heater and heated hoses to cool.

Use Optional Solvent Pump

1. Close the main air shutoff valve (CA) to turn off the

system. Engage trigger lock. Remove the spray tip

and soak in solvent.

CA

TI1949a

r_571100_3A0420A_11a-1

2. Close the dual shutoff handle (AE).

3. Open the solvent pump air valve (DA). Slowly turn

the solvent pump air regulator (DB) clockwise to

increase air pressure.

TI1950a

TI1953a

6. Close the solvent pump air valve (DA). Trigger the

gun to relieve pressure. Close the solvent flush

valve (AD) after relieving the pressure.

DA

AD

r_571101_3A0420A_12a-2

r_571101_3A0420A_12a

7. Follow Pressure Relief Procedure, page 22.

8. Engage the trigger lock. Disassemble and clean the

spray tip with solvent by hand. Reinstall on the gun.

DB

DA

r_571101_3A0420A_5a-2

28 3A0420T

TI1949a

4)!

TI1948a

Page 29

Empty and Flush Entire System (new system or end of job)

Empty and Flush Entire System

(new system or end of job)

2. Engage the trigger lock. Turn the main pump air

regulator (CB) fully counter-clockwise to shut off.

NOTE:

• If the system includes heaters and heated hose,

turn them off and allow to cool before flushing.

Do not turn on the heaters until the fluid lines

are clear of solvent.

• Cover fluid containers and use the lowest possible pressure when flushing to avoid splashing.

• Before color change or shutdown for storage,

circulate the solvent at a higher flow rate and for

a longer time. Change the solvent when it gets

dirty.

• To only flush the fluid manifold, see Flush Mix

Manifold, Hose, and Spray Gun, page 28.

• If the machine is inoperable, use drain plugs on

the pump inlet fittings.

Guidelines

Flush new systems if the coating materials will be contaminated by mineral oil.

Flushing will help prevent materials from settling or gelling in the pumps, lines, and valves. Flush the system

when any of the following situations occur.

• anytime the system will not be used for more

than one week (depending on materials used)

• if the materials used have fillers that will settle

• if using materials that are moisture sensitive

• before servicing

• if the machine is going into storage, replace the

flush solvent with light oil. Never leave the

equipment empty of any fluid.

CB

TI1949a

r_571100_3A0420A_11a-1

3. Move the recirculation lines (U) to separate fluid

containers to pump remaining fluid out of the system.

U

4. Open the circulation handle (AC). See F

page 15.

5. Increase the main pump air regulator (CB) pressure

to 20 psi (138 kPa, 1.38 bar).

6. Open the main air shutoff valve (CA).

CB

IG

. 2 on

Procedure

1. Follow Prime Empty System, page 23 and Flush

Mix Manifold, Hose, and Spray Gun, page 28, as

required.

3A0420T 29

NOTE: If the system does not start with static pressure, increase the air pressure by 5 psi (35 kPa,

0.35 bar) increments. To avoid splashing, do not

exceed 35 psi (241 kPa, 2.4 bar).

CA

Page 30

Shutdown

7. Run the pumps until the A and B hoppers (J) are

empty. Salvage the material in separate, clean containers.

8. Close the main air shutoff valve (CA).

CA

r_571100_3A0420A_11a-1

9. Wipe the hoppers (J) clean, then add solvent to

each. Move the circulation lines (U) to waste containers and push out the dirty fluids.

10. Move the recirculation lines (U) back to the hoppers.

Continue recirculating until the system is thoroughly

flushed.

U

14. Close the dual shutoff handle (AE).

15. Remove pump fluid filters, if installed, and soak in

solvent. Clean and replace the filter cap. Always

replace the filter o-rings.

NOTE:

• Fill the A and B pump packing nuts with TSL.

Also, always leave some type of fluid, such as

solvent or oil, in the system to prevent scale

build up. This build up can flake off later. Do not

use water.

