Page 1

Instructions-Parts

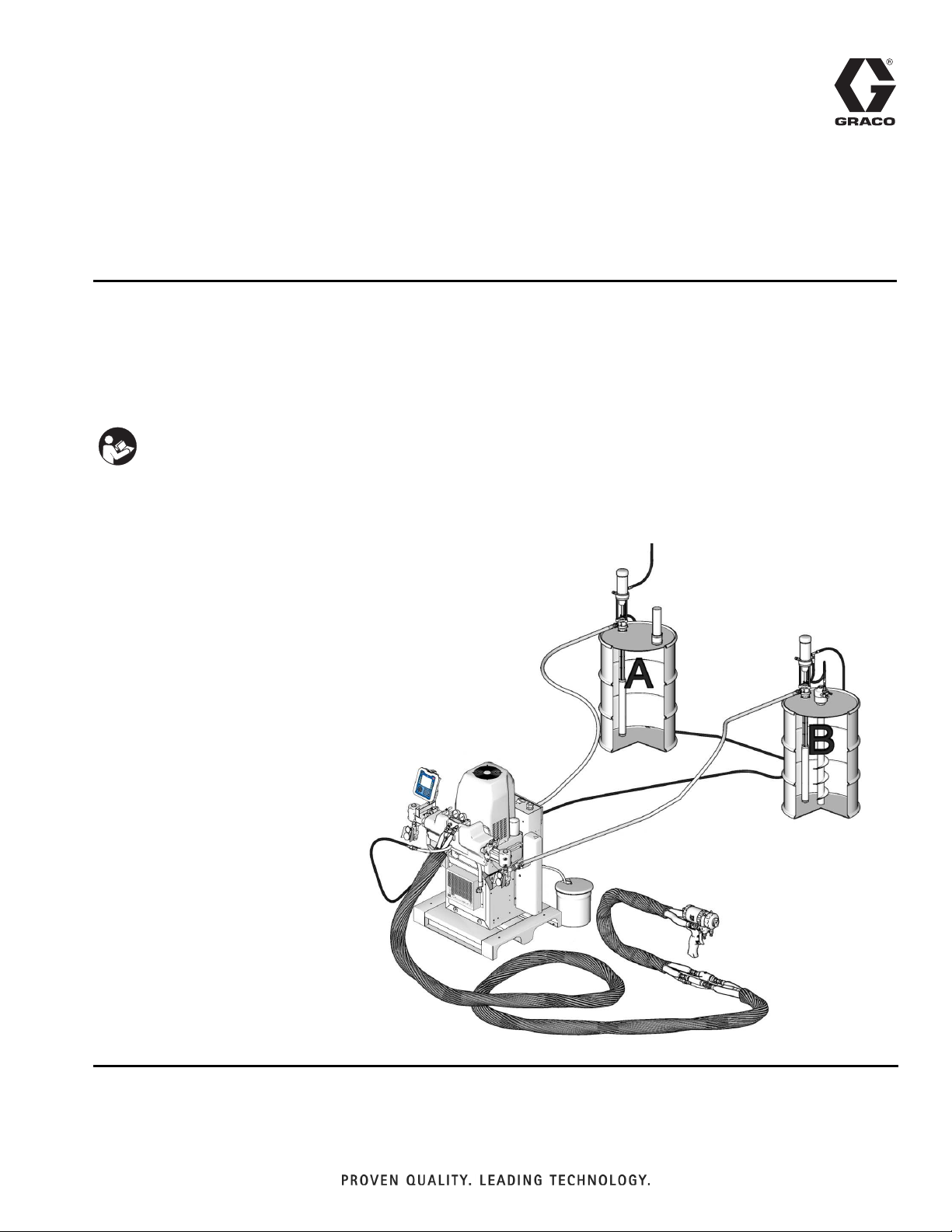

Feed Supply Kits

For supplying viscous materials to Graco® HFR™ Metering System.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual. Save these instructions.

See page 3 for model information, including maximum working pressure and approvals.

