Page 1

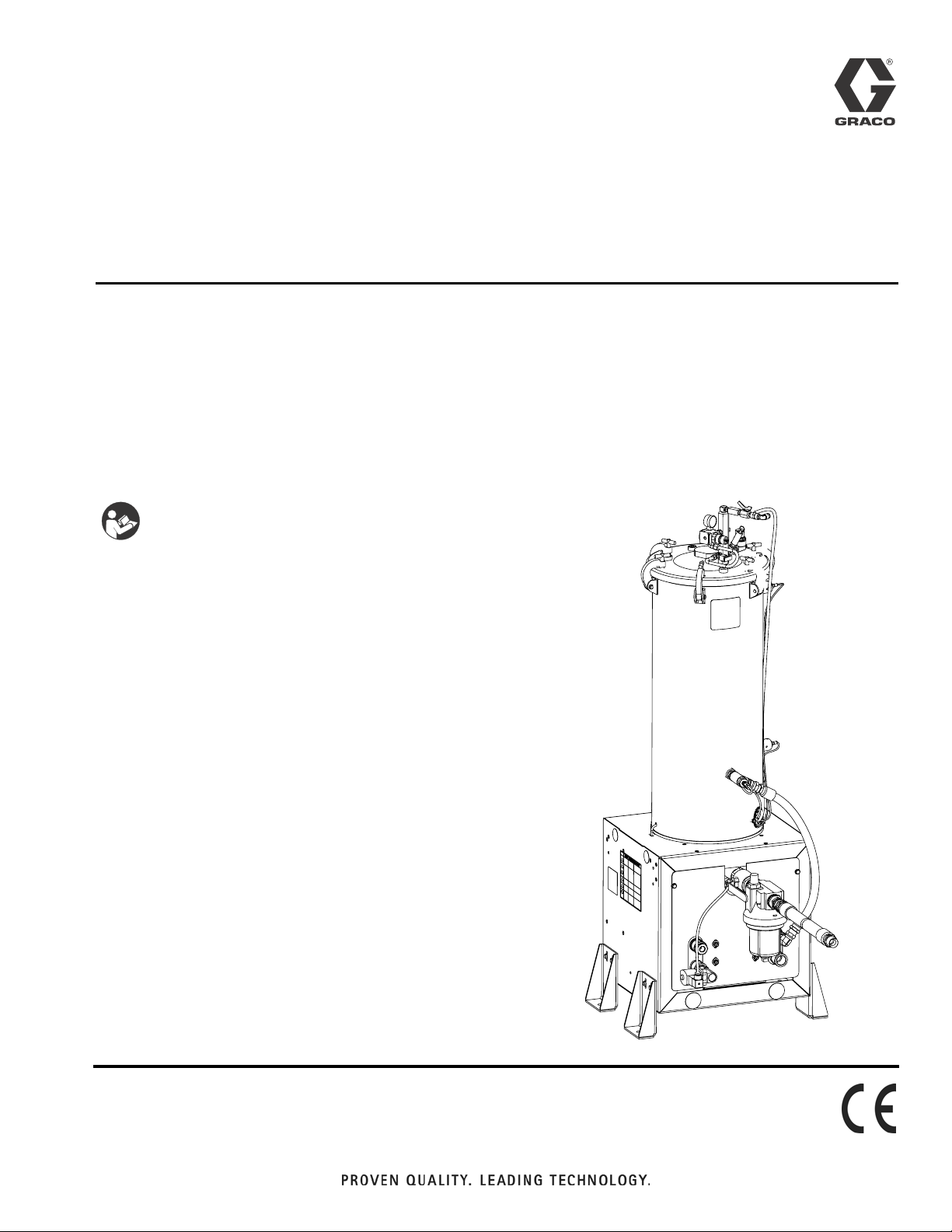

Instructions - Parts

Stainless Steel

3A0395R

Tank Stands

For supplying material to HFR™ plural-component proportioners. For professional use

only.

Not approved for use in European explosive atmosphere locations.

100 psi (0.7 MPa, 7.0 bar) Maximum Working Pressure

100 psi (0.7 MPa, 7.0 bar) Maximum Air Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 3 for model information.

r_24C317_3A0395a_1c

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Two-Component Material Information . 6

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 6

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 6

Keep Components A and B Separate . . . . . . . . . 6

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 6

Foam Resins with 245 fa Blowing Agents . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 7

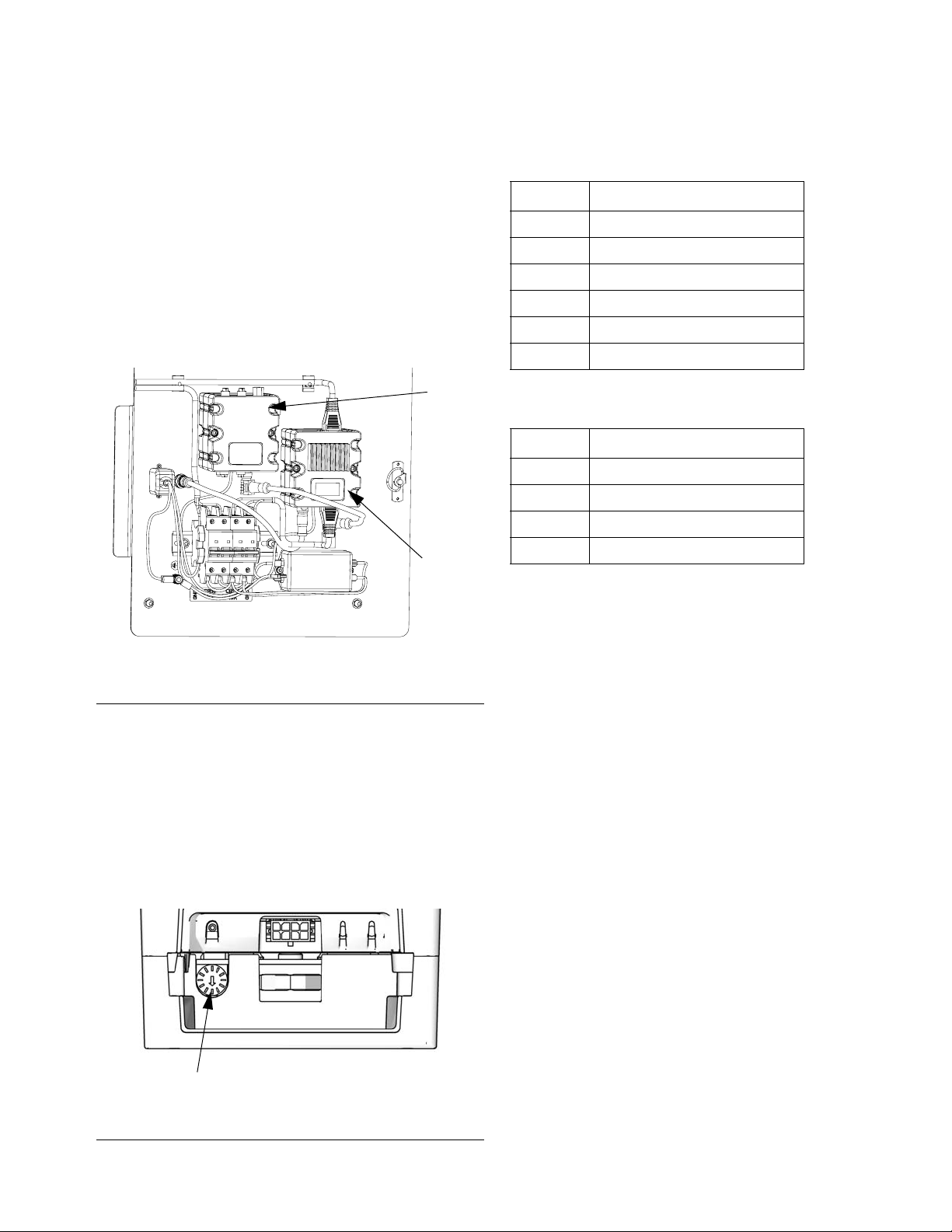

Component Identification . . . . . . . . . . . . . . . . . . . . 8

Tank Feed System . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Panel Components . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install Tank Stand . . . . . . . . . . . . . . . . . . . . . . . 12

Install Barrel Style Level Sensors . . . . . . . . . . . 12

Install Ultrasonic Level Sensor . . . . . . . . . . . . . 14

Install Chiller (customer supplied) . . . . . . . . . . . 14

Auto-Refill Installation: customer supplied feed

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Auto-Refill Installation: Graco supplied feed system

15

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Calibrate Barrel Style Level Sensors . . . . . . . . . 16

Vacuum De-gas . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pressure Relief Procedure . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . 18

Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . 18

Install Upgrade Tokens . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replace Agitator Fuse . . . . . . . . . . . . . . . . . . . 27

Tank Lid Gasket . . . . . . . . . . . . . . . . . . . . . . . . 27

Level Sensor and Well . . . . . . . . . . . . . . . . . . . 29

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . 30

Electrical Panel, Tank Stand with Agitator,

Heater/Chiller . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical Panel, Tank Stand with Agitator . . . . . 34

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

38L and 75L Tank Modules . . . . . . . . . . . . . . . . 37

2 Gallon Tank Module - 24J243 . . . . . . . . . . . . . 43

Heated Tank Assemblies . . . . . . . . . . . . . . . . . . 46

Tank Lid Assemblies . . . . . . . . . . . . . . . . . . . . . 47

Electrical Panel, 230V for Heat . . . . . . . . . . . . . 50

Electrical Panel, 230V for No Heat . . . . . . . . . . 51

Electrical Panel, 230V for 2 Gallon Tanks Only . 54

Heat Exchanger Assembly . . . . . . . . . . . . . . . . 56

Air Dryer Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Ball Valve Assemblies . . . . . . . . . . . . . . . . . . . . 58

Recirculation Probe Assembly . . . . . . . . . . . . . . 59

Transfer Pump Valve, 24C157 . . . . . . . . . . . . . . 60

Accessories and Kits . . . . . . . . . . . . . . . . . . . . . . . 61

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 68

2 3A0395R

Page 3

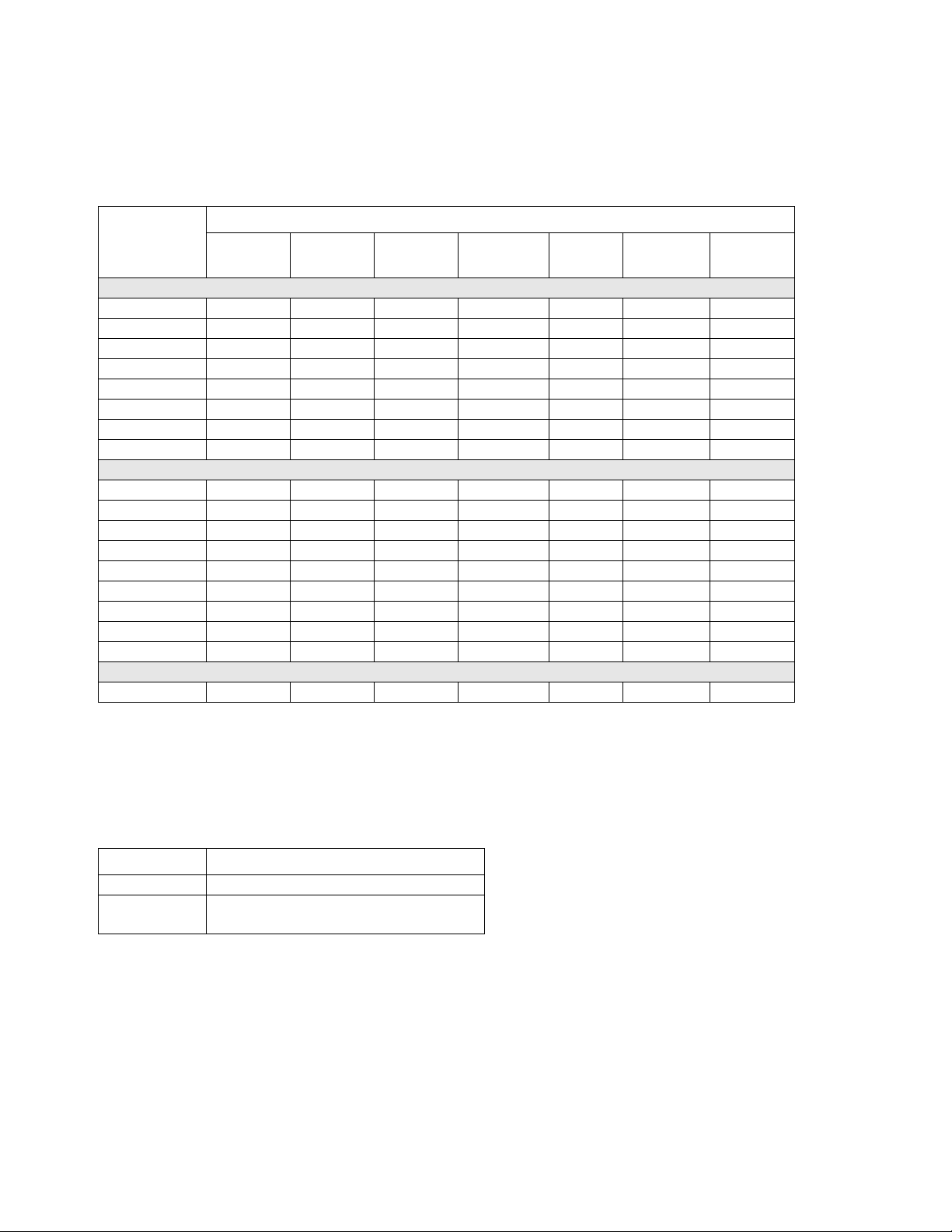

Models

The following table lists the tank stand module part numbers and the components included with each.

Includes:

Models

Part

24D562

24D564

24D568

24D569

24D570

24D571

24D572

24D573

24D565

24C317

24D574

24D575

24D576

24D577

24D578

24D579

24P091

24J243

Slinger

Agitator

✔✔✔✔

✔✔

✔✔ ✔

✔✔✔ ✔ ✔

✔✔✔ ✔

✔✔✔✔

✔✔

✔✔ ✔

✔✔✔ ✔ ✔

✔✔✔ ✔

✔✔✔✔✔

Plate Heat Insulation Chiller

46 Liter Tanks

✔✔ ✔

75 Liter Tanks

✔✔ ✔

7.5 Liter Tanks

Desiccant

Dryer

Level

Sensors

✔

✔

✔

Related Manuals

Component manuals listed below are in English. Manuals are available at www.graco.com.

