Page 1

Model 254975 Shown

ti8867a

Repair

Interior Texture Sprayers

RTX 900 & RTX 1250

-For Water-Based Materials Only-

Models: 254974 and 254975

70 psi (0.49 MPa, 4.9 bar)

Maximum Fluid Working Pressure

311772P

EN

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Related Manuals

311777

311768

Page 2

Warnings

Warnings

The following are general warnings related to the setup, use, grounding, maintenance and repair of this equipment.

Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols

appearing in the body of the manual refer to these general warnings. When these symbols appear through the

manual, refer back to these pages for a description of the specific hazard.

WARNINGS

Fire and Explosion Hazard

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result

in fire or explosion and serious injury.

• The system is for use with water-based materials only. Only use fluids compatible with the

equipment. Refer to Technical Data of all equipment manuals. Read fluid and solvent manufacturers

warnings.

• Ground all equipment in the work area. See Grounding and Electrical Requirements, page 6.

• If there is any static sparking or you feel an electric shock while using this equipment, stop spraying

immediately. Do not use the equipment until you identify and correct the problem.

• Keep work area free of debris, including solvent, rags and gasoline.

• Comply with all applicable state and national fire, electrical and safety regulations.

• Keep a fire extinguisher in the work area.

Equipment Misuse Hazard

Equipment misuse can cause equipment to rupture, malfunction, or start unexpectedly and cause serious

injury.

• Before operating this equipment, read all manuals, tags, and labels, including material labels and

instructions.

• Do not expose system to rain. Always store system indoors.

• Do not alter or modify equipment.

• Do not spray cementitious materials.

• Do not exceed maximum working pressure of lowest rated component in your system.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• To reduce risk of serious injury, including electric shock and splashing fluid in eyes, follow Pressure

Relief Procedure on page 6 before servicing the unit.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Route hoses away from traffic areas, sharp edges, moving parts and hot surfaces. Do not expose

Graco hoses to temperatures above 130° F (55° C) or below -35° F (-37° C).

• Air hoses at the compressor end, can get very hot! Allow sprayer to cool down 15 minutes before

removing air hose.

• Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

• Never directly inhale compressed air. Compressed air may contain toxic vapors.

2 311772M

Page 3

Warnings

WARNINGS

Electric Shock Hazard

To reduce the risk of electric shock:

• Be sure sprayer is adequately grounded through electrical outlet, page 6.

• Use only 3-wire, extension cords.

• Make sure ground prongs are intact on sprayer and extension cords.

• Do not operate with cover removed.

• Turn off sprayer. Follow Pressure Relief Procedure, page 6, and unplug unit, before removing any

parts.

Pressurized Equipment Hazard

Fluid from gun, leaks or ruptured components can splash in the eyes or on skin and cause serious injury.

• Follow Pressure Relief Procedure, page 6 when you stop spraying and before cleaning, checking

or servicing.

• Do not point spray gun at anyone; put hand, fingers or rag over nozzle, or stop or deflect leaks with

your hand, body, glove, or rag.

• Wear protective clothing, gloves, and eyewear.

Cleaning Solvent Hazard with Plastic Parts

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many

solvents can degrade plastic parts to the point where they could fail. Such failure could cause serious

injury or property damage. See Technical Data on page 33 of this instruction manual and in all other

equipment manuals. Read fluid and solvent manufacturer’s warnings.

Burn Hazard

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns,

do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

Personal Protective Equipment

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Gloves

• Hearing Protection

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

311772M 3

Page 4

Warnings

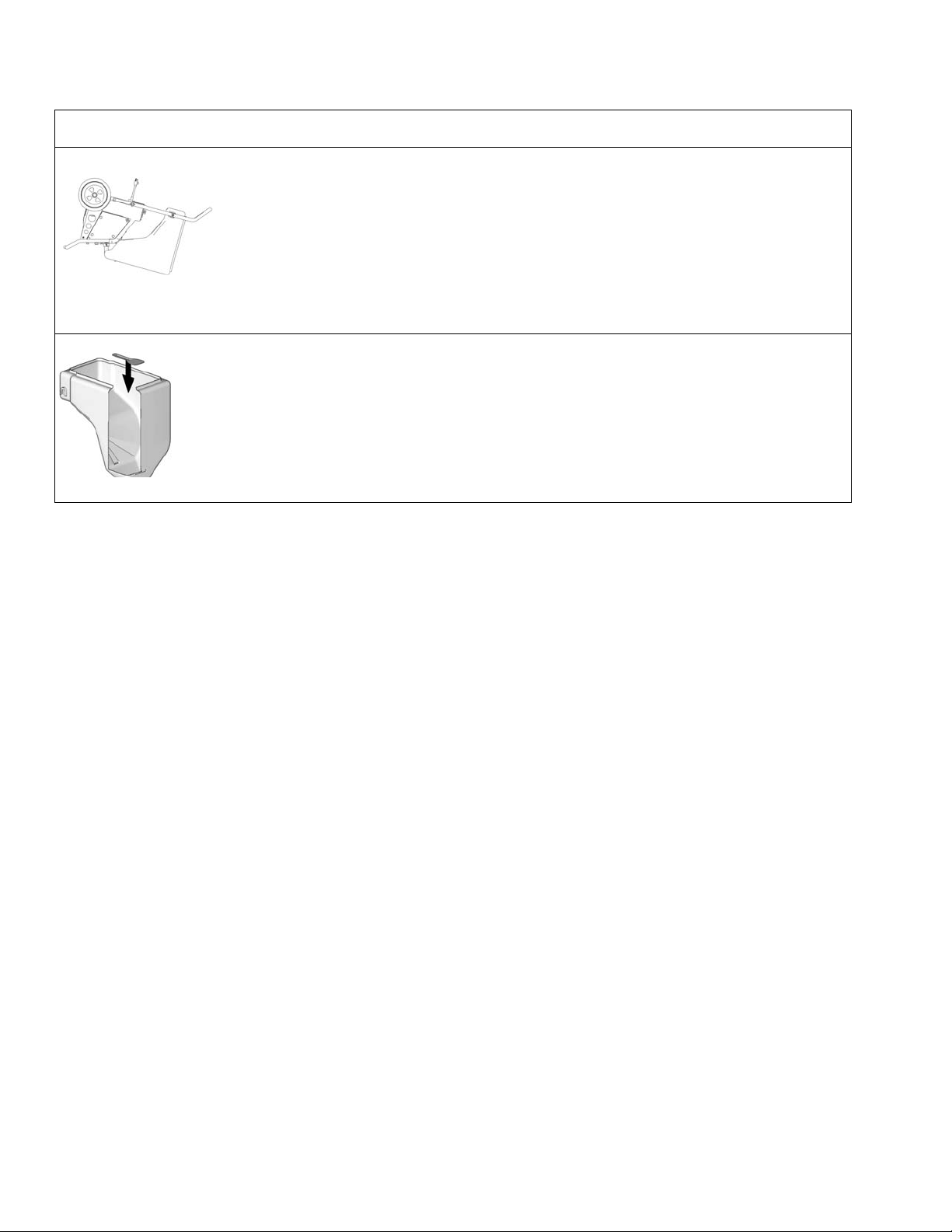

ti9016a

ti9010a

CAUTION

Water or material remaining in unit when temperatures are below freezing can damage

motor and/or delay pump startup.

To insure water and material are completely drained out of unit:

1. Remove material line from sprayer.

2. Tip sprayer up as shown.

Before adding material or starting unit in cold weather, run warm water through pump.

Before adding material to hopper, install burp guard. When only a small amount of material

remains in the hopper, the burp guard prevents material from shooting out when the unit is

turned off. This material could splash in the operator’s eyes or on skin, or into the air.

