Page 1

Instructions - Parts

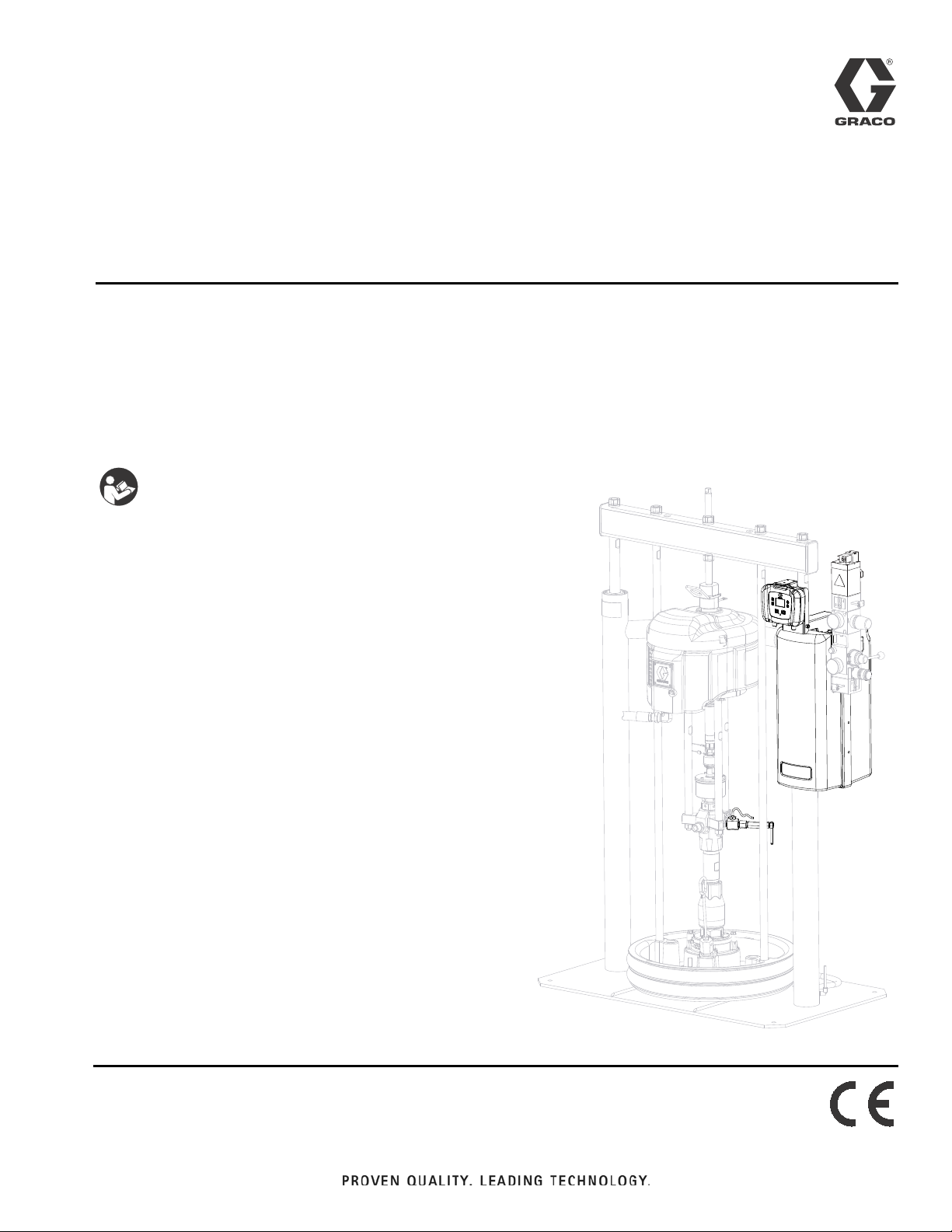

Kit 262370 Shown

™

SmartWare

Dispense Kit

Accurate metered dispensing kit for one component materials. Kits are compatible with

Check-Mate® pumps and Dura-Flo™ pumps; both alone and as part of a supply system. For

professional use only.

Not approved for use in European explosive atmosphere locations.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Shot

3A0294G

EN

Kit 262370 for D200 and D60

For D200 3 inch dual post ram with NXT®2200 and larger air motors

For D60 3 inch dual post ram with NXT2200 and larger air motors

Kit 262371 for D200

For D200 3 inch dual post ram with NXT1800 and smaller air motors

Kit 262372 for D200S

For D200S 6 inch dual post ram with NXT2200 and larger air motors

Kit 262373 for S20

For S20 3 inch single post ram NXT2200 and larger air motors

Kit 262374 for S20

For S20 3 inch single post ram with NXT1800 and smaller air motors

Kit 262375 for pumps

For wall mount or floor stand pump with NXT2200 and larger air

motors

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Description . . . . . . . . . . . . . . . . . . . . . . . . . 6

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . 6

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Critical System Parameters . . . . . . . . . . . . . . . . . 6

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . . 8

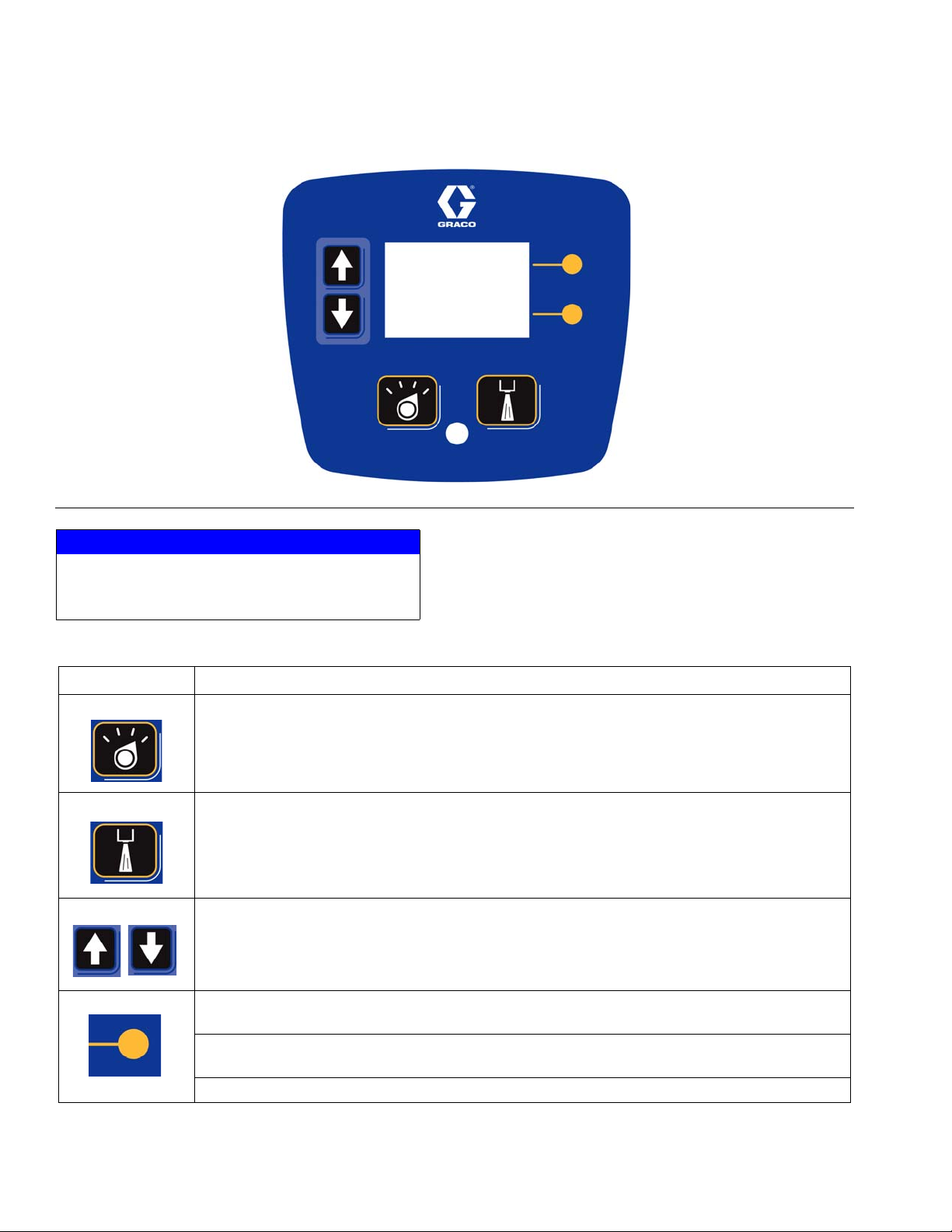

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install Kits 262370 and 262372 . . . . . . . . . . . . . 16

Install Kit 262371 . . . . . . . . . . . . . . . . . . . . . . . 24

Install Kit 262373 . . . . . . . . . . . . . . . . . . . . . . . 30

Install Kit 262374 . . . . . . . . . . . . . . . . . . . . . . . 37

Install Kit 262375 . . . . . . . . . . . . . . . . . . . . . . . 43

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Enter Password . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setup Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 51

Prime/Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Set System Parameters . . . . . . . . . . . . . . . . . . . . . 53

Set Units and Specific Gravity . . . . . . . . . . . . . . 53

Define Shot Size . . . . . . . . . . . . . . . . . . . . . . . . 54

Define Shot Sequence . . . . . . . . . . . . . . . . . . . 55

Set Password . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Select Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Enable/Disable Pump Functions . . . . . . . . . . . . 57

Enable/Disable Errors . . . . . . . . . . . . . . . . . . . . 58

Set Low/Empty Drum Error . . . . . . . . . . . . . . . . 58

Set Pump Runaway Error . . . . . . . . . . . . . . . . . 59

Set Maintenance Parameters . . . . . . . . . . . . . . 59

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Set Shot Accuracy Errors . . . . . . . . . . . . . . . . . 61

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Change Operation Mode . . . . . . . . . . . . . . . . . . 62

Select a Shot Number . . . . . . . . . . . . . . . . . . . . 64

Select a Shot Sequence . . . . . . . . . . . . . . . . . . 64

Dispense a Shot . . . . . . . . . . . . . . . . . . . . . . . . 65

Pause or Cancel a Shot . . . . . . . . . . . . . . . . . . 65

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Errors with Light Tower . . . . . . . . . . . . . . . . . . . 66

Clear Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Preventive Maintenance Schedule . . . . . . . . . . 71

Pump Maintenance . . . . . . . . . . . . . . . . . . . . . . 71

Supply System Maintenance . . . . . . . . . . . . . . . 71

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . 71

Upgrade Display Software . . . . . . . . . . . . . . . . . 72

Clean User Interface Display . . . . . . . . . . . . . . . 72

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Replace Display . . . . . . . . . . . . . . . . . . . . . . . . . 74

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . 75

Digital Output Schematic . . . . . . . . . . . . . . . . . . 75

Digital Input Schematic . . . . . . . . . . . . . . . . . . . 76

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Kits 262370 and 262372 . . . . . . . . . . . . . . . . . . 77

Kit 262371 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Kit 262373 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Kit 262374 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Kit 262375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix A - User Interface Display . . . . . . . . . . 93

Display Overview . . . . . . . . . . . . . . . . . . . . . . . . 93

Display Details . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Setup Mode Details . . . . . . . . . . . . . . . . . . . . . . 94

Run Mode Details . . . . . . . . . . . . . . . . . . . . . . 100

Appendix B - Tips . . . . . . . . . . . . . . . . . . . . . . . . 102

Calibration Procedure . . . . . . . . . . . . . . . . . . . 102

Tips for Better Accuracy . . . . . . . . . . . . . . . . . 102

Appendix C - Breakout Module (258999)

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix D - Y-Adapter (124273) Connections 105

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Graco Standard Warranty . . . . . . . . . . . . . . . . . . 108

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 108

2 3A0294G

Page 3

Related Manuals

Manuals are available at www.graco.com.

Component manuals in U.S. English:

Manual Description

313526 Supply Systems Operation

313527 Supply Systems Repair-Parts

Related Manuals

312376

312375

311827

311825

311828

311826

312796

311238

Check-Mate

®

Pump Packages

Instructions-Parts

Check-Mate

®

Displacement Pumps

Instructions-Parts

Dura-Flo

™

Displacement Pumps

(145cc,180cc, 220cc, 290cc) Instructions-Parts

Dura-Flo

™

Displacement Pumps (430cc,

580cc) Instructions-Parts

Dura-Flo

™

Pump Packages (145cc,

180cc, 220cc, 290cc) Instructions-Parts

™

Dura-Flo

Pump Packages (430cc,

580cc) Instructions-Parts

®

NXT

Air Motor (Mxxxxx models)

Instructions-Parts

®

NXT

Air Motor (Nxxxxx models)

Instructions-Parts

3A1161 Foot Switch Kit Instructions-Parts

3A1162 Changeover Solenoid Kits

Instructions-Parts

3A0294G 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

+

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

4 3A0294G

Page 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment and

follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

3A0294G 5

Page 6

System Description

< 20% > 100%

> 10%

< 3%

< 50 > 80

> 40 < 10

System Description

SmartWare shot dispense kits contain everything

needed to convert a supply system or a pump system

into a dosing system. The kits enable you to dose a preset amount of single-component material without using

flowmeters or gear meters in the fluid stream. Instead, a

sensor tracks the pump position so that the pump acts

like a flowmeter. The amount dispensed is based on the

pump size.

Typical Applications

• Cartridge fill

• Potting

• Encapsulating

• Mold making

• Batching or kitting

Critical System Parameters

If any of the following parameters are below the recommended value, see Appendix B - Tips, page 102, for

tips for better accuracy.

Percentage (shot size/pump size) -

Percentage (overshoot/shot size) (function of valve time and pump speed)

Air motor pressure (PSI) -

Compatibility

SmartWare shot dispense kits are compatible with J

series NXT2200 and larger air motors, and D series

NXT1800 and smaller air motors.

Pump Speed (CPM) -

6 3A0294G

Page 7

Theory of Operation

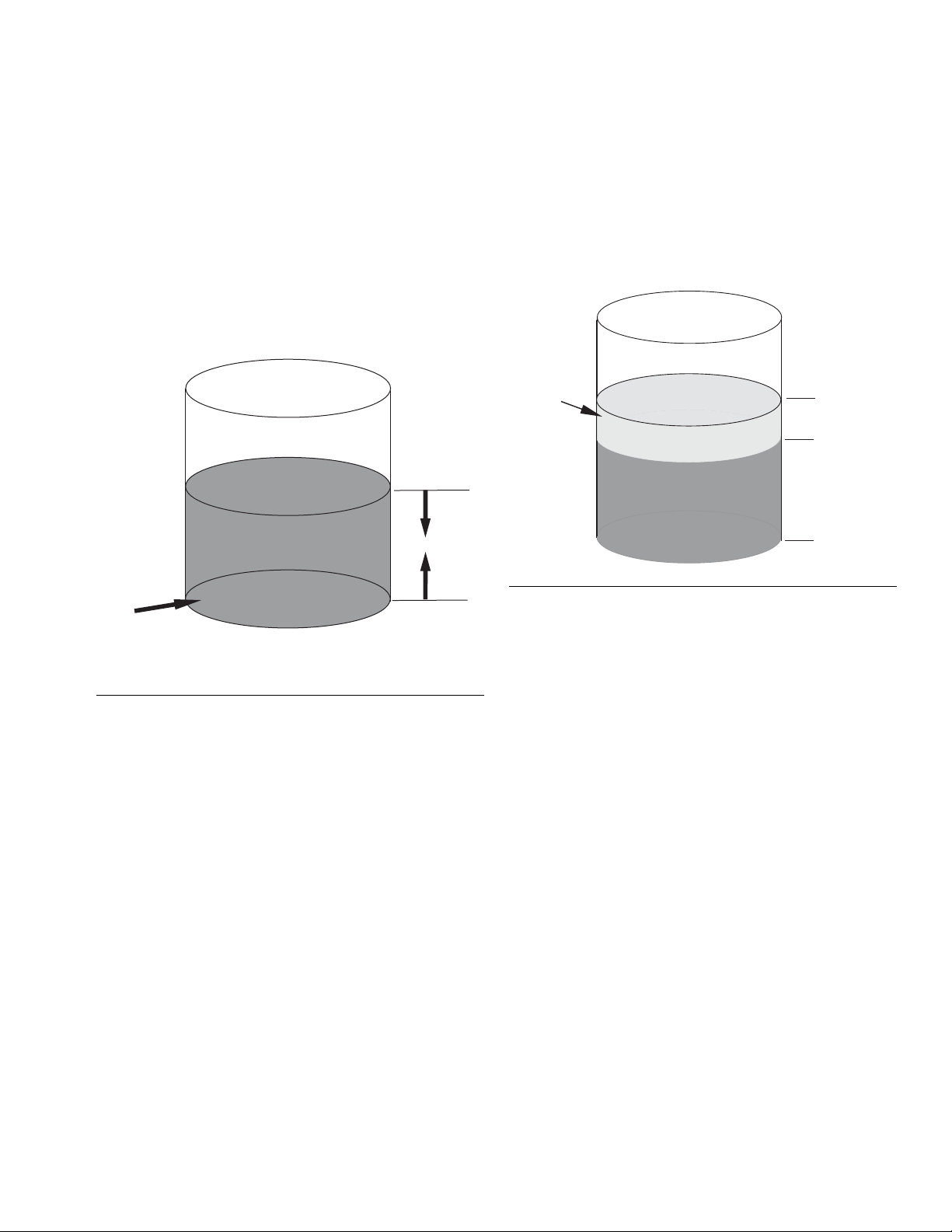

Distance

Area

Volume pumped = Area x Distance

Overshoot

Volume

Stop Position

Stop Signal

Start Signal

Theory of Operation

SmartWare shot dispense kits do not use flowmeters in

the material path to measure the volume pumped.

Instead the kit measures the volume pumped by using

the following calculation. See F

resentation.

Area of the pump piston x distance traveled (measured

by the linear sensor) = volume pumped

IG. 1 for a graphical rep-

Just like a car does not stop the instant you push on the

brake, the SmartWare kit pump does not stop pumping

the instant it receives a stop signal. Therefore, during

the time it takes for the dispense valve to physically

close fluid is still being pumped; the volume pumped

during this time is called the overshoot volume. See F

IG.

2 for a a graphical representation.

FIG. 2: Overshoot Volume

FIG. 1: Volume Pumped

When the system receives the start signal, the dispense

valve opens. Once the correct distance is traveled,

which equates to the desired shot volume, the dispense

valve closes and the pump stalls.

The SmartWare kit automatically compensates for overshoot by taking previous shots into consideration and

then sending the stop signal early.

The pressure transducer compensates for pump travel

during changeovers. Since only a few shots end in a

changeover, this compensation will take longer than the

basic overshoot compensation.

