Repair - Parts

312068M

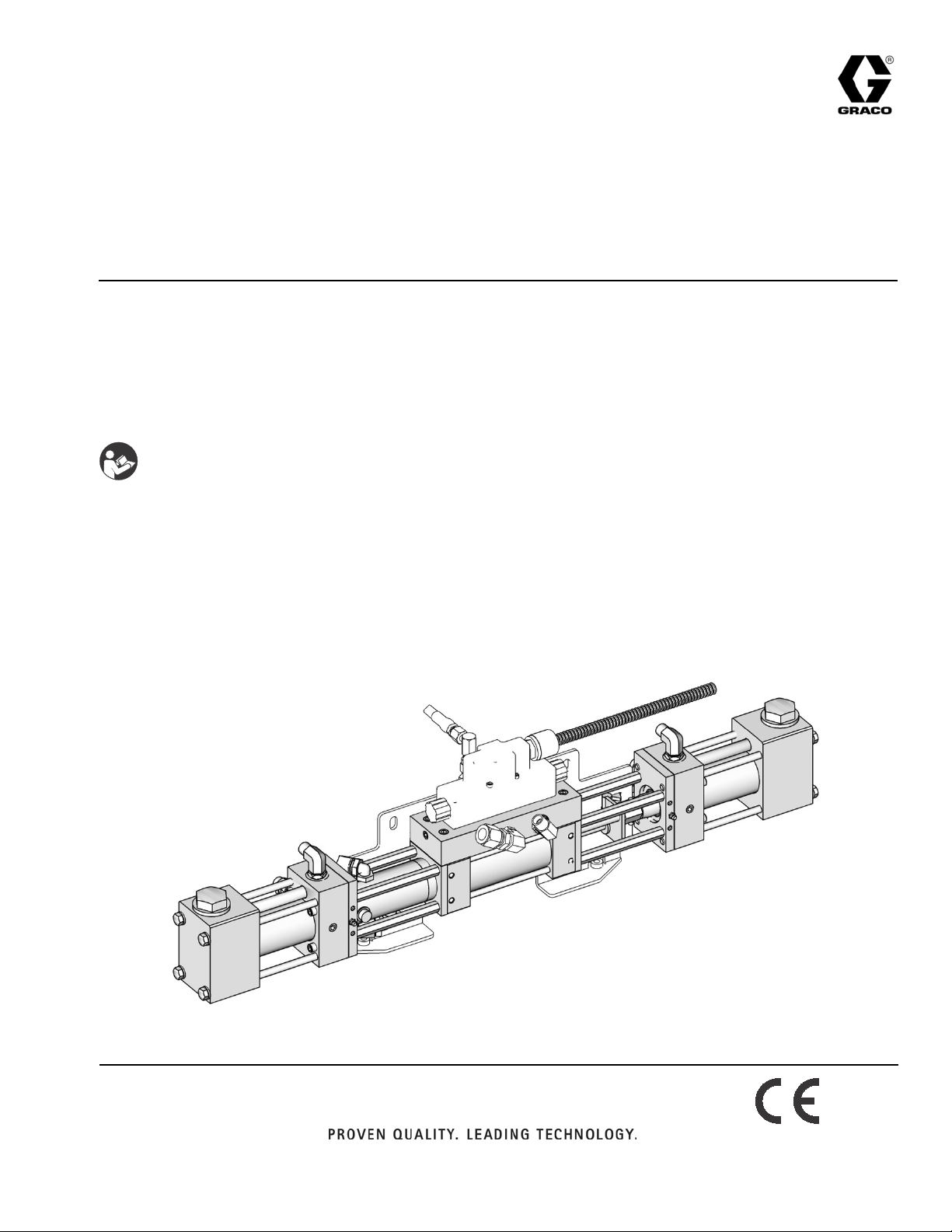

Proportioning Pumps

Proportioning pumps and hydraulic cylinders used on Hydraulic Proportioners. For

professional use only. For professional use only.

Not for use in explosive atmospheres.