4 311772M

Page 5

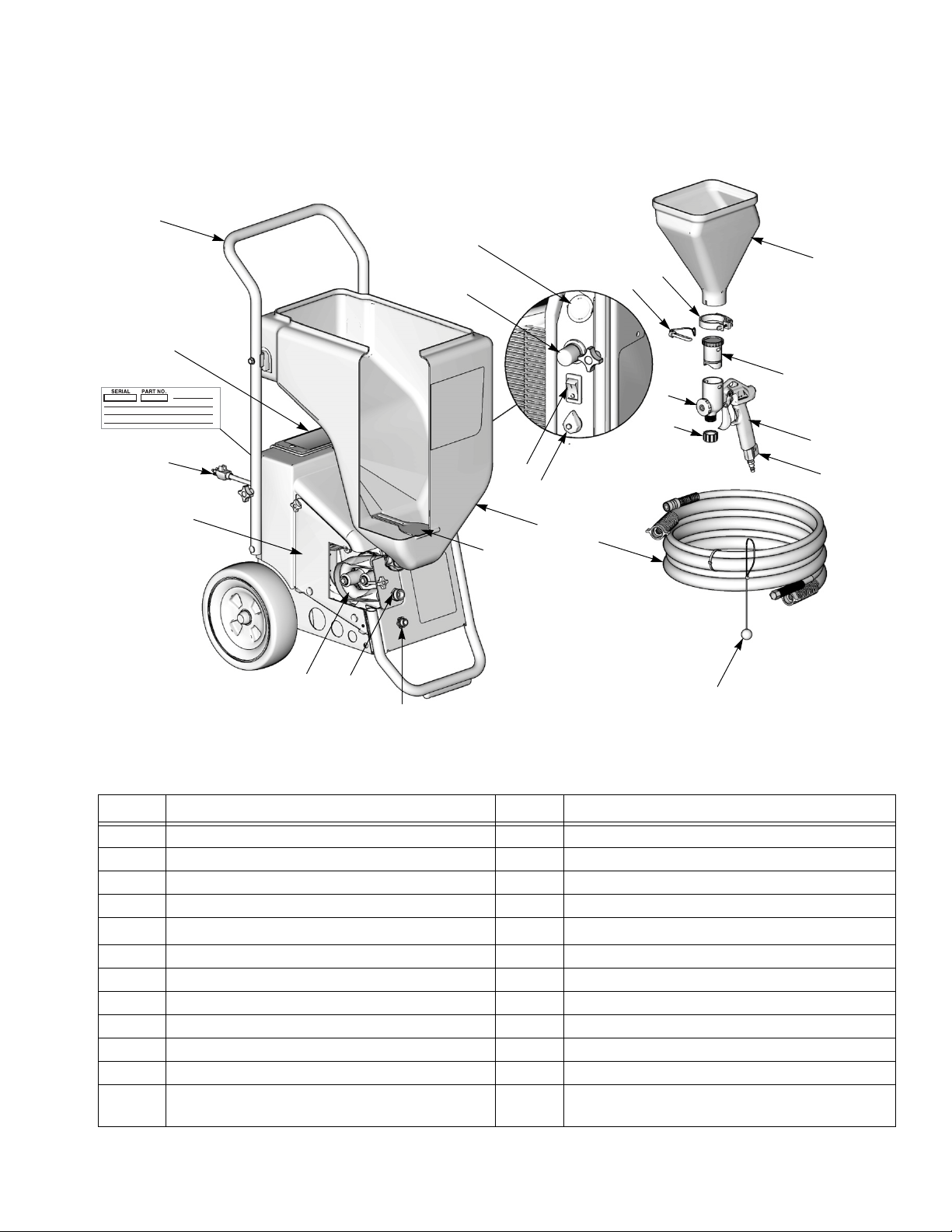

Component Identification

M

D

F

A

G

C

L

Model 254975 Shown

E

K

U

T

V

B

S

W

R

P

bb

N

H

J

ti8939a

cc

dd

Component Identification

Item Component Item Component

A Handle N Burp Guard

B Toolbox P Material/Air Hose

C Power Cord (120V, 25 ft) Q Accessories Bag

D Side Pump Access Panel (RTX 1250 Only) R Material Thickness Gauge

E

F Pump Hose Outlet T Hose Plug

G Air Hose Outlet U Touch-Up Hopper (3/4 gallon) (sold separately)

H Material Flow Gauge V Gun Plug

J Material Flow Control W Air Control

K ON/OFF Switch bb Hopper Clamp (sold separately)

L Selector Switch (Hopper Gun/Sprayer) cc Gun Plug Clip

M Material Hopper - 10 gallon, RTX 900

RotoFlex

Material Hopper - 12 gallon, RTX 1250

™

II Pump (inside)

SNozzle (4 Total)

dd Hopper Gun

311772M 5

Page 6

Component Identification

ti9221a

ti9084a

ti8528a

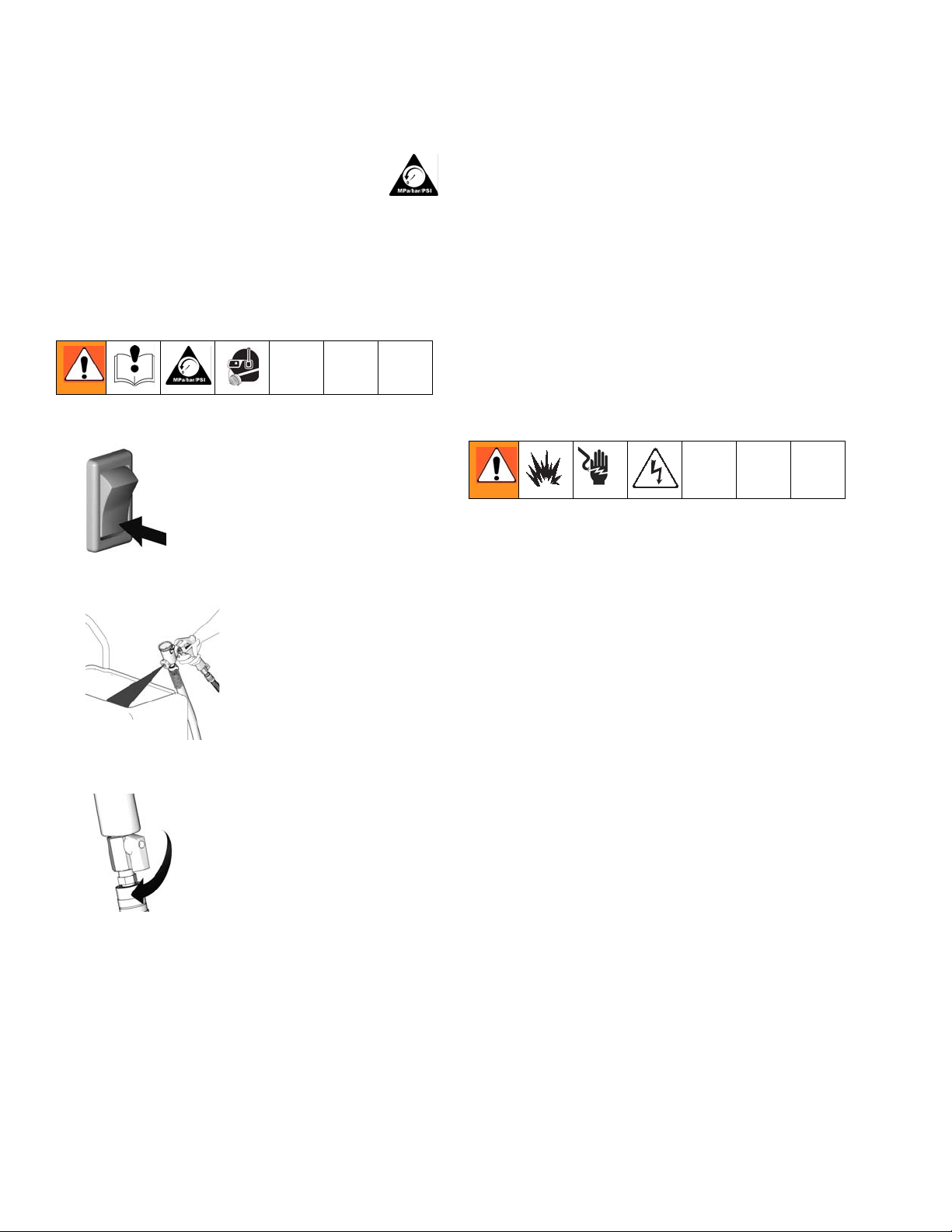

Pressure Relief Procedure

To reduce risk of injury, follow this procedure

whenever you see this symbol throughout this

manual, Also, perform this procedure

whenever you:

• Stop spraying

• Check or repair any part of this system

• Install or clean spray nozzle

1. Turn Power Switch OFF.

2. Trigger gun into material hopper.

Grounding and Electrical

Requirements

This sprayer must be grounded. Grounding reduces the

risk of electrical shock by providing an escape wire for

the electrical current. The sprayer cord includes a

grounding wire with an appropriate grounding plug. The

plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Check with a qualified electrician or if grounding

instructions are not completely understood, or if in doubt

as to whether the product is properly grounded. Do not

modify plug provided; if it will not fit the outlet, have

proper outlet installed by a qualified electrician.