• If machine is set up with a remote mix manifold,

the A and B hose can be disconnected from the

mix manifold, and secured in back of each hopper for circulation of flush solvent.

• Change the flush solvent at least once until it

circulates clean.

• Always keep the A side and B side flush solvent

separate.

J

11. Close the circulation handle (AC) and open the dual

shutoff handle (AE).

12. Dispense fresh solvent through the mix manifold

valves and out the gun.

13. Turn off the air motors and follow Pressure Relief

Procedure, page 22.

AC

AE

Shutdown

1. Follow Pressure Relief Procedure, page 22.

2. Flush mix manifold, hoses, and gun. See Flush Mix

Manifold, Hose, and Spray Gun, page 28.

3. Close the main air shutoff valve (CA).

Park

1. Open the circulation handle (AC) and adjust the air

regulator (CB) so that the pump runs slowly.

2. Close the circulation handle (AC) when the pump is

at the bottom of the stroke.

3. Close the air regulator (CB) and open the circulation

handle (AC).

AD

30 3A0420T

Page 31

System Verification

System Verification

Graco recommends running the following tests daily.

Check for Normal Operation

Every time you start spraying:

• Watch the fluid gauges (AF). A pressure drop

occurs during pump stroke changeover. It should be

quick and synchronous.

• Stop the pumps on the upstroke. Check that both

gauges hold pressure for at least 20 seconds. See

Pump Troubleshooting on page 34.

NOTE: If one gauge drops, the others will rise.

• Stop the pumps on the downstroke. Check that all

gauges hold pressure.

• If using feed pumps, check that both feed pumps

run during the proportioner upstroke.

Mix and Integration Tests

Use the following tests to check for proper mix and integration.

NOTE: Spots that take longer to cure indicate insufficient pump loading, leakage, or lead/lag errors at a

remote mix manifold.

Appearance Test

Spray material onto foil. Look for variations in color,

gloss, or texture that may indicate improperly catalyzed

material.

Monitor Fluid Supply

NOTICE

To prevent pumping air into the system, which causes

incorrect proportioning, never allow the feed pump or

solvent pump containers to run dry.

An empty pump will quickly accelerate to a high speed,

and may damage itself and the other displacement

pump because it causes a pressure rise in the other

pump. If a supply container runs dry, stop the pump

immediately, refill the container, and prime the system.

Be sure to eliminate all air from the system.

Check Pot Life

Butterfly Test

At low pressure, and with the spray tip reversed, dispense a 1/2 in. (12.7 mm) bead of material onto foil until

multiple changeovers of each pump have occurred. Fold

the sheet of foil over the fluid then peel it back and look

for unmixed material (appears marble-like), or color

changes.

Curing Test

Spray a single continuous pattern on foil at typical pressure setting, flow rate, and tip size until multiple changeovers of each pump have occurred. Trigger and

de-trigger at typical intervals for the application. Do not

overlap or cross over your spray pattern.

Check curing at various time intervals, listed on the

material data sheet. For example, check for dry to touch

by running your finger along the test pattern’s entire

length at the time listed on the data sheet.

Check the fluid manufacturer's instructions for fluid pot

life at your fluid temperature. Flush mixed fluid out of the

mix manifold, hose, and gun before pot life time expires,

or before a rise in viscosity affects the spray pattern.

Ratio Check

Check the ratio at the mix manifold after any changes to

the proportioning system. Use Ratio Check Kit 24F375

to check the ratio at the mix manifold. See manual ratio

check kit manual for instructions and parts.

NOTE: To prevent an inaccurate ratio check when

feed pumps are used in your system, the feed pressure cannot be more than a maximum of 25% of the

proportioner outlet pressure. High feed pressure

can float the proportioner pump check balls, resulting in an inaccurate ratio check. There must be back

pressure on both sides of the mix manifold when

checking the ratio.