Manual No.

3A1936 Pneumatic and Electric Agitator Kits

3A1962 Pneumatic and Electric Agitators with

3A0395R 3

Description

Heat Blanket Kits

Page 4

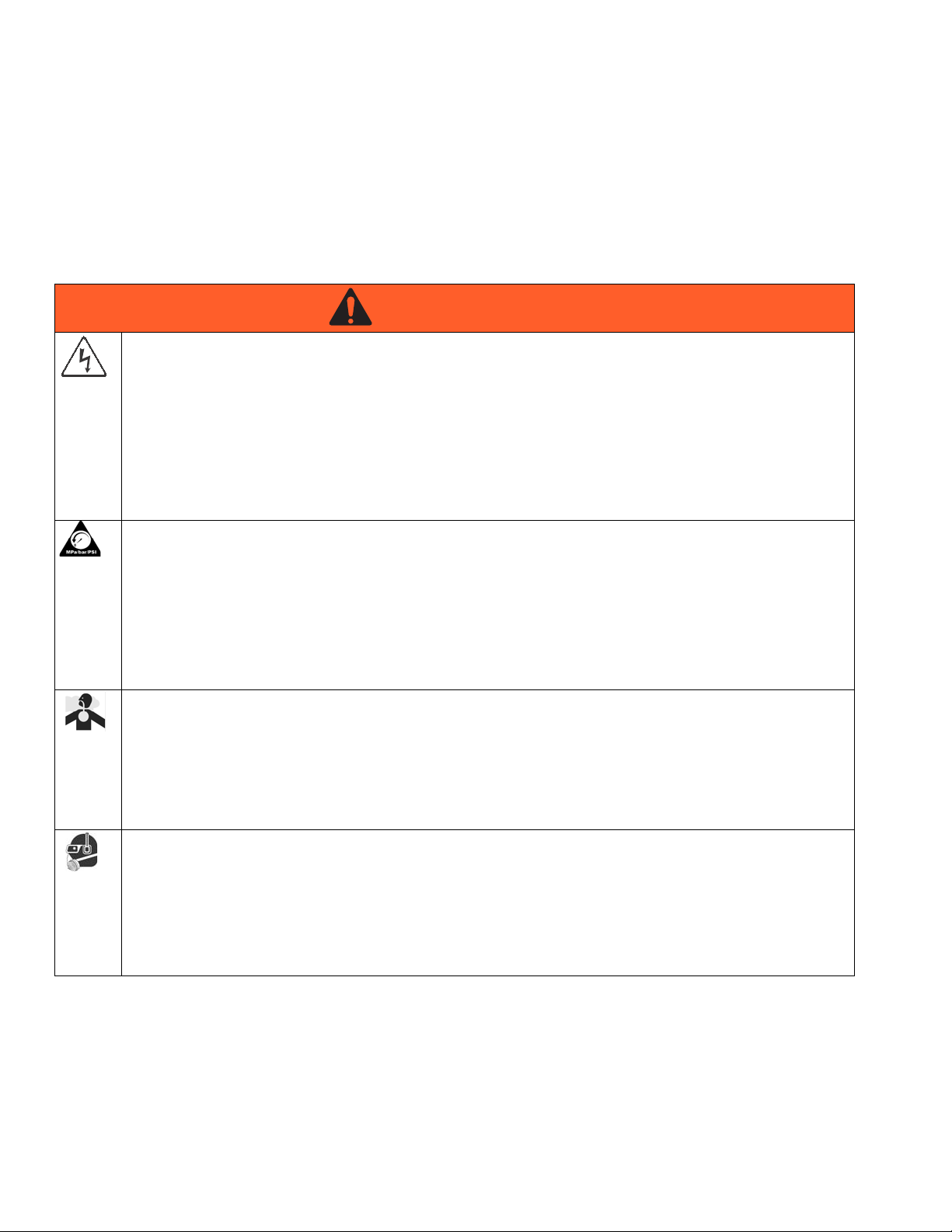

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

•Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or ser-

vicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

4 3A0395R

Page 5

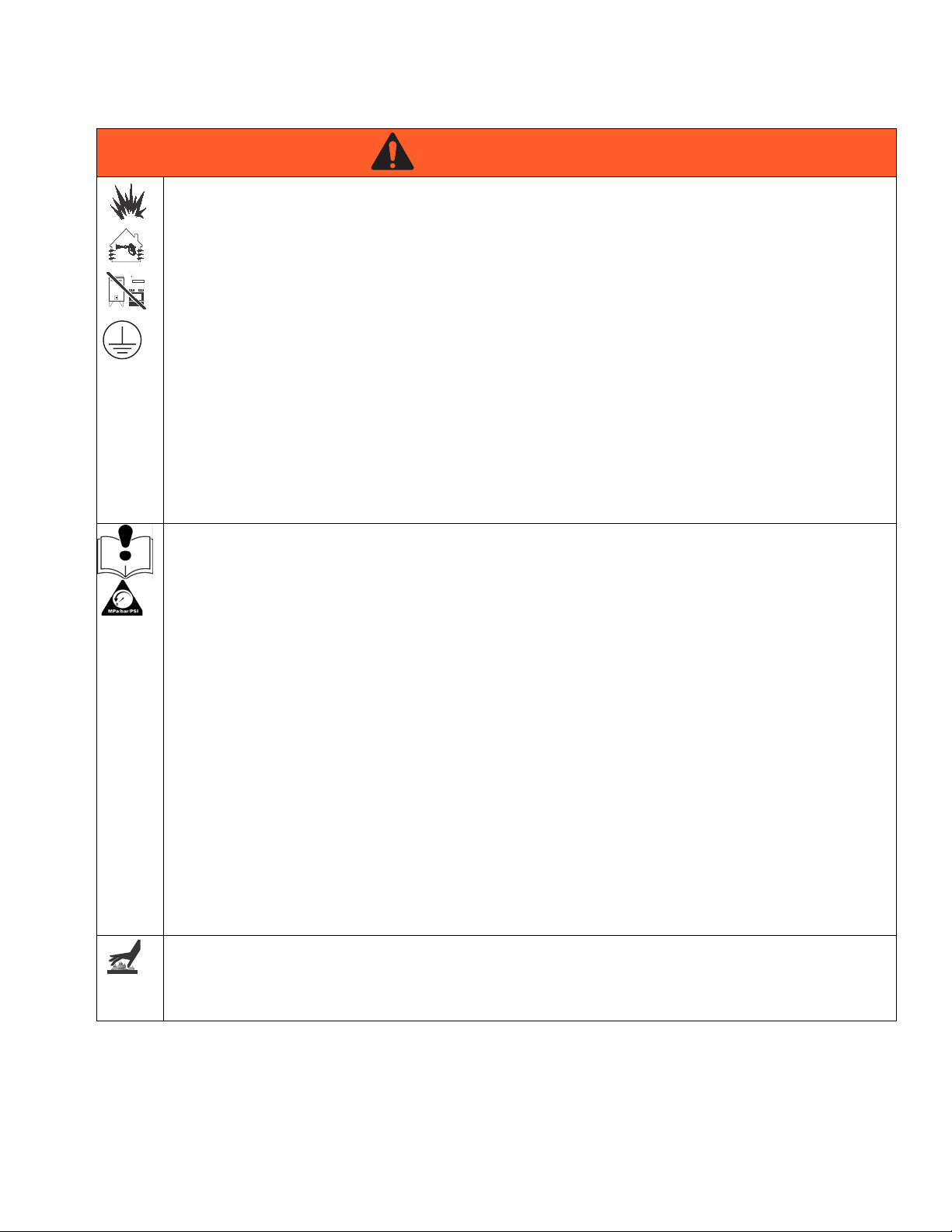

Warnings

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

3A0395R 5

Page 6

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Keep Components A and B

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid

206995. The lubricant creates a barrier between the

ISO and the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

™

(TSL™), Part

Separate

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage equipment. To prevent cross-contamination of

the equipment’s wetted parts, never interchange

component A (isocyanate) and component B (resin)

parts.