3A0294G 7

Page 8

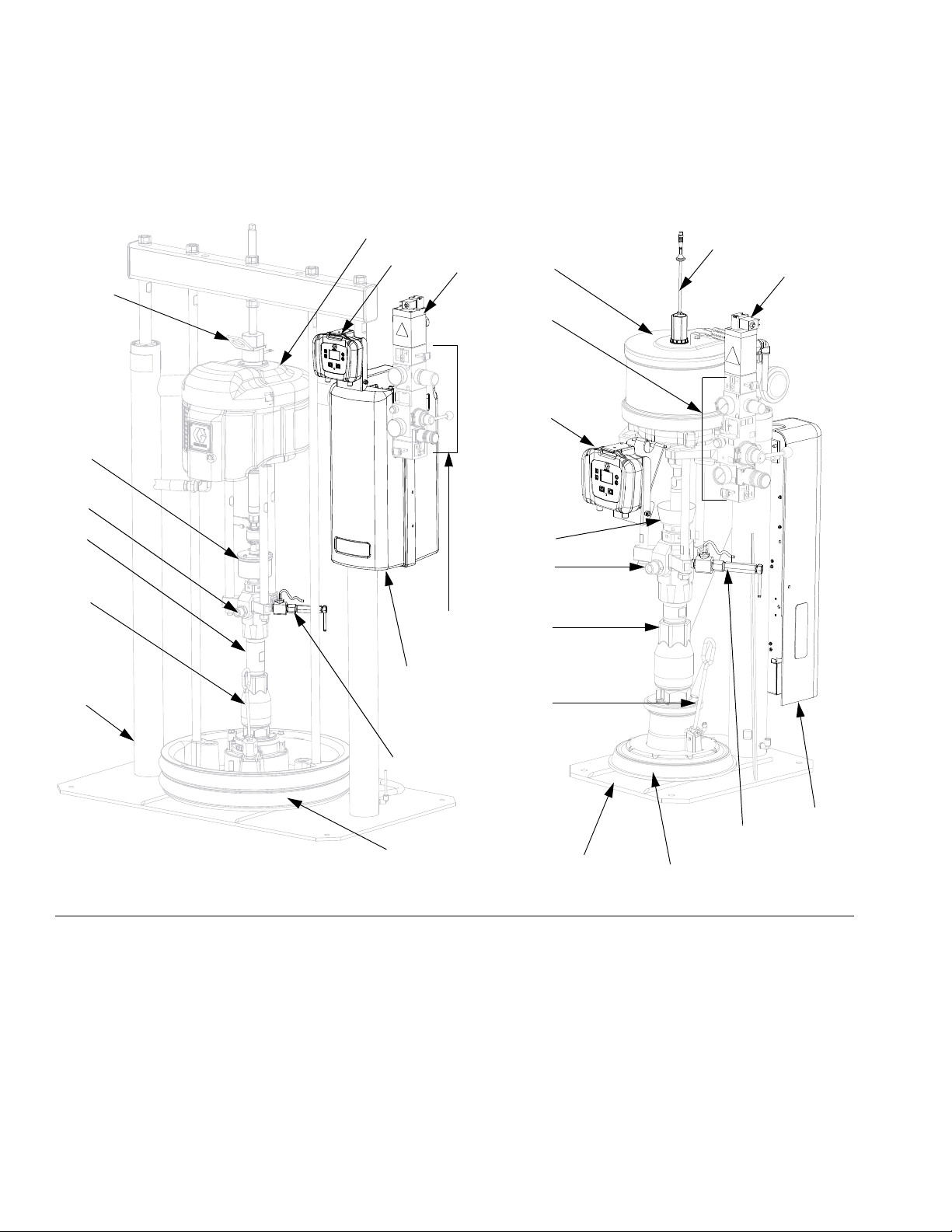

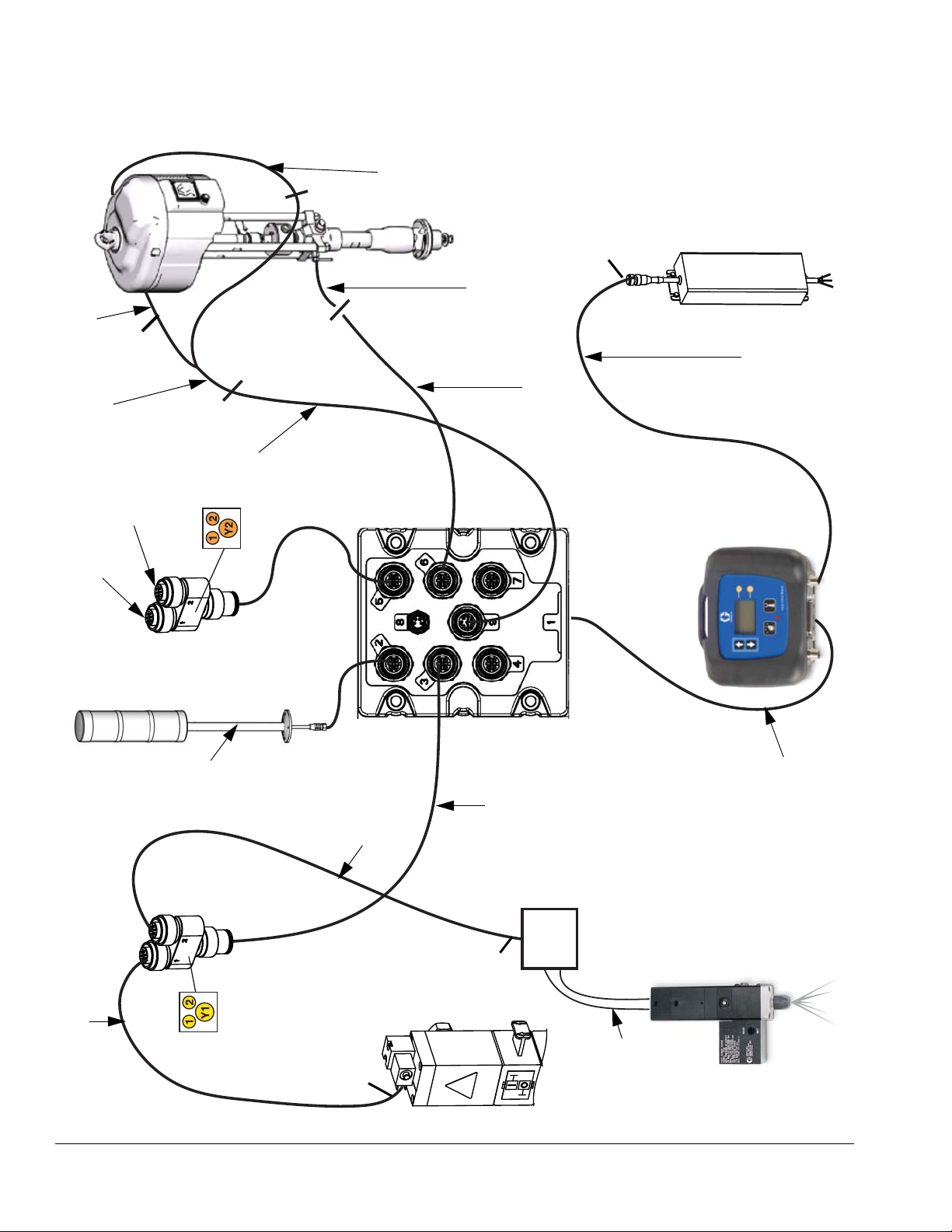

Component Identification

R

A

B

C*

J

K

H

M

D

N

E*, F*, G*

SmartWare Kit for D200 and D60 Rams

SmartWare Kit for S20 Rams

S*

T*

B

C*

S*

E*, F*, G*

D

R

J

K

H

M

N

T*

U*

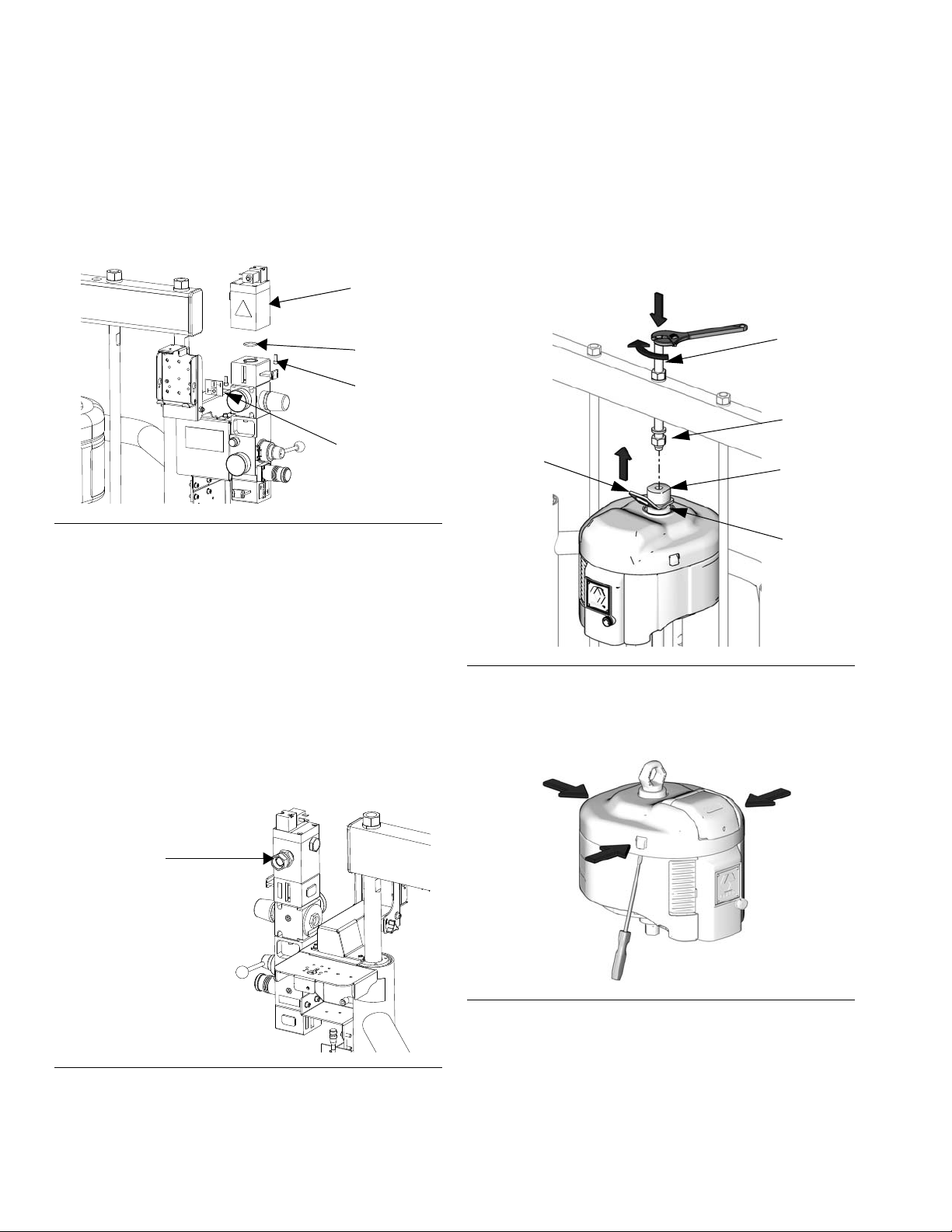

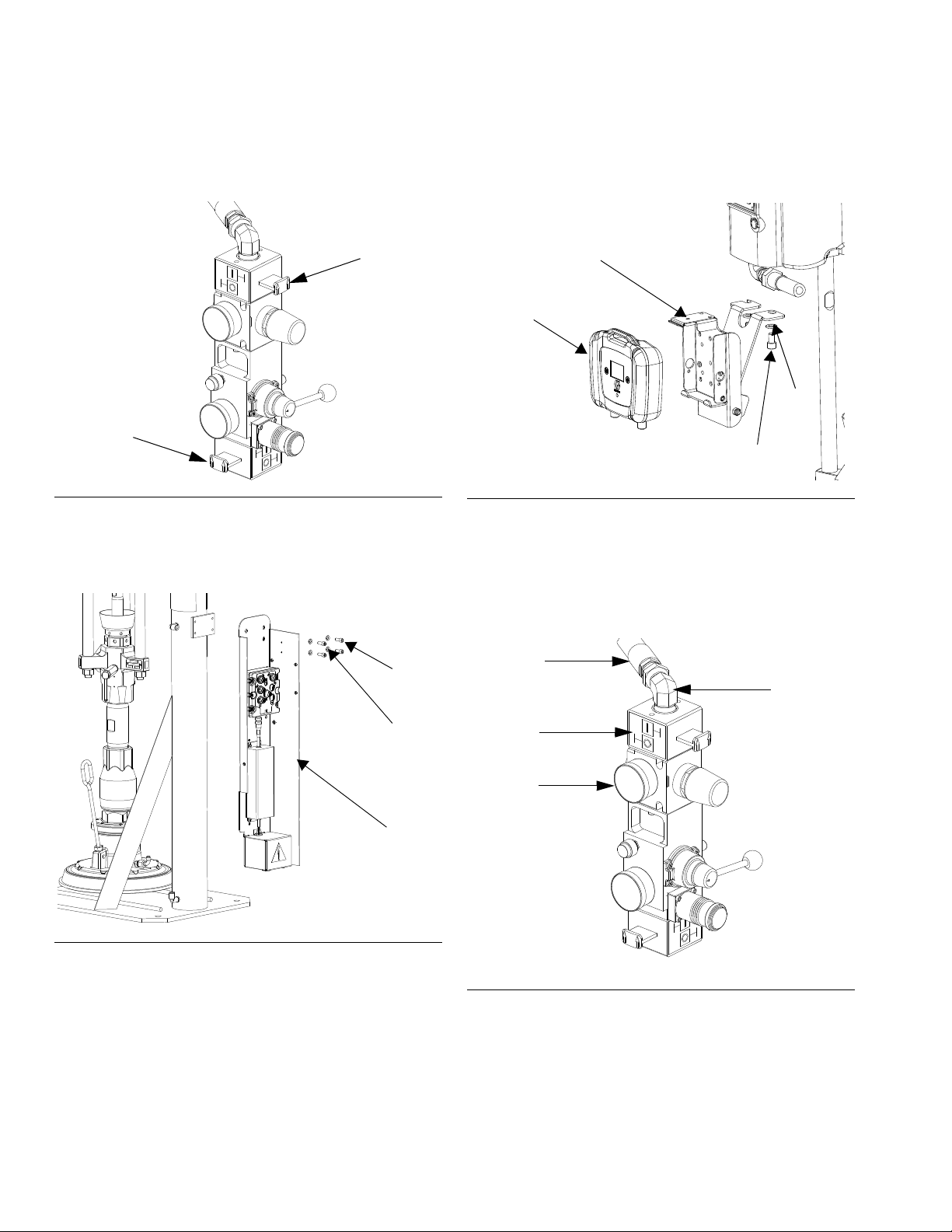

Component Identification

FIG. 3: Component Identification

Key:

A Lift Ring

B Air Motor

C* Display Module

D Air Controls

E* Air Solenoid (under shroud)

F* Power Supply (under shroud)

G* Power Switch (within shroud)

H Displacement Pump

JWet Cup

K Fluid Outlet

L Fluid Inlet

M Platen Bleed Port

NPlaten

RRam

S* Air Valve Assembly

T* Pressure Sensor Assembly

U* Linear Sensor Assembly

* Included in SmartWare kits.