120V AC Systems

• This equipment requires a 120V AC, 60 Hz, 15A

circuit with a grounding receptacle. Do not use an

adapter with this product.

3. Open gun air valve.

Extension Cords

• Use only an extension cord with an undamaged,

3-prong plug.

• For 25 to 50 ft (7.6 to 15.2 m) cords, use 3-wire, 14

AWG (1.5 mm

• For up to 100 ft. (30.48 m) cord, use 3-wire, 12

AWG (2.5 mm

2

) minimum.

2

) minimum.

Auxiliary Air Compressor

Do not use an auxiliary air compressor with this spray

system.

Generator Requirements

3500 W (3.5 KW) minimum.

Hose Size and Length

The system comes with a hose set consisting of a 3/4 in.

ID x 25 ft (25 mm x 7.6 m) material hose and a 3/8 in-ID

air hose. Do not use more than 25 ft (7.6m) of material

and air hose.

6 311772M

Page 7

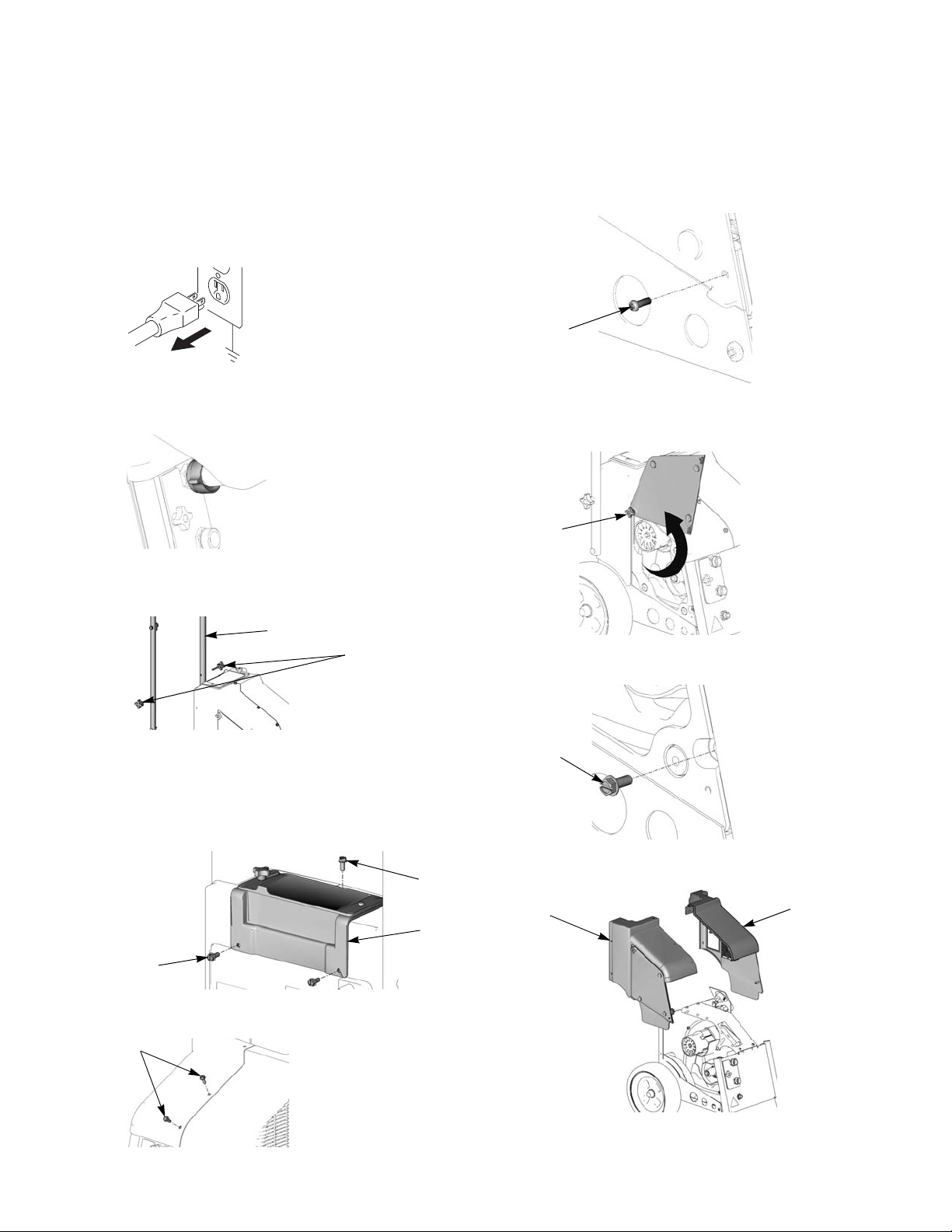

Shroud Removal

ti2810b

ti8871a

ti8875a

14

12

ti8884a

31

2

30

ti8882a

31

70

ti8874a

ti8872a

42

ti9283a

30

ti8883a

5

7

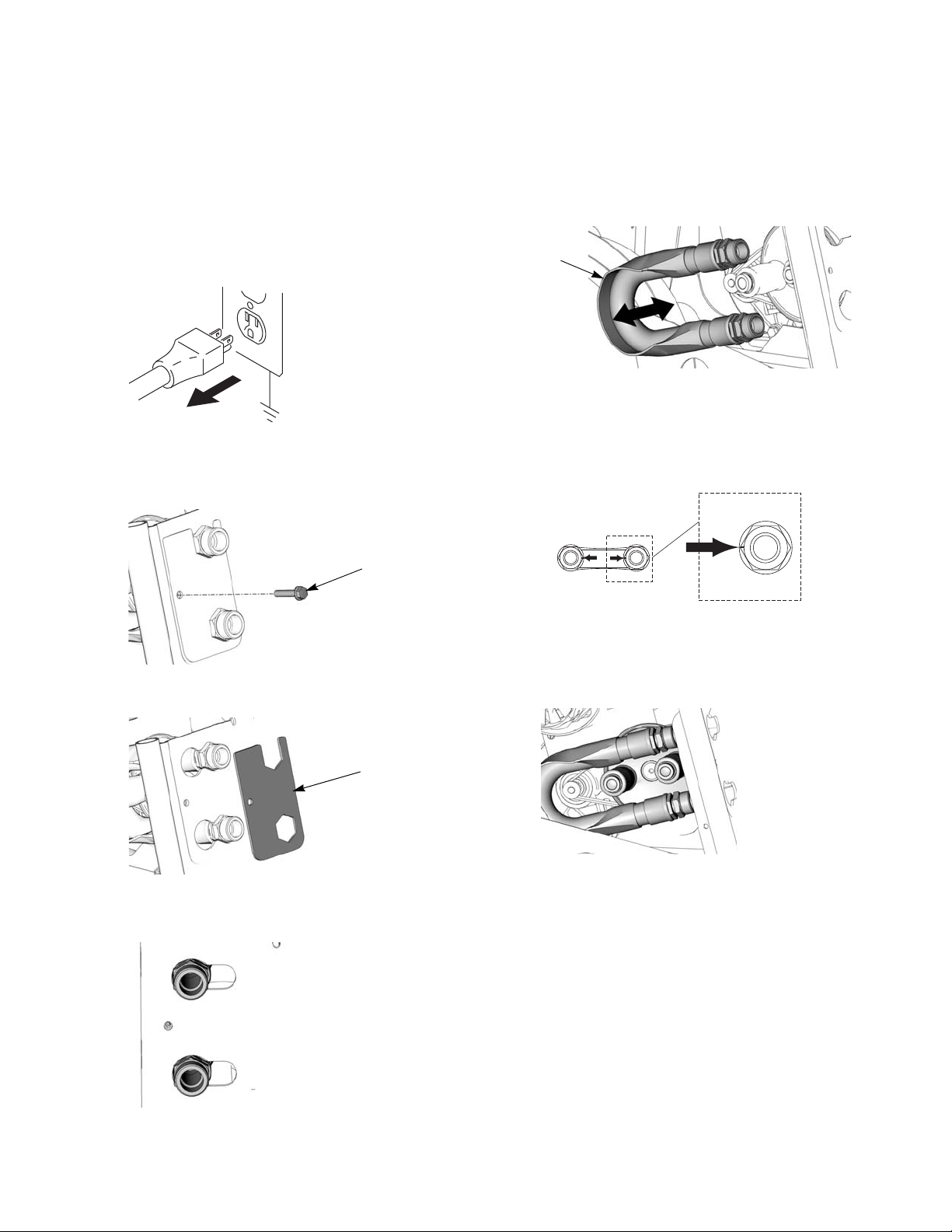

Shroud Removal

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Loosen bottom hopper fitting by hand and pull

hopper up and off from handle.