3A0235G

EN

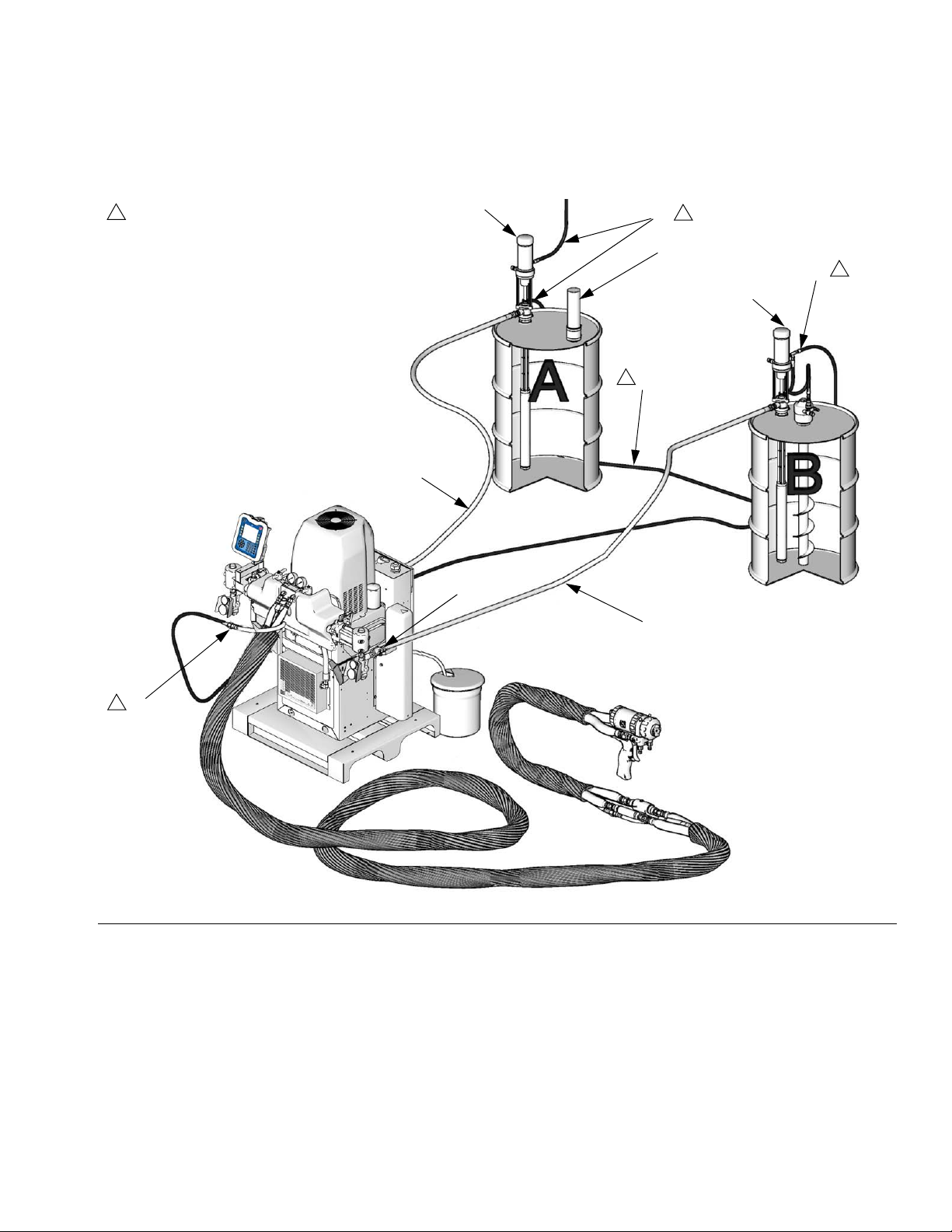

246081 Package shown installed in HFR

proportioning system. Some parts shown

are not included in kit.

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Complete Supply Pump Systems . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . . 6

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . . 6

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . 6

Keep Components A and B Separate . . . . . . . . . . 6

Foam Resins with 245 fa Blowing Agents . . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . 6

A and B Components . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flush Pumps Before Using . . . . . . . . . . . . . . . . . . . 8

Position Drums . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Feed Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

T2 2:1 and Monark 5:1 . . . . . . . . . . . . . . . . . . . 10

Husky 1050 Wall Mount . . . . . . . . . . . . . . . . . . 10

Husky 515 and 716 . . . . . . . . . . . . . . . . . . . . . . 11

High-Flo

Install Air Supply Kit . . . . . . . . . . . . . . . . . . . . . . . 12

T2 2:1, Husky 515, Husky 716, and Husky 1050 Kits

Air Regulator Kit 248829 . . . . . . . . . . . . . . . . . . 12

Connect Air Lines . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Changing Drums . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Complete Supply Pump Systems . . . . . . . . . . . 14