6 3A0395R

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Page 7

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

Important Two-Component Material Information

3A0395R 7

Page 8

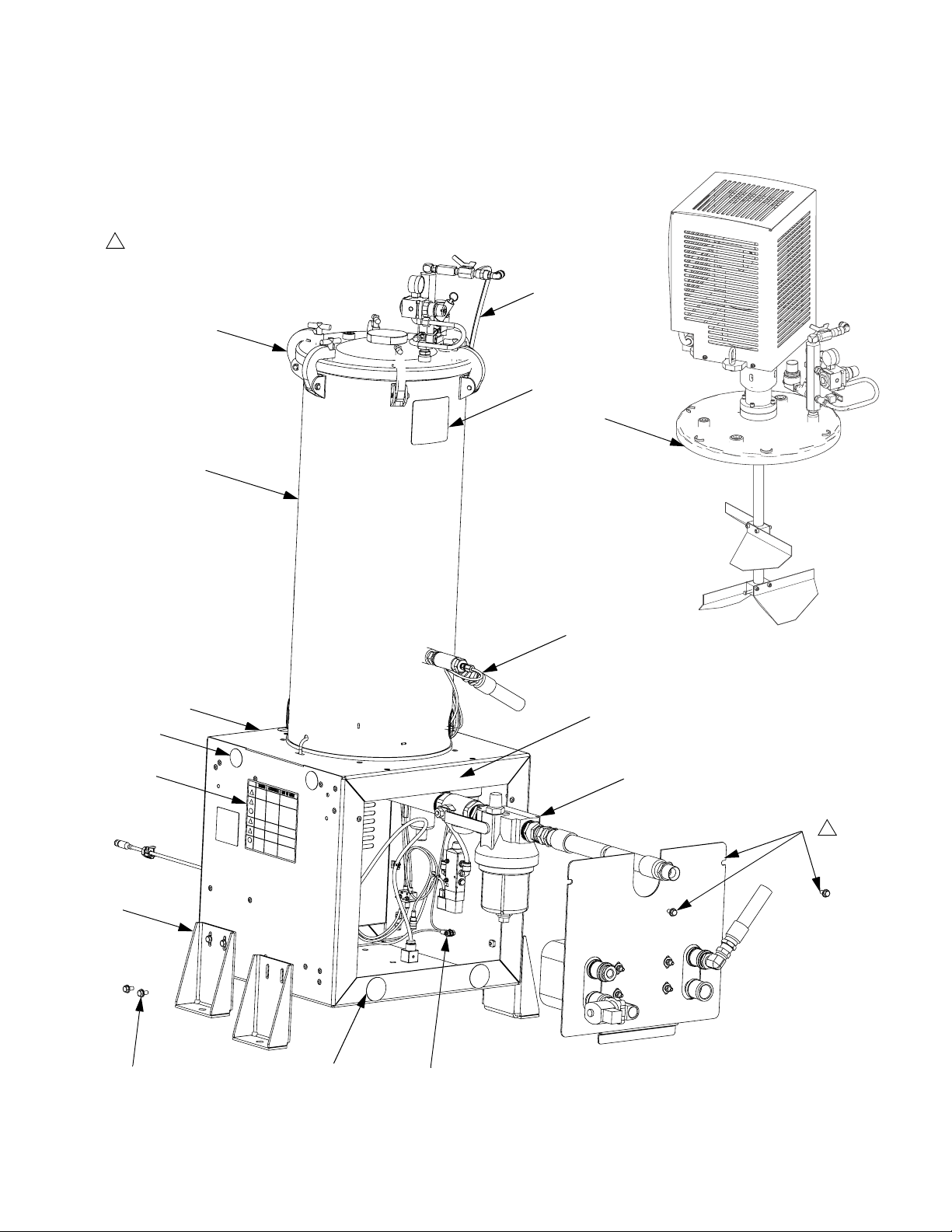

Component Identification

Component Identification

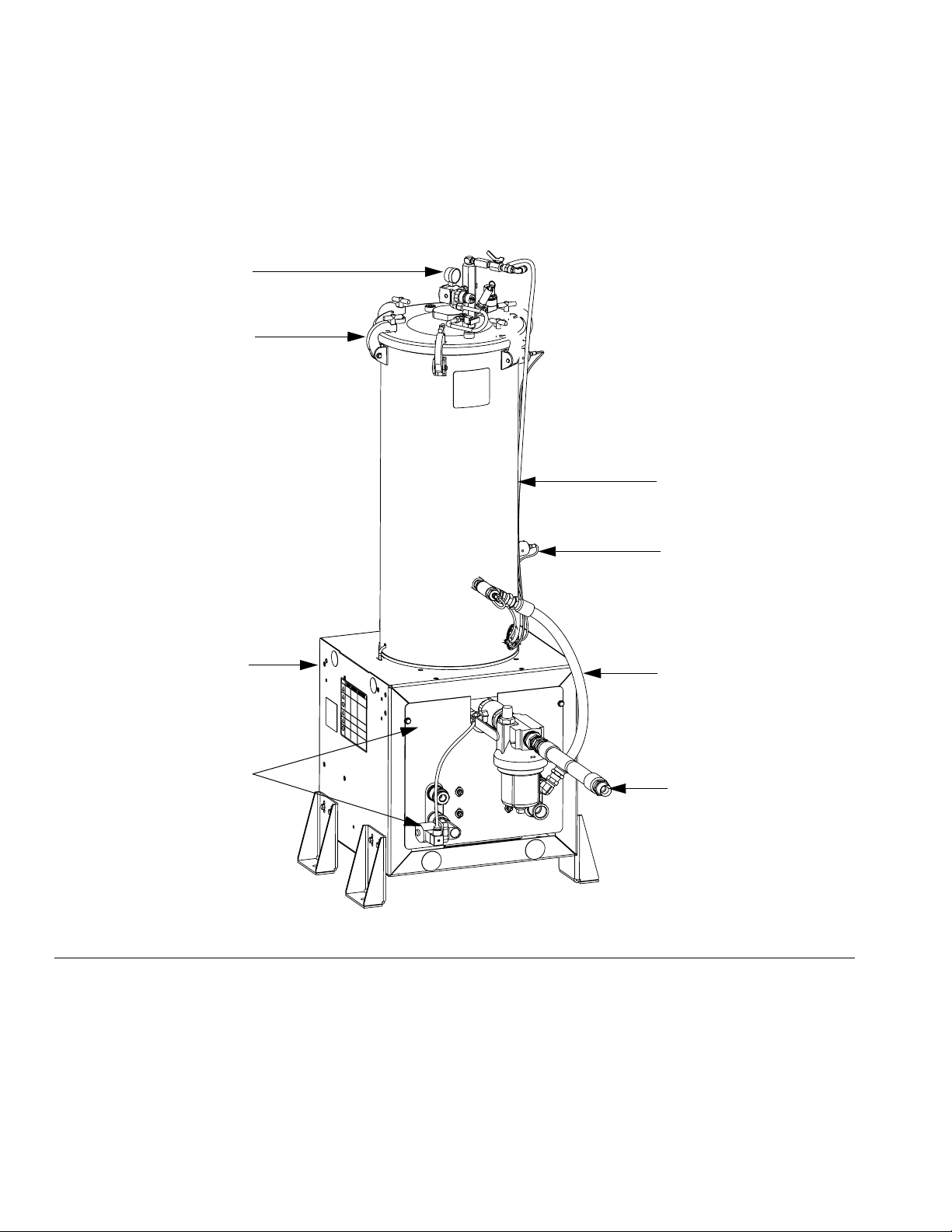

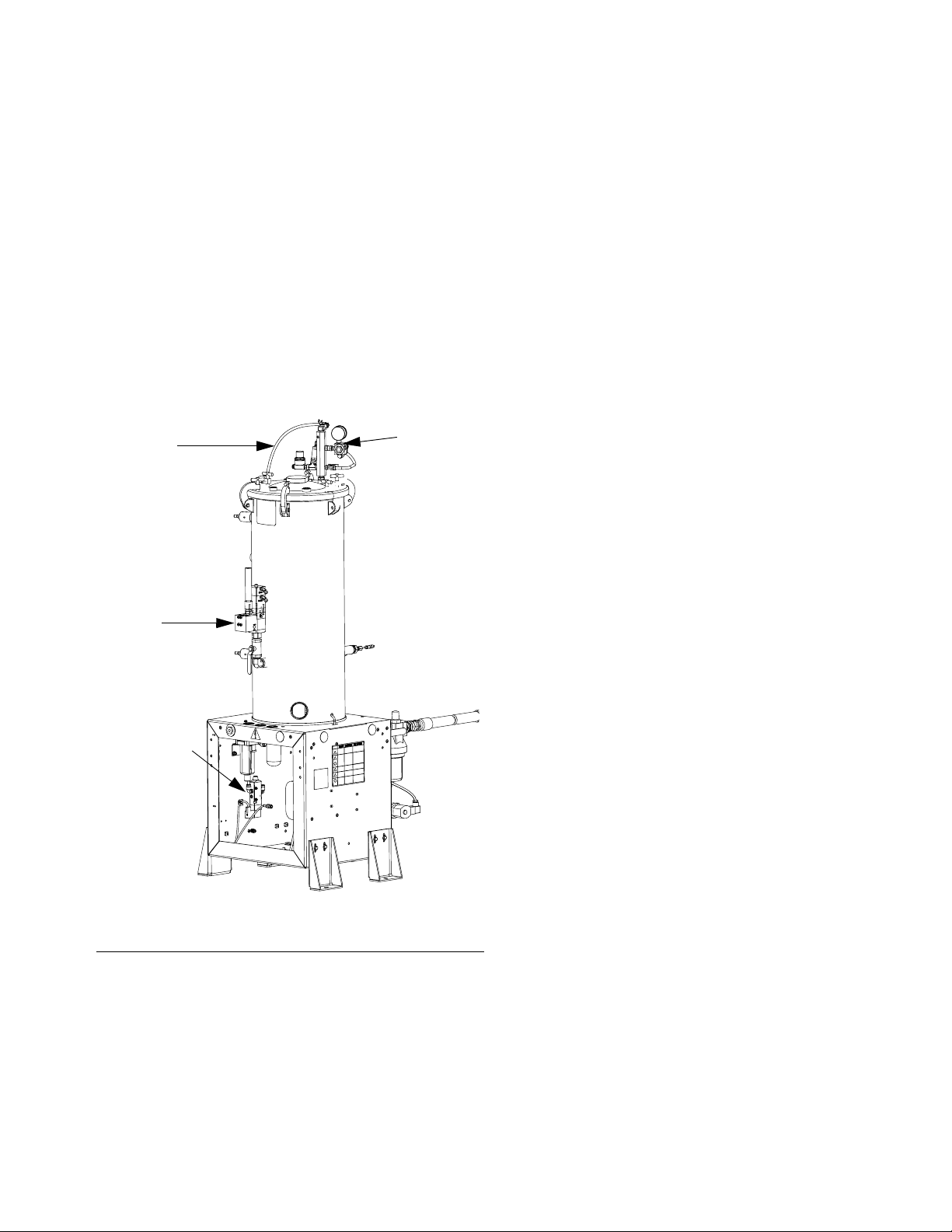

Tank Feed System

A

B

C

H

G

FIG. 1: Component Identification - Tank Feed System

Key:

A Air Pressure Gauge and Valve

B Lid or Lid with Agitator

CTank

D Material Valve

E Recirculation Probe Assembly

F Ball Valve Assembly

G Heat Exchanger Assembly

HEnclosure

J Level Sensors (not shown)

D

E

F

r_24C317_3A0395a_1c

8 3A0395R

Page 9

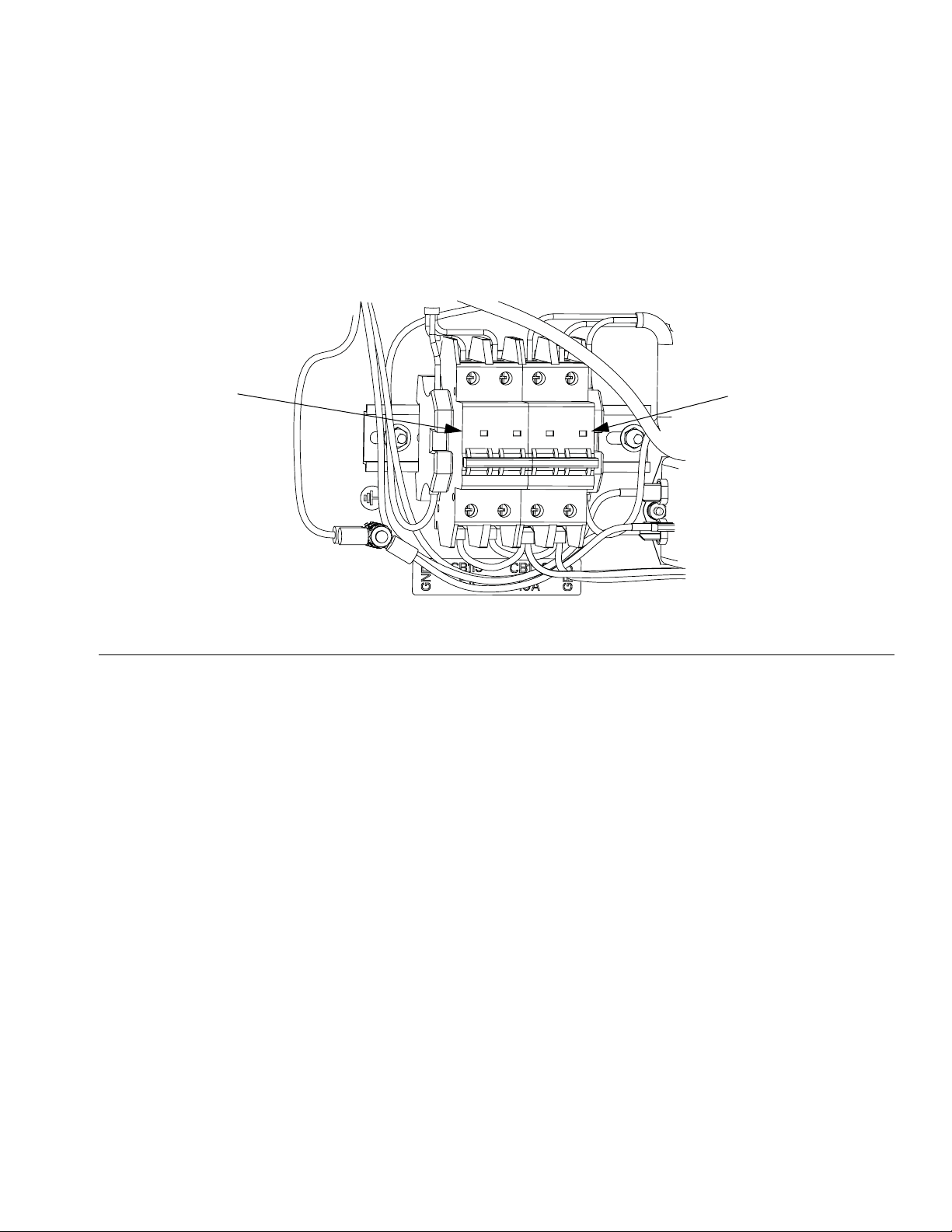

Electrical Panel Components

The electrical panel is located on the inside of the tank

stand enclosure, and includes the circuit breakers, a

fluid control module, and a low power temperature control module.

Circuit Breakers

Component Identification

CB115

FIG. 2: Component Identification - Circuit Breakers

Ref. Size Component

CB115 5A Agitator

CB130 10A Low power temperature control

module / heat blanket / chiller

CB130

3A0395R 9

Page 10

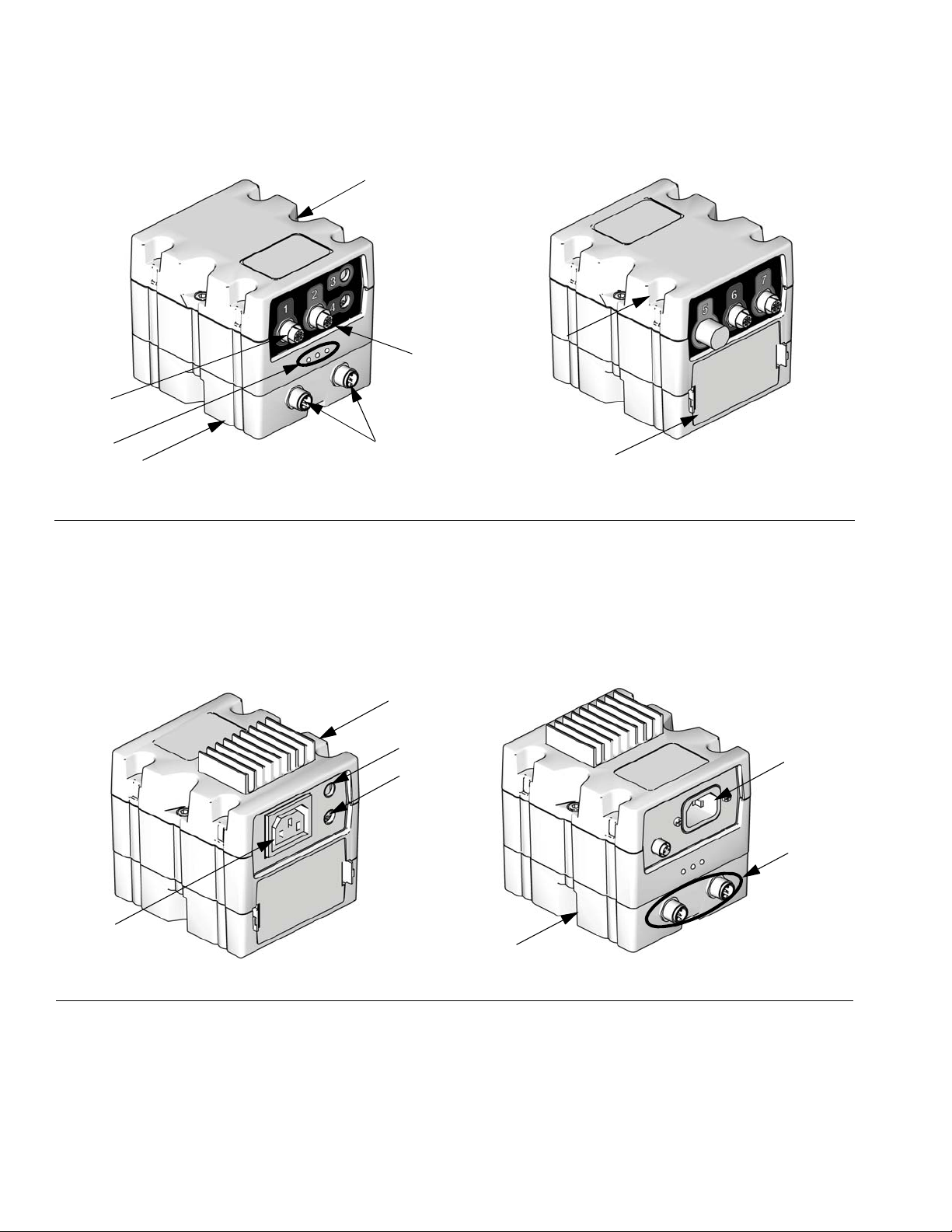

Component Identification

Fluid Control Module (FCM)

AA

AC

AH

AG

AE

ti12337a

AF

AB

FIG. 3: Component Identification - FCM

Key:

AA Fluid Control Module (FCM)

AB Base

AC Module Connection Screws

AD Access Cover

Low Power Temperature Control Module

BA

ti12336a

AD

AE Module Status LEDs

AF CAN Connectors

AG Level Sensor Input

AH Fill Solenoid Signal

BG

BD

BB

BE

BC

ti12356a

BF

ti12357a

FIG. 4: Component Identification - Low Power Module

Key:

BA Low Power Module

BB RTD Temperature Sensor Connection (for chiller or for

RTD in bottom of tank when using a heated blanket)

BC Output Power Connection

10 3A0395R

BD Input Power Connection

BE CAN Connectors

BF Base

BG RTD Temperature Sensor Connection (for RTD under

heated blanket)

Page 11

Component Identification

Heat Zone and Fluid Control Selection

The tank feed system supports independent temperature control by utilizing a low power temperature control

module. The system also supports fluid control by utilizing an FCM. Both the low power temperature control

module and the FCM are located on the electrical panel

within the enclosure.

NOTE: Tank stands are configured for the A (Red)

side. Adjust rotary switch setting if tank is being

used on B (Blue) side.

FCM

Low

Power

Te mp

Control

Low Power Temperature Control Module Rotary Switch

Settings

Setting Zone

0-4 Not Used

5 B (Blue) Tank Heater

6 A (Red) Tank Heater

7 B (Blue) Chiller

8 A (Red) Chiller

9-F Not Used

FCM Rotary Switch Settings

Setting Zone

0-2 Not Used

3 B (Blue) Tank Refill

4 A (Red) Tank Refill

5-F Not Used

r_24C169_3A0395_1a

FIG. 5: Electrical Panel

Adjust Rotary Switch

The rotary switch setting indicates which zone the temperature control module will control in the system. The

low power module and FCM use a 16-position rotary

switch to make selections.