Important Safety Instructions

Read all warnings and instructions in this manual

and all supplied manuals. Save all instructions.

Model 247576: 2000 psi (13.8 MPa, 138 bar) Maximum Working Pressure

EN

All other models: 3500 psi (24.0 MPa, 240 bar) Maximum Working Pressure

See page 2 for model information.

TI9778c

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Proportioning Pumps . . . . . . . . . . . . . . . . . . . . . 2

Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . 2

Pumplines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

In-Plant Pumpline . . . . . . . . . . . . . . . . . . . . . . . . 2

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 3

Preventive Maintenance . . . . . . . . . . . . . . . . . . . 3

Pumpline Disassembly . . . . . . . . . . . . . . . . . . . . 4

Pumpline Reassembly . . . . . . . . . . . . . . . . . . . . 4

Pump Base Disassembly . . . . . . . . . . . . . . . . . . 6

Pump Base Reassembly . . . . . . . . . . . . . . . . . . . 6

Piston and Cylinder Seals . . . . . . . . . . . . . . . . . . 7

Hydraulic Cylinder . . . . . . . . . . . . . . . . . . . . . . . 9

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pumpline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Piston and Cylinder Seals . . . . . . . . . . . . . . . . . 16

Hydraulic Cylinder . . . . . . . . . . . . . . . . . . . . . . . 18

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 22

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 22

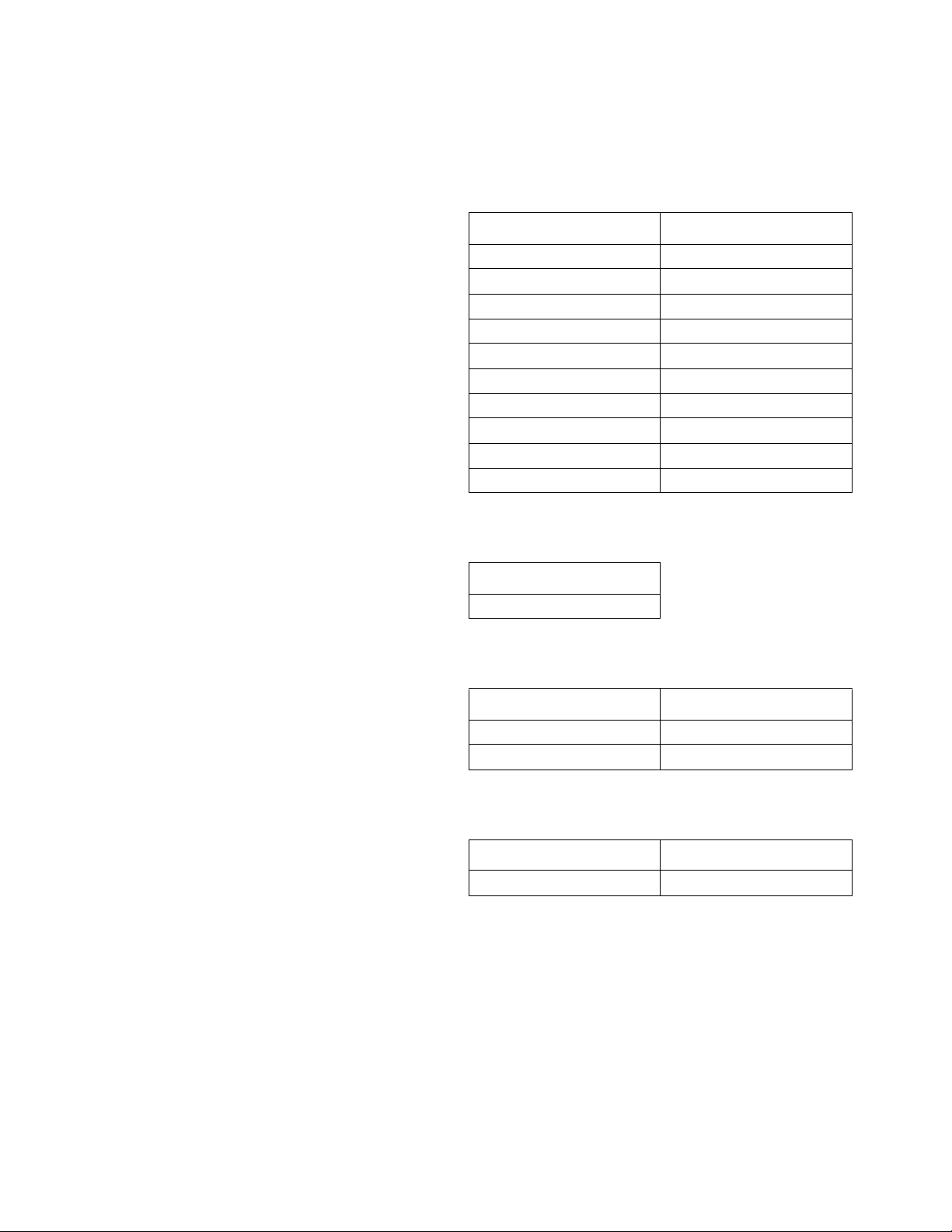

Models

Proportioning Pumps

Part, Series Cylinder Size

24F291, A #28

247371, A #30

247372, A #40

247373, A #48

247374, A #60

