Page 1

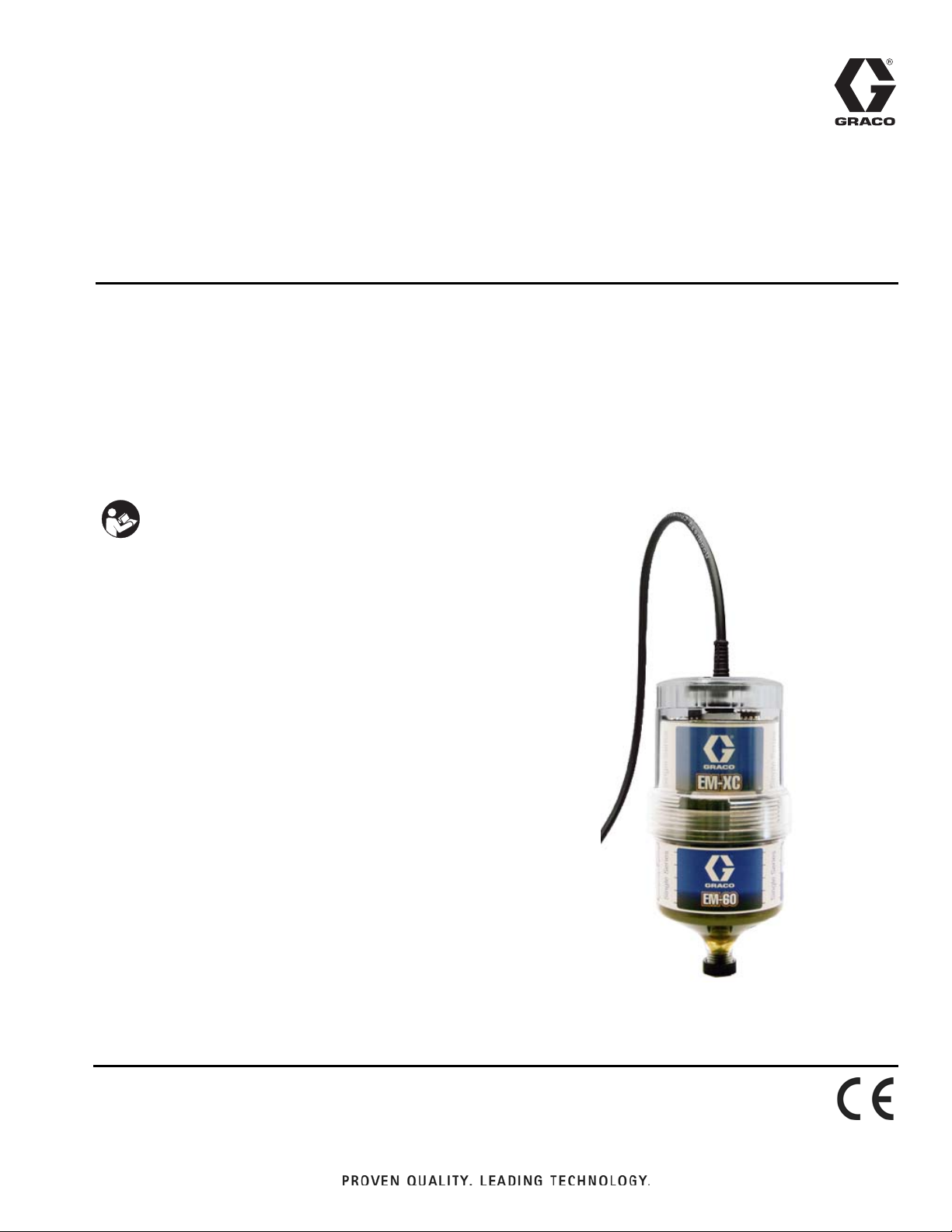

Instructions

XC Impulse

3A0416C

Lubricators

Uses an external power impulse to control the discharge of grease or oil lubrication to all

lubrication points of sliding- and roller bearings, drive- and transport chains, sliding

guideways, open gears and seals. For professional use only.

Not approved for use in European explosive atmospheres.

75 psi (0.5 MPa, 5 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 4 for model information.

Page 2

WARNINGWARNINGWARNING

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer

to procedure-specific risks. When these symbols appear in the body of this manual, refer back to

these Warnings. Product-specific hazard symbols and warnings not covered in this section may

appear throughout the body of this manual where applicable.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system

can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and

before servicing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local

codes and regulations.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield

wiper fluid, be aware that flammable fumes can ignite or explode. To help prevent fire

and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of sol-

vent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are

present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not

use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applica-

ble guidelines.

2 3A0416C

Page 3

PRESSURIZED EQUIPMENT HAZARD

WARNINGWARNINGWARNING

WARNING

Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on

skin and cause serious injury.

• Follow the Pressure Relief Procedure before cleaning, checking, or servicing

equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts

immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest

rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See

Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s

warnings. For complete information about your material, request MSDS from

distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is

not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with

genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Do not puncture, open or take lubricator apart.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot

surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

3A0416C 3

Page 4

Models

WARNINGWARNINGWARNING

WARNING

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in

the operating area of the equipment to help protect you from serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes

but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and sol-

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth

defects or other reproductive harm. Wash hands after handling.

