Page 1

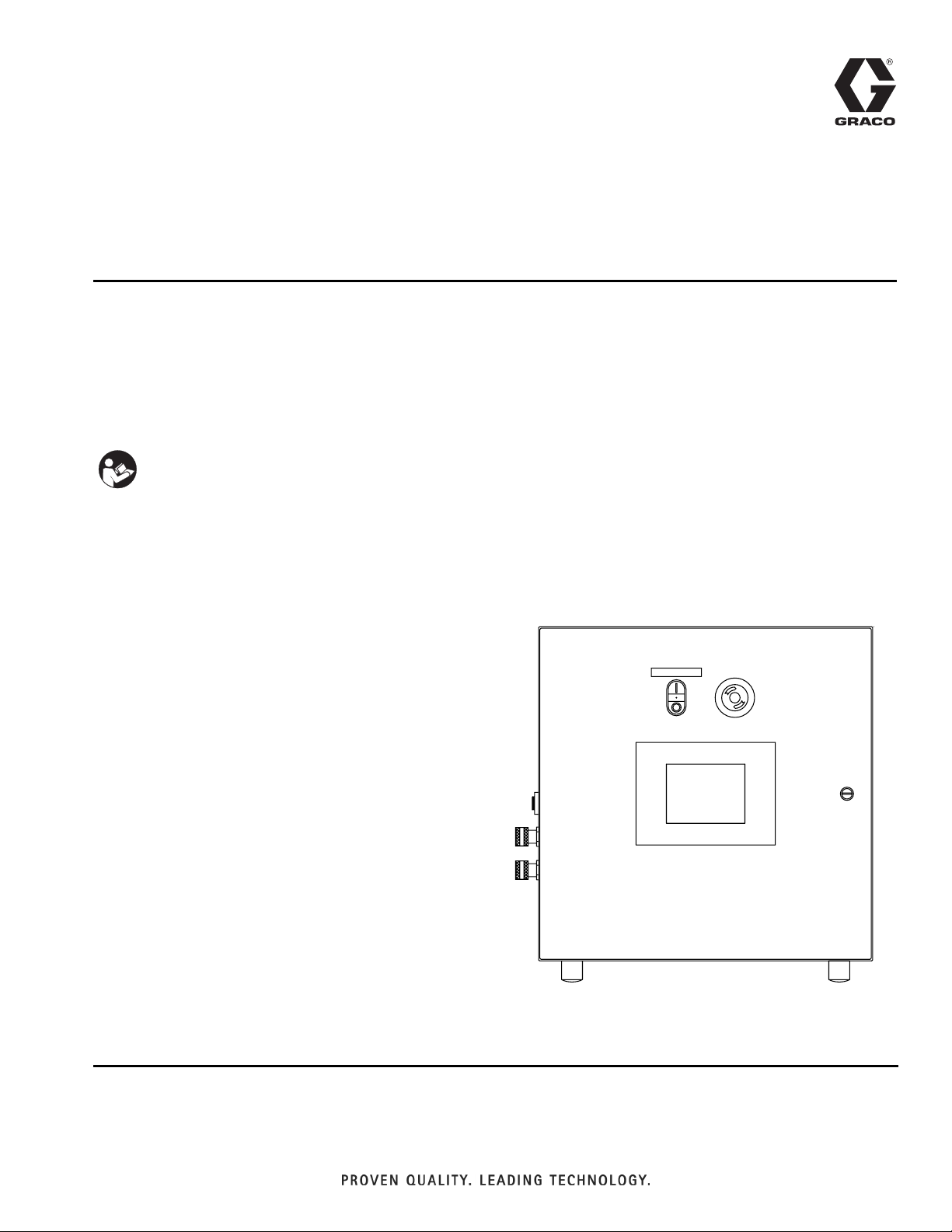

Setup - Operation

1053/1093

Control Box

Patented meter and dispense system for precise one-component micro-dispensing. Not for

use in explosive atmospheres.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

CONTROL POWER

3A0261H

EN

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Control Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Valve Connection Kits . . . . . . . . . . . . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Motor Driven . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjust Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Dispensing Operation . . . . . . . . . . . . . . . . . . . . . . 15

HMI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Screen Navigation Diagrams . . . . . . . . . . . . . . 16

Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Metering Valve Control Screen . . . . . . . . . . . . . 18

Shot Size Screen . . . . . . . . . . . . . . . . . . . . . . . 20

Level 1 Control Screen . . . . . . . . . . . . . . . . . . . 21

Level 2 Control Screen . . . . . . . . . . . . . . . . . . . 22

Purge Timer Screen . . . . . . . . . . . . . . . . . . . . . 24

Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Motor Status Screen . . . . . . . . . . . . . . . . . . . . . 27

Supervisor Screen . . . . . . . . . . . . . . . . . . . . . . 28

Supervisor Help Screen . . . . . . . . . . . . . . . . . . 30

Motor Error Codes Screen . . . . . . . . . . . . . . . . 31

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 32

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Customer Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 40

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 40

2 3A0261H

Page 3

Related Manuals

Component manuals in U.S. English.

Part Description

313812 Dispensit 1093

313566 Dispensit 1053-10B

334001 1053 Valve 24V Solenoid Replacement Kit,

Instructions

334002 1093 Valve 24V Solenoid Replacement Kit,

Instructions

Related Manuals

3A0261H 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

• If this equipment is used with isocyanate material, see additional information on isocyanates in Isocyanate Conditions Section of this manual.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

4 3A0261H

Page 5

Warnings

WARNING

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many

solvents can degrade plastic parts and cause them to fail, which could cause serious injury or property

damage. See Technica l Data in this and all other equipment instruction manuals. Read fluid and solvent

manufacturer’s warnings.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

3A0261H 5

Page 6

Component Identification

Component Identification

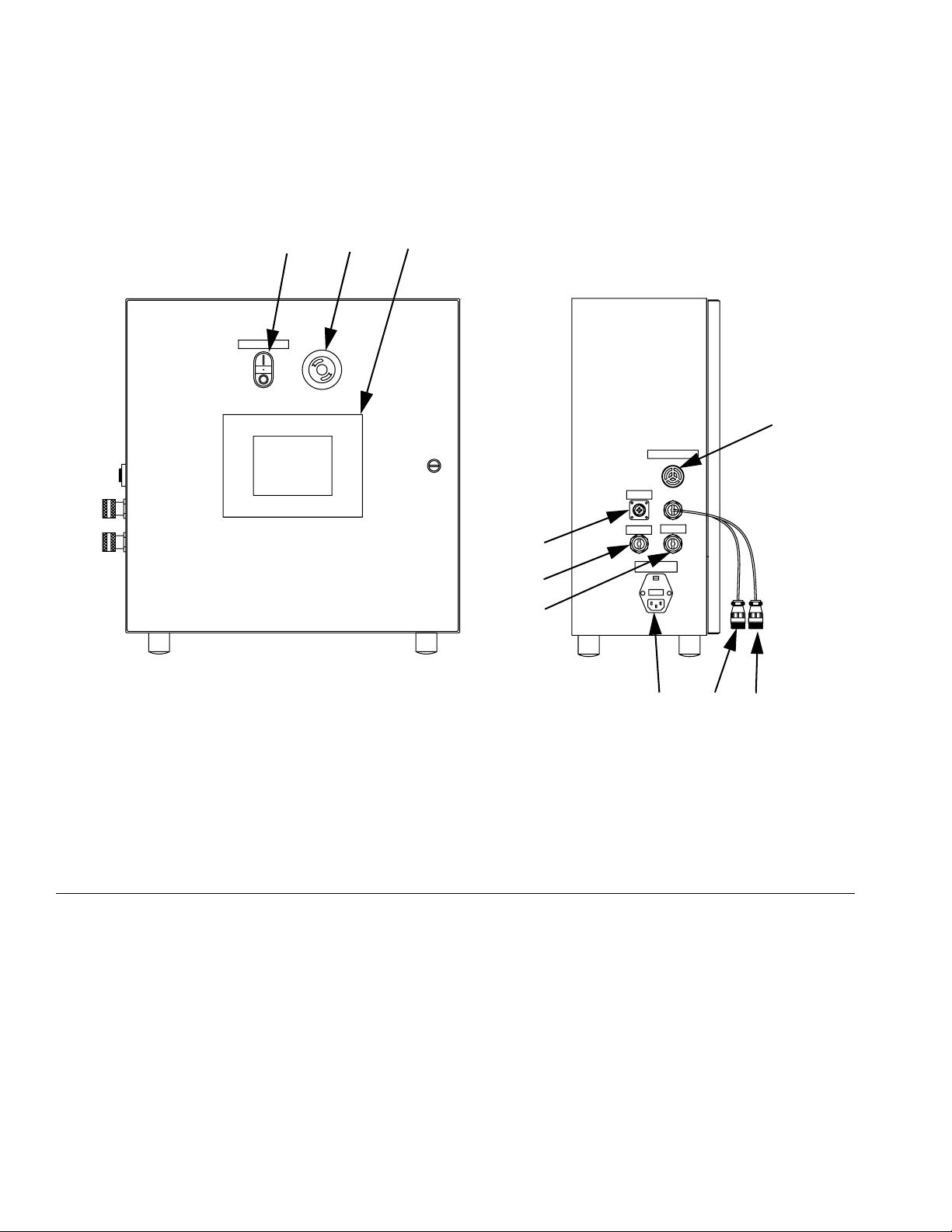

Control Boxes

BAC

CONTROL POWER

D

AUDIO ALARM

START OPTIONS

1

24

3

MOTOR

VALVE I/O

F

VERIFY INCOMING VOLTAGE

WITH VOLTAGE SWITCH SETTING

BEFORE CONNECTING POWER

L

U

J

E

H

Key:

A Emergency Stop

B Control Power Switch

C Touch Panel

D Alarm Speaker

E Power Input

F

IG. 1: Motor Driven Control Box

F Start Options Connection

H A Tank Level Controls Connection

J B Tank Level Controls Connection

L Dispense Valve I/O Connection

U Motor Connection

Power input/fuse holder, 81/0365-3/11, can be set to either 115V or 230V. To determine what voltage it is currently

set to, look at the port and read what is showing through the cover window. To switch voltage, open the fuse holder

cover with a small screwdriver, pull the fuse holder out, flip the fuse holder 180°, push the fuse holder back in, and

snap the fuse holder cover back into place.

