Page 1

Repair

Interior Texture Sprayer

RTX 650

For Water-Based Materials Only

Model: 254973

50 psi (0.35 MPa, 3.5 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7.0 bar) Maximum Air Pressure

311771E

EN

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Related Manuals

311777

311767

ti8370a

Model 254973 Shown

Page 2

Warnings

Warnings

The following are general warnings related to the setup, use, grounding, maintenance and repair of this equipment.

Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols

appearing in the body of the manual refer to these general warnings. When these symbols appear through the man-

ual, refer back to these pages for a description of the specific hazard.

Warnings

Fire and Explosion Hazard

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result

in fire or explosion and serious injury.

• The system is for use with water-based materials only. Only use fluids compatible with the equipment. Refer to Technical Data of all equipment manuals. Read fluid and solvent manufacturers warnings.

• Ground all equipment in the work area. See Grounding and Electrical Requirements, page 6.

• If there is any static sparking or you feel an electric shock while using this equipment, stop spraying

immediately. Do not use the equipment until you identify and correct the problem.

• Keep work area free of debris, including solvent, rags and gasoline.

• Comply with all applicable state and national fire, electrical and safety regulations.

• Keep a fire extinguisher in the work area.

Equipment Misuse Hazard

Equipment misuse can cause equipment to rupture, malfunction, or start unexpectedly and cause serious

injury.

• Before operating this equipment, read all manuals, tags, and labels, including material labels and

instructions.

• Do not expose system to rain. Always store system indoors.

• Do not alter or modify equipment.

• Do not spray cementitious materials.

• Do not exceed maximum working pressure of lowest rated component in your system.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• To reduce risk of serious injury, including electric shock and splashing fluid in eyes, follow Pressure

Relief Procedure on page 6 before servicing the unit.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Route hoses away from traffic areas, sharp edges, moving parts and hot surfaces. Do not expose

Graco hoses to temperatures above 130° F (55° C) or below -35° F (-37° C).

• Air hoses at the compressor end, can get very hot! Allow sprayer to cool down 15 minutes before

removing air hose.

• Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

• Never directly inhale compressed air. Compressed air may contain toxic vapors.

2 311771E

Page 3

Warnings

Warnings

Electric Shock Hazard

To reduce the risk of electric shock:

• Be sure sprayer is adequately grounded through electrical outlet, page 6.

• Use only 3-wire, extension cords.

• Make sure ground prongs are intact on sprayer and extension cords.

• Do not operate with cover removed.

• Turn off sprayer. Follow Pressure Relief Procedure, page 6, and unplug unit, before removing any

parts.

Pressurized Equipment Hazard

Fluid from gun, leaks or ruptured components can splash in the eyes or on skin and cause serious injury.

• Follow Pressure Relief Procedure, page 6 when you stop spraying and before cleaning, checking

or servicing.

• Do not point spray gun at anyone; put hand, fingers or rag over nozzle, or stop or deflect leaks with

your hand, body, glove, or rag.

• Wear protective clothing, gloves, and eyewear.

Cleaning Solvent Hazard with Plastic Parts

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many

solvents can degrade plastic parts to the point where they could fail. Such failure could cause serious

injury or property damage. See Technical Data on page 19 of this instruction manual and in all other

equipment manuals. Read fluid and solvent manufacturer’s warnings.