Complete Supply Pump Systems, continued . . 15

Fluid Supply Kits (1) . . . . . . . . . . . . . . . . . . . . . 16

Fluid Supply Kits (1), continued . . . . . . . . . . . . 18

Pump with Riser Tube Kits . . . . . . . . . . . . . . . . 19

Pumps with Riser Tube Kits, continued . . . . . . . 21

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 24

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 24

®

Pumps . . . . . . . . . . . . . . . . . . . . . . . 11

12

Related Manuals

Manual Description

313997 HFR Operation

313998 HFR Repair-Parts

311882

307044

307043

308116

308981

309116

312877 Husky 1050 Pump

311211

T2 2:1 Ratio Transfer Pump

Instructions-Parts

55 Gallon 5:1 Ratio Monark

Instructions-Parts

5:1 Ratio Monark Air Motor,

Instructions-Parts

Stainless Steel Pumps,

Instructions-Parts

™

Husky

Husky 515 and Husky 716 Drum Pump

Kits and Packages, Instructions-Parts

High-Flo

515 and Husky 716 Pump

®

Pumps, Instructions-Parts

®

Pump,

2 3A0235G

Page 3

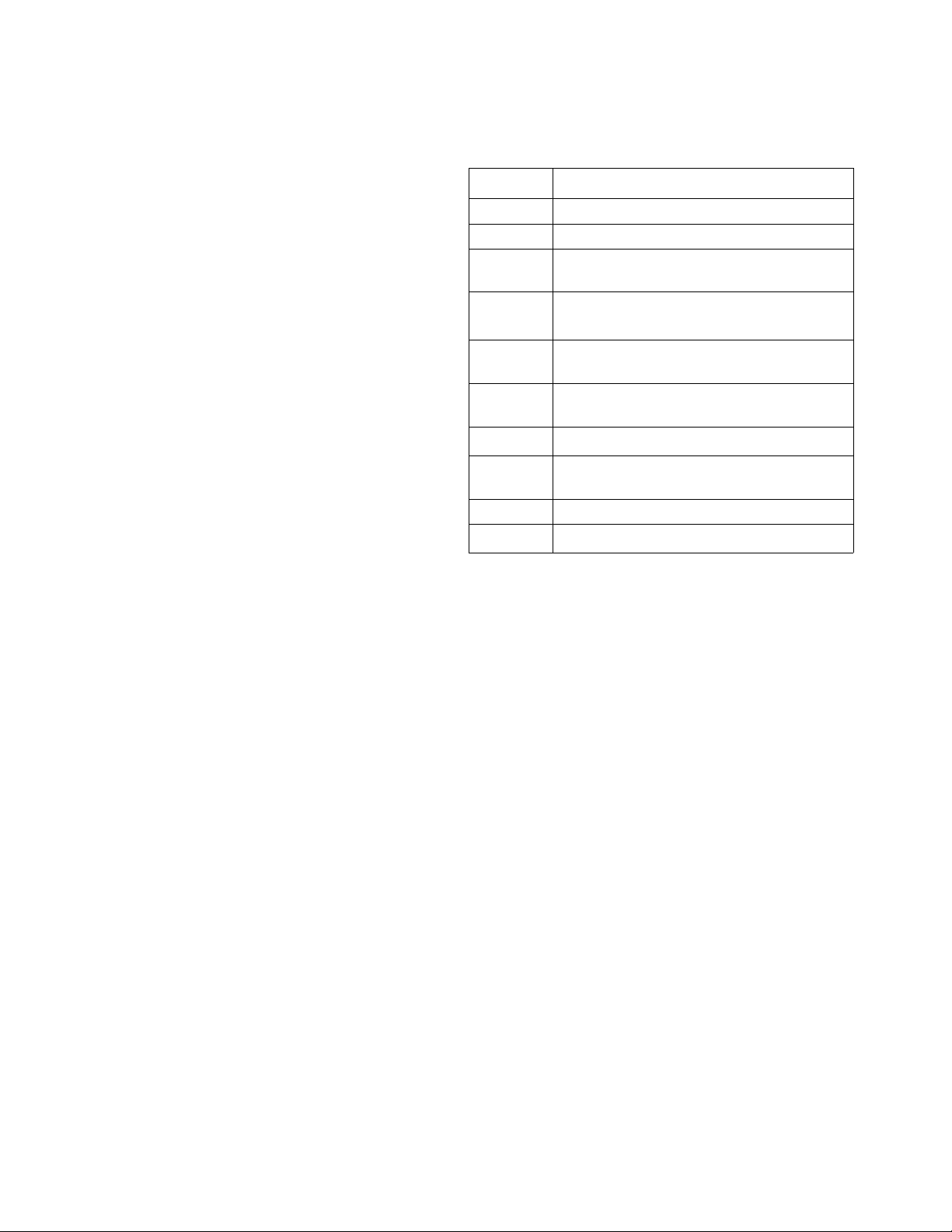

Complete Supply Pump Systems

Complete Supply Pump Systems

Most packages include all air and fluid fittings and hoses. Approvals are only for the pumps and not for the entire

package.

★ Complete Package only comes with one pump, air and fluid fittings, and hoses.

