Page 1

Instructions - Parts

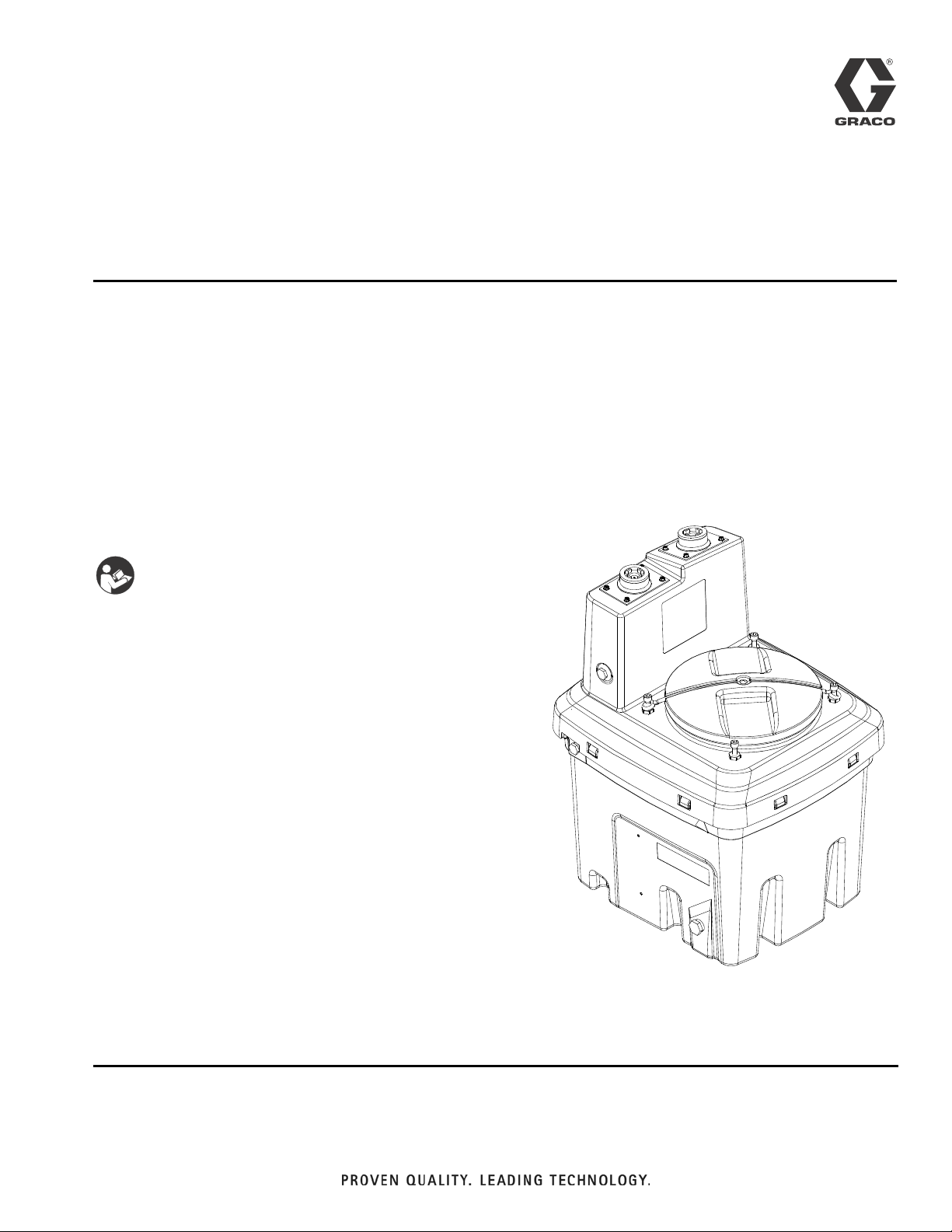

Double Wall Hopper

For use with XM™ plural-component sprayers and immersion heaters.

For professional use only.

255963, Double Wall Hopper

20 Gallon (75 liter) Spray Material Fluid Capacity

12 Gallon (45 liter) Heated Material Fluid Capacity

See page 12 for optional accessories and approvals.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

312747L

EN

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keep Components A and B Separate . . . . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Double Wall Hoppers Mounted on Side of Frame 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Optional Accessories . . . . . . . . . . . . . . . . . . . . 12

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect Return Tube and Recirculation Hose . 14

Fill Heating Fluid . . . . . . . . . . . . . . . . . . . . . . . . 15

Fill Spray Material . . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Flush Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Check Heating Fluid Level . . . . . . . . . . . . . . . . 18

Check for Heating Fluid Leakage . . . . . . . . . . . 18

Drain Heating Fluid . . . . . . . . . . . . . . . . . . . . . . 18

Drain Spray Material . . . . . . . . . . . . . . . . . . . . . 19

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Remove Immersion Heater . . . . . . . . . . . . . . . . 20