4. Loosen and remove 2 knobs (14) on sprayer handle

(12).

8. Loosen and remove screw (70) from lower right corner of side access panel (RTX1250) only.

9. Loosen knob (42) on side access panel and swing

open door.

10. Use screwdriver to remove second screw (30).

5. Spread handle bars apart and pull up to remove

from sprayer.

6. Loosen screws (30) and screw (31) from toolbox

and remove toolbox (2) from sprayer.

11. Remove two shroud halves (5 and 7) from sprayer.

7. Loosen screws (31) on shroud.

311772M 7

Page 8

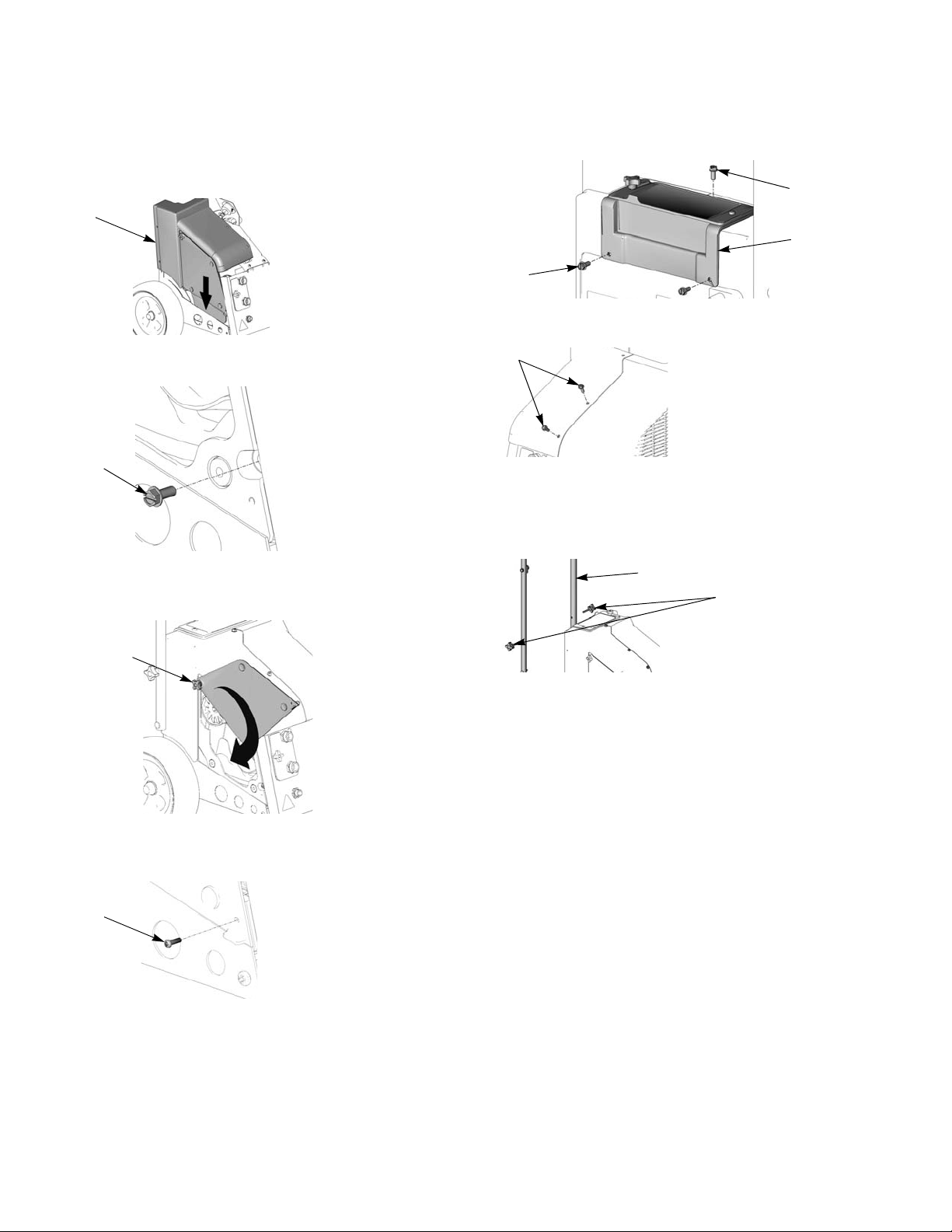

Shroud Removal

ti9015a

5

ti9283a

30

42

ti8938a

ti8874a

70

ti8884a

31

2

30

ti8882a

31

ti8875a

14

12

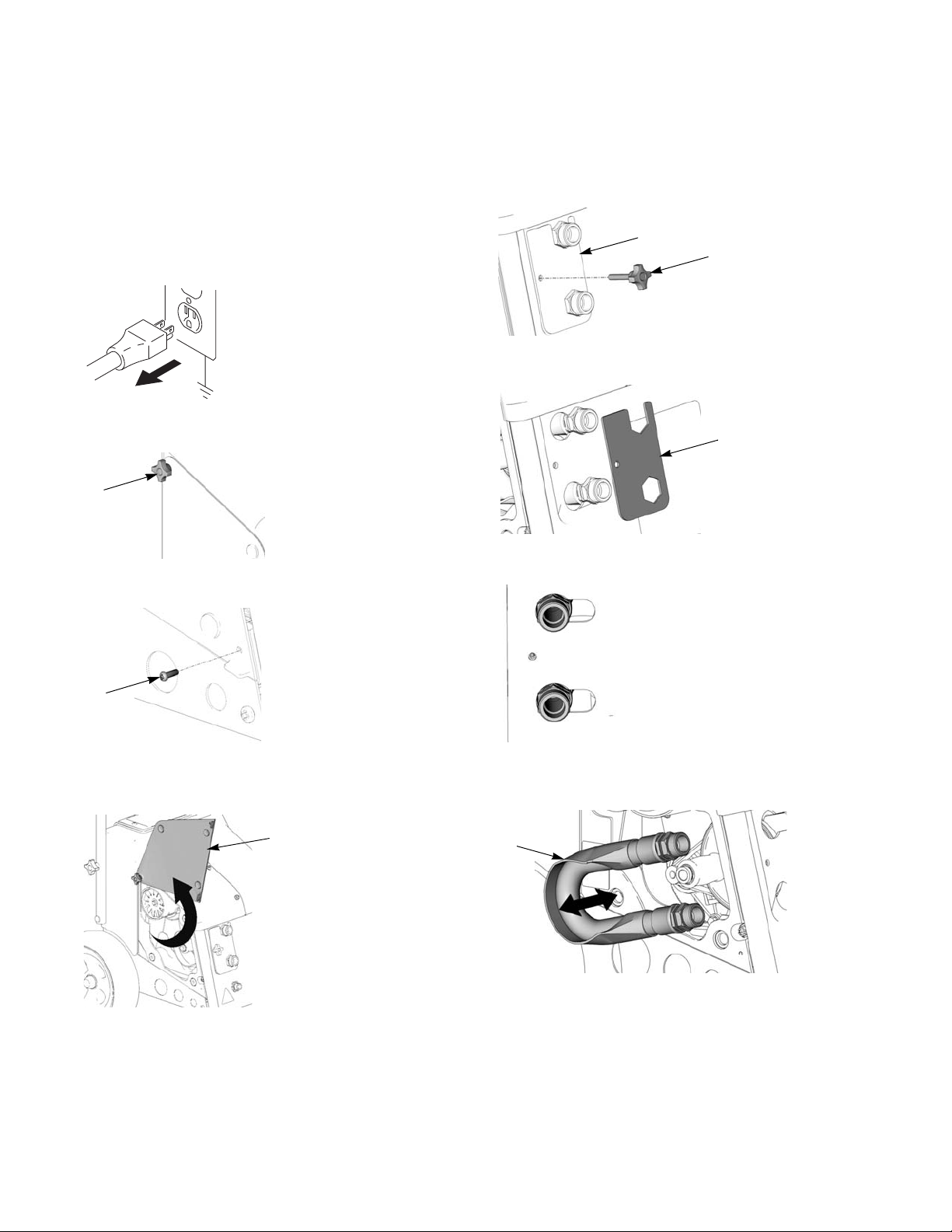

Reassembly

1. Angle left shroud half (5) into base and push down

into place. Then replace right shroud half (7).