Complete

Package (fluid

and air)

Pump

Model

T2 2:1 Ratio

246081 295616

24D091 295616

24E396★ 295616

24E397★ 295616

Husky™ 515

246369 246484

24D092 241564

Husky™ 716

246375 246485

24D093 D54311

Husky™ 1050

24D328 647673

Material

✔

✔

✔

✔

✔

Maximum Air

Input Pressure

✔

180 psi

(1.2 MPa, 12.5 bar)

✔

100 psi

(0.7 MPa, 7 bar)

✔

100 psi

(0.7 MPa, 7 bar)

✔

Maximum Fluid

Working Pressure ApprovalsCS SS

405 psi

(2.8 MPa, 28 bar)

100 psi

(0.7 MPa, 7 bar)

100 psi

(0.7 MPa, 7 bar)

0359

0359

II 2 GD c IIC T4

0359

II 2 GD c IIC T4

24D094 651458

125 psi

(0.86 MPa, 8.6 bar)

✔

125 psi

(0.86 MPa, 8.6 bar)

Monark® 5:1 Ratio, 55 Gallon

24D095 218956

24E398★ 218956

24G714 224350

✔

✔

180 psi

(1.2 MPa, 12.5 bar)

✔

900 psi

0359

(6.2 MPa, 62 bar)

II 1/2 G T2

ITS03ATEX11228

Monark® 5:1 Ratio, 5 Gallon

24D096 902278

24E399★ 902278

✔

180 psi

(1.2 MPa, 12.5 bar)

✔

900 psi

(6.2 MPa, 62 bar)

High-Flo® Pumps

257769 JC20L1

257777 JS20L1

3A0235G 3

✔

100 psi

(0.7 MPa, 7 bar)

✔

200 psi

(1.4 MPa, 14 bar)

II 2 Gc T3

Page 4

Warnings

Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

• If this equipment is used with isocyanate material, see additional information on isocyanates in Isocyanate Conditions Section of this manual.

4 3A0235G

Page 5

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure. Disconnect power or air supply.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0235G 5

Page 6

Isocyanate Conditions

Isocyanate Conditions

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO lube pump reservoir (if installed) filled

with Graco IsoGuard Select

The lubricant creates a barrier between the ISO and

the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

®

(ISG), Part 24D086.

Keep Components A and B Separate

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of

crystallization varies depending on the blend of ISO,

the humidity, and the temperature.

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (red)

and component B (blue) parts.

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

6 3A0235G

Page 7

A and B Components

A and B Components

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

Be aware that when standing in front of the manifold on

proportioner:

• Component A (Red) is on the left side.

• Component B (Blue) is on the right side.

For all machines:

• The A (Red) side is intended for ISO, hardeners,

and catalysts.

• If one of the materials being used is moisture-sensitive, that material should always be in the A (Red)

side.

• The B (blue) side is intended for polyols, resins, and

bases.

• For ratios higher than 1:1, the higher volume is

typically the B (Blue) side.

3A0235G 7

Page 8

Grounding

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pump: follow instructions in separate feed pump manual, supplied.

HFR: see operation manual.

Spray gun: see gun manual.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun or

dispense valve firmly to the side of a grounded metal

pail, then trigger the gun or valve.

Flush Pumps Before Using

Position Drums

Place component A (red) and component B (blue)

drums as desired. Air hose (C) connecting feed pumps

is 15 ft (4.57 m) long. See F

Fluid hose (103) connecting feed pumps to systems are

10 ft (3.05 m) long.

IG. 1.

Installation

Feed Pump

1. Complete Setup instructions in pump manual

before installing in drum or pail.

a. For Riser Tube Kit 246419: Inspect bung o-ring

(309) and gasket (303) in place. If either is worn

or damaged, or if material shows signs of crystallization, replace. See page 22.

b. If required, install desiccant dryer (Graco part

no. 247616 not included). Remove elbow and 2

in. bushing supplied with desiccant dryer (6).

Screw dryer 3/4 npt fitting into vent of moisture

sensitive drum.

NOTICE

Lubricate bung o-ring with 217374 ISO Pump Oil

each time you change drums. This keeps air and

moisture from reacting with material and allows bung

adapter to rotate freely.

NOTICE

Tighten pump clamps and external fasteners before

first use. See pump manual.

Flush equipment only in a well-ventilated area. Do not

spray flammable fluids. Do not turn on heaters while

flushing with flammable solvents.

8 3A0235G

Page 9

Complete Package 246081 shown installed in HFR proportioning system. Includes *parts only.

101* (red)

2

Air Supply Kit. See 309827.

2

2

6*

101* (blue)

2

C*

*103 (Ref)

Installation

2*

2

2

2*

IG. 1: Installation

F

D

103* (Ref)

3A0235G 9

Page 10

Installation

T2 2:1 and Monark 5:1

1. Flush pumps, page 8.

2. Position drums, page 8.

3. Open drum bung hole. Screw bung adapter with

gasket into bung hole. See pump manual.