3A0420T 31

Page 32

Maintenance

Maintenance

Hose Electrical Resistance

Check electrical resistance of hoses regularly. If total

resistance to ground exceeds 29 megohms, replace

hose immediately.

Filters

Once a week check, clean, and replace (if needed) the

following filters.

• Both pump filters; see lower manual for instructions.

• Main air inlet manifold filter; see Replace Air Filter

Element, page 36.

• Spray gun handle filter; see spray gun manual.

Seals

Once a week, check and tighten throat seals on both

pumps. See table for torque specifications. Be sure to

follow the Pressure Relief Procedure, page 22, prior to

tightening seals. There must be zero pressure on the

pumps when adjusting.

Pump Size Torque Specification

All 25-30 ft-lb (34-41 N•m)

6. Shutdown the sprayer and turn off all power. See

Shutdown, page 30.

7. Clean the external surfaces only using a rag soaked

in solvent that is compatible with the spray material

and surfaces being cleaned.

8. Allow enough time for the solvent to dry before

using the system.

Recommended Spare Parts

Keep these spare parts on hand to reduce downtime.

See Recommended Spare Parts, page 54.

Change the Mix Ratio

In order to change the mix ratio, one or both pumps

need to be replaced, the air motor needs to be re-positioned, and the over pressure relief valves may need to

be installed.

NOTE: Only Xtreme XP lower pumps come with a

rod coupling.

1. Check the Varying Parts table on page 51 for the

correct pump sizes.

2. Remove and replace pump. See page 35.

3. Adjust the position of the air motor. See page 20.

Cleaning Procedure

1. Ensure all equipment is grounded. See Grounding,

page 18.

2. Ensure the area where the system will be cleaned is

well ventilated and remove all ignition sources.

3. Turn off all heaters and allow equipment to cool.

4. Flush mixed material. See Flush Mixed Material,

page 28.

5. Relieve pressure. See Pressure Relief Procedure,

page 22.

32 3A0420T

4. If changing from one type of XP system to

another (for example - changing from XP35 to

XP70 or from XP70 to XP35): remove the existing

over pressure relief valves (302) and install the correct valves for the new system type. See Replace

Over Pressure Relief Valves on page 38.

5. Change air pressure relief valve as required,

depending on ratio. See air relief valve (64) in tables

starting on page 46.

Page 33

Troubleshooting

Troubleshooting

✖ Fluid ratio will be wrong.

◆ Purge all air from system before proportioning

fluids.

Problem Cause Solution

System stops or will not start. Air pressure or volume too low. Increase; check air compressor.

Closed or restricted air line or air

valve.

Fluid valves closed. Open.

Clogged fluid hose. Replace.

Air motor worn or damaged. Repair air motor; see 311238.

Displacement pump stuck. Repair pump; see 311762.

System speeds up or runs erratically. Fluid containers are empty.◆ Check often; keep filled.

Air in fluid lines.◆ Purge; check connections.

Displacement pump parts worn or

damaged.

Pump operates, but resin output

pressure drops on upstroke.✖

Pump operates, but resin output

pressure drops on downstroke.

Pump operates, but resin output

pressure drops on both strokes.✖

Pump operates, but hardener output

pressure drops on upstroke.✖

Pump operates, but hardener output

pressure drops on downstroke.✖

Pump operates, but hardener output

pressure drops on both strokes.

Fluid leak in packing nut. Loose packing nut or worn throat

Fluid leak under packing nut Packing cartridge o-ring. Replace o-ring; see 311762

Relief valve (AM) leaks back to supply, opens too soon, or will not close.

No pressure on hardener side; fluid

leaking from hardener pump outlet

rupture disc fitting.

Pressure and flow surges on

upstroke.

Dirty, worn, or damaged resin pump

piston valve or piston packings.

Dirty, worn, or damaged resin pump

intake valve.

Hardener output restriction. Clean, unplug hardener side. Open

Fluid supply low.◆ Refill or change container.

