Page 1

Instructions

Important Safety Instructions

Read all warnings and instructions in this manual and in the

sprayer operation manual. Save these instructions.

Lacquer Conversion Kit 256212

312933D

EN

ti11870a

Page 2

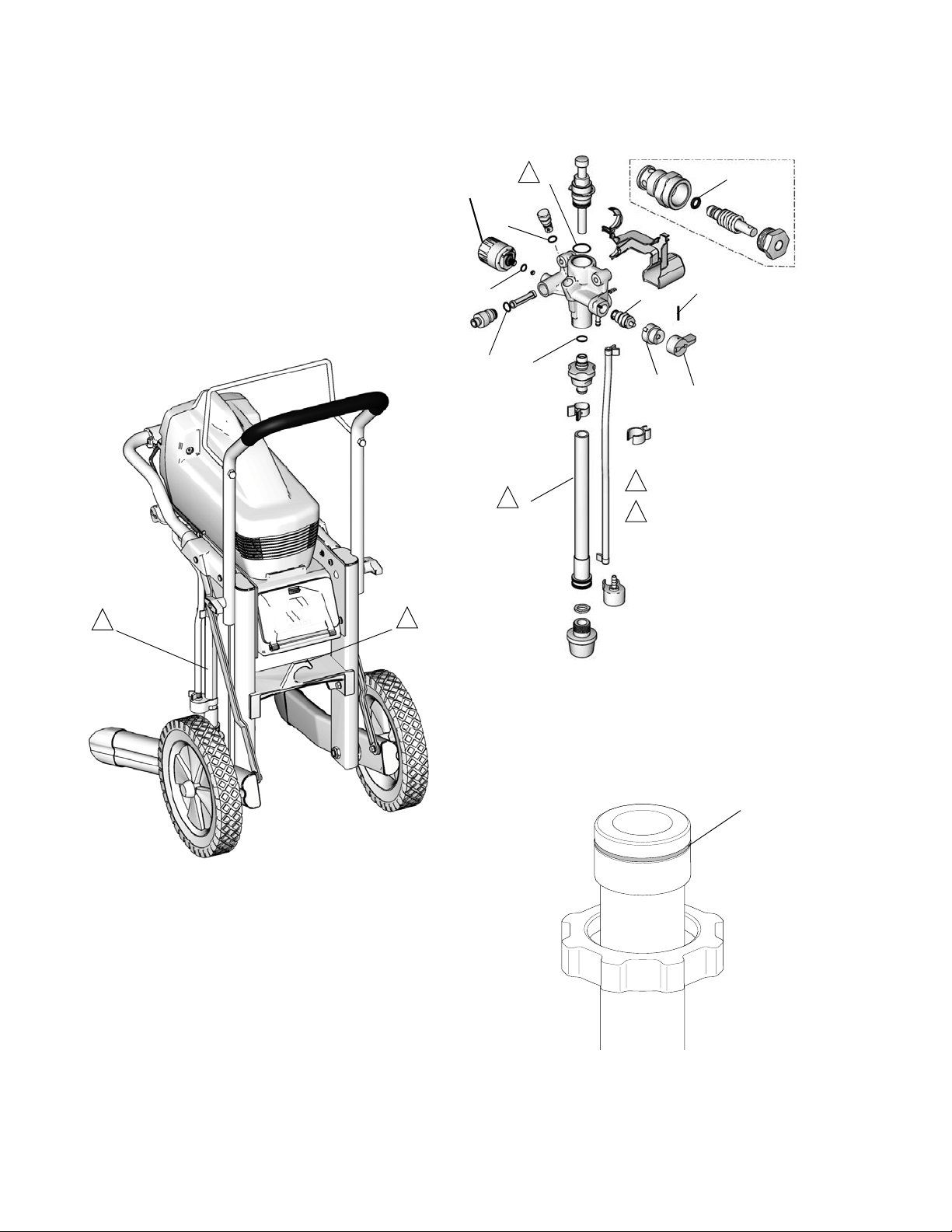

Lacquer Conversion Kit 256212

Qty

Ref. Part No. Description

1 117559 O-RING, CV-75, size 020 2

2 111507 O-RING, CV-75, size 013 1

3 111316 O-RING, CV-75, size 012 1

4 15D370 O-RING, CV-75, size 022 1

5 15D371 O-RING, CV-75, size 015 2

6 15D252 O-RING, CV-90, size 008 1

7 119400 SEALANT, pipe, sst 1

8 15D883 TUBE, suction 1

See Pressure

.

Control

Replacement

1

4

2

3

5

1

2

8

D

C

1

Apply light coat of lithium-based grease

2

Do not use hook storage with new suction

tube as it is not flexible enough to allow

for bending. Damage will occur.

6

B

A

2

2

ti11871a

240V Sprayers Only

ti11872a

1

2 312933D

Page 3

Pressure Relief Procedure

To help prevent injection injuries, follow this procedure

when you stop spraying and before you service or

clean the sprayer, remove parts, or repair leaks.

1. Turn power switch to OFF.

2. Unplug sprayer.

3. Turn knob (A) down to PRIME/DRAIN.

4. Hold metal part of gun firmly to a grounded metal

pail. Pull gun trigger to relieve pressure.

