Page 1

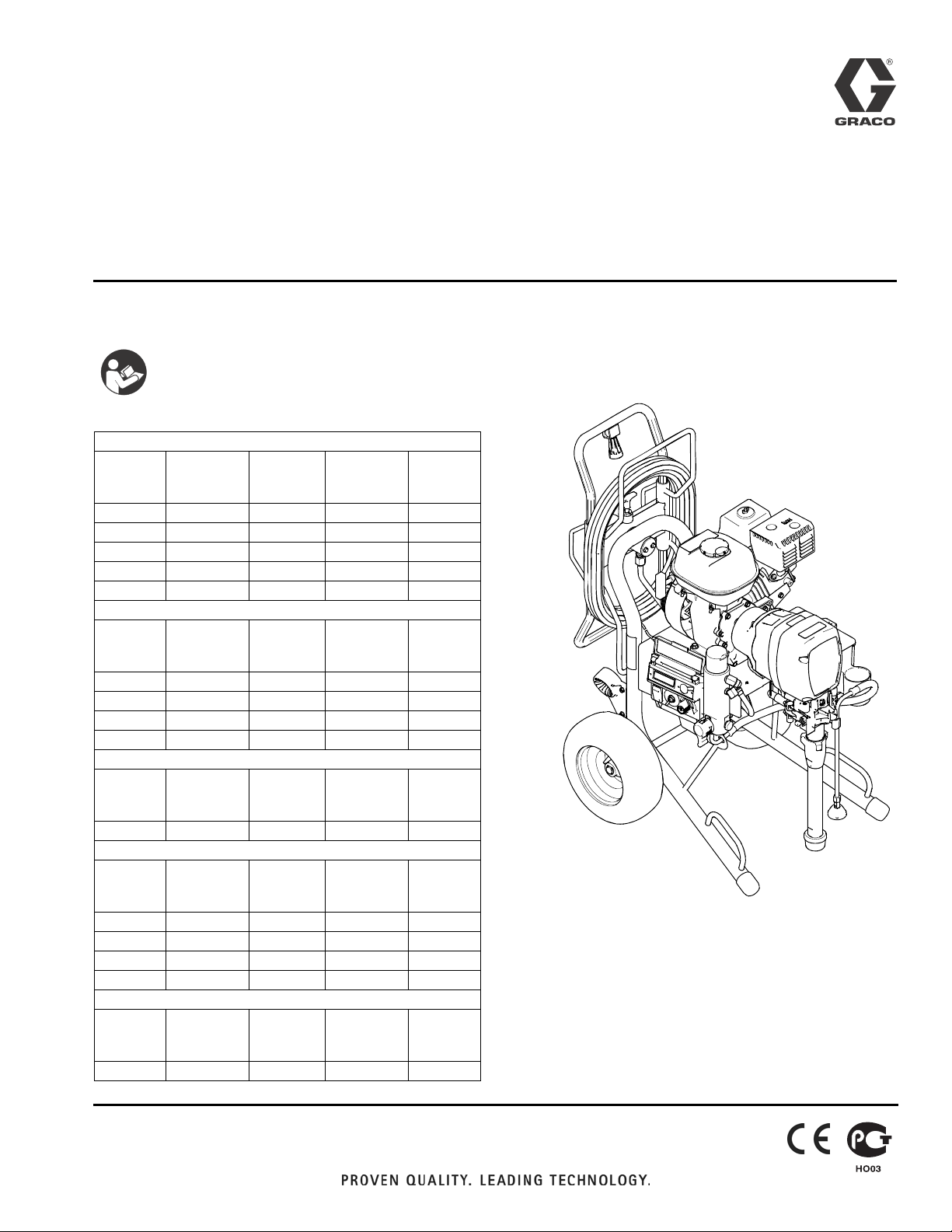

Repair

GMAX™ II 3900/5900/7900

™

TexSpray

5900HD/7900HD

Airless Sprayers

Korean patent: 10-0647761

- For Portable Airless Spraying of Architectural Coatings and Paints -

3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

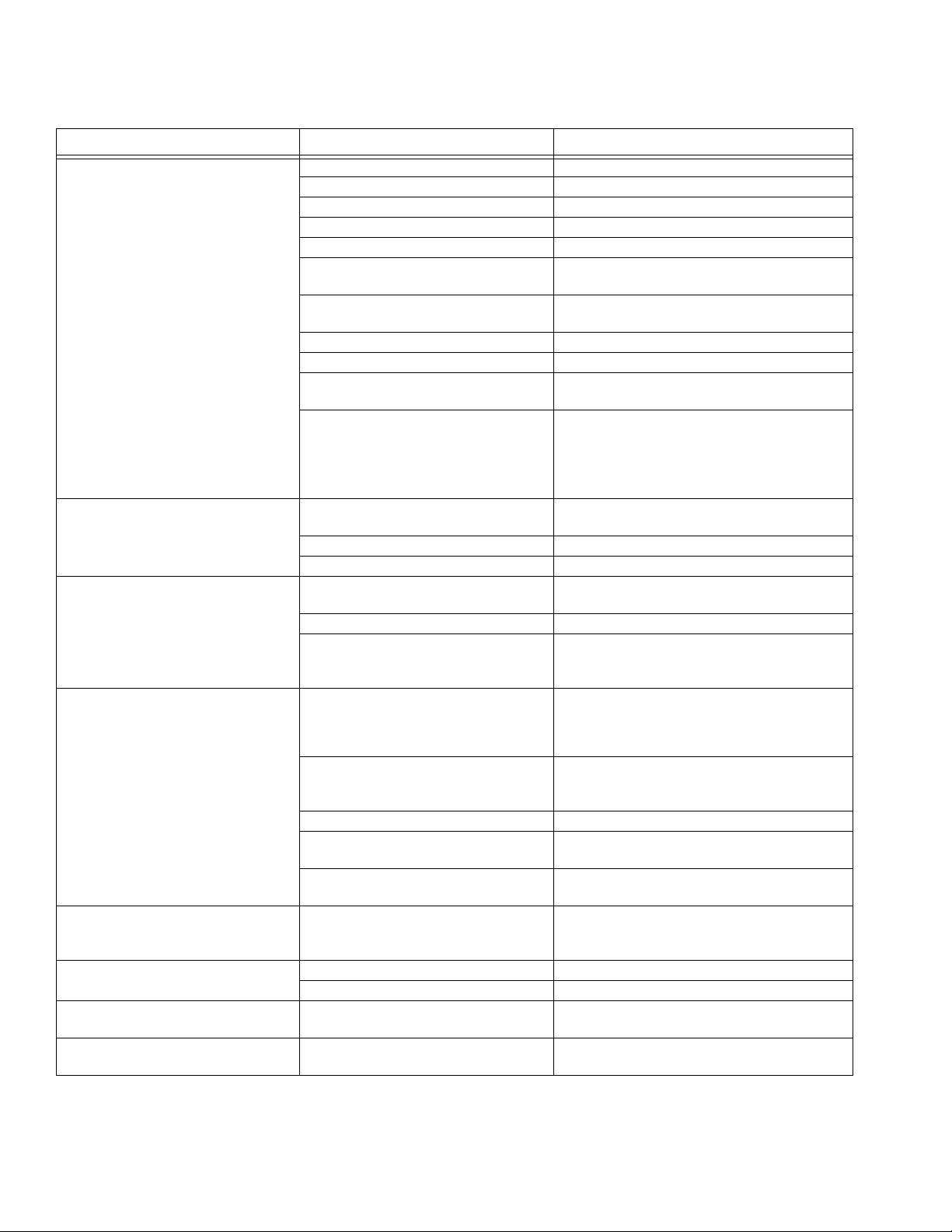

GMAX 3900

Model Hi-Boy

Premium

(QuikReel)

248683 ✓

248684 ✓

249335 ✓

258731 ✓

258736 ✓

Model Hi-Boy

Premium

(QuikReel)

248687 ✓

248688 ✓

258732 ✓

258737 ✓

Model Hi-Boy

Premium

(QuikReel)

258734 ✓

Model Hi-Boy

Premium

(QuikReel)

248700 ✓

248701 ✓

258733 ✓

258738 ✓

Model Hi-Boy

Premium

(QuikReel)

258735 ✓

Hi-Boy

Standard

GMAX 5900

Hi-Boy

Standard

TexSpray 5900 HD

Hi-Boy

Standard

GMAX 7900

Hi-Boy

Standard

GMAX 7900

Hi-Boy

Standard

Lo-Boy

Premium

(QuikReel)

Lo-Boy

Premium

(QuikReel)

Lo-Boy

Premium

(QuikReel)

Lo-Boy

Premium

(QuikReel)

Lo-Boy

Premium

(QuikReel)

Lo-Boy

Standard

Lo-Boy

Standard

Lo-Boy

Standard

Lo-Boy

Standard

Lo-Boy

Standard

3A0243A

ENG

ti14916a

Related Manuals:

Operation 3A0242

Parts 3A0244

Gun 311861

Page 2

Warning

Warning

The following are general warnings related to the setup, use, maintenance and repair of this equipment. Additional,

more specific, warnings may be found throughout the text of this manual, where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable

and can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure and disconnect all power sources.

2 3A0243A

Page 3

Warning

WARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

SUCTION HAZARD

Powerful suction could cause serious injury.

• Never place hands near the pump fluid inlet when pump is operating or pressurized.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide can cause death.

• Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0243A 3

Page 4

Maintenance

Maintenance

Pressure Relief Procedure

1. Lock gun trigger safety.

2. Turn engine ON/OFF switch to OFF.

3. Move pump switch to OFF and turn pressure control

knob fully counterclockwise.

4. Unlock trigger safety. Hold metal part of gun firmly

to side of grounded metal pail, and trigger gun to

relieve pressure.

5. Lock gun trigger safety.

6. Open pressure drain valve. Leave valve open until

ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY loosen

tip guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Now clear

tip or hose.