247375, A #80

247577, A #88

247376, A #96

247377, A #120

247576, A #140

Hydraulic Cylinders

Part, Series

295027

Pumplines

Part, Series Cylinder Size

288638 #80

288639 #120

In-Plant Pumpline

Part, Series Cylinder Size

P7758-255773 #80

2 312068M

Repair

Repair

Flushing

Flush equipment only in a well-ventilated area. Do not

spray flammable fluids. Do not turn on heaters while

flushing with flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use lowest possible pressure when flushing.

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• Always leave some type of fluid in system. Do not

use water.

Pressure Relief Procedure

Trapped air can cause the pump to cycle unexpectedly,

which could result in serious injury from splashing or

moving parts.

1. Select Park on Pump Control Switch if available, or

turn off.

2. Turn off feed pumps.

3. Trigger gun to relieve pressure.

4. Close gun inlet valves.

5. Close fluid supply inlet valves.

6. Service spray gun. See corresponding spray gun

manual.

Preventive Maintenance

When pumps are functioning properly, it is not unusual

for a trace amount of resin to seep past the pump packing onto the resin pump shaft. Routinely inspect shaft

and wipe away any residue when the proportioner is

turned off. Disassemble and clean the proportioning

pumps annually. For pumpline P7758-255773, disassemble and clean the proportioning pumps every six

months. Inspect the pistons and cylinder for marks or

scratches, which may cause leakage and damage to

packings. Replace all packings, o-rings, and bushings

annually. For pumpline P7758-255773, replace these

items every six months.