2. Replace and tighten second screw (30).

5. Replace toolbox (2) and tighten screws (30) and

screw (31).

6. Tighten screws (31) on shroud.

7. Spread handle bars apart and slide handle down

into place.

8. Tighten 2 knobs (14) on sprayer handle (12).

3. Swing access door down (RTX 1250) and tighten

knob (42).

4. Tighten screw (70) into lower right corner of side

access plate.

9. Replace hopper and tighten hopper fitting by hand

until snug.

8 311772M

Page 9

RotoFlex™ II Pump (RTX 900)

ti2810b

28

ti9009a

ti8881a

25

ti8869a

16

ti8949a

ti9331a

ti8868a

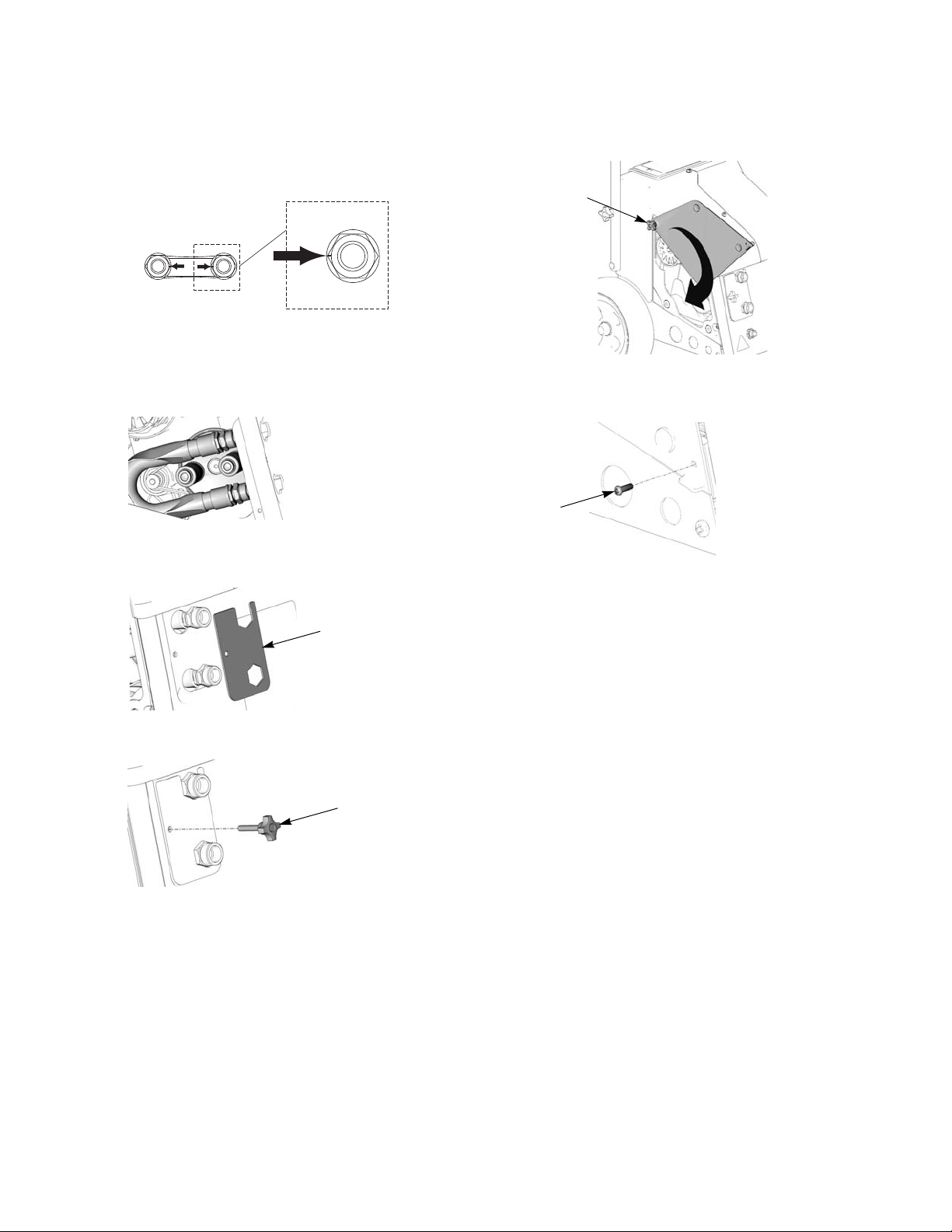

RotoFlex™ II Pump (RTX 900)

Disassemble

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

4. Loosen and remove screw (28) on hose bracket.

5. Remove hose bracket (25).

7. Grab pump hose (16) from side of unit and remove

pump hose by hand.

Reassemble

1. Bend hose (16) so colored dots on hose fittings face

each other.

2. Slide new pump hose (16) over rollers. Move pump

rollers by hand until or flip power switch to rotate

rollers until they are positioned correctly with pump

hose.

3. Feed pump fittings through front access panel

6. Slide pump fittings over and push through keyhole

keyhole slots and slide into place.

slots.

4. Replace hose bracket (25) to lock pump hose fittings into place.

5. Replace hose bracket (25) and tighten screw (28).

6. Replace Shroud, page 7.

7. Break in new pump by adding 1 cup of water to

pump and running dry for 3 minutes.

311772M 9

Page 10

RotoFlex™ II Pump (RTX 1250)

ti2810b

ti8870a

42

70

ti8874a

ti8872a

13

42

ti8945a

25

ti9288a

25

ti8869a

16

ti9333a

RotoFlex™ II Pump (RTX 1250)

Disassemble

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Loosen knob (42) on side access panel.

4. Remove screw (70) from side access panel.

6. Loosen and remove knob (42) on hose bracket (25).

7. Remove hose bracket (25).

8. Slide pump fittings over and through keyhole slots.

5. Pull access panel (13) out to release 3 fastening

tabs and flip up to expose side access to pump.

9. Grab pump hose (16) from side access panel and

remove pump hose from unit.

10 311772M

Page 11

RotoFlex™ II Pump (RTX 1250)

ti9331a

ti8868a

ti9288a

25

42

ti8945a

42

ti8938a

70

ti8874a

Reassemble

1. Bend hose (16) so colored dots on hose fittings face

each other.

2. Slide new pump hose (16) in from side access

panel. Move pump rollers by hand until or flip power

switch to rotate rollers until they are positioned correctly with pump hose.

3. Replace hose bracket (25) to lock pump hose into

place.

5. Flip side access panel (13) down and tighten knob

(42).

6. Replace and tighten screw (70) from side access

panel.

7. Break in new pump by adding 1 cup of water to

pump and running dry for 3 minutes.

4. Tighten hose bracket knob (42).

311772M 11

Page 12

Compressor

ti2810b

49

ti8941a

ti8878a

26

27

49

ti9013a

ti8877a

29

21

ti8879a

49

ti8952a

ti8951a

Compressor

Use Compressor Repair Kit, 288612.

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

4. Remove RotoFlex

5. Unscrew and remove grounding screw (49) from

compressor.

™

II Pump hose; page 9 or 10.

8. Remove 4 screws (29) and lift bracket (21) off of

compressor.

9. Remove shoulder bolt (49) holding pump roller in

place.

10. Use a wrench to push down on push-to-connect

fittings and pull out all nylon hoses.

6. Use 9/16 in. socket and wrench to remove pivot bolt

(26) and nut (27).

11. Disconnect all electrical wire connectors, see

Wiring Diagram, page 27.