Remove Fluid Outlet Assembly Kit . . . . . . . . . . 20

Remove Hopper . . . . . . . . . . . . . . . . . . . . . . . . 21

Replace Gaskets . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 32

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 32

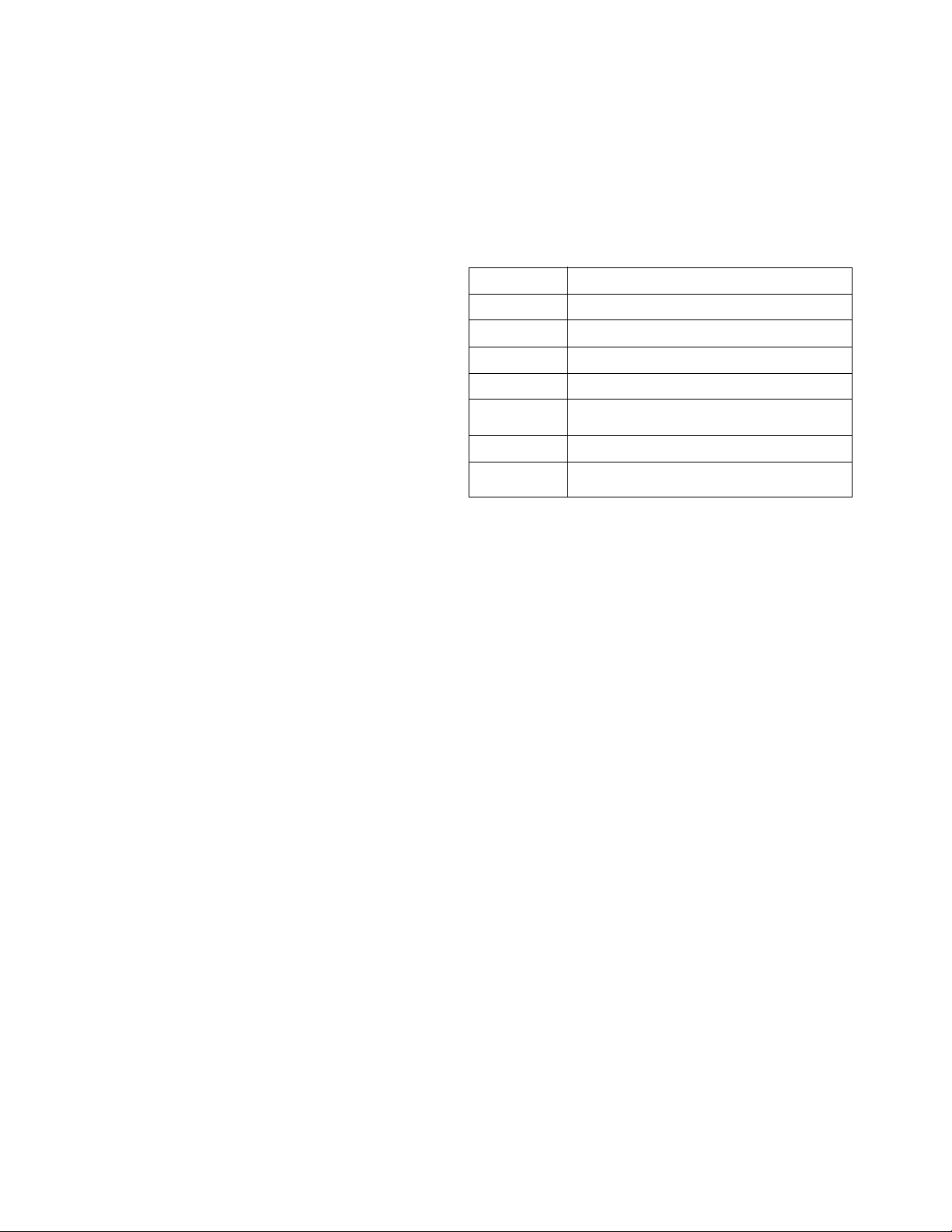

Related Manuals

Manuals are available at www.graco.com.

Component Manuals in English:

Manual Description

312359 XM Operation

313289 XM Repair

313292 XM OEM, Instructions-Parts

309524 Viscon HP Heater, Instructions-Parts

312769

406739 Desiccant Dryer Kit, Instructions-Parts

313259

Feed Pump and Agitator Kits, Instructions-Parts

Hopper or Hose Heat Circulation Kit,

Instructions-Parts

2 312747L

Page 3

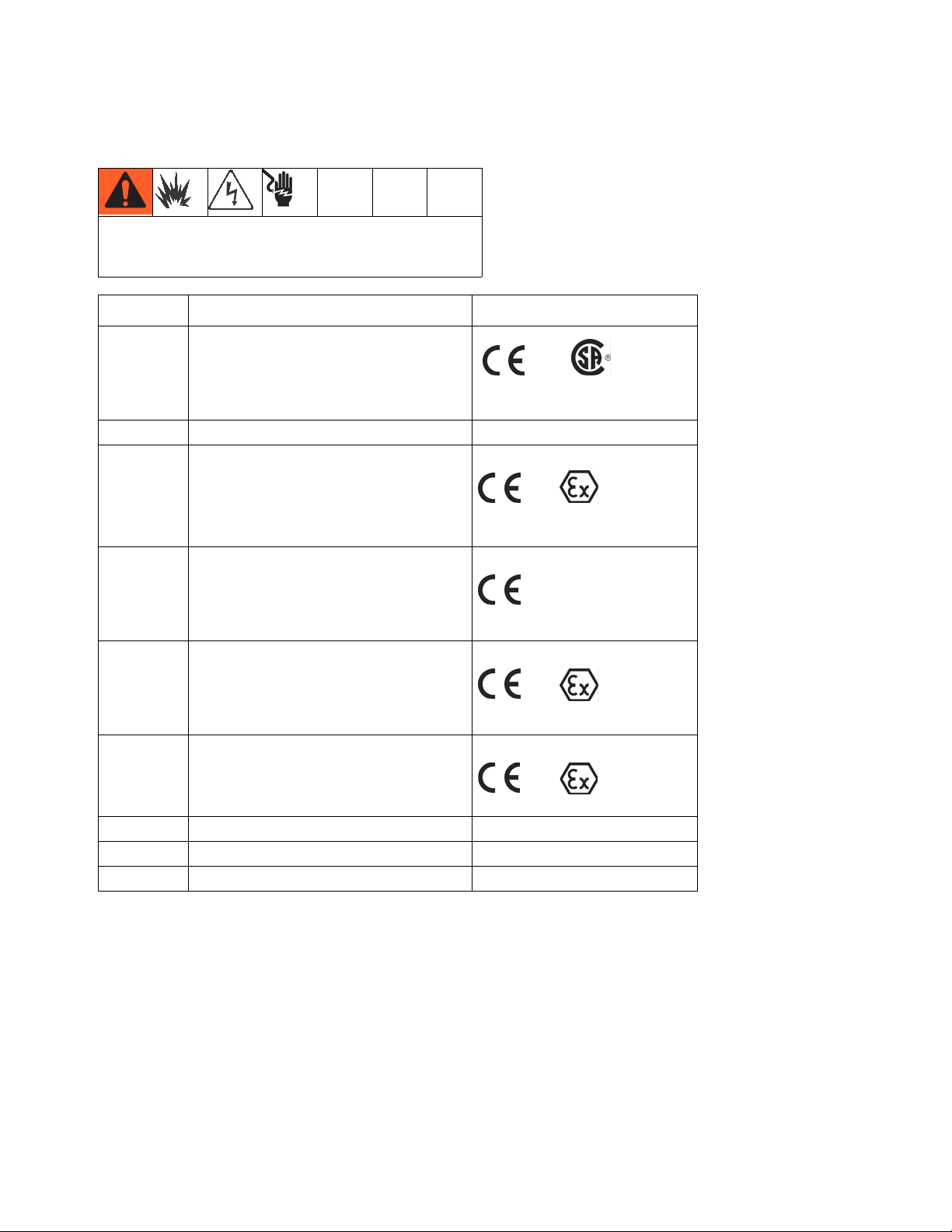

Optional Accessories

Not all accessories and kits are approved for use in

hazardous locations. Refer to the specific accessory

and kit manuals for approval details.

Part Description Approvals

256257 240V 1 PH Immersion Heater

(For heater 121376.)

256512 Desiccant Kit N/A

256274 Agitator Kit

CUS

207901

Optional Accessories

0359

(For agitator 224854.)

256275 T2 2:1 Ratio Transfer Pump Kit

(For pump 295616.)

256276

Monark

®

5:1 Ratio Transfer Pump Kit

0359

(For pump 218956.)

239326

10:1 Ratio President

®

Pump

0359 II 1/2 G T2

15V074 Hopper Outlet Plug Not applicable

262824 Hopper Stand Not applicable

262820 Flexible Fluid Connection Kit Not applicable

See Accessories on page 28 for parts lists.