Dirty, worn, or damaged hardener

pump piston valve or piston packings.

Dirty, worn, or damaged hardener

pump intake valve.

Resin output restriction. Clean, unplug resin side.

Fluid supply low.◆ Refill or change container.

packings.

Relief valve is dirty or damaged. Replace over pressure relief

Overpressure rupture disk blown. Determine cause of overpressuriza-

Feed pressure too high. Every 1 psi

of feed pressure adds 2 psi during

upstroke.

Open or clean.

Repair pump; see 311762.

Clean, repair pump; see 311762.

Clean, repair pump; see 311762.

manifold restrictor.

Clean, repair pump; see 311762.

Clean, repair pump; see 311762.

Tighten; replace; see 311762.

valve (302)

tion and correct. Replace rupture disk

assembly 258962 (see page 51) and

over pressure relief valve (302).

Reduce feed pressure. See Techni-

cal Data, page 57.

3A0420T 33

Page 34

Troubleshooting

Problem Cause Solution

Fluid outlet pressure gauges split

only at the top changeover (if one

Not fully loading one side on

upstroke.

Increase feed pressure on side that

dropped.

gauge drops the other will rise).

Increase feed hose size.

Clean inlet strainer or hopper screen.

Air mixed in fluid from excessive agi-

Flush and add new fluid.

tation or circulation.

Pump Troubleshooting

This chart uses proportioning fluid gauges to determine pump malfunctions. Observe the gauge readings during the

stroke direction indicated by the bold arrow, and immediately after closing the gun or mix manifold. Refer to other

manuals to troubleshoot individual components.

TROUBLE AREA:

Resin Pump Leakage

1. Throat packing

2. Piston packing

3. Piston ball check

Resin

Pump

Hardener

Pump

TROUBLE AREA:

Hardener Pump Leakage

1. Throat packing

2. Piston packing

3. Piston ball check

Resin

Pump

Hardener

Pump

TROUBLE AREA:

Resin Pump Leakage

1. Throat packing

2. Intake ball check

Resin

Pump

Falling Rising

r_258914_3a0420a_11a r_258914_3a0420a_11a

Hardener

Pump

TROUBLE AREA:

Hardener Pump Leakage

1. Throat packing

2. Intake ball check

Resin

Pump

FallingRising

Hardener

Pump

FallingFalling Rising Rising

r_258914_3a0420a_10ar_258914_3a0420a_10a

34 3A0420T

Page 35

Repair

To avoid serious injury due to the pump assembly

falling, secure a hoist to the lift ring.

Follow Shutdown procedure on page 30, which

includes flushing, if service time may exceed pot life

time, before servicing fluid components, and before

transporting system to a service area.

Repair

4. Remove the spring clamp (130) and coupling (119

or 120).

106

135

105

Pump Assembly

The displacement pumps and air motor may be

removed and serviced separately or the entire pump

and motor assembly can be removed with a hoist.

Remove Pump Assembly

1. Stop the pumps near the bottom of their stroke. Fol-

low Shutdown, page 30.

2. Disconnect all hoses from the pump assembly.

3. If hoppers are installed, disconnect the hopper fluid

lines from the pump fluid inlet. See Hoppers, page

40.

NOTE: The hopper and hopper bracket do not need

to be removed from the cart.

4. Remove screws (6) and washers (5) under the tie

plate (101).

5. Use hoist to remove the pump assembly by the lift

ring and carefully lift out of cart (1).

130

119

117

118

108

r_258914_3a0420a_5a

5. Use a wrench to hold the tie rod (105, 106) flats to

keep the rods from turning. Unscrew the nuts (108)

from the tie rods and carefully remove the displacement pump (117 or 118) and lower straps (135).

6. Refer to the Xtreme Displacement Pump manual to

service or repair the displacement pump.

Remove Displacement Pump

1. Follow Shutdown, page 30.

2. If hoppers are installed, remove the hopper and

hopper bracket from the cart. See Hoppers, page

40.