12. Thoroughly clean inside housing, removing dust and

debris.

To service the compressor, remove it from the sprayer

body and place it a vice. Tighten the vice onto the main

7. Unscrew and remove second 1/2 in. grounding

pulley to hold the compressor in place while servicing.

screw (49) from bracket (21).

12 311772M

Page 13

Compressor

ti8940a

ti8950a

49

ti8941a

ti8873a

ti8879a

49

ti8877a

29

21

ti8878a

26

27

80

49

ti9013a

21

Reassembly

1. Carefully position compressor back into sprayer

body. Make sure piston head facing front of sprayer.

2. Replace and tighten grounding screw (49).

6. Replace bracket (21) and tighten 4 screws (29).

7. Replace grounding screw (49) and tighten onto

bracket (21).

8. Replace pivot bolt (26), washers (80) and nut (27).

Use 9/16 in. socket and wrench to tighten into place.

Tighten bolt (26) until spring washers (80) are flattened. Back off nut (27) 1/4 turn. Compressor must

rotate freely with bolt (26) and bracket (21).

3. Reattach air lines to compressor.

4. Reattach 2 wires to compressor see Wiring

Diagram, page 27.

5. Replace air cylinder and tighten shoulder bolt (49) to

lock into place.

9. Replace and tighten second grounding screw (49)

to bracket (21).

10. Replace RotoFlex

™

II Pump hose; page 9 or 10.

11. Replace Shroud, page 7.

311772M 13

Page 14

Piston/Cylinder

ti2810b

100

74

75

76

110

ti8887a

ti8893a

87

77

Piston/Cylinder

Use Piston/Cylinder Repair Kit 288609.

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

4. Remove RotoFlex

5. Remove Compressor, page 12.

6. Remove muffler (110) from head (74) by pulling

straight out by hand.

7. Use 1/2 in. socket to remove three bolts (100) from

head (74).

™

II Pump hose; page 9 or 10.

8. Use flat-blade screwdriver to pry head (74) from top

of valve plate (75) and cylinder (76) from bottom of

valve plate (75).

9. Use 7/32 in. allen wrench to remove hex screw (87)

from piston rod (77).

14 311772M

Page 15

Piston/Cylinder

ti8943a

ti8893a

87

77

100

74

75

76

110

ti8887a

Reassembly

CAUTION

Piston and cylinder come packaged

together. Do NOT let piston and cylinder

come apart. If they do, make sure you

drop the piston down through the top of

the cylinder and tilt the piston as you

pull it through the cylinder. Do NOT

push the piston up from the bottom. You

could easily damage the piston gasket.

1. Replace piston (77) and cylinder (76) and use 7/32

in. allen wrench to tighten hex screw (87) into piston

rod.

3. Replace three bolts (100) and use 1/2 in. socket to

tighten into head (74). Torque all three bolts to 75

in-lb, then torque all bolts again to 210 in-lb.

4. Position muffler (110) as seen below and press onto

head (74) until it snaps into place.

5. Replace Compressor, page 12.

6. Replace RotoFlex

™

II Pump hose; page 9 or 10.

7. Replace Shroud, page 7.

2. Replace valve plate (75) with ribs facing up toward

head.

311772M 15

Page 16

Valve Plate

ti2810b

100

74

75

76

110

ti8887a

Valve Plate

Use Valve Plate Repair Kit 288610.

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

4. Remove RotoFlex

5. Remove Compressor, page 12.

6. Remove muffler (110) from head (74) by pulling

straight out by hand.

7. Use 1/2 in. socket to loosen and remove three bolts

(100) from head (74).

™

II Pump hose; page 9 or 10.

8. Use flat-blade screwdriver to pry head (74) from top

of valve plate (75) and cylinder (76) from bottom of

valve plate (75).

Reassembly

1. Replace valve plate (75) with ribs facing up toward

ribs on head (74).

2. Replace three bolts (100) and use 1/2 in. socket to

tighten into head (74). Torque all three bolts to 75

in-lb, then torque all bolts again to 210 in-lb.

3. Replace Compressor, page 12.

4. Replace RotoFlex

5. Replace Shroud, page 7.

™

II Pump hose; page 9 or 10.

16 311772M

Page 17

Motor

ti2810b

ti8951a

ti8892a

72

ti8891a

105

71

ti9012a

71

ti8893a

87

77

84

ti8894a

Motor

Use Motor Repair Kit 288613.

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

4. Remove RotoFlex

5. Remove Compressor, page 12.

6. Remove compressor from sprayer body and place it

in a vice. Tighten the vice onto the main pulley to

hold the compressor in place while servicing motor.

™

II Pump hose; page 9 or 10.

8. Use a box end wrench to loosen and remove two

mounting bolts (105) on motor (71).

CAUTION

Be careful not to bend or damage the cooling tube

when removing it from the motor.

9. Angle motor (71) and slide motor pulley through

compressor belt to remove motor from compressor.

7. Loosen set screw and remove fan (72).

Compressor belt (84) should be replaced every

time motor is replaced.

10. Use 7/32 in. allen wrench to remove hex screw (87)

from piston rod (77).

11. Remove compressor belt (84).

311772M 17

Page 18

Motor

SQ

ti8890a

71

84

ti8891a

105

71

ti8896a

104

ti8892a

72

Reassembly

1. Angle motor pulley through compressor belt (84)

and pull motor (71) into position.

When replacing motor (71), make sure the

square-shaped hole (SQ) is facing toward the outside of the compressor. This hole will be used to

torque the mounting bolts.

2. Tighten two mounting bolts (105) on motor (71) until

snug, then back 1/8 of a turn.

5. Place compressor back into vice and torque bolts as

described in steps 2 and 3.

6. Replace fan (72) and tighten set screw.

7. Replace Compressor; page 12.

8. Replace RotoFlex

™

II Pump hose; page 9 or 10.

9. Replace Shroud, page 7.

3. Insert torque wrench into square hole (SQ) on motor

and tighten bolts to 130-150 in-lb (this may require

two people; one to torque while the other tightens

mounting bolts). Tighten motor bolts (105).

4. Take compressor out of vice and rotate pump pulley

(104) one full revolution to seat the belt properly.

18 311772M

Page 19

Cooling Tube

ti2810b

ti8886a

101

102

79

ti8952a

ti8944a

Cooling Tube

Use Cooler Repair Kit 288614.

The cooling tube is extremely hot and can cause

serious burns. Allow unit to completely cool before

servicing the cooling tube.

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

6. Use 3/8 in. socket to remove screw (101) and

washer (102) under cooling tube (79).

7. Use wrench to push against fitting (86) and carefully

pull cooling tube (79) out.

8. Use 5/8 in. wrench to unscrew cooling tube fitting.

4. Remove RotoFlex

5. Remove Compressor, page 12.

™

II Pump hose; page 9 or 10.

311772M 19

Page 20

Cooling Tube

ti8942a

ti8895a

79

86

ti9014a

ti8886a

101

102

79

Reassembly

1. Insert new cooling tube fitting and use 5/8 in.

wrench to tighten.

2. Insert cooling tube (79) and push into new fitting

(86). Make sure tube is fully seated.

3. Rotate cooling tube around and insert free end into

push-to-connect fitting. Make sure tube is fully

inserted.

4. Replace screw (101) and washer (102) under cooling tube (79) and use 3/8 in. socket to tighten.

CAUTION

When replacing cooling tube, make sure coil is facing

up when you push the tubing into the fitting. If you

push from any other angle you could bend or damage

the tube.

5. Replace Compressor; page 12.

6. Replace RotoFlex

™

II Pump hose; page 9 or 10.

7. Replace Shroud, page 7.

20 311772M

Page 21

Idler

ti2810b

ti8892a

79

ti8889a

39

106

Idler

Use Idler Repair Kit 288611.

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

4. Remove RotoFlex

5. Remove Compressor, page 12.

6. Remove compressor belt, page 17.

7. Loosen set screw and remove fan (79).

™

II Pump hose; page 9 or 10.

Reassembly

1. Install new compressor belt, page 17.

2. Replace new Idler (106) and tighten screw (39).

3. Replace fan (79) and tighten set screw.

4. Replace Compressor, page 12.

5. Replace RotoFlex

6. Replace Shroud, page 7.

™

II Pump hose; page 9 or 10.