4. Install swivel fitting (102) in pump fluid outlet. See

F

IG. 2.

5. Connect hose (103) between swivel fitting (102) and

the system swivel inlet (D, see F

6. Install air supply kit and connect air lines, page 12,

to finish installation.

IG. 1).

201

Husky 1050 Wall Mount

1. Be sure wall can support weight of pump, hoses,

and accessories, and can withstand stress during

operation.

2. Position wall bracket (204) no more than 5 ft (1.52

m) above floor. Check that bracket is level. Attach to

wall, using screws long enough to keep bracket from

vibrating. See F

3. Connect swivel union (209) to pump inlet.

4. Install bushing (105) in pump air inlet.

5. Install pump (201) on bracket (204) securely, using

screws (211), washers (210), and nuts (212).

6. Connect elbow (210) to top of riser tube kit (202).

7. Connect suction hose (203) to elbow (210) and inlet

swivel (209).

8. Install swivel fitting (102) in pump fluid outlet. See

F

IG. 4.

IG. 3.

bung adapter

F

IG. 2. Standard 2:1 Kit

102

TI10281a

103

9. Connect hose (103) between swivel fitting (102) and

™

GMS

swivel inlet fitting. See FIG. 4.

10. Install air supply kit and connect air lines, page 12,

to finish installation.

201

105

209

203

210

212

211

213

204

202

r_24D329_3a0235_1a

F

IG. 3. Husky 1050 Wall Mount

10 3A0235G

Page 11

Installation

Husky 515 and 716

1. Place riser tube (202) into drum. Tighten bung

adapter securely.

2. For carbon steel supply pump systems, Install

swivel fitting (102) in pump (201) fluid outlet.

3. Connect hose (103) between swivel fitting (102) and

GMS swivel fluid inlet fitting.

4. Install air supply kit and connect air lines, page 12,

to finish installation.

201

102

103

High-Flo® Pumps

1. Install elbow fitting (106) in pump (101) fluid outlet.

2. Connect hose (103) between elbow fitting (106) and

fitting (102). Install nipple (109) and swivel fitting

(110).

3. Connect swivel fitting (110) and GMS swivel fluid

inlet fitting.

For A-Side only: remove 1/2 npt swivel fitting from GMS

swivel fluid inlet prior to connecting swivel fitting (10).

4. Connect air lines (not supplied), page 12, to finish

installation.

101

202

F

IG. 4. Husky 716

r_246481_3a0235a_1a

102

110

109

F

IG. 5: High-Flo

106

103

111

r_257769_3a0235a_1a

3A0235G 11

Page 12

Install Air Supply Kit

Install Air Supply Kit

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

T2 2:1, Husky 515, Husky 716, and Husky 1050 Kits

1. Supply clean, dry filtered air to feed pumps.

2. See manual 309827 to install air supply kit.

Air Regulator Kit 248829

The air regulator kit (7) is only used with the Monark kits.

1. Install air regulator kit (7).

2. Interconnect tee fitting (1f) and quick disconnect fitting (1b) on pump with air hose (1a).

Connect Air Lines

T2 2:1, Husky 515, Husky 716, and Husky 1050.

See manual 309827 to install air supply kit.

5:1 Monark Kits

1. Shut off air valves (V) at feed pumps (201).

201

V

7

1b

1a

2. Install air line (1a) with quick disconnect coupler

(1b) provided.

3. Connect air line and quick disconnect coupler to air

regulator (7).

r_256276_312769_2A

12 3A0235G

Page 13

Operation

Startup

1. See Load fluid with feed pumps in system operation manual.

2. Open feed pump air regulator.

3. Open feed pump bleed-type master air valve.

4. Adjust air to feed pump with needle valve.

NOTE:

• Cold, viscous material may be difficult to prime.

Use needle valve to reduce air flow to motor.

• Do not plug or shut off pump fluid outlet when

priming. Fluid must be free to flow through

pump to prime.

• To increase pump flow rate and reduce icing,

remove pump muffler. This will increase exhaust

noise.

Operation

Maintenance

NOTE:

See supplied pump manual for maintenance, repair, and

parts information.

Lubricate bung o-ring (309) with 217374 ISO Pump Oil

each time you change drums. This keeps air and moisture from reacting with ISO.

Whenever pump is removed from drum, inspect bung

o-ring (309) and gasket (303) in place. If either is worn

or damaged, or if ISO shows signs of crystallization,

replace. See page 22.

Tighten pump clamps and external fasteners periodically. See pump manual.

Repair

5. Never let pump run when drum is empty. A dry

pump can accelerate and damage itself. If pump is

running too fast, stop it immediately. Check and refill

fluid supply, or flush with compatible solvent. Always

prime entire system to remove any air. Do not let

material harden in pump.