312068M 3

Repair

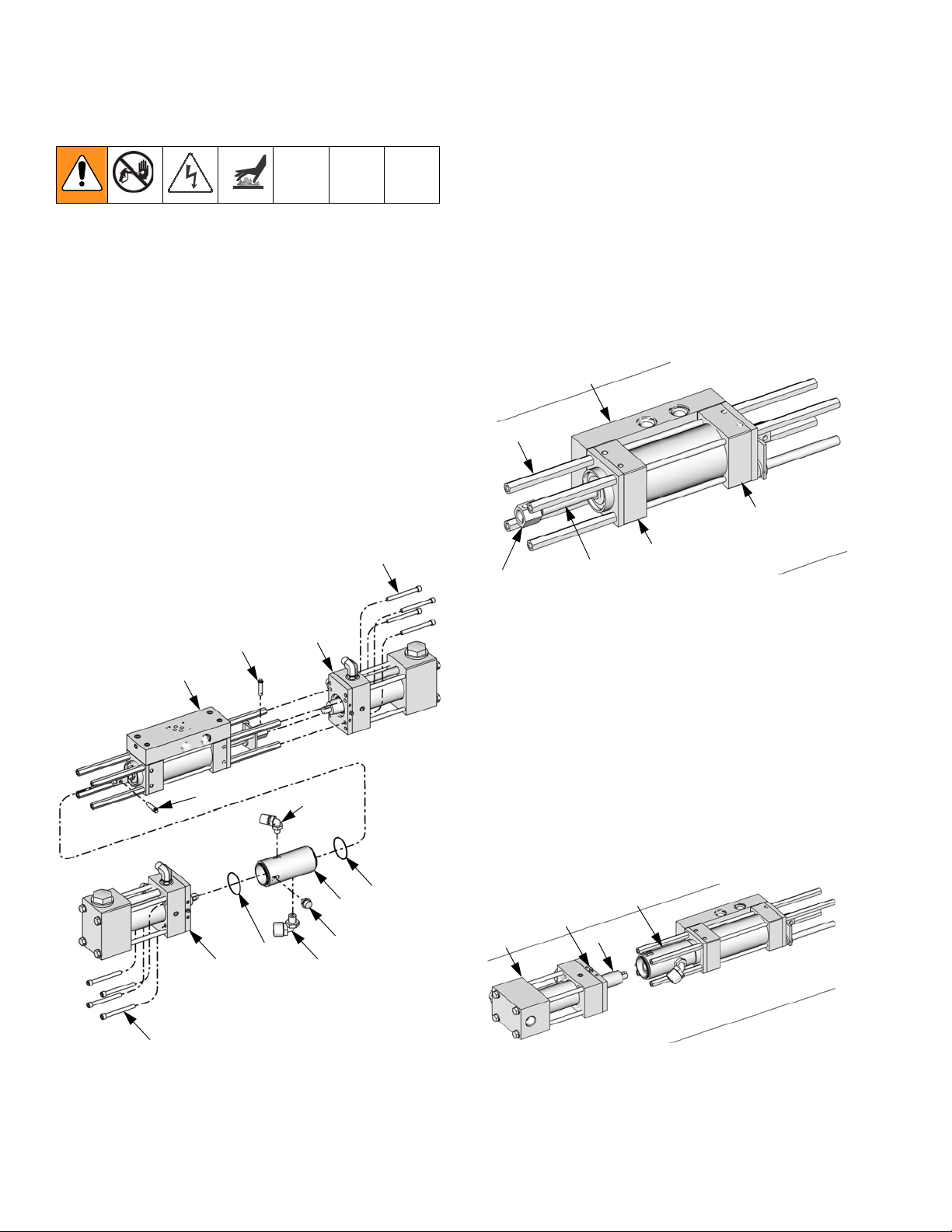

Pumpline Disassembly

1. Remove plug fitting (206) from lube cylinder (205).

2. Insert clevis pin removal tool 296607 through opening in lube cylinder (205) and screw tool into left

clevis pin (219). Pull clevis pin out of clevis (117).

3. Use hex key to remove four socket head cap

screws (203) from left proportioning pump (202).

Remove left proportioning pump.

4. Remove lube cylinder (205).

5. Screw pin removal tool 296607 into right clevis

pin (219). Pull clevis pin out of clevis (117).

6. Use hex key to remove four socket head cap

screws (203) on right proportioning pump (202).

Remove right proportioning pump.

203

Pumpline Reassembly

1. Slide the hydraulic piston (104) in the hydraulic

cylinder (201) out to its left-most position. The left

end of the left clevis (117) should be nearly in line

with the left end of the spacers (113). See the following image.

2. Place hydraulic cylinder (201) on flat surface with

both the manifold (125) and the port blocks (116)

contacting the surface. The two main ports in the

manifold should be facing up. See the following

image.

125

113

116

116

117

104

ti13871a

203

201

219

202

219

204

202

207

208

205

206

204

ti13870a

3. Install elbow fittings (207, 208) into lube

cylinder (206) and install lube cylinder over left

clevis (117). Ensure clevis pin hole in lube cylinder

is vertical, in line with the hole in the left clevis.

4. Place left proportioning pump (202) on flat surface

with the wide end of the outlet flange (26) facing

down.