AFTER THE FIRST 20 HOURS OF OPERATION:

Drain engine oil and refill with clean oil. Reference

Honda Engines Owner's Manual for correct oil viscosity.

WEEKLY: Remove engine air filter cover and clean element. Replace element, if necessary. If operating in an

unusually dusty environment: check filter daily and

replace, if necessary.

Replacement elements can be purchased from your

local HONDA dealer.

AFTER EACH 100 HOURS OF OPERATION:

Change engine oil. Reference Honda Engines Owner's

Manual for correct oil viscosity.

SPARK PLUG: Use only BPR6ES (NGK) or W20EPR-U

(NIPPONDENSO) plug. Gap plug to 0.028 to 0.031 in.

(0.7 to 0.8 mm). Use spark plug wrench when installing

and removing plug.

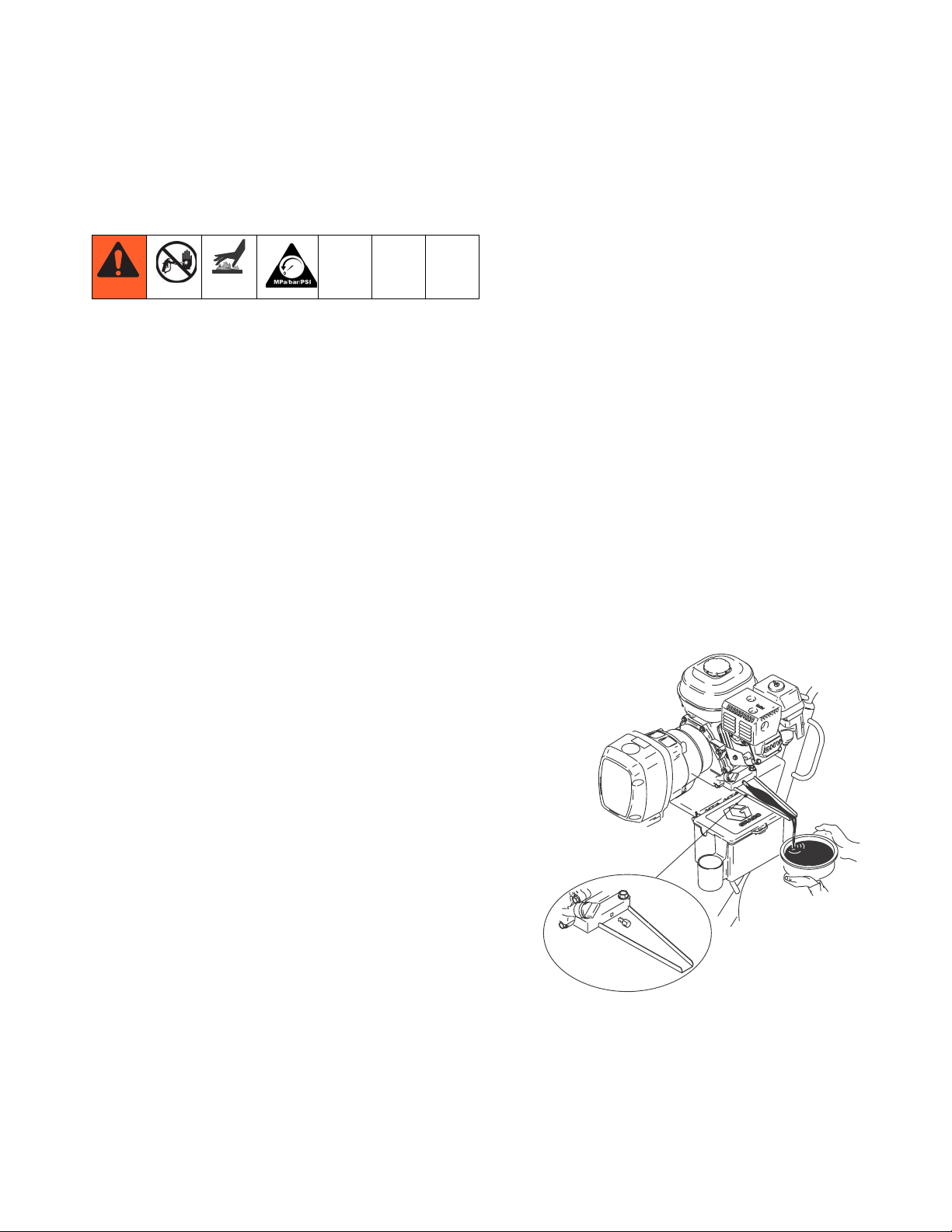

Premium Sprayers Engine Oil Funnel:

Use the supplied engine oil funnel when draining oil.

NOTE: For detailed engine maintenance and specifications, refer to separate Honda Engines Owner's Manual,

supplied.

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check that all hose fittings are secure.

DAILY: Check gun safety for proper operation.

DAILY: Check pressure drain valve for proper operation.

DAILY: Check and fill the gas tank.

DAILY: Check level of TSL in displacement pump pack-

ing nut. Fill nut, if necessary. Keep TSL in nut to help

prevent fluid buildup on piston rod and premature wear

of packings and pump corrosion.

ti6200a

OIL FUNNEL

4 3A0243A

Page 5

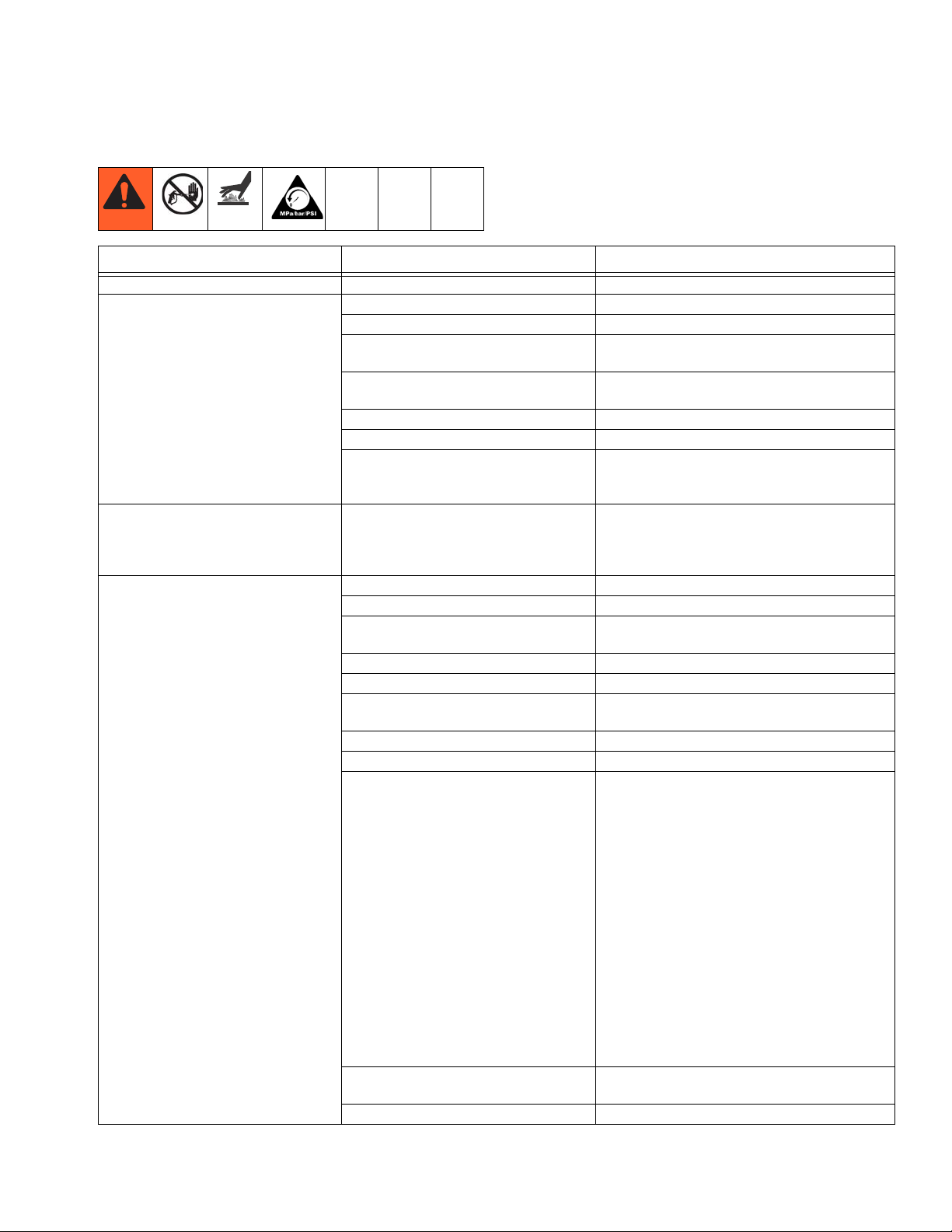

Troubleshooting

Troubleshooting

Problem Cause Solution

E=XX is displayed Fault condition exists. Determine fault correction from table, page 14.

Engine will not start Engine switch is OFF. Turn engine switch ON.

Engine is out of gasoline. Refill gas tank. Honda Engine Manual.

Engine oil level is low. Try to start engine. Replenish oil, if necessary.

Honda Engine Manual.

Spark plug disconnected or damaged. Connect spark plug cable or replace spark

plug.

Engine is cold. Use choke.

Fuel shutoff lever is OFF. Move lever to ON position.

Oil is seeping into combustion chamber. Remove spark plug. Pull starter 3 to 4 times.

Clean or replace spark plug. Start engine.

Keep sprayer upright to avoid oil seepage.

False tripping of WatchDog system.

EMPTY is displayed. Pump does not

run.

Engine operates, but displacement

pump does not operate

Operating conditions out of WatchDog

parameters.

Pump output is low, page 6.

Error code displayed. Reference Pressure Control repair, page 21.

Pump switch is OFF. Turn pump switch ON.