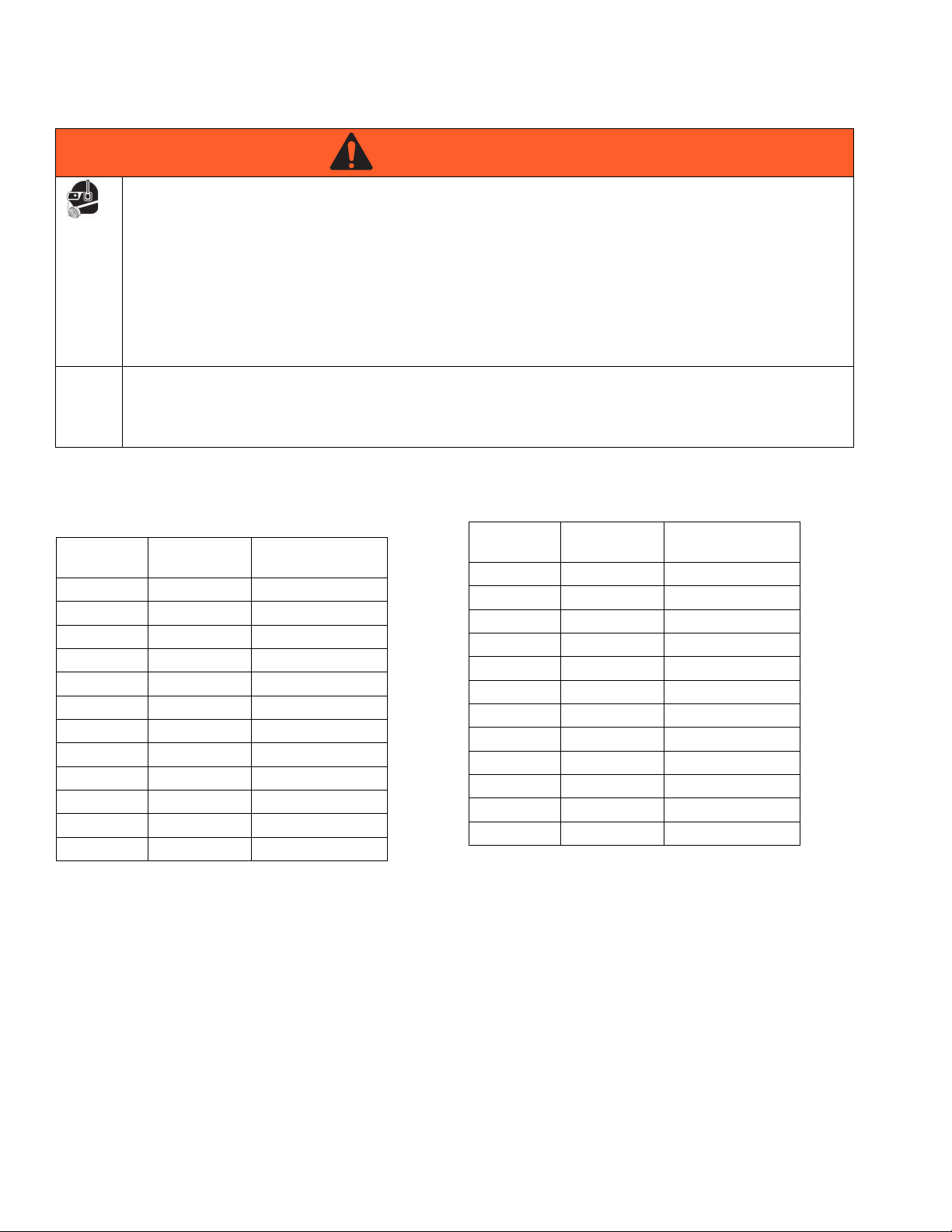

Models

vent manufacturer.

Part No.

24E090

24E089

24E092

24E091

24E095

24E088

24E093

24E094

24E098

24E097

24E100

24E099

Volume

Output

120CC

120CC

120CC

120CC

120CC

120CC

120CC

120CC

250CC

250CC

250CC

250CC

Application

Bearing

Construction

Food Grade H1

Milling

Lithium EP1

Lithium EP2

Synthetic Industrial

Ultra Spindle

Bearing

Construction

Food Grade H1

Milling

Part No.

24E103

24E096

24E101

24E102

24E082

24E081

24E084

24E083

24E087

24E080

24E085

24E086

Volume

Output

250CC

250CC

250CC

250CC

60CC

60CC

60CC

60CC

60CC

60CC

60CC

60CC

Application

Lithium EP1

Lithium EP2

Synthetic Industrial

Ultra Spindle

Bearing

Construction

Food Grade H1

Milling

Lithium EP1

Lithium EP2

Synthetic Industrial

Ultra Spindle

4 3A0416C

Page 5

Component Identification

A

B

C

D

E

F

Component Identification

APlug

B Lubrication Canister

NOTE: Canister cannot be refilled.