5. Use clevis pin removal tool 296607 to slide the proportioning pump piston rod (28) out to its limit.

Ensure the hole in the proportioning pump shaft is

vertical, in line with the hole in the left clevis and

lube cylinder.

206

35

26

28

ti13875a

4 312068M

Repair

6. Attach the clevis pin (219) to the clevis pin tool.

Insert clevis pin through hole in lube cylinder and

into the left clevis.

7. Gently tap end of clevis pin tool with hammer to

slide clevis pin (219) into place. Remove clevis pin

tool from clevis pin.

8. Insert four hex head cap screws (203) through holes

in proportioning pump (202) and partially screw into

spacers (113) in hydraulic cylinder (201).

9. With the four hex head cap screws in place but not

tightened, slide the proportioning pump against the

hydraulic cylinder.

10. Clamp the hydraulic cylinder and proportioning

pump assembly to the flat surface so the proportioning pump and hydraulic cylinder will not twist when

tightened against each other.

11. Tighten the hex head cap screws in a criss-cross

pattern.

12. Repeat steps 4-11 with the right proportioning

pump.

13. Install plug fitting (206) into lube cylinder (205).

14. Use grease pump to apply grease to grease

fittings (35) in proportioning pumps.

312068M 5

Repair

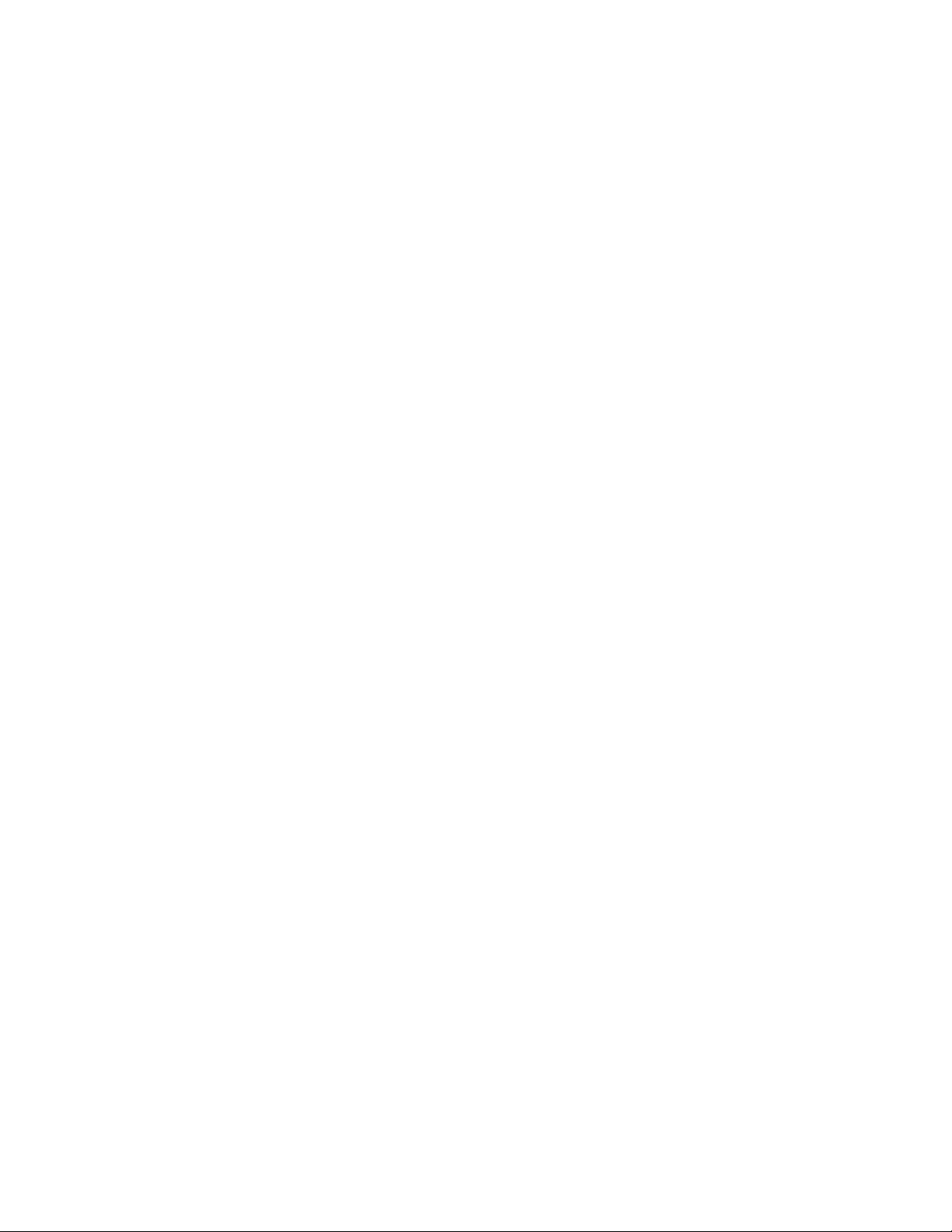

Pump Base Disassembly

Disassemble and clean pump base annually. For

pumpline P7758-255773, disassemble and clean the

pump base on every six months.

1. Relieve pressure, page 3.

2. Turn OFF the main disconnect and lock out power at

the source.

3. Remove pump cap (19) from pump base (23), and

remove o-ring (6):

a. Remove outlet ball (4) and o-ring (9).

b. Remove inlet ball cage (14), spring (22) and

inlet ball (10).