8 3A0294G

Page 9

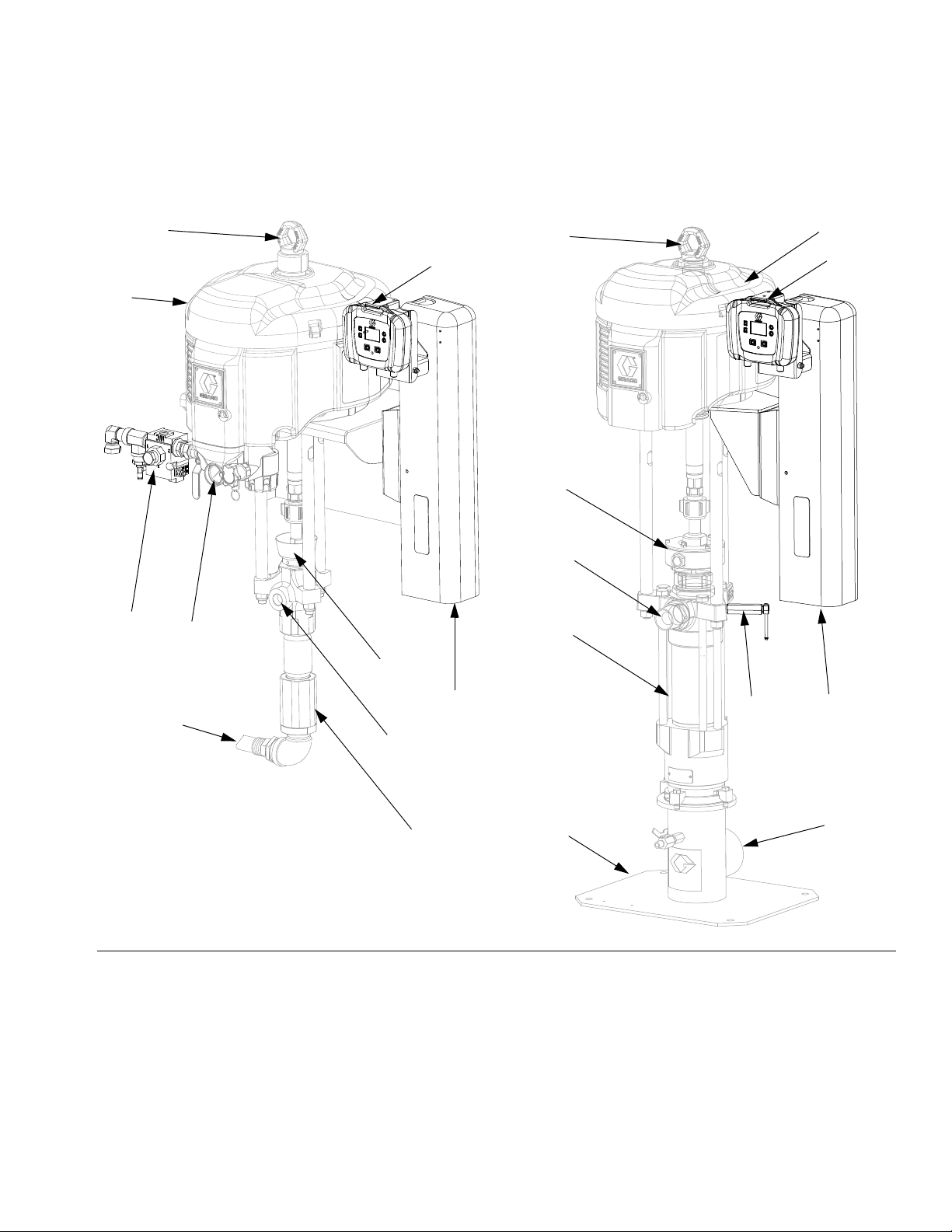

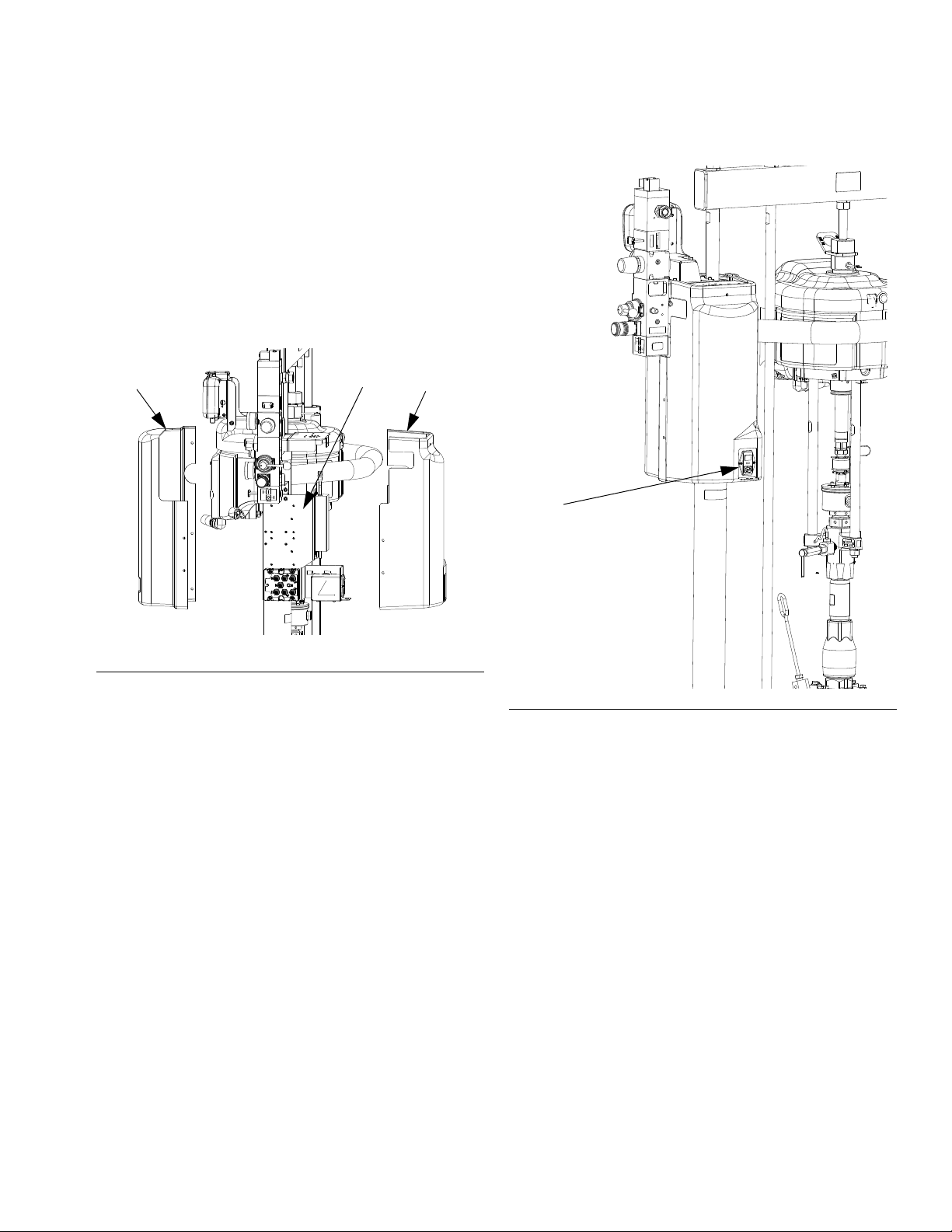

Component Identification (cont.)

SmartWare Kit for Wall Mount Pumps

J

A

C*

B

K

H

L

E*, F*, G*

SmartWare Kit for Floor Mount Pumps

E*, F*, G*

C*

A

B

J

K

L

H

P

D

V*

T*

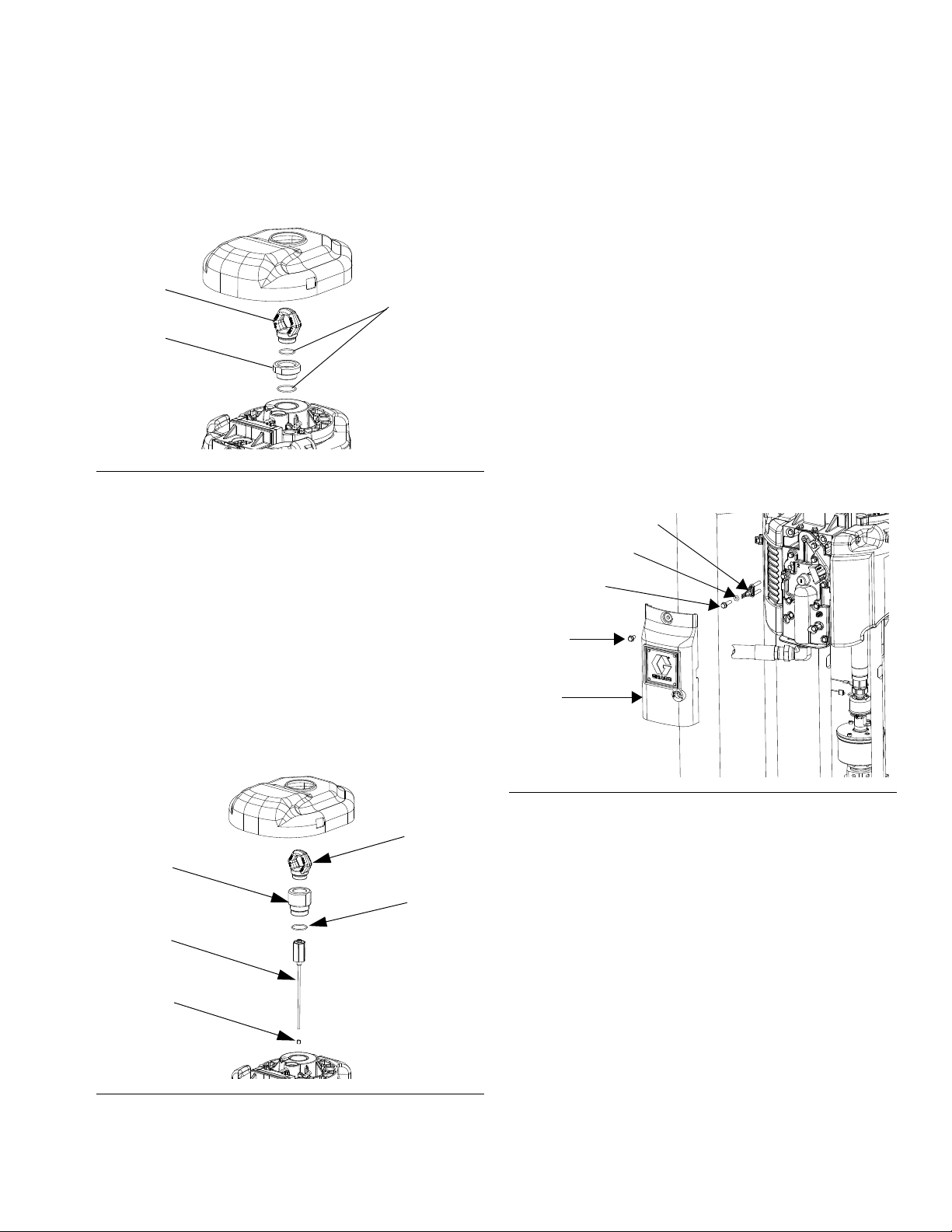

Component Identification

FIG. 4: Component Identification

Key:

A Lift Ring

B Air Motor

C* Display Module

D Air Controls

E* Air Solenoid (under shroud)

F* Power Supply (under shroud)

G* Power Switch (within shroud)

H Displacement Pump

JWet Cup

K Fluid Outlet

L Fluid Inlet

P Floor Mount Stand

T* Pressure Sensor Assembly

V* Valve Assembly

* Included in SmartWare kits.

3A0294G 9

Page 10

Component Identification

User Interface

FIG. 5: Display Module

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

Table 1: Display Module Button Functions

Button Function

Mode Select between Run and Setup modes.

Shot Start the present operation mode. Possible operation modes: shot mode, sequence mode,

manual mode, and park mode

Arrows Up/Down Navigate up or down within a screen or to a new screen.

Soft Keys Soft keys activate the mode or action represented by the icon next to each soft key.

See Table 2 for soft key icons and actions.

Top Soft Key: Turn air solenoid on/off, pause shot, continue shot, edit data, accept edited data,

or move right within a number field.

Bottom Soft Key: Enter a screen, exit a screen, cancel a shot, or cancel edited data.

10 3A0294G

Page 11

Component Identification

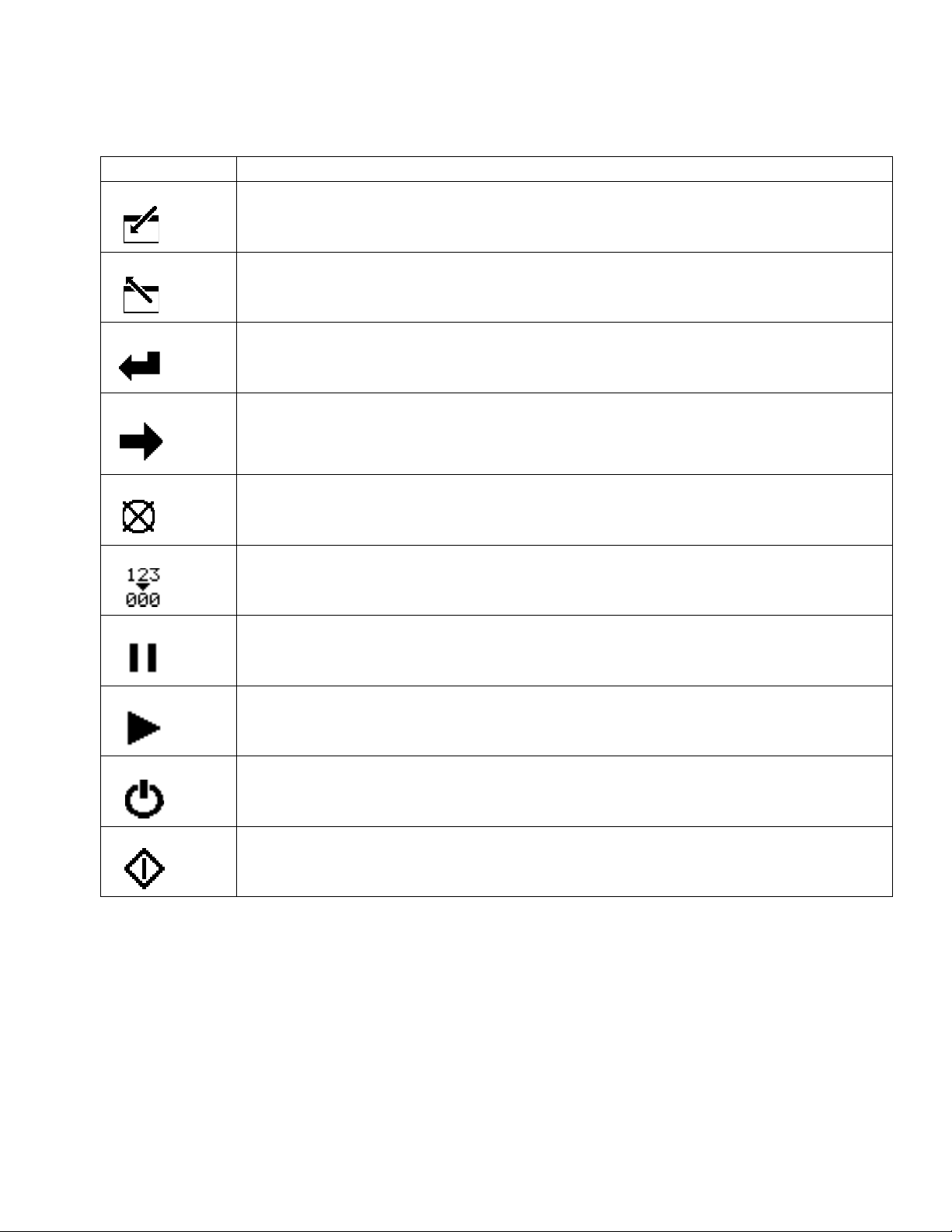

Table 2: Display Soft Key Icons

Icon Function

Enter Screen In screens that have editable fields, press to access the fields and make changes.

Exit Screen In screens that have editable fields, press to exit edit mode.

Enter In screens that have editable fields, press to make data selections or to enter changes.

Right In screens that have editable fields, press to move to the right while in a field.

Cancel Cancel a selection or edited data. Returns to the original data. Cancel a shot when the shot is

active.

Reset Reset the selected field or value.

Pause Pause the shot that is currently active.

Continue Continue the shot that is currently active.

Air On/Off Turn the air valve on and off.

Start Process Start the automatic calibration process.

3A0294G 11

Page 12

Component Identification

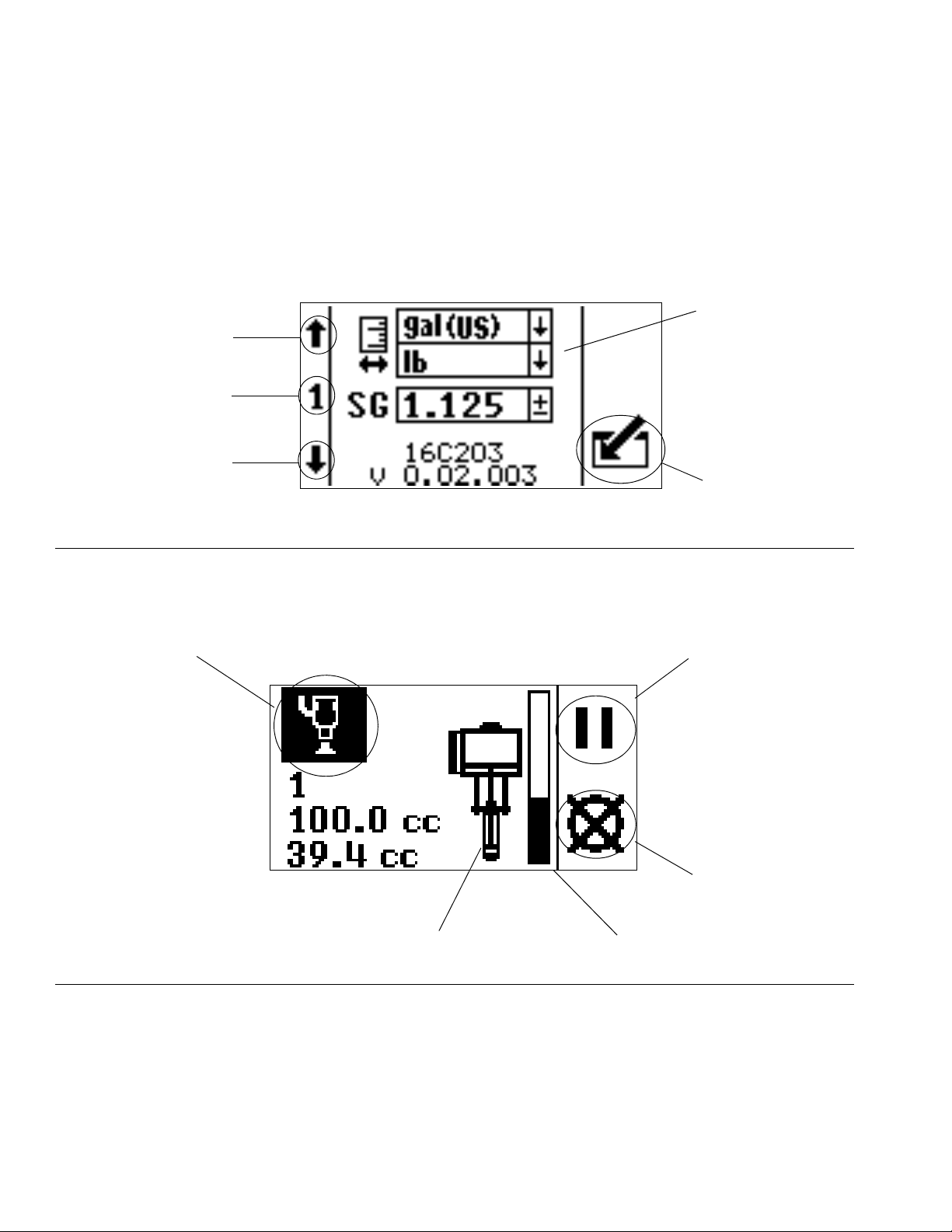

}

Soft Keys

Enter/Exit Screen

Setup fields specific to current

setup screen

Scroll up

through screens

Current setup

screen number

Scroll down

through screens

Pause Shot

Cancel

Shot Progress Bar Graph

Current Mode

Pump or Dispense Valve

Run Screen in Shot Mode Shown

}

Soft Keys

{

Information

specific to current

run screen mode

(Air on- shaded)

(Air off - not shaded)

User Interface Display

For details regarding the user interface display, see , page 92.

Display Screen Components

The following figures call out the navigational, status, and general informational components of each display screen.