Pressure setting too low. Turn pressure adjusting knob clockwise to

Fluid filter is dirty. Clean filter.

Tip or tip filter is clogged. Clean tip or tip filter (see gun manual).

Displacement pump piston rod is stuck

due to dried paint.

Connecting rod is worn or damaged. Replace connecting rod. Page 15.

Drive housing is worn or damaged. Replace drive housing. Page 16.

Electrical power is not energizing clutch

field.

Turn pressure down. Contact Graco Technical

Assistance to adjust WatchDog parameters.

Operate without WatchDog active (see Opera-

tion manual).

increase pressure.

Repair pump (see pump manual).

Check wiring connections. Page 21.

Reference Digital Display Messages.

Page 14.

Reference wiring diagram. Page 21.

With pump switch ON and pressure turned to

MAXIMUM, use a test light to check for power

between clutch test points on control board.

Remove clutch wires from control board and

measure resistance across clutch coil. At 70° F,

the resistance must be between 1.2 + 0.2 Ω; if

not, replace pinion housing.

Have pressure control checked by authorized

Graco dealer.

Clutch is worn, damaged, or incorrectly

positioned.

Pinion assembly is worn or damaged. Repair or replace pinion assembly. Page 17.

3A0243A 5

Adjust or replace clutch. Page 19.

Page 6

Troubleshooting

Problem Cause Solution

Pump output is low Strainer is clogged. Clean strainer.

Piston ball is not seating. Service piston ball (see pump manual).

Piston packings are worn or damaged. Replace packings (see pump manual).

O-ring in pump is worn or damaged. Replace o-ring (see pump manual).

Intake valve ball is not seating properly. Clean intake valve (see pump manual).

Intake valve ball is packed with mate-

rial.

Engine speed is too low. Increase throttle setting (see operation man-

Clutch is worn or damaged. Adjust or replace clutch. Page 17.

Pressure setting is too low. Increase pressure (see operation manual).

Fluid filter, tip filter or tip is clogged or

dirty.

Large pressure drop in hose with heavy

materials.

Excessive paint leakage into throat

packing nut

Fluid is spitting from gun Air in pump or hose. Check and tighten all fluid connections. Rep-

Pump is difficult to prime Air in pump or hose. Check and tighten all fluid connections.

Throat packing nut is loose. Remove throat packing nut spacer. Tighten

Throat packings are worn or damaged. Replace packings (see pump manual).

Displacement rod is worn or damaged. Replace rod (see pump manual).

Tip is partially clogged. Clear tip (see gun manual).

Fluid supply is low or empty. Refill fluid supply. Prime pump (see operation

Clean intake valve (see pump manual).

ual).

Clean filter (see gun manual).

Use larger diameter hose and/or reduce overall

length of hose. Use of more than 100 ft of 1/4

in. hose significantly reduces performance of

sprayer. Use 3/8 in. hose for optimum performance (50 ft minimum).

throat packing nut just enough to stop leakage.

rime pump (see operation manual).

manual). Check fluid supply often to prevent

running pump dry.

Reduce engine speed and cycle pump as

slowly as possible during priming.

Intake valve is leaking. Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well. Reas-

semble valve.

Pump packings are worn. Replace pump packings (see pump manual).

Paint is too thick. Thin the paint according to the supplier's rec-

ommendations.

Engine speed is too high. Decrease throttle setting before priming pump

(see operation manual).

Clutch squeaks each time clutch

engages

High engine speed at no load Misadjusted throttle setting. Reset throttle to 3300 engine rpm at no load.

Gallon counter not working Bad sensor, broken or disconnected

No display, sprayer operates Display damaged or has bad connec-

Clutch surfaces are not matched to

each other when new and may cause

noise.

Worn engine governor. Replace or service engine governor.

wire. Displaced or missing magnet.

tion.

Clutch surfaces need to wear into each other.

Noise will dissipate after a day of run time.

Check connections. Replace sensor or wire.

Reposition or replace magnet.

Check connections. Replace display.

6 3A0243A

Page 7

Fluid Pump Runs Constantly

Troubleshooting Procedure:

Troubleshooting

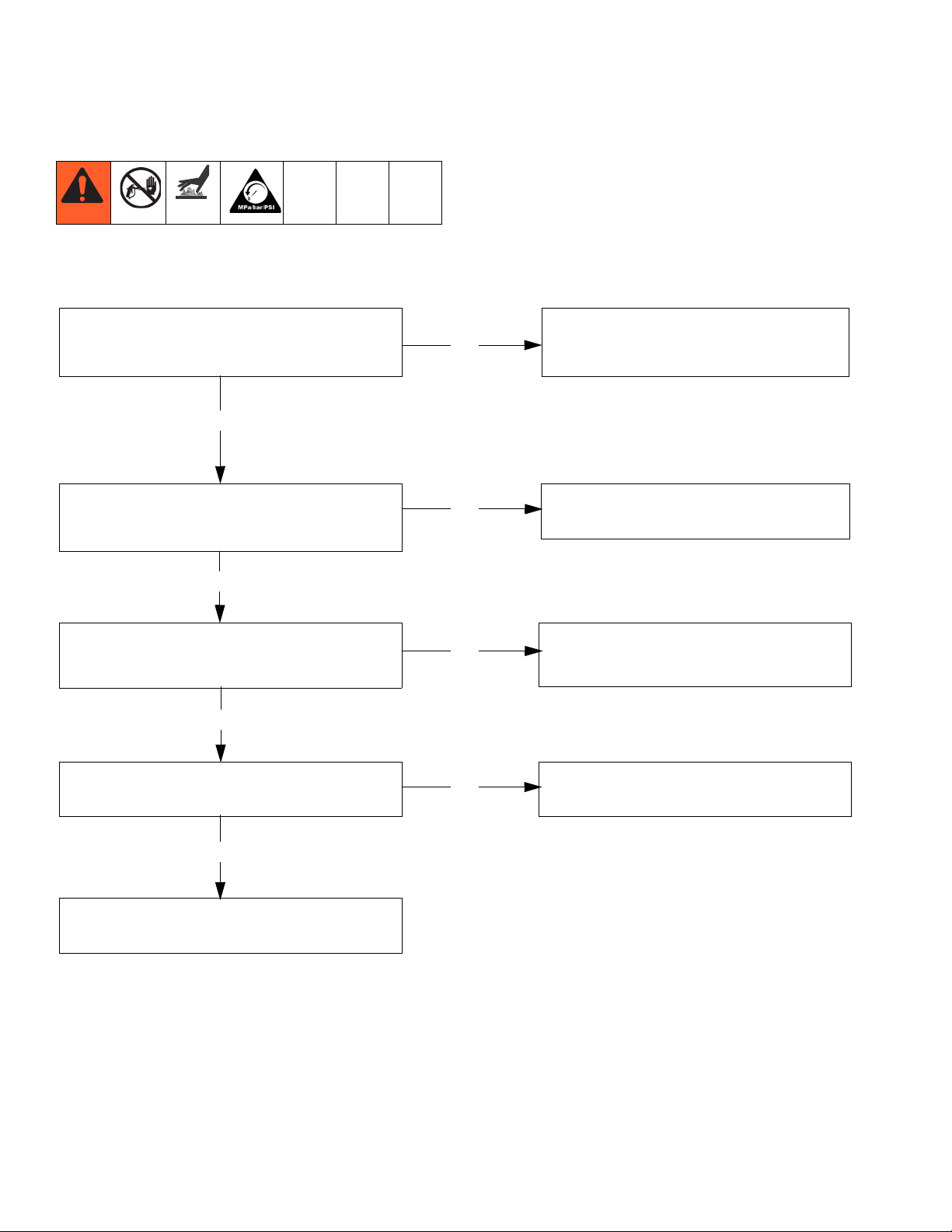

1. Perform Pressure Relief Procedure (page 4), turn

prime valve forward to SPRAY position, and turn

power switch OFF.

2. Remove control box cover.

With a pressure gauge plumbed into the paint

hose, start the engine. Turn pump switch ON.

Does sprayer exceed maximum pressure?

YES

Disconnect clutch wires from control board (see

diagram, page 12). Does the pump stop running?

YES

Make sure clutch wires are plugged in (see diagram, page 12). Do the clutch test points read

10-18 DC volts?

YES

NO

NO

NO

Pump problem. See the proper fluid pump

manual for the sprayer for further troubleshooting procedures.

Mechanical problem in the clutch pinion assembly (clutch may be close to the rotor).

Check for a short from the two clutch wires

to the frame. If shorted, repair or replace

faulty wire.

Unplug transducer from control board.

YES

Bad transducer.

Replace and test with a new one.

3A0243A 7

NO

Replace the control board.