NOTE: Fuse part number: V-21610P

120 V power cord part number: 81/1051-1/11

240 V power cord part number: 121054

6 3A0261H

Page 7

Grounding

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

Grounding plug units: this product is equipped with a

cord having a grounding wire with an appropriate

grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded in accordance

with all local codes and ordinances.

Hard-wired units: the grounding wire must be used. All

electrical wiring must be done by a qualified electrician

and comply with all local codes and regulations.

Air and fluid hoses: use only electrically conductive

hoses.

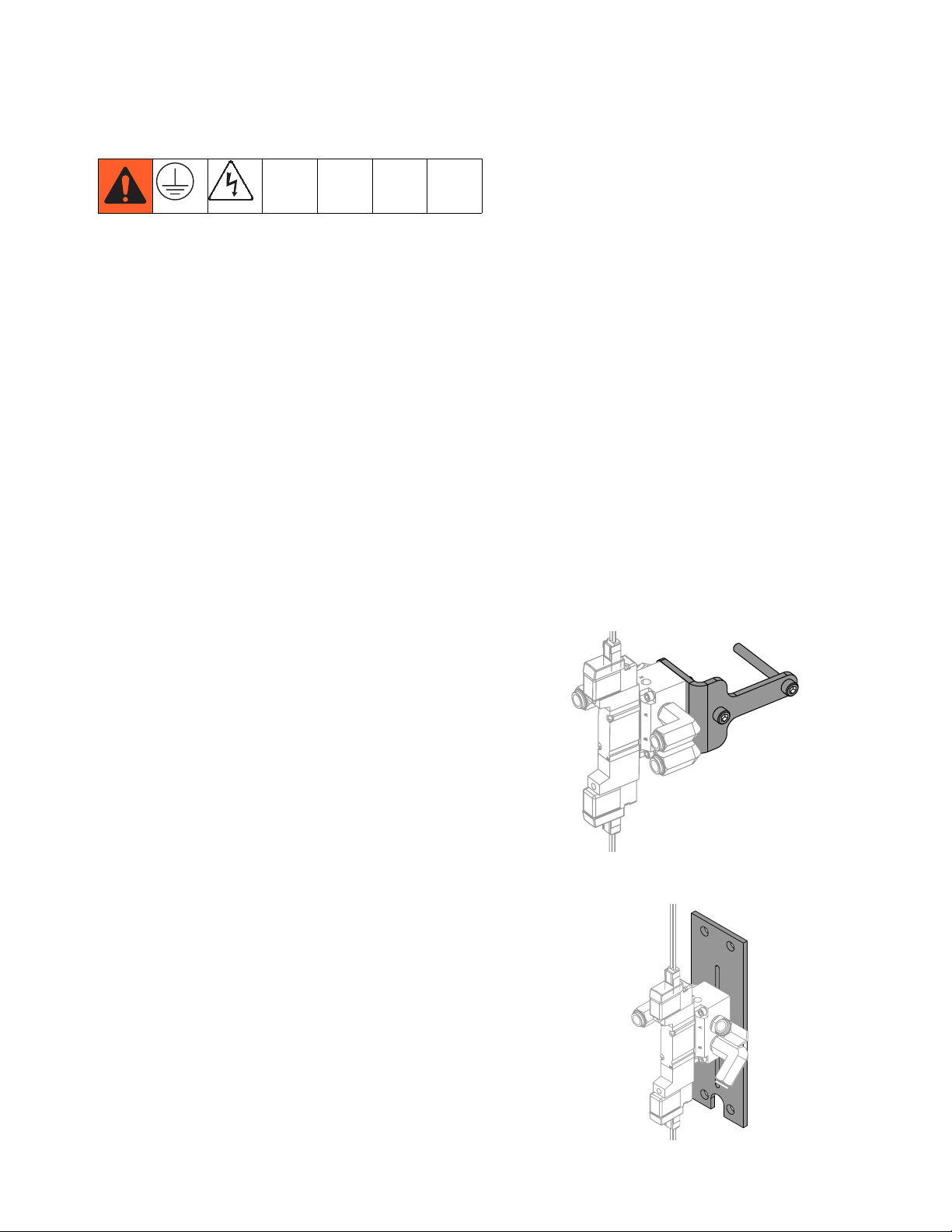

Kits

NOTE: 80/2957-1/50 1053/1093 control requires three

sensor switches to operate. Valve, control, and connection kits are sold separately. Some assembly required.

Part Description

24E845★ Connection kit; for 1053 models that include

1 switch

24E846★ Connection kit; for 1053 models that include

2 switches, including the following assemblies:

A2A10007, A2A10008, A2A10009,

A2A10010, A2A10011, A2A1001,

A2A10015, A2A10016, A2A10018,

A2A10019, A2A10020, A2A10200,

A2A10300, A2A10301, A2A10302,

A2A10303, A2A10304, A2A10305,

A2A10306, A2A10307, A2A10308,

A2A10309

24E847‡ Connection kit; for 1093 models, including

the following assemblies:

A2A05401, A2A05402, A2A05403,

A2A05404, A2A05405, A2A05406

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a non-conductive surface, such as paper or cardboard, which interrupts

grounding continuity.

★ Mounting adapter kit 24V674 may be required for

mounting the solenoid to the 1053 valve.

‡ Mounting side plate 01/2983/97 may be required for

mounting the solenoid to the 1093 valve.