Instructions

1. Turn knob (A) up to SPRAY position.

2. Remove pin (B) with pin punch and hammer.

B

5. Replace brown o-ring (6) on end of valve stem.

Apply sealant (7) to valve threads. Install valve stem

in pump manifold. Torque to 185 in-lb (21 N•m).

6. Install base (C) on valve, aligning pin (E) on base

(C) with hole (F) on manifold.

F

E

7. Rotate valve stem with a pin punch until hole is perpendicular.

C

A

3. Remove knob (A) and base (C).

C

4. Remove valve stem (D) from manifold. Be sure gasket (X) and seat (Z) do not stay in manifold.

B

A

Z

X

D

8. Install knob (A) over base (C).

9. Place knob in SPRAY position.

10. Insert end of pin punch through hole in knob (A), to

make sure knob and valve stem are aligned.

A

11. Install pin (B) through hole in knob (A). Tap pin

through knob with hammer. End of pin will be flush

with top of hole in knob when correctly installed.

312933D 3

Page 4

X5, X7, LTS 15, and LTS 17 Pressure Control Replacement

Disassembly

1. Unplug electrical cord and Relieve Pressure. See

Pressure Relief Procedure on page 3.

2. X7 and LTS 17 Only: Remove underside shroud

mounting screw (D).

3. Remove side shroud screws (E) (T-20 Torx).

4. Remove 4 front cover screws (F) (T-30 Torx).

5. Remove shroud (G).

6. Disconnect power cord connectors (H) from

ON/OFF switch (L).

7. Remove shroud (K).

8. Series A: Remove 2 pump housing mounting

screws (ps). Be sure to support pump housing (ph).

9. Series A: Remove pump housing (ph). X7 and LTS

17 Only: Pull power cord (N) through opening in

pump housing mounting bracket (pb).

10. Disconnect pressure control harness from control

board connector (cb). Take note of wire routing; new

wires will be rerouted the same way.

11. Series A: Remove AutoPrime cover (A) by releas-

ing tab underneath pressure control knob.

Series B: Release tab underneath function indicator

(fi) and remove indicator and front cover.

12. Turn pressure control knob fully counterclockwise to

expose wrench flats. Remove pressure control (P).

Verify the o-ring seal (or) has been removed from

the pump (J).

nect to control board connectors (cb) (connect with

tab in front). Install AutoPrime cover (A) and latch

tab.

4. Install pump housing (ph) with 2 pump housing

mounting screws (ps) onto pump housing mounting

bracket (pb). Torque to 110 to 120 in-lb (12.4 to 13.6

N•m).

5. Series B: Route pressure control harness through

function indicator (fi) and front cover. Install indicator

on pump and snap together. Align indicator and

front cover as they are positioned loosely on pump.

Connect harness to control board terminals (cb).

6. Reattach power cord connectors (H) to ON/OFF

switch (L).

7. Install shroud (K).

8. X7 and LTS 17 Only: Route power cord (N) through

opening in pump housing mounting bracket (pb).

9. Install power cord (N) into recess on left shroud (K).

10. Install shroud (G) to shroud (K) and front cover.

11. Install side shroud screws (E) (T-20 Torx). Torque to

20 to 25 in-lb (2.3 to 2.8 N•m).

12. Install 4 front cover screws (F) (T-30 Torx). Torque

to 26 to 32 in-lb (2.9 to 3.6 N•m).

13. X7 and LTS 17 Only: Install underside shroud

mounting screw (D). Torque to 25 to 35 in-lb (2.8 to

3.9 N•m).

14. Turn pressure control switch knob (P) clockwise as

far as it will go. Apply pressure control label (cl) to

knob. To position label correctly, see note below:

Assembly

NOTICE

Do not pinch wires between pressure control (P) and

pump housing (ph) pump mounting bracket (pb) and

shrouds (G and K) while assembling.

1. Examine new pressure control (P) to verify o-ring

seal (or) is in place. If o-ring seal is not installed on

pressure control, install seal.

2. Apply one or two drops of thread locking adhesive

(included in kit) to threads of pressure control switch

(P). Assemble pressure control switch (P) into pump

(J). Torque to 140-160 in.-lbs (16-18 N•m).

3. Series A: Route pressure control (P) harness as

shown in harness routing detail on page 12. Con-

4 312933D

NOTE: When properly positioned, the function indicator

(fi) and hi-spray position symbol on pressure control

label (cl) are aligned.

fi

hi-spray symbol

cl

P

ti10041a

Page 5

X5 and LTS 15 Model Sprayers (Series A unit shown)

F

G

E

ps

N

ph

J

Tab

A

L

H

K

or

P

ti11886a

X7 and LTS 17 Model Sprayers (Series A unit shown)

E

G

ps

N

pb

H

D

ph

Ta b

A

L

K

F

J

or

P

ti11887a

312933D 5

Page 6

X5, X7, LTS15, and LTS17 (Series A) Wire Routing

cb

A

ti11888a

Ta b

Graco Information

For the latest information about Graco products, visit www.graco.com

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312933

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised September 2013

Loading...

Loading...