C † Drive Unit (Includes gear motor and

circuit board)

D LED function display

E † Cover

F † Cable with plug

† Reusable parts

3A0416C 5

Page 6

Component Identification

4

3

1

2

A

B

D

C

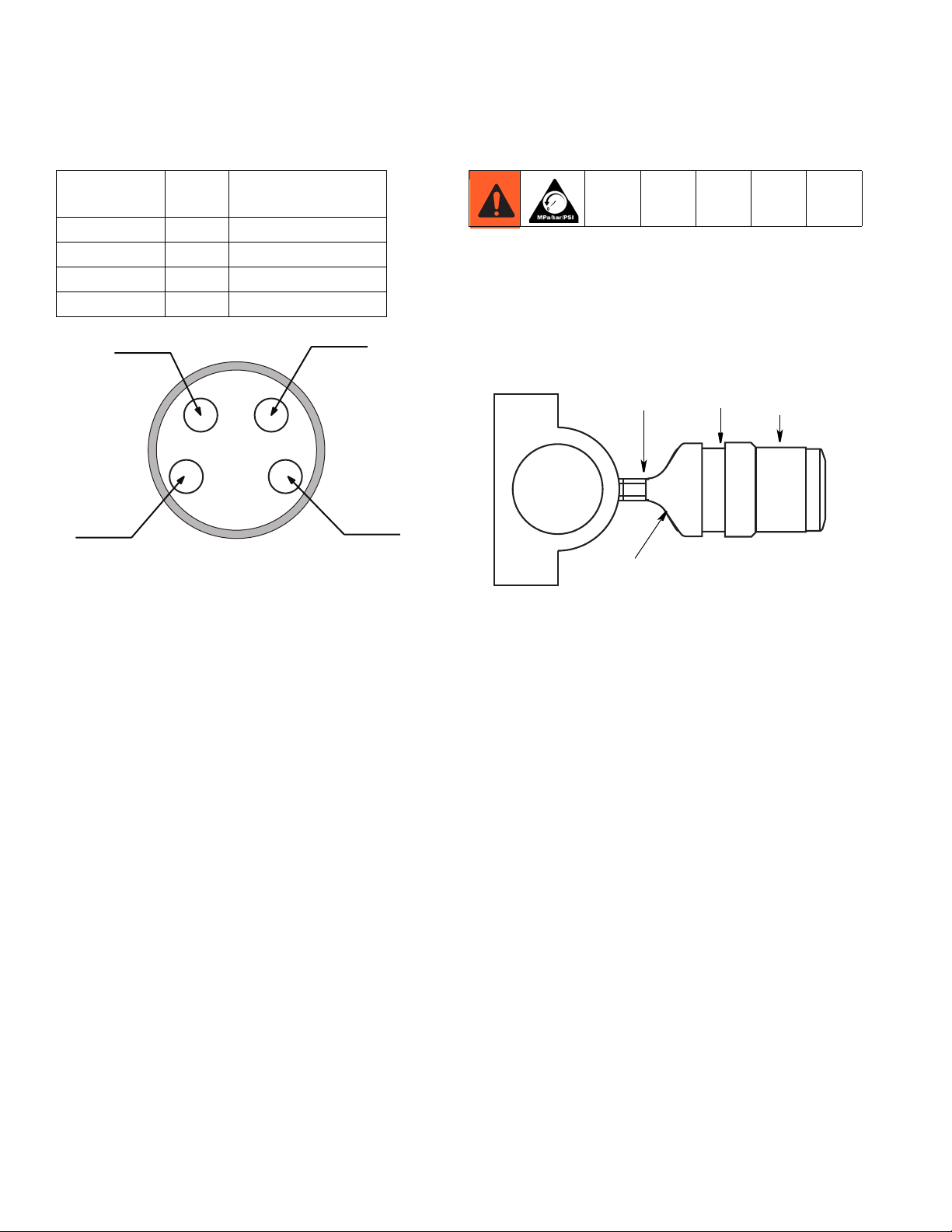

Pin Assignment Pressure Relief Procedure

Pin

Assignment

1 brown current +

2 white LED green digital

3 blue current 4 black LED red digital

Cable

Color Signal

1. Cover lubrication point (A) and lubricator

(B) with a heavy rag to absorb any fluid that

may leak out while loosening the adapter.

2. Carefully unscrew support adapter (D) from

the lubrication point (A).