II 1/2 G T3

ITS03ATEX11226

II 1/2 G T2

ITS03ATEX11228

ITS03ATEX11228

Not approved for use in explosive atmosphers or hazardous locations

312747L 3

Page 4

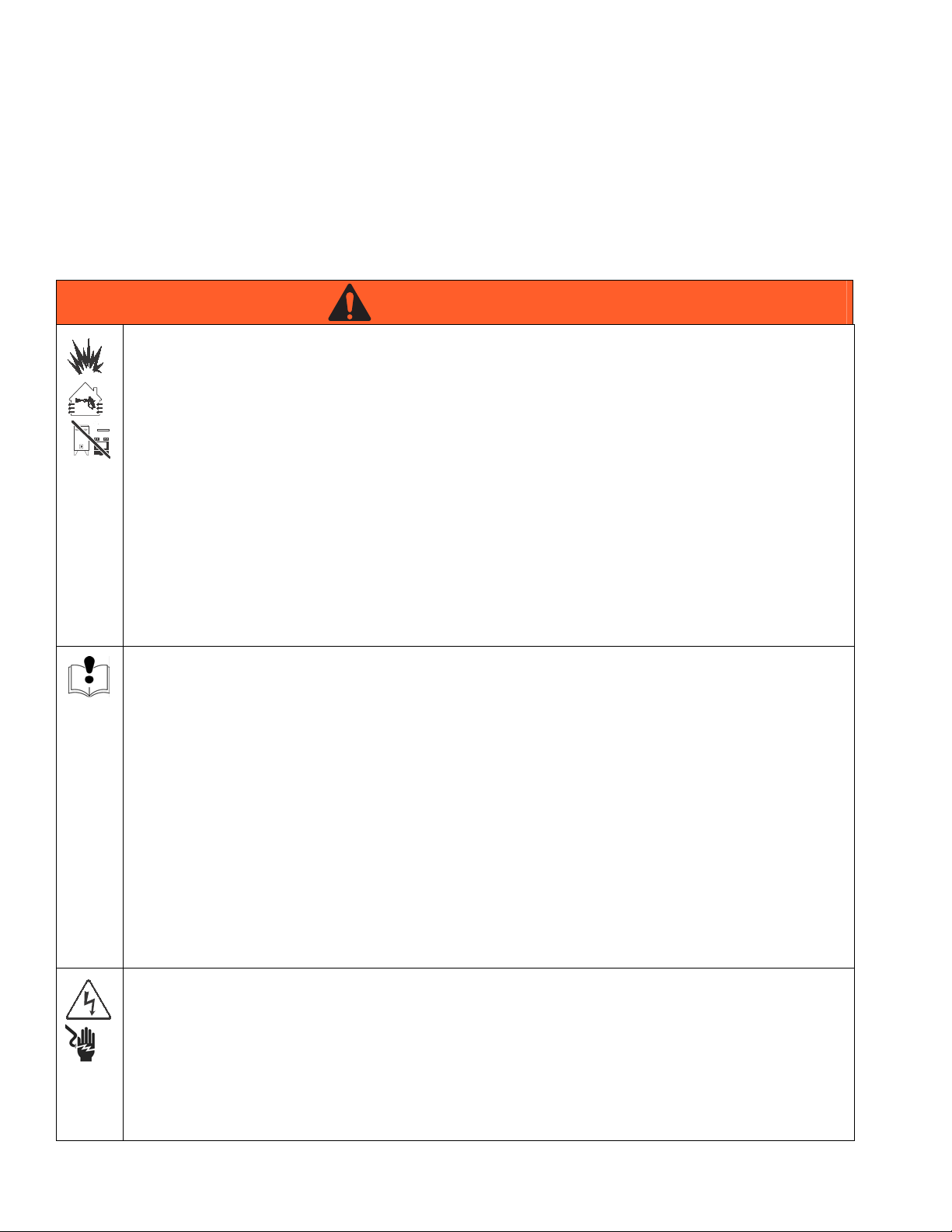

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

• Not for use in explosive atmospheres unless all components and wiring are appropriately approved.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

4 312747L

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many

solvents can degrade plastic parts and cause them to fail, which could cause serious injury or property

damage. See Technical Data in this and all other equipment instruction manuals. Read fluid and solvent

manufacturer’s warnings.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

SUCTION HAZARD

Never place hands near the pump fluid inlet when pump is operating or pressurized. Powerful suction

could cause serious injury.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312747L 5

Page 6

Warnings

Keep Components A and B Separate

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A and

component B.

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Check with your material manufacturer for chemical

compatibility.

• Some materials use catalyst on the A side, but

some applications may use catalyst on the B side.

6 312747L

Page 7

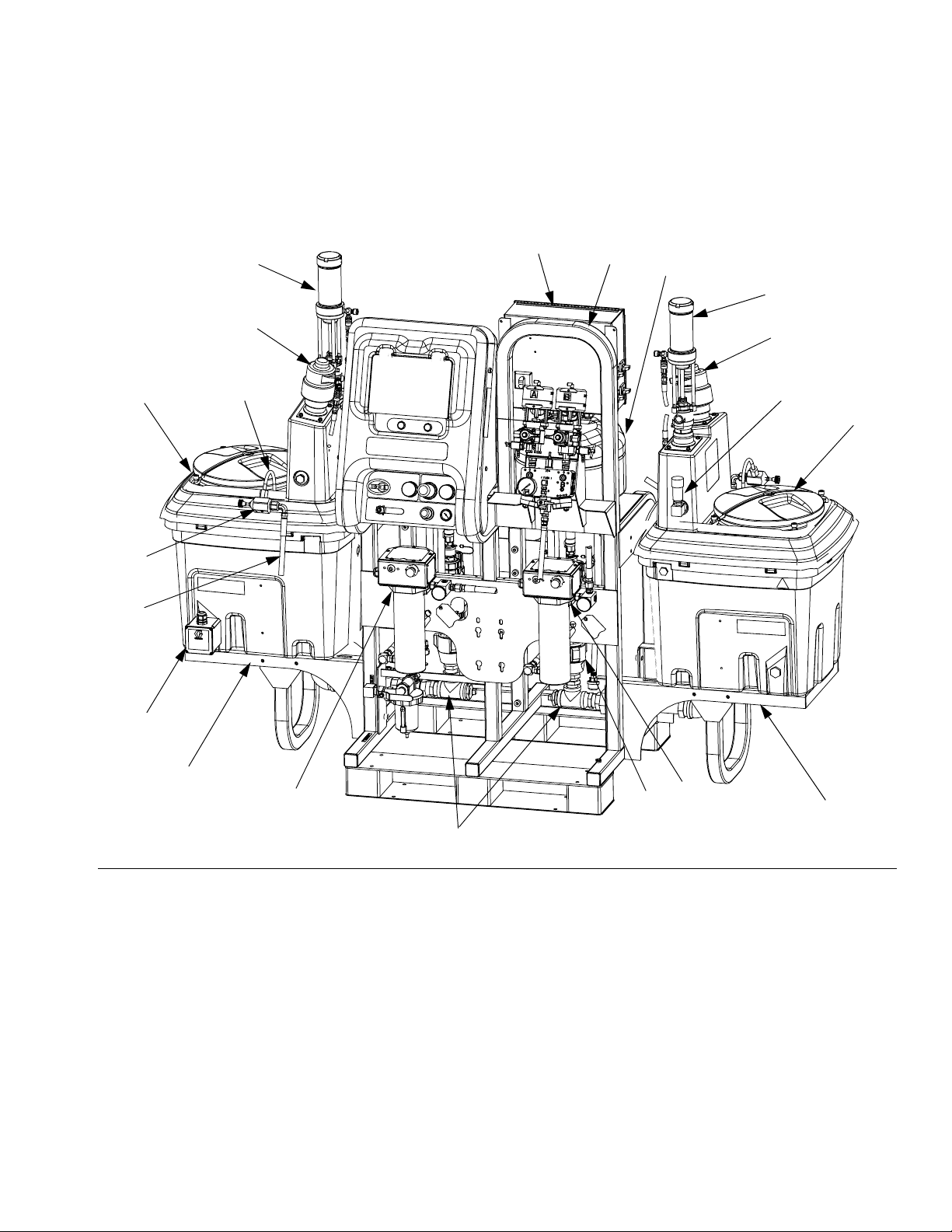

Component Identification

Double Wall Hoppers Mounted on Side of Frame

Component Identification

R

H

A

C

H

J

D

G

J

K

D

N

P

L

E

M

FIG. 1: Typical Installation

Key:

AFrame

BXtreme® lower (behind the frame)

CNXT

D Double wall hopper

E Universal hopper mounting kit

F Fluid inlet assembly

G Return tube

H Feed pump

J Agitator

K Desiccant dryer

L Immersion heater

M Fluid heater

™

air motor (behind the frame)

M

B

E

F

N Restrictor valve (recirculation return)

P Recirculation hose

R Junction box

312747L 7

Page 8

Overview

Overview

Double wall hoppers (D) can be mounted on the back or

side of the frame (A) to gravity feed spray material to the

Xtreme lower (B). Feed pumps (H) and agitators (J) can

be mounted on top of the hoppers to pressure feed

spray material directly to the pump.