Page 8

Troubleshooting

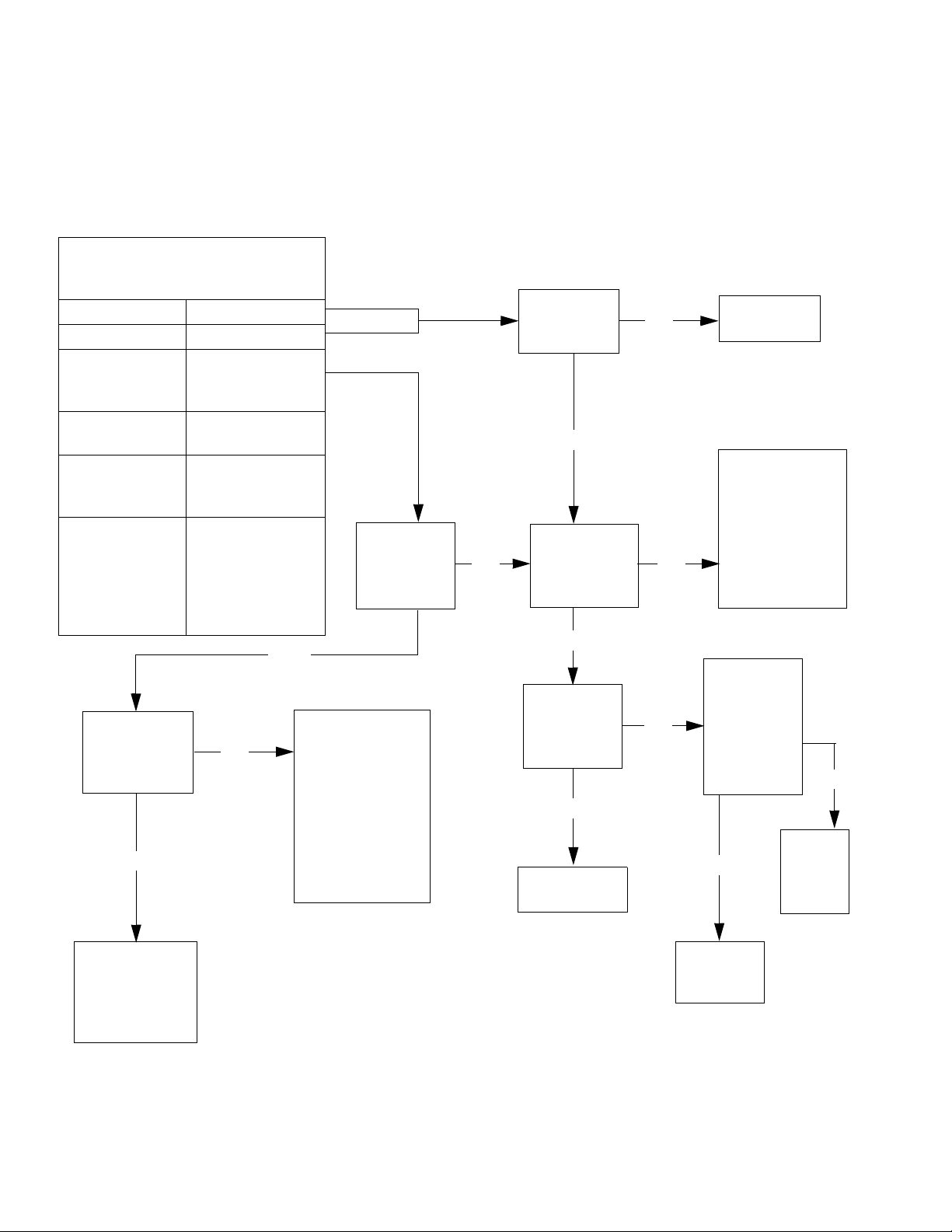

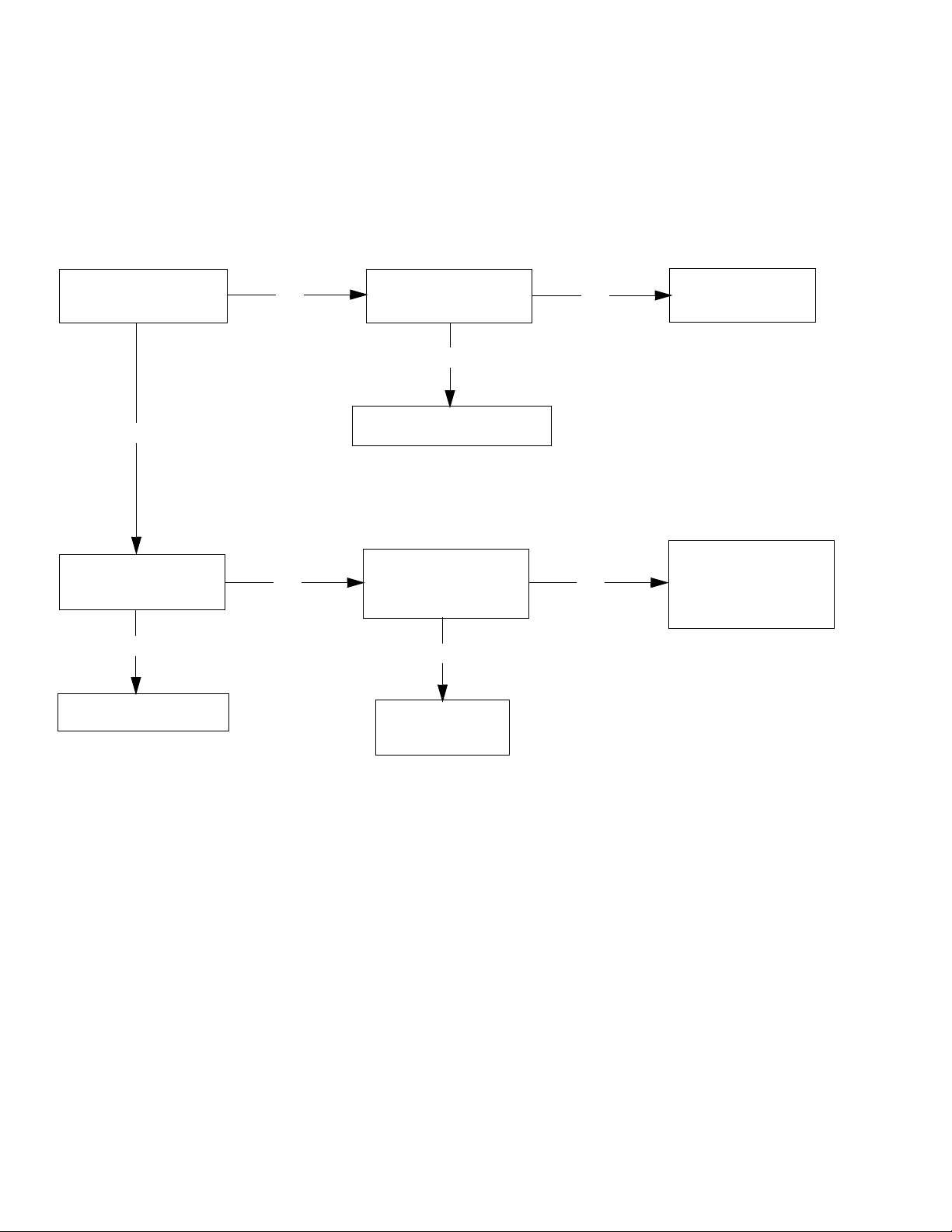

Control Board Malfunction

Troubleshooting Procedure

(see following page for actual steps):

Remove control box cover. Turn

sprayer ON. Observe control board

Green and Red LED lights.

No light

Once Normal operation

Red light on

continuously

Green light on

continuously

Flashing See error code

Red light on

continuously with

potentiometer

OFF after a

replacement

board is installed

Go to step 4.

Is 1-3 Ohms

reading present?

YES

Control board

commanding

engine to run

WatchDog

enabled

section for further

troubleshooting

Model not

selected

YES

If low resistance is

NO

present in step 4,

the problem is a

shorted field.

Replace pinion.

If an open in the

wiring is present,

check pinion

wiring

connections.

Go to step 3.

Is 10-12

VDC

present?

NO

Go to step 1.

Does switch

test positive?

YES

Go to step 2.

Do you have

proper engine

voltage?

YES

Go to step 5.

Does the

clutch

engage?

YES

Replace the

potentiometer.

NO

NO

NO

Replace the

switch.

Check wiring

from J1 and J2

for proper connection. If proper

connection is

detected, repair

or replace engine

generator.

Connect

a test

transducer to

the board.

Does the

clutch

engage?

Replace

YES

the

control

board.

NO

Mechanical

problem. Repair

or replace

clutch/pinion

assembly.

8 3A0243A

Replace

the

transducer.

Page 9

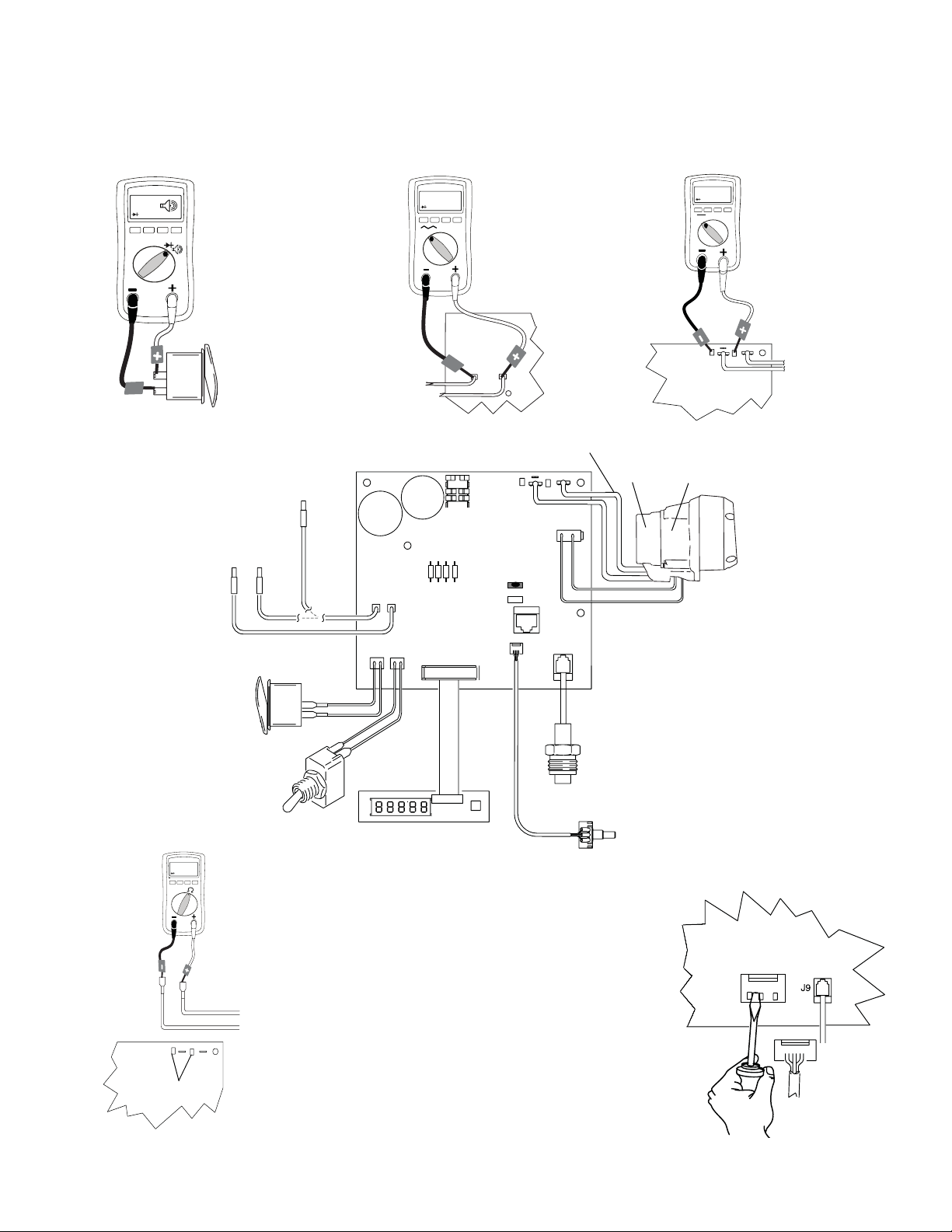

Control Board Malfunction (Steps)

Troubleshooting

BEEP

-

-

+

STEP 1.