Shutdown

See Shutdown and Pressure Relief Procedure in system

operation manual. Close feed pump bleed-type master

air valve.

Changing Drums

NOTICE

To prevent cross-contamination of fluid when changing drums, complete changing one component

before changing second component.

1. See Shutdown above.

2. Remove riser tube from drum. Install in new drum,

page 8.

See supplied pump manual for maintenance, troubleshooting, and repair procedures.

3. Lubricate bung o-ring, page 8.

4. See Load fluid with feed pumps in GMS operation

manual.

3A0235G 13

Page 14

Parts

Parts

Complete Supply Pump Systems

Each complete supply pump system includes a fluid supply kit, air supply kit, and desiccant dryer. See parts lists on

pages 15.

Two Pump Systems One Pump Systems

Pump Material

Complete

Pump System

Fluid Supply Kit (1)

(See Page 16)

Complete Pump

System

Husky 515 CS 246369 246481

SS 24D092 24D100

Husky 716 CS 246375 246482

SS 24D093 24D101

Husky 1050 CS 24D328 24D332

SS 24D094 24D102

T2 2:1 CS 246081 246898 24E396

SS 24D091 24D103 24E397

Monark 5:1, 5 Gallon SS 24D096 24D104 24E399

Monark 5:1, 55 Gallon CS 24D095 24D105 24E398

Monark 5:1, 55 Gallon SS

24D105 24G714

High-Flo CS 257769 257769 (page 18)

High-Flo SS 257777 257777 (page 18)

246081 Package shown installed in HFR

proportioning system. Includes * parts only.

2*

6*

2

1* (blue)

1* (red)

2*

2

1*(Ref)

1

1* (Ref)

2*

2

14 3A0235G

1

1

Fluid Supply Kit. See page 16.

2

Air Supply Kit. See 309827.

Page 15

Complete Supply Pump Systems, continued

Parts

Ref. Part Description Qty.

1★ 246481 KIT, fluid supply, Husky 515;

246369

24D100 KIT, fluid supply, Husky 515;

24D092

246482 KIT, fluid supply, Husky 716;

246375

24D101 KIT, fluid supply, Husky 716;

24D093

24D332 KIT, fluid supply, Husky 1050;

24D328

24D102 KIT, fluid supply, Husky 1050;

24D094

246898 KIT, fluid supply, T2 2:1; 246081 1

24D103 KIT, fluid supply, T2 2:1; 24D091 1

24D104 PUMP, Monark 5:1, 5 gallon;

24D095

24D105 PUMP, Monark 5:1, 55 gallon;

24D096; see manual 307044

257769 KIT, complete, High-Flo; cs 1

257777 KIT, complete, High-Flo; ss 1

2 246483 AIR SUPPLY KIT; see 309827 1

6 247616 KIT, desiccant dryer; for A (red)

side; see page 14

7❖ 248829 REGULATOR KIT, air, feed pump 1

★ See Fluid Supply Kits on page 16.

❖ Only for Monark 5:1 kits.

Husky and T2 2:1 Kits

1

See illustration on page 14.

1

24D096 and 24E399 Monark 5:1

1

5 Gallon Feed Pump Kit

1

1

1

1

1

1

1

7

r_24D095_3a0235_1a

24D095 and 24E398 Monark 5:1 Kit

55 Gallon Feed Pump Kit

1

7

r_24D096_3a0235a_1a

3A0235G 15

Page 16

Parts

Fluid Supply Kits (1)

Carbon Steel Husky Kits

101

102

Stainless Steel Husky Kits

101

24D105 55 Gallon Monark 5:1 Kit

101

103

103

r_246481_3a0235a_1a

103

246898 and 24D103 T2 2:1 Kits

r_24d101_3a0235a_1a

24D104 Monark 5:1 5 Gallon Kit

103

101

102

103

101

TI10282a

r_24D104_3a0235a_1a

16 3A0235G

Page 17

Parts

Fluid Supply Kits (1), continued

Each fluid supply kit contains two pumps with riser tubes, fittings, and hoses needed to supply fluid from the pumps

to the proportioner. Use the tables below to identify what parts are used for the carbon steel and stainless steel fluid

supply kits. See page 16 for fluid supply kit illustrations.

High-Flo pumps are on page 18.

Carbon Steel Fluid Supply Kits

Husky

Ref.