Set the rotary switch to the specific selection according

to the settings listed in the following tables.

Rotary Switch

ti12361a

FIG. 6: Adjust Rotary Switch

3A0395R 11

Page 12

Installation

Installation

Grounding

Products that include heated tanks must be grounded.

Grounding reduces the risk of static and electric shock

by providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

Improper installation of the grounding plug increases the

risk of electric shock. Do not modify the plug provided; if

it does not fit the outlet, have the proper outlet installed

by a qualified electrician. Only connect the product to an

outlet having the same configuration as the plug. Do not

use an adapter with this product.

Install Tank Stand

1. Install the tank stand no more than 6 ft. (1.8 m) from

the rear of the material pumps on the HFR system.

2. Anchor the tank stand to the floor. (Suggested

anchors: McMaster-Carr anchor, 92403A400.) See

Dimensions, page 66.

3. Plug the tank stand power cable into the bottom of

the HFR power distribution box.

4. Plug the tank stand CAN cable into the CAN splitter

inside the distribution box.

NOTE: Tank stands are configured for the A (Red)

side. Adjust rotary switch setting if tank is being

used on B (Blue) side.

Install Barrel Style Level Sensors

1. Turn main power off.

2. Relieve tank air pressure. See Pressure Relief Pro-

cedure, page 17.

3. Drain tanks below the lowest level sensor well.

If installing high temperature level sensors:

4. Apply PTFE paste and PTFE tape to the male

threads of the level sensor.

5. Being careful to not cross-threads, thread the level

sensor (CB) into the corresponding tank port.

NOTICE

To avoid improper operation, ensure the mark (dot

or arrow) found on the hex of the level sensor is

pointing towards the top or bottom of the machine

after tightening.

6. Plug the sensor cable adapter into the level sensor.

7. Plug the sensor connector (CD) into the level sensor

adapter.

8. Plug the sensor connector into the connector on the

FCM.

If installing low temperature level sensors:

NOTE: For proper level sensor function, the tip of

the level sensor well must protrude at least 1/8 in.

into the tank (C).

12 3A0395R

Page 13

Installation

9. Route each level sensor (H) wire (J1, J2, J3)

through the corresponding well nut (CC). See F

IG. 8

for wire location on tank.

CA

CB

CC

Wires

CD

r_24b969_3A0395a_7a

FIG. 7: Level Sensor Assembly

10. Measure the length of the level sensor well housing,

and then measure the depth of the hole in the tank

where the well is inserted. Note these measurements as they will be need later.

11. Being careful to not cross-threads, thread assembled level sensor (CB) into well housing until it bottoms out against the bottom of the well. The bottom

of the level sensor will be slightly visible through the

bottom of the well.

NOTE: In the following step, do not allow PTFE

paste or tape to cover the tip of the level sensor

well. If paste comes in contact with the tip of the

level sensor well, thoroughly wipe it clean.

13. Being careful to not cross-threads, thread the level

sensor well (CA) into the corresponding tank port

and lightly tighten with a crescent wrench.

J3

J2

J1

FIG. 8: Tank Ports

14. Measure the amount of the level sensor well housing that is visible beyond the day tank hole, then

perform the following equation:

P = L1 - (L2 + L3)

P = Protrusion length (inside of day tank)

L1 = Length of level sensor well

L2 = Visible length of level sensor well

L3 = Length of well threads in day tank

15. The protrusion length must be at least 1/8 in.

(3.2 mm). If not, remove the level sensor well and

restart at step 10.

16. Rotate level sensor to optimal position for wire routing.

12. Apply PTFE paste and PTFE tape to the male

threads of the level sensor well housing.

17. Plug the sensor connector (CD) into the level sensors.

Ensure the level sensors are installed in the sensor

well housings before pressurizing the tank. Failing to

do so could cause the well housings to rupture, which

may result in serious injury and material leakage.

18. Plug the sensor connector into the connector on the

FCM.

19. Calibrate the sensor. See Calibrate Barrel Style

Level Sensors, page 16.

3A0395R 13

Page 14

Installation

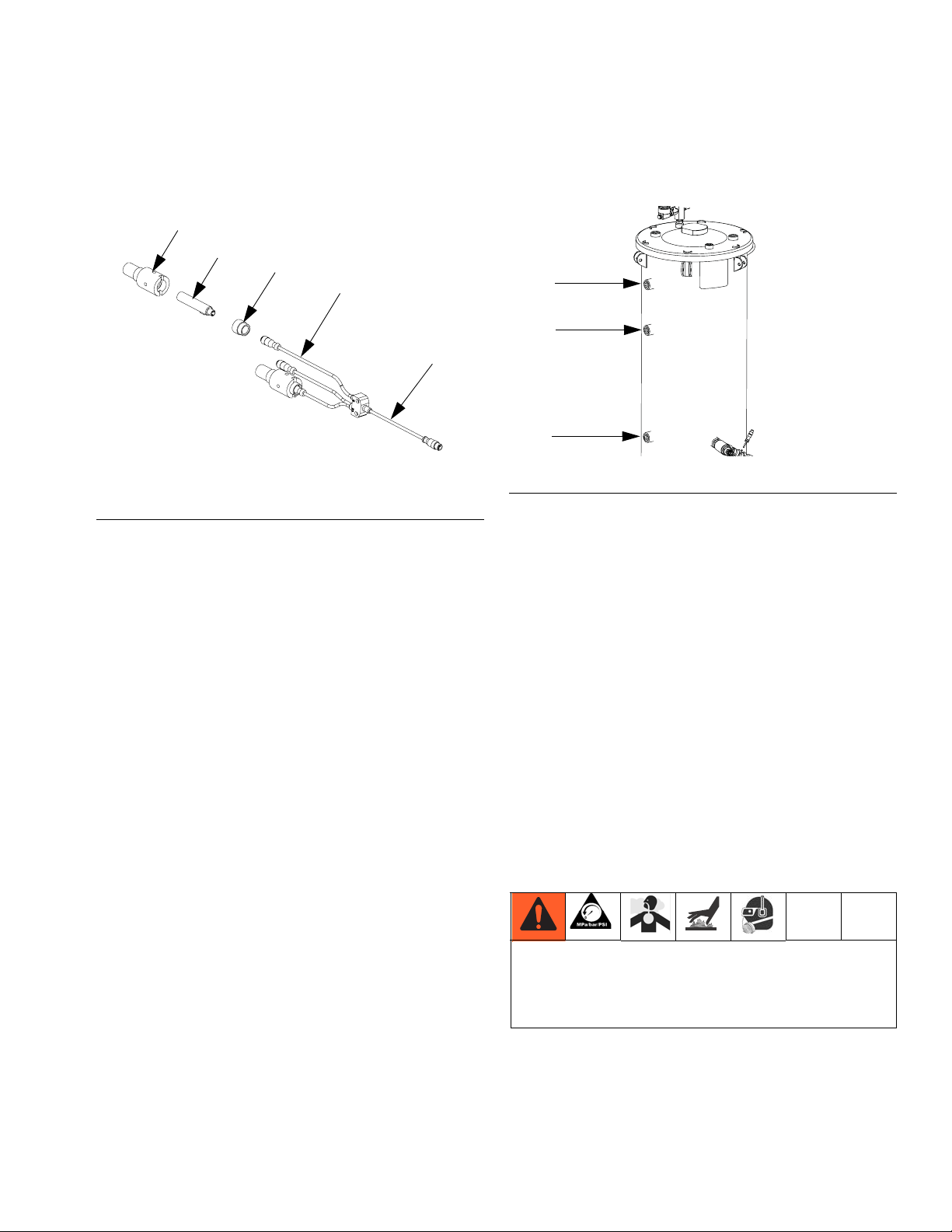

Install Ultrasonic Level Sensor

NOTE: The ultrasonic level sensor is only used on two

gallon tanks.

1. Turn main power off.

2. Relieve tank air pressure. See Pressure Relief Pro-

cedure, page 17.

3. Drain tank.

4. Remove the tank lid (DA).

5. Insert the o-ring (DB) and sensor well housing (DC)

into the tank port.

DE

DC

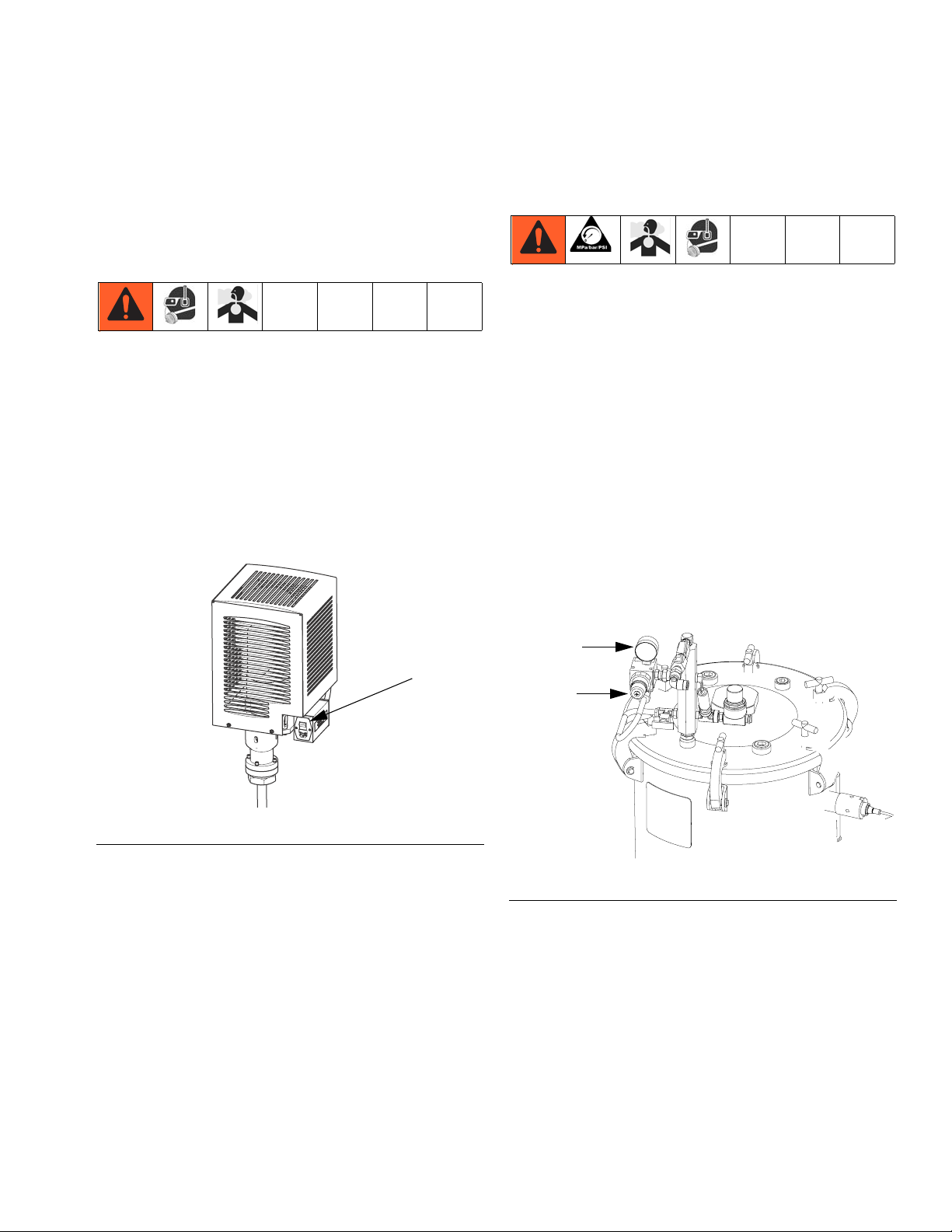

Install Chiller (customer supplied)

The following instructions apply to tank modules

(24C317, 24D562, 24D564, 24D565) that include the

heat exchanger assembly (G).

NOTE: Graco does not supply the chiller assembly.

1. Connect incoming water to inlet heat exchanger

port.

2. Connect outgoing water to outlet heat exchanger

port.

DB

DA

DD

ti17772a

FIG. 9: Ultrasonic Level Sensor

6. Tighten the jam nut (DD) to ensure there will not be

any air leakage.

7. Hand tighten the level sensor (DE).

8. Plug the sensor connector into the connector on the

FCM.

r_24C317_3A0395a_1c

Water Outlet

FIG. 10: Level Sensor Assembly

3. Configure the advanced display module (ADM) for

the chiller option. See the HFR Setup-Operation

manual for instructions.

Water Inlet

14 3A0395R

Page 15

Installation

Auto-Refill Installation: customer supplied feed system

NOTE: The auto-refill assembly is not assembled

when shipped.

1. Empty tank (C).

2. Remove plug from lower, rear of tank.

3. Install auto-refill assembly in 3/4 npt port.

4. Connect hose (not supplied) to 1/2 npt port on

material valve.

Air Valve

Air Line

Auto-Refill Installation: Graco supplied feed system

NOTE: The auto-refill assembly is not assembled

when shipped.

1. Empty tank (C).

2. Remove plug from lower, rear of tank.

3. Connect feed pump outlet hose to tank.

4. Connect air lines from air valve to feed pump.

5. Connect main air line to air valve.

Material

Valve

Air Solenoid

Valve

r_24C317_3A0395a_10b

FIG. 11: Tank Assembly

5. Connect air lines from air valve (A) to material valve

(D).