3. If feed pumps are installed, close the inlet ball valve.

Remove inlet union (61).

3A0420T 35

7. Follow the steps in reverse order to reinstall the displacement pump.

NOTE: Torque nuts (108) to 50-60 ft-lb (68-81 N•m).

Page 36

Repair

Remove Motor

1. Stop the pumps near the bottom of their stroke. Fol-

low Shutdown, page 30.

2. Disconnect the air line from the air motor (103).

3. Remove the air motor rod cover (121) and pump

guards (122).

Air Motor shown

122

r_258914_3a0420a_7a

4. Use a wrench to hold the tie rod (102) flats to keep

the rods from turning. Unscrew the nuts (108) and

washers (107) from the tie rods.

Air Motor shown

103

121

lift ring

8. Refer to the air motor manual to service or repair the

air motor.

9. Follow the steps in reverse order to reinstall the air

motor.

NOTE: Position air motor for correct mix ratio. See

Motor Position on page 20 for instructions. Torque

nuts (108) to 50-60 ft-lb (68-81 N•m).

Air Controls

See FIG. 10 on page 37.

Replace Air Control Assembly

1. Close the main air shutoff valve on the air supply

line and on the system. Depressurize the air line.

2. Disconnect the air motor air lines and system air

line.

3. Remove the nut (8) and washer (5). Remove the

bottom air control manifold assembly from the cart.

4. Loosen the upper air control assembly from the air

motor.

102

104

111

107

108

109

5. Place a wrench on adapter rod (104). Use tool (70)

to loosen the serrated yoke nut (109) that holds the

air motor (103) above the yoke (111).

6. Face the front of the machine and slide the air motor

(103) to the opening in the yoke (111).

r_258914_3a0420a_8a

5. Follow the steps in reverse order to reinstall the new

air control assembly.

Replace Air Filter Element

1. Close the main air shutoff valve on the air supply

line and on the system. Depressurize the air line.

2. Unscrew the serrated ring on filter bowl (210).

3. Remove and replace the filter element (210a). See

Air Controls, 258983, page 52.

Replace System Air Regulator

1. Close the main air shutoff valve on the air supply

line and on the system.

2. Disconnect air motor air lines and system air line.

3. Remove the regulator assembly (201) and replace

with new regulator. See Air Controls, 258983,

page 52.

4. Follow the steps in reverse order to reassemble.

7. Use a hoist to remove the air motor by the lift ring.

36 3A0420T

Page 37

201

Repair

211

206

214

207

Air Flow

216

215

208

213

204

203

209

206

Air Flow

214

202

205

209

210

5, 8

r_571101_3A0420A_1a-2

FIG. 10: Air Control Assembly 258983

3A0420T 37

Page 38

Repair

Mix Manifold Assembly

1. Follow Pressure Relief Procedure, page 22.

2. Disconnect the fluid hose (25) and the flush hose

from the mix manifold (36).

3. Loosen the union fittings (306) that connect to the

mix manifold adapter fittings.

4. Remove the mix manifold assembly (36).

5. See mix manifold manual for service and repair

instructions.

306

36

r_571101_3a0420a_38a

1

35

37

r_571101_3a0420a_39a

FIG. 11: Fluid Circulation Manifold

Replace Over Pressure Relief Valves

1. Flush before repairing equipment, if possible. See

Empty and Flush Entire System (new system or

end of job), page 29.

2. Follow Pressure Relief Procedure, page 22.

3. Ensure handle (312) is in the down position.

Remove the screws (313), jam nut (304), handles

(311), handle rod (312), clips (318), and

springs (320).

311

Fluid Circulation Manifold with Over Pressure Relief Valves

See FIG. 11.

1. Flush before repairing equipment, if possible. See

Empty and Flush Entire System (new system or

end of job), page 29.

2. Follow Pressure Relief Procedure, page 22.