Personal Protective Equipment

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing Protection

J

311771E 3

Page 4

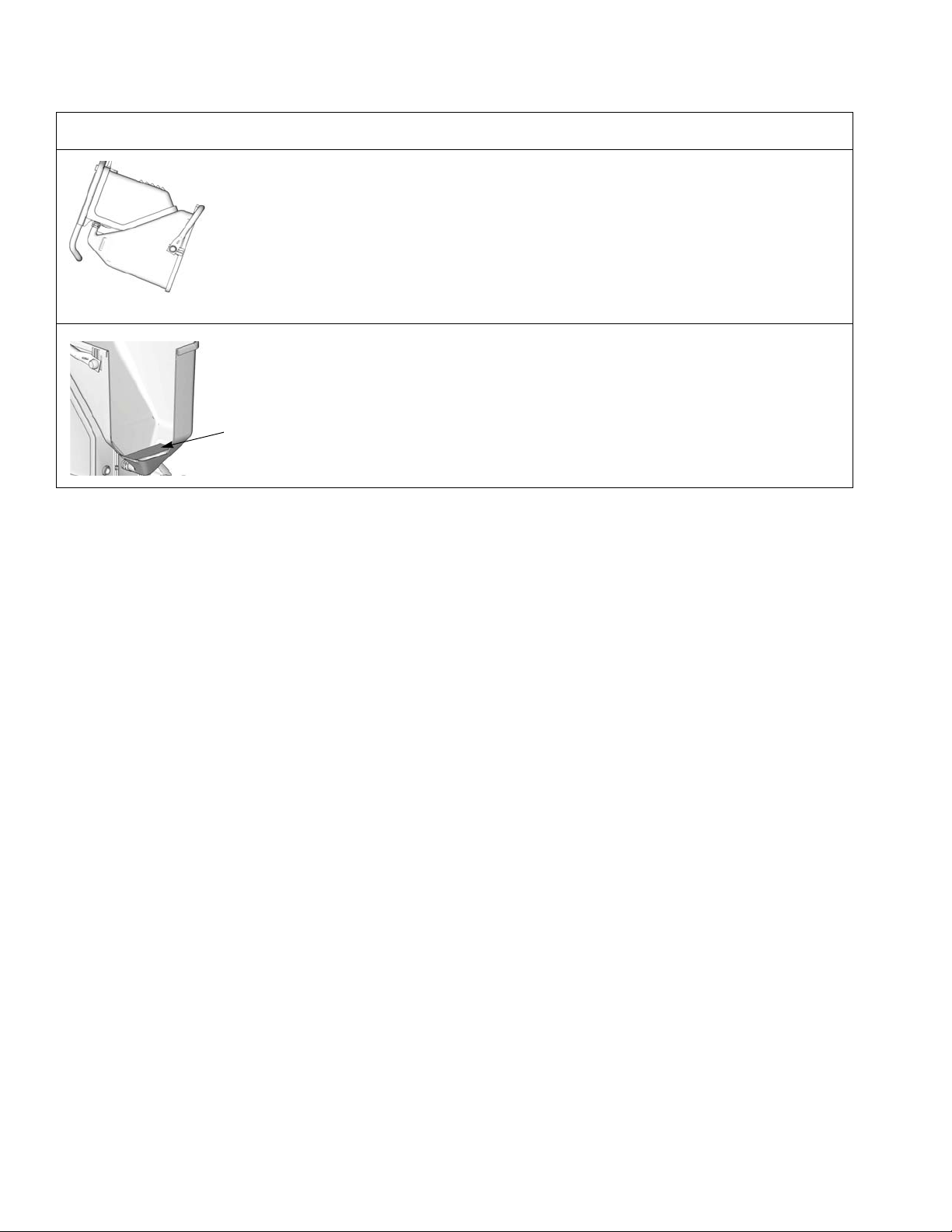

ti9075a

ti9075a

Warnings

CAUTION

Water or material remaining in unit when temperatures are below freezing can damage

motor and/or delay pump startup.

To insure water and material are completely drained out of unit:

1. Remove material line from sprayer.

2. Tip sprayer up as shown.

Before adding material or starting unit in cold weather, run warm water through pump.

Install burp guard (J) before adding material to hopper. When only a small amount of

material remains in the hopper, the burp guard prevents material from shooting out when

the sprayer is turned off. This material could splash into the operator’s eyes or skin.