6. Connect main air line to air valve.

3A0395R 15

Page 16

Setup

Setup

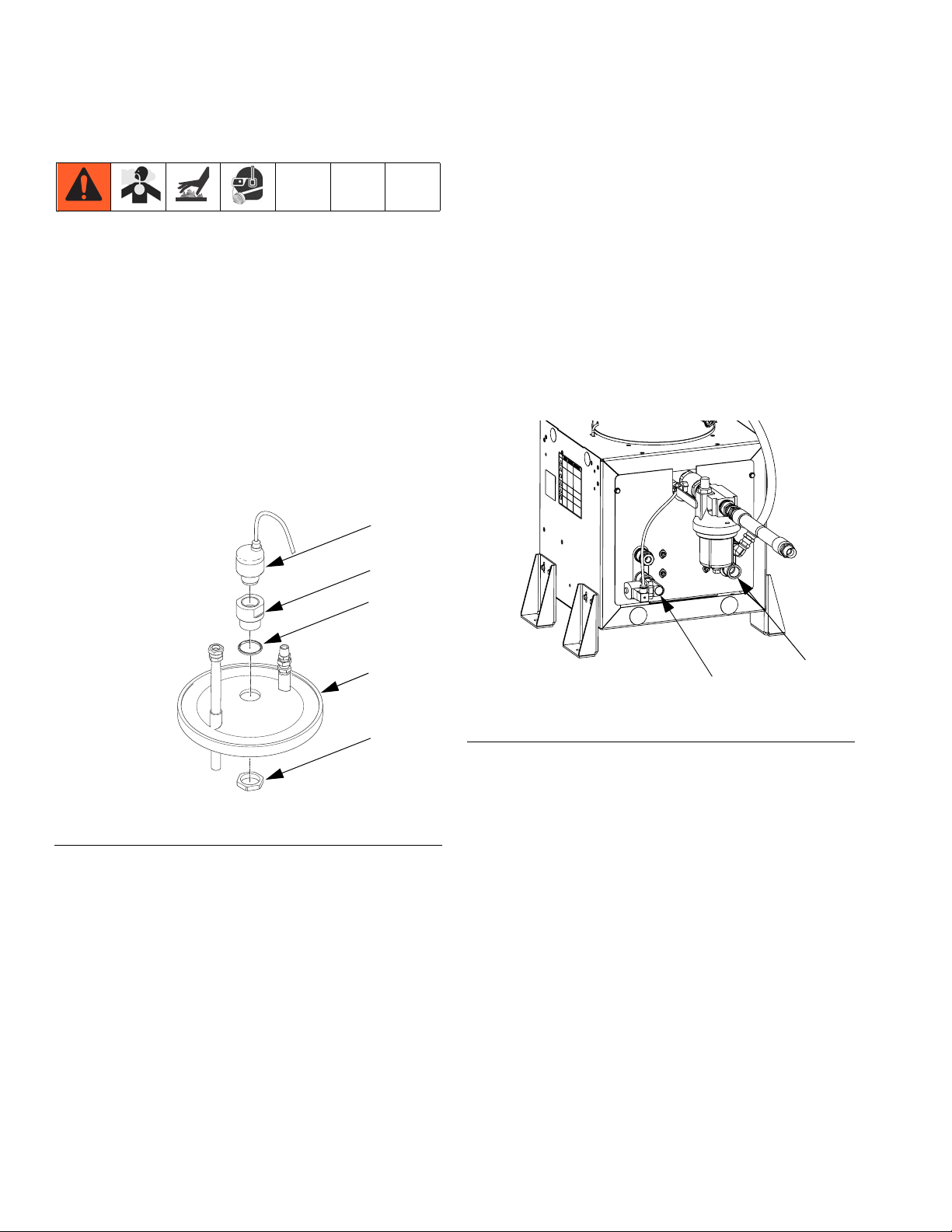

Calibrate Barrel Style Level Sensors

NOTE: Calibration is not required for ultrasonic

style level sensors or high temperature level sensors.

1. Locate the calibration button on the sensor (11)

closest to the electrical connector through one of

the four holes of the sensor well housing (CA).

2. If the calibration button cannot be seen through one

of the four holes in the sensor well, rotate the sensor.

a. Loosen the sensor well nut (CC).

b. Rotate sensor until the calibration button can be

seen through one of the four holes in the sensor

well housing.

2. Close the shut-off ball valves at the base of the

tanks.

3. If the tank lid has a fill port, turn off any systems that

might refill the tank during the vacuum de-gas procedure.

4. Close the fill port ball valve.

5. If the tank lid requires a desiccant dryer, install it into

the top ball valve of the vacuum tree manifold.

6. Close the top ball valve of the vacuum tree manifold.

7. Attach vacuum pump to the bottom ball valve of the

vacuum tree manifold. Open the ball valve.

8. Turn on the vacuum pump.

9. Continue to de-gas the material.

10. Close bottom ball valve of the vacuum tree manifold.

11. Turn off the vacuum pump.

12. Open the top ball valve of the vacuum tree manifold.

c. Tighten sensor well nut.

d. Press and hold the button down with the ball

end of an allen wrench for two seconds. The

light will flash slowly and then go out.

3. Test for proper sensor function.

a. Loosen the sensor well nut.

b. Back the sensor out of the well. The sensor

should sense the tank wall.

Vacuum De-gas

NOTE: Only perform the following procedures for

tank volumes other than two gallons.

1. Shut down the HFR system. Refer to the HFR

Setup-Operation manual for instructions.

NOTICE

Operating the tank after the vacuum de-gas procedure without the top ball valve open will result in

pump cavitation, off-ratio conditions, and possible

collapse of the tank.

13. Open the shutoff valves at the base of the tanks.

16 3A0395R

Page 17

Operation

Operation

See HFR Setup-Operation manual for system operation

instructions.

Startup

Start System

See HFR Setup-Operation manual for system startup

instructions.

Start Agitation

Press agitator manual switch on and off to start agitation.

Pressure Relief Procedure

NOTE: Relieving air pressure in the machine means

that the supplied dry air will be replaced by moist

air. Do not leave the machine exposed to moist air

for more than 30 minutes. If the machine must be

left without air pressure for more than 30 minutes,

the day tanks must first be emptied and thoroughly

flushed.

1. Turn off main power.

2. Close day tank incoming air supply valve.

3. Disconnect pressurized air supply hose from water

separator.

4. Open the pressure relief valve on top of each day

tank to bleed air pressure from system.

FIG. 12: Agitator Switch

ti17620a

Switch

Pressure

Gauge

Pressure

Relief

Valve

FIG. 13: Tank Pressure Relief

5. Ensure there is no air pressure in the tanks; look at

the pressure gauges.

3A0395R 17

Page 18

Maintenance

Maintenance

Daily Maintenance

Desiccant Dryer

Replace silica gel units when the desiccant color or

moisture indicator has changed color from Blue (meaning dry) to Pink (meaning wet).

1. Turn off and depressurize the line containing the

dryer unit.

2. Loosen the camp ring and remove the bowl from the

top housing.

3. Pour out used desiccant.

4. Open new container and refill bowl

5. Shake or tap bowl to settle desiccant. Add or

remove desiccant until it is 1/8 in. below the inner

step of the bowl.

Air Filter (123377)

1. Drain water separator if necessary.

2. Pressurize the air system.

3. If desired, place a container underneath water separator to catch water.

4. Push purge valve.

5. Release valve when filter is empty.

Replacement Filters

• 108111 – 30 stainless steel mesh

• 108112 – 60 stainless steel mesh

• 108113 – 100 stainless steel mesh

• 108114 – 200 stainless steel mesh

• 108115 – 150 stainless steel mesh

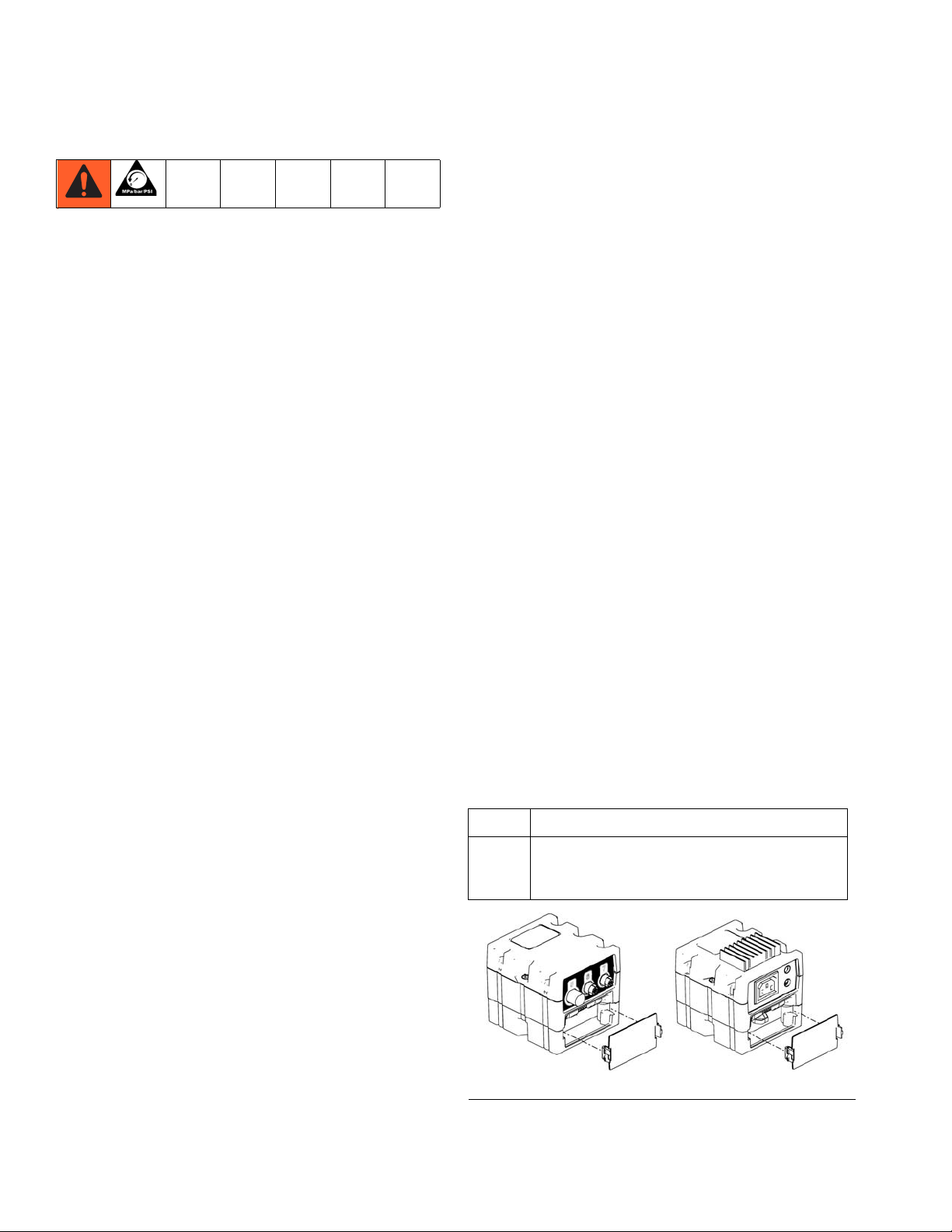

Install Upgrade Tokens

NOTE: The Fluid Control Module and Temperature Con-

trol Module connection to the system is temporarily disabled during the installation of upgrade tokens.

To install software upgrades:

1. Use correct software token stated in the table. See

Graco Control Architecture

manual for instructions.

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module (System Settings, USB Logs,

Recipes, Maintenance Counters) may be reset to

factory default settings. Download all settings and

user preferences to a USB before the upgrade, for

ease of restoring them following the upgrade.

See manuals for locations of specific GCA components.

The software version history for each system can be

viewed in the technical support section at

www.graco.com.

™

Module Programming

Weekly Maintenance

Material Filter (213062)

The red alert filter indicator provides gradual warning of

a dirty element. When the indicator displays as 3/4 red,

clean the element. If the element is not cleaned

promptly, the filter bypass valve opens and fluid will not

be filtered.

To clean the element:

1. Clean the filter element with a small paint brush.

2. Use air to blow out lodged particles.

3. Inspect for damage.

4. Replace if ruptured. See manual 307283.

18 3A0395R

Token Application

16G584 Tank St and:

- Fluid Control Module

- Low Power Temperature Control Module

ti12334a1

F

IG. 14: Remove Access Cover

ti12358a1

Page 19

Troubleshooting

Problem Cause Solution

Troubleshooting

No agitation. Agitator motor is not turning.

Intermittent electrical connections.

Ensure the system main power is

ON.

Ensure all electrical connections to

the motor are secure. See electrical

schematic in either the HFR

Repair-Parts manual.

Check fuse at agitator switch.

Check if motor circuit breaker in

base cube has tripped. See electrical schematic in either the HFR

Repair-Parts manual.

Check if tank stand circuit breaker in

power distribution module has

tripped. See electrical schematic in

either the HFR Repair-Parts manual.

Replace motor.

No vacuum suction in tank. Vacuum pump is not functioning.

Vacuum lines damaged or leaking.

3A0395R 19

Check power cord from wall.

Ensure vacuum pump power is ON.

Ensure connections from vacuum

line to tank lid are secure.

Ensure there are no kinks or links in

vacuum line to tank lid.

Replace vacuum pump.

Page 20

Troubleshooting

Problem Cause Solution

Material is not heating. Blanket heater not working.

Intermittent electrical connections.

Material temperature variations.

FCM errors.

Ensure the system main power is

ON.

Ensure all electrical connections to

the blanket heater are secure. See

electrical schematic in either the

HFR Repair-Parts manual.

Ensure the tank RTD connections

are secure. See electrical schematic in either the HFR

Repair-Parts manual.

Check if FCM circuit breaker has

tripped. See electrical schematic in

either the HFR Repair-Parts manual.

Check if tank stand circuit breaker in

™

GMS

power distribution box has

tripped. See electrical schematic in

either the HFR Repair-Parts manual.

Check FCM. A red LED indicates a

problem with the module. See electrical schematic in either the HFR

Repair-Parts manual.

Replace tank RTD.

Replace blanket heater RTD.

Replace blanket heater.

Replace FCM

20 3A0395R

Page 21

Problem Cause Solution

Troubleshooting

Material is not cooling. Chiller control solenoid not working.

Intermittent electrical connections.

Material temperature variations.

FCM errors.

Ensure the system main power is

ON.

Ensure all electrical connections to

the chiller control solenoid are

secure. See electrical schematic in

either the HFR Repair-Parts manual.

Ensure the tank RTD connections

are secure. See electrical schematic in either the HFR

Repair-Parts manual.

Check FCM circuit breaker in base

cube to see if it has tripped. See

electrical schematic in either the

HFR Repair-Parts manual.

Check tank stand circuit breaker in

GMS power distribution box to see if

it has tripped. See electrical schematic in either the HFR

Repair-Parts manual.

Check FCM. A red LED indicates a

problem with the module. See electrical schematic in either the HFR

Repair-Parts manual.

Replace tank RTD.

Replace chiller control solenoid.

Replace FCM.

3A0395R 21

Page 22

Troubleshooting

Problem Cause Solution

Level sensor is not sensing material

when material is present.

Level sensor is sensing material

when material is not present.

Level sensors out of calibration.

Level sensors blocked inside tank.

Intermittent electrical connections.

FCM errors.

Ensure the system main power is

ON.

Calibrate level sensor.

Check inside tank to ensure there is

nothing blocking the level sensor.

Ensure all electrical connections to

the level sensor are secure. See

electrical schematic in either the

HFR Repair-Parts manual.