A strainer inside the hopper (D) prevents objects larger

than 1/4 in. from clogging or damaging pumps. When

the XM sprayer is running, spray material exits the hopper through the fluid inlet assembly or transfer pump and

circulates through the lowers (B), mix manifold, fluid

heaters (M), and returns to the hopper (D) through the

recirculation hose (P). Immersion heaters (L) installed

through the sides of the hopper help to maintain the

temperature of the spray material during recirculation.

XM sprayers are not approved for use in hazardous

locations unless the base model, all accessories, all

kits, and all wiring meet local, state, and national

codes.

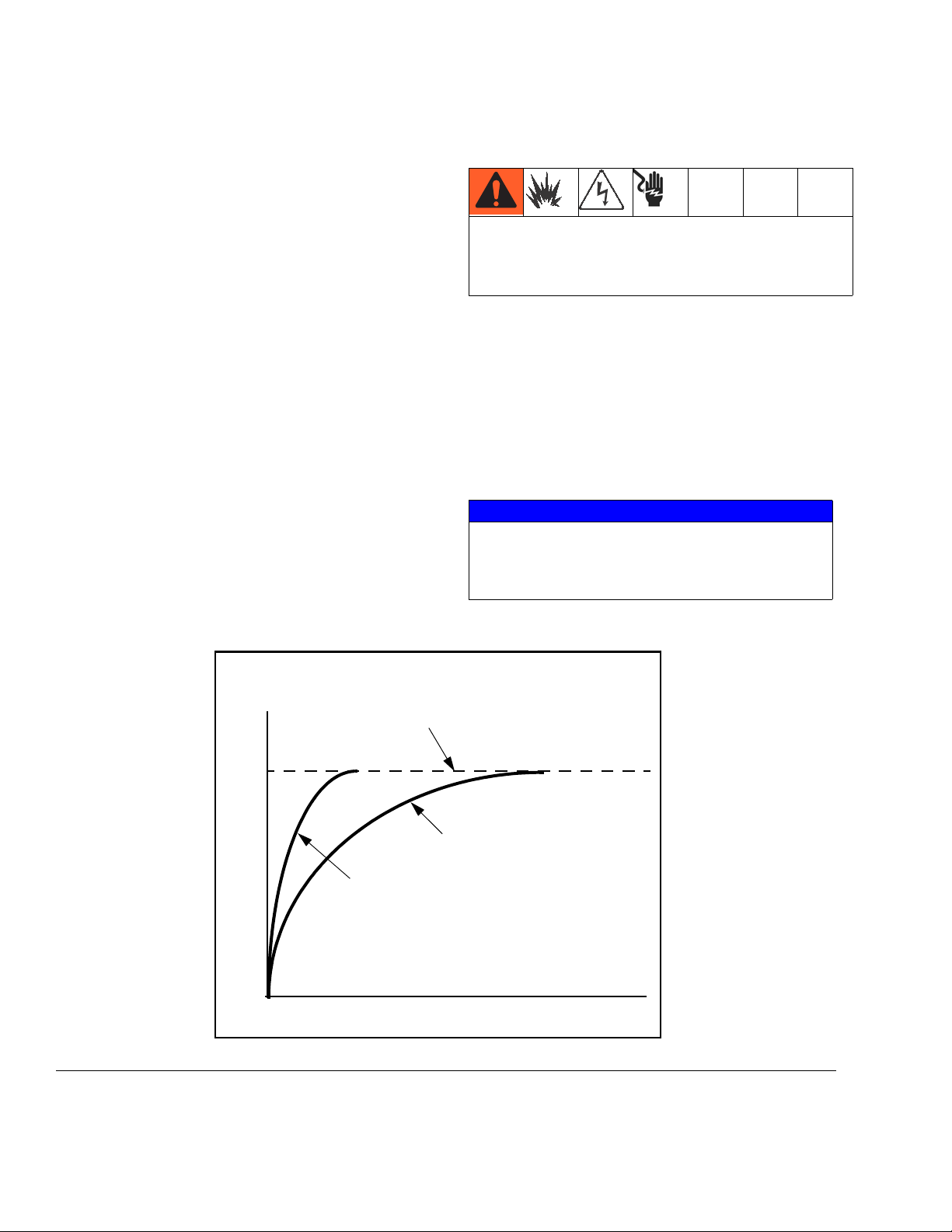

Oil or a 50% water and 50% ethylene glycol mixture can

be added to the hopper’s outer cavity to a controlled

temperature and help maintain the temperature of the

spray material. The heated fluid in the outer jacketed

area helps prevent heat loss of the spray material.

A 50% mixture of water and ethylene glycol mixture

heats up faster than typical hydraulic oil. See F

IG. 2.

Spray material temperature

Temperature

50/50 water mixture

NOTICE

Use the Hopper or Hose Heat Circulation Kit 256273

to heat the hopper outer cavity fluid or special fluid

hoses in hazardous environments. See manual

313259 for installation and repair parts.