3A0261H 7

Page 8

Valve Connection Kits

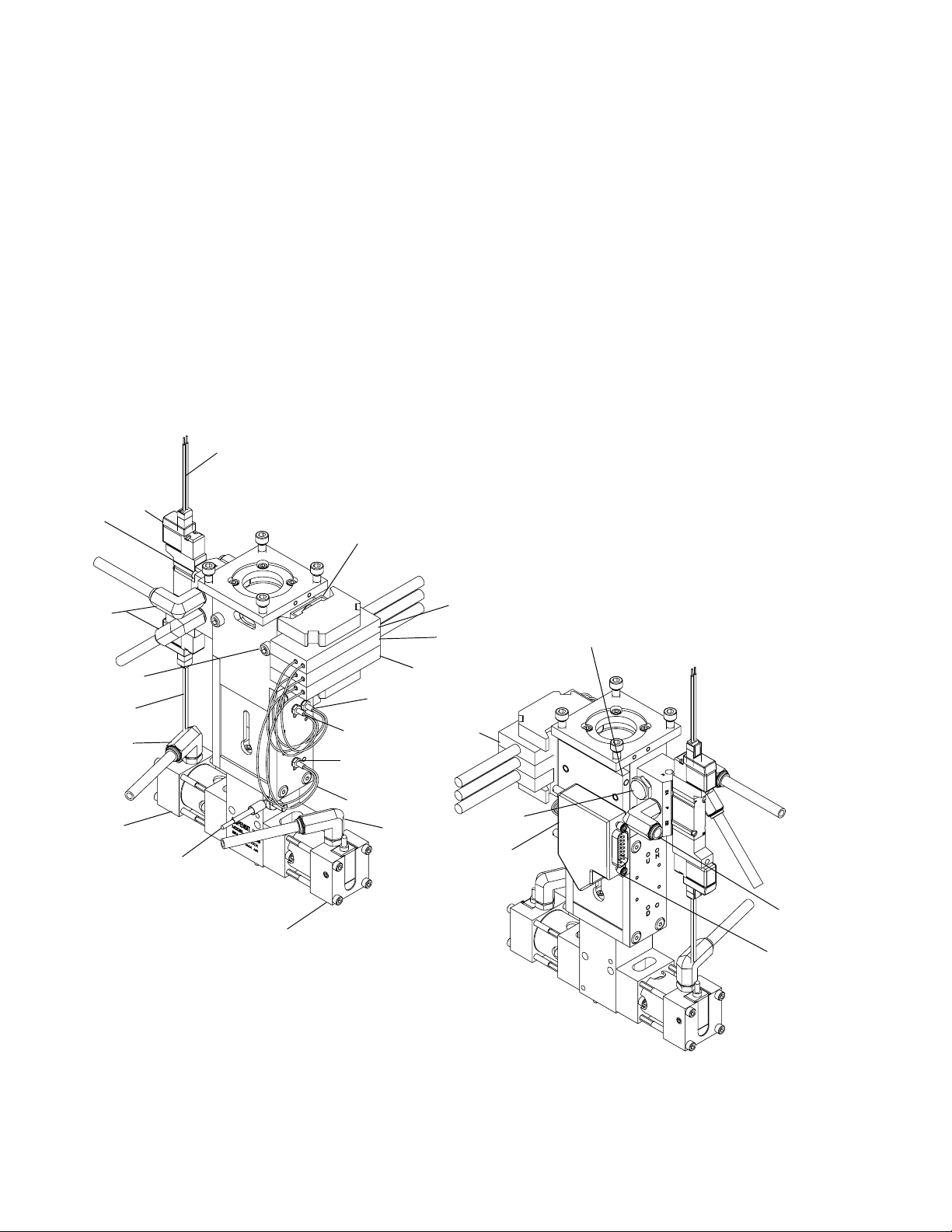

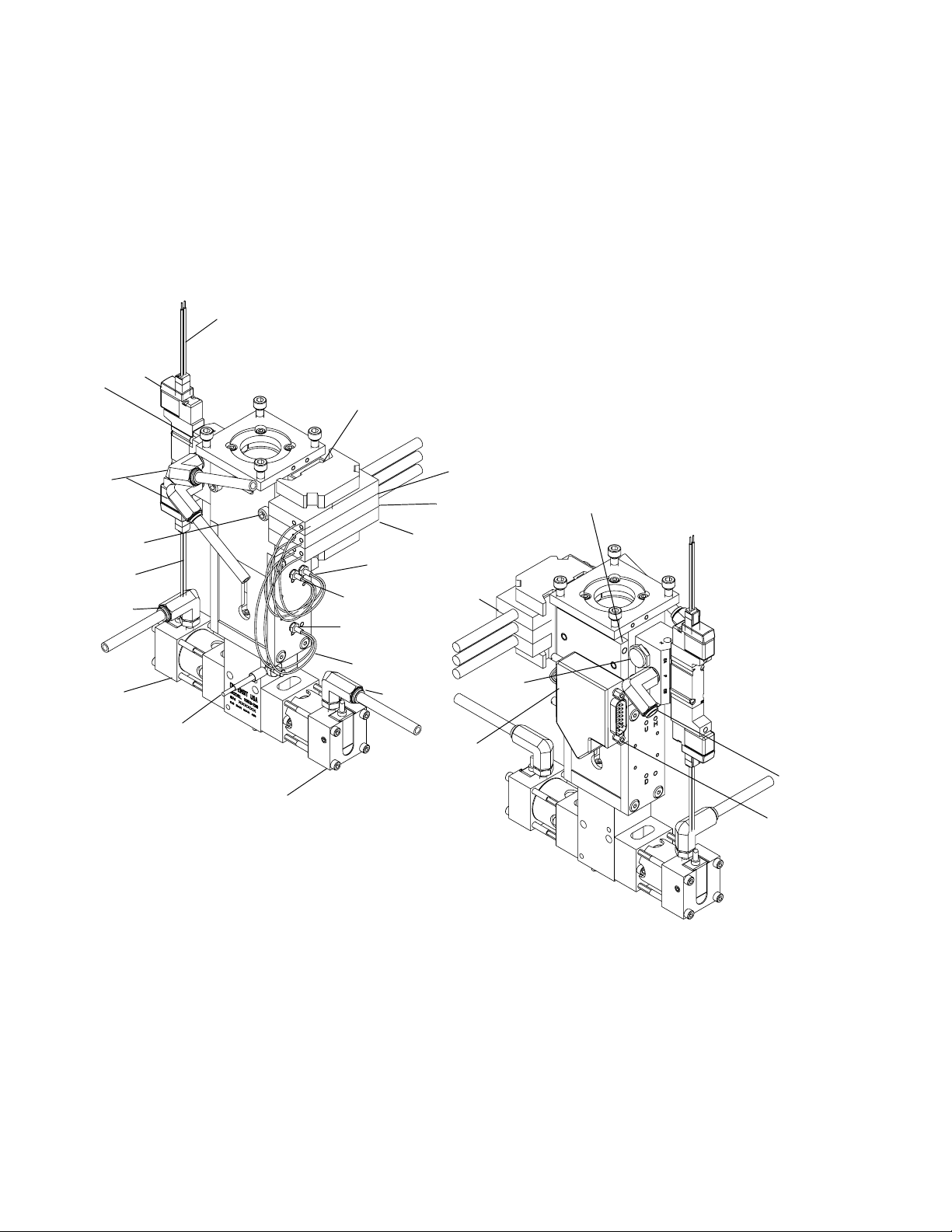

Valve Connection Kits

These valve connection kits enable certain valves to be used with this control package. Each kit contains the

mechanical, electrical, and pneumatic hardware needed to install the valve. See associated drawing for hardware

location and wiring information.

24E845, 1053 Dispense Valve with Added

Up and Down Validation/Actuation Kit

NOTE: PX-HOME must be below PX-UP. PX-HOME

may have been supplied in top hole. If so move to the

appropriate location as shown.

SOL-CSV

24

26,

28

14, 15, 16

27

SOL-OSV

23

LS-CSV

AMP-HOME

AMP-U

23

AMP-D

22

25

3,

6

PG-2

1

PX-HOME

PX-U

PX-D

17

18,

19,

20,

21

LS-OSV

2

27

4, 5

8 3A0261H

Page 9

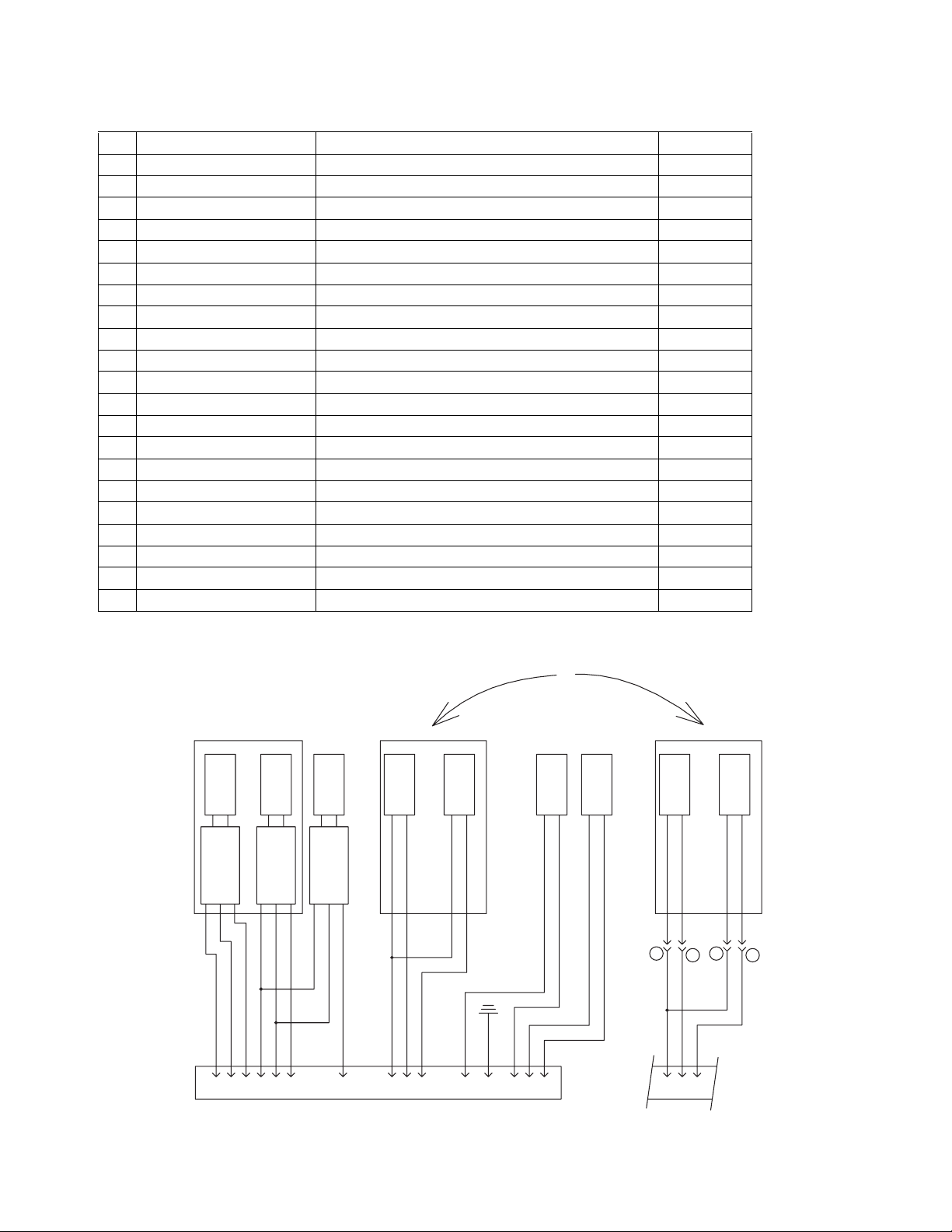

Ref Part Description Quantity

1 96/0098/99 SCREW, socket head, 10-24x1.50 2

2 16C798 PLATE, mounting, 1053, dsub, 15 pin 1

3 ADM00022 COVER, connector, dsub, 15p, 45deg 1

4 81/0360-N/11 SCREW, jack, connector, dsub, type a 2

5 B2050001 NUT, allen, 4-40, alloy 2

6 297331 SCREW, cap, 4x1/4 2

14 81/1265/11 BRACKET, end 2

15 297639 SCREW, cap, button head 2

16 81/0283-DIN/11 RAIL, din 0.01

17 F0200075 CABLE, prox-photo 2

18 81/0378-2/25 STRAP, ground, ring, #10, 16ga 1

19 100166 NUT, full hex 1

20 96/0005-2/99 WASHER, lock, ext, #10 1

21 84/0130-25/11 LABEL, prot earth(grnd).375x.375 1

22 16D050 AMPLIFIER, 1chan, photo, pnp, 24vdc 2

23 94/0740-A/99 FITTING, elbow, swivel, 1/4tubex10-32 2

24 127629 VALVE, solenoid, 4 way, 3 position, 24V 1

25 82/0217-A/11 MUFFLER, air, 1/8 NPT 2

26 127632 SCREW, socket head, 4-40x1.00 2

27 94/0705-1/96 FITTING, elbow, swivel, 1/4 tube 3

28 17A412 WASHER, split, #4 2

Valve Connection Kits

24E845 Electrical socket schematic

%/.

%/8

3;8

$038

,1&/8'(':,7+%$6(9$/9(

+22.83)25)6:,7&+

%51

%/.

3;+

$03+

,1&/8'(':,7+%$6(9$/9(

%51

%/8

%/.

%/8

%51

3;'

$03'

/6&69

:+,7(

%52:1

:+7

%51

:+7

/6269

:+,7(

%52:1

5('

*51

%/.

5('

62/&69

%/$&.

5('

%/.

25

5('

62/269

/6&69

+22.83)2586:,7&+

,1&/8'(':,7+%$6(9$/9(

%/$&.

%51

%/8

%/8

%51

WLDB(H

/6269

%/8

&211(&7,21729$/9(&21752/6

3,1'68%&211(&7253*

3A0261H 9

Page 10

Valve Connection Kits

24E846, 1053 Dispense Valve with Added

Up Validation/Actuation Kit

NOTE: PX-HOME must be below PX-UP. PX-HOME

may have been supplied in top hole. If so move to the

appropriate location as shown.

SOL-CSV

24

26,

28

14, 15, 16

27

SOL-OSV

23

LS-CSV

AMP-HOME

AMP-U

23

AMP-D

22

25

3,

6

PG-2

1

PX-HOME

PX-U

PX-D

17

18,

19,

20,

21

LS-OSV

2

27

4, 5

10 3A0261H

Page 11

Ref Part Description Quantity

1 96/0098/99 SCREW, socket head, 10-24x1.50 2

2 16C798 PLATE, mounting, 1053, dsub, 15 pin 1

3 ADM00022 COVER, connector, dsub, 15p, 45deg 1

4 81/0360-N/11 SCREW, jack, connector, dsub, type a 2

5 B2050001 NUT, allen, 4-40, alloy 2

6 297331 SCREW, cap, 4x1/4 2

14 81/1265/11 BRACKET, end 2

15 297639 SCREW, cap, button head 2

16 81/0283-DIN/11 RAIL, din 0.01

17 F0200075 CABLE, prox-photo 1

18 81/0378-2/25 STRAP, ground, ring, #10, 16ga 1

19 100166 NUT, full hex 1

20 96/0005-2/99 WASHER, lock, ext, #10 1

21 84/0130-25/11 LABEL, prot earth(grnd).375x.375 1

22 16D050 AMPLIFIER, 1chan, photo, pnp, 24vdc 1

23 94/0740-A/99 FITTING, elbow, swivel, 1/4tubex10-32 2

24 127629 VALVE, solenoid, 4 way, 3 position, 24V 1

25 82/0217-A/11 MUFFLER, air, 1/8 NPT 2

26 127632 SCREW, socket head, 4-40x1.00 2

27 94/0705-1/96 FITTING, elbow, swivel, 1/4 tube 3

28 17A412 WASHER, split, #4 2

Valve Connection Kits

24E846 Electrical socket schematic

%/8

3;8

$038

+22.83)25)6:,7&+

,1&/8'(':,7+%$6(9$/9(

%52:1

%51

%/.