A Lubrication Point

B Lubrication Canister

CDrive Unit

D Support Adapter

6 3A0416C

Page 7

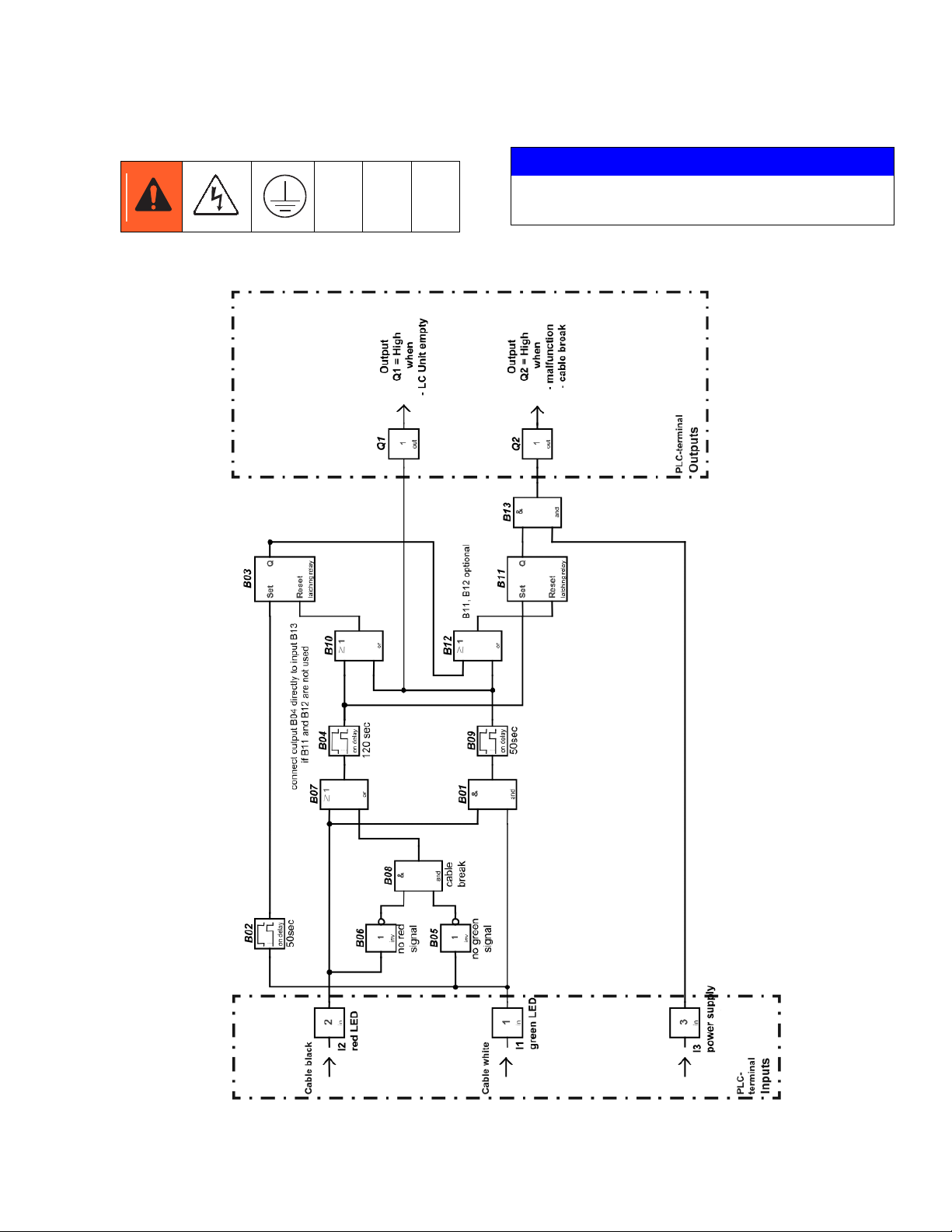

Wiring Diagrams

PLC Connection - One Output Signal

Component Identification

NOTICE

Incorrect connection of the lubrication unit

could destroy electronics.