Turn engine

OFF and set

meter to

continuity.

ti14938a

Pump

On/Off

Switch

To Ground

To Engine

5900/7900

On/Off Switch

3900

ti14939a

Engine

Generator

J1J2

J4J3

12 -20 AC

V

-

-

Control

Board

STEP 2.

Turn engine

ON. Set meter

to AC volts and

connect wires

to control

board.

Control

Board

+

J1

J2

Clutch Test Points

LED

D12

J5

J10

J9

To Clutch

Field

+

Pinion

Assembly

ti14943a

ti14940a

Control

Board

10-12 DC

V

-

Drive

Housing

STEP 3.

Leave engine

running and turn

switch ON. Turn

potentiometer to

high and set

meter to DC

volts.

+

+

Clutch

Field

WatchDog

Transducer

Premium Display Board

1-3 ohms

STEP 4.

Turn engine

Potentiometer

OFF and

unplug

ti14942a

Control

Board

Clutch Test Points

-

clutch wires.

-

Set meter to

+

Ohms.

+-

Clutch

Field

3A0243A 9

STEP 5.

Turn engine

ON and turn

switch ON.

Control

Board

J5

ti14941a

Page 10

Troubleshooting

Convertible Electric Motor Will Not Run

Troubleshooting Procedure

(see following page for actual steps):

See Step 1. Is there

over 100 AC volts?

YES

See Step 3. Is there

over 100 DC volts?

YES

See engine test section.

NO

NO

See step 2. Is there

over 100 AC volts?

YES

Replace the power switch.

See Step 4. Is there

continuity through the

thermal sensor?

YES

Replace engine

control board.

NO

NO

Repair or replace

the power cord.

If engine is hot, let

cool and retest. If

step 4 still shows an

open, replace engine.

10 3A0243A

Page 11

Convertible Electric Motor Will Not Run (Steps)

Troubleshooting

STEP 1.

Plug in cord and turn

switch ON. Connect

V

wires to control board

and turn meter to AC

volts.

-

ti14920a

+

-

Black

Electric Engine Control Board

L1

L2

White

Ground

Black

Black

Transformer

White

Black

Black

STEP 2.

Plug in cord and turn

switch ON. Connect

wires to control board

and turn meter to AC

volts.

power cord

Jack

Power Cord

AC power to

control board

Black to

V

-

ti14921a

-

Black

Electric Engine Control Board

White to Barrel

Black to Tips

L1

L2

+

White

100 + DC

V

-

+

+M -M

Electric

Engine

STEP 3.

Plug in cord and turn

switch ON. Turn meter

to DC volts.

Engine

-

Control

Board

TS TS

ti14923a

Ye l l o w Ye l l o w

Engine Control Board

Black

+M -M

ti14924a

Electric

Engine

White

L1

L2

TS TS

BEEP

STEP 4.

Check the engine thermal sensor (meter

should read continuity).

Note: engine should

-

be cooled down. Turn

meter to continuity test.

Engine

Control

TS

-

Board

TS

ti14922a

+M

Electric

Engine

-M

3A0243A 11

Page 12

Troubleshooting

Convertible Electric Motor Runs No AC Output to Sprayer Control Board

Troubleshooting Procedure

(see following page for actual steps):

See step 1.

Is there over 10-20

AC volts?

YES

See the sprayer

control board troubleshooting in this

manual.

NO

See step 2.

Is there continuity?

YES

See step 3.

Is there continuity?

YES

See step 4.

Is there over 100

AC volts?

YES

See step 5.

Is there over

10-20 AC volts.

NO

NO

NO

NO

Repair or replace

the power cord.

Repair or replace

the power cord.

Repair or replace

wire splice(s) on

the power cord

wires.

Replace transformer.

YES

Replace cord jack.

12 3A0243A

Page 13

Troubleshooting

Convertible Electric Motor Runs - No AC Output to Sprayer Control Board (Steps)

10-20 AC

V

-

ti14925a

Jack

Transformer

STEP 1.

Plug in cord and turn

switch ON. Connect

wires to transformer

and power cord. Turn

meter to AC volts.

-

Power Cord

AC power to

control board

Ground

Ground

+

Black

Black

White to barrel

Black to tips

Transformer

Black

Black

Black

White

Engine Control Board

L1

+M -M

Jack

L2

TS TS

Power Cord

AC power to

control board

White

ti14926a

-

ti14927a

White to barrel

Black to tips

BEEP

-

-

STEP 2.

Check AC power cord

for an open wire. Turn

meter to continuity

test. Meter should

read continuity.

Power Cord

AC power to

control board

STEP 3.

BEEP

Check AC power

cord for an open

wire. Turn meter to

continuity test.

-

Meter should read

continuity.

Power Cord

AC power to

control board

White to barrel

Black to tips

White to barrel

Black to tips

Power

Cord

STEP 4.

Plug in cord and turn

switch ON. Partially

V

connect wires to

splice. Turn meter to

-

-

Black

AC volts.

Tr a ns f or m e r

+

White

L1

Electric Engine Control Board

ti14929a

L2

ti14930a

Electric

Engine

White

10-20 AC

V

-

STEP 5.

Plug in cord and

turn switch ON.

Partially connect

wires to splice.

Turn meter to AC

volts.

ti14928a

Transformer

+

Black

Black

Black

-

Jack

3A0243A 13

Page 14

Digital Display Messages

Digital Display Messages

• Digital messages are not available on all sprayers

• Blinking LED total count equals digital error code

i.e., two blinks is the same as E=02

DISPLAY* SPRAYER OPERATION INDICATION ACTION

No Display Sprayer may be

pressurized.

Sprayer may be

ti6314a

pressurized.

Loss of power or display

not connected.

Pressure less than

200 psi (14 bar, 1.4 MPa).

Check power source. Relieve pressure before repair

or disassembly. Verify display is connected.

Increase pressure as needed.

psi

bar

MPa

ti6315a

ti6316a

ti6317a

ti6318a

(with

constant

green LED)

ti6320a

Sprayer is pressurized.

Power is applied.

(Pressure varies with tip

size and pressure

control setting).

Sprayer stops. Engine is

running.

Sprayer stops. Engine is

running.

Sprayer stops. Engine is

running.

Sprayer stops. Engine is

running.

Sprayer stops. Engine is

running.

Normal operation. Spray

Exceeded pressure limit. 1. Check fluid path for clogs, such as clogged filter.

2. Open prime valve and gun if running AutoClean.

3. Use Graco paint hose, 1/4 in. x 50 ft minimum.

Smaller hose or metal braid hose may result in

pressure spikes.

4. Replace transducer if fluid path is not clogged

and proper hose is used.

Pressure transducer faulty,

bad connection or broken

wire.

1. Check transducer connection.

2. Disconnect and reconnect transducer plug to

ensure good connection with control board

socket.

3. Open prime valve. Replace sprayer transducer

with known good transducer and run sprayer.

Replace transducer if sprayer runs or control

board if sprayer does not run.

High clutch current. 1. Check wiring connections.

Measure: 1.2 + 0.2 Ω (GMAX II 3900);

2.

1.7 + 0.2 Ω (GMAX II 5900/ 7900 & TexSpray

7900HD) across clutch field at 70°F.

3. Replace clutch field assembly.

Loss of paint to pump or

severe pressure loss.

1. Check for empty paint condition, clogged inlet

strainer, failed pump or severe leak.

2. Reduce pressure and turn pump switch OFF

and ON to restart pump.

3. WatchDog function can be deactivated by

turning WatchDog switch OFF.

Pressure greater than

2000 psi (138 bar, 14 MPa)

while in Flush Timer Mode.

1. Open prime valve and gun.

2. Verify no flow obstructions or clogged filter.

* Error codes also appear on control board as a blinking red

LED. LED is an alternate to digital messages.

1. Remove two screws (71) and swing down cover (130).

2. Start engine. Blink count is the same as error code(E=0X).

After a fault, follow these steps to restart sprayer:

1. Correct fault condition

2. Turn sprayer OFF

3. Turn sprayer ON

14 3A0243A

Page 15

Bearing Housing and Connecting Rod

NOTE: The item numbers referenced are for the 5900

Hi-Boy models. The 3900, 7900 and all Lo-Boy models

may have different item numbers. Use the 5900 Hi-Boy

item number and part to find the corresponding alternate part and item number.

Bearing Housing and Connecting Rod

NOTICE

DO NOT use bearing housing screws (41) to align or

seat bearing housing with drive housing. Align these

parts with locating pins, to avoid premature bearing

wear.

Removal

1. Relieve pressure; page 4.

2. Remove four screws (45) and front cover (44)

3. Remove pump. Refer to Displacement Pump,

Removal, page 23.