J

4 311771E

Page 5

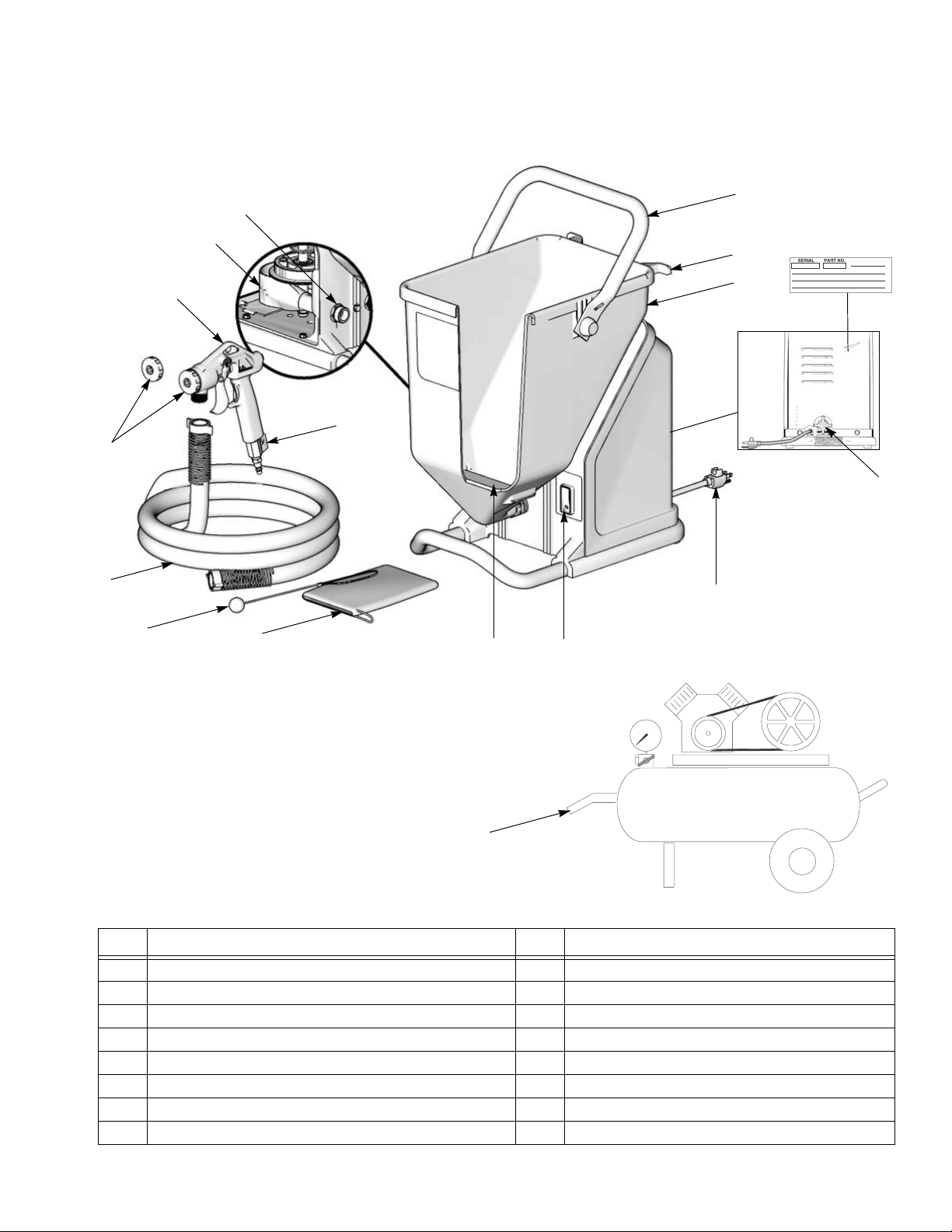

Component Identification

Model 254973 Shown

A

Component Identification

P

B

C

H

D

E

F

G

J

K

ti8369a

N

M

R

L

Q

3.5 cfm@40 min.