3A0416C 7

Page 8

Component Identification

PLC Connection - Two Output Signals

8 3A0416C

Page 9

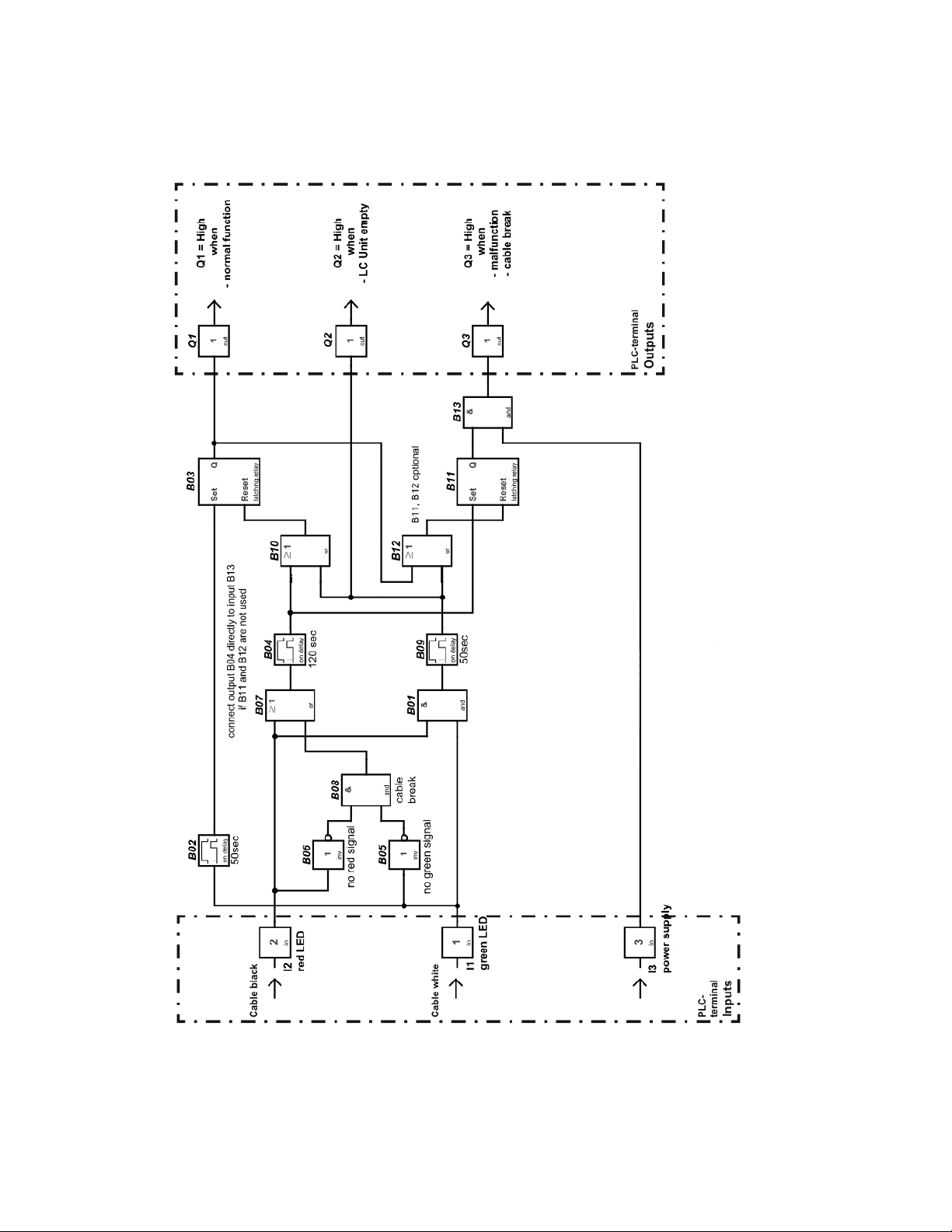

PLC Connection - Three Output Signals

Component Identification

3A0416C 9

Page 10

Installation and Setup

A

B

Installation and Setup

Determining Correct Mounting Method

NOTE:

• Direct mounting should be used for lubrica-

tion points that are easily accessible.

• Remote mounting is recommended if you

answer YES to any of the questions below.

1. Is the ambient temperature at the lubrication point higher than +50°C (122°F)?

2. Is it necessary to remove protective

screens, walls or other types of protection

in order to reach the lubrication point?

3. Is the lubrication point exposed to high

vibrations?

4. Is it difficult to access the lubrication point

during operation of the machine?

NOTE:

• Be sure to use a lubricant cartridge that

contains the same grease used in the

application.

• The best measurement results are

achieved during operation.

Checking the Counter Pressure

1. Clean the lubrication point to remove any

potential contaminants.

2. Install reducers, extensions, grease line,

etc. (if necessary).

3. Prime the grease line and all accessories

with the same grease that is contained in

the lubricator. (See Parts, page 22 for a

complete list of available grease cartridges).

4. Remove the plug (A).

5. Is the lubrication point exposed to any of

the following:

• water jets for high-pressure cleaning

machines?

• corrosive chemicals?

• extreme temperature?

• falling materials?

Preparing Lubricator for Installation

The lubricator has a self-protection mechanism which shuts off the drive unit at counter

pressures higher than 5 bar (72.5 psi). Most

bearings require 0.5 - 2 bar (7.2 to 29 psi)

pressure (without tubes, extensions, angles,

etc.).

Use the following procedure to check the

counter pressure of the application prior to

installation.

5. Install lubricator unit

into adapter (B).

6. Screw a pressure manometer into the lubrication point (dd) (F

IG. 1, page 11).

10 3A0416C

Page 11

A pressure manometer is a simple device that

aa

bb

cc

dd

ee

ff

measures pressure output. To build a pressure

manometer you need a pressure gage (aa),

tee fitting (bb) and stop valve (cc). FIG. 1

shows a correctly assembled pressure

manometer, connected to the lubricator and a

lubrication point.

Installation and Setup

12. To disconnect lubricator from manometer,

follow pressure relief procedure , page 6.

NOTE: In this application, you will be disconnecting adapter (B) from manometer

instead of lubrication point.

NOTICE

Do NOT disconnect lubricator from adapter

(B). Screwing anything into lubricator a second time will damage self-sealing threads.

FIG. 1

aa

bb

cc

dd

ee

ff

Pressure Gauge

Tee Fitting

Stop Valve

Lube Point

Lubricator

ON / OFF Switch

7. Ensure the stop valve (cc) of the pressure

manometer is open.

8. Attach lubricator and adapter (B) to the

pressure manometer (aa - cc) and turn the

switch to “ON” (ff) (F

IG. 1).

9. Run the manometer for about 20 seconds.

Observe the gauge and repeat this procedure until the pressure registered on the

gauge stays constant.

10.To determine the counter pressure, wait

approximately 5 minutes until the system

has relaxed. Do one

more discharge by

turning the unit OFF; then ON again until it

dispenses for no more than 5 seconds.

13.If the counter pressure is 5 bar (72.5 psi) or

higher, flush the lubrication point with a

grease gun.

If the counter pressure does not decrease

you may need a different lubricant or size

lubricator canister. Contact Graco Customer service for assistance.

Priming/Pre filling Fittings and

Grease Lines

All accessories and grease lines must be

primed/pre filled. Without this priming/pre filling, the lubricator would first have to fill the

accessories with lubricant.

Example: A tube that is one meter long

requires about 28 cm3 of lubricant. It would

take the lubricator with a 12 month setting and

an EM-120 grease canister about 3 months to

fill this 1 meter tube.

IG. 2 illustrates one way to pre fill using a

F

grease gun to dispense the grease.

11.Wait approximately 5 more minutes to

make sure the system does not lose pressure and remains constant.