Oil

Time

FIG. 2: Heated Fluid Temperature Comparison

8 312747L

Page 9

Installation

Installation

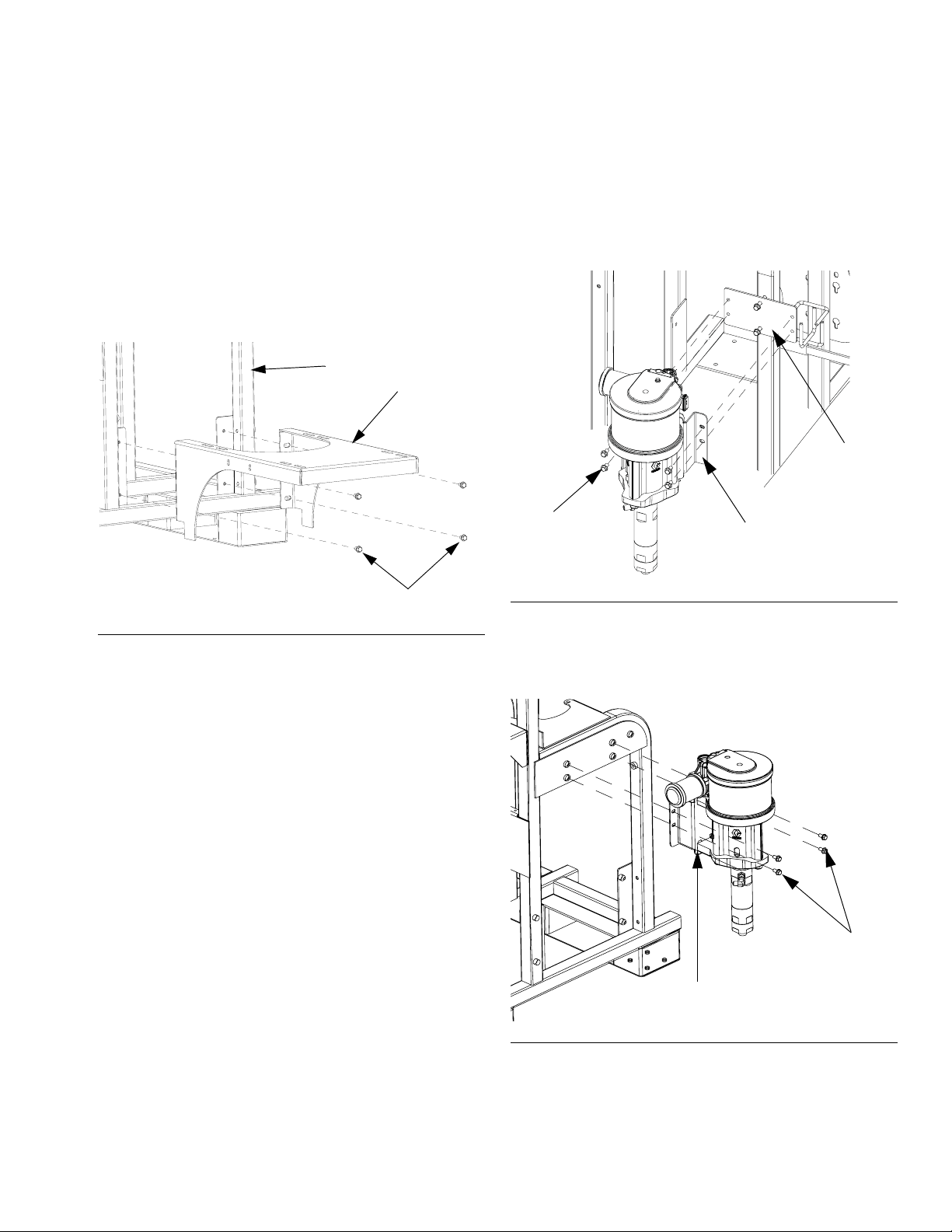

Hopper mounting kit 256259 allows the hoppers (D) to

mount on the sides or back of the frame (A).

1. Mount hoppers (D) on sides of the frame (A). See

F

IG. 3.

a. Attach main bracket (101) to frame (A) with

screws (107).

A

F

IG. 3: Sides of Frame

b. Repeat for second hopper (D) on opposite side

of frame (A).

101

107

a. Remove four screws (306) holding solvent

pump bracket (307) to mounting plate (308).

Leave pump attached to bracket. Remove pump

and bracket.

308

306

307

FIG. 4: Remove Solvent Pump

b. Use four screws (306) to attach solvent pump

and bracket (307) to side of frame.

2. Mount hoppers (D) on back of the frame (A). See

F

IG. 6.

NOTE: The solvent pump must be moved to the side

of the frame before the hoppers can be mounted to

the back. Follow sub-steps a and b to move the solvent pump to either side of the frame.

307

IG. 5: Attach Solvent Pump to Side of Frame

F

306

312747L 9

Page 10

Installation

c. Attach the corner bracket (103) to frame (A) with

screws (108) and washers (110).

d. Attach lower mount bracket (104) to frame (A)

with screws (108) and washers (110).

e. Attach main bracket (101) to frame (A) with

screws (107).

f. Repeat steps b and c for second hopper (D).

A

108

110

103

101

107

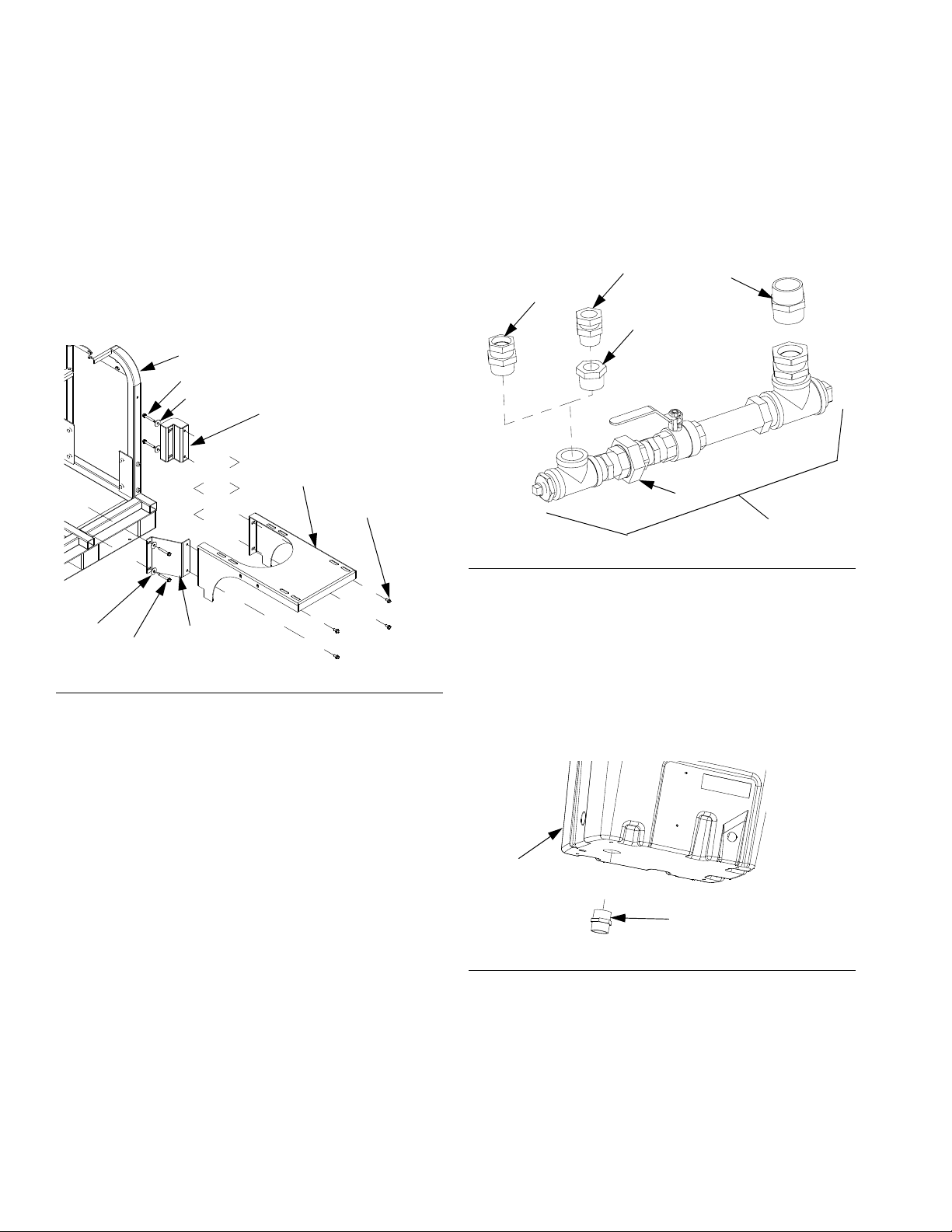

3. Connect reducing swivel (211) to fluid outlet assembly (F) if your system uses a 50:1 pump. Connect

reducer bushing fitting (212) and swivel fitting (215)

to fluid outlet assembly (201) if your system uses a

70:1 pump. Do not use pipe sealant on swivel end of

swivel fittings.