c. Remove inlet ball seat (11) and o-ring (9) from

bottom of cavity.

d. Thoroughly clean all metal parts in a compatible

solvent and inspect for wear or damage. Inspect

each ball and seat for nicks or scratches;

replace as required.

e. Replace all o-rings. Kit 261859 contains all

o-rings for pump base rebuild.

Pump Base Reassembly

1. Install inlet valve in pump base by inserting o-ring

(9), inlet ball seat (11), ball (10), spring (22), and

inlet ball cage (14) into pump base cavity. See Parts

on page 15.

2. Install outlet valve in pump base:

a. Install o-ring (9) and valve ball (4) into the cavity.

b. Install the o-ring (6) on pump cap (19). Install

and tighten cap to pump base. Torque to 75 ft-lb

(101.3 N•m).

TI9780b

19

6

4

9

14

22

10

11

9

23

6 312068M

Repair

Piston and Cylinder Seals

Piston Seal and Cylinder Seal Repair Kits are available. See Table 1 on page 17 to order the correct

kits for your pump. Also see kit manual 312071.

Disassembly

1. Relieve pressure, page 3.

2. Turn OFF the main disconnect and lock out power at

the source.

3. Disconnect the pump inlet and outlet lines; see your

proportioner repair manual. Remove the four screws

(30) holding the pump outlet flange (26) to the

hydraulic cylinder. Disconnect pump from drive and

take pump assembly to a workbench.

4. Remove the four bolts (8) and washers (5). See

Parts on page 15.

5. Remove the flange retainer (27), gasket (17), bushing (13), and throat seal (29).

6. Use a soft-faced mallet to help separate pump base

(23) and outlet flange (26) from cylinder (12).

Remove crossover tube (24)

7. Remove piston from cylinder bore. Remove piston

cap bolt (25), then slide bushing (18) and u-cup seal

(15) from rod.