4. Remove four screws (41) and washers (42) from

bearing housing (40).

5. Pull connecting rod (43) and lightly tap lower rear of

bearing housing with plastic mallet to loosen from

drive housing (33). Pull bearing housing and connecting rod assembly off drive housing.

6. Inspect crank (B) and connecting rod (43) for excessive wear and replace parts as needed.

Installation

5. Install screws (41) and washers (42) in bearing

housing. Torque evenly to note 3 value below.

6. Install pump. Refer to Displacement Pump,

Installation, page 14.

"

%

$

&

#

!

TIB

1. Evenly lubricate inside of bronze bearing (C) in

bearing housing (40) with high-quality motor oil. Liberally pack top roller bearing (E), lower bearing (D)

inside connecting rod (43) with bearing grease.

2. Assemble connecting rod (43) to bearing housing

(40). Rotate connecting rod to lowest position.

3. Clean mating surfaces of bearing and drive hous-

Oil

1

Pack with bearing grease 114819

2

GMAX II 3900: Torque to 200 in-lb (22.6 N•m)

3

GMAX II 5900: Torque to 25 ft-lb (34 N•m)

GMAX II 7900: Torque to 40 ft-lb (54 N•m)

TexSpray 5900HD: Torque to 40 ft-lb (54 N•m)

TexSpray 7900HD: Torque to 40 ft-lb (54 N•m)

ings.

4. Align connecting rod with crank (B) and carefully

align locating pins (F) in drive housing (33) with

holes in bearing housing (40). Push bearing housing

onto drive housing or tap into place with plastic mallet.

3A0243A 15

Page 16

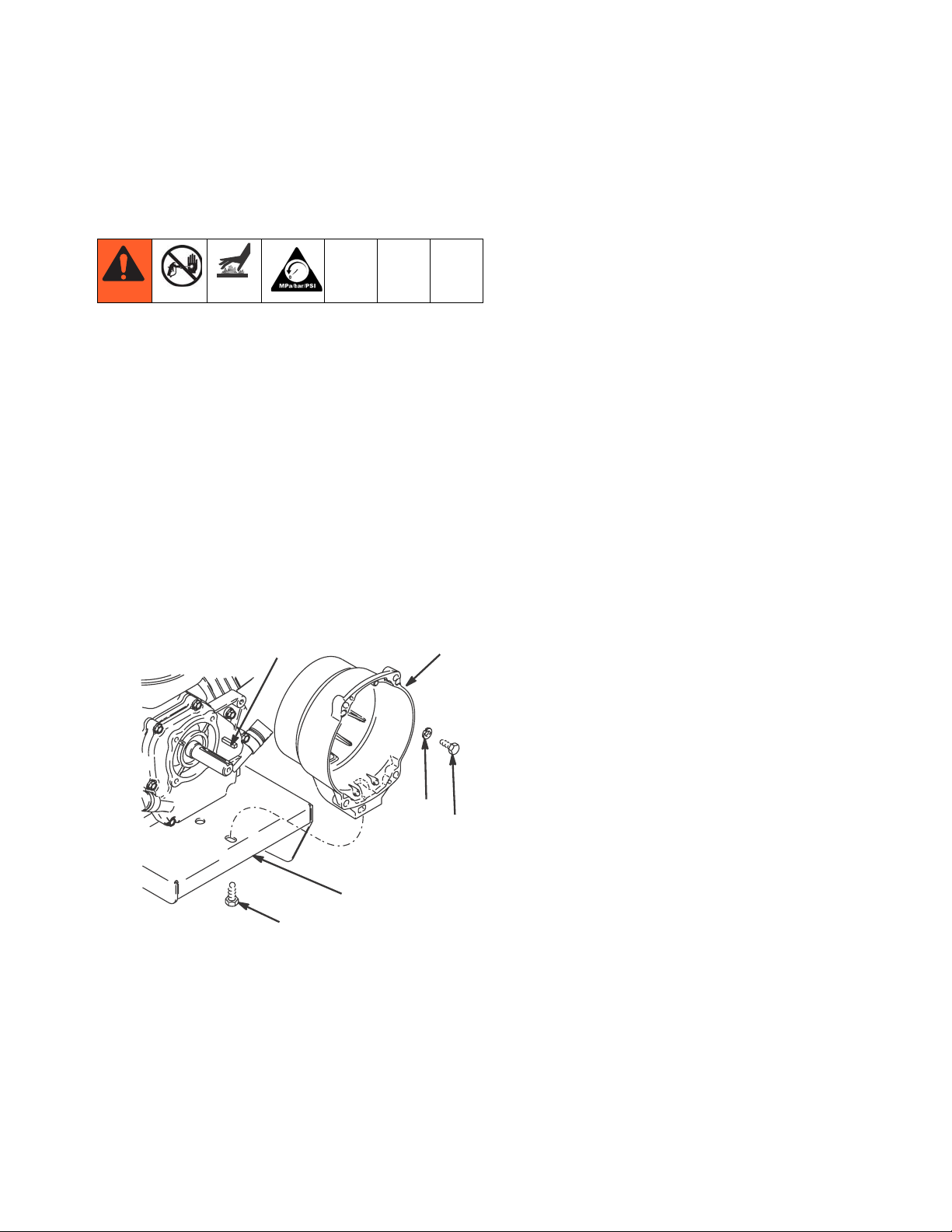

Drive Housing

Drive Housing

Removal

1. Relieve pressure; page 4.

2. Remove bearing housing. Refer to Bearing Hous-

ing and Connecting Rod, Removal, page 15.

NOTICE

Premium models: Gallon counter sensor is connected to

control board in pressure control. Pulling on the sensor

wires could cause damage.

3. Premium sprayers: Remove two screws (108) and

gallon counter sensor (39).

NOTICE

Thrust washers may stick to grease inside of drive

housing. Do not lose or misplace.

4. Remove six screws (38).

5. Lightly tap around drive housing (33) to loosen drive

housing. Pull drive housing straight off pinion housing. Be prepared to support combination gear (32)

which may also come out.

7. Install bearing housing. Refer to Bearing Housing

and Connecting Rod, Installation, page 15.

NOTICE

DO NOT use drive housing screws (38) to align or seat

drive housing with pinion housing. Align these parts with

locating pins, to avoid premature bearing wear.

8. Install screws (38) in drive housing. Torque evenly to

note 3 value below.

9. Install pump. Refer to Displacement Pump,

Installation, page 14.

"

TIA

"

A

B

1

Installation

1. Apply all grease supplied with replacement gear

cluster to gear teeth and to areas called out by note

3.

2. Ensure thrust washers (30, 31; 5900/7900) (30, 31,

72; 3900) are on combination gear (32) and wash-

GMAX II 3900: Torque to 140 ±10 in-lb (15.8 ±1.1 N•m)

1

GMAX II 5900: Torque to 200 ±10 in-lb (22.6 ±1.1 N

GMAX II 7900: Torque to 200 ±10 in-lb (22.6 ±1.1 N

Texspray 5900HD: Torque to 200 ±10 in-lb (22.6 ±1.1 N

Texspray 7900HD: Torque to 200 ±10 in-lb (22.6 ±1.1 N

Gallon counter sensor

2

Pack with grease 114819

3

•m)

•m)

•m)

•m)

ers (33a, 33b) are on crankshaft of drive housing

(33) as shown.

3. Clean mating surfaces of pinion and drive housings.

4. Align gears and push new drive housing straight

onto pinion housing (29) and locating pins (B).

5. Install six screws (38).

6. Install gallon counter sensor (39) with two screws

(108).

16 3A0243A

TIA

1

2

Copper

Steel

Page 17

Pinion Assembly/Clutch Armature/Clamp

Pinion Assembly/Clutch Armature/Clamp

Pinion Assembly/Clutch Armature Removal

Pinion Assembly

If pinion assembly (29) is not removed from clutch housing (19), do 1. through 3. Otherwise, start at 4.

1. Remove drive housing; page 16.

2. Disconnect clutch cable connectors from inside of

pressure control.

a. Remove two screws (71) and swing down cover

(130a).

b. Disconnect engine leads from board to engine.

c. Remove strain reliefs 130r and 123.

3. Remove four screws (36) and pinion assembly (29).

36

37

19

29

6. Remove retaining ring (29b).

7. Turn pinion assembly over and tap pinion shaft

(29a) out with plastic mallet.

27

29b

29a

29d

ti5482a

Clutch Armature

8. Use an impact wrench or wedge something

between clutch armature (25) and clutch housing to

hold engine shaft during removal.

9. Remove four screws (23) and lock washers (24).

36

37

ti5480a

4. Place pinion assembly (29) on bench with rotor side

up.

5. Remove four screws (28) and lock washers (24).

Install two screws in threaded holes (E) in rotor.

Alternately tighten screws until rotor comes off.

28

24

E

29

ti5481a

E

ti5987b

10. Remove armature.

TIA

3A0243A 17

Page 18

Pinion Assembly/Clutch Armature/Clamp

Installation

Clutch Armature

1. Lay two stacks of two dimes on smooth bench surface.

2. Lay armature (25) on two stacks of dimes.

3. Press center of hub (26) down to bench surface.

25

ti6321a

26

0.12+01 in (3.0+.25 mm)

dimes

4. Install armature (25) on engine drive shaft.

5. Install four screws (23) and lock washers (24) with

torque of 125 in-lb.

Clamp Removal

1. Remove engine.

Pinion Assembly

1. Check o-ring (29d) and replace if missing or damaged.

2. Tap pinion shaft (29a) in with plastic mallet.

3. Install retaining ring (29b) with beveled side facing

up.

4. Place pinion assembly on bench with rotor side up.

5. Apply thread sealant to screws. Install four screws

(28) and lock washers (24). Alternately torque

screws to 125 in-lb until rotor is secure. Use

threaded holes to hold rotor.

6. Install pinion assembly (29) with four screws (36)

and washers (37).