3A0416C 11

FIG. 2

Page 12

Installation and Setup

12 34

C

A

B

D

E

Circuit Board Settings

Function Display

Red and green LED’s (Light Emitting Diodes) are on the circuit board and visible through the

transparent cover. The following signals about operating conditions/malfunctions are displayed

by these LED’s for the user:

LED Signal Meaning

Green Steady System functions OK

Red Steady for less than 30 seconds with

Red Steady signal for more than 30 sec-

Green and Red Steady signal Lubricator unit is empty.

FIG. 3

ALED Red

BLED Green

C 4-way code switch

Lubricator is discharging

motor running

Malfunction / error

onds

Change canister.

Setting Dip Switches

1. Unscrew and remove the cover of the drive

unit.

2. Use a small screwdriver or your finger to

move dip switches to the desired position.

Refer to Table 1.

• Dip switches 1and 2 marked “TIME” are

used to set the discharge amount per

impulse.

• Dip switches 3 and 4 marked “VOL” are

used to set the lubrication canister size.

If the 4-way code switch does not correspond to the actual size of the lubrication canister, it will lead to a wrong

signal and over or under lubrication.

D Plug connection

E Circuit board

12 3A0416C

Page 13

TABLE 1: Dip Switch Settings / Discharge Amounts in CC / Impulse

VOL

VOL

VOL

ON

TIME

12

ON

TIME

ON

TIME

ON

TIME

• Amount of discharge in cc per impulse.

• White square indicates position of dip switch.

Installation and Setup

Lubrication

Canister Size

Dip Switch

Position

12

12

EM-60 EM-120 EM-250

34

2.11 2.11 2.11

1.06 1.06 1.06

0.53 0.53 0.53

34

34

0.26 0.26 0.26

12

NOTE:

• As soon as power is supplied, the controller will discharge the set amount once. Power must

be applied at least until the discharge has taken place (approximately 2 minutes).

• In order to get another discharge cycle, the power must be interrupted for at least 15 sec-

onds, and then supplied again.

3A0416C 13

Page 14

Installation and Setup

Correct

Incorrect

Selecting Mounting Location

Installation Guidelines

• Before installing the lubricator, the lubrica-

tion points and any extensions must be

adequately pre-lubricated with the same

lubricant contained in the lubricator. A 400

gram lubricant cartridge for grease guns is

available from Graco. See Parts, page 22

for a complete list of available lubricant cartridges.

• Install one lubricator per lubrication point.

• When oil is used for lubrication, a

non-return valve (oil throttle) must be

installed. This will prevent oil leakage from

the lubricator. An oil throttle, part number

124102 is available from Graco. See Parts,

page 22.

• For all metal to metal connections (i.e.,

extensions, reducers, etc.) make sure to

use LOCTITE® 243* (semi-tight screw lock-

ing).

*Loctite

ration.

®

is a registered trademark of the Loctite Corpo-

Direct Mounting Installation

Refer to FIG. 4 for examples of correct and

incorrect direct mounting installations.

• An oil-filled lubricator must be installed ver-

• For horizontal mounting a bracket clip must

• For vertical installations always use a sup-

• The grease nozzle of the lubricator has a

• Do not overtighten the plastic thread of the

tically (outlet down).

be used to hold the lubricator in place. A

horizontal clip bracket part number 124086

is available from Graco. See Parts, page

22

port adapter part number 124105 is available from Graco. See Parts, page 22.

npt 1/4 inch male thread. If your application

has a different thread you may need to use

an adapter. See Parts, page 22 for a complete list of available adapters.

lubricator.

FIG. 4

14 3A0416C

Page 15

Installation and Setup

A

B

C

D

E

F

Remote Mounting Installations

Refer to FIG. 5 - FIG. 7 for examples of correct

remote mounting installations.

• Remote installations require a grease line.

Graco recommends using a 5/16 inch flexible hose.

• Select a position for the lubricator that is

easy to access and protected from

high-pressure water jets, falling materials,

corrosive chemicals and extreme temperatures.

Grease Lubrication with Tube

FIG. 5

A Clip, 124086

B Support adapter, 124105

C Bracket, 124087

D Tube connector (User supplied)

E Nylon tube (User supplied)

F Tube connections (User supplied)

Must be at least 5/16 inch diameter tube.

3A0416C 15

Page 16

Installation and Setup

A

B

C

D

E

F

G

C

H

J

K

From-top-lubrication of a Chain with Oil

A Clip, 124086

B Support adapter, 124105

C Bracket, 124087

D Tube connector (User supplied)

E Nylon tube (User supplied)

F Tube connections (User supplied)

G Oil throttle, 124102*

H L-Bracket, 124098

J Bulkhead mounting plate, 124099

K Oil brush, 1”x 1.5”, 124090

*The non-return valve (oil throttle (G) should

always be placed at the lowest point of the

application.

Must be at least 5/16 inch diameter tube.

FIG. 6

16 3A0416C

Page 17

Lubrication of Elevated Chain with Oil

F

E

A

B

C

G

D

Installation and Setup

FIG. 7

A Clip, 124086

B Support adapter, 124105

C Bracket, 124087

D Tube connector (User supplied)

E Nylon tube (User supplied)

F Tube connections (User supplied)

G Oil throttle, 124102*

*The non-return valve (oil throttle: G) should

always be placed at the lowest point of the

application.

Must be at least 5/16 inch diameter tube.

3A0416C 17

Page 18

Operation

A

B

Installing Lubricator to Lubrication Point

1. Clean the lubrication point to remove any

potential contaminants.