Check FCM circuit breaker in base

cube to see if it has tripped. See

electrical schematic in either the

HFR Repair-Parts manual.

Check tank stand circuit breaker in

GMS power distribution box to see if

it has tripped. See electrical schematic in either the HFR

Repair-Parts manual.

Check FCM. A red LED indicates a

problem with the module. See electrical schematic in either the HFR

Repair-Parts manual.

Replace level sensor.

Replace FCM.

22 3A0395R

Page 23

Problem Cause Solution

Troubleshooting

Tank is not refilling. Air solenoid valve not operating.

Leaking or damaged air lines.

Intermittent electrical connections.

Level sensors out of calibration.

Supply/feed system is off or empty.

Check the material supply feed to

the tank.

Check inside tank to ensure there is

nothing blocking the level sensor.

Ensure the main air to tank connections are secure.

Ensure the air lines from the air

solenoid valve to the fill valve or

feed pump are securely connected

and that there are no leaks.

Ensure all electrical connections to

the air solenoid valve are secure.

See electrical schematic in either

the HFR Repair-Parts manual.

Ensure the air solenoid valve is

operating by removing the outgoing

air line to determine if air is flowing.

Check FCM. A red LED indicates a

problem with the module. See electrical schematic in either the HFR

Repair-Parts manual.

Replace air solenoid valve.

Replace level sensor.

Replace fill valve.

Replace feed pump.

Replace FCM.

3A0395R 23

Page 24

Troubleshooting

Problem Cause Solution

Tank is overfilling. Level sensors out of calibration.

Level sensors blocked inside tank.

Intermittent electrical connections.

Calibrate level sensors.

Check inside tank to ensure there is

nothing blocking the level sensor.

Ensure the main air to tank connections are secure.

Ensure the air lines from the air

solenoid valve to the fill valve or

feed pump are securely connected

and that there are no leaks.

Ensure all electrical connections to

the air solenoid valve are secure.

See electrical schematic in either

the HFR Repair-Parts manual.

Ensure the air solenoid valve is

operating by removing the outgoing

air line to determine if air is flowing.

Check FCM. A red LED indicates a

problem with the module. See electrical schematic in either the HFR

Repair-Parts manual.

Replace air solenoid valve.

Replace level sensor.

Replace fill valve.

Replace feed pump.

Replace FCM.

24 3A0395R

Page 25

Problem Cause Solution

Troubleshooting

System is not circulating material. Bypass valve damaged or not oper-

ating.

Material hoses incorrectly connected.

Material hose leakage.

Ensure the system main power is

ON.

Ensure the main air to tank connections are secure.

Ensure the air lines from the bypass

air solenoid valve to the bypass

valve are securely connected and

that there are no leaks.

Ensure all electrical connections to

the bypass air solenoid valve are

secure. See electrical schematic in

either the HFR Repair-Parts manual.

Ensure the bypass air solenoid

valve is operating by removing the

outgoing air line to determine if air is

flowing.

Check FCM. A red LED indicates a

problem with the module. See electrical schematic in either the HFR

Repair-Parts manual.

Check tank stand circuit breaker in

GMS power distribution box to see if

it has tripped. See electrical schematic in either the HFR

Repair-Parts manual.

Replace bypass valve.

Replace bypass air solenoid valve.

3A0395R 25

Page 26

Troubleshooting

Problem Cause Solution

Tank stand module is not communicating with system.

Intermittent electrical connections.

FCM errors.

Ensure the system main power is

ON.

Ensure power disconnect on base

cube is ON.

Ensure all power and communication connections from the GMS system to the tank stand are secure.

See electrical schematic in either

the HFR Repair-Parts manual.

Check tank stand circuit breaker in

GMS power distribution box to see if

it has tripped. See electrical schematic in either the HFR

Repair-Parts manual.

Check FCM. A red LED indicates a

problem with the module. See electrical schematic in either the HFR o

Repair-Parts manual.

Replace power cable.

Replace communications cable.

26 3A0395R

Page 27

Repair

Repair

Replace Agitator Fuse

1. Turn off main power.

2. Slide open the fuse drawer.

3. Remove old fuse and replace with new fuse.

Fuse Drawer

and Fuse

ti17620a

FIG. 15: Agitator Fuse

Tank Lid Gasket

NOTE: If the tank includes an agitator, use a capable

hoist to lift the tank lid and agitator assembly out of

the day tank.

Tools/Supplies Required:

• Hoist (if an agitator is installed)

• Drop cloth

• Crescent wrench

• 3 ft. x 3 ft. air tight plastic sheet and removable tape

•Screwdriver

• Lithium o-ring grease

1. Turn off main power.

2. Relieve tank air pressure. See Pressure Relief Pro-

cedure, page 17.

3. Use a drop cloth to set the tank lid assembly on.

4. Remove pressurized air supply tubing from tank air

pressure inlet. Press on locking collar and pull out

the tube.

5. Use a crescent wrench to loosen all of the bolts

(CE) on the tank lid (B) in a cross-wise pattern.

3A0395R 27

Page 28

Repair

6. Lift the tank lid assembly (B) off of the tank and set

on the drop cloth.

NOTICE

Damage to the level sensors may occur when there

is an agitator installed and the lid is removed. To

avoid damage to level sensors, remove the tank lid

assembly while keeping the agitator away from the

level sensor assemblies.

CE

B

CG

7. Use an air tight plastic sheet and removable tape to

cover the day tank opening. Tape the sheet in place.

8. Use a screwdriver to remove the tank lid gasket

(CG, part 117571) from the groove on the bottom of

the tank lid.

9. Apply lithium grease to the new tank lid gasket and

press the gasket into the groove.

10. Remove air tight plastic sheet and tape from tank.

11. Replace the tank lid (B) and new gasket onto the

day tank.

12. Hand-tighten the bolts onto the lid. Then use a crescent wrench to tighten the bolts (CE) in a cross-wise

pattern.

13. Re-attach pressurized air supply tubing by pressing

in on locking collar and sliding in the tube.

14. With air pressure now supplied to the tank, purge

the moist air from the tank by opening the air purge

valve on the tank lid for 60 seconds.

FIG. 16: Tank Lid

15. Turn on main power and run the machine for 30 minutes to circulate material.

r_24c317_3A0395a_6a

28 3A0395R

Page 29

Repair

Level Sensor and Well

NOTE: For proper level sensor function, the tip of

the level sensor well must protrude at least 1/8 in.

into the tank (C).

CA

CB

CC

CD

r_24b969_3A0395a_7a

FIG. 17: Level Sensor Assembly

1. Turn main power off.

9. Apply PTFE paste and PTFE tape to the male

threads of the level sensor well housing.

10. Being careful to not cross-threads, thread the level

sensor well into the tank (C) and lightly tighten with

a crescent wrench.

11. Measure the amount of the level sensor well housing that is visible beyond the day tank hole, then

perform the following equation:

P = L1 - (L2 + L3)

P = Protrusion length (inside of day tank)

L1 = Length of level sensor well (A10)

L2 = Visible length of level sensor well

L3 = Length of well threads in day tank

12. The protrusion length must be at least 1/8 in.

(3.2 mm). If not, remove the level sensor well and

restart at step 7.

13. Rotate level sensor to optimal position for wire routing and connect cable to connector.

2. Relieve tank air pressure. See Pressure Relief Pro-

cedure, page 17.

3. Drain tanks to below level sensor well.

4. Unscrew level sensor harness cable (CD) from level

sensor well housing (CA).

5. Use a crescent wrench to remove level sensor

well housing from tank (C).

6. Remove the old level sensor (CB) from well housing.

7. Measure the length of the level sensor well housing,

and then measure the depth of the hole in the tank

where the well is inserted. Note these measurements as they will be needed later.

8. Being careful to not cross-threads, thread assembled level sensor (CB) into well housing until it bottoms out against the bottom of the well. The bottom

of the level sensor will be slightly visible through the

bottom of the well.

NOTE: In the following step, do not allow PTFE

paste or tape to cover the tip of the level sensor

well. If paste comes in contact with the tip of the

level sensor well, thoroughly wipe it clean.

3A0395R 29

Page 30

Electrical Schematics

Electrical Schematics

Electrical Panel, Tank Stand with Agitator, Heater/Chiller

30 3A0395R

Page 31

Continued

Electrical Schematics

3A0395R 31

Page 32

Electrical Schematics

Continued

32 3A0395R

Page 33

Continued

Electrical Schematics

3A0395R 33

Page 34

Electrical Schematics

Electrical Panel, Tank Stand with Agitator

34 3A0395R

Page 35

Continued

Electrical Schematics

3A0395R 35

Page 36

Electrical Schematics

Continued

36 3A0395R

Page 37

Parts

Parts

38L and 75L Tank Modules

1

Mounting screws supplied with assembly.

Front View Shown

2

1

Ref. 4 Shown

4

29

28

19

20, 21

22

43

18

3

24

33, 34

41

5

r_24C317_3A0395a_11b

ti17773a

6

1

3A0395R 37

Page 38

Parts

38L and 75L Tank Modules

1

Mounting screws supplied with assembly.

Rear View Shown

7

26

16

23

17

(within

tank)

22

27

35, 36, 37, 38

12

13

12

13

25

11

10

1

r_24C317_3A0395a_12b

13

15

14

8

13

15

14

38 3A0395R

Page 39

Parts

38L and 75L Tank Module Parts

The following tables on this and the next three pages list the varying part numbers, common part numbers, and quantities by tank module assembly.

Tank Module and Quantity

Ref Part Description

1 ★ TANK, assy, 38L, sst 1 1 1 1 1 1

TANK, assy, 75L, sst 1 1

★ TANK, assy, heat, 38L,

sst

★ TANK, assy, heat, 75L,

sst

2 LID, assy, 38L/75L, rim1111111

★ LID, assy, agitator, vac

degas, fill

3 ENCLOSURE, frame 1 1 1 1 1 1 1 1

4 LID, assy, plug,

38L/75L, rim

★ LID, assy, 38L,

agitator, rim

LID, assy, 75L,

agitator, rim

5 VALVE, assy, ball; 1-1/2

npt, sst

★ VALVE, assy, ball; 1-1/2

npt, sst

6 24D852★ COVER, assy, tank

stand

EXCHANGER, assy,

heat, tank, single

7 ★ COVER, enclosure,

slotted, assy

PANEL, assy, electric,

tank, agit/heat

★ PANEL, assy, electric,

tank, agit

8 24C157 VALVE, assy, power,

tank, transfer pump

10 FILTER, dryer, assy,

tank

11 SWITCH, assy, level, 2

prox

12 117683 SCREW, mach, pan

head

13107016WASHER, plain 88888888

14 100072 NUT, hex mscr 4 4 4 4 4 4 4 4

15100079WASHER, lock, spring44444444

24C317 24D562 24D564 24D565 24D568 24D569 24D570 24D571

1

1 111

1 11

1

1 1 1 1

1 1 1 1

1111

1111

1

1 1 1 1

1 1 1

1111

1 1 1 1 1 1 1 1

1111

4 4 4 4 4 4 4 4

111

111

3A0395R 39

Page 40

Parts

Tank Module and Quantity

Ref Part Description

16 FITTING, assy,

bulkhead; 1/4 npt

17 GUARD, trim, edge 2929292929292929

18 PROBE, assy, recircula-

tion, heat exchange

1924D021BRACKET, anchor 44444444

20 111800 SCREW, cap, hex head 8 8 8 8 8 8 8 8

22123398PLUG, hole; 1.5 in. dia.55556555

23 123679 BUSHING, wire protec-

tor, snap-in

24123590PLUG, hole; 2 in. dia.22222222

25 123944 HARNESS, power cord,

tank stand; 20A

26 124003 CABLE, CAN,

male-female, 5 m

27 122005 BUSHING, strain relief 1 1 1 1 1 1 1 1

28 257606 PLATE, slinger, 38L/75L

2915G476LABEL, identification11111111

30★ 123395 HARNESS, power,

valve

33100015NUT, hex 33333333

34 100985 WASHER, lock 4 4 4 4 4 4 4 4

35116610SCREW, mach, pan4444

36 123452 HOLDER, anchor 4 4 4 4 4 4 4

37100020WASHER, lock 4444

38 100016 NUT, full hex 4 4 4 4 4 4 4

41▲ 196548LABEL, caution 11111111

43▲ 15M511 LABEL, warning 1 1 1 1 1 1 1 1

24C317 24D562 24D564 24D565 24D568 24D569 24D570 24D571

1 1 1 1 1 1 1 1

1 1 1 1

3 3 3 3 2 2 2 2

1 1 1 1 1 1 1 1

11111111

1

1 1 1 1

444

444

★ Not shown.

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

40 3A0395R

Page 41

38L and 75L Tank Module Parts (continued)

Parts

Tank Module and Quantity

Ref Part Description

1 ★ TANK, assy, 38L, sst

TANK, assy, 75L, sst 1 1 1 1

★ TANK, assy, heat, 38L,

sst

★ TANK, assy, heat, 75L,

sst

2 LID, assy, 38L/75L, rim

★ LID, assy, agitator, vac

degas, fill

3 ENCLOSURE, frame 1 1 1 1 1 1 1 1 1

4 LID, assy, plug,

38L/75L, rim

★ LID, assy, 38L,

agitator, rim

LID, assy, 75L,

agitator, rim

5 ★ VALVE, assy, ball; 1-1/2

npt, sst

6 24D852 COVER, assy, tank

stand

EXCHANGER, assy,

heat, tank, single

7 ★ COVER, enclosure,

slotted, assy

PANEL, assy, electric,

tank, agit/heat

★ PANEL, assy, electric,

tank, agit

8 24C157 VALVE, assy, power,

tank, transfer pump

10 FILTER, dryer, assy,

tank

11 SWITCH, assy, level, 2

prox

24F519★KIT, level sensor, high

temperature

12 117683 SCREW, mach, pan

head

13107016WASHER, plain 888888888

14 100072 NUT, hex mscr 4 4 4 4 4 4 4 4 4

15100079WASHER, lock, spring444444444

24D572 24D573 24D574 24D575 24D576 24D577 24D578 24D579 24P091

1 1

1 1 1

1111 11

1

11

11

11111

1 1 1 1 1 1 1 1 1

111111111

1

1 1 1 1 1

1 1 1

11 111111

1 1 1 1 1 1 1 1 1

11

4 4 4 4 4 4 4 4 4

11111

11

3

3A0395R 41

Page 42

Parts

Tank Module and Quantity

Ref Part Description

16 FITTING, assy,

bulkhead; 1/4 npt

17 GUARD, trim, edge 292929292929292929

18 PROBE, assy, recircula-

tion, heat exchange

1924D021BRACKET, anchor 444444444

20 111800 SCREW, cap, hex head 8 8 8 8 8 8 8 8 8

22123398PLUG, hole; 1.5 in. dia.556555555

23 123679 BUSHING, wire protec-

tor, snap-in

24123590PLUG, hole; 2 in. dia.222222222

25 123941 HARNESS, power cord,

tank stand; 20A

26 124003 CABLE, CAN,

male-female, 5 m

27 124005 BUSHING, strain relief 1 1 1 1 1 1 1 1 1

28 257606 PLATE, slinger, 38L/75L 1

29 15G476 LABEL, identification 1 1 1 1 1 1 1 1 1

30★ 123395 HARNESS, power,

valve

33 100015 NUT, hex 3 3 3 3 3 3 3 3 3

34100985WASHER, lock 444444444

35 116610 SCREW, mach, pan 4 4 4 4 4 4 4 4

36 123452 HOLDER, anchor 4 4

37 100020 WASHER, lock 4 4 4 4 4 4 4 4

38 100016 NUT, full hex 4 4

41▲ 196548 LABEL, caution 1 1 1 1 1 1 1 1 1

43▲ 15M511 LABEL, warning 111111111

44★ 123394 HARNESS, sensor,

level, tank, (3)

24D572 24D573 24D574 24D575 24D576 24D577 24D578 24D579 24P091

1 1 1 1 1 1 1 1 1

3 3 3 3 3 3 3 3 3

1 1 1 1 1 1 1 1 1

111111111

11

1

444444

444444

1

★ Not shown.