215

201

211

212

208

F

IG. 7: Connect Fluid Outlet Assembly to Lower

F

110

108

F

IG. 6: Back of Frame

104

4. Loosen union (208).

5. Connect swivel fitting (211 or 215) to pump foot

valve. See F

IG. 7.

6. Apply pipe sealant paste to one end of nipple

threads (201) and install that end in bottom of hopper (D).

D

201

F

IG. 8: Install Nipple

10 312747L

Page 11

Installation

7. Align holes on main bracket (101) and thread inserts

of the hopper (D). Loosely fasten hopper (D) to

bracket (101) with four screws (107) and washers

(110).

D

101

110

107

IG. 9: Attach Hopper to Bracket

F

8. Connect swivel fitting (202) to nipple (201).

9. Tighten union (208) and ensure fluid outlet assembly is aligned. See F

10. Tighten hopper mounting screws (107). See F

IG. 7 on page 10.

IG. 9.

11. Install screws (107) and bottom support (109).

107

D

107

109

IG. 11: Install Bottom Support

F

201

202

IG. 10: Connect Fluid Inlet Assembly to Hopper

F

12. Repeat steps 3-11 for second hopper (D).

312747L 11

Page 12

Installation

Optional Accessories

See Accessories page 28 for a list of all accessories

that can be used with double wall hoppers.

Immersion Heater Kit 256257

The immersion heater (L) is only approved for

non-explosive atmosphere applications. Using the

immersion heater in hazardous locations, or explosive

atmospheres, may cause ignition or explosion.

• For hazardous environments use the Hopper or

Hose Heat Circulation Kit 256273; see manual

312359.

• Ensure the outer cavity of the hopper is empty

before installing immersion heater to prevent oil or

water mixture from exiting hopper.

Immersion heater kit 256257 can only be used with a

water mixture or oil in the outer jacketed area of the hopper.

4. Install bushing (302) in top of wiring outlet. Route

power cable (303) through bushing (302).

D

28

FIG. 12: Immersion Heater

5. Remove screws (HS) and immersion heater cover

(HC).

HS

L

HC

302

1. Remove plug (28) from side of hopper (D).

2. Apply thread sealant to immersion heater threads

(L) and screw immersion heater into hopper (D).

3. After installation, remove plug (28) from opposite

side and verify element end is visible through plug

hole.

NOTICE

Vertically orientate wiring outlet. Ensure bushing (302)

is positioned on top of the immersion heater (L) before

installing the cover (HC). Failing to do so will allow overheating, and therefore the overtemperature switch will

trip.

Do not bend heating elements during installation. Bent

elements may cause hopper wall failure allowing spray

material to contact heater.

IG. 13: Immersion Heater Cover

F

6. Connect white and black wires from cable (303) to

white wires inside immersion heater box. Tighten

together with wire nuts (304).

7. Connect green wire from cable (303) and green wire

inside immersion heater box. Tighten together with

with wire nut (304).

12 312747L

Page 13

8. Set thermostat knob (TK) to desired spray material

conditioning temperature. Align temperature setting

to set point (SP).

NOTE: Set point (SP) is a “V” notch in the metal

bracket at the top of the thermostat dial. Maximum

setting is 140°F (60°C).

303

Installation

TK

L

IG. 14: Connect Immersion Heater

F

HC

SP

9. Install immersion heater cover (HC) with screws

(HS). See F

IG. 13.

10. Open junction box door and remove plug for appropriate heater wire. Install cord grip of bushing (302).

Route power cable (303) up through cord grip.

BA

BB

302

303

FIG. 15: Immersion Heater Power Cables

11. Press the top lever up on the power switch body

(BA, BB) and pull away from the junction box. Install

by pushing the power switch body onto the switch

lever post. Flip lever down to engage.

12. Loosen lugs 2 and 4 on immersion heater A power

switch (BA) or immersion heater B power switch

(BB). Insert power leads and tighten lugs.

13. Connect green wire to 102GND grounding lug.

Feed Pump and Agitator Kits

See manual 312769 for installation and operation

instructions.

312747L 13

Page 14

Setup

Setup

1. Remove the large A or B label from the label sheet

(24) and apply to front face of the appropriate hopper to help avoid filling the wrong materials and

causing cross-contamination.

24

F

IG. 16: Apply Label

2. Remove the small A or B from the label sheet (24)

and apply on lid.

Connect Return Tube and

3. Connect other end of recirculation hose to recirculation valve (V) on XM sprayer.

R

R

V

F

IG. 18: Recirculation Hose and Recirculation Valve

4. Repeat for second hopper.

Recirculation Hose

1. Install return tube (G) in port on top of hopper (D).

G

P

D

R

F

IG. 17: Connect Return Tube and Recirculation

Hose

2. Connect recirculation hose (R) and recirculation

restrictor valve (P) to return tube (G).

14 312747L

Page 15

Setup

Fill Heating Fluid

Fill the hopper’s outer jacketed area with oil or a 50%

water and 50% ethylene glycol mixture to heat your

spray material. The double wall hopper design prevents

the spray material from losing heat during downtime and

overnight.

NOTICE

Algae can form inside the outer jacketed area if you

are using only water to heat your spray material.

Always add ethylene glycol to the water to prevent

the formation of algae.

Replace heating fluid inside hopper once a year to

improve heating efficiency. See Check Heating

Fluid Level on page 18.

Table 1: Fluid Capacities of 20 Gal. Hopper

Gallons (Liters) of

Heating Fluid

12 (45) 20 (76)

Gallons (Liters) of

Spray Material

3. Fill outer jacketed area of the hopper through the filling port until the fluid reaches the opposite fill port

when using the Immersion Heater Kit 256257,

page 12.

NOTICE

Do not fill the outer jacketed area fully if using the

hopper or hose circulation kit. See fill instructions in

the Hopper or Hose Circulation Kit manual. Overfilling may cause heating fluid to overflow vent fittings

(see F

IG. 21) during startup.

NOTICE

Do not plug top ports. Always have venting fittings

(36, 39) installed to prevent outer cavity pressurization. Failure to do so may cause leakage into spray

material.

4. Vent fittings may be installed on either side. See

F

IG. 21 for correct orientation of venting fittings.

1. Remove plug (6) from opposite end of 3/4 npt filling

port.

6

F

IG. 19: Filling Overflow Port

2. Insert fluid hose into one filling port and place an

empty 5 gallon pail beneath opposite filling port to

catch access fluid from filling port.

39

36

F

IG. 20: Install Venting Fittings

312747L 15

Page 16

Setup

Left Side

Shown

(45°)

Open Port

F

IG. 21: Orientation of Venting Fittings

5. Install plug (6) in opposite port and torque to 20-30

ft-lbs (27-41 N•m).

NOTE: Occasionally inspect the inside of the hopper

for any leakage of outer cavity heating fluid.