%51

%/.

%/8

3;'

$03'

%/.

%51

3;+

$03+

,1&/8'(':,7+%$6(9$/9(

%/8

%51

/6&69

:+,7(

:+7

:+7

/6269

:+,7(

%52:1

5('

*51

%/.

5('

5('

%/.

25

62/&69

%/$&.

5('

62/269

%/$&.

/6&69

+22.83)2586:,7&+

,1&/8'(':,7+%$6(9$/9(

%/8

%51

%/8

%51

/6269

%/8

WLDB(H

&211(&7,21729$/9(&21752/6

3,1'68%&211(&7253*

3A0261H 11

Page 12

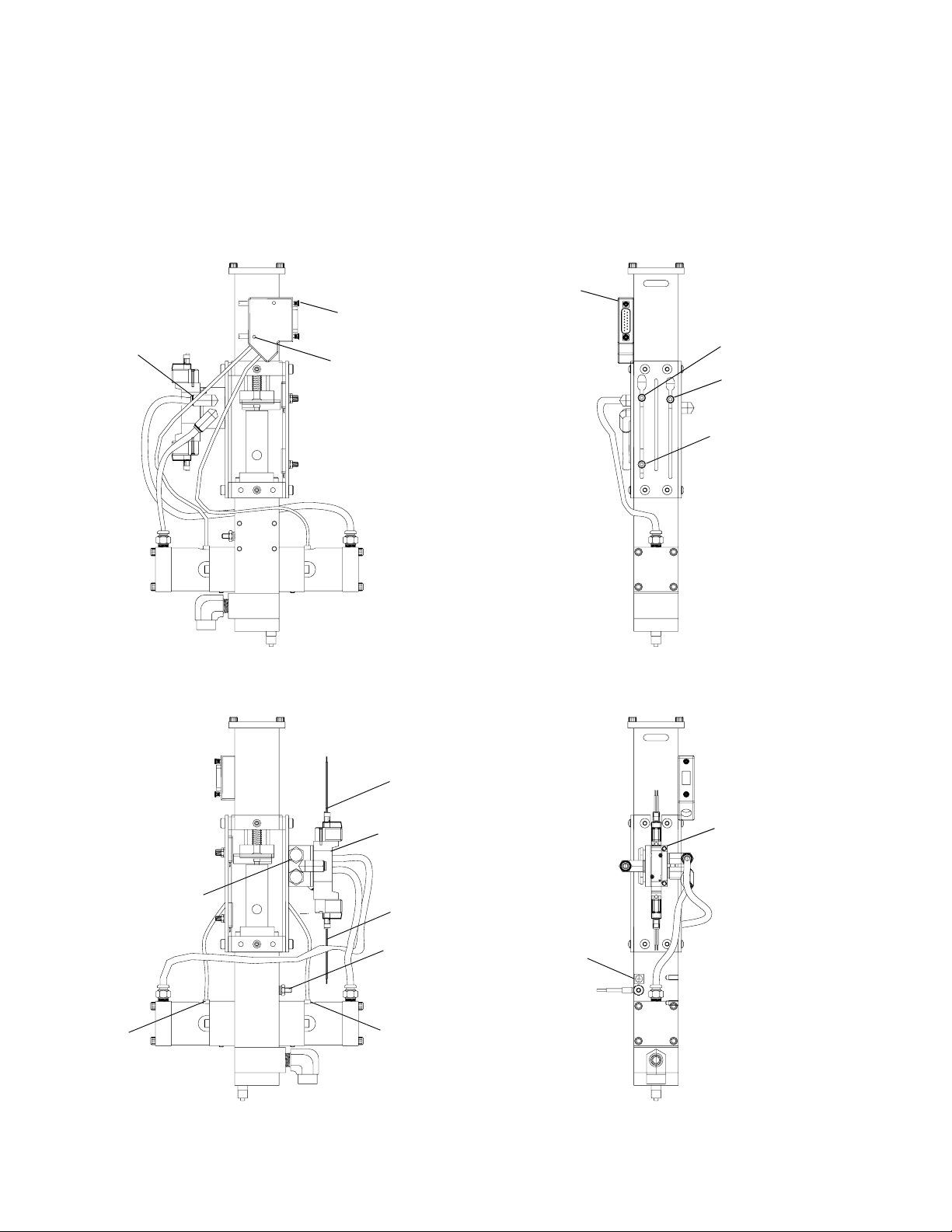

Valve Connection Kits

24E847, 1093 Dispense Valve with Added

Actuation Kit

NOTE: PX-HOME must be below PX-UP. PX-HOME

may have been supplied in top hole. If so move to the

appropriate location as shown.

4, 5

3

PG-2

27

PX-UP

6

PX-HOME

PX-DOWN

SOL-CSV

24

25

LS-CSV

12 3A0261H

SOL-OSV

18, 19, 20

LS-OSV

21

26, 28

Page 13

Ref Part Description Quantity

3 ADM00022 COVER, connector, dsub, 15p, 45deg 1

4 81/0360-N/11 SCREW, jack, connector, dsub, type a 2

5 B2050001 NUT, allen, 4-40, alloy 2

6 297331 SCREW, cap, 4x1/4 2

18 81/0378-2/25 STRAP, ground, ring, #10, 16ga 1

19 100166 NUT, full hex 1

20 96/0005-2/99 WASHER, lock, ext, #10 1

21 84/0130-25/11 LABEL, prot earth(grnd).375x.375 1

24 127629 VALVE, solenoid, 4 way, 3 position, 24V 1

25 82/0217-A/11 MUFFLER, air, 1/8 NPT 2

26 127632 SCREW, socket head, 4-40x1.00 2

27 94/0705-1/96 FITTING, elbow, swivel, 1/4 tube 3

28 17A412 WASHER, split, #4 2

24E847 Electrical socket schematic

Valve Connection Kits

%/.

%/8

3;'

%51

%/.

3;+

,1&/8'(':,7+%$6(9$/9(

%/8

%51

&211(&7,21729$/9(&21752/6

3,1'68%&211(&7253*

%/8

3;8

%51

%/.

/6&69

%51

%/.

%/8

/6269

%51

5('

%/.

62/&69

%/$&.

5('

%/.

5('

%/.

*51

62/269

5('

%/$&.

WLDB(H

3A0261H 13

Page 14

Setup

Setup

Motor Driven

1. Connect Dispense Valve I/O, Start Options, and

Motor logic cables. If level controls are installed,

connect Level Controls logic cables.

NOTICE

Feed system and main logic control system must

use separate air supplies.

AUDIO ALARM

START OPTIONS

1

24

3

MOTOR

VALVE I/O

VERIFY INCOMING VOLTAGE

WITH VOLTAGE SWITCH SETTING

BEFORE CONNECTING POWER

Adjust Amplifier

The amplifier should be adjusted if:

• Debris or vibration changed the distance/axis

between the sensor and metering block (13).

• Replacing the sensor.

1. Navigate to the Motor Status screen.

2. Ensure the metering rod connection block (13) is

aligned with the sensor.

3. If the display shows a “0” for the sensor switch being

adjusted, increase the amplifier intensity adjustment

screw until the sensor switch display changes to “1”.

4. Repeat for each sensor switch installed on assembly.

2. Adjust customer supplied air pressure regulator to

80 psi (0.6 MPa, 6 bar).

3. Perform Setup procedure for dispense valve and

feed system components. See Related Manuals on

page 3.

14 3A0261H

Page 15

Startup

Startup

NOTE: See HMI Operation starting on page 16 for

detailed HMI instructions.

1. Press the Control Power On button.

2. Navigate to the Metering Valve Control screen.

3. Press the Retract button.

NOTE: On Motor Driven models, when there is an

Emergency Stop condition or the system power is lost,

the shot selection resets to “0”. The operator must then

select a shot.

4. Navigate to the Supervisor screen.

5. Press the Valve Type selection button to select your

configuration.

6. Navigate to the Shot Size screen.

7. Select a shot number.

8. Navigate to the Metering Valve Control screen.

Dispensing Operation

NOTE: See HMI Operation on page 16 for detailed HMI

instructions.

The foot switch, the “Start” button, and the optional Customer Start Signal can be used to initiate shots. These

are referred to as start devices.

Perform a Shot

1. Navigate to the Metering Valve Control screen.

2. Press the Retract button.

3. Press the Shot button to select Shot Mode.

4. Press and release the start device to perform one

shot.

Dispense Continuously

The valve dispenses continuously until the end of the

stroke is reached.

9. Press the Shot button to select Shot Mode.

10. Verify air pressure is set to 80 psi (5.6 bar).

11. Perform feed system startup procedure(s). See

Related Manuals on page 3.

12. Perform dispense valve startup procedure. See

Related Manuals on page 3.

1. Navigate to the Metering Valve Control screen.

2. Under Metering Valve Control, press the Retract

button.

3. Press the Continuous button.

4. On Motor Driven models, press and hold the start

device to dispense continuously. Release the start

device to stop dispensing and retract the metering

rods.

Retract Piston

1. Navigate to the Metering Valve Control screen.

2. Under Metering Valve Control, press the Retract

button.

Extend Piston

1. Navigate to the Metering Valve Control screen.

2. Under Metering Valve Control, press the Extend button.

3A0261H 15

Page 16

HMI Operation

HMI Operation

Screen Navigation Diagrams

Motor Driven

Main Screen

Metering Valve Control

Shot Size/Flow Rate

FIG. 2

Level 1 Control

Purge Timer

Status

Supervisor Supervisor Help

Motor Status Motor Error Codes

Level 2 Control

16 3A0261H

Page 17

Main Screen

NOTE: The Error Code button is shown on every screen

on the Motor Driven model.

HMI Operation

Screen Access Buttons

All buttons on the main screen except for the Password

and Error Code buttons open a new specified screen.