2. Verify the thread of the lubricator corresponds to the thread of the screw point.

3. Install reducers, extensions, grease line,

etc. (if necessary).

4. Verify Dip Switches are correctly set. See

Table 1, page 13.

5. Prime the grease line and all accessories

with the same grease that is contained in

the lubricator. (See Parts, page 22 for a

complete list of available grease cartridges).

6. Remove the plug (A).

7. Install lubricator unit

into adapter (B).

8. Screw lubricator to lubrication point, hand

tight only.

NOTICE

To ensure optimal lubrication:

• Seal threads of all connecting parts with a

suitable, standard sealant.

• Mount oil filled lubricators properly with the

outlet pointing down.

Operation

Before operation verify:

• The lubricator does not have any visible

damage.

• The lubricator canister is filled with the

requested grease or oil.

• Never screw in the lubricator a second time

or the self-sealing threads will be damaged.

• For remote mounting installations, make

sure bracket does not squeeze the lubrication canister as this could block the piston

inside the canister.

• The “VOL” switches 3 and 4 of the 4-way

code switch match the correct size of the

lubrication canister.

• The “TIME” switches 1 and 2 of the 4-way

code switch in the drive unit match the

desired discharge impulse.

• For oil filled lubrication canisters, an oil

throttle must be attached.

18 3A0416C

• All components are properly assembled

and screwed together hand tight.

Page 19

Changing the Lubrication Canister

B

To begin the discharge:

Plug power cable into lubricator (FIG. 8).

.

FIG. 8

During Operation:

• Carry out regular performance checks.

Check for possible leakages and the status

of the lubricator.

• Regularly monitor the fill-level of the trans-

parent lubrication canister.

Changing the Lubrication

Canister

When the red and green LED light up at the

same time, the lubrication canister is empty

and should be replaced.

NOTICE

The drive unit and circuit board must always

be protected from moisture to prevent damaging these components. Always change the

lubrication canister in a dry place.

Removing Lubrication Canister

1. Unplug cable from lubricator (F

IG. 9).

FIG. 9

2. To disconnect adapter from lubrication

point, follow pressure relief procedure

provided on page 6.

3. Unscrew and completely remove adapter

(B) from the lubricator.

Adapter will be reused.

4. Unscrew cover from

drive unit.

5. Remove drive unit from

the lubrication control.

3A0416C 19

Page 20

Changing the Lubrication Canister

A

Installing New Lubrication Canister

1. If a different size lubrication canister or discharge period is going to be used, change

dip switches to reflect the new canister size

and/or impulse change. See Table 1, page

13.

2. Place drive unit on top of new lubrication

canister until the teeth of both pieces are

locked.

3. Screw the cover of the drive unit onto the

lubrication canister - hand tighten only.

4. Remove plug (A) from

bottom of lubrication

canister.

5. Install lubricator unit into adapter (B).

6. Screw lubricator into the lubrication point hand tighten only. DO NOT screw it in a

second time.

NOTICE

Never screw in the lubricator a second time

or the self-sealing threads will be damaged.

FIG. 10

9. The control will wait for a pulse to start discharging.

Lubrication Canister Disposal

Dispose of hazardous fluid in approved containers, and according to applicable guidelines. Read the MSDS to know the specific

hazards of the fluids you are using.

Storage

When lubricators are not immediately installed,

they must be stored in a dry, dust free, sunlight

protected room, indoors.

7. For oil filled lubricators, make sure the

lubricator is installed vertically (outlet pointing down).

8. Plug cable back into lubricator (FIG. 10).

20 3A0416C

Page 21

Troubleshooting

Malfunction Possible Cause Solution

Wrong cable connection

Troubleshooting

Connect cable according to pin

assignment (page 6). Check pin

assignment.

Break in cable

Lubricator does not function

No power supply

Relay defect in machine Change relays.

Setting of VOL switch different

Lubricator signals “system functions OK” (green LED), although

lubrication canister is empty

Lubricator signals “system malfunctions” (red LED)

Lubricator discharges too fast Wrong position of TIME switch

than attached lubrication canister

Partly filled lubrication canister

was replaced by an almost

empty lubrication canister

Clogged tube and/or connection

parts

Counter pressure too high

Check voltage at plug. Attach

new cable.

Check power supply. Make sure

there is sufficient power available for the number of lubricators used.

Replace lubrication canister with

a full lubrication canister

Clean tube and connecting

parts, then shut off and restart

lubricator.

Replace lubrication canister with

a full lubrication canister

Set TIME dip switches (1 and

2) to correct setting.

Setting of VOL switch different

than attached lubrication canis-

ter

Lubricator signals “end of discharge” (red and green LED)

although the unit is not empty

Lubricator does not discharge

the correct amount

3A0416C 21

Almost empty lubrication canis-

ter was replaced with a partially

filled canister

Reset peg was not pushed down

during assembly

Dip switch setting was done

incorrect

Replace with full lubrication canister.

Move drive unit a few teeth so

reset peg is pushed down.

Replace lubrication canister with

a full lubrication canister

Set TIME dip switches (1 and

2) to correct setting.

Page 22

Parts

Parts

Miscellaneous Accessories

Part No. Description Qty.