No. Description

101 KIT, pump with riser tube 246484 246485 647673 295616 2

102 UNION, swivel; UNION, swivel; 3/4 npt(m) x 3/4

npsm(f)

103 HOSE, fluid; 3/4 npt (mbe); 3/4 in. (19 mm) ID; 10 ft

(3.05 m); nylon

104 FITTING, swivel; 1/2 npt(m) x 3/4 nps(f); (not shown)

(use as necessary to adapt 1/2 npt A side “red” inlet)

105 BUSHING, reducer, 1/2 npt(m) x 3/4 npt(f); use on 1/2

npt A side (red) inlet hose (not shown)

515

(246481)

157785 157785 157785 157785 2

217382 217382 217382 217382 2

104969 104969 104969

Husky

716

(246482)

Husky

1050

(24D332)

T2 2:1

(246898) Qty.

113344 1

Stainless Steel Fluid Supply Kits

Husky

Ref.

No. Description

101 KIT, pump with riser tube 233052 233057 651458 295616 902278 224350 2

102 UNION, swivel; UNION,

swivel; 3/4 npt(m) x 3/4

npsm(f)

103 HOSE, fluid; 3/4 npt

(mbe); 3/4 in. (19 mm) ID;

10 ft (3.05 m); ss

105 BUSHING, reducer (not

shown)

106 NIPPLE, reducing; 1 in.

npt x 3/4 npt, ss; see page

19.

515

(24D100)

24C656 24C656 24C656 24C656 24C656 24C656 2

Husky

716

(24D101)

16C628 1

Husky

1050

(24D102)

16C632 1

T2 2:1

(24D103)

122268 1

Monark

5:1

(24D104)

Monark

5:1

(24D105) Qty.

1

3A0235G 17

Page 18

Parts

Fluid Supply Kits (1), continued

257769, Carbon Steel High-Flo Fluid Supply Kit

257777, Stainless Steel High-Flo Fluid Supply Kit

110

101

102

109

111

106

103

112

r_257769_3a0235a_1a

Ref.

No. Description 257769 257777 Qty.

101 PUMP, High-Flo JC20L1 JS20L1 2

102 UNION, swivel 202966 122639 2

103 HOSE, coupled;

1/2 npt; 6 ft (10.9

m); nylon

HOSE, coupled;

1/2 npt; 6 ft (10.9

m); ss

106 FITTING, union,

adapter, 90°; 1/2

npt(f) x 1/2 nps(m)

FITTING, union,

adapter, 90°

109 NIPPLE; 3/4-14

npt

NIPPLE; 3/4 in.

npt

110 FITTING, union,

swivel; 3/4 npt

FITTING, union,

swivel; 3/4 npt

111 FRAME 253692 253692 2

112 KIT, floor/stand

bracket

113 CONTROL, air,

integrated, locking

114 SCREW, cap, sch 112566 112566 4

220372 2

214959 2

102806 2

510786 2

100627 2

123111 2

118459 2

112268 2

247312 247312 2

NXT011 NXT011 2

18 3A0235G

Page 19

Pump with Riser Tube Kits

Parts

Pump Kit No. Material

Husky 515 246366 CS

233052

(see manual 309116)

Husky 716 246367 CS

233057

(see manual 309116)

Husky 1050 24D329 CS

24D097 SS

T2 2:1 295616

(see manual 311882)

Monark 5:1,

5 Gallon

Monark 5:1,

55 Gallon

24D098 SS

24D099 CS

246366 Husky 515 Pump

201

202

Plastic

SS

SS

246367 Husky 716 Pump

201

203

202

TI3450a

Ref. Part Description Qty.

201 246485 PUMP, Husky 716; see 308981 and

read NOTICE below

202 246419 RISER TUBE KIT; see page 22 1

203 158555 NIPPLE, reducing; 1 in. npt x 3/4

npt

16C628 NIPPLE, reducing; 1 in. npt x 3/4

npt, ss; only used with fluid supply

kit 24D101

1

1

1

NOTICE

246485 Husky 716 Pump is built specifically for use

with isocyanates and is tested with oil. To order

replacement parts and repair kits, refer to the Husky

716 parts list in manual 308981.

Ref. Part Description Qty.

201 246484 PUMP, Husky 515; see 308981 and

read NOTICE below

202 246419 RISER TUBE KIT; see page 22 1

NOTICE

246484 Husky 515 Pump is built specifically for use

with isocyanates and is tested with oil. To order

replacement parts and repair kits, refer to the Husky

515 parts list in manual 308981.

3A0235G 19

1

Page 20

Parts

Pumps with Riser Tube Kits, continued

24D329 CS Husky 1050 Pump 24D097 SS Husky 1050 Pump

201

105

209

203

210

212

211

213

204

202

r_24D329_3a0235_1a

Ref. Part Description Qty.