FIG. 6: Setup Mode Screen Components

FIG. 7: Run Mode Screen Components

12 3A0294G

Page 13

Component Identification

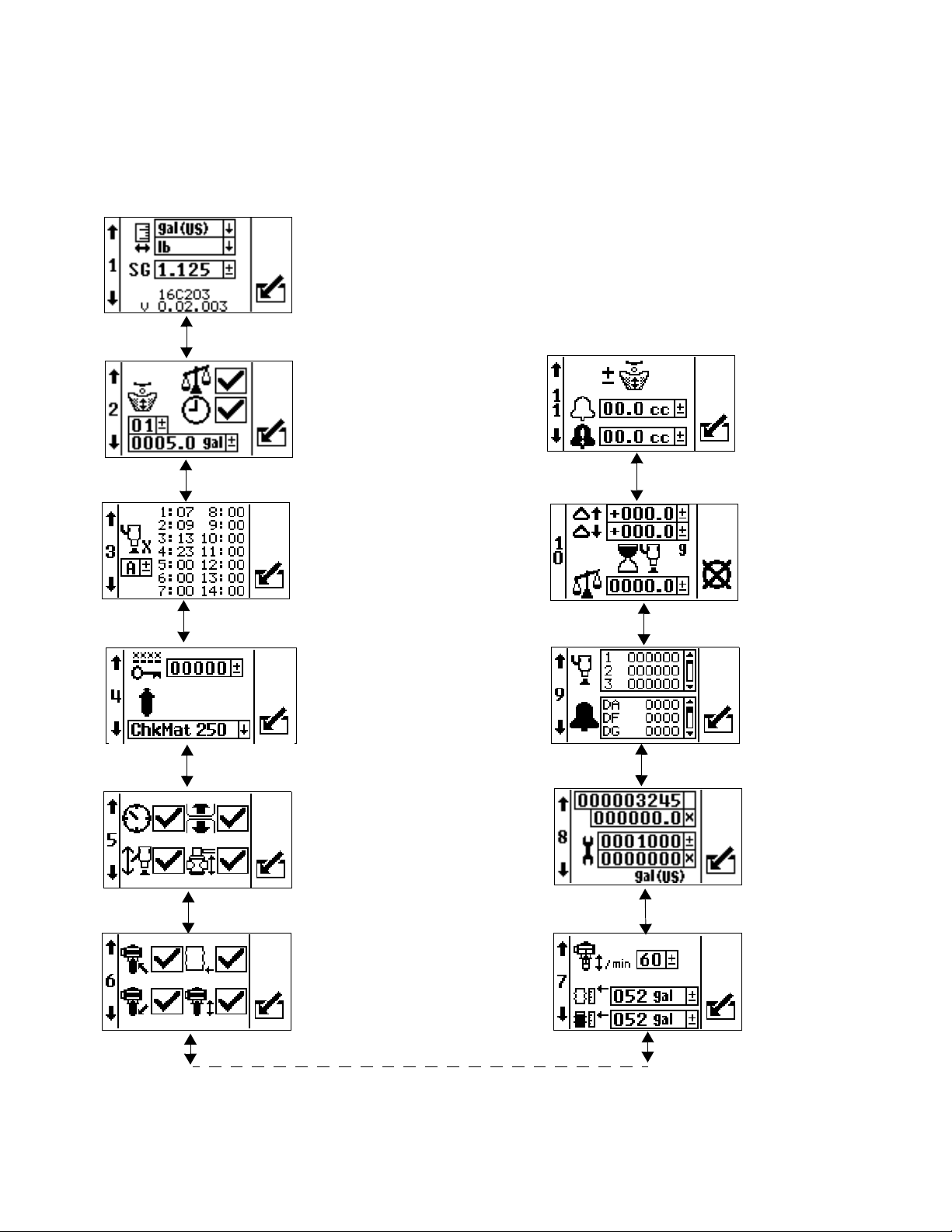

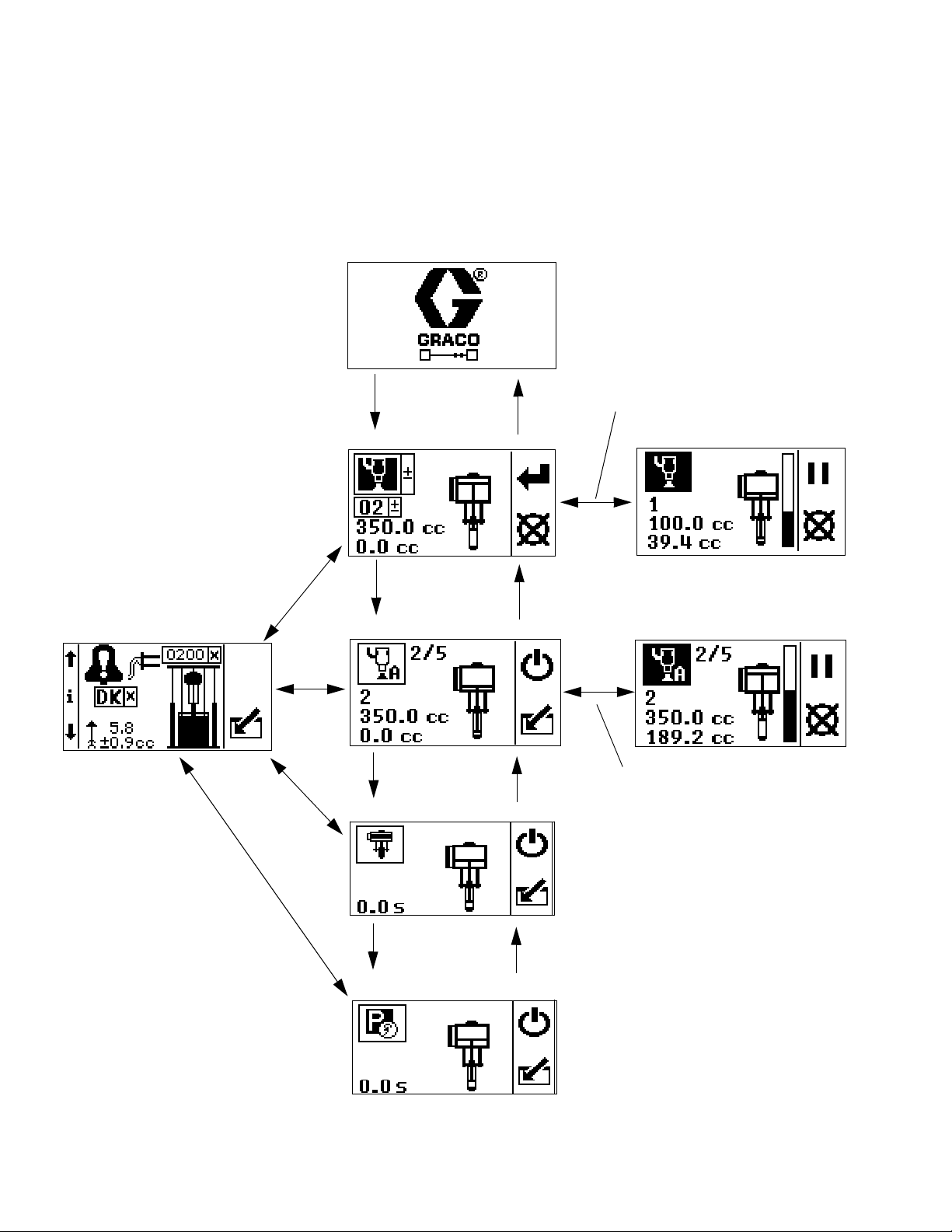

Setup Mode Screen Structure

The following figure demonstrates the flow of the setup mode screens beginning with setup screen 1. For details on

each setup screen, see - Setup Mode Details on page 94.

3A0294G 13

Page 14

Component Identification

Run Screen - Shot Mode

Run Screen - Sequence Mode

Run Screen - Manual Mode

Run Screen - Park Mode

Information Screen

Dispense a Shot

Dispense a Shot Sequence

Power Up Screen

Enter screen to

dispense a shot

Enter screen to

dispense a shot

sequence

Run Mode Screen Structure

There are only two run mode screens: run and information. However, there are four modes within the run screen:

shot, sequence, manual and park. The following figure demonstrates the flow of the modes in the run screen beginning with power up screen 1. For details on each run mode, see - Run Mode Details on page 100.

14 3A0294G

Page 15

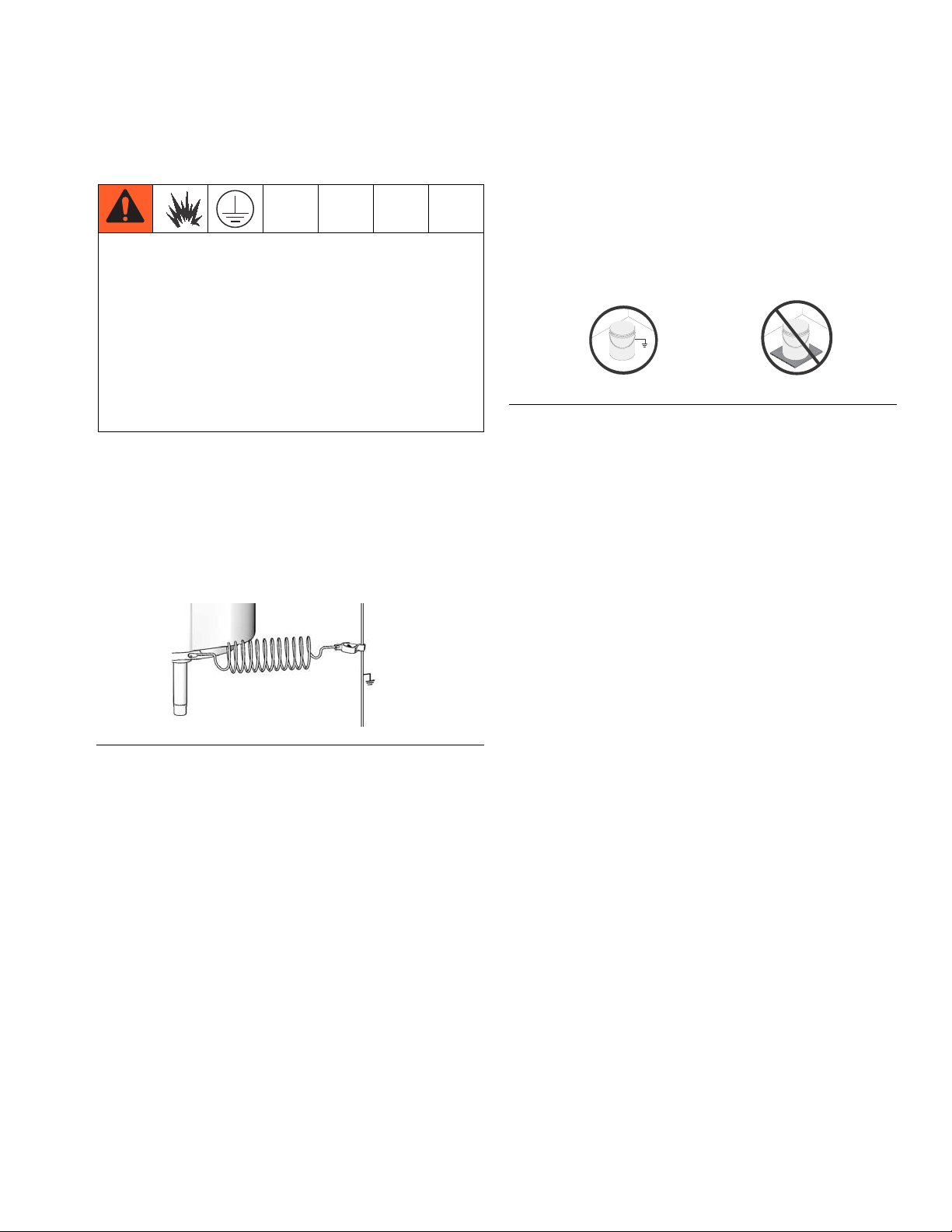

Grounding

TI8250a

TI1102-2

TI1102-1

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by

providing an escape wire for the electrical current due

to static build up or in the event of a short circuit. To

reduce the risk of static sparking, ground the pump,

the object being dispensed to, and all other

dispensing equipment used or located in the

dispensing area. All electrical wiring must be done by

a qualified electrician and comply with local codes

and regulations.

Supply System: ground the supply system as

instructed in the grounding section of the Supply Systems Operation manual.

Grounding

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

FIG. 9

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Pump: use a ground wire and clamp. Connect the

ground wire to the ground stud on the air motor. Con-

nect ground clamp to a true earth ground.

FIG. 8

Air and fluid hoses: use only electrically conductive

hoses.

Air compressor: follow manufacturer’s recommendations.

Dispense valve: ground through connection to a properly grounded fluid hose and pump. See dispense valve

manual for instructions and guidelines.

Fluid supply container: follow local code.

3A0294G 15

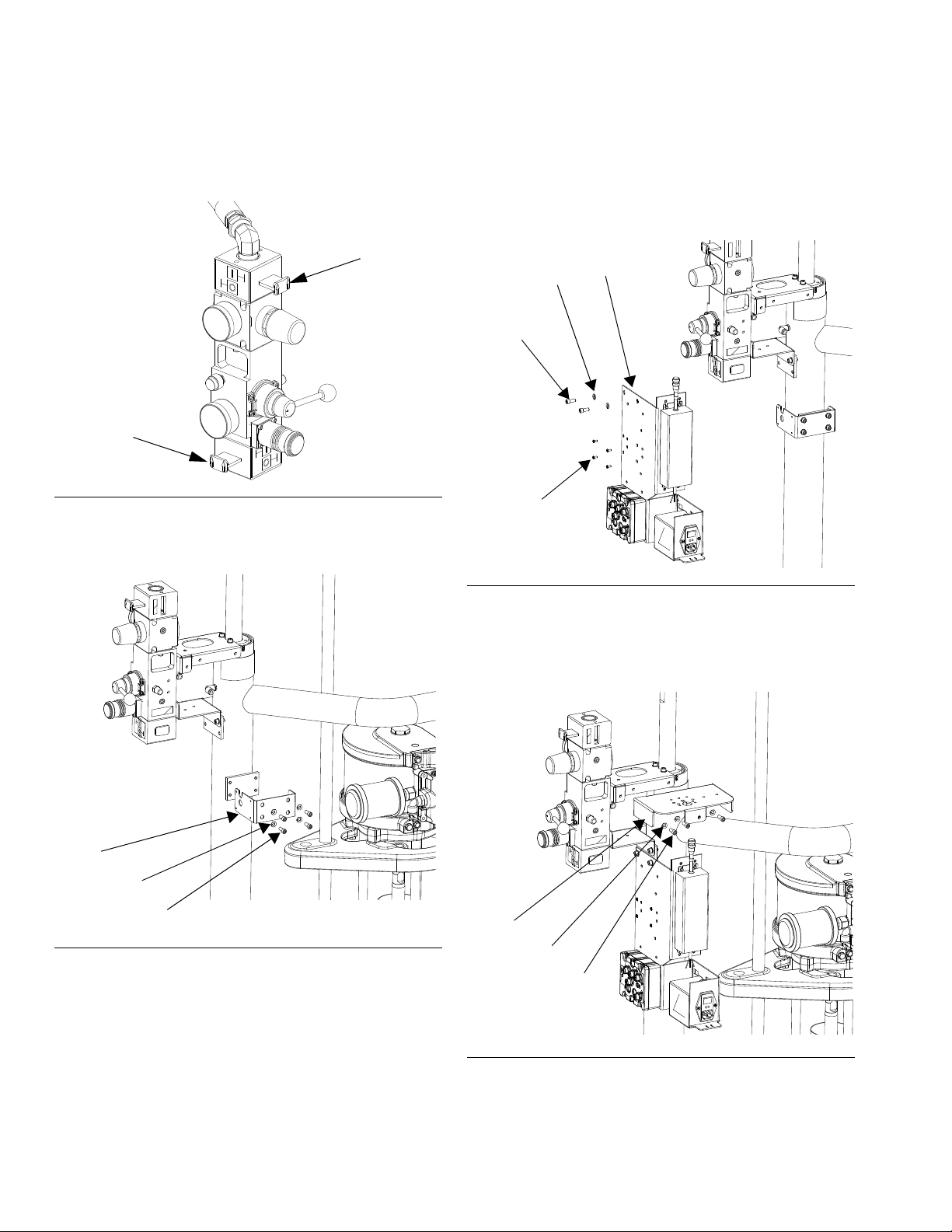

Page 16

Installation

Shutoff

Valve

Shutoff

Valve

33

28

29

r_262370_3A0294_6a

Installation

The procedures in this section are specific to each shot

dispense kit. Follow only the installation instructions for

your particular kit.

For supply system or pump assembly installation

instructions, refer to the Supply Systems Operation

manual or your pump packages instructions-parts manual.

Location

NOTE: SmartWare Shot Dispense kits are not approved

for use in explosive atmospheres.

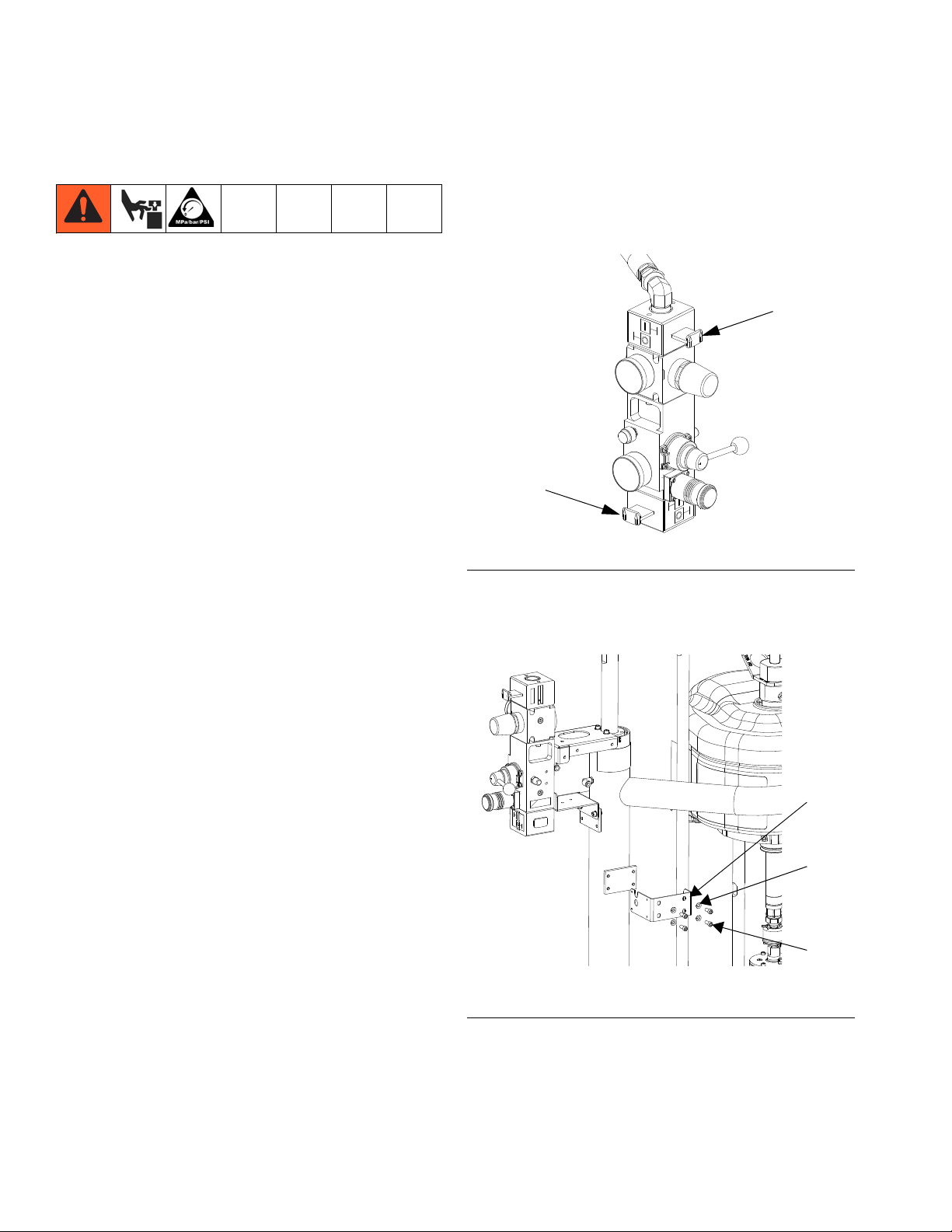

Install Kits 262370 and 262372

1. Close both shutoff valves on the air control panel.

Follow the location guidelines and instructions provided

in the Supply Systems Operation manual or your pump

packages instructions-parts manual before installing the

shot dispense kit.