123951 MOTOR, EM-XC 1

124279 HARNESS, cable, power

EM-XP/XC

124086 CLIP 1

124087 BRACKET, plastic 1

124089 BRUSH, pig hair, 1/4 fnpt - 3/4 1

124090 BRUSH, oil, 1 x 1.5 1

124091 BRUSH, oil, 1 x 2.4 1

124092 BRUSH, oil, 1 x 4 1

124093 BRUSH, link chain 1

124100 CLAMP, beam, 1” 1

124101 BRACKET, dual unit 1

124102 VALVE, check, oil throttle

124109 KIT, accessory, purge 1

124113 APPLICATOR, chain, felt 1

124114 BRUSH, nylon, 1/8 mnpt x 5/8 1

124115 BRUSH, nylon, 1/8 mnpt x 2 1

124116 KIT, SA heavy green 1

124119 PADDLE, open gear lube 1

Mounting Brackets

Part No. Description Qty.

124094 BRACKET, mounting, small 1

124095 BRACKET, mounting, medium 1

124096 BRACKET, mounting, large 1

124097 BRACKET, mounting, flat 1

124098 BRACKET, mounting, L 1

124099 BRACKET, mounting, bulk-

head

Replacement Cap

Part No. Description Qty.

124110 CAP, top 1

1

124111 CAP, full, 60-120 cc 1

124112 CAP, full, 250 cc 1

400 Gram Lubricant Cartridges

Part No. Description Qty.

124176 CARTRIDGE, lubricant, Lith-

ium EP-2

124177 CARTRIDGE, lubricant, Con-

struction

124178 CARTRIDGE, lubricant, Bear-

ing

124179 CARTRIDGE, lubricant, Milling 1

124180 CARTRIDGE, lubricant, Food

Grade H1

124181 CARTRIDGE, lubricant, Syn-

thetic Industrial

124182 CARTRIDGE, lubricant, Ultra

Spindle

124183 CARTRIDGE, lubricant, Lith-

ium EP-1

1

1

1

1

1

1

1

1

Fitting Adapter

Part No. Description Qty.

124105 ADAPTER, 1/4 fnpt x 1/4 mnpt 1

124106 ADAPTER, 1/4 fnpt x 1/8 mnpt 1

Pressure Relief Valve

Part No. Description Qty.

124107 VALVE, relief, 1/8 m, 5 lb 1

124108 VALVE, relief, 1/8 m, 1 lb 1

22 3A0416C

Page 23

Technical Data

Refill Kits

Part No. Description Qty.

24E582 KIT, refill, 60 cc, multi EP-2 1

24E583 KIT, refill, 60 cc, construction 1

24E584 KIT, refill, 60 cc, bearing 1

24E585 KIT, refill, 60 cc, mill 1

24E586 KIT, refill, 60 cc, food 1

24E587 KIT, refill, 60 cc, synthetic 1

24E588 KIT, refill, 60 cc, ultra 1

24E589 KIT, refill, 60 cc, multi EP-1 1

24E590 KIT, refill, 120 cc, multi EP-2 1

24E591 KIT, refill, 120 cc, construction 1

24E592 KIT, refill, 120 cc, bearing 1

24E593 KIT, refill, 120 cc, mill 1

Part No. Description Qty.

24E594 KIT, refill, 120 cc, food 1

24E595 KIT, refill, 120 cc, synthetic 1

24E596 KIT, refill, 120 cc, ultra 1

24E597 KIT, refill, 120 cc, multi EP-1 1

24E598 KIT, refill, 250 cc, multi EP-2 1

24E599 KIT, refill, 250 cc, construction 1

24E600 KIT, refill, 250 cc, bearing 1

24E601 KIT, refill, 250 cc, mill 1

24E602 KIT, refill, 250 cc, food 1

24E603 KIT, refill, 250 cc, synthetic 1

24E604 KIT, refill, 250 cc, ultra 1

24E605 KIT, refill, 250 cc, multi EP-1 1

Technical Data

Cable Construction Cable is drag chain qualified, approved for the

smallest bending radius 60 mm.

Conductor cross-section dimensions

4 x 0.25 mm

2

Power Supply 15 - 25 VDC (max 30 VDC, 5% residual ripple)

for the duration of the actual lubricant discharge.

Total current consumption 0.2 A (current at discharge can be up to 1.2 A).

Maximum output load Pin 2 and 4 cannot exceed 400mA each

Temperature range -10°C to +50 °C (+14°F to +122°F)

Maximum output pressure 5 bar (75 psi)

Storage

Conditions Dry, dust free

Temperature +20°C ± 5°C (+68°F ± 9°F)

Air born Noise Emission <70 dB(A)†

Loctite® is a registered trademark of the Loctite Corporation.

† Emission sound pressure level of the lubrication system measured at distance of 1 m / height

1.6 m.

3A0416C 23

Page 24

Technical Data

Drive

Lubrication

Canister

1/4 npt

L

D

Weights and Measurements

Type Volume Diameter (D)

3

cm

fl. oz mm in. mm in. kg lbs

Length (L) Weight (empty)

EM-60 60 2.03 71 2.8 142 5.60 0.310 0.68

EM-120 120 4.06 71 2.8 165 6.50 0.320 0.7

EM-250 250 8.45 71 2.8 215 8.46 0.360 0.79

24 3A0416C

Page 25

Notes

Notes

3A0416C 25

Page 26

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A0416

Patent information: www.graco.com

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

December 2014

Loading...

Loading...