Page 1

SG20 and SGPro Airless Spray Guns

Models: 255108 and 255109

Maximum Working Pressure: 3600 psi (248 bar, 24.8 MPa)

IMPORTANT SAFETY INSTRUCTIONS. Refer to your

sprayer instruction manual for Pressure Relief, priming and

spray instructions. Keep these instructions.

Model 255108

English

The following Warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point

symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer back to these Warnings.

Additional, product-specific warnings may be found throughout the body of this manual where applicable.

- For the application of architectural paints and coatings -

Model 255109

311979E

ti8906ati8905a

EQUIPMENT MISUSE HAZARD

WARNINGS

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured

components will pierce skin. This may look like just a

cut, but it is a serious injury that can result in amputation. Get

immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove,

or rag.

• Do not spray without tip guard and trigger guard

installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when

you stop spraying and before cleaning, checking, or servicing equipment.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes,

in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Keep work area free of debris, including solvent, rags

and gasoline.

• Do not plug or unplug power cords, or turn power or light

switches on or off when flammable fumes are present.

• Ground all equipment in the work area. See Grounding

instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering

into pail.

• If there is static sparking or you feel a shock, stop oper-

ation immediately. Do not use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

ids containing such solvents in pressurized aluminum

equipment. Such use can cause serious chemical reaction

and equipment rupture, and result in death, serious injury,

and property damage.

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your

distributor for information.

• Route hoses and cables away from traffic areas, sharp

edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull

equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or flu-

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment

when operating, servicing, or in the operating area of

the equipment to help protect you from serious

injury. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and

solvent manufacturer

•Gloves

• Hearing protection

ENG

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2007, Graco Inc. is registered to I.S. EN ISO 9001

Instructions/Parts

Page 2

Pressure Relief Procedure

WARNING

Follow this Pressure Relief Procedure

whenever instructed to relieve pressure,

stop spraying, check or service equipment,

or install or clean spray tip.

1. Turn OFF power and turn sprayer pressure control to lowest pressure setting.

2. Hold gun against side of grounded metal flushing pail.

Trigger gun into pail to relieve pressure.

If you suspect spray tip or hose is clogged or that pressure has

not been fully relieved after following the steps above, VERY

SLOWLY loosen tip guard retaining nut or hose end coupling

to relieve pressure gradually, then loosen completely. Clear

hose or tip obstruction.