FIG. 10: Close Shutoff Valves

2. Install the power supply bracket (33) to the ram post

using four screws (29) and lock washers (28).

FIG. 11: Install Power Supply Bracket

16 3A0294G

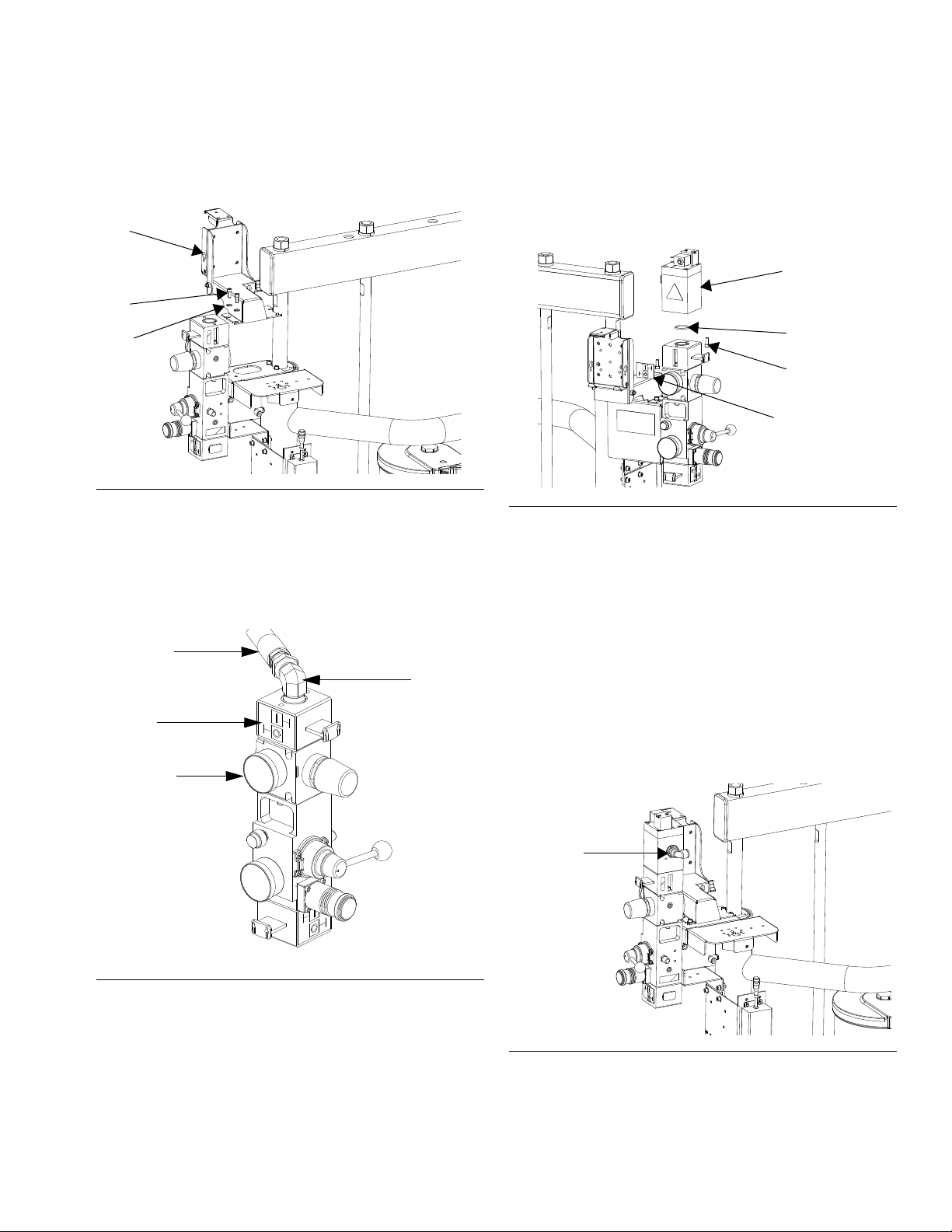

Page 17

Installation

1

34

29

28

r_262370_3A0294_7a

31

28

29

r_262370_3A0294_8a

2

29

28

r_262370_3A0294_9a

Air Hose

Label

Elbow

Fitting

Pressure

Gauge

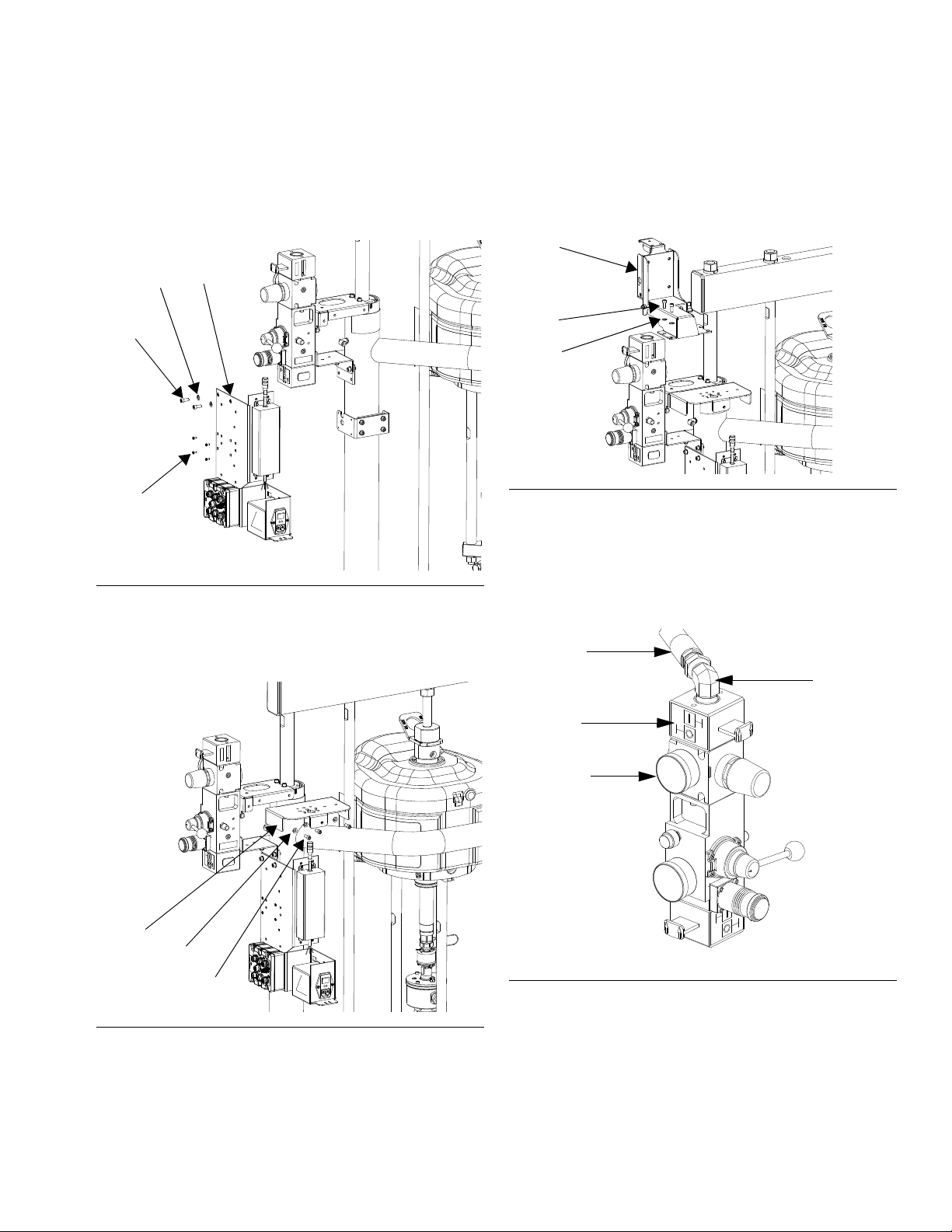

3. Install the electronics subassembly (1) to the side of

the power supply bracket using four screws (34).

Also secure the bracket to the bottom of the air control bracket using two screws (29) and two lock

washers (28).

FIG. 12: Install Electronics Assembly

4. Install the light tower bracket (31) to the top air controls bracket using three screws (29) and lock wash-

ers (28).

5. Loosen two screws on the top air controls bracket.

Install the display module bracket (2) using two

screws (29) and lock washers (28) to secure it to the

air controls bracket.

FIG. 14: Install Display Module Bracket

6. Install the air valve subassembly (3).

a. Use two wrenches to remove the air hose,

elbow fitting, and pressure gauge from the air

controls.

FIG. 13: Install Light Tower Bracket

FIG. 15: Air Control Assembly

b. Remove the air motor slider valve label. See

F

IG. 15.

3A0294G 17

Page 18

Installation

3

O-ring

Screw

r_262370_3A0294_11a

Slider Valve

Label

32

Nut

Lift Ring

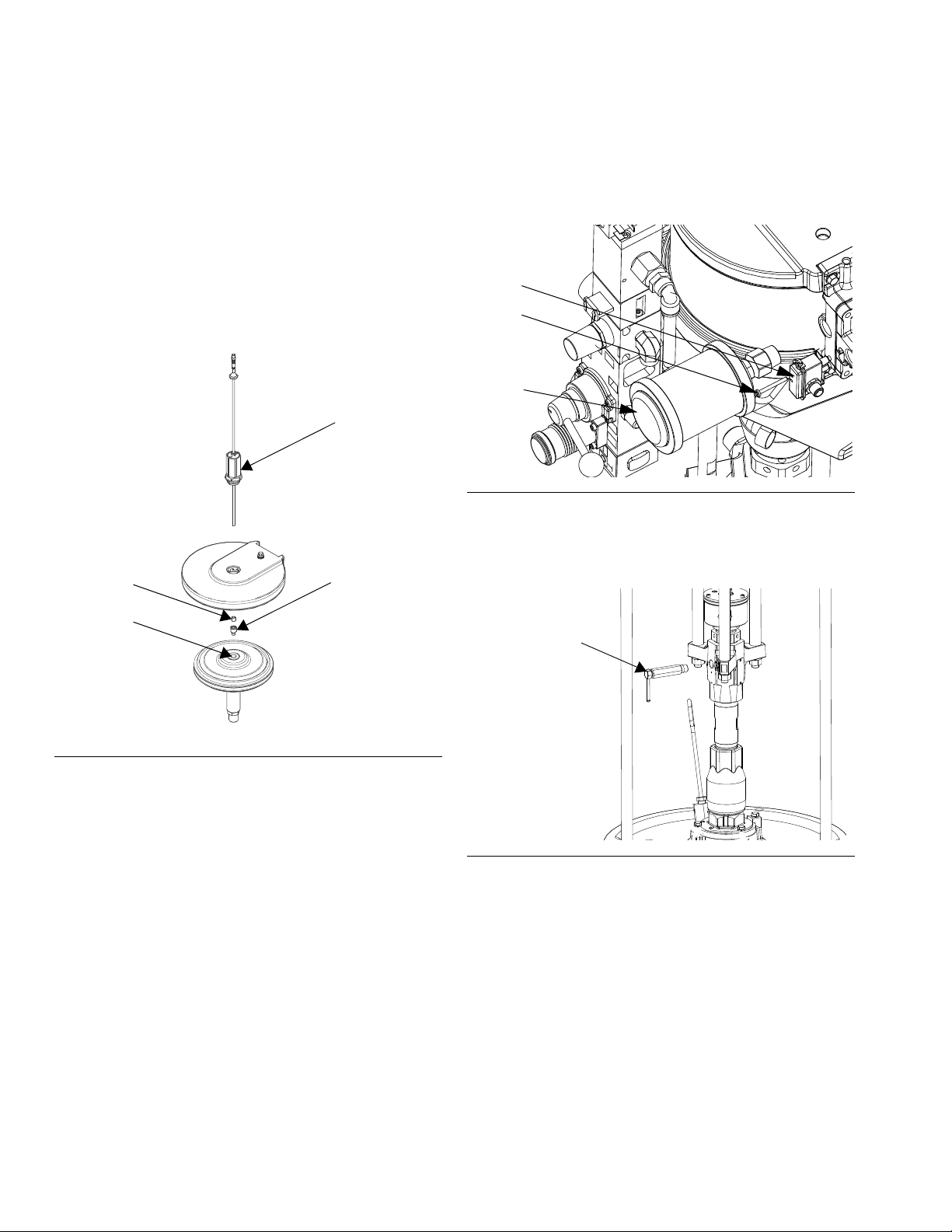

Adapter

Rod

ti10649a

Lift Ring

Plate

Thread

Adapter

ti8218b

c. Loosely install the air valve assembly (3).

Grease the o-ring included with the air valve

assembly. Install the o-ring and then finish

installing the air valve assembly. Secure with

screw.

FIG. 16: Install Air Valve Assembly

d. Install the new air motor slider valve label that is

included with the air valve assembly. See F

15.

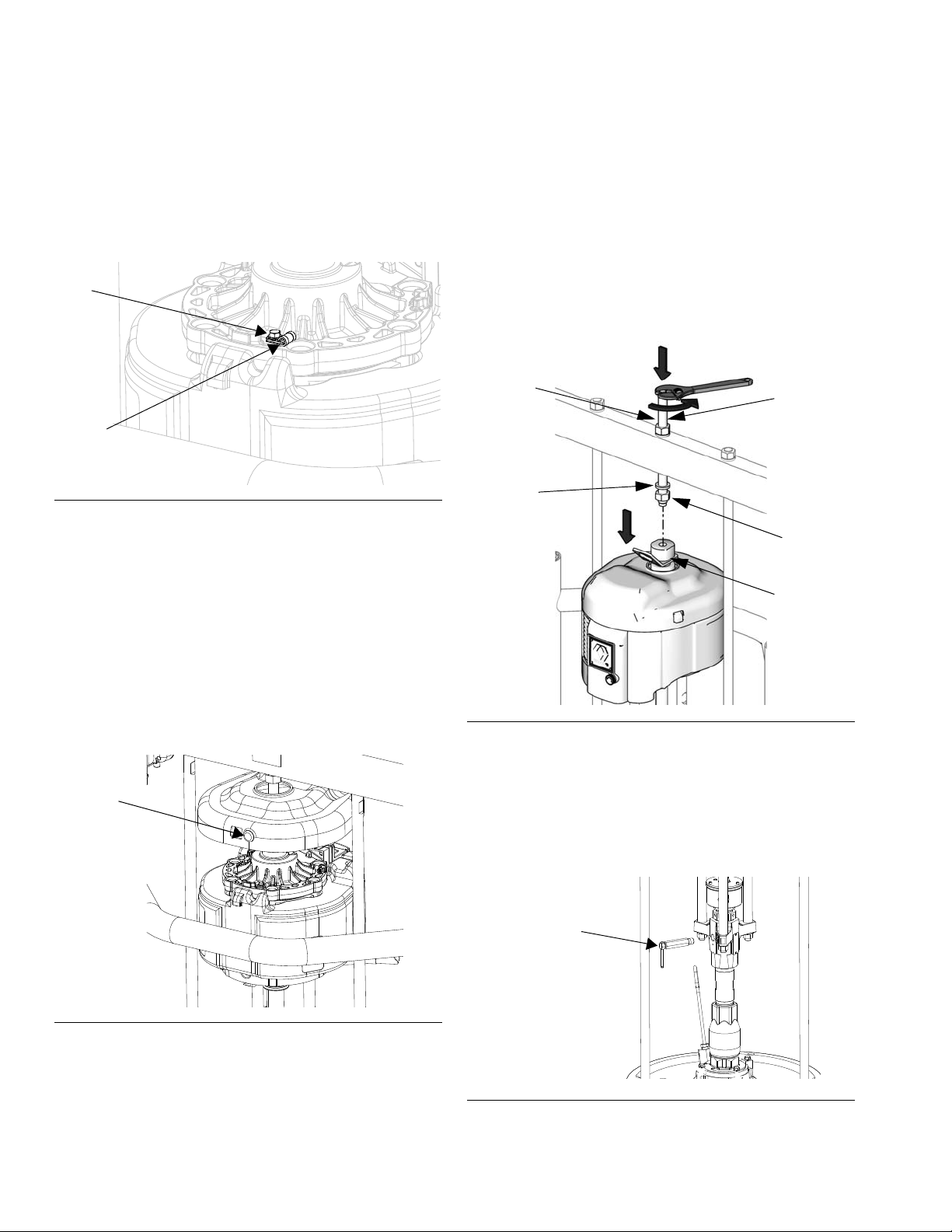

7. Install the linear sensor assembly (18) and the reed

switch sensor (22).

a. D200 systems only: disconnect the air motor.

Loosen nut below crossbar. Use wrench to hold

thread adapter in place and loosen threaded rod

above crossbar with another wrench.

IG.

e. Coat the gauge fitting with PTFE tape, and then

reinstall. Use a wrench to tighten. See F

f. Coat the swivel fitting (32) with PTFE tape.

Install the fitting and air hose on the back of the

new air valve assembly. Use two wrenches to

tighten.

FIG. 17: Install Swivel Fitting

IG. 15.

FIG. 18: Disconnect Air Motor

b. Remove the air motor top cover using a flat

head screwdriver.

FIG. 19: Remove Air Motor Cover

18 3A0294G

Page 19

Installation

r_262373_3A0294_before _linear

O-rings

Adapter

Lift Ring

13

18

19

Lift Ring

20

r_262373_3A0294_after_linear

Screw

Cover

24

23

22

r_262370_3A0294_16a

c. Use a wrench to remove the air motor lift ring.

Then remove the lift ring adapter and both

o-rings. Discard the adapter and both o-rings.

FIG. 20: Remove Lift Ring Adapter and O-rings

d. Place the linear sensor magnet (13) on the

installation tool (27), and then insert the magnet

down into the top of the motor shaft.

g. Route the linear sensor cable through the lift

ring adapter. Install the lift ring adapter; torque

to 30-36 ft-lbs (40.6-48.8 N•m). See F

IG. 21.

h. Route the linear sensor cable through the hole

on the lift ring adapter.

i. Apply the supplied adhesive to the lift ring

threads. Install the lift ring; torque to 30-36 ft-lbs

(40.6-48.8 N•m). See F

IG. 21.

j. Remove the screw on the valve cover to remove

the cover. See F

IG. 22.

k. Install the reed switch sensor (22). Secure with

the 1 in. (25 mm) screw (24) and o-ring (23) provided. See F

IG. 22.

e. Apply the supplied adhesive to the linear sensor

assembly (18) threads. Install the linear sensor;

torque to 30-36 ft-lbs (40.6-48.8 N•m). See F

21.

f. Place the new o-ring (20) on the lift ring adapter

(19), and apply the supplied adhesive to the

threads. See F

FIG. 21: Install Linear Sensor

IG.

IG. 21.

FIG. 22: Install Reed Switch Sensor

3A0294G 19

Page 20

Installation

25

26

Plug

r_262370_3A0294_17a

Rod

Nut

Nut

Washer

Lift Ring

Adapter

ti11169a

Pressure Valve

r_262370_3A0294_19a

l. Connect the strain relief guide (26) to the reed

switch sensor. Use a wrench to tighten the

1/4-20 x 1/2 in. screw (25) on the strain relief

guide and to secure it to the top plate of the air

motor.