For example, pressing the “Status” button opens the

Status screen.

Password

The password button enables the user to changes

values in certain screens.

To access the password press the Password Access

button (shown as “=0000”). When the keyboard appears

enter “5810”

Error Code

NOTE: The Error Code button is shown on every screen

On all screens that it is shown, the Error Code button

resets the error seen in the error string (shown as

“<0000000000”) and the error code number (shown as

“<000”). See the Motor Error Codes screen for more

information, page 31.

then press the Enter key.

3A0261H 17

Page 18

HMI Operation

Metering Valve Control Screen

NOTE: A “1” indicates that the button is in the “ON” posi-

tion. A “0” indicates that the button is in the “OFF” position.

NOTE: The Error Code button is shown on every

screen. See the Main screen for definition.

Start button

When the Start button is pressed, the machine starts

the cycle for the selected Pump Mode.

Pump Mode

NOTE: The metering rods must be retracted prior to

changing any setting under Pump Mode. See Retract

Piston, page 15.

Retract Mode

The air cylinder and pumps immediately retract and

remain in the retracted position. This is used for maintenance purposes only.

Extend Mode

The air cylinder and pumps immediately extend and

remain in the extended position. This position must be

selected when the pump is idle for a long period of time.

Shot Mode

The machine cycles the number of times displayed in

the Cycle Counter field when the start device is pressed

and released. The machine cycles continuously when

the start device is pressed and held.

Continuous (Operator Control) Mode

In this mode, the machine to dispense while the start

device is pressed. When the start device is released the

metering rods retract to the home position.

18 3A0261H

Page 19

DV Valve Mode

This mode actuates an optional dispense valve.

OPEN

In this mode, the dispense valve is held in the open position, allowing material to pass through.

AUTO

In this mode, the dispense valve opens automatically

whenever the pump is cycled.

CLOSE

In this mode, the dispense valve is held closed.

HMI Operation

3A0261H 19

Page 20

HMI Operation

Shot Size Screen

NOTICE

Erratic operation results if the shot size value entered is

not greater than the absolute value of the Shot Size Offset setting. For example, if the Shot Size Offset setting

is -1%, a shot size greater than 1% must be entered.

See Supervisor screen, page 28.

Select Shot Size/Flow Rate Combination

Use this to change the selected shot by entering a number between 1 and 7. The selected shot size and flow

rate is shown in the Shot Size (percent) section and

Flow Rate (mm/sec) section.

Number of Strokes

This displays the number of shots of material when the

machine is dispensing.

For example, if the purge shot size is set at 150%, Number of Strokes displays a “2”, and the Amount Per

Stroke % displays “75.00”.

Amount Per Stroke %

Shot Size (percent), Flow Rate (mm/sec)

These are the 7 preset Shot Size (percent) and Flow

Rate (mm/sec) values. Shot size is in percent of stroke.

The preset values can be selected using Select Shot

Size/Flow Rate Combination.

To edit the preset Shot Size or Flow Rate values, log-in

as the supervisor. See Main Screen, page 17.

Below is the minimum and maximum field allowance for

this design.

Shot Size:

Minimum = 2.5%

Maximum = 500.0%

Flow Rate:

Minimum = 0.50 mm/second

Maximum = 25.00 mm/second

This displays the stroke per shot in percent of stroke.

For example, if the purge shot size is set at 340%,

Amount Per Stroke % displays “85.00” and Number of

Strokes During Purge displays a “4”.

20 3A0261H

Page 21

Level 1 Control Screen

NOTE: The Error Code button is shown on every

screen. See the Main screen for definition, page 17.

NOTE: If ‘A Tank Status’ and ‘B Tank Status’ both display 'Levels Not Active' then the level control feature is

not installed on this machine.

HMI Operation

A Tank Status, B Tank Status

This displays information about each component tank

filling process. The following are the possible messages.

Message Description

Material

High

Material

Low

Filling The tank is currently refilling in the tank refilling

Material

Present

Level Sensor Fault

Levels Not

Active

Fill Fault The tank began refilling and the fluid level did not

The tank level is at or above the high level sensor.

The tank level is below the low level sensor.

process.

The tank level is between the high and the low

level sensors.

The machine senses material at the high level

sensor but not at the low level sensor.

Level sensors are not installed for the tank.

reach the high level sensor within the preset time

entered into the Fill Timer button seen in the

Level2 Control screen. Tank has stopped refilling.

Silence Alarm button

Start Fill A, Start Fill B button

When this button is pressed the transfer pump fills the

tank until the material level reaches the high level sensor on that tank.

NOTE: The Start Fill A, Start Fill B and the Stop Fill buttons are inoperable if the high level automatic tank refilling feature was not purchased with this machine.

Stop Fill button

This button stops the automatic tank refilling process for

both the A and B component material tanks.

This button silences the audible alarm when pressed.

3A0261H 21

Page 22

HMI Operation

Level 2 Control Screen

NOTE: A “1” indicates that the button is in the “ON” posi-

tion. A “0” indicates that the button is in the “OFF” position.

NOTE: The Error Code button is shown on every screen

on the Motor Driven PD44. See the Main screen for definition, page 17.

NOTE: In the Level 1 Control Screen, if ‘A Tank Status’

and ‘B Tank Status’ both display 'Levels Not Active' then

the level control feature is not installed on this machine.

Press the Main button to exit from this screen.

Low Level Shutdown button

When this button displays ‘1’ and the material level of

either the ‘A’ component tank or the ‘B’ component tank

goes below the low level sensor, the machine shuts

down. To recover, refill the component tank with material

to above the low level sensor. When ‘0’ is displayed, the

low level shutdown feature is disabled.

Alarm Engage button

When this button displays ‘1’ and the material level of

either the ‘A’ component tank or the ‘B’ component tank

goes below the low level sensor the audible alarm is

activated.

Auto Fill Engage button

When this button displays ‘1’ the automatic filling function is activated.

Clear Fill Fault button

This button clears the Fill Timer Fault message displayed in the corresponding ‘A Tank Status’ or ‘B Tank

Status’ field in the Level 1 Control screen.

Silence Alarm button

Press this button to silence the low fluid level audible

alarm. The audible alarm will be activated again when

the low level condition reoccurs.

22 3A0261H

Page 23

HMI Operation

Shutdown Timer button/indicator

NOTE: If the level control option has not been pur-

chased the Shutdown Timer button is disabled.

This changes the delay before the Fill Timer Fault message is displayed in the corresponding ‘A Tank Status’ or

‘B Tank Status’ field on the Level 1 Control screen. If the

material level is below the low level sensor for more than

the duration of the Shutdown Timer setting, the machine

shuts down.

To change the Shutdown Timer setting, perform the following steps.

1. Select the Shutdown Timer button (shown as

“=00000”). A numeric keypad appears.

2. Enter the desired Shutdown Timer setting in tenths

of a second.

NOTE: For example, if 15 is entered, the shutdown time

is 1.5 seconds.

3. Press the button. The new Shutdown Timer setting is shown.

NOTE: For example, if 15 is entered, the Fill Timer setting is 1.5 seconds.

3. Press the button. The new Fill Timer setting

appears in the Fill Timer field.

NOTE: The current Fill Timer time is shown by

“<00000”. This counts up to the preset time.

NOTE: The current time of the Shutdown Timer is

shown by “<00000”. This counts up to the preset time.

Fill Timer

NOTE: If the automatic refilling option has not been pur-

chased the Fill Timer function is disabled.

This changes the delay before the Fill Timer Fault message is displayed to the corresponding ‘A Tank Status’

or ‘B Tank Status’ field in the Level 1 Control screen. If

the material level reaches the tank high level sensor

before the preset fill time elapses, the ‘Tank High Level’

message is displayed in the Tank Status field and the Fill

Timer is reset. If the preset fill time expires before material reaches the high level sensor, “Fill Timer Fault”

appears in the Level1 Control Screen.

To change the Fill Timer setting, perform the following

steps.

1. Select the Fill Timer button (shown as “=00000”). A

numeric keypad appears.

2. Enter in the Fill Timer time in tenths of a second.

3A0261H 23

Page 24

HMI Operation

Purge Timer Screen

NOTE: The Error Code button is shown on every

screen. See the Main screen for definition, page 17.

Purge Timer On /Off

Always set the dwell/alarm timer to a value that will

give the user adequate warning that the machine is

about to dispense a purge shot.See Dwell / Alarm

Timer section on page 25.

The Purge Timer On/Off switch is used to enable/disable the Purge Timer.

OFF: The Purge Timer is disabled.

ON: The Purge Timer is enabled. The machine initiates

a purge shot when the purge timer expires provided the

fluid ball valves are open, Shot Mode is selected, and no

errors exist.

Enter Purge Time Button

The Enter Purge Time button is shown as “=000.0”

below the Purge Timer On /Off button. The Enter Purge

Time button allows the operator to set the required time

between cycles. When the Purge Timer switch is in the

ON position and the Pump Mode switch is in the Shot or

Operator Control position, the purge timer unit counts up

to the preset time. When it reaches the preset time, a

purge shot is initiated.

The timer then automatically resets and continues with

the sequence of cycling and resetting. It continues until

the Purge Timer is turned to the OFF position.

To change the Purge Timer setting, perform the following steps.

1. Select Purge Timer button. A numeric keypad

appears.

2. Enter the desired purge time in seconds. Use the “.”

button to enter tenths of a second.

3. Press the button. The Purge Timer screen

appears. The new purge time appears in the Purge

Timer button.

24 3A0261H

Page 25

HMI Operation

NOTE: The current Purge Timer time is shown in the

bottom text box below the Purge Timer button.

Calculating the Purge Timer Setting

If the shot size is larger than the mixer volume, set the

timer for one-half the gel time of the material. If the shot

size is smaller, use the following formula to determine

the Purge Timer setting.

Gel Time X Shot Size

= Timer Setting

2 X Mixer Volume

For example, with mixer volume = 13.3cc, shot size =

10cc, gel time = 10 minutes, use the following equation.

10 min X 10 cc

100 cc*min

= 3.76 min=

2 X 13.3 cc

26.6 cc

Dwell / Alarm Timer

Always set the dwell/alarm timer to a value that will

give the user adequate warning that the machine is

about to dispense a purge shot.

1. Select Purge Shot Size % button. A numeric keypad

appears.

2. Enter the desired material shot size volume.

3. Press the button. The Purge Timer screen

appears. The new shot size percentage appears in

the Purge Shot Size % field.