Fill Spray Material

Condition materials prior to adding to hoppers. Ensure

resin materials are thoroughly agitated, homogenous,

and pourable prior to adding to hopper. Stir hardeners

back into suspension prior to adding material to hopper.

1. Disconnect spring strap (7) from front post and

remove lid (1c). Keep connected to lanyard (10).

10

7

1c

F

IG. 22: Remove Lid

2. Pour desired amount of spray material through

strainer inside hopper (D). See Table 1: Fluid

Capacities of 20 Gal. Hopper.

D

IG. 23: Fill Spray Material

F

3. Tightly secure lid (1c) on hopper (D) and reconnect

spring strap (7).

16 312747L

Page 17

Operation

Operation

Startup

1. Ensure that the outer jacketed area is filled with

water mixture or oil and the accessories are correctly installed.

2. Follow Setup procedure in manual 312359.

3. See manual 312359 for testing material and operation instructions before spraying material.

Flush Hopper

1. Drain Spray Material. See page 19.

2. Flush hoppers and fluid inlet assemblies (F) with

compatible solvent before switching materials or

cleaning hopper (D). See Flushing section in manual 312359.

3. Visually inspect the inside of the empty hopper for

any leakage of outer cavity heating fluid.

Shutdown

1. See Shutdown and Pressure Relief procedures in

manual 312359.

312747L 17

Page 18

Maintenance

Maintenance

Drain Heating Fluid

1. Turn off all heaters and allow heating fluid to cool for

a minimum of 8 hours.

Check Heating Fluid Level

Gradual fluid evaporation can occur, therefore, check

the level of heating fluid monthly.

1. Remove plug (6).

2. Place flexible object in port so that it protrudes

down. Pull out to observe level.

3. Refill heating fluid as necessary. See Fill Heating

Fluid, page 15, for instructions.

Check for Heating Fluid Leakage

When spray material is drained and heating fluid is full,

inspect the inside of the hopper for any signs of heating

fluid leakage.

2. Place either a 1-gallon (4-liter) or 3-gallon (7-liter)

pail directly beneath drain plug (37).

NOTE: Only 1-gallon (4-liter) pails fit beneath drain

plug if hoppers are mounted on the back of the

frame.

37

FIG. 24: Place Pail Beneath Drain Plug

3. Use wrench to hold reducer fitting (36) secure while

using another wrench to remove drain plug (37) and

capture heating fluid in pail.

4. Use additional pails as necessary until all fluid is

drained.

5. Install plug (37) into reducer fitting (36) after fluid is

completely drained from the hopper’s (D) outer jacketed area.

18 312747L

Page 19

Maintenance

Drain Spray Material

1. Flush and Shutdown XM sprayer. See XM opera-

tion manual.

2. Turn off all fluid heaters (S) and allow heating fluid to

cool for a minimum of 8 hours.

3. Place a clean 1 gallon (4 liter) pail directly beneath

union (208) and ball valve (206).

4. Close ball valve (206) and open union (208) with

wrench.

206

208

F

IG. 25: Closed Ball Valve

5. Drain spray material from pump lower in pail. If necessary, remove fittings from opposite end, then use

a brush and compatible solvent to clean out fittings.

206

FIG. 27: Drain Hopper

8. Use additional pails as necessary until all material is

drained.

9. Close ball valve (206) and use two wrenches to

retighten union (208).

F

IG. 26: Drain Lower

6. Use additional pails as necessary until material is

drained.

7. Open ball valve (206) and drain spray material from

hopper. If necessary, remove plug from opposite

end, then use a brush and compatible solvent to

clean out plug and fittings.

312747L 19

Page 20

Repair

Repair

Remove Immersion Heater

1. Turn off power to system. See the XM Operation

manual.

2. Drain Heating Fluid. See page 18.

3. Remove screws (HS) and immersion heater cover

(HC).

303

302

HS

HC

FIG. 28: Connect Immersion Heater

Remove Fluid Outlet Assembly Kit

1. Drain Spray Material. See page 19.

2. Loosen fitting (212) or (211).

3. Loosen fitting (202).

4. See Installation on page 9 for assembly instruc-

tions.

211

IG. 29: Fluid Outlet Assembly

F

215

212

201

202

206

208

4. Disconnect white, black, and green wires from

power cable (303).

5. Loosen bushing (302) and pull power cable (303)

out of bushing.

6. Slowly remove immersion heater (L) from hopper

(D).

NOTICE

To prevent damage to the heater element coils,

ensure fold-back end of heater coil can pass back

through threaded opening of hopper (D).

7. Inspect the heater element coils for excessive corrosion. If necessary, replace entire immersion heater.

8. To install immersion heater (L) see Immersion

Heater Kit 256257 on page 12.

20 312747L

Page 21

Repair

Remove Hopper

1. Check Heating Fluid Level. See page 18.

2. Drain Spray Material. See page 19.

3. Disconnect swivel fitting (202). See F

4. If a transfer pump (H) or agitator (J) is mounted to

the hopper:

a. Relieve pressure. See manual 312769.

b. Disconnect air hoses from agitator and feed

pump. Disconnect fluid hose from feed pump.

5. Remove bolts (107) and washers (110) from under

mounting bracket (101).

IG. 29.

101

Replace Gaskets

The following procedure applies to both the hopper gaskets (13) and hopper lid gasket (12).

1. Remove old gasket and residual adhesive using

MEK solvent.

2. Clean groove in hopper using isopropyl alcohol. Let

air dry.

3. Remove adhesive backing from new gasket. Press

gasket firmly into groove. Be careful not to stretch

gasket material.

4. Trim excess length if necessary.

5. Reassemble rest of hopper parts to keep pressure

on gasket.

6. Allow 24 hours for full bonding.

110

110

F

IG. 30: Remove Hopper

6. Lift hopper (D) and carefully rest on a flat surface.

Use caution to avoid damaging fitting (201).

107

312747L 21

Page 22

Troubleshooting

Troubleshooting

Problem Cause Solution

Lid does not properly seal on hopper. Material build up. Remove built up material from gas-

Damaged gasket.

Material leaking between cover and

hopper.

Algae in water. Ethylene glycol was not added to

Immersion heater no longer heating. Overtemperature switch tripped on

Heating fluid leaking into spray material inside hopper.

Hopper is not heating all the way to

the top.

Gasket is not sealed properly. Check for built up material on gasket.

water.

immersion heater.

Inside wall of hopper is damaged. Replace hopper.

Heating fluid level is low. Refill heating fluid.

ket. Replace as necessary.

Replace as necessary.

Drain fluid. Add 50/50 water and eth-

ylene glycol mixture in outer cavity

Ensure it is mounted correctly. See

Immersion Heater Kit 256257, page

12.

Refill heating fluid level.

Locate heating fluid leak and correct.

If heating fluid level and immersion

heater is mounted correctly, remove

heater cover and press reset button.

Replace cover.

22 312747L

Page 23

Troubleshooting

312747L 23

Page 24

Parts

Parts

255963, Double Wall Hopper

1

Assemble with lips facing down.

2

Torque to 20-30 ft-lbs.

3

Clean groove with isopropyl alcohol

before applying gasket adhesive to

plastic. Cut to length.