FIG. 23: Install Strain Relief Guide

m. Use a zip tie to secure the reed switch sensor

cable.

p. D200 systems only: reconnect the air motor.

Install threaded rod through center hole in the

crossbar. Install lock washers and nuts onto

threaded rod, both above and below crossbar.

Use wrench to hold lift ring adapter and tighten

threaded rod into lift ring adapter using another

wrench. Tighten nut below crossbar to 25 ft-lb

(34 N•m) maximum. Tighten nut above crossbar

to lock motor in place.

n. Reinstall the valve cover, and tighten the nut.

See F

IG. 22.

o. Remove the plug in the air motor cover. Route

the linear sensor cables through the hole in the

back of the cover. Snap the air motor cover back

into place.

FIG. 24: Reinstall Air Motor Cover

FIG. 25: Reconnect Air Motor

8. Install the pressure sensor on the pump bleed port.

D60 rams only: If pump bleed valve is longer than

the supplied, replace it with the supplied bleed valve

(65).

a. Use a wrench to remove the pressure valve.

20 3A0294G

FIG. 26: Remove Pressure Valve

Page 21

Installation

37

Pressure

Valve

r_262370_3A0294_20a

36

38

41

Pressure

Sensor

Extension

Air Motor

Cable

Cable

LCM Cable

Solenoid

Extension

Cable

Light Tower

Shot Status

Drum Low (1)/

Start/Stop (2)

Not Used

Changeover

Solenoid

b. Apply the supplied sealant to the adapter (36),

the manifold (37), and the pressure valve. Install

all three in the order listed. See F

IG. 27.

c. Disconnect sensor cable at PT1. Install the

o-ring (41) and pressure sensor (38); use zip

ties (35) to secure the cable to the ram and air

hose.

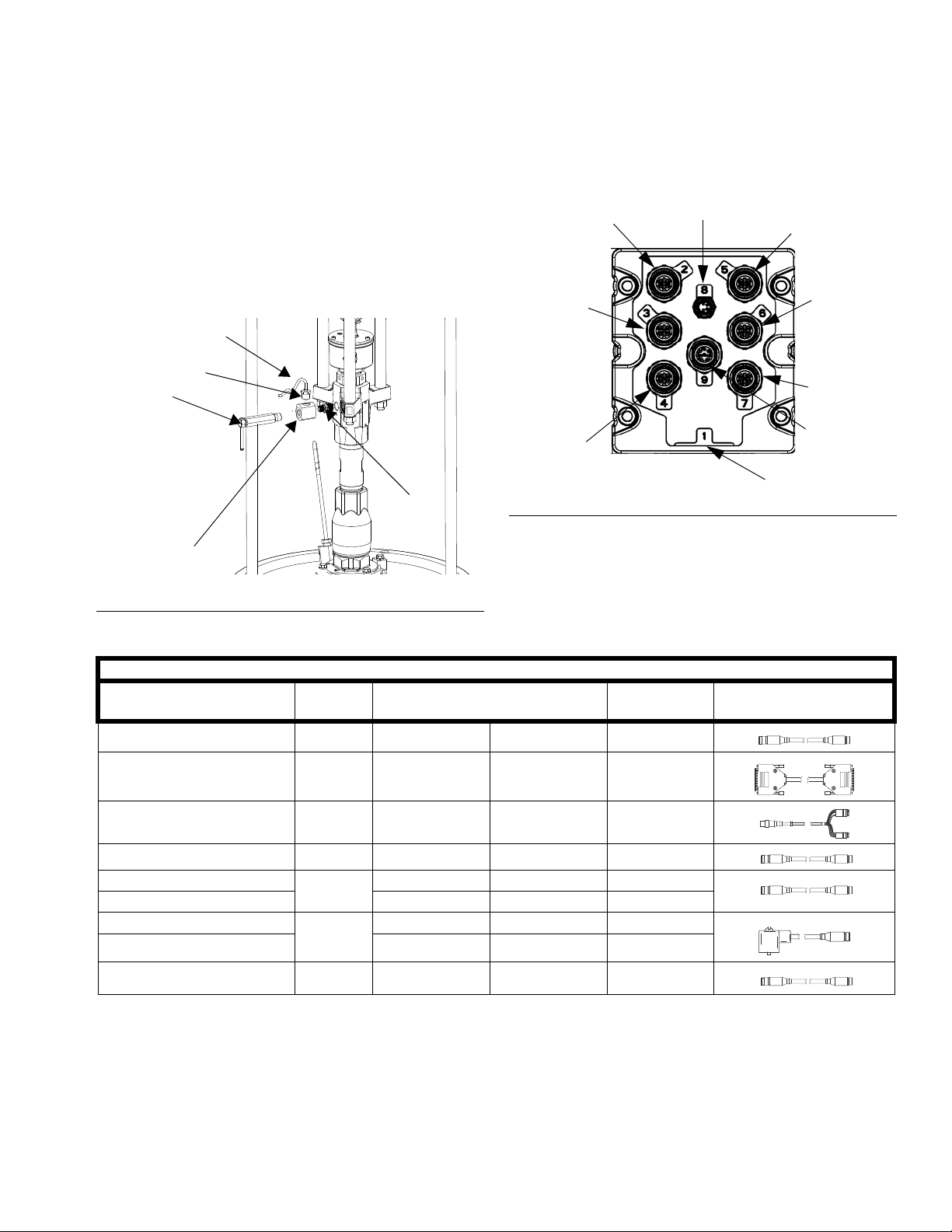

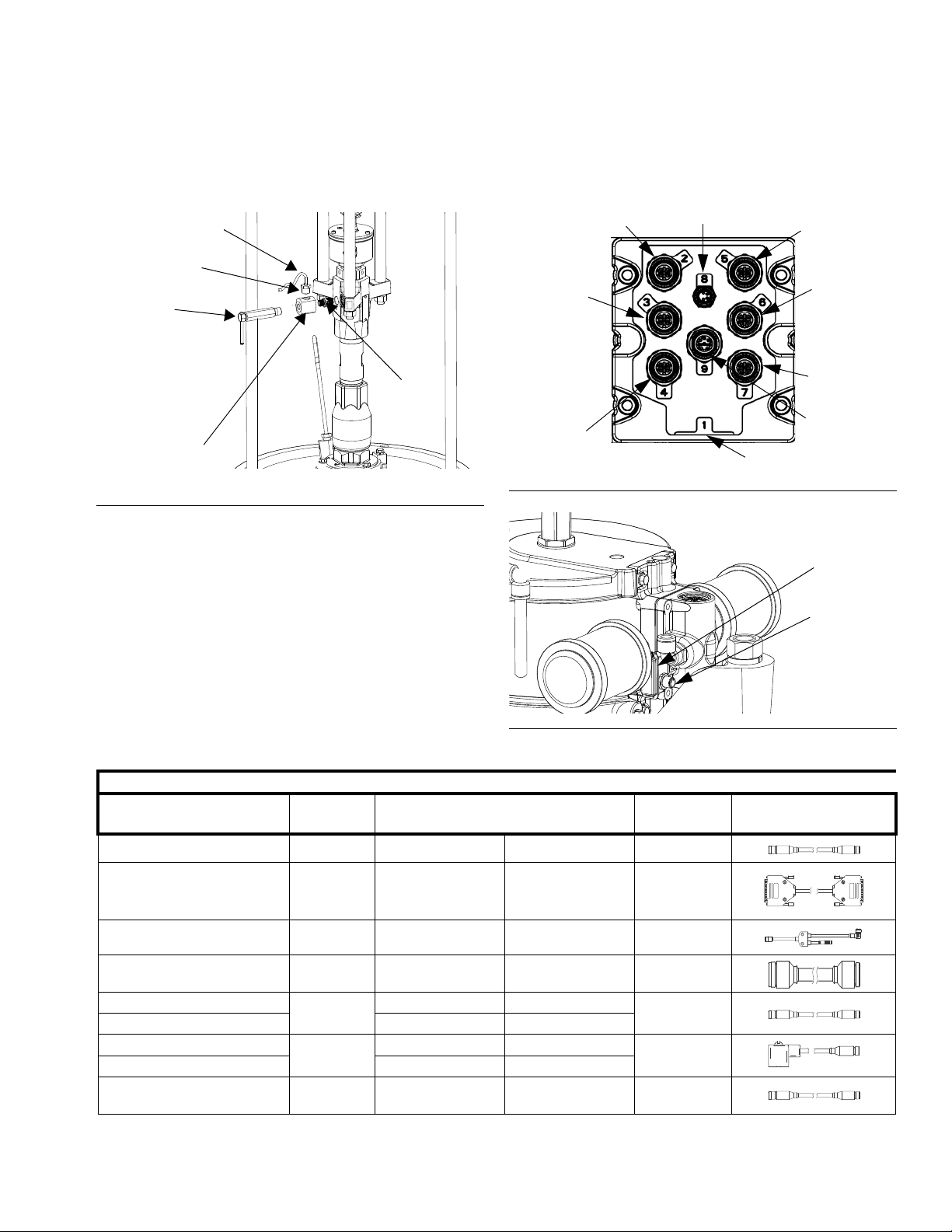

9. Install cables. Reference F

IG. 29 for a diagram of

cable connections and

FIG. 28: Breakout Module Connections

FIG. 27: Install Pressure Sensor

Description Part labels (relative to graphic)

Power

DB25

Pigtail

Motor

Solenoid Extension

Accessory Kit

Air Solenoid

Fluid Solenoid

Pressure Sensor Extension

262370 and 262372 Cable Identification

Length

in. (mm) Connectors

121226 PS1 None 16 (406.4)

15T859 1(blue) None 120 (3048)

15X619 AM1 LS1/RS1 17 (431.8)

15Y051 9(grey) AM1 118 (2997.2)

122030

3(red) Y1(yellow) 20 (508)

5(grey) Y2(orange) 20 (508)

AV 1(yellow) 20 (508)

121806

FV 2(yellow) 20 (508)

16F562 6(blue) PT1 80 (2032)

3A0294G 21

Page 22

Installation

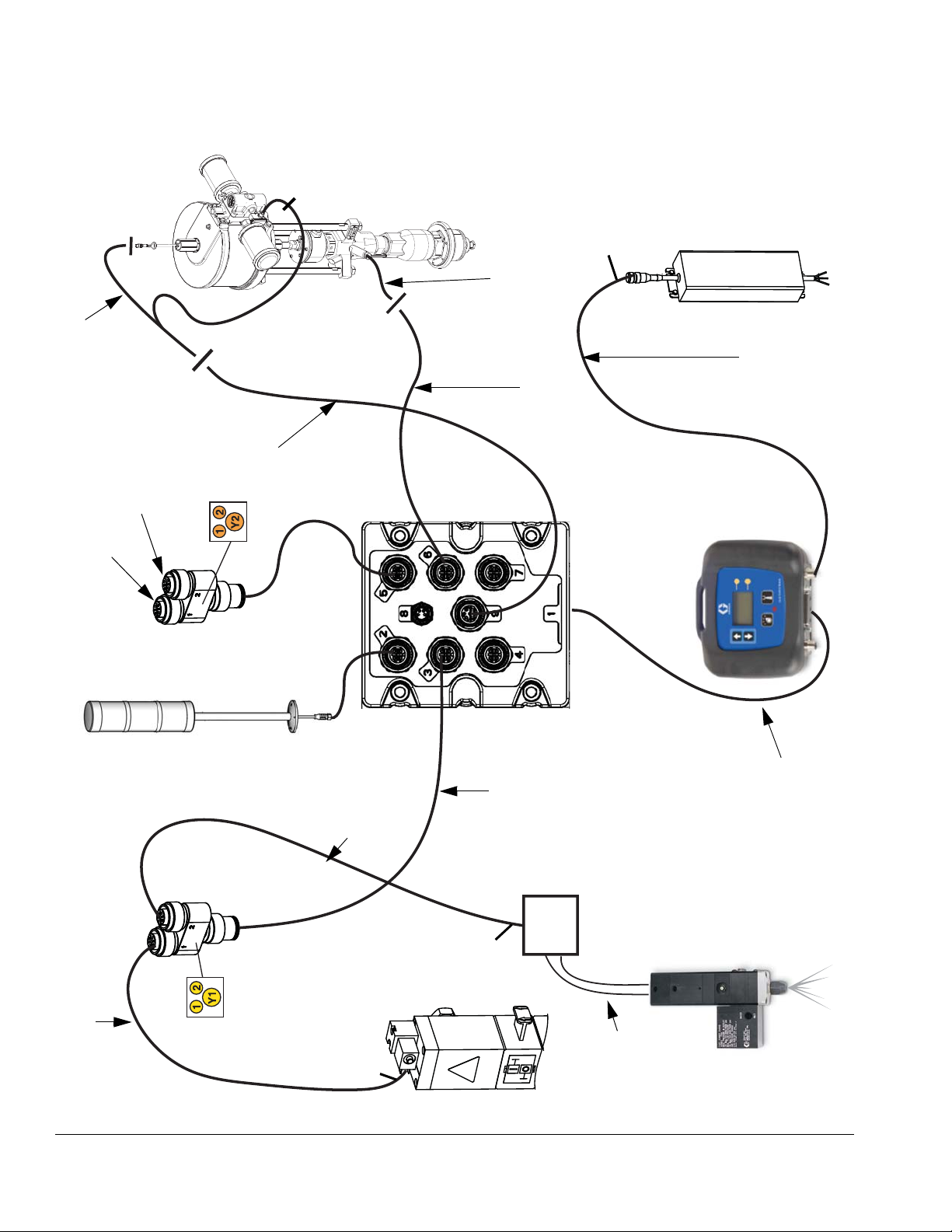

Light Tower

Pump

Power

Supply

Display

Y-Adapter

Air Valve

Assembly

Breakout Module

Dispense Valve

Solenoid Valve

Pressure Sensor Cable

Air Motor Cable

Pressure Sensor

Extension Cable

CAN Cable

LCM Cable

Solenoid Extension Cable

Solenoid Cable

Solenoid Cable

Optional

Air Lines

(supplied by user)

(supplied by user)

Pigtail

LS1

AM1

Kit

PT1

PS1

FV

AV

Low drum

(optional kit)

Foot switch

(optional kit)

ti18232a

Linear Sensor

Cable

Reed

Switch

Cable

RS1

FIG. 29: Cable Connections - D200S, D200, and D60 with Large NXT

22 3A0294G

Page 23

Installation

r_262370_3A0294_23a

4 (Front)

1

4 (Back)

Install

Power

Supply

Cord

r_262370_3A0294_24a

10. Secure cables to the air hose using zip ties. Tighten

all zip ties and then cut off the excess.

11. Bundle the cables and zip tie them close to the electronics bracket (1) so that they will fit under the electronics subassembly cover (4).

12. Install the electronics subassembly cover. Install the

back cover first and hand tighten the screws to

secure. Then install the front cover; hand tighten the

screws to secure.

13. Install the power supply cord (14).

FIG. 30: Install Covers

FIG. 31: Install Power Supply Cord

14. Open the air shutoff valves on the air control assembly.

3A0294G 23

Page 24

Installation

Shutoff

Valve

Shutoff

Valve

27

23

24

r_262371_3A0294_28a

1

28

24

23

r_262371_3A0294_29a

26

23

24

r_262371_3A0294_30a

Install Kit 262371

1. Close both shutoff valves on the air control panel.

FIG. 32: Close Shutoff Valves

2. Install the power supply bracket (27) to the ram post

using four screws (24) and lock washers (23).

3. Install the electronics subassembly (1) to the side of

the power supply bracket using four screws (28).

Also secure the bracket to the bottom of the air control bracket using two screws (24) and two lock

washers (23).

FIG. 34: Install Electronics Assembly

FIG. 33: Install Power Supply Bracket

4. Install the light tower bracket (26) to the top air controls bracket using three screws (24) and lock wash-

ers (23).

FIG. 35: Install Light Tower Bracket

24 3A0294G

Page 25

Installation

2

24

23

r_262371_3A0294_31a

Air Hose

Label

Elbow

Fitting

Pressure

Gauge

3

O-ring

Screw

r_262370_3A0294_11a

Slider Valve

Label

Elbow

Fitting

r_262370_3A0294_34a

5. Loosen two screws on the top air controls bracket.

Install the display module bracket (2) using two

screws (24) and lock washers (23) to secure it to the

air controls bracket.

FIG. 36: Install Display Module Bracket

6. Install the air valve subassembly (3).

a. Use two wrenches to remove the air hose,

elbow fitting, and pressure gauge from the air

controls.

c. Loosely install the air valve assembly (3).

Grease the o-ring included with the air valve

assembly. Install the o-ring and then finish

installing the air valve assembly. Secure with

screw.

FIG. 38: Install Air Valve Assembly

d. Install the new air motor slider valve label that is

included with the air valve assembly. See F

37.

e. Coat the gauge fitting with PTFE tape, and then

reinstall. Use a wrench to tighten. See F

IG.

IG. 37.

FIG. 37: Air Control Assembly

b. Remove the air motor slider valve label. See

F

IG. 15.

f. Coat the elbow fitting with PTFE tape. Reinstall

the fitting and air hose on the back of the new

air valve assembly. Use two wrenches to

tighten.

FIG. 39: Install Elbow Fitting

7. Snap the display (5) into the display bracket.

3A0294G 25

Page 26

Installation

ti18237a

17

Magnet

Magnet

Holder

Motor

Shaft

r_262374_3A0294_71a

Muffler

20

21

Pressure Valve

r_262370_3A0294_19a

8. Install the linear sensor (17).

a. Remove the lift ring or plug.

b. Insert magnet and magnet holder into the top of

the motor shaft using the magnet installation

tool.

c. Install the linear sensor assembly into the top

plate of the air motor.

NOTE: For air motor models M07xxx, M12xxx, and

M18xxx, which have the large mufflers, remove the muffler before installing the reed switch. Reinstall the muf-

fler after the reed switch in installed.

FIG. 41: Install Reed Switch

10. Install the pressure sensor on the pump bleed port.

a. Use a wrench to remove the pressure valve.

FIG. 40: Install Linear Sensor

9. Install the reed switch assembly (20).

a. Remove the air line to the motor.

b. Adjust the air fitting to make room for the reed

c. Install the reed switch (20) into the air valve as

26 3A0294G

switch (20).

shown in F

(21).

IG. 41, and secure with the screw

FIG. 42: Remove Pressure Valve

b. Apply the supplied sealant to the adapter (30),

the manifold (31), and the pressure valve. Install

all three in the order listed. See F

IG. 43.

c. Disconnect pressure sensor at PT1.

Page 27

Installation

Pressure

Valve

r_262370_3A0294_20a

32

30

31

33

Pressure

Sensor

Extension

Air Motor

Cable

Cable

LCM Cable

Solenoid

Extension

Cable

Light Tower

Shot Status

Drum Low (1)/

Start/Stop (2)

Not Used

Changeover

Solenoid

r_262371_3A0294_75a

Connect

Cable

20

d. Install the o-ring (33) and pressure sensor (32);

use zip ties (35) to secure the cable to the ram

and air hose.