8. Loosen screw (39) and remove Idler (106).

Every time you replace the Idler you should also

replace the compressor belt, page 17.

311772M 21

Page 22

Roller Pulley/Belt

ti2810b

87

73

ti8947a

83

ti8946a

Roller Pulley/Belt

Use Roller Pulley Repair Kit 288616.

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

3. Remove Shroud, page 7.

4. Remove RotoFlex

5. Remove Compressor, page 12.

6. Use 7/32 in. allen wrench to loosen roller mounting

bolt (87) and remove roller pulley (73).

™

II Pump hose; page 9 or 10.

Reassembly

1. Install new compressor belt (83).

2. Loop belt over roller pulley and align roller with bolt

hole.

3. Use 7/32 in. allen wrench to tighten bolt (87) to 20 ±

2 ft-lb.

4. Replace Compressor, page 12.

5. Replace RotoFlex

6. Replace Shroud, page 7.

™

II Pump hose; page 9 or 10.

7. Remove belt (83) and discard.

Every time you replace the roller pulley, you should

also replace the belt.

22 311772M

Page 23

Selector Switch Knob

ti9219a

ti9278a

ti9277a

ti9280a

ti9281a

Selector Switch Knob

Use Knob Repair Kit 288756.

Disassembly

1. Turn selector switch knob clockwise as far as it will

go.

2. Use wrench to remove nut from knob.

Assembly

1. Position new knob to point right (approximately 45°

from vertical) and slide it onto exposed spline.

2. Apply Locktite (1 drop or small amount) to knob nut

and tighten with wrench.

3. Pull knob straight off from sprayer.

Once knob has been removed, don’t move the

exposed spline. If it is moved, use your fingers to

turn it clockwise as far as it will go for a tight fit prior

to reassembly of knob. This will properly align knob

to spline.

311772M 23

Page 24

Regulator Valve

ti8952a

ti9279a

ti9282a

ti9275a

ti9279a

Regulator Valve

Use Regulator Repair Kit 288757.

Disassembly

1. Remove Knob, page 23.

2. Remove Shroud, page 7.

3. Use wrench to push against fitting (86) and carefully

pull cooling tube (79) out.

4. Use phillips screwdriver to remove two screws.

Assembly

1. Replace new regulator valve and feed through 3

holes on side of sprayer.

2. Reattach two air lines.

5. Remove old regulator valve.

3. Replace two screws and tighten with phillips screwdriver.

4. Replace Knob, page 23.

5. Replace Shroud, page 7.

24 311772M

Page 25

Troubleshooting

Troubleshooting

Problem Cause Solution

Sprayer won’t run Power switch not on Turn switch on.

No power at wall outlet Check outlet by plugging in another

appliance. If appliance does not

work, try another outlet.

Wrong size generator Use a 3500 watt or larger generator.

Refer to Generator Requirements,

page 6.

Breaker tripped Reset breaker.

Pump won’t pump material Air lock Open air valve on gun.

Selector switch in wrong position Move selector switch to correct posi-

tion for application.

Mix too thick Add water to thin material. Use Mate-

rial Thickness Gauge.

Loose fittings Check and retighten all fittings.

Plugged gun Relieve Pressure, page 6. Remove

gun from hose. Clean gun.

Pump hose worn out Replace hose. Recommended hose

replacement - once every year.

Pump cold Move pump to warm room and allow

it to warm up or run hot water through

sprayer.

Material runs out of bottom of sprayer Pump hose worn out Replace hose.

Loose fittings Check and retighten all fittings.

No air from compressor Gun air valve closed Open gun air valve.

Low voltage Check extension cord length and

gauge. Replace if different than recommended. Refer to Grounding and

Electrical Requirements, page 6.

Gun needle plugged Clean needle and retry.

Worn compressor Replace compressor. Contact a qual-

ified Graco Service Center.

Lines not connected Check all quick disconnect connec-

tions to gun and hoses.

Damaged hose Replace hose.

311772M 25

Page 26

Troubleshooting

Problem Cause Solution

Speed of application slow or slower Material too thick Thin material.

Nozzle too small Change nozzles to a larger size. See

Operation manual 311768.

Too much air being used. Partially close gun air valve to reduce

air flow.

Pump hose worn Replace hose.

Plugged or dirty gun Relieve Pressure, page 6. Clean

gun.

Kinked hose Unkink hose.

Gun adjustment set too low Increase flow adjustment with flow

adjustment nut.

Too many items on same circuit Unplug other items from circuit.

Extension cord too long or wrong

gauge

Use a different extension cord. Refer

to Grounding and Electric Requirements, page 6.

Intermittent flow/sputtering Hopper connection not tight Check gasket. TIghten connection.

Debris in system Clean system.

Quick disconnect does not stay connected.

Dirty or corroded fitting Clean thoroughly. Soak in oil. Apply a

few drops of light oil.

Gun will not shut off Worn nozzle or needle. Relieve Pressure, page 6. Replace

worn parts.

Debris in needle passage Relieve Pressure, page 6. Clean.

Fluid leaking at Flow Adjustment Nut Damaged seal. Relieve Pressure, page 6. Replace

seal.

Fluid leaking out of either plug Missing or damaged o-rings Relieve Pressure, page 6. Replace

o-rings.

Gun damaged Replace gun.

Needle adjustment won’t adjust Dirty threads Clean threads.

Nozzle not on gun Put nozzle on gun.

26 311772M

Page 27

Wiring Diagram

40

19

34

21

49

Switch

Motor

White Wire

Black Wire

Power Cord

Green Wire (GND)

ti8937a

49

Cylinder

Air Valve

Manifold on Compressor

Compressor

Air Outlet

38

84

15

34

ti8936a

55

59

Relief Valve

53

53

68

66

81

Gauge

Regulator

69

RTX 1250RTX 900

Cylinder

Air Valve

Manifold on Compressor

Compressor

Air Outlet

Relief Valve

38

56

59

55

34

15

84

ti9232a

41

Wiring Diagram

Air Diagram

311772M 27

Page 28

Parts Drawing

23

42

43

2

7

25

42

10

11

40

31

30

14

12

63

5

62

32

15

ti8901c

14

8

62

47

37

22

46

29

71

28

(RTX 900)

47

(RTX 900)

70

76

82

77

79

(RTX 900)

(RTX 900)

83

(RTX 1250)

45

85

85

85

Parts Drawing

Models 254974 and 254975

28 311772M

Page 29

Parts Drawing

6

19

61

3

4

16

38

21

26

29

29

35

50

59

51

54

15

29

ti8902b

52

27

34

36

49

•

•

•

RTX 1250 Only

66

33

65

69

80

49

•

57

RTX 1250 Only

60

31

31

1

68

58

78

41

Parts Drawing

Models 254974 and 254975

311772M 29

Page 30

Parts List

Parts List

Models 254974

Ref. Part Description Qty.

1 288386 PLATE, front, RTX 1

2 15J600 TOOLBOX 1

3 15H069 SUPPORT, hopper, RTX 1

4 288384 FRAME, back, RTX (painted) 1

5 288350 COVER, shroud; RTX 900 1

6 277319 SHIELD, bottom 1

7 288351 COVER, shroud; RTX 900 1

8 15J670 AXLE 1

10 115095 WHEEL, 9 in. 2

11 112612 CAP, hub 2

12 288314 HANDLE 1

14 15H641 KNOB 2

15 288336 FITTING, bulkhead, assembly 1

16 288623 HOSE, pump, (Roto-Flex

19 120660 SWITCH 1

21 15H910 BRACKET, pump, RTX 1

22 15C090 GAUGE, thickness, fluid 1

23 288093 HOPPER 1

25 288515 PLATE, support, RTX (painted) 1

26 105240 SCREW, cap hex hd 1

27 113981 NUT, lock, high tensile 1

28 120444 SCREW 1

29 117630 SCREW, torx, tri lob 6

30 117633 SCREW, slot hex wash hd 2

31 120771 SCREW, mach, pnh 5

32 15H605 HANGER 2

34 288856 COMPRESSOR, pump assembly 1

35 120236 SCREW, shoulder 1

36 120731 WASHER, flat 1

38 289591 CYLINDER, RTX 1

40 15J758 CORD, power 1

41 113318 FITTING, elbow, plug-in 1

42 15J862 KNOB, 1/4-20, 4 prong 1

™

)1

Ref. Part Description Qty.