201 647673 PUMP, Husky 1050; 24D332, see

313435

202 246419 RISER TUBE KIT; 24D332, see page 221

203 214961 HOSE, suction; 3/4 npt (mbe);

3/4 in. (19 mm) ID; 6 ft (1.8 m);

neoprene

204 189233 BRACKET, wall 1

209 202965 UNION, swivel, pump inlet;

1 in. npt(m) x 3/4 npsm(f)

210 107409 ELBOW, swivel, riser tube; 90°;

1 in. npt(m) x 3/4 npsm(f); 24D332

211 100214 WASHER, lock; 5/16 4

212 100450 SCREW, cap, hex-hd; 5/16-18;

1 in. (25 mm)

213 111303 NUT, hex; 5/16-18 4

201

105

209

203

212

211

202

213

204

r_24D097_3a0235_1a

Ref. Part Description Qty.

201 651458 PUMP, Husky 1050; 24D102, see

1

manual 313435

202 183549 TUBE, section; 24D100 1

203 221171 HOSE, suction; 3/4 npt (mbe);

1

3/4 in. (19 mm) ID; 6 ft (1.8 m);

neoprene

204 189233 BRACKET, wall 1

209 16C629 FITTING, adapter, swivel; 1 npt(m) x

1

3/4 npt(f), ss

210 16C631 ELBOW, swivel 90°, 1/2 npt(m) x 1/2

1

nps(f), ss; 24D102

211 100214 WASHER, lock; 5/16 4

212 100450 SCREW, cap, hex-hd; 5/16-18;

4

1 in. (25 mm)

213 111303 NUT, hex; 5/16-18 4

214 183553 PLUG, bung; 24D102 2

210

1

1

1

1

4

20 3A0235G

Page 21

Pumps with Riser Tube Kits, continued

24D098, 5 Gallon 5:1 Monark 24D099, 55 Gallon 5:1 Monark

Parts

Ref.

No. Part No. Description Qty.

2 246483 AIR SUPPLY KIT; see 309827 1

6 247616 KIT, desiccant dryer; for A (red)

side; see page 14

7 248829 REGULATOR KIT, air, feed pump 1

201 902278 PUMP, Monark 5:1; includes

902147, see manual 308116

7

201

Ref.

No. Part No. Description Qty.

2 246483 AIR SUPPLY KIT; see 309827 1

1

6 247616 KIT, desiccant dryer; for A (red)

side; see page 14

7 248829 REGULATOR KIT, air, feed pump 1

1

201 218956 PUMP, Monark 5:1; see 307044 1

201

7

air inlet fitting

1/4 npt

1

r_24D098_3A0235A_1a

3A0235G 21

Page 22

Accessories

Accessories

Riser Tube Kit, 246419 Return Tube Accessories

Ref. Part Description Qty.

301 159101 HOUSING, valve, intake 1

302 156592 TUBE, riser 1

303 106537 GASKET, bung 1

304 15B728 ADAPTER, bung 1

305 15B727 FITTING; 1 in. npt 1

306 15B921 SPACER 1

307 100279 BALL 1

308 159100 RETAINER, ball 1

309 110831 O-RING 1

1

Lubricate with 217374 ISO Pump Oil

each time you change drums.

305

309

304

302

1

303

See manual 309852 for installation and parts.

Material Part

Carbon Steel 246477

Stainless Steel 24D106

Circulation Kits

See manual 309852 for installation and parts.

Material Part

Carbon Steel 24E379

Stainless Steel 24D107

246483 Air Supply Kit

See manual 309827 for installation and parts.

15C381 Desiccant Dryer Cartridge

233048 Husky 716 Accessory Kit

307

301

TI3445a

308

306

Includes stainless steel bung base and stainless steel

suction tube. See manual 309116.

Material Filters

Material Part

Carbon Steel 213058 (60 mesh)

Stainless Steel 244053 (60 mesh)

NOTE: See manual 307282 for installation and parts.

22 3A0235G

Page 23

Technical Data

Maximum air input pressure

T2 Feed Pump Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 psi (1.2 MPa, 12 bar)

Monark 5:1 Feed Pump Kit. . . . . . . . . . . . . . . . . . . . . . . . 180 psi (1.2 MPa, 12 bar)

Husky 716 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Husky 1050 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 psi (0.86 MPa, 8.6 bar)

High-Flo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Maximum fluid working pressure

T2 Feed Pump Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405 psi (2.8 MPa, 28 bar)

Monark 5:1 Feed Pump Kit. . . . . . . . . . . . . . . . . . . . . . . . 900 psi (6.2 MPa, 62 bar)

Husky 716 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Husky 1050 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 psi (0.86 MPa, 8.6 bar)

High-Flo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 psi (1.4 MPa, 14 bar)

Wetted parts

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See supplied pump manual

Riser tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Carbon steel

Fluid hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nylon

Suction hose (Husky 1050 only). . . . . . . . . . . . . . . . . . . . Neoprene

Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Carbon steel

Technical Data

3A0235G 23

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 or Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2010, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A0235

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised February 2012

Loading...

Loading...