FIG. 43: Install Pressure Sensor

11. Install cables. Reference the table below and FIG.

46 for a diagram of cable connections.

FIG. 44: Breakout Module Connections

FIG. 45: Connect Linear Sensor/Reed Switch Cable

262371 Cable Identification

Length

Description Part Labels (relative to graphic)

Power Cable

DB25

Pigtail

Motor cable

Solenoid Extension

Accessory Kit

Air Solenoid

Fluid Solenoid

Pressure Sensor Exten-

sion

121226 PS1 None 16

15T859 1(blue) None 120

16G589 AM1 LS1/RS1 52

15Y051 9(grey) AM1 118

122030 3(red) Y1(yellow)

5(grey) Y2(orange)

121806 AV 1(yellow)

16F562 6(blue) PT1 80

FV 2(yellow)

in. (mm) Connectors

20

20

3A0294G 27

Page 28

Installation

Light Tower

Pump

Power

Supply

Display

Y-Adapter

Air Valve

Assembly

Breakout Module

Dispense Valve

Solenoid Valve

Linear Sensor/Reed Switch Cable

Pressure Sensor Cable

Air Motor Cable

Pressure Sensor

Extension Cable

CAN Cable

LCM Cable

Solenoid Extension Cable

Solenoid Cable

Solenoid Cable

(optional kit)

Air Lines

(supplied by user)

(supplied by user)

(supplied by user)

LS1

AM1

PT1

PS1

AV

FV

Low drum

(optional kit)

Foot switch

(optional kit)

RS1

ti18235a

FIG. 46: Cable Connections - D200 with Small NXT

28 3A0294G

Page 29

Installation

r_262371_3A0294_39a

4 (Front)

1

4 (Back)

Install

Power

Supply

Cord

r_262371_3A0294_40a

12. Secure cables to the air hose using zip ties. Tighten

all zip ties and then cut off the excess.

13. Bundle the cables and zip tie them close to the electronics bracket (1) so that they will fit under the electronics subassembly cover (4).

14. Install the electronics subassembly cover. Install the

back cover first and hand tighten the screws to

secure. Then install the front cover; hand tighten the

screws to secure.

15. Install the power supply cord (13).

FIG. 47: Install Covers

FIG. 48: Install Power Supply Cord

16. Open the air shutoff valves on the air control assembly.

3A0294G 29

Page 30

Installation

Shutoff

Valve

Shutoff

Valve

1

29

28

r_262373_3A0294_28a

2

31

30

5

r_262373_3A0294_29a

Air Hose

Label

Elbow

Fitting

Pressure

Gauge

Install Kit 262373

1. Close both shutoff valves on the air control panel.

FIG. 49: Close Shutoff Valves

2. Install the electronics subassembly (1) to the back

of the bracket on the ram post using four screws

(29) and washers (28).

3. Install display bracket subassembly (2) to the bottom of the air motor using two screws (30) and two

washers (31).

FIG. 51: Install Display Bracket

4. Install the air valve subassembly (3).

a. Use two wrenches to remove the air hose,

elbow fitting, and pressure gauge from the air

controls.

FIG. 50: Install Electronics Assembly

30 3A0294G

FIG. 52: Air Controls

b. Remove the air motor slider valve label.

Page 31

Installation

Screw

Slider Valve

O-ring

3

r_262373_3A0294_31a

Label

Fitting

Air Hose

r_262373_3A0294_32a

ti8218b

r_262373_3A0294_before _linear

O-rings

Adapter

Lift Ring

c. Loosely install the air valve assembly (3).

Grease the o-ring included with the air valve

assembly. Install the o-ring and then finish

installing the air valve assembly. Secure with the

two screws that are included with the air valve

assembly.

FIG. 53: Install Air Valve Assembly

d. Install the new air motor slider valve label that is

included with the air valve assembly.

5. Snap the display (5) into the display bracket. See

F

IG. 51.

6. Install the linear sensor assembly (18) and the reed

switch sensor (22).

a. Remove the air motor top cover using a flat

head screwdriver.

FIG. 55: Remove Air Motor Cover

b. Use a wrench to remove the air motor lift ring.

Then remove the lift ring adapter and both

o-rings. Discard the adapter and both o-rings.

e. Coat the gauge fitting and elbow fitting with

PTFE tape, and then reinstall. Use a wrench to

tighten.

f. Install the fitting and air hose on the back of the

new air valve assembly. Use two wrenches to

tighten.

FIG. 54: Install Fitting and Air Hose

FIG. 56: Remove Lift Ring Adapter and O-rings

c. Place the linear sensor magnet (13) on the

installation tool (27), and then insert the magnet

down into the top of the motor shaft.

d. Apply the supplied adhesive to the linear sensor

assembly (18) threads. Install the linear sensor;

torque to 30-36 ft-lbs (40.6-48.8 N•m). See F

57.

IG.

3A0294G 31

Page 32

Installation

13

18

19

Lift Ring

20

r_262373_3A0294_after_linear

Screw

Cover

24

23

22

25

26

e. Place the o-ring (20) on the lift ring adapter (19),

and apply the supplied adhesive to the threads.

See F

IG. 57.

FIG. 57: Install Linear Sensor

f. Route the linear sensor cable through the lift

ring adapter. Install the lift ring adapter; torque

to 30-36 ft-lbs (40.6-48.8 N•m). See F

g. Route the linear sensor cable through the hole

on the lift ring adapter.

IG. 57.

j. Install the reed switch sensor (22). Secure with

the 1 in. (25 mm) screw (24) and o-ring (23) provided. See F

IG. 58.

FIG. 58: Install Reed Switch Sensor

k. Connect the strain relief guide (26) to the reed

switch sensor. Use a wrench to tighten the 1/2

in. screw (25) on the strain relief guide and to

secure it to the top plate of the air motor.

h. Apply the supplied adhesive to the lift ring

threads. Install the lift ring; torque to 30-36 ft-lbs

(40.6-48.8 N•m). See F

IG. 57.

i. Remove the screw on the valve cover to remove

the cover. See F

IG. 58.

FIG. 59: Install Strain Relief Guide

l. Use a zip tie to secure the reed switch sensor

cable.

m. Reinstall the valve cover, and tighten the nut.

See F

IG. 58.

n. Remove round plug and route the linear sensor

cable through the opening in the back of the

cover. Snap the air motor cover back into place.

32 3A0294G

Page 33

Installation

Pressure Valve

Pressure

Valve

33

34

35

38

Pressure

Sensor

Extension

Air Motor

Cable

Cable

LCM Cable

Solenoid

Extension

Cable

Light Tower

Shot Status

Drum Low (1)/

Start/Stop (2)

Not Used

Changeover

Solenoid

7. Install the pressure sensor on the pump bleed port.

a. Use a wrench to remove the pressure valve.

FIG. 60: Remove Pressure Valve

b. Apply the supplied sealant to the adapter (33),

the manifold (34), and the pressure valve. Install

all three in the order listed. See F

IG. 61.

8. Install cables. Reference the cable identification

table on the next page and F

IG. 63 for a diagram of

cable connections.

FIG. 62: Breakout Module Connections

c. Disconnect pressure sensor at PT1.

d. Install the o-ring (38) and pressure sensor (35);

use zip ties (32) to secure the cable to the ram

and air hose.

FIG. 61: Install Pressure Sensor

3A0294G 33

Page 34

Installation

262373 Cable Identification

Length

Description Part Labels (relative to graphic)

in. (mm) Connectors

Power Cable 122487 PS1 None 60 (1524)

DB25 15T859 1(blue) None 120 (3048)

Pigtail 16G589 AM1 LS1/RS1 52 (1320.8)

Motor cable 15Y051 9(grey) AM1 118 (2997.2)

Air Solenoid Extension

122030

1(yellow) SX1

20 (508)Solenoid Extension 3(red) Y1(yellow)

Accessory Kit cable 5(grey) Y2(orange)

Air Solenoid

Fluid Solenoid FV 2(yellow)

121806

AV SX1

20 (508)

Pressure Sensor

Extension

16F562 6(blue) PT1 80 (2032)

34 3A0294G

Page 35

Installation

Light Tower

Pump

Power

Supply

Display

Y-Adapter

Air Valve

Assembly

Breakout Module

Dispense Valve

Solenoid Valve

Pigtail

Pressure Sensor Cable

Air Motor Cable

Pressure Sensor

Extension Cable

CAN Cable

LCM Cable

Solenoid Extension Cable

Solenoid Cable

Solenoid Extension Cable

(optional kit)

Air Lines

(supplied by user)

(supplied by user)

LS1

AM1

PT1

PS1

Low drum

(optional kit)

Foot switch

(optional kit)

SX2

FV

AV

Solenoid Cable

ti18234a

Linear Sensor

Cable

Reed

Switch

Cable

RS1

FIG. 63: Cable Connections - S20 with Large NXT

3A0294G 35

Page 36

Installation

4

r_262373_3A0294_41a

1

Install Power

Supply Cord

r_262373_3A0294_42a

9. Secure cables to the air hose using zip ties. Tighten

all zip ties and then cut off the excess.

10. Bundle the cables and zip tie them close to the electronics subassembly bracket (1) so that they will fit

under the electronics subassembly cover (4).

11. Install the electronics subassembly cover; hand

tighten the screws to secure.

12. Install the power supply cord (14).

FIG. 65: Install Power Supply Cord

13. Open the air shutoff valves on the air control assembly.

FIG. 64: Install Electronics Cover

36 3A0294G

Page 37

Installation

Shutoff

Valve

Shutoff

Valve

1

23

22

r_262373_3A0294_28a

2

25

24

5

r_262374_3A0294_66a

Air Hose

Label

Elbow

Fitting

Pressure

Gauge

Install Kit 262374

1. Close both shutoff valves on the air control panel.

FIG. 66: Close Shutoff Valves

2. Install the electronics subassembly (1) to the back

of the bracket on the ram post using four screws

(23) and washers (22).

3. Install display bracket subassembly (2) to the bottom of the air motor using two screws (25) and two

washers (24).

FIG. 68: Install Display Bracket

4. Install the air valve subassembly (3).

a. Use two wrenches to remove the air hose,

elbow fitting, and pressure gauge from the air

controls.

FIG. 67: Install Electronics Assembly

3A0294G 37

FIG. 69: Air Valve

b. Remove the air motor slider valve label.

Page 38

Installation

Screw

Slider Valve

O-ring

3

r_262374_3A0294_68a

Label

Fitting

r_262374_3A0294_69a

ti18237a

17

Magnet

Magnet

Holder

Motor

Shaft

c. Loosely install the air valve assembly (3)

Remove air pressure gauge if necessary.

Grease the o-ring included with the air valve

assembly. Install the o-ring and then finish

installing the air valve assembly. Secure with the

two screws that are included with the air valve

assembly.

FIG. 70: Install Air Valve Assembly

5. Install the linear sensor (17).

a. Remove the lift ring or plug.

b. Insert magnet holder and magnet into the top of

the motor shaft using the magnet installation

tool.

c. Install the linear sensor assembly into the top

plate of the air motor.

d. Install the new air motor slider valve label that is

included with the air valve assembly.

e. If removed, coat the gauge fitting and elbow fit-

ting with PTFE tape, and then reinstall. Use a

wrench to tighten.

f. Install the fitting and air hose on the back of the

new air valve assembly. Use two wrenches to

tighten.

FIG. 71: Install Fitting

FIG. 72: Install Linear Sensor

6. Install the reed switch assembly (19).

a. Remove the air line to the motor.

b. Adjust the air fitting to make room for the reed

switch (19).

c. Install the reed switch into the air valve as

shown in F

IG. 41, and secure with the screw

(20).

38 3A0294G

Page 39

Installation

r_262374_3A0294_71a

Muffler

19

20

Pressure Valve

r_262370_3A0294_19a

Pressure

Valve

r_262370_3A0294_20a

27

29

28

33

Pressure

Sensor

Extension

Air Motor

Cable

Cable

LCM Cable

Solenoid

Extension

Cable

Light Tower

Shot Status

Drum Low (1)/

Start/Stop (2)

Not Used

Changeover

Solenoid

NOTE: For air motor models M07xxx, M12xxx, and

M18xxx, which have the large mufflers, remove the muffler before installing the reed switch. Reinstall the muf-

fler after the reed switch is installed.

FIG. 73: Install Reed Switch

7. Install the pressure sensor on the pump bleed port.

a. Use a wrench to remove the pressure valve.

d. Install the o-ring (33) and pressure sensor (29);

use zip ties (26) to secure the cable to the ram

and air hose.

FIG. 75: Install Pressure Sensor

8. Install cables. Reference the cable identification

table on the next page and F

IG. 77 for a diagram of

cable connections.

FIG. 74: Remove Pressure Valve

3A0294G 39

b. Apply the supplied sealant to the adapter (27),

the manifold (28), and the pressure valve. Install

all three in the order listed. See F

IG. 75.

c. Disconnect pressure sensor at PT1.

FIG. 76: Breakout Module Connections

Page 40

Installation

262374 Cable Identification

Description Part Labels (relative to graphic)

Power Cable

122487 PS1 None 60 (1524)

Length

in. (mm) Connectors

DB25

Pigtail

Motor cable

Air Solenoid Extension

Accessory Kit

Air Solenoid

Fluid Solenoid

Pressure Sensor Exten-

sion

15T859 1(blue) None 120 (3048)

16G589 AM1 LS1/RS1 52(1320.8)

15Y051 9(grey) AM1 118 (2997.2)

122030

121806

3(red) Y1(yellow)

5(grey) Y2(orange)

AV SX1

FV 2(yellow)

20 (508)

20 (508)

16F562 6(blue) PT1 80 (2032)

40 3A0294G

Page 41

Installation

Light Tower

Power

Supply

Display

Y-Adapter

Air Valve

Assembly

Breakout Module

Dispense Valve

Solenoid Valve

Pump

Pigtail

Pressure Sensor Cable

Air Motor Cable

Pressure Sensor

Extension Cable

CAN Cable

LCM Cable

Solenoid Extension Cable

Solenoid Cable

Air Lines

(supplied by user)

(supplied by user)

(optional kit)

LS1

AM1

PT1

PS1

Low drum

(optional kit)

Foot switch

(optional kit)

RS1

Solenoid Extension Cable

SX2

Solenoid Cable

FV

AV

ti18236a

Reed

Switch

Cable

Linear Sensor Cable

FIG. 77: Cable Connections - S20 with Small NXT

3A0294G 41

Page 42

Installation

4

1

Install Power

Supply Cord

r_262373_3A0294_42a

9. Route all cables out the top of the electrical enclosure. Make sure there is enough slack to extend ram

to full height. Secure cables to the air hose using zip

ties. Tighten all zip ties and then cut off the excess.

10. Bundle the excess cable length and zip tie them

close to the electronics bracket (1) so that they will

fit under the electronics subassembly cover (4).

11. Install the electronics subassembly cover. Install the

back cover first and hand tighten the screws to

secure. Then install the cover and hand tighten the

screws to secure.

13. Open the air shutoff valves on the air control assembly.

FIG. 78: Install Cover

12. Install the power supply cord (12).

FIG. 79: Install Power Supply Cord

42 3A0294G

Page 43

Installation

39

40

37

36

r_262375_3A0294_26a

35

36

37

38

37

r_262375_3A0294_27a

1

29

30

r_262375_3A0294_28a

2

30

29

r_262375_3A0294_29a

5

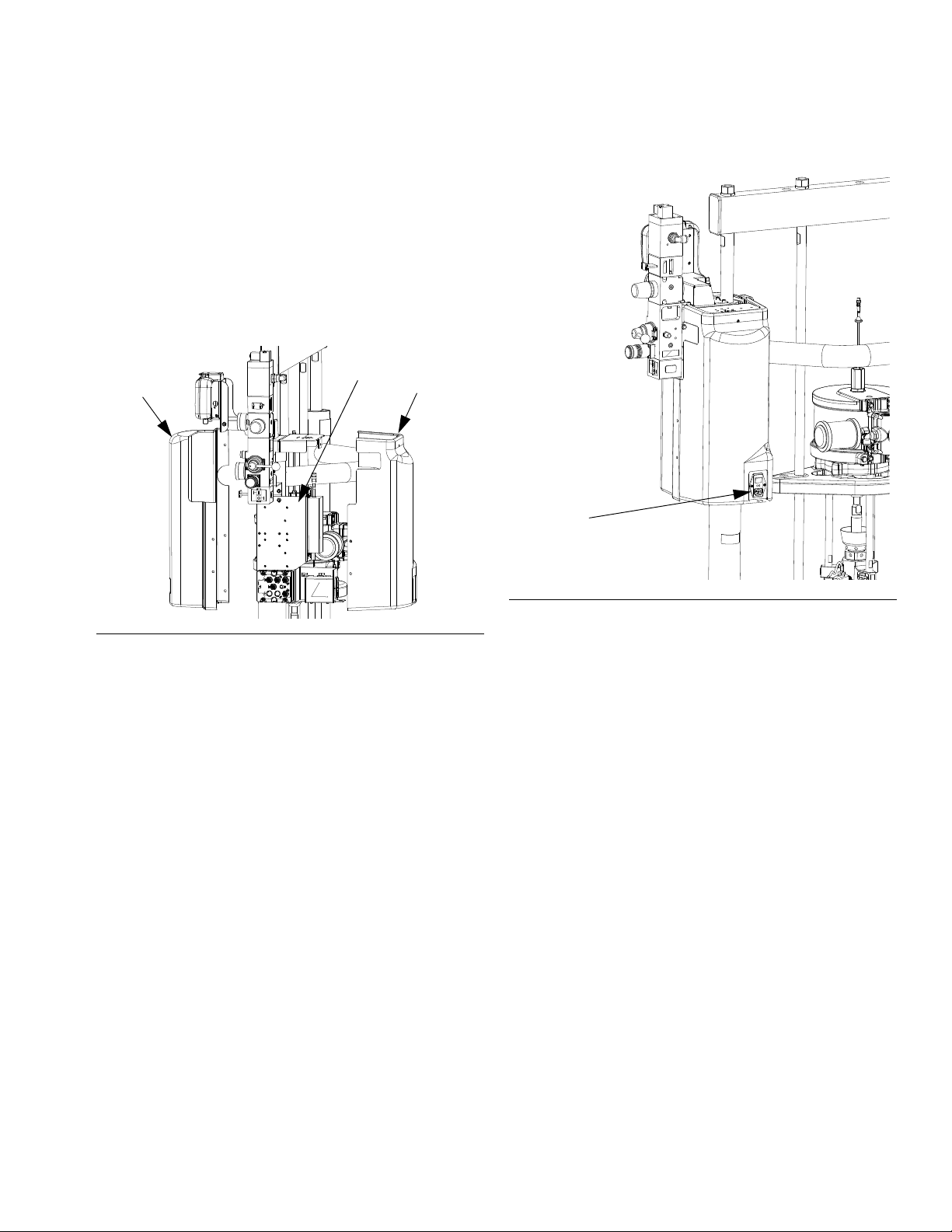

Install Kit 262375

1. Shut off the air supply to the system.

2. Floor stand kit only: Install the control mount bracket

(39) to the pump using two screws (36), and wash-

ers (37 and 40).