Number of Strokes During Purge button/indicator

This displays the number of strokes used during the

purge shot.

For example, if the purge shot size is set at 150%, Number of Strokes During Purge displays “2” and Amount

Per Stroke % displays “75”.

Amount Per Stroke %

This displays the percent of the stroke used during a

shot.

For example, if the shot size is set at 150%, Number of

Strokes During Purge displays “2” and Amount Per

Stroke % displays “75”.

This changes the duration that the audible alarm is

active prior to the purge shot being initiated.

To change the Dwell Timer, perform the following steps.

1. Select the Dwell Timer button. A numeric keypad

appears.

2. Enter the desired Dwell Timer time in seconds. Use

the “.” button to enter tenths of seconds.

3. Press the button. The new Dwell Timer time

appears in the Dwell Timer field.

NOTE: The current Dwell Timer time is shown by

<000.0.

Purge Shot Size % button

This button shows the Shot Size volume in percent of

stroke. This volume is dispensed during the ratio check.

To change the Purge Shot Size % volume, perform the

following steps.

3A0261H 25

Page 26

HMI Operation

Status Screen

NOTE: A “1” indicates that the button is in the “ON” posi-

tion. A “0” indicates that the button is in the “OFF” position.

NOTE: The Error Code button is shown on every

screen. See the Main screen for definition, page 17.

Maintenance Totalizer

This counter increments each time the machine cycles.

Press the Reset Maintenance Totalizer button to reset.

This counter is used for maintenance purposes.

# Of Times Maintenance Totalizer has been Reset

This counter increments each time the Reset Maintenance Totalizer button is pressed.

Reset Maintenance Totalizer button

This button resets the Maintenance Totalizer.

Cycle Totalizer

This counter increments each time the machine cycles.

Dispense Ready

This displays “1” if the metering rods are loaded with

material and ready to dispense. It displays a “0” if the

metering tube is reloading or at the end of the dispense

cycle.

Dispense Complete

This displays “1” if the metering rods are reloaded with

material or at the end of the dispense cycle, and displays a “0” if the metering tube is loaded with material

and ready to dispense.

Contrast + button

This button increases the contrast of the screen.

Contrast - button

This button decreases the contrast of the screen.

PLC=XXXX, HMI=XXXX

These fields display the programs downloaded into the

PLC and HMI.

26 3A0261H

Page 27

Motor Status Screen

HMI Operation

NOTE: A “1” indicates that the button is in the “ON” position. A “0” indicates that the button is in the “OFF” position.

NOTE: The Error Code button is shown on every

screen. See the Main screen for definition, page 17.

To navigate to the Motor Status screen, press the “Motor

Status” button on the Status screen.

CSV Switch (Closed Spool Valve Switch)

This displays “1” when the spool valve is in the closed or

reload position.

OSV Switch (Open Spool Valve Switch)

This displays “1” when the spool valve is in the open or

dispense position.

Home Switch (Home Limit Switch)

This displays “1” when the metering valve rod home

switch is activated.

Upper Switch (Upper Over Limit Switch, Extend)

This displays “1” when the metering valve rod upper

over-travel limit switch is activated. The dispense valve

is in the most-retracted position.

Lower Switch (Lower Over Limit Switch, Retract)

This displays “1” when the metering valve rod lower

over-travel limit switch is activated. The dispense valve

is in the most-extended position. Put the dispense valve

in this position when it is idle for a long period of time.

Motor Position (Steps)

This gives the motor step position in terms of transducer

steps.

Shot Size %

This shows the Shot Size volume in percent of stroke.

Flow Rate (mm/sec)

This allows the operator to view the current flow rate in

millimeters per second.

Shot Mode Step #

This gives the current step in the shot mode program.

This is used for troubleshooting.

Reload Mode Step #

This gives the current step in the reload mode program.

This is used for troubleshooting.

Oper. Mode Step #

This gives the current step in the operator mode program. This is used for troubleshooting.

3A0261H 27

Page 28

HMI Operation

Supervisor Screen

NOTE: A “1” indicates that the button is in the “ON” posi-

tion. A “0” indicates that the button is in the “OFF” position.

NOTE: To change the values on this screen, log-in as

the supervisor. See Main Screen, page 17.

Error Code button

This button resets the error in the error string (shown as

“<0000000000”) and the error code number (shown as

“<000”). See the Motor Error Code screen for more

information, page 31.

Reload Setup

Only one of the three Reload Setup Options can be

enabled at any given time.

Reload After Each Shot button

In this mode, the metering rods retract after every shot.

This is the default system setup.

Reload After Multiple Shots button

In this mode, the metering rods retract only when the

metering rods are about to reach the end of the stroke.

This feature is only available when in Operator Control

mode.

For example, if the selected shot size is 30% of the

metering rods stroke, three shots will be taken (90% of

the stroke) then the metering rods will retract. The rods

retract after three shots because it cannot do another

shot without going over 100% stroke. If the selected shot

size is greater than 50% of the metering rods stroke, the

metering rods will retract after every shot.

Manual Reload W/ Customer Signal button

In this mode, the customer must send a signal to reload

the valve before the lower switch is activated. Otherwise,

the dispense valve will initiate a shot using the selected

shot size and flow rate combination.

NOTE: This can be linked with a PLC input for system

integration. See the logic drawings for more information.

Reload Speed (mm/sec) button

This allows the operator to change the retract or reload

speed in millimeters per second.

Feed Setup

This allows the operator to choose the low level setting

for the feed system with tanks or a feed system with cartridge or syringes. This inverts the switch function in the

PLC logic.

28 3A0261H

Page 29

Valve Type

Only one of the three valve type options can be enabled

at any given time. This feature is enabled at the time of

build based on Valve Type and should not be manipulated.

Enabling the Valve Type with a 1053 - 1 in. when a 1053

- 2 in. or 1093 is used will cause the improper maximum

shot size allowed by the mechanics of the valve.

Enabling the Valve Type with the 1053 - 2 in. when a

1053 - 1 in. will cause the Low Switch to be tripped and

will not allow the Valve to cycle.

Enabling the Valve Type with the 1053 - 2 in. when a

1093 is used will cause the improper maximum shot size

allowed by the mechanics of the valve.

Enabling the Valve Type with the 1093 when a 1053 - 1

in. or 1043 - 2 in. is used will cause the Low Switch or

PF44 to be tripped and will not allow the Valve to cycle.

HMI Operation

3A0261H 29

Page 30

HMI Operation

Supervisor Help Screen

This screen describes the various reload and shot

options in the Supervisor screen.

To get to the Setup Help screen, press the “Help” button

on the Supervisor screen.

30 3A0261H

Page 31

Motor Error Codes Screen

These screens give descriptions of the motor error

codes.

HMI Operation

3A0261H 31

Page 32

Pressure Relief Procedure

Pressure Relief

Procedure

1. Turn main air supply shut-off/bleed valve to the off

position. This will bleed air from the system.

2. Perform feed system pressure relief procedure. See

Related Manuals on page 3.

3. Perform dispense valve pressure relief procedure.

See Related Manuals on page 3.

Shutdown

1. Go to the Metering Valve Control screen.

2. Press the Retract button.

3. Press the Extend button.

4. Press the Emergency Stop button. Ensure everything is off.

5. Twist Emergency Stop to reset.

6. Perform Pressure Relief Procedure.

7. Perform feed system shutdown procedure. See

Related Manuals on page 3.

8. Perform dispense valve shutdown procedure. See

Related Manuals on page 3.

32 3A0261H

Page 33

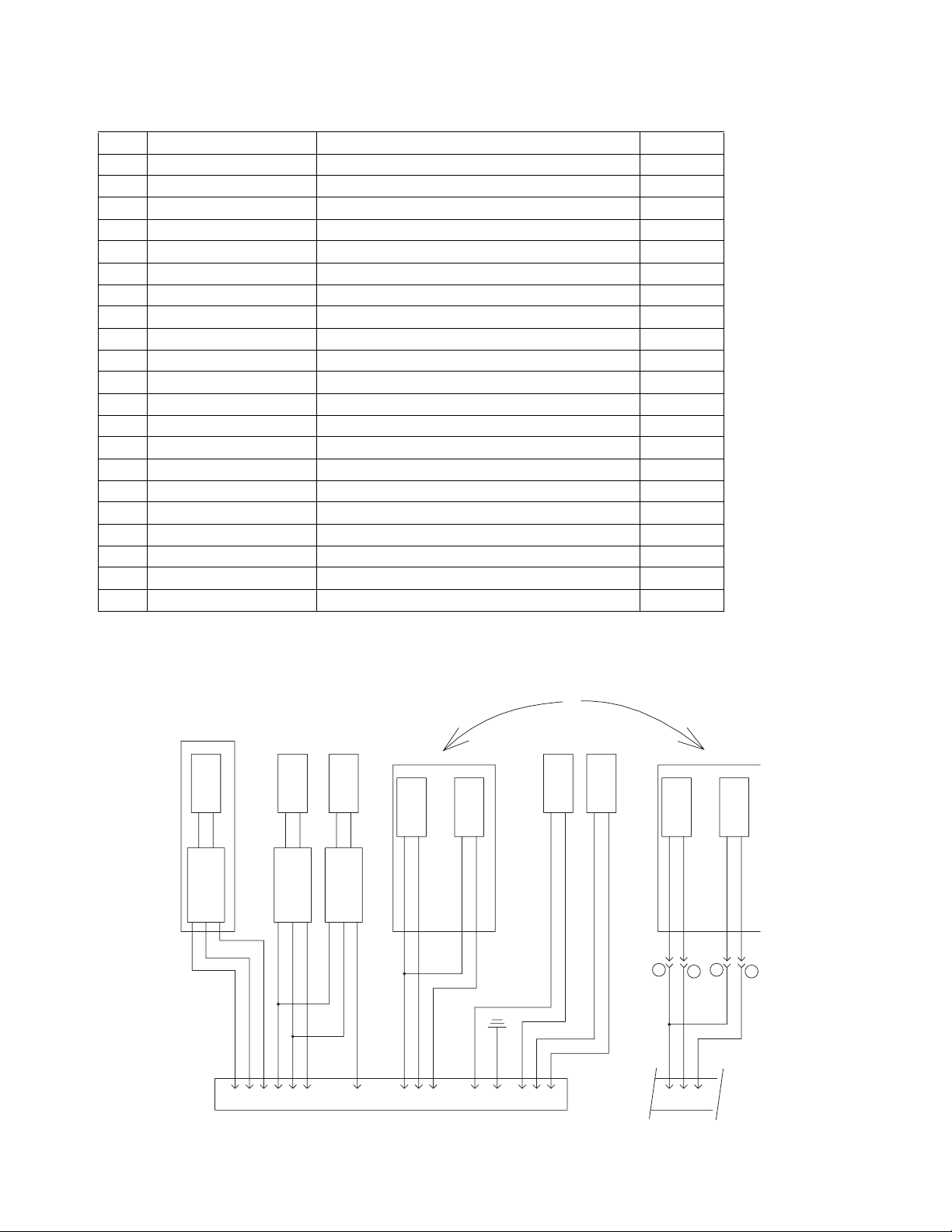

Customer Inputs

Customer Inputs

Name Description

Customer Start (Input) When a momentary contact closure is applied to this input, the start device is

activated.