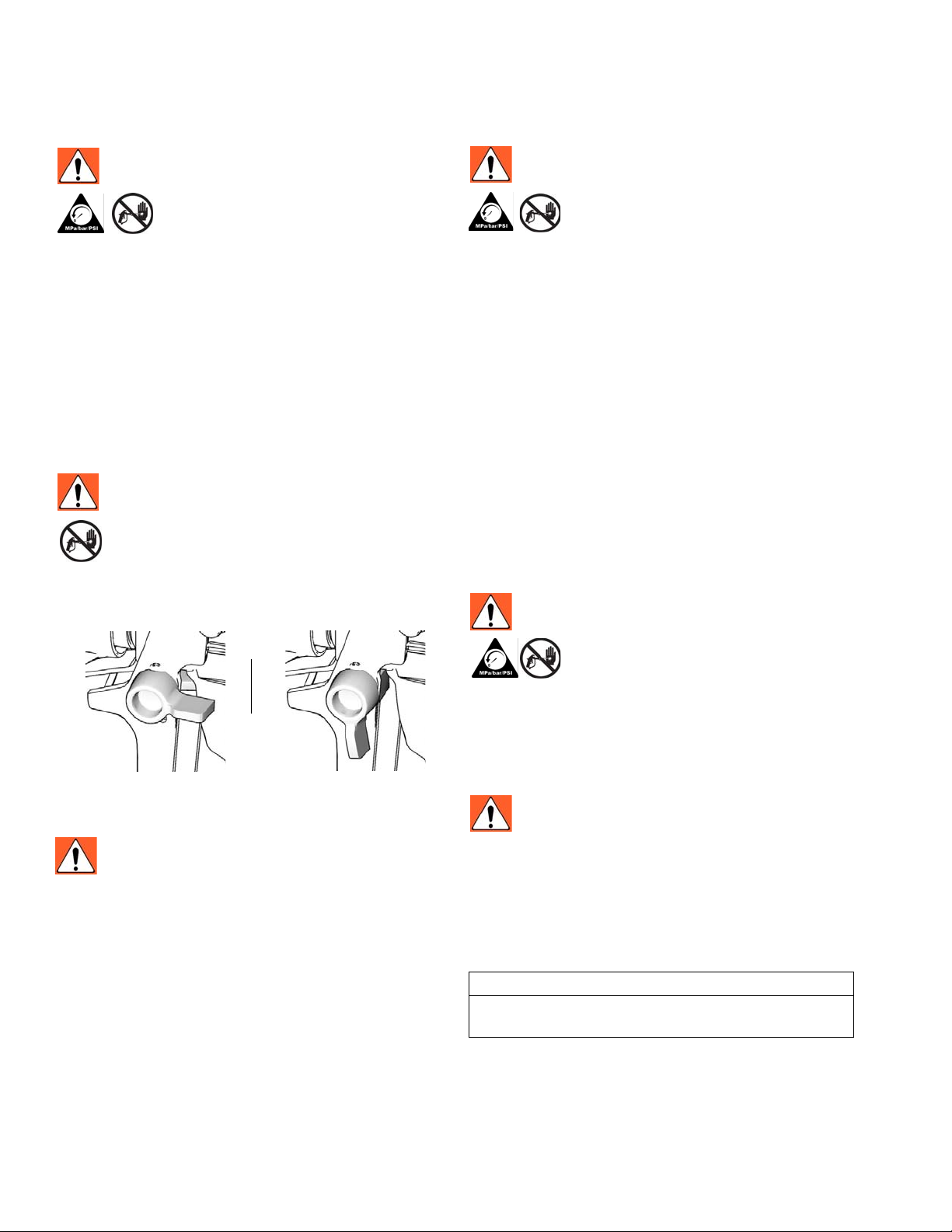

Gun Trigger Lock (3a)

WARNING

To prevent injury when the gun is not in use, always

set the gun’s trigger lock (3a) if unit is being shut

down or left unattended.

Installing Tip (15) and Guard (2) on Gun

WARNING

1.If equipment has recently been operated,

relieve pressure. Set trigger lock (3a).

2. Using a pencil or similar object, insert seat (16) into back

of guard (2).

3. Install guard (2) over end of gun (21). Tighten retaining

nut.

4. Insert tip (15) into slot on guard (2).

Operation

Spraying

1. Unlock trigger lock (3a).

2. Be sure the arrow shaped tip (15) faces forward (spray).

3. Hold gun perpendicular and approximately 12-inches

(304 mm) from surface. Move gun first, then pull gun

trigger (3) to spray a test pattern.

4. Slowly increase pump pressure until coverage is uniform

and even (see sprayer instruction manual for additional

information).

Aligning Spray

Trigger Locked

(no spray)

ti8908a

Tri gg er U nl ock ed

(spray)

ti8909a

Setup

WARNING

Make sure sprayer is turned off and unplugged from power

source. Refer to your sprayer instruction manual for priming

and spray instructions.

Connect Gun to Sprayer

1. Attach supply hose to sprayer fluid outlet.

2. Attach other end of supply hose to gun swivel (5). Use two

wrenches (one on the swivel (5) and one on the hose), to

tighten all connections securely.

3. Refer to sprayer instruction manual for priming

instructions.

WARNING

1.Relieve pressure. Set trigger lock (3a).

2. Loosen guard retaining nut.

3. Align guard (2) horizontally to spray a horizontal pattern.

4. Align guard (2) vertically to spray a vertical pattern.

Clearing Clogs

WARNING

1. Relieve pressure. Set trigger lock (3a).

2. Rotate tip (15) 180°. Unlock trigger lock (3a). Trigger gun

into pail or onto ground to remove clog.

3. Set trigger lock (3a). Rotate tip (15) 180° back to spray

position.

Cleanup

CAUTION

Never soak gun in solvents. Do not leave the gun or

any parts in water.

Flush gun after each work shift and store in a dry location.

Clean handle grip with water or with a rag wetted in mineral

spirits or paint thinner. Do not soak.