Item Component Item Component

A Pump Hose Outlet J Burp Guard

B RotoFlex™ II Pump (inside) K ON/OFF Switch

C Texture Spray Gun (Manual 311777) L Power Cord (120V, 15 ft)

D Nozzle (2 included) M Material Hopper - 5 gallon

E Material Hose (20 ft) N Cord Wrap

F Material Thickness Gauge P Handle

G Accessories Bag Q Air Compressor (Not Supplied by Graco)

H Gun Air Valve R Knob/Pressure Control

311771E 5

Page 6

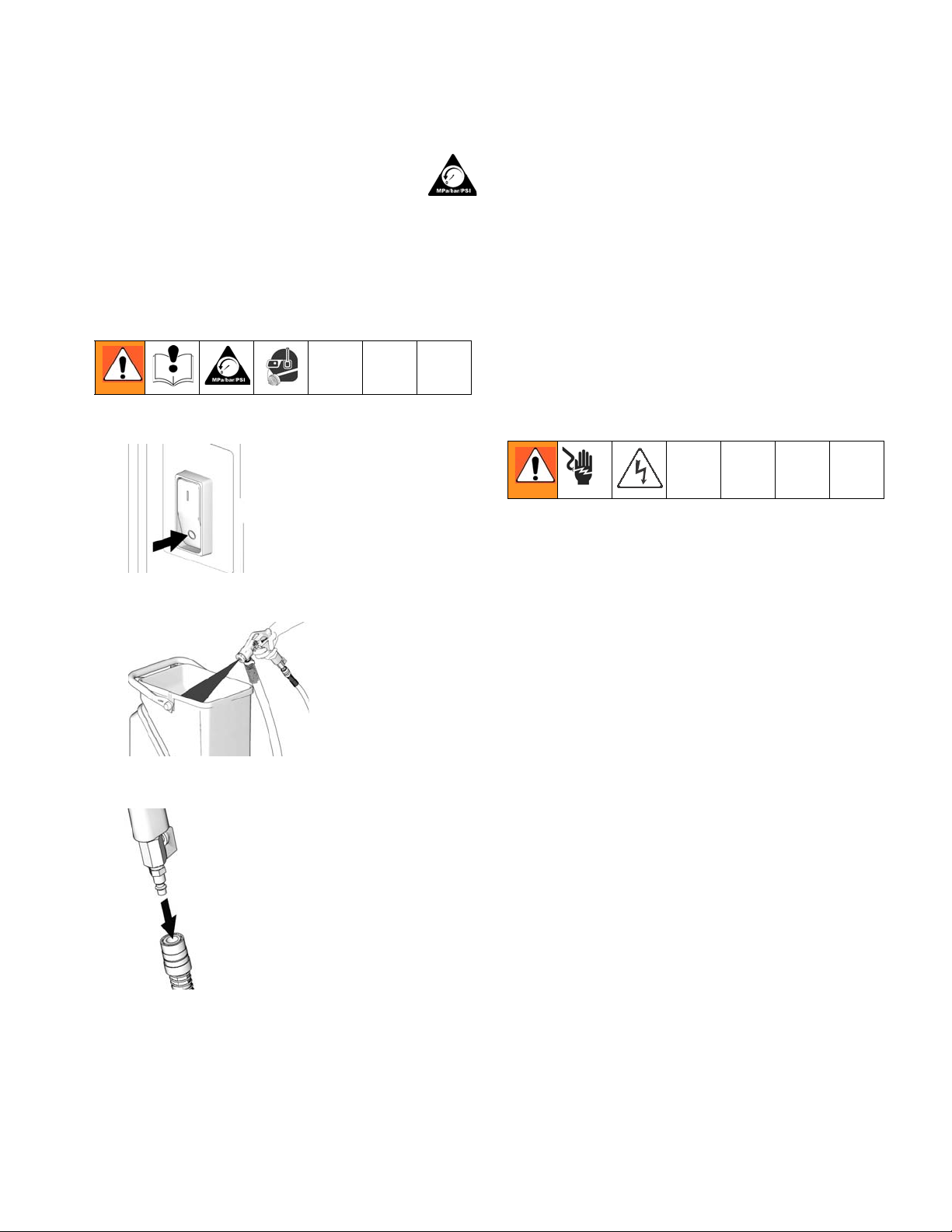

Component Identification

Pressure Relief Procedure

To reduce risk of injury, follow this procedure

whenever you see this symbol throughout this

manual, Also, perform this procedure whenever

you:

• Stop spraying

• Check or repair any part of this system

• Install or clean spray nozzle

1. Turn Power Switch OFF.

ti9165a

2. Trigger gun into material hopper.

Grounding and Electrical

Requirements

This sprayer must be grounded. Grounding reduces the

risk of electrical shock by providing an escape wire for

the electrical current. The sprayer cord includes a

grounding wire with an appropriate grounding plug. The

plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Check with a qualified electrician or if grounding

instructions are not completely understood, or if in doubt

as to whether the product is properly grounded. Do not

modify plug provided; if it will not fit the outlet, have

proper outlet installed by a qualified electrician.

120V AC Systems

• This equipment requires a 120V AC, 60 Hz, 15A

circuit with a grounding receptacle. Do not use an

adapter with this product.

Extension Cords

3. Disconnect air gun.

ti8568a

ti8371a

• Use only an extension cord with an undamaged,

3-prong plug.

• For 25 to 50 ft (7.6 to 15.2 m) cords, use 3-wire, 14

AWG (1.5 mm

• For up to 100 ft. (30.48 m) cord, use 3-wire, 12 AWG

(2.5 mm

2

) minimum.

2

) minimum.

Auxiliary Air Compressor (Required)

Minimum requirements 3.5 cfm @ 40 psi or 2.5 cfm @

90 psi (see manual 311763 for detailed

recommendations).

Generator Requirements (Alternate)

3500 W (3.5 KW) minimum.

Hose Size and Length

The system comes with a hose set consisting of a 3/4 in.

ID x 20 ft (25 mm x 7.6 m) material hose.

6 311771E

Page 7

Shroud Removal

Shroud Removal

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

ti2810b

3. Remove two screws (15) and two screws (64) from

back of shroud (7).

64

15

7

Reassembly

1. Slide shroud (7) onto base (2).

2. Tighten two bottom screws (15) and two top screws

(64 ) into shroud (7).

ti9658a

4. Pull shroud (7) back and up over knob (41).

7

2

ti9659a

311771E 7

Page 8

RotoFlex™ II Pump

RotoFlex™ II Pump

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

ti2810b

3. Remove Shroud, page 7.

4. Loosen two spacers (56) and knob (41).

41

56

6. Use 3/8 in. socket to remove screw (36) from hose

bracket (27).

36

ti9065a

7. Slide hose fittings out of hose bracket (27) and

remove hose (23) from base (2).

ti3084a

ti9657a

5. Loosen hopper fitting by hand to remove hopper (1).

1

ti8781a

8 311771E

Page 9

RotoFlex™ II Pump

Reassembly

1. Bend hose (23) so colored dots on hose fittings face

each other and slide hose fittings through hose

bracket (27).

ti3084a

CAUTION

Make sure protective fabric faces outside of hose.

Roller will touch exposed area of pump hose when

pump is in place.

2. Squeeze hose ends together to keep hose (23) and

bracket (27) together and feed pump hose fittings

through holes on front of base.

5. To set pressure, apply petroleum jelly to threads

(41), tighten knob (41) until back of bracket (25) is

approximately 1/2 in. from front of tensioning

bracket (16).

25

16

ti9710a

Tighten front spacer (56) until flush to front of tensioning bracket (16). Tighten back spacer (56) 3/8

in. from tensioning bracket.

25

16

27

23

ti8780a

3. Use 3/8 in. socket to tighten screw (36) on hose

bracket (27).

4. Install hopper and tighten hopper fitting on hopper

(1) by hand until snug.

ti9656a

41

To break in new pump, run sprayer dry for no longer

than two minutes.