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

42 3A0395R

Page 43

2 Gallon Tank Module - 24J243

Parts

526

500A

500D

598

500E

500F

500C

599

596

518

500B

500d

520

519

517

518

527

583

521

505

597

596

515

519

590

508

511

507

516

518

523

522

526

513

512

503

504

524

543

503

592

533

532

503

501

529

528

527

530

591

534

587

591

536

536

514

583

546

553

577

539

540

541

565

566

542

533

568

595

594

554

570

3A0395R 43

593

ti17775b

Page 44

Parts

2 Gallon Tank Module (continued)

544

556

553

548

567

547

549

550

545

549

551

552

561

553

578

575

569

555

572

573

575

574

571

575

578

573

ti7774a

577

44 3A0395R

562

563

Page 45

Parts

2 Gal Tank Module (continued)

Ref. Part Description Qty.

501 236086 TANK, pressure assy, 2 gal 1

502 125312 PACKING, o-ring 1

503 16H698 ADAPTER, sensor, ultrasonic 1

504 188784 NUT, jam, hex 1

505 156849 PIPE, nipple 1

506 189016 MANIFOLD, air, inlet 1

507 100030 BUSHING 1

508 110476 ADAPTER, union, straight

swivel

509 110475 FITTING, street, tee 1

510 101759 FITTING, drain cock 1

511 151519 FITTING, nipple, reducing 1

512 110341 REGULATOR, air 1

513 124339 GAUGE, press, 0-160psi 1

514 100840 FITTING, elbow, street 1

515 100139 PLUG, pipe 1

516 208390 VALVE, ball 1

517 104813 PLUG, pipe 1

518 123256 FITTING, tee, 1/4npt 1

519 123257 FITTING, nipple, hex 2

520 123258 FITTING, valve, bleed 1

521 121021 MUFFLER 1

522 103347 VALVE, safety, 100 psi 1

523 112307 ELBOW, street 1

524 164724 HOSE, coupled 1

525 121089 FITTING, nipple 1

526 121018 FITTING, elbow, male, swivel 1

527 111928 TEE, male branch pipe 1

528 191931 NIPPLE 1

529 114243 VALVE, check 1

530 125214 BUSHING, hex 1

532 125213 ADAPTER, reducer 1

533 112268 SWIVEL, union 2

534 501867 VALVE, check 1

536 262206 FITTING, swivel 2

539 125217 FITTING, nipple 1

540 102325 FITTING, elbow, 90 degrees 1

541 125218 FITTING, nipple 1

542 122770 VALVE, ball 1

543 24N004 SENSOR, ultrasonic, pro-

grammed

544 24H179 PANEL, gms, tank, levels only 1

545 24C157 VALVE, assy, pwr, tank, xfer

pump

546 257965 ENCLOSURE, frame, painted 1

547 24C159 FILTER, dryer, assy, tank 1

548 24C228 FITTING, assy, bulkhead, 1

549 107016 WASHER, plain 4

550 117683 SCREW, mach 2

551 100079 WASHER, lock, spring 2

552 100072 NUT, hex mscr 2

553 123398 PLUG, hole, 1.5"dia 5

554 123590 PLUG, hole, 2" dia 4

555 16A221 BRACKET, anchor 4

556 124334 PLUG, hole, 1.375"dia, blk 3

★557 123452 HOLDER, anchor, wire tie, nylon 4

1

1

1

★558 116610 SCREW, mach, phil, pan, #10 4

★559 100020 WASHER, lock 4

★560 100166 NUT, full hex 4

561 123395 HARNESS, pwr valve, tank 1

★564 24D847 HARNESS, ground, tank 1

565 16D782 BLANK, label, kit, 3x3 1

▲567 196548 LABEL, caution 1

▲568 15M511 LABEL, warning, eng/span/fre 1

569 111800 SCREW, cap, hex hd 8

570 24D852 COVER, assy, tank stand, blank 1

571 16H696 PLATE, mtg, tank, 2gal 2

572 125221 BOLT, "j", 1/4-20 2

573 112689 SCREW, button hd 4

574 100016 WASHER, lock 3

575 100527 WASHER, plain 5

▲577 15G476 LABEL, a-b identification 2

578 100015 NUT, hex mscr 3

★580 123673 HARNESS, ext, m12xm12 1

581 123424 GUARD, trim, edge 2.5

582 185531 TUBE, siphon 1

583 235208 FITTING, union, swivel 1

584 155665 UNION, adapter 1

585 24C656 HOSE, coupled, 10 ft, sst 1

586 166866 FITTING, elbow, street, sst 1

587 124962 FITTING, tee 1

590 125848 VALVE, check, 1/4 npt, 250 psi,

brass

591 121907 FITTING, nipple, hex, 1/4 npt,

stainless steel, swivel

592 126135 HARNESS, M12xM12, 8-pin x 5

pin, female x male, 1.5 meter

593 24N437 BRACKET, filter, 2 gallon tank 2

594 100057 SCREW, cap, hex head 2

595 112904 WASHER, lock, spring 2

596 217430 FITTING, swivel, union, 90

degree

597 100081 BUSHING, pipe 1

598 156971 FITTING, nipple, short 1

599 6311-381 VALVE, 1/4 ball valve with relief 1

500A 6312-74 MUFFLER, silencer 1

500B 126302 VALVE, chemical relief 1

500C 16F259 FITTING, run tee, 3/4 npt 1

500D 122327 FITTING, elbow, street 1

500E 123376 FITTING, tee, run, 1/4 tube x

1/4 npt, brass

500F 100615 BUSHING, hex steel 1

1

2

1

2

1

★ Not shown.

▲Replacement Danger and Warning labels, tags, and

cards are available at no cost.

3A0395R 45

Page 46

Parts

Heated Tank Assemblies

38L and 75L Heated Tank Assemblies

50

Ref. Part Description Qty.

50 TANK, assy. 1

✓257762 38L, SST

◆257772 75L; SST

51 INSULATOR, blanket assy. 1

✓257757 38L

◆257758 75L

52 BLANKET, assy., heat 1

✓257760 38L, 240V

◆257761 75L, 240V

53 257759 SENSOR, thermowell assy., RTD 1

54 256611 SENSOR, assy.; 1.5 in., RTD, 4-pin m81

52

61

60

55

59

51

54

53

58

55 256558 SWITCH, assy., thermal; 125c, 3p, m81

56 121615 HARNESS, splitter; m8, 4-pin ffm, 3m1

57 121682 CABLE; m8, 3-pin, mf, 3 meter,

molded

58 121599 CORD, power, v-lock; c14/c13,10A 1

59 24D847 HARNESS, ground, tank 1

60 124270 TAPE, fiberglass; 6 ft. 61 261076 TIE, hose lacing; 6 ft. -

✓ 38L heated tank assemblies only.

◆ 75L heated tank assemblies only.

1

56

57

ti7043a

46 3A0395R

Page 47

Parts

Tank Lid Assemblies

Lid with Agitator

101f,

101e,

101t

101c,

101d

101h

101j

101i

101j

101m

101l

101r,

101s

101g

101l

101n

101x,

101y,

101aa

101m

101o

101p

101q

102a

102b

101u

107

109

108

101a

101k

101b

101z

101af

101ag

101z

101v,

101w,

101ab,

101ac,

101ad,

101ae,

103,

104,

105,

106

Lid with agitator for 38L tanks

Lid with agitator for 75L tanks

Ref Part Description Qty

101 257605 HOUSING, agitator 1

. 101a 124741 MOTOR, agitator 1

. 101b 16K267 ADAPTER, plate, agitator

motor

. 101c 158223 WASHER 4

. 101d 108803 SCREW, hex 4

. 101e 100021 SCREW, cap 2

. 101f 122775 NUT, eye, 1/4-20 2

. 101g 15Y358 HOUSING, upper, agitator 1

. 101h 15V746 SPACER, agitator 1

. 101i 122760 COUPLING, alignment 1

. 101j 122761 HOSE, alignment 2

. 101k 101885 SCREW, cap 4

. 101l 122774 BEARING, ball 2

. 101m 15Y360 SPACER, seal, shaft 1

. 101n 122772 SEAL 1

. 101o 15Y357 HOUSING, lower 1

. 101p 15Y363 GASKET 1

. 101q 15Y355 NUT, shaft 1

. 101r 105510 WASHER, lock 4

. 101s 112222 SCREW, cap 4

. 101t 100985 WASHER, lock 2

. 101u 15R328 JUNCTION BOX, motor

switch

. 101v 111307 WASHER, lock 2

. 101w 102598 SCREW, cap 2

. 101x 120910 SOCKET, electrical 1

. 101y 120916 SCREW 2

. 101z 121172 GRIP, cord 2

. 101aa 115142 FUSE, 5.0 amp, time lag 2

. 101ab▲ 125008 LABEL, earth ground 1

. 101ac 121013 SCREW, socket head 1

. 101ad 120993 NUT, hex 3

. 101ae 24H375 HARNESS, ground 1

. 101af 24H376 HARNESS, power 1

. 101ag▲ 15X092 LABEL, 240 volts 1

1702 257608 BLADE, assy 1

. 102a 257604 BLADE, assy, 38L/75L 2

. 102b 15M625 SHAFT, blade assy 1

1703 122776 TERMINAL, ring 1

1704 124436 CAP, splice 3

1705 124437 CONNECTOR, splice 3

1706 124442 TERMINAL, ring 1

1707 24K356 COVER, motor 1

1708 116876 WASHER 4

1709 102598 SCREW, cap 4

1

1

▲ Replacement Danger and Warning labels, tags, and

ti17777a

3A0395R 47

cards are available at no cost.

Page 48

Parts

Lid Assembly

153

149

150

151

152

142

146

148

163

155

154

147

144

141

158

166

162

158

157

143

r_24B967_3A0395a_1a

156

159

164

165

161

160

141

Ref. Part Description Qty.

141 15M621 LID, agitator 1

142 111384 PLUG, pipe 2

143 159239 NIPPLE, pipe 1

144 189016 MANIFOLD, air, inlet 1

145 100030 BUSHING 1

146 110475 FITTING, street, tee 1

147 101759 FITTING, drain 1

148 110476 ADAPTER, union, straight swivel 1

149 151519 NIPPLE, reducing 1

150 110341 REGULATOR, air 1

151 112307 ELBOW, street 1

152 164724 HOSE, coupled 1

153 124339 GAUGE, pressure, air 1

154 100840 ELBOW, street 1

155 100139 PLUG, pipe 1

156 208390 VALVE, ball 1

157 123256 FITTING, tee; 1/4 npt 1

158 123257 NIPPLE, hex; 1/4 npt 2

159 123258 VALVE, bleed; 1/4 npt 1

160 121021 MUFFLER; 1/4 npt 1

161 103347 VALVE, safety; 100 psi 1

162 104813 PLUG, pipe 1

163 100361 PLUG, pipe 1

164 121089 COUPLING; 1/4 npt, f-f 1

165 121018 ELBOW, male, swivel; 1/4 npt 1

166 125848 VALVE, check, 1/4npt 1

48 3A0395R

Page 49

Plug Assembly for Lid Vacuum Degas Lid Assembly

Parts

171

172

173

r_24B967_3A0395a_1b

Ref. Part Description Qty.

171 16A354 PLUG 1

172 15Y363 GASKET, mounting 1

173 15Y355 NUT 1

184

181

2

Apply thread sealant and PTFE thread tape.

183

r_257756_3A0395a_1a

187

185

2

186

182

Ref. Part Description Qty.

181 15M621 LID, agitator 1

182 122767 BUSHING,; 1/2 x 1/4 npt 2

183 103347 VALVE, safety; 100 psi 1

184 257746 KIT, vacuum tree 1

185 124400 GAUGE, pressure/vac 1

186 257602 VALVE, assy., ball, fill; 3/4 SST 1

187 FITTING, assy., inner fill port 1

3A0395R 49

Page 50

Parts

Electrical Panel, 230V for Heat

201

Ref. 210

218

211

229

227

223

203

235

222

202

211

234

237

212

216, 226

231

219

240

206

236

213, 214

215

209

210

228

221

228, 233

r_24C169_3A0395Aa_1b

50 3A0395R

229

230

223

219

220

239

219

228

224

219

228

207

208

Page 51

Electrical Panel, 230V for No Heat

Parts

201

Ref. 210

229

218

223

227

235

203

202

234

237

212

216, 226

231

206

213, 214

236

219, 240

210

215

221

230

228, 233

r_24C307_3A0395_1b

223

220

219

228

239

208

219

228

224

219

228

3A0395R 51

Page 52

Parts

Electrical Panel, 230V for Heat Parts

Electrical Panel, 230V for No Heat Parts

Ref. Part Description Qty.