4. Install the electronics subassembly (1) to the side of

the adapter bracket using four screws (30) and

washers (29).

FIG. 80: Install Control Mount Bracket

3. Install the adapter bracket (35) to the wall mount

bracket or the control mount bracket using two

screws (36), washers (37), and nuts (38).

FIG. 82: Install Electronics Assembly

5. Install the display bracket (2) to the electronics subassembly using four screws (30) and washers (29).

FIG. 83: Install Display Bracket

FIG. 81: Install Adapter Bracket

3A0294G 43

Page 44

Installation

ti8218b

r_262373_3A0294_before _linear

O-rings

Adapter

Lift Ring

13

18

19

Lift Ring

20

r_262373_3A0294_after_linear

6. Snap the display (5) into the display bracket.

7. Install the linear sensor assembly (18) and the reed

switch sensor (22).

a. Remove the air motor top cover using a flat

head screwdriver.

FIG. 84: Remove Air Motor Cover

b. Use a wrench to remove the air motor lift ring.

Then remove the lift ring adapter and both

o-rings. Discard the adapter and both o-rings.

e. Place the new o-ring (20) on the lift ring adapter

(19), and apply the supplied adhesive to the

threads. See F

IG. 86.

FIG. 86: Install Linear Sensor

f. Route the linear sensor cable through the lift

ring adapter. Install the lift ring adapter; torque

to 30-36 ft-lbs (40.6-48.8 N•m). See F

IG. 86

FIG. 85: Remove Lift Ring Adapter and O-rings

c. Place the linear sensor magnet (13) on the

installation tool (27), and then insert the magnet

down into the top of the motor shaft.

d. Apply the supplied adhesive to the linear sensor

assembly (18) threads. Install the linear sensor;

torque to 30-36 ft-lbs (40.6-48.8 N•m). See F

86.

IG.

g. Route the linear sensor cable through the hole

on the lift ring adapter.

h. Apply the supplied adhesive to the lift ring.

Install the lift ring; torque to 30-36 ft-lbs

(40.6-48.8 N•m). See F

IG. 86.

i. Remove the screw on the valve cover to remove

the cover. See F

IG. 87.

44 3A0294G

Page 45

Installation

Screw

Cover

25

24

23

26

27

Plug

33

6

31

32

r_262375_3A0294_34a

j. Install the reed switch sensor (23). Secure with

the 1 in. (255 mm) screw (25) and o-ring (24)

provided.

FIG. 87: Install Reed Switch Sensor

k. Connect the strain relief guide (27) to the reed

switch sensor. Use a wrench to tighten the 1/2

in. screw (26) on the strain relief guide and to

secure it to the top plate of the air motor.

n. Remove the plug in the air motor cover. Route

the linear sensor cables through the hole in the

back of the cover. Snap the air motor cover back

into place.

FIG. 89: Remove Plug

8. Without integrated air controls only: Install valve

subassembly (6) and fittings.

a. Apply the supplied adhesive to the adapter fit-

ting (31). Screw the fitting into bottom of the air

valve so that the fitting points away from the display module.

FIG. 88: Install Strain Relief Guide

l. Use a zip tie to secure the reed switch sensor

cable.

m. Reinstall the valve cover, and tighten the nut.

b. Apply the supplied adhesive to the pipe nipple

fitting (32) and the pipe swivel fitting (33). Screw

both fittings onto the valve assembly as shown.

FIG. 90: Install Valve Assembly (without air controls)

c. Screw entire assembly onto the adapter fitting.

Use two wrenches to tighten.

3A0294G 45

Page 46

Installation

r_262375_3A0294_35a

6

31

33

32

Air Motor

Cable

LCM Cable

Solenoid

Extension

Cable

Light Tower

Shot Status

Drum Low (1)/

Start/Stop (2)

Not Used

Changeover

Solenoid

9. With integrated air controls only: Install valve

assembly (6) and fittings.

a. Apply the supplied adhesive to the pipe nipple

fitting (32). Screw the fitting into the air control

assembly.

b. Apply the supplied adhesive to the adapter fit-

ting (31) and the pipe swivel fitting (33). Screw

both fittings onto the valve assembly as shown.

c. Screw the entire assembly onto the pipe nipple

fitting. Use two wrenches to tighten.

10. Install cables. Reference the cable identification

table below and F

IG. 93 for a diagram of cable con-

nections.

FIG. 91: Install Valve Assembly (with air controls)

Description Part Labels (relative to graphic)

Power Cable

DB25

Pigtail

Motor cable

Solenoid Extension

Accessory Kit

Air Solenoid

Fluid Solenoid

Pressure Sensor Extension

121226 PS1 None 16 (406.4)

15T859 1(blue) None 120 (3048)

15X619 AM1 LS1/RS1 17 (431.8)

9(grey) AM1 118 (2997.2)

122030

121806

-- - - -

FIG. 92: Breakout Module Connections

262375 Cable Identification

3(red) Y1(yellow)

5(grey) Y2(orange)

AV 1(yellow)

FV 2(yellow)

Length

in. (mm) Connectors

20 (508)

20 (508)

46 3A0294G

Page 47

Installation

Linear Sensor Switch Cable

Air Motor Cable

CAN Cable

LCM Cable

Solenoid Extension Cable

Solenoid Cable

Solenoid Cable

Air Lines

(supplied by user)

(supplied by user)

(optional kit)

AM1

PS1

Low drum

(optional kit)

Foot switch

(optional kit)

LS1

FV

AV

ti18233a

RS1

Pigtail

Reed

Switch

Cable

Pump

Power

Supply

Light Tower

Y-Adapter

Display

Breakout Module

Solenoid Valve

Dispense Valve

Air Valve

Assembly

FIG. 93: Cable Connections - Wall Mount or Floor Stand Pumps with Large NXT

3A0294G 47

Page 48

Installation

Pressure Valve

Pressure

Valve

44

42

43

45

Plugged

r_262375_3A0294_41a

Top Por t

Bottom Port

11. Install the pressure sensor on the pump bleed port.

a. Use a wrench to remove the pressure valve.

FIG. 94: Remove Pressure Valve

b. Apply the supplied sealant to the adapter (42),

the manifold (43), and the pressure valve. Install

all three in the order listed.

13. Install the air lines (34).

a. Connect the air lines to the valve subassembly

(6) as shown.

FIG. 96: Install Air Lines - Air Valve

FIG. 95: Install Pressure Sensor

c. Disconnect pressure sensor at PT1.

d. Install the o-ring (45) and pressure sensor (44).

12. Bundle the cables and zip tie them close to the electronics bracket (1) so that they will fit under the electronics subassembly cover (4).

See F

IG. 95.

b. Run the air lines between the adapter bracket

and connect them to the top port and bottom

port of the solenoid valve assembly as shown.

See F

IG. 96 and FIG. 97.

FIG. 97: Install Air Lines - Solenoid Valve

c. Zip tie both air lines to the pump tie rod.

48 3A0294G

Page 49

Installation

4

r_262375_3A0294_43a

Install Power

Supply Cord

r_262375_3A0294_43a

14. Install the electronics subassembly cover (4); hand

tighten the screws to secure.

15. Install the power supply cord (14).

FIG. 98: Install Cover

FIG. 99: Install Power Supply Cord

16. Turn on air supply to the system.

3A0294G 49

Page 50

Setup

Wet Cup

Air Inlet

Air Inlet

NXT1800 and Smaller Air Motors

NXT2200 and Larger Air Motors

Setup

NOTE: For setup procedures specific your supply sys-

tem or pump assembly, refer to the Supply Systems

Operation manual or your specific pump package

instructions-parts manual.

Enter Password

If a password is enabled, the password entry screen

automatically opens when you change to setup mode.

Enter the password to access setup mode.

Setup Pump

8. Connect the air line from the air source to the system air inlet. See F

pump manual to determine the correct air supply

flow requirements. Connect an air supply hose that

is capable of meeting the required flow to the air

motor air inlet.

NOTE: Quick disconnects restrict flow for NXT2200 and

larger air motors.

IG. 101. Refer to your specific

1. Follow the Installation guidelines on page 16.

2. Follow the Installation procedure for your particular

shot dispense kit. The procedures start on page 16.

3. Fill displacement pump wet cup 2/3 full with Graco

Throat Seal Liquid (TSL

FIG. 100: Fill Wet Cup

4. Attach electrically conductive fluid hose to pump

outlet and tighten.

5. Attach other end of electrically conductive fluid hose

to dispense valve and tighten.

™

).

FIG. 101: Connect to Air Inlet

9. Connect air supply and electrical cable to the dispense valve and solenoid valve. See the dispense

valve manual for instructions.

10. Flush and/or prime before using. See Prime/Purge,

page 52, for instructions.

6. Shut off the air valve by pressing the Air On/Off soft

key on the display module.

7. Back off the air regulators to their full counterclockwise position and close all shutoff valves for the

rams.

50 3A0294G

Page 51

Pressure Relief Procedure

Drain/Purge

+

Valve

Trapped air can cause the pump to cycle

unexpectedly, which could result in serious injury

from splashing or moving parts

1. Lock the gun/valve trigger.

2. Change to manual mode in the run screen. See

Change Operation Mode, page 62.

3. Shut off the air supply to the system.

4. Shut off the air valve by pressing the Air On/Off soft

key on the display module.

5. Close the manual air valve.

Pressure Relief Procedure

10. Leave the pump bleeder valve open until you are

ready to spray/dispense again.

11. If you suspect that the spray tip/nozzle or hose is

completely clogged, or that pressure has not been

fully relieved after following the previous steps, very

slowly loosen the tip guard retaining nut hose end

coupling and relieve pressure gradually; then loosen

completely. Now clear the tip/nozzle or hose.

6. Unlock the gun/valve trigger.

7. Hold a metal part of the gun/valve firmly to the side

of a grounded metal pail, and press or step

on the foot switch.

8. Lock the gun/valve trigger.

9. Open the material line drain valve and the pump

bleeder valve. Have a container ready to catch the

drainage.

FIG. 102: Drain Material

3A0294G 51

Page 52

Prime/Purge

+

Drain/Purge

Valve

Prime/Purge

1. Follow Pressure Relief Procedure on page 51.

9. Prime or purge hose and gun/valve.

a. If necessary, change to manual mode in the run

screen. See Change Operation Mode, page

62.

2. Priming only: replace pail of material if necessary.

3. Remove the spray tip and tip guard from gun or

remove the nozzle from the dispense valve.

4. Flushing only: If desired, remove built-in fluid filter

(present on some models). Reinstall filter cap after

removing fluid filter.

5. Place pump in material (if priming) or solvent (if

flushing).

6. Turn air regulator to 0 psi.

7. Open the manual shutoff valve(s).

8. Perform a manual purge.

a. Change to manual mode in the run screen. See

Change Operation Mode, page 62.

b. Place a drain tube in a grounded waste pail.

Open drain/purge valve slightly by rotating

counterclockwise.

b. Hold a metal part of the gun/valve firmly to the

side of a grounded metal pail.

c. Press and hold or step on the foot

switch (purchase separately) until all air in the

hose is purged

10. If priming, the system is now ready to dispense; go

to Dispense a Shot, page 65.

If flushing, follow the Operation on page 62; leave

the solvent in and store the equipment.

FIG. 103: Flush with Solvent

c. Increase pressure on the air regulator until the

pump begins to move. Run the pump until no air

is released from the drain/purge valve or until

clean solvent flows from the drain tube. Close

drain/purge valve by rotating clockwise. The

pump will stall.

52 3A0294G

Page 53

Set System Parameters

Set System Parameters

NOTE: Refer to Appendix B - Tips, page 102, for setup

guidelines and tips.

Set Units and Specific Gravity

1. Navigate to setup screen 1.

2. Press to access fields to make changes.

3. Press to navigate to the units of mea-

7. Press to navigate to the specific gravity (SG)

field.

NOTE: If the specific gravity is unknown, use the calibration routine to enter it automatically. See Calibrate

on page 60 for calibration instructions.

8. Press and to increment or decrement to the specific gravity of the material being dis-

pensed.

9. Press to save the selection.

10. Press to exit edit mode.

sure fields.

4. Press to open the first drop-down box. Press

to select the desired units.

5. Press to save selection.

6. Press to navigate to the next drop-down box,

and perform the same two steps.

3A0294G 53

Page 54

Set System Parameters

Define Shot Size

Up to 25 shots (1 – 25) can be defined in the setup shot

screen.

To define a shot size:

1. Navigate to setup screen 2.

2. Press to access fields to make changes.

6. Press to navigate to the fluid weight field.

7. Press and to increment or decrement to the desired shot size.

8. Press to accept the shot size.

9. Define another shot size.

a. Press to move to the shot number field.

b. Repeat steps 4 through 8 to define the next shot

size.

10. Press to exit edit mode.

3. Press to navigate to the shot number

field.

4. Press to scroll through the 25 shot

numbers.

5. Press to select the desired shot number.

54 3A0294G

Page 55

Set System Parameters

Define Shot Sequence

Up to 5 sequences (A – E) can be programmed. Each

sequence can have up to 14 shot positions and each

shot position can be one of the possible 25 shots.

NOTE: Only shots that are already defined can be

added to a shot sequence.

To edit a shot sequence:

1. Navigate to setup screen 3.

2. Press to access the fields.

7. Press and to navigate through

each shot position and to select shot numbers.

NOTE: When a shot number is selected the shot volume

box will display.

8. Press to select the desired shot.

9. Once all shot positions and shot numbers are con-

figured for the shot sequence, press to exit

edit mode.

3. Press to navigate to the shot sequence

field. Press to select the field.

4. Press to scroll through the shot

sequences.

5. Press to select the desired shot sequence.

6. Press to navigate to the shot positions.

3A0294G 55

Page 56

Set System Parameters

Set Password

NOTE: When the password is “00000,” the setup

screens can be accessed without entering a password.

1. Navigate to setup screen 4.

2. Press to access fields to make changes.

3. Press to navigate to the first password

Disable Password

To disable the password, follow Set Password, page 56,

to change the password to “00000.”

Reset Password

If the password is forgotten, it can be reset without losing the current settings or shot data.

1. Disconnect power to the user interface.

2. Reconnect power to the user interface.

3. When the power up screen appears, immediately

press and hold both the top soft key and the

for six seconds. The password automatically resets

to “00000.”

4. Follow the Set Password, page 56, instructions to

set the password if desired.

field.

4. Press and to increment or decrement to the desired digits of the password.

5. Press to enter the password.

6. Press to navigate to the next password field.

Follow steps 4-5 to enter and confirm the password.

7. Press to exit edit mode.

56 3A0294G

Page 57

Set System Parameters

Select Pump

1. Navigate to setup screen 4, if necessary.

2. Press to access fields to make changes.

3. Press to navigate to the pump selection

field.

4. Press to scroll through the pump

Enable/Disable Pump Functions

See Setup Screen 5 - Enable/Disable Pump Functions, page 96, for a description of each pump function.

1. Navigate to setup screen 5.

2. Press to access fields to make changes.

3. Press to navigate to each pump function field.

options.

5. Press to select the correct pump size for the

system.

6. Press to exit edit mode.

4. Press to enable or disable each pump function.

5. Press to exit edit mode.

3A0294G 57

Page 58

Set System Parameters

Enable/Disable Errors

See , page 92, for an explanation of each error function.

1. Navigate to setup screen 6.

2. Press to access fields to make changes.

3. Press to navigate to each error field.

4. Press to enable or disable each error code.

Set Low/Empty Drum Error

Follow the Enable/Disable Errors steps to set either the

empty drum alarm or low drum advisory.

Refer to the Errors section on page 66 for more information on alarms and advisories, and how to clear an

alarm or advisory.

The low/empty drum error code

empty drum alarm , and error code

for the low drum advisory .

L1 is enabled the drum empty alarm is enabled

When

and displays. The alarm icon displays if an

empty drum alarm occurs.

L2 is enabled the low drum advisory is enabled

When

L1 is used for the

L2 is used

5. Press to exit edit mode.

and displays. The advisory icon displays if

a low drum advisory occurs.

58 3A0294G

Page 59

Set System Parameters

Maintenance

Total Volume

Dispensed

Setpoint

Set Pump Runaway Error

1. Navigate to setup screen 7.

2. Press to access fields to make changes.

3. Press to navigate to the pump runaway

cycle rate field.

Set Maintenance Parameters

Set the amounts of material moved through the pump

and dosing valve that will result in a maintenance advisory or alarm.

1. Navigate to setup screen 8.

4. Press and to increment or decrement to the desired cycle rate. Graco recommends

setting the cycle rate to 60 or less. Choose a value

that is just above the maximum cycle rate of the

application.

5. Press to save the set cycle rate.

6. Press to exit edit mode.

2. Press to access fields to make changes.

3. Press to navigate to the maintenance

setpoint field.

4. Press and to increment or decrement to the desired amount of material that will

result in an advisory when the total volume dispensed exceeds the maintenance setpoint.

5. Press to save this amount.

6. If an advisory occurs, press to navigate to the

total volume dispensed field. Clear the field to reset

the advisory.

7. Press to exit edit mode.

3A0294G 59

Page 60

Set System Parameters

Calibrate

The actual weight/volume of material dispensed may

vary slightly from the displayed weight/volume. Use the

following procedure to calibrate the system as needed.

Calibration values can be set manually. However, it is

recommended to run the calibration procedure when

needed.

1. Navigate to setup screen 10.

2. Press to start the overshoot calibration process. The icons will display.

5. Release the start button or foot switch. The hour

glass icon is updated and the shot mode icon will

display.

6. Remove any excess material from the dispense

valve, if necessary.

7. Empty the container, if necessary. Set the scale to

zero.

8. Press to dispense a shot into the container.

When the shot completes the shot icon will disappear and the first digit of the weight field will be highlighted.

3. Place a container that is at least as large as the

pump volume under the dispense valve.

4. Hold down or the foot switch to run the system. The manual mode icon will flash. The pump will

go through the first changeover, stop to measure the

overshoot, then complete the second changeover

and stop.

60 3A0294G

Page 61

Set System Parameters

9. Remove any excess material from the dispense

valve, if necessary. Include this material in the

weight of the shot.

10. Weigh the shot on the scale.

11. Press and to enter the shot

weight in the weight field.

12. Set the scale to zero.

13. Perform steps 1-6 three more times.

After you have entered the fourth shot weight in the

weight field, the material delta top and bottom fields

(calibration values) will automatically update and the

specific weight on setup screen 1 will update. The

calibration procedure is now complete.

Set Shot Accuracy Errors

Use this screen to set the shot volume deviation from

the shot setpoint that will cause an advisory or alarm.

NOTE: If either the advisory field or alarm field is set to

zero, the error is disabled.