Replace hose when mud seeps through slots in the

base and leaves material on the floor.

ti8787a

311771E 9

Page 10

Motor

Motor

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

ti2810b

3. Remove Shroud, page 7.

4. loosen knob (41) until spring relaxes.

41

ti9657a

5. Remove Pump, page 8.

6. Disconnect all electrical Wiring, page 16.

9. Remove two clevis pins (20) from base.

20

ti8783a

10. Slide motor tray (32) out of slots in base (2) to

remove motor and tray from sprayer.

2

32

ti9070a

11. Remove Belt, page 13.

12. Loosen bolts (4) and remove motor (31) from motor

tray (32).

7. Use 1/4 in. socket to remove grounding screw (22).

22

ti9064a

8. Disconnect extension cable (29) from pulley (17)

and spring (19) to allow motor tray to pivot.

19

17

29

ti9058a

32

31

4

ti9214a

10 311771E

Page 11

Motor

Reassembly

1. Tighten Belt, page 13.

2. Use petroleum jelly to grease area of shaft that

makes contact with extension cable (29).

29

ti9060a

3. Slide pin on motor tray (32) into slots on base and

push motor and tray back into position.

32

6. Pull back on motor tray (32) to create slack in

extension cable (29). Loop extension cable (29)

through pulley (17) and connect to extension spring

(19). Apply petroleum jelly to pulley (17) and threads

on knob (41).

19

17

29

ti9059a

7. Tighten knob (41).

41

ti9708a

4. Replace two clevis pins (20) in base (2).

20

ti8783a

5. Reconnect all electrical wiring including ground wire

(22), Wiring, page 16.

22

ti9656a

8. To set pressure, tighten knob (41) until back of

bracket (25) is approximately 1/2 in. from front of

tensioning bracket.

Tighten front spacer (56) until flush to front of tensioning bracket (16). Tighten back spacer (56) 3/8

in. from tensioning bracket (16).

25

56

16

ti9656a

41

ti9064a

311771E 11

9. Reassemble Shroud, page 7.

Page 12

Motor Fuse Removal

Motor Fuse Removal

When replacing fuse, use only Bussman GMF-3 (3A) to

prevent premature trips or equipment damage.

The motor has a replaceable fuse attached to the motor

bracket. The fuse assembly (A) is fastened to the motor

bracket along with a clamp.

A

ti9206a

To remove the motor fuse, press down on the round

center cover (C) and turn it counterclockwise.

C

ti9200a

The cover will pop up to allow the fuse (F) to be

inspected and replaced if needed.

F

ti9201a

12 311771E

Page 13

Belt

Belt

Disassembly

1. Relieve Pressure, page 6.

2. Unplug sprayer from outlet.

ti2810b

3. Remove Shroud, page 7.

4. Remove Motor, page 10.

5. Place motor tray (32) into vice and tighten until

snug.

32

Reassembly

1. Loop one end of belt over extension cable (29) and

pulley (17), then loop other end of belt over motor

shaft (make sure teeth of belt (24) and pulley are

aligned).

24

ti8784a

2. Insert flat screwdriver into slot on back of motor tray

(32) and use screwdriver as a lever to pull motor

(31) into position.

3. Use 9/16 in. wrench to tighten two mounting screws

(4) while keeping motor (31) in position with screwdriver.

ti9063a

6. Use 9/16 in. wrench to loosen two mounting screws

(4) on motor tray (32) to allow motor to slide around.

ti9069a

ti9066a

7. Remove old belt and discard.

ti9073a

Once the motor is in place, you can test the belt to

make sure it is properly tightened. When you push

on the belt (24) with one finger it should move no

more than 1/4 in. If it moves more than 1/4 in., go

back to step 8 and re-tighten the belt.

24

ti9071a

4. Reassemble Motor, page 10.

5. Reassemble Shroud, page 7.

311771E 13

Page 14

Troubleshooting

Troubleshooting

Problem Cause Solution

Sprayer won’t run Power switch not on Turn switch on.