43 15D561 COVER, tool tray 1

45 288628 GUN, spray (for use w/ hopper) 1

46 234147 HOSE 1

47 120759 PAD, non-slip, foot 1

48 103473 STRAP, tie, wire 1

49 115498 SCREW, mach, slot hex wash hd 2

50 104227 NUT, lock 1

51 15H841 LABEL, warning 1

52 15K616 LABEL, caution 1

53 120694 TUBE, air 1

54 15H868 LABEL, instruction 1

55 120694 TUBE, air, .250 1

56 120569 TUBE, air, .250 1

58 288756 KIT, repair, knob 1

59 288757 KIT, repair, regulator

(includes 59, 60)

60 120744 SCREW, mach, pnh 2

61 120637 NUT, acorn 1

62 15C753 SCREW, machine, hex

washer head

63 111831 SCREW, cap, skt, button hd 1

71 15H912 GUARD, burp 1

76 15K323 LABEL, hopper, RTX 900 1

77 15K329 LABEL, control, RTX 900 1

78 15K335 LABEL, front, RTX 900 1

79 15K338 LABEL, shroud, RTX 900 1

80 120215 WASHER, belleville 2

84 120567 TUBE, air, .250 OD 1

85 115099 GASKET 3

Additional warning labels are available at no cost.

1

2

30 311772M

Page 31

Parts List

Parts List

Models 254975

Ref Part Description Qty

1 288386 PLATE, front, RTX 1

2 15J600 TOOLBOX 1

3 15H069 SUPPORT, hopper, RTX 1

4 288384 FRAME, back, RTX (painted) 1

5 288650 COVER, shroud 1

6 277319 SHIELD, bottom 1

7 288382 COVER, shroud (painted) 1

8 15J671 AXLE, RTX 1250 1

10 115094 WHEEL, 10 2

11 112612 CAP, hub 2

12 288314 HANDLE, RTX (painted) 1

14 15H641 KNOB 2

15 288336 FITTING, bulkhead, assembly 1

16 288623 HOSE, coupled 1

19 120660 SWITCH 1

21 15H910 BRACKET, pump, RTX 1

22 15C090 GAUGE, thickness, fluid 1

23 288265 HOPPER 1

25 288515 PLATE, support, RTX (painted) 1

26 105240 SCREW, cap hex hd 1

27 113981 NUT, lock, high tensile 1

29 117630 SCREW, torx, tri lob 6

30 117633 SCREW, slot hex wash hd 3

31 120771 SCREW 5

32 15H605 HANGER 2

33 115494 SCREW, mach, phillips, pan hd 3

34 288651 COMPRESSOR, pump assembly 1

35 120236 SCREW, shoulder 1

36 120731 WASHER, flat 1

37 120411 RIVET, blind 3

38 289591 CYLINDER, RTX 1

40 15J758 CORD, power 1

41 113318 FITTING, elbow, plug-in 1

42 15J862 KNOB, 1/4-20, 4 prong 3

43 15D561 COVER, tool tray 1

46 234147 HOSE 1

Ref Part Description Qty

48 103473 STRAP, tie, wire 1

47 15K049 ISOLATOR, foot 1

49 115498 SCREW, mach, slot hex wash hd 2

50 104227 NUT, lock 1

51 15H841 LABEL, warning 1

52 15K616 LABEL, caution 1

53 120694 TUBE, air 2

54 15H868 LABEL, instruction 1

55 120568 TUBE, air, .250 OD 1

57 198492 LABEL, warning 1

58 288756 KIT, repair, knob (includes 58, 61) 1

59 288757 KIT, repair, regulator

(includes 59, 60)

60 120744 SCREW, mach, pnh 2

61 120637 NUT, acorn 1

62 15C753 SCREW, machine, hex washer head 2

63 111831 SCREW, cap, skt, button hd 1

65 115244 NUT, regulator 1

66 117694 REGULATOR, air, 1/8 in. npt 1

68 120665 GAUGE, pressure 1

69 120653 FITTING, elbow 1

70 120994 SCREW, mach, pnh 1

71 15H912 GUARD, burp 1

76 15K322 LABEL, hopper, RTX1250 1

78 15K334 LABEL, front, RTX 1250 1

80 120215 WASHER 2

81 TUBE, air, .250 OD 1

82 15K328 LABEL, control, RTX1250 1

83 15K364 LABEL, side panel, RTX1250 1

84 120567 TUBE, air, .250 OD 1

85 115099 GASKET 3

Additional warning labels available at no cost.

1

311772M 31

Page 32

Parts Drawing and List

110

100

74

75

71

108

109

106

105

77

73

87

83

84

87

101

102

72

79

ti8903a

86

76

117

Compressor 288856 & 288651

Parts Drawing and List

Ref. Part Description Qty.

288856 KIT, repair, compressor, complete

(includes all items) RTX 900

288651 KIT, repair, compressor, complete

(includes all items) RTX 1250

288612 KIT, repair, compressor, rebuild

(includes 100, 74, 86, 75, 76,

77, 87)

71 288613 KIT, repair, motor, universal, 120v

(includes 71, 72, 84, 105, 106)

72 120466 FAN, repair, motor 1

73 288616 KIT, repair, pulley, w/rollers

(includes 73, 83, 87)

74 288746 KIT, repair, head, compressor

(includes 74, 75)

75 288610 KIT, repair, plate, valve 1

76 CYLINDER, compressor 1

77 288609 KIT, repair, piston/cylinder

(includes 75, 76, 77, 87)

Ref. Part Description Qty.

79 288614 KIT, repair, cooler

(includes 79, 86)

83 120234 BELT 1

84 120233 BELT 1

86 120245 FITTING 1

87 120204 SCREW, mach, hex flat head 2

95 120593 SCREW, mach, torx pan hd 3

100 120229 SCREW, hex flange 3

1

101 119872 SCREW, shoulder 1

102 120659 WASHER, flat 1

105 260215 SCREW, hex hd 2

1

106 100023 WASHER, flat 2

108 288611 KIT, repair, idler (includes 108, 84) 1

1

109 104272 SCREW, cap, sch 1

110 15H940 FITTING 1

117 120617 VALVE, pressure relief, RTX 1250 1

117 120251 VALVE, pressure relief, RTX 900 1

1

1

32 311772M

Page 33

Technical Data

Technical Data

Main unit power requirements 120 Vac, 60 Hz, 15A, 1 phase

Maximum fluid working pressure 70 psi, (4.9 bar)

Maximum air working pressure 50 psi, (3.5 bar)

Compressor specifications Universal motor thermally protected, oil-less

Compressor air displacement 4.0 scfm at 45 psi

Generator required 3500W minimum

Electric Motor Universal AC 14 Amp 1.5 Hp

Power Cord 16 AWG, 3-wire, 25 ft

Material hopper capacity Model 254974: 8 gallons

Model 254975: 10 gallons

Gun material hopper: 3/4 gallon

Maximum delivery with texture RTX 900 - 0.9 gpm (3.4 lpm)

RTX 1250 - 1.25 gpm (4.7 lpm)

Dimensions: RTX 900

Length 23 in. (584 mm) with handle

Width 18 in. (456 mm)

Height 40 in. (1016 mm)

Weight (includes hose and gun) 60 lb (27.2 kg)

Dimensions: RTX 1250

Length 24 in. (609 mm) with handle

Width 20 in. (508 mm)

Height 41 in. (1041 mm)

Weight (includes hose and gun) 65 lb (29.5 kg)

Wetted parts brass, aluminum, plastic

Sound data

Sound pressure level* 83.2 dB(A)

Sound power level** 97.5 dB(A)

Storage Temperature Range 35°F - 160°F (1.6°C - 71°C)

Operating Temperature Range 40°F - 115°F (4°C - 46°C)

Gun:

Maximum Working Pressure 70 psi (4.9 bar)

Air Maximum Working Pressure 100 psi (6.895 bar)

CFM Rating 3.5 - 11 CFM

Weight 1.1 lb (500 g)

* Measured while spraying at 1 m

** Measured per ISO-3744

311772M 33

Page 34

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any

special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any

part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained

in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 311770

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised P August 2014

Loading...

Loading...