201 COVER, enclosure 1

202 117644 LATCH, spring, slotted 1

203 102556 RIVET, blind 2

204★ 123352 PLUG, inlet, electric 1

205★ 102410 SCREW, cap socket head 2

206 289697 MODULE, cube, base 2

207❖ 256270 MODULE, low power temp 1

208 289696 MODULE, fluid control 1

209❖ 121597 CABLE, CAN 90 female / 90

female, 0.4 meter

210 121226 CABLE,CAN, male / female,

0.4m

211❖ 24D747 HARNESS, power, cube,

heat/chiller

212 124064 FILTER 1

213 114993 SCREW, machine pan head 2

214 102063 WASHER, lock, ext 2

215 113003 SCREW, cap, socket head 8

216 100015 NUT, hex 2

218 RAIL, mounting, din; 35mm, 6 in. 1

219 112776 WASHER, plain 6

220 ENCLOSURE 1

221 123296 CIRCUIT, breaker; 2P, 5A 1

222❖ 123297 CIRCUIT, breaker; 2P, 10A 1

223 123363 BLOCK, terminal, ground; 10mm 2

224 123381 TRIM, serrated 12

225★ 121612 CONNECTOR, thru; m12, m x f 1

226 100985 WASHER, lock ext 3

227 123351 COVER, inlet 1

228 100166 NUT, full hex 8

229 24C292 HARNESS, ground, strap, cube 2

Ref. Part Description Qty.

230 24D748 HARNESS, power, cube 1

231 24D847 HARNESS, ground, tank 1

232 123944 HARNESS, power cord, tank

stand; 20A

233 124338 CLAMP, harness; 3/8 in., nylon 3

234 24E278 HARNESS, filter, power in 2

235 24E277 HARNESS, power in/ground 2

236 ❖24E279 HARNESS, filter/breaker 2

1

237 LABEL, identification 1

238 24E236 HARNESS, filter/ground 1

1

239▲ 196548 LABEL, caution 1

240 124337 NUT, allen 2

1

★ Not shown.

▲ Replacement Danger and Warning labels, tags, and

❖ Included in electrical panel for heat only.

† Included in electrical panel for no heat only.

†24E346 HARNESS, filter/breaker, single

cards are available at no cost.

1

52 3A0395R

Page 53

Parts

3A0395R 53

Page 54

Parts

Electrical Panel, 230V for 2 Gallon Tanks Only

503

519

517

518

504

520

521

501

502

524

505

510

506

508

516

509

507

511

525

522

523

513

515

512

514

ti7778a

54 3A0395R

Page 55

Ref. Part Description Qty.

501 24C116 COVER, enclosure, electrical, tank 1

502 117644 LATCH, spring, slotted 1

503 102556 RIVET, blind 2

504 121612 CONNECTOR, thru, m12, mxf 1

505 289697 MODULE, gca, cube, base 1

506 289696 MODULE, gca, cube, fcm 1

507 24H240 HARNESS, wire, ground, term, 9" 1

508 102063 WASHER, lock, ext 1

509 114993 SCREW, mach, pan wash hd 1

510 102598 SCREW, cap, socket head 4

511 100985 WASHER, lock ext 3

512 24C115 ENCLOSURE, elec, tank stand 1

513 112776 WASHER, plain 4

514 123381 TRIM, serrated 2

515 100166 NUT, full hex 4

516 121226 CABLE, can, male / female, 0.4m 1

517 121000 CABLE, can, female / female 0.5m 1

518 124005 BUSHING, strain relief 1

519▲ 16D656 LABEL, identification, electronics 1

520 24H241 COVER, electrical 1

521 15U075 SCREW, cap, bh, 8-32 x .37 2

522 100015 NUT, hex mscr 2

523▲ 196548 LABEL, caution 1

524 277674 ENCLOSURE, cube door 1

525 24D847 HARNESS, ground, tank 1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

Parts

3A0395R 55

Page 56

Parts

Heat Exchanger Assembly

255

251

266

266

268

264

256

262

257

252

253

264

254

2

Apply thread sealant and PTFE thread tape to all male npt threads as needed.

Ref. Part Description Qty.

251 123072 EXCHANGER, heat, tank, 0.50

1

plates

252 123071 COUPLING, pipe; 1 in. npt, ff 2

253 123073 NIPPLE, hex; 1 in. npt x 3/4 in. npt 1

254 123028 VALVE, solenoid; 240V 1

256 123998 ELBOW; 3/4 in. npt x 3/4 in. nps,

1

m x f

257 513299 BUSHING, reducer 1

261 123093 HARNESS, valve, chiller; 230V 1

262 COVER, enclosure, heat exchange 1

264 123996 COUPLING, 1 in. npt, sst 2

266 111800 SCREW, cap, hex head 2

267 123997 ADAPTER, 1 in. npt x 3/4 in. npt,

1

m x f, sst

268 221170 HOSE, coupled; 3 ft 1

267

252

261

r_257968_3A0395Aa_1a

56 3A0395R

Page 57

Air Dryer Filter

Parts

285

284

283

282

281

289

290

291

292

2

Apply thread sealant and PTFE thread tape to all male npt threads as needed.

293

Ref. Part Description Qty.

281 121019 ELBOW, male, swivel; 3/8 npt 1

282 123377 FILTER, air; 3/8 npt 1

283 123379 FITTING, reducer; 3/8 npt x 1/4 npt 1

284 104984 FITTING, tee, pipe 1

285 156971 NIPPLE, short 1

286 DRYER, air, with desiccant; 1/4 npt 1

287 121018 ELBOW, male, swivel; 1/4 npt 2

288 123376 FITTING, tee, run; 1/4 tube x 1/4

1

npt

289 123380 BRACKET, filter, air; 3/8 npt 1

290 112944 SCREW, cap, button head 2

291 107194 WASHER, plain 2

292 100214 WASHER, lock 2

293 111303 NUT, hex 2

295★ 054106 TUBE, PET; 0.375 OD -

287

286

287

r_24C159_3A0395Aa_1a

★ Not shown.

3A0395R 57

Page 58

Parts

Ball Valve Assemblies

Ball Valve Assembly

301

302

301

303

302

303

304

305

306

307

308

309

2

Apply thread sealant and PTFE thread tape to all male npt threads as needed.

Ball Valve Assembly with Filter

304

305

306

r_24E107_3A0395Aa_1a

310

311

307

308

r_257742_3A0395Aa_1a

309

Ref. Part Description Qty.

301 121136 BUSHING, hex; 2 in. npt x 1-1/2 in. npt 1

302 123001 NIPPLE; 1-1/2 x 6 in., sst 1

303 123003 ELBOW; 1-1/2 x 1-1/2, f x f, sst 1

304 123000 NIPPLE; 1-1/2 x 10 in., sst 1

305 121135 VALVE, ball; 1-1/2 npt full port 1

306 123002 BUSHING; 1-1/2 npt x 1-1/4 npt 1

307 123348 BUSHING; 1-1/4 npt x 1 npt, mf 1

308 123349 FITTING, union, swivel; 1 npt, mf, sst 1

309 24E024 HOSE, tank to system 1

309 24P094 HOSE, coupled, 72L, 1ID, 1NPT, SST

(Assembly 24P091 only)

310 123346 NIPPLE, close; 1-1/4 npt, sst (with filter

version only)

311 213062 FILTER, fluid (with filter version only) 1

1

1

58 3A0395R

Page 59

Recirculation Probe Assembly

326

2

324

327

2

321

322

2

Parts

2

Apply thread sealant and PTFE thread tape.

2

325

328

Ref. Part Description Qty.

321 166466 FITTING, tee, pipe, female 1

322 124280 BUSHING; 3/4 npt x 1/4 npt 1

324 121478 FITTING, compression; 3/16 x 1/4

npt

325 124233 SENSOR, RTD, 4 pin; 1kohm, 4.25

in.

326 123082 FITTING, swivel; 3/4 nps x 3/4 npt 1

327 119992 FITTING, pipe, nipple; 3/4 x 3/4 npt 1

328 121686 CABLE, CAN; m8 x m8, 4P 1

r_24C156_3A0395A_2

1

1

3A0395R 59

Page 60

Parts

Transfer Pump Valve, 24C157

331

332

333

332

r_24C157_3A0395Aa_1b

Ref. Part Description Qty.

331 120900 VALVE, solenoid, 3 way 1

332 121021 MUFFLER; 1/4 npt 2

333 121018 ELBOW, male, swivel; 1/4 npt 2

334 100721 PLUG, pipe 1

333

334

60 3A0395R

Page 61

Accessories and Kits

Accessories and Kits

Level Switch Assembly, 24D271

Third level sensor proximity switch option.

410

403

401

Ref. Part Description Qty.

401 16A511 HOUSING, well, proximity 1

402 121511 SENSOR, capacitive, 18 mm 1

403 16A512 NUT, well, proximity 1

410 123394 HARNESS, sensor, level, tank, (3) Ref

402

r_24D271_3A0395Aa_1a

High Temperature Level Sensor, 24F519

Vacuum Tree Kit, 257746

Connection kit to add vacuum to the tank.

408

407

406

405

r_257746_3A0395Aa_1a

Ref. Part Description Qty.

405 122844 FITTING, tee; 3/4 npt(m), 3k, sst 1

406 122770 VALVE, ball; 3/4 npt(f), 2k, sst 2

407 122769 COUPLING, full; 3/4 npt, sst 1

408 121116 ELBOW; 3/4 npt(m) 1

461

462

Ref. Part Description Qty.

461 125325 HARNESS, M12 x M12 1

462 16H657 SENSOR, level, vibrating 1

3A0395R 61

ti17779a

Page 62

Accessories and Kits

Supplied Feed Refill Kit, 257770

Refill kit for customer-supplied feed systems.

415

414

417

r_257770_3A0395Aa_1b

Ref. Part Description Qty.

410 121116 ELBOW; 3/4 npt(m) 1

411 122770 VALVE, ball; 3/4 npt(f), 2k, sst 1

412 15T005 ADAPTER; 5/8-18 to 3/4 npt, sst 1

413 244910 VALVE, endure 1

414 054130 TUBE, PET; 0.25 OD, 12 ft. 415 112698 ELBOW, swivel, male 2

416 112268 SWIVEL, union 1

417 121022 ELBOW; 1/4 npt(m) 2

413

412

411

416

410

High Flow Supplied Feed Refill Kit, 24P673

Refill kit for customer-supplied feed systems.

502

503

503

506

507

Ref. Part Description Qty.

501 V1M350 VALVE, ball, 3/4” 1

502 054106 TUBE, plyeth, .375 OD 503 121018 FITTING, elbow, male, swivel,

1/4 NPT

504 112268 SWIVEL, union 2

505 122763 FITTING, elbow, str, 3/4 NPT, 90,

3K, sst

506 122770 VALVE, ball, 2way, 3/4 NPT, female,

2k, sst

507 123111 FITTING, nipple, hex, 3/4 NPT, 3k,

sst

501

504

504

505

r_24p673

2

1

1

1

62 3A0395R

Page 63

Accessories and Kits

Insulator Blanket Assembly, 257757

For use with heated 46 liter tanks.

Part Description Qty.

15U022 BLANKET, insulation 1

121208▲ LABEL, warning 1

TA PE 2

ADHESIVE 1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

Insulator Blanket Assembly, 257758

For use with heated 75 liter tanks.

Part Description Qty.

15U023 BLANKET, insulation 1

121208▲ LABEL, warning 1

TA PE 2

ADHESIVE 1

Single Nitrogen Harness 257778

421

424

425

427

426

428

429

430

r_257778_3A0395Aa_1a

422

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

Agitator with Heat Blanket Kits

The following kits are only for 20 gal (75L) tank stands.

For additional information and parts breakdown, refer to

Related Manuals on page 3.

Part Description Qty.

24K346 Heat blanket with pneumatic agita-

tor

24K347 Heat blanket with electric agitator 1

1

Insulator Blankets

Part Description Qty.

125390 For use with 2 gal (7.5L) tanks 1

125388 For use with 20 gal (75L) tanks 1

125389 For use with 10 ga (38L) tanks 1

125391 2”x2” port cover 1

Ref. Part Description Qty.

421 122647 REGULATOR, nitrogen; 1/4 npt,

1-15 psi

422 122649 NUT 1

423 122654 FERRULE 1

424 122773 GLAND, spiral, 1/4 in. 1

425 122758 HOSE, air; 0.25 ID, 0.53 OD, nylon,

10 ft.

426 122759 FITTING; 3/16 hose x 1/8 npt(m) 1

427 122762 COUPLER; 1/8 npt(f) 1

428 122766 COUPLER; 1/8 npt x 1/4 1

429 122768 BUSHING; 1/4 npt x 1/8 npt 1

430 123249 ELBOW, street, 90 deg.; 1/4 npt 1

1

-

3A0395R 63

Page 64

Accessories and Kits

Double Nitrogen Harness 257779 Vacuum Pump Assembly, 257916

437, 438

439, 440, 441

441

436

433

440

431

439

436

437

438

r_257779_3A0395Aa_1a

433

435

432

453

454

455

r_257916_3A0395Aa_1a

452

451

Ref. Part Description Qty.

431 122647 REGULATOR, nitrogen; 1/4 npt,

1-15 psi

432 122771 CONNECTOR, Y 1

433 122649 NUT 2

434 122654 FERRULE 2

435 122773 GLAND, spiral, 1/4 in. 2

436 122758 HOSE, air; 0.25 ID, 0.53 OD, nylon,

20 ft.

437 122759 FITTING; 3/16 hose x 1/8 npt(m) 2

438 122762 COUPLER; 1/8 npt(f) 2

439 122766 COUPLER; 1/8 npt x 1/4 2

440 122768 BUSHING; 1/4 npt x 1/8 npt 2

441 123249 ELBOW, street, 90 deg.; 1/4 npt 2

Ref. Part Description Qty.

451 123029 PUMP, vacuum; 6.9 cfm, 1 ph 1

452 123030 FILTER, mist 1

1

453 123031 FILTER, trap 1

454 123032 RING 1

455 123033 CLAMP 3

-

Desiccant Dryer Adapter, LC0097

Desiccant dryer (3/8 mpt) with adapter and cartridge.

Desiccant Dryer, LC0098

Desiccant dryer refill cartridge.

64 3A0395R

Page 65

Accessories and Kits

3A0395R 65

Page 66

Dimensions

Dimensions

Bolt Mounting Pattern and

Dimensions

D = 24.0 in. (609.6 mm)

E = 13.0 in. (330.2 mm)

D

A

E

C

r_24C317_3A0395a_1c

Right

Front

B

A = 83.0 in. (2108 mm); 38L/75L tanks with agitation

A = 69.4 in. (1763 mm); 38L/75L tanks without agitation

A = 54.0 in. (1372 mm); 7.5L tanks without agitation