No power at wall outlet Check outlet by seeing if light in the

plug is illuminated. If not, try another

outlet.

Wrong size generator Use a 3500 watt or larger generator.

Refer to Generator Requirements,

page 6.

Too many items on same circuit Unplug other items from circuit

Extension cord too long or wrong

gauge

Breaker tripped Reset breaker.

Blown motor fuse Check to see if fuse needs to be

Pump won’t pump material Failed motor or motor shield Replace motor or motor fuse.

Mix too thick Add water to thin material. Use Mate-

Plugged gun Relieve Pressure, page 6. Remove

RotoFlex II pump worn out Replace hose. Recommended hose

Pump cold or material frozen in pump Move pump to warm room and allow

Material in hose Remove material hose from outlet

Material runs out of bottom of sprayer

onto floor

No air flowing from gun Gun air valve closed Open gun air valve.

RotoFlex II pump worn out Replace hose.

Gun needle plugged Clean needle and retry.

Lines not connected Check all connections to gun and

Damaged hose Replace hose.

Worn compressor Replace compressor.

Use a different extension cord. Refer

to Grounding and Electric Require-

ments, page 6.

replaced, page 12.

rial Thickness Gauge.

gun from hose. Clean gun.

replacement - once a year or every

3000 gallons.

it to warm up or run hot water through

sprayer.

and run until material flows.

hoses.

14 311771E

Page 15

Troubleshooting

Problem Cause Solution

Speed of application too slow New pump hose not broken in

properly

Run pump dry for no longer than 2

minutes.

Material too thick Thin material.

Nozzle too small Change nozzles to a larger size. See

Operation Manual, Recommended

Nozzle Selection Chart, page 10.

Plugged or dirty gun Relieve Pressure, page 6. Clean

gun.

Kinked hose Unkink hose.

Gun fluid flow adjustment set too low Increase flow adjustment with flow

adjustment nut.

Intermittent flow/sputtering Hopper connection not tight Check gasket. TIghten connection.

Debris in system Clean system.

Gun will not shut off Worn nozzle or needle. Relieve Pressure, page 6. Replace

worn parts.

Debris in needle passage Relieve Pressure, page 6. Clean.

Fluid leaking at Flow Adjustment Nut

on gun

Damaged seal. Relieve Pressure, page 6. Replace

seal.

Fluid leaking out of either plug on gun Missing or damaged o-rings Relieve Pressure, page 6. Replace

o-rings.

Gun damaged Replace gun.

Needle adjustment on gun won’t

adjust

Dirty threads Clean threads.

Nozzle not on gun Put nozzle on gun.

311771E 15

Page 16

Wiring Diagram

Wiring Diagram

25

31

Green

Wire

Chassis Ground

Motor

White

Wire

Black Wire

Green Wire

Red

Wire

White

Wire

1039

ON/OFF

Switch

Black Wire

8

Power Cord

ti9199a

16 311771E

Page 17

Parts

Parts

Models 254973

42

1

46

12

9

6

7

64

55

•

9

42

2

65

13

18

•

•

64

15

56

•

47

25

41

ti9654a

•

8

10

3

37

14

5

28

26

38

30

31

24

22

33

39

32

63

19

29

37

16

20

20

21

23

4

2

43

17

11

36

ti9655b

27

44

311771E 17

Page 18

Parts

Models 254973

Parts

Ref. Part Description Qty.