35

19

9

32

32

8

7

10

1c

4

12

3

11

26

34

24

6

2

5

2

1b

14

1

6

2

13

3

39

2

36

2

1a

33

28

2

36

37

2

24 312747L

Page 25

255963, Double Wall Hopper

Ref. Part Description Qty

1a HOPPER 1

1b COVER 1

1c LID 1

4 255965 PLATE, weldment 2

5 15T007 ADAPTER, return tube 4

6 121621 PLUG, 3/4 in. npt 3

7 255966 STRAP, spring, hopper lid 1

8 109570 WASHER, plain; 1/2 in. 2

9 513764 SCREW, cap, socket head;

1/2-13 x 0.75

10 122097 CABLE, SST lanyard, 12 in. 1

11 256008 STRAINER 1

12 15T010 GASKET, lid, hopper 1

13 15T011 GASKET, hopper 2

14 15R403 SEAL, return tube 2

19 112547 SCREW, flange, hex head;

1/4-20 x 1

24 15R424 LABEL, A-B identification; not

shown

26 121378 PLUG, 2 in. npt, poly, w/gasket 2

28 121485 PLUG, 1 in. npt 2

32 121797 SCREW, cap, socket head;

1/2-13 x 1.5

33 189285 LABEL, caution 2

34 15R331 PLATE, accessory, hopper 2

35 104105 NUT, lock, hex; 1/4-20 8

36 117326 FITTING, bushing;

3/4 npt(m) x 1/2 npt(f)

37 100737 PLUG, pipe; 1/2 npt 1

39 158683 FITTING, elbow, 90 deg.;

1/2 npt (m-f)

40† 24K965 KIT, spacer, 5:1 pump (not shown) 1

Parts

1

8

1

2

2

2

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

† Supplied spacer kit is for installation of a 5:1 pump

on this hopper. See manual 312769 for instructions.

312747L 25

Page 26

Parts

256259, Double Wall Hopper Mounting Kit

110

108

Back Mounted Double Wall Hopper

108

110

104

103

101

107

Side Mounted Double Wall Hopper

101

107

107

107

107

109

109

Ref. Part No. Description Qty.

101 256224 BRACKET, hopper, 20-gallon 1

103 256254 BRACKET, hopper, wldmt, bottom

mount

104 256256 BRACKET, hopper, bottom mount,

lower

107 112395 SCREW, cap, flng hd; 3/8-16 x 0.75 14

108 121488 SCREW, hex hd, flanged;

3/8-16 x 2.75

109 256928 SUPPORT, hopper bracket, rear 1

110 115625 WASHER, fender, 3/8 8

107

1

1

4

26 312747L

Page 27

256170, Universal Hopper Fluid Outlet Kit

215

211

212

216

207

206

205

Parts

201

202

217

203

204

208

207

210

209

Ref. Part No. Description Qty.

201 121435 NIPPLE, hex; 2 in. 1

202 121436 FITTING, swivel, male; 2 in. 1

203 121437 FITTING, tee, female; 2 in. 1

204 121438 BUSHING, reducer; 2 x 1 1/2 in. 1

205 121439 NIPPLE, pipe; 1 1/2 npt x 6 1

206 121440 VALVE, ball; 1 1/2 npt 1

207 121441 NIPPLE, hex; 1 1/2 npt 2

208 121442 FITTING, union; 1 1/2 npt 1

209 121443 FITTING, tee; 1 1/2 npt 1

210 101496 BUSHING, pipe; 1 1/2 x 3/4 npt 1

211* 121445 SWIVEL, reducing; 1 1/2 x 1 1/4 1

212† 121446 BUSHING, reducer; 1 1/2 x 1 1/4 1

215† 121447 FITTING, swivel; 1 1/4 1

216 104663 PLUG, pipe; 3/4 npt 1

217 123807 PLUG, pipe; 2 in. 1

* Parts used for 50:1 pumps only.

1

Apply sealant to all non-swiveling pipe threads.

2

Do not use pipe sealant on swivel fittings.

† Parts used with 70:1 pumps only.

312747L 27

Page 28

Accessories

Accessories

262820, Flexible Fluid Connection Kit

For gravity feeding from 20 gallon hopper to proportioner with Xtreme lower.

412

411

401

410

407

404

402

405

406

408

409

Ref Part Description Qty

401 120291 PIPE, elbow female 1

402 125995 FITTING, hose, barbed, 1-1/2 npt 2

403 126320 HOSE, 1-1/2 ID, 200 psi, 3 ft 1

404 126889 CLAMP, hose 2

405 121440 VALVE, ball, 1-1/2 npt 1

406 121441 FITTING, nipple, hex, 1-1/2 npt 1

407 121443 FITTING, tee, 1-1/2npt 1

408 101496 BUSHING, pipe 1

409 104663 PLUG, pipe 1

410 121445 SWIVEL, reducing, 1-1/2 x 1-1/4 1

411 121436 FITTING, swivel, male, 2 in. 1

412 121435 FITTING, nipple, hex, 2 in. 1

403

402

404

256512, Desiccant Kit

For removing moisture in replacement air for moisture-sensitive spray materials.

See manual 406739 for parts list.

Feed Pump and Agitator Kits

Part Description

256274 Agitator Kit

256275 T2 2:1 Ratio Transfer Pump Kit

256276

239326

See manual 312769 for installation and parts list.

Monark

President

®

5:1 Ratio Transfer Pump Kit

®

10:1 Ratio Transfer Pump

256260, 7 Gallon Hopper Kit

For mounting one seven gallon hopper to XM proportioner frame. Includes hopper, brackets, fasteners, and

fluid fittings.

See manual 406699 for parts list.

15V074, Hopper Outlet Plug

Plug is required when a 2:1 or 5:1 feed pump is used.

262824, Hopper Shroud

For mounting 20 gallon heated hopper independently.

256257, 240V 1 PH Immersion Heater Kit

For non-explosive atmospheres only. Includes

re-settable overtemperature switch.

1500 watts; 140°F (60°C) maximum temperature.

Ref. Part No. Description Qty.

301 121376 HEATER, hopper, 1 in. npt, 240V 1

302 116171 BUSHING, strain relief 2

303 15T968 CABLE, heater, hopper, 3 cond, 14

gauge

304 122032 NUT, wire 3

28 312747L

1

Page 29

Technical Data

20 Gallon Heated Compatible Hopper 256233

Maximum (continuous) temperature rating . . . . . . . . . . . . 140°F (60°C)

Maximum pressure rating (outer cavity) . . . . . . . . . . . . . . 0 psi (0 MPa, 0 bar)

Inner Tank Capacity (spray material) . . . . . . . . . . . . . . . . 22 gal. (83.3 liter)

Outer Jacketed Area Capacity (heating fluid). . . . . . . . . . 12 gal. (45.4 liter)

Outlet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 npt anodized aluminum

Hopper Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Conductive polyethylene

Weight (dry) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75.5 lb (34.2 kg)

Dimensions

Hopper

Technical Data

30 in.

(762 mm)

40 in.

(1016 mm)

14.5 in.

(368 mm)

18.2 in.

(462 mm)

ti19013a

312747L 29

Page 30

Technical Data

Hopper Stand Hopper on Stand

36 in.

(914 mm)

14.5 in.

(368 mm)

1.5 in.

(38 mm)

75.4 in.

(1915 mm)

26.5 in.

(673 mm)

17.5 in.

(445 mm)

1.5 in.

(38 mm)

42.3 in.

(1074 mm)

ti19011a

30 312747L

Page 31

Technical Data

312747L 31

Page 32

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312747

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised October 2013

Loading...

Loading...