2 311979E

Page 3

Parts

15

21

33

13

11

12

1

15a

2

4

3a

8

6

3

9

10

32

7

23

24

22

5

Ref

No. Part. No. Description Qty

1 SEAT, valve 1

2✓ 237859 GUARD, RAC IV 1

3 243639 TRIGGER, kit, 4 finger, assy, includes

32 and 33 (model 255108)

288816 TRIGGER, kit, 2 finger, assy, includes

32 and 33 (model 255109)

3a LOCK, trigger, included with 3 1

4 195495 GUARD, trigger 1

5 238817 SWIVEL, gun 1

6✓ 288749 FILTER, gun; latex, 50 mesh 1

288750 FILTER, gun, latex, 100 mesh 1

7✓ 179733 SEAL, sleeve 1

8 195395 CAP, end 1

9 115483 NUT, lock 1

10 115484 PIN, actuator 2

11 195419 HOUSING, needle 1

12 156766 GASKET 1

13 NEEEDLE, gun 1

15✓ 221515 TIP, spray, RAC IV 1

15a 243004 RAC IV, gasket and seal kit, (includes 2

rubber gaskets and 2 metal seals)

1

1

1

ti8904a

Ref

No. Part. No. Description Qty

21 195389 HOUSING, fluid (sand blasted) 1

195390 HOUSING, fluid (tumbled) 1

22 113409 RETAINER, guard 1

23 15J775 HANDLE, grip (model 255108) 1

15J776 HANDLE, grip (model 255109) 1

24 115485 PACKING, o-ring 1

32 177538 STUD, trigger 1

33 105334 NUT, lock, hex 1

34 288817 KIT, repair, gun, includes 1, 9, 12, 13 1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

✓ Keep these spare parts on hand to reduce downtime.

311979E 3

Page 4

Maintenance

WARNING

Before performing any maintenance on gun, read all warnings

on front cover of this manual and relieve pressure.

Cleaning/Replacing Filter (6)

1. Relieve pressure. Set trigger lock (3a).

2. Disconnect fluid hose from gun at swivel (5).

3. Disconnect trigger guard (4) from guard retainer (22).

4. Unscrew handle (23) from gun (21).

5. Remove filter (6) through top of handle (23).

6. Clean filter (6). Use a soft brush to loosen and remove

excess debris.

Replacing Needle

8

7. Insert clean filter (6) into handle (7).

8. Reattach handle (7) to gun (21). Tighten securely.

9. (Model 255109 only) If finger guard is not aligned, apply

torque manually, rotating the grip until it is aligned with the

trigger.

10. Reconnect trigger guard (4) to guard retainer (22).

12. Squeeze trigger (3) while installing gasket (12) and

diffuser seat (1). Torque.

13. Hold gun with nozzle facing up.

14. Turn locknut (9) clockwise until you see and feel trigger (3)

raise slightly.

15. Turn locknut (9) 3/4 turn counter-clockwise.

ti9211a

1. Relieve pressure. Set trigger lock (3a).

2. Remove tip (15) and guard (2) from gun (21).

3. Disconnect fluid hose from gun at swivel (5).

4. Release trigger lock (3a). Squeeze trigger (3) while

unscrewing seat diffuser (1) from front of gun.

5. Remove locknut (9) and end cap (8).

6. Tap needle assembly (13) out, with the needle exiting

through front of gun.

7. Use a soft brush to clean out internal passages of gun.

8. Grease outside of needle seal and in front of locknut

thread with non-silicon grease.

9. Guide new needle (13) through front of gun (21).

10. Loosely install end cap (8) and locknut (9).

11. Grease threads of diffuser/seat (1). Place gasket (12) on

diffuser/seat (1).

NOTE: When needle is properly adjusted, trigger will move

freely.

16. Connect fluid hose. Install tip (15) and guard (2).

17. Prime sprayer. See sprayer instruction manual.

18. Trigger gun into bucket until fluid flows from gun.

19. Release trigger (3). Fluid flow should stop immediately.

20. Set trigger lock (3a).

21. Aim gun into bucket. Trigger gun. No fluid show flow.

22. If the gun fails tests, steps 19 and/or 21, relieve pressure

and disconnect hose. Readjust needle. Repeat tests.

For complete warranty information contact your local Graco distributor, call Graco customer

All written and visual data contained in this document reflects the latest product information available at the time of publication.

service: 1-800-690-2894 or visit our website: www.graco.com.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 311979

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

01/2007, Revised 09/2008

Loading...

Loading...