1 15K225 HOPPER, 5 gallon 1

2 15J181 BASE 1

3 15K227 FRAME, tubular, painted, silver 1

4 117791 SCREW, cap, tri lobe 2

5 120783 SCREW, mach, pnh 3

6 15K228 HANDLE, tubular, painted, silver 1

7 288608 COVER, adjustable 1

8 15J505 CORD, power 1

9 120817 FASTENER, push-on hat w/hole 2

10 117693 SWITCH, power 1

11 120700 SCREW, shoulder 1

12 15J222 GUARD, burp 1

13▲† 15K512 LABEL, warning 1

14 15J388 DAMPENER, feet 2

15 120648 SCREW 2

16 15K154 LEVER, spring, tensioning 1

17 15J459 PULLEY 1

18▲ 15H868 LABEL, instruction 1

19 120657 SPRING, extension 1

20 15J510 PIN, detent clevis 2

21 101242 RING, retaining, ext. 2

22 115498 SCREW, mach, slot hex wash hd 2

23 288623 HOSE 1

24 288718 BELT, timing 1

25 15K155 BRACKET, cover/cord 1

26 288622 HOSE, coupled, 20 feet 1

27 15J500 BRACKET, hose 1

Ref. Part Description Qty.

28 15J506 BAG, accessories 1

29 120658 CABLE, extension 1

30 288629 GUN, spray, texture 1

31 288740 MOTOR (includes item 39) 1

32 288229 TRAY, motor, weld 1

33 288225 PULLEY, w/rollers 1

36 120444 SCREW, hex hd, flanged 1

37 117633 SCREW, slot hex wash hd 5

38 15C090 GAUGE, thickness, fluid 1

39 288739 FUSE, Bussman GMF-3 (3A) 1

41 15K143 KNOB 1

42 114538 SCREW, mach, torx, pan hd 2

43 120757 SCREW, carriage, shoulder 1

44 102040 NUT, lock, hex 1

45 103473 STRAP, tie, wire 2

46▲ 15K324 LABEL, hopper RTX 650 1

47▲ 15K339 LABEL, control 1

55▲ 15E298 LABEL, ident 2

56 120770 SHAFT, collar 2

57 338507 DVD 1

63 120830 CLAMP, loop 1

64 120771 SCREW 3

65 100527 WASHER 2

▲Labels are not included with components. They must

be ordered separately.

† Additional warning labels are available at no cost.

18 311771E

Page 19

Technical Data

Technical Data

Main Unit Power Requirements . . . . . . . . . . . . . . . . . . . . 120 Vac, 60 Hz, 15A, 1 phase

Maximum Fluid Working Pressure . . . . . . . . . . . . . . . . . . 50 psi, (3.5 bar)

Maximum Air Working Pressure . . . . . . . . . . . . . . . . . . . . 100 psi (7.0 bar)

Compressor Specifications. . . . . . . . . . . . . . . . . . . . . . . . Universal motor thermally protected, oil-less

Compressor (Not Supplied) . . . . . . . . . . . . . . . . . . . . . . . 3.5 @ 40 psi minimum

Generator (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3500 W minimum

Electric Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Permanent Magnet DC-5A

Power Cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 AWG, 3-wire, 15 ft

Material Hopper Capacity. . . . . . . . . . . . . . . . . . . . . . . . . 5 gallons

Maximum Delivery with Texture . . . . . . . . . . . . . . . . . . . . 0.65 gpm

TX 65 Dimensions and Weight

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 in. (482 mm) with handle

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 in. (305 mm)

Height (no handle) . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 in. (508 mm)

Weight (includes hoses or gun) . . . . . . . . . . . . . . . . . 33 lb (14.9 kg)

Wetted Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . brass, aluminum, plastic

Sound Data (less compressor)

Sound Pressure Level . . . . . . . . . . . . . . . . . . . . . . . . N/A

Sound Power Level . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Storage Temperature Range . . . . . . . . . . . . . . . . . . . . . . 35°F - 160°F (1.6°C - 71°C)

Operating Temperature Range. . . . . . . . . . . . . . . . . . . . . 40°F - 115°F (4°C - 46°C)

Gun:

Maximum Fluid Working Pressure . . . . . . . . . . . . . . . 70 psi (3.5 bar)

Maximum Air Working Pressure. . . . . . . . . . . . . . . . . 125 psi (8.75 bar)

CFM Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 - 11 CFM

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 lb (500 g)

311771E 19

Page 20

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any

special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part

of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

20 311771E

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Orginial instructions. This manual contains English: MM 311771

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised September 2012

Loading...

Loading...