Customer Purge Start

(Input)

Customer SS/FR Bit 1,2,3

(Input)

Customer Signal Done

(Output)

Customer Signal Dispense Ready (Output)

Customer Signal Time to

Purge (Output)

Customer Signal Open

Auxiliary Dispense Valve

(Output)

Customer Signal Reload

(Input)

When a momentary contact closure is applied to this input, the purge shot is

activated.

When these inputs are activated in the proper sequence, the machine activates the Shot Size and Flow Rate Combination seen on the Shot Sizes

screen. See the machine logic drawings for more information.

This output activates for 2 seconds after the dispense cycle is complete.

This output is active when the machine is in the Shot Mode and the dispense

valve is retracted and loaded with material. This output deactivates when the

dispense valve is dispensing or if the machine is not in the shot mode.

If the Manual Reload W/ Customer Signal button under the Supervisor screen

is selected, this output is active when it is time for the machine to take a purge

shot.

NOTE: The dispense valve will not perform a purge shot until the start device

is activated.

This is to be used only when there is a metering valve feeding an on/off type

dispense valve. This signal is used to open and close the dispense valve.

When in customer reload mode, after each shot the dispense “Done” signal is

turned on for 2 seconds. During this time the customer can toggle the customer reload signal to reload the system. If the timer expires, the machines

assumes the customer does not want to reload and finishes the sequence

then turns on the ready signal and does not allow another reload until after the

next shot.

3A0261H 33

Page 34

Maintenance

Maintenance

NOTE: If material is leaking, see Troubleshooting on

page 34.

See Related Manuals on page 3 for dispense valve and

feed system maintenance socket schedule and procedures.

Air-Water Separator/Filter

Drain water once a shift or as necessary.

Troubleshooting

Perform Pressure Relief Procedure before performing any troubleshooting procedure.

Problem Cause Solution

Dispense valve stalling and no material being dispensed despite adequate input pressure

Dispense valve not discharging normal or full volume

Material leaks past spool valves Spool valve worn or damaged Replace the spool valve and sleeve

Material leaks around needle while

dispensing

The horn beeps after each shot Dispense is longer than the dispense

The horn beeps continuously If the low level sensors are on, the

Blocked needle Check needle for cured material,

replace mixer as required

Flow control valve closed Open

Low material level in reservoirs Fill material reservoirs and prime the

machine

Air in material tanks Fill reservoirs and prime machine

Cured material in needle Check mixer for cured material,

replace needle

Check mixer for cured material

limit timer

Check level screen for low level con-

system may be low on material

dition, if low level condition is present,

fill tank with material

34 3A0261H

Page 35

Schematics

Schematics

78

ON ON

CLOSEST TO DRIVE MOUNTING FACE

SW-2 LOCATED UNDER DRIVE HOUSING

CLOSEST TO DRIVE FACE

SW-1 LOCATED UNDER DRIVE HOUSING

OFF ON

3456

OFF ON

1 2

ON OFF

ON

OFF

8

ON

654 7

OFF

ON OFF

OFF

ON

23

ON

1

OFF

ON

OFF

M1

RED

50% REDUCTION

SERIES

5000

WIRING CONFIG:

RESOLUTION:

ENABLED

-4% 3rd HARMONIC

WAVE FORM:

ANTI-RESONANCE:

AUTO STANDBY:

8

ORANGE

BROWN

9

S57-102-MO

PG-5

MOTOR:

BLUE

RED

BARE

GREEN

BLACK

YELLOW

1

7

3

5

624

RED

BARE

GREEN

BLACK

WHITE WHITE

GREEN

2.60 AMPS

<32mH

LEDS

AC POWER APPLIED

NO AC POWER SUPPLIED

FAULT CONDITION

* DRIVE OVERTEMPERATURE

GAIN:

CURRENT:

LED COLOR:

OFF

RED

GREEN

* SHORT CIRCUIT

OFF

ON

NOTE: SET DIP SWITCHES BEFORE WIRING DRIVE

ONONOFF

21

23

22

20

16

E-AC

PARKER

GND

N

L1

MOTOR DRIVE

PINOUT

LOOKING

AT DRIVE

1714151918

1

5

3

2

6

4

24

9

8

7

11

101213

PG-DRIVE

25

CN-4

B+B-A+A-GND

-

-

3

46-5-

22

LMT-

-

FAULT + (C)

8-

7

MODULE

EM-253

POSITION

M

+5V

STEP -14

RESET +

DIRECTION -

SHUTDOWN +

12 -

11-9

10

25

M

P0-

16

15

13 -

272826

25

ORG

WHITE

BLUE

21

P1+

P1-

PO+

FAULT - (E)

SHUTDOWN -

17

18 -

RESET -23

24 -

22 -2021-19 -

25-

NOTE: USE WIRE FERRULES ON DRIVE CONNECTIONS

BLACK

28

27

26

CONNECT SHIELD TO GROUND

USE 81/0056-MC10S/11

P1

P0

T1

DIS

CLR

20

BLU/WHT

7

PG-2

BLK

PX-UP

BLU

BRN

4

PG-2

5

PG-2

GRN/BLK

BLU

6

8

369

368

367

360320

362

363

361

359

358

357

2L2

22 AWG

CRM

366

364

365

6

WHT/BLU

24VDC

372

371

370

DC COM DC COM

2L2

EXP-1

22 AWG 22 AWG

68

GM

L+

14 AWG

8

326

349

6

22 AWG

BLU

329

328

327

8 6 68

24VDC

332

331

330

N

EEPROM

BATTERY

PROGRAMMING

PROGRAMMING

6789

2

FOR DP/MPI

6

NOTE: SET SWITCHES

0V

22 AWG

G

+24V

HMI-1

22 AWG

34 1

PORT-0

5

IF2

IF1BIF1A

G

6789

2

34 1

PORT-1

5

14 AWG

L1

PLC-1

CAB-1

2L1

86

2L1

325

324

322

323

321

319

318

317

STEP +1

DIRECTION +

CONTROL

PB-2

PB-1

6

354

314

3M

6

5

6

POWER

8

22 AWG

10

13 14

8

2

DRIVE I/O

22

21

GRAY

RED

4M

LMT+

6

19

WHT/BLU WHT/BLU WHT/BLU

BLK/WHT

PG-2

BLK

PX-DN

BLU

BRN

4

PG-2

PG-2

GRN/BLK

BLU

6

8

356

355

6

A2

W

PL-1

A1

8

22 AWG

CRM

8

316

315

16 AWG

RED

WHITE

CLAMP TO

52

55

N

L

LOAD

2. CONNECT SHIELD TO GROUND

5

5

FU-L

G

300

BACK PANEL AS SHOWN:

3. JUMPER PINS 1 AND 2 ON PANEL SIDE OF CONNECTOR

4. JUMPER PINS 8 AND 9 ON PANEL SIDE OF CONNECTOR.

5. CABLE FROM PANEL TO PG-5 TO BE 10 FEET.

6. STRIP MOTOR CABLE TO SHIELD AND

FIL-1

LINE

54

1 2

WHT

51

53

X1

TRANS-1

L2

H2 H4

X3

CB-2

7

H1 H3

(5 AMP)

RED

120VAC

X2

50

X4

346

344

343

342

345

BLK

14 AWG

14 AWG

CB-1

1L2

L1 L2

7

L2

DCB

FU-N

(10 AMP)

N

301

1L1

(4 AMP)

14 AWG

DEFAULT TO 115 VAC FOR 1053

ACCORDING TO NAMEPLATE

120V TO 250 VAC, 50-60 HZ

NOTE: VOLTAG E TO BE FAC TORY SET

305

306

304

303

302

1. USE 81/0056-MC10S/11 MAKE 10 FT.

NOTE:

L1

L1

A

230V

115V

(10 AMP)

AC-CONN

L

GREEN/YELLOW

DRIVE-1

52

55

GND

ZP

2M

1M

STP

EXP-1

CRM

16 AWG

RPS

6

6

15

22 AWG

328

17

16

RED/BLK

3

PG-2

BLK

PX-HOME

BLU

BRN

1

PG-2

2

PG-2

WHT/BLK

WHT

6

DC COM

8

8 6

24VDC

353

352

351

350

349

347

348

CRM

56

1L2

1L2

1L1

BLK BLK

1L1

307

2L2

22 AWG22 AWG

6

M

1L2

N(L2)

24V DC

L+

L1

1L1

12 6

12

2L1

311

STOP

EMERGENCY

11

0

10

I

8

312

XO

XO

0X

PB-1A

313

120V

230V

PS-1

CRM

34

310

309

308

3A0261H 35

Page 36

Schematics

WITH 4W,3P,2S

SOLENOID VALVE

1053/1093

DC COM

NONE

CLOSE

SPOOL

VALVE

6

C

PR

(PD/1093

WITH 4W,2P,1S

SOLENOID VALVE

SOL

NOTE:

C

PR

RED RED BLK BLK

ISOLATED WITH RELAYS

22 AWG

56

OUTPUTS FOR CUSTOMER USE MUST BE

PLC OUTPUTS

Q0.1

Q0.0

1L

AA

NONE

NONE

NONE

NONE

FILL "A" SIDE

VALVE

SPOOL

OPEN

6

6

ORG

C

PR

BLK

AA-1

BLK

(1053)

AUDIO ALARM

FILL "B" SIDE

NONE

SIGNAL

TIME TO

PURGE

CUSTOMER

OPEN DV

NONE

CUSTOMER

CUSTOMER

22 AWG

CUSTOMER

DISPENSE

READY

SIGNAL

CUSTOMER

DISPENSE

DONE

SIGNAL

6

6

C1

C1

C2

CRM

CRM

C2

SOL

BLK

(PD/1093)