7. Connect clutch cable connectors to inside of pressure control.

3. Check dimension: Place rigid, straight steel bar (B)

across face of clutch housing (19). Use accurate

measuring device to measure distance between bar

and face of clamp. Adjust clamp as necessary.

Torque two screws (24) to 125 ±10 in-lb (14 ±1.1

N·m).

2. Drain gasoline from tank according to Honda manual.

3. Tip engine on side so gas tank is down and air

cleaner is up.

4. Loosen two screws (24) on clamp (22),

5. Push screwdriver into slot in clamp (22) and remove

clamp.

ti6199a

Clamp Installation

1. Install engine shaft key (18).

2. Tap clamp (22) onto engine shaft (A). Maintain

dimension shown note 2. Chamfer must face

engine.

1

Face of clutch housing

1.550 ± .010 in. (39.37 ± .25 mm) - GMAX 3900

2

2.612 ± .010 in. (66.34 ± .25 mm) - GMAX 5900 & 7900

Torque to 125 ±.10 in-lb (14 ±1.1 N·m)

3

Chamfer this side

4

19

TIA

"

!

18 3A0243A

Page 19

Clutch Housing

Removal

1. Remove four screws (20) and lock washers (21)

which hold clutch housing (19) to engine.

2. Remove screw (35) from under mounting plate (D).

3. Pull off clutch housing (19).

Installation

1. Push on clutch housing (19).

Clutch Housing

2. Install four capscrews (20) and lock washers (21)

and secure clutch housing (19) to engine. Torque to

200 in-lb (22.6 N·m).

3. Install screw (35) from beneath mounting plate (D).

Torque to 26 ft-lb (35.2 N·m).

19

21

20

ti5486a

18

D

35

3A0243A 19

Page 20

Clutch Housing

Removal

Engine

NOTE: All service to the engine must be performed by

an authorized Honda dealer.

1. Remove Pinion Assembly/Clutch Arma-

ture/Clamp and Clutch Housing, as instructed on

pages 17, and 18.

2. Disconnect all necessary wiring.

3. Remove two locknuts (17) and screws (16) from

base of engine.

4. Lift engine carefully and place on work bench.

1

To the field

2

To the engine

3

To gallon counter

3

4

To ground

1

Bottom View

3900

Green

16

ti5487a

17

Installation

1. Lift engine carefully and place on cart.

2. Install two screws (16) in base of engine and secure

with lock nuts (17). Torque to 26 ft-lb (22.6 N·m).

3. Connect all necessary wiring.

4. Install Pinion Assembly/Clutch Armature/Clamp

and Clutch Housing, as instructed on pages 17,

and 18.

ti5485b

2

4

2

Bottom View

5900/7900

20 3A0243A

Page 21

Pressure Control

Pump ON/OFF Switch

Pressure Control

Removal

1. Remove two screws (71) and swing down

cover (130a).

2. Disconnect pump ON/OFF switch (130f) connector

from control board.

CLUTCH (-)

TO ENGINE 15

5900/7900

CLUTCH (+)

3. Press in on two retaining tabs on each side of pump

ON/OFF switch (130f) and remove switch from

cover.

Installation

1. Install new pump ON/OFF switch (130f) so tabs of

switch snap into place on inside of cover.

2. Connect pump ON/OFF switch connector to control

board.

3. Swing up cover (130a) and secure with two screws

(71).

GROUND 129

3900

130a

130r

130c

123

130f

130g

CLUTCH

39 GALLON COUNTER

130b

66

130a

130f

72

130j

130d

130h

71

3A0243A 21

113

66

67

ti14915a

130d

130e

Page 22

Pressure Control

Control Board

Removal

1. Remove two screws (71) and swing down

cover (130a).

2. Remove strain relief bushings (130r and 123).

3. Disconnect at control board (130b):

• Lead from potentiometer (130d)

• Lead from transducer (66)

• Lead from WatchDog switch (130g)

• Lead from pump ON/OFF switch (130f)

• Lead from gallon counter sensor (39)

• Display connector (130m)

• Engine, ground and clutch wires

4. Remove four screws (130c) and control board (130b).

Pressure Control Transducer

Removal

1. Remove two screws (71) and swing down

cover (130a).

2. Disconnect transducer (66) lead from control board

(130b).

3. Pull transducer connector through rubber grommet (113).

Installation

1. Install control board (130b) with four screws (130c).

2. Connect engine wires to control board (130b).

3. Connect at control board (130b):

• Ground and clutch wires

• Display connector (130m)

• Lead from gallon counter sensor (39)

• Lead from pump ON/OFF switch (130f)

• Lead from WatchDog switch (130g)

• Lead from transducer (66)

• Lead from potentiometer (130d)

4. Install new strain relief bushings (123 and 130r).

5. Swing up cover (130a) and secure with two screws (71).

4. Remove pressure control transducer (66) and o-ring (67)

from filter housing (72).

Installation

1. Install o-ring (67) and pressure control transducer (66) in

filter housing (72). Torque to 35 - 45 ft-lb.

2. Install transducer connector and rubber grommet in control housing.

3. Connect transducer (66) lead to control board (130b).

4. Swing up cover (130a) and secure with two screws (71).

Pressure Adjust Potentiometer

Removal

1. Remove two screws (71) and swing down

cover (130a).

2. Disconnect potentiometer (130d) lead from control board

(130b).

3. Loosen set screws on potentiometer knob (130h) and

remove knob, shaft nut, lock washer and potentiometer

(130d).

4. Remove shaft spacer (130e) from potentiometer.

22 3A0243A

Installation

1. Install shaft spacer (130e) on potentiometer (130d).

2. Install potentiometer, shaft nut, lock washer and potentiometer knob (130h).

a. Turn potentiometer shaft clockwise to internal stop.

Assemble potentiometer knob (130h) to strike pin on

cover (130a).

b. After adjustment of step a., tighten both set screws in

knob 1/4 to 3/8 turn after contact with shaft.

3. Connect potentiometer lead to control board (130b).

4. Swing up cover (130a) and secure with two screws (71).

After a fault, follow these steps to restart sprayer:

1. Correct fault condition.

2. Turn sprayer OFF.

3. Turn sprayer ON.

Page 23

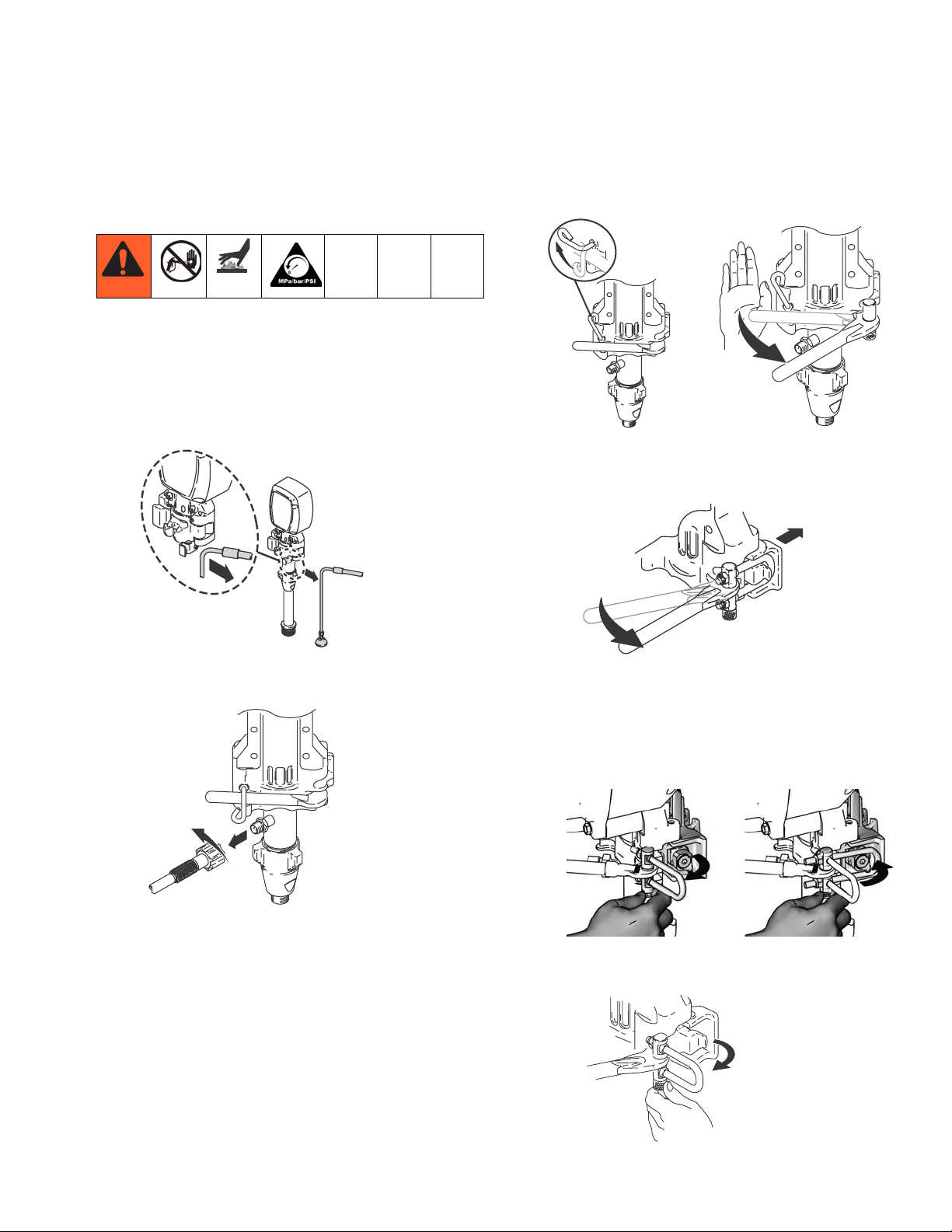

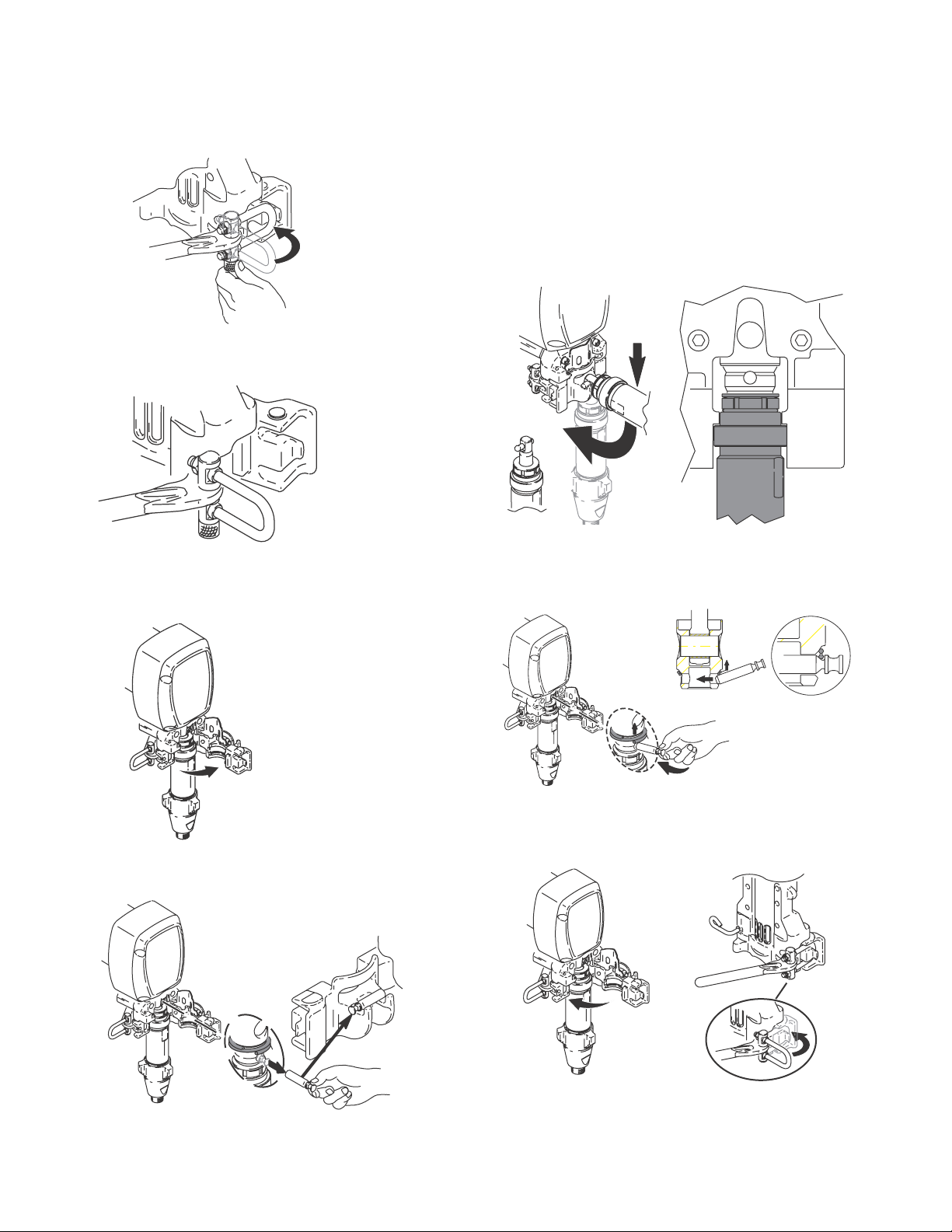

Displacement Pump

Displacement Pump

Removal

1. Flush pump.

2. Stop pump with piston rod in its lowest position.

3. Do Pressure Relief, page 4.

4. Separate drain hose from sprayer.

ti14904a

6. Raise latch lock. Push latch open.

ti6369a

ti11422a

ti6370a

7. Ratchet open pump door.

a. Ratchet pump door forward.

ti6373a

5. Disconnect material hose from pump.

ti6300a

b. Twist latch u-bolt out of pump door recess.

c. Place u-bolt on pump door outer edge.

d. If pump door is stuck, do steps e., f. and 8., oth-

erwise go to step 9.

ti11425a ti11426a

e. Twist latch u-bolt back from pump door outer

edge

ti6374a

3A0243A 23

Page 24

Displacement Pump

f. Place u-bolt on pump door protrusion

ti6375a

8. Ratchet pump door forward.

9. Open pump door.

Installation

1. Adjust piston rod with pin holder to pull out piston

rod. Tap piston rod on hard surface to push in piston

rod.

2. Push pump collar flush with bearing housing ledge

to be able to close pump door.

ti6325a

ti5492a

3. Slide pump into connecting rod. Push pump pin until

it is fully retained.

NOTE: Pin will snap into position.

ti14905a

10. Pull out pump pin and place in pin holder

ti6378a

ti14907a

4. Close pump door and rotate latch into position. Do

not tighten latch.

ti6313a

ti14908a

ti14906a

24 3A0243A

Page 25

Displacement Pump

5. Rotate pump to align with material hose. Connect

material hose and hand tighten to 70 in-lb.

ti6299a

6. Tighten latch and rotate latch lock into locked position.

ti6204a

7. Attach drain hose to sprayer.

ti14909a

8. Fill pump with Graco TSL until fluid flows onto top

of seal.

ti5493a

ti6312a

TI6312a

ti6204a

3A0243A 25

Page 26

Hose Reel

Hose Reel

Removal

Be sure to keep your head clear of hose reel while

winding up hose.

4. Remove swivel cap.

1. Remove hose fitting from swivel cap and completely

remove hose.

ti15023a

2. Remove cap from swivel.

ti13675a

3. Remove E-clip from swivel shaft.

ti13543a

5. Remove snap ring.

ti13542a

6. Remove hose reel.

ti15024a

ti13538a

26 3A0243A

Page 27

Installation

Hose Reel

1. Grease shaft.

ti13537a

2. Make sure two washers and wave spring are on hub

before hose reel is installed.

ti13545a

3. Install hose reel onto frame. Place C-clamp on reel

and frame to allow snap ring to fit into place. Install

snap ring.

5. Install E-clip.

ti13538a

6. Install hose to hose cap. Make sure to route hose

through side arm of hose reel.

ti15023a

7. Wrap up hose. Make sure hose is routed through

hose guide.

ti13536a

4. Install swivel cap.

ti13543a

3A0243A 27

ti13504a

Page 28

Pivot Replacement

Pivot Replacement

Removal

1. Remove Hose Reel, page 26.

2. Remove rigid fluid tube from swivel shaft.

ti15025a

3. Remove two screws on pivot plate (A), swivel shaft

(B) if necessary, and remove coupling (C) from

swivel shaft.

B

D

Installation

1. Install pivot (D).

2. Install pivot plate (A) on pivot and tighten two screws

on pivot plate.

B

D

A

C

3. Install o-ring and replace swivel shaft (B) if it was

removed.

ti13544a

4. Replace coupling (C).

ti15022a

B

A

C

4. Remove pivot (D).

ti15022a

5. Replace rigid fluid tube to swivel shaft if it was

removed.

ti15025a

6. Replace Hose Reel, page 27.

28 3A0243A

Page 29

Technical Data

Technical Data

Honda GX120 Engine

ANSI Power Rating @ 3600 rpm 4.0 Horsepower (3.0 kW)

Honda GX160 Engine

ANSI Power Rating @ 3600 rpm 5.5 Horsepower (4.1 kW)

Honda GX 200 Engine

ANSI Power Rating @ 3600 rpm 6.5 Horsepower (4.8 kW)

Maximum working pressure 3300 psi

(228 bar, 22.8 MPa)

Noise Level

Sound power 105 dBa

per ISO 3744

Sound pressure 96 dBa

measured at 3.1 feet (1 m)

Maximum delivery rating

3900 1.25 gpm (4.73 liter/min)

5900/5900HD 1.60 gpm (6.06 liter/min)

7900 2.20 gpm (8.33 liter/min)

Maximum tip size

3900 1 gun with 0. 036 in. tip

2 guns with 0. 023 in. tip

3 guns with 0. 018 in. tip

5900/5900HD 1 gun with 0. 043 in. tip

2 guns with 0. 029 in. tip

3 guns with 0. 023 in. tip

4 guns with 0. 019 in. tip

7900 1 gun with 0. 048 in. tip

2 guns with 0. 035 in. tip

3 guns with 0. 027 in. tip

4 guns with 0. 023 in. tip

Inlet paint strainer 12 mesh (893 micron)

stainless steel screen, reusable

Outlet paint filter 60 mesh (250 micron)

stainless steel screen, reusable

Pump inlet size 1-5/16–12 UN-2A

Fluid outlet size: 3900/5900 ¼ npsm from fluid filter

Fluid outlet size: 7900 3/8 npsm from fluid filter

Wetted parts zinc-plated carbon steel, PTFE, nylon, polyurethane, UHMW

polyethylene, fluoroelastomer, acetal, leather, aluminum, tung-

sten carbide, nickel- and zinc-plated carbon steel, stainless

steel, chrome plating

3A0243A 29

Page 30

Technical Data

Dimensions

Sprayer

(no hose and gun)

3900 109 (50) 31.5 (80.0) 22.25 (56.5) 32.0 (81.3)

5900 139 (64) 32.25 (81.9) 24.5 (62.2) 32.25 (81.9)

7900 146 (67) 32.25 (81.9) 24.5 (62.2) 33.0 (83.8)

TexSpray 7900HD 157 (71) 32.25 (81.9) 24.5 (62.2) 33.0 (83.8)

Weight lb (kg) Height in. (cm) Width in. (cm) Length in. (cm)

30 3A0243A

Page 31

Notes

Notes

3A0243A 31

Page 32

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 3A0243

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

2009

Loading...

Loading...