Reassembly

CAUTION

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

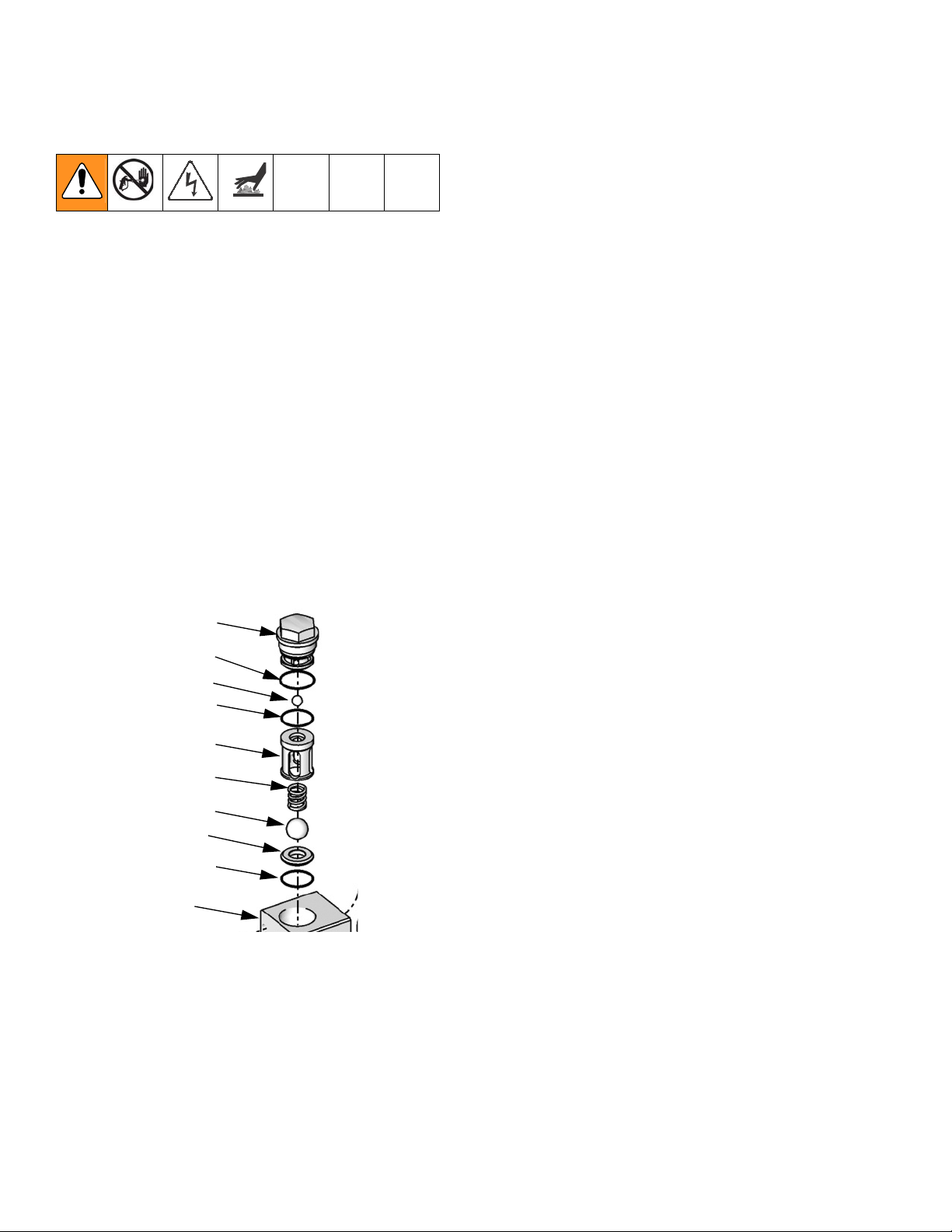

1. Install piston rod seal (15); ensure u-cup faces piston rod (28) as shown in F

15

18

F

IG. 1: U-Cup Orientation

28

2. Assemble piston bolt (25) to piston rod (28). Apply

supplied thread sealant to piston bolt and tighten.

See Torque Specification table for torque according

to pump size.

15

3

25

1

#28 Pump Size

IG. 1.

TI9823a

28

1

Apply supplied sealant to threads.

28

TI9822a

8. Thoroughly clean all parts in a compatible solvent

and inspect for wear or damage. Replace as

25

18

15

1

required.

r_24f290_312068

IG. 2: Piston Head and Rod

F

Torque Specification

Pump Size Torque

30 130 in-lb (14.7 N•m)

28, 40, 48, 60 22 ft-lb (29.7 N•m)

80, 88, 96, 120, 140 45 ft-lb (60.8 N•m)

312068M 7

Loading...

Loading...