C

GRN

57

Q0.2

22 AWG

RED

(1053)

PR

22 AWG

22 AWG

49

Q0.3

Q0.5

Q0.4

Q0.7

Q0.6

2L

Q1.1

Q1.0

3L

22 AWG

41

48

47

Q1.3

Q1.2

Q1.4

40

24

Q1.7

Q1.6

Q1.5

24VDC

DC COM

24VDC

DC COM

24VDC

8

TUBE#TUBE#TUBE#TUBE#

462

461

460

NONE

6

2M

I1.5

465

464

463

NONE

I1.6

466

NONE

I1.7

8

475

474

473

472

471

470

469

467

468

NONE

NONE

I2.1

I2.0

22 AWG

NONE

START PURGE

I2.3

I2.2

23

46

CUST PURGE START

8

34

CUST RELOAD

8

8

492

491

490

489

488

487

486

480

482

481

479

478

477

476

RELOAD

SEE TABLE 1

SEE TABLE 1

SEE TABLE 1

I2.6

I2.5

I2.4

35

CUST SS/FR BIT 1

8

I2.7

37

36

CUST SS/FR BIT 3

CUST SS/FR BIT 2

8

8

485

484

483

DC COM

CUSTOMER SIGNAL

TB

43

ORG

ORG

42

TB

DISPENSE DONE

CR-

CUSTOMER SIGNAL

TB

45

ORG

22 AWG

CC

ORG

22 AWG

44

TB

TUBE#TUBE#

DISPENSE READY

CR-

1

1

1

1

0

0

00

0

0

TOUCH SCREEN CONTROLLED

0

1

1

1

1

0

0

111

1

000

22 AWG

CC

SHOT SIZE / SPEED 1

SHOT SIZE / SPEED 2

22 AWG

SHOT SIZE / SPEED 3

SHOT SIZE / SPEED 5

SHOT SIZE / SPEED 6

SHOT SIZE / SPEED 7

SHOT SIZE / SPEED 4

12.5

12.6

DIGITAL INPUTS

12.7

TABLE 1

CUSTOMER SELECT (0=0FF, 1=0N)

FLOW RATE (MM/SEC) / SHOT SIZE (%)

24VDC

451

450

449

448

447

446

440

442

441

439

438

437

436

435

434

433

432

431

430

429

427

428

426

425

424

423

422

421

420

SPOOL RELOAD

POSITION

START SIGNAL

6

1M

PLC-1

INPUTS

22 AWG

I0.1

I0.0

29

30

BLU/BLKWHT

9

PG-2

4

29

CUST START

8

TUBE#TUBE#

380

381

PG-1

2

PG-1

8

8

FS

FUNCTION

1

382

PG-2

RED/WHT BRN

PG-1

8

8

385

383

384

POSITION

SPOOL DISPENSE

I0.2

31

ORG/BLKWHT

10

PX-CSV

RELOAD

BRN

386

387

388

NONE

NONE

"A" LOW

6

I0.3

I0.5

I0.4

32

BLK

22 AWG

PG-2

PX-OSV

DISPENSE

ASSEMBLY FOR

SEE TANK OR FEED

PAR T IDENTIFICATION

THIS CONTROL PAC KAGE.

ARE NOT INCLUDED WITH

LEVEL CONTROL SWITCHES

393

389

390

391

394

392

22 AWG

C

PR

C

PR

BLKBRN

BLU

PX-

C

PR

RED WHT

8

397

395

396

Z-LIFT

CONNECTED

"B" LOW

I0.6

33

C

BLK

PX-

BRN

C

RED WHT

8

398

"A" HI

6

6

I0.7

I1.0

38

WHTRED

BLK

C

PR

BLU

PR

BLK

22 AWG

C

PR

C

PR

BLK

BLU

PX-

BRN

C

PR

8

400

401

399

402

445

444

443

"B" HI

I1.1

NONE

6

NONE

I1.3

I1.2

NONE

I1.4

452

DC COM

TUBE#TUBE#

39

WHTRED

BLK

22 AWG

C

PR

PR

C

PR

BLK

BLU

PX-

BRN

C

PR

8

24VDC

409

410

405

406

407

404

403

408

411

412

36 3A0261H

Page 37

HOUSING

Schematics

CONNECTOR

15

8

14

7

13

6

12

5

11

4

10

3

9

2

1

F

RED

GRAY

BLUE

WHITE

BLACK

COLOR

PAR T NUMBER

SIZE

WIRE

REFERENCE WIRE FERRULE CHART

T. BLUE

L

112516

81/0725/11

81/0724/11

81/0723/11

81/0720/11

81/0721/11

24AWG

18AWG

16AWG

14AWG

12AWG

20-22AWG

PD/10931053/1093

12 (A)

SPOOL

(DISPENSE)

OPEN

DV-1

YEL

A

B

SOL-OSV

P

EA

EB

100

MF-1

100

80 PSIG

1/2" DIA

PLANT AIR

OPEN

SPOOL

VALVE

(DISPENSE)

YEL

SOL-CSV

(A)

4

(P) 1

(EA) 5

MF-1

100

80 PSIG

1/2" DIA

PLANT AIR

JOINTS AS SHOWN

BLK

BLU

RED

WHT

ORG

BRN

NUMBER

NUMBER

NUMBER

---

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

1

2

3

7

456

BLK

BLU

RED

WHT

BRN

ORG

---

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

1

7

2

3

456

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

1

2

9

3

785

6

4

101412

*DISCARD PIN

11

13

NTS

COLOR

81/1061-7H/25

FREE HANG FREE HANG

81/1061-7H/25

FREE HANG

345

12

67

PG-1

345

12

PG-1

891011

4567

123

PG-1

PIN USAGE

HTR-1

PIN

COLOR

67

PIN USAGE

HTR-1

PIN

121314

PIN USAGE

HTR-1

PIN

GROUND DIST BAR

84/0130-23/11

PLACE NEAR

TUBING COVERING ALL SOLDER

VALVE

(RELOAD)

CLOSE

GRN

MF-2

FL-1

NOTE: FILTER SUPPLIED

BY CUSTOMER

CLOSE

(RELOAD)

1/16 X 3/8"LG HEAT SHRINK

8

15

FREE HANG

75

14

6

1310

41

PG-2

11 12

32

9

COLOR DEVICE

VALV-I/O

PIN USAGE

PIN

NUMBER

COLOR

2

1

4

PG-1

IN BOX

81/1060-4/25(7AF)

81/1061-4/25(7AM)

81/1060-4H/25(13AF)

3

81/1061-4H/25(13AM)

PIN USAGE

HTR-1

PIN

NUMBER

+24 VDC

VDC COMMON

WHT

WHT/BLK

6

8

1

2

BLUE

BROWN

SPARE

SPARE

1

2

PX-HOME

RED/BLK

16

3

---

SPARE

3

+24 VDC

VDC COMMON

BLU

GRN/BLK

8

6

4

GRN/YEL

SPARE

4

PX-DN

PX-UP

LS-CSV

LS-OSV

GROUND

+24 VDC

SOL-CSV-SIGNAL

SOL-OSV-SIGNAL

SOL-OSV COMMON

SOL-CSV-COMMON

BLK

RED

GRN

BLU/BLK

ORG/BLK

BLK/WHT

BLU/WHT

RED/WHT

GRN/WHT

8

19

6

6

31

30

20

50

56

GND

9

875

15 6 ORG

13

121110

14

81/1060-7/25

81/1061-7/25

81/1060-7H/25

NOTE: USE LEAD FREE SOLDER

81/1060-7/25

81/1061-7/25

81/1060-7H/25

FIGURE 2

GRN

(B)

2

(EB) 3

SOL-OSV

(B)

1414

TO GROUND

DIST. BAR

SEE FIGURE 2

GRN/YEL

MIN 14 AWG

TO GROUND

STUD ON DOOR

GRN/YEL

MIN 14 AWG

MF-2

NTS

FIGURE 1

FL-1

NOTE: FILTER SUPPLIED

BY CUSTOMER

STAR WASHER

STAR WASHER

TO TERMINAL GROUND.

GROUNDING NOTES:

. CONDUCTOR (GROUND STUD).

1. PLACE LABEL 84/0130-26/11 "PE" AT EXTERNAL PROTECTIVE

END

2. NO PAINT UNDER GROUND STUD.

3. REFER TO FIGURE 1 FOR GROUND STUD DETAIL.

9. GROUND ALL DOORS

12. DO NOT JUMPER GROUND WIRES. SEE FIGURE 2

11. DO NOT WIRE TIE POWER WIRES WITH SIGNAL WIRES.

10. SHIELD CABLE TO BE CONNECTED AT ONE

PROTECTIVE EARTH

INCOMING GROUND

GRN/YEL

MIN 14 AWG

PE

ENCLOSURE

SEE NOTE 1

GROUND STUD

VALVE

FS-1 (22 AWG)

M1 SHLD

DRIVE-1 I/O SHLD

DRIVE-1 GRN/YEL (16 AWG)

FIL-1 GRN/YEL (16 AWG)

EXP-1 GRN/YEL (16 AWG)

PLC-1 GRN/YEL (14 AWG)

HMI GR/YEL (22 AWG)

GROUND DIST. BAR

TRANS-1 NEUTRAL GND (14 AWG)

PE GROUND STUD GRN/YEL (14 AWG)

545

547

546

544

543

542

541

540

550

549

548

560

559

558

557

556

555

554

553

552

551

563

561

572

571

570

569

568

567

566

565

564

562

3A0261H 37

Page 38

Schematics

38 3A0261H

Page 39

Technical Data

Technical Data

Maximum Ambient Temperature. . . . . . . . . . . . . . . . . . . . 110°F (43°C)

Maximum Operating Temp . . . . . . . . . . . . . . . . . . . . . . . . 150°F (65°C)

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 120/240V, 50/60 Hz

Fuses Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 x 20 mm, 10A, fast, type F, 250 VAC

(Graco part V-21610P, Qty = 2)

Maximum Amperage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 amps

Dimensions (H x L x W) . . . . . . . . . . . . . . . . . . . . . . . . . . 20 in. x 8 in. x 20 in. (508 mm x 203 mm x 508 mm)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 lb (27.2 kg)

3A0261H 39

Page 40

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 or Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original Instructions. This manual contains English. MM 3A0261

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised August 2